High-extrusion-rate heat-shrinkable tube and production method thereof

A heat-shrinkable sleeve and extrusion rate technology, which is applied in the high-extrusion-rate heat-shrinkable sleeve and its production field, can solve problems such as extrusion difficulties and poor product appearance, and achieve good processing and use performance, extrusion The effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation material of the heat-shrinkable sleeve provided by the present invention contains by weight:

[0031] 100 parts of vinyl polymer;

[0032] Flame retardant 0-70 parts;

[0033] Filling agent 0-60 parts;

[0034] Lubricant 0.1-5 parts;

[0035] Fluxing and dispersing agent 0.1-3 parts;

[0036] Antioxidant 0.1-10 parts;

[0037] 0-3 parts of cross-linking accelerator;

[0038] Masterbatch 0-10 parts.

[0039] Preferably, the vinyl polymer is low-density polyethylene, medium-density polyethylene, high-density polyethylene, ethylene-vinyl acetate copolymer, ethylene-octene copolymer, ethylene-methyl acrylate copolymer, ethylene- One or several kinds of butyl acrylate copolymer and ethylene-propylene copolymer.

[0040] Preferably, the flame retardant is compounded from red phosphorus flame retardant and magnesium hydroxide.

[0041] Preferably, the red phosphorus-type flame retardant is one or a combination of two of the following flame retardants: r...

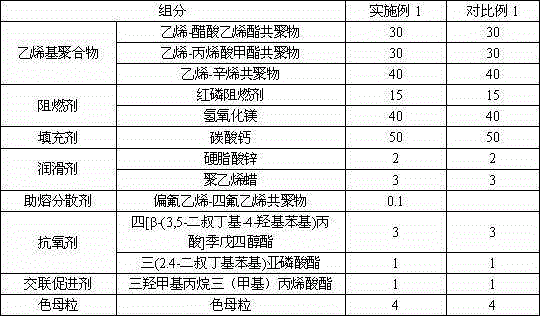

Embodiment 1

[0055] Take the following components according to the weight fraction:

[0056]

[0057] The above-mentioned materials are mixed and granulated by a banbury mixer, the banbury temperature is 90-130°C, and the banbury time is 10-20min. The granulated material from the banburying plant is then kneaded 1-3 times by a twin-screw extruder for granulation and packaging.

[0058] Then use a single-screw extruder with a length-to-diameter ratio of 25:1 to extrude a heat-shrinkable tube with an inner diameter of 32mm, a wall thickness of 2.8mm, and an extrusion temperature of 90-130°C.

[0059] The extruded pipe is irradiated with an electron accelerator with an energy above 4 MeV, and the cross-linked pipe is expanded by 1.5-4 times at 80-140°C.

[0060]Table 1 is the performance parameter table of the main test of embodiment 1 and comparative example 1.

[0061] Table 1

[0062] performance Example 1 Comparative example 1 Extrusion rate / Hz 21 39 Limitin...

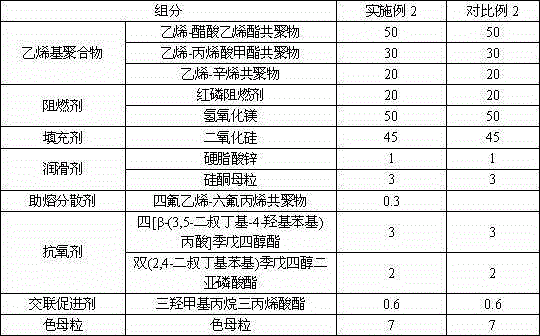

Embodiment 2

[0064] Take the following components according to the weight fraction:

[0065]

[0066] The above-mentioned materials are mixed and granulated by a banbury mixer, the banbury temperature is 90-130°C, and the banbury time is 10-20min. The granulated material from the banburying plant is then kneaded 1-3 times by a twin-screw extruder for granulation and packaging.

[0067] Then use a single-screw extruder with a length-to-diameter ratio of 25:1 to extrude a heat-shrinkable tube with an inner diameter of 75mm, a wall thickness of 1.5mm, and an extrusion temperature of 90-130°C.

[0068] The extruded pipe is irradiated with an electron accelerator with an energy above 4 MeV, and the cross-linked pipe is expanded by 1.5-4 times at 80-140°C.

[0069] Table 2 is the performance parameter table of embodiment 2 and comparative example 2 main tests.

[0070] Table 2

[0071] performance Example 2 Comparative example 2 Extrusion rate / Hz 25 42 Limiting Oxy...

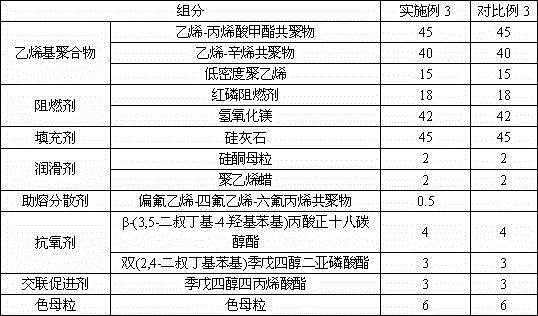

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com