A kind of rapidly prototyping PVC-U pipe material and preparation method thereof

A PVC-U, fast technology, applied in the field of plastic pipes, can solve the problems of poor impact resistance of carbon fiber ball modified composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

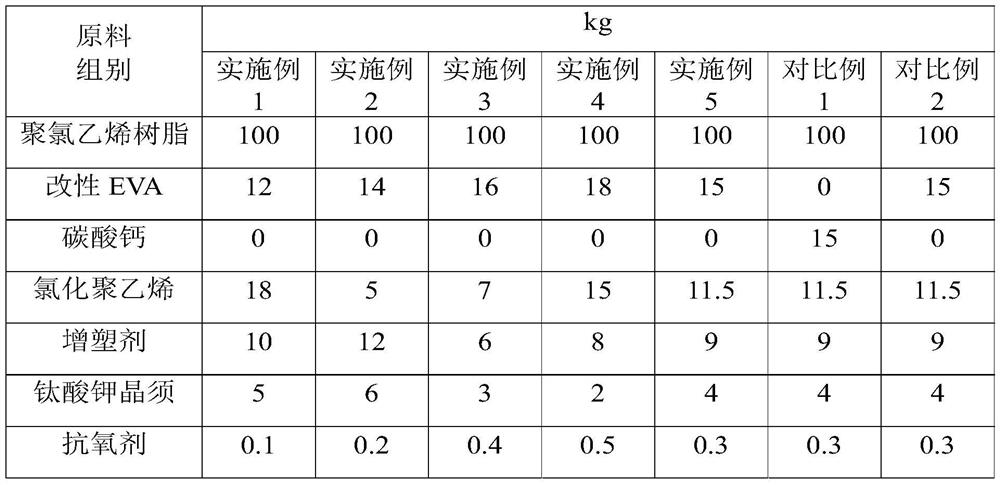

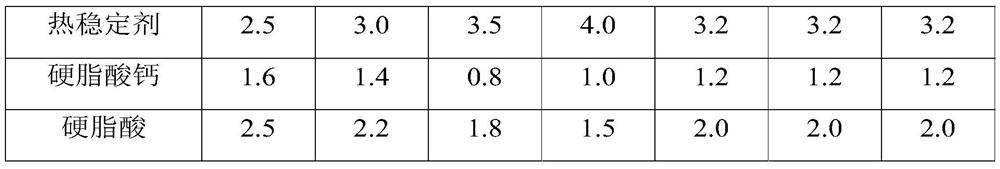

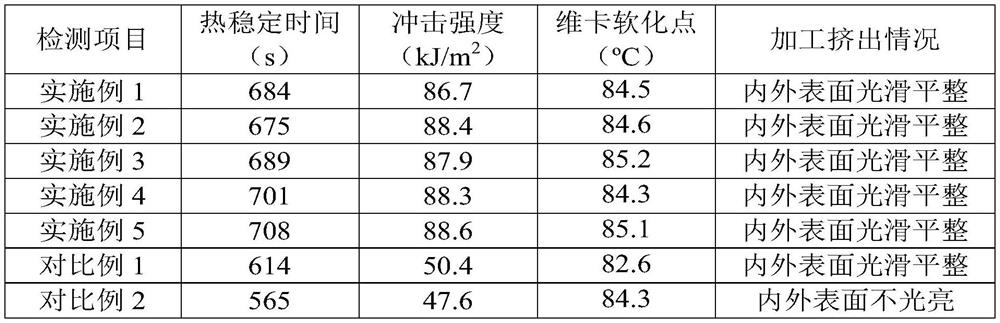

Examples

Embodiment 1

[0033] A rapid prototyping PVC-U pipe, prepared by the following method:

[0034] Step S10, preparing pretreated calcium carbonate: put the calcium carbonate in an oven at 95°C to dry for 2 hours, put it in a high-speed mixer, add silane coupling agent KH-550 with a weight of 0.7% of calcium carbonate, and mix at high speed for 5 minutes;

[0035] Step S20, preparing modified EVA: adding 10 parts of EVA, 1.2 parts of pretreated calcium carbonate, 0.3 parts of ethylene / octene copolymer and 0.3 parts of lubricating dispersant to a high-speed mixer for high-speed stirring at a rate of 2°C / min The heating rate was raised to 85°C, and the temperature was kept constant for 3 minutes to obtain modified EVA;

[0036] Step S30, weighing the raw materials for preparing the rapid prototyping PVC-U pipe according to the above weight parts, wherein the heat stabilizer is barium ricinoleate, zinc anthranilate and epoxy soybean oil mixed in a weight ratio of 2:1:1, The antioxidant is triiso...

Embodiment 2

[0040] A rapid prototyping PVC-U pipe, prepared by the following method:

[0041] Step S10, preparing pretreated calcium carbonate: put the calcium carbonate in an oven at 95° C. to dry for 2 hours, put it in a high-speed mixer, add silane coupling agent KH-550 of 0.8% by weight of calcium carbonate, and mix at high speed for 5 minutes;

[0042] Step S20, preparing modified EVA: adding 10 parts of EVA, 1.5 parts of pretreated calcium carbonate, 0.5 parts of ethylene / octene copolymer and 0.15 parts of lubricating dispersant to a high-speed mixer for high-speed stirring at a rate of 2°C / min The heating rate was raised to 85°C, and the temperature was kept constant for 3 minutes to obtain modified EVA;

[0043]Step S30, weighing the raw materials for preparing the rapid prototyping PVC-U pipe according to the above weight parts, wherein the heat stabilizer is barium ricinoleate, zinc anthranilate and epoxy soybean oil mixed in a weight ratio of 2:1:1, The antioxidant is selected...

Embodiment 3

[0047] A rapid prototyping PVC-U pipe, prepared by the following method:

[0048] Step S10, preparing pretreated calcium carbonate: put the calcium carbonate in an oven at 95° C. to dry for 2 hours, put it in a high-speed mixer, add silane coupling agent KH-550 with 0.9% by weight of calcium carbonate, and mix at high speed for 5 minutes;

[0049] Step S20, preparing modified EVA: adding 10 parts of EVA, 2.5 parts of pretreated calcium carbonate, 0.4 parts of ethylene / octene copolymer and 0.2 parts of lubricating dispersant to a high-speed mixer for high-speed stirring at a rate of 2°C / min The heating rate was raised to 85°C, and the temperature was kept constant for 3 minutes to obtain modified EVA;

[0050] Step S30, weighing the raw materials for preparing the rapid prototyping PVC-U pipe according to the above weight parts, wherein the heat stabilizer is barium ricinoleate, zinc anthranilate and epoxy soybean oil mixed in a weight ratio of 2:1:1, The antioxidant is triiso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com