Rubber composition

一种橡胶组合物、天然橡胶的技术,应用在橡胶组合物领域,能够解决高发热化、难以充分得到耐破坏性、炭黑分散恶化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

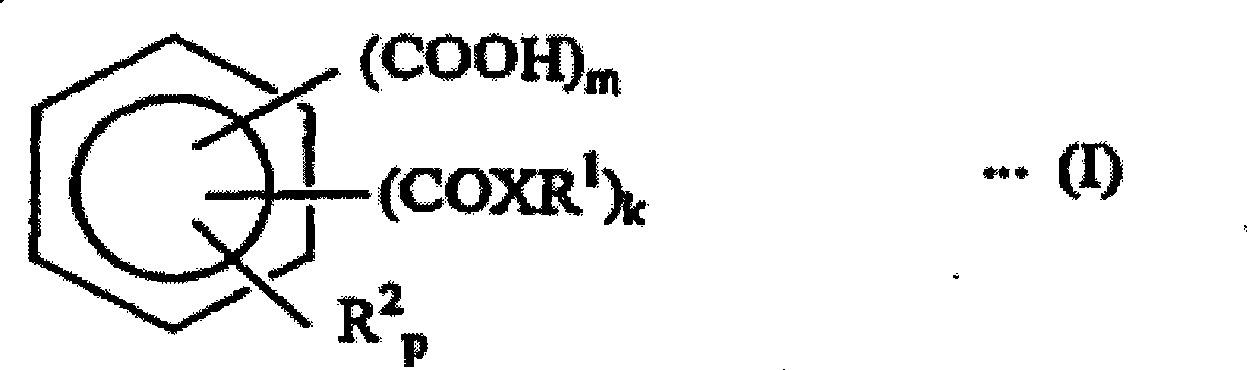

Method used

Image

Examples

Embodiment

[0034] Next, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples.

[0035] In addition, various measurements in each Example and Comparative Example were performed as follows.

[0036] (1) Measurement of particle size distribution of carbon black in slurry solution (volume average particle diameter (mv), 90% by volume particle diameter (D90))

[0037] Measurement was performed using a laser diffraction particle size distribution meter (MICROTRAC FRA type) with a water solvent (refractive index: 1.33). The particle refractive index (Particle refractive index) used 1.57 in the whole measurement. In addition, in order to prevent reaggregation of carbon black, measurement was performed immediately after dispersion|distribution.

[0038] (2) CTAB specific surface area

[0039] Measured based on ISO 6810.

[0040] (3) 24M4DBP

[0041] Measured based on ISO 6894.

[0042] (4) Tinting power (TINT) ...

manufacture example 1

[0050] Production example 1 Production of carbon black

[0051] Carbon blacks C, D and E were produced under the production conditions shown in Table 1 using a general oil-furnace carbon black production apparatus. In addition, as the carbon black A (N326), "Asahi #70L" (trademark) manufactured by Asahi Carbon Co., Ltd. was used as the commercial item, and the commercially available Asahi Carbon Co., Ltd. was used as the carbon black B (N330). "Asahi #70" (trade mark).

[0052] Table 1

[0053] Carbon black type

manufacture example 2

[0054] Production Example 2 Production of Natural Rubber Latex

[0055] 1. Natural rubber latex 1

[0056] Fresh latex of natural rubber (rubber content 24.2%) was diluted with deionized water to prepare a latex with a rubber content of 20%.

[0057] 2. Natural rubber latex 2

[0058] Fresh latex of natural rubber (rubber content 24.2%) was diluted with deionized water to prepare a latex with a rubber content of 20%. Add 0.5% anionic surfactant (Demor N manufactured by Kao) and 0.1% alkaline protease (Alcalase 2.5L Type DX manufactured by Novozymes Co., Ltd.) to this latex, and stir at 40° C. for 8 hours to decompose the natural rubber. the amide bond.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com