Patents

Literature

242results about "Ink receptacles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

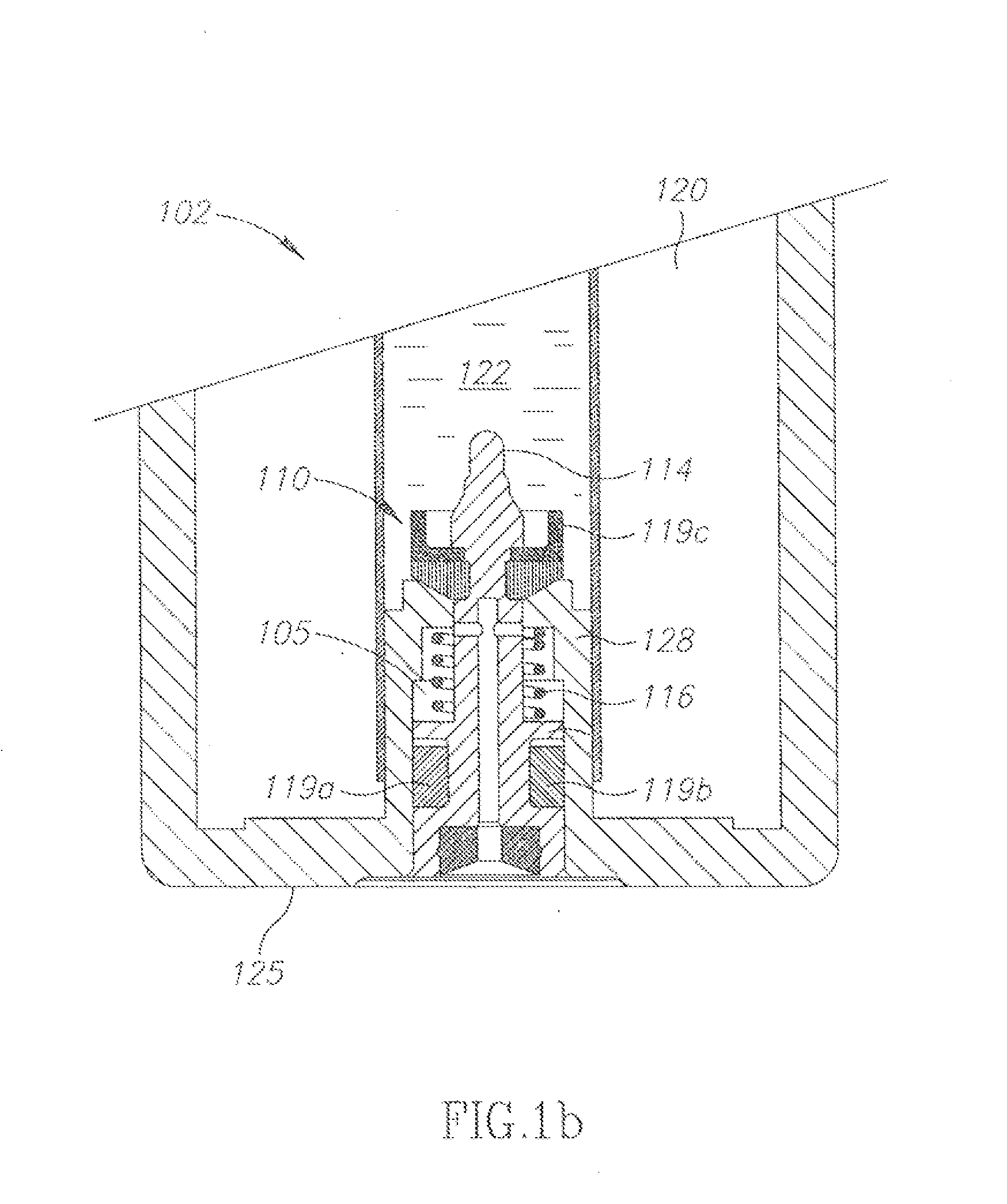

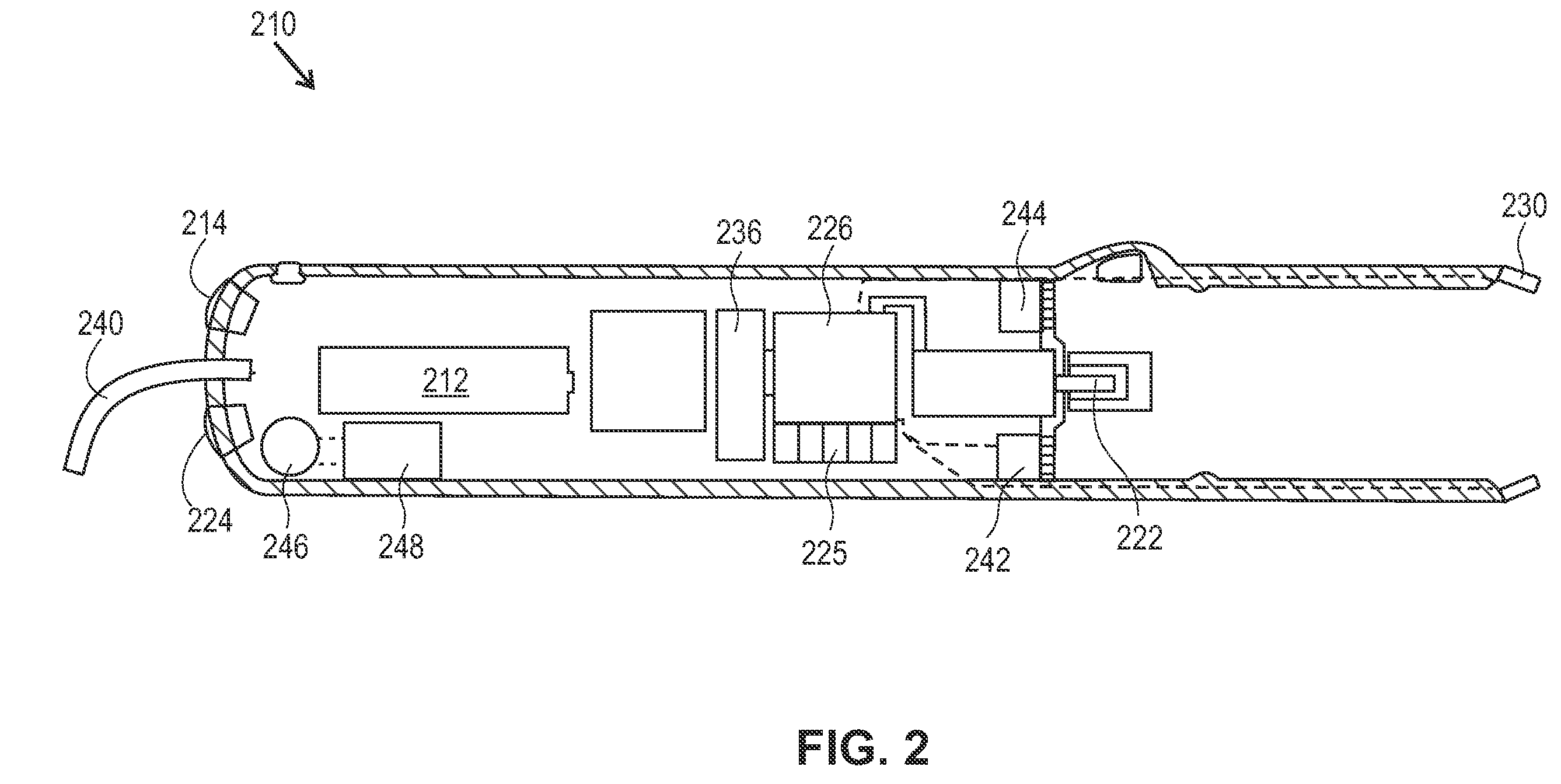

Methods and apparatus for ink delivery to nanolithographic probe systems

InactiveUS7034854B2Improve the level ofEasy to printRecording apparatusMaterial nanotechnologyNanolithographyEngineering

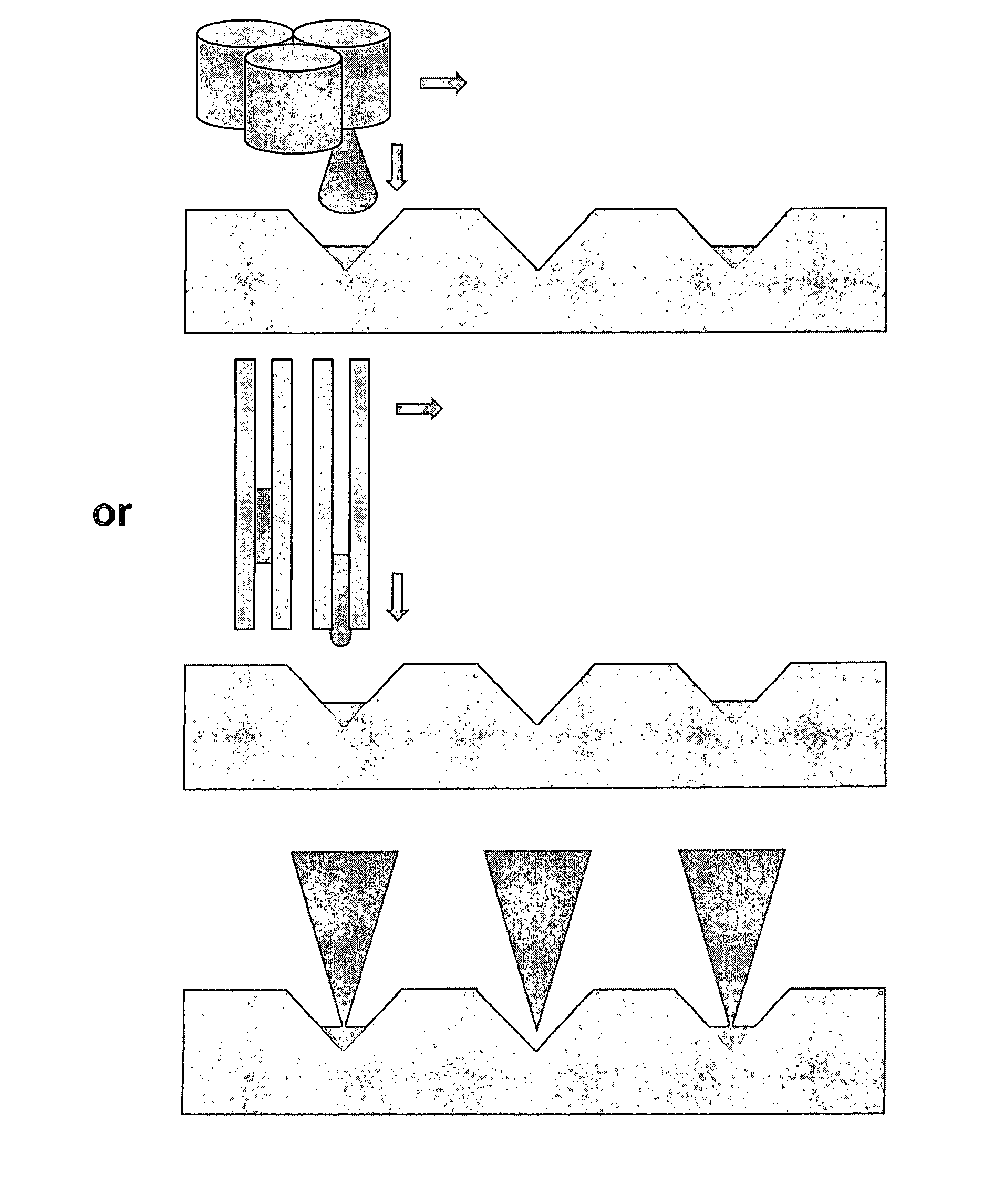

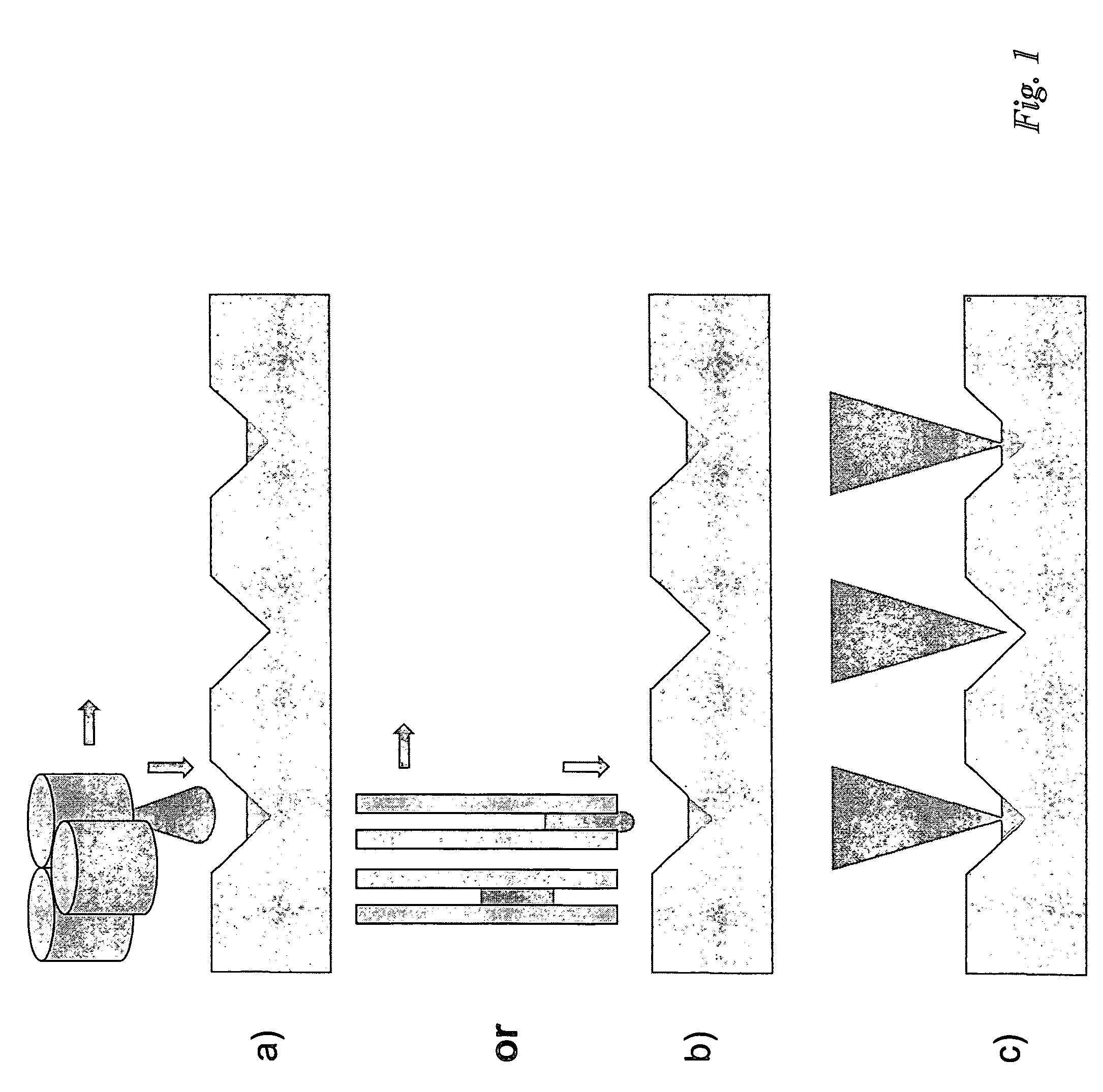

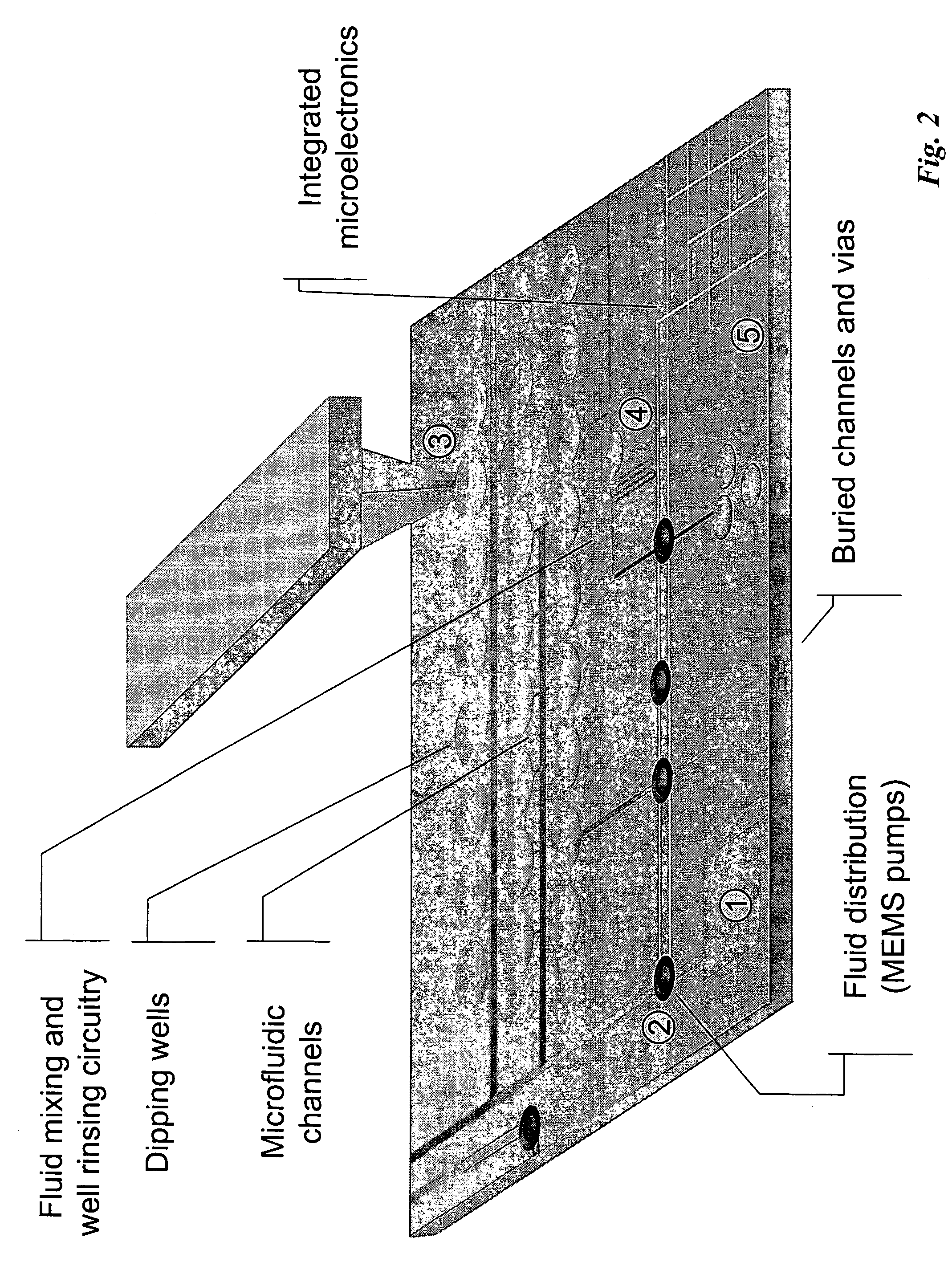

Inkwells adapted for use in direct-write nanolithography and other applications including use of wells, channels, and posts. The wells can possess a geometry which matches the geometry of tips which are dipped into the inkwells. The channels can be open or closed. Hydrophilicity and hydrophobicity can be used to control ink flow. SEM can be used to characterize the inkwells. Ink flow can be monitored with video. Hydrophobic material layers can be used to prevent cross contamination. Microsyringes can be used to fill reservoirs. Satellite reservoirs can be used to prevent bubble formation.

Owner:NANOINK INC

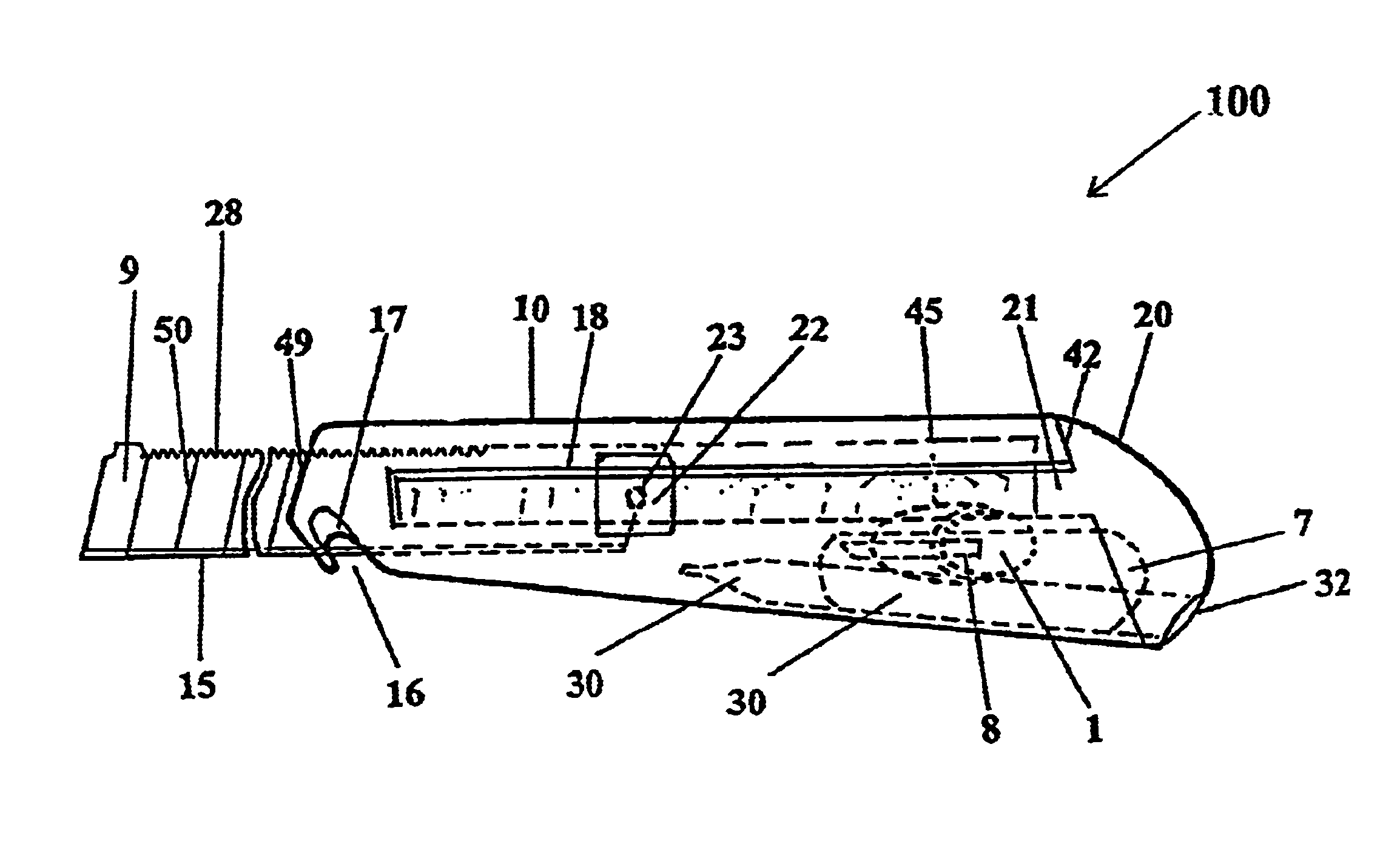

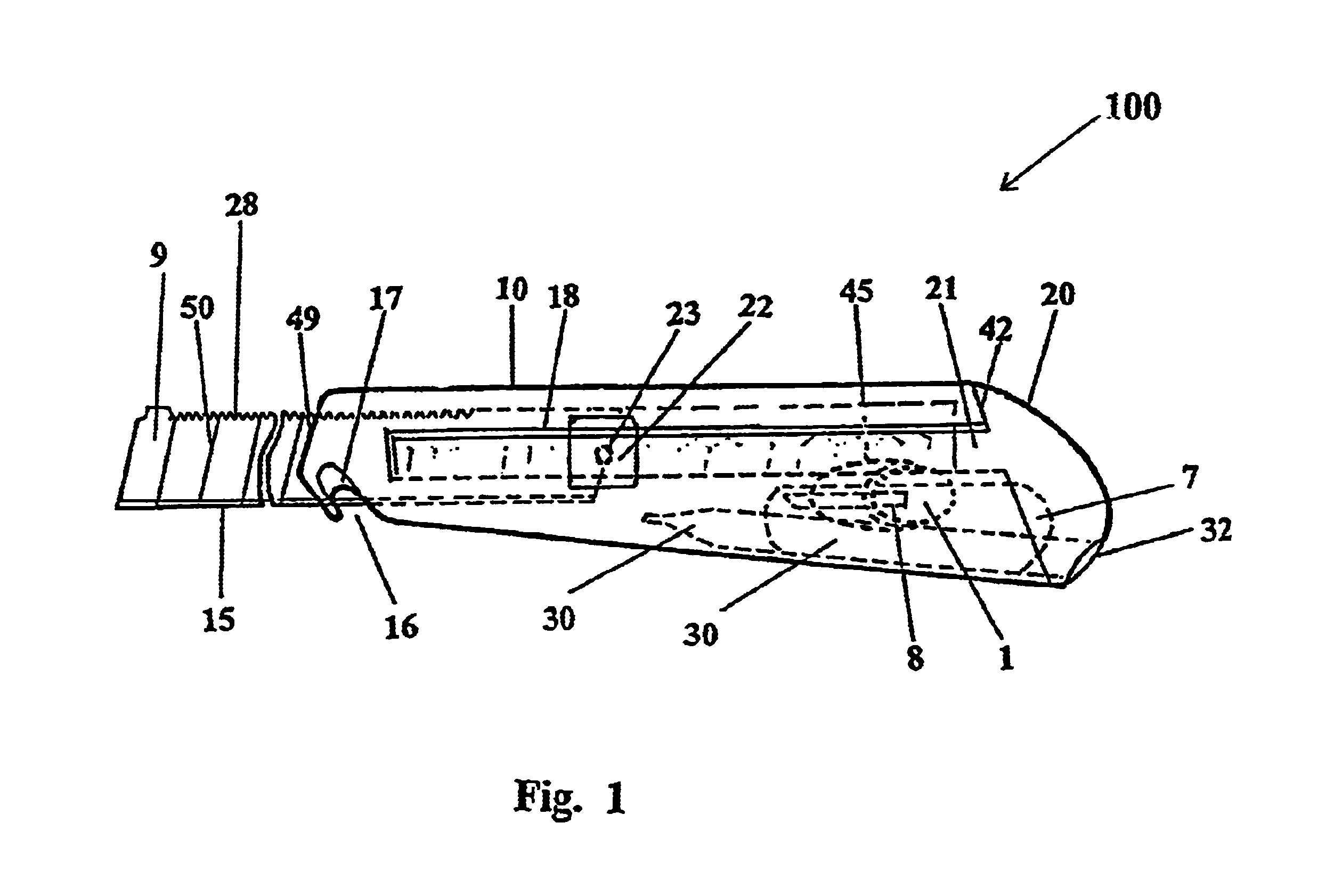

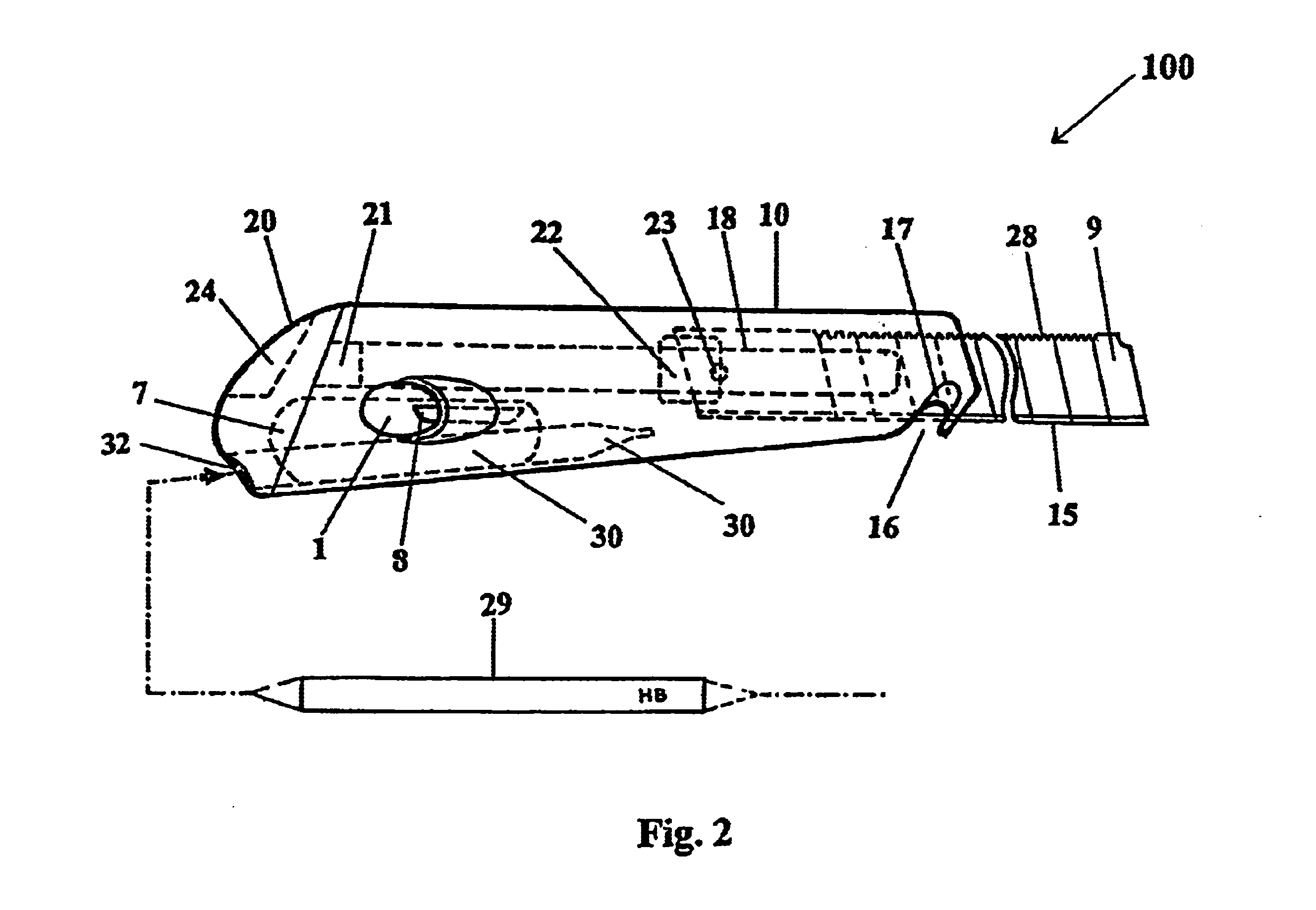

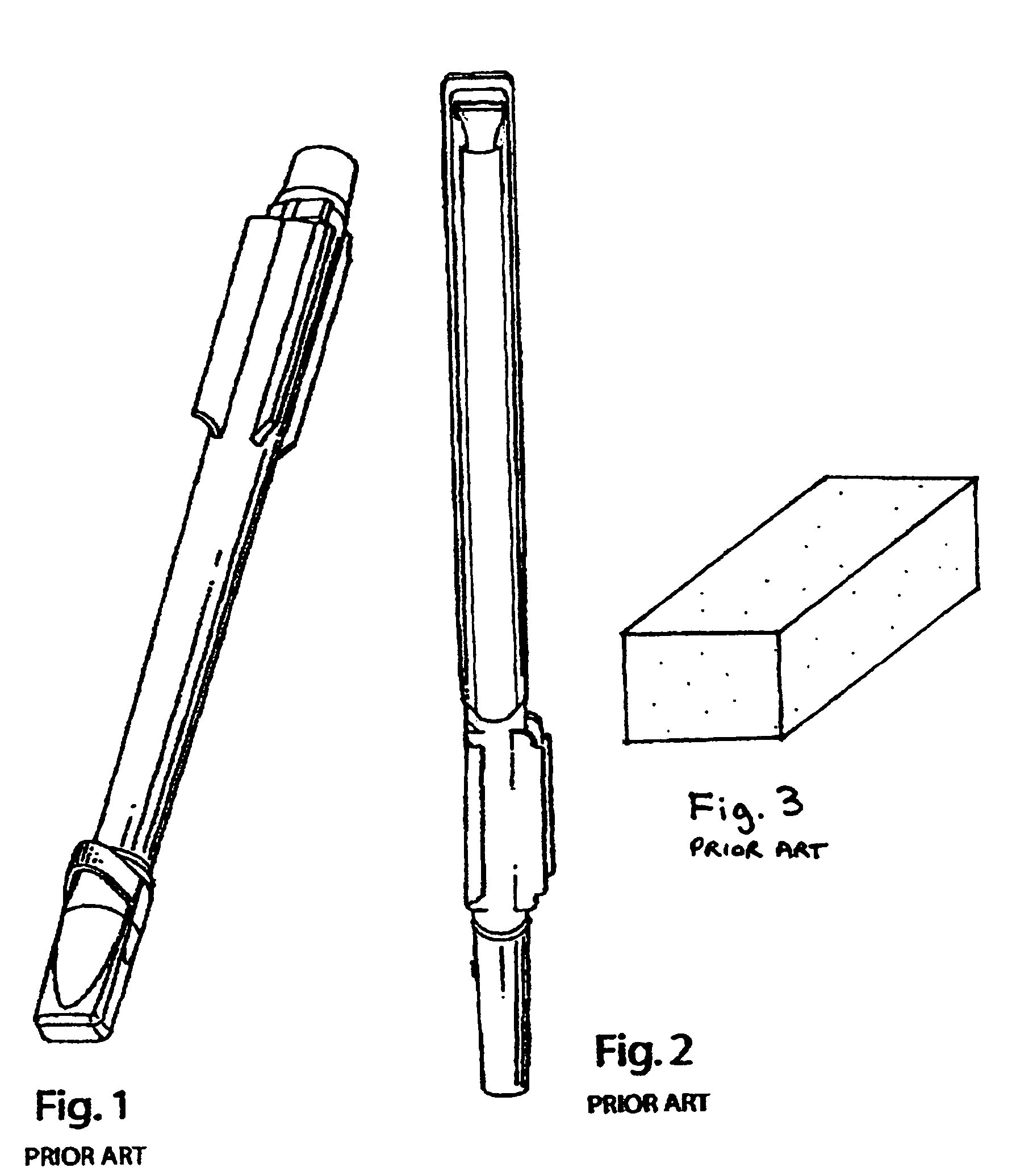

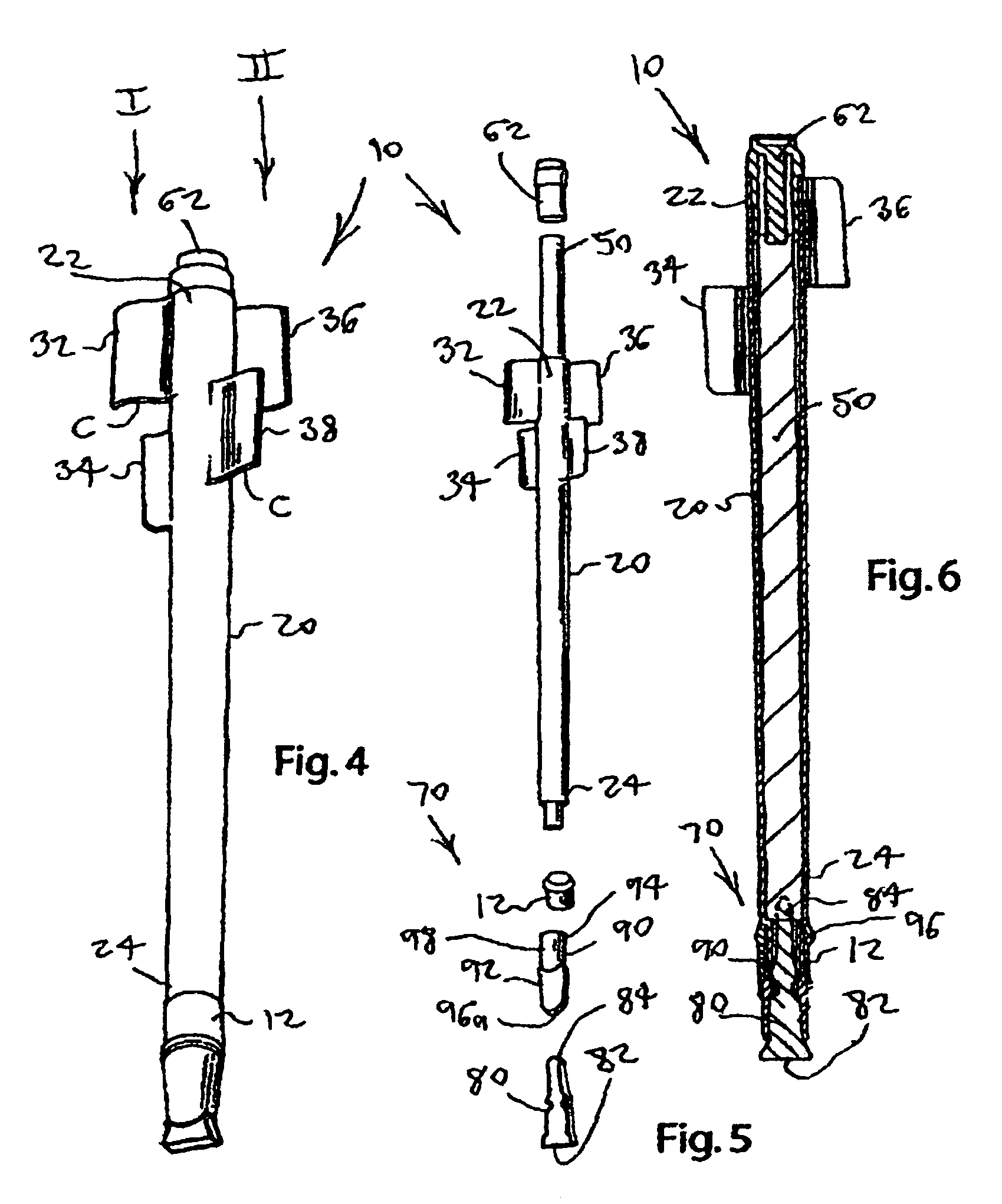

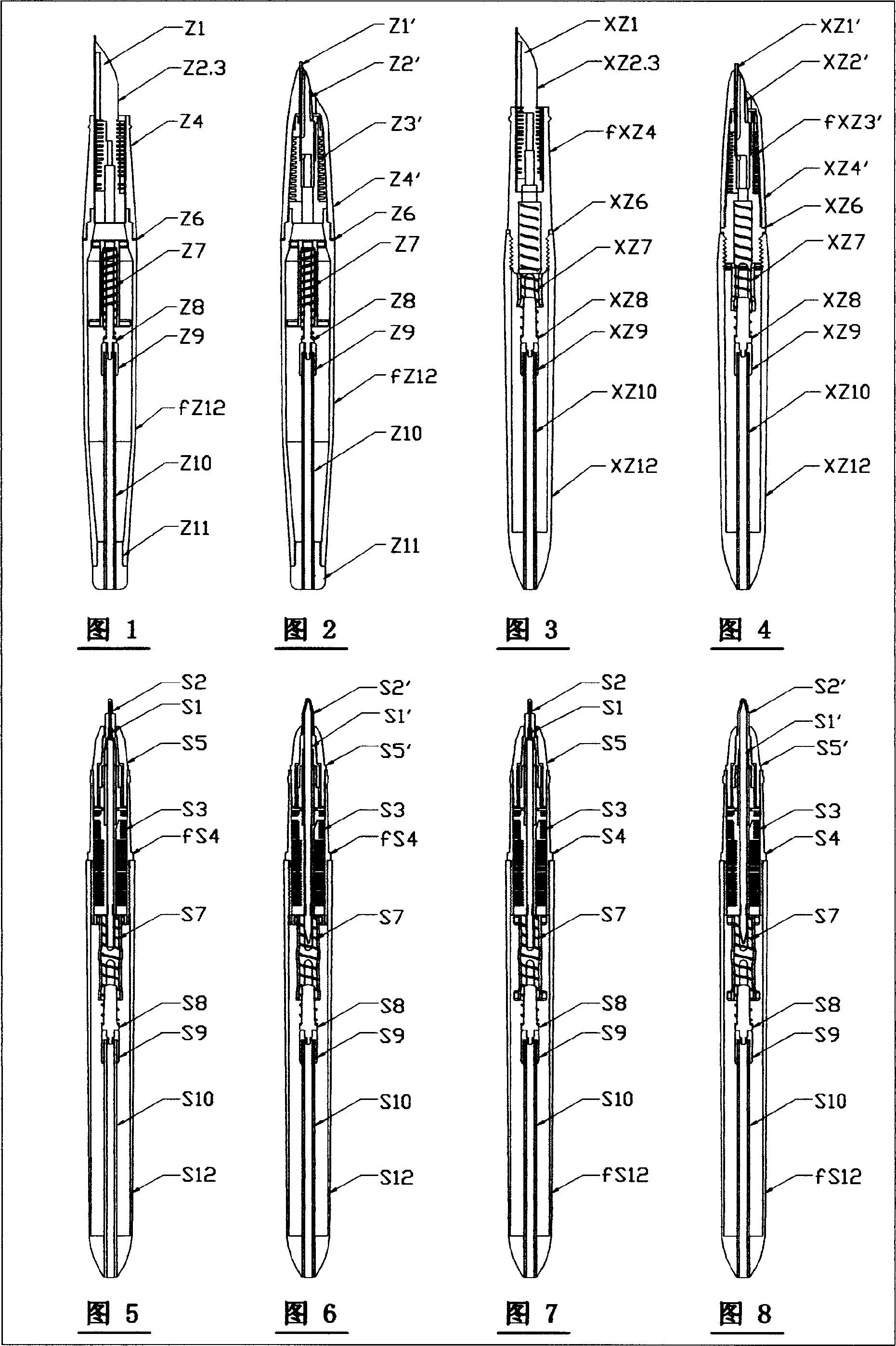

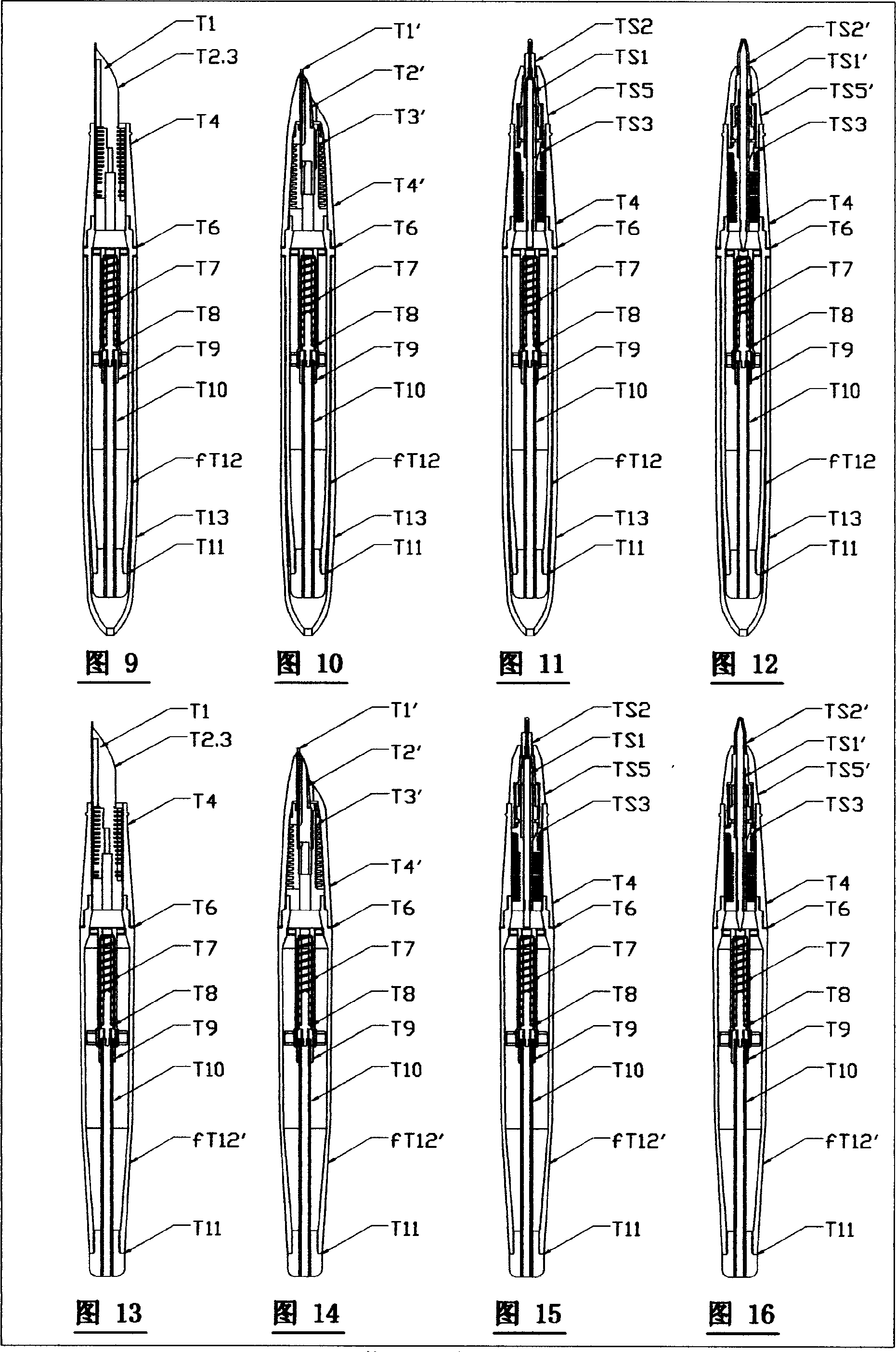

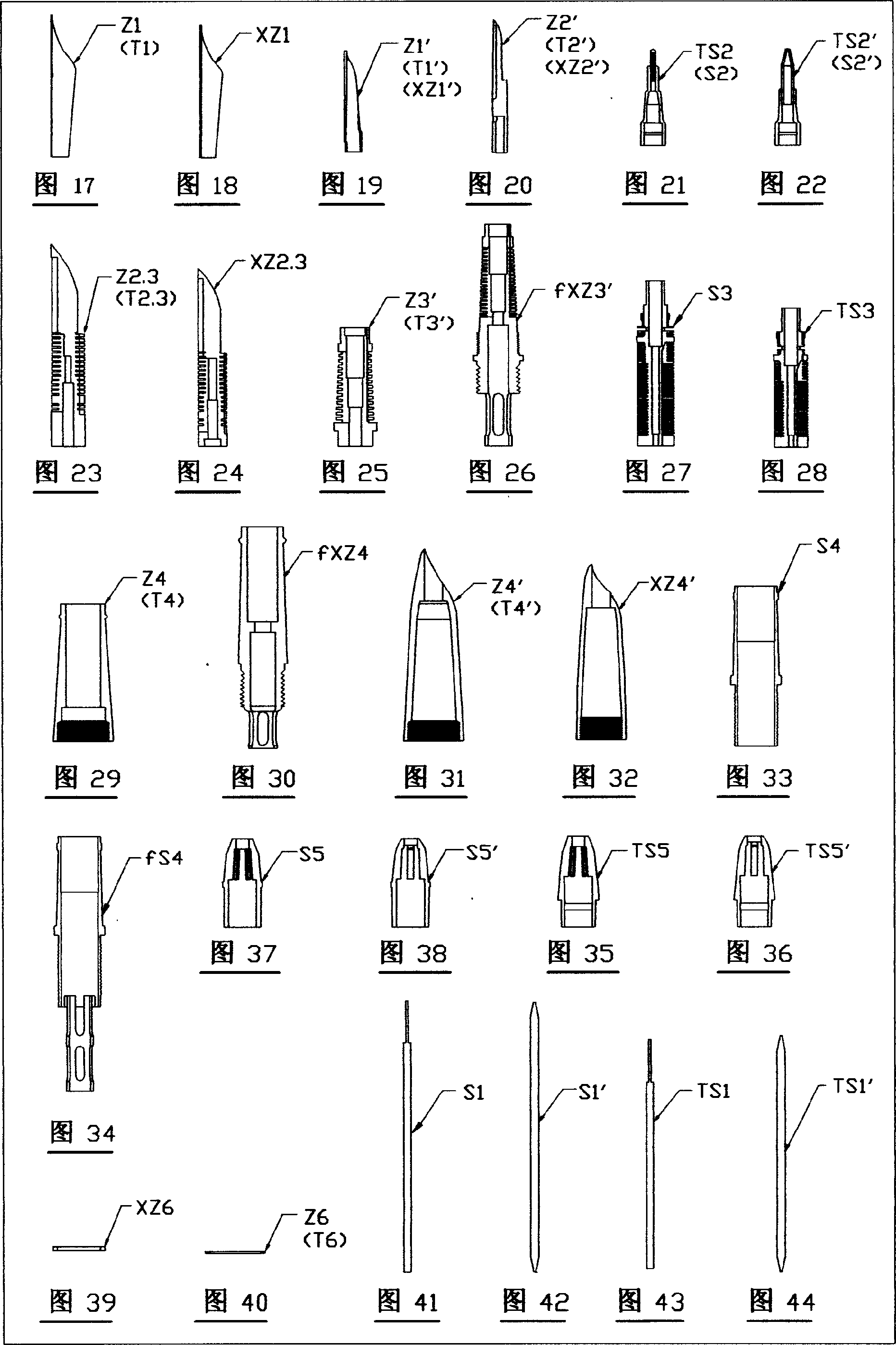

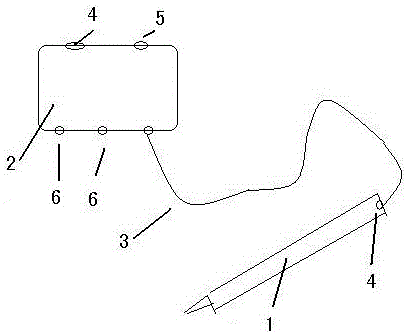

Combination utility knife

A retractable blade utility knife includes a knife housing, a blade, a pencil housing, a pencil sharpening slot, and a rear cover. The knife may further include a rope-cutting recess and a cutting surface in a lower end and a sawing surface in an upper end of the blade. The pencil housing forms in a lower rear part of the knife housing to keep hold of a pencil. The pencil sharpening slot is connected to a conical bore and a pencil chips storage room. The rope-cutting recess facilitates rope cutting by the blade. The blade carrier carries the blade and slides along a longitudinal axis of a knife groove formed in one side of the knife housing. The rear cover of the knife includes a pencil inlet hole and a rear cover fixed switch. The rear cover is detachably coupled to a rear portion of the knife housing via the rear cover fixed switch. The rear cover includes a pencil chip storage space and a pencil chip outlet.

Owner:YU ZU SHENG

Refill system and method

InactiveUS20130078025A1Reduce leakageInhibition releaseInk receptaclesWriting boardsBiomedical engineeringMarking out

A portable refillable marker-fluid cartridge comprising a marker-chamber, a marker-fluid applicator extending from out of the cartridge wherein the marker fluid applicator is in fluid communication with the marker-chamber, a filling mechanism configured to open from a delivery tube being pushed theretowards, thereby allowing the marker fluid to pass into the marker-chamber, and at least one seal-ring configured to minimize leak of the marker-fluid out of the marker-chamber.

Owner:BEAUTY UNION GLOBAL

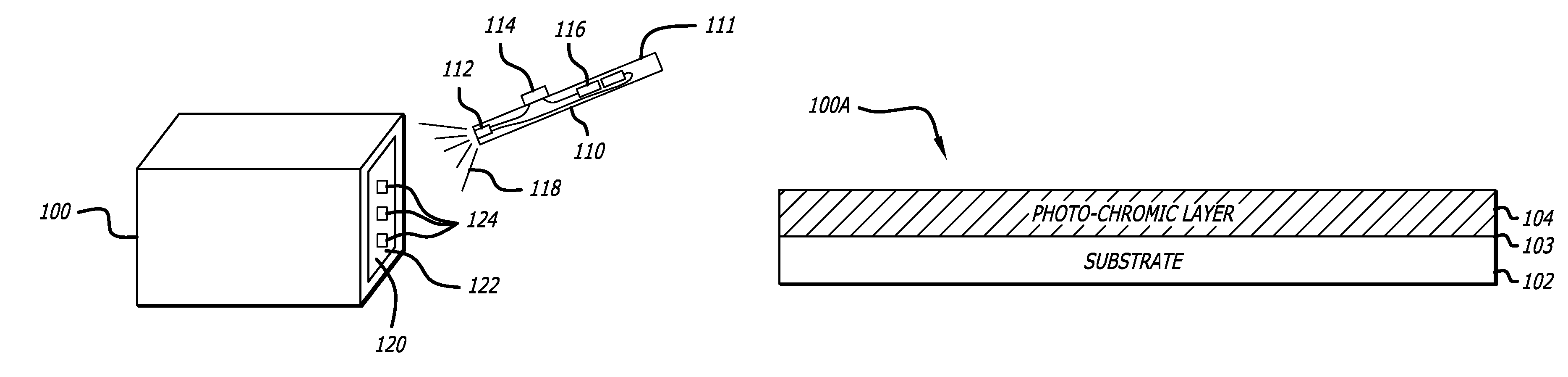

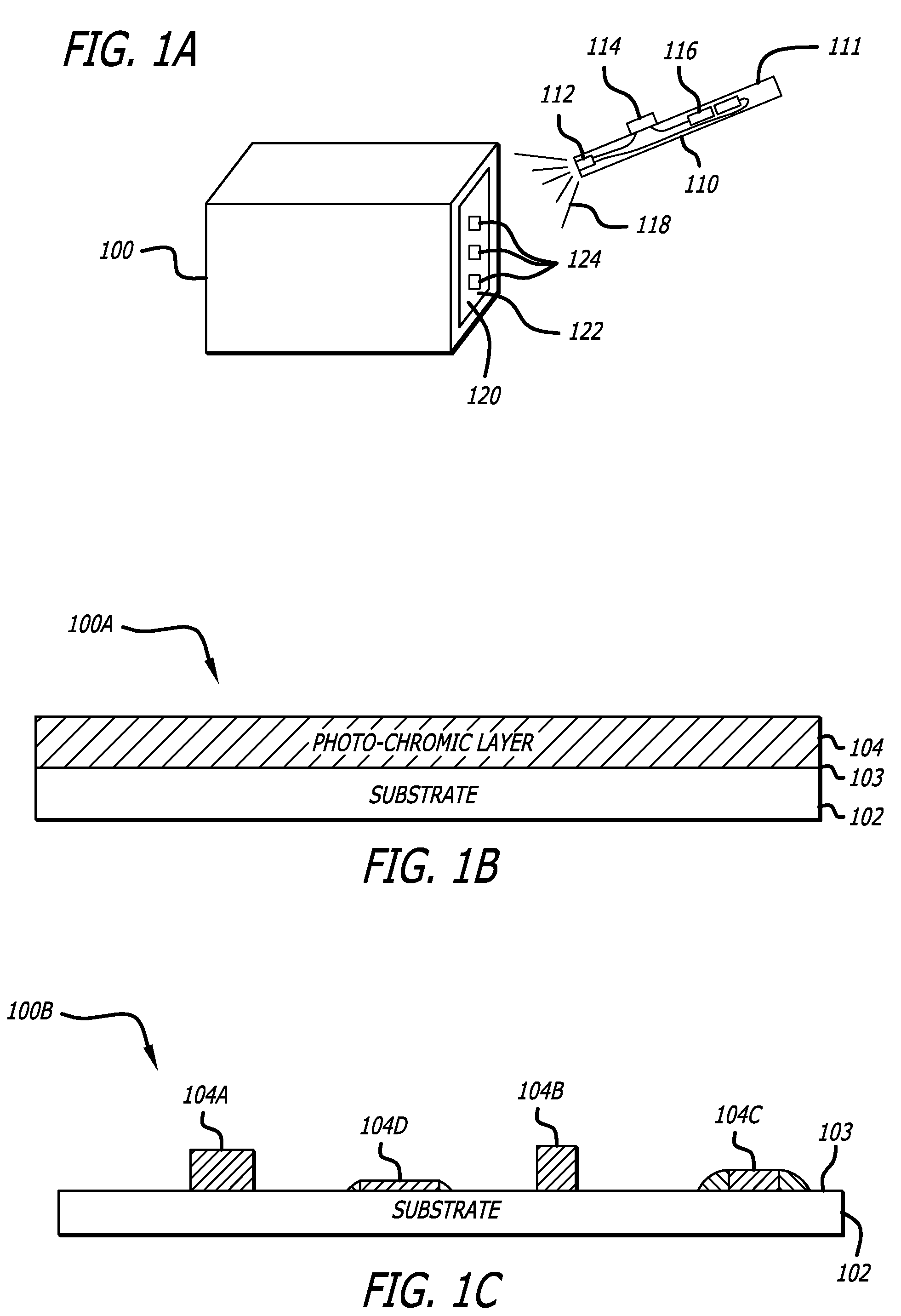

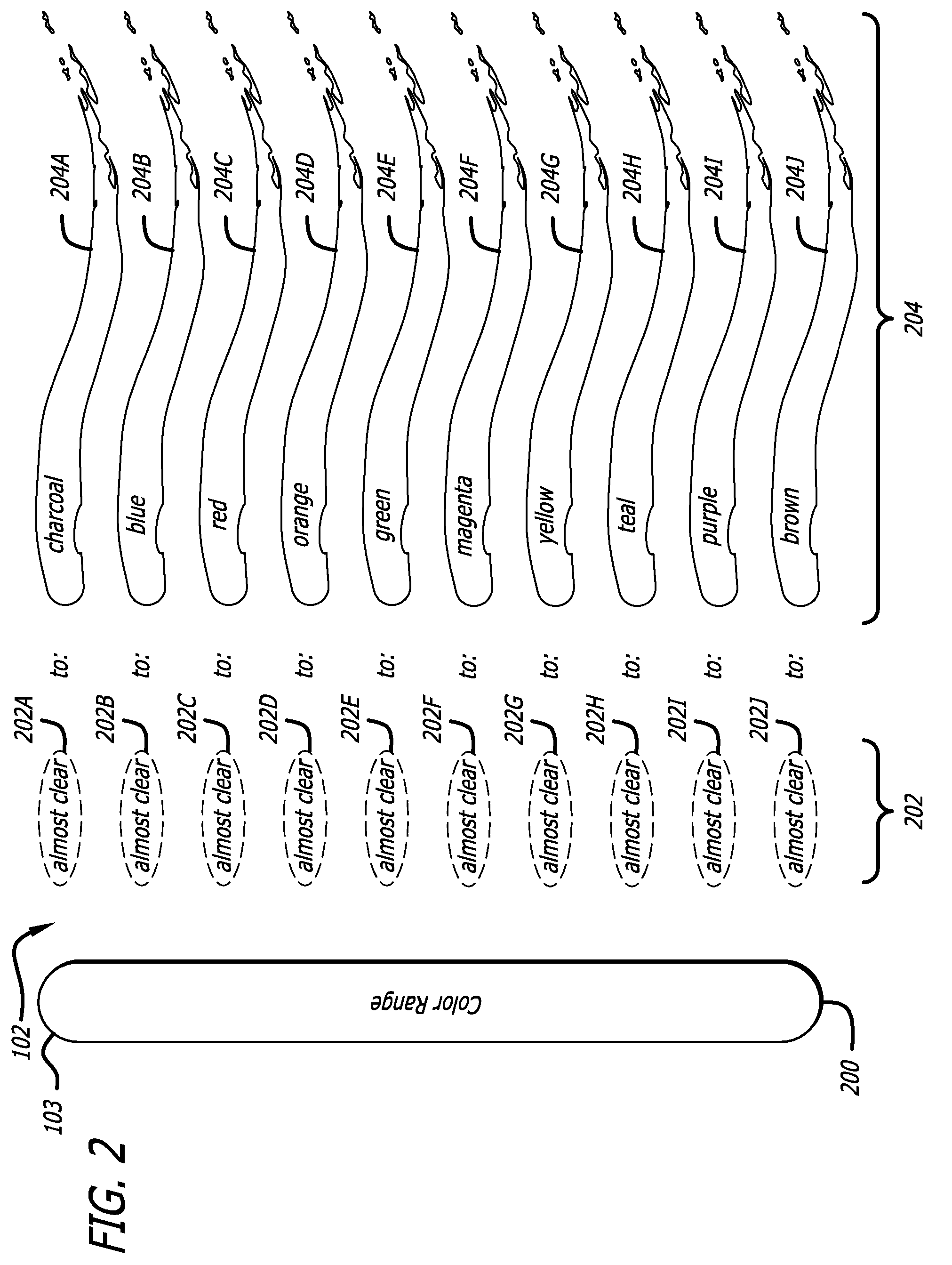

Photo-chromic material application apparatus

Owner:SPIN MASTER INC

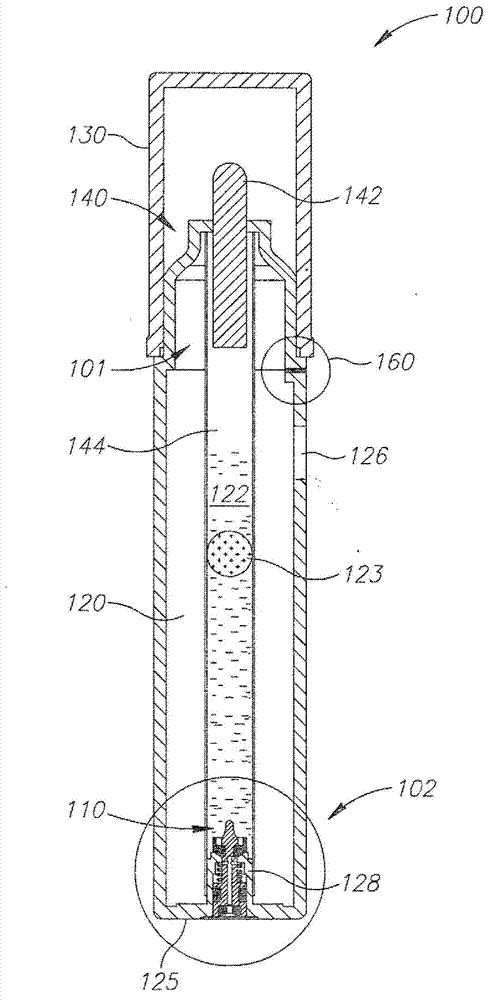

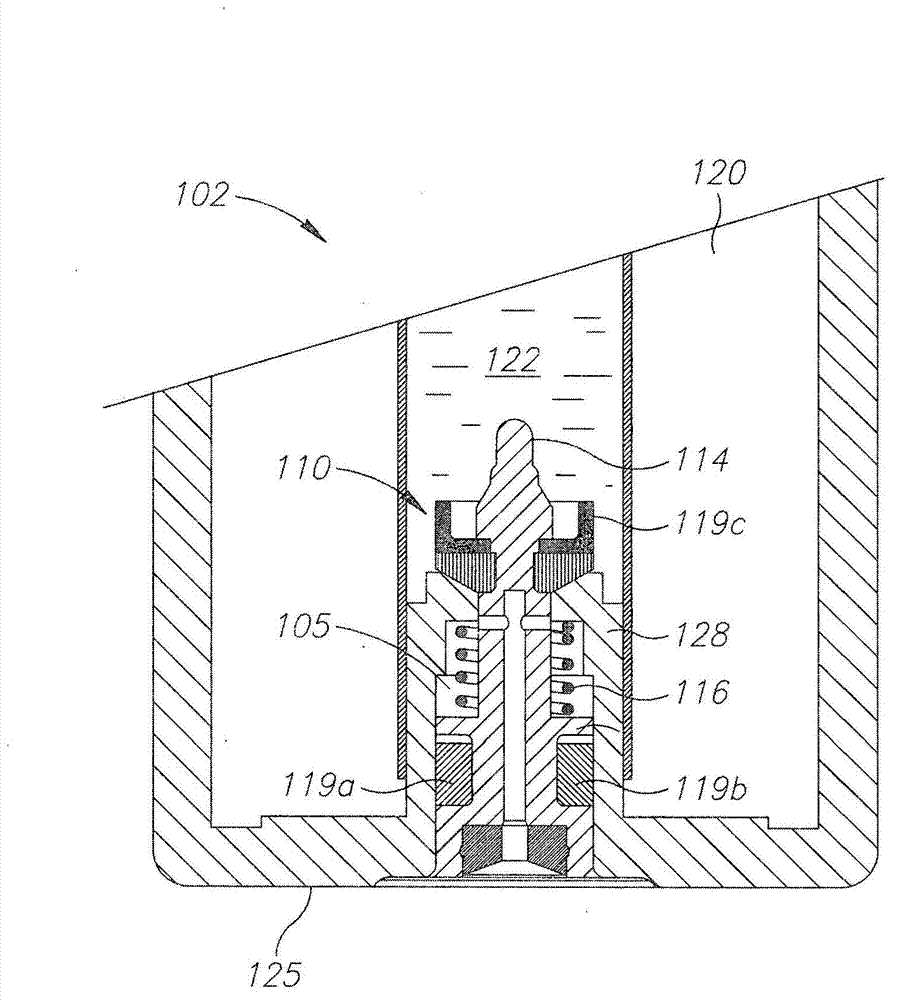

Fluid dispenser

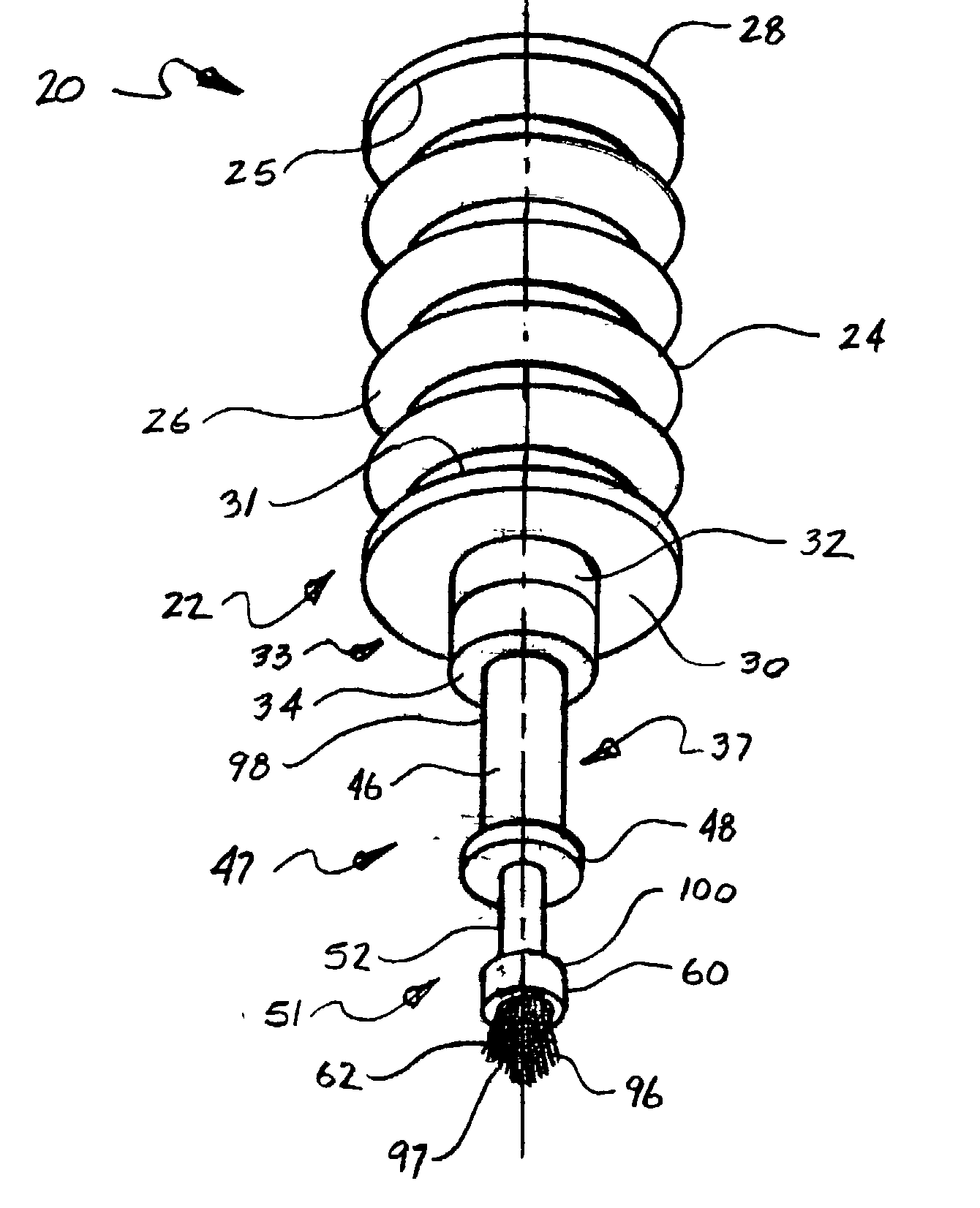

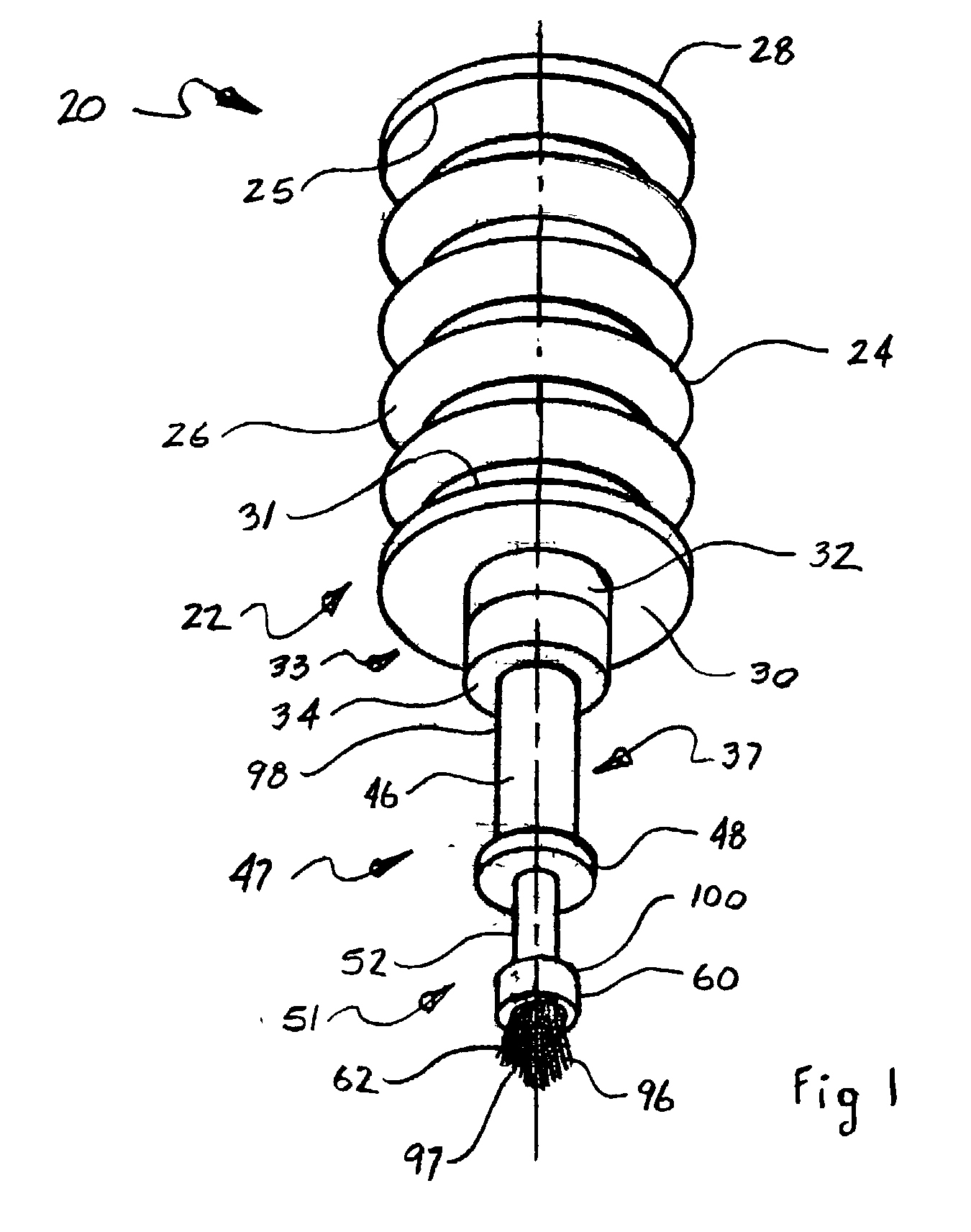

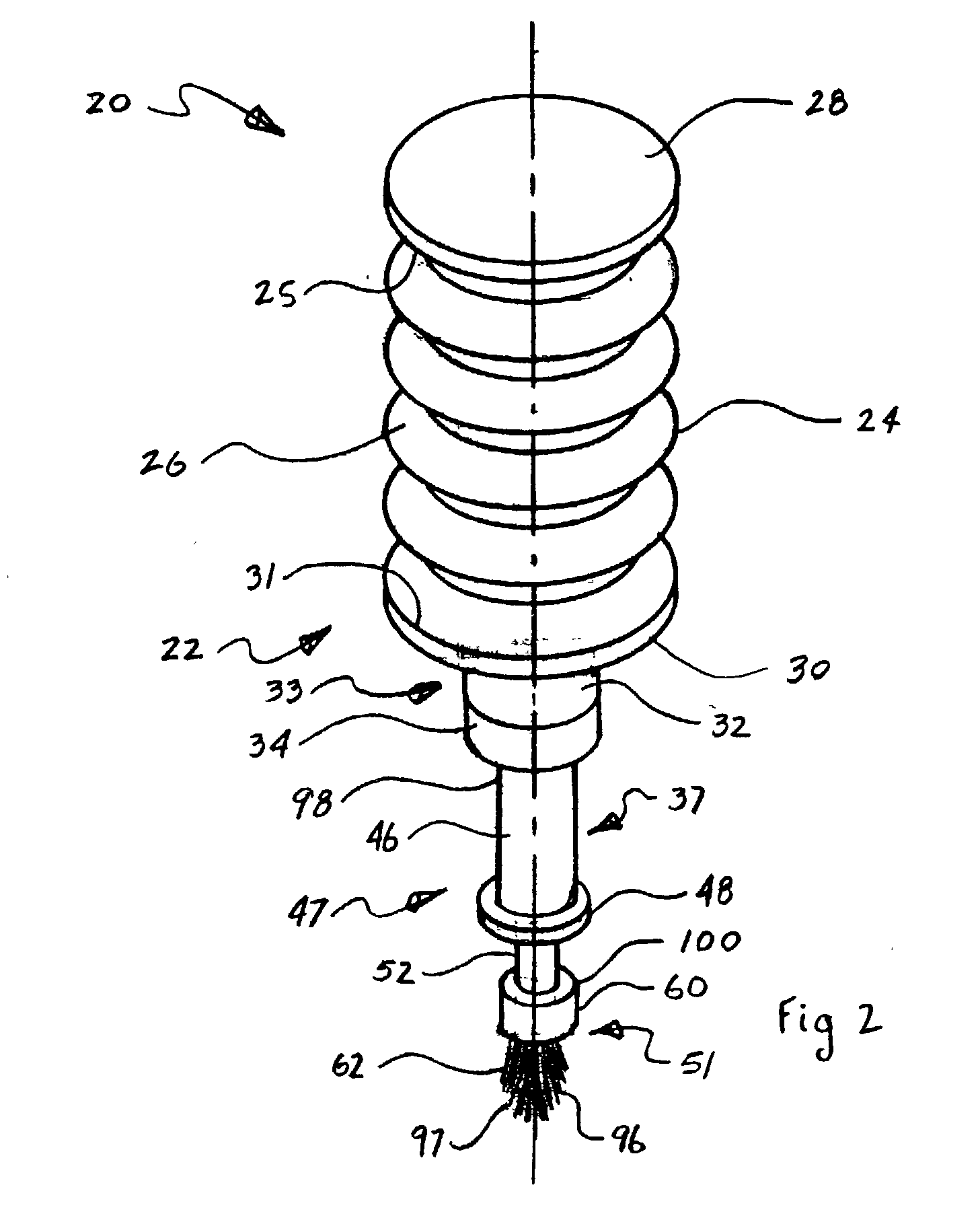

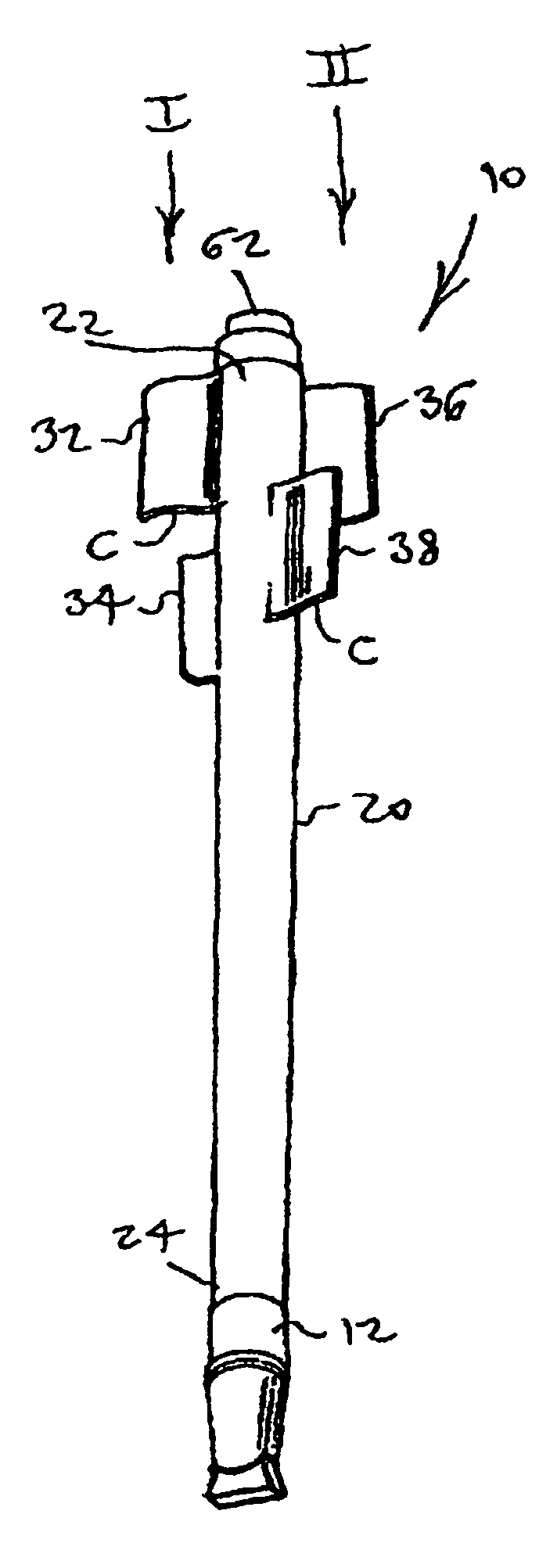

A fluid dispenser and method for applying a selected fluid to a desired location includes a reservoir containing the fluid, the reservoir includes a resilient body having a first end and a second end, a first end sealing cap, and a second end sealing cap assembly with a penetrable elastomeric member to define a reservoir interior. The body includes bellows oriented to retract or extend the body between the first end and the second end creating a variable reservoir interior volume. Also included is an applicator having a proximal end and a distal end, the proximal end includes a non coring cannula with a lumen having an insertion end adapted to penetrate through the elastomeric member and protrude into the reservoir interior. This enables fluid communication between the reservoir interior and the lumen; the distal end also includes an application element that is in fluid communication with the lumen.

Owner:KING PATRICIA ANNE

Selectably combinable multicolor modular marker and kit and pigment material dispensing means

InactiveUS7607848B1Fully compressedPrevent rotationInk receptaclesWriting connectorsEngineeringMechanical engineering

A modular marker kit for delivering pigment onto a receiving surface includes a first modular marker and a second modular marker, each module marker including a tubular housing having a housing proximal end and a housing distal end, a quantity of pigment material contained within the housing, and first and second arm sets of interconnection arms connected to and protruding laterally from the housing in opposing directions for engaging an adjacent such marker, the arms forming each arm set being staggered in that they are spaced apart from each other along the length of the housing from which they protrude, each arm set including an upper arm and a lower arm; so that spaced apart upper and lower arm pairs interconnect the first and second markers, preventing the first and second markers from pivoting relative to each other when interconnected, and so that the upper arm of one arm set on the first marker combines with the upper arm of an adjacent arm set of the second marker, and so that each arm set contributes one arm to the upper arm pair and one arm to the lower arm pair.

Owner:AHMED CYNTHIA G +1

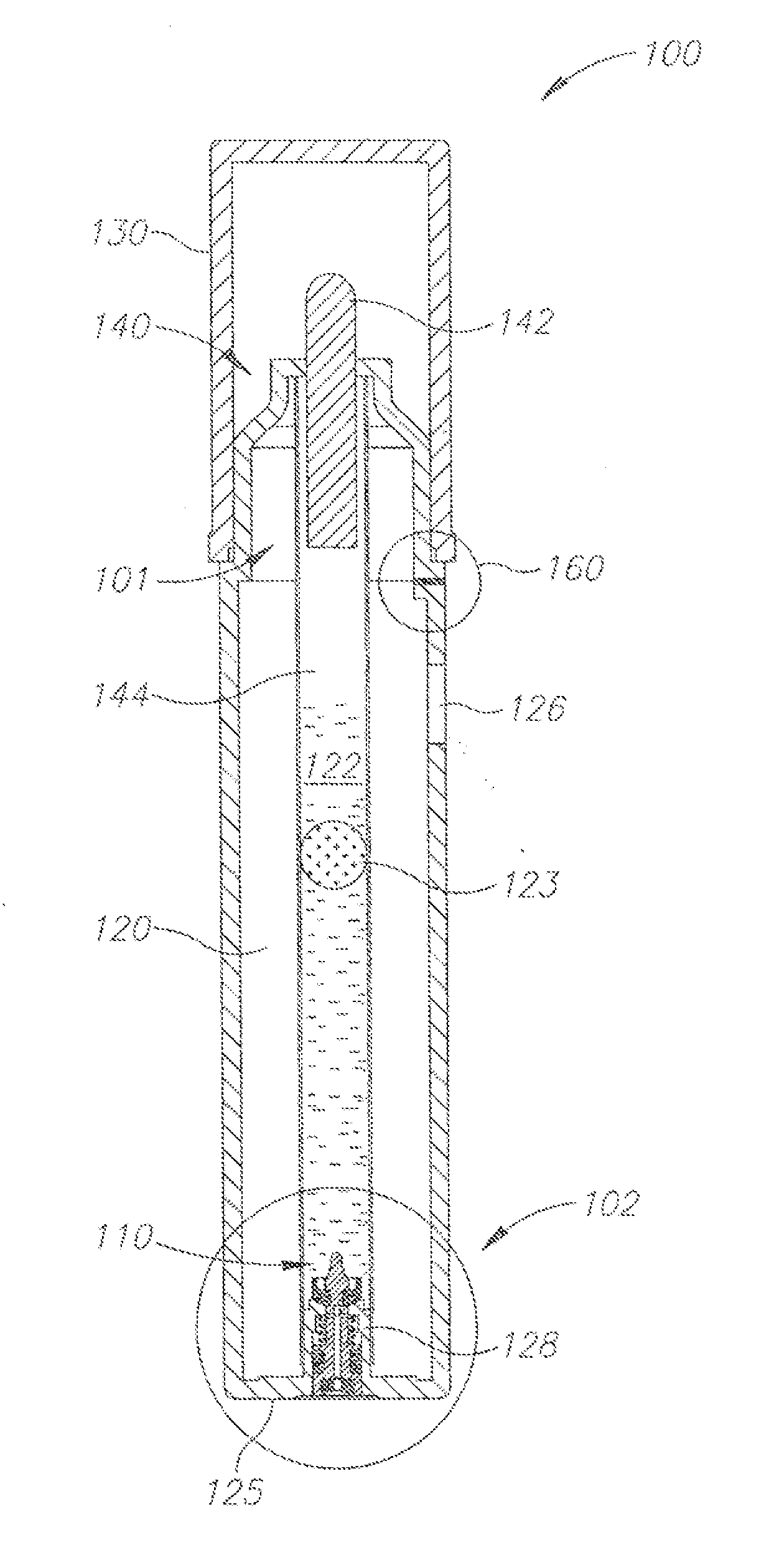

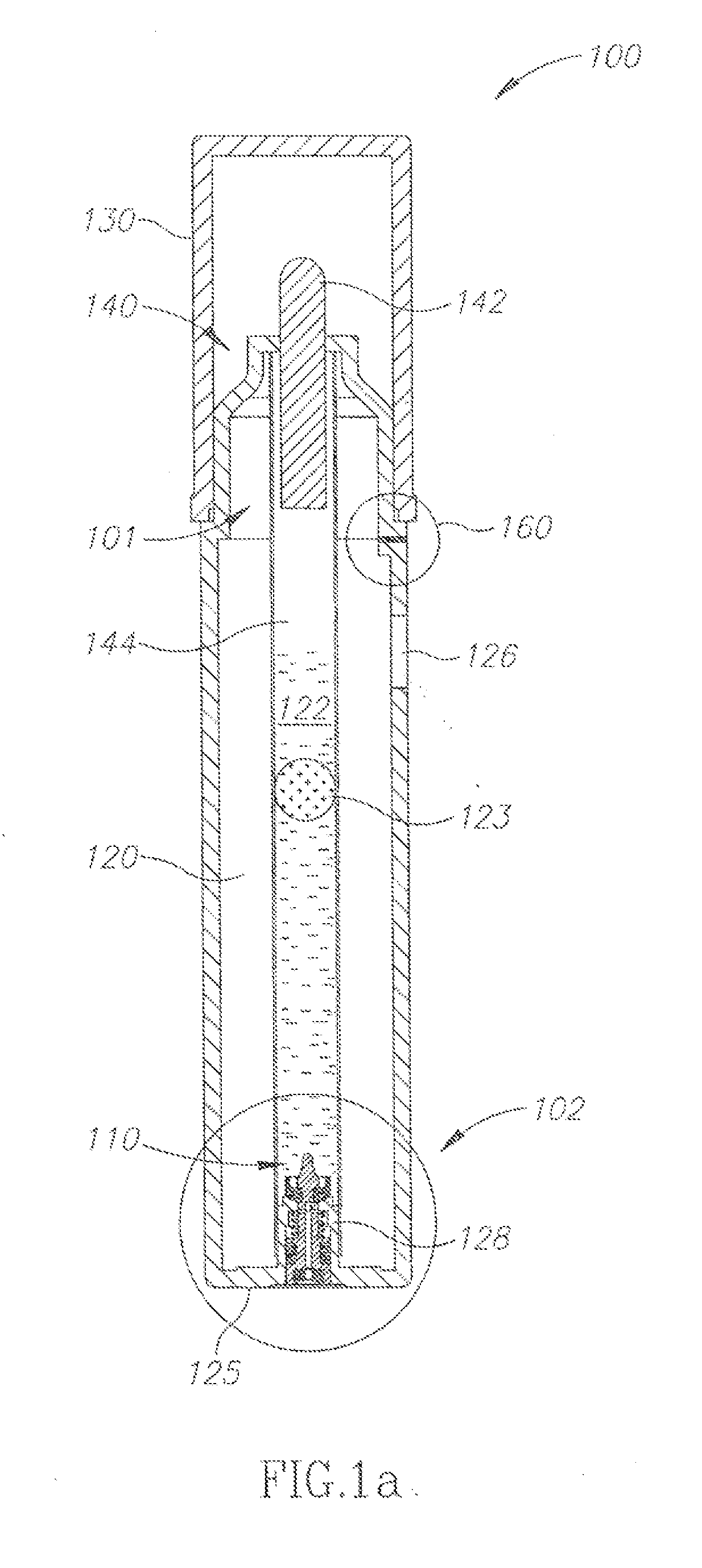

Refill system and method

A portable refillable marker-fluid cartridge comprising a marker-chamber; a marker-fluid applicator extending from out of the cartridge wherein the marker fluid applicator is in fluid communication with the marker-chamber; a filling mechanism configured to open from a delivery tube being pushed theretowards, thereby allowing the marker fluid to pass into the marker-chamber, and at least one seal-ring configured to minimize leak of the marker-fluid out of the marker-chamber.

Owner:BEAUTY UNION GLOBAL

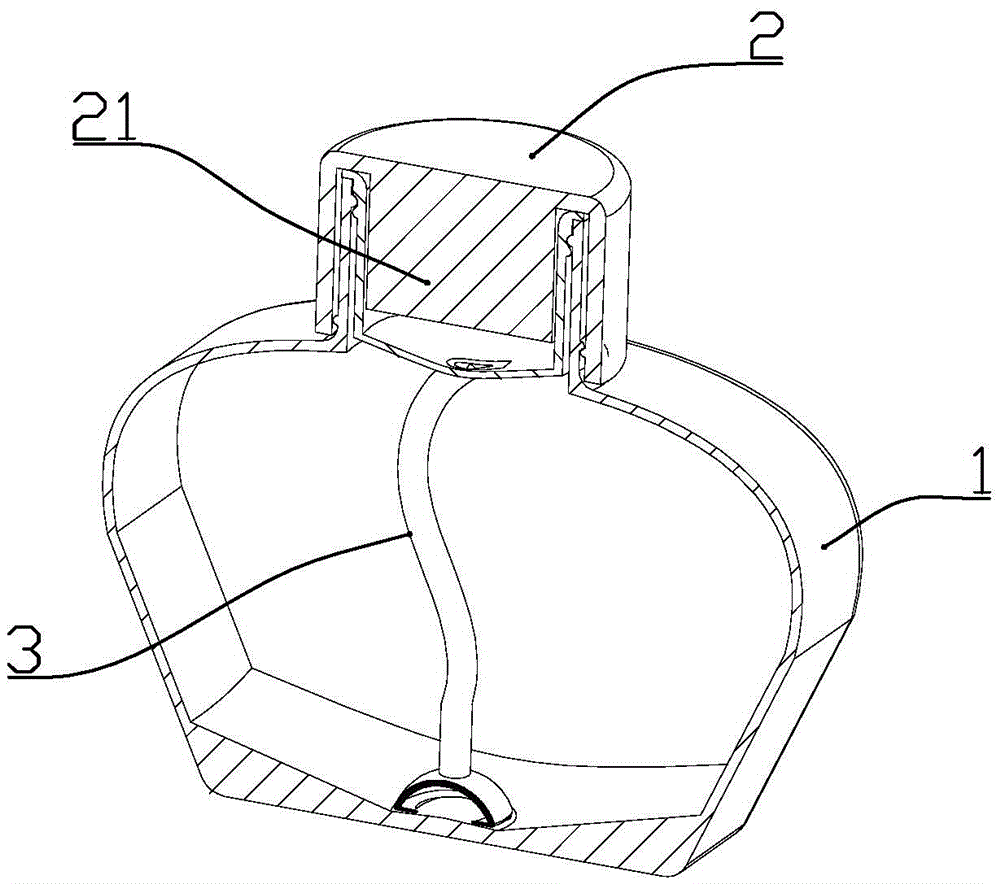

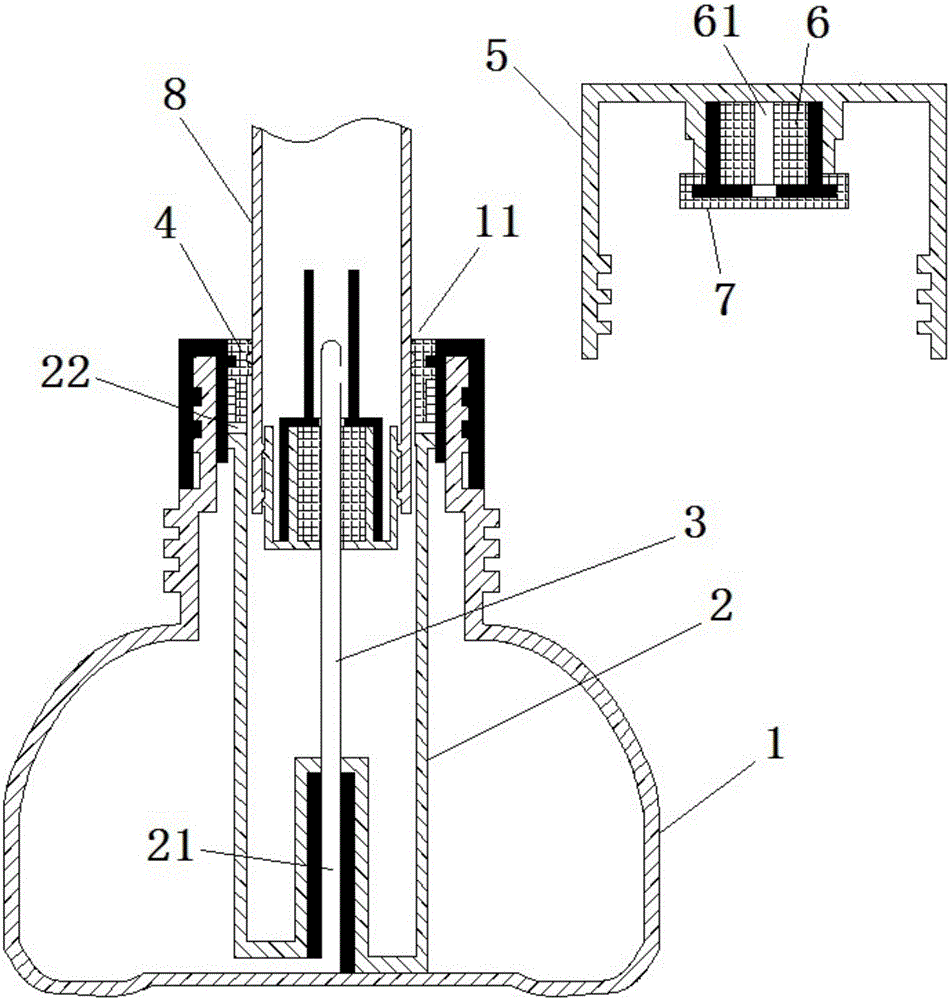

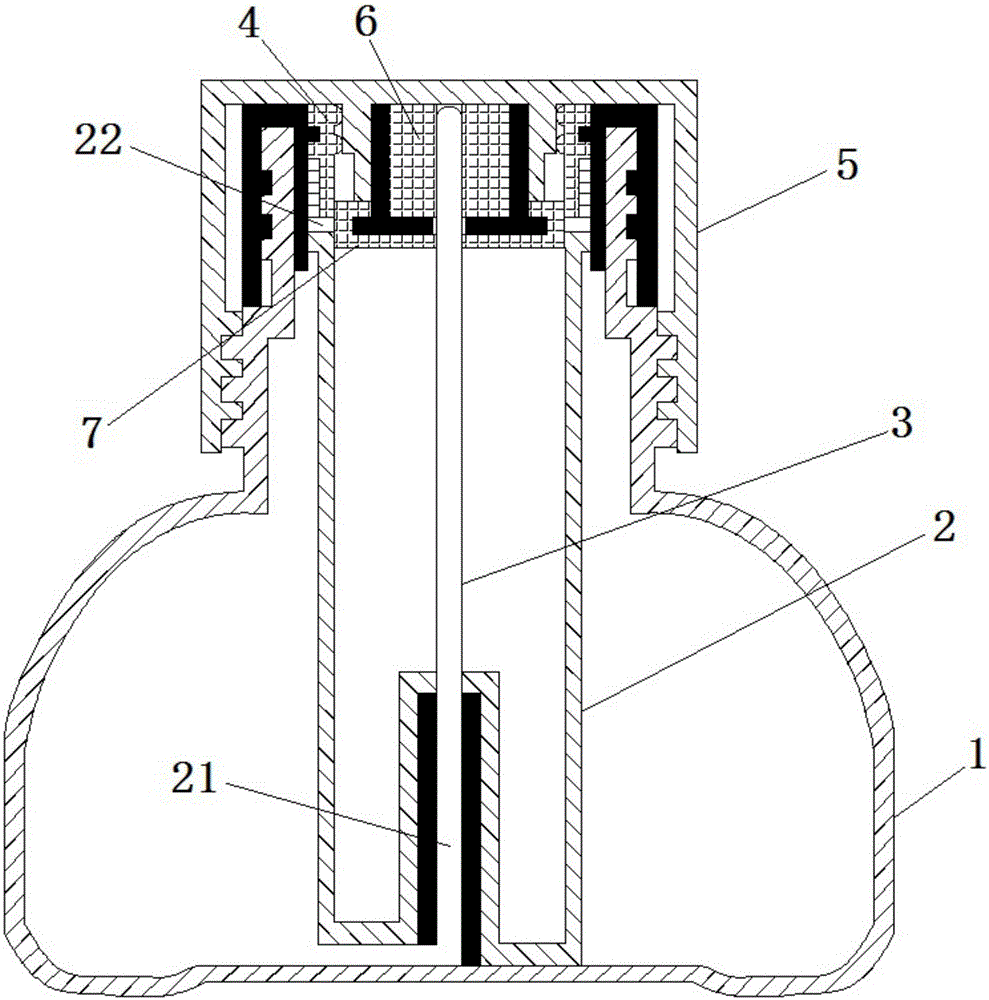

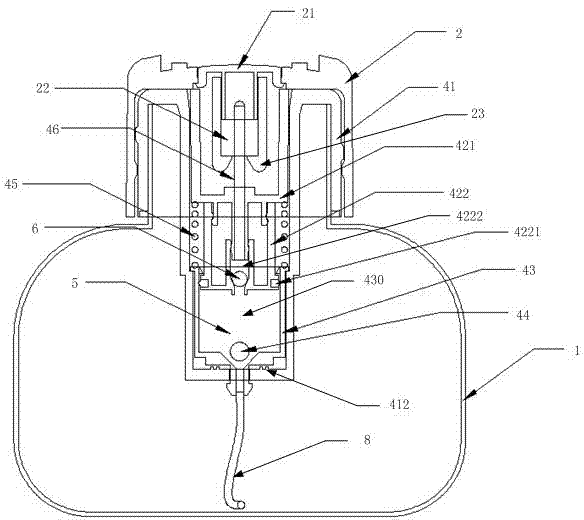

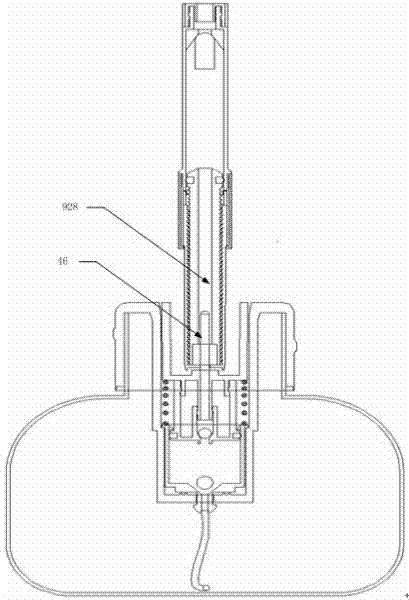

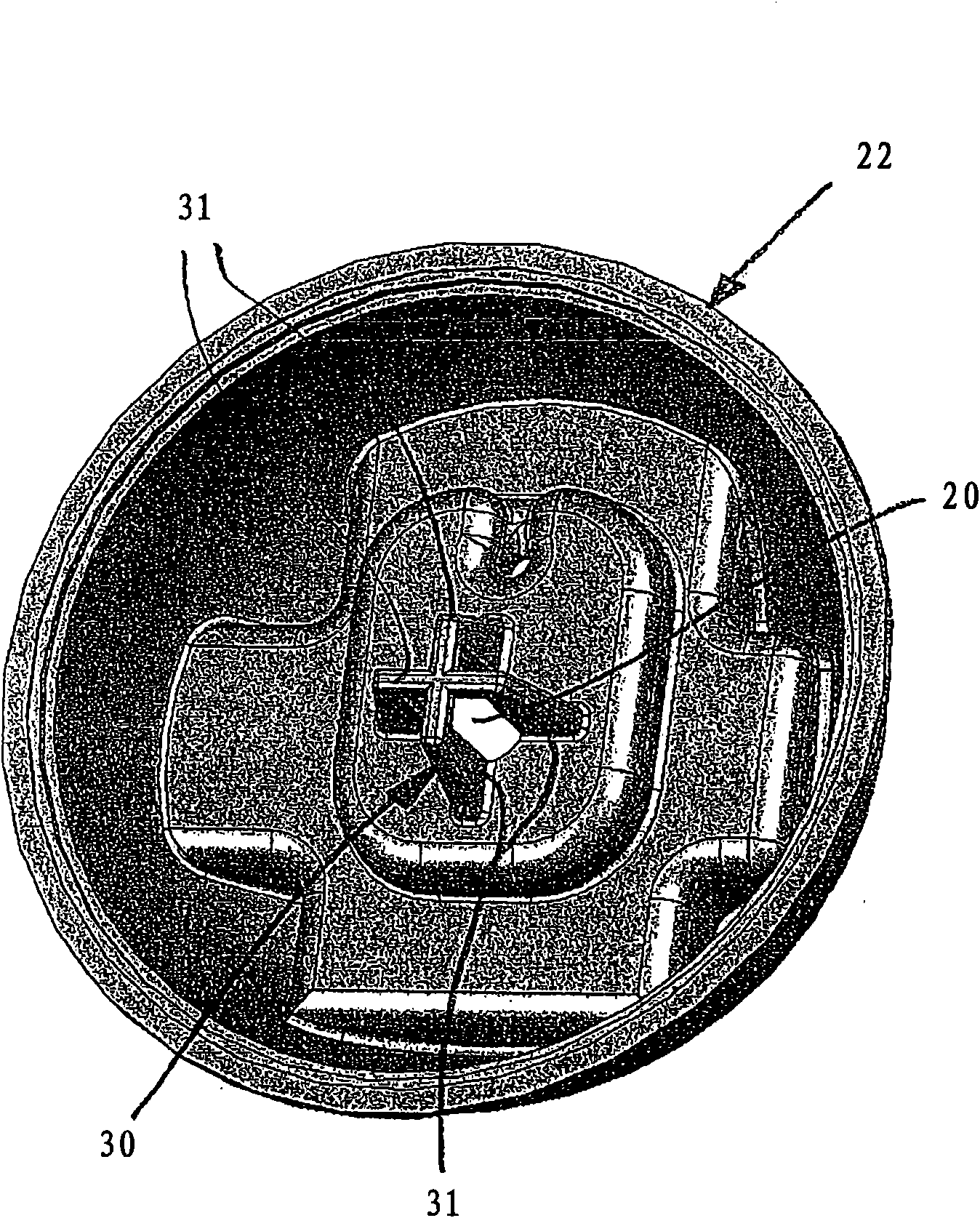

Folding and resilience type ink injection bottle

The invention provides a folding and resilience type ink injection bottle. The folding and resilience type ink injection bottle comprises a bottle body, a needle base and a liquid injection tube. The bottle body is provided with a bottle neck, and an opening is formed in the upper end of the bottle neck. A folding and resilience part is arranged between the bottle body and the bottle neck, and the bottom surface of the bottle body is an inwardly concave elastic surface. The needle base is fixedly arranged on the bottle neck. The needle base comprises a supporting base and a sleeve base, wherein the supporting base is located on the upper portion of the needle base, the pen body of an ink pen can be inserted in the supporting base, and the sleeve base is located on the lower portion of the needle base and fixedly sleeved with the liquid injection tube. The upper end of the liquid injection tube is exposed out of the supporting base and communicated with the outside. The lower end of the liquid injection tube abuts against the bottom surface of the bottle body, and the liquid injection tube is provided with a hose communicated with the interior of the bottle body. A first sealing part connected with the pen body of the ink pen in a sealing mode is fixedly arranged on the supporting base. The supporting base is provided with a ventilation hole making the interior of the bottle be communicated with the outside. By the adoption of the folding and resilience type ink injection bottle, ink return of the pen sac of the ink pen can be achieved before ink injection, and ink can be prevented from overflowing.

Owner:GUANGZHOU XINQI PATENT TECH EXTENSION SERVICE CO LTD +2

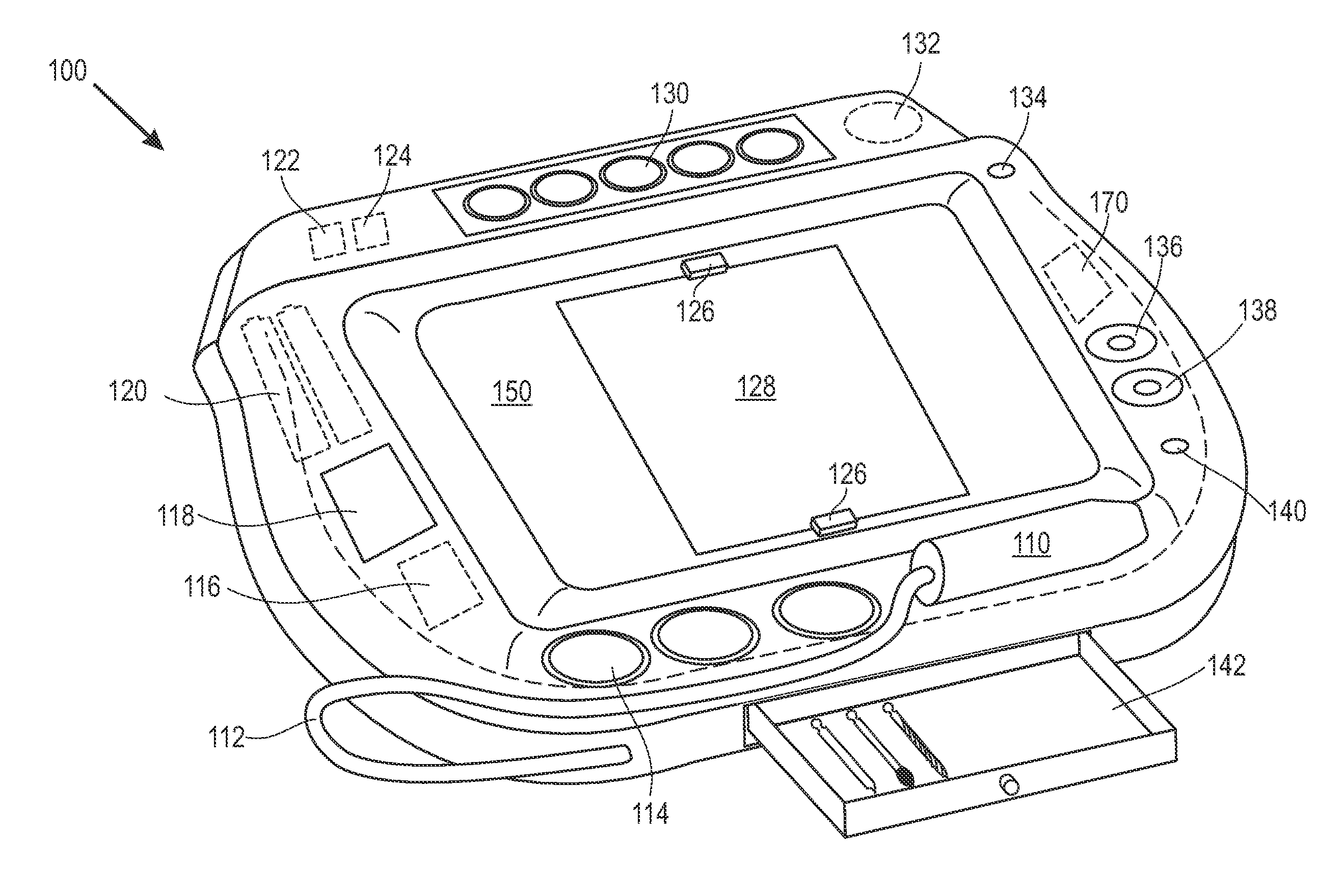

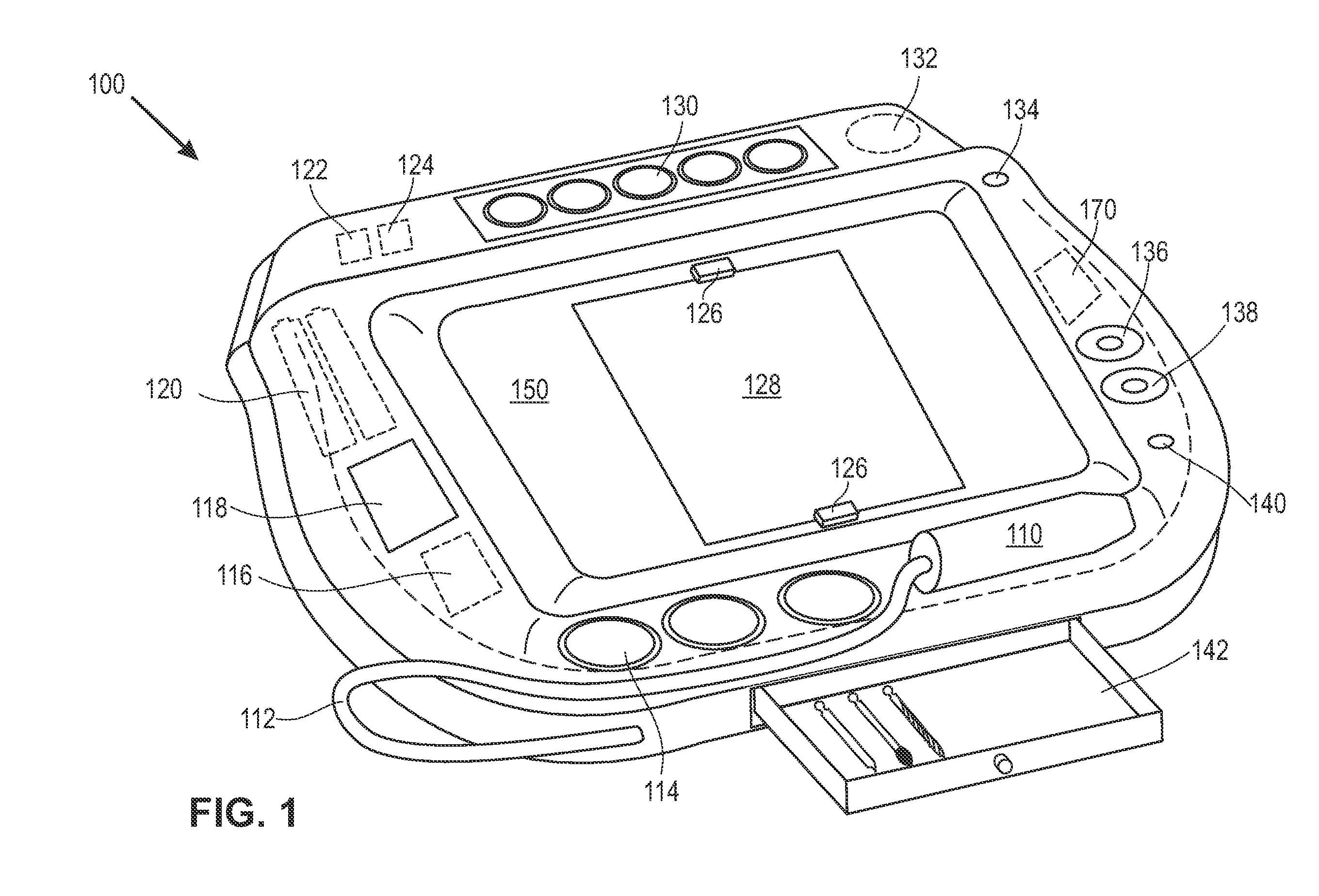

Methods and Apparatus for Art Supply Useage Compliance

ActiveUS20100253468A1Increase activity timeIncrease consumptionInk receptaclesWriting connectorsEngineeringYoungest child

Techniques are addressed for providing young children with an art experience in which opportunities to misuse art supplies, such as crayons, markers and the like are substantially reduced. To such ends, an art supply system is provided in which selectively enabled art supplies are automatically enabled so that they are useable only within a compliant usage zone, such as within a predetermined distance of an acceptable work surface.

Owner:DEVECKA ENTERPRISES

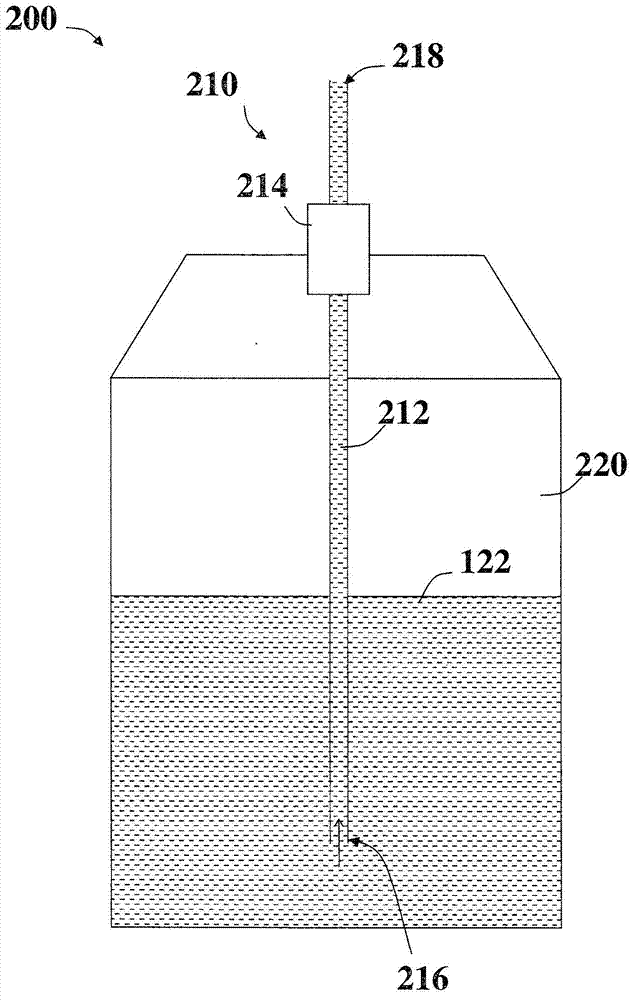

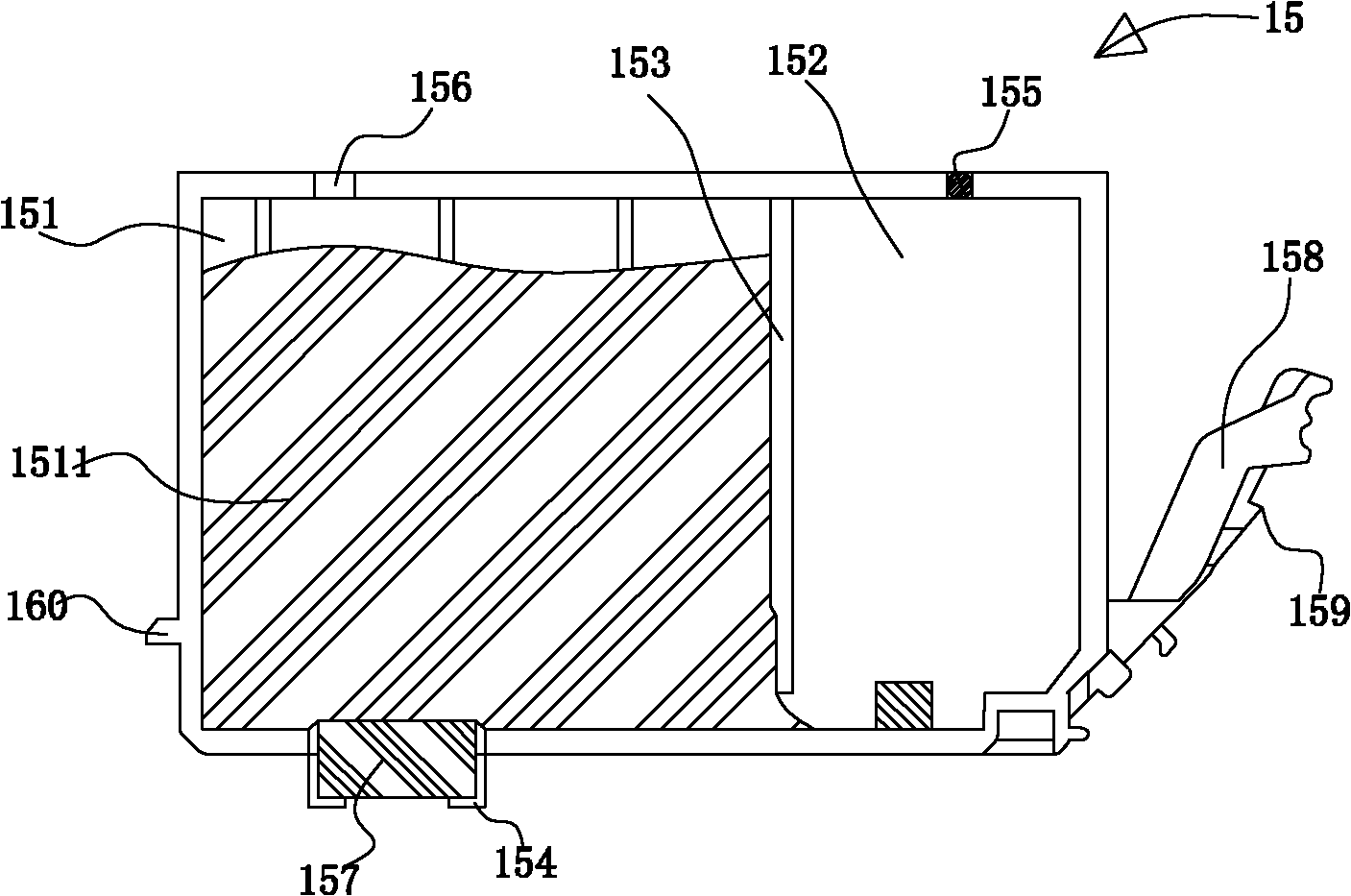

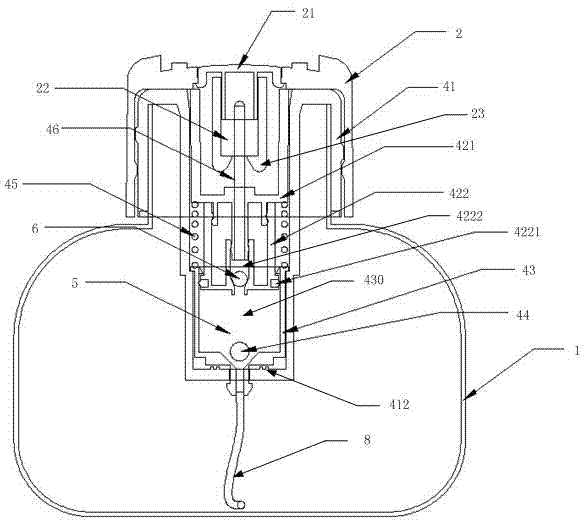

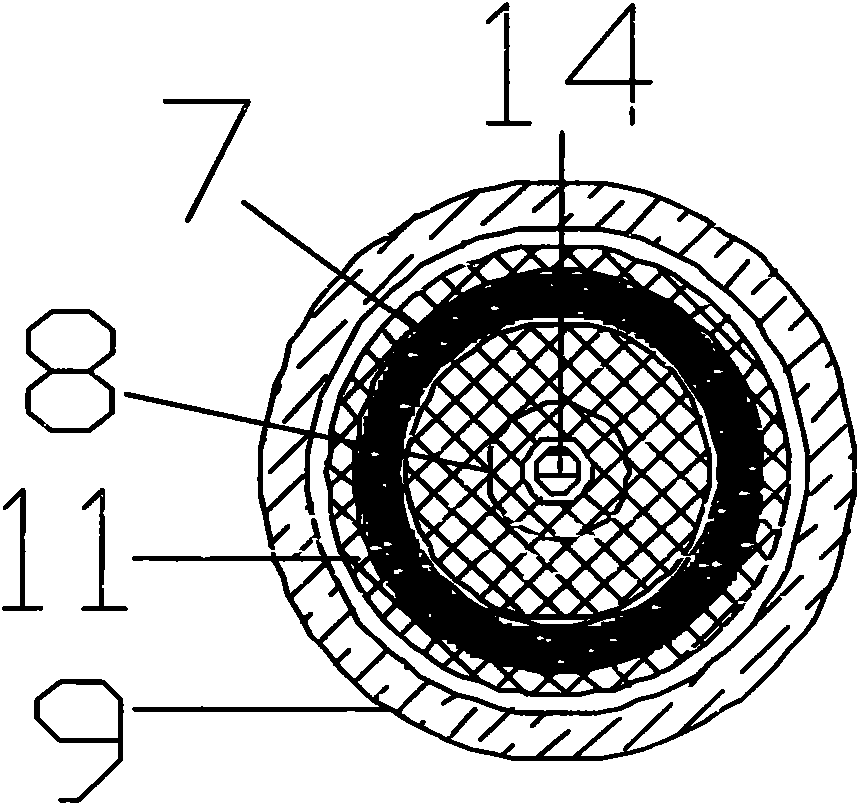

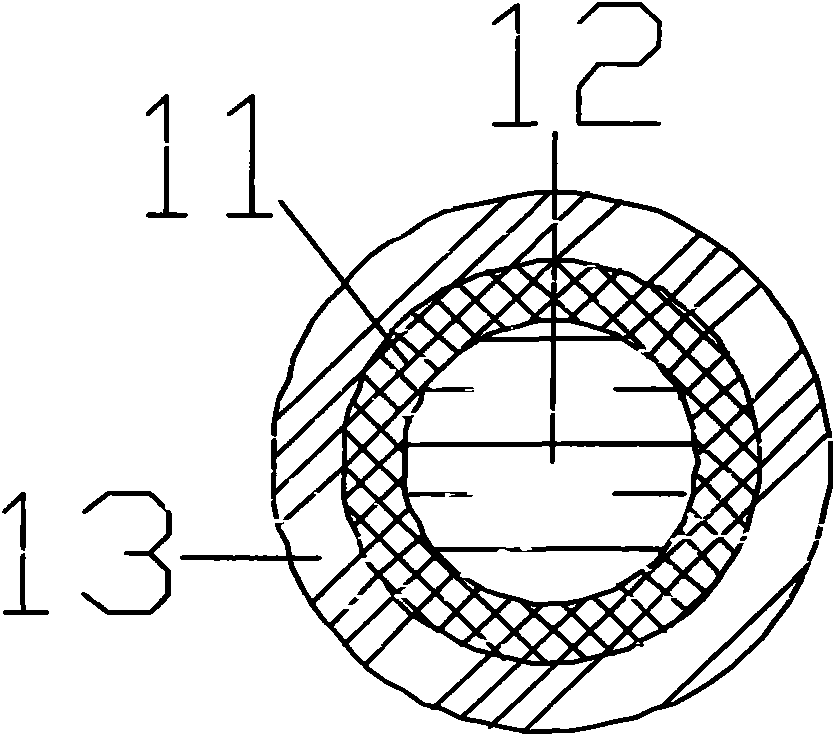

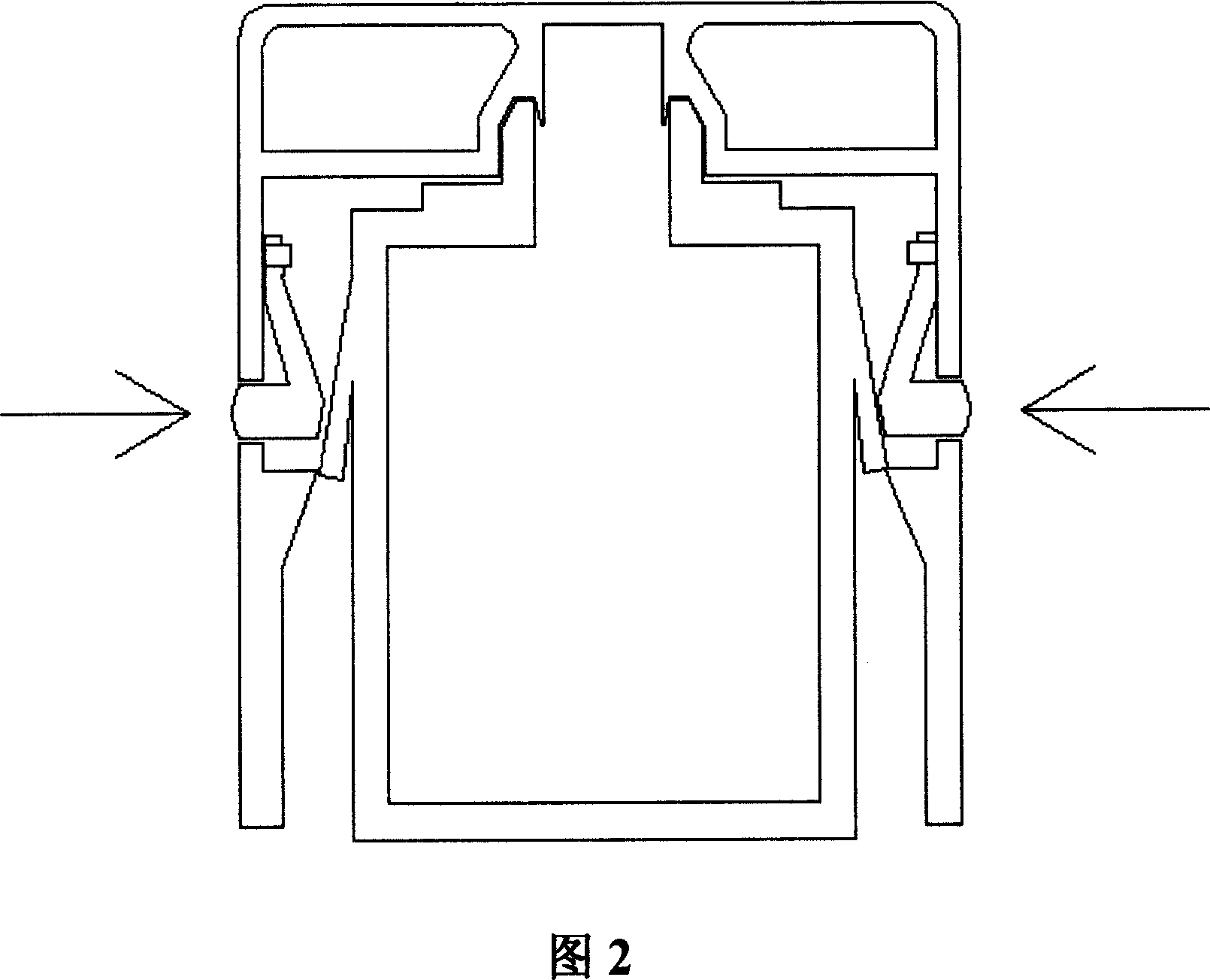

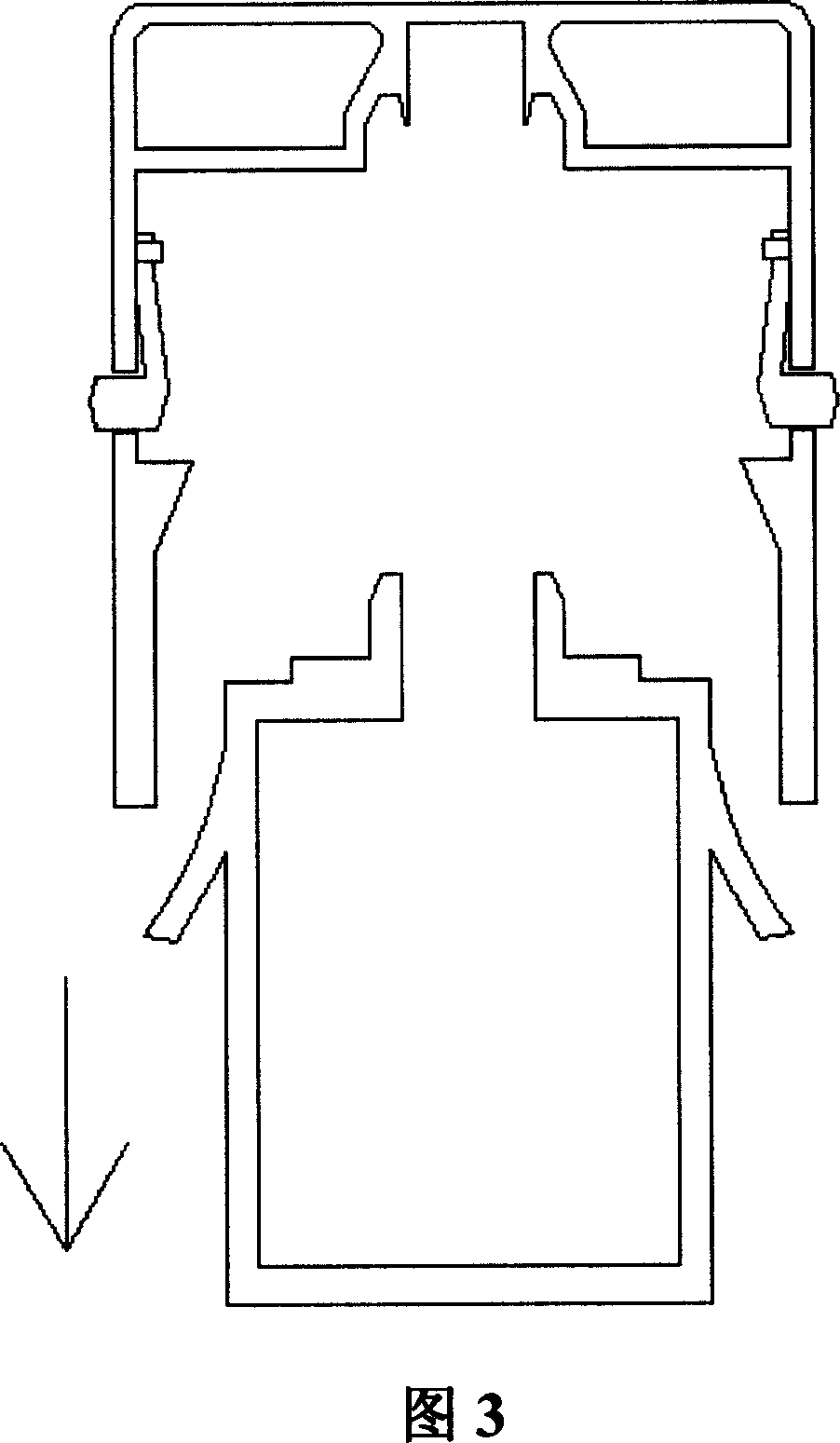

Negative pressure type ink box filling apparatus, filling system thereof and filling method thereof

ActiveCN102371767ASolve technical problems prone to ink splashingAvoid drippingInk receptaclesFilling devicesEngineeringMechanical engineering

The invention relates to a negative pressure type ink box filling apparatus, which comprises an ink container, an ink injection channel, a sucker, and a suction channel. The ink injection channel is used for conveying ink to a to-be-filled ink box; one end of the ink injection channel is an inlet end where ink in the ink container enters the ink injection channel; and the other end of the ink injection channel is an outlet end that is connected with the to-be-filled ink box. The suction channel is communicated with the ink container and a suction entrance that is connected with the sucker is arranged on the suction channel. And the inlet end is above a horizontal plane of the ink in the ink container. Because the inlet end is above the horizontal plane of the ink in the ink container, the ink in the ink container can not overflow through the ink injection channel no matter how an environmental factor is changed; therefore, a technical problem that an ink splashing phenomenon occurs when a user uses a current negative pressure type ink filling apparatus at the first time is solved.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

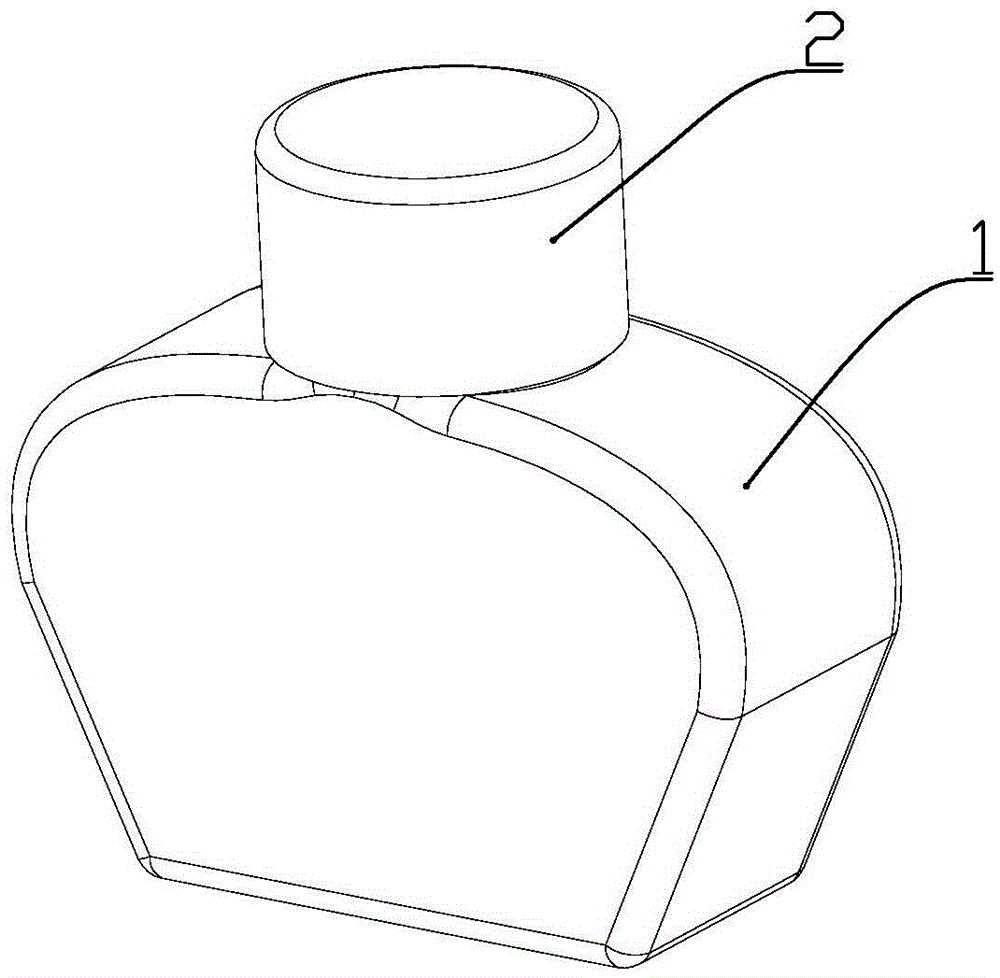

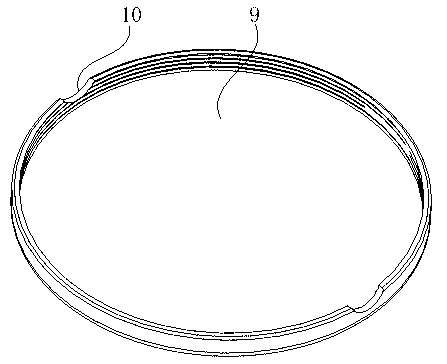

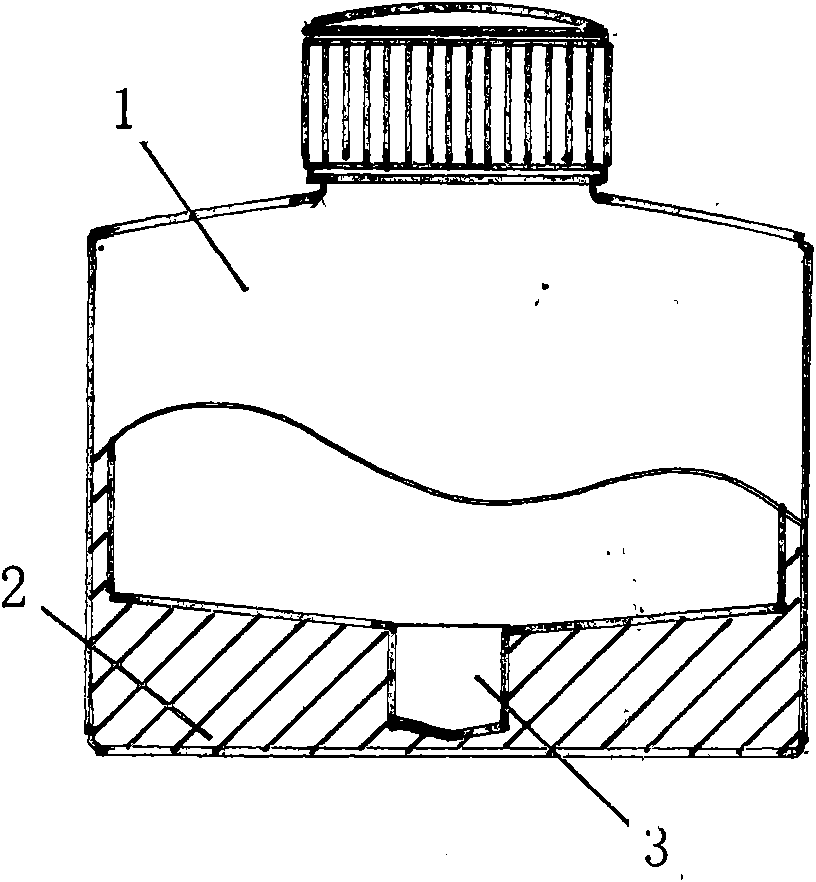

Ink bottle

The invention discloses an ink bottle which comprises a bottle body, an inner bottle body arranged in the bottle body and a cap connected to a bottle opening in the upper portion of the bottle body in a threaded manner. A conical surface is formed in the middle of the inner bottom of the bottle body. The portion, located on the periphery of the conical surface, of the inner bottom of the bottle body is a slope face. The inner bottle body comprises a circular temporary storage groove, a soft connecting pipe integrally connected to the lower portion of the temporary storage groove and a liquid inflow cover connected to the lower end of the connecting pipe. An outer turned edge abutting against the upper end of the bottle opening is formed at the upper end of the temporary storage groove. The whole connecting pipe is in an arc shape. A flow stop wall extending in the direction of the sphere center of a semi-spherical surface is formed at the lower end of the liquid inflow cover. A supporting head is formed on the periphery of the lower end portion of the flow inflow cover. The inner top of the cap is integrally provided with a piston body matched with the inner wall of the temporary storage groove. According to the ink bottle, little ink can be sucked into the temporary storage groove through the piston body while the cap is unscrewed, the ink can be sucked conveniently, contamination to the upper portion of a pen is avoided, meanwhile the whole bottle of ink can be used completely, and resources are saved.

Owner:XUZHOU XUANKE AGRI MASCH CO LTD

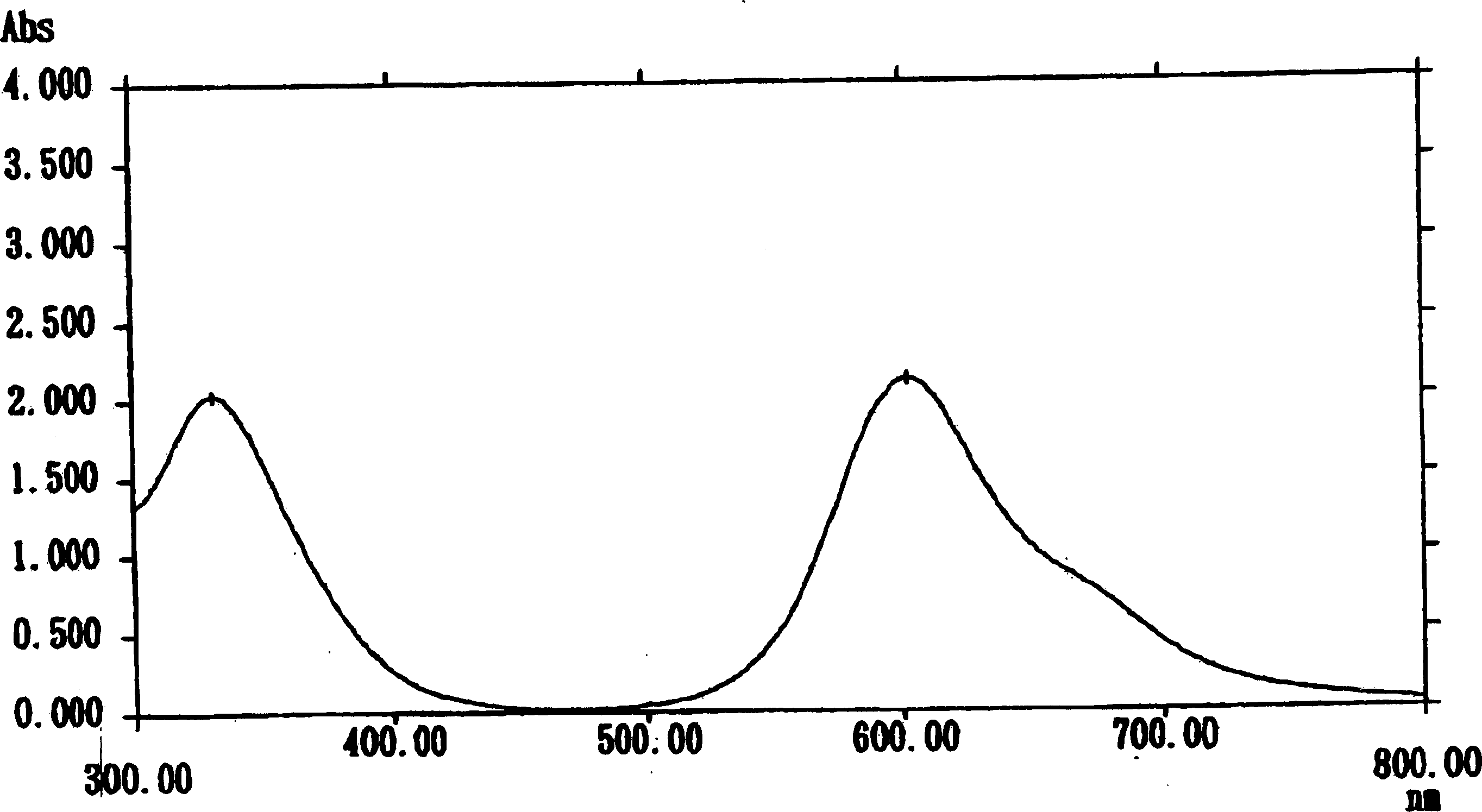

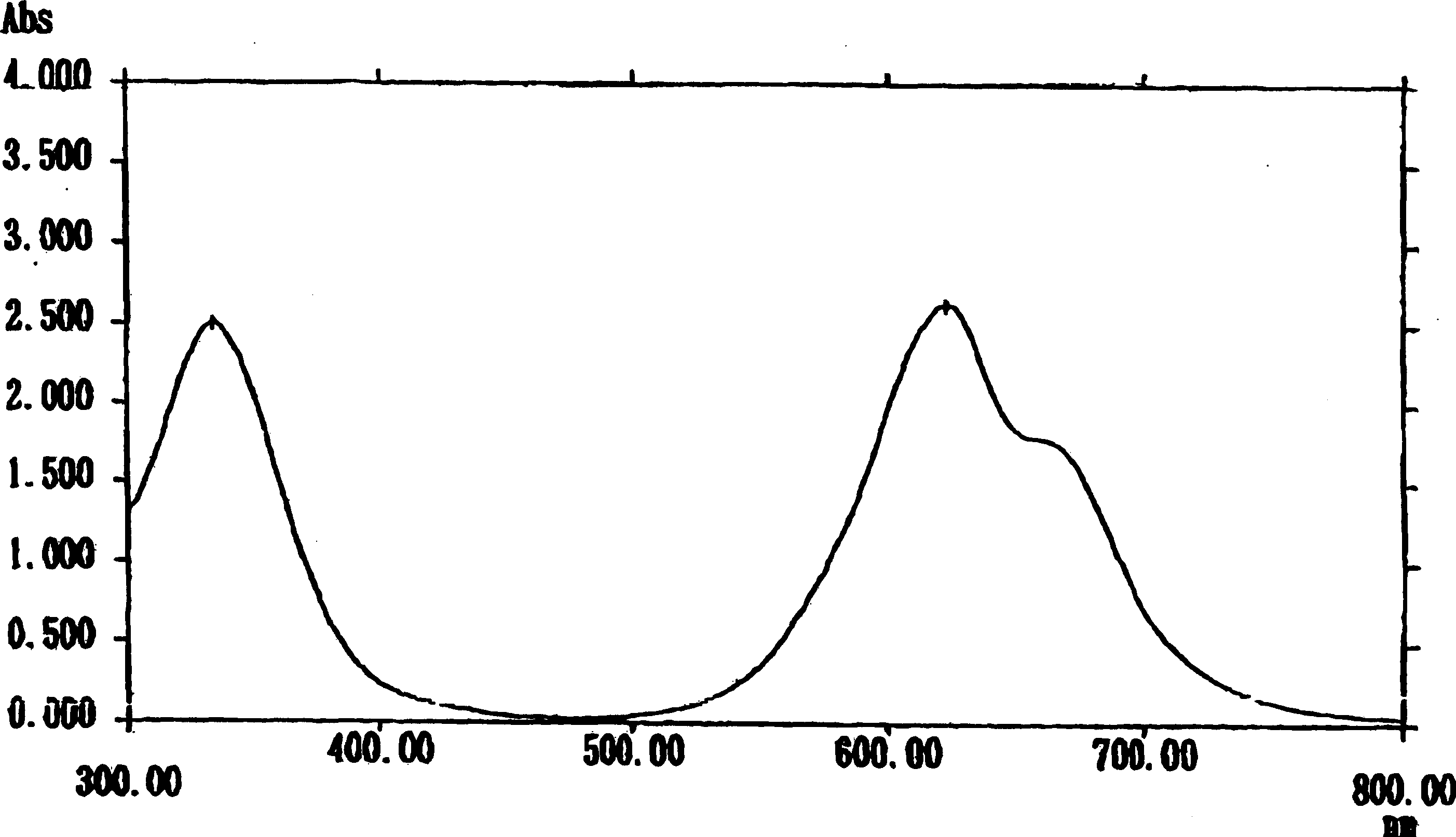

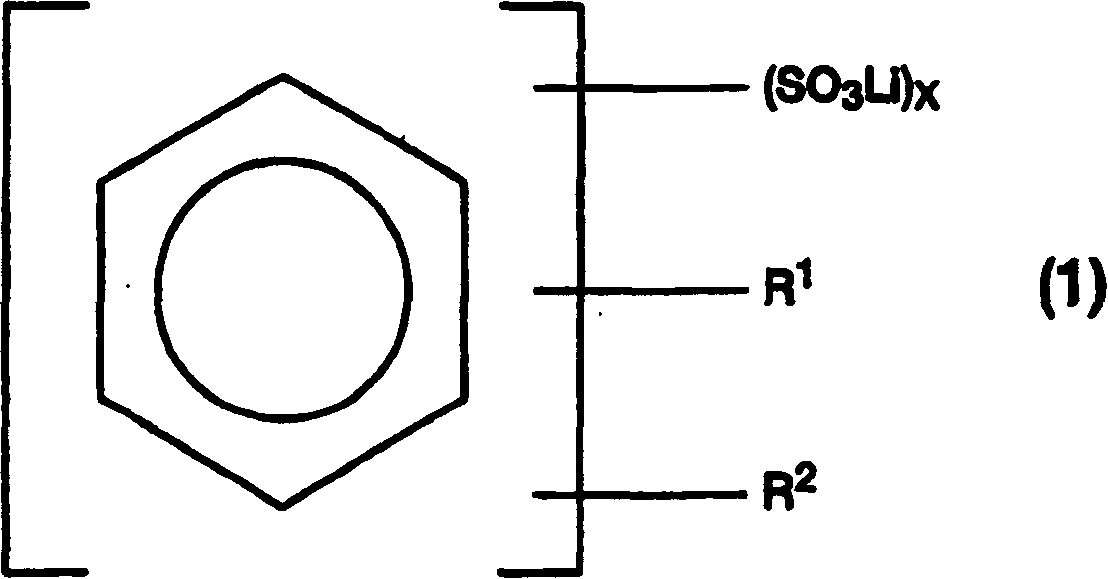

Ink composition, ink cartridge, inkjet recording method, and recorded matter

InactiveCN1831054ADoes not cause precipitationWill not cause copper light floating phenomenonInk receptaclesInksLithiumPhthalocyanine

It is an object of the present invention to provide an ink composition with which the indoor storage stability (gas resistance) of an image produced with an ink composition featuring a phthalocyanine-based cyan dye can be increased without causing any additive precipitation or bronzing. The present invention provides an ink composition containing at least water, a phthalocyanine-based cyan dye, and a lithium salt of an aromatic compound having a sulfo group and expressed by General Formulas 1 and / or 2 in the claims. The present invention also provides an ink composition containing at least water, a phthalocyanine-based cyan dye, and a lithium salt of an aromatic compound having a sulfo group and expressed by General Formulas 5 and / or 6 in the claims. The present invention further provides an ink composition containing at least water, a phthalocyanine-based cyan dye, and a lithium salt of an aromatic compound having a sulfo group and expressed by General Formulas 1 and / or 2 in the claims or a lithium salt of an aromatic compound having a sulfo group and expressed by General Formulas 5 and / or 6 in the claims, wherein the phthalocyanine-based cyan dye is expressed by Formula 3 in the claims.

Owner:SEIKO EPSON CORP

Motor-driven ink grinding device

A motor-driven ink grinding device comprises an inkstone-shaped base frame and a multiple-action ink grinding arm. An ink grinding ink pool is arranged on one side of the top surface of the inkstone-shaped base frame; a column-shaped box body is arranged on the other side of the top surface of the inkstone-shaped base frame; an ink box cabin is arranged at the bottom of the column-shaped box body; a clean water box cabin is arranged at the top of the column-shaped box body; the multiple-action ink grinding arm comprises an overhang arm frame, a rotating pipe sleeve, an arm rod rotating machine and an ink grinding arm rod; the overhang arm frame is connected with the column-shaped box body; the rotating pipe sleeve is arranged in a shaft seat of the end of the overhang arm frame; the ink grinding arm rod is mounted at the center of the rotating pipe sleeve in a sleeving mode; and an ink block clamping opening is formed in the lower end of the ink grinding arm rod. According to the motor-driven ink grinding device, the multiple-action ink grinding arm drives a strip-shaped ink block to conduct continuous ink grinding in the ink grinding ink pool in rotating and swinging modes, the ink grinding time is shortened, ink in the ink grinding ink pool is more even, and the ink box cabin can store the ink in the ink grinding ink pool, and can input the stored ink to the ink grinding ink pool to be directly used, and thus, the motor-driven ink grinding device is reasonable in structure and convenient to use.

Owner:宁津润科创投有限公司

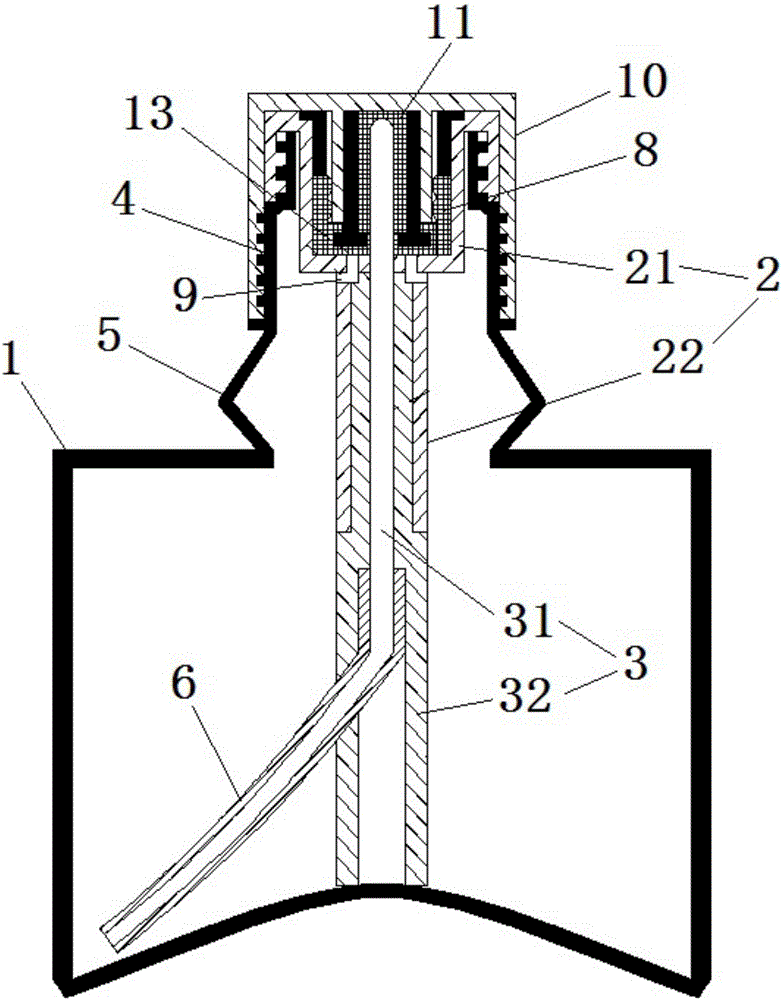

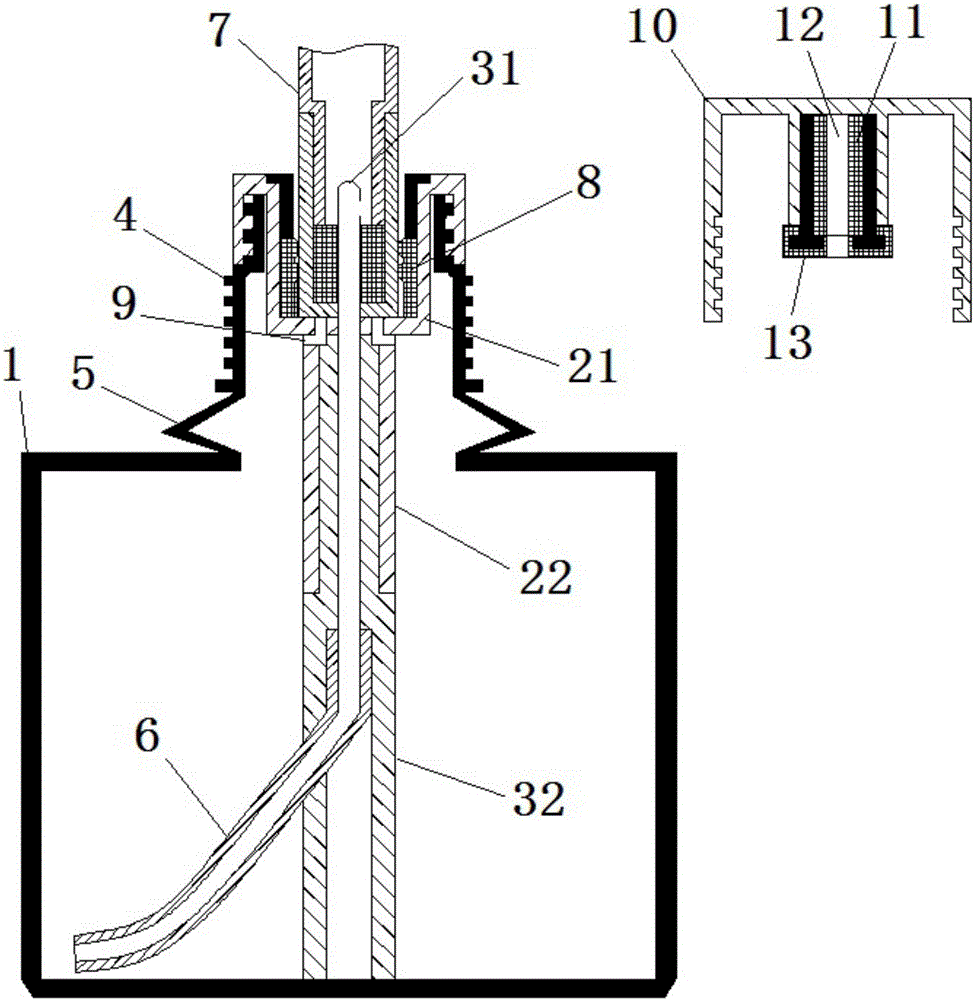

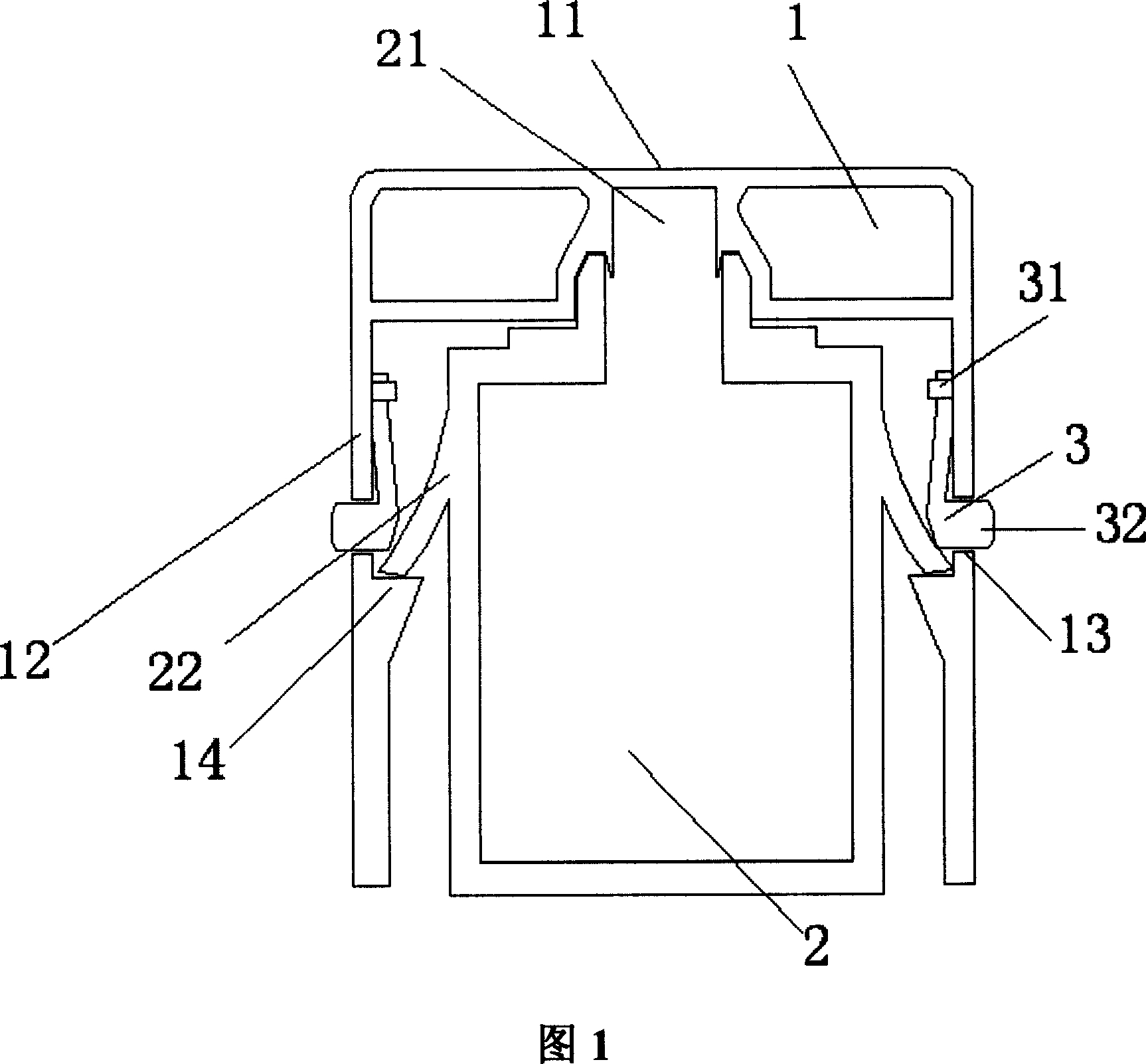

Direct-plugging inking bottle

The invention provides a direct-plugging inking bottle. The direct-plugging inking bottle comprises a bottle body, a needle cylinder and a needle tube, wherein the bottle body is provided with a bottle opening; the needle cylinder is arranged in the bottle body, and a first through hole communicated with the interior of the bottle body is formed in the bottom end of the needle cylinder; the lower end of the needle tube is inserted into the first through hole, and the upper end of the needle tube extends to the bottle opening; a first sealing part connected to an ink pen body in a sealing manner is fixedly arranged in the bottle opening; and a second through hole communicating the interior and exterior of the bottle body is formed in the upper end of the needle tube. The direct-plugging inking bottle has the advantages of simplicity in structure, convenience in use, overflow prevention and low cost.

Owner:GUANGZHOU XINQI PATENT TECH EXTENSION SERVICE CO LTD +2

Ink bottle for quantitatively injecting ink

The invention provides an ink bottle for quantitatively injecting ink. The ink bottle comprises a bottle body and a pump body seat connected with the bottle body; a piston seat, a pump body and an ink delivery tube are sequentially arranged in the pump body seat from top to bottom, wherein the piston seat comprises a second one-way valve, and a needle tube and an ink injection passage which are mutually communicated; the chamber of the pump body is communicated with the ink injection passage through the second one-way valve; the pump body comprises a first one-way valve; the ink delivery tube is communicated to the chamber of the pump body through the first one-way valve; a spring is connected between the piston seat and the pump body; the flowing direction of the first one-way valve faces the ink injection passage; and the flowing direction of the second one-way valve faces the needle tube. When the ink bottle is used for injecting ink to an ink pen, the quantity of the ink injected every time is the same, so that a user can control the proper ink injection quantity.

Owner:SHANGHAI PICASSO STATIONERY PRODS +1

Ink bottle

An ink bottle comprises a bottle body and a bottle cap and further comprises an inner bottle body. The inner bottle body is sequentially provided with a bottle opening matching part, a cavity A, a spherical cavity, a cavity B and a flow stop wall from top to bottom. The cavity A is a cylindrical cavity overall, the spherical cavity is communicated with the cavity B, and the flow stop wall is arranged at the lower portion of the cavity B and is soft. The flow stop wall is annular, the inner circumference is lower than the outer circumference, and a round hole is formed in the lower portion of the flow stop wall. A bottom plane is formed at the bottom of the inner side of the bottle body and provided with a conic face, and a slope face is arranged on the conic face. The lowest end of the slope face and the highest end of the conic face are located in the same horizontal position. The lowest end of the conic face and the bottom plane are located in the same horizontal position. A gap is formed between the flow stop wall and the conic face. The inner diameter of the bottle cap is equal to the outer diameter of the bottle opening matching part of the inner bottle body, and a protrusion is formed in the bottle cap.

Owner:王刚

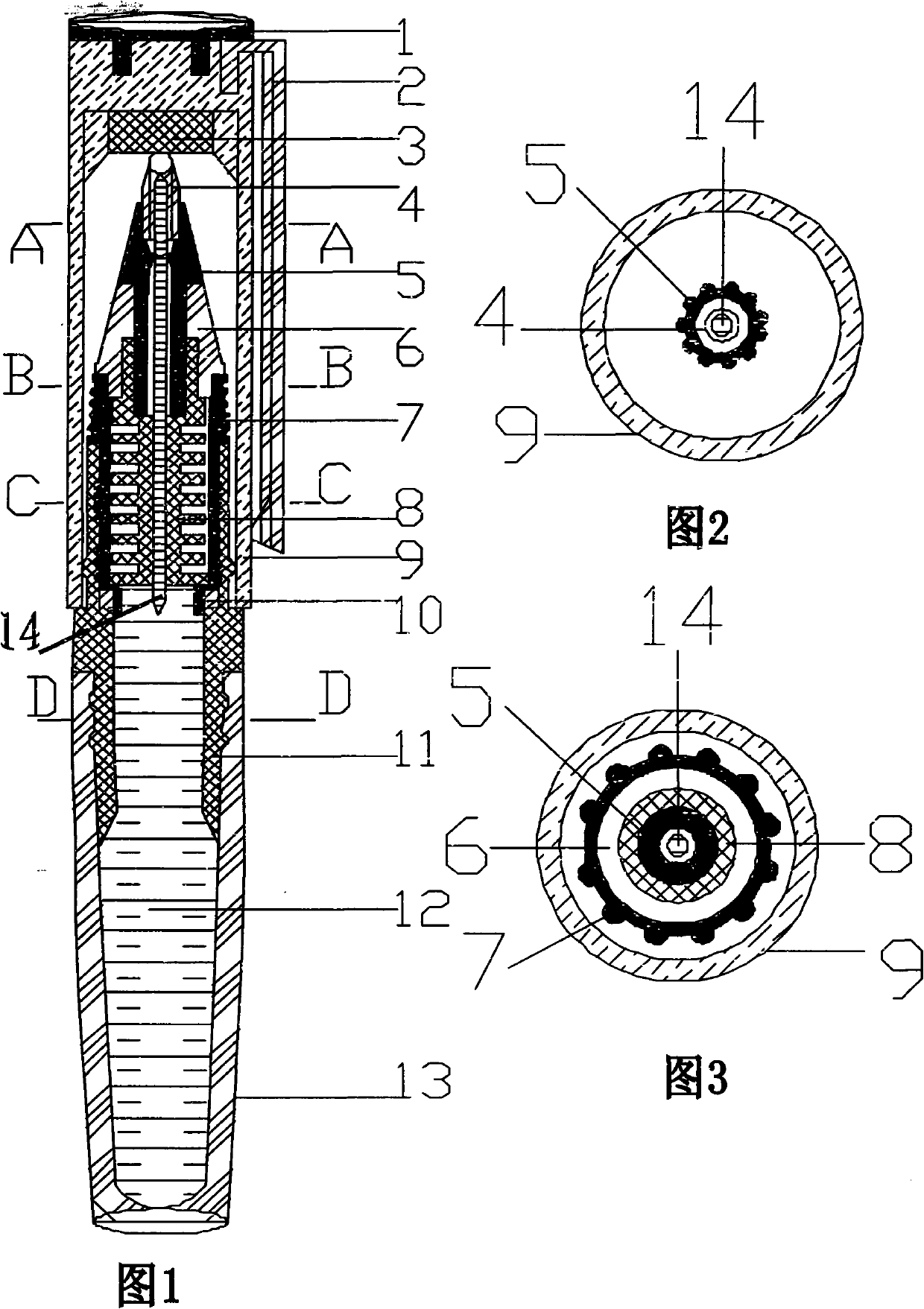

Joyful fountain pen. joyful water pen. joyful universal pen and joyful ink filling apparatus

InactiveCN1559806ASimple structureFunction increaseInk receptaclesBall-point pensSteel ballEngineering

A fountain pen, liquid ink pen, or universal pen features that its ink storage tube is composed of a transparent rigid tube and a coaxial fine tube as the internal ink-filling channel, the ink is stored in the space between said two tubes, and its tail end has an impervious rubber sleeve and an elastic plug. Its ink filler is composed of a thick tube and a thin tube, which are parallel and fixed to the cap of ink bottle. In said fine tube, there are spring, piston, check steel ball and ink suction tube. In said thick tube, there is an ink-filling tube whose bottom end is connected with the bottom end of said fine tube.

Owner:熊开怀

Environment-friendly and energy-saving marker and development and application of automatic assembly machine system

InactiveCN102555590ASmall ink storage capacitySimple structureInk receptaclesWriting connectorsEngineeringSystem development

An environment-friendly and energy-saving marker is simple in structure, attractive in appearance, small in volume, convenient to be carried and suitable for fast writing, is energy-saving, environment-friendly, clean and sanitary, not only solves problems that ink is filled in a fountain pen or a cartridge pen inconveniently, the fountain pen or the cartridge pen is unclean and unhygienic and is not environment-friendly, a nib is easy to leak ink, ink storage capacity is low, the fountain pen or the cartridge pen cannot be used for writing for a long time, ink filling period is short, ink filling frequency is high and the fountain pen or the cartridge pen is inconvenient to be carried, complicated in structure and high in cost, but also solves problems that a ballpoint pen or a roller pen or a marking pen or a sign pen or an existing marker cannot be recycled and belongs to a disposable pen, and ink and other substance components of the ballpoint pen or the roller pen or the marking pen or the sign pen or the existing marker are easy to severely pollute environments, and are high in recycling cost and not easy to be recycled. The environment-friendly and energy-saving marker is applicable to different working fields, is convenient in use, can be reused for a long time, and is well received by different people.

Owner:张峰

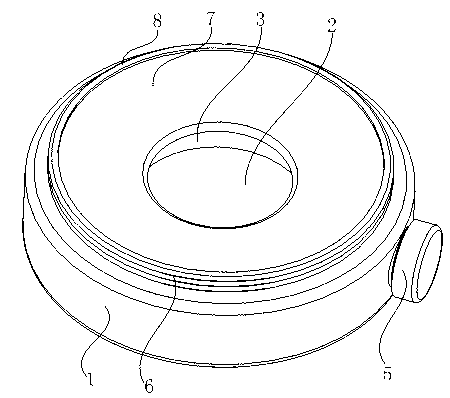

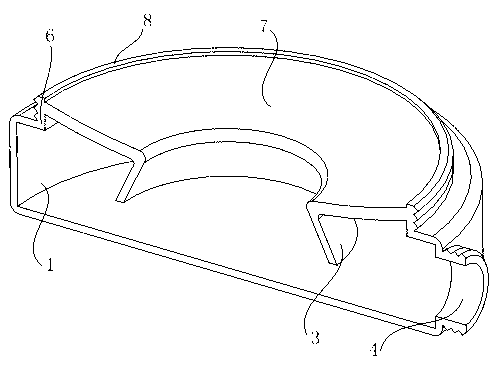

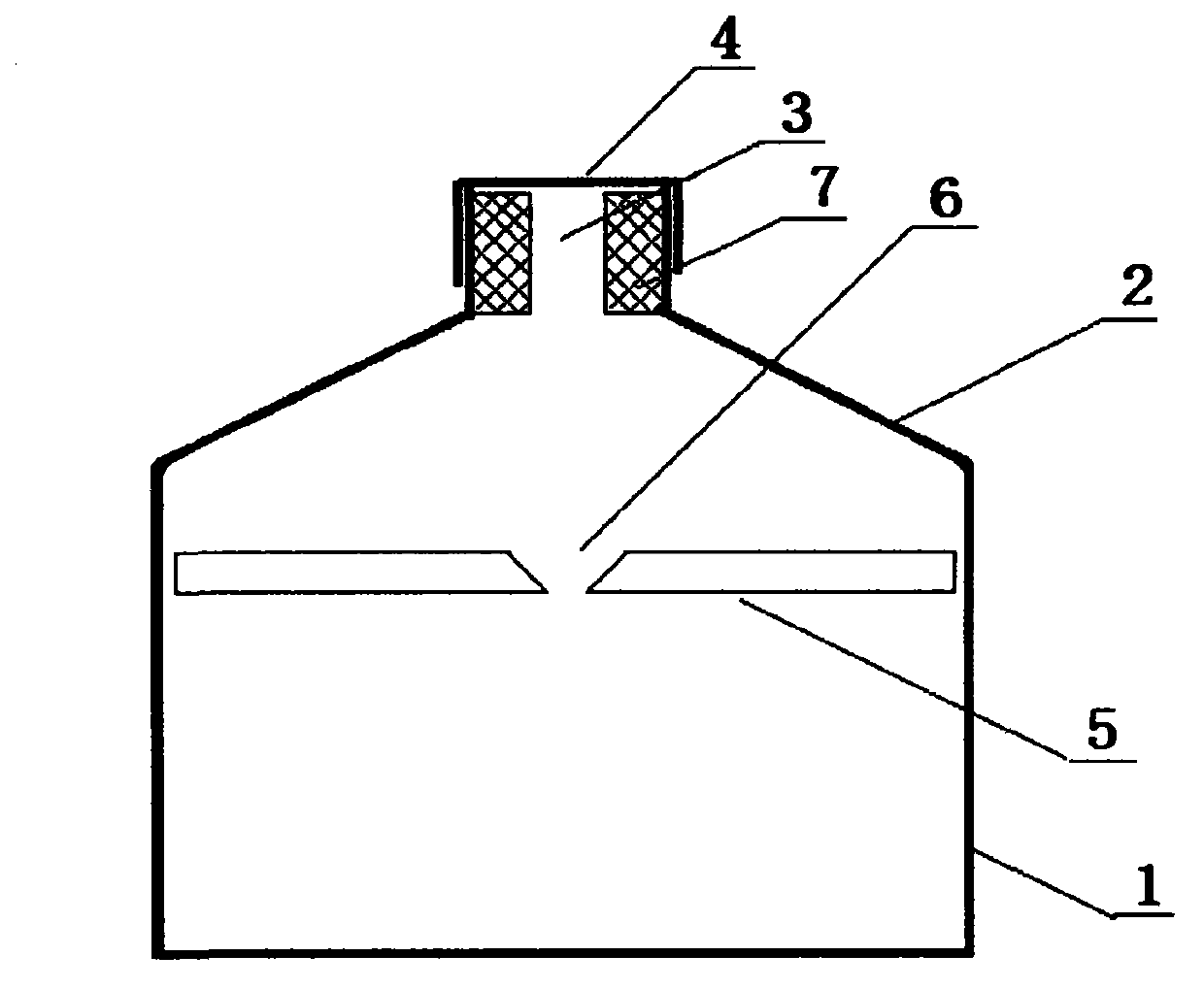

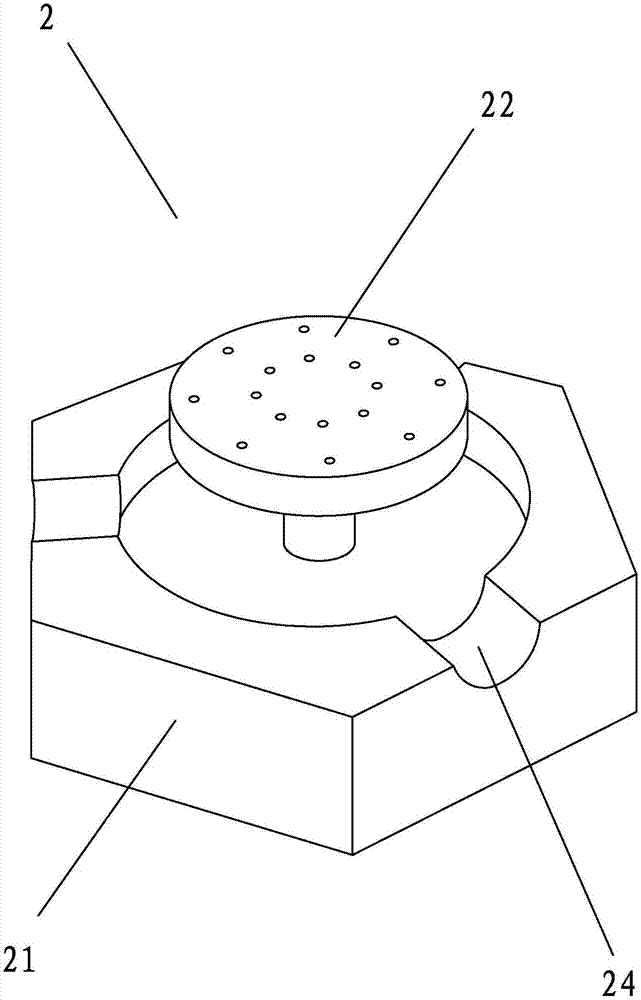

Anti-upsetting multifunctional ink stone box

The invention discloses an anti-upsetting multifunctional ink stone box. The multifunctional ink stone box comprises an ink box body, wherein an ink dipping hole is formed in the upper part of the ink box body and the ink box body is hollow; the cross section of the ink box body is of a central symmetry shape; the ink dipping hole is round and the circle center of the ink dipping hole and the center of the cross section of the ink box body are located on a same vertical straight line; the edge of the ink dipping hole is provided with an ink retaining plate in the shape of a bell with a small external part and a large internal part, and the ink retaining plate is located in the ink box body and is fixed with the ink box body to form a whole body; an ink outlet facilitating ink removing and cleaning is formed in the ink box body; an ink outlet cover is arranged on the ink outlet; and in order to increase the sealing performance of the ink outlet cover, the ink outlet cover is also internally provided with a sealing gasket. The multifunctional ink stone box is simple in structure and smart in conception; the ink in the ink stone box is effectively retained by the ink retaining plate which is specially arranged in the ink box body, so that the ink in the ink box body does not leak in any position states of the ink box body; simultaneously the ink stone box is provided with the special ink outlet and the special ink outlet cover which facilitate ink removing and cleaning; and the ink stone box is especially suitable for primary and secondary students to practice Chinese brush calligraphy.

Owner:王道林

Ink slab capable of recycling ink

The invention discloses an ink slab capable of recycling ink. Four slab legs are fixed at the bottom of the ink slab, a round bottom is arranged in the slab legs, an ink hole is formed in the center of the round bottom, the ink hole is connected with an ink pipe, the ink pipe extends out of the bottom of the ink slab, and a small valve is mounted at the bottom end of the ink pipe; the bottom ends of the slab legs are placed on an ink bottle, a bottle mouth is formed in the center of the ink bottle, and an outlet of the small valve is arranged in the bottle mouth; the heights of the slab legs are greater than the total height of the ink pipe and the small valve; both of the ink slab and the ink bottle are square, and the side lengths are equal. According to the ink slab disclosed by the invention, the bottom of the ink slab is made into a funnel type, the small valve is mounted at the mouth of the ink pipe at the bottom of the funnel, when the ink slab is used, the small valve is closed, and as the four slab legs are higher than the small valve, the ink slab can be flatly placed on a desk. After writing with a writing brush, the four slab legs of the ink slab are placed on the ink bottle, the outlet of the small valve is aligned to the bottle mouth of the ink bottle, the small valve is opened, and the residual ink flows back into the ink bottle, so that the ink cannot be wasted, and the purposes of hygiene and high convenience are achieved.

Owner:何羽丰

Novel ink bottle

The invention relates to a novel ink bottle. The novel ink bottle comprises a bottle body (1), a bottleneck (2), a bottle mouth (3) and a bottle cap (4), wherein a floating plate (5) is arranged in the bottle body (1); a hopper-shaped ink sucking hole (6) which is dead against the bottle mouth (3) is arranged in the middle of the floating plate (5); and the bottle mouth (3) is internally provided with a circular ring shaped ink absorbing sponge (7). A nib of a pen is limited in the ink sucking hole when ink is sucked, and the part of the pen above the nib is located above the liquid surface of the ink due to the blocking of the ink sucking hole. Therefore, the novel ink bottle, disclosed by the invention, has the advantages of preventing a pen body from being adhered to by a plenty of ink, and avoiding pollution to fingers and other articles as little ink on the pen body can be absorbed by the ink absorbing sponge in the bottle mouth.

Owner:崔子嘉

Ink-continuous public pen

InactiveCN106553471AAvoid pollutionReduce the number of pen replacementsInk receptaclesInk reservoir pensEngineeringBottle

The invention discloses an ink-continuous public pen and relates to the field of machines. When people go to a public sector and fill out a form with a public pen, ink in the pen runs out soon, and therefore people needs a public pen capable of supplying the ink continuously. The ink-continuous public pen is capable of supplying the ink continuously for a long time almost without ink lack. To achieve the purpose, the ink-continuous public pen comprises a hanging type large ink bottle (2) and further comprises at least one automatic ink conveying tube (3) and at least one ink filling pen body (1), wherein the tail end of each ink filling pen body (1) is provided with a small ink inlet hole (4). The ink-continuous public pen has the beneficial effects that the times of replacing the pen can be reduced greatly, or ink refilling is reduced greatly.

Owner:赵丽玫

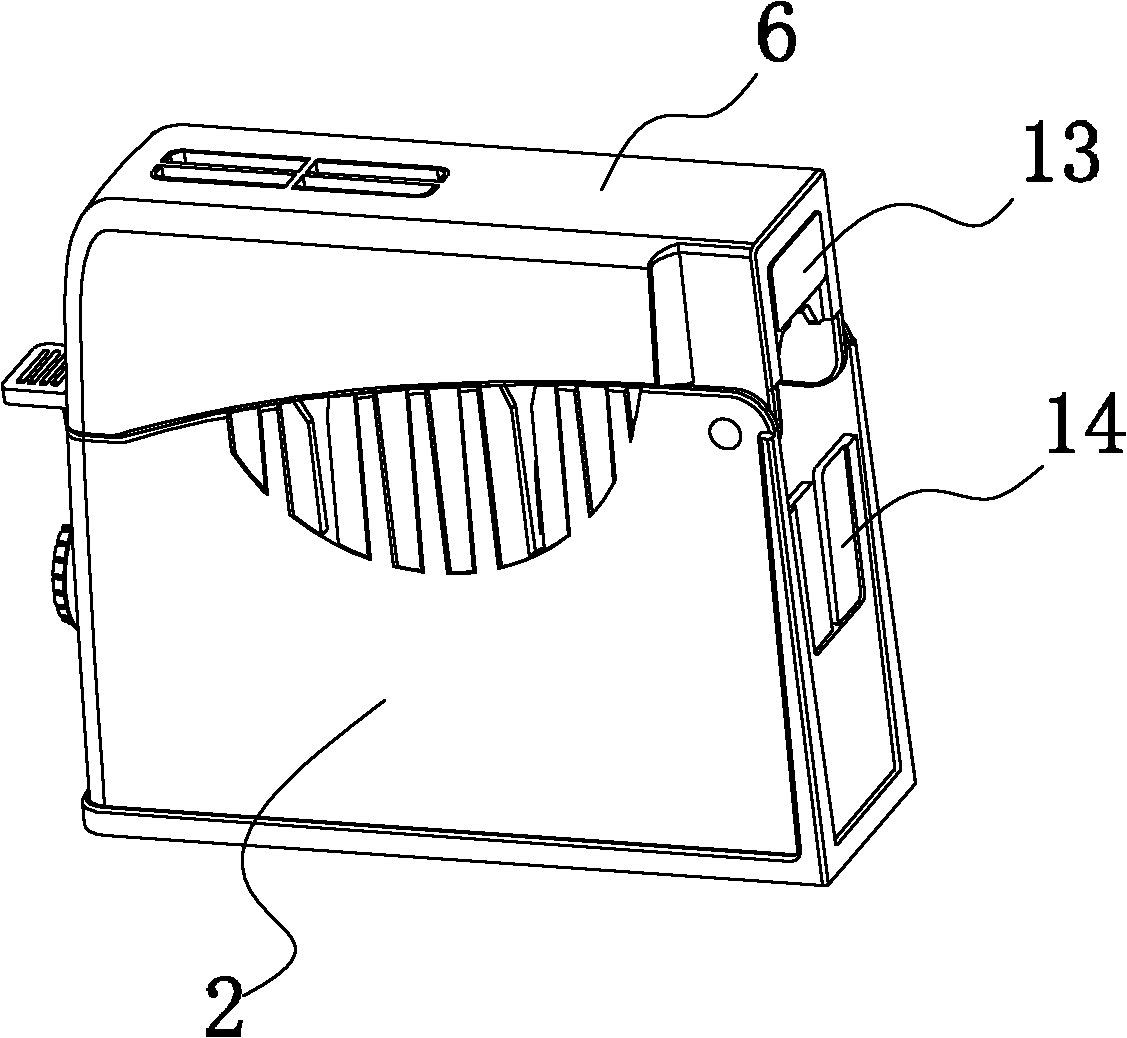

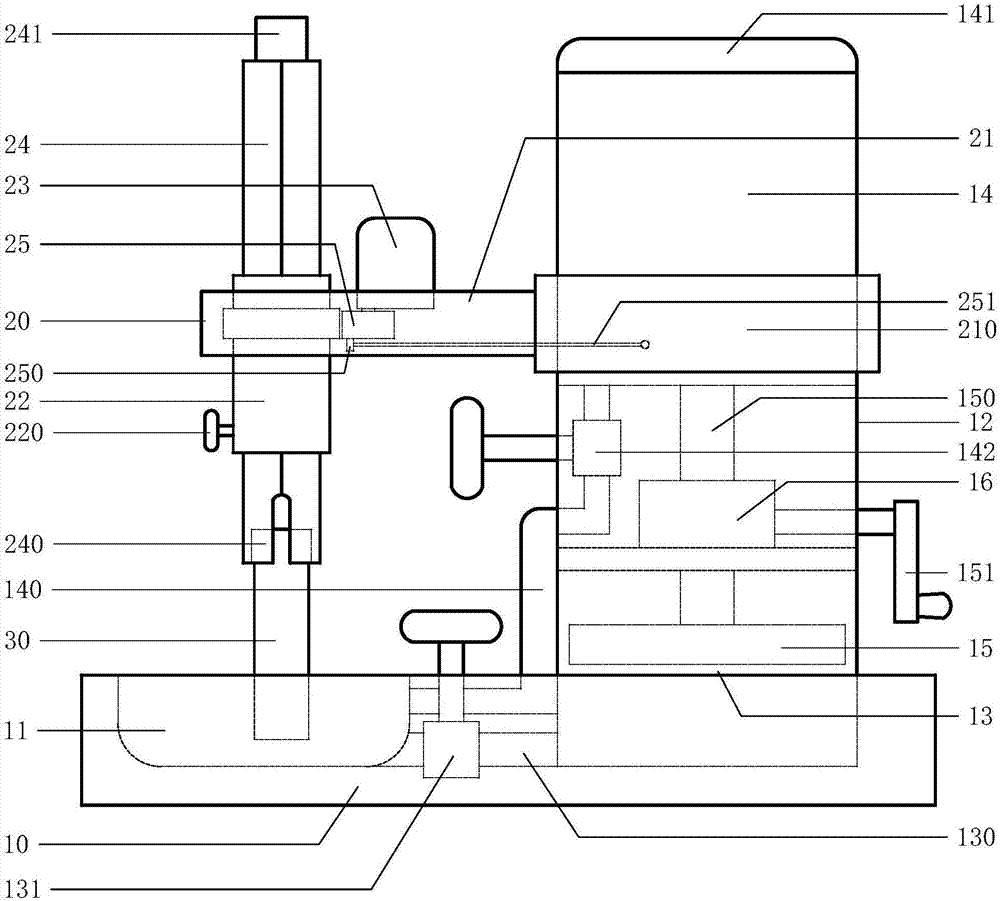

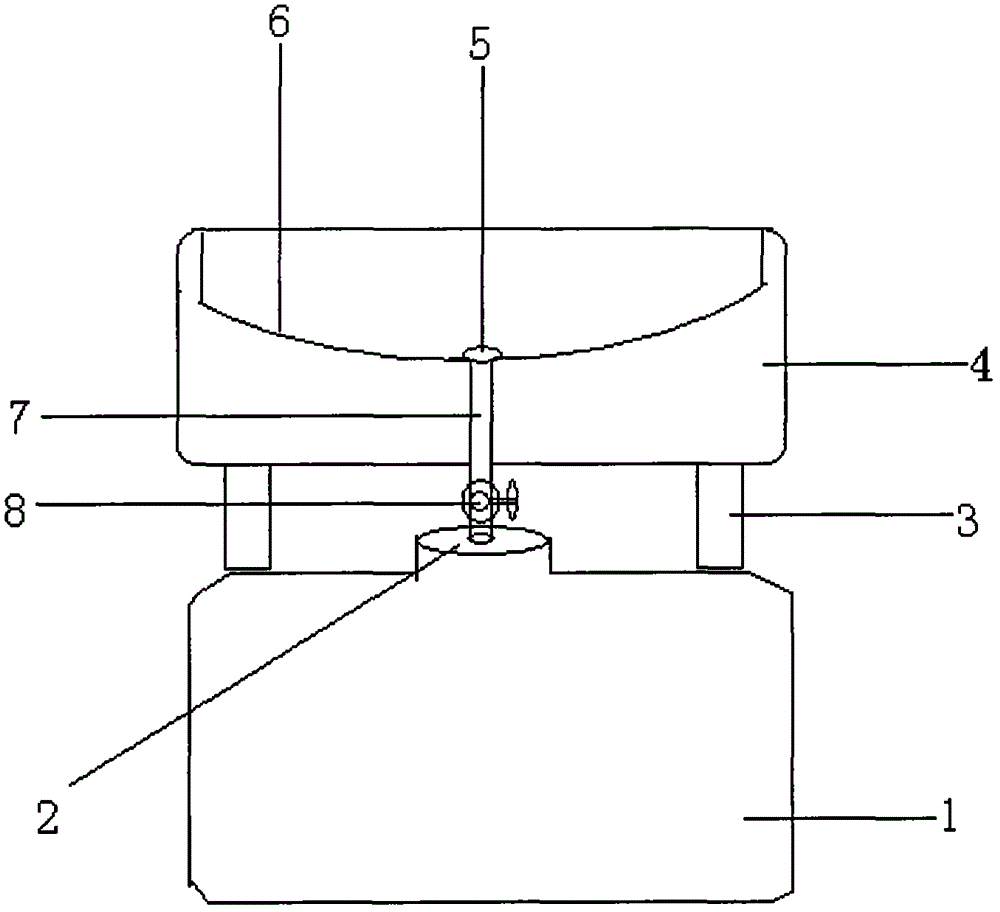

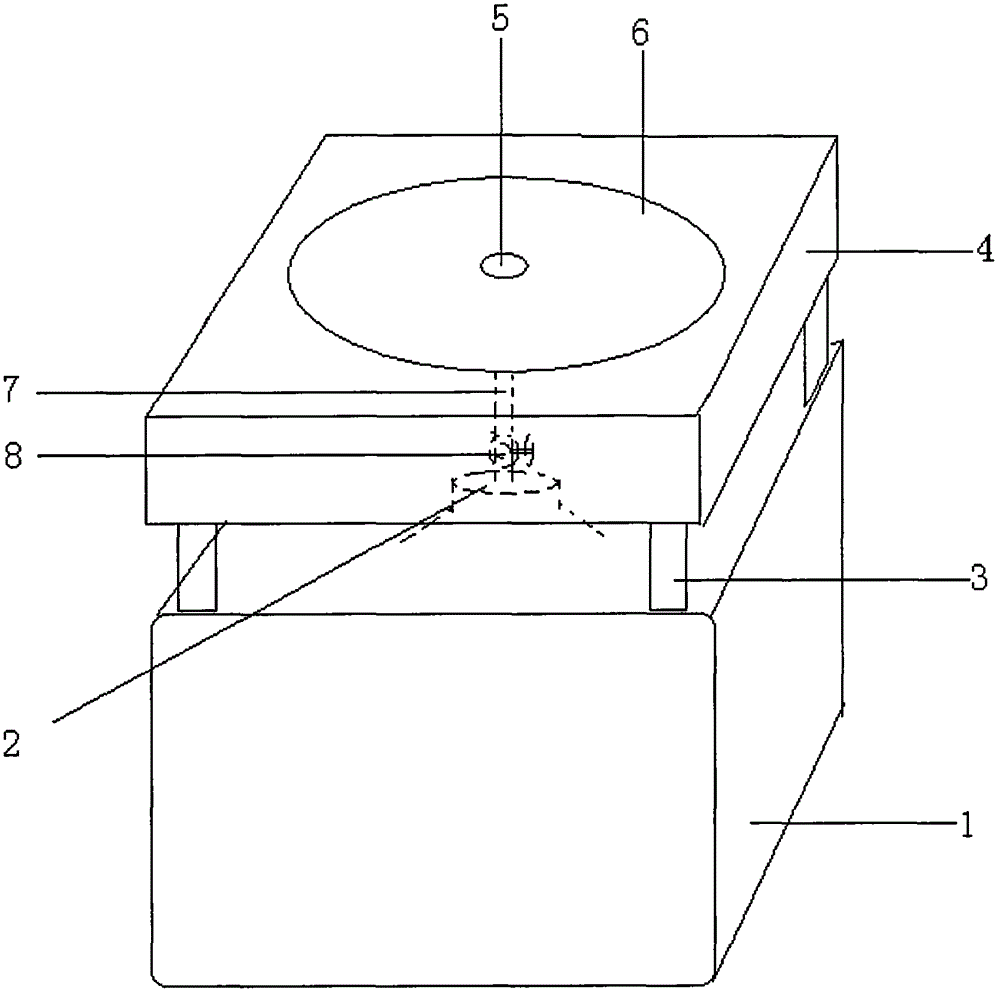

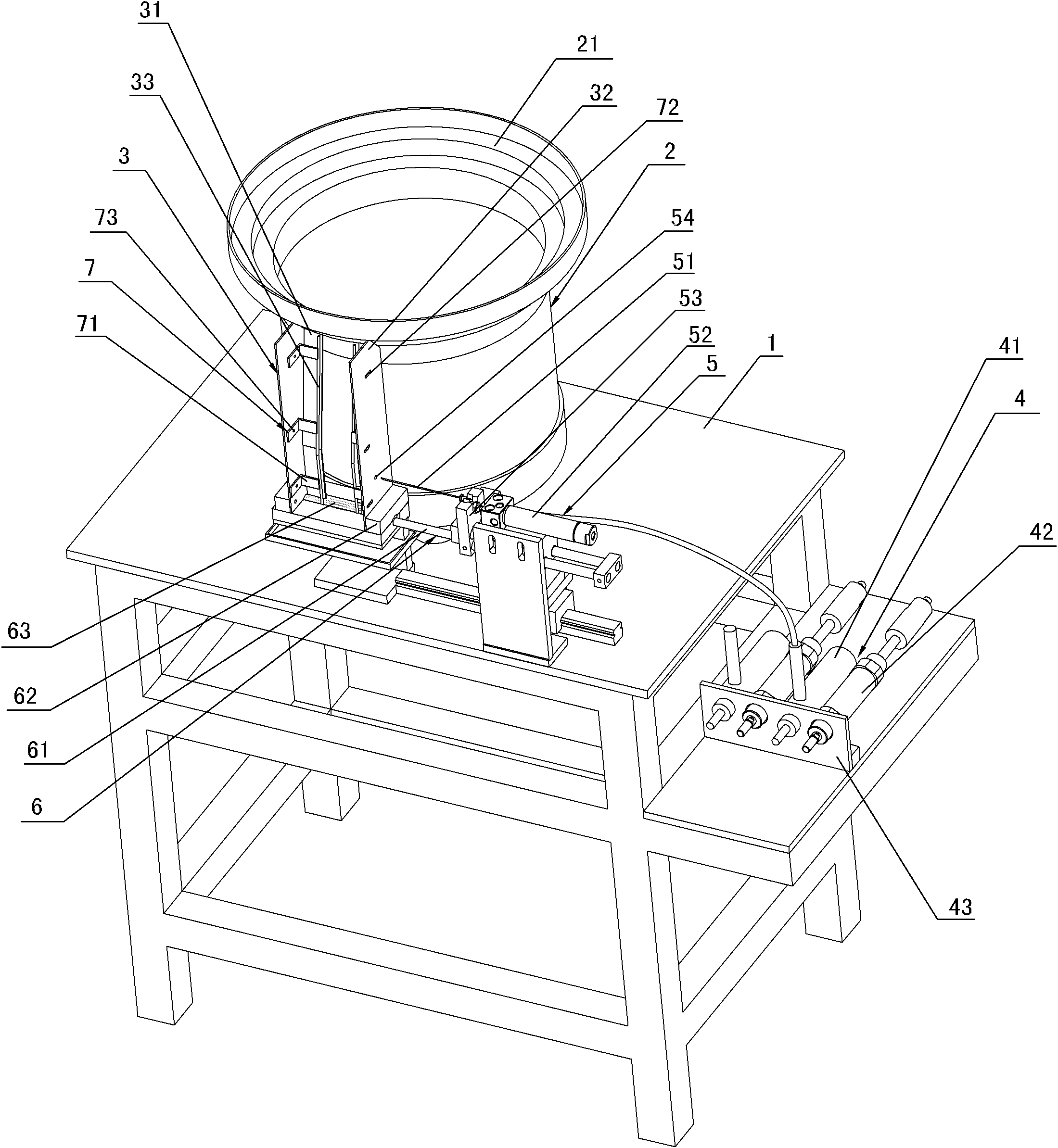

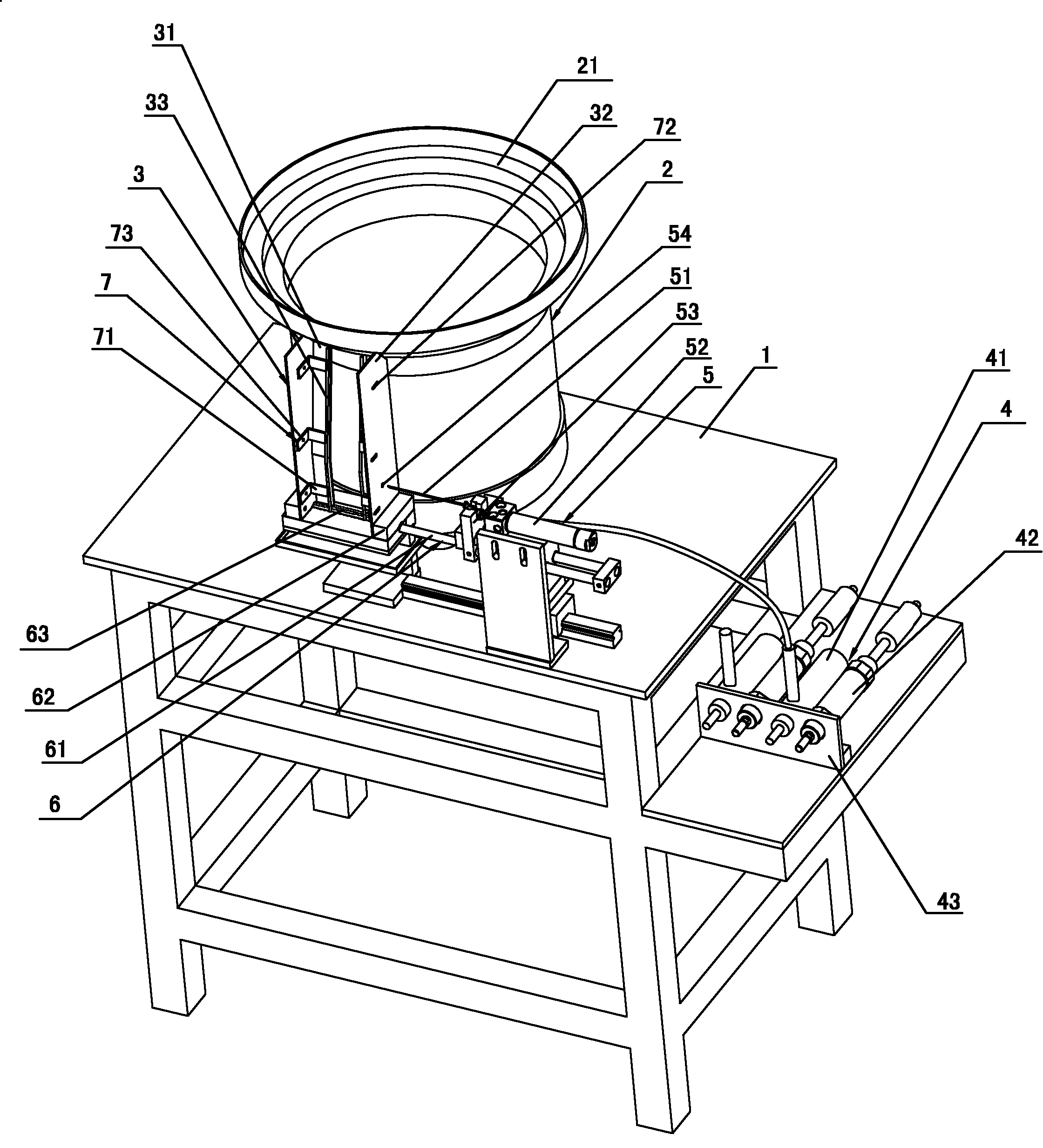

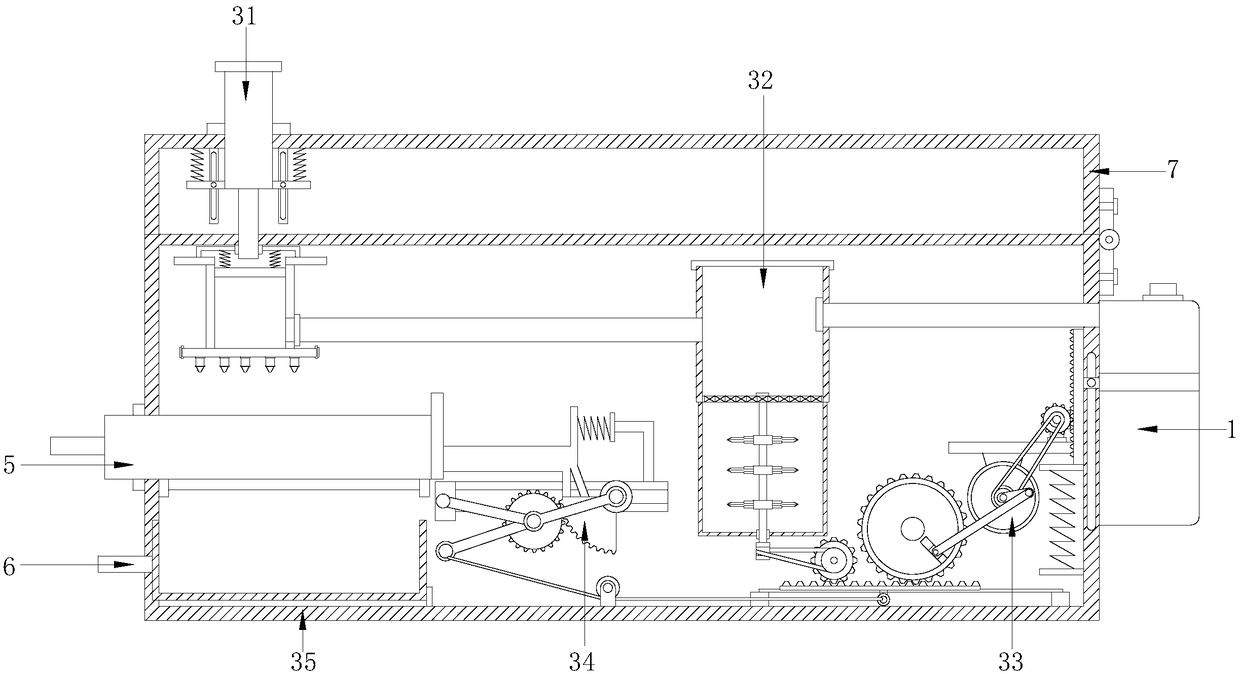

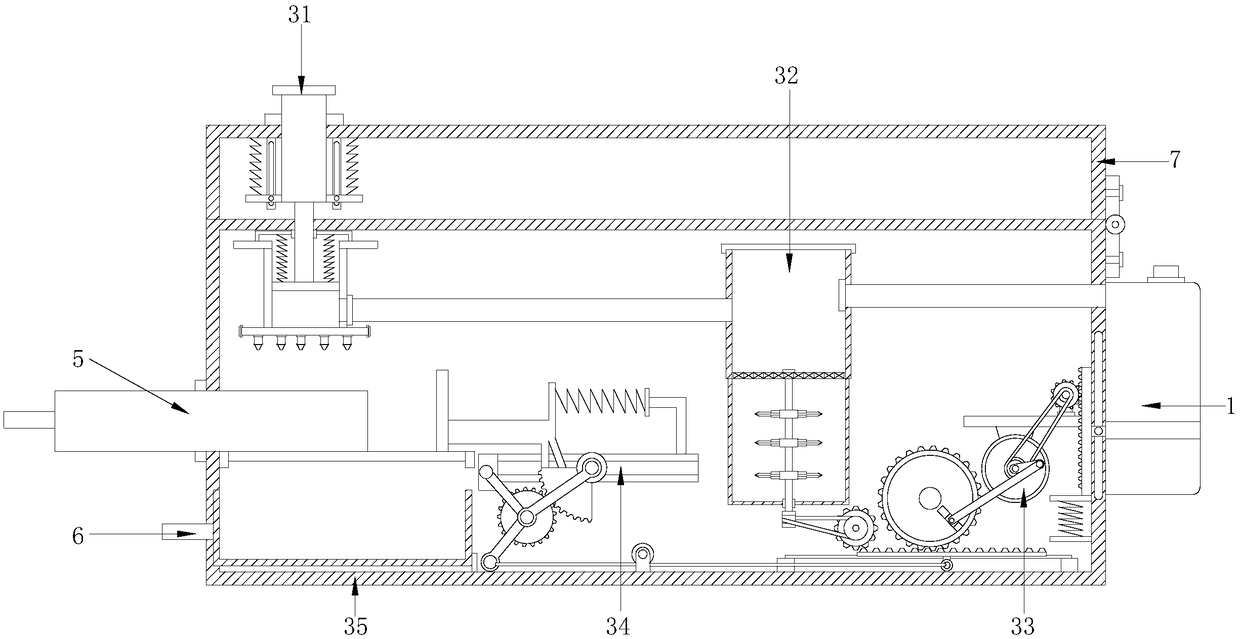

Reservoir ink-filling machine

ActiveCN102529504AGuaranteed writing lengthPrevent ink leakageInk receptaclesFilling devicesDrive shaftPlunger pump

The invention discloses a reservoir ink-filling machine which comprises a machine frame, a feeding mechanism, a feeding arrangement rail, an ink injecting mechanism, an ink filling mechanism and a controller, wherein the feeding mechanism, the feeding arrangement rail, the ink injecting mechanism, the ink filling mechanism and the controller are mainly arranged on the machine frame, the feeding mechanism mainly comprises a directional feeding vibrating disc, the ink injecting mechanism is composed of a plunger pump, an ink injecting cylinder and a first connecting plate, the ink filling mechanism is composed of an ink feeding needle, a needle tube cylinder and a second connecting plate, and the pushing mechanism is composed of a push rod and a locating block; the ink injecting cylinder drives the transmission shaft of the plunger pump to reciprocate so as to enable the plunger pump to suck ink from an ink box and discharge the ink into the ink feeding needle; the needle tube cylinder drives the ink feeding needle and the push rod to reciprocate; when the ink feeding needle moves to reservoirs on the feeding arrangement rail, ink in the ink feeding needle is just filled into the reservoirs, and the push rod pushes off the reservoirs which fall in a locating groove on the locating block from the feeding arrangement rail and are filled with ink; and the amount of ink that the plunger pump sucks each time is constant, so that ink filled in each reservoir is uniform. The reservoir ink-filling machine has the advantage of not only ensuring the writing amount but also avoiding the phenomenon of ink leakage.

Owner:NINGBO BEIFA GRP CO LTD

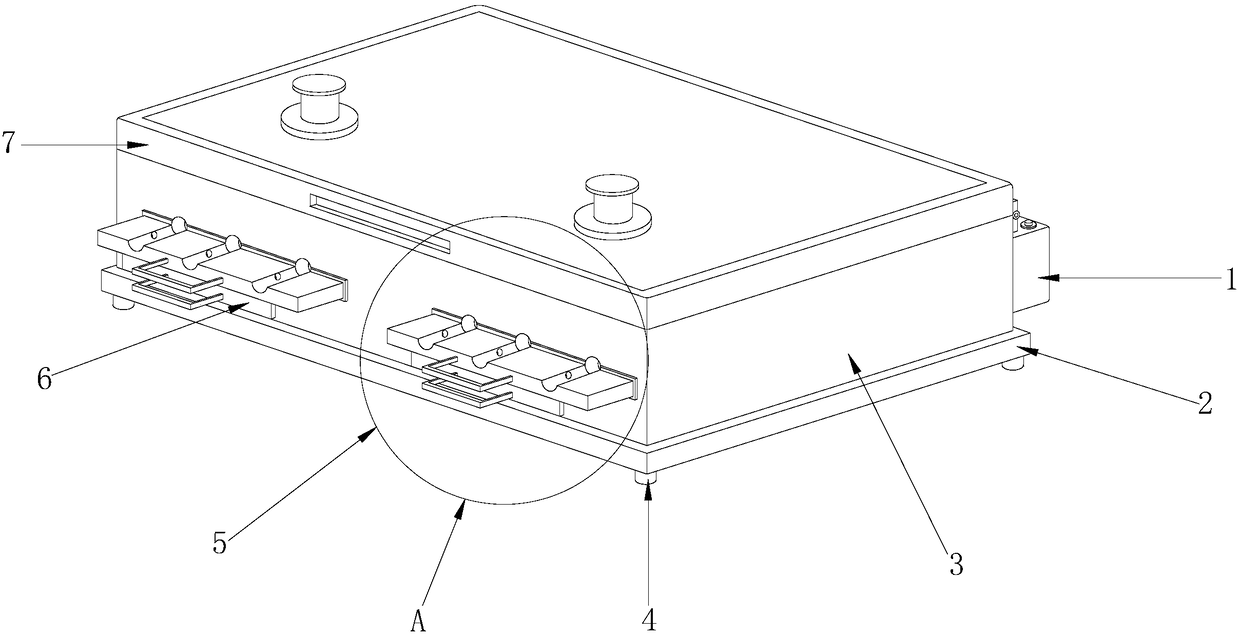

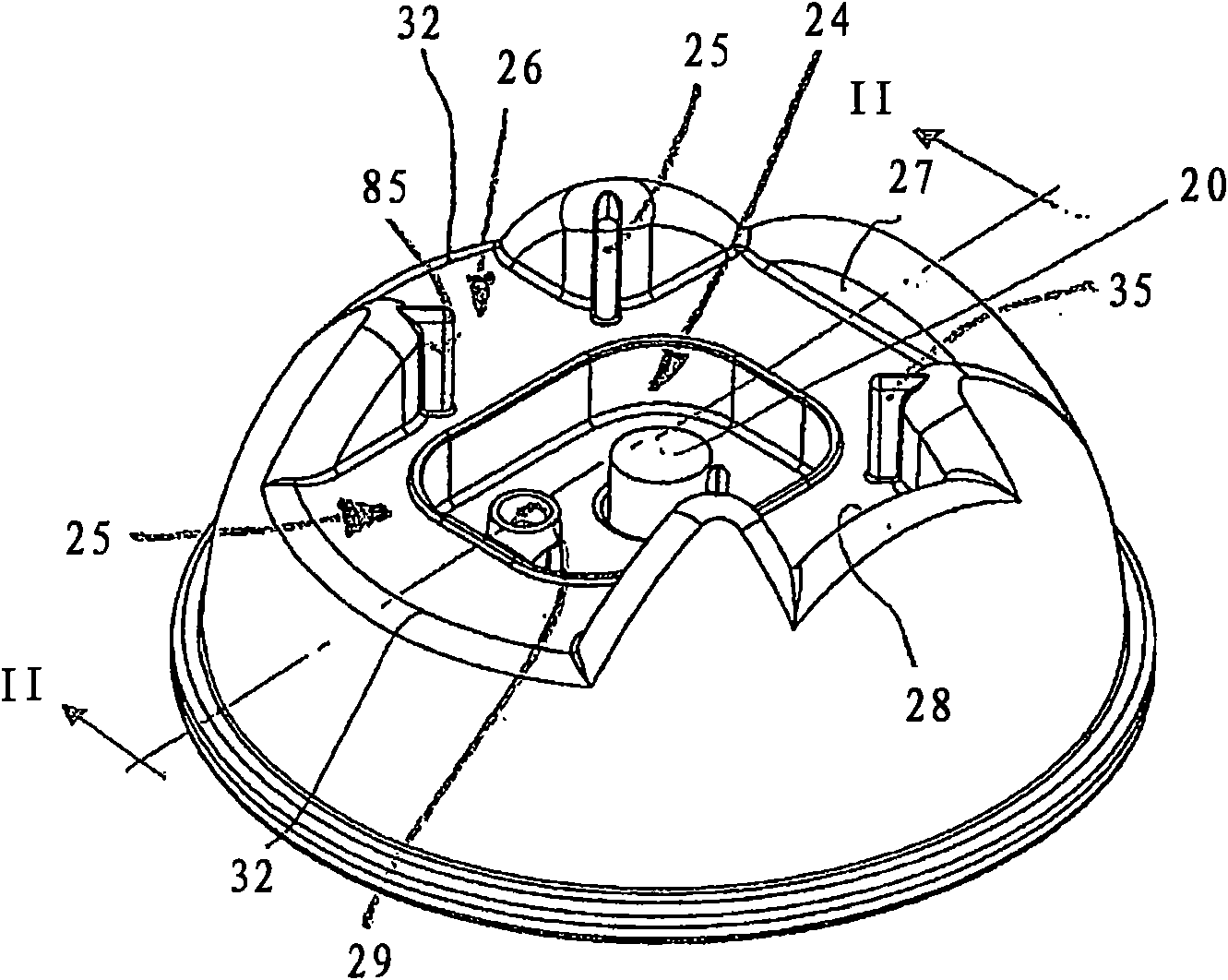

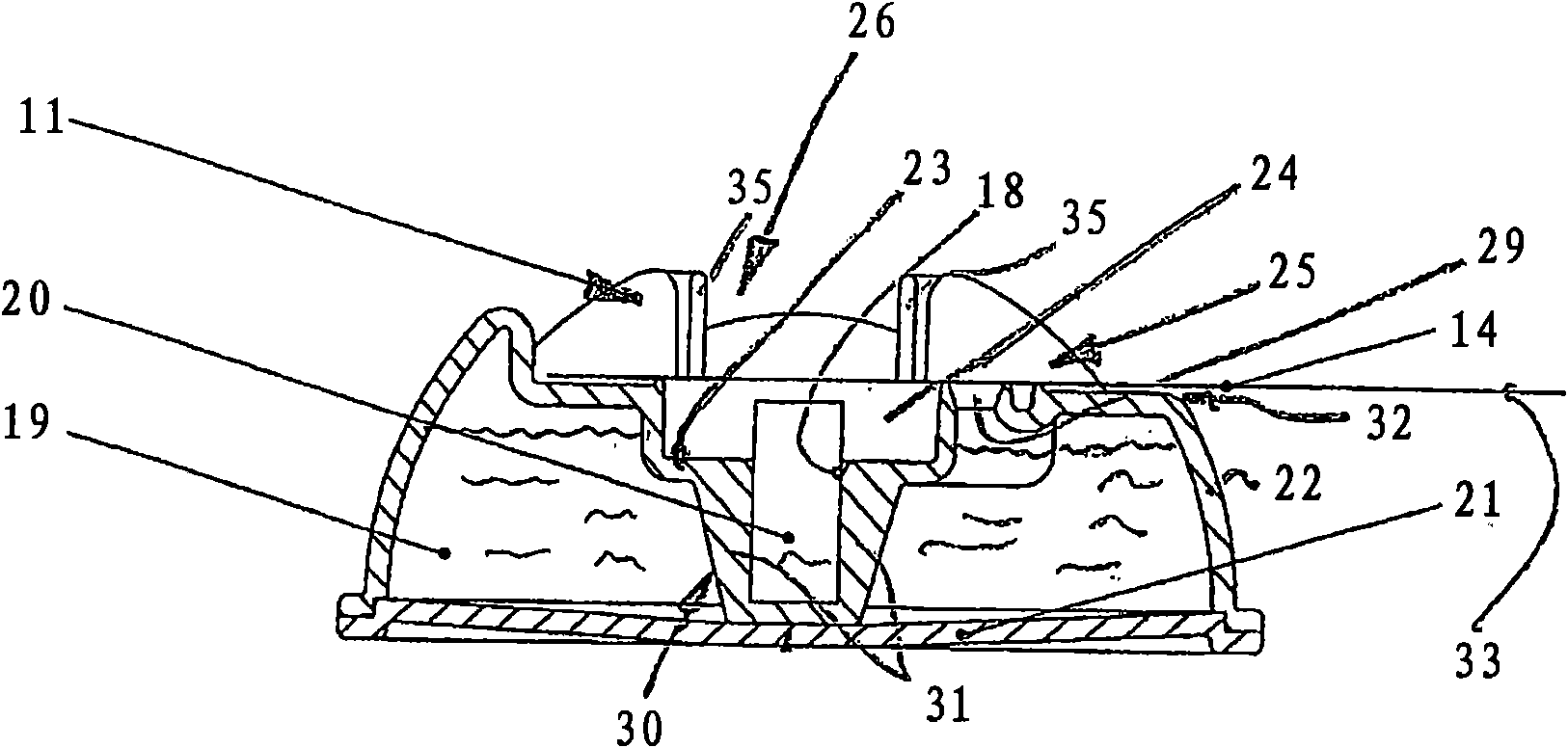

Novel moisturizing ink box

InactiveCN108819578AAvoid drippingPrevent drynessInk receptaclesMechanical engineeringGear transmission

The invention discloses a novel moisturizing ink box. The novel moisturizing ink box is characterized by structurally comprising small water tanks, a bottom frame, an automatic ink loading device, supporting legs, pen-placing and inking brackets, an ink recycling box and a top cover, wherein the front end of the automatic ink loading device is equipped with two pen-placing and inking brackets at equal distance; the pen-placing and inking brackets are in clearance fit to the automatic ink loading device; the two small water tanks are uniformly arranged at the rear end of the automatic ink loading device at equal distance; and the small water tanks are buckled with the automatic ink loading device. The pen-placing and inking brackets can prevent ink from dropping onto a table and an ink box,and also can recycle excessive ink into the ink recycling box; the automatic ink loading mechanism can automatically load ink to a pen point, so that inking speed is increased; and an automatic waterinlet mechanism is matched with a gear transmission mechanism, so that automatic grinding of an ink grinding mechanism can be realized, and the ink box and an ink piece block are prevented from a drying and hardening phenomenon.

Owner:崔浩轩

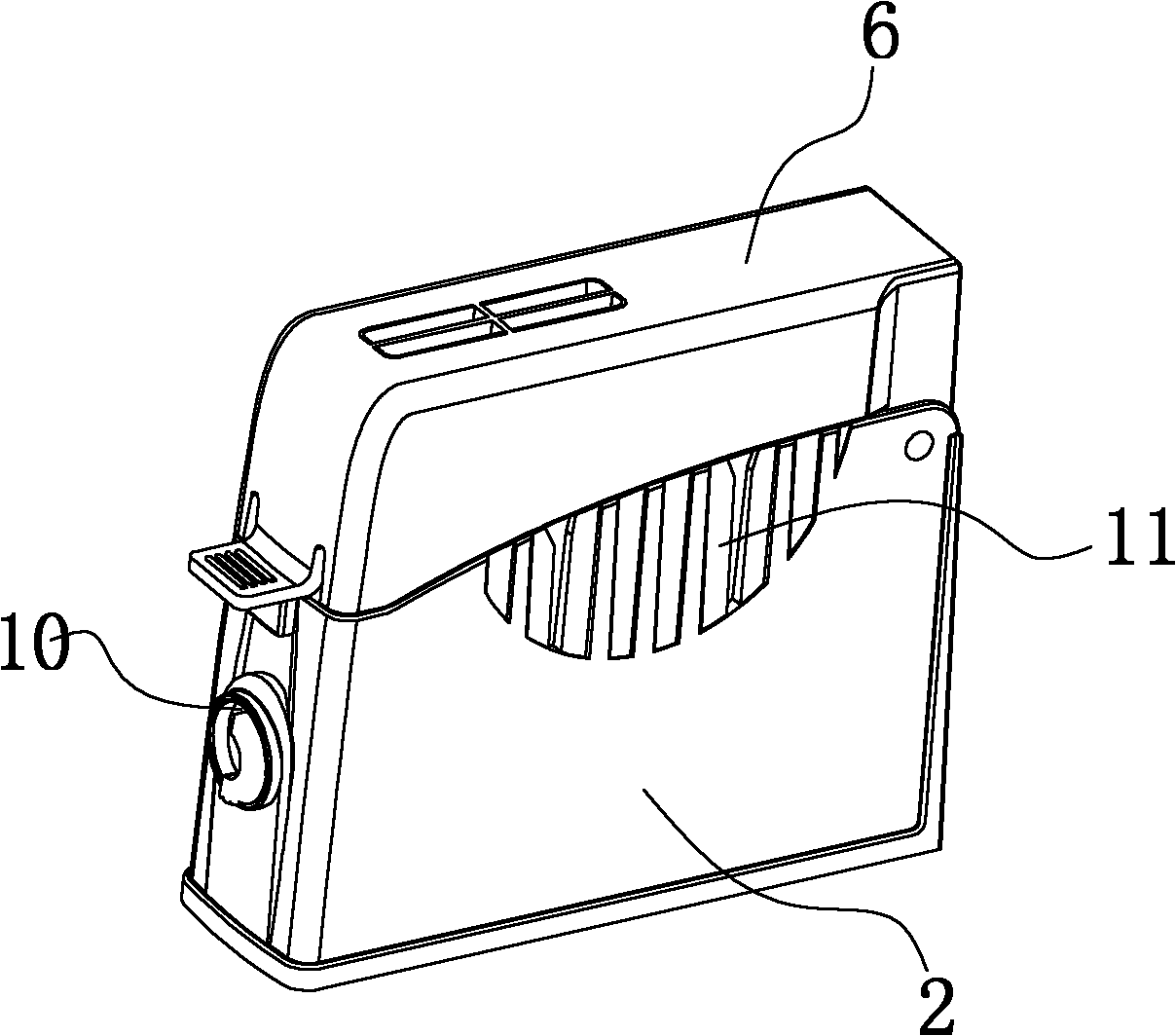

Apparatus for refilling an ink cartridge for an inkjet printer

InactiveCN101573238ANo risk of soilingAvoid contamination riskInk receptaclesFilling devicesEngineeringNozzle

Apparatus for refilling an ink cartridge (10 or 13) for an inkjet printer having a print head which comprises nozzles or having an ink outlet opening (16) which can be coupled to the ink supply of an inkjet head, wherein either the nozzles of the print head directly or, in the case of an ink outlet opening (16) which can be coupled to the ink supply of an inkjet head, said ink outlet opening (16) are or is fluidically connected via a wick to an ink storage element (17) which is arranged within the ink cartridge (10 or 13) and comprises, for example, absorbent. Said apparatus comprises a container (11) which is filled with ink and has an opening (18), in which a capillary element (wick 20) is situated which is dipped into the ink (19) and can be brought into contact with the ink storage element (17) of the ink cartridge (10 or 13).

Owner:PELIKAN HARDCOPY PRODN

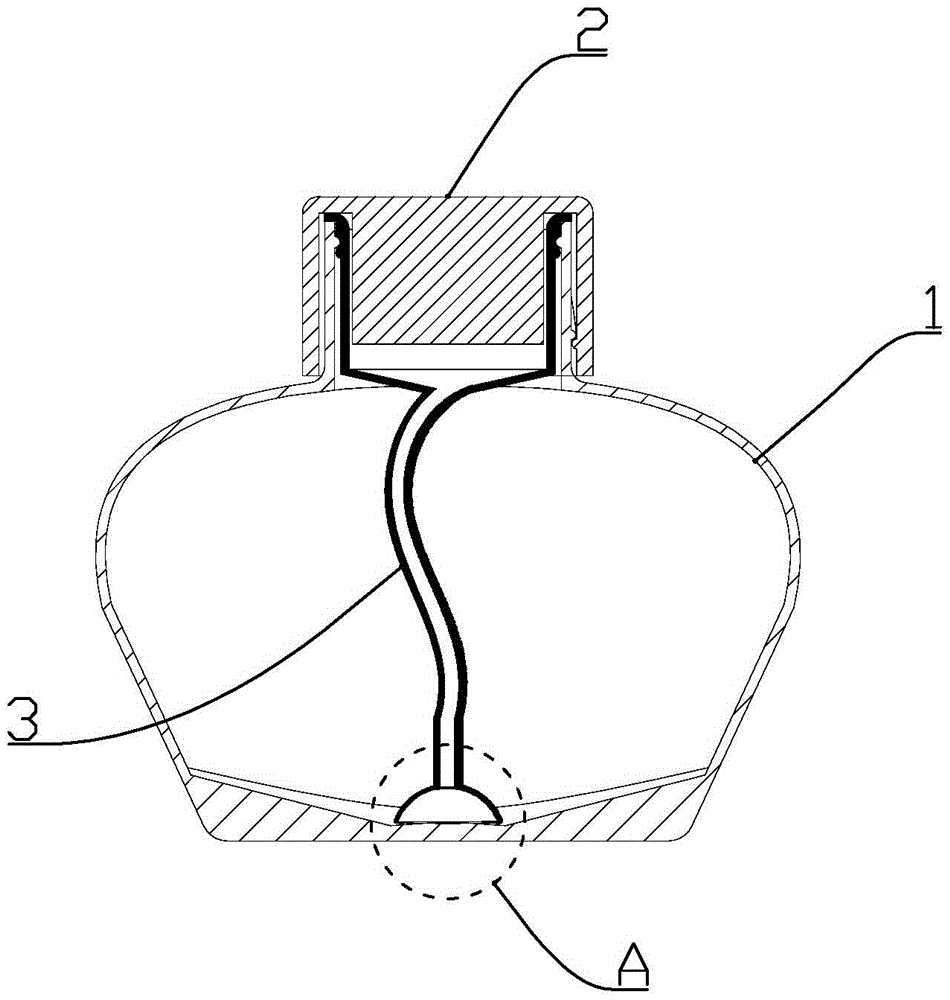

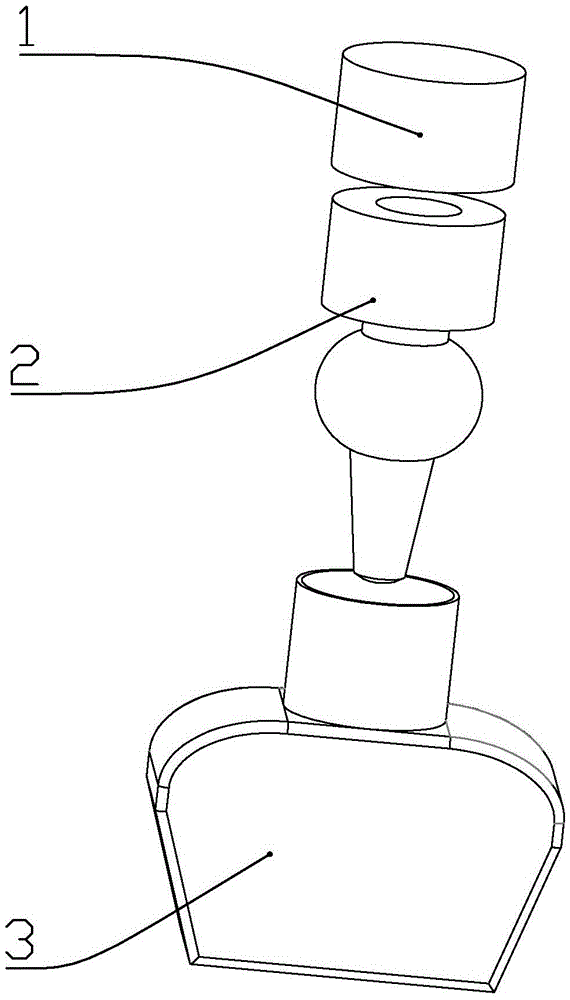

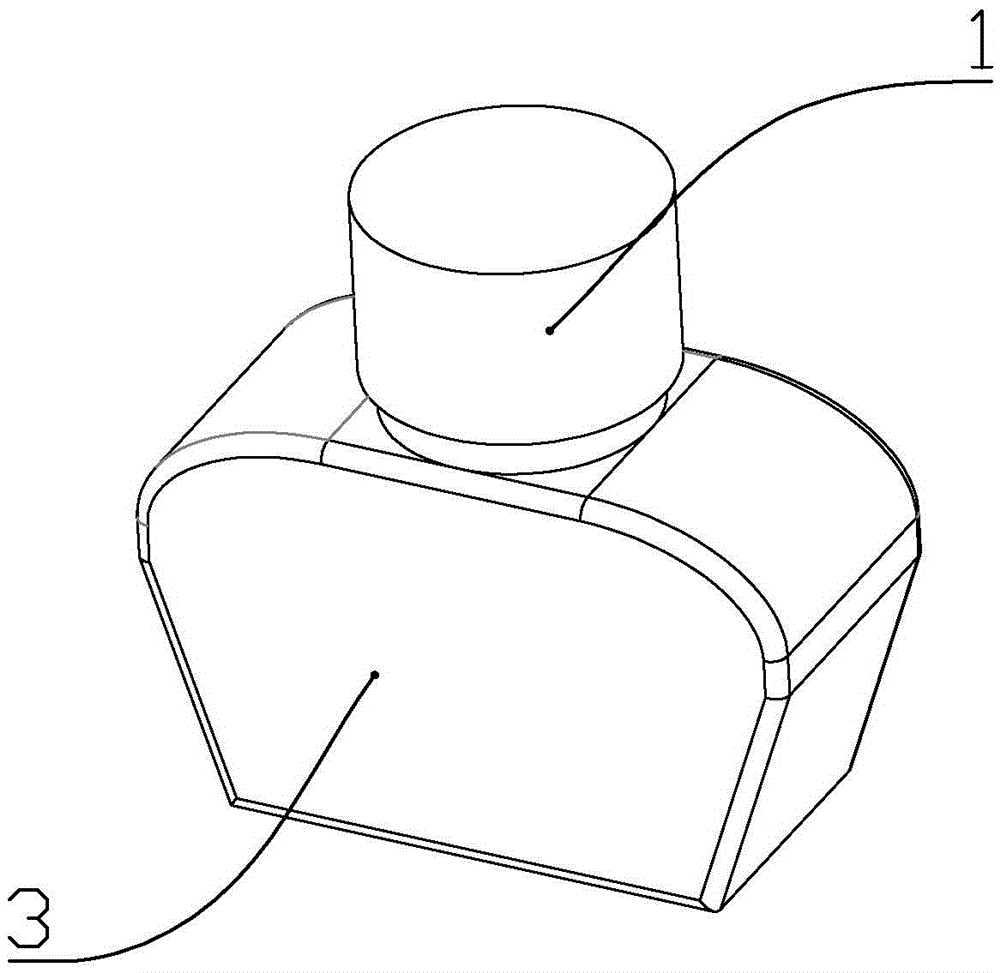

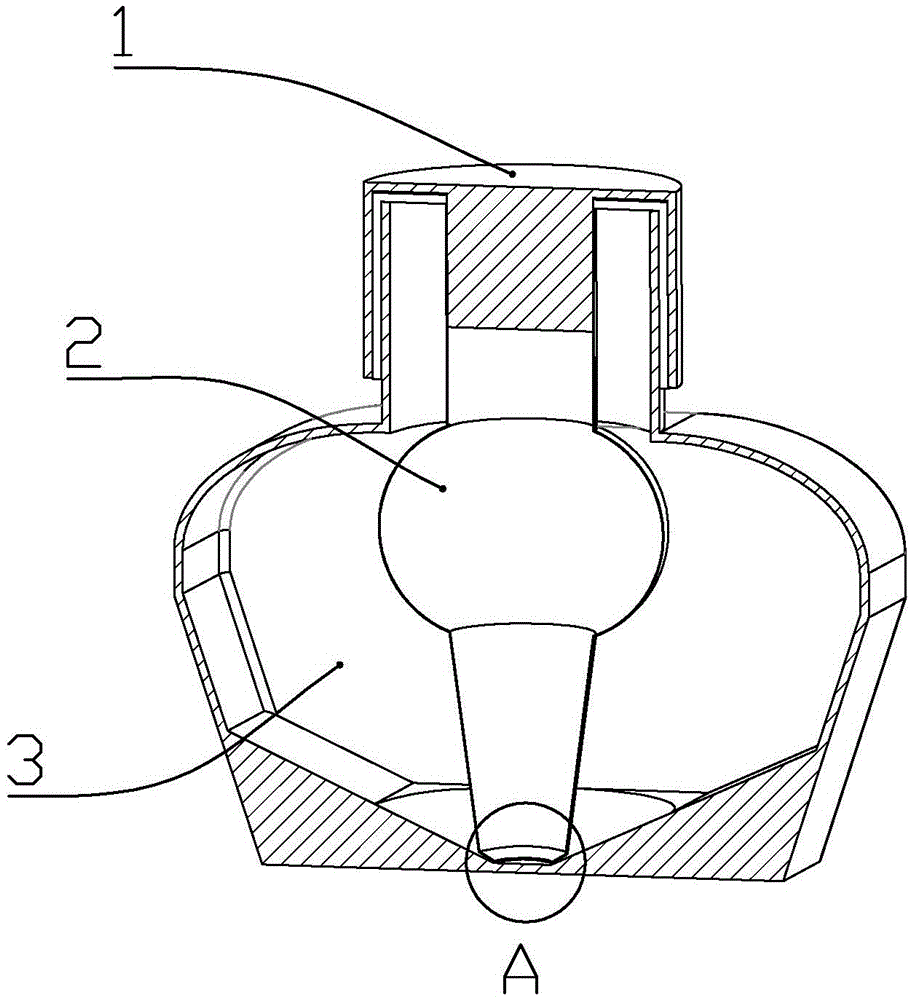

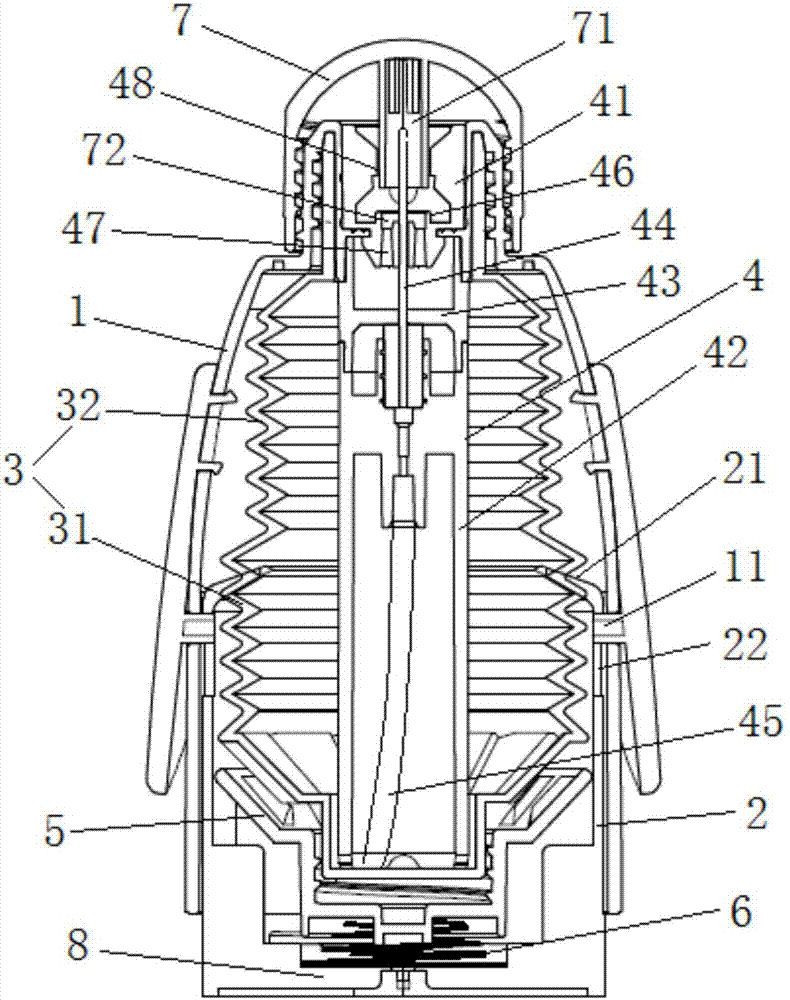

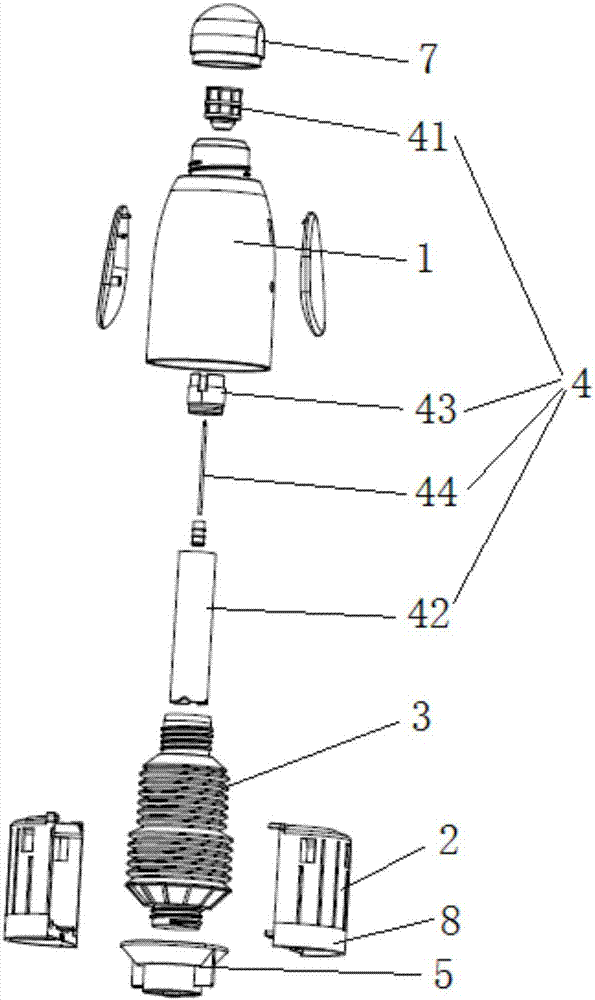

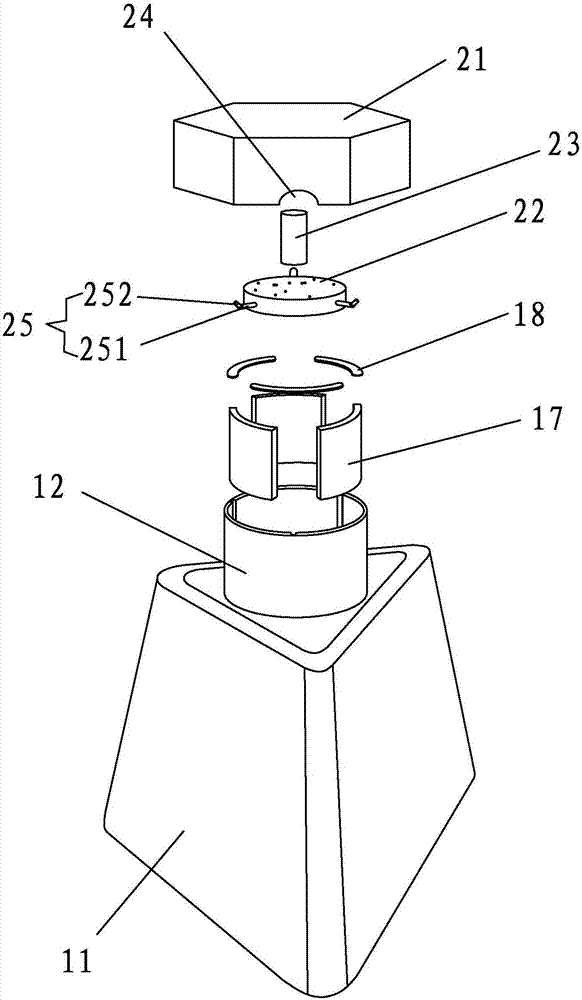

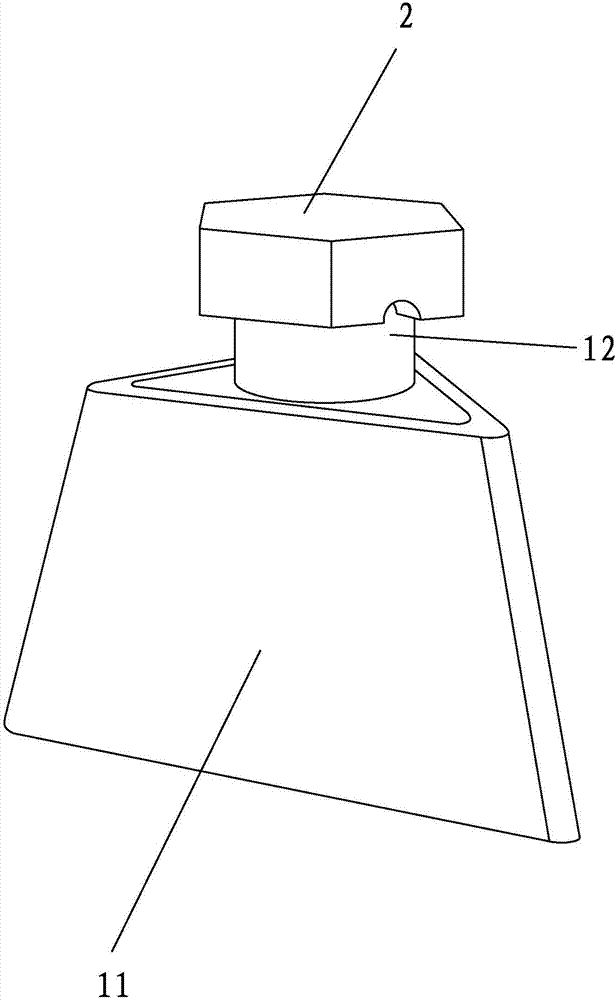

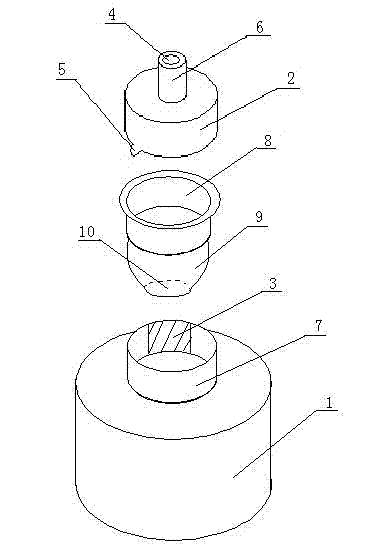

Ink bottle

ActiveCN107160925AThere is no overflow problemRealize ink return actionInk receptaclesEngineeringBottle

The invention provides an ink bottle. The ink bottle comprises an upper bottle body, a lower bottle body, a glass liner, a needle cylinder, a base and a spring. The upper bottle body is movably connected to the lower bottle body in a sleeved manner, and the glass liner is arranged in the space enclosed by the upper bottle body and the lower bottle body; the opening portion of the glass liner is connected with the opening portion of the upper bottle body, the middle portion of the glass liner is provided with an inverted-T-shaped compressible folding and bouncing structure, and the bottom of the lower bottle body is connected with the base; the top of the lower bottle body is provided with a limiting portion for partitioning the inverted-T-shaped middle portion of the glass liner; the spring is arranged between the base and the bottom of the lower bottle body; the needle cylinder comprises a supporting seat located on the upper portion of the needle cylinder and a supporting and jacking seat located on the lower portion of the needle cylinder; the supporting and jacking seat is internally provided with a connection seat, a needle pipe and a hose, the lower end of the needle pipe is inserted into a hollow channel of the connection seat and communicates with the interior of the glass liner through the hose, and the upper end of the needle pipe penetrates through the supporting seat to communicate with the outside; and the lower end of the supporting and jacking seat abuts against the bottom of the glass liner. The ink bottle has the advantages that the ink bottle is simple in structure, low in cost, attractive in appearance and has two functions of ink return and ink injection.

Owner:GUANGZHOU XINQI PATENT TECH EXTENSION SERVICE CO LTD +1

Set for connecting parent bottle to son bottle

A coupling mechanism between the primary bottle with the first port and the second bottle with the second port connected to the first port for the fast butt connection of said two ports or fast separation from each other is disclosed. Said primary bottle has a casing for arranging a secondary bottle in it. The wall of said casing has two small holes, two push button whose lower end is extended out via said small hole, and two bosses on its inner surface. Said secondary bottle has two elastic parts on its outer surface for supporting the secondary bottle on said bosses.

Owner:TOPRET IND DESIGN(SHANGHAI) CO LTD

Portable ink bottle

ActiveCN106881982AQuick and easy assemblyEasy and fast assemblyInk receptaclesEngineeringBottle neck

The invention discloses a portable ink bottle which comprises an ink bottle main body and a bottle cap which are matched with each other. The bottle cap comprises a bottle cap main body and a shielding plate which are connected through a connection middle pillar, and the circumferential edge of the shielding plate is provided with at least one folding rod with a bending function; the ink bottle main body comprises a bottle body and a bottle neck which are integrally connected, the inner side wall of the bottle neck is provided with sliding chutes matched with the folding rods, and the inner side wall of the bottle neck is provided with sponge layers for absorbing fountain pen ink remaining on a pen in an attached manner. After the above structure is adopted for the portable ink bottle, the sponge layers can be utilized to absorb the fountain pen ink remaining on the pen tip, the sponge layers can be squeezed rapidly by bending of the folding rods, when the portable ink bottle is not used, the folding rods which are not bent penetrate through the sliding chutes, and the ink bottle can be covered with the cap. Compared with the traditional technology, the whole process that people fill the pen with the pen ink can be convenient and rapid, the hands cannot be stained with the ink, and the pen ink and paper are not wasted.

Owner:FUJIAN NARKII INFORMATION TECH

Practicalink bottle

The invention discloses a practical ink bottle, which comprises a bottle body and a bottle cover, and is characterized in that a sponge pen wiping pad is arranged on the inner wall of a bottle opening of the bottle body; the bottle cover comprises an inner cover and an outer cover; a pipe barrel which is hollow in interior and sealed in the upper end is arranged on the upper part of the outer cover; a flow guide port is formed in the edge of the outer cover; a sponge pen wiping layer is arranged on the outer wall of the pipe barrel; a conical rubber sleeve is arranged on the lower end of the inner cover; a pen penetrating hole is formed in the bottom of the conical rubber sleeve. According to the practical ink bottle, when ink is too much, a pen point passes a wiper sleeving the conical rubber sleeve after the ink is absorbed, so that the pen is prevented from being attached by the ink to the greatest extent; when the pen cannot be used to directly absorb the ink of the bottom, the inner cover is taken down, the outer cover covers the bottle body, the bottle body is inverted, and residual ink flows into the pipe barrel inside the outer cover, so the pen can be used to directly absorb the ink. The ink in the practical ink bottle can be thoroughly absorbed, no waste is caused, the use is convenient, the practicability is high, the structure is simple, and the cost is low.

Owner:申怡然

Ink bottle

The invention provides an ink bottle. A circular groove is arranged in the middle of the inside of the bottom part of a bottle body of the ink bottle. The circular groove can gather ink about to run out in the bottle body till the ink runs out. The ink bottle has the advantages of saving ink and reducing pollution.

Owner:张富毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com