Patents

Literature

175results about How to "Prevent ink leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

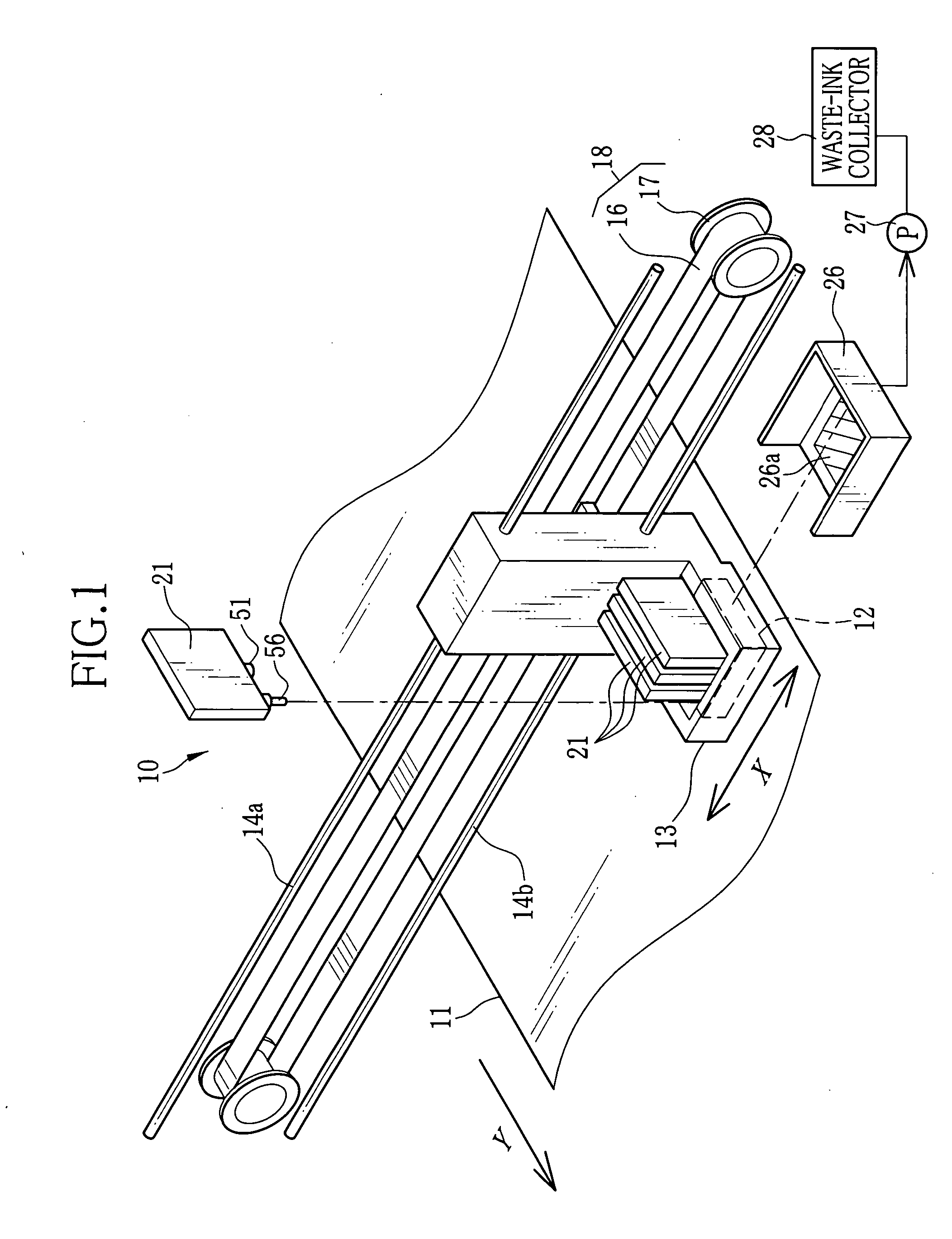

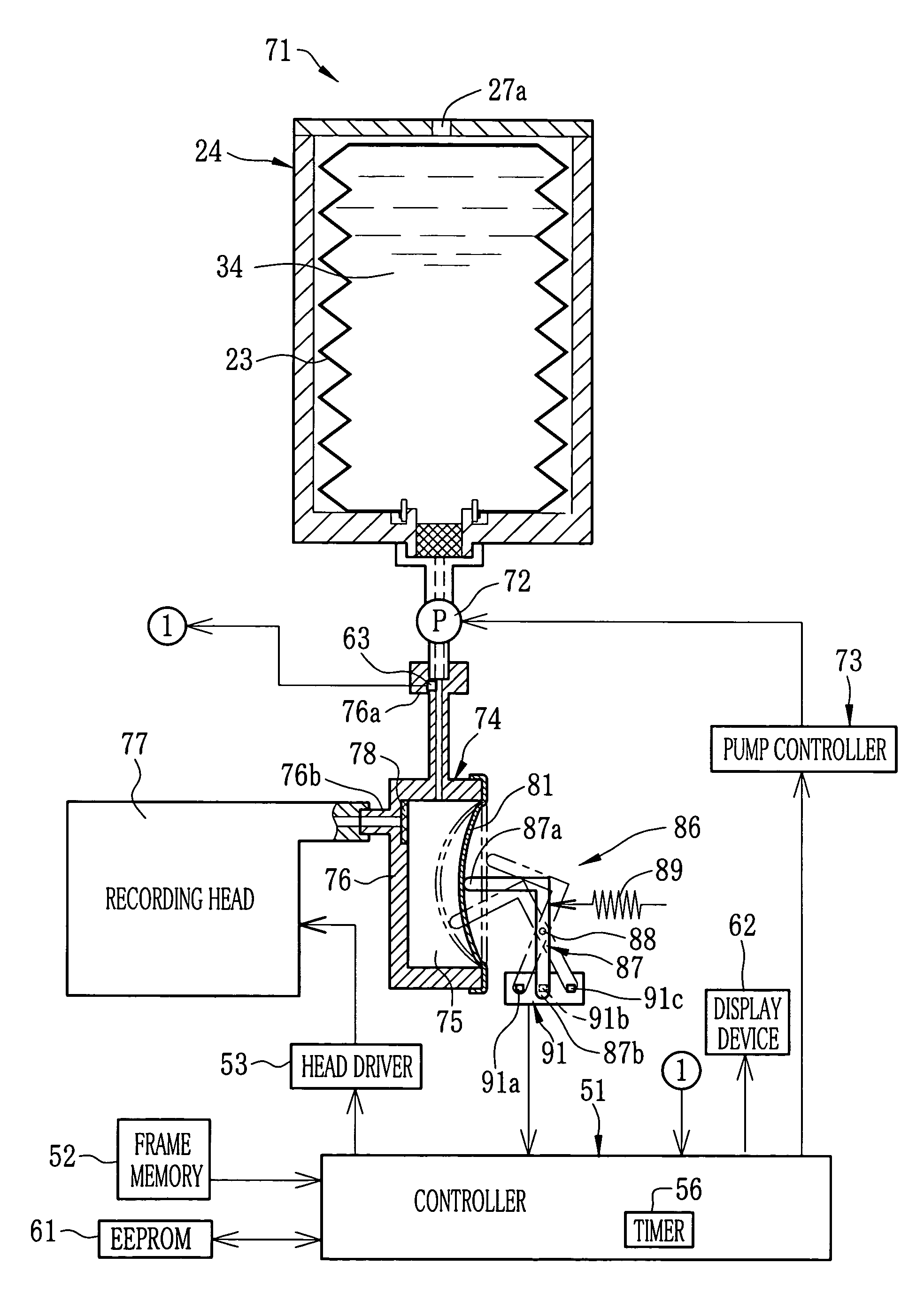

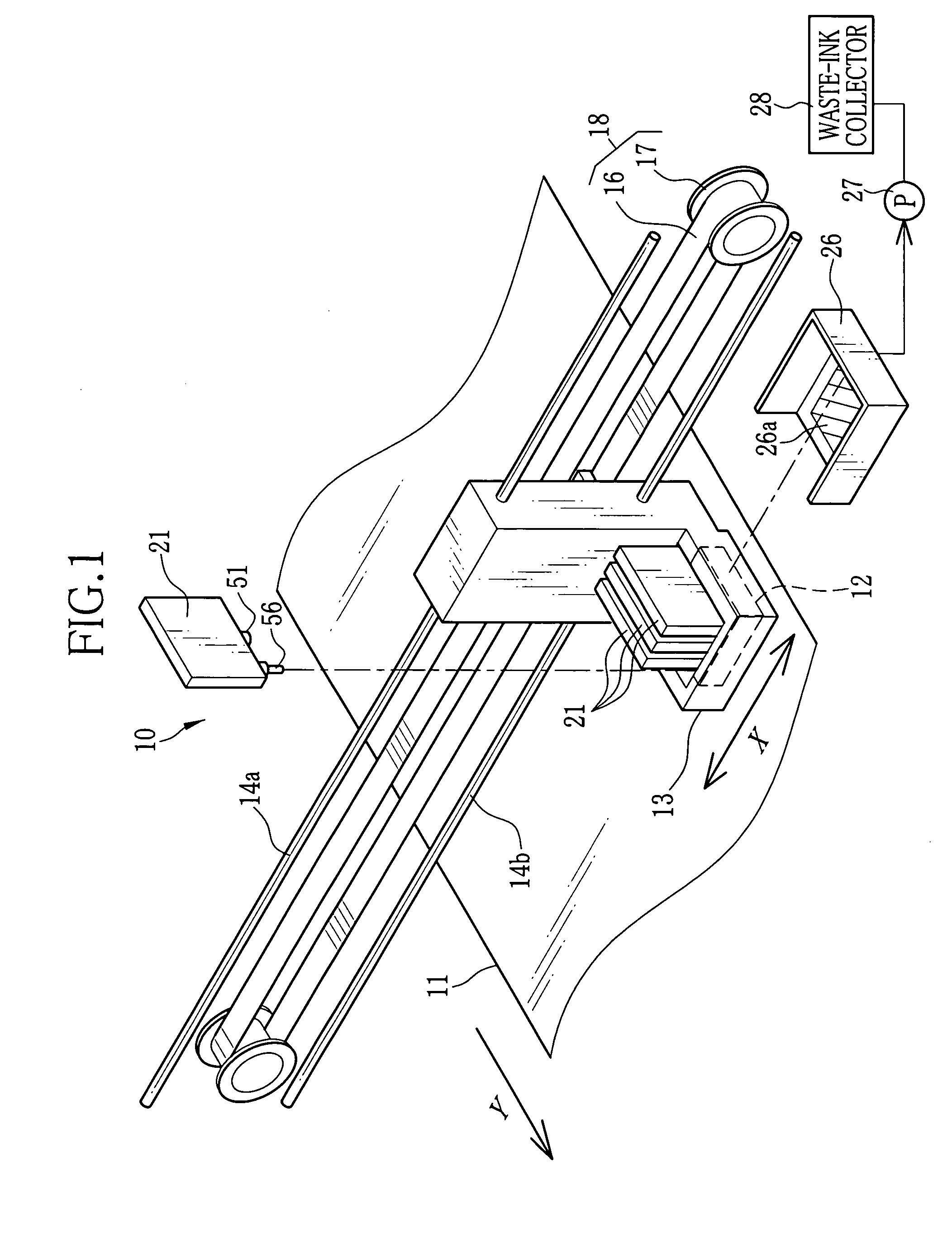

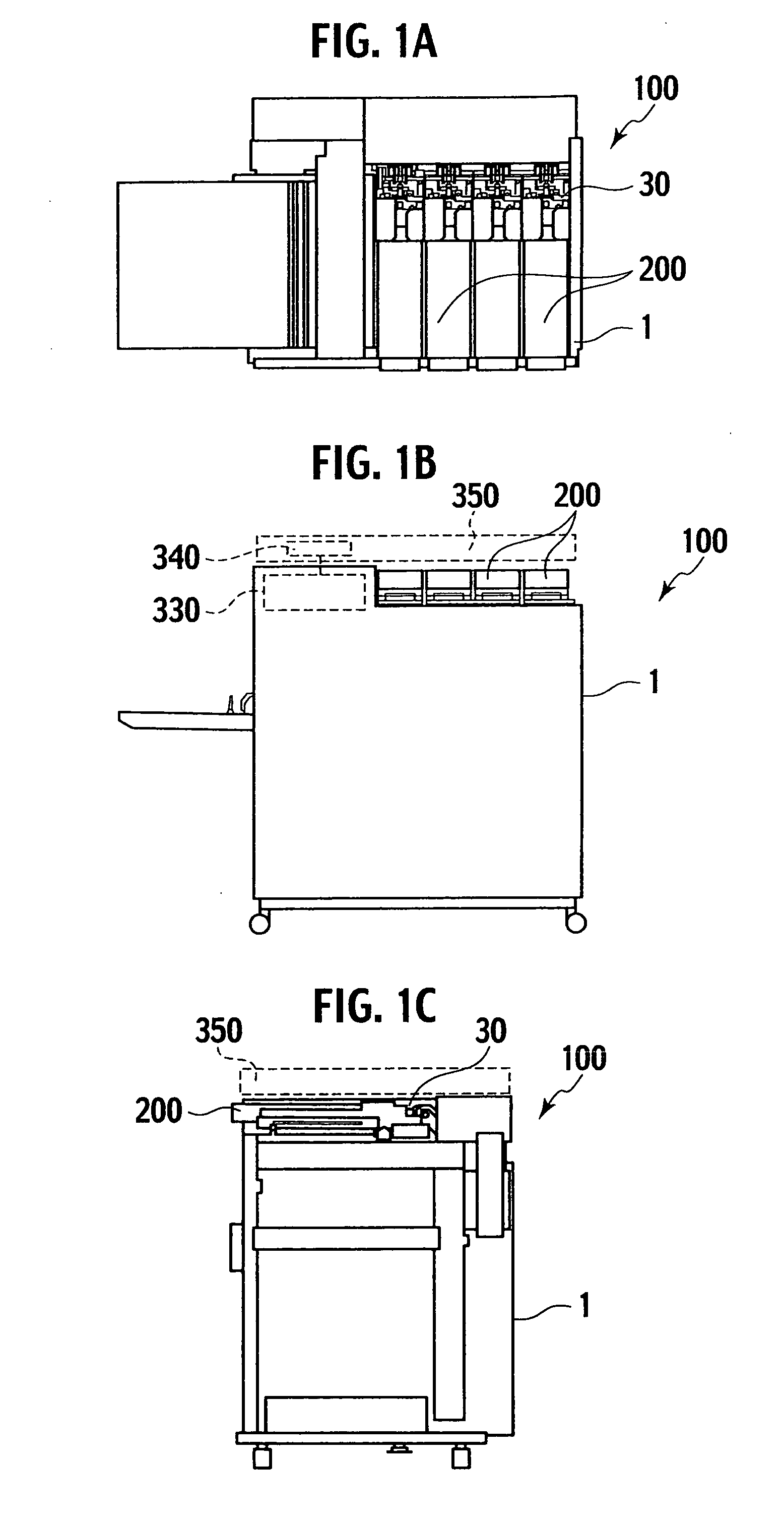

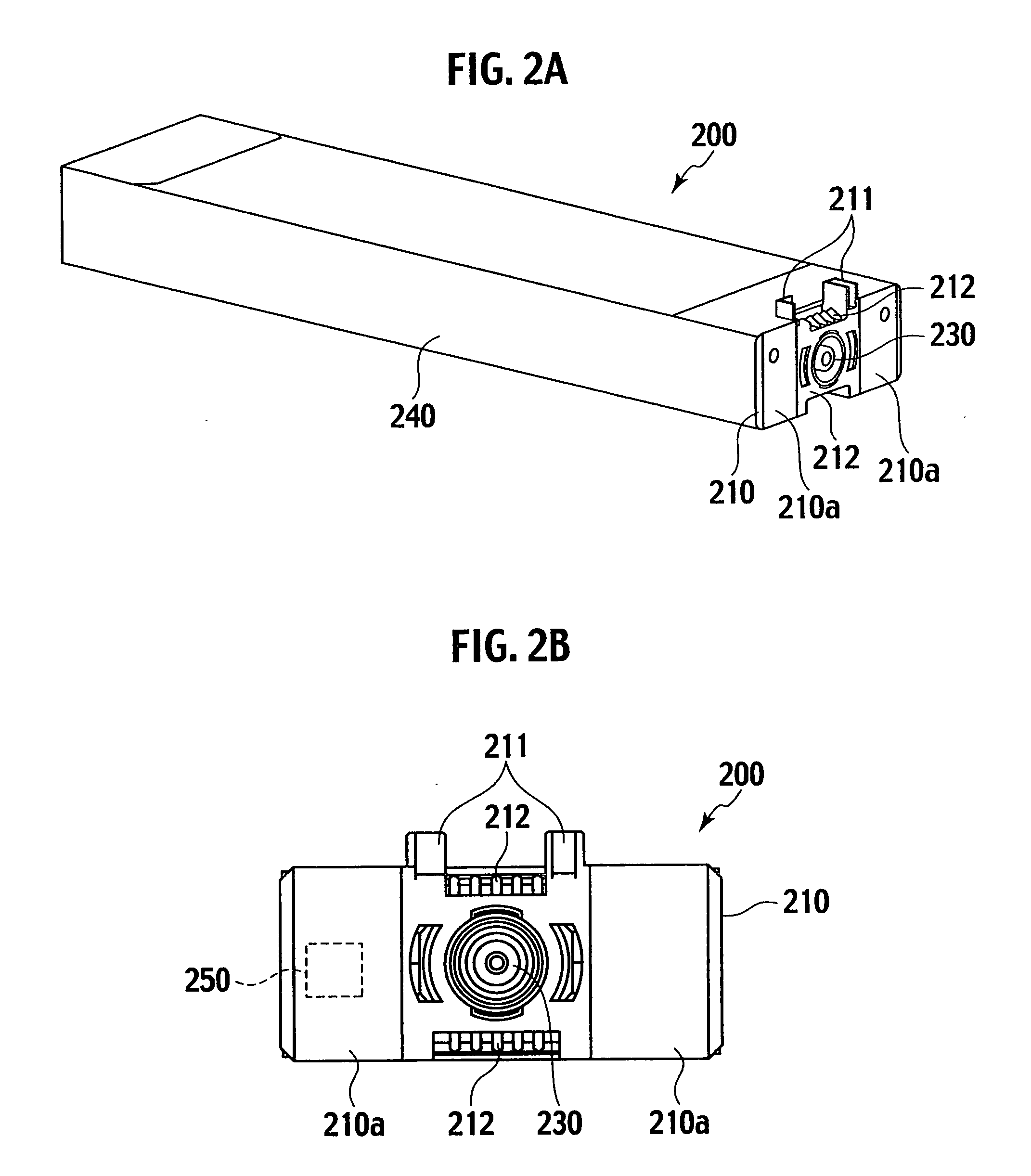

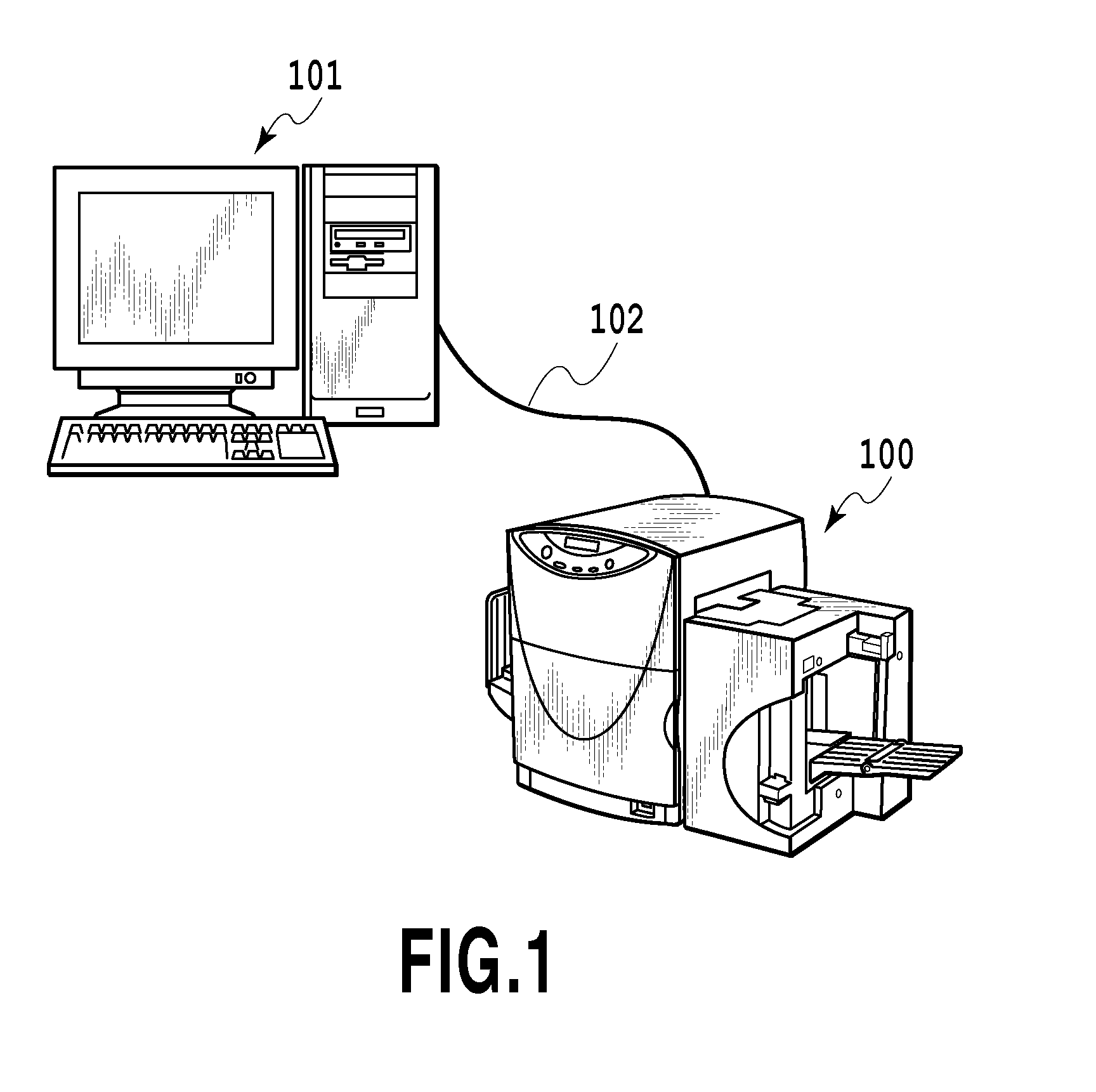

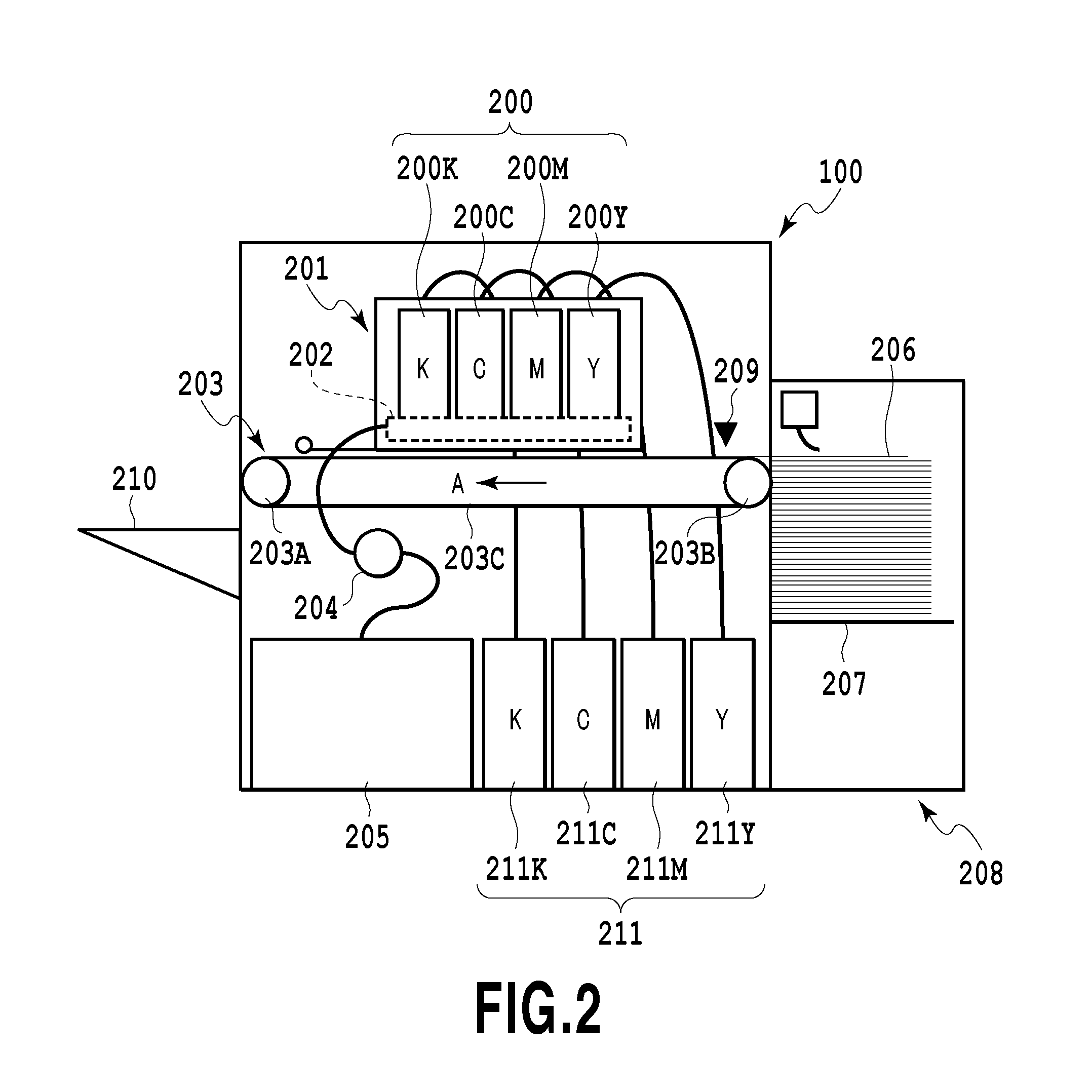

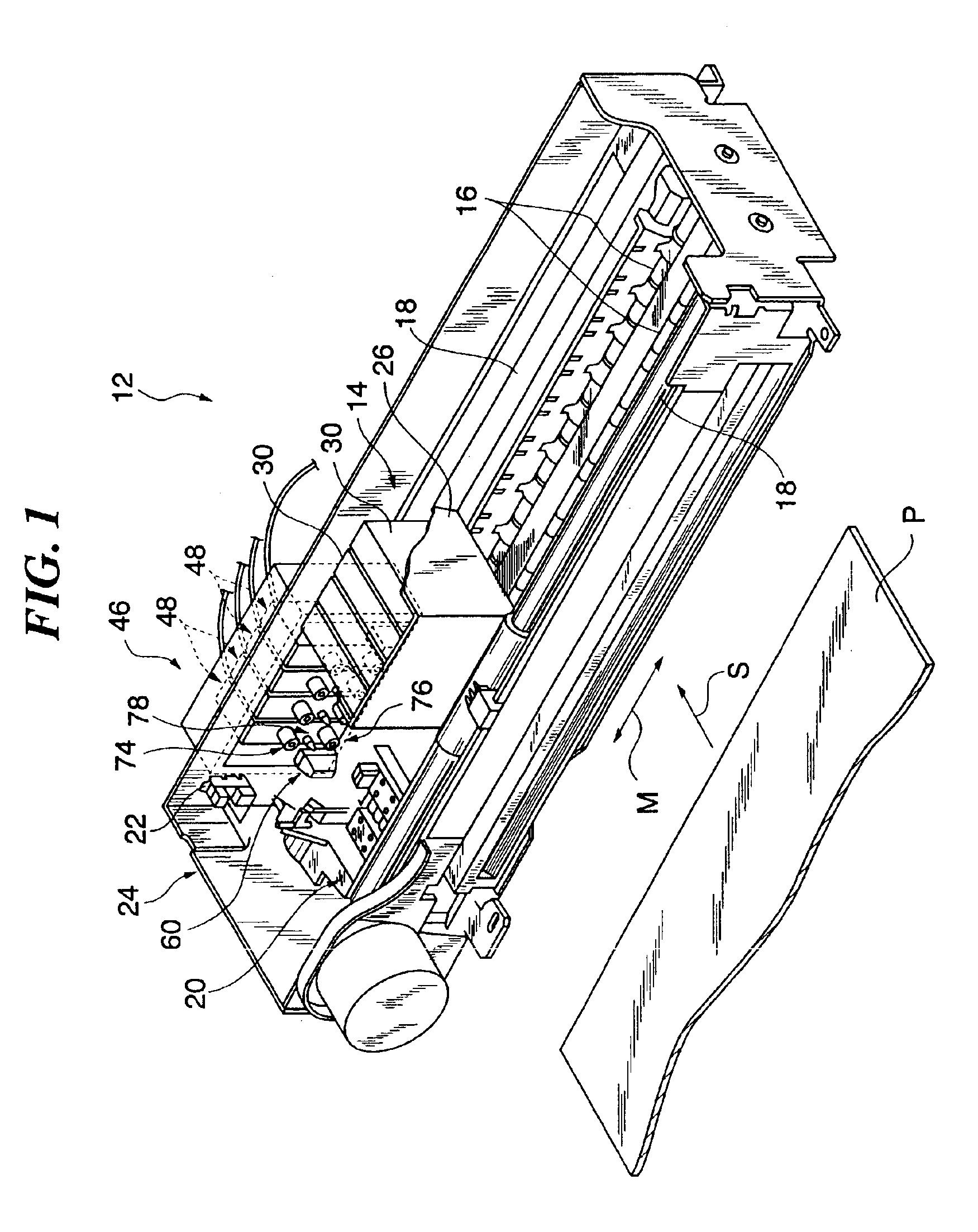

Ink supply device, ink jet recording apparatus and ink cartridge

An ink cartridge consists of an ink bag storing ink and a case holding the ink bag. A valve unit is placed on an ink supply path from the ink bag to a recording head. During the printing, the amount of ink discharged from the recording head is measured at predetermined time intervals, and the valve unit is controlled to supply the recording head with the ink by an amount corresponding to the discharged amount. So the pressure inside the recording head is kept approximately constant, improving stability of ink-discharging from nozzles of the recording head. A head internal pressure detecting mechanism detects pressure inside a sub-tank as a value representative of the head internal pressure.

Owner:FUJIFILM CORP

Ink supply device, ink jet recording apparatus and ink cartridge

InactiveUS7648230B2Guaranteed smooth progressPrevent ink leakagePrintingInternal pressureEngineering

Owner:FUJIFILM CORP

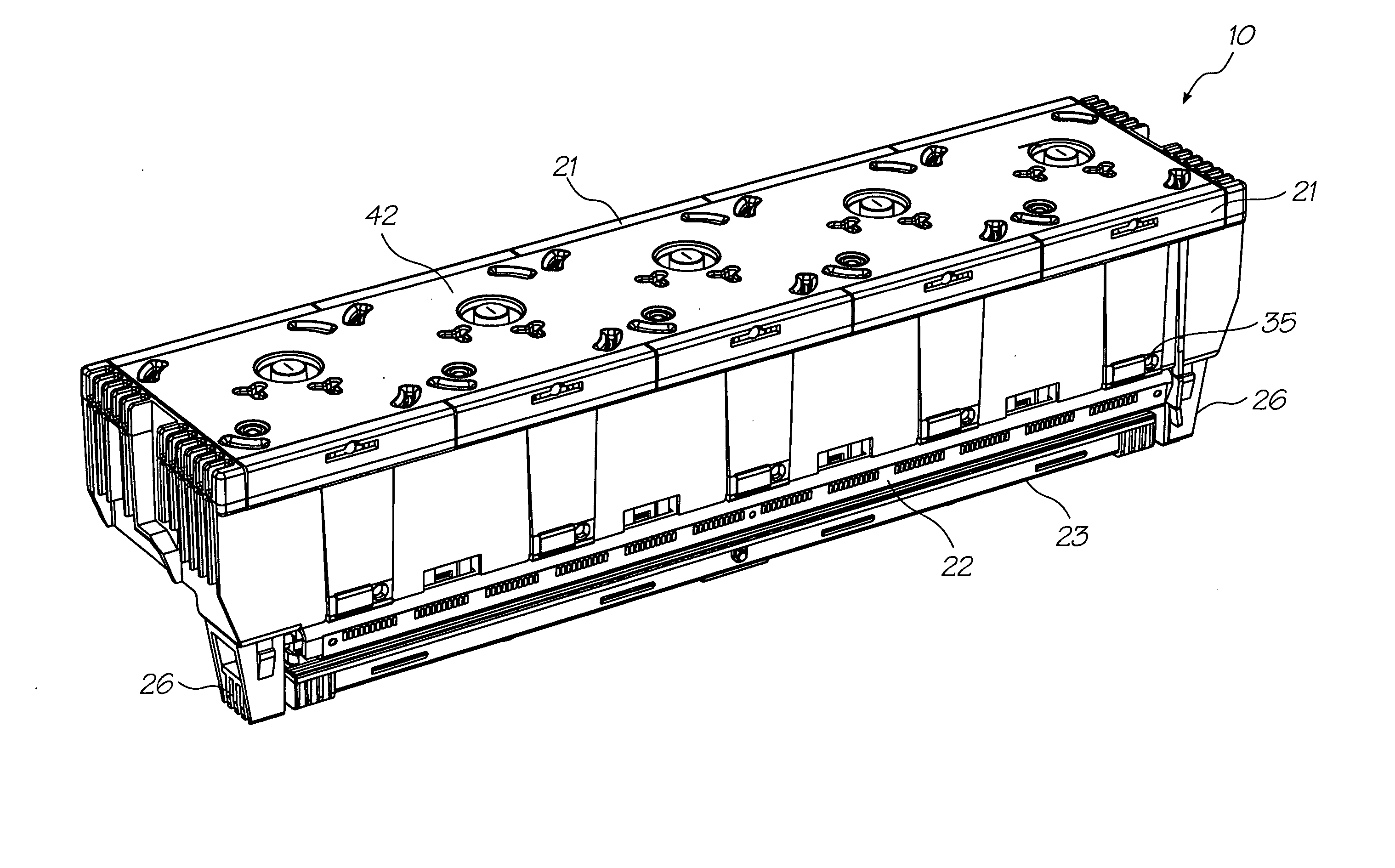

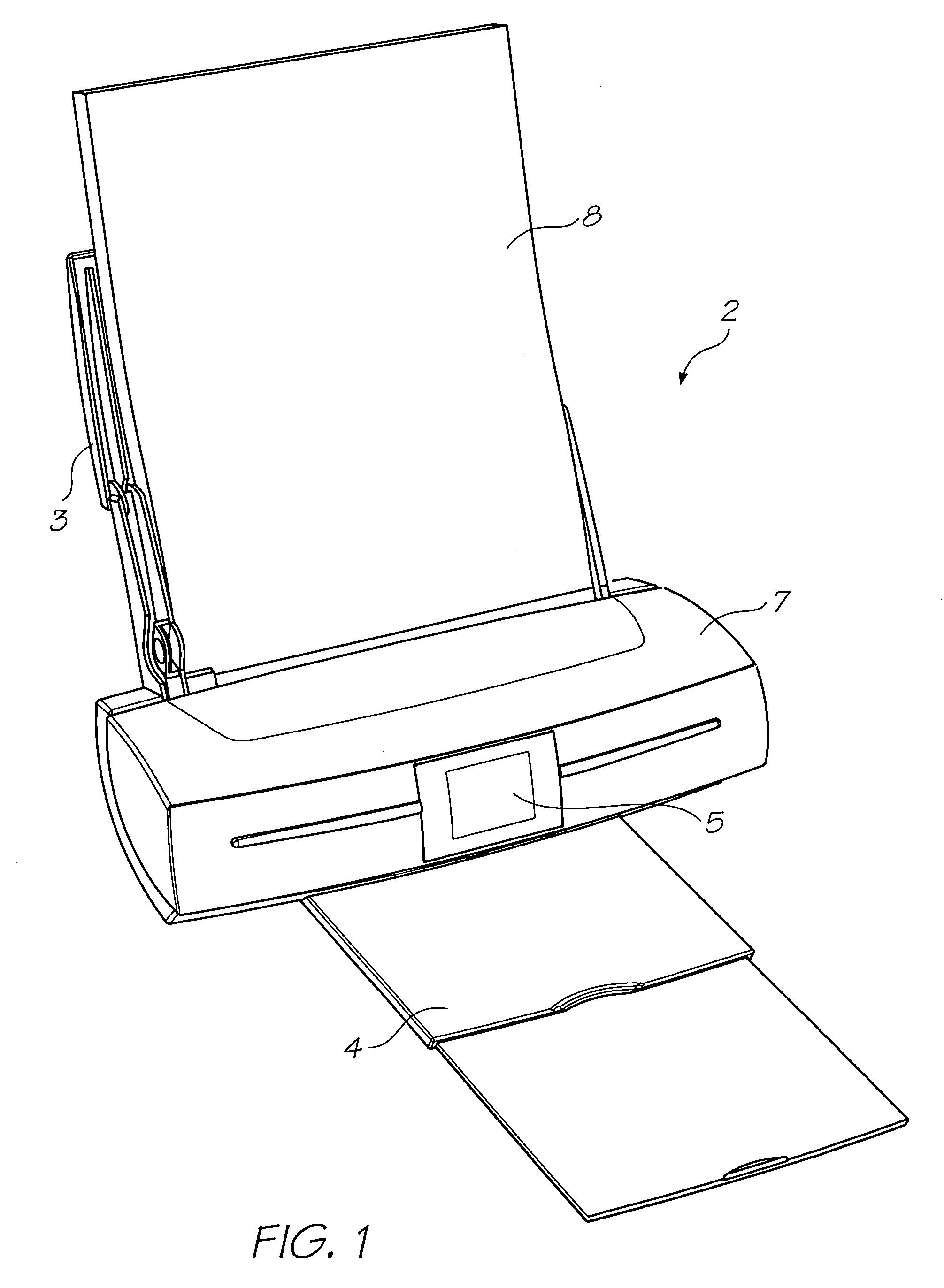

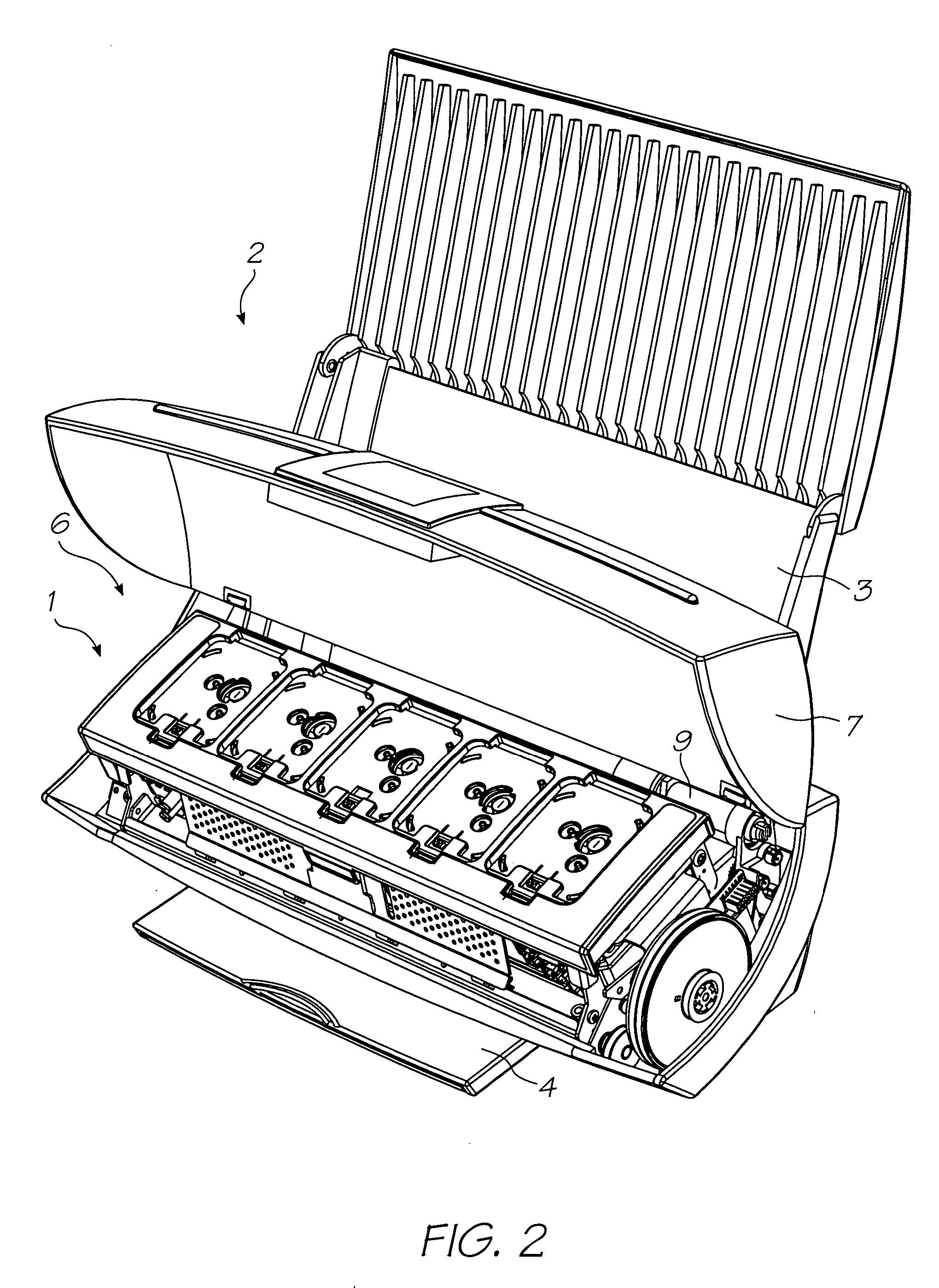

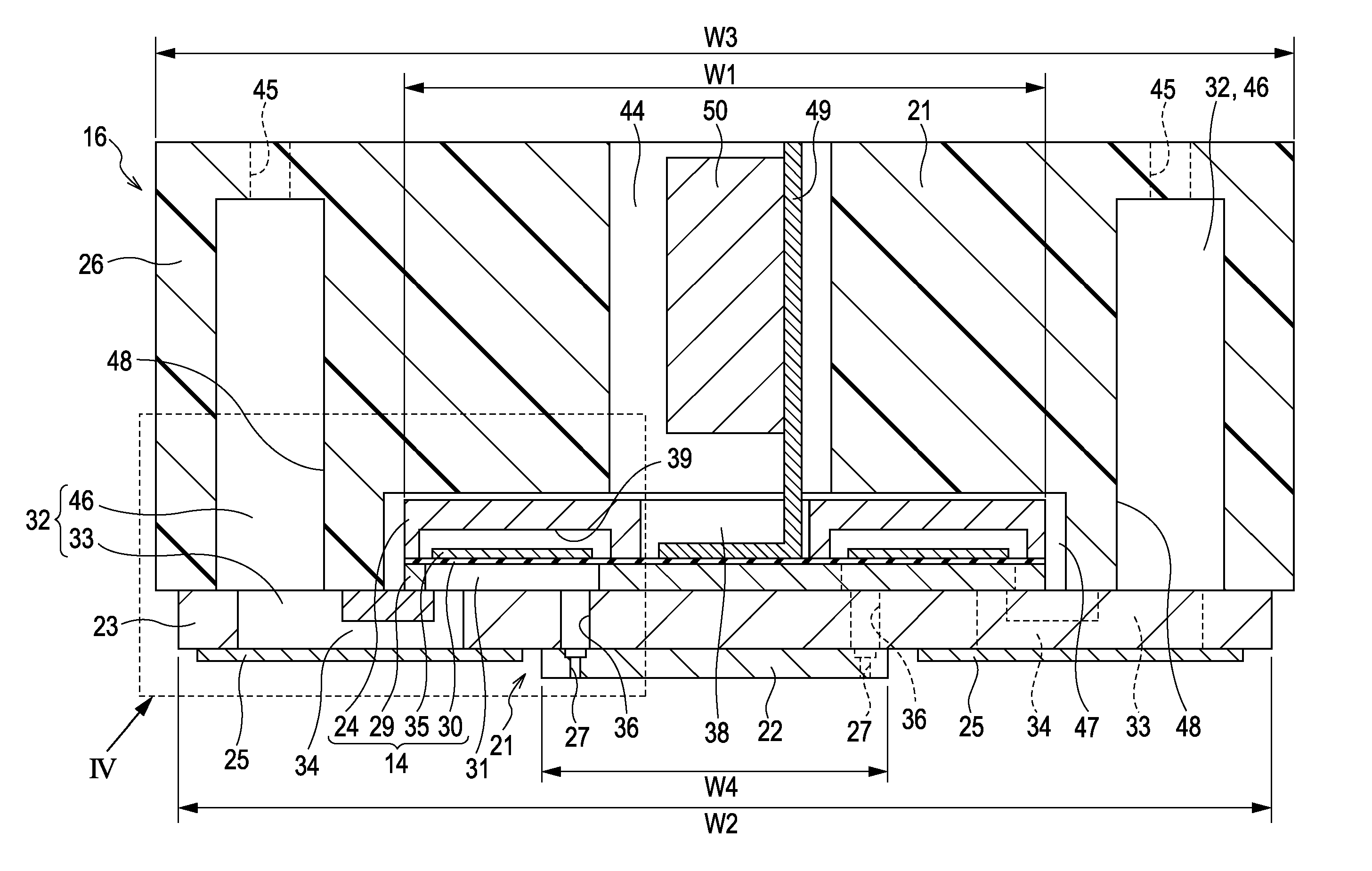

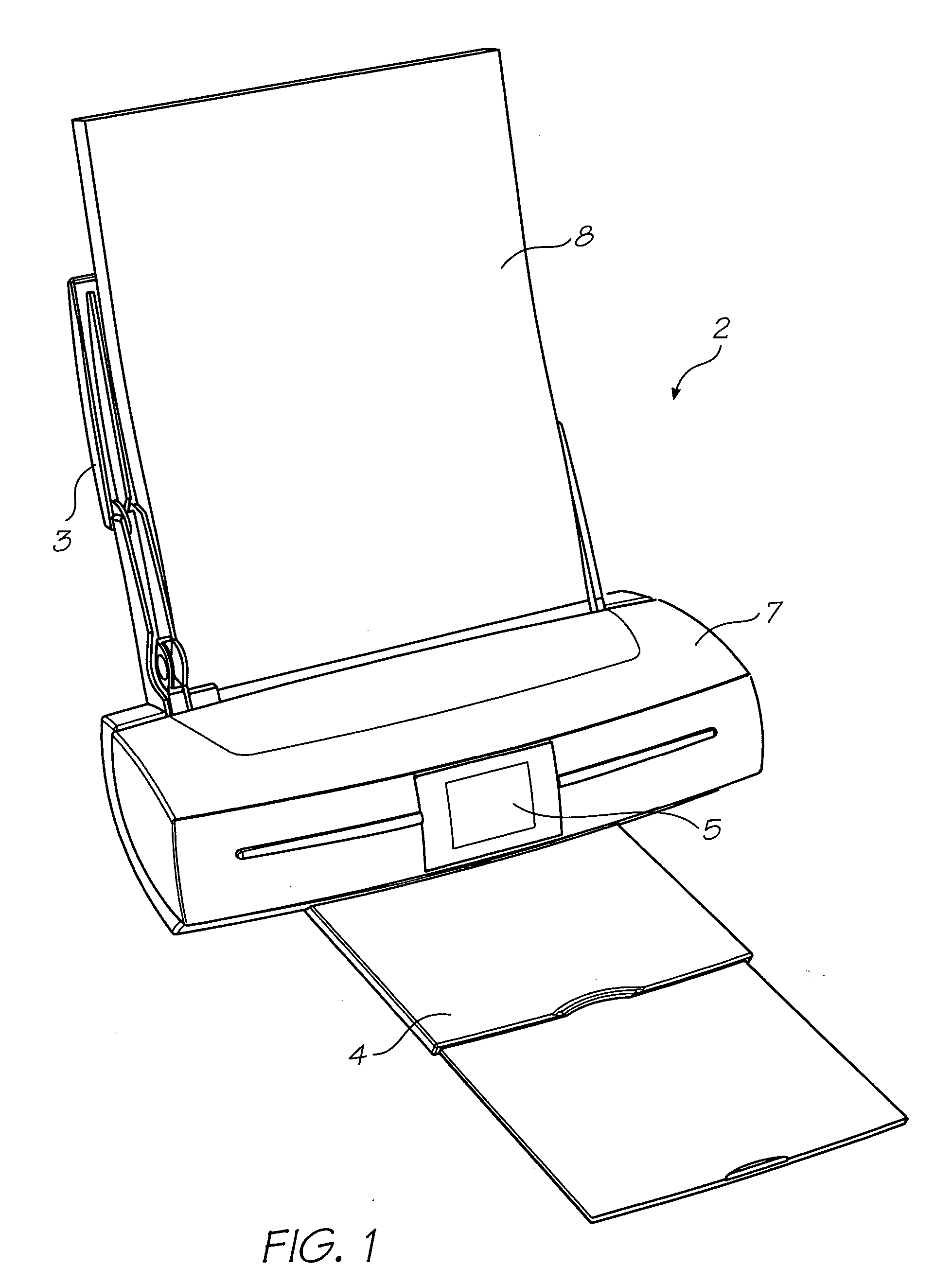

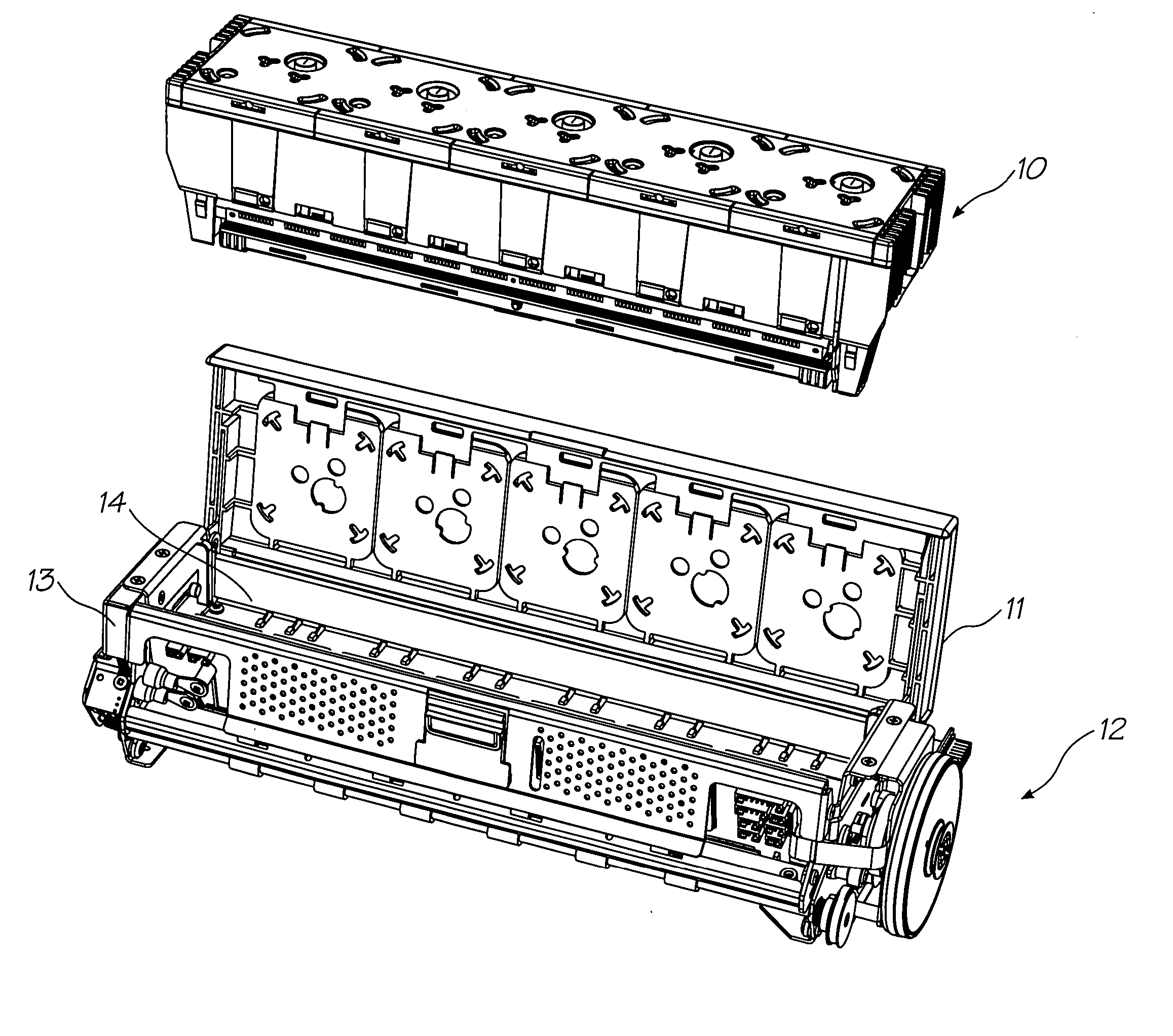

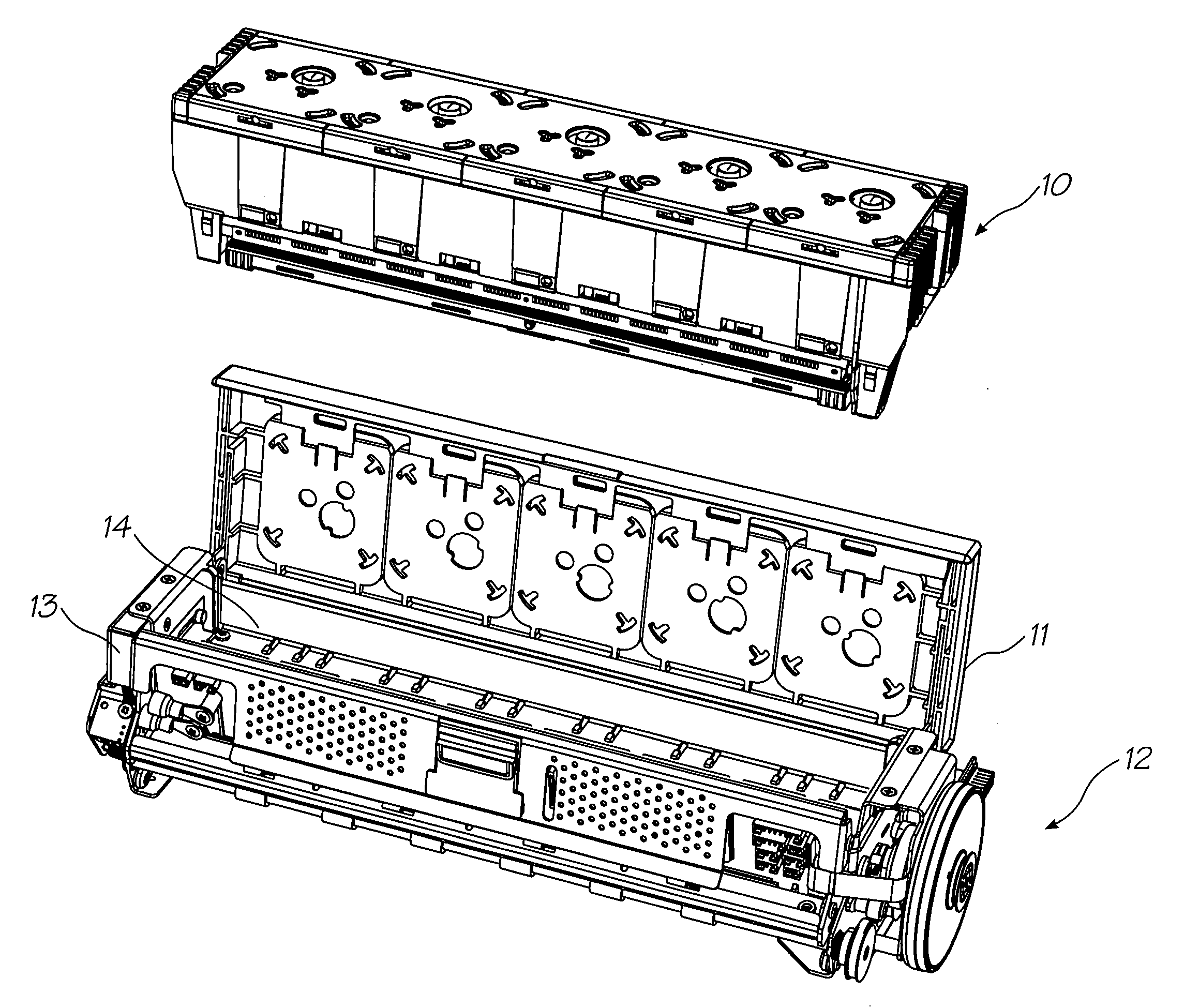

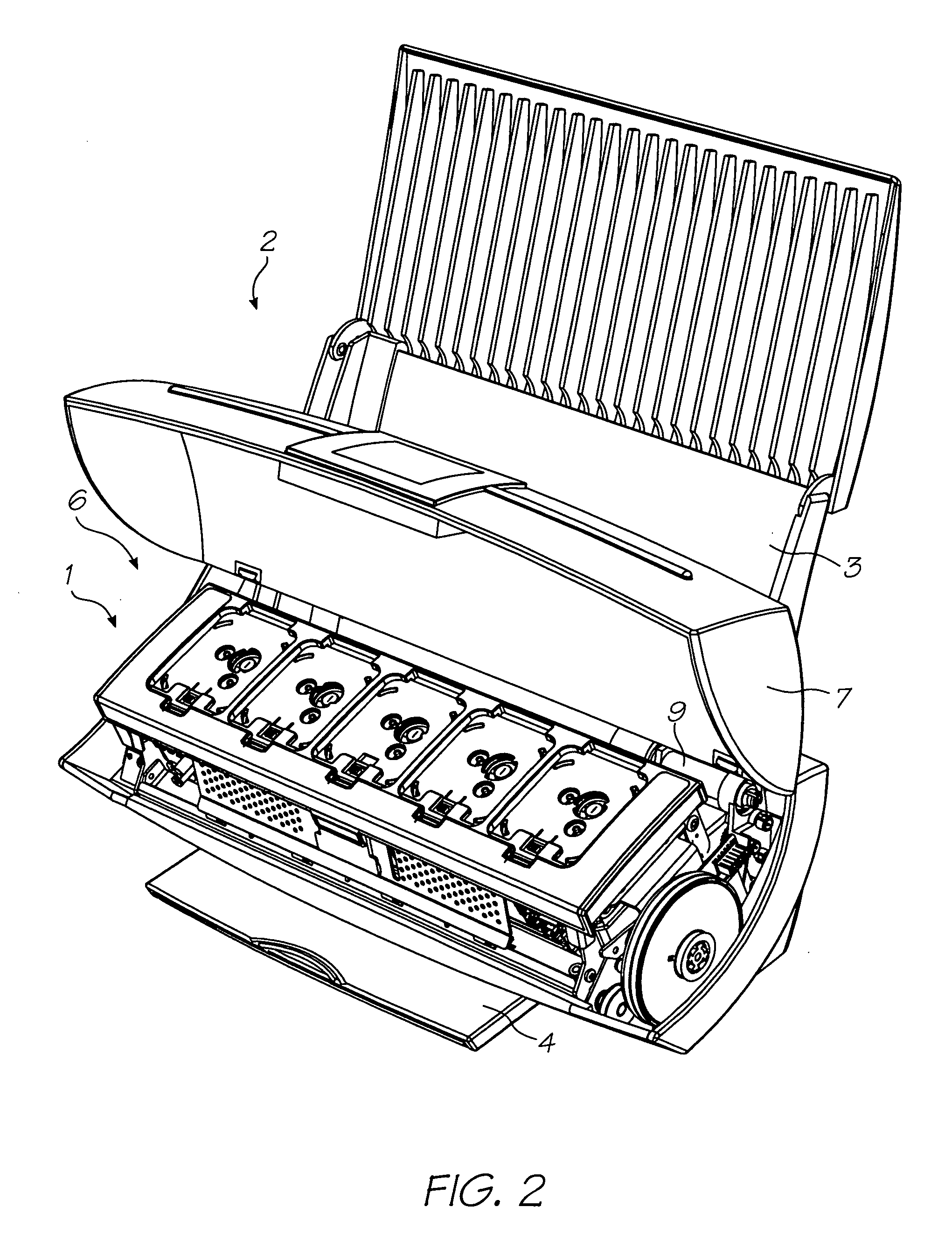

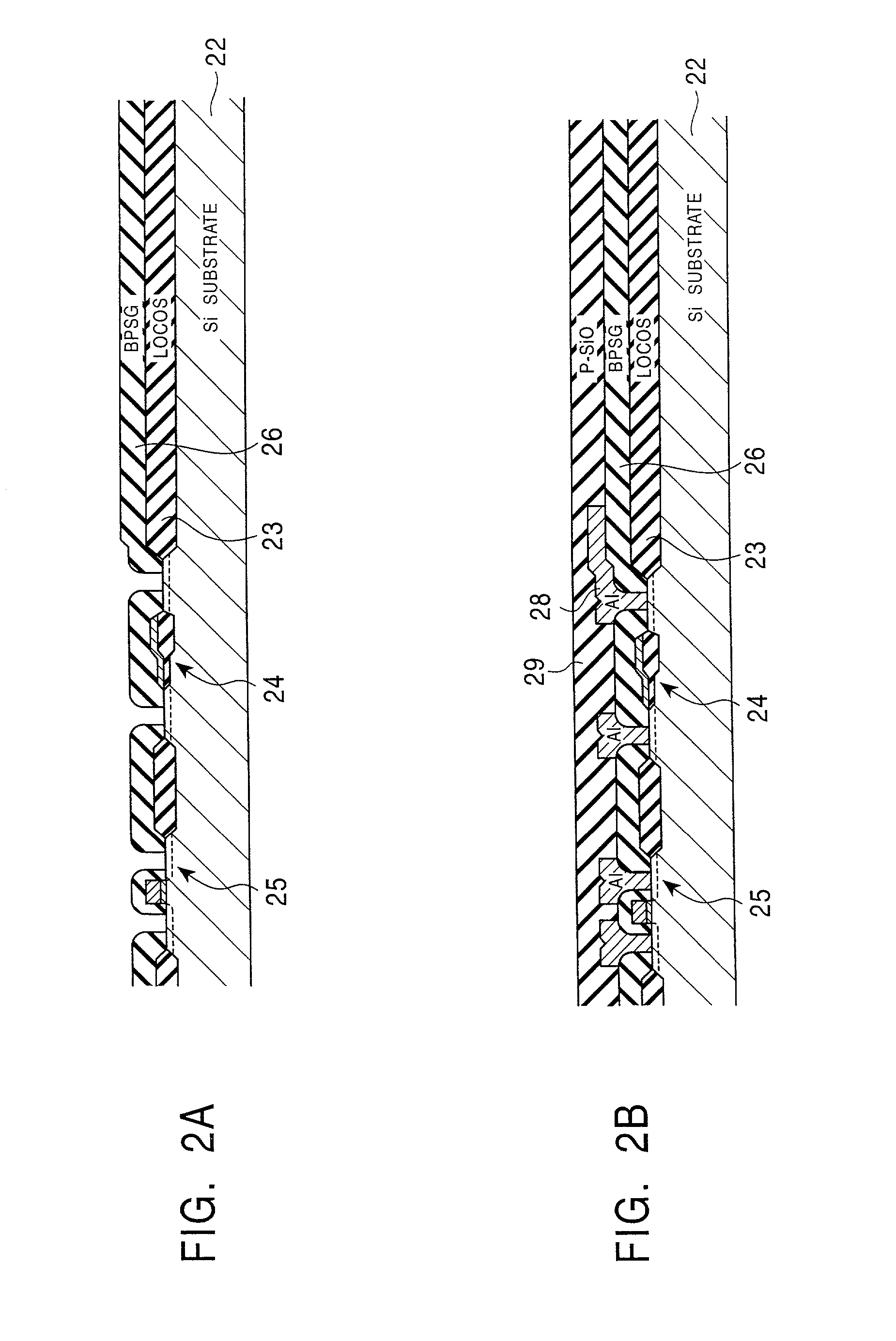

Inkjet printhead with integrated circuit mounted on polymer sealing film

InactiveUS20050156985A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusPower drive mechanismsEtchingInk printer

A printhead for an inkjet printer, the printhead comprising: a printhead integrated circuit formed on a wafer substrate using lithographically masked etching and deposition techniques; an integrated circuit support structure for mounting in the printer adjacent a media feed path; and, a polymer sealing film between the integrated circuit support structure and the printhead integrated circuit for fixing the printhead integrated circuit to the integrated circuit support structure.

Owner:SILVERBROOK RES PTY LTD +1

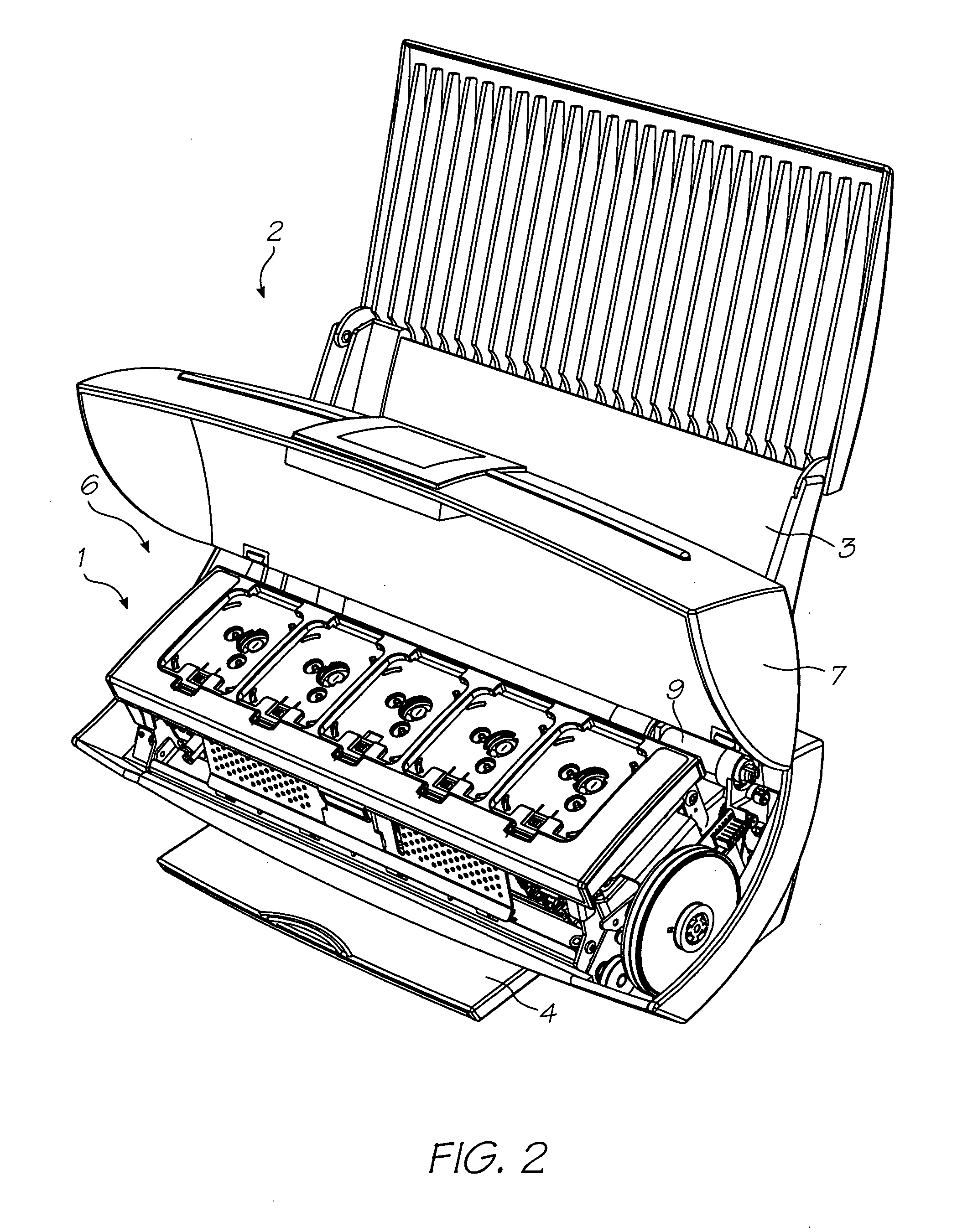

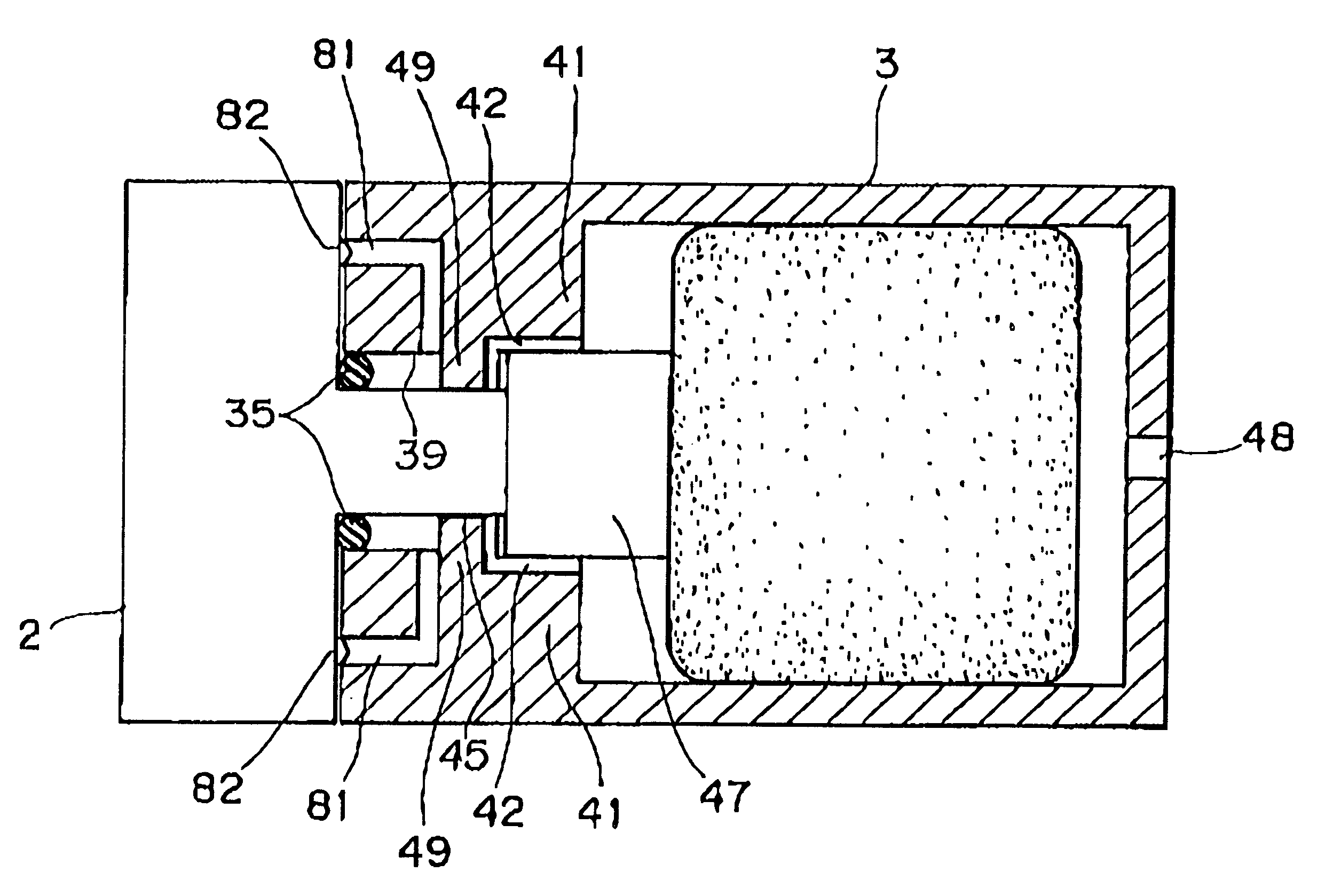

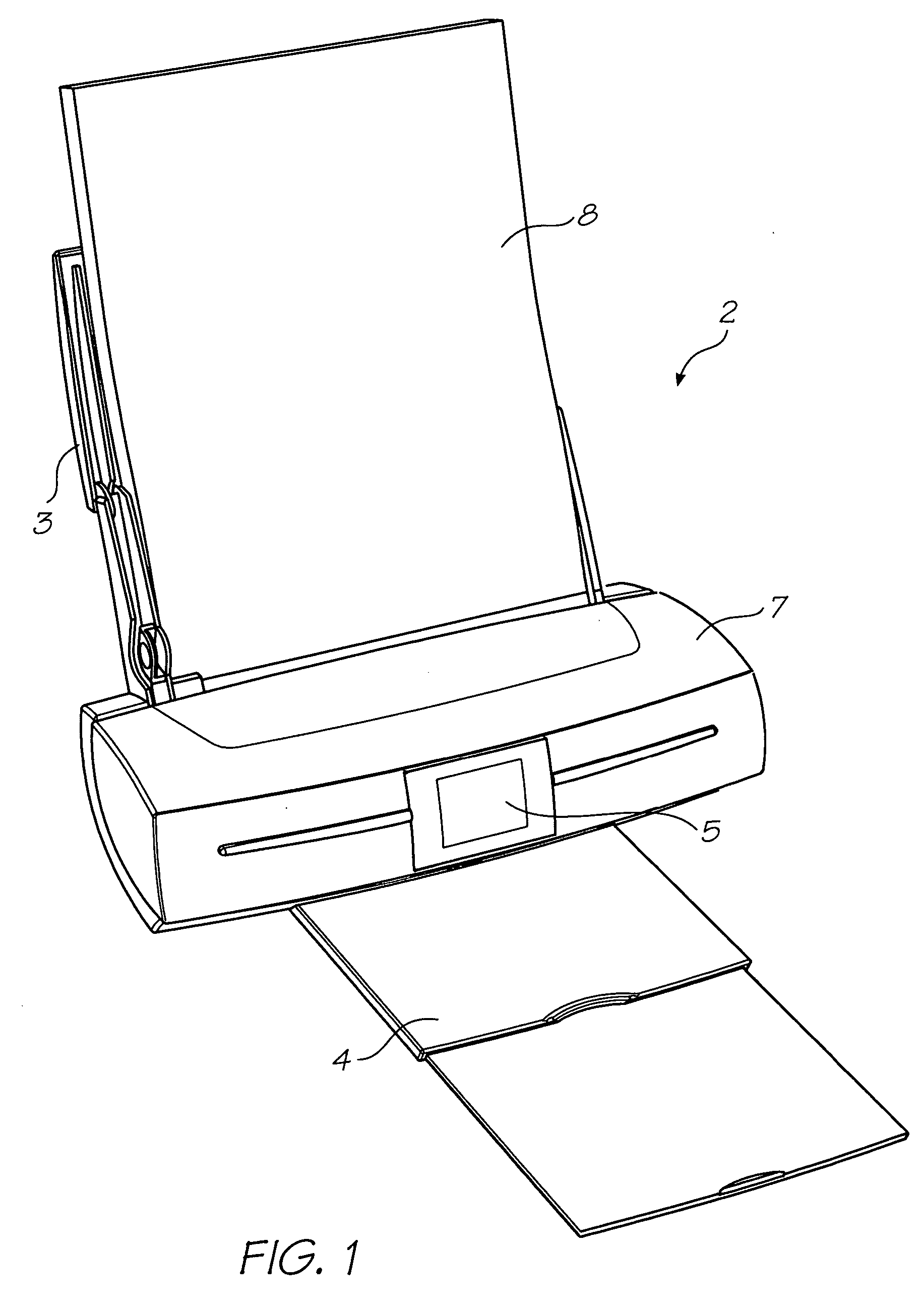

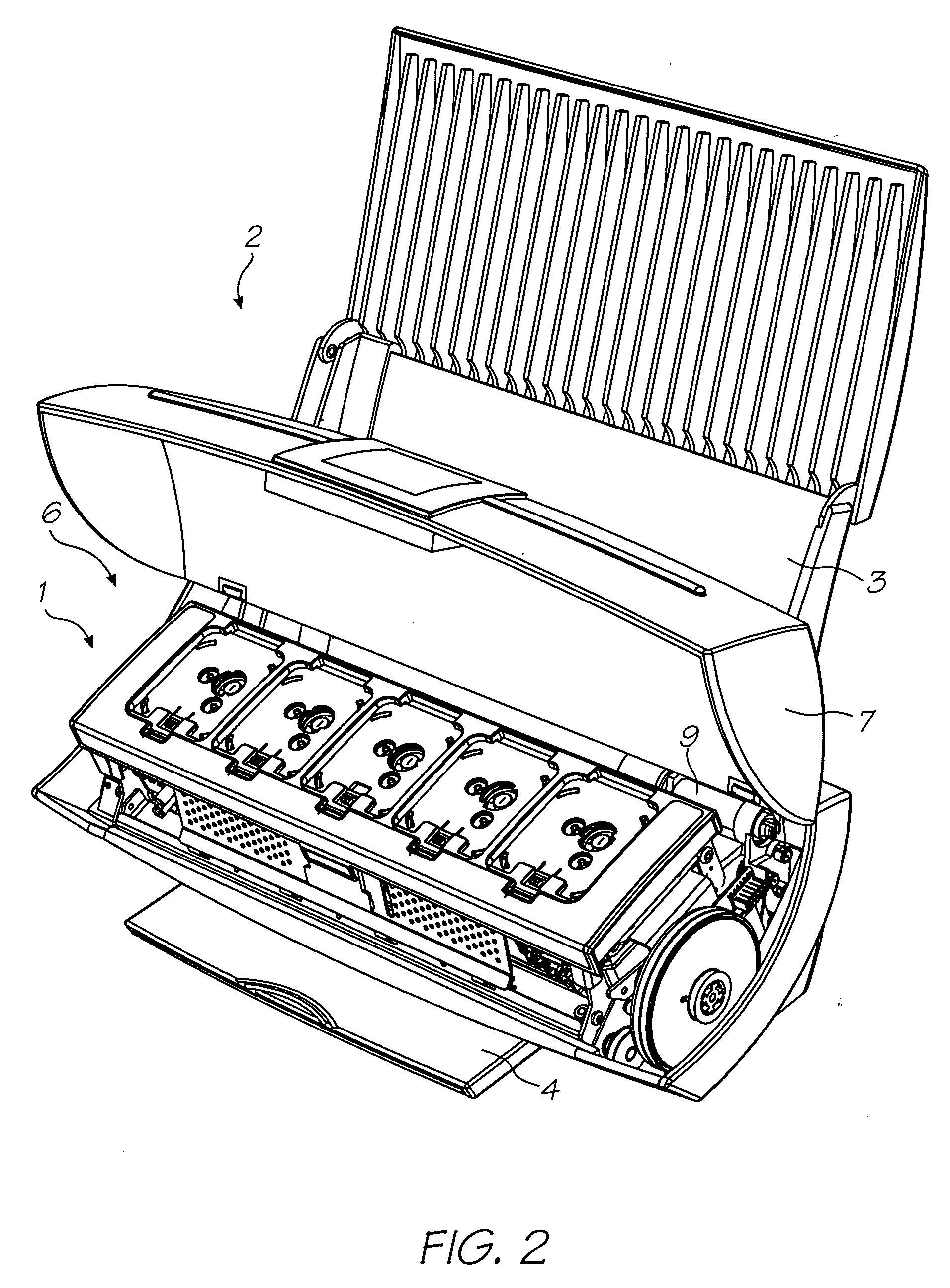

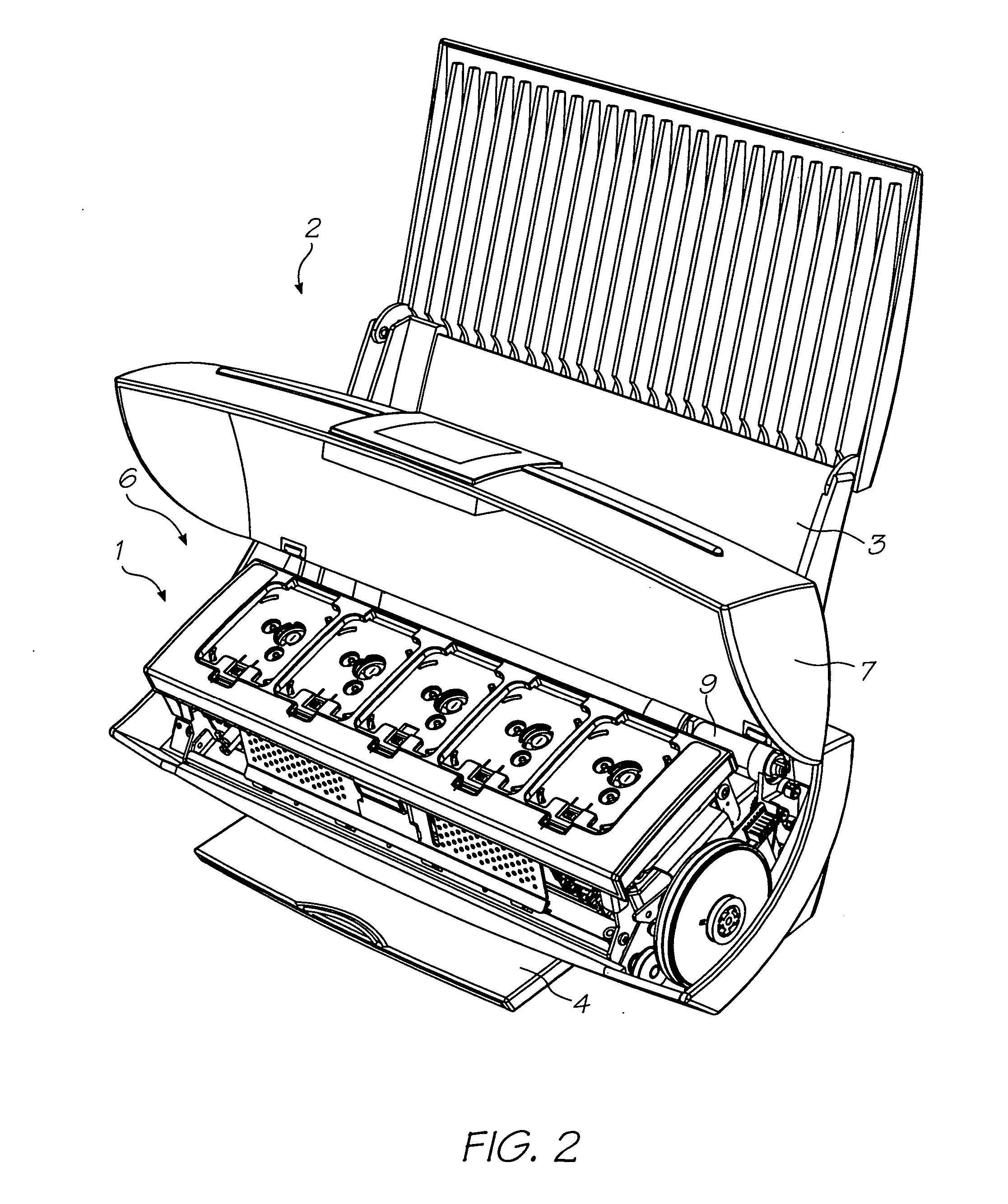

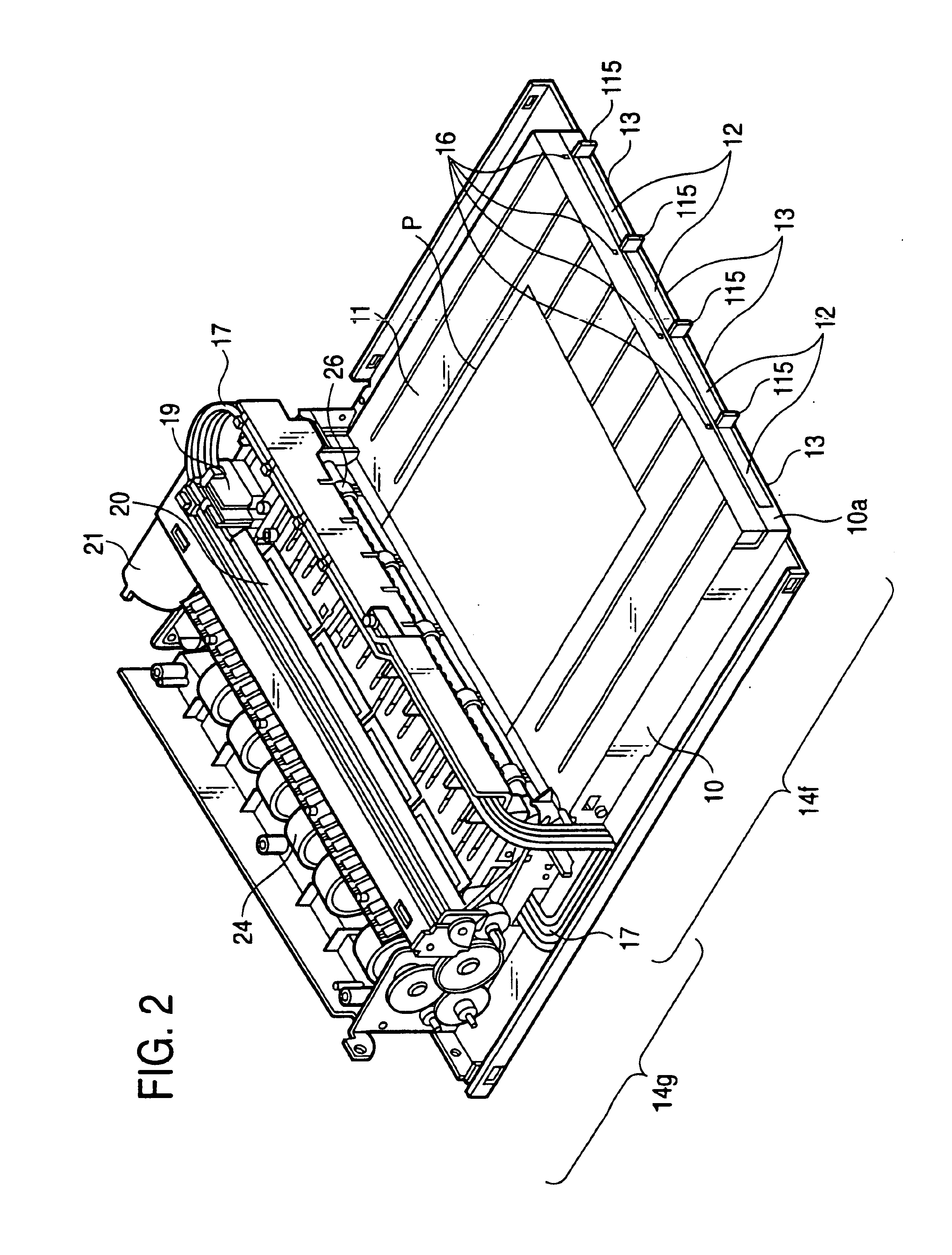

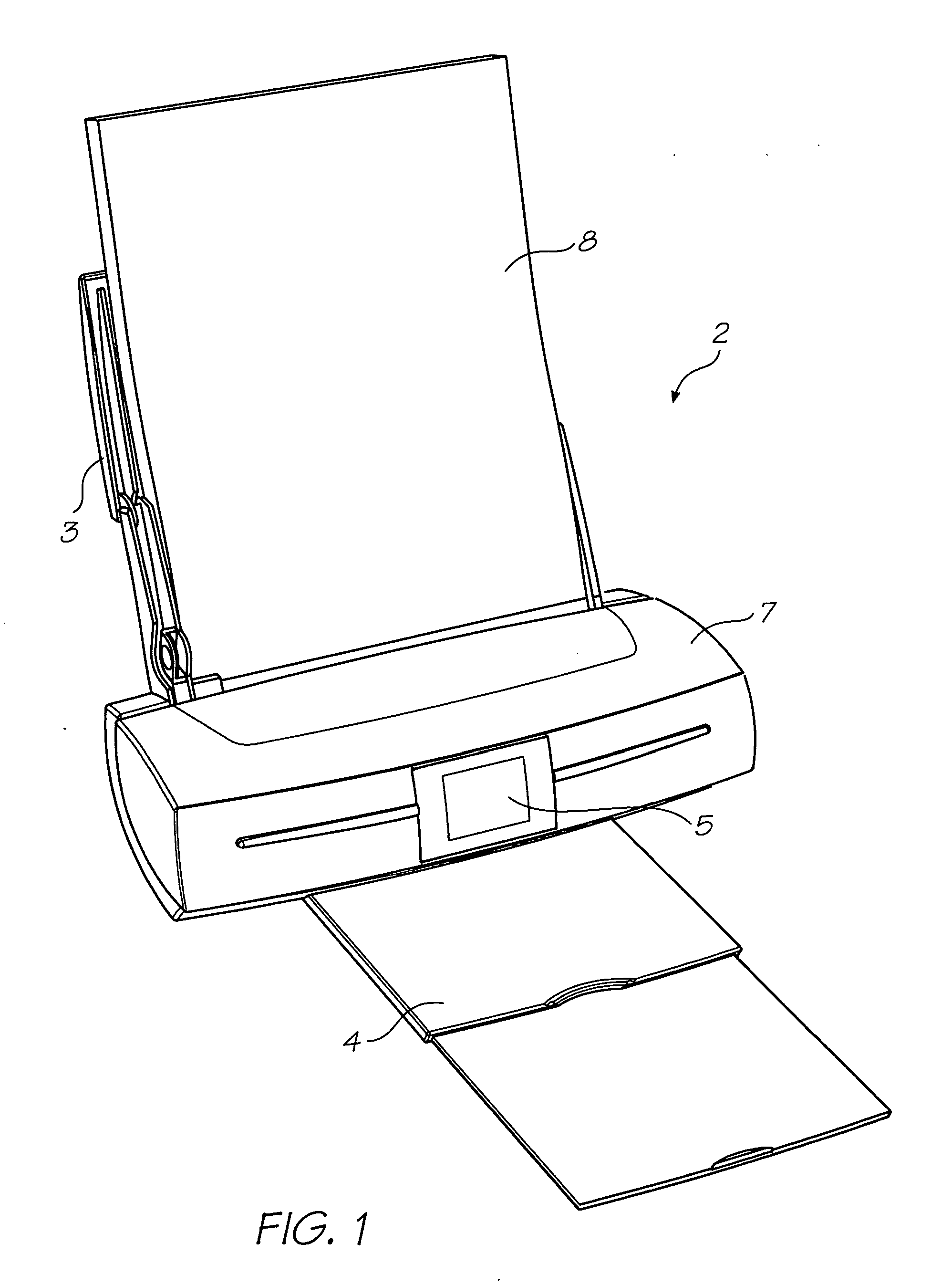

Ink jet recording apparatus using recording unit with ink cartridge having ink inducing element

An ink cartridge (3) including an ink reservoir portion having a porous member (37) for storing ink and an ink supply portion (39) has an ink inducing element (47) disposed between the ink reservoir portion and the ink supply portion (39). The ink inducing element (47) is made of bundle of fibers in which each fiber is disposed in parallel to the direction of ink supplying from the ink reservoir to the ink supply portion (39), and one end of the ink inducing element (47) is press-touched to the porous member (37).

Owner:CANON KK

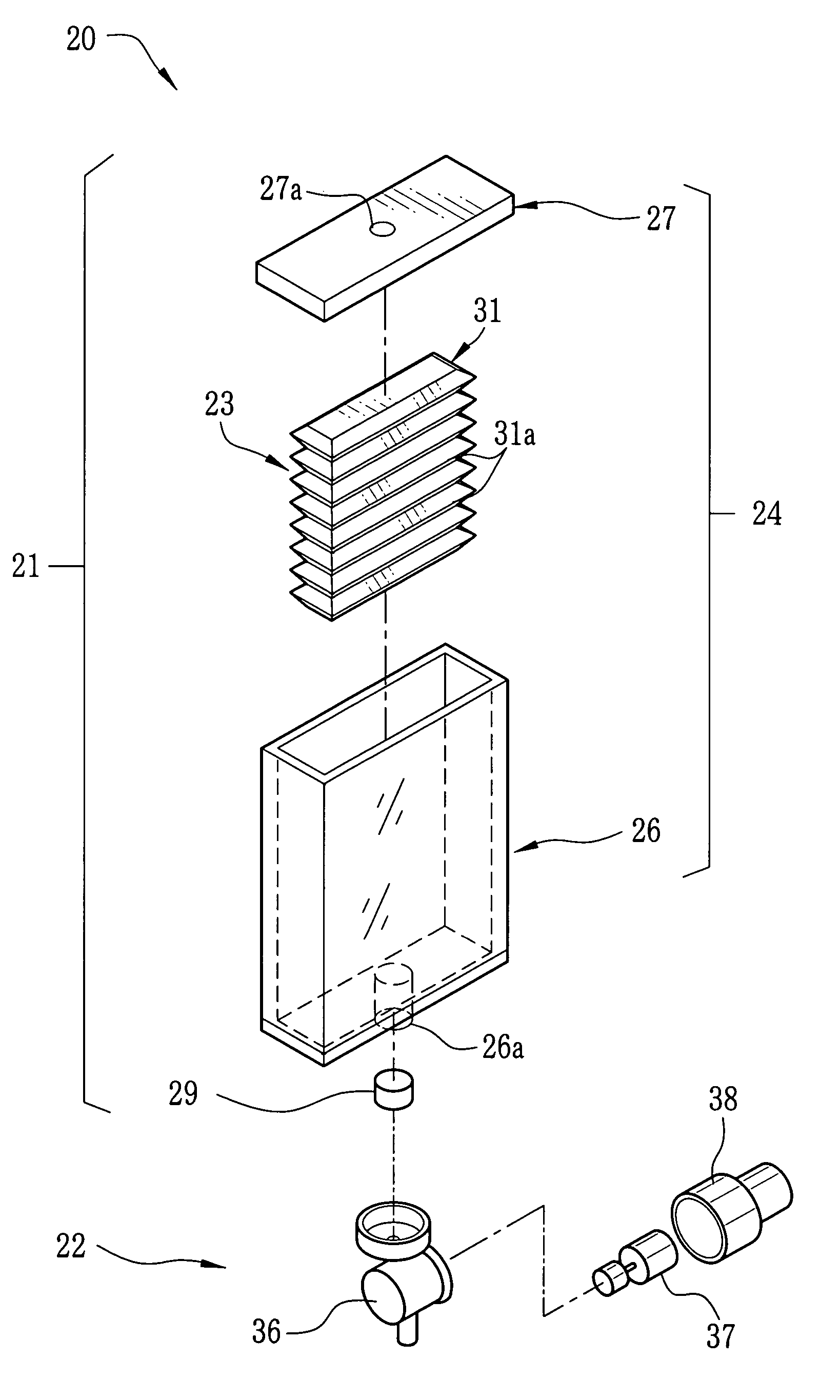

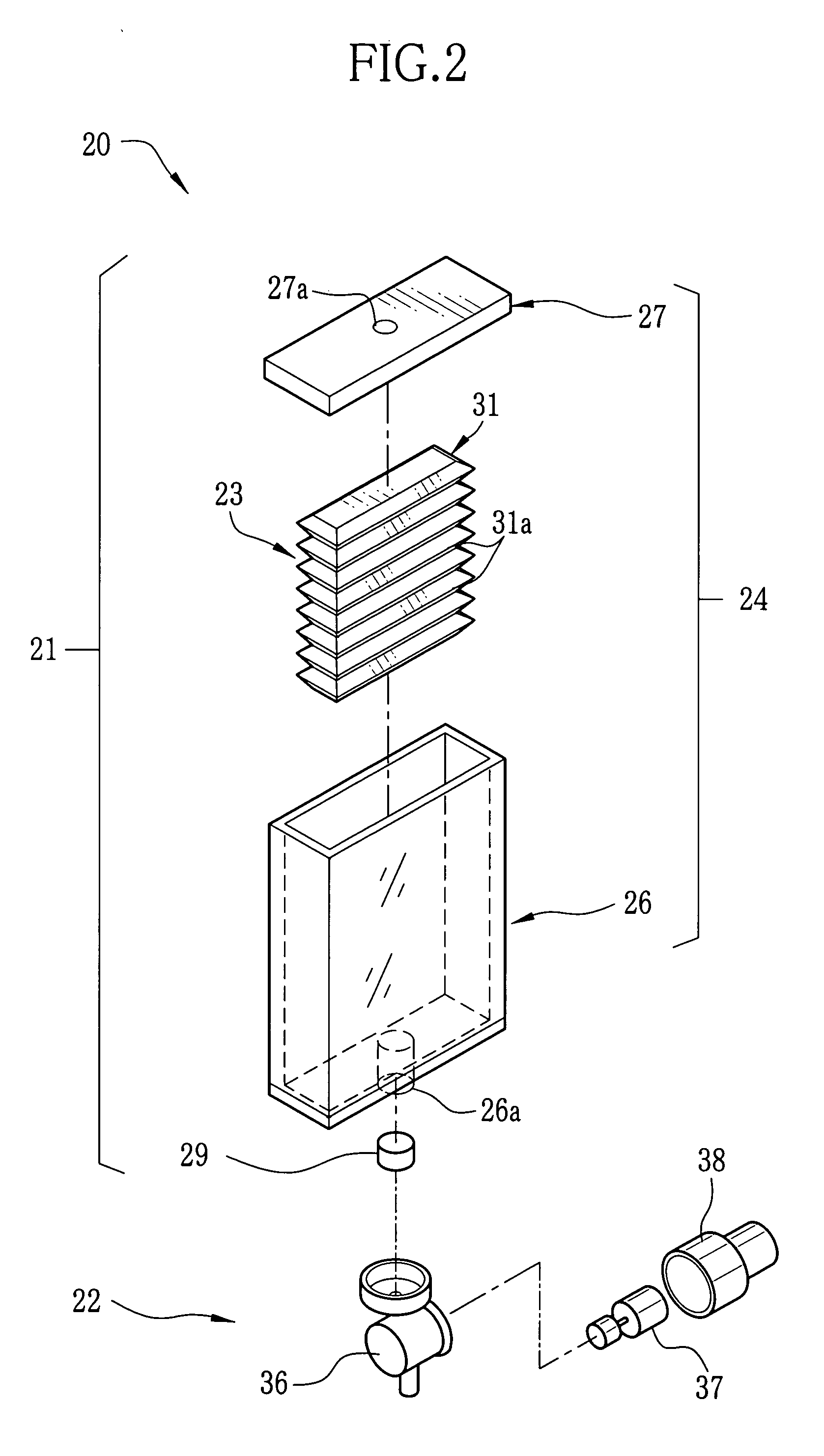

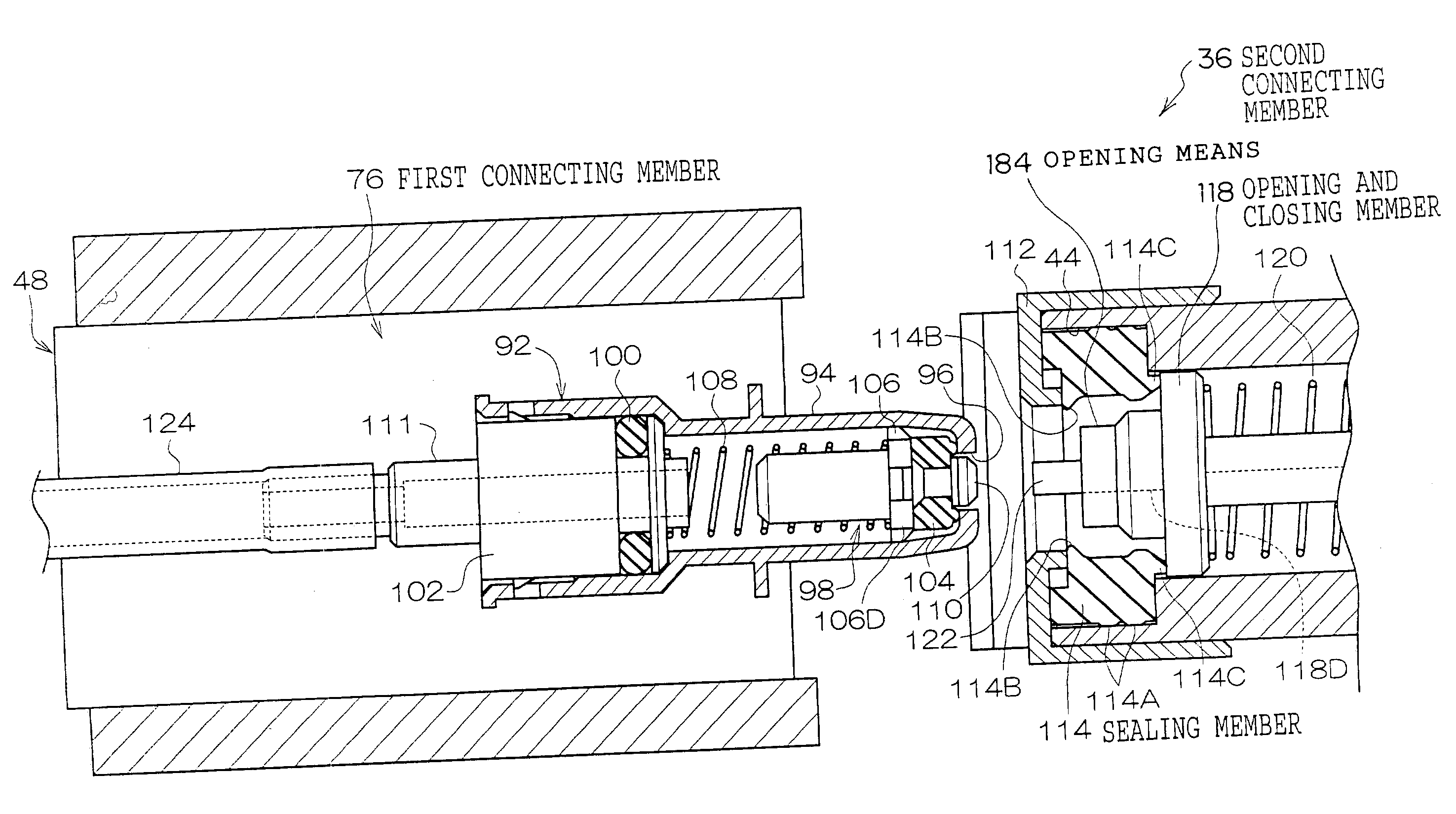

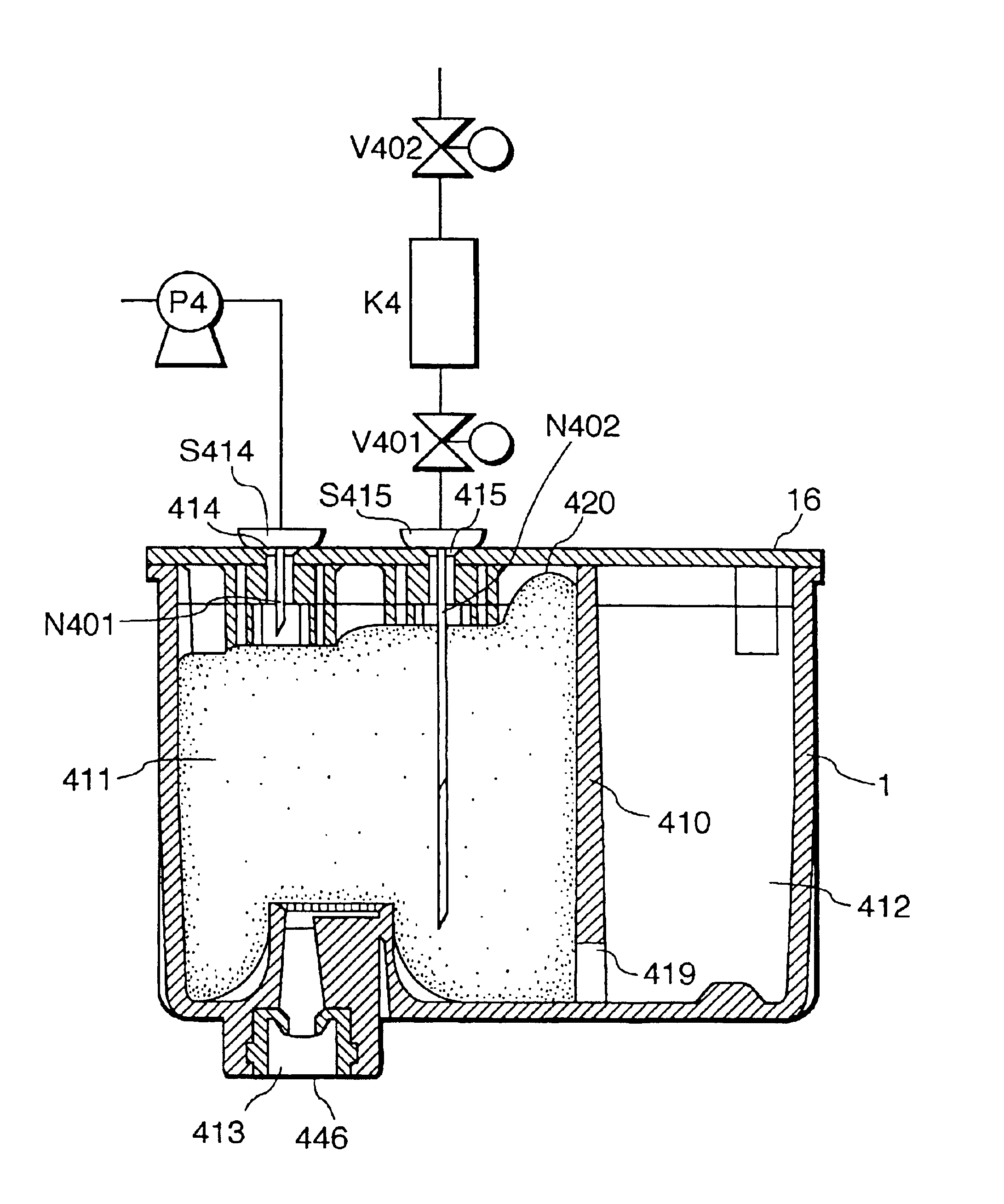

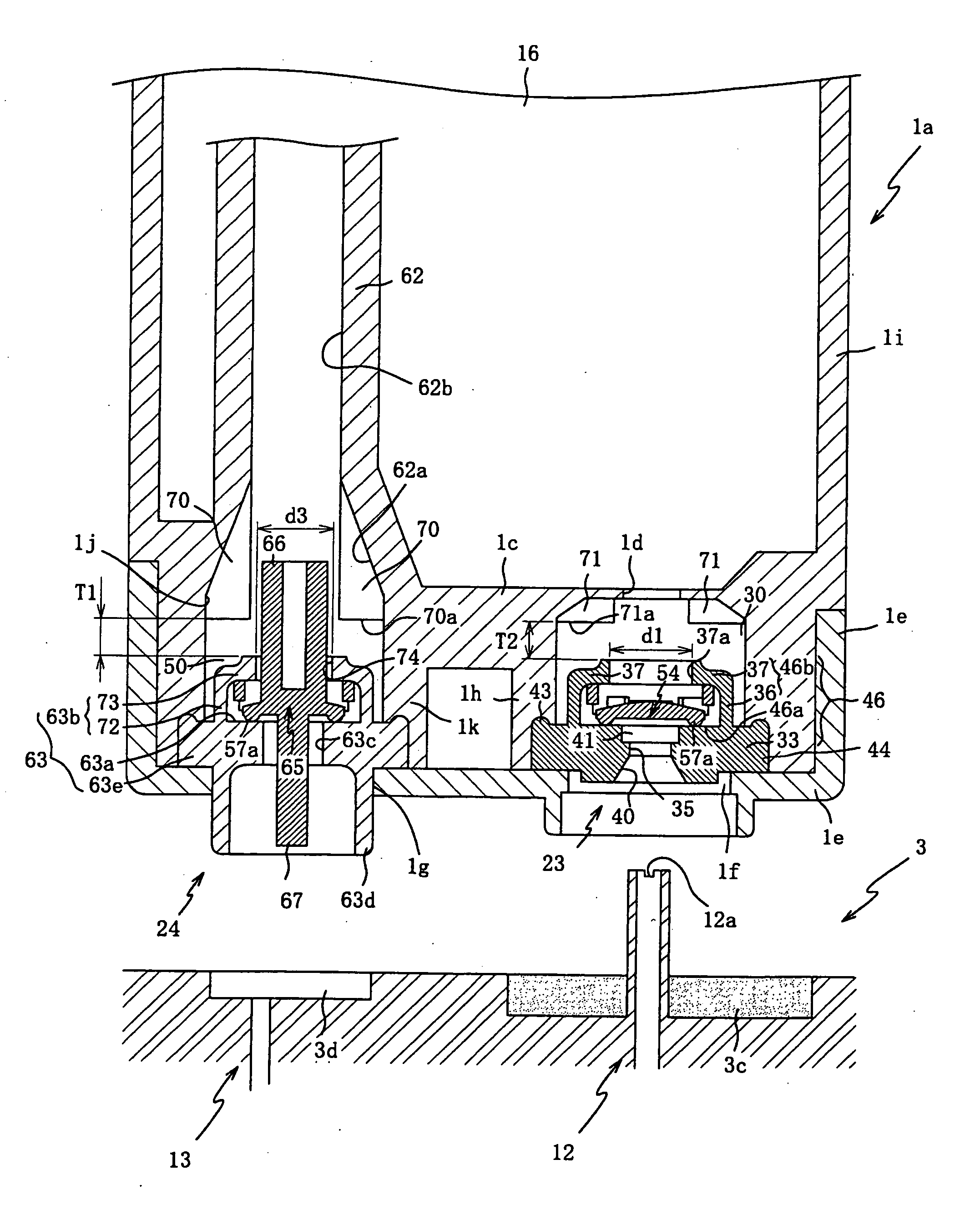

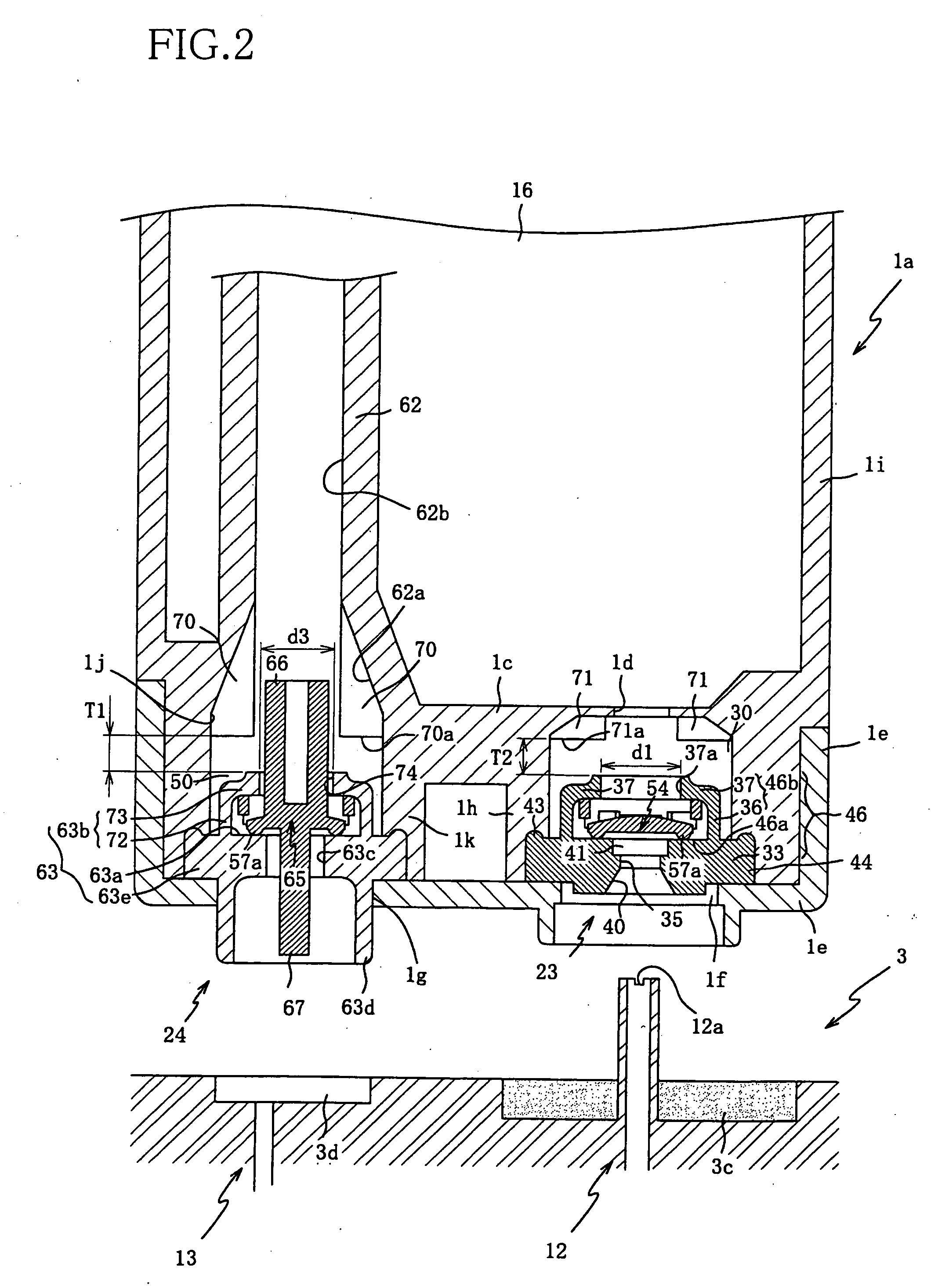

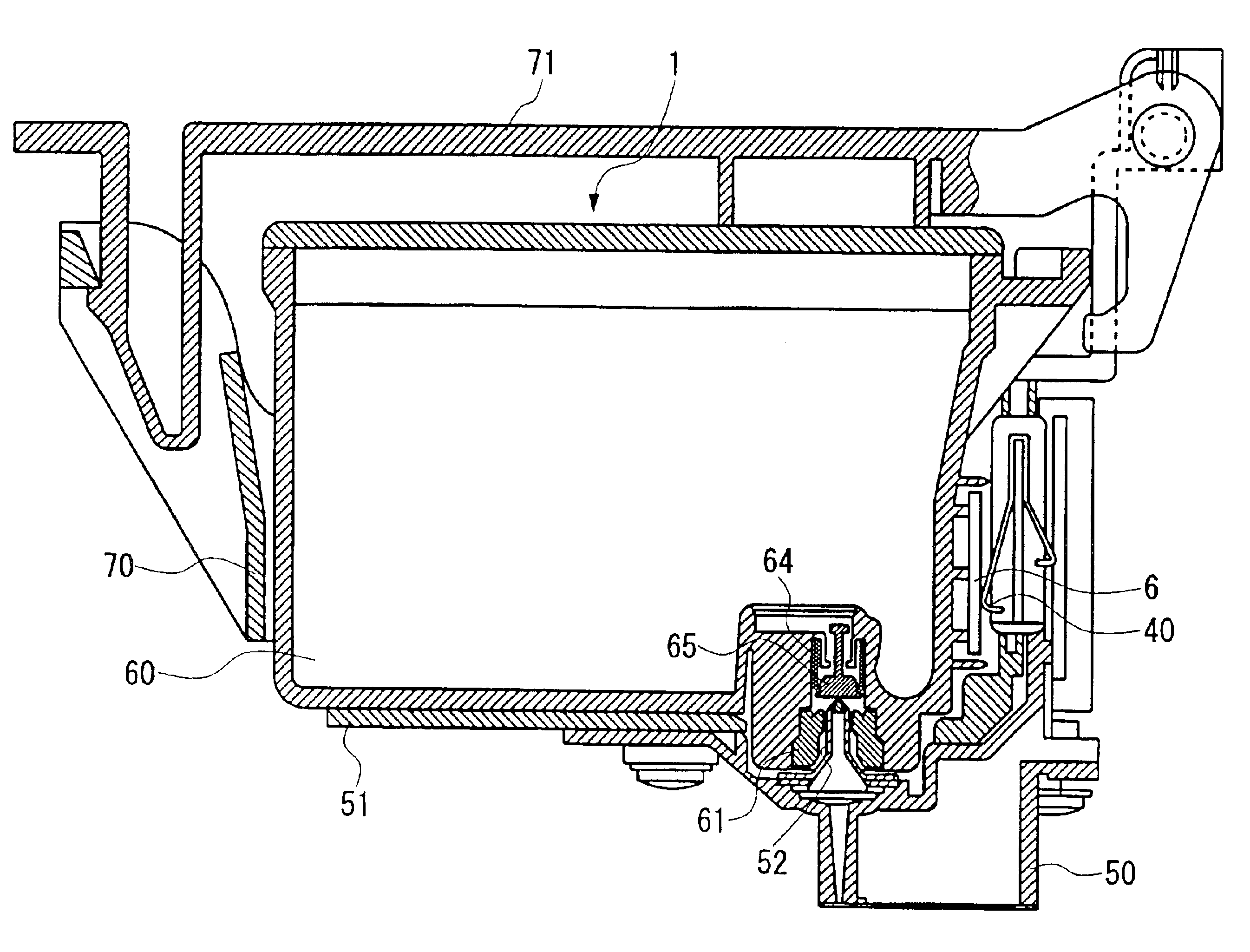

Ink replenishing device, sub ink tank, and ink jet recording apparatus

A port for replenishing ink on the side of a main ink tank advances and the nose or tip end of a main body of a pipe enters an ink replenishing opening on the side of a sub ink tank. When a valve body in the main body of the pipe and a valve on side of the sub ink tank are pressed with each other, a communicating port is opened by the valve body. When the main body of the pipe is further inserted into the ink replenishing opening, the valve is separated from a projection portion of a gasket, and a space therebetween starts to be widened. At this stage, as a lip portion of the gasket is not in contact with an outer peripheral portion of the main body of the pipe, an ink channel is opened to the atmosphere, the ink which is remained in or adhered to the outer peripheral portion of the main body of the pipe or an inside of the ink replenishing opening is absorbed into the sub ink tank dye ti a negative pressure in the sub ink tank. Namely, the present invention provides an ink replenishing device which can reliably prevent ink dirt from being caused by ink replenishing and an ink jet recording apparatus which is provided with the ink replenishing device.

Owner:FUJIFILM BUSINESS INNOVATION CORP

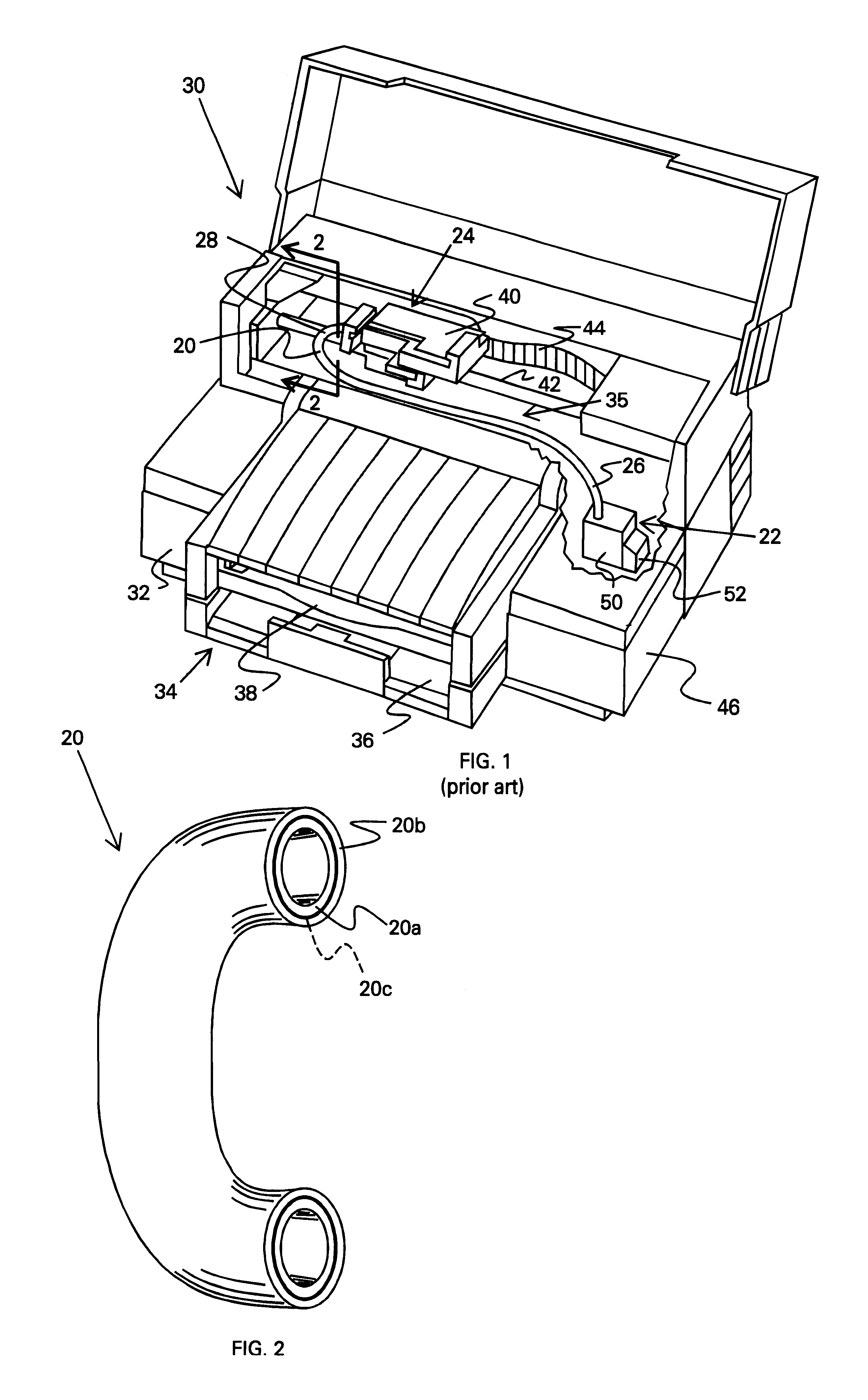

Printhead maintenance station

ActiveUS20050156987A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusPower drive mechanismsSpray nozzleEngineering

A printhead maintenance assembly for an inkjet printhead, the printhead having a nozzle plate with an array of nozzles formed therein, the printhead maintenance assembly comprising: a capper to cover the array of nozzles when the printhead is not in use; and, a cleaner for engaging the nozzle plate and wiping across the nozzles; wherein, the cleaner is positioned between opposing sides of the capper.

Owner:SILVERBROOK RES PTY LTD +1

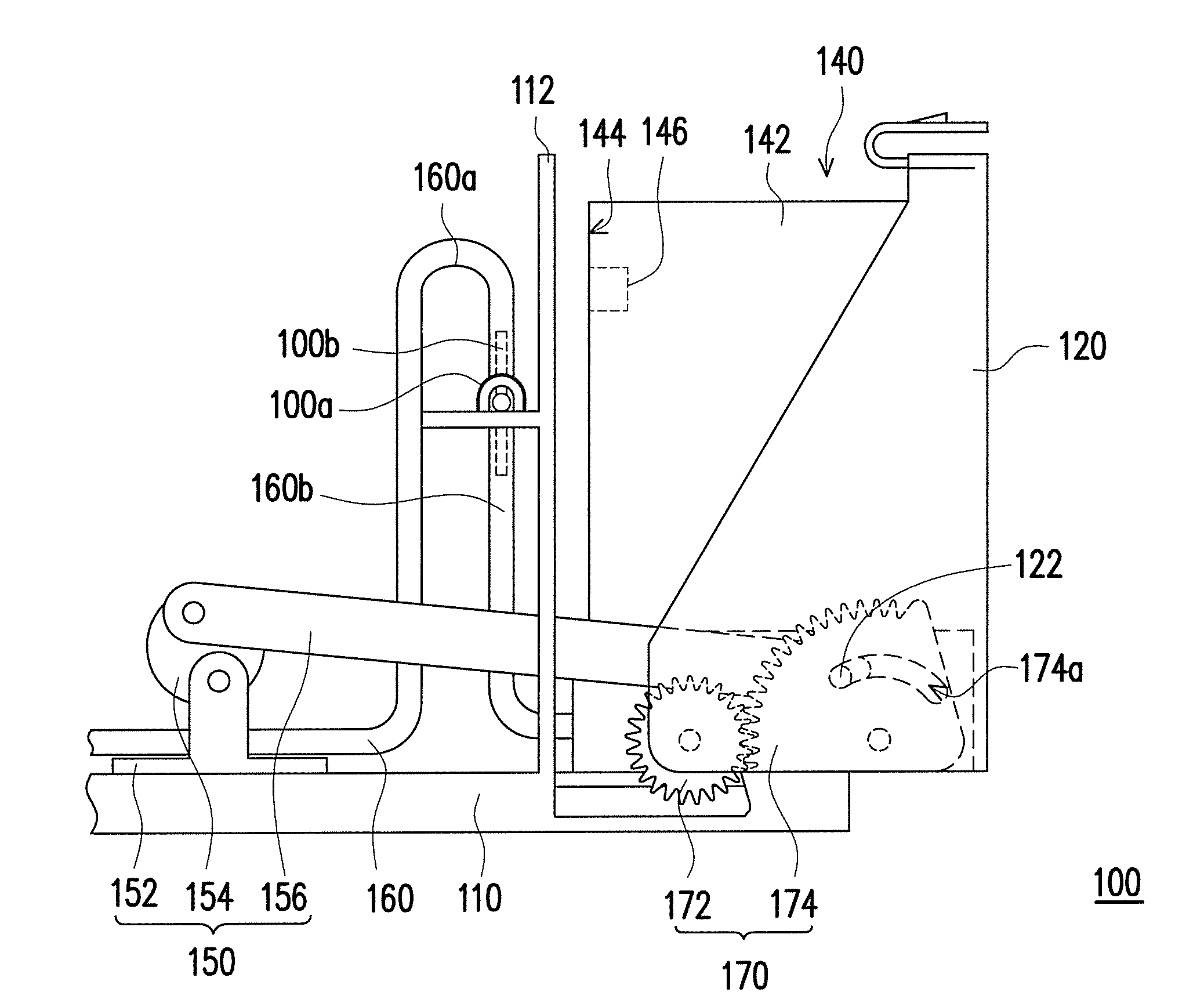

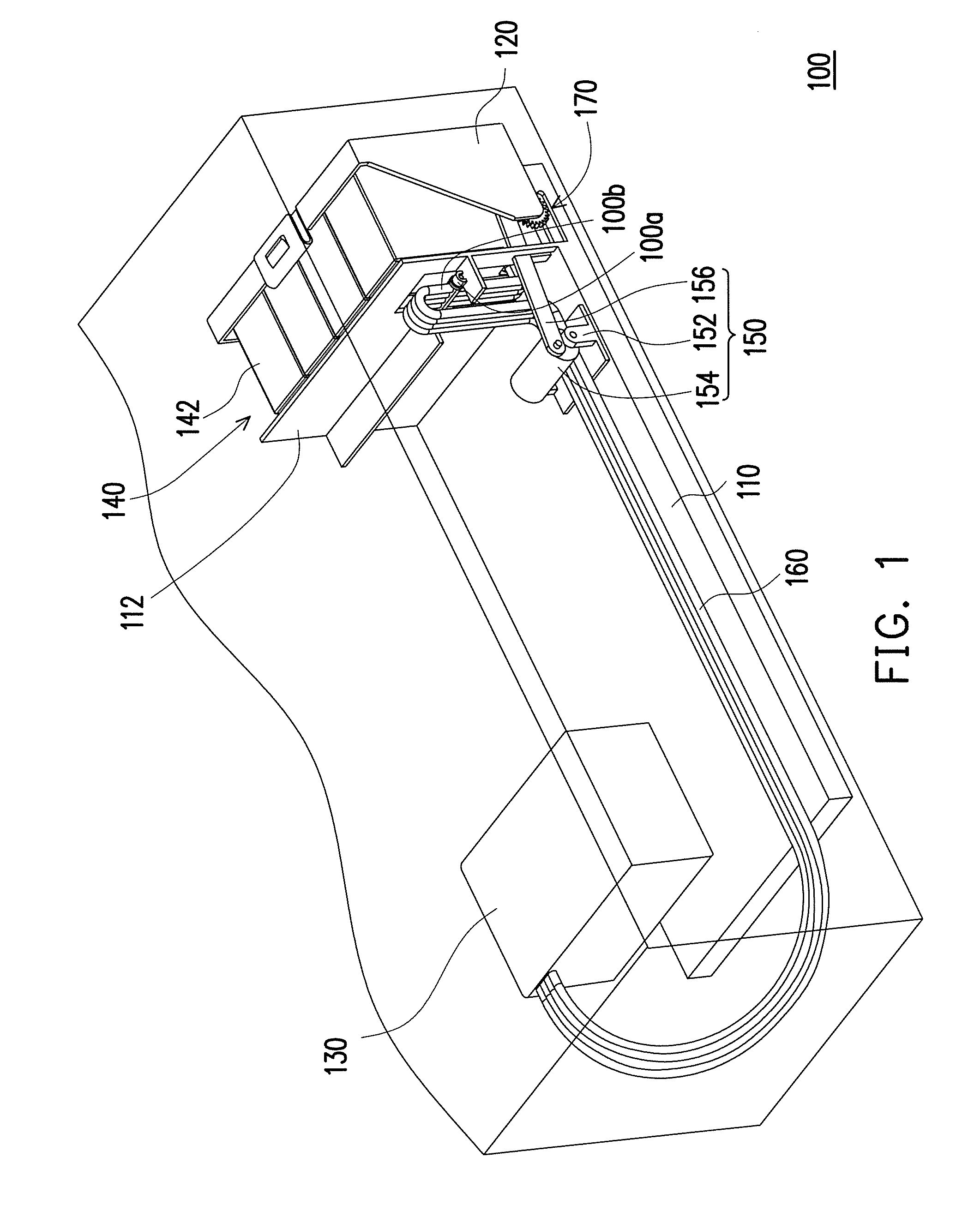

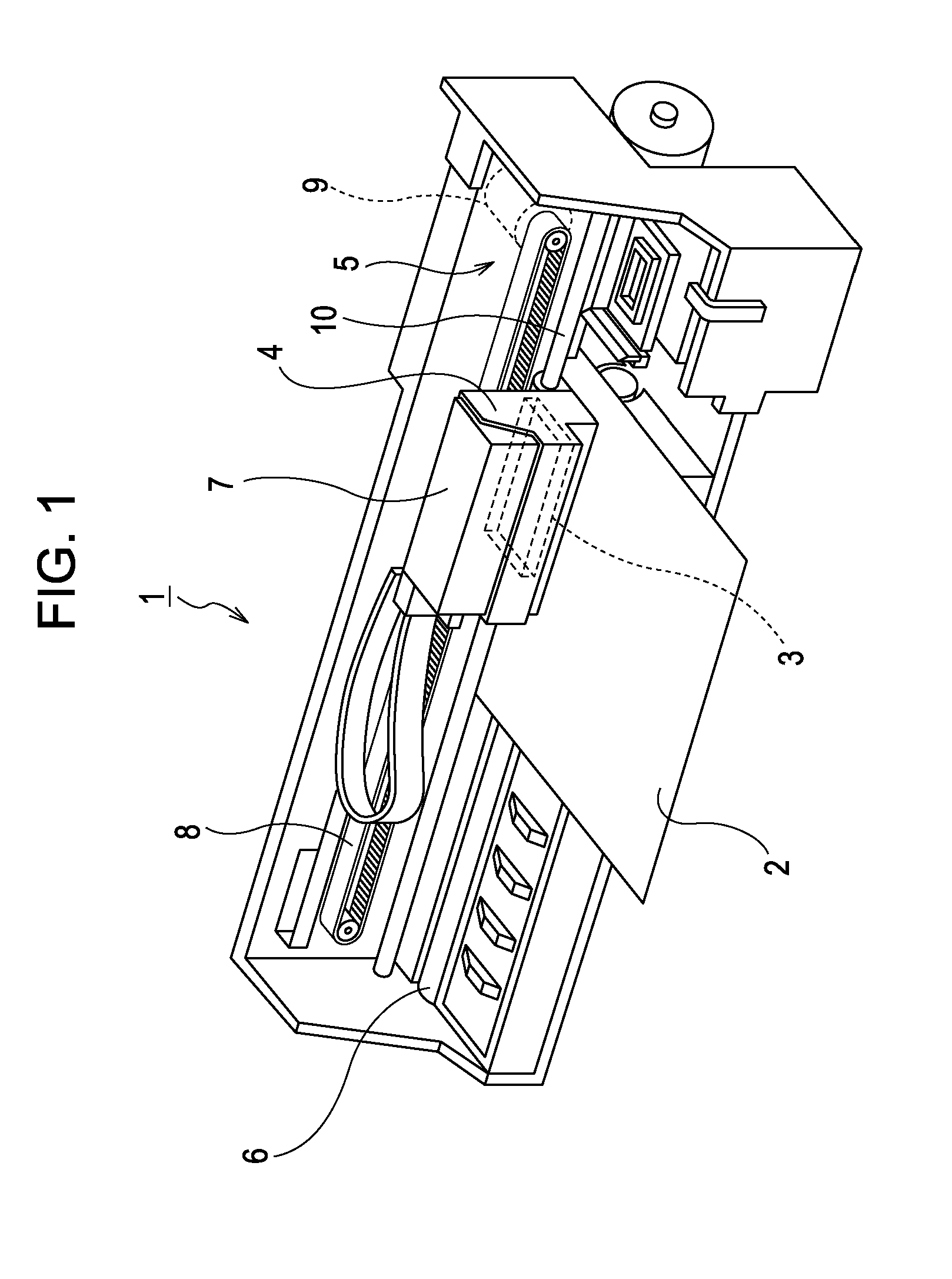

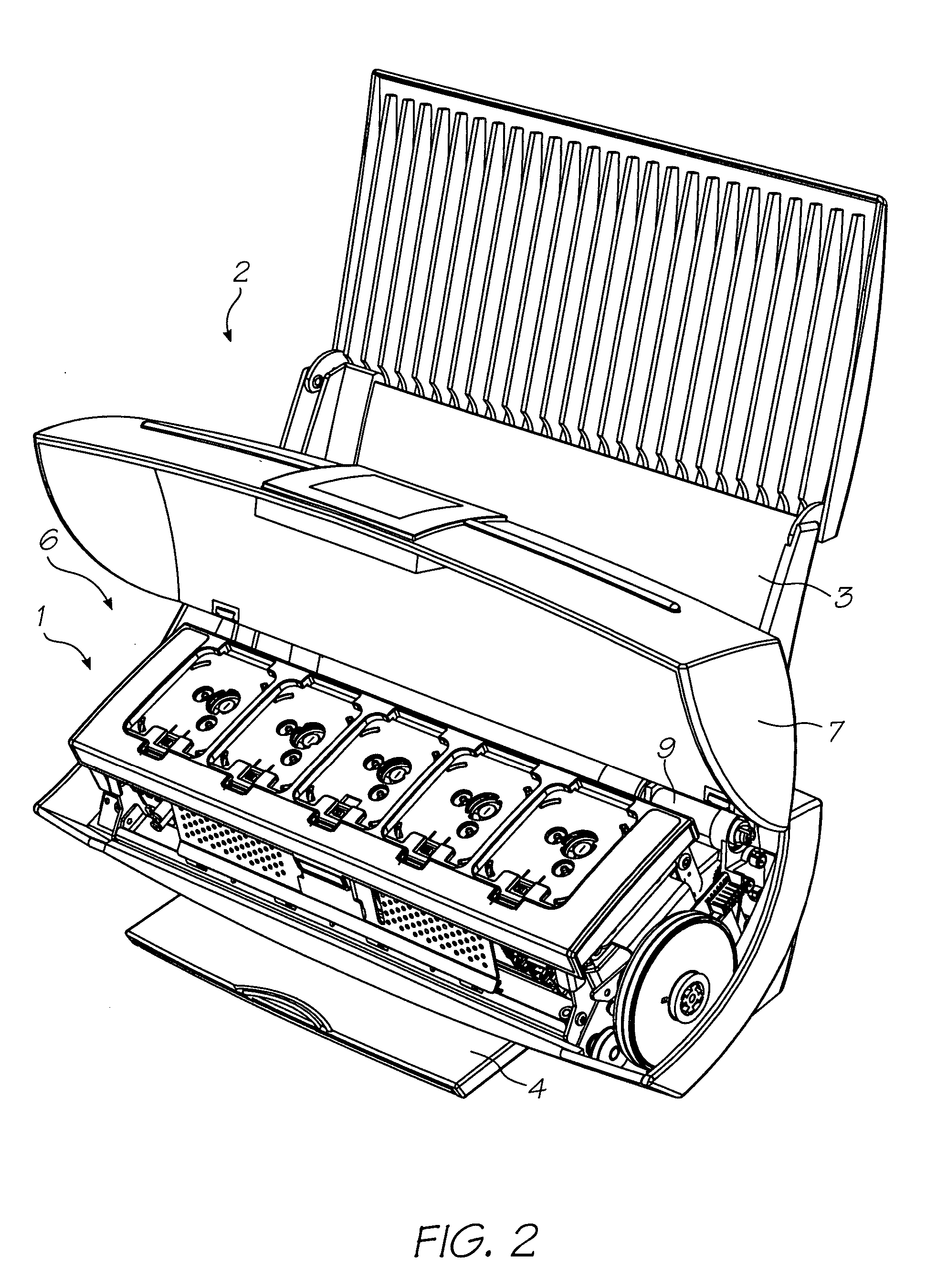

Ink supply system and media recording device

InactiveUS20140085386A1Prevent ink leakageAvoid flowOther printing apparatusEngineeringClosest relatives

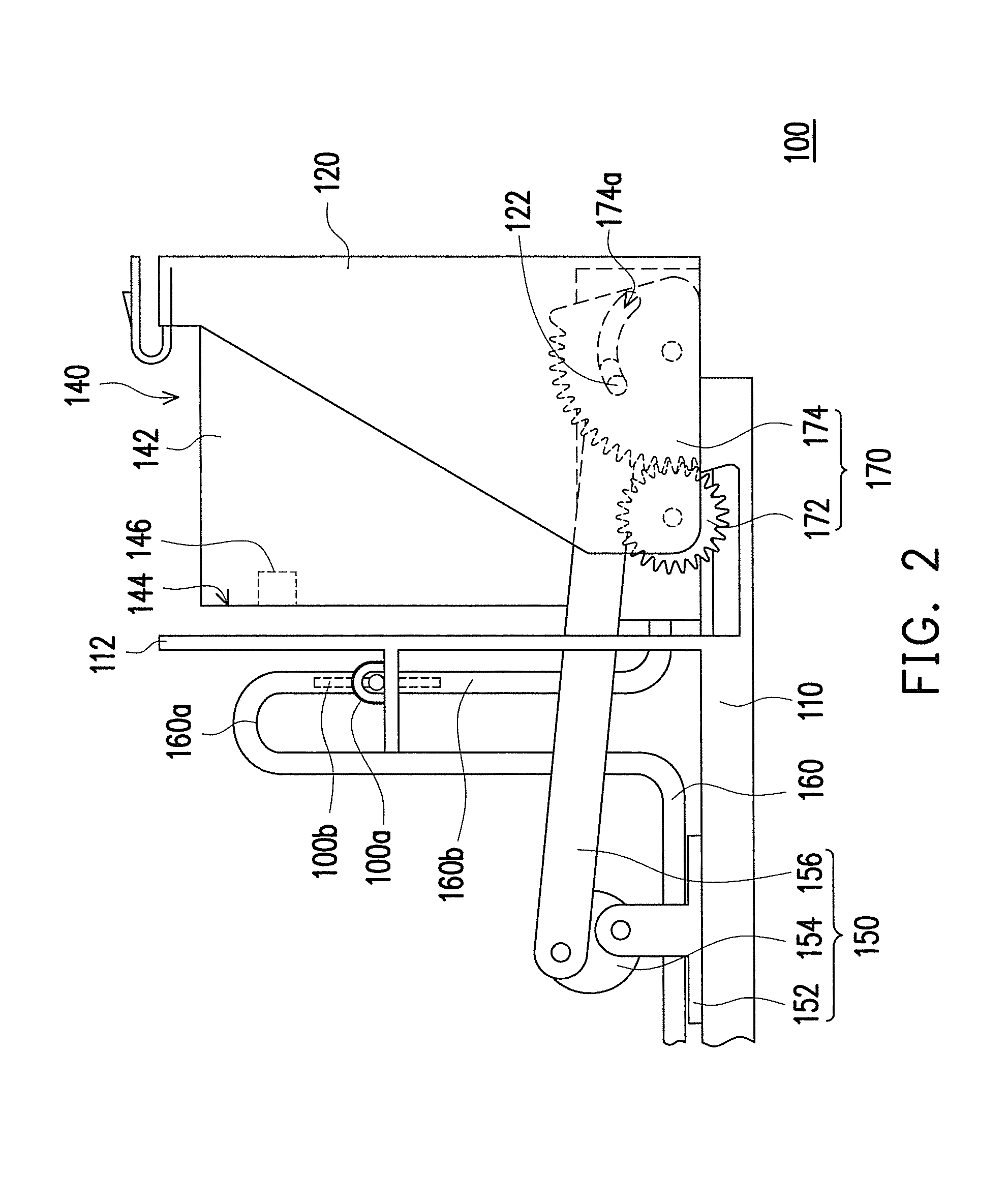

An ink supply system including a cover, an ink delivery module, delivery pipes and a shut-off valve module, and a media recording device including a body and a print head disposed therein are provided. The cover is pivoted to the body, and the ink delivery module is disposed therein and next to the cover. The shut-off valve module includes a base disposed in the body, an eccentric wheel pivoted to the base, and a linkage connected between the eccentric wheel and the cover. The delivery pipes are connected between the print head and the ink delivery module and they pass between the base and the eccentric wheel. The cover is opened or closed relative to the body and it drives the linkage to drive the eccentric wheel to rotate relative to the base so as to press against or release the delivery pipes.

Owner:CAL COMP ELECTRONICS +1

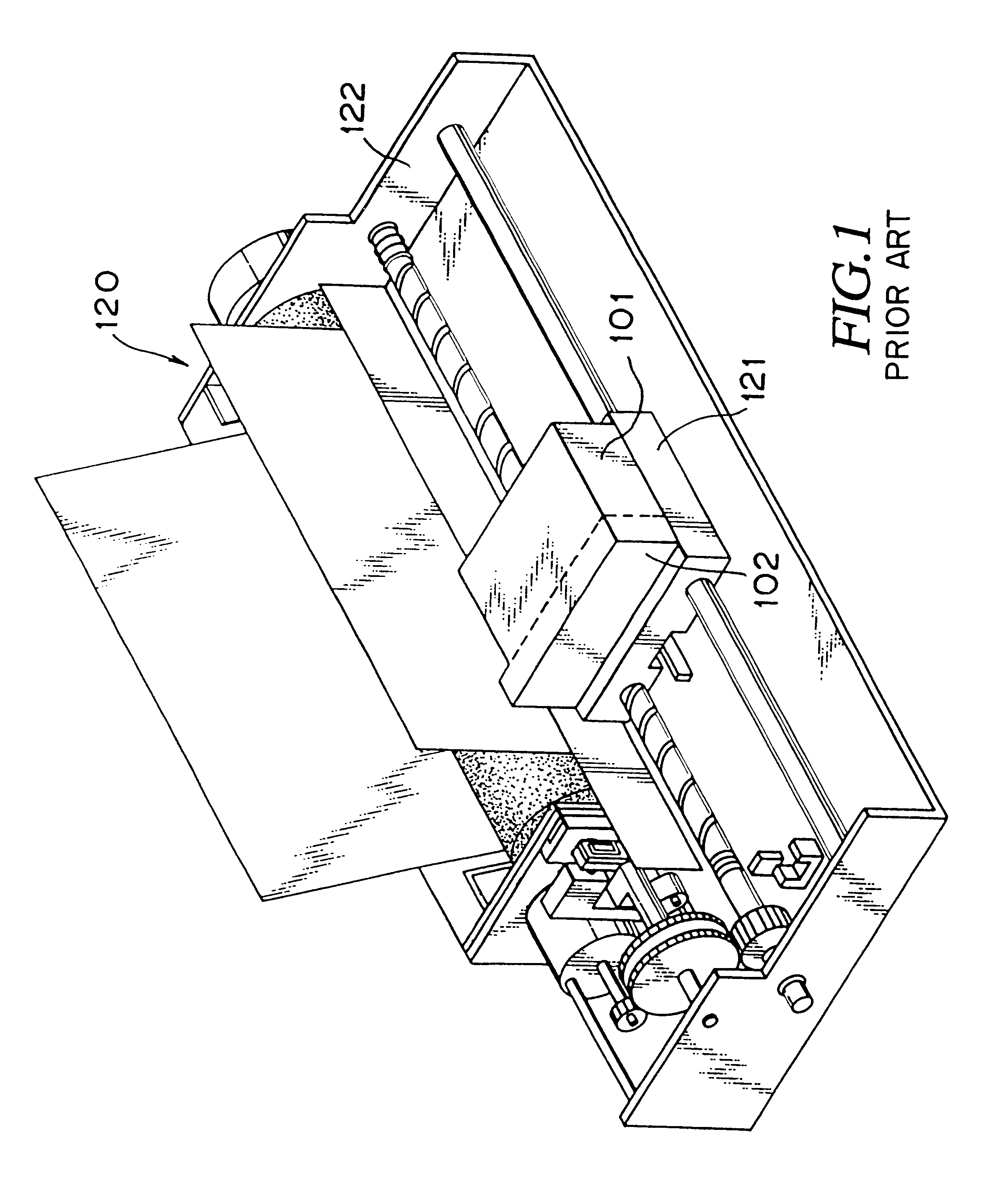

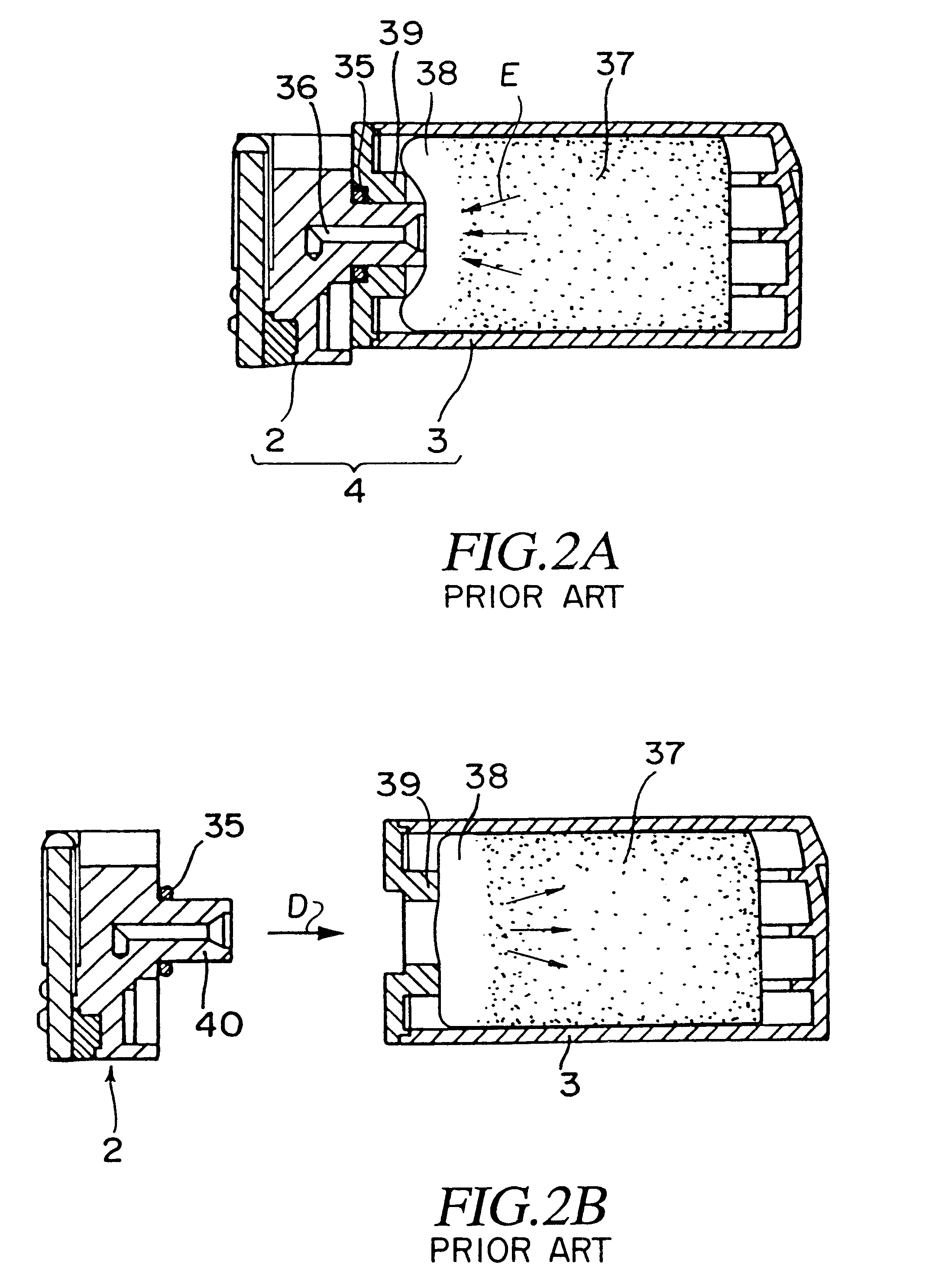

Ink cartridge for ink jet printer and method of charging ink into said cartridge

An ink cartridge including: an ink chamber for retaining liquid ink; a foam chamber maintained in fluid communication with the ink chamber through a communication hole. An ink supply port for supplying ink from a porous body accommodated in the foam chamber to a recording head is provided. The portion of the foam body confronting the ink supply port is compressed by the ink supply port. The ratio between the amount of ink initially charged in the ink chamber and that of ink absorbed in the porous body is in the range from 1:1 to 1:3. When a cartridge uses more than one color of ink for printing in color, a plurality of foam and ink cartridges are used. The cartridge is filled under reduced pressure while the interior of the cartridge is further evacuated before filling with ink.

Owner:SEIKO EPSON CORP

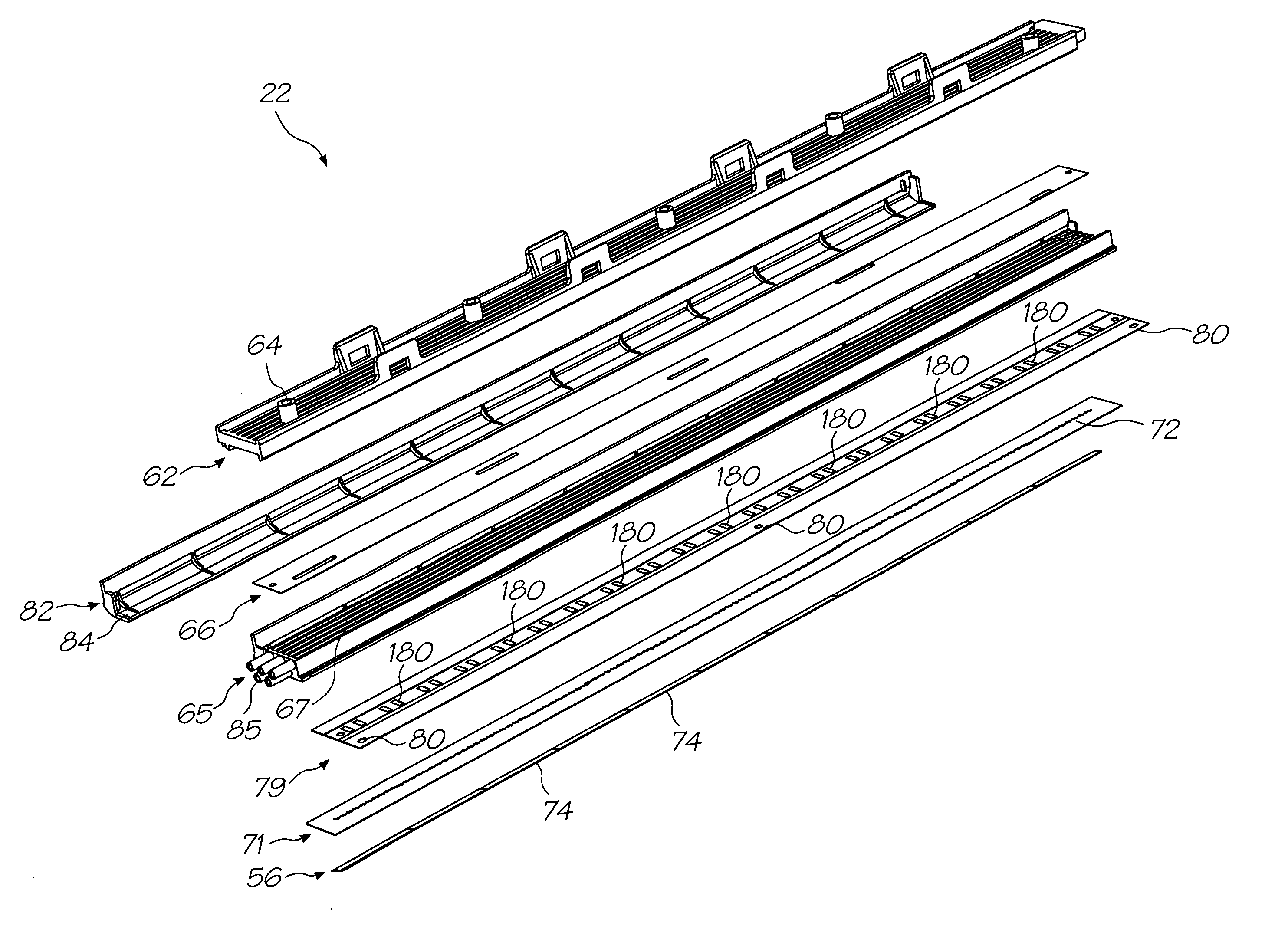

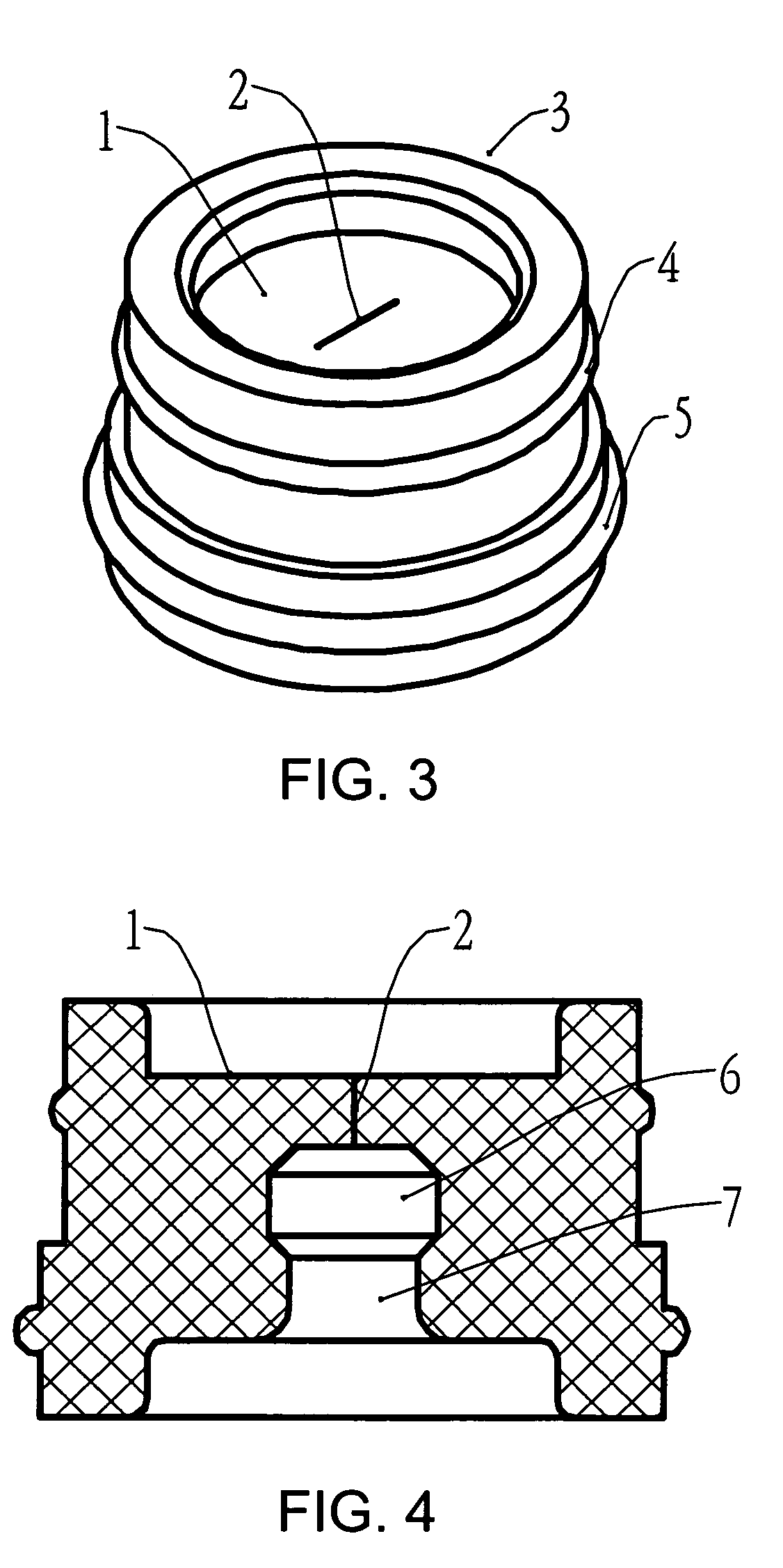

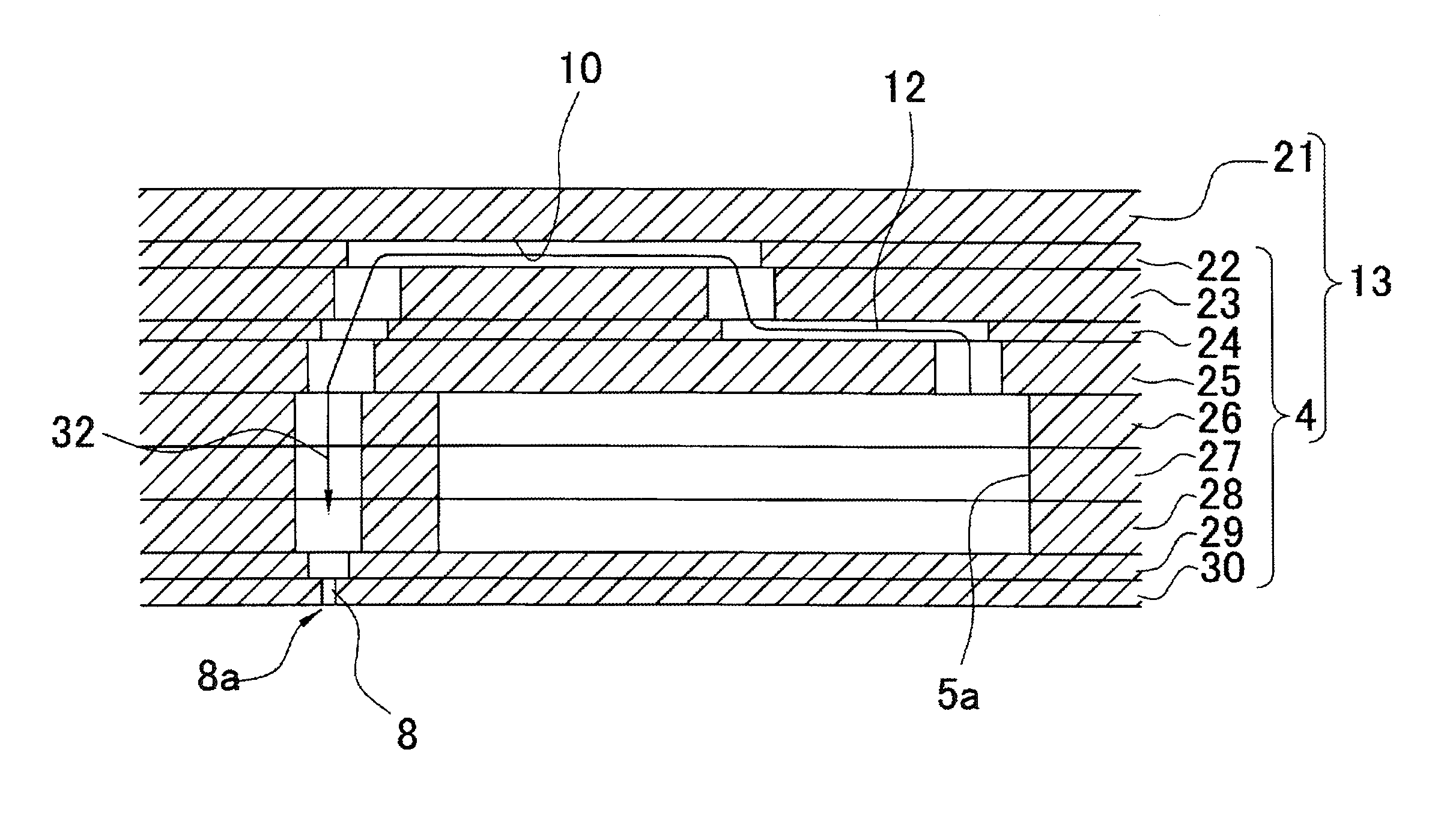

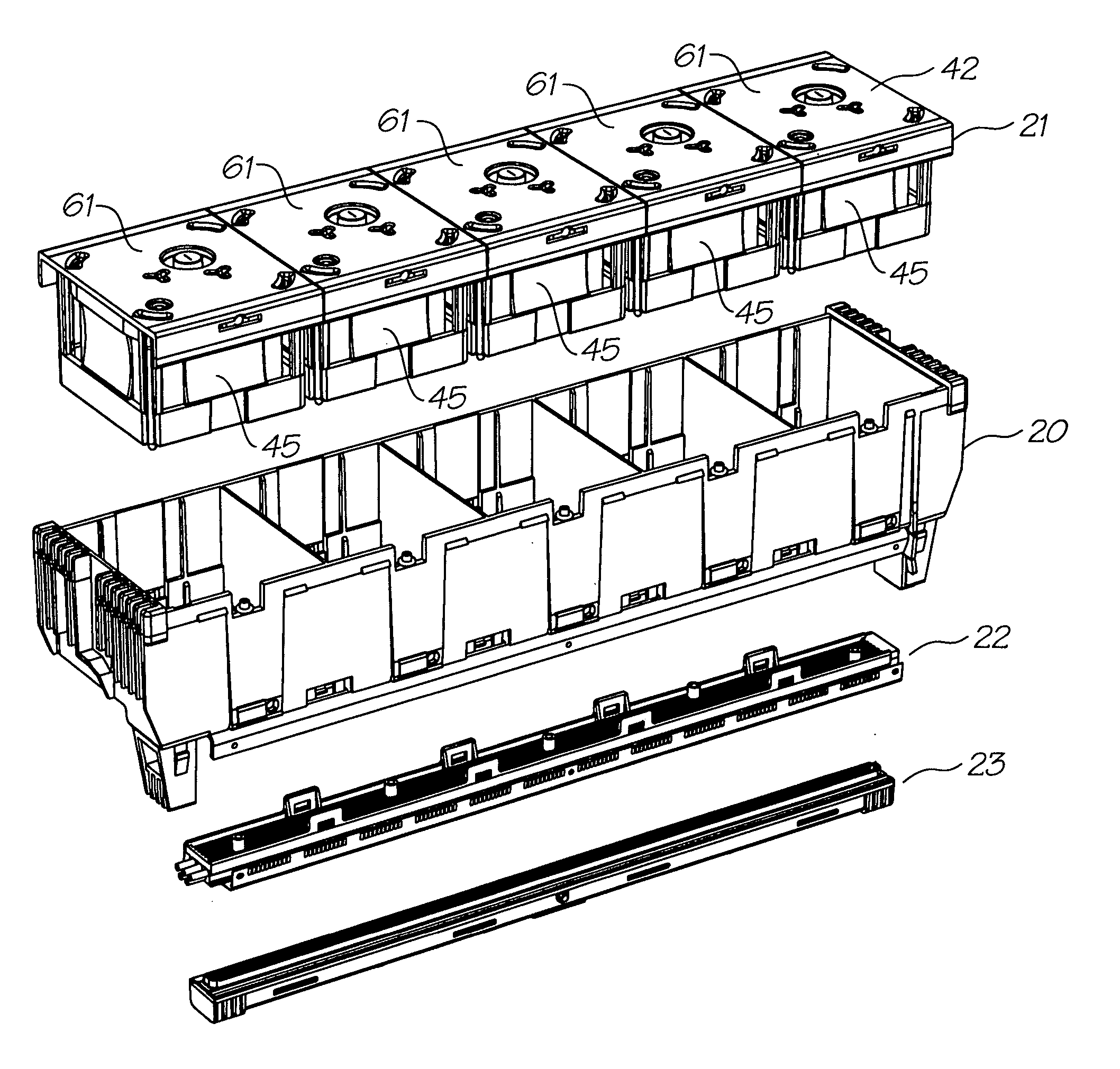

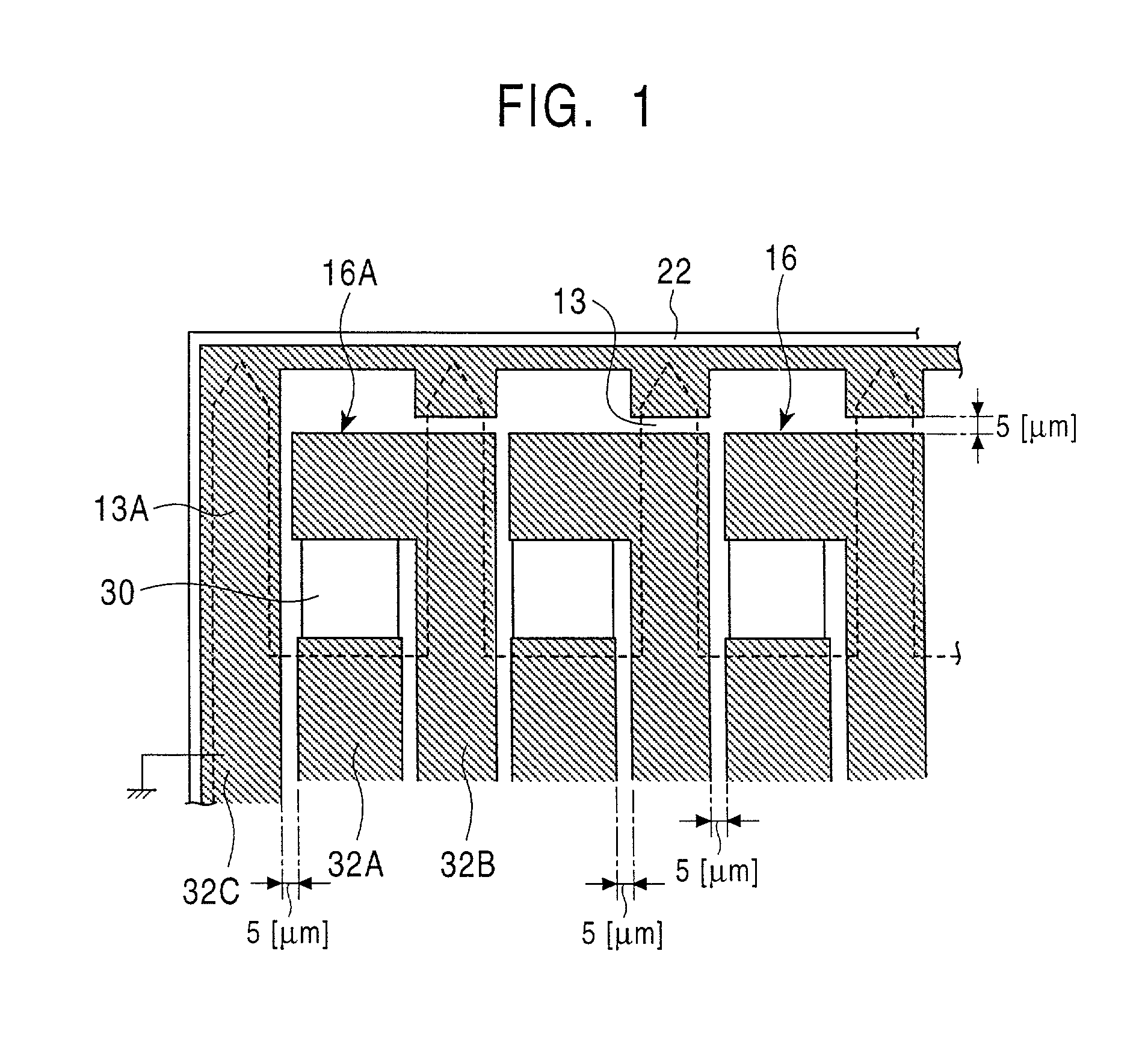

Printhead chip having longitudinal ink supply channels interrupted by transverse bridges

ActiveUS20050168542A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusOther printing apparatusIntegrated circuitNozzle

A printhead integrated circuit is provided. The printhead integrated circuit comprises: (a) a plurality of nozzles formed on a frontside of a substrate, the nozzles being arranged in rows extending longitudinally along the substrate, each nozzle having a respective nozzle inlet; and (b) a plurality of ink supply channels extending longitudinally along a backside of the substrate. Each ink supply channel is configured for supplying ink from the backside to at least one corresponding row of nozzle inlets. Further, each ink supply channel is interrupted along its length by one or more transverse bridges. The transverse bridges provide the printhead integrated circuit with strength in a transverse direction.

Owner:MEMJET TECH LTD +1

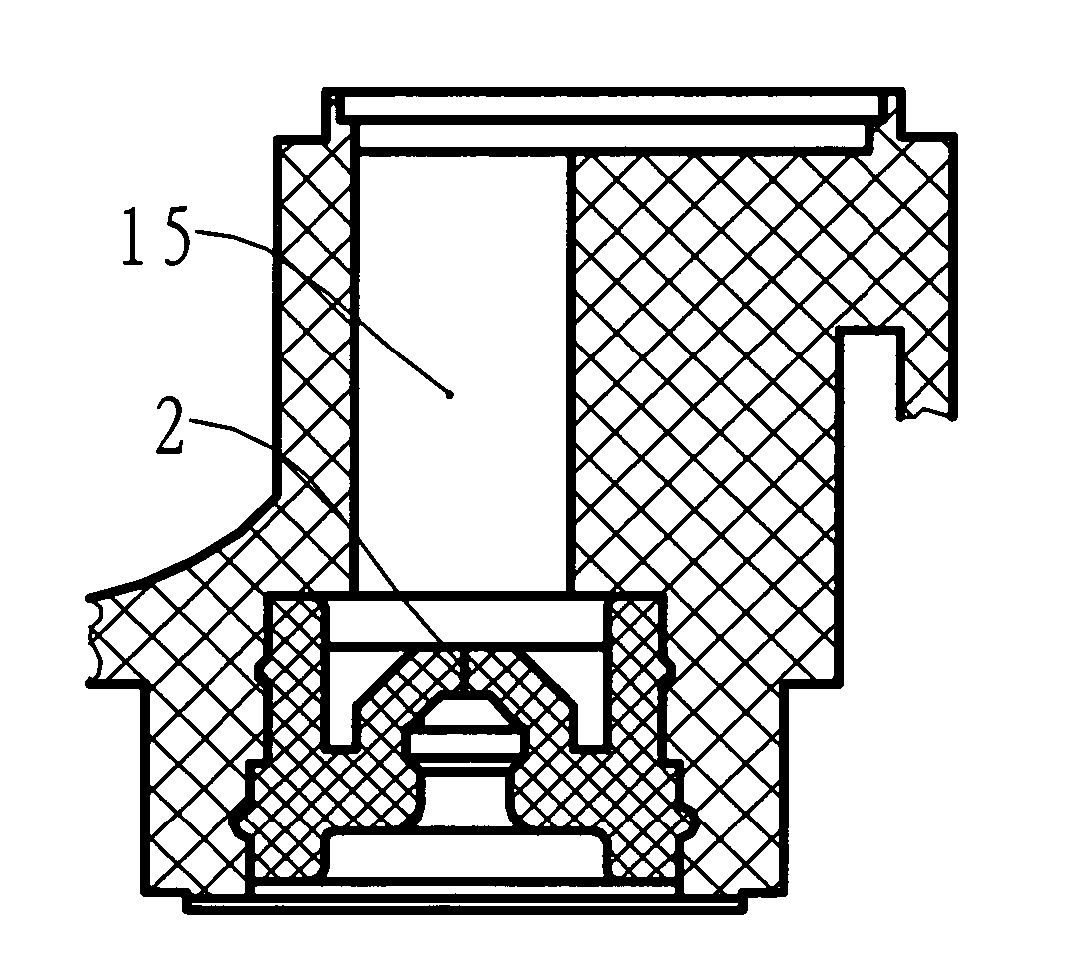

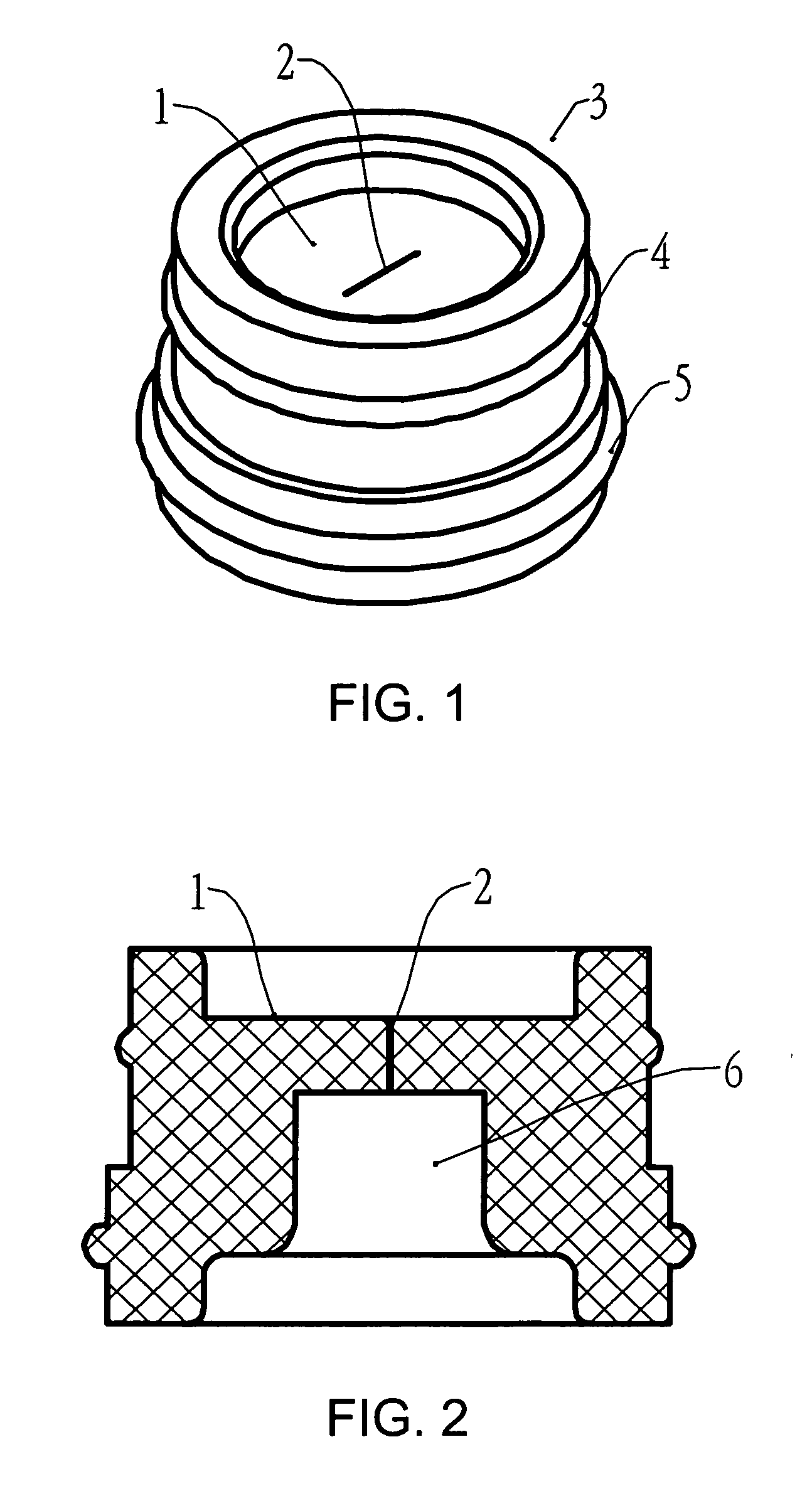

Seal ring and ink cartridge using thereof

InactiveUS20060017790A1Avoid disadvantagesPrevent ink leakagePrintingNatural stateMechanical engineering

The invention involves seal rings useful for ink cartridges. The invention also involves ink cartridges having such seal rings. The seal ring comprises a tube-shaped, elastic part having an insertion opening at its lower end for receiving an ink supply needle. The top of the insertion opening includes a top sealing film. The top sealing film closes in its natural state and prevents ink from leaking through. The seal ring of the invention is simple in structure and effective in preventing ink from leaking out.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Inkjet printhead with apertured sealing film

ActiveUS20050156988A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusPower drive mechanismsInk printerEngineering

A printhead for an inkjet printer, the printhead comprising: a printhead integrated circuit having an array of ink ejection nozzles formed on a substrate; a plurality of ink feed conduits for establishing fluid communication with at least one ink storage compartment; and, a polymer sealing film between the ink feed conduits and the printhead integrated circuits, the polymer film having an array of apertures such that the ejection nozzles are in fluid communication with the ink feed conduits; wherein, the polymer sealing film is more than 25 microns thick.

Owner:SILVERBROOK RES PTY LTD +1

Liquid Ejecting Head and Liquid Ejecting Apparatus

Owner:SEIKO EPSON CORP

Methods for producing a nozzle plate and nozzle plate

ActiveUS20050035999A1Reducing projection amountPrevent ink leakagePhotomechanical apparatusOriginals for photomechanical treatmentEngineeringWater repellent

A method for producing a nozzle plate includes the following steps. A photocuring resin is applied onto a surface of a substrate that includes a nozzle while an ink ejection port of the nozzle being filled with the photocuring resin. Light is irradiated to the photocuring resin from a rear surface of the substrate through the nozzle to form a columnar cured portion. The columnar cured portion includes a head portion and a base portion. The head portion protrudes from the surface of the substrate and has an outer diameter equal to or smaller than an inner diameter of the ink election port. The base portion is disposed in the nozzle and has an outer diameter equal to the inner diameter of the ink ejection port. The photocuring resin except for the columnar cured portion is removed. A water-repellent film is formed on the surface of the substrate.

Owner:BROTHER KOGYO KK

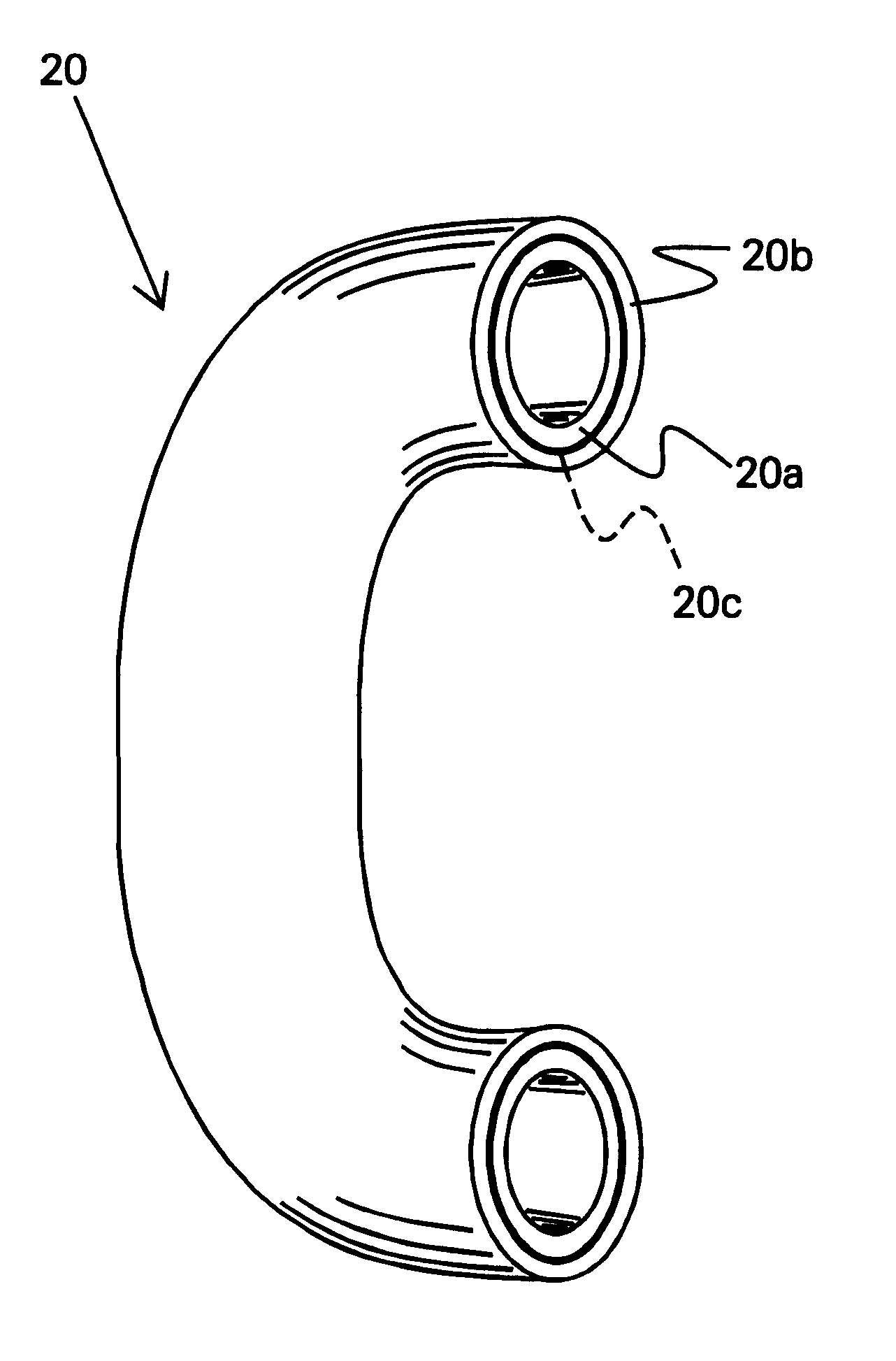

Co-extruded tubing for an off-axis ink delivery system

A fluid transport conduit for conveying ink-jet ink from a reservoir to a printhead in an ink-jet printer is provided. The fluid transport conduit comprises at least one inner layer, such as high density polyethylene, cyclic olefin copolymer, or polypropylene homopolymer, that is flexible and is a barrier to liquids, and at least one outer layer, such as nylon or polyvinyl alcohol, that is a barrier to air and is softer, or more compliant, than the inner layer, with the inner layer bonded to the outer layer. The two layers are advantageously co-extruded to form the fluid transport conduit.

Owner:HEWLETT PACKARD DEV CO LP

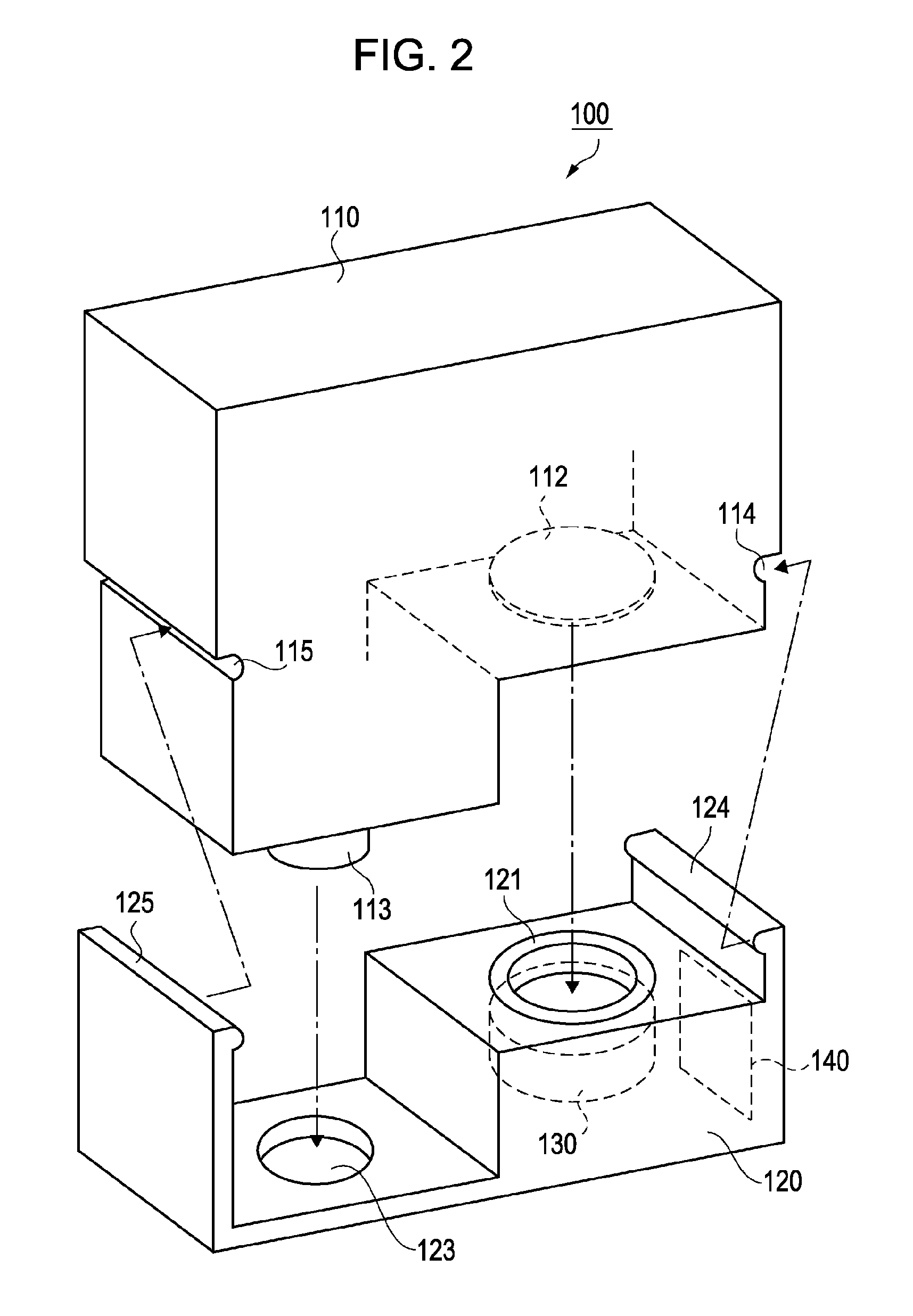

Ink cartridge

An ink cartridge including: an ink chamber storing ink; a communication chamber communicating the ink chamber with the exterior of the ink cartridge; a valve member disposed in the communication chamber such that the valve member is displaceable between a first position to shut off communication between the ink chamber and the exterior, and a second position to permit the communication; a biasing member including a side wall portion surrounding the valve member, and an engaging portion extending inward from an end of the side wall portion and engaging with the valve member, the biasing member normally holding the valve member at the first position but allowing the valve member to be placed at the second position by an elastic deformation of at least one of the side wall portion and the engaging portion, and generating a biasing force to restore the valve member to the first position; and a disengagement preventer which prevents the valve member from disengaging from the engaging portion when the valve member is abnormally operated toward the second position.

Owner:BROTHER KOGYO KK

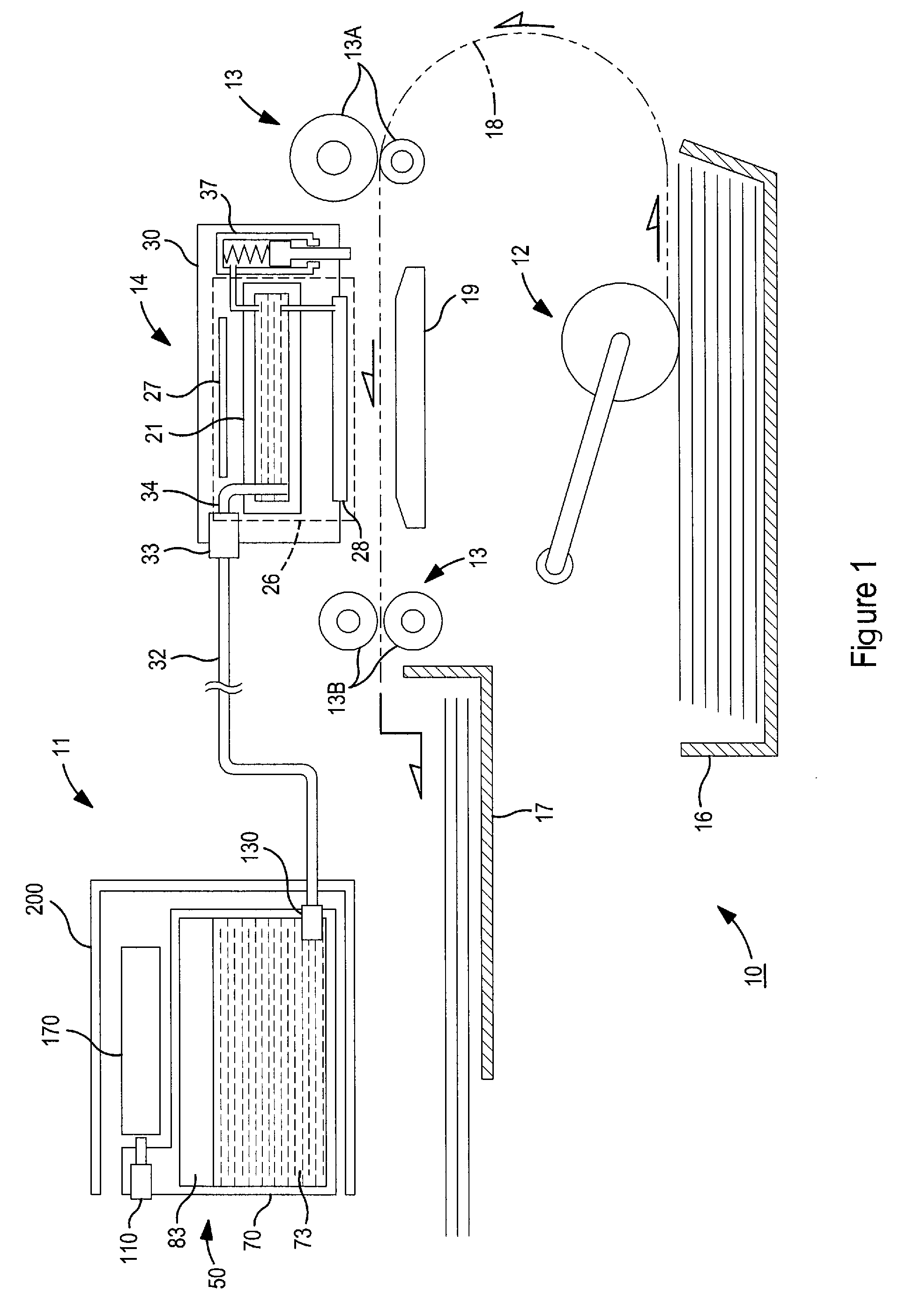

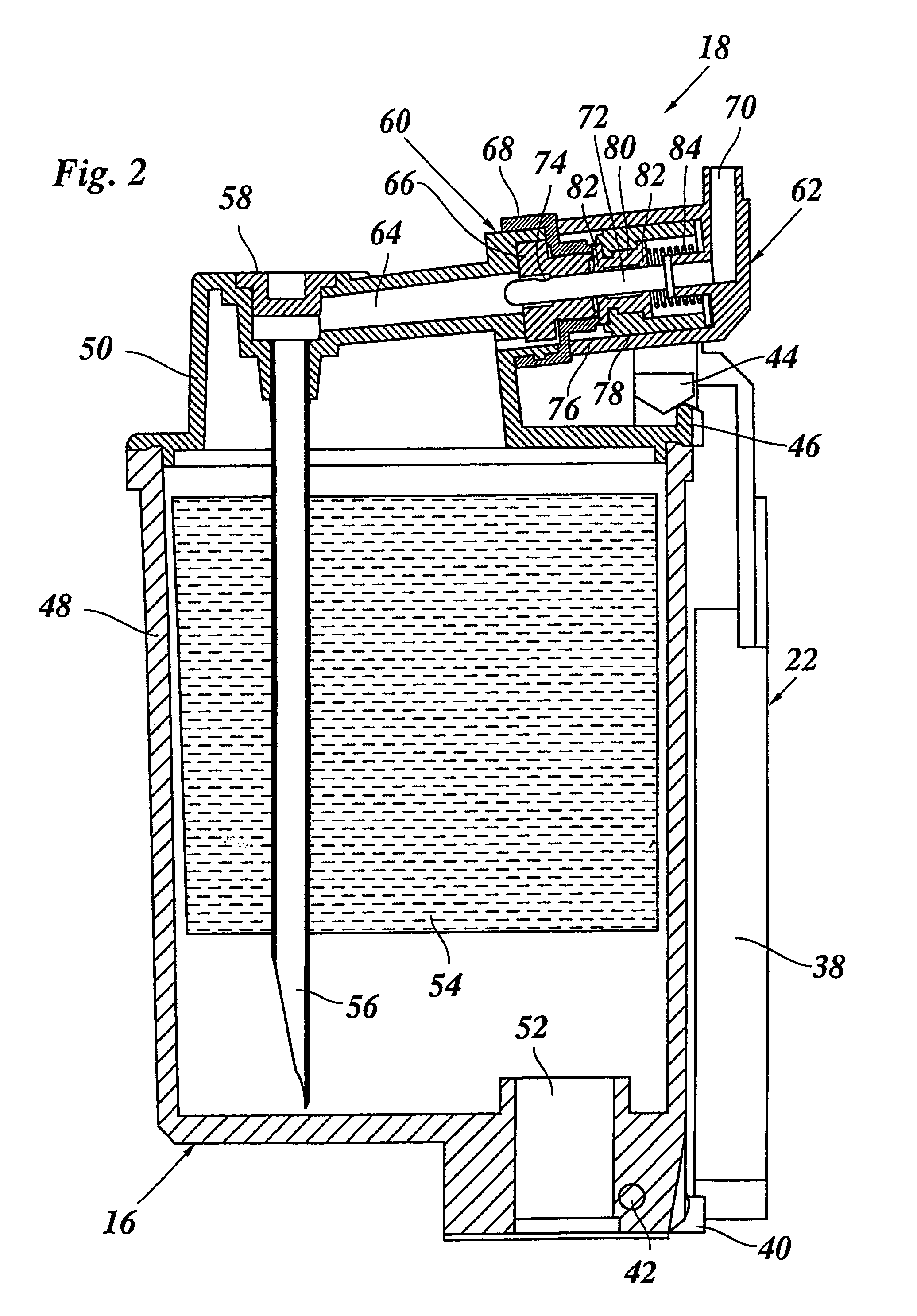

Refill unit for engaging with, and closing the outlet valve from an ink storage compartment

ActiveUS20050157016A1High riskRaise the possibilityInking apparatusPower drive mechanismsValve actuatorEngineering

A refill unit 155 contains a body of ink for refilling a negatively pressurized ink storage compartment 46 that in thurn supplies ink to a printhead assembly 22. The ink storage compartment supplies the printhead 22 via a normally open outlet valve 16. When refill unit 155 releasably engages the ink storage compartment 46, an outlet valve actuator 159 closes the outlet valve 16 as the refill unit 155 engages the ink storage compartment 46. The ink storage compartment is maintained at a negative pressure to avoid ink leakage from the printhead. However, during an ink refill process, the negative pressure is removed when the ink storage volume is filled to capacity. Without the negative pressure in the ink storage compartment, there is a high risk of ink leakage. It is possible to re-establish the negative pressure by slightly increasing the compartments capacity immediately after refilling, but until the negative pressure is re-established, there is a high likelihood of leakage. By designing the refill unit to shut the outlet valve as it engages the storage compartment, ink leakage is prevented until the negative pressure is re-established.

Owner:SILVERBROOK RES PTY LTD +1

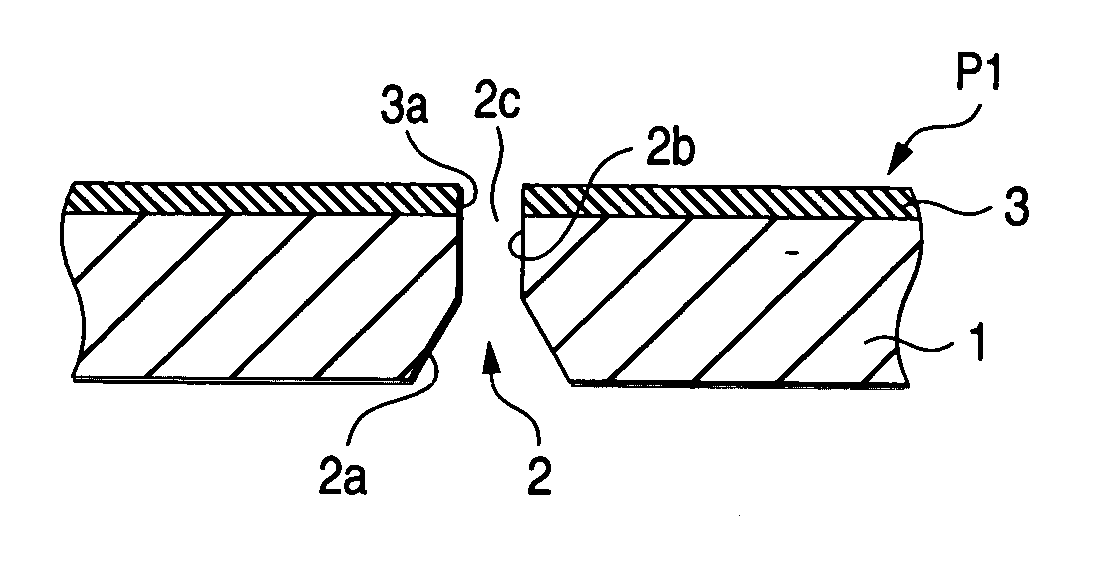

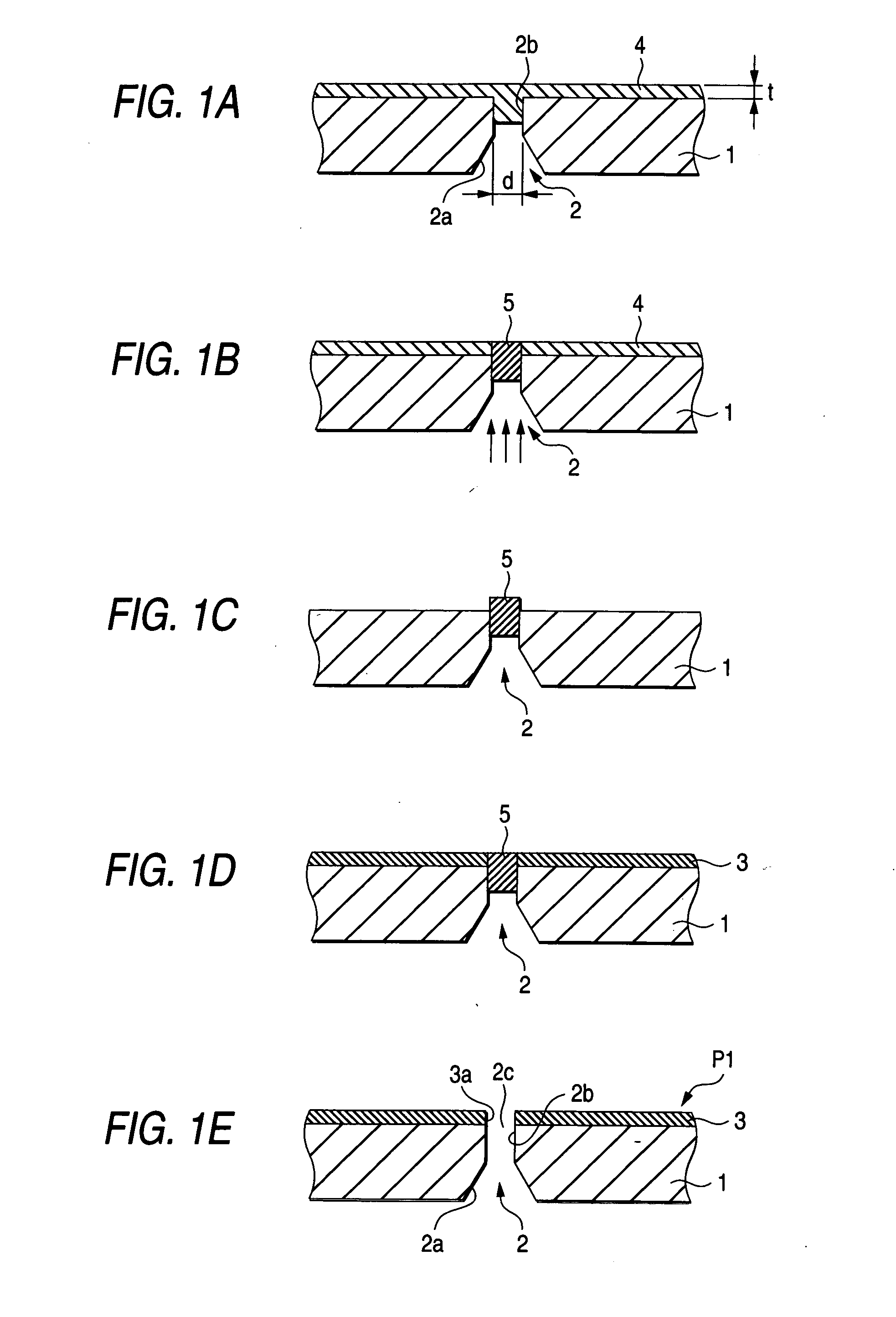

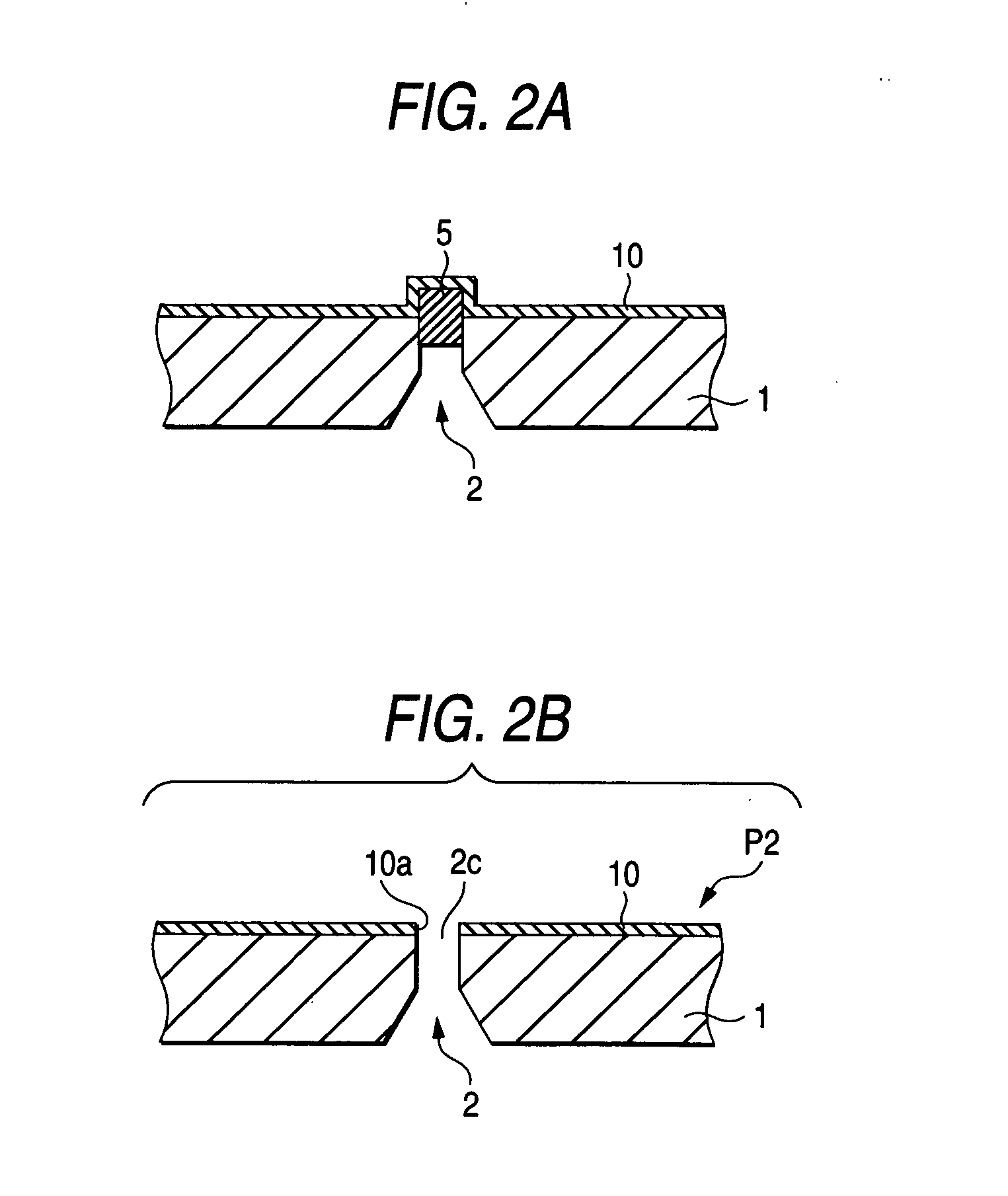

Detachable structure for ink cartridge

ActiveUS20100073442A1Prevent ink leakageNot reduce or prevent ink drippingPrintingBiomedical engineering

A detachable structure for an ink cartridge includes a supply port, a joint section, an insertion rod and an anti-outflow member. The port is provided in the cartridge. The stopper is provided in the port and urged outward to close the port. The joint section is provided in a printer and coupled with the port. The joint section has an ink flow path that communicates with the port while the port is coupled. The insertion rod is provided in the joint section for pushing the stopper inward to communicate the ink flow path with the port while the port is coupled. The anti-outflow member is slidably provided in the joint section. The anti-outflow member is urged outward and slides along the insertion rod when the port is being inserted into the joint section. According to the structure, ink leakage on attaching or detaching of the cartridge can be prevented.

Owner:RISO KAGAKU CORP

Ink cartridges and ink supply systems

Owner:BROTHER KOGYO KK

Ink supply system for an ink jet printer

An in supply system for an ink jet printer, comprising:an ink cartridge for accommodating a limited volume of liquid ink,and ink tank having a volume larger than said limited volume and connectable to the ink cartridge, andan ink supply line including a disengageable coupling, for connecting the ink tank to the ink cartridge,wherein the coupling includes a valve mechanism which, when the coupling is disengaged, automatically blocks the ink supply line and opens a vent passage for venting the interior of the cartridge.

Owner:OCE TECH

Ink jet printing apparatus

An ink jet printing apparatus prints an image by employing a print head capable of ejecting ink from ejection ports. The printing apparatus comprises a cap configured to cover the ejection ports, a valve configured to open and close an atmospheric communicating portion that communicates an inside of the cap and the atmosphere, a suction unit configured to generate a suction force, and a control unit. The control unit performs a first operation where the suction unit applies a first suction force to the inside of the cap in a state where the cap covers the ejection ports and the valve closes the atmospheric communicating portion, and a second operation where the suction unit applies a second suction force, less than the first suction force, to the inside of the cap in a state where the cap covers the ejection ports and the valve opens the atmospheric communicating portion.

Owner:COPYER

Cap and ink-jet head protection assembly

ActiveUS20080284814A1Reduce pressure differencePrevent ink leakagePrintingEngineeringMechanical engineering

Owner:BROTHER KOGYO KK

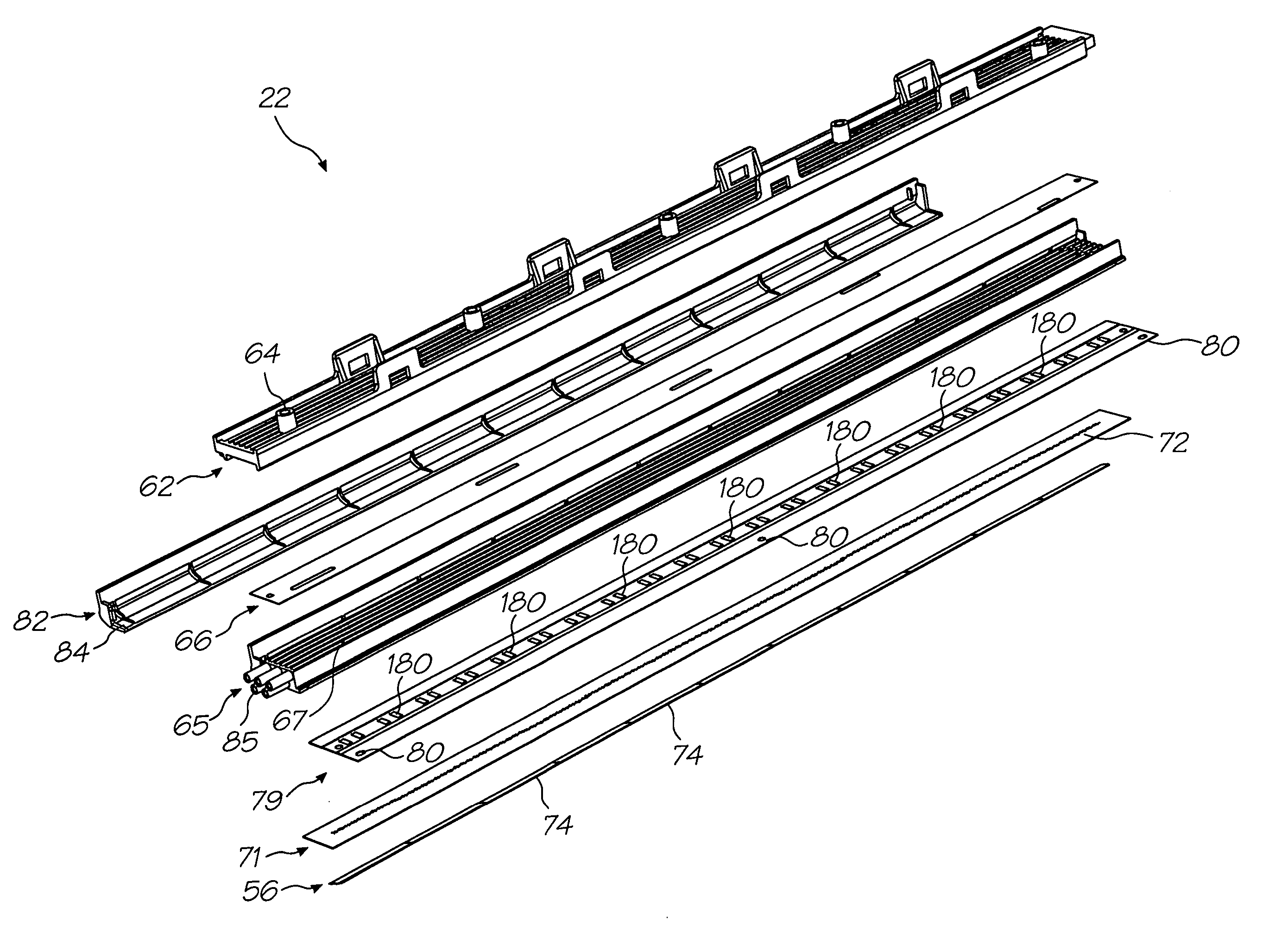

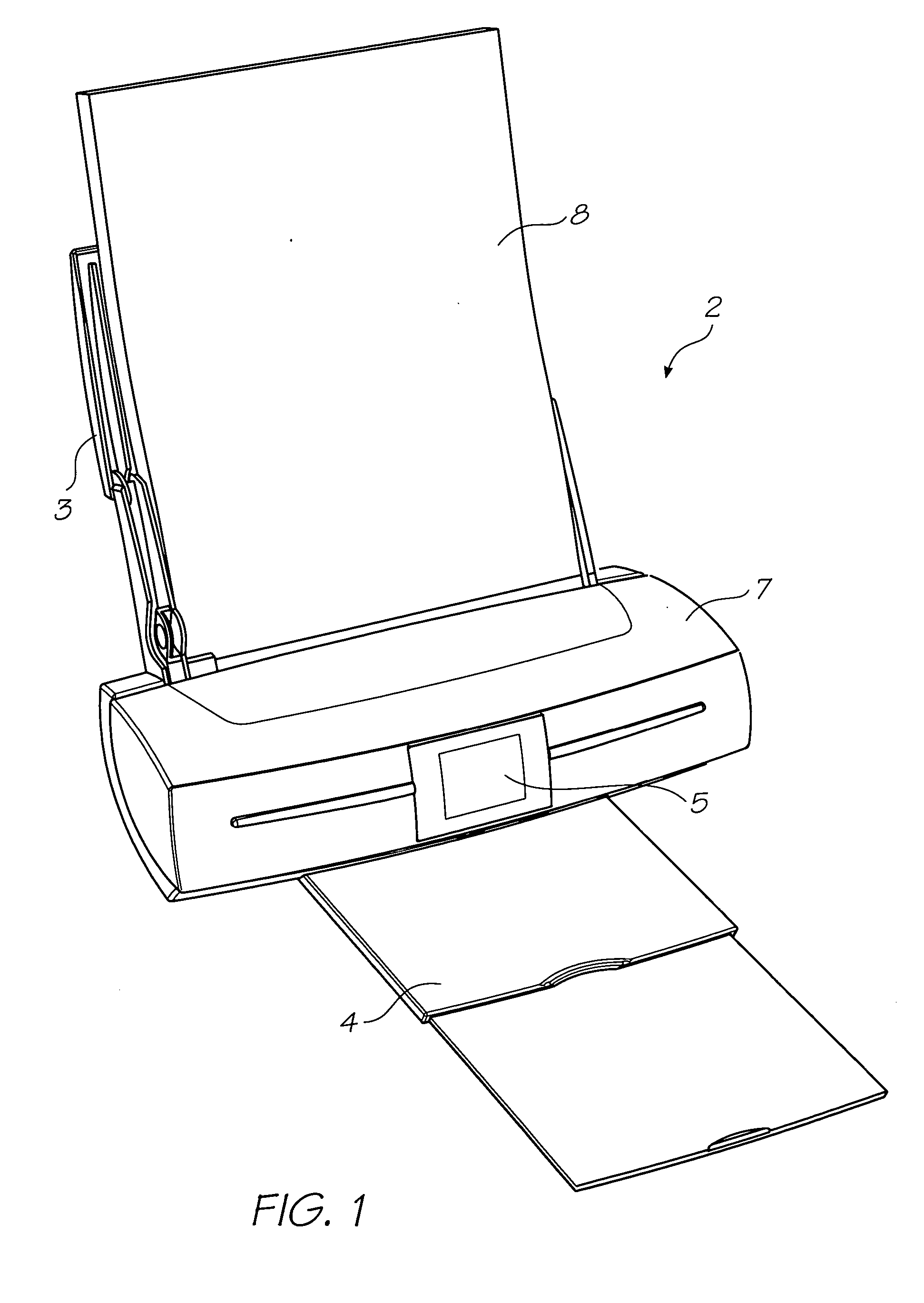

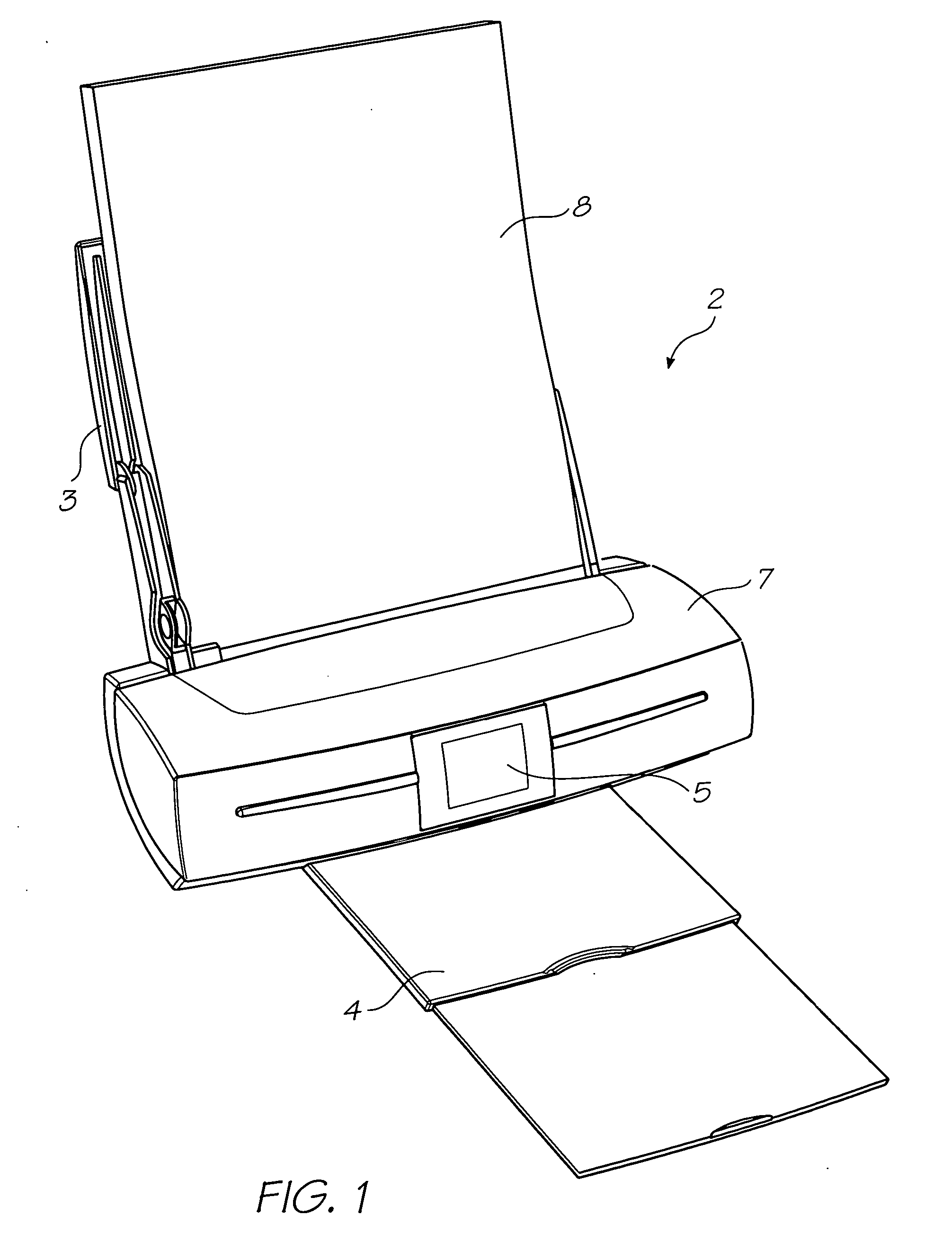

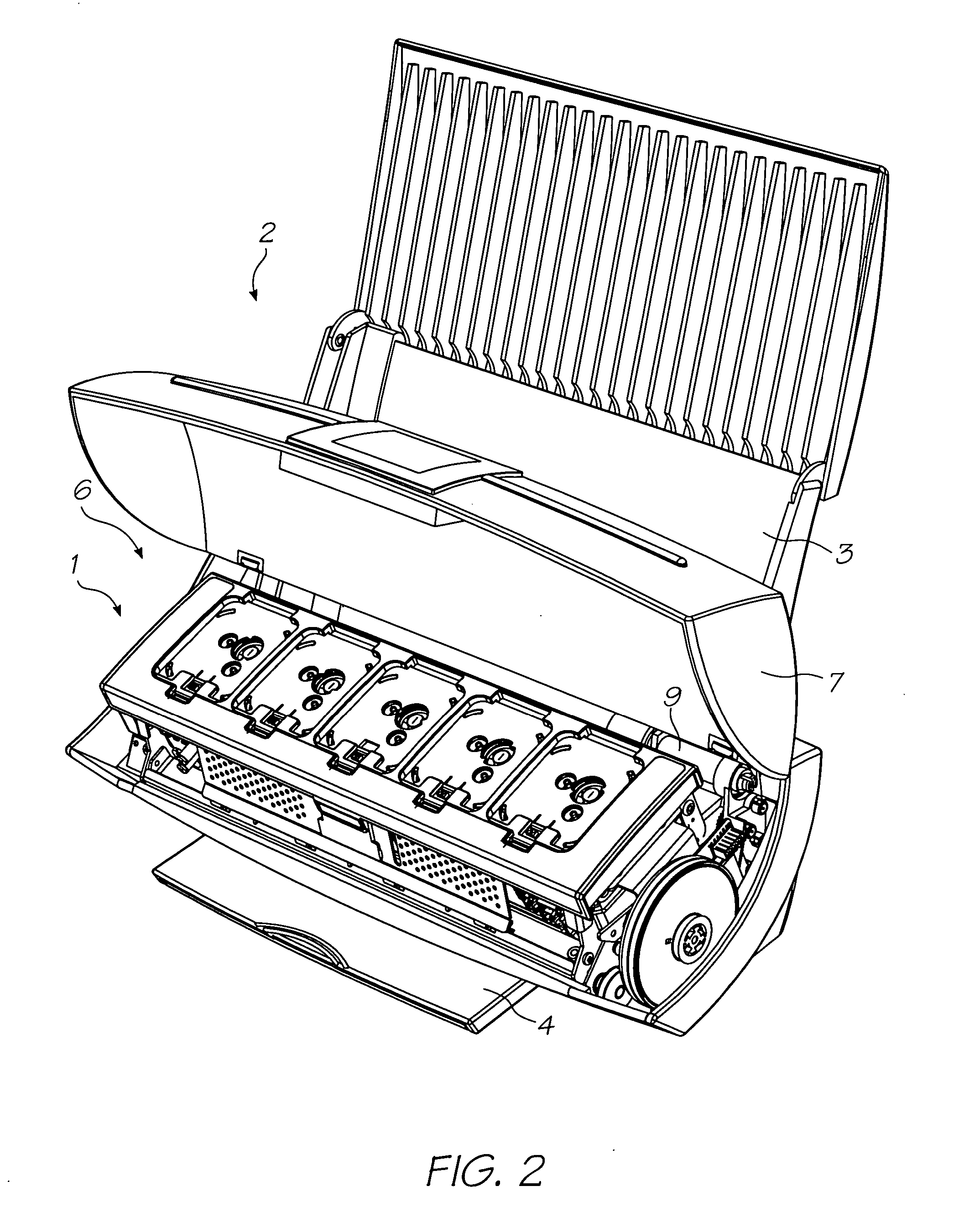

Ink-jet recording device and control method thereof

An ink-jet recording device according to the present invention includes: a paper supply tray arranged inward of a predetermined face of a main body to supply recording sheets; a paper display tray arranged inward of the same face as the paper supply tray to receive recording sheets discharged after recording; an ink cartridge loading unit, which is arranged inward of the same face as the paper supply tray, and into which an ink cartridge containing ink used for recording is loaded detachably; and a controller which disables removal of the ink cartridge during a removal inhibited period.

Owner:PANASONIC CORP

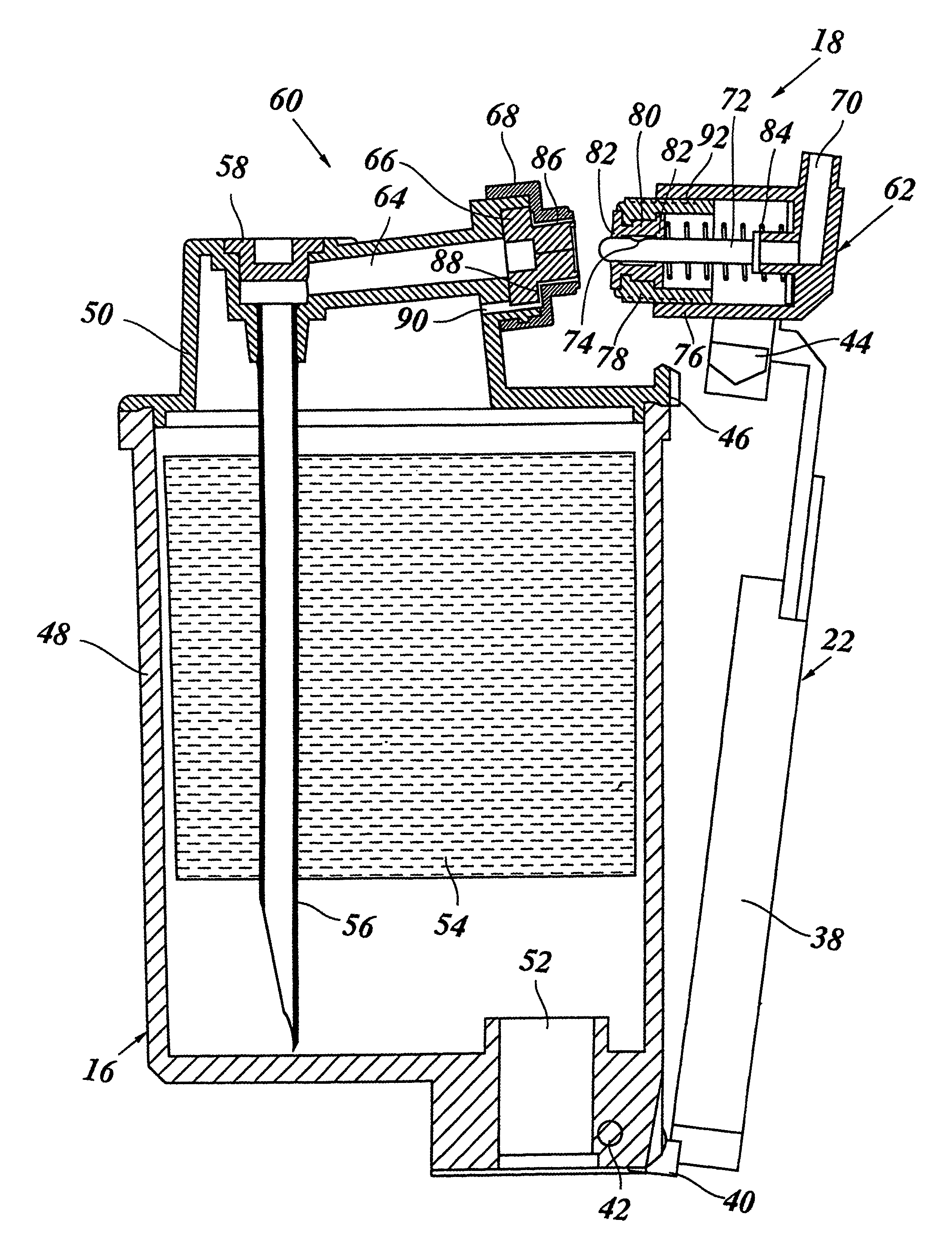

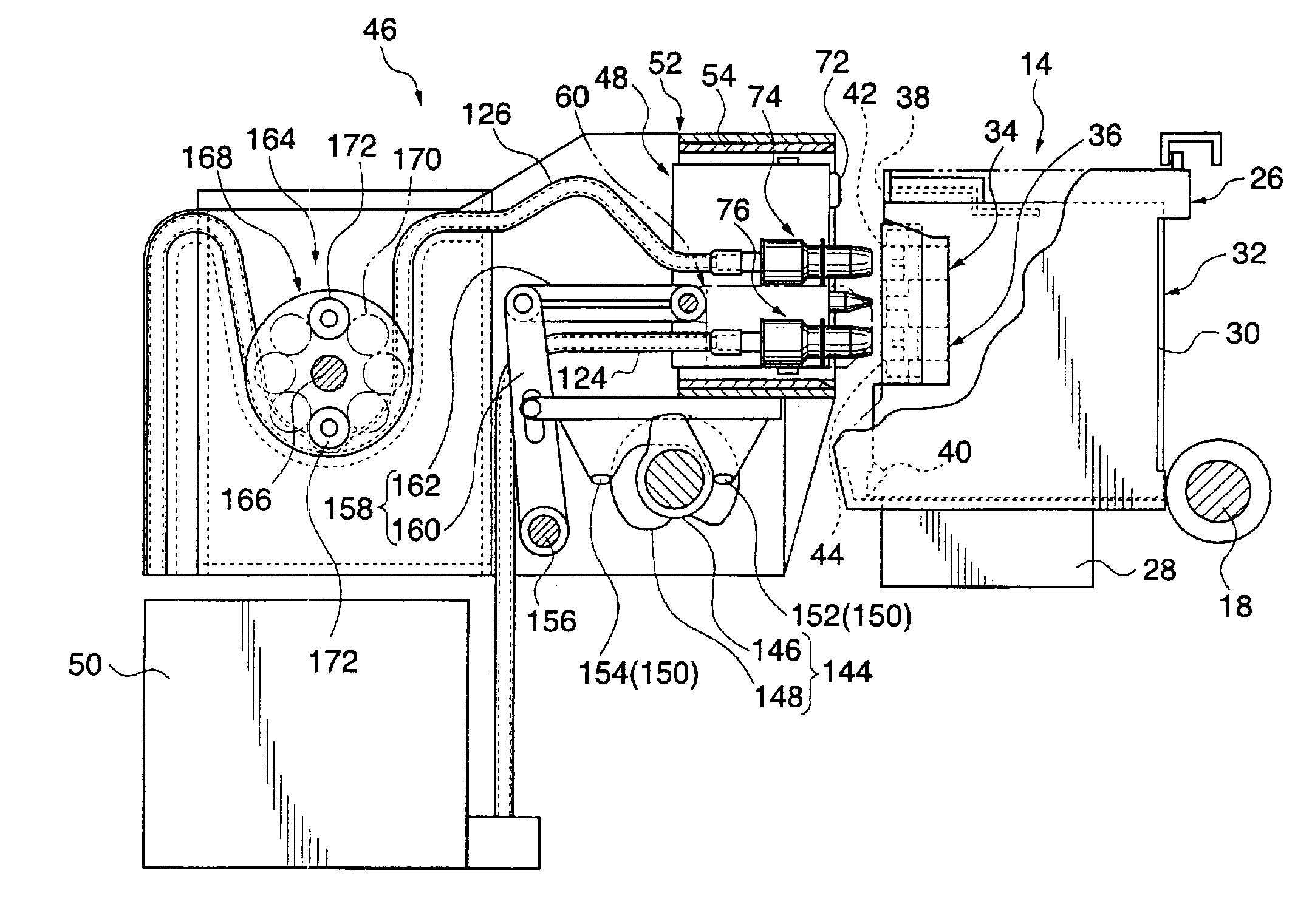

Refill unit for simultaneously engaging with, and opening inlet valve to, an ink cartridge

ActiveUS20050157015A1Improve performanceIncreased operating lifeInking apparatusPower drive mechanismsInlet valveActuator

A refill unit 155 for refilling a ink storage compartment 46 that supplies ink to a printhead 22. The ink storage compartment 46 having an interface 61 for receiving the refill unit 155. The interface 61 having an inlet valve 18 biased to its closed configuration. The refill unit 155 has an inlet valve actuator 152 for opening the inlet valve 18 as the refill unit 155 engages the ink interface 61 so that the ink in the body is in fluid communication with the ink storage compartment 46. By configuring the refill unit so that it opens the inlet valve on the ink cartridge at the same time that it docks with the cartridge, the risk of dust or other contaminants getting into the cartridge is reduced. This improves the performance and operational life of the printhead nozzles.

Owner:SILVERBROOK RES PTY LTD +1

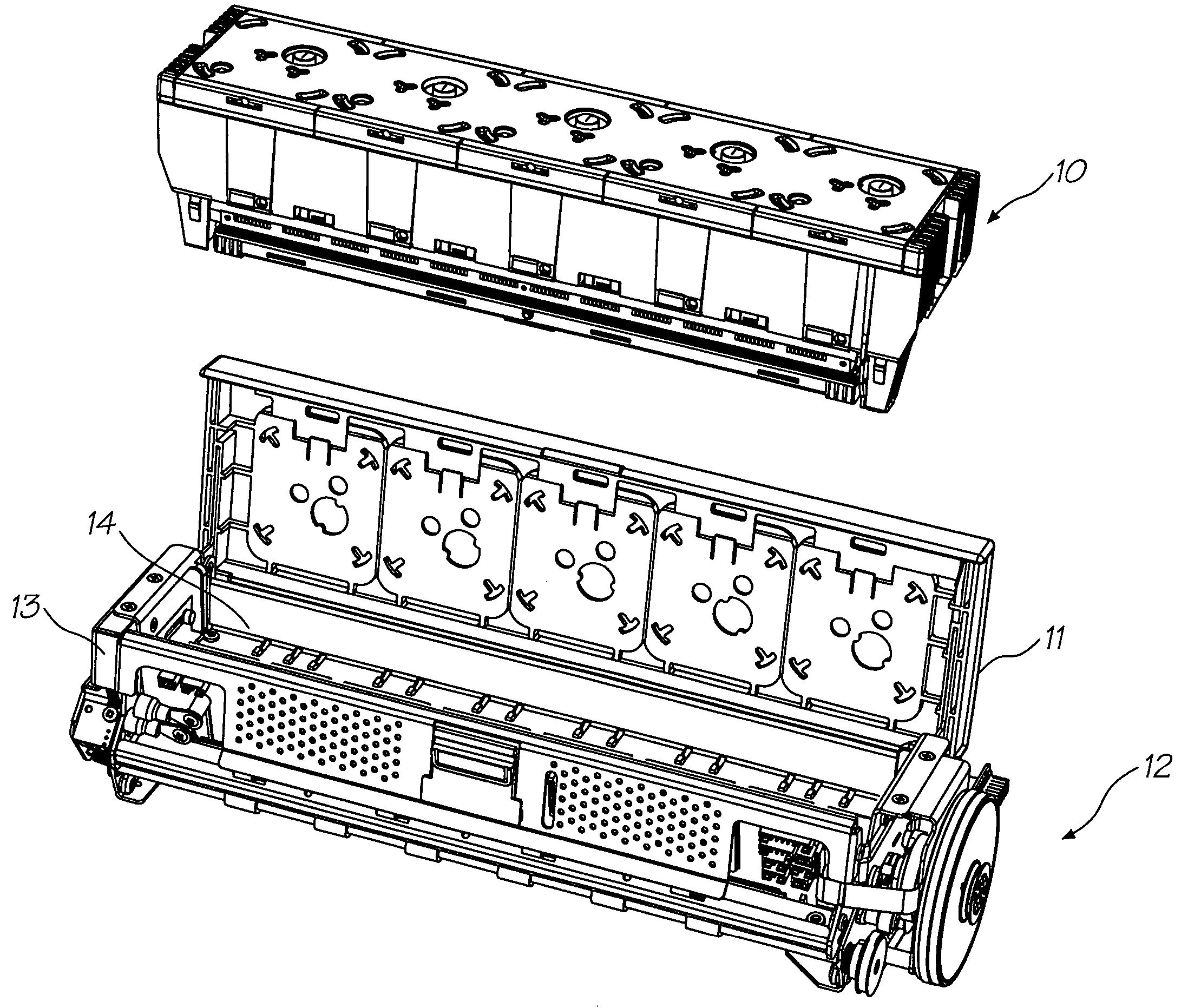

Liquid storage container and liquid storage body-receiving mamber

A liquid storage container is provided which is configured to be detachable from a liquid ejecting apparatus. The storage container includes a liquid storage body having a liquid storage portion for storing liquid therein, a liquid storage body-receiving member configured as a separate body from the liquid storage body and detachably receiving the liquid storage body, and a detection sensor provided to the liquid storage body-receiving member and used in detecting the liquid within the liquid storage body.

Owner:SEIKO EPSON CORP

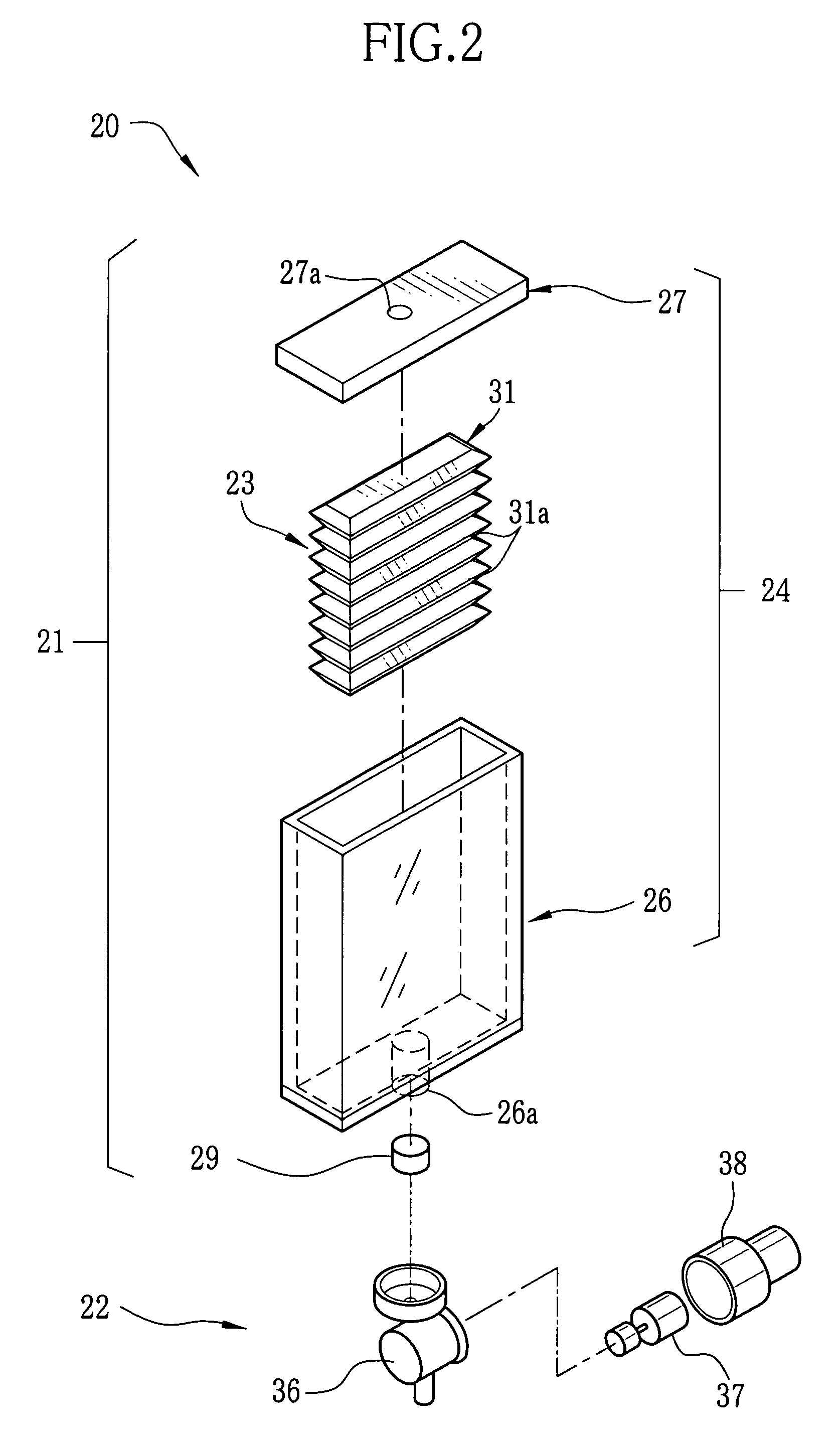

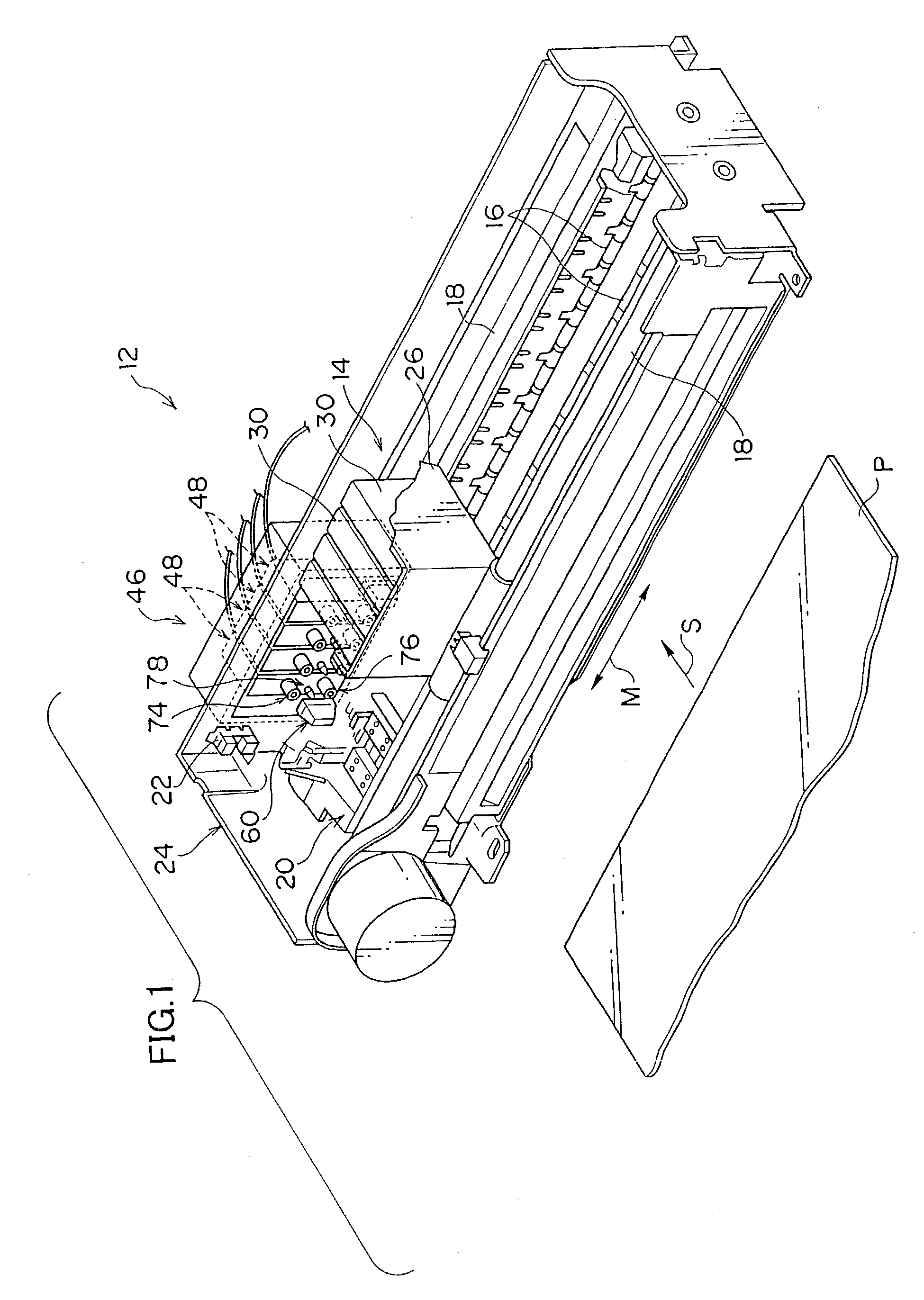

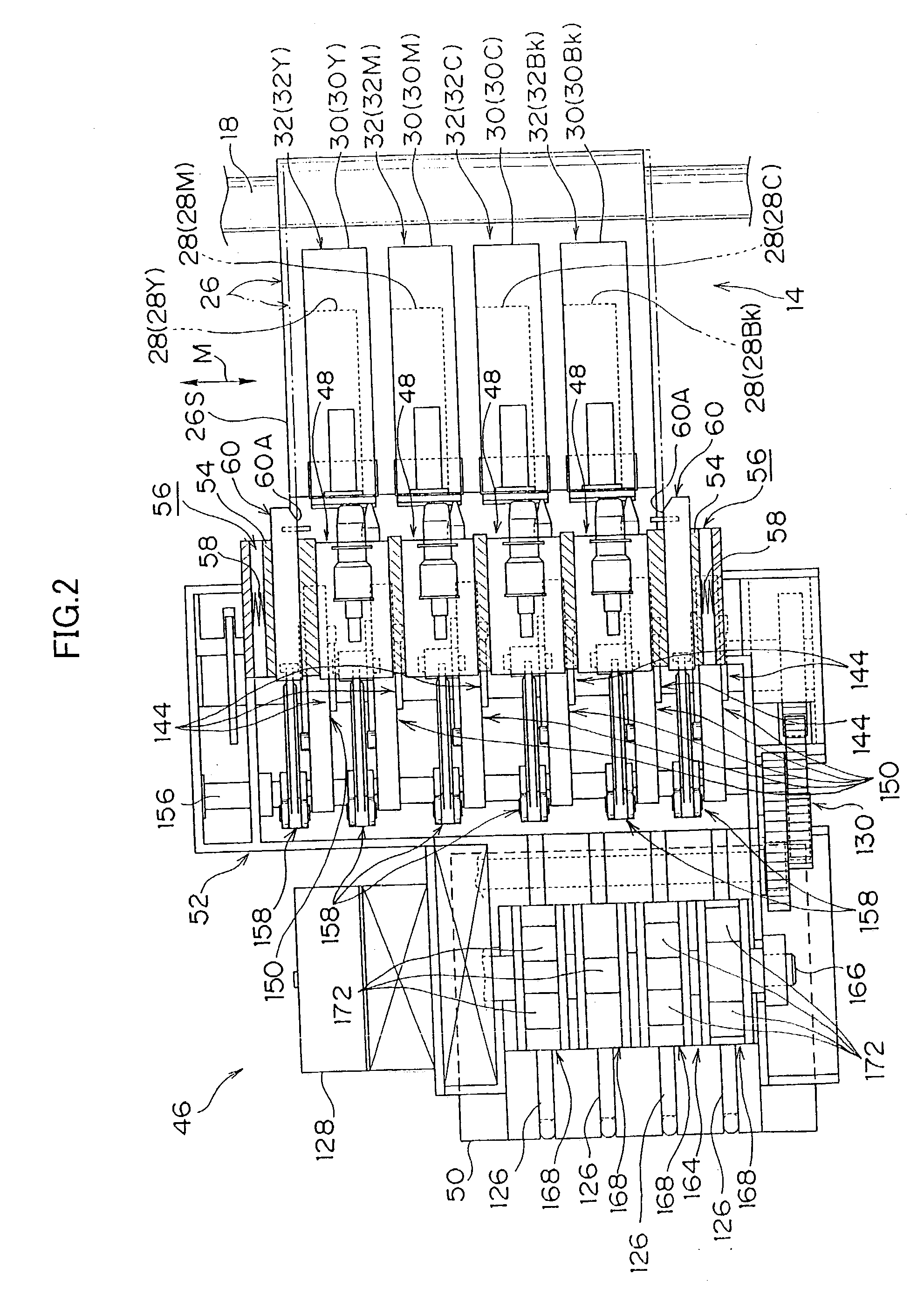

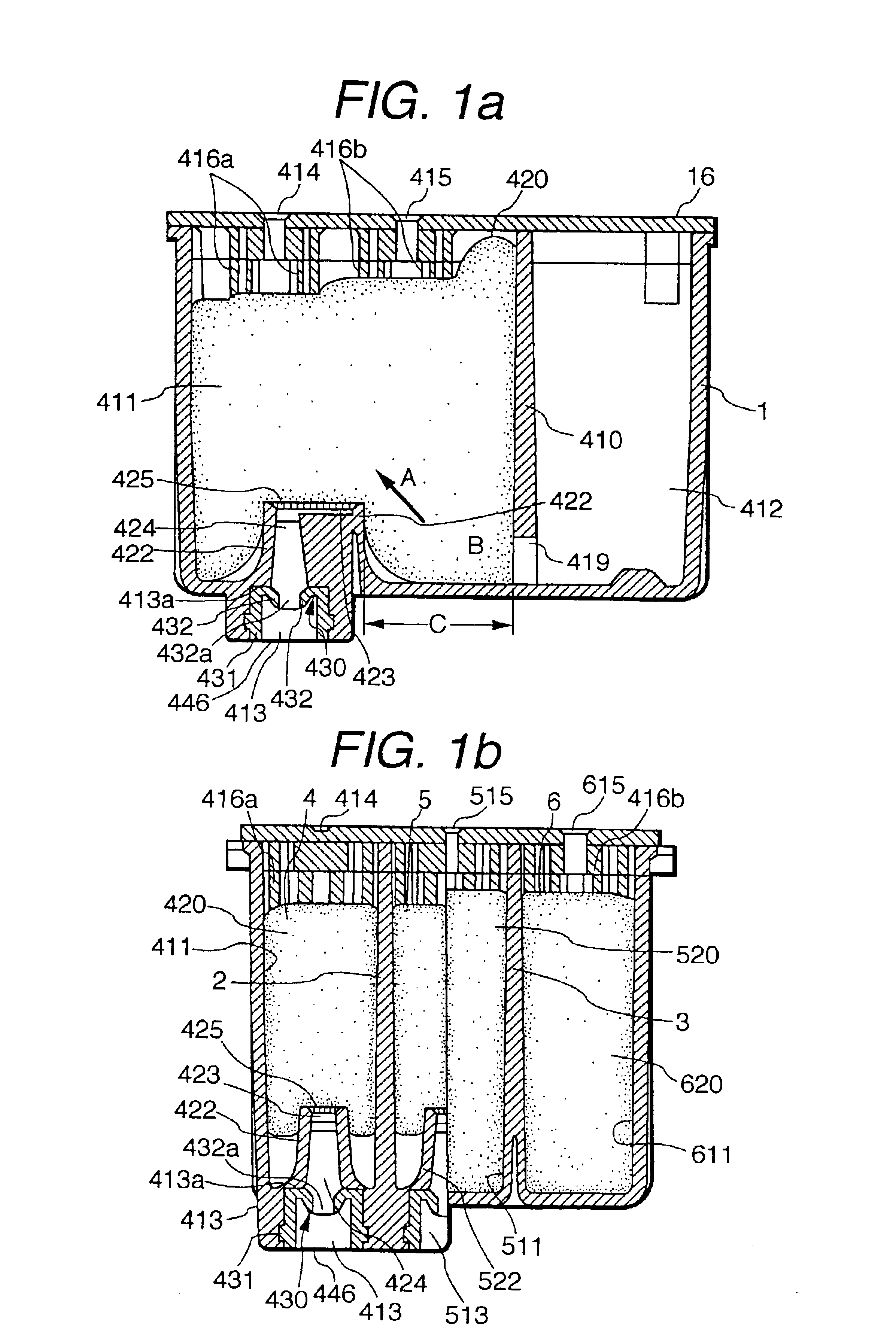

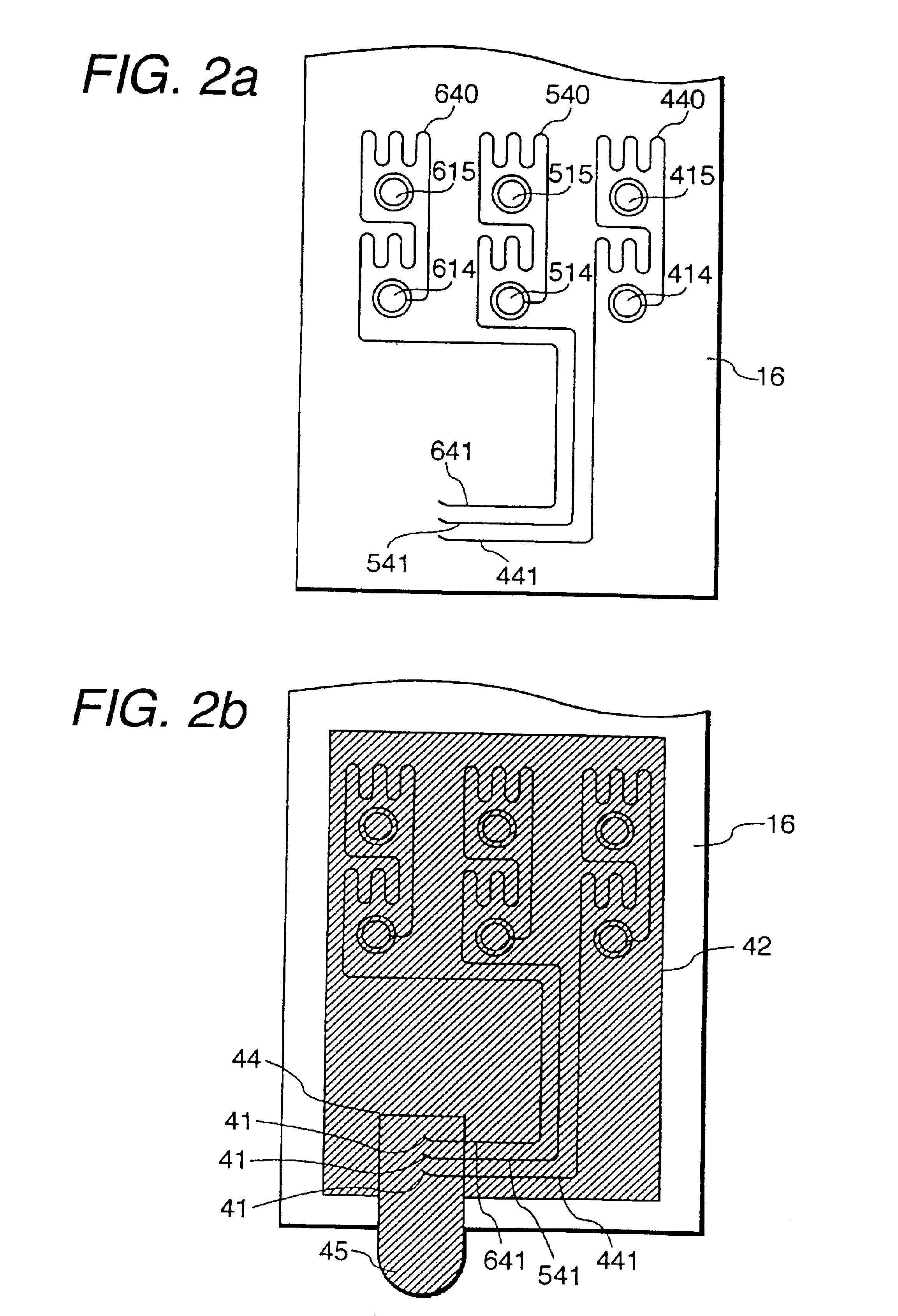

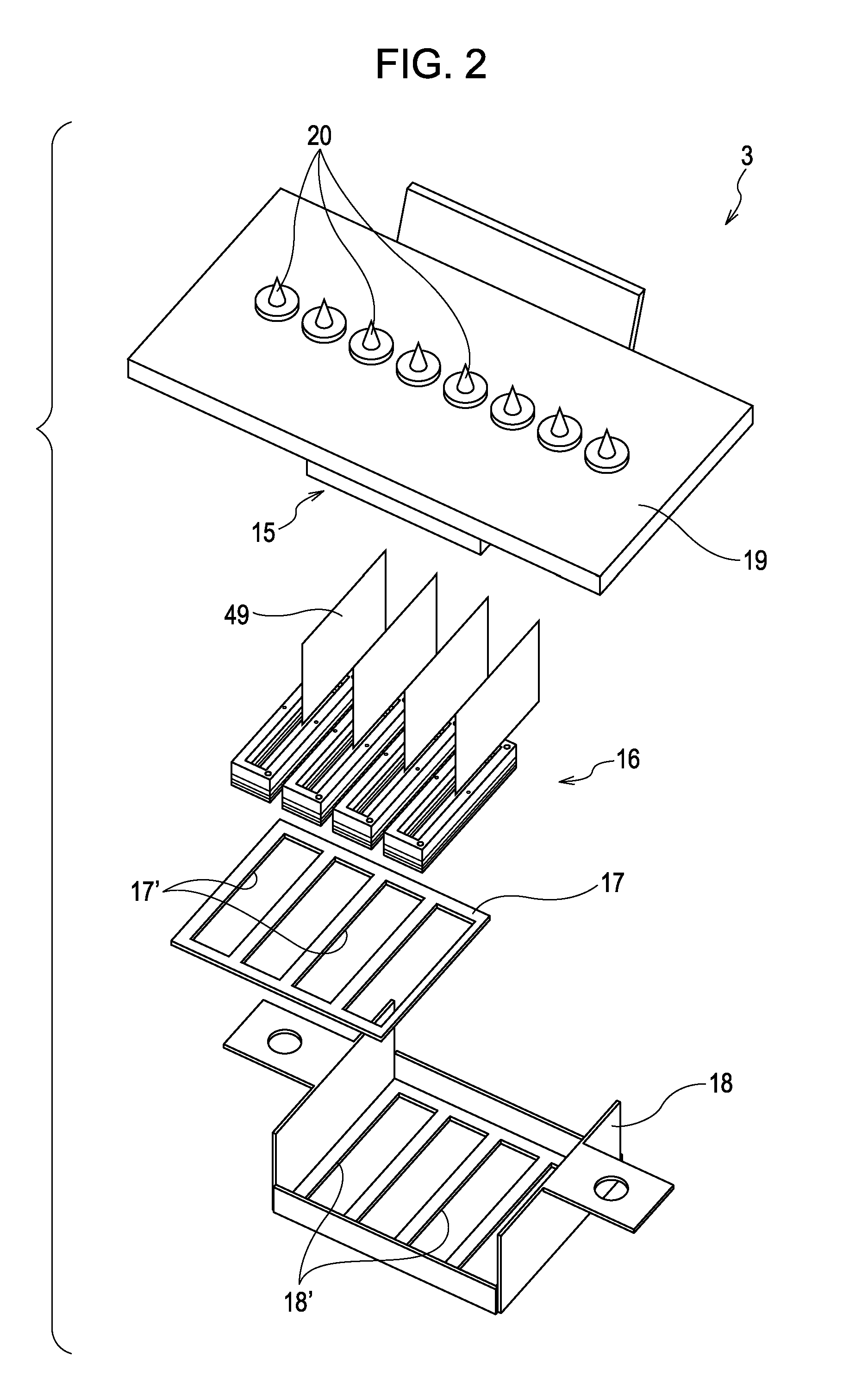

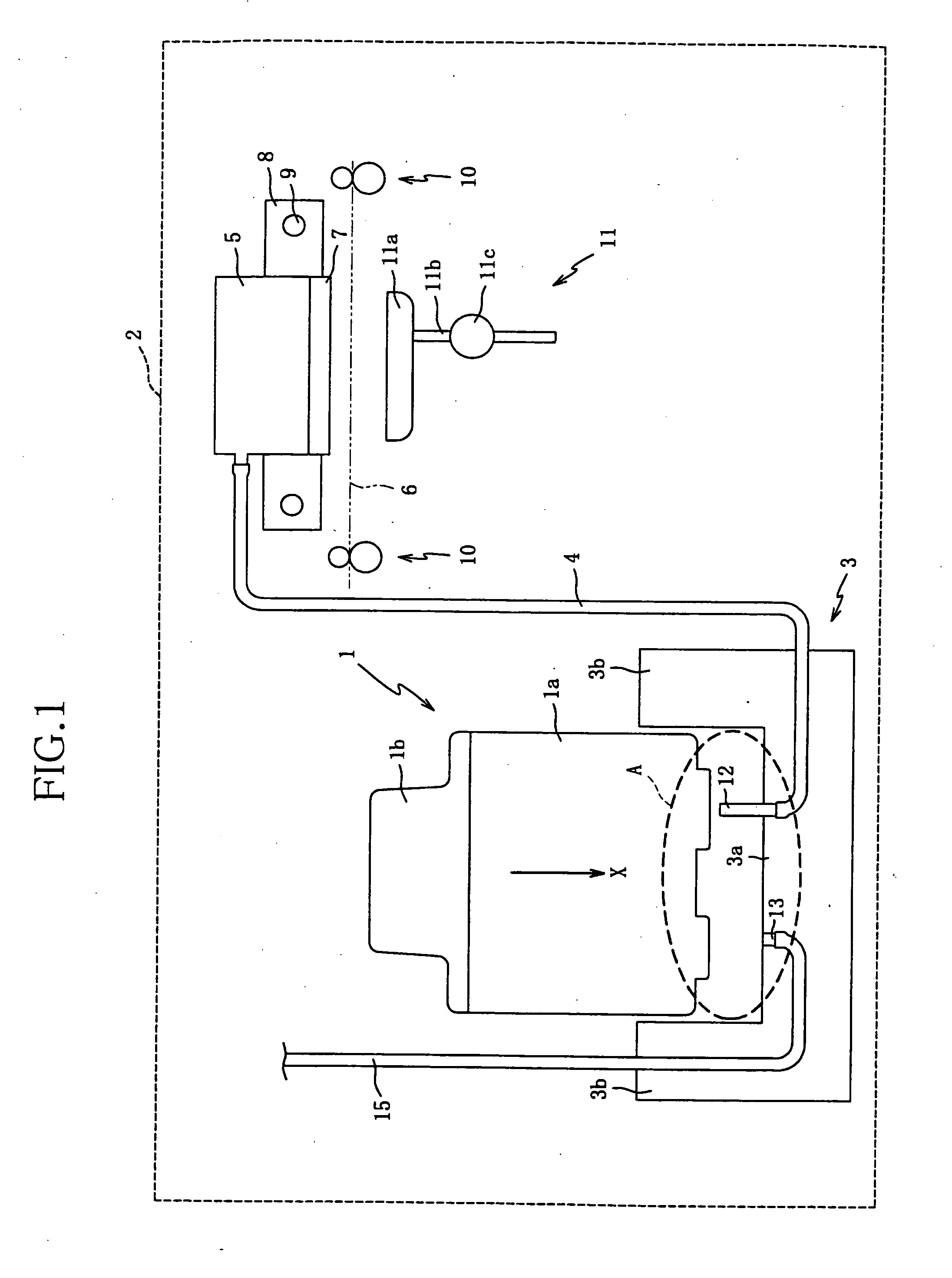

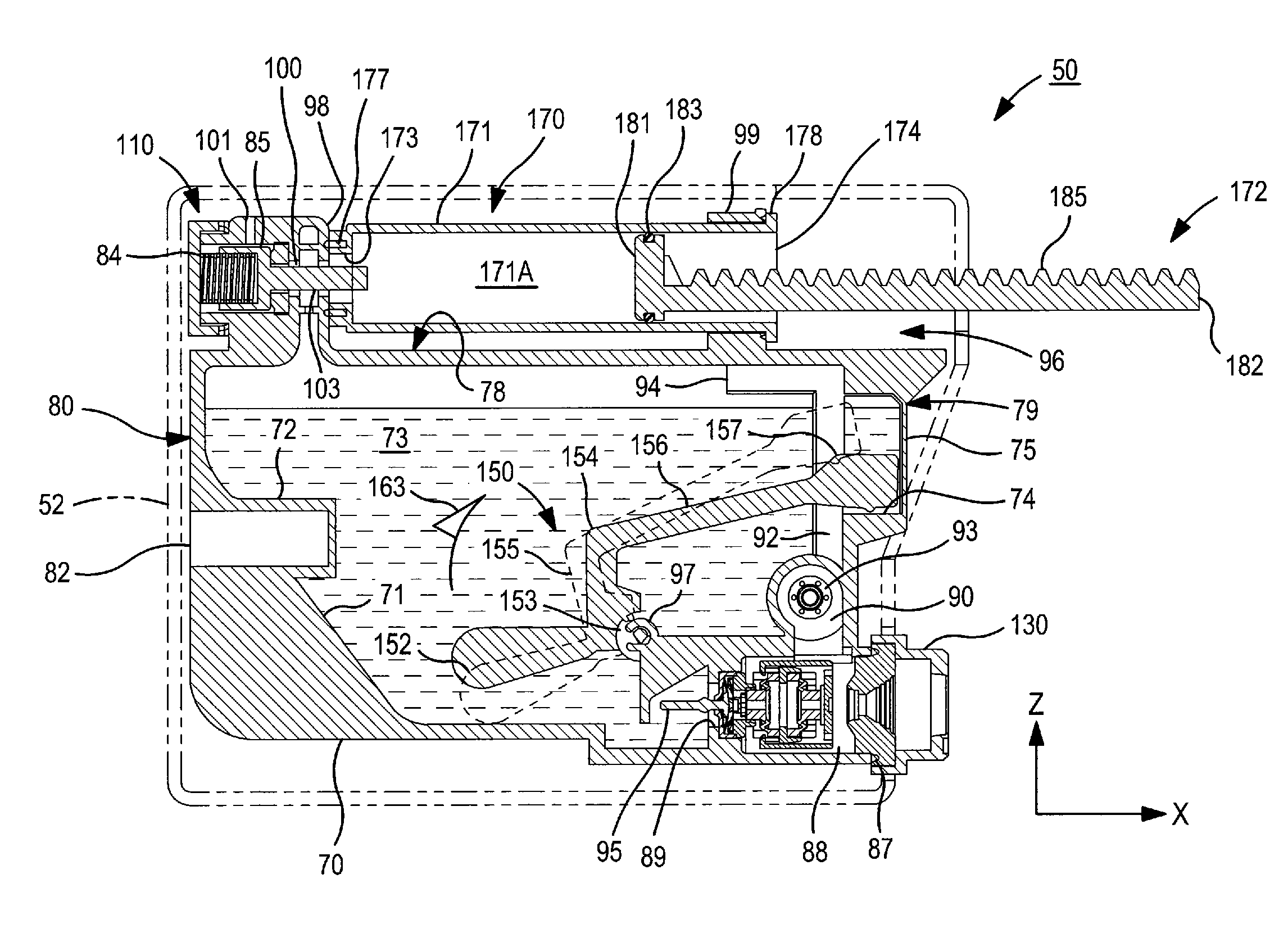

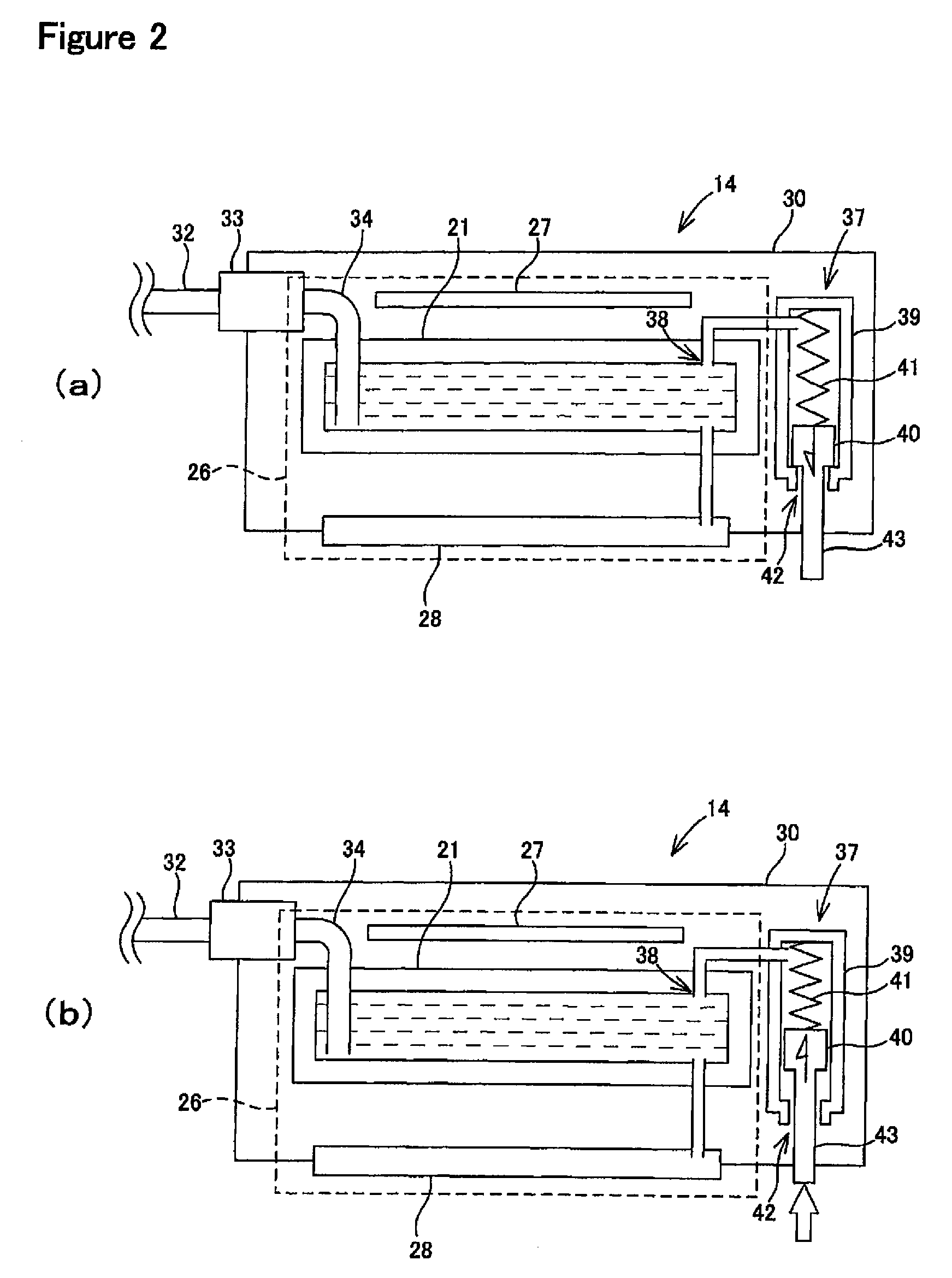

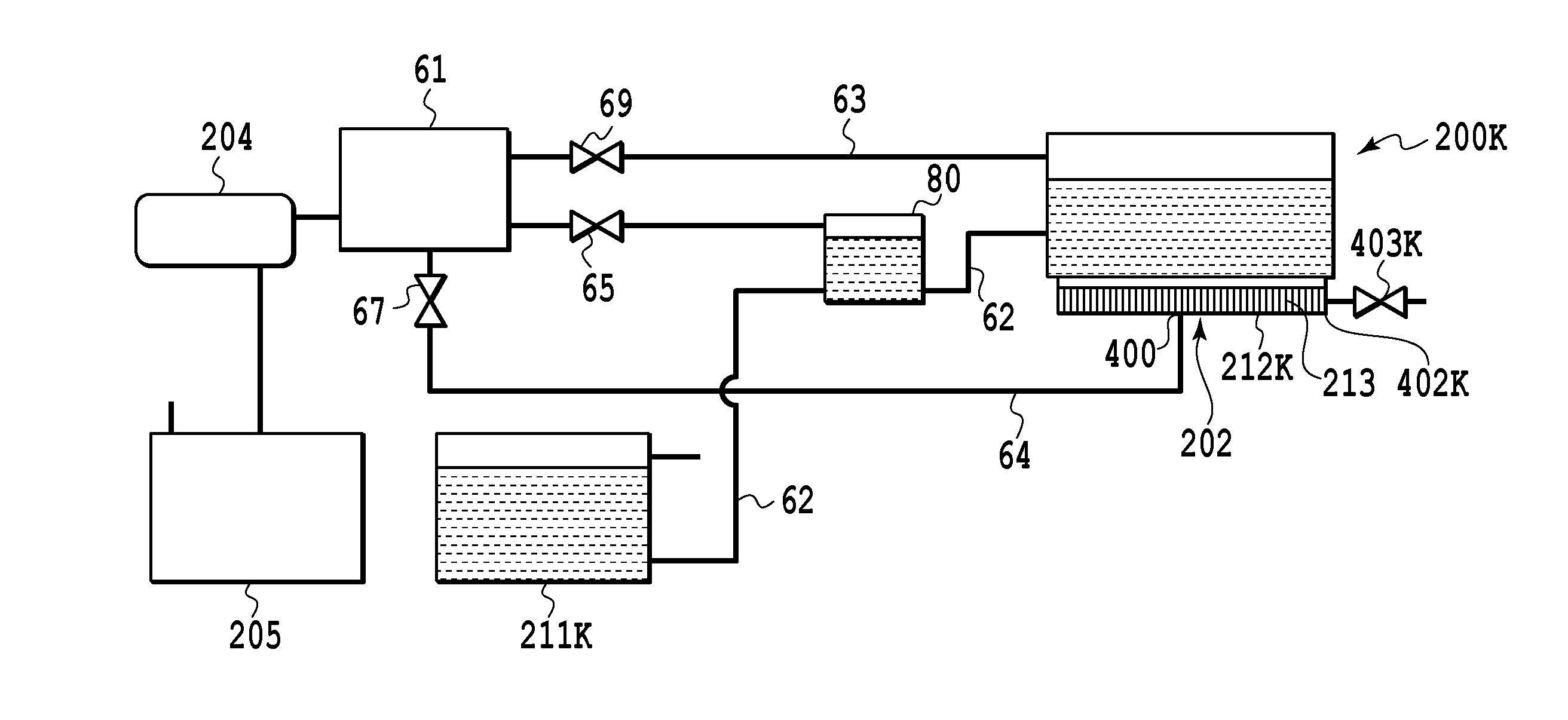

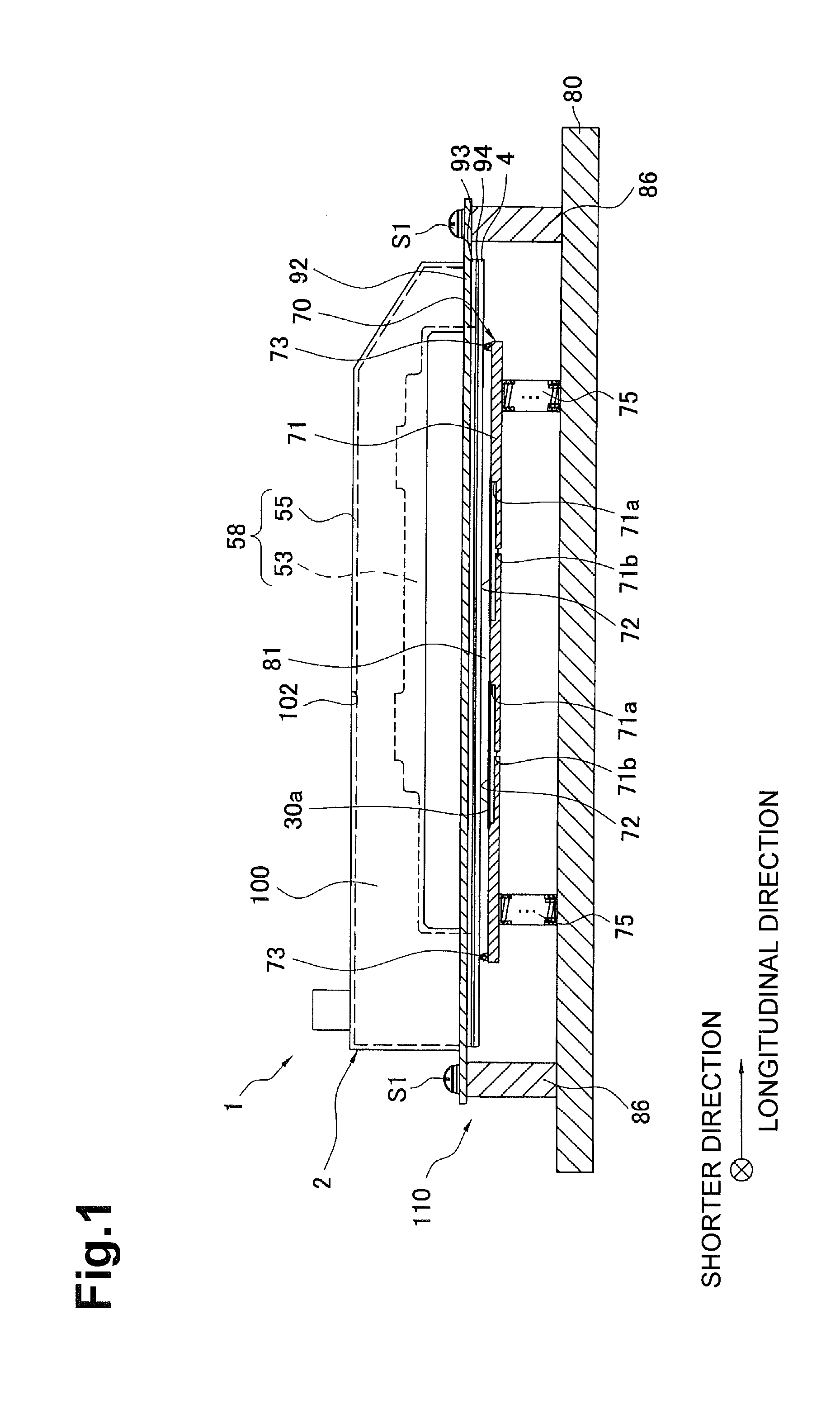

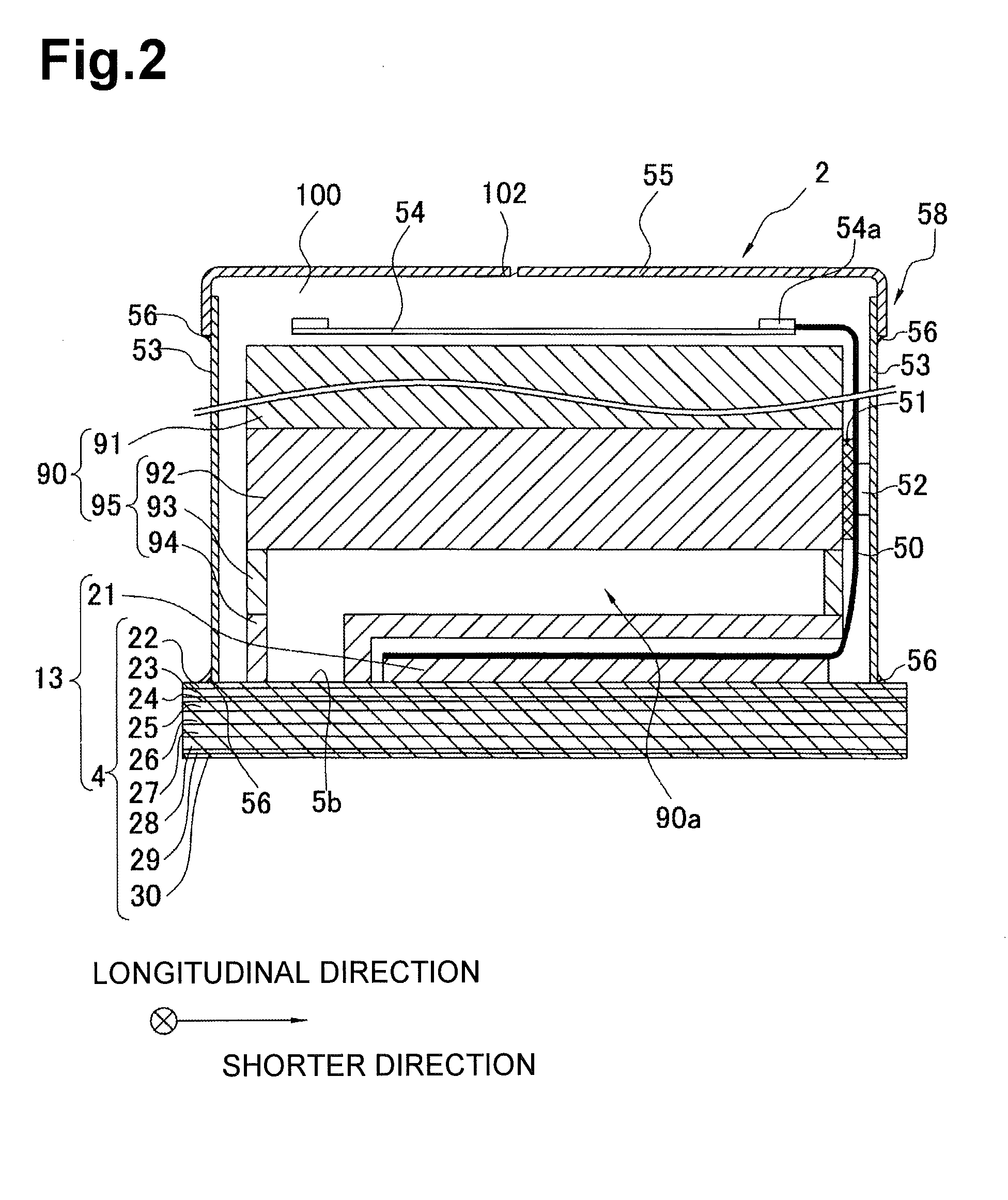

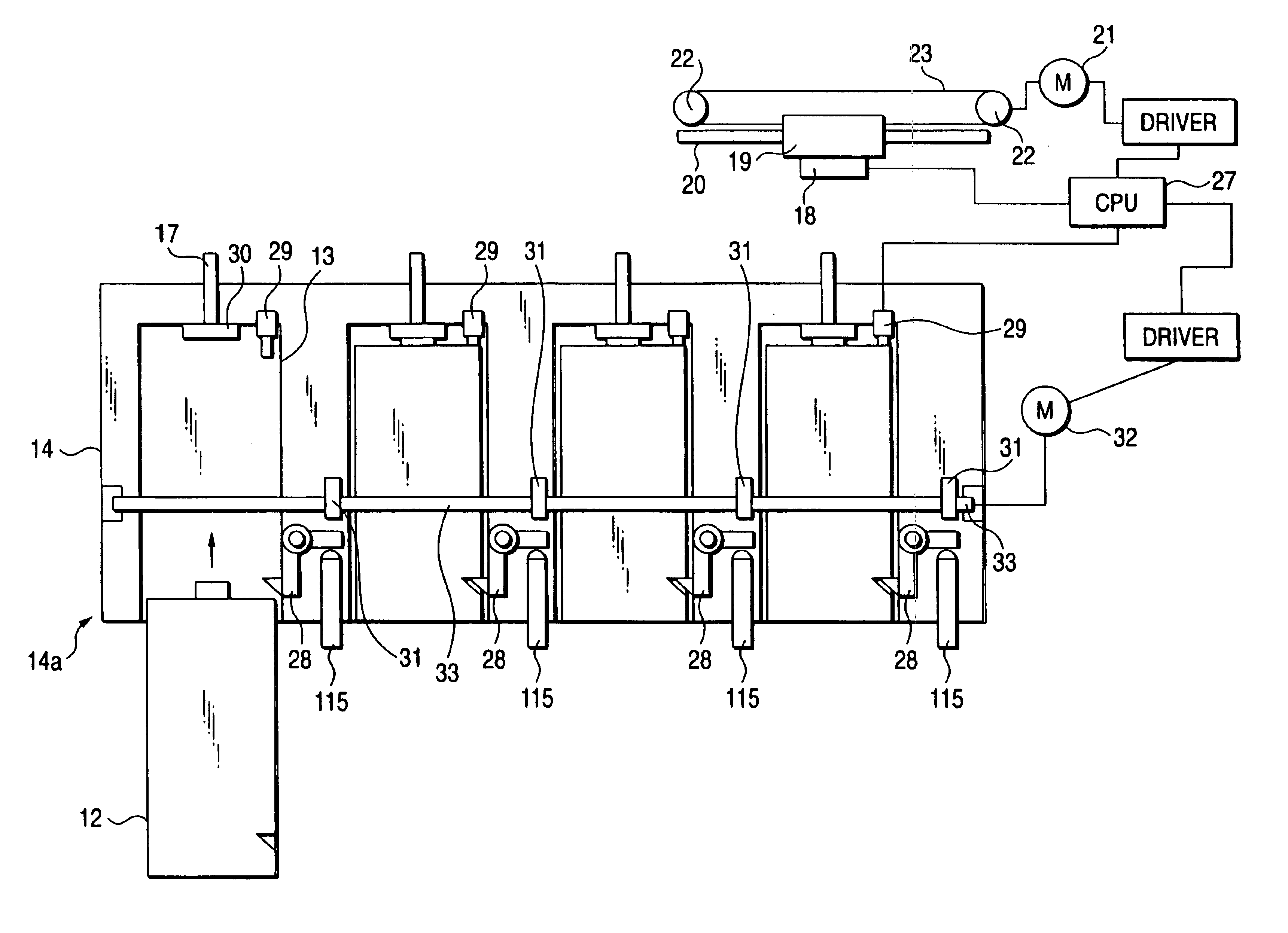

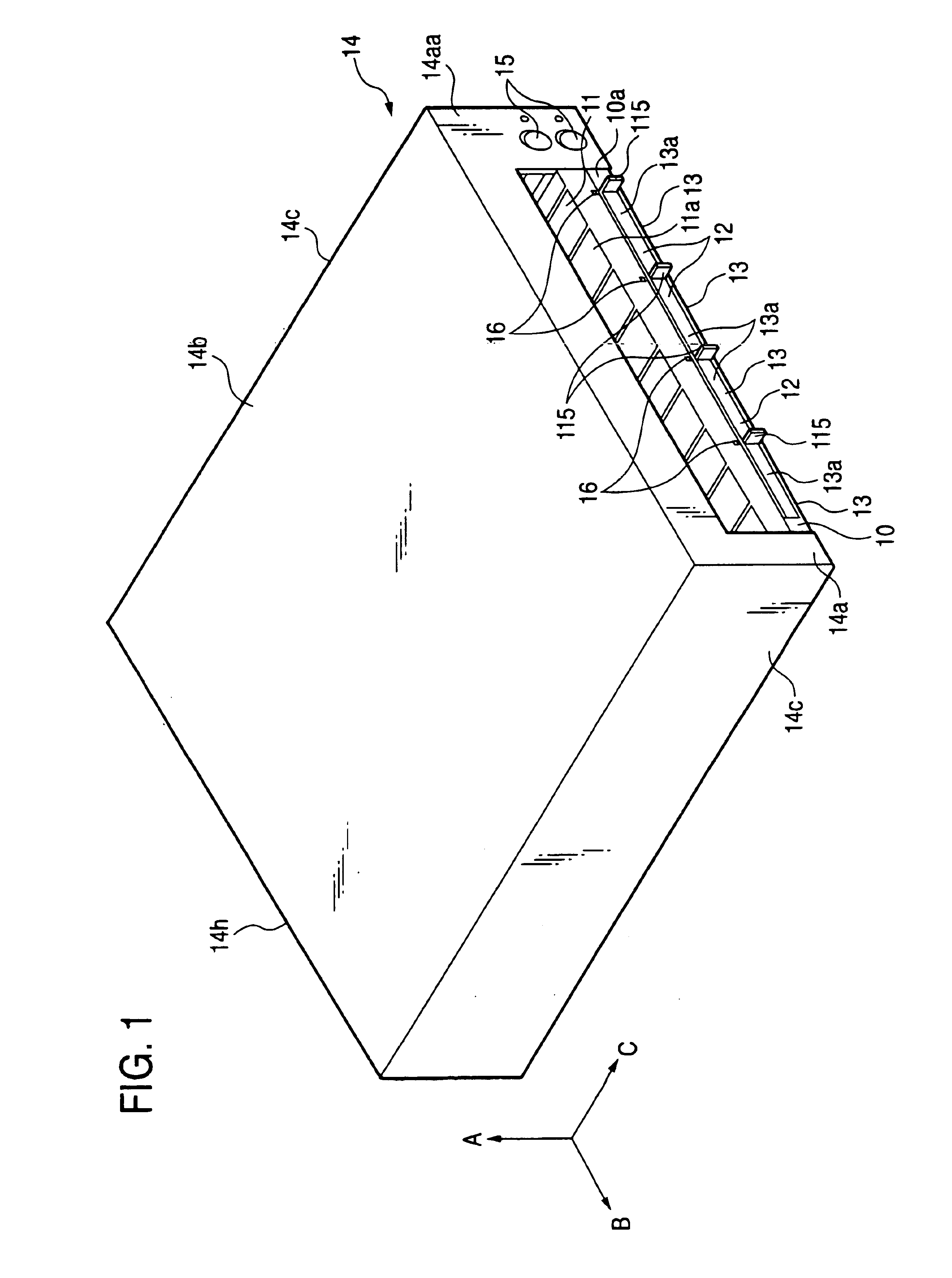

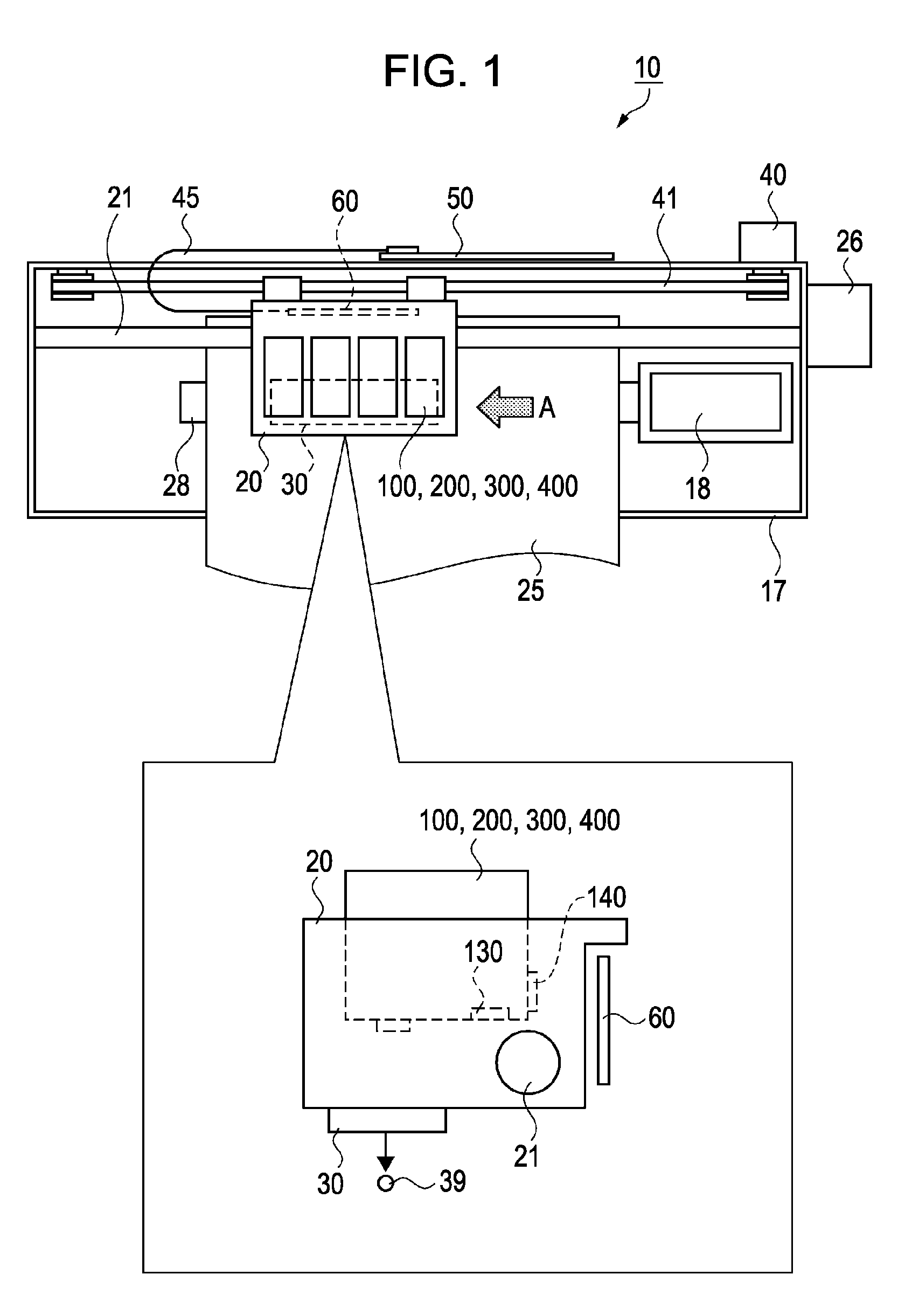

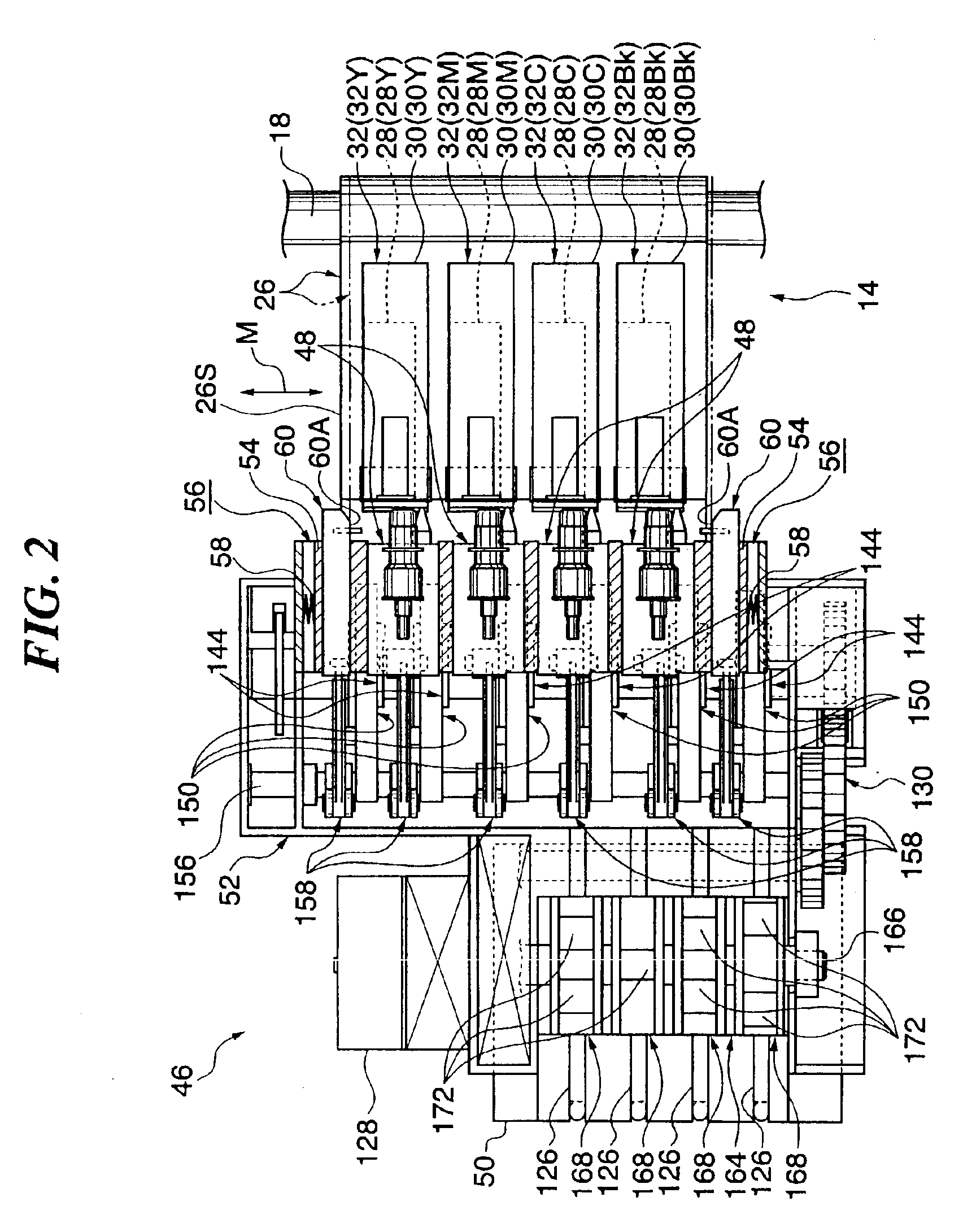

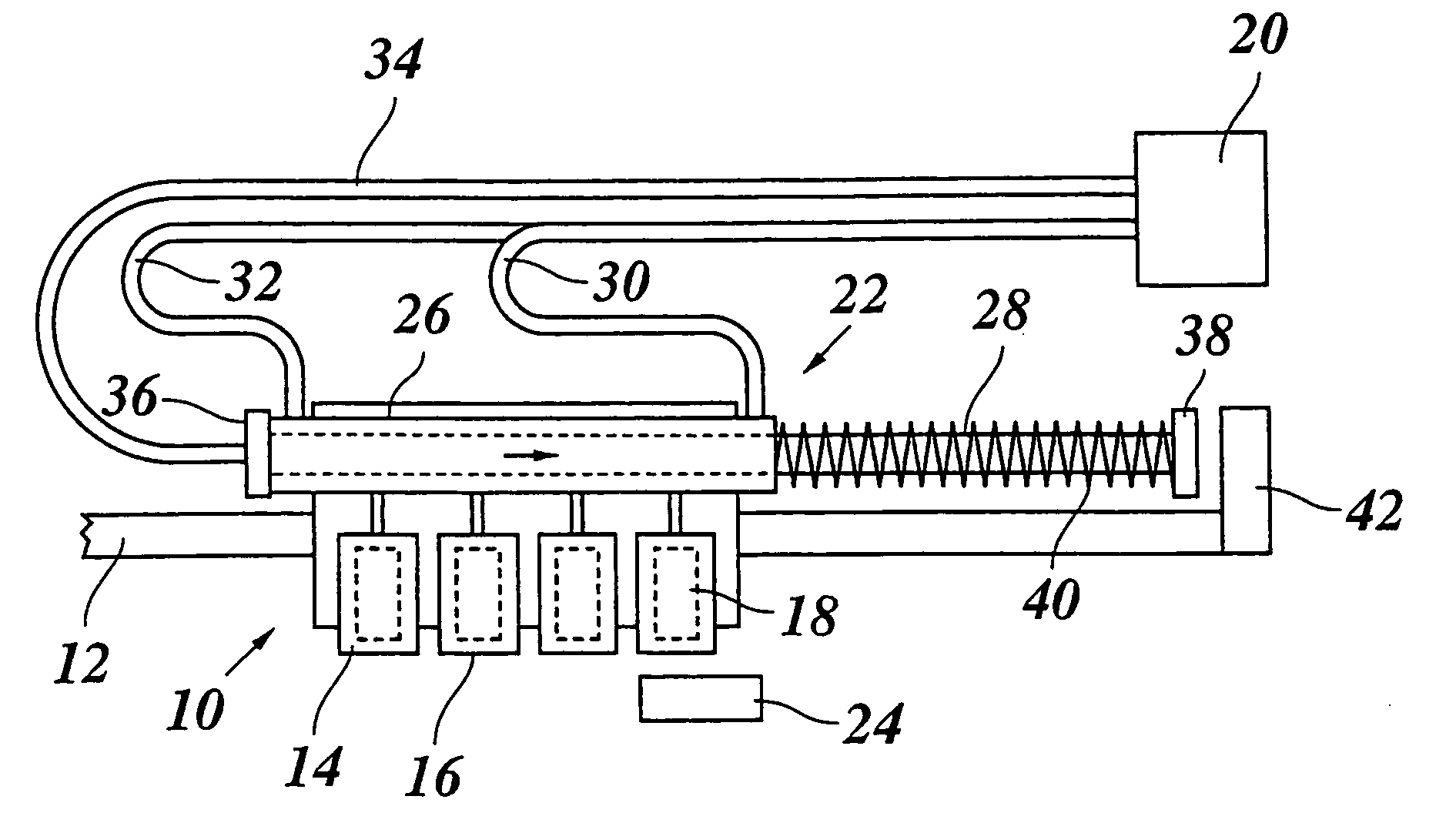

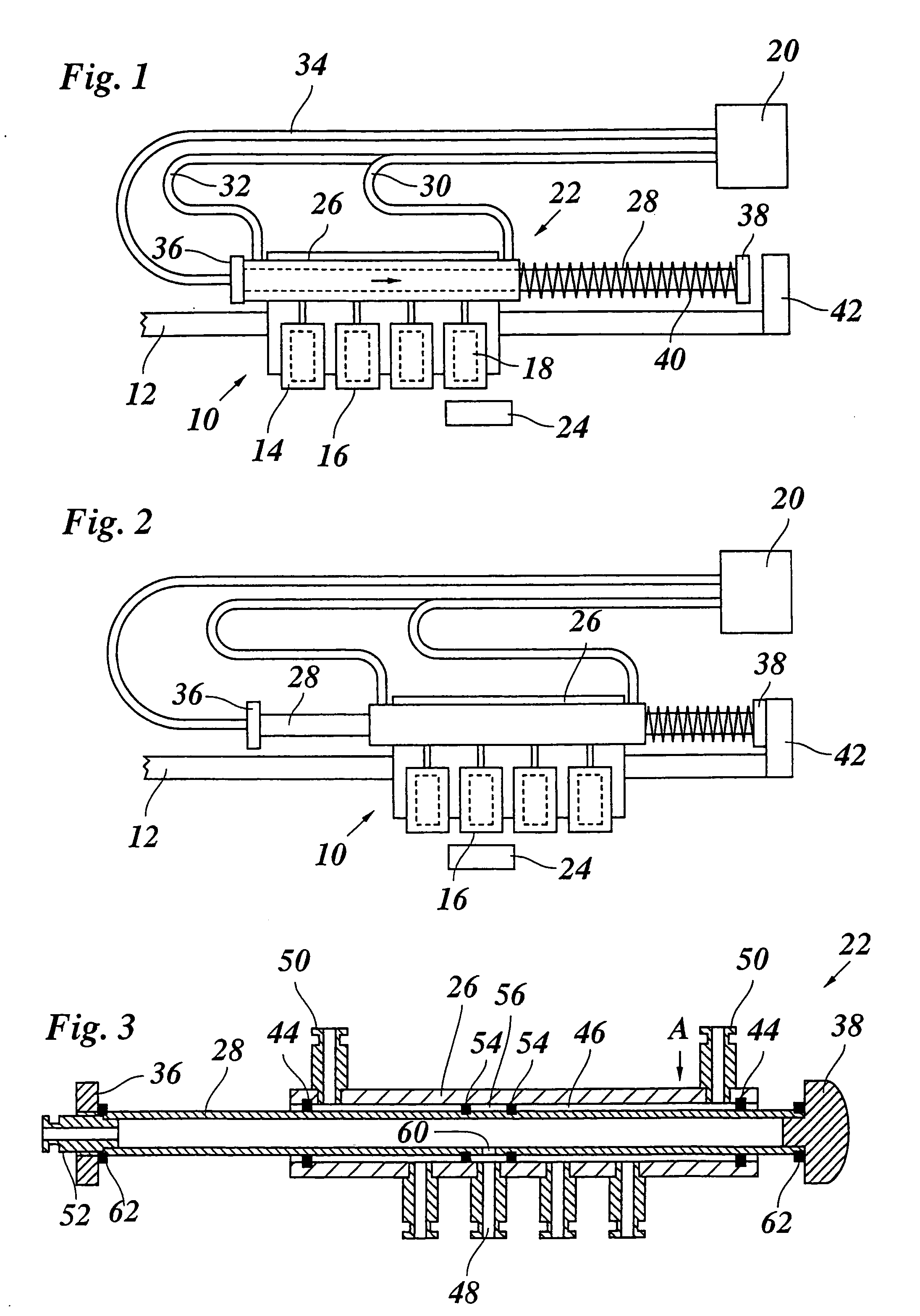

Ink supply device, ink-jet recording device, and method of supplying ink

InactiveUS6905197B2Pressure variationExcellent statePrintingPressure reductionMechanical engineering

An ink supply device is provided in correspondence with a recording head unit. The recording head unit has a recording head that ejects ink drops onto a recording medium on the basis of image information. Additionally the recording head unit has a sub ink tank provided with an air communication hole. The ink supply device includes an ink supply unit that supplies ink to the sub ink tank by reducing pressure on the inside of the sub ink tank through a pressure reduction part. A sealing part at least implements sealing of the air communication hole while the ink supply unit is reducing the pressure inside the sub ink tank.

Owner:FUJIFILM BUSINESS INNOVATION CORP

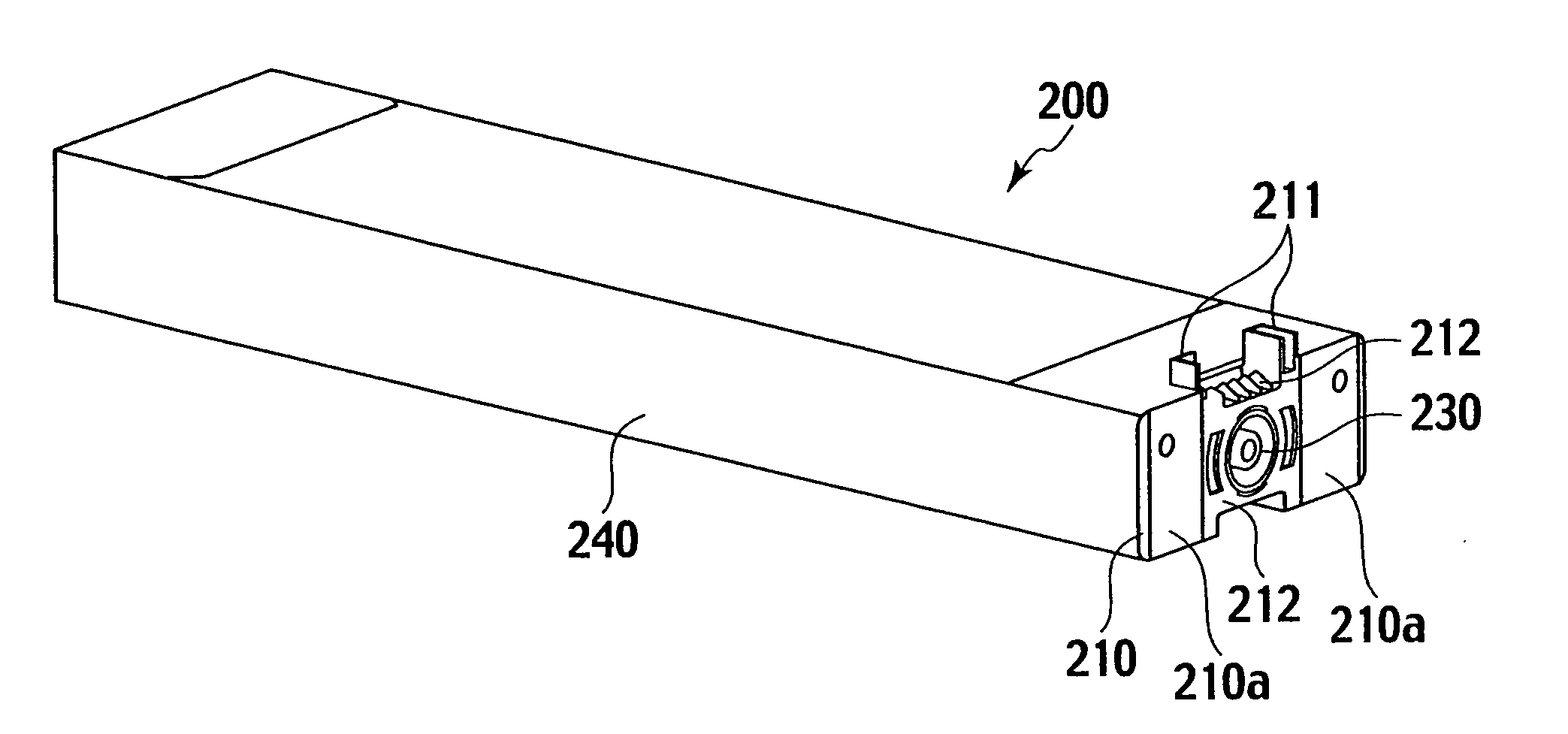

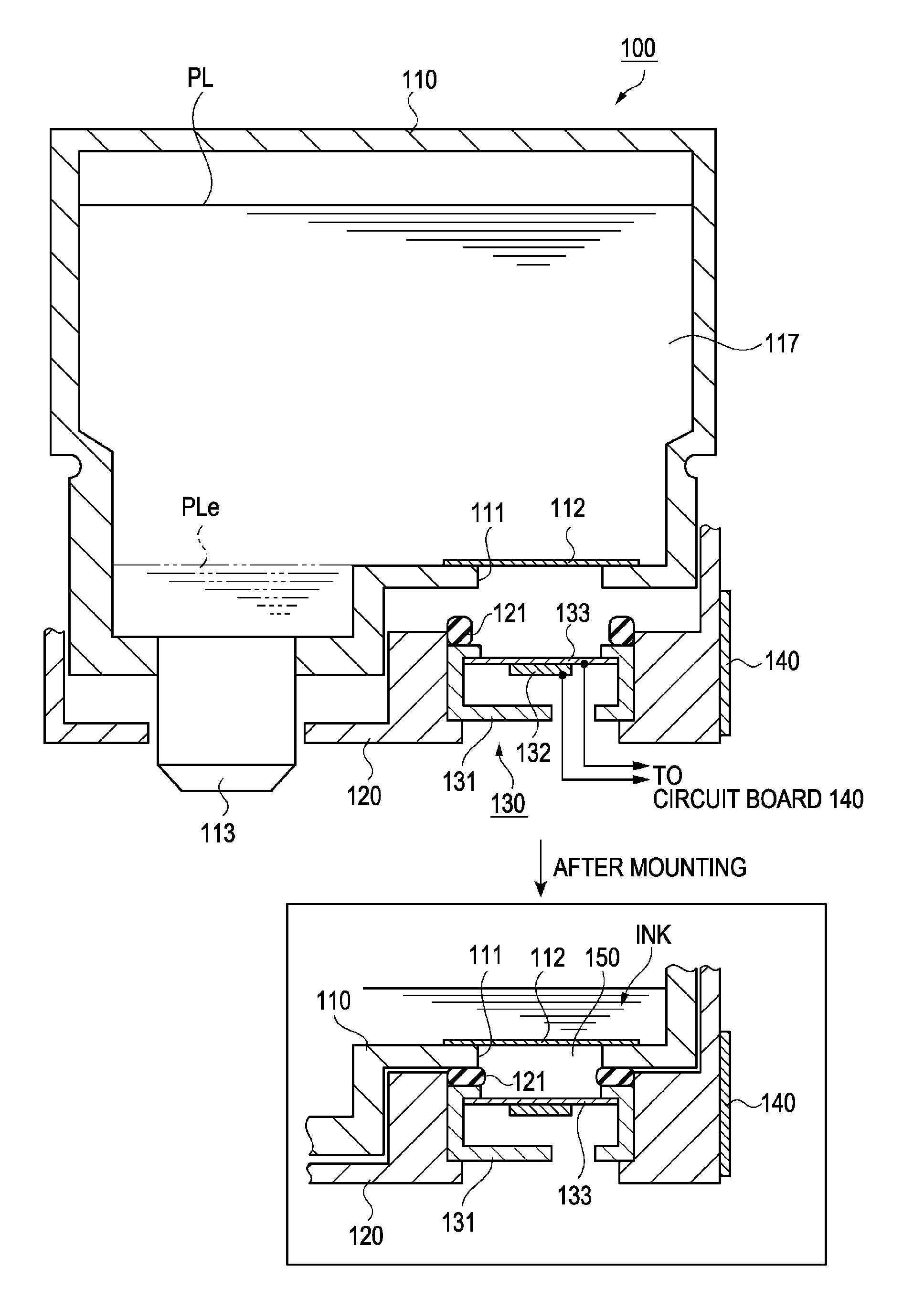

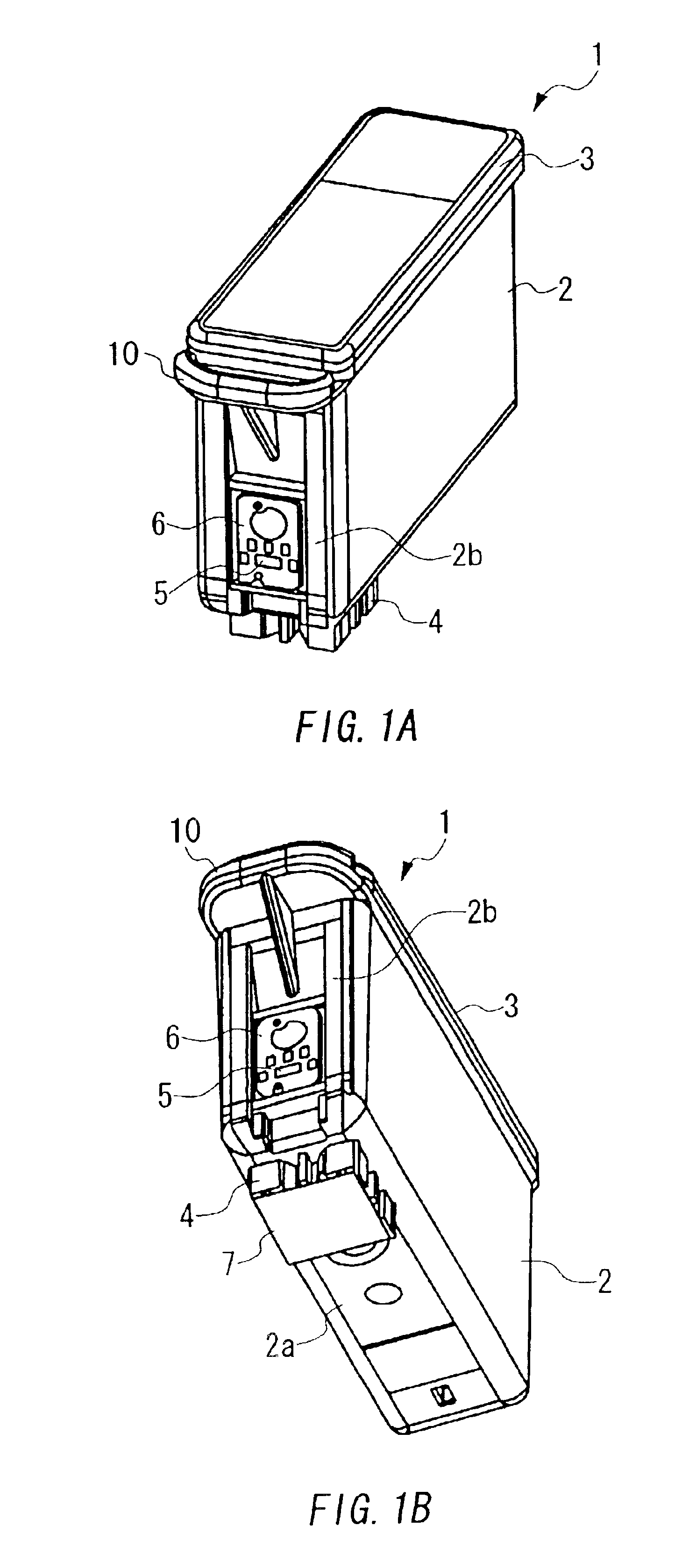

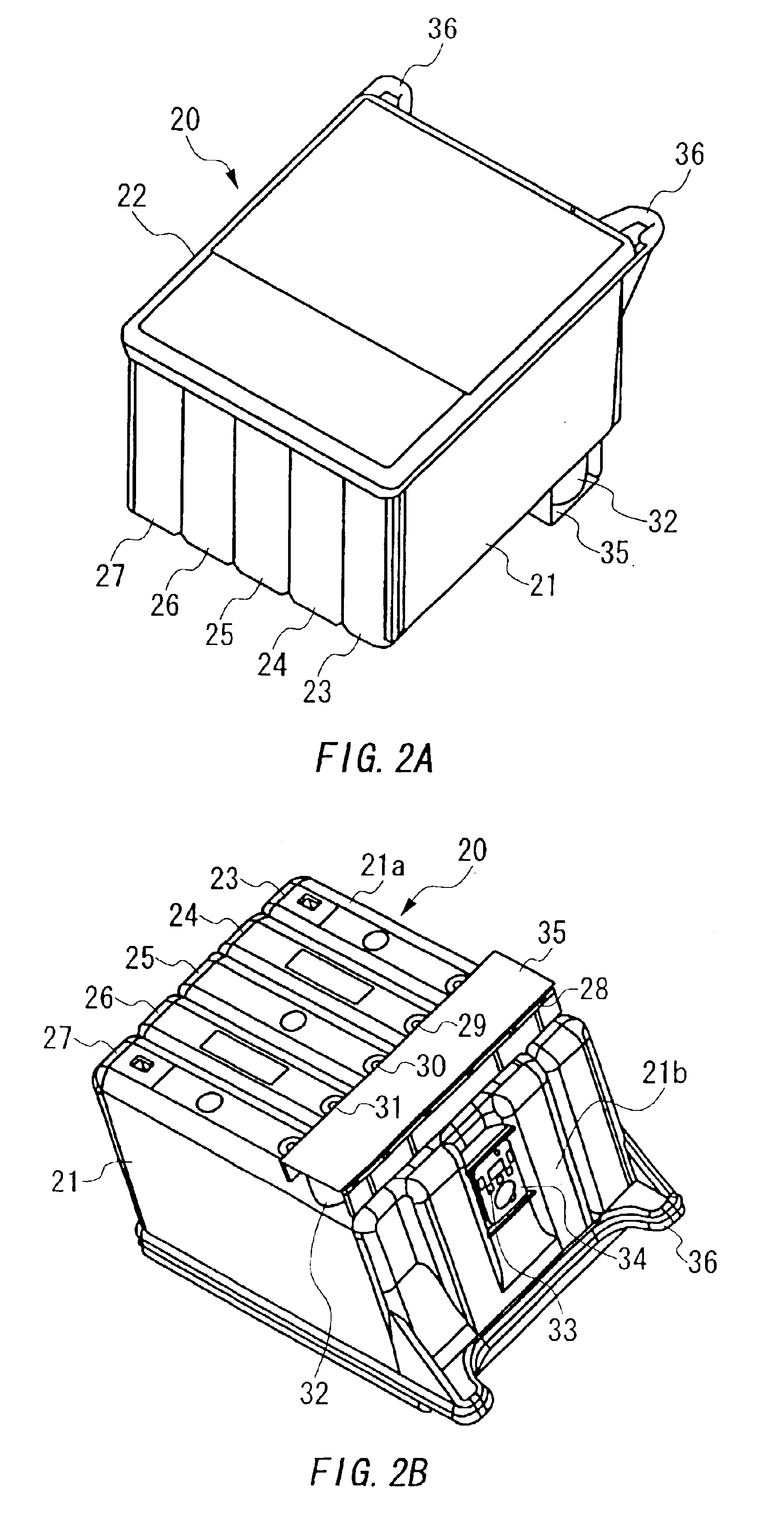

Ink cartridge for ink-jet printing apparatus

InactiveUS6908184B2Prevent inkPrevent ink leakageInk ribbon cartridgesNon-linear opticsInkjet printingVALVE PORT

An ink cartridge for an ink jet printing apparatus having a printhead which ejects ink droplets onto a recording medium and an ink supply needle introducing ink to the printhead, the ink cartridge having a substantially rectangular housing containing ink therein, the housing having a first outer wall and a second outer wall which is substantially perpendicular to the first outer wall; an ink supply port formed in the first wall for directing ink in the housing to the printhead; a valve mechanism arranged in the ink supply port including a valve seat allowing the ink supply needle to pass therethrough; a valve body movable along the axis of the ink supply port; and an elastic member biasing the valve body against the valve seat, and a memory device for storing information relating to ink mounted on the second wall of the housing and substantially in parallel therewith, the memory device being formed in the vicinity of the ink supply port, which wall directing in parallel with a direction along which the ink supply needle is inserted into the valve seat.

Owner:SEIKO EPSON CORP

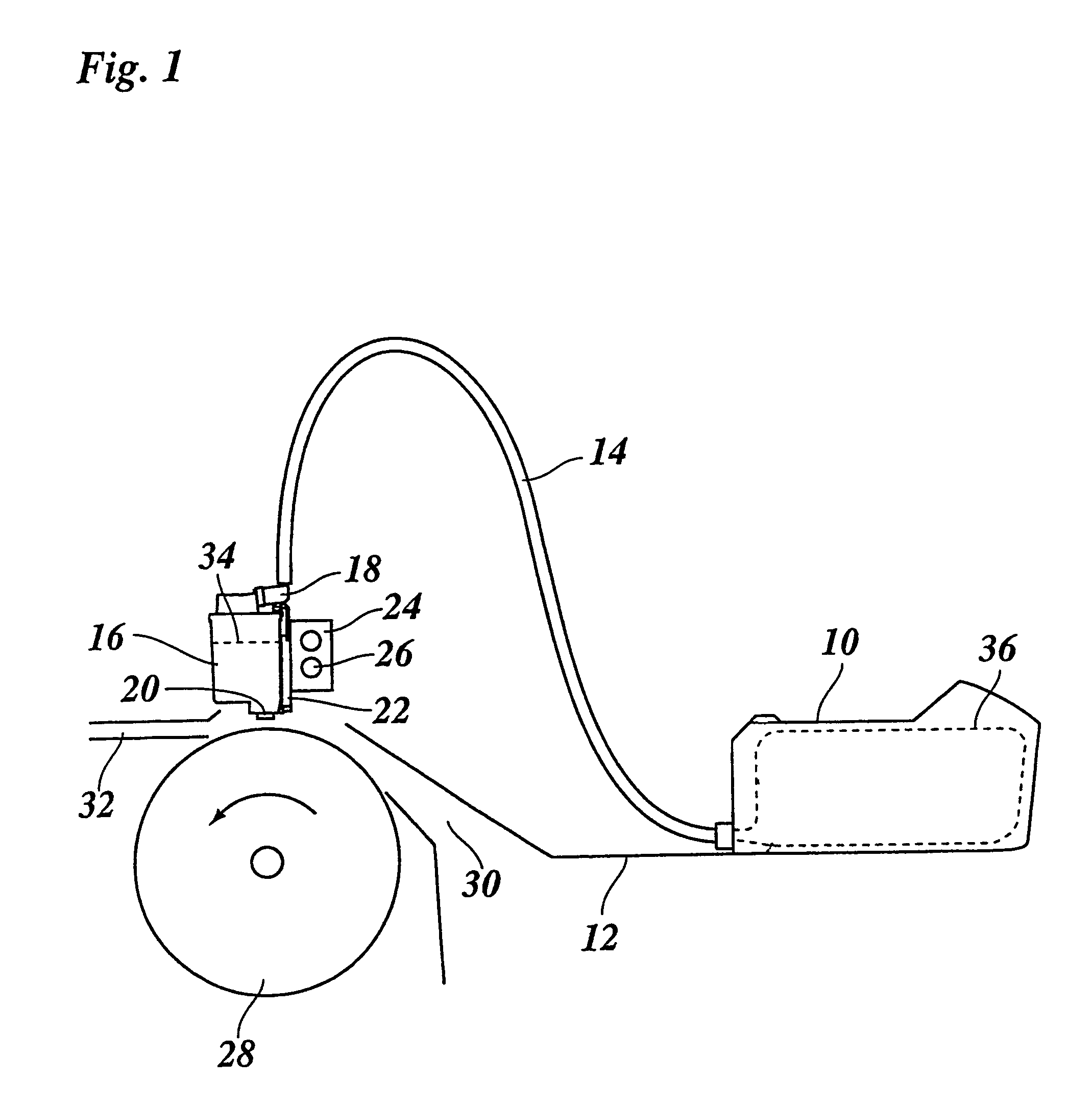

Ink refill unit for docking with an ink cartridge

InactiveUS20050157022A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusPower drive mechanismsEngineering

An ink refill unit 155 is adapted for use with an ink cartridge that has a negatively pressurized ink storage compartment 46 that supplies ink to a printhead assembly 22, and an interface for receiving the refill unit 155. The refill unit has a body 157 containing a quantity of ink and a docking portion with an ink outlet. During use, the docking portion establishes fluid communication between the body and the ink storage compartment through the ink outlet upon releasable engagement with the interface, such that ink is drawn from the body into the cartridge because of the negative pressure in the ink storage compartment. Automatically establishing a fluid connection upon engagement with the cartridge, makes the use of the refill unit very simple and intuitive. Using the negative pressure in the cartridge to draw the ink out of the refill speeds the refilling process.

Owner:MEMJET TECH LTD +1

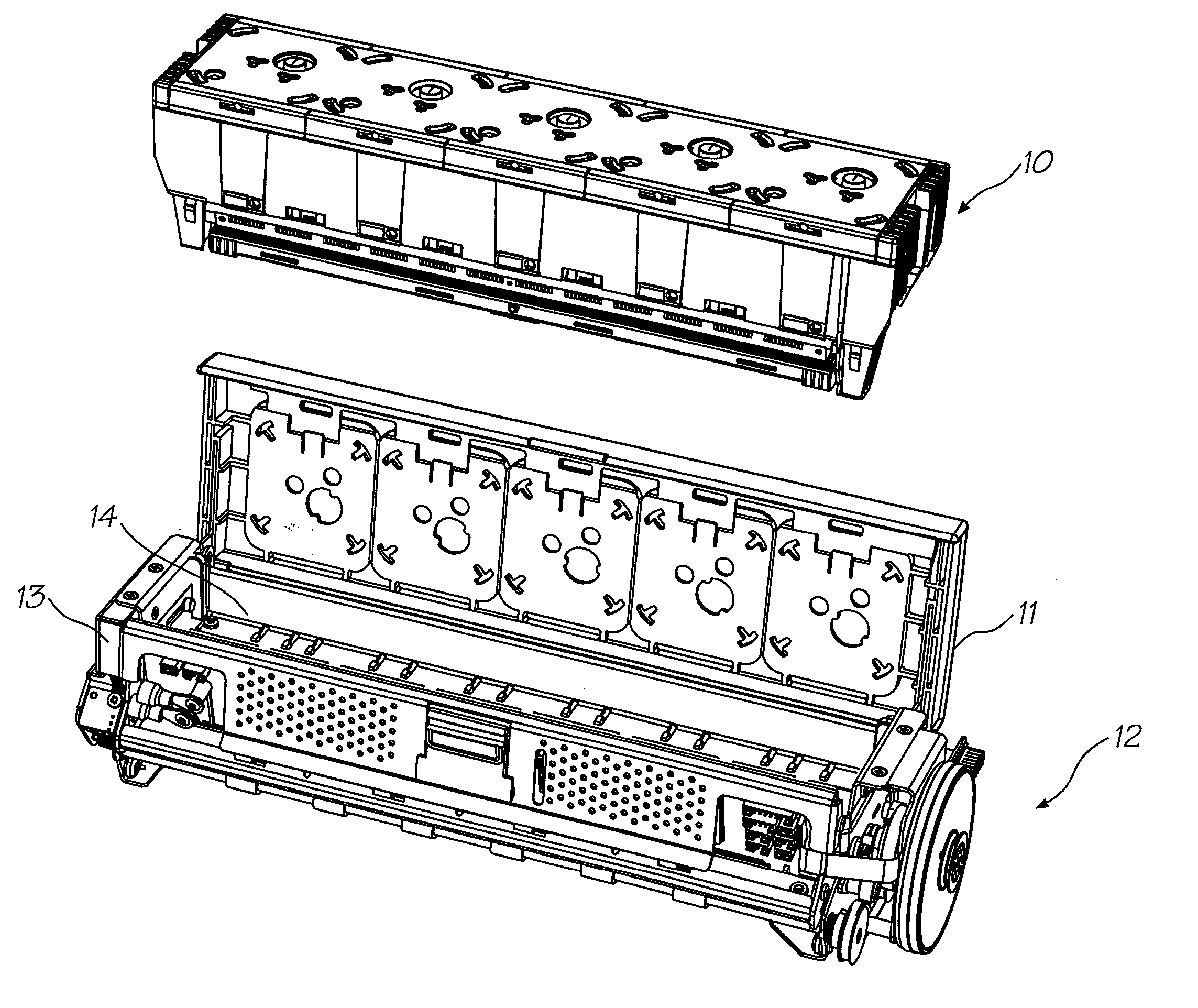

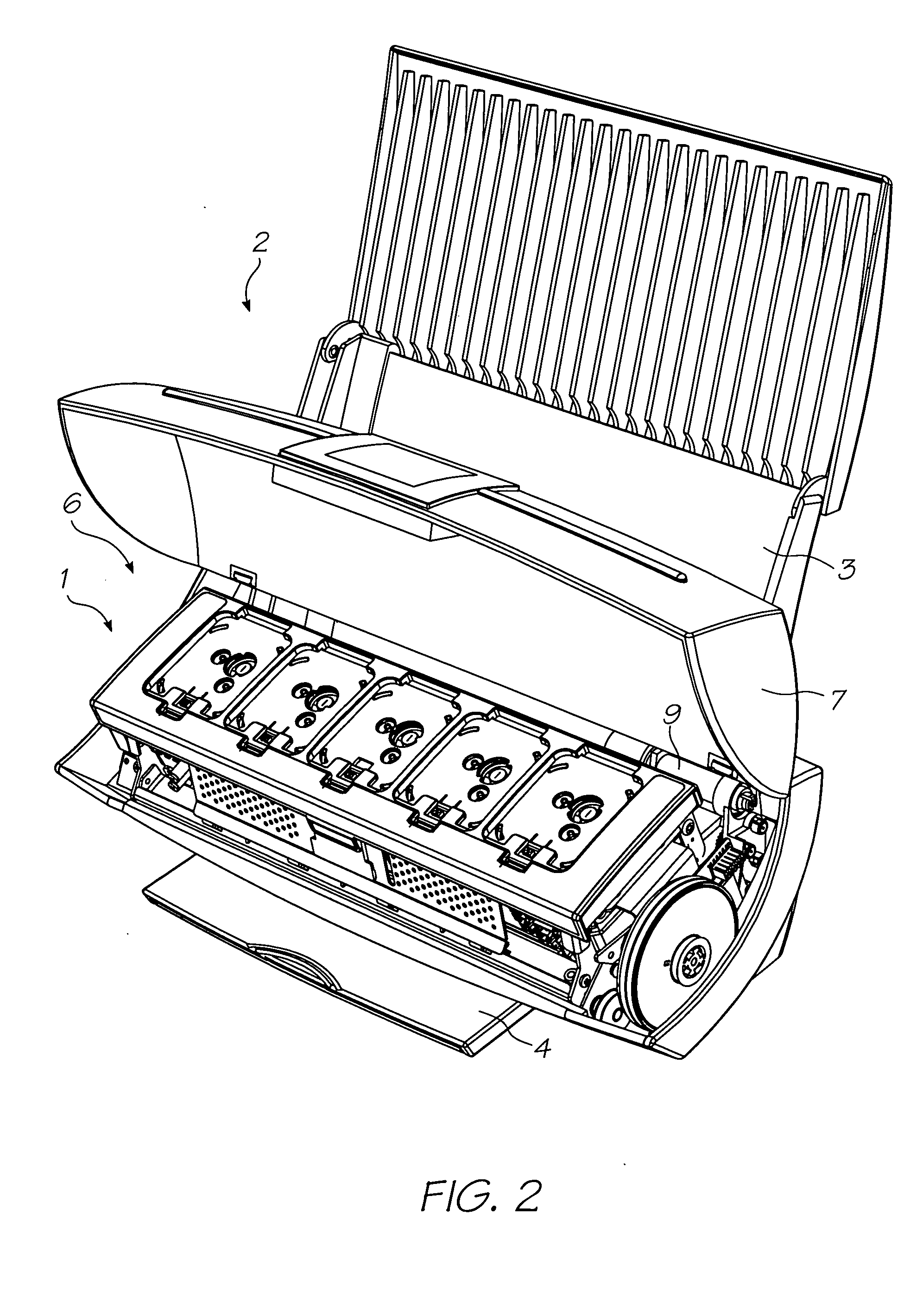

Ink cartridge with printhead maintenance station for inkjet printer

InactiveUS20050157011A1Avoid ink leakagePrevent ink leakageInking apparatusPower drive mechanismsComputer printingInk printer

Owner:MEMJET TECH LTD

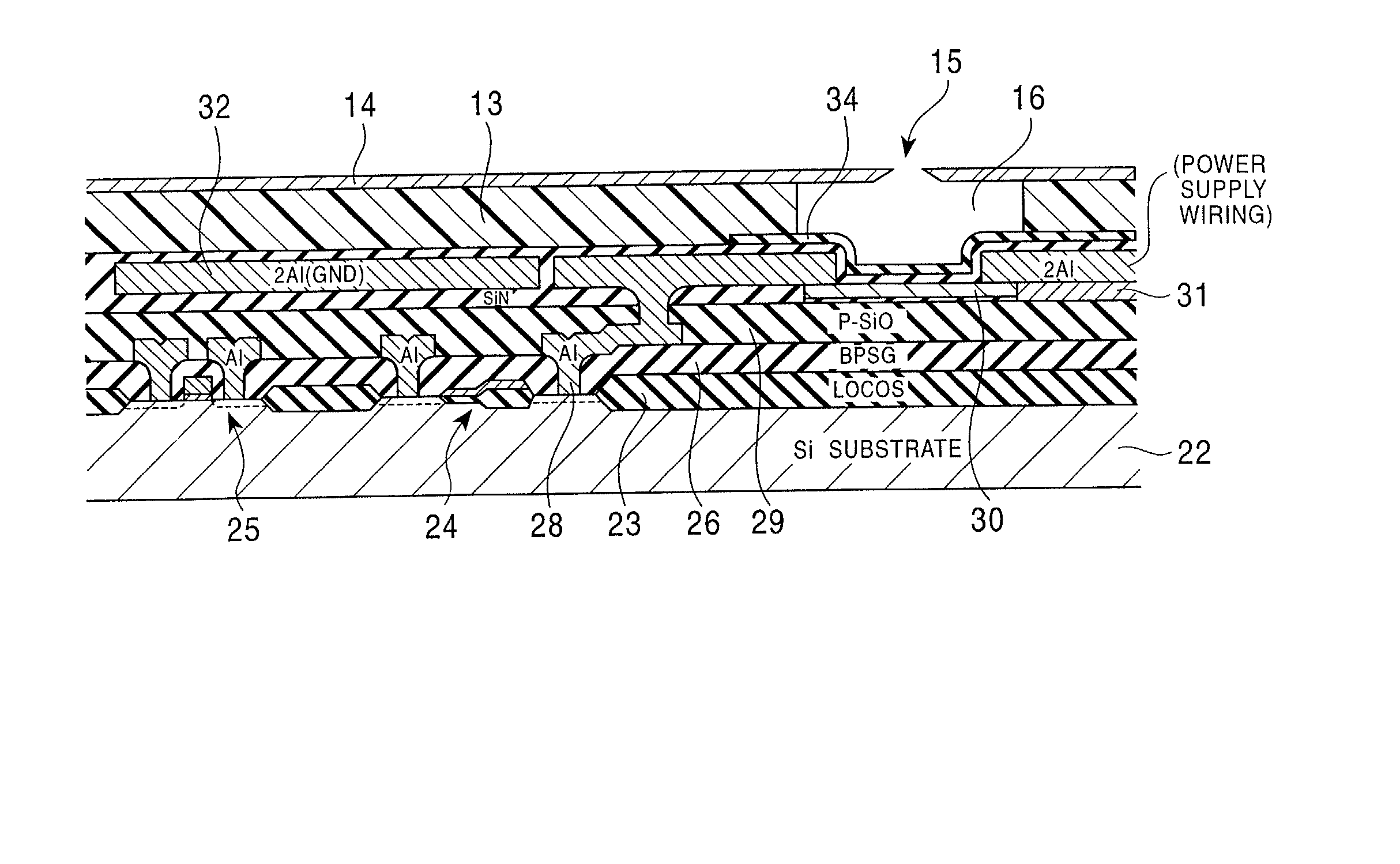

Printer, Printer head, and method of producing the printer head

InactiveUS20020126181A1Avoid formingSimple structureInking apparatusVena contracta diameterEngineering

The invention provides a printer, a printer head, and a method of producing the printer head. In particular, the invention is applied to a printer which makes use of a process in which ink drops are caused to flow out by heating using a heater, so that an orifice plate can be bonded by sufficiently bringing it into close contact with what it is to be bonded to. In the invention, by disposing first, second, and third wiring patterns below partitions of corresponding ink chambers, thickness-direction stepped portions are prevented from being formed at at least the partitions of the corresponding ink chambers.

Owner:SONY CORP

Nozzle cleaning device for an ink jet printer

A nozzle cleaning device for an ink jet printer containing a plurality of ink reservoirs, the cleaning device including a pressure source and a valve mechanism for selectively coupling the pressure source to the ink reservoirs, wherein the valve mechanism comprises a valve housing, and a piston movable within the valve housing and defining therewith a first pressure chamber and a second pressure chamber, said first and second pressure chamber being connected to the pressure source such that during idle conditions, the pressure source is in communication with the ink reservoirs through said first pressure chamber, and during cleaning conditions and through the movement of the piston, the pressure source is in selective communication with individual ink reservoirs through said second pressure chamber.

Owner:OCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com