Patents

Literature

135results about "Filling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

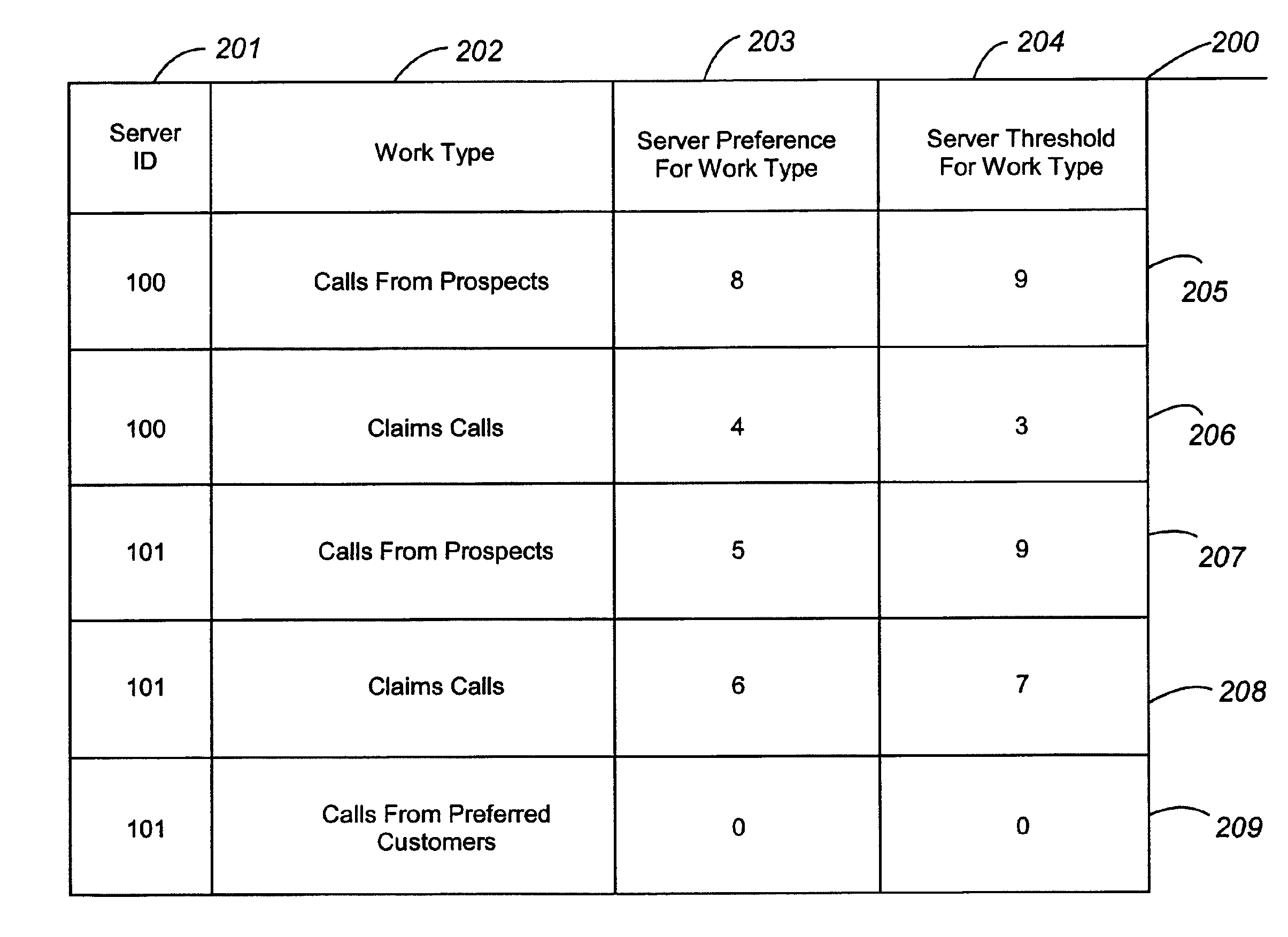

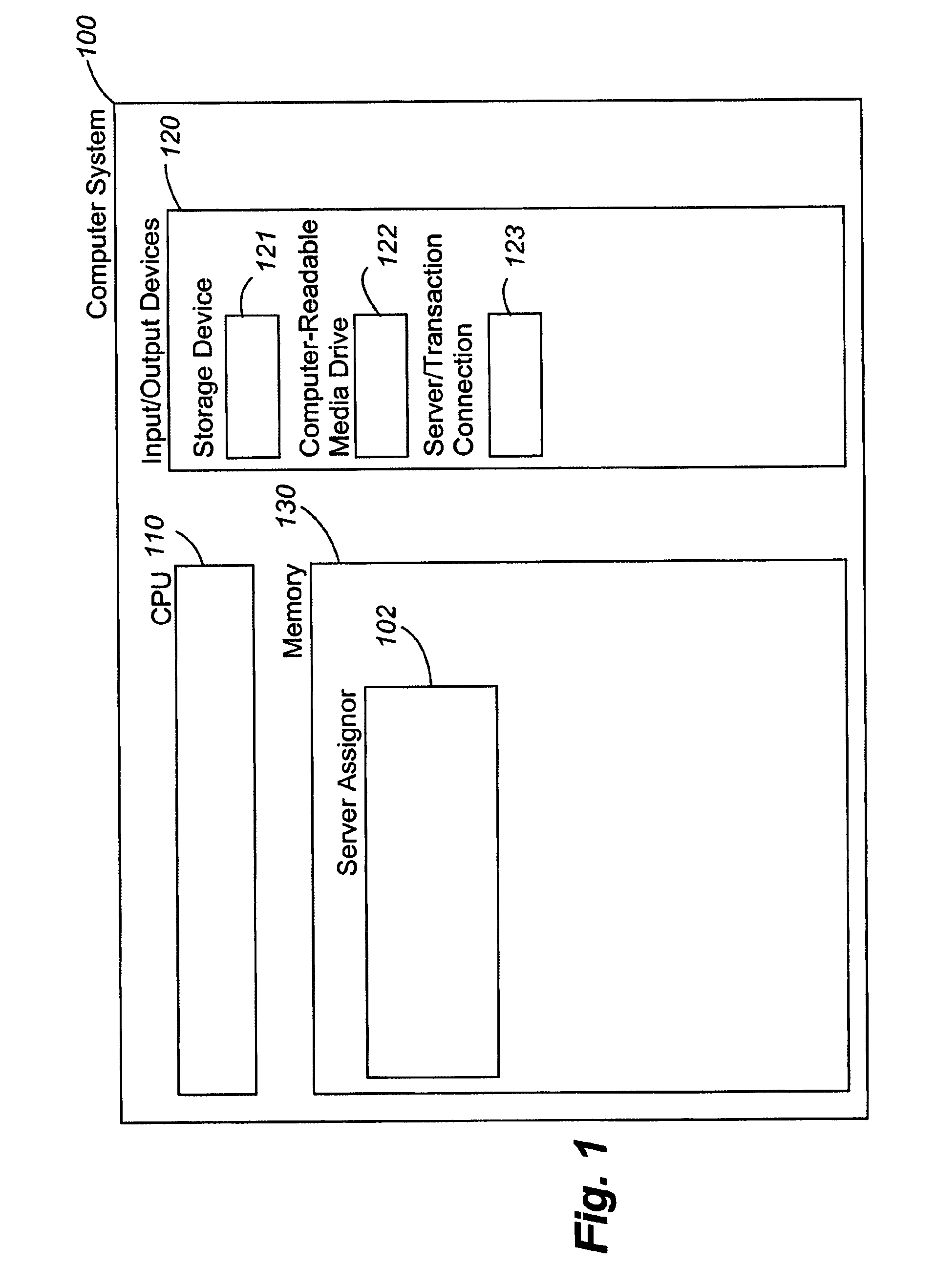

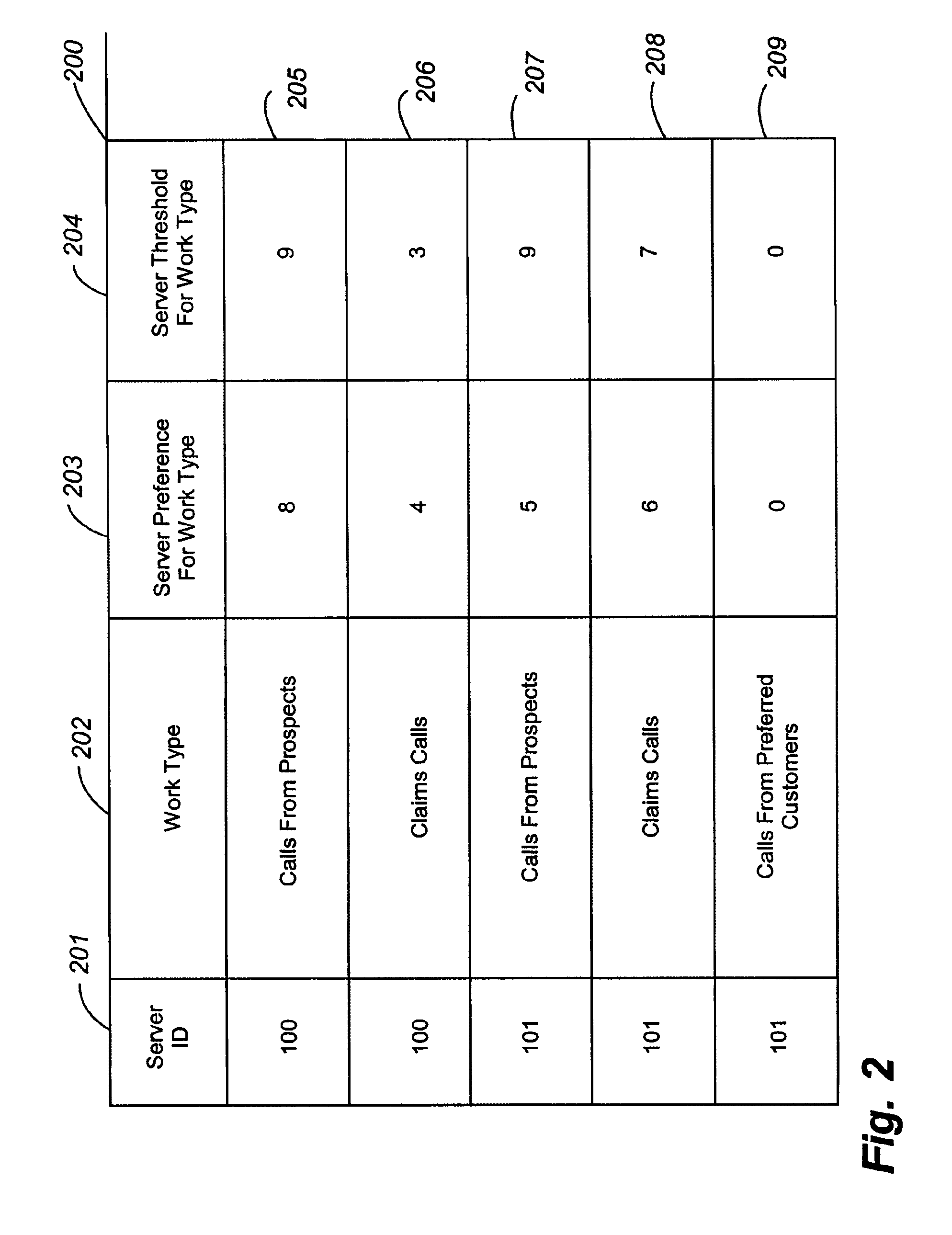

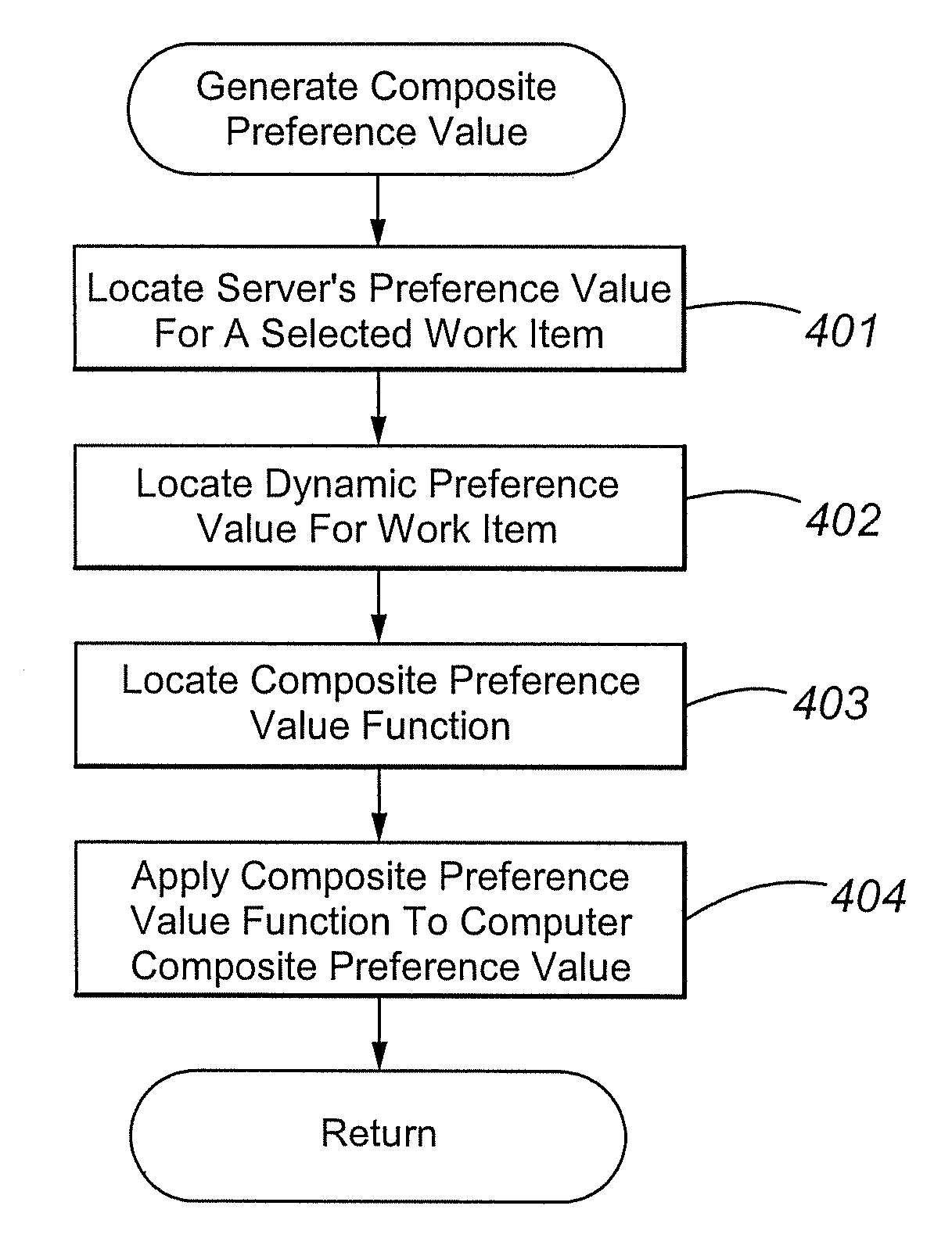

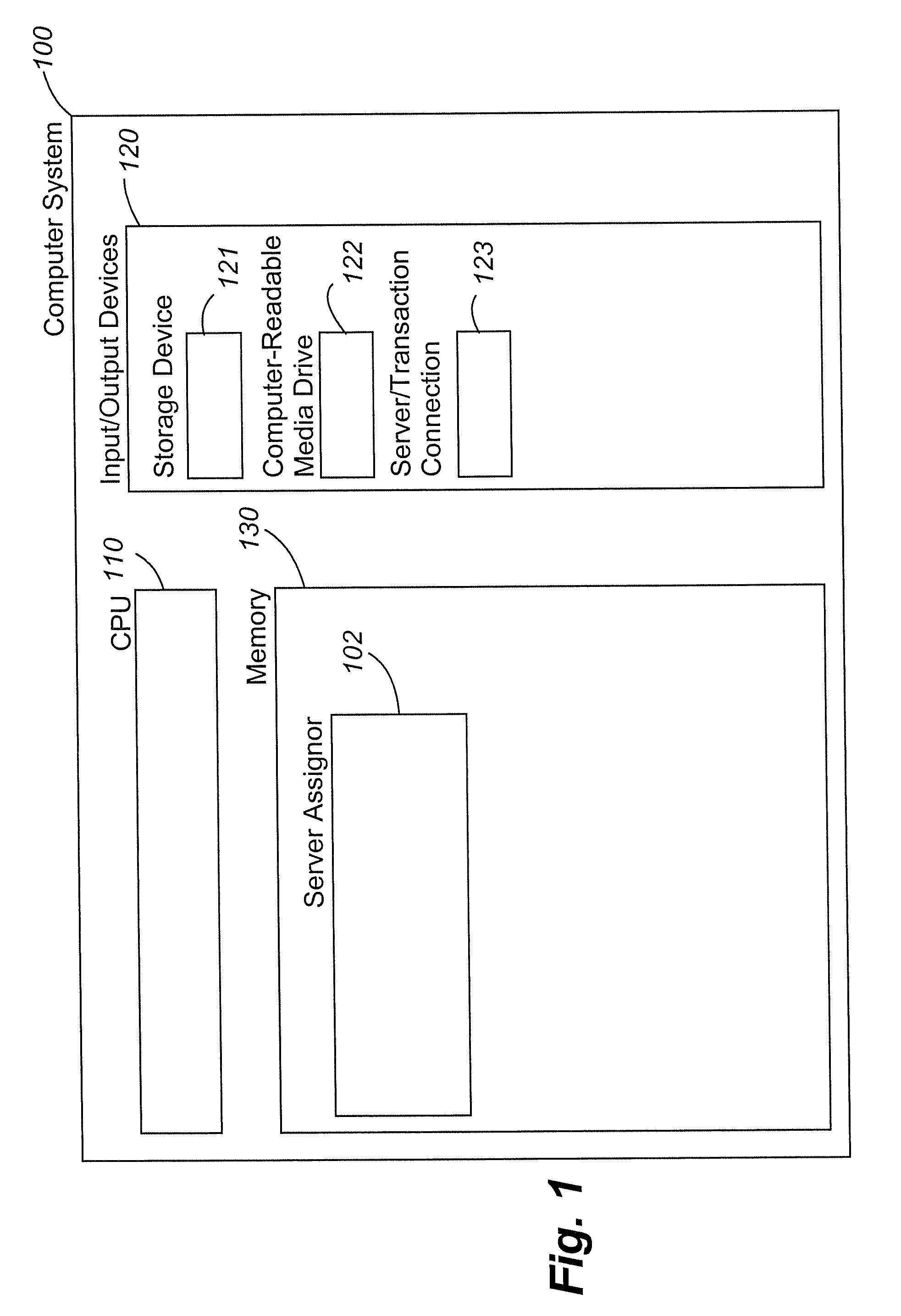

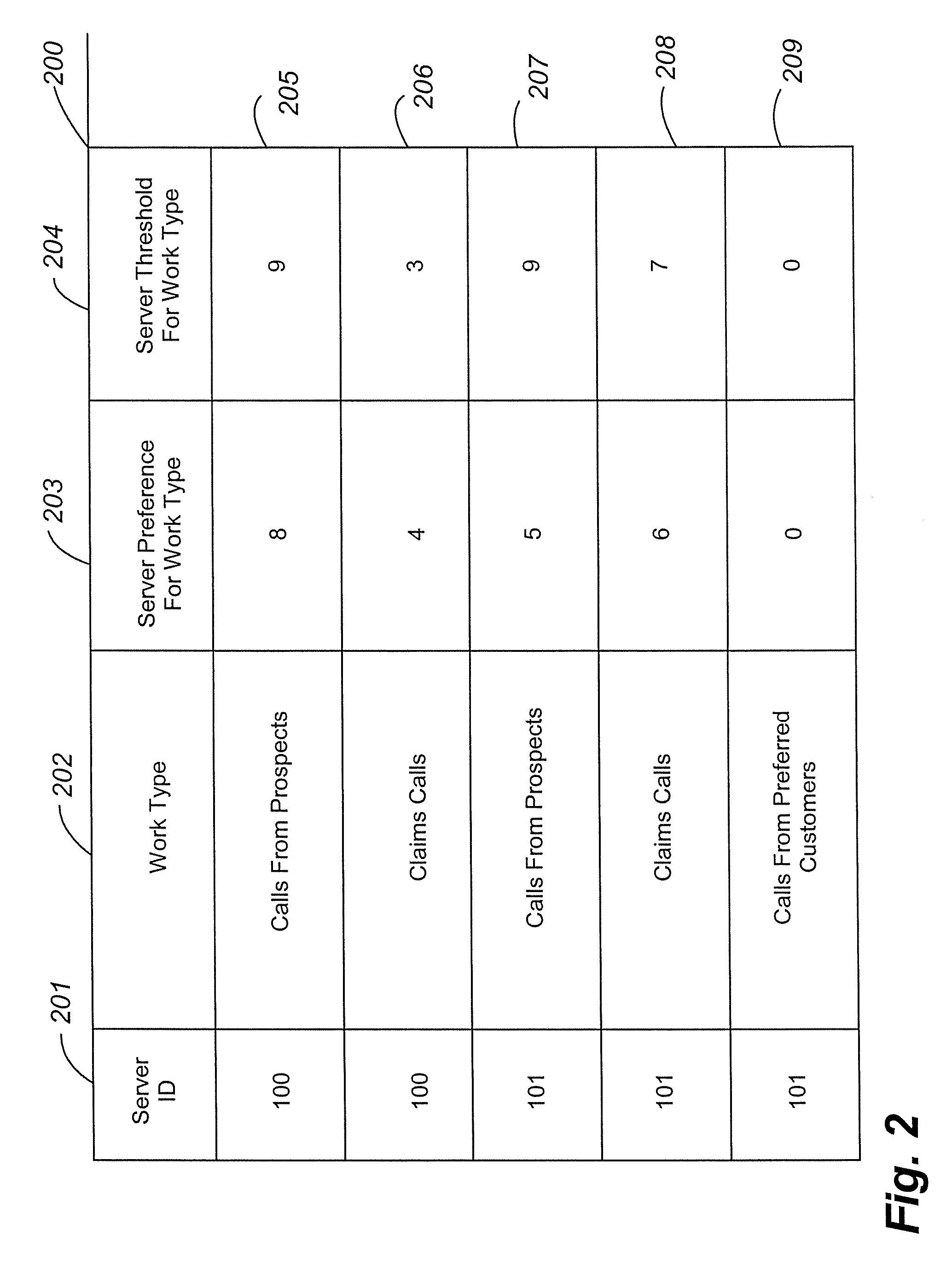

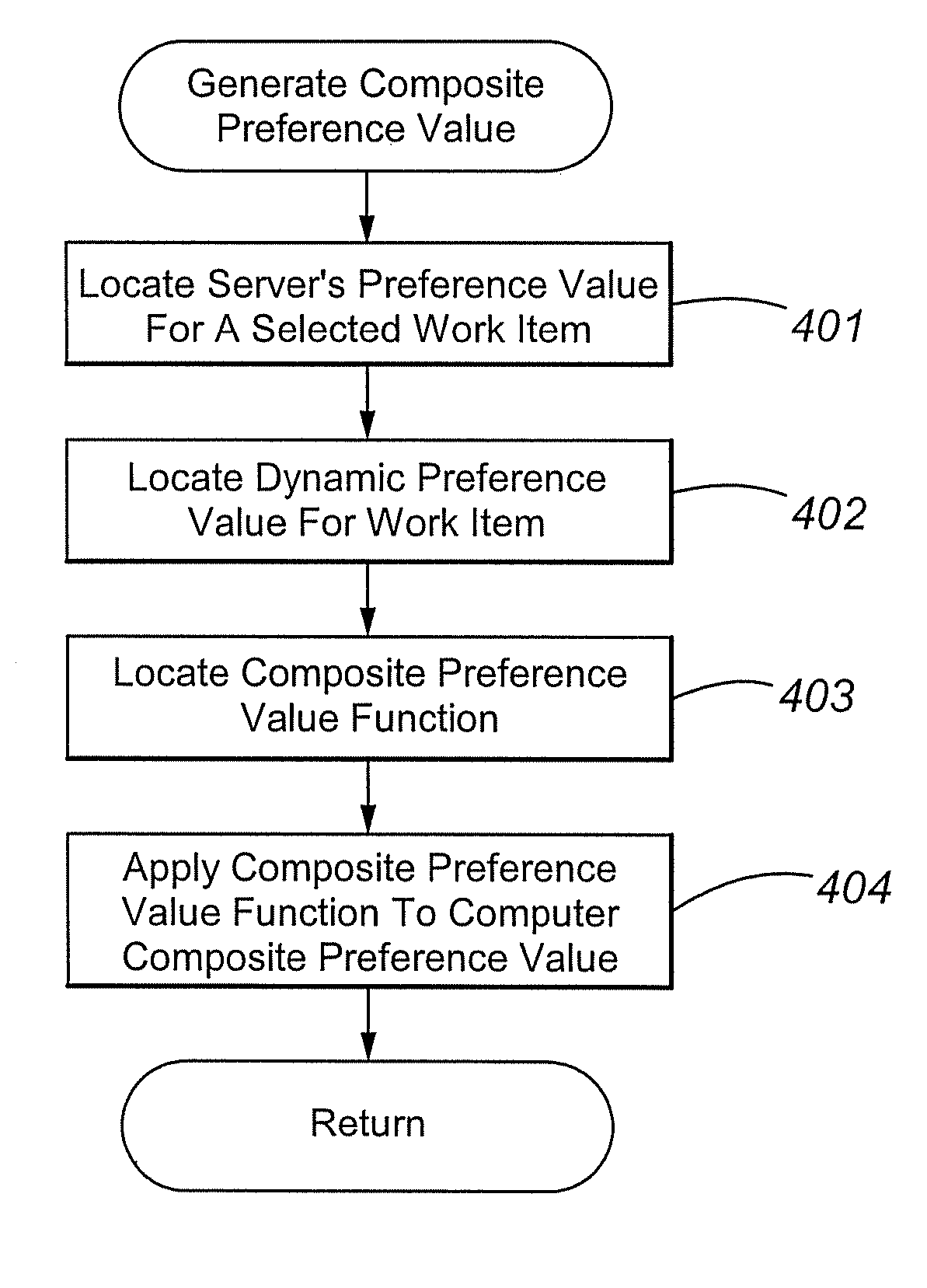

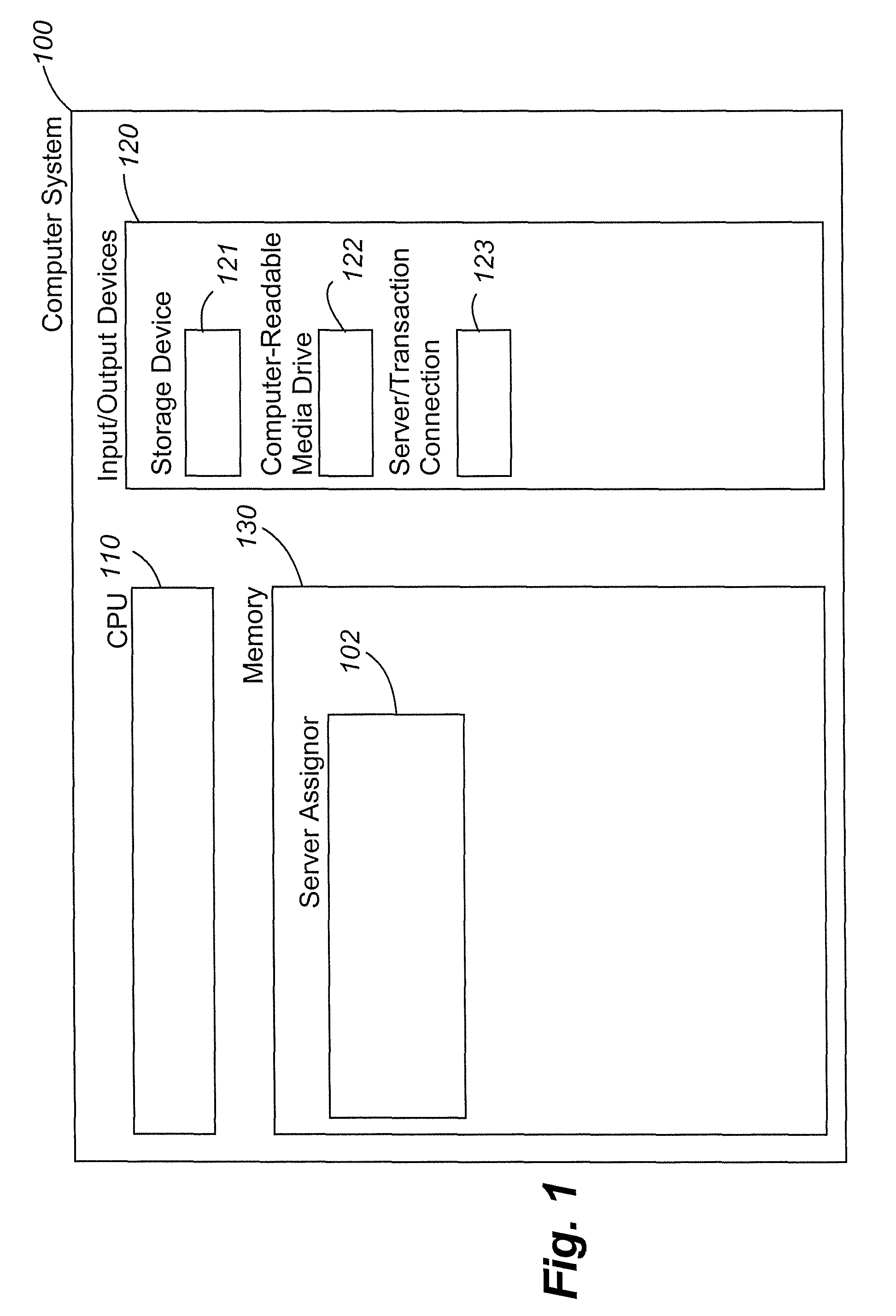

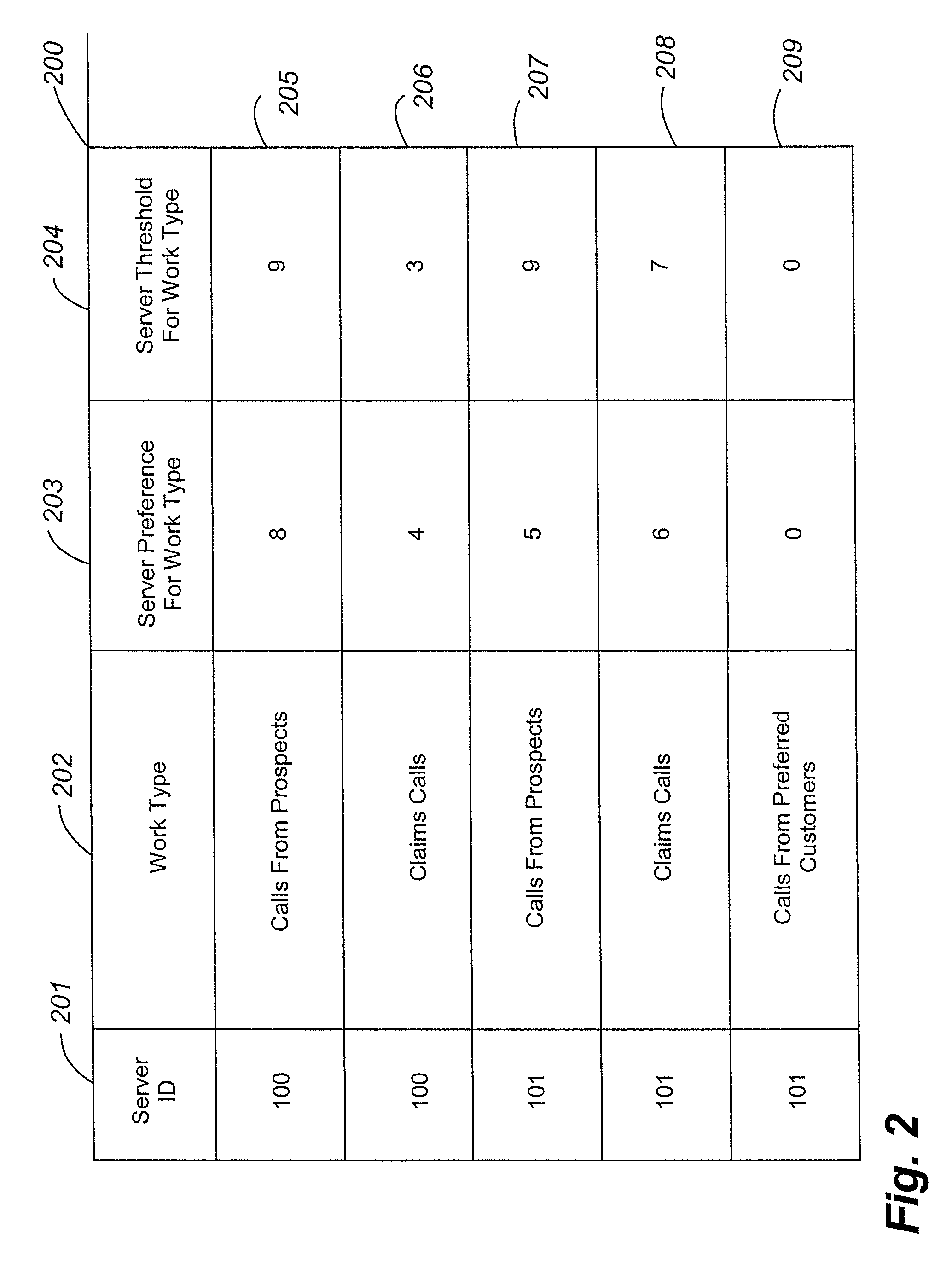

Dynamically allocating server resources to competing classes of work based upon achievement of service goals

A facility for adjusting a number of servers assigned to server pools for performing certain work types on the basis of unmet service needs in a work processing facility. Servers may include service agents, both human and robotic. A server assignor and corresponding server assignment method may each be employed in a work distributor or an automatic call distributor (“ACD”) to conditionally adjust server availability in server pools. The server assignor compares a composite preference value for a work type against each server's threshold value for the work type. When the server assignor determines that the composite preference value is greater than or equal to a server's threshold value, then the server assignor indicates that the server may be included in the server pool for that work type. Each server has preference values and threshold values for different kinds of work. The magnitude of a preference value represents an affinity for the work type. The server's threshold value represents a reluctance to perform work having that work type. The server does not normally receive work for which the preference value is less than the threshold value, unless the server assignor determines that the composite preference value exceeds the server's threshold value for that work type. The server assignor and corresponding server assignment method may compute the composite preference value from a number of user-selectable inputs and utilize a number of user-selectable functions.

Owner:AVAYA TECH CORP

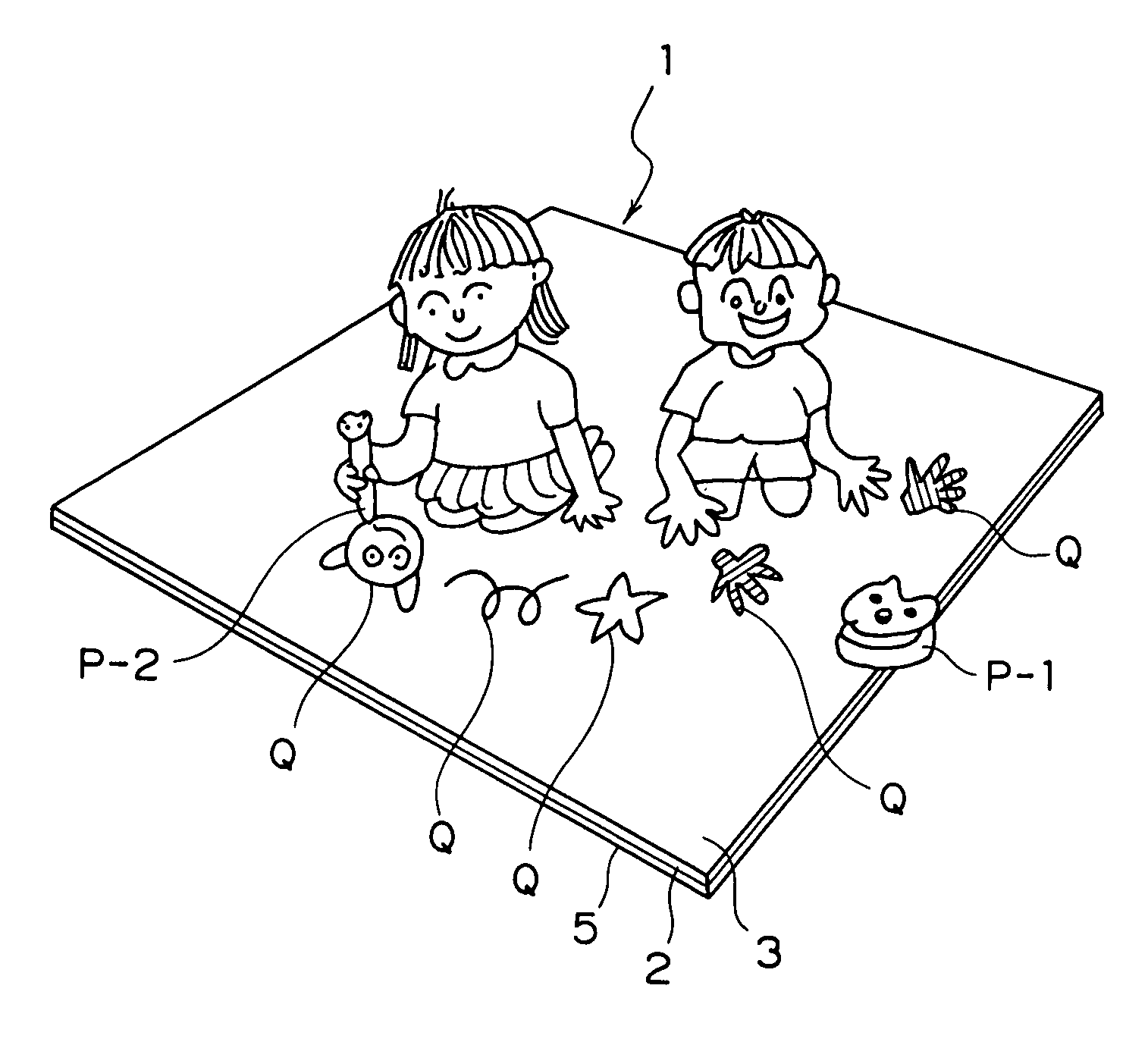

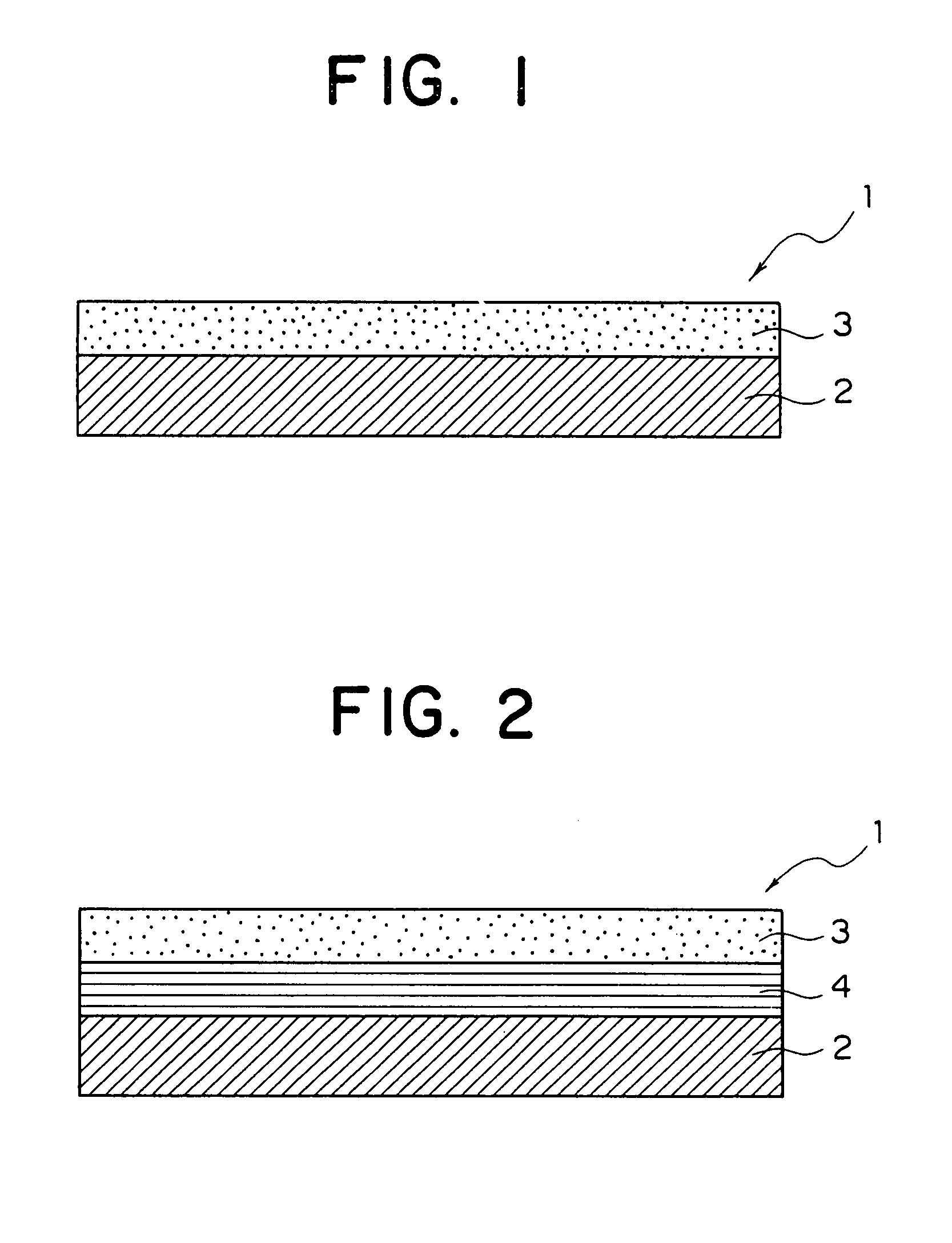

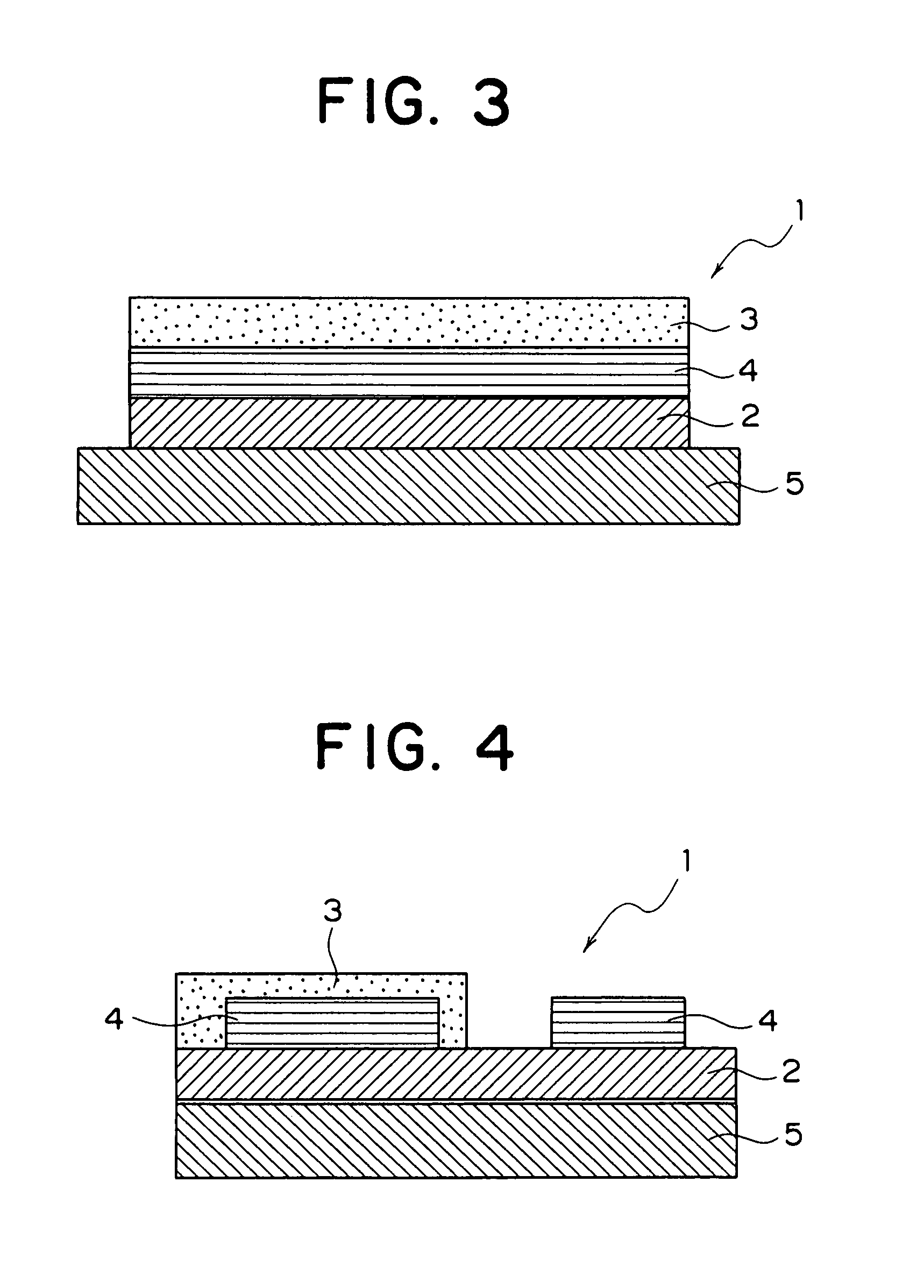

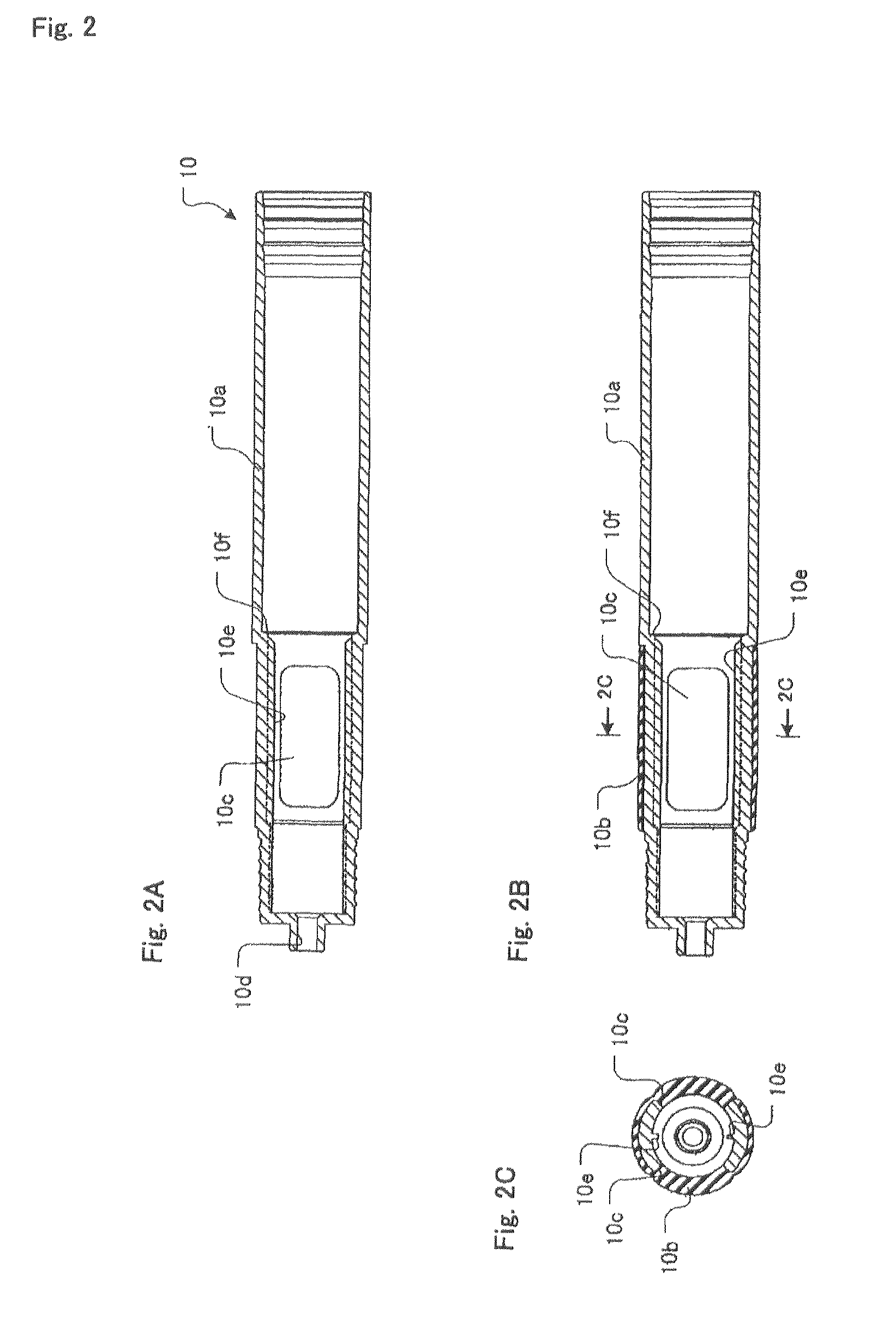

Water-metachromatic cloth sheet, toy set using the same, and writing instrument for water-metachromatic members

InactiveUS6953345B1Reduced durabilityIncrease resistanceFibre treatmentWriting boardsPorous layerSilicic acid

A water-metachromatic sheet has a support with a porous layer containing a binder resin with dispersed fine-particle silicic acid. The sheet is capable of rendering different transparency between water absorbed and unabsorbed states. The support is a cloth having a weight per unit area of 30 gm2 to 1,000 gm2, the fine-particle silicic acid is contained in an amount of from 1 gm2 to 30 gm2, and the fine-particle silicic acid is incorporated in an amount from 0.5 to 2 parts by weight based on 1 part by weight of the binder resin.

Owner:THE PILOT INK CO LTD

Dynamically allocating server resources to competing classes of work based upon achievement of service goals

A facility for adjusting a number of servers assigned to server pools for performing certain work types on the basis of unmet service needs in a work processing facility. Servers may include service agents, both human and robotic. A server assignor and a corresponding server assignment method may each be employed in a work distributor or an automatic call distributor (“ACD”) to conditionally adjust server availability in server pools. The server assignor compares a composite preference value for a work type against each server's threshold value for the work type. When the server assignor determines that the composite preference value is greater than or equal to a server's threshold value, then the server assignor indicates that the server may be included in the server pool for that work type. Each server has preference values and threshold values for different kinds of work. The magnitude of a preference value represents an affinity for the work type. The server's threshold value represents a reluctance to perform work having that work type. The server does not normally receive work for which the preference value is less than the threshold value, unless the server assignor determines that the composite preference value exceeds the server's threshold value for that work type. The server assignor and corresponding server assignment method may compute the composite preference value from a number of user-selectable inputs and utilize a number of user-selectable functions.

Owner:AVAYA TECH LLC

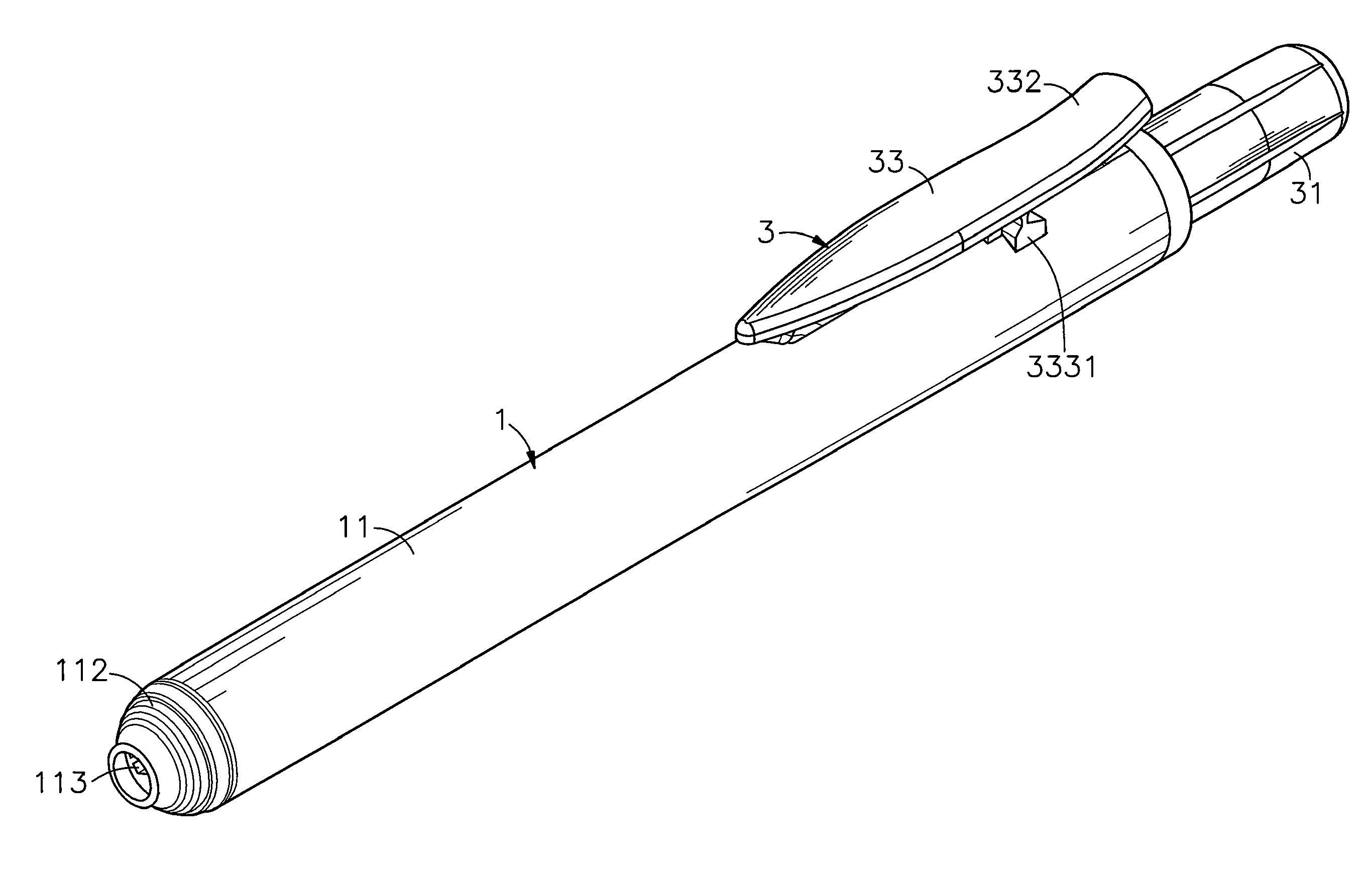

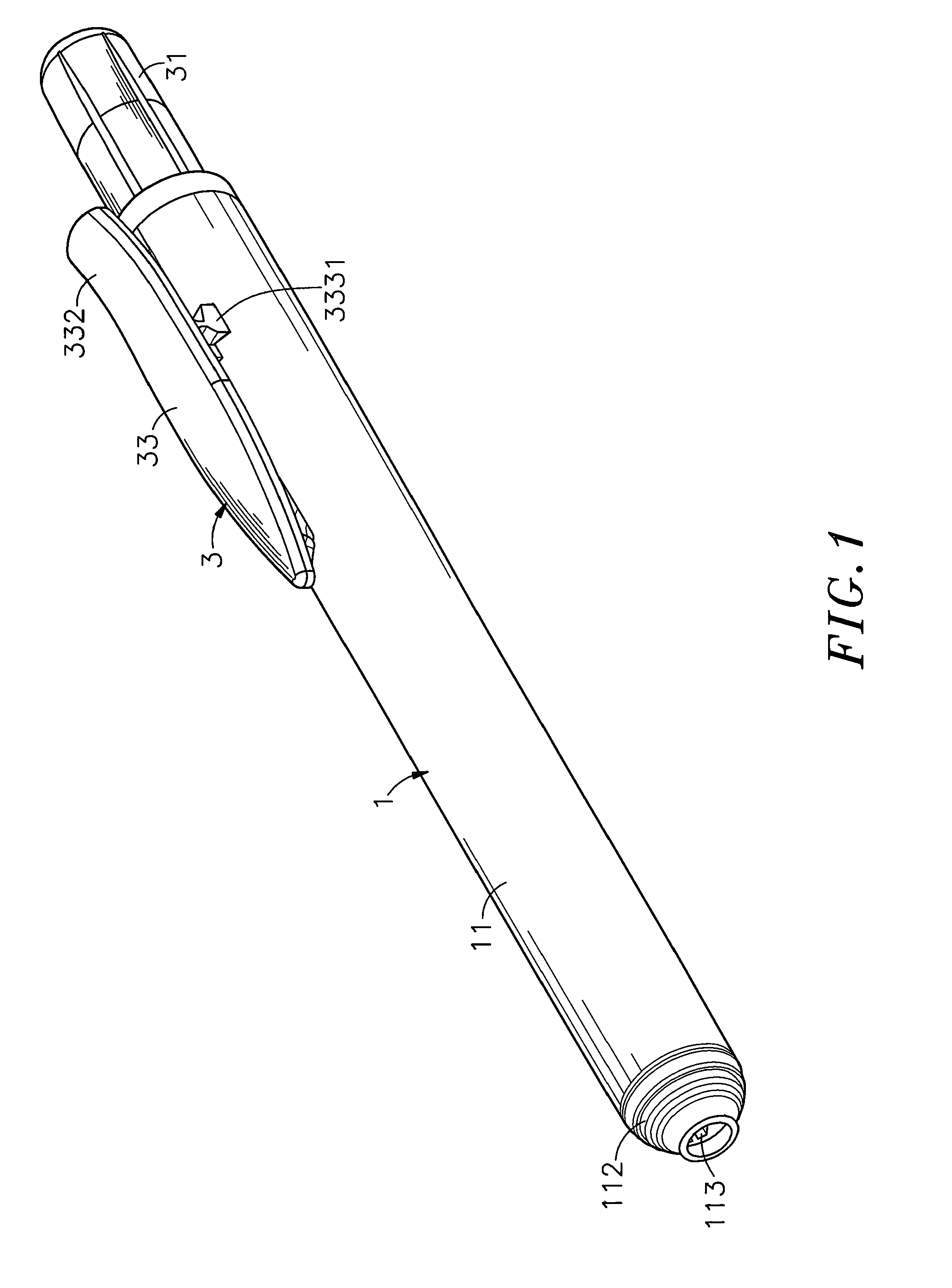

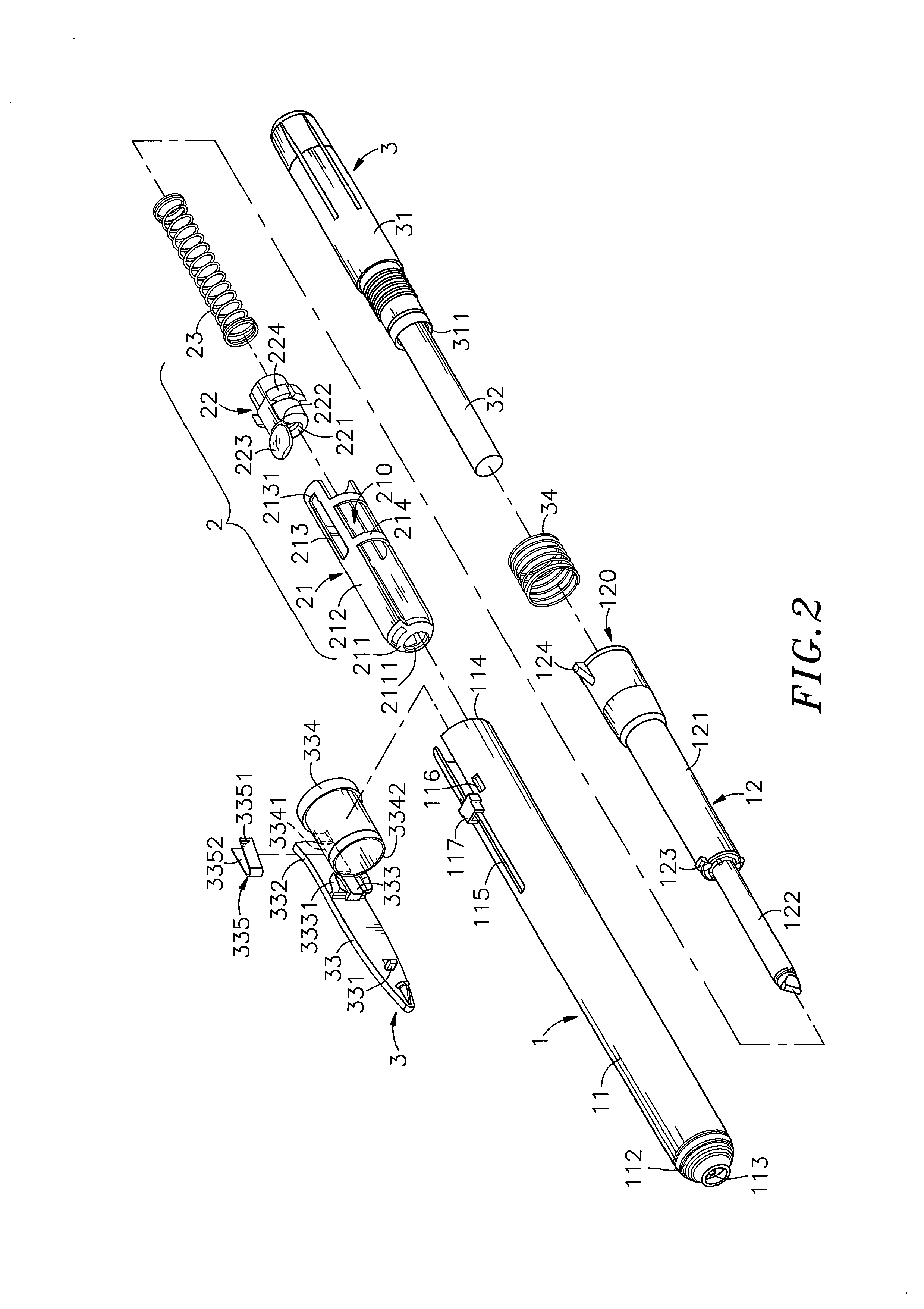

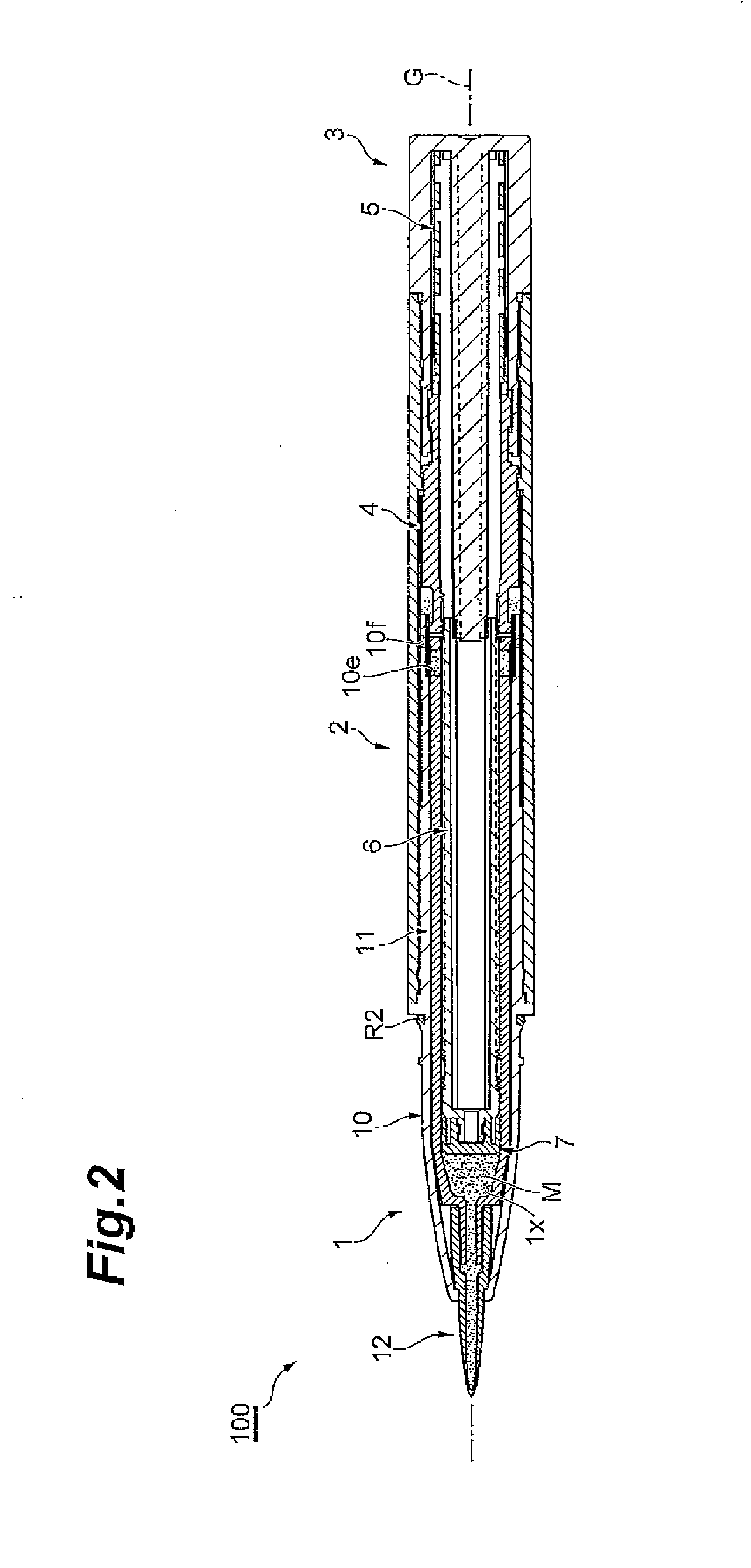

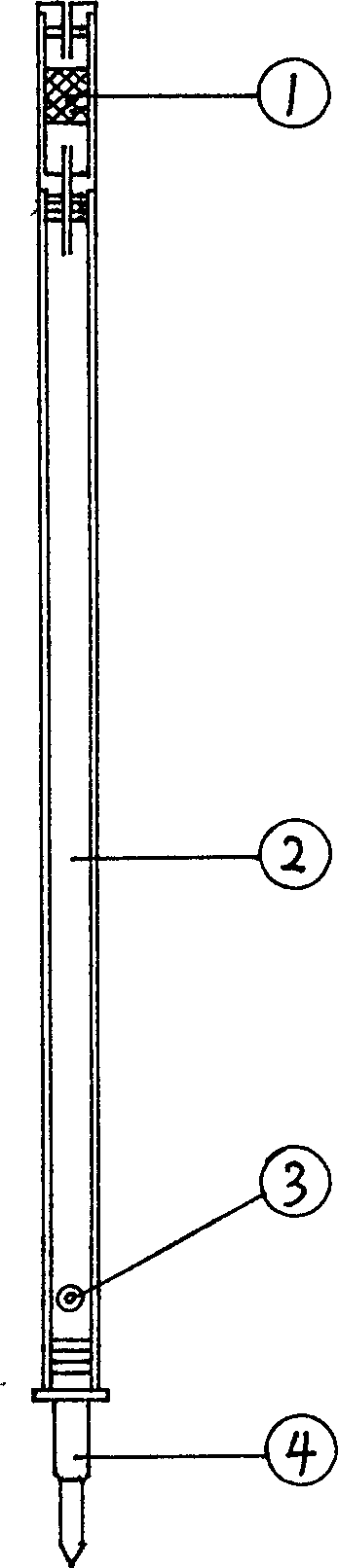

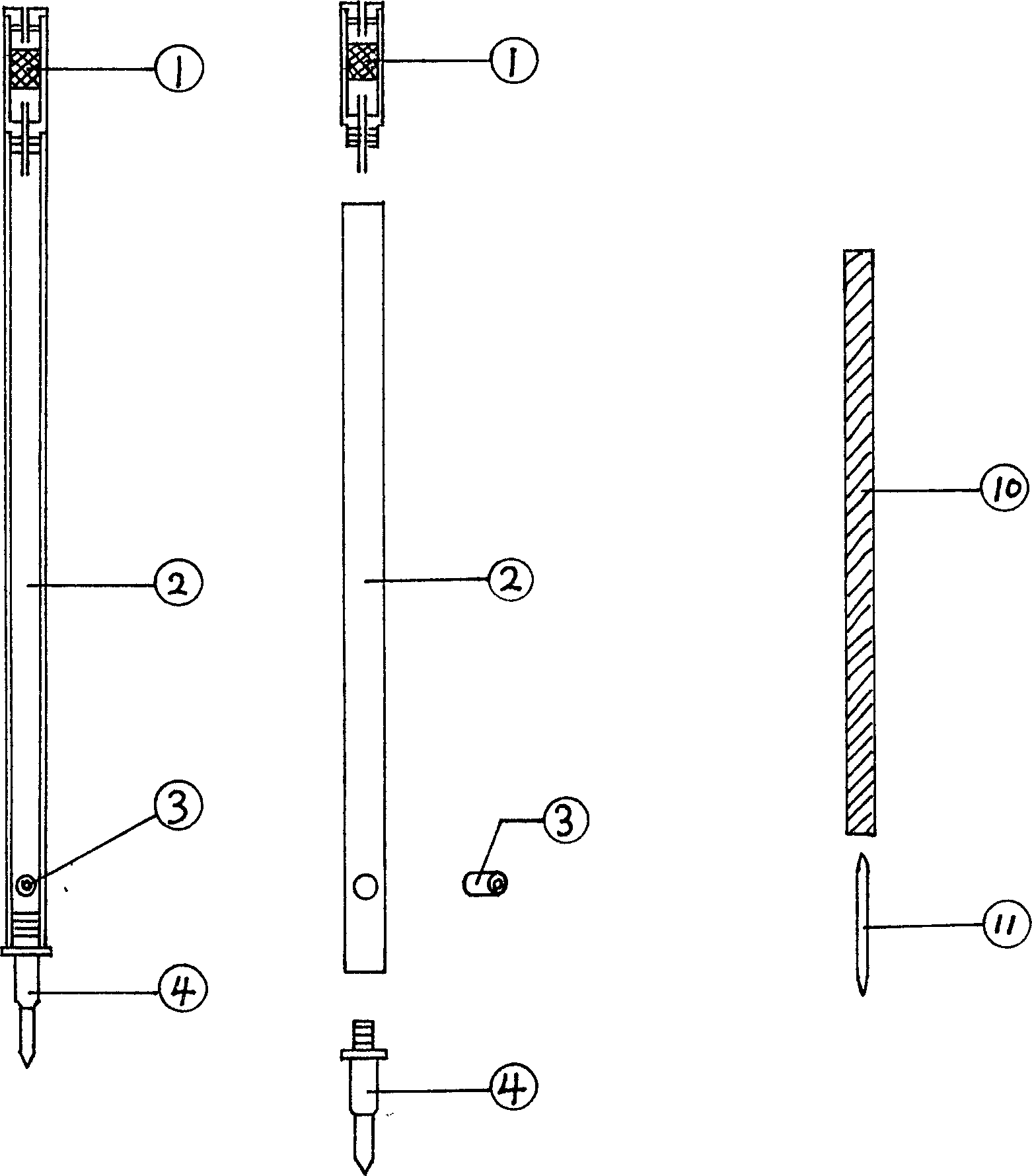

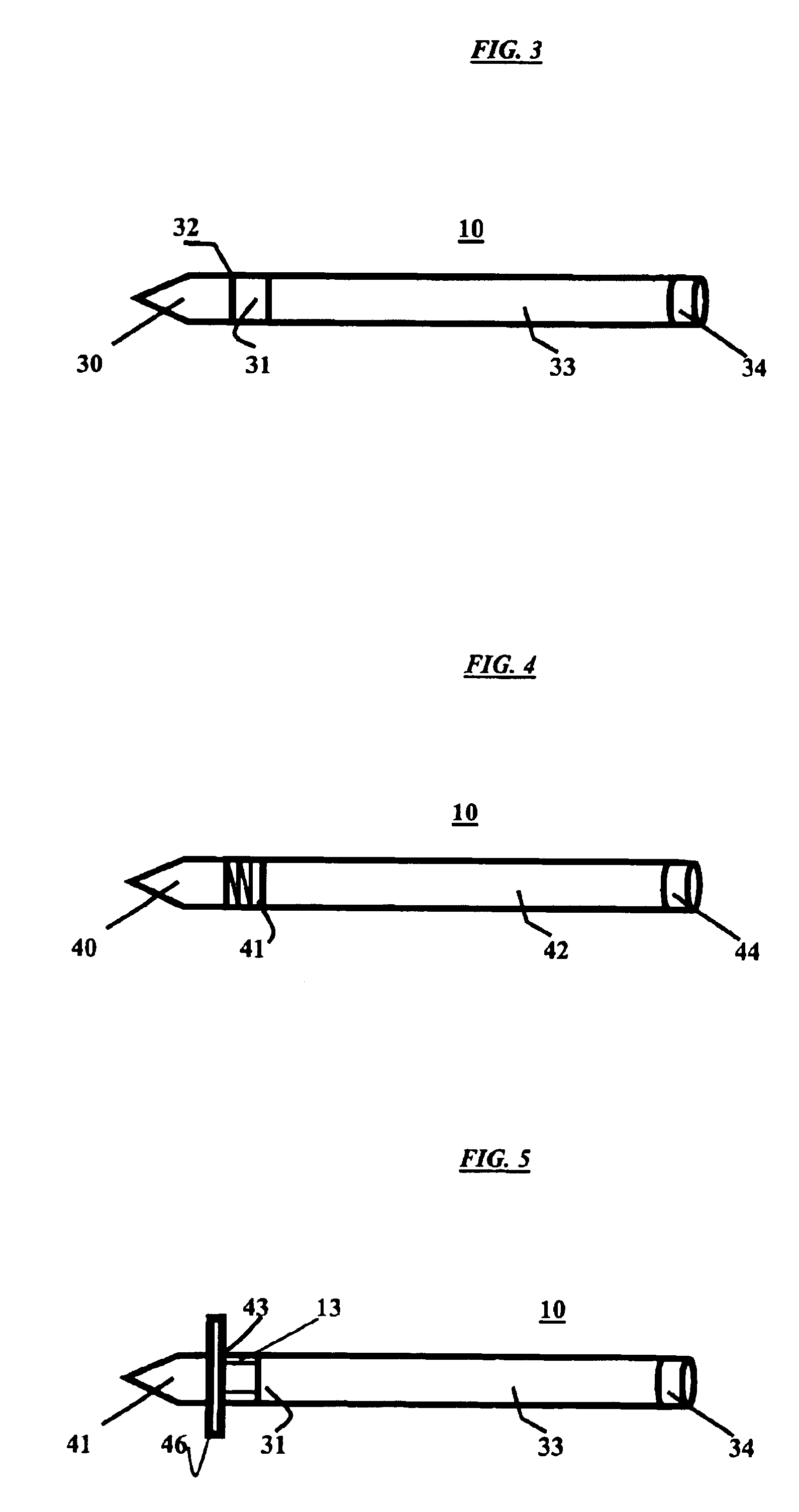

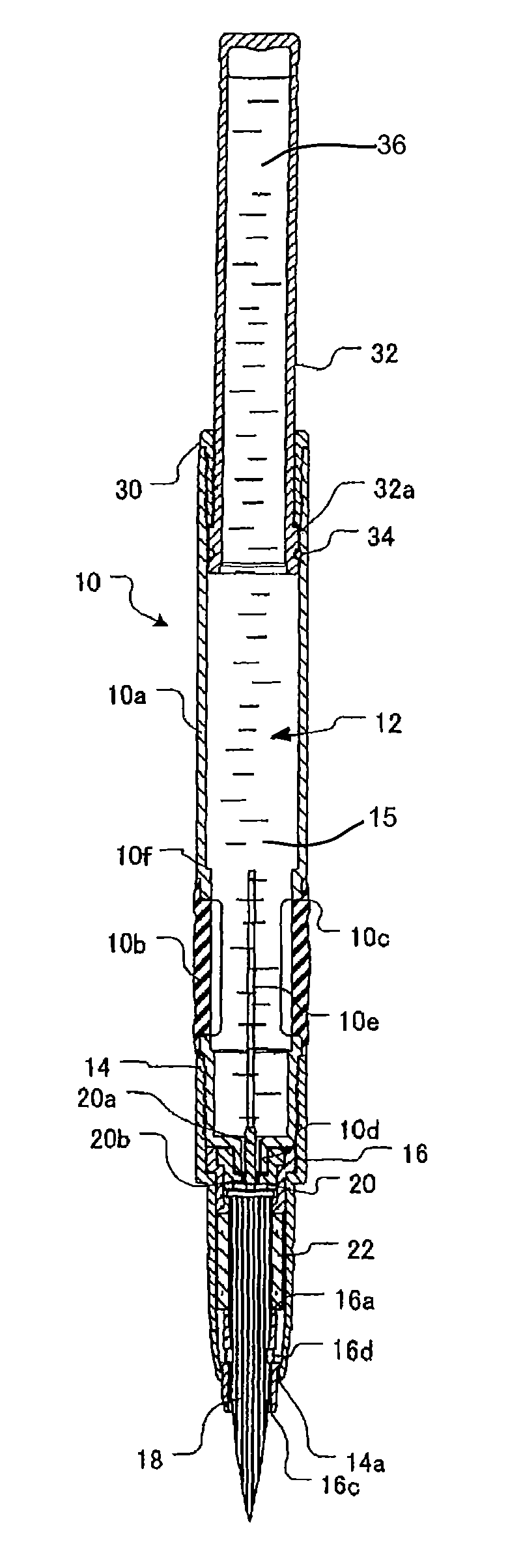

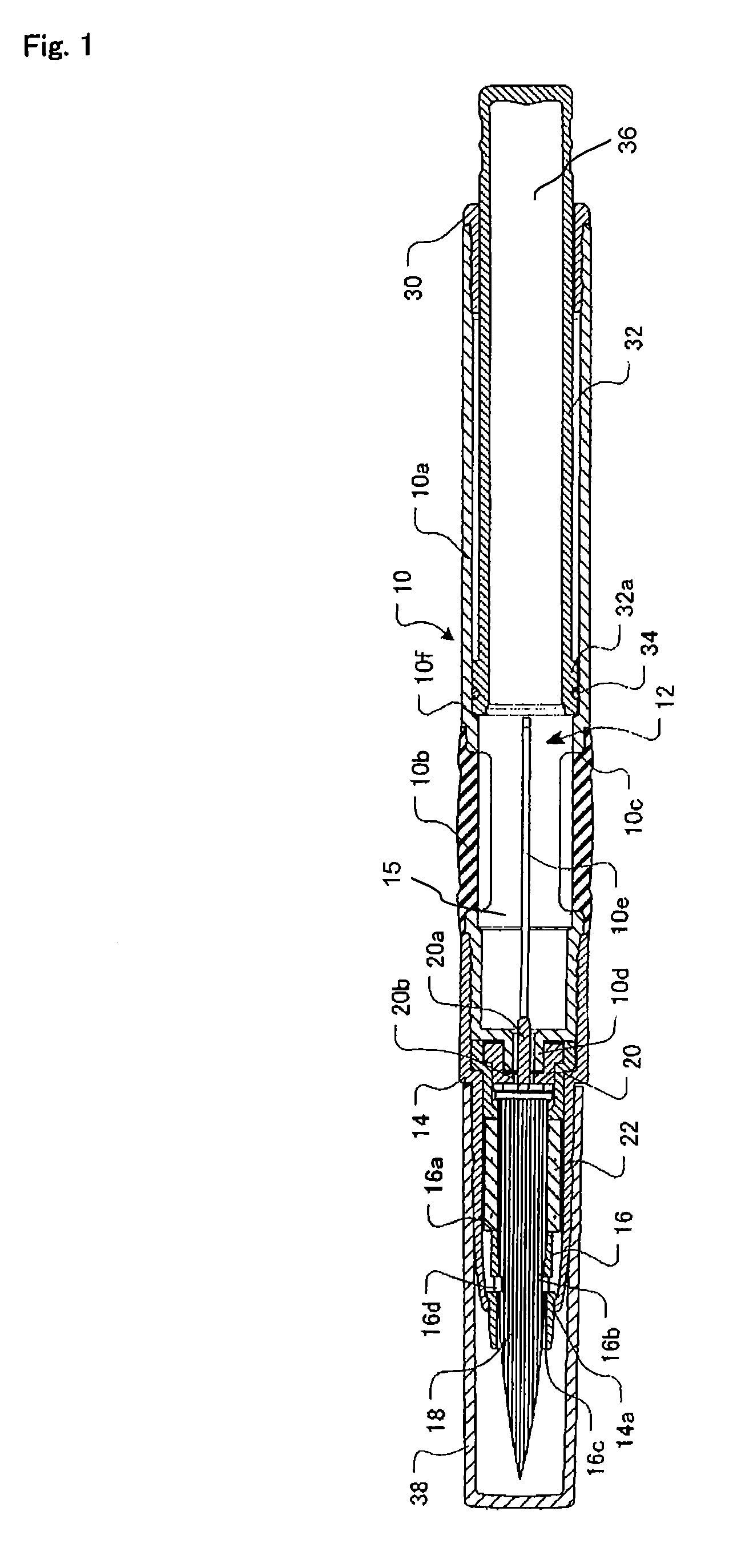

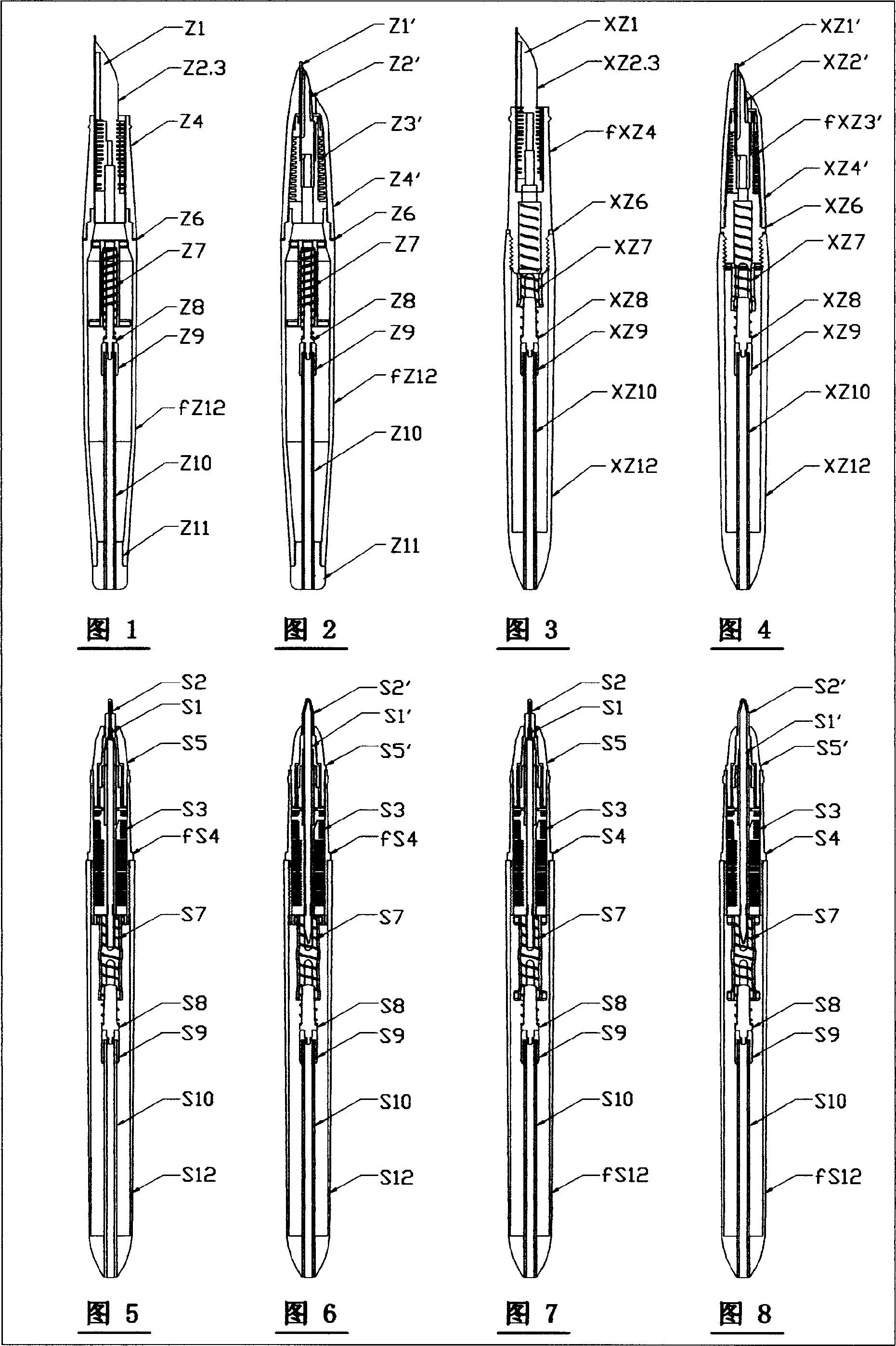

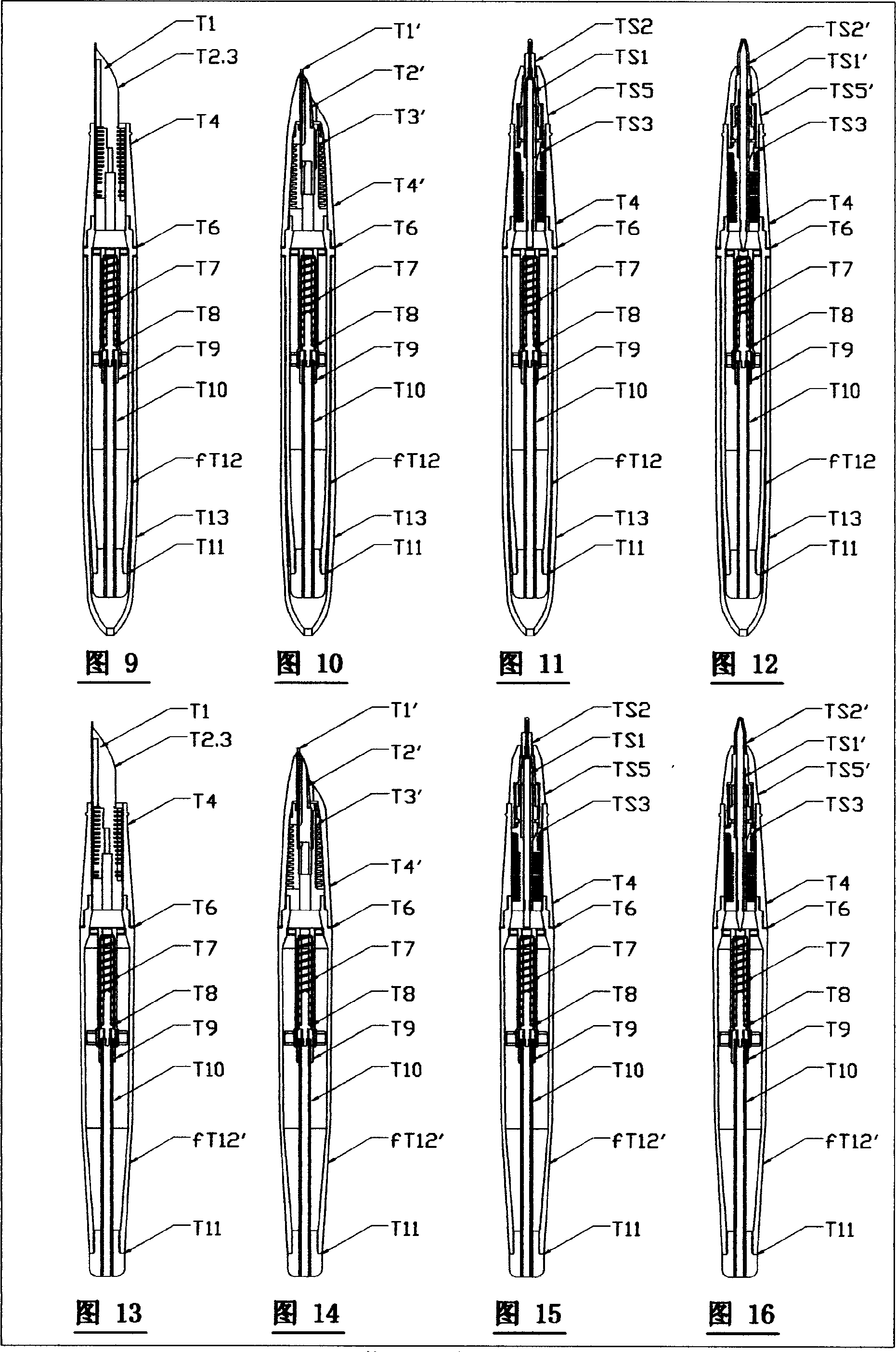

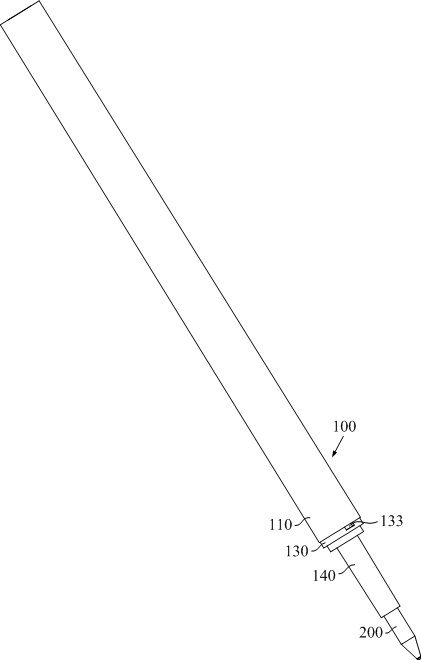

Retractable push button pen

InactiveUS20110103875A1Avoid noiseAvoid wear damagePen repairingBall-point pensEngineeringPush-button

A retractable push button pen includes a barrel, a pen refill, which has a refill body with hooks at the front side and a writing tip extended out of the front side of the refill body, an extending and retracting mechanism formed of a slide, a limiter and a spring member and received inside the barrel around the writing tip received in the barrel, and a press-control mechanism formed of an absorption rod, which is connected to the writing tip to supply an ink, a cylindrical cap holding the absorption rod and extending out of the rear side of the barrel for pressing by a user to move the writing tip out of the barrel for writing and a pen clip, which has a positioning protrusion engageable into the barrel to lock the pen refill in the extended position and a press portion for pressing by a user to unlock the positioning protrusion from the pen refill.

Owner:SUNNY PRO +1

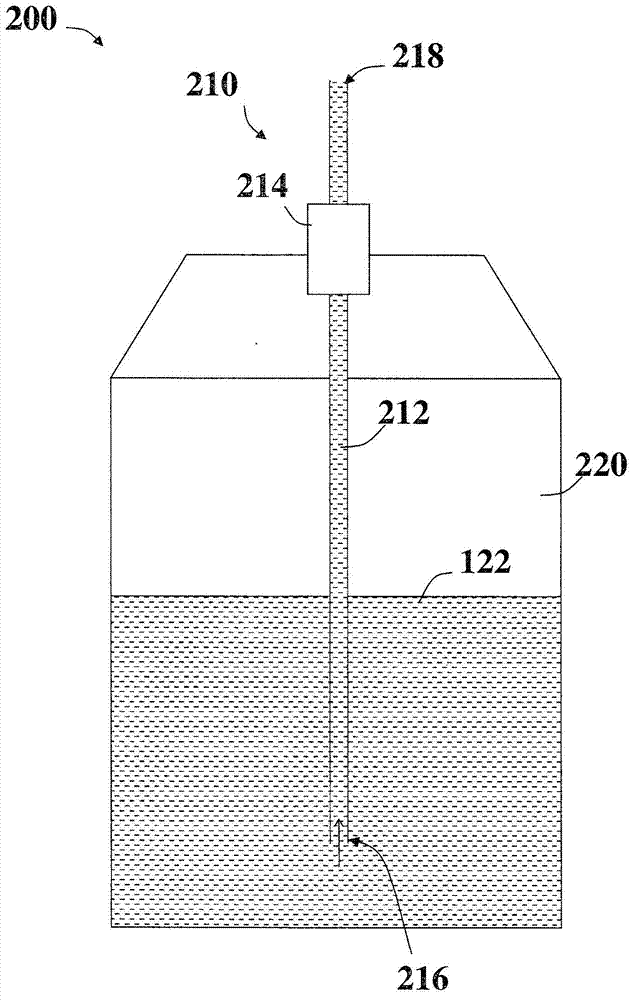

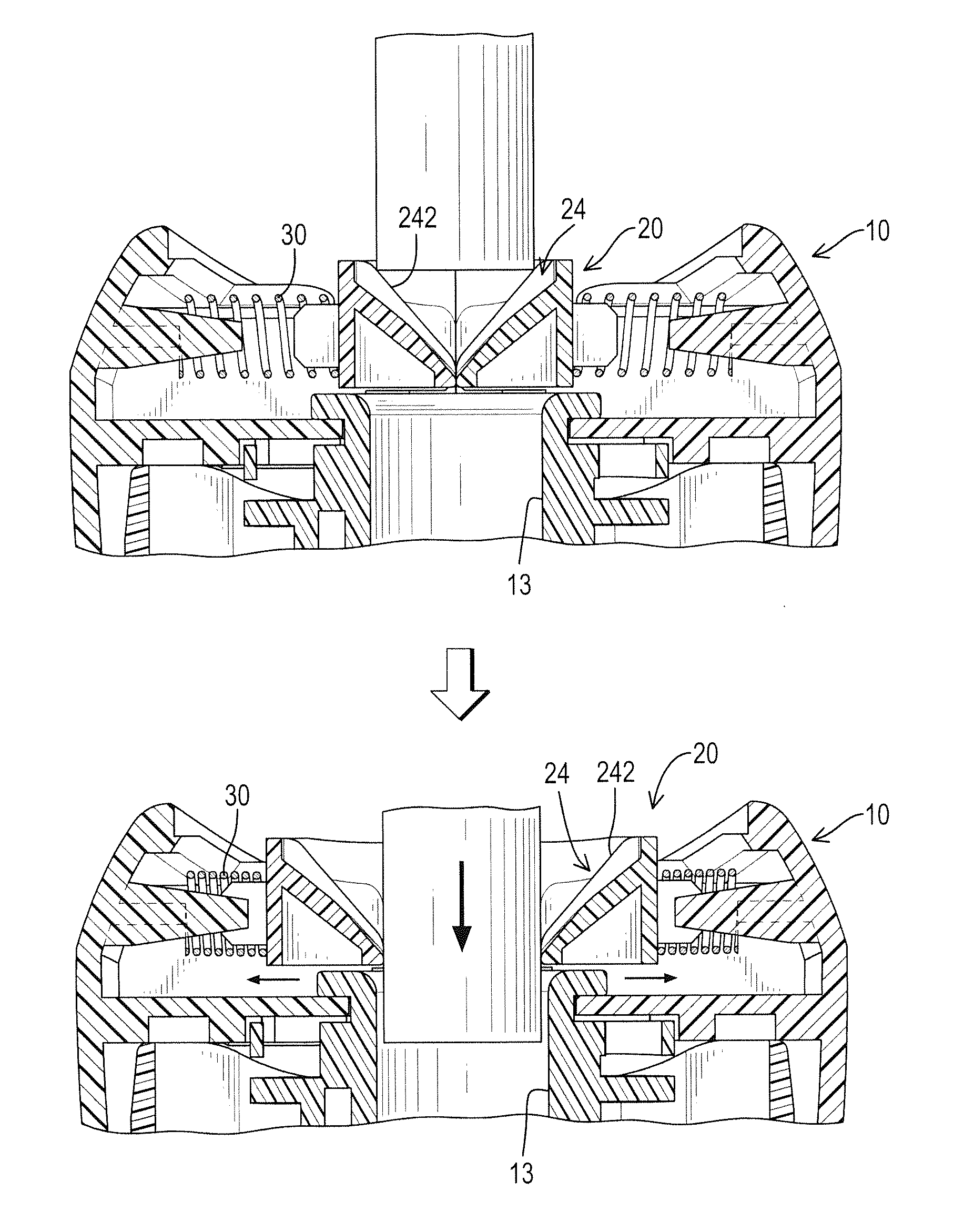

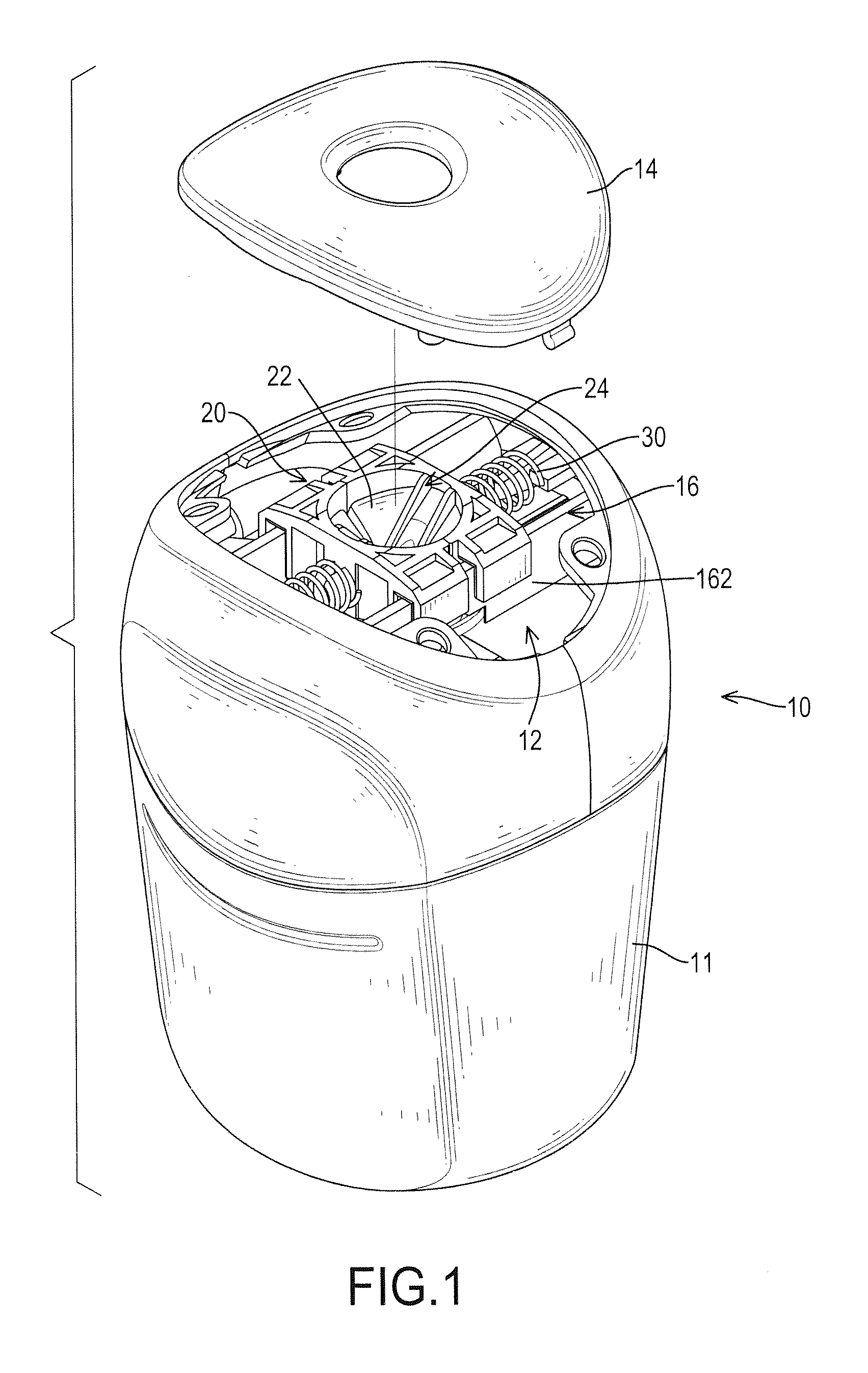

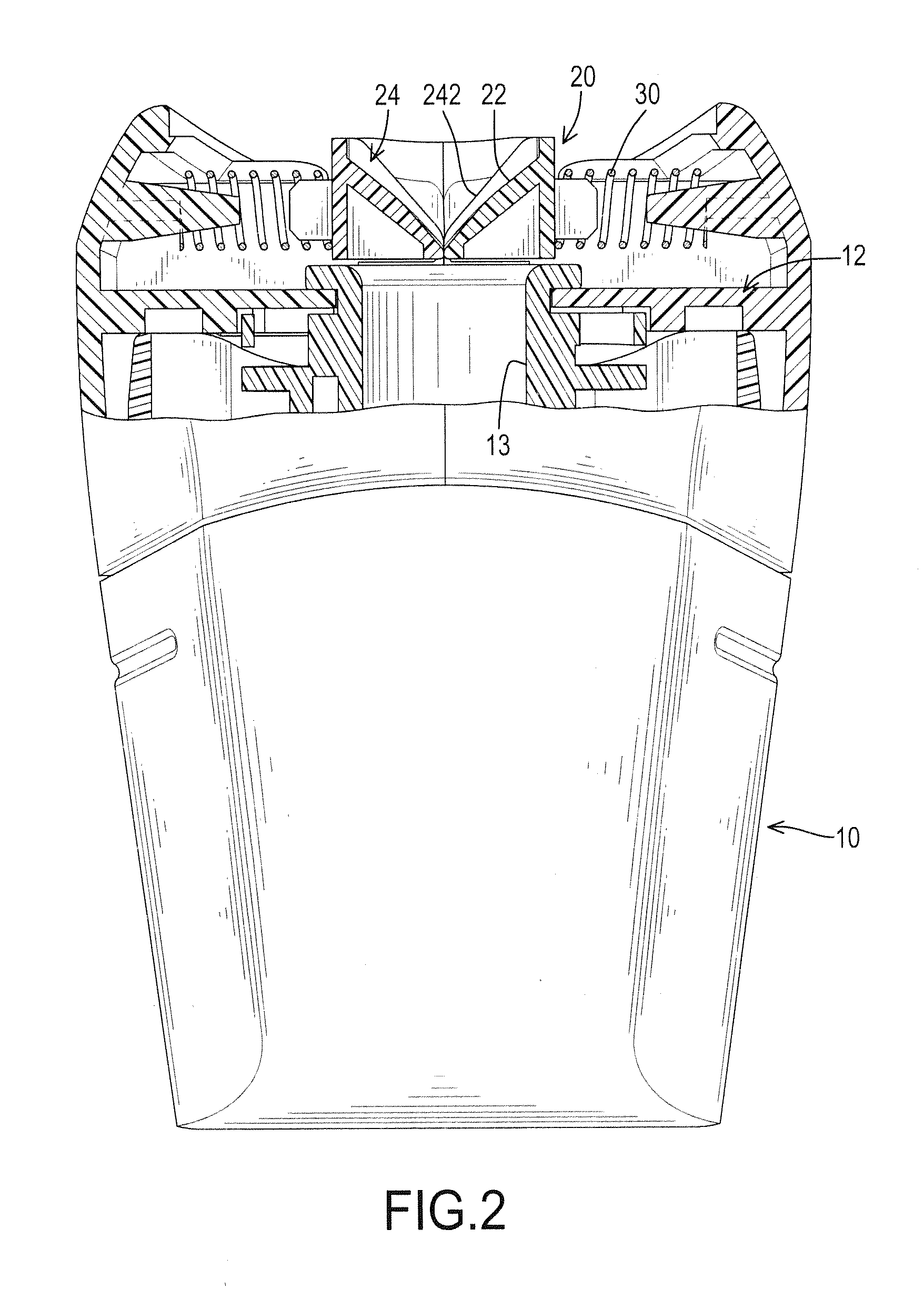

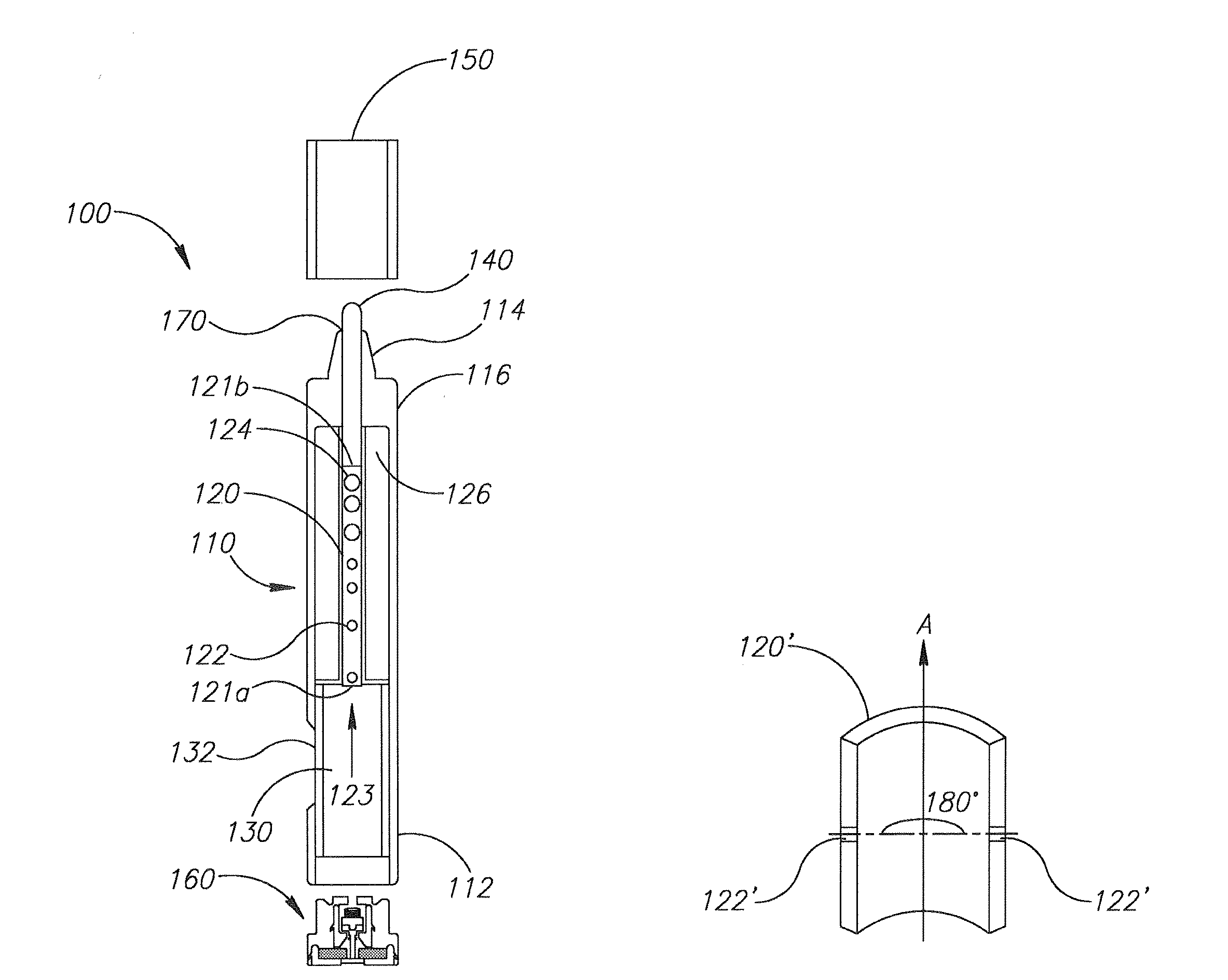

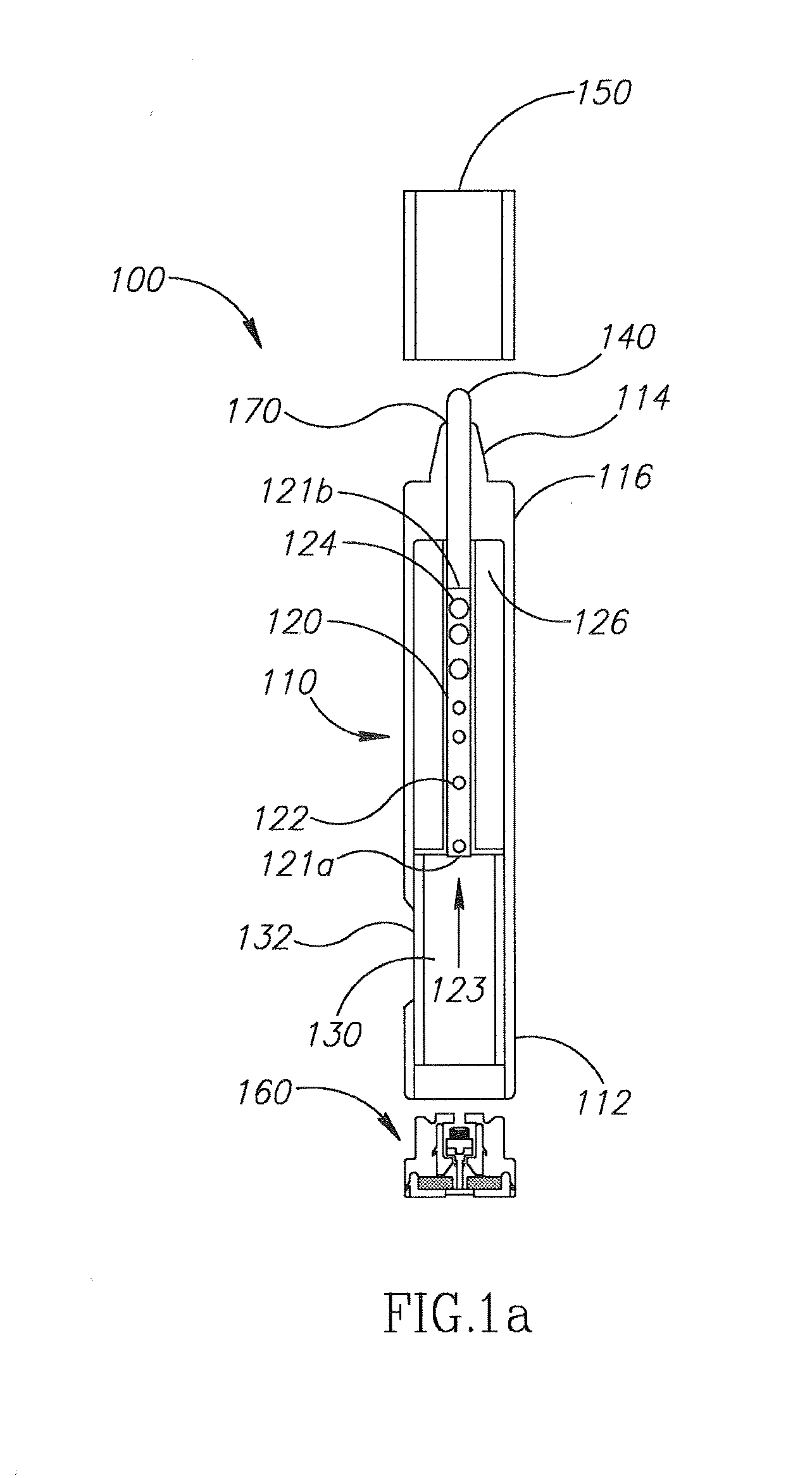

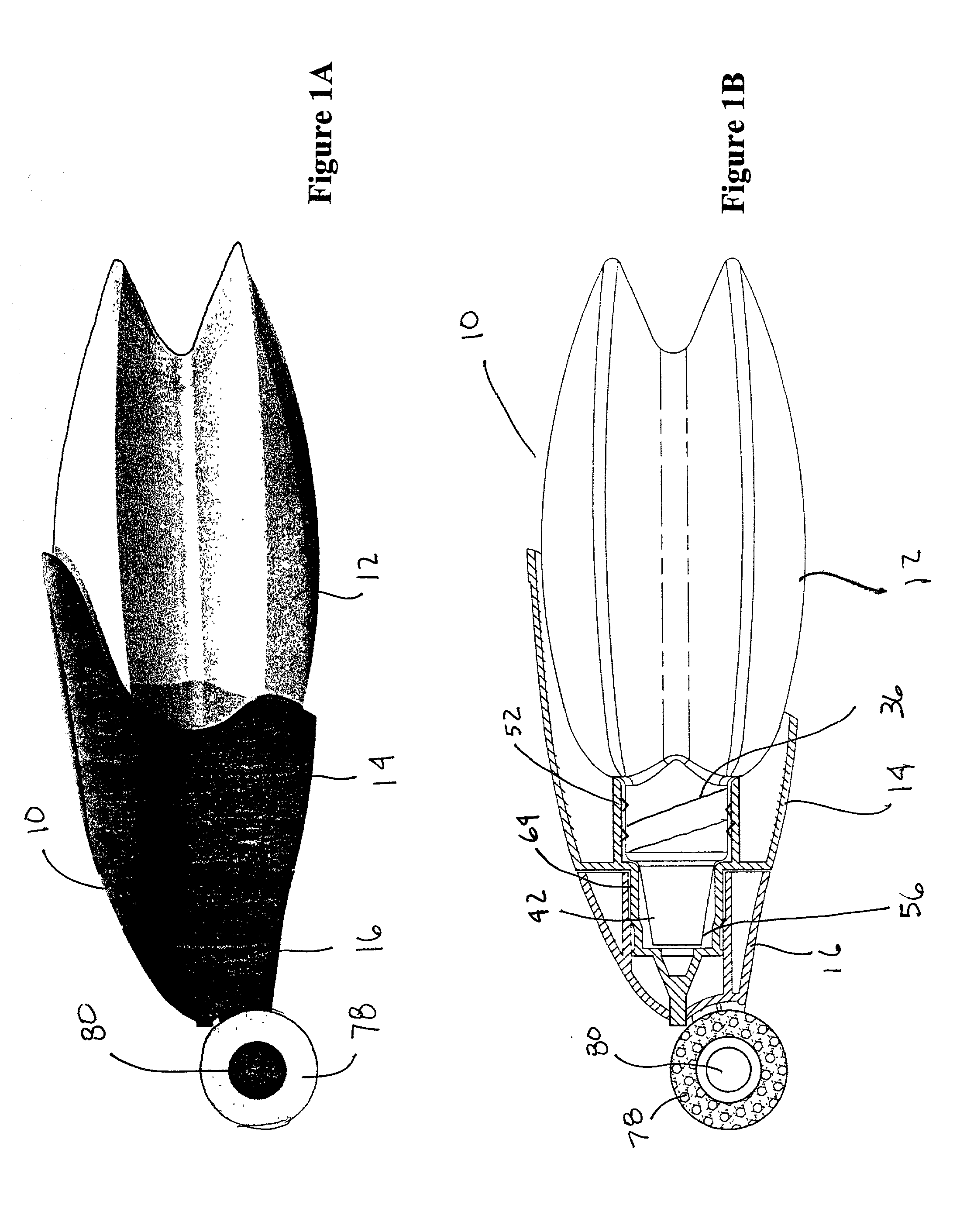

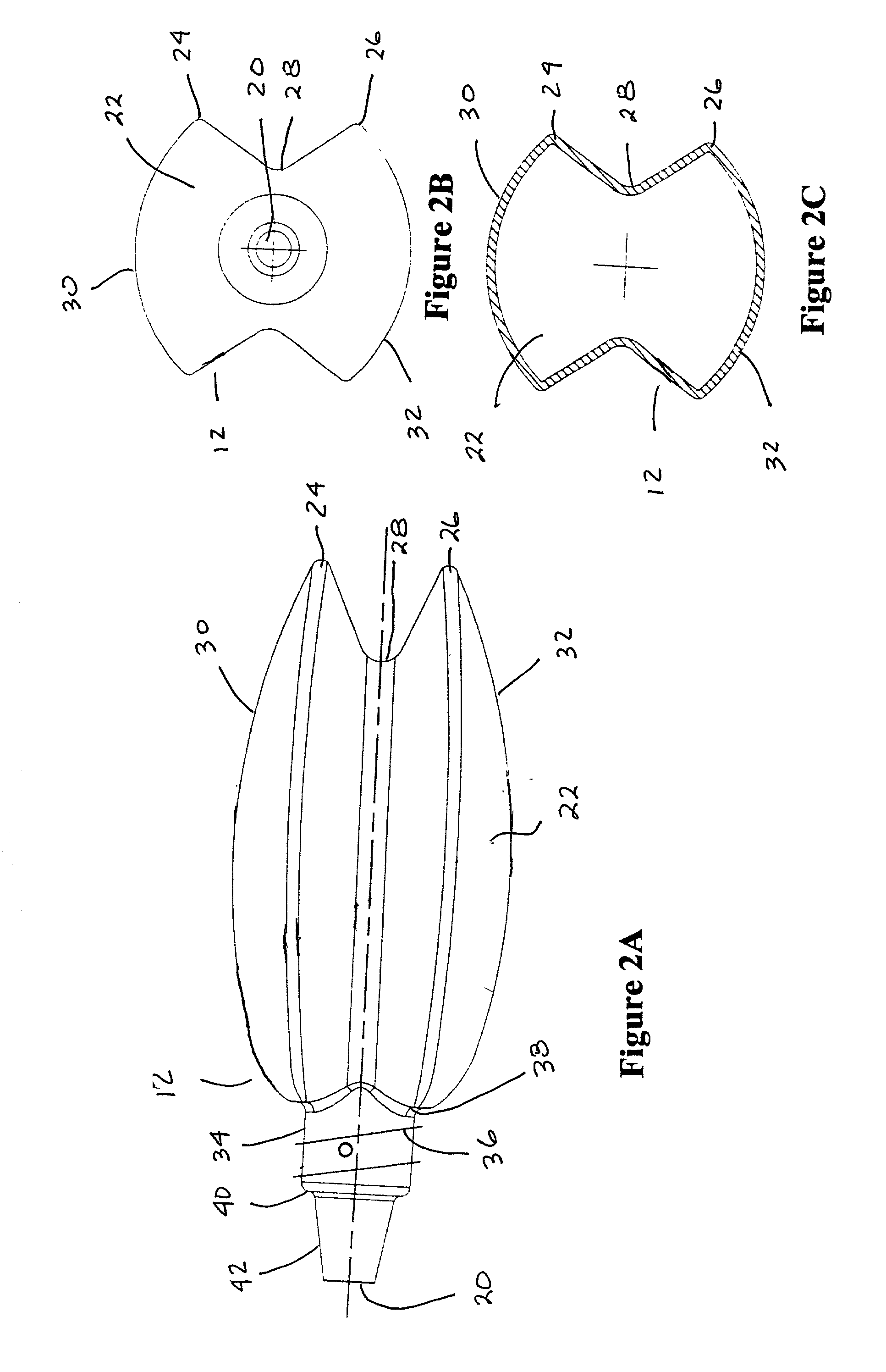

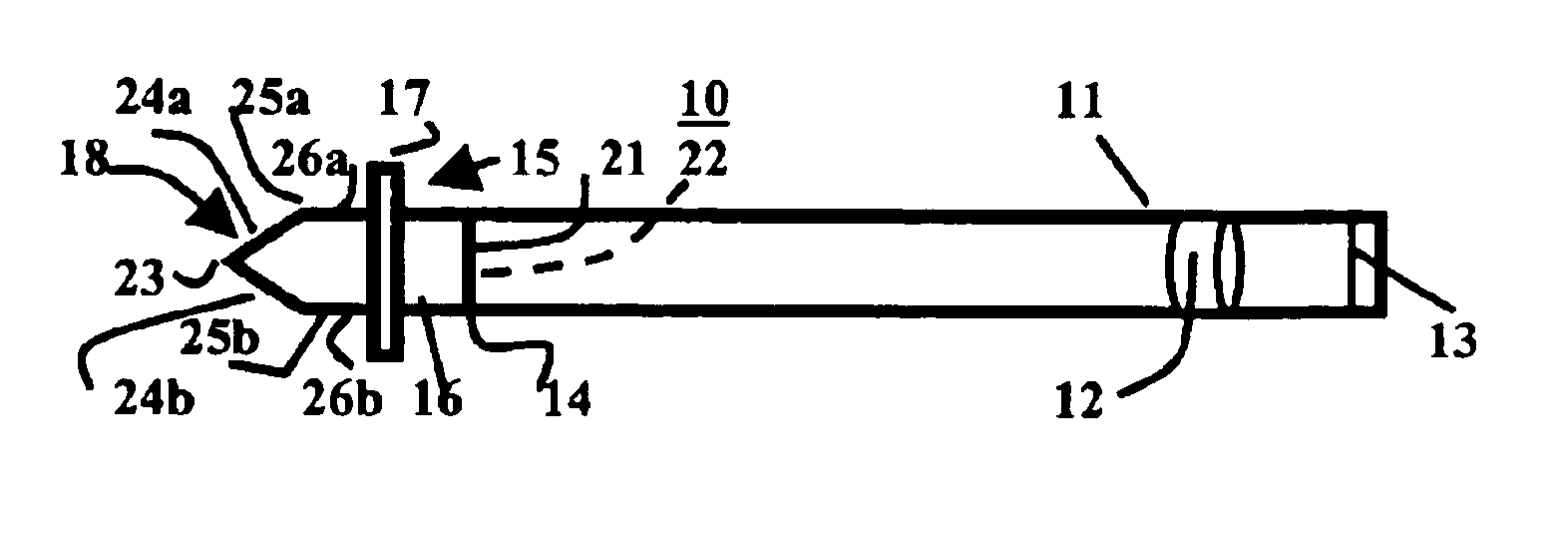

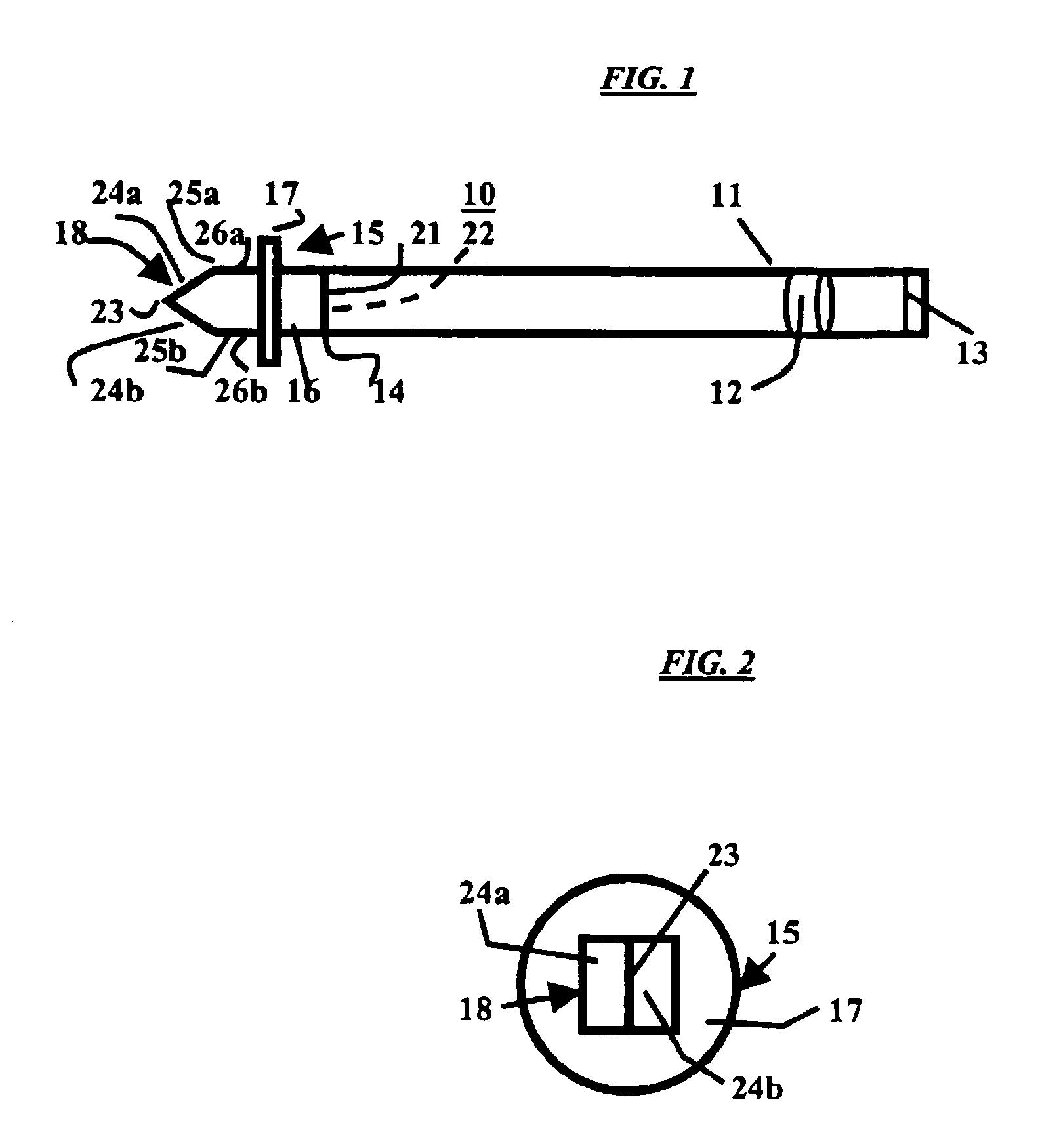

Refill system and method

InactiveUS20130078025A1Reduce leakageInhibition releaseInk receptaclesWriting boardsBiomedical engineeringMarking out

A portable refillable marker-fluid cartridge comprising a marker-chamber, a marker-fluid applicator extending from out of the cartridge wherein the marker fluid applicator is in fluid communication with the marker-chamber, a filling mechanism configured to open from a delivery tube being pushed theretowards, thereby allowing the marker fluid to pass into the marker-chamber, and at least one seal-ring configured to minimize leak of the marker-fluid out of the marker-chamber.

Owner:BEAUTY UNION GLOBAL

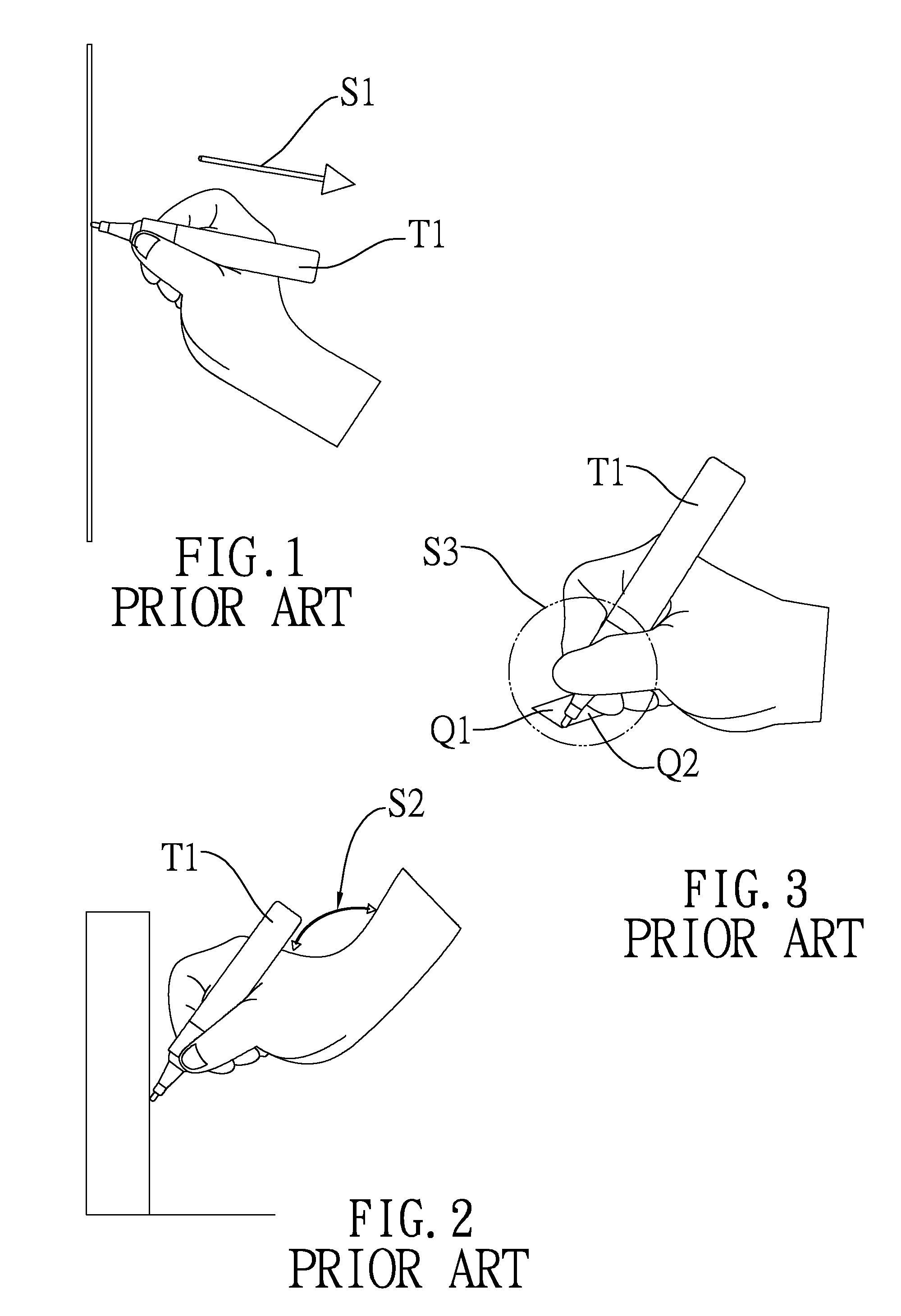

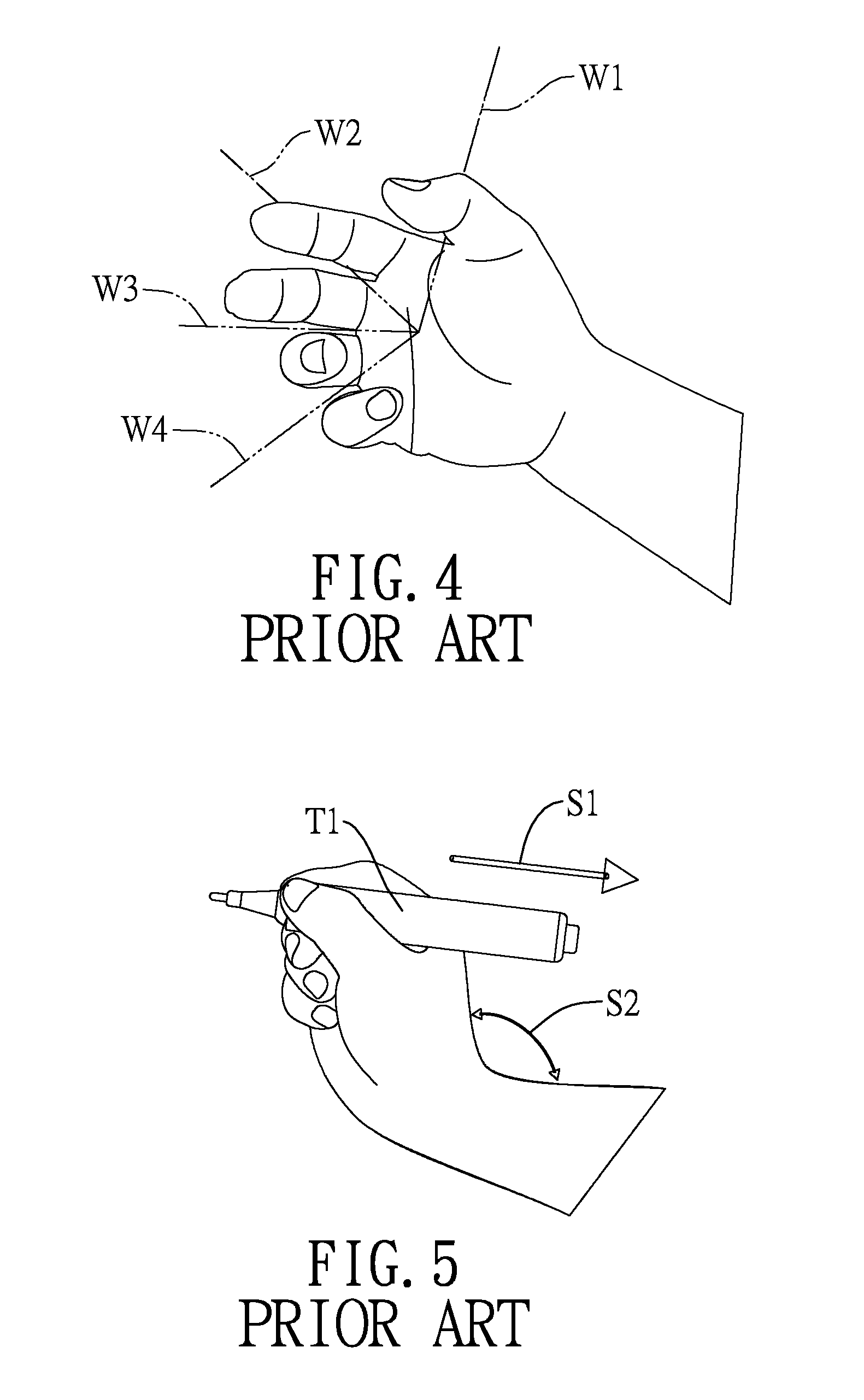

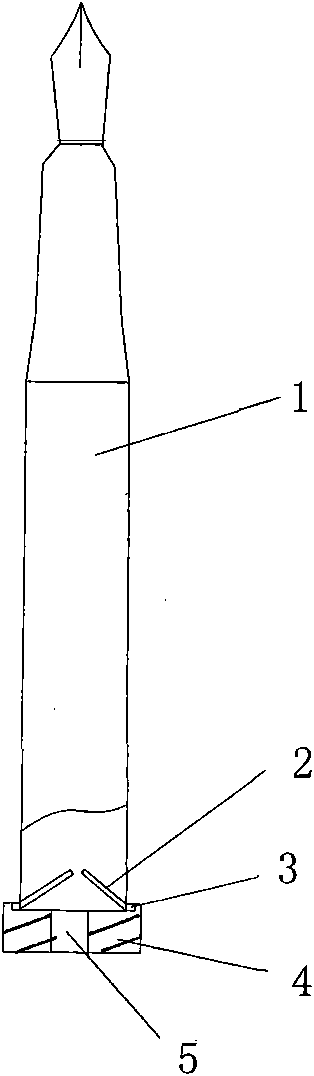

Marker pen with a bending assembly

InactiveUS20120207533A1Convenient can be held in user 's handConveniently heldCarpet cleanersWriting connectorsFiberEngineering

A marker pen has a penholder, a bending assembly and a writing part. The bending assembly is mounted on the penholder and includes a bending angle, a first section and a second section. The first section and the second section are connected with each other. The first section is connected to the penholder. The writing part is made of fibers being able to contain ink, is mounted through the bending assembly and is inserted in the penholder. Therefore, it is convenient for a user to hold the marker pen in the hand to meet different situations and the user's line of sight to the writing area is not obscured.

Owner:LIU BAO SHEN +1

Method for manufacturing a coating instrument

ActiveUS20150231916A1Reliably prevent leakagePrevent leakageDispensing apparatusPen repairingEngineeringMechanical engineering

There is provided a method for manufacturing a coating instrument provided with a filling member having a filling region in which a coating material is filled and a body portion including an extruding portion inserted inside so as to be brought into close contact with the filling member and constituting a rear end of the filling region, in which the coating material is discharged from a discharge outlet on a tip end side of the filling member by advance of the extruding portion, including a step of filling the coating material into the filling region of the filling member from behind in a state in which a front side of the filling member is located below the rear side, a step of feeding a predetermined amount of air from the discharge outlet into the filling region so that a space is formed on the tip end side in the filling region after the coating material is filled, and a step of assembling the body portion to the filling member after the air is fed.

Owner:TOKIWA CORP

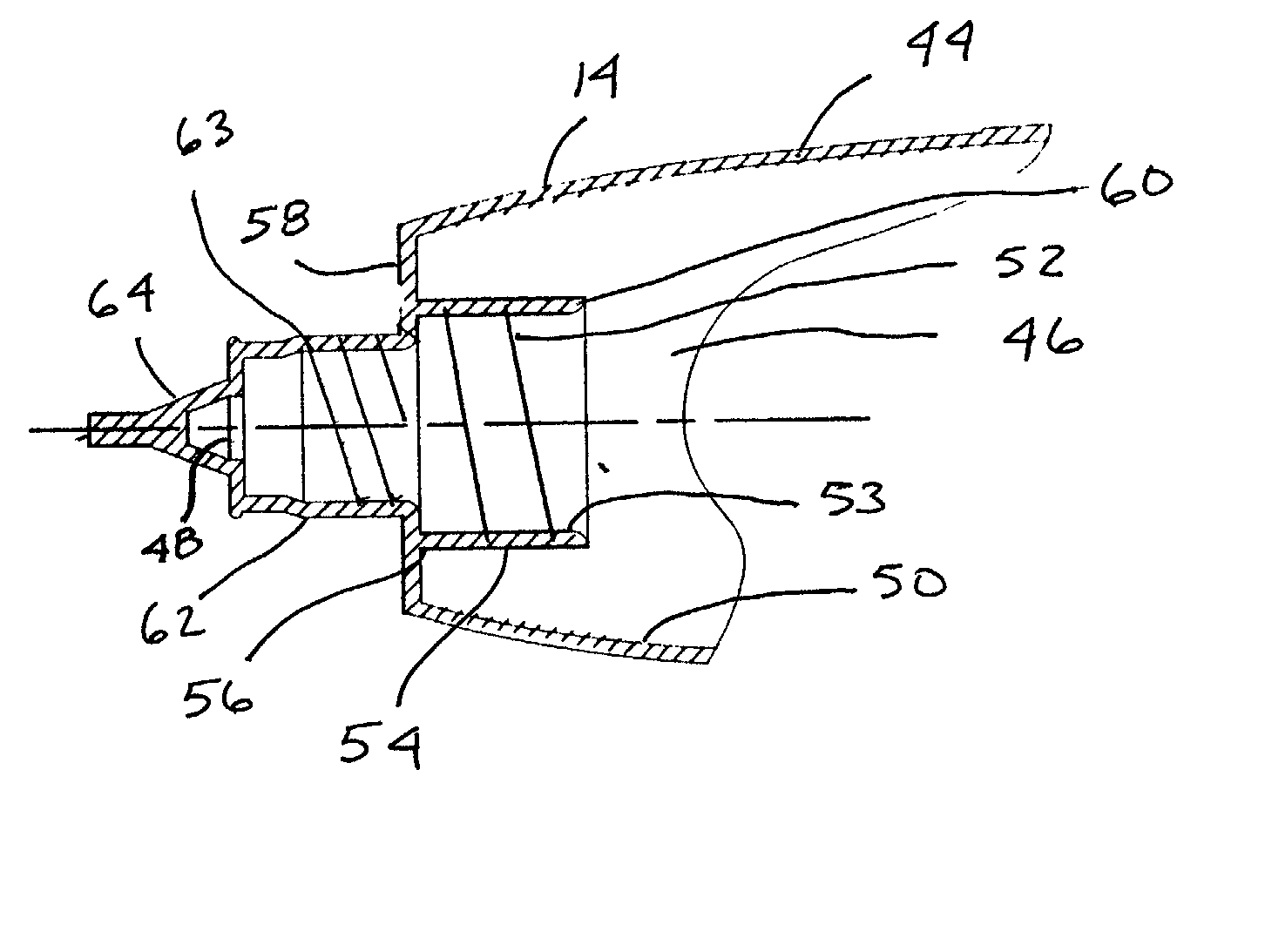

Refill system and method

A portable refillable marker-fluid cartridge comprising a marker-chamber; a marker-fluid applicator extending from out of the cartridge wherein the marker fluid applicator is in fluid communication with the marker-chamber; a filling mechanism configured to open from a delivery tube being pushed theretowards, thereby allowing the marker fluid to pass into the marker-chamber, and at least one seal-ring configured to minimize leak of the marker-fluid out of the marker-chamber.

Owner:BEAUTY UNION GLOBAL

Neutral pen refill capable of being re-filled

InactiveCN1491810AEasy to writeSolve the problem of not being able to raise multiple timesInk reservoir pensFilling devicesBiochemical engineeringBottle

The present invention consists of neutral pen refill capable of being refilled and ink bottle for refilling, and aims at making neutral pen refill with excellent writing performance refillable, like a fountain pen. The present invention can save resource and lower writing cost.

Owner:倪国森

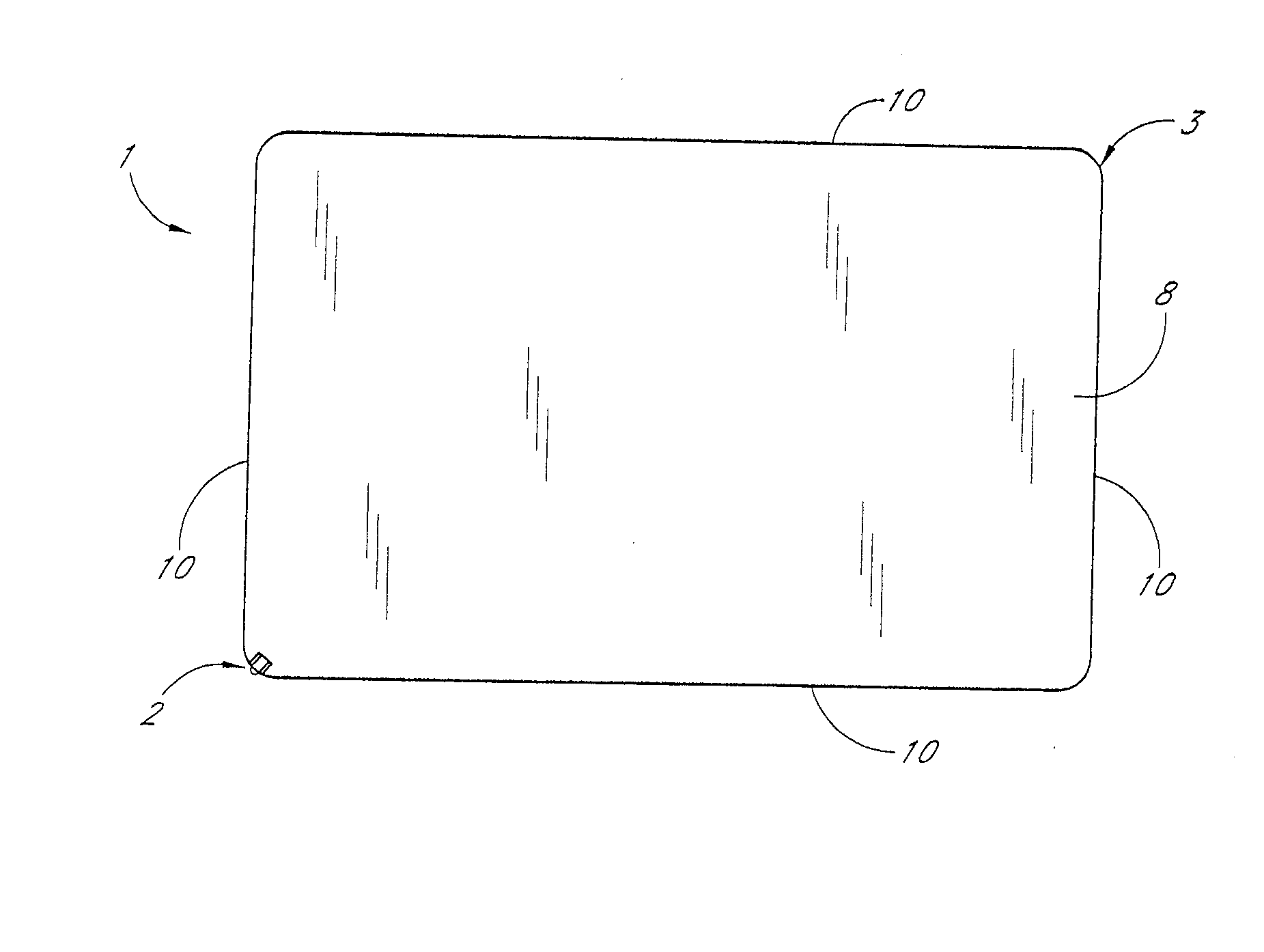

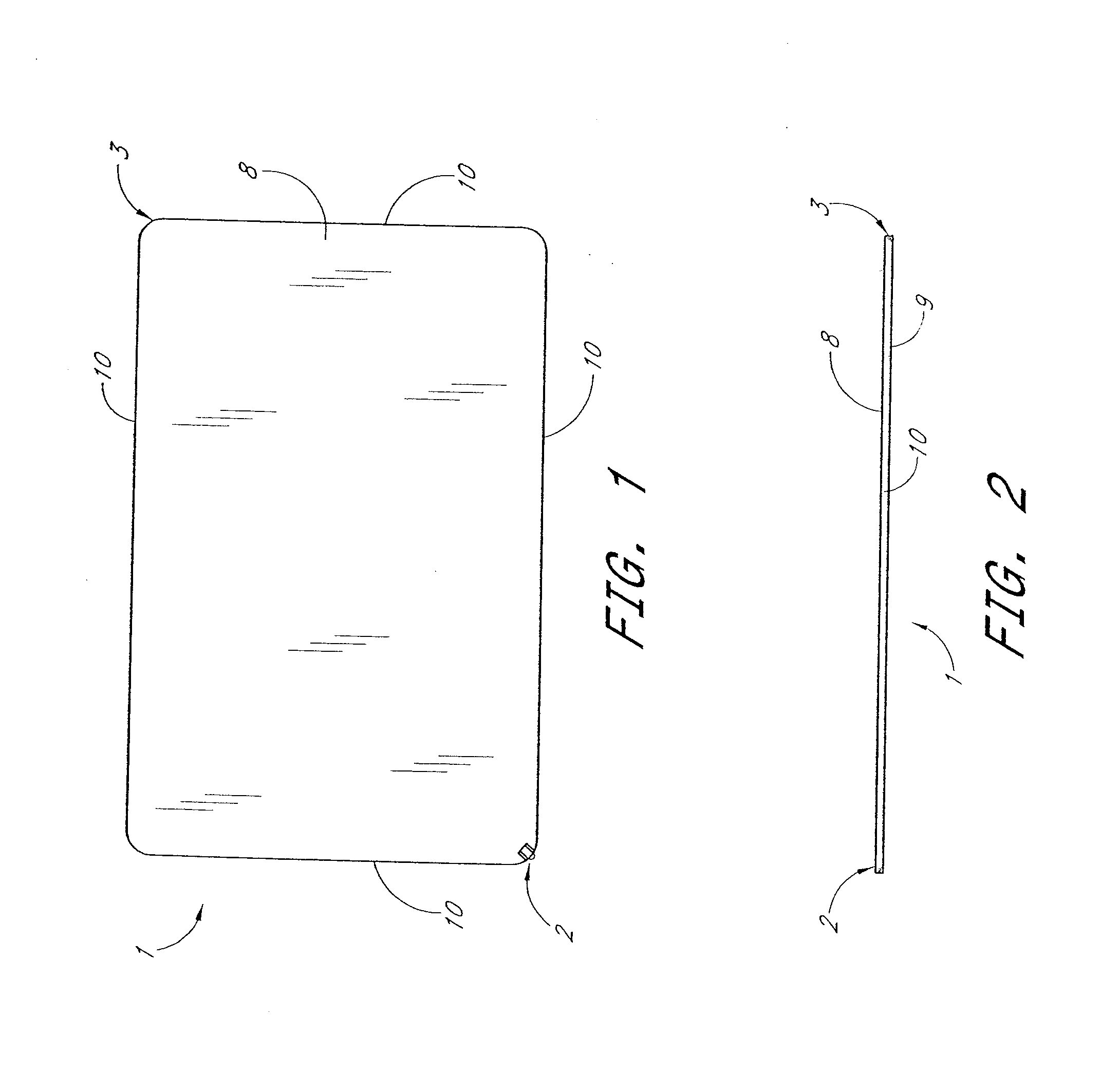

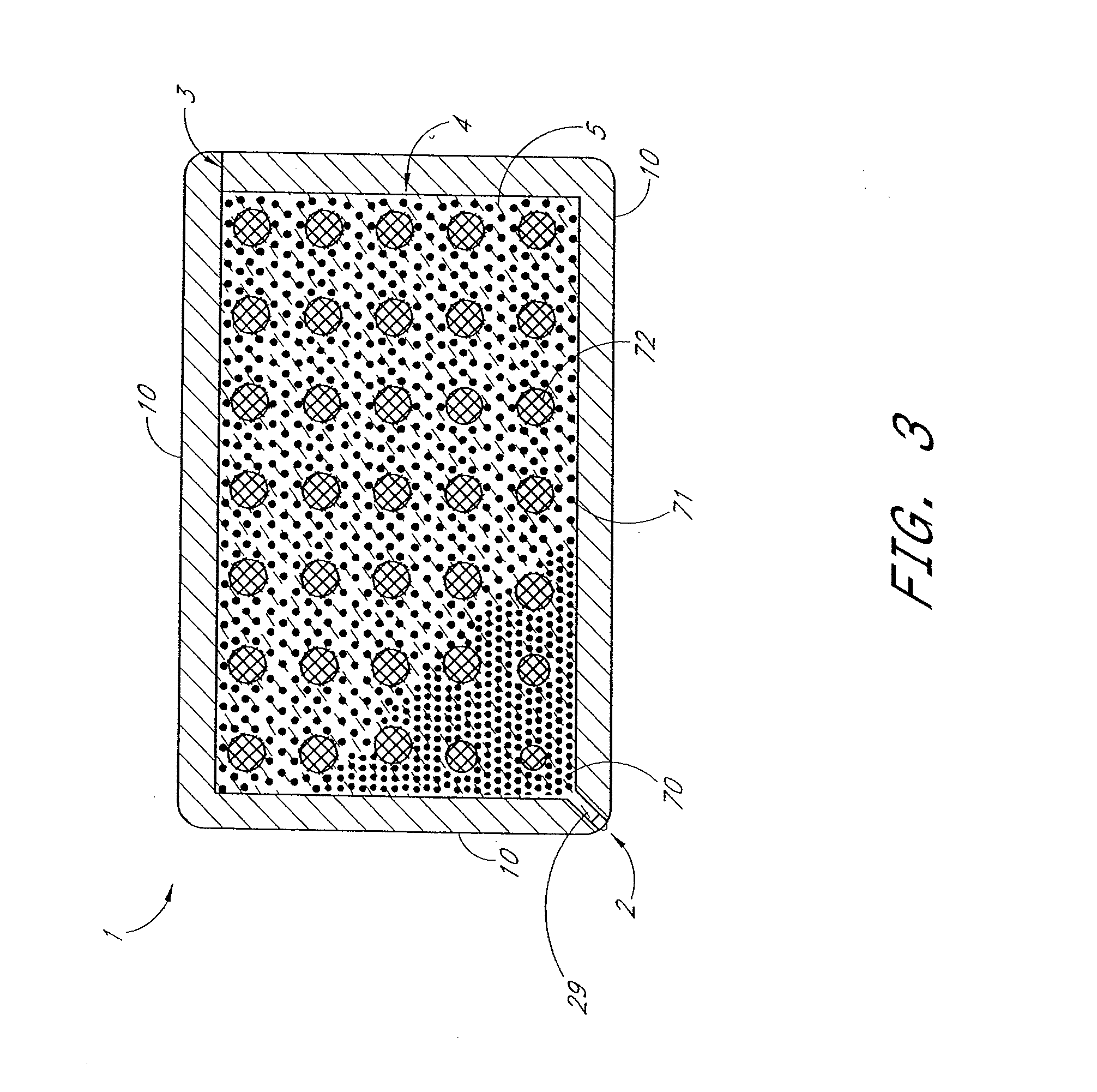

Marking instruments and methods of manufacturing marking instruments

InactiveUS20080063462A1Conveniently continuously available for useIncreasing potential fatigueWriting connectorsPropelling pencilsHand heldFinancial transaction

A handheld marking instrument includes a body having a substantially flat shape, a first chamber formed within the body and having an inner surface configured to receive and contain a marking substance within the body, and a first marking device configured to deliver the marking substance to a desired surface during marking. The first marking device is incorporated in the body and in communication with the first chamber to access the marking substance contained by the inner surface. At least a part of the first marking device is moveable between an exposed position for marking on the desired surface, and a retracted position. In one embodiment, the body has a form factor of a financial transaction card.

Owner:STEINSCHADEN ANDRE R

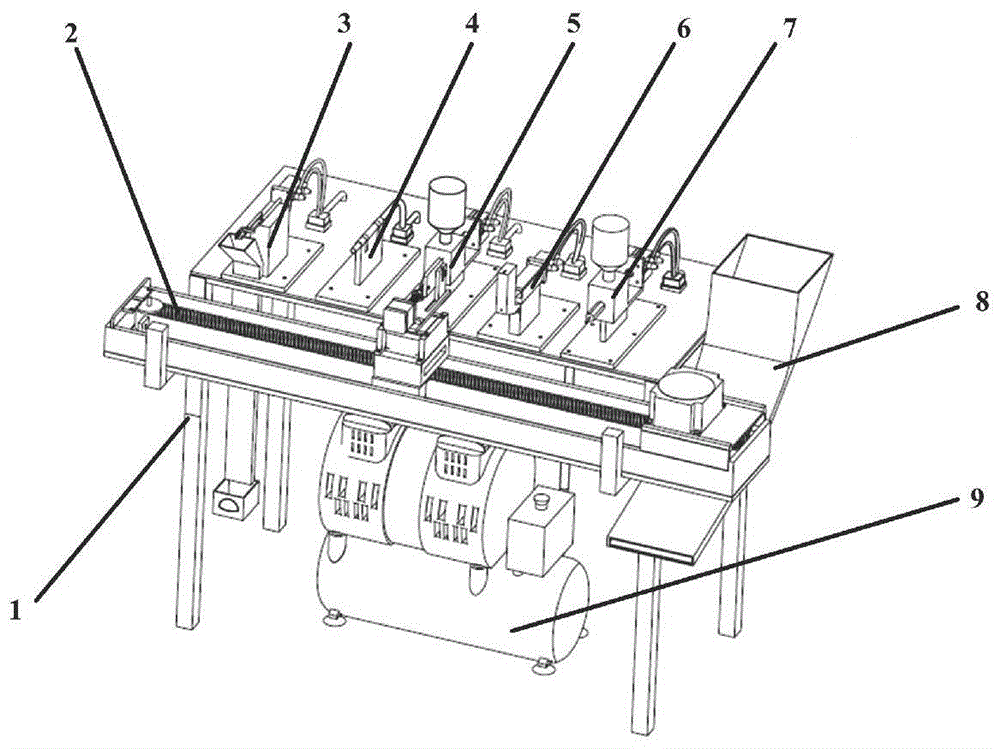

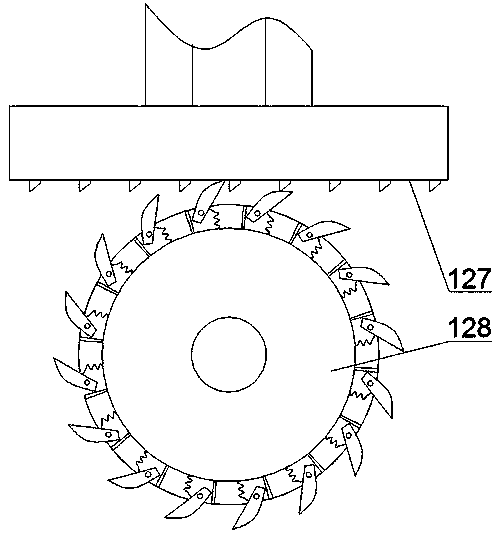

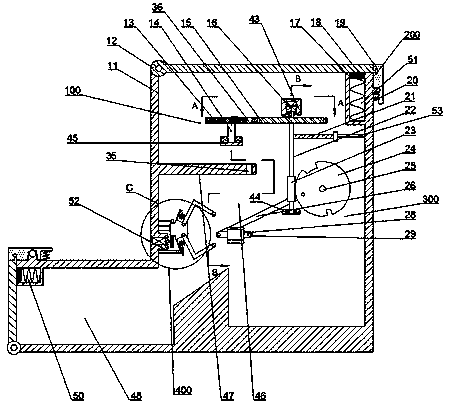

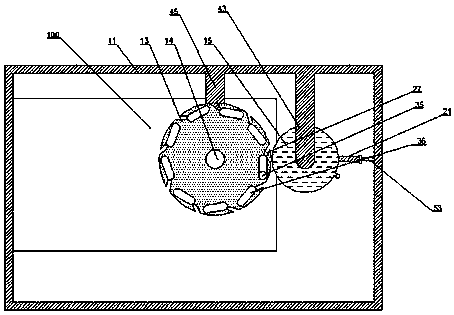

Selling device capable of adding ink into fountain pen refill and replacing pen point automatically

InactiveCN105856903AEfficient recyclingReduce pollutionPen repairingNib removersEngineeringAssembly line

The invention relates to a selling device capable of adding ink into a fountain pen refill and replacing a pen point, in particular to an assembly line type producing and selling device for adding ink into a waste fountain pen refill and replacing a pen point fully automatically. The selling device comprises a machine frame, a moving platform, a pulling-out mechanism, an air blowing mechanism, an ink adding mechanism, a pen point installation mechanism, a tail ink injection mechanism and a selling mechanism. According to the selling device, the overall structure is compact, and disassembly, assembly and maintenance are easy; the waste refill can be refilled with ink to be used repeatedly, effective recovery of the refill and tail ink can be achieved, and pollution of harmful substances in the refill and the tail ink to the living environment is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

Automatic cover-opening device

ActiveUS20150322704A1Easy to openVersatile and convenient in useSharpenersWing fastenersAxial forceEngineering

Owner:SDI CORPORATION

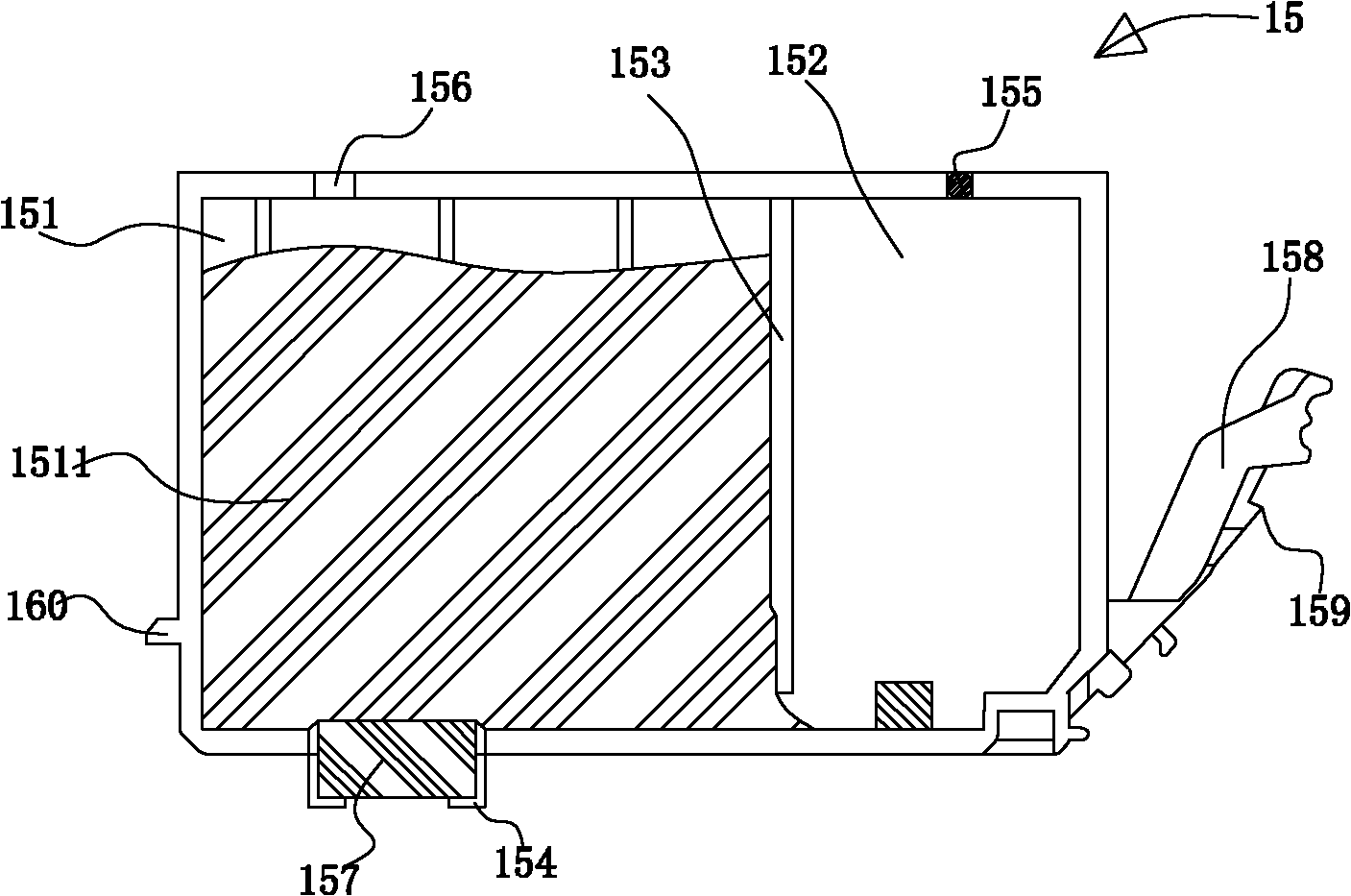

Negative pressure type ink box filling apparatus, filling system thereof and filling method thereof

ActiveCN102371767ASolve technical problems prone to ink splashingAvoid drippingInk receptaclesFilling devicesEngineeringMechanical engineering

The invention relates to a negative pressure type ink box filling apparatus, which comprises an ink container, an ink injection channel, a sucker, and a suction channel. The ink injection channel is used for conveying ink to a to-be-filled ink box; one end of the ink injection channel is an inlet end where ink in the ink container enters the ink injection channel; and the other end of the ink injection channel is an outlet end that is connected with the to-be-filled ink box. The suction channel is communicated with the ink container and a suction entrance that is connected with the sucker is arranged on the suction channel. And the inlet end is above a horizontal plane of the ink in the ink container. Because the inlet end is above the horizontal plane of the ink in the ink container, the ink in the ink container can not overflow through the ink injection channel no matter how an environmental factor is changed; therefore, a technical problem that an ink splashing phenomenon occurs when a user uses a current negative pressure type ink filling apparatus at the first time is solved.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

Ink adding method of mark pen

InactiveCN106079967ASolve the phenomenon of discardingExtended service lifeInk reservoir pensFilling devicesConical tubeEngineering

The invention discloses an ink adding method of a mark pen. The ink adding method comprises the steps that A, a front end of a conical opening sealing tube of a stretching tube of disposable bag ink is cut through a cutter, and the conical opening sealing tube is inserted into a taper hole of a transition tube of the mark pen of which a pen cover is opened; and B, an end cover on another stretching tube conical tube is taken down through a handle, the conical tube is mounted on a conical head, of which the front part is small and the back part is large, at the front end of an injection tube in a sleeving manner, an injection rod of the injection tube is pushed to inject air into a bag body, and air pushes ink in the bag body to enter the taper hole of the transition tube of the mark pen through an opening of the conical opening sealing tube. Compared with the prior art, the problem that a conventional mark pen cannot be circularly utilized can be solved.

Owner:温莉

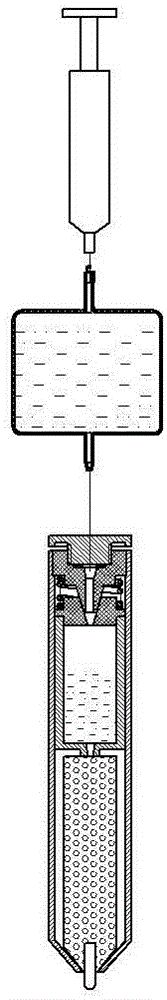

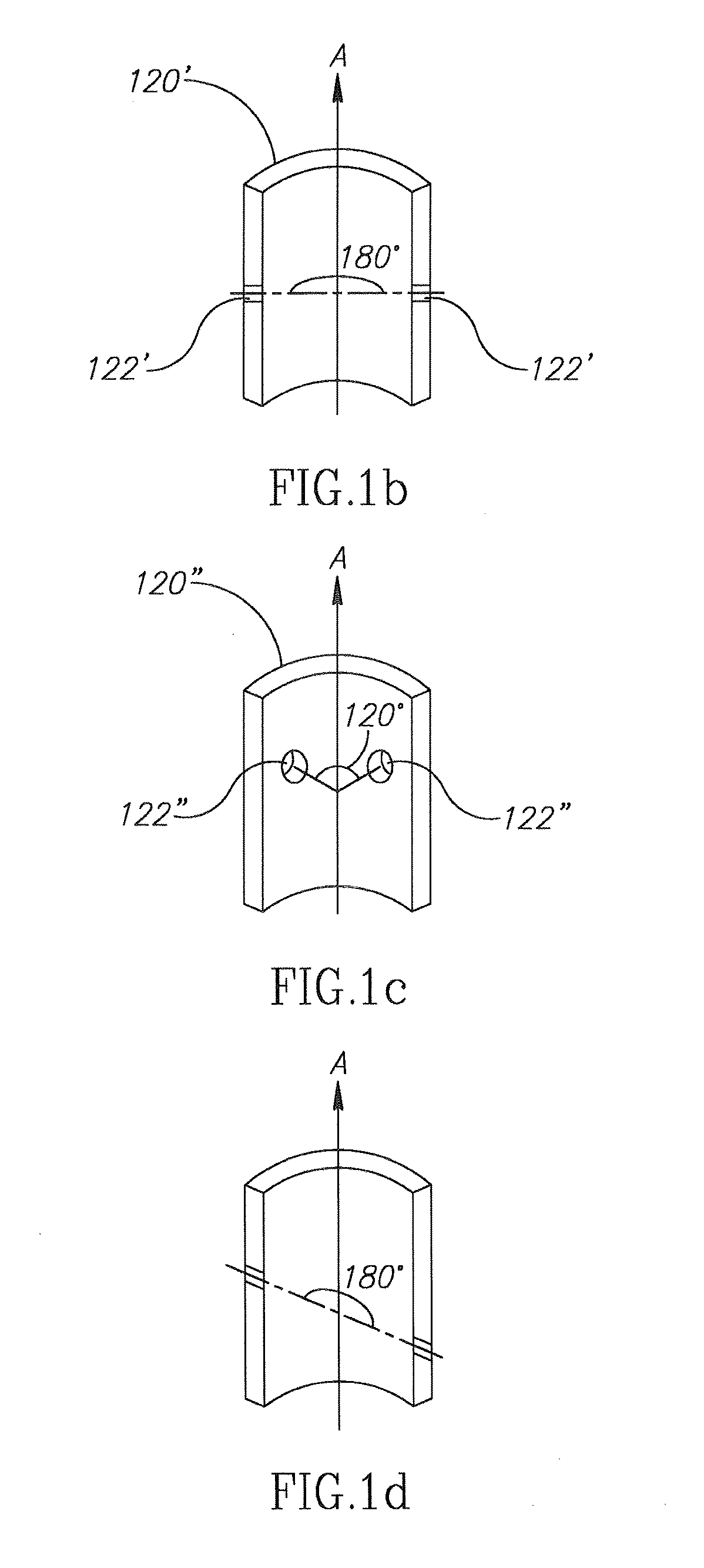

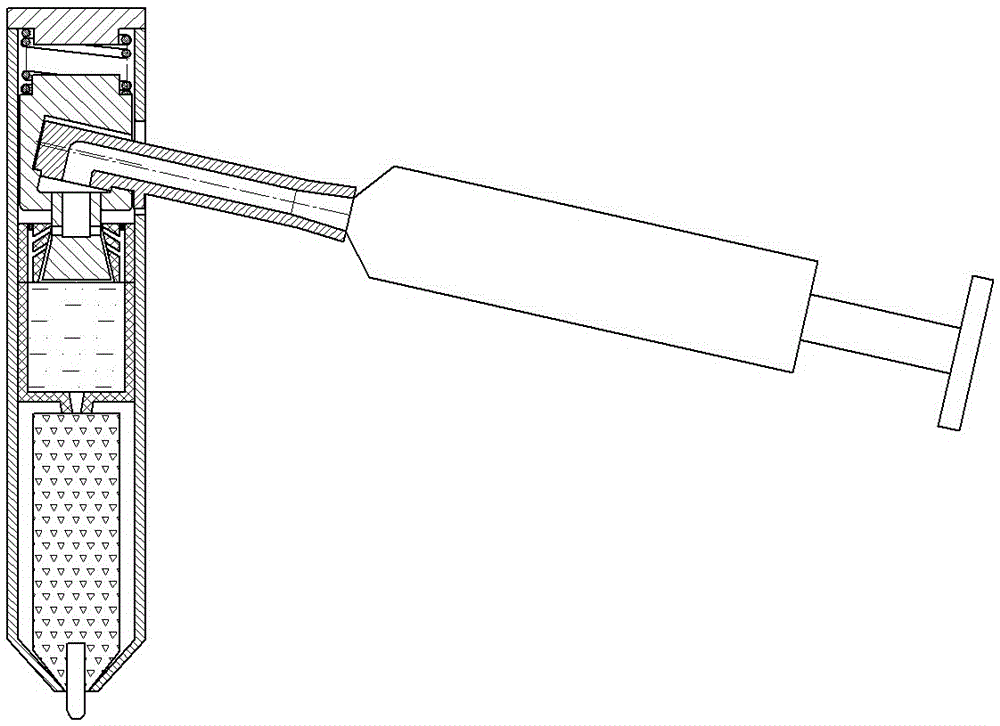

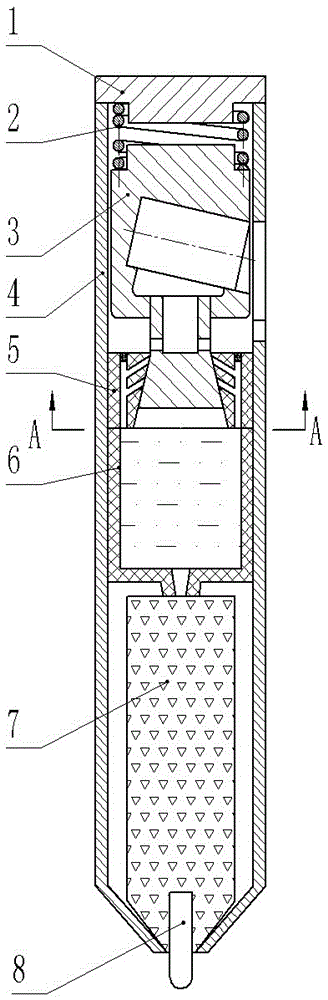

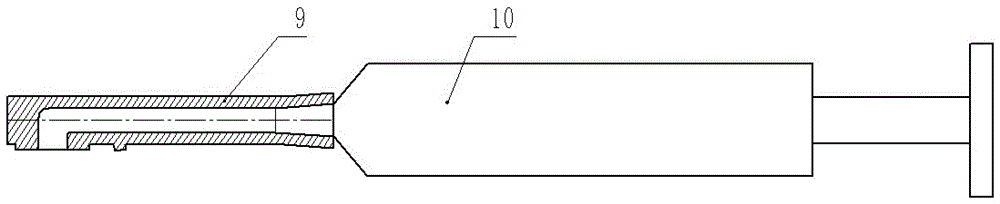

Method for injecting ink into marker pen

InactiveCN105730064AReduce stressShort tripInk reservoir pensFilling devicesBiomedical engineeringSyringe

The invention discloses a method for injecting ink into a marker pen. The method comprises the following steps: A, firstly inserting an injection head connecting pipe part of an ink injection head into an injection syringe having a certain volume; B, inserting an injection head inserting part of the ink injection head into an inserting inclined hole of an injecting plug through a positioning hole of a pen barrel to enable a positioning column at the lower part of the injection head inserting part to be engaged with a round positioning rabbet of the injecting plug; then, pressing down the injection head connecting pipe part to enable a positioning protrusion on the injection head connecting pipe part to be inserted into a positioning slot of the pen barrel; C, operating the injection syringe to inject the ink into an ink injection passage of the injecting plug; and D, lifting up the injection head inserting part finishing ink injection and taking out the injection head inserting part from the positioning hole of the pen barrel. Compared with the prior art, the method disclosed by the invention is capable of solving a problem that an existing marker pen cannot be reused.

Owner:温其洲

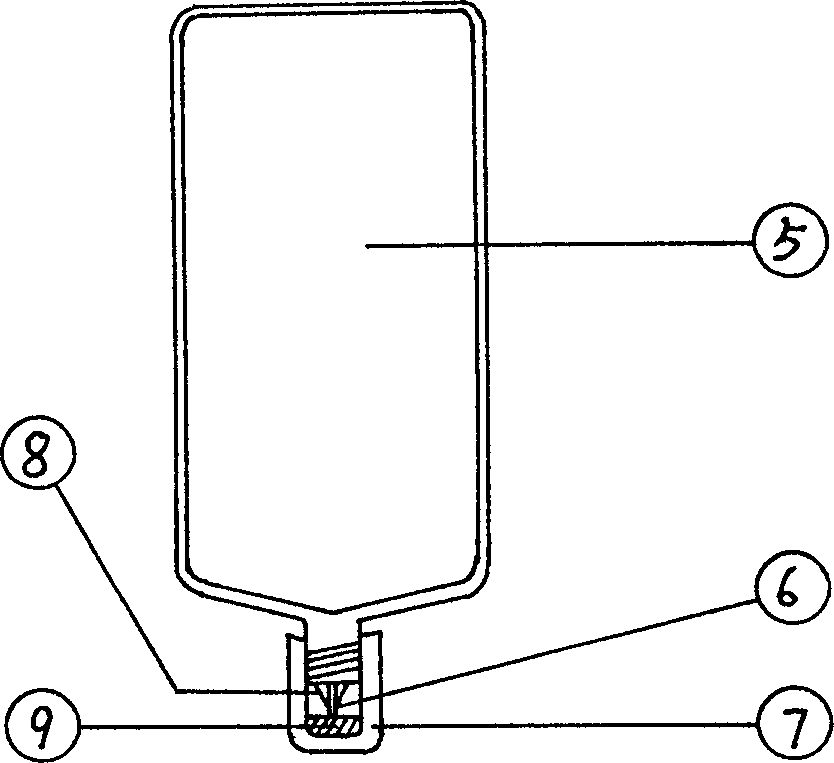

Liquid applicator

A fillable container and applicator for storing and then later applying liquids such as paints, dyes, and varnishes to a surface the container including a resilient bottle adapted to hold a liquid including a open end, a pin that fits over the bottle open end that includes a opening complementary to the bottle open end, a cap that fits over the pin that includes an opening complementary to the bottle open end, an applicator holder and a liquid applicator.

Owner:RUST OLEUM CORP

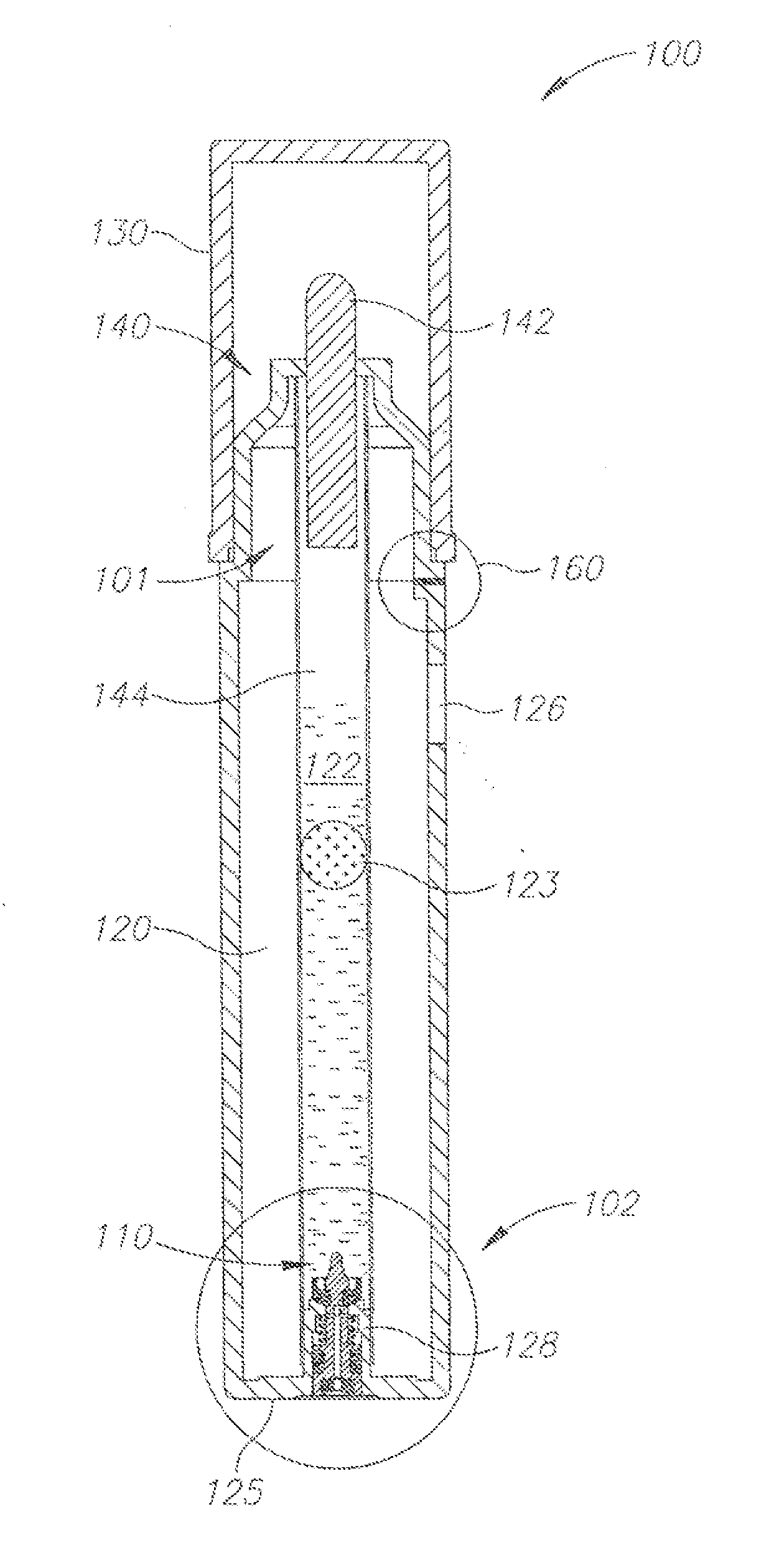

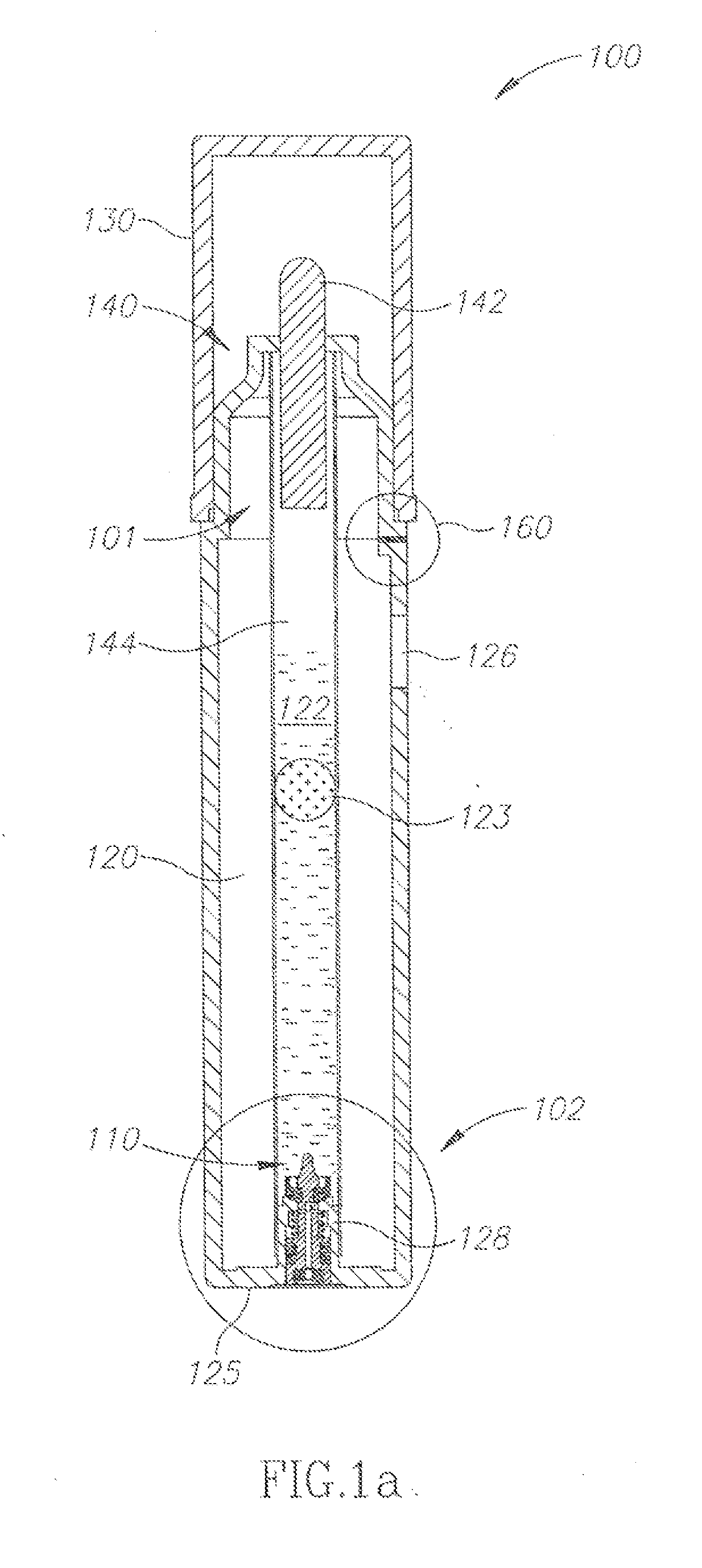

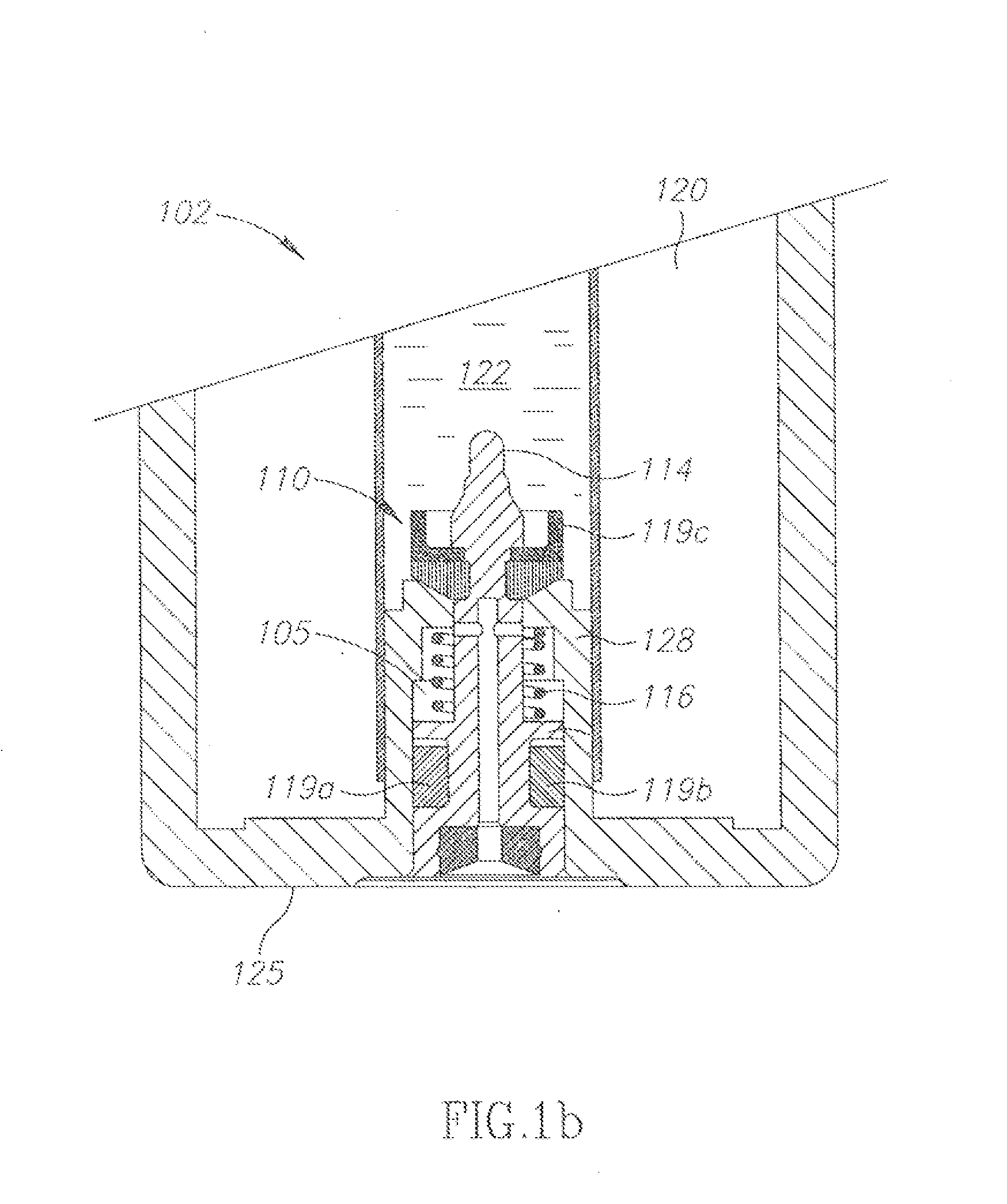

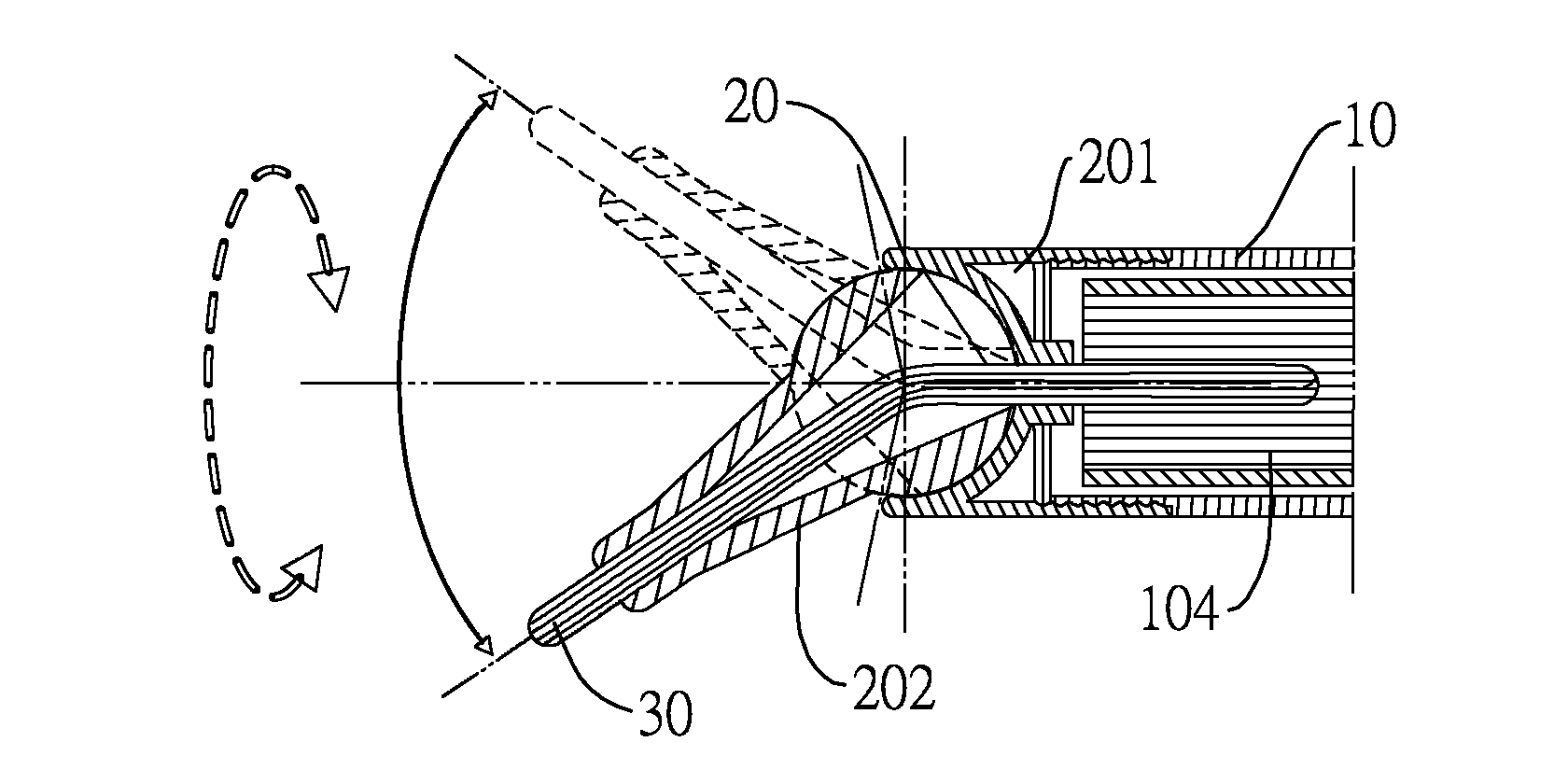

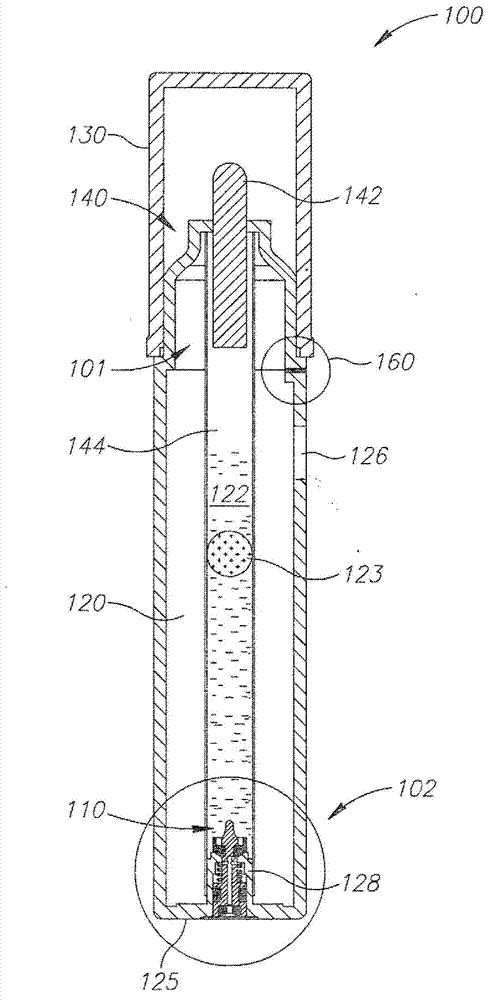

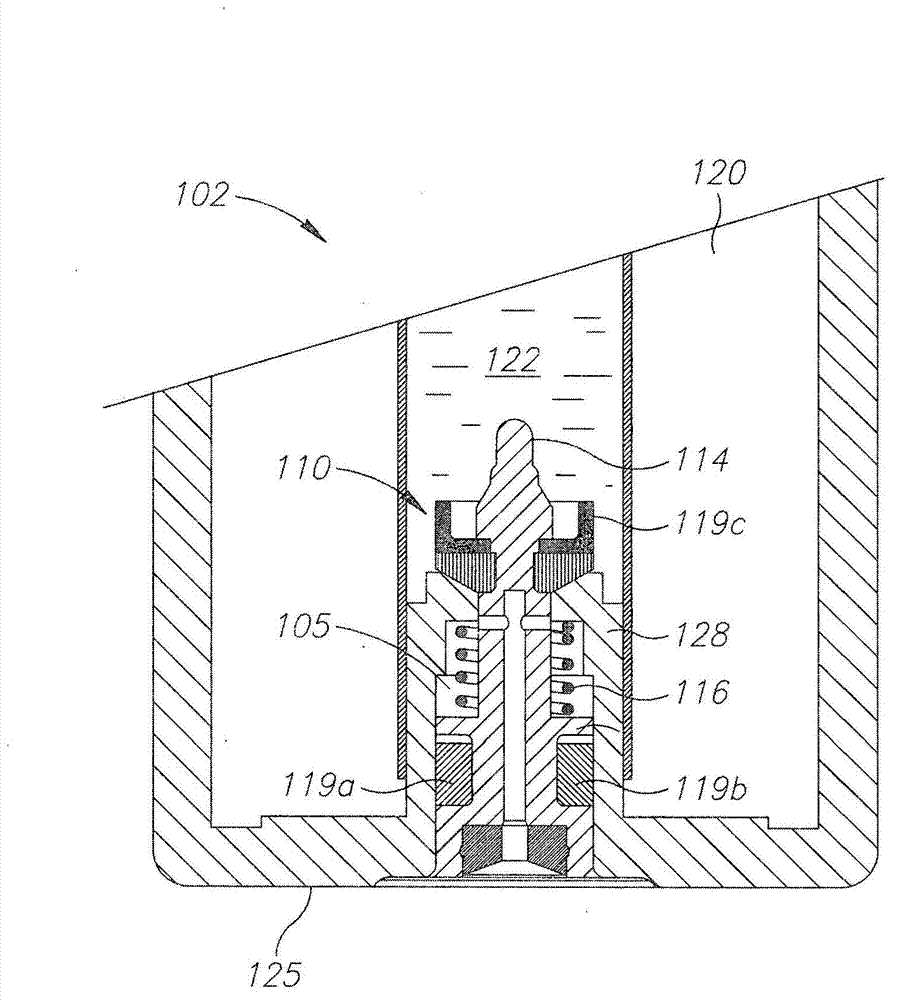

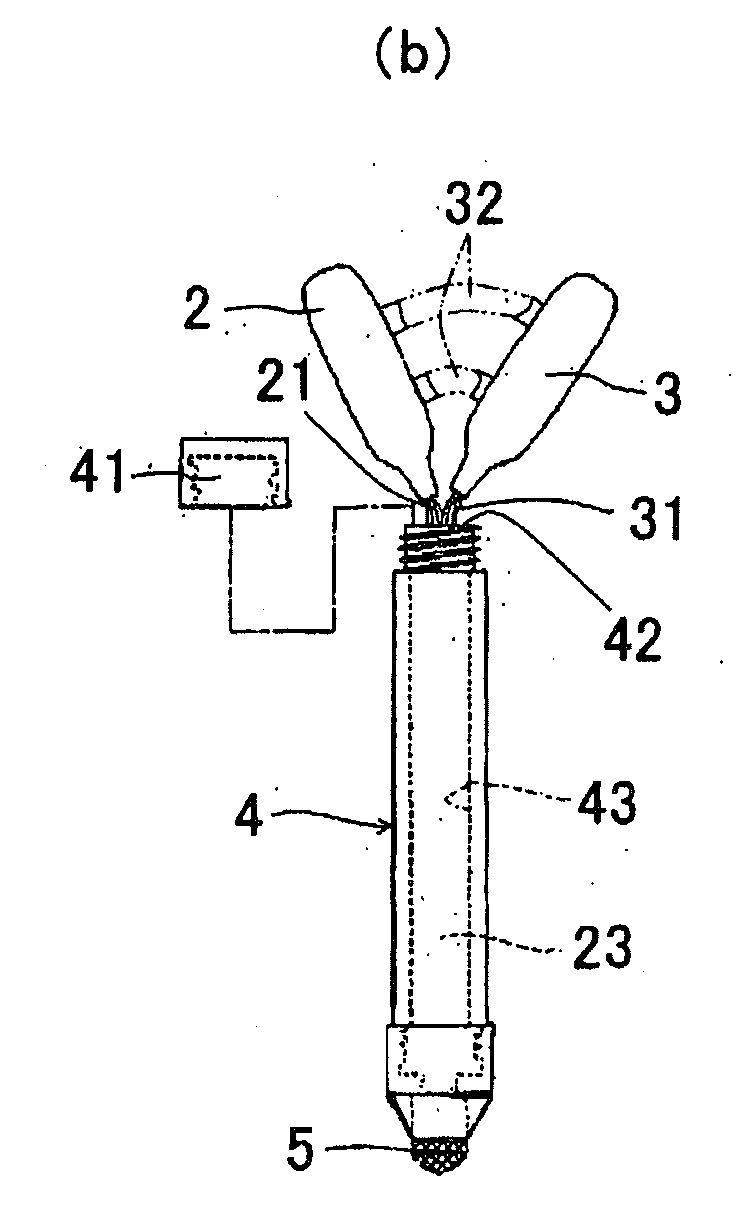

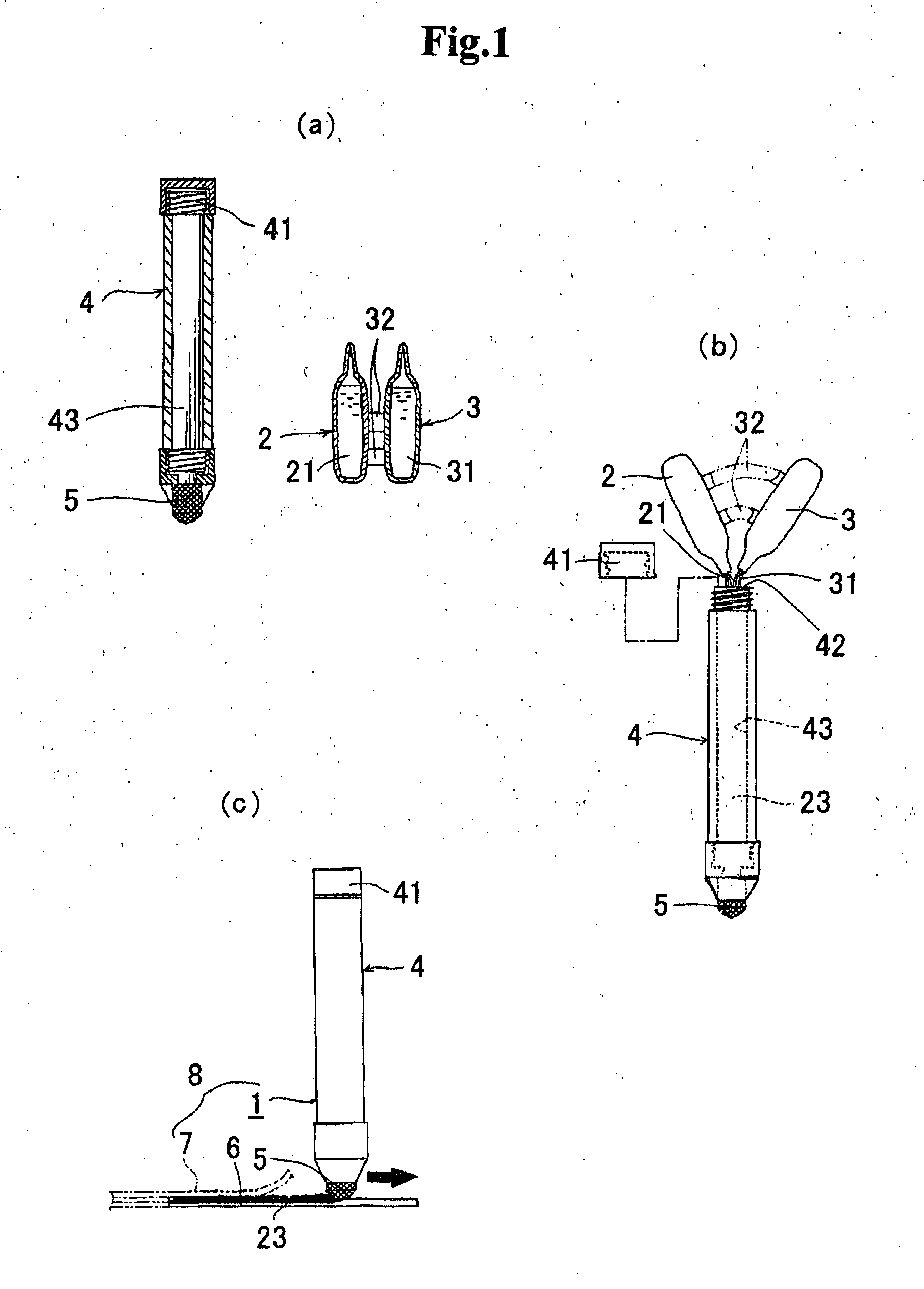

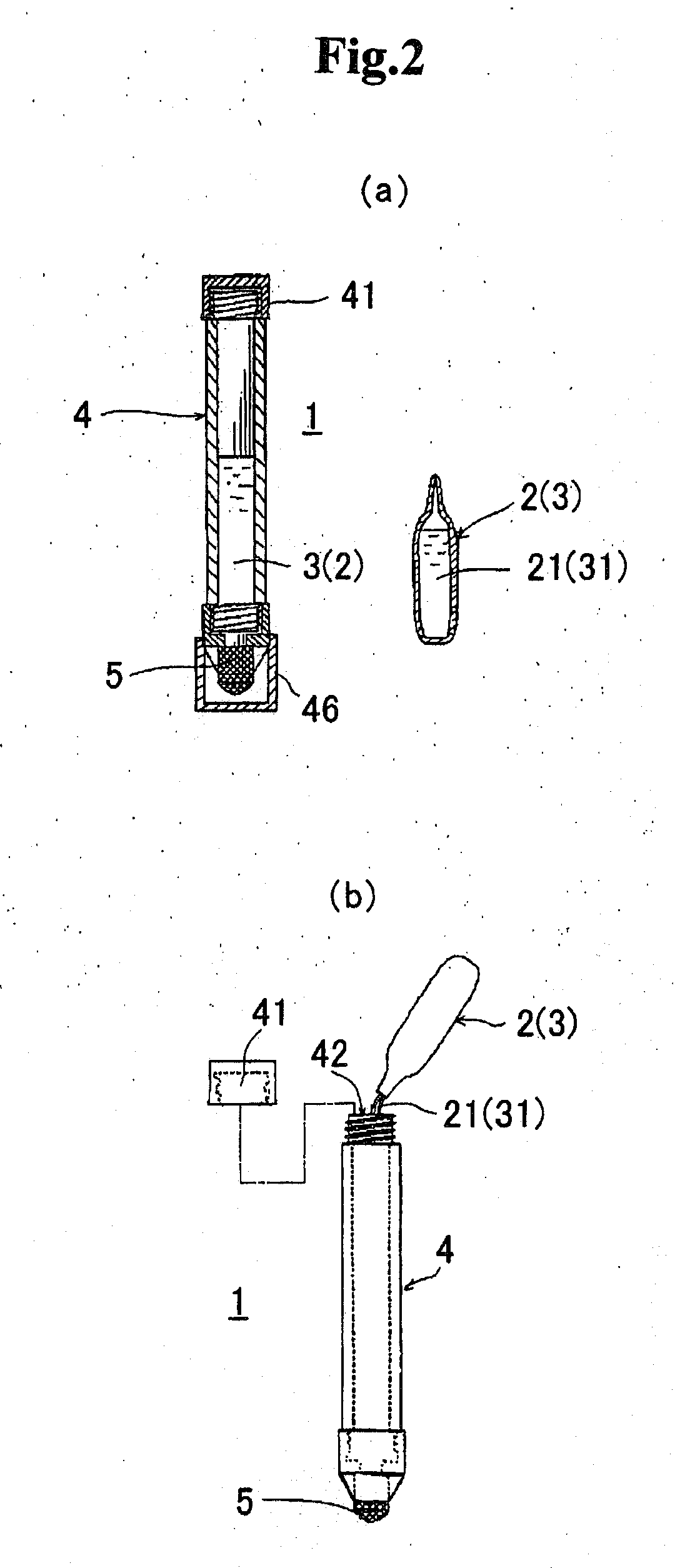

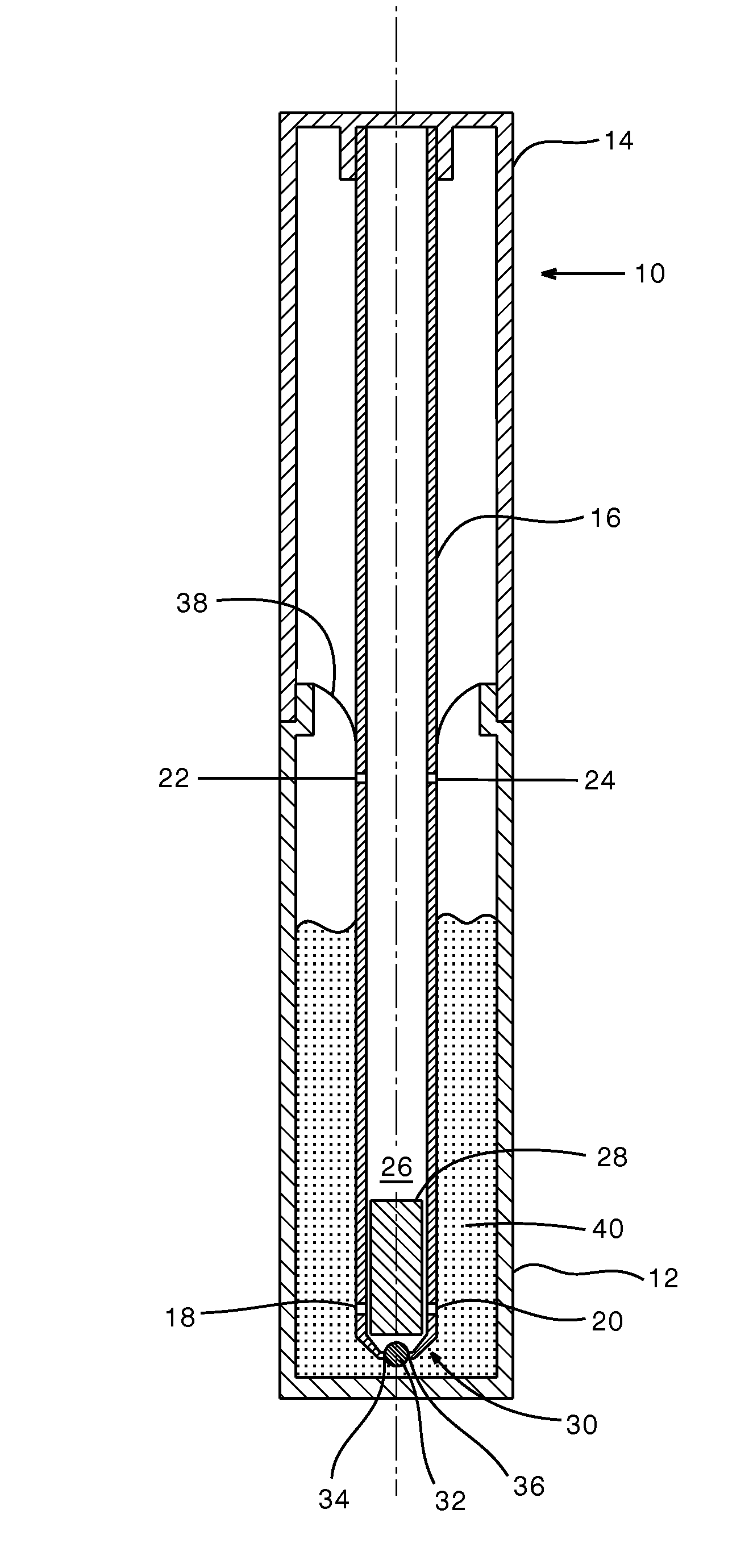

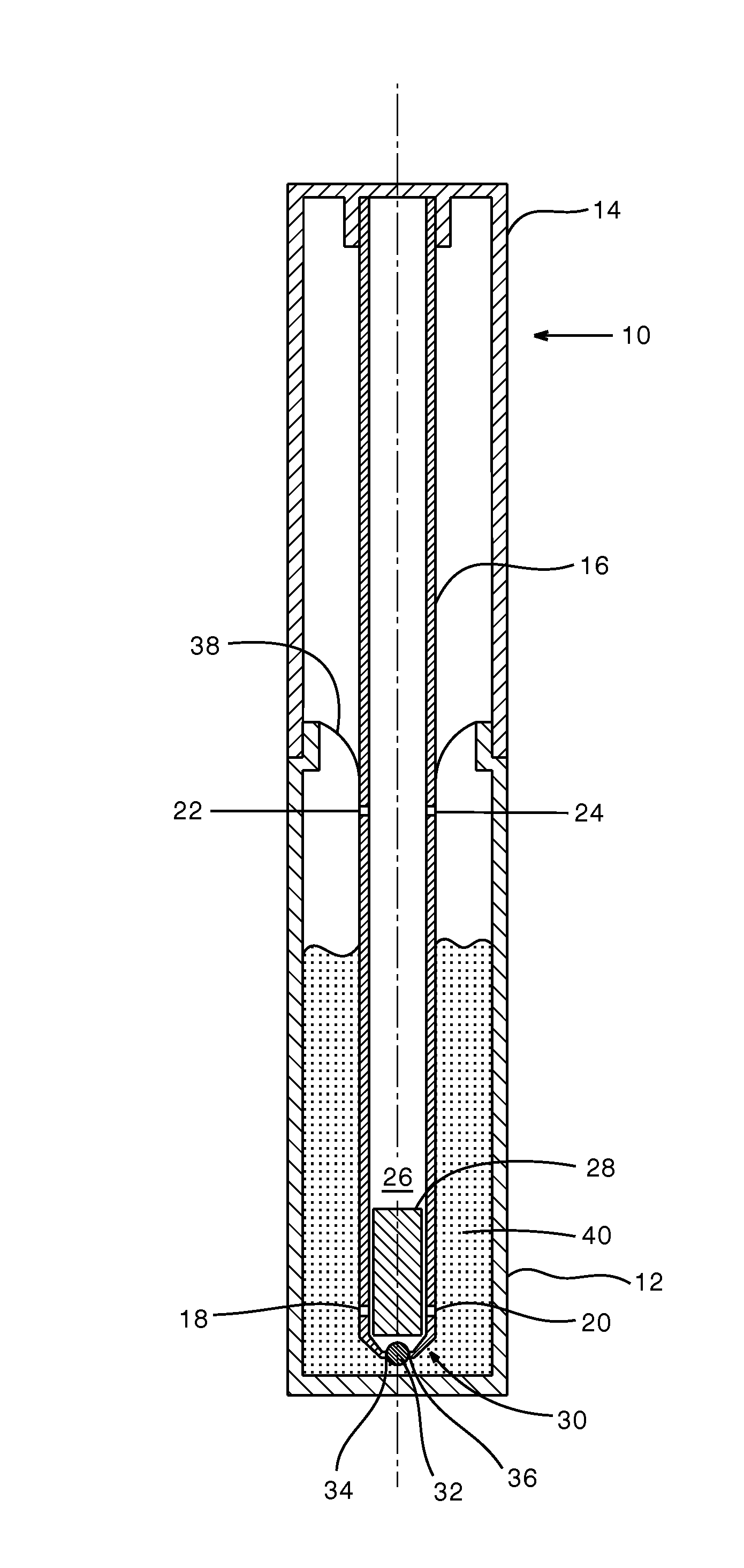

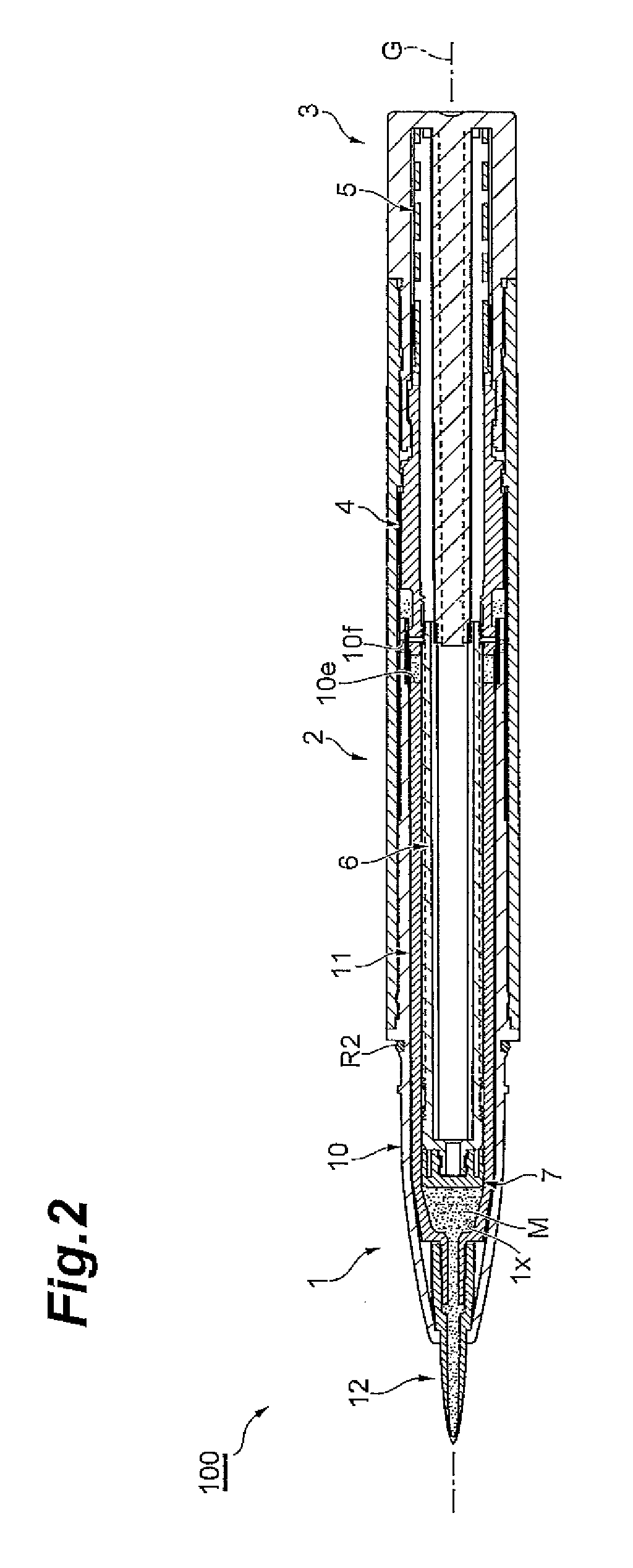

Light-emitting writing instrument and light-emitting indicator using the same

InactiveUS20100047005A1Simple instructionsOther printing matterWriting connectorsFluorescenceEngineering

An object of the present invention is to provide a light-emitting writing instrument that can indicate characters and figures by utilizing chemiluminescence phenomena and a light-emitting indicator using the light-emitting writing instrument. A light-emitting wiring instrument 1 includes a fluorescent liquid 21 and an oxidizing liquid 31 that are respectively sealed in destructible containers 2 and 3 and that generate a chemiluminescence phenomenon when mixed with each other; a rod-shaped cylindrical container 4 that also functions as a grip and accommodates a mixture of the fluorescent liquid 21 and the oxidizing liquid 31 discharged from the destructible containers 2 and 3; and an application portion 5 liquid-tightly attached to a tip of the cylindrical container 4 so as to be communicated with the cylindrical container 4. A light-emitting indicator 8 using the light-emitting writing instrument 1 (to be continued).

Owner:LUMICA

Decorating applicator

A decorating applicator for use in a decorating kit comprises a self-feeding hollow plastic tube or wand having a sponge foam rubber applicator tip at one end and a base at the other end of the tube. The applicator tip is held in place with a plastic plug or cap mounted in the open end of the tube. A food dye is placed within the tube, water added and the plug with the applicator extending therefrom is sealingly mounted in the tube opening. The colored liquid is drawn onto the sponge tip through an aperture in the plug. The tip has a specific tapered configuration to facilitate decorating.

Owner:LAMOND JOAN BAILLIE +1

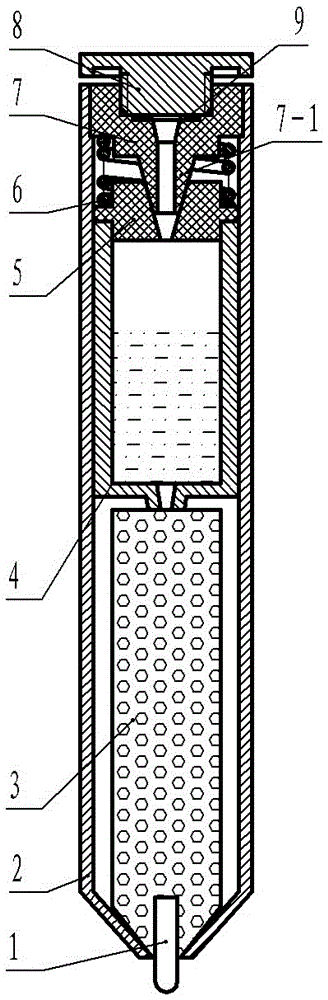

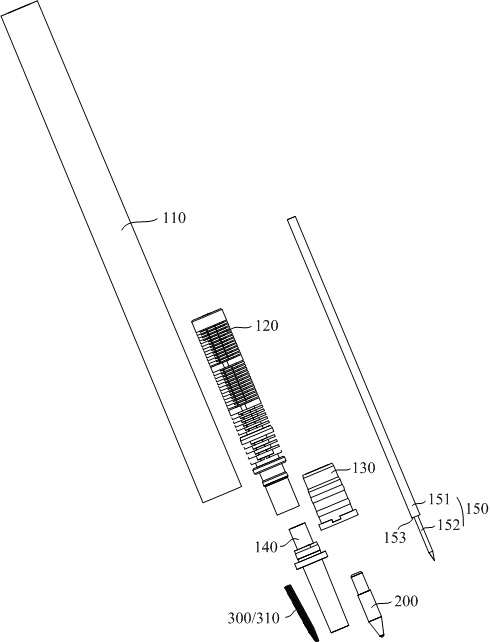

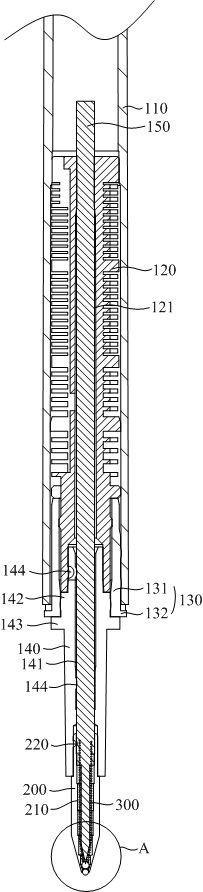

Pen and automatic ink injection device thereof

InactiveCN108556515AEasy to removeEasily detachable, does not take upInk reservoir pensFilling devicesEngineeringInjection device

The invention provides a pen. The pen comprises a pen body, an ink container prepared from a hard material is fixedly installed in the pen body, the bottom surface of the ink container is fixedly connected with the upper end of an ink pipe, and the ink pipe is communicated with the inside of the ink container. A piston is arranged in the ink container, the piston is collinear with the central lineof the ink container, the periphery of the piston makes cooperative contact with the inner wall of the ink container, and the piston can slide up and down along the ink container. An insertion hole is formed in the top surface of the piston, the top surface of the insertion hole is communicated with the outside, insertion grooves are formed in the front face and the rear face of the insertion hole respectively, the top surfaces of the insertion grooves are communicated with the outside, and the insertion grooves are communicated with the inside of the insertion hole. Arc-shaped grooves are formed in the two sides of each insertion groove respectively, and the arc-shaped grooves are communicated with the insides of the corresponding insertion grooves. The pen further comprises an adjustingrod and a dust-proof plug, wherein the dust-proof plug can be inserted into a through hole in the top surface of the pen body, and the periphery of the dust-proof plug can make close cooperative contact with the inner wall of the through hole in the top surface of the pen body so that dust and other debris can be prevented from entering the pen body through the through hole.

Owner:SHANDONG WOMENS UNIV

Dynamically allocating server resources to competing classes of work based upon achievement of service goals

A facility for adjusting a number of servers assigned to server pools for performing certain work types on the basis of unmet service needs in a work processing facility. Servers may include service agents, both human and robotic. A server assignor and a corresponding server assignment method may each be employed in a work distributor or an automatic call distributor (“ACD”) to conditionally adjust server availability in server pools. The server assignor compares a composite preference value for a work type against each server's threshold value for the work type. When the server assignor determines that the composite preference value is greater than or equal to a server's threshold value, then the server assignor indicates that the server may be included in the server pool for that work type. Each server has preference values and threshold values for different kinds of work. The magnitude of a preference value represents an affinity for the work type. The server's threshold value represents a reluctance to perform work having that work type. The server does not normally receive work for which the preference value is less than the threshold value, unless the server assignor determines that the composite preference value exceeds the server's threshold value for that work type. The server assignor and corresponding server assignment method may compute the composite preference value from a number of user-selectable inputs and utilize a number of user-selectable functions.

Owner:AVAYA TECH LLC

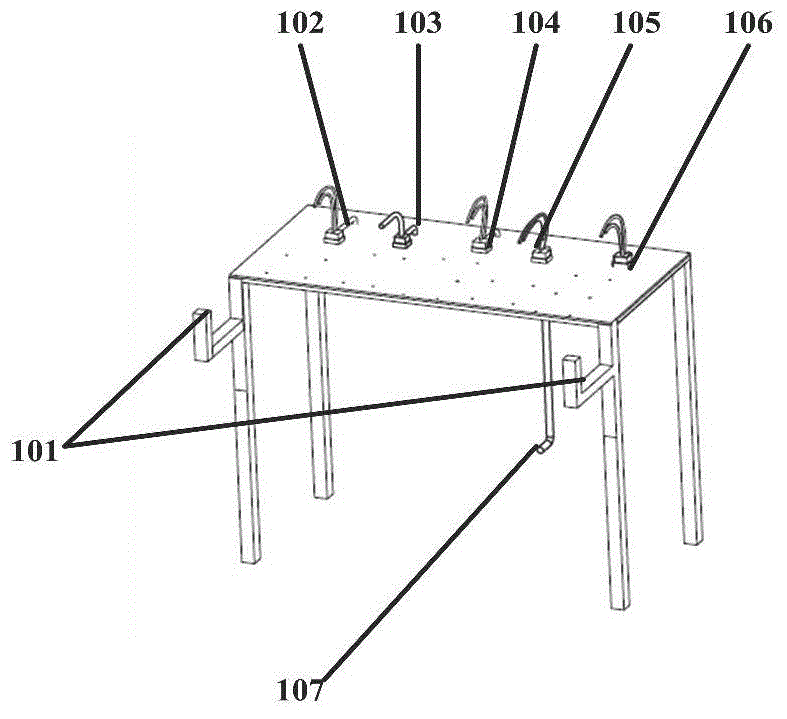

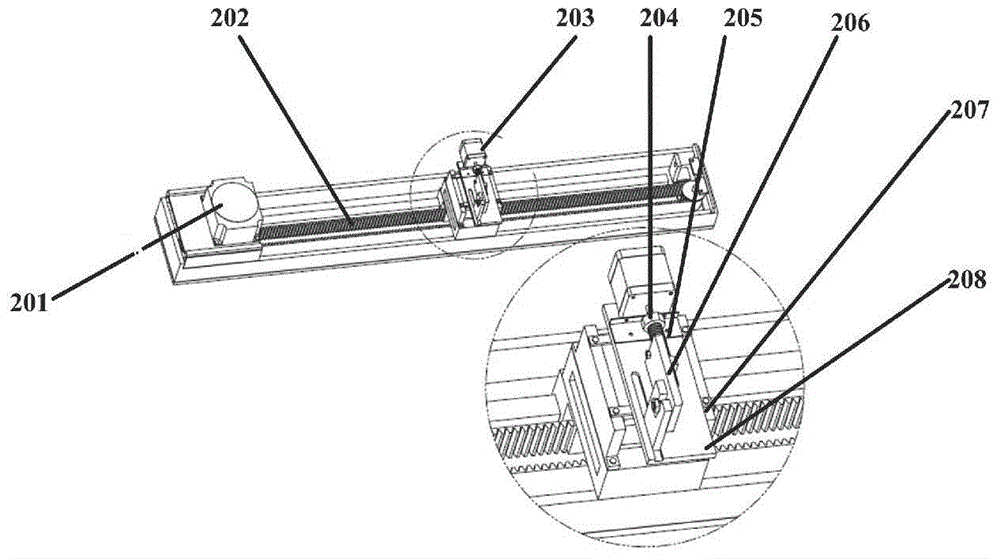

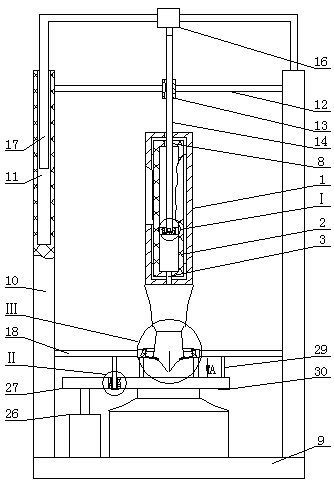

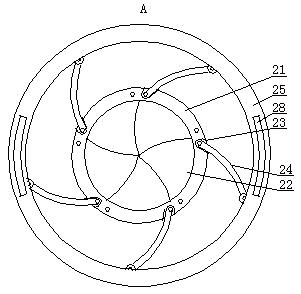

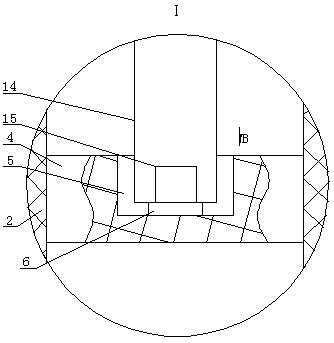

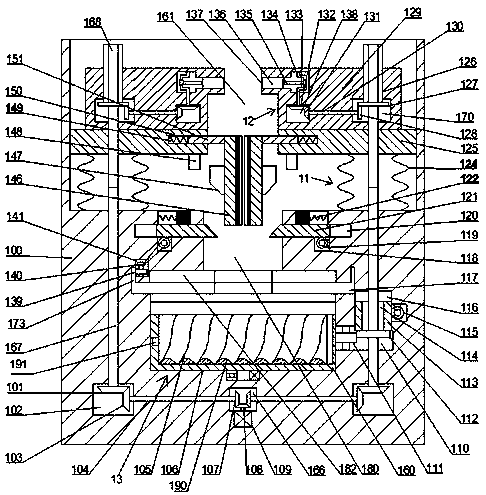

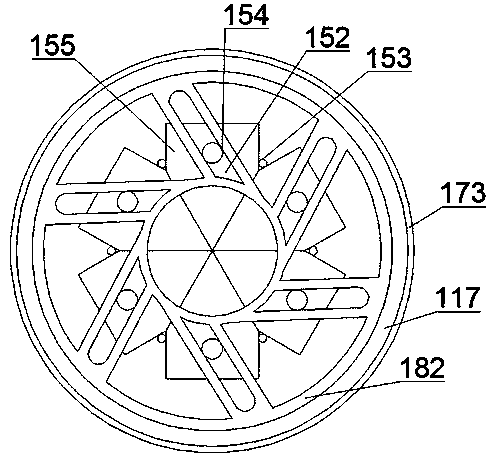

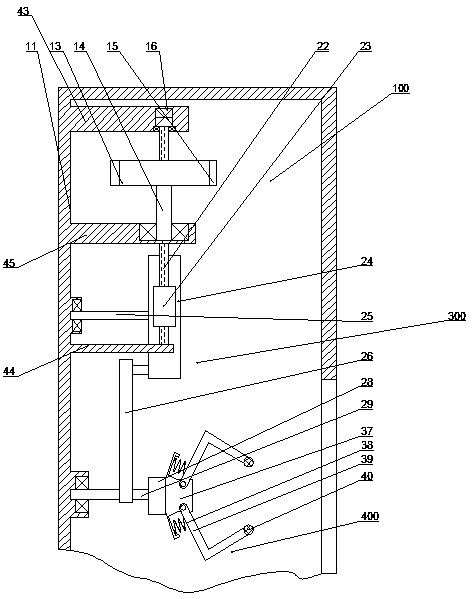

Fountain pen ink filling device

InactiveCN110053395ARealize automatic ink fillingAutomatic automatic ink fillingFilling devicesEngineeringSlide plate

The invention relates to a fountain pen ink filling device comprising a main machine body. A working cavity is arranged on the top end surface of the main machine body, supporting sliding plates whichare arranged in a bilateral symmetry manner are arranged in the working cavity in a sliding manner, clamping mechanisms are arranged in the supporting sliding plates, top fixing blocks are fixedly arranged on the top ends of the supporting sliding plates, ink filling mechanisms are arranged in the top fixing blocks, a cylindrical cavity is arranged at the bottom end of the working cavity, and thecylindrical cavity and the working cavity communicate with each other through a through hole cavity. By means of the fountain pen ink filling device, automatic ink filling of a fountain pen can be realized, the problem that ink splashes and contaminates the hand in the manual ink absorption process is solved, and meanwhile, the ink can be automatically stirred to prevent the ink from being precipitated. Moreover, the fountain pen ink filling device is simple in transmission structure, faults are not prone to being caused, and maintenance is facilitated.

Owner:YANTAI WEIHAI STATIONERY CO LTD

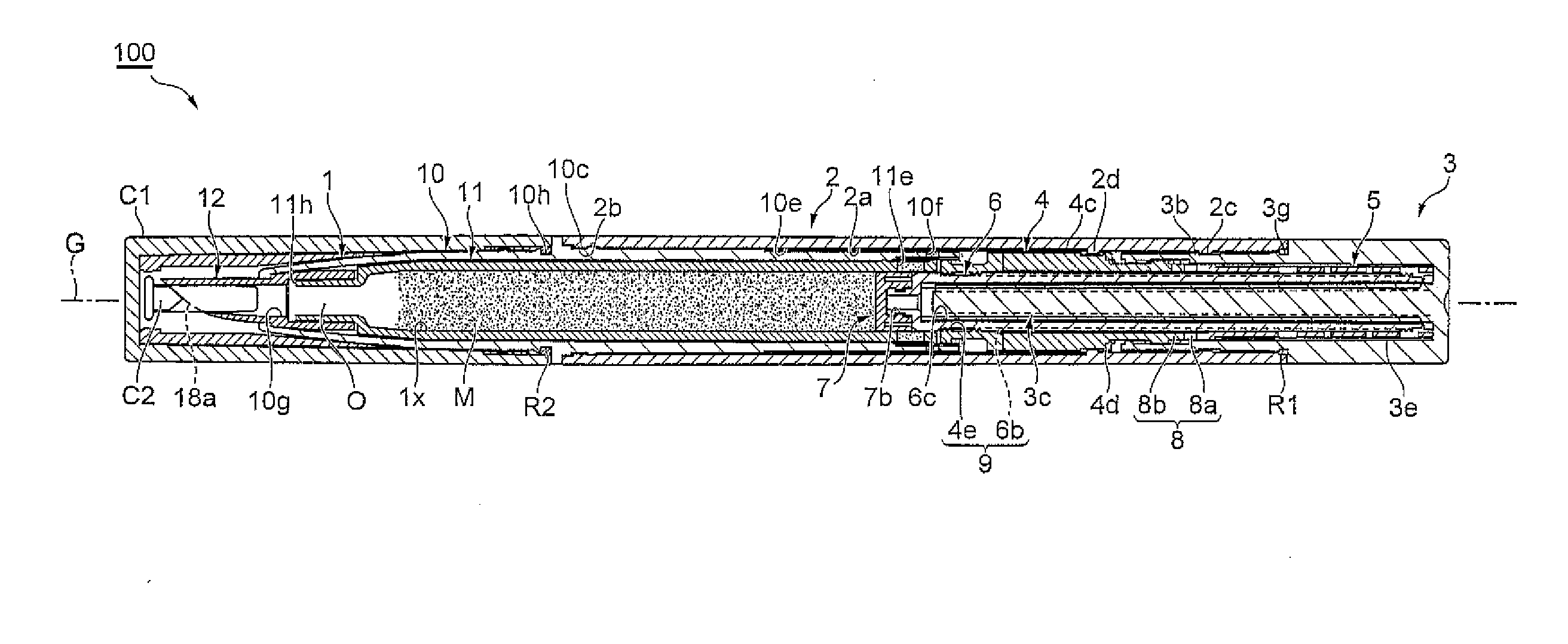

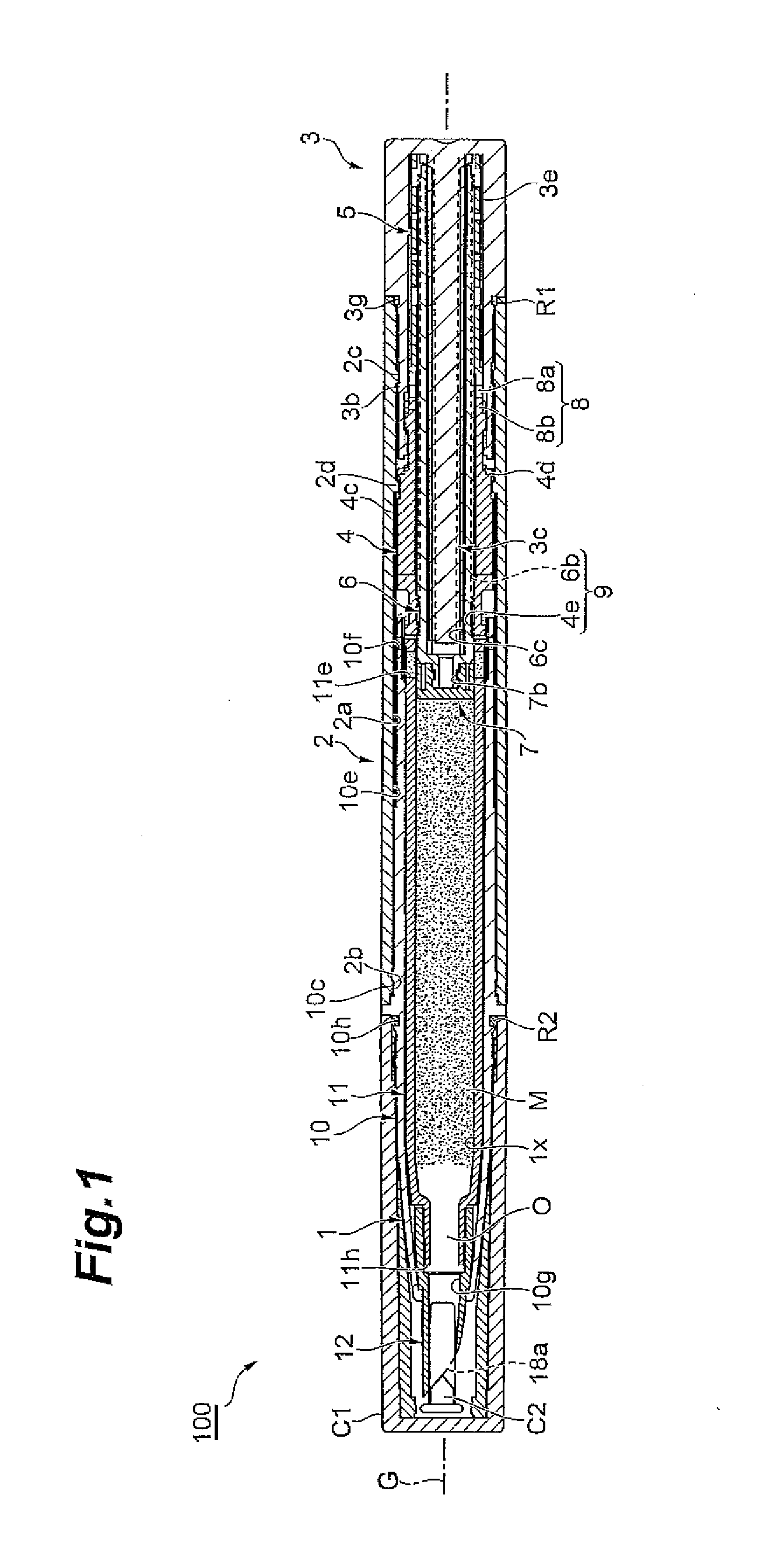

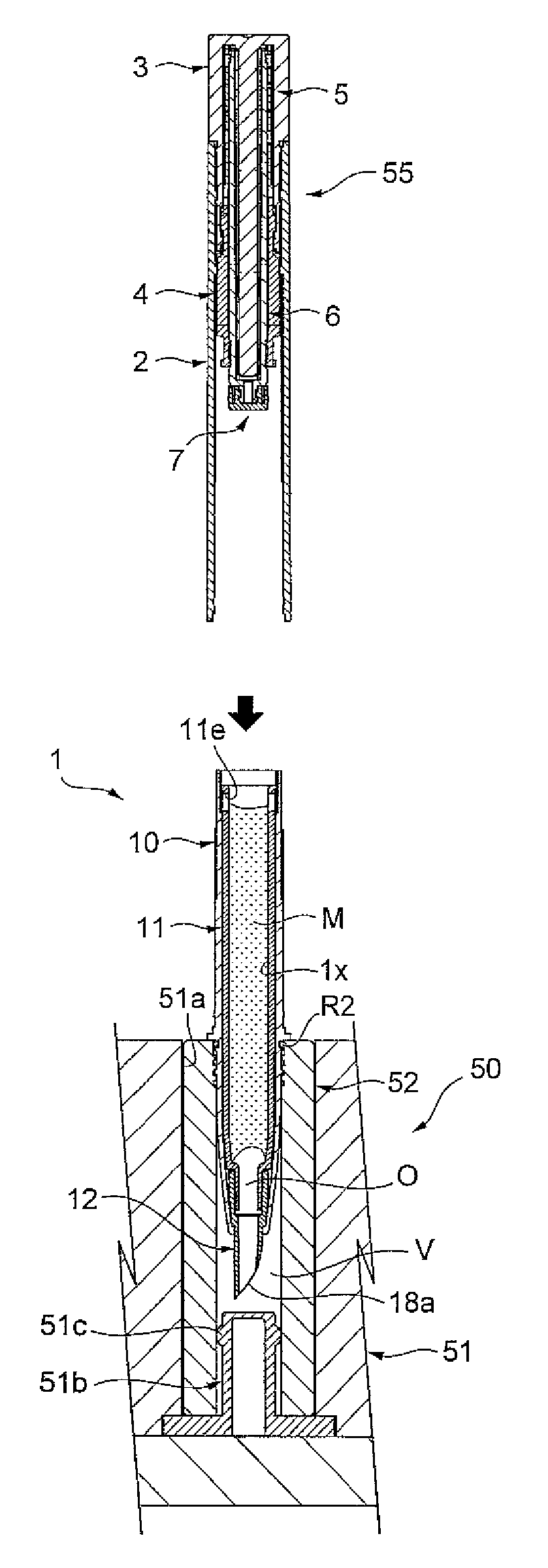

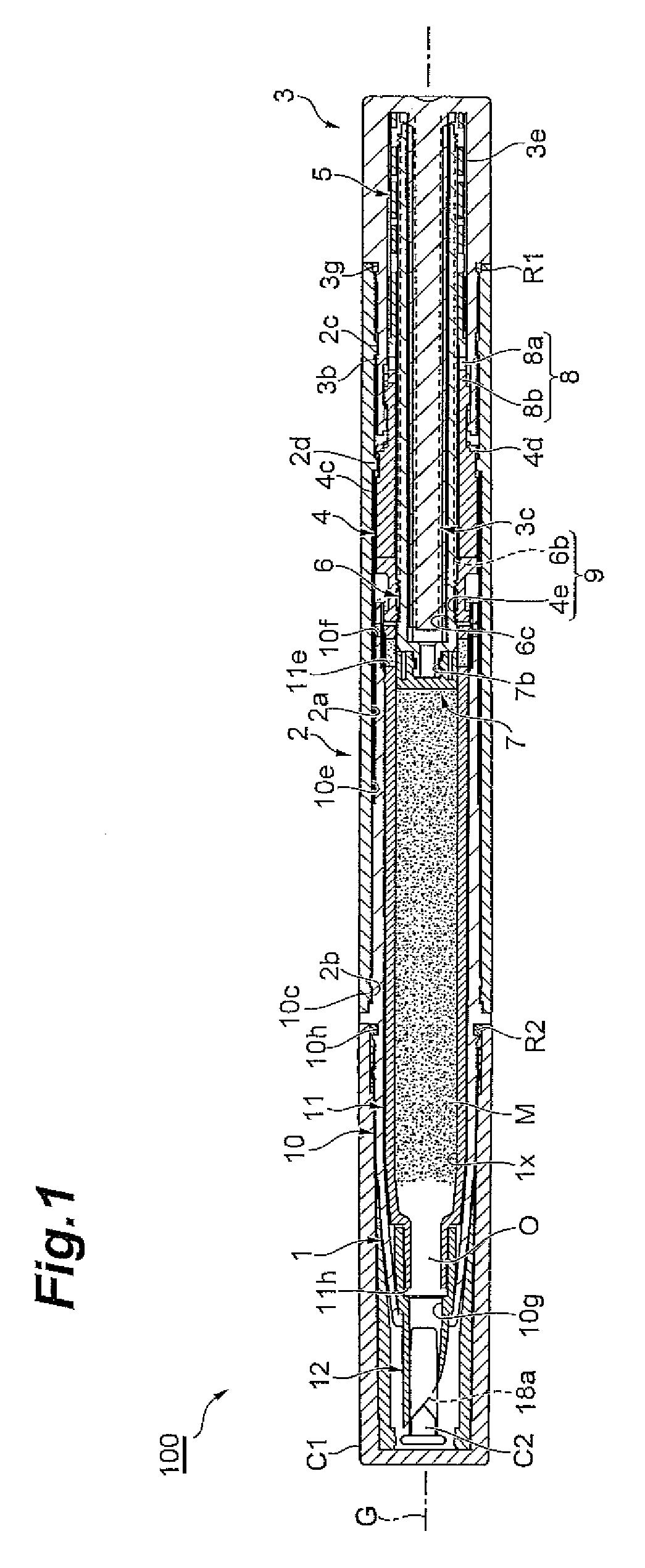

Liquid applicator

ActiveUS8740489B2Easily replenished and replacedIncrease capacityLiquid surface applicatorsBrushesCouplingEngineering

There is provided a liquid applicator allowing a liquid to be easily replenished and replaced, as well as capable of containing a large amount of liquid. The liquid applicator includes a main body provided with a tank inside thereof, a tip shaft that is coupled to the tip end side of the main body, and a brush that is fixed in the tip shaft and projecting from the tip end of the tip shaft. A liquid may be sucked into a tank by releasing the coupling of the main body and the tip shaft, sinking a tip end opening of the main body in the liquid, and sliding a sliding cylinder attached to the rear portion of the main body.

Owner:KOTOBUKI & CO LTD

Applicator device

ActiveUS20080118297A1Simple designLess-flexible materialBrushesBall-point pensMechanical engineering

Owner:SCHWAN STABILO COSMETICS

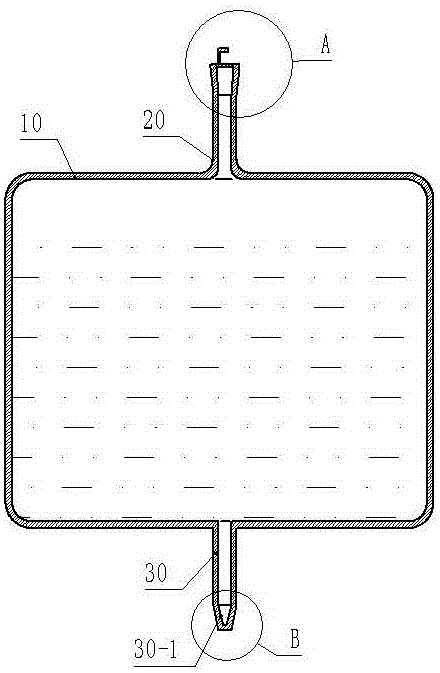

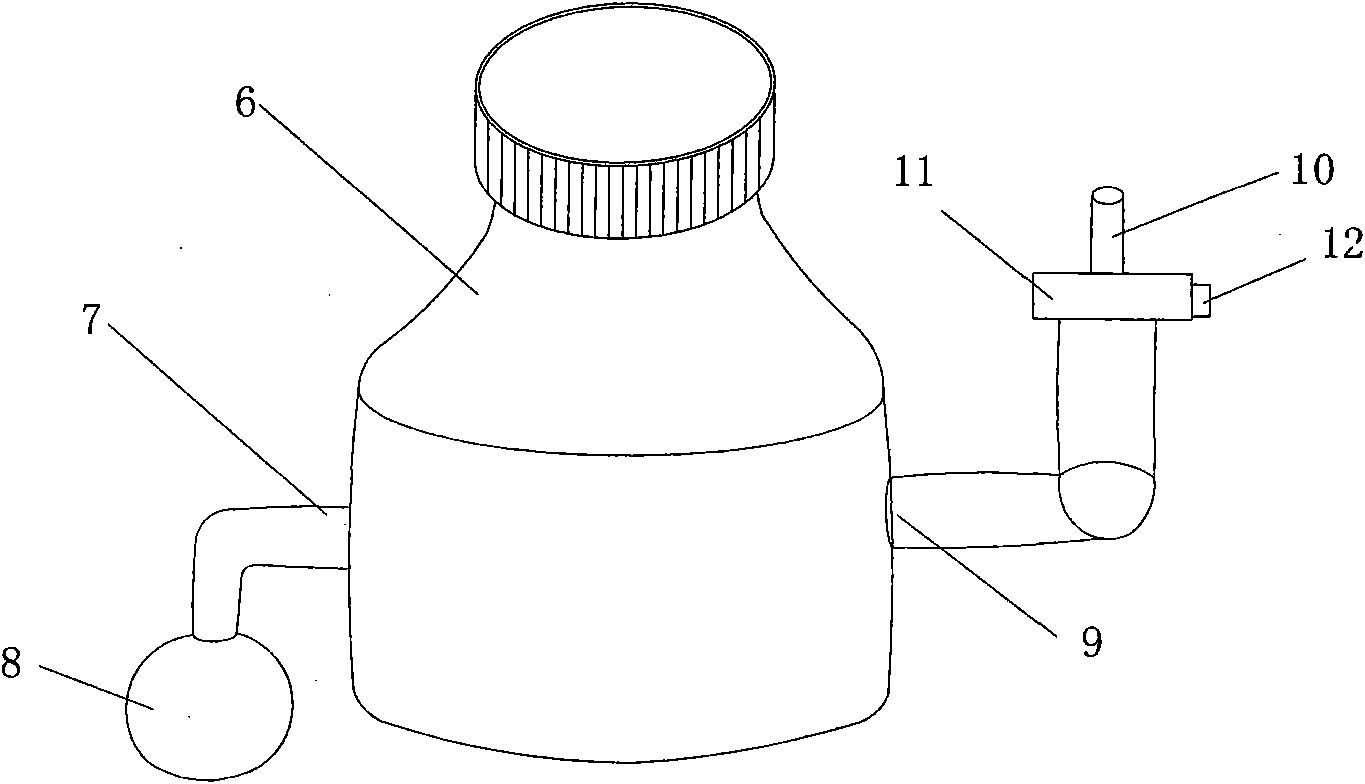

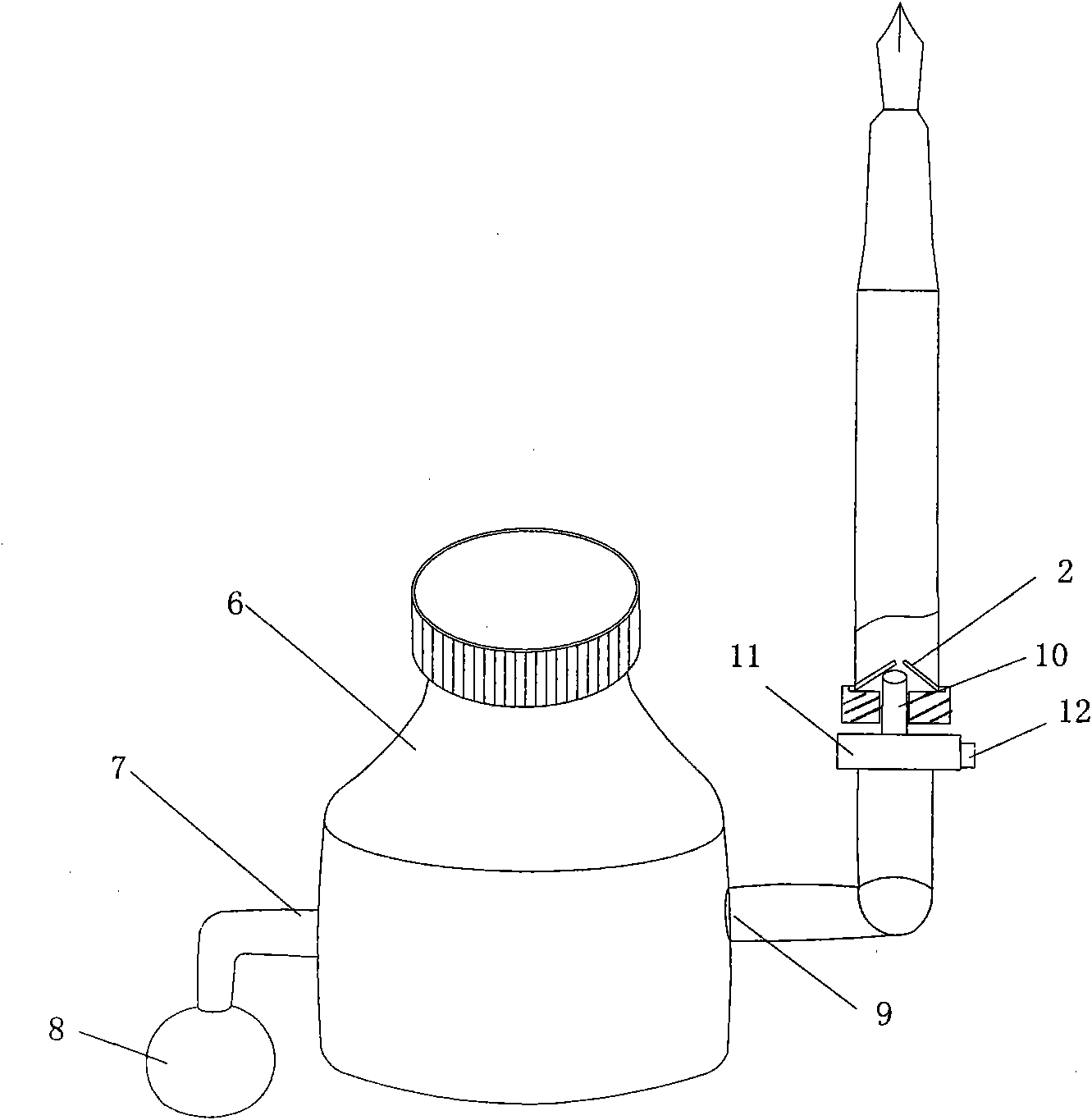

Pen and automatic ink-injection device

InactiveCN102009548AAvoid pollutionRealize automatic ink fillingInk reservoir pensFilling devicesInjection portPetal

The invention relates to a stationery, in particular to a pen and a special automatic ink injection device. The pen comprises a pen holder; the tail end of the pen holder is screwed with a pen cover which is provided with an ink injection port; the ink injection port is provided with an one-way valve petal which is opened towards the inner cavity of the pen holder; the automatic ink injection device comprises an ink bottle which is provided with an ink outlet and an inflation inlet; an intubation tube is inserted in the ink outlet and is provided with a valve and a button for controlling the on-off of the valve; and the inflation inlet is connected with an air bag. In the invention, the ink is injected into the pen by utilizing the air pressure difference, thus automatic ink injection is realized, the operation is convenient, the quantity of work is reduced greatly, the device can effectively prevent fingers from being polluted by the ink, and has strong practicability.

Owner:王梓菲

Joyful fountain pen. joyful water pen. joyful universal pen and joyful ink filling apparatus

InactiveCN1559806ASimple structureFunction increaseInk receptaclesBall-point pensSteel ballEngineering

A fountain pen, liquid ink pen, or universal pen features that its ink storage tube is composed of a transparent rigid tube and a coaxial fine tube as the internal ink-filling channel, the ink is stored in the space between said two tubes, and its tail end has an impervious rubber sleeve and an elastic plug. Its ink filler is composed of a thick tube and a thin tube, which are parallel and fixed to the cap of ink bottle. In said fine tube, there are spring, piston, check steel ball and ink suction tube. In said thick tube, there is an ink-filling tube whose bottom end is connected with the bottom end of said fine tube.

Owner:熊开怀

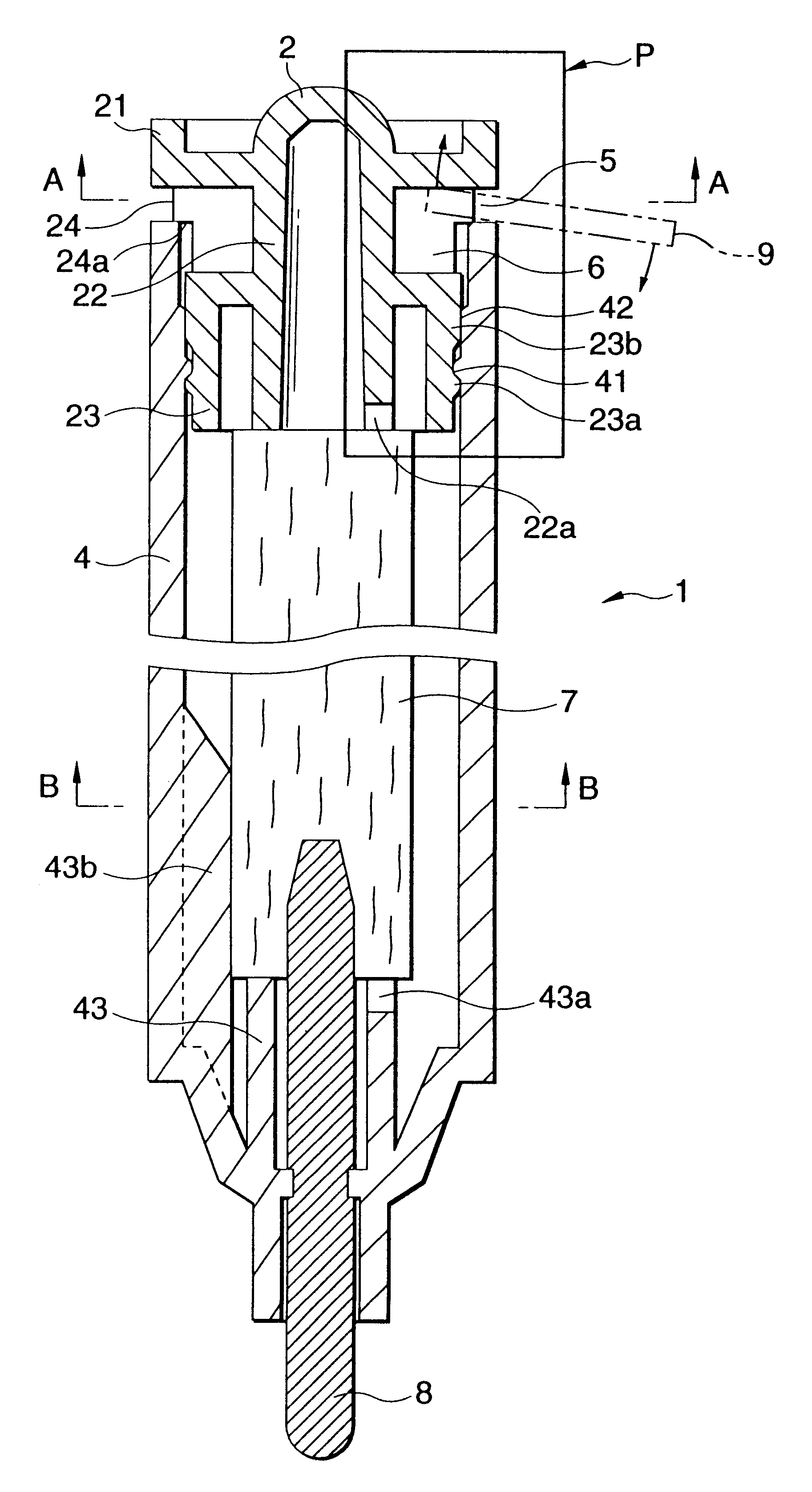

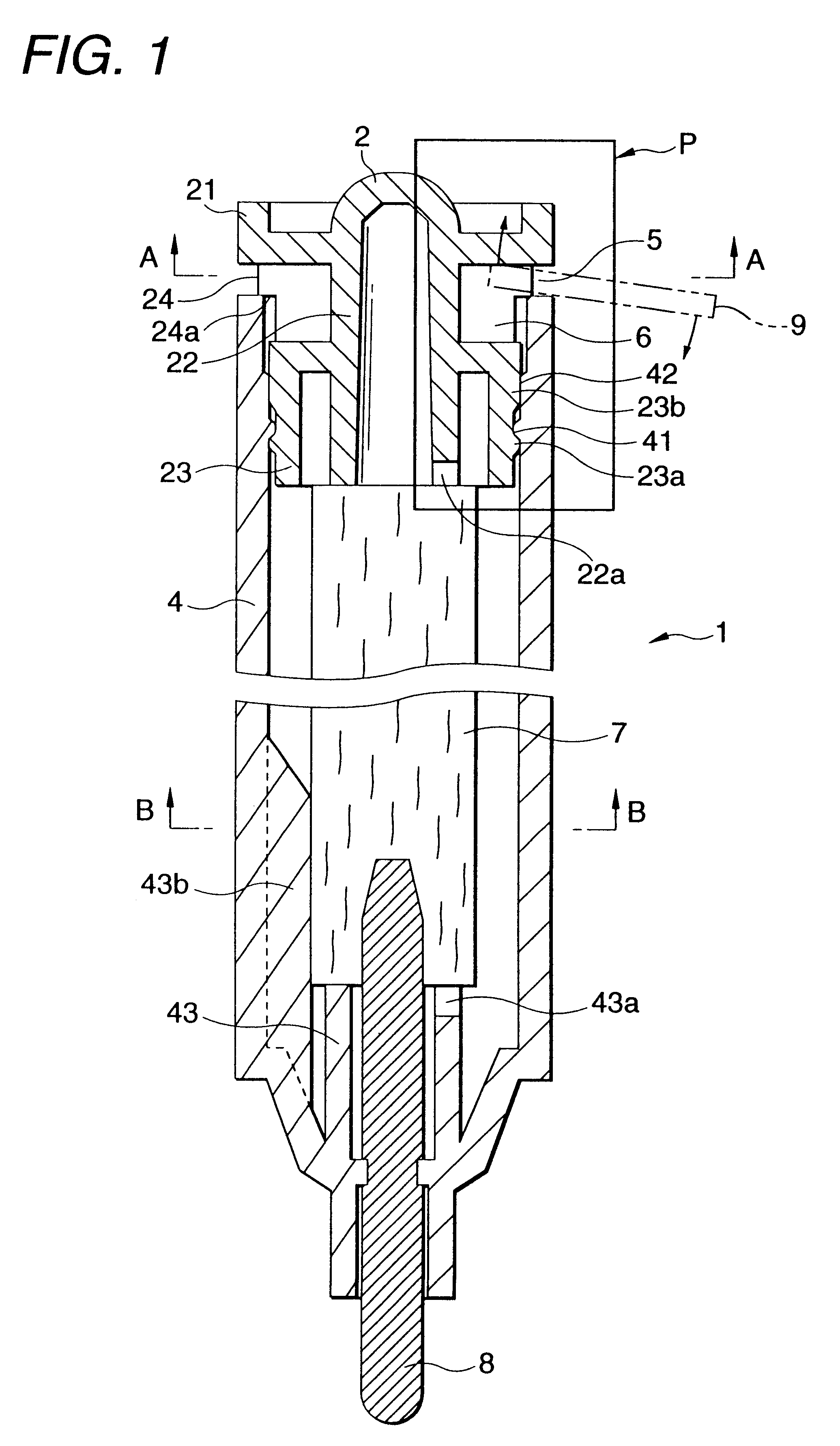

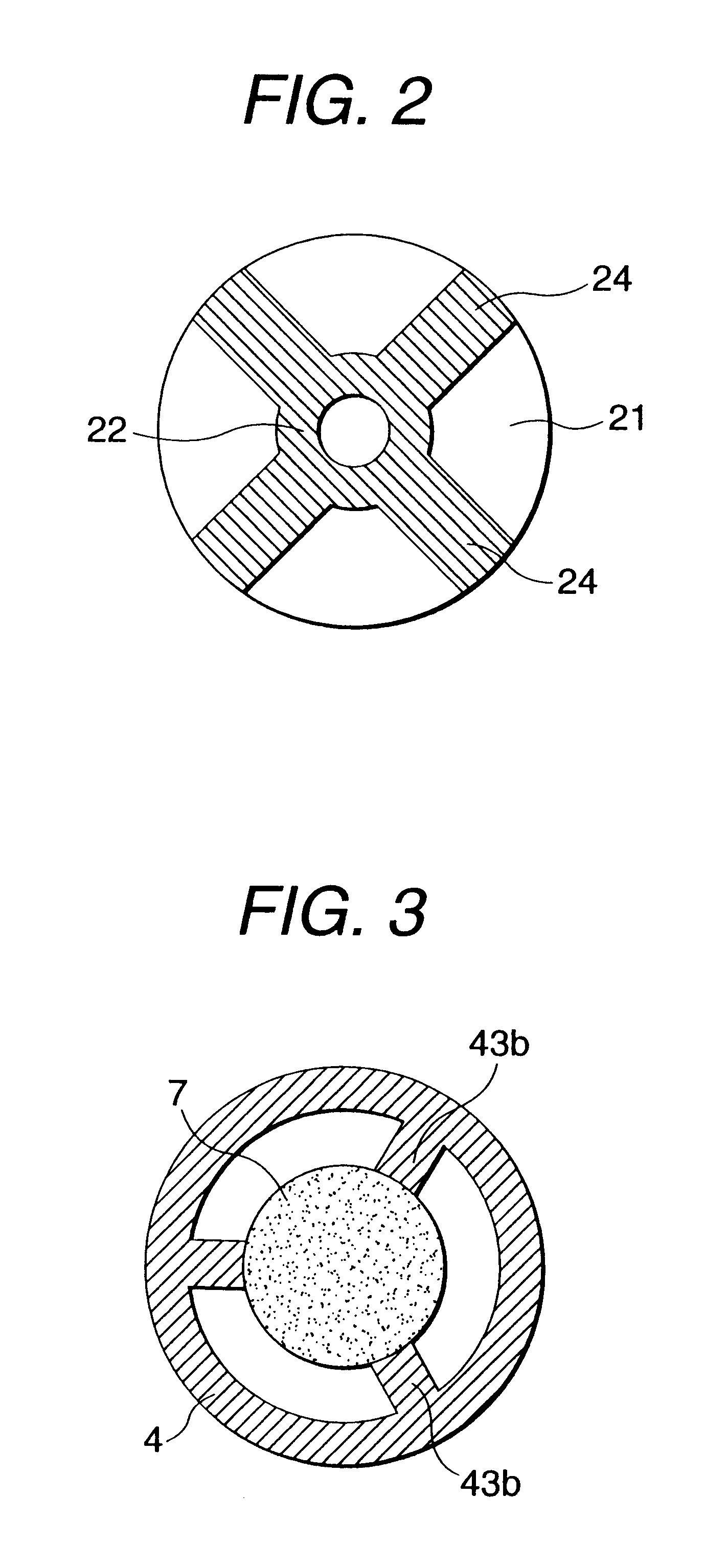

Writing implement

The writing implement 1 comprises a shaft barrel 4 and a tail plug 2. The shaft barrel 4 includes an ink storing body 7 stored in an interior portion thereof and a pen point 8 mounted on a front end portion thereof. The tail plug 2 is removably mounted on an opening formed at the rear end of the shaft barrel 4. The tail plug 2 includes a flange portion 21 which is provided backwardly of the rear end portion of the shaft barrel 4. Between the front surface of the flange portion 21 and the rear end portion of the shaft barrel 4, there is formed a groove 5 for forcibly opening. The groove 5 is formed more deeply inwardly in the diameter direction of the shaft barrel 4 than the inner surface of the rear end opening of the shaft barrel 4.

Owner:THE PILOT INK CO LTD

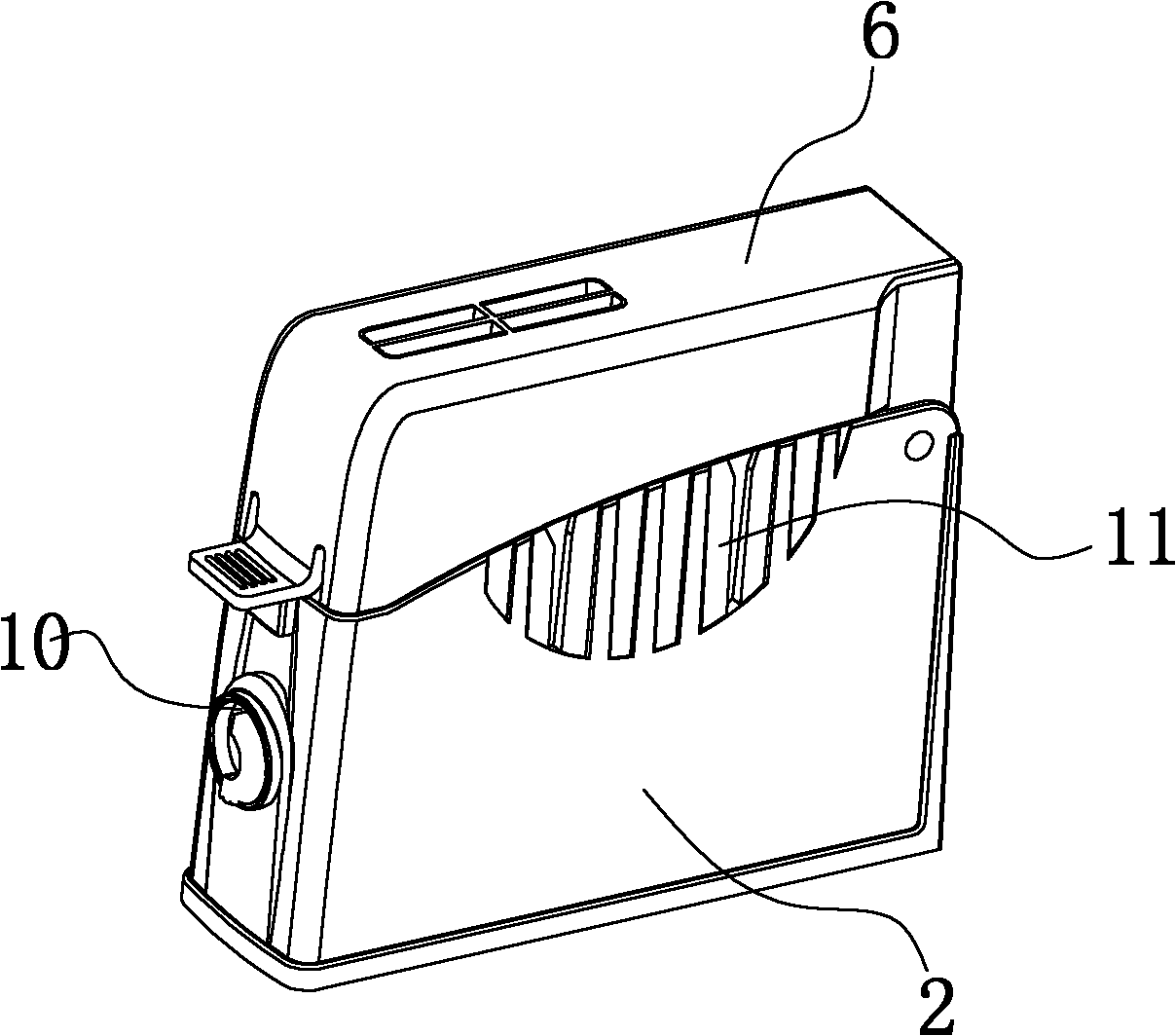

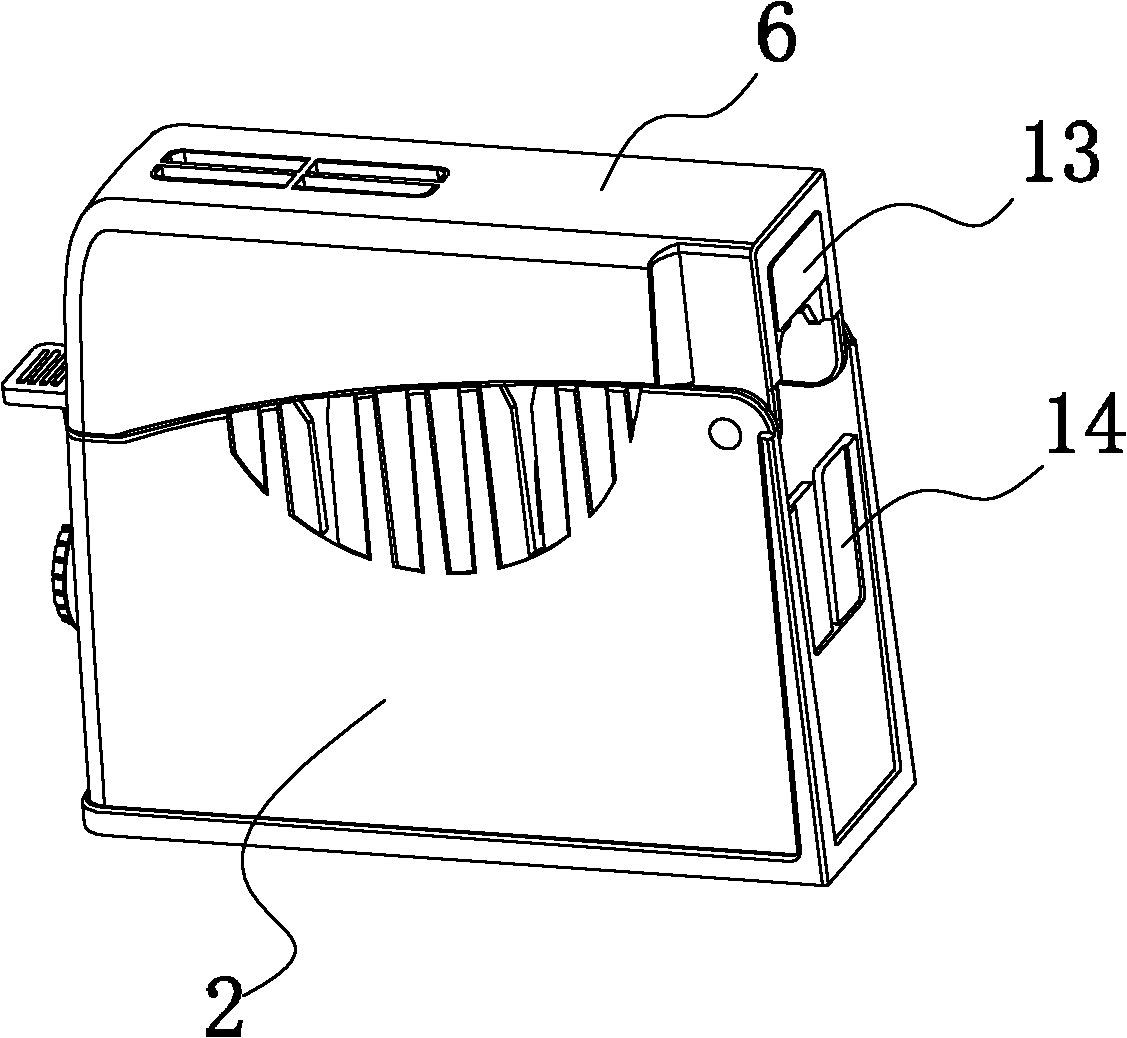

Device capable of automatically changing cartridge of fountain pen

The invention discloses a device capable of automatically changing the cartridge of a fountain pen. The device comprises a box body, wherein a left cavity and a right cavity are formed in the left side and the right side of the interior of the box body separately; an upper boss is fixedly connected with the inner wall of the upper section part of the right cavity; a lower boss at the lower left part of the upper boss is fixedly connected with the inner wall of the upper section part of the right cavity; the lower boss is rotatably connected with a grooved wheel device; a rotary rod device is connected below the grooved wheel device; and a gripper is fixedly connected with the lower section part of the rotary rod device. The device is more efficient in automatically changing the cartridge of the fountain pen and can collect the changed wasted cartridge to save the time for changing and treating the wasted cartridges.

Owner:启东市天汾电动工具技术创新中心

Pressing capillary system type refill assembly and writing pen

PendingCN112092518APrevent volatilizationPrevent ink leakageBall-point pensFilling devicesEngineeringMechanical engineering

The invention discloses a pressing capillary system type refill assembly and a writing pen. The pressing capillary system type refill assembly comprises an ink barrel assembly, a pen point and an elastic piece, wherein an ink leading core is arranged in the ink barrel assembly, the pen point is arranged at one end of the ink barrel assembly, a through ink flowing channel is formed inside the pen point, a ball bead portion is arranged at the ink outlet end of the ink flowing channel, the ink leading core partially penetrates through the ink flowing channel, one end of the ink leading core abutsagainst the ball bead portion, the elastic piece is arranged on the periphery of the ink leading core in a sleeve mode and located in the ink flowing channel, the elastic piece abuts against the ballbead portion to apply acting force enabling the ball bead portion to abut against the inner wall of the ink outlet end, contact sealing is formed between the ball bead portion and the inner wall of the ink outlet end, and ink volatilization and ink leakage are avoided.

Owner:QINGDAO DIANSHI STATIONERY

Method for manufacturing a coating instrument

ActiveUS9283801B2Reliably prevent leakagePrevent leakageDispensing apparatusPen repairingEngineeringMechanical engineering

There is provided a method for manufacturing a coating instrument provided with a filling member having a filling region in which a coating material is filled and a body portion including an extruding portion inserted inside so as to be brought into close contact with the filling member and constituting a rear end of the filling region, in which the coating material is discharged from a discharge outlet on a tip end side of the filling member by advance of the extruding portion, including a step of filling the coating material into the filling region of the filling member from behind in a state in which a front side of the filling member is located below the rear side, a step of feeding a predetermined amount of air from the discharge outlet into the filling region so that a space is formed on the tip end side in the filling region after the coating material is filled, and a step of assembling the body portion to the filling member after the air is fed.

Owner:TOKIWA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com