Selling device capable of adding ink into fountain pen refill and replacing pen point automatically

A technology for automatic water supply and nib replacement, which is applied to the device for dismantling the nib, the ink filling device, and the repair of ink pens. It can solve the problems of high price, too precise mechanism design, and inconvenient maintenance, and achieve easy disassembly and assembly. and maintenance, the overall structure is compact, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

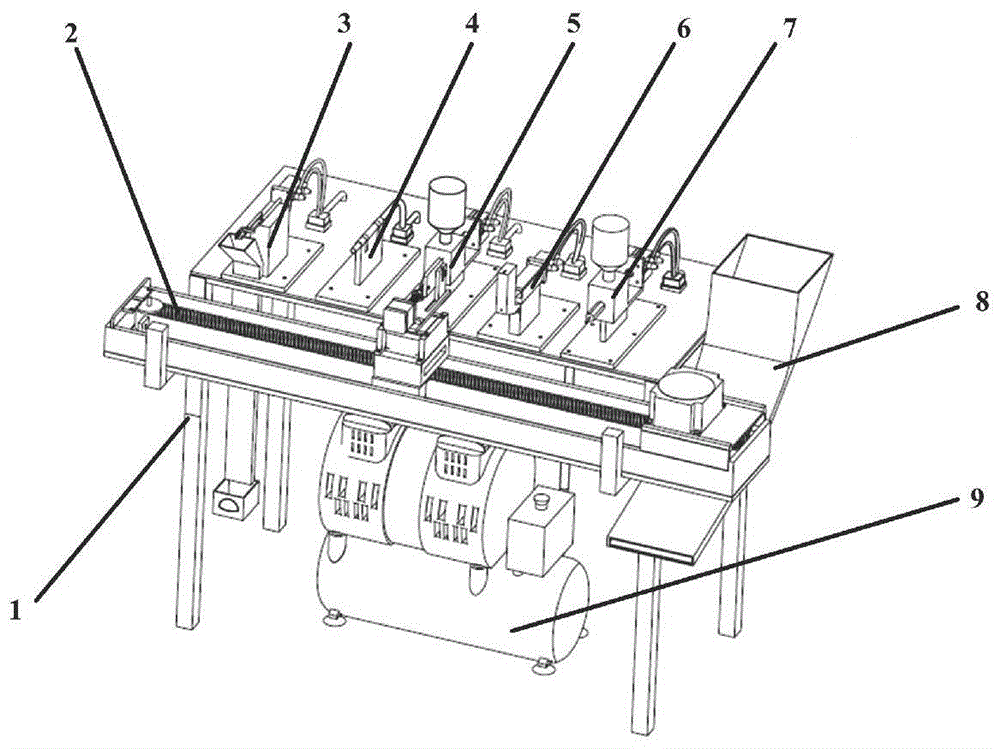

[0030] as attached figure 1 Shown, the present invention comprises frame 1, mobile platform 2, pull-out mechanism 3, air blowing mechanism 4, add ink mechanism 5, upper nib mechanism 6, end oil mechanism 7, vending mechanism 8, air pump 9.

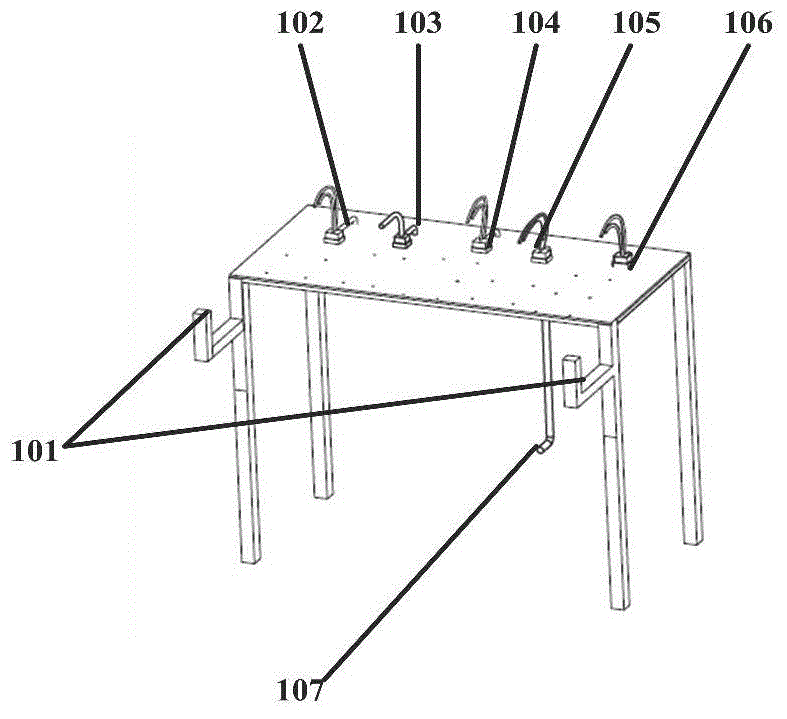

[0031] as attached figure 2 As shown, two frame support frames 101 are installed on the front side of the frame 1 to facilitate the placement of the mobile platform 2, and an electromagnetic reversing valve 102 of a pulling mechanism and an electromagnetic reversing valve of an air blowing mechanism are installed on the upper end of the frame 1. 103, ink adding mechanism electromagnetic reversing valve 104, upper nib mechanism electromagnetic reversing valve 105, end oil injection mechanism electromagnetic reversing valve 106, frame 1 lower end is provided with air pressure output pipe 107.

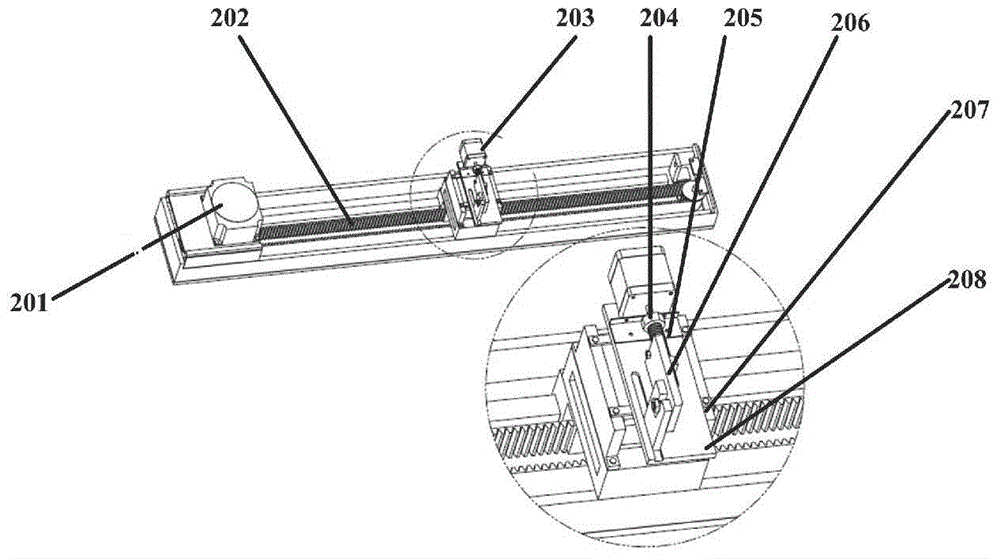

[0032] as attached image 3 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com