Pen and automatic ink-injection device

A pen and ink filling port technology, applied in the field of stationery, can solve the problems of easy contamination of fingers, short service life, troublesome operation, etc., and achieve the effects of convenient operation, preventing contamination of fingers, and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

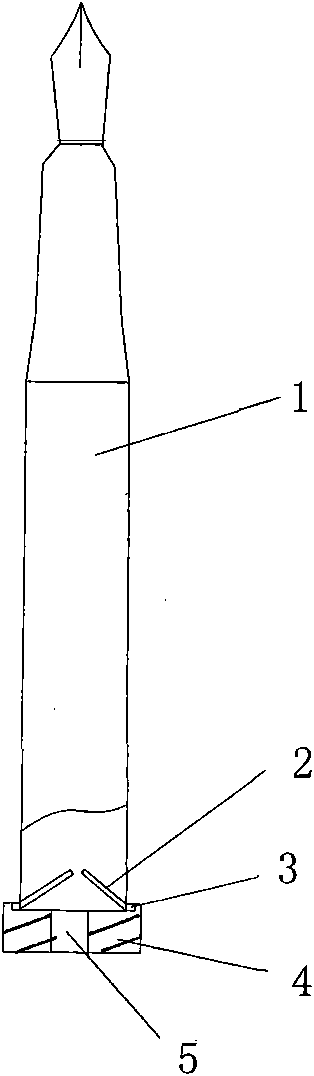

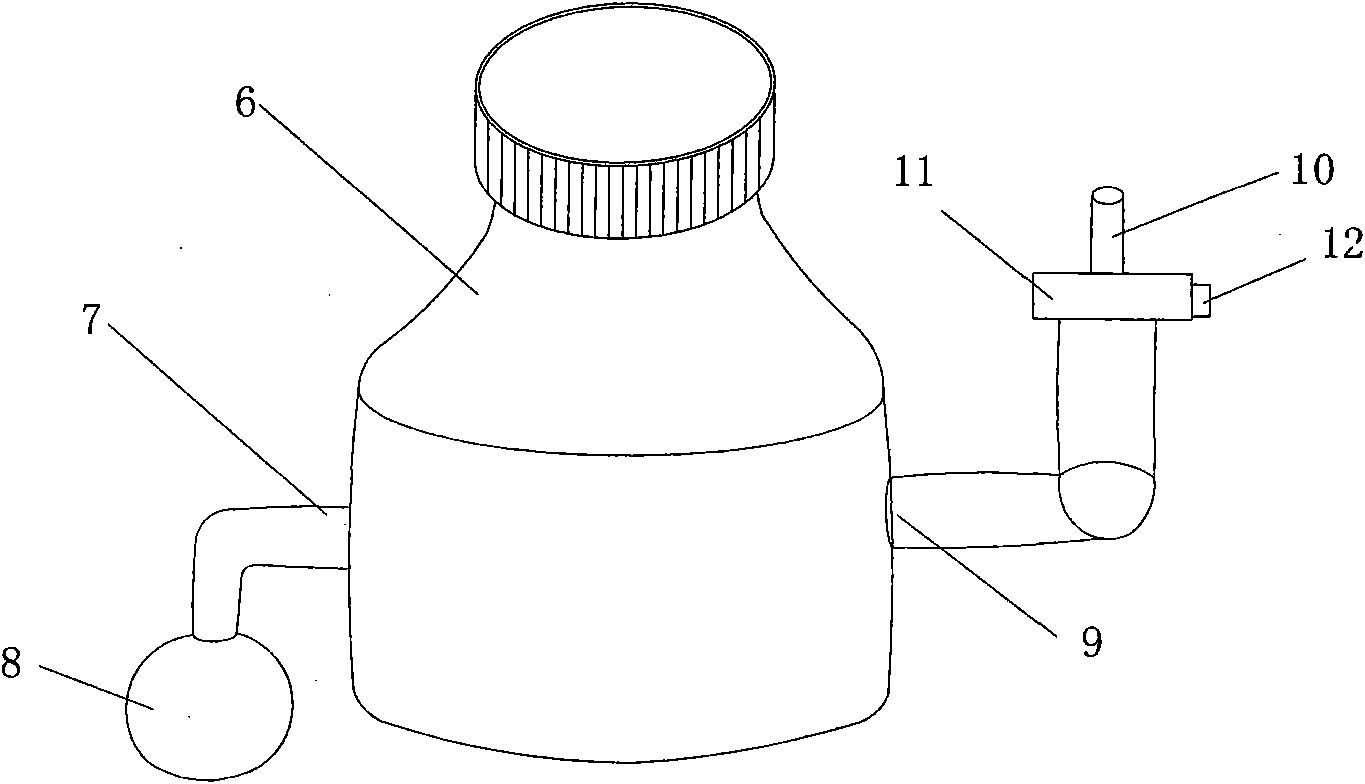

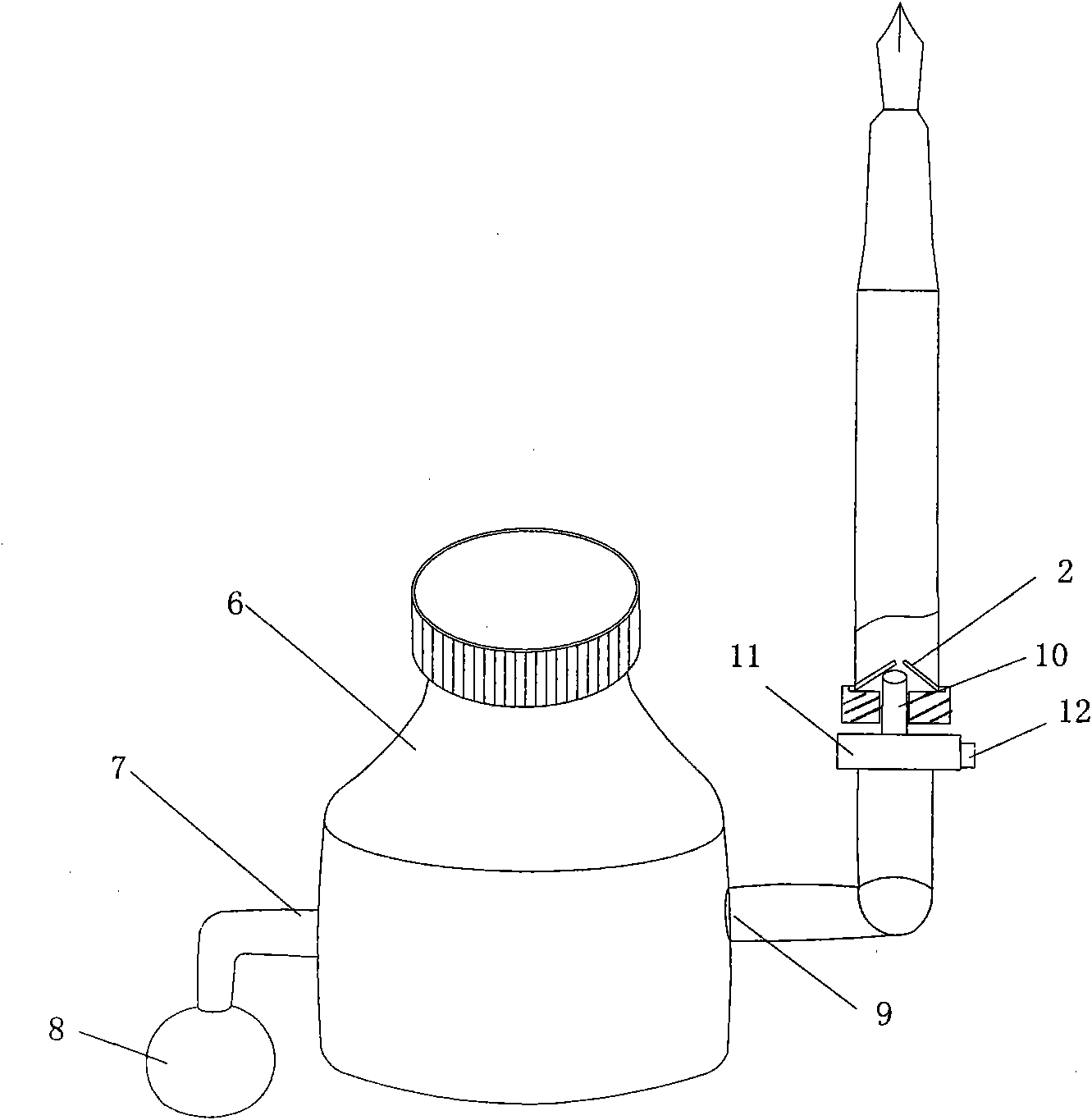

[0015] a fountain pen, such as figure 1 As shown, it includes a penholder 1, the penholder 1 is made of transparent material, the tail end of the penholder 1 is screwed with a pen cover 4, a sealing gasket 3 is provided between the penholder 1 and the pen cover 4, and an ink filling port 5 is provided on the pen cover 4. The front end of the ink filling port 5 is provided with a one-way valve flap 2 that opens to the inner cavity of the pen holder. The automatic ink filling device used by this fountain pen, such as figure 2 Shown, comprise ink bottle 6, and ink bottle 6 side is provided with an inflation port 7, and inflation port 7 communicates with air bag 8; Ink bottle 6 other side is provided with an ink outlet 9, and ink outlet 9 is connected with a flexible pipe, The end of the hose is connected to a sealing plate 11 with a through hole in the middle, and the through hole communicates with the intubation tube 10 above the sealing plate 11. The intubation tube 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com