Pressing capillary system type refill assembly and writing pen

A direct-liquid, component-based technology, applied in the field of stationery, can solve problems such as seal failure, ink volatilization, and insufficient sealing force of writing balls, and achieve the effect of avoiding ink leakage, avoiding volatilization, and better and more reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

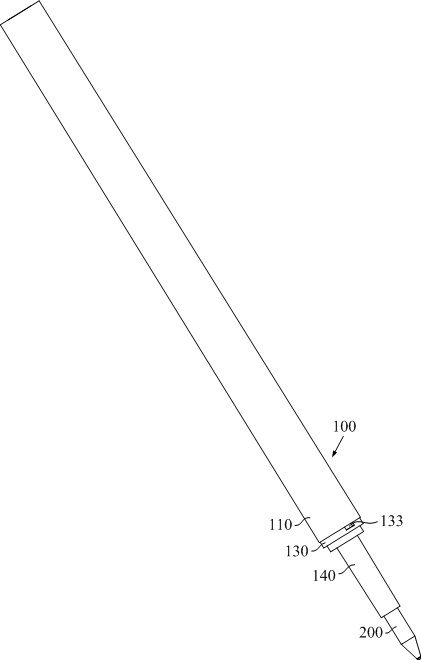

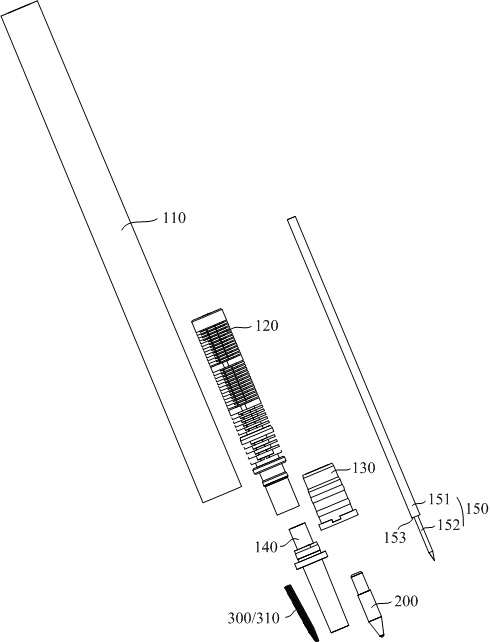

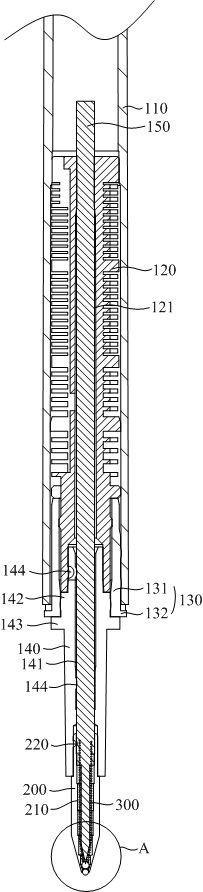

[0047] refer to Figure 1 to Figure 3 , The tilting straight liquid refill assembly in this embodiment mainly includes the ink cartridge assembly 100 , the nib 200 , the elastic member 300 and other parts.

[0048] The ink cartridge assembly 100 is provided with an ink lead core 150, and the ink cartridge assembly 100 is used for storing ink and leading ink, leading the ink to the nib 200 for writing.

[0049] The nib 200 is arranged at one end of the ink cartridge assembly 100, and the inside of the nib 200 is formed with a penetrating ink flow channel 210, and the ink outlet end of the ink flow channel 210 is provided with a ball portion 230, and the ink leading core 150 has a part penetrating the ink flow channel 210. , One end of the ink lead 150 abuts against the ball portion 230 . The ink cartridge assembly 100 guides the ink into the ink flow channel 210 and reaches the ball portion 230 , and utilizes the shearing and rolling of the ink by the ball portion 230 to achie...

Embodiment 2

[0081] The difference between the second embodiment and the first embodiment lies in the arrangement of the ball portion 230 , and the other structures are the same, so only the ball portion 230 will be described in detail below.

[0082] In embodiment two, refer to Figure 5 , the ball portion 230 is a double-ball structure, including an upper ball 231 and a lower ball 232, the upper ball 231 abuts against the lower ball 232, the conical spring 310 abuts against the upper ball 231, and the ink core 150 Abut against the upper ball 231.

[0083] The conical spring 310 directly acts on the upper ball 231, and the upper ball 231 directly acts on the lower ball 232 to form a power transmission, so that a contact seal is formed between the lower ball 232 and the inner wall of the ink flow channel 210 to avoid ink leakage. Evaporation and ink leakage.

[0084] The conical spring 310 bears against the upper ball 231, no matter how well the conical spring 310 and the upper ball 231 ...

Embodiment 3

[0087] This embodiment provides a writing pen, which includes the tilting direct liquid refill assembly disclosed in Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com