Method for preparing polyamide

A technology for polyamide and pre-polycondensation, applied in the field of preparation of polyamide 5X, can solve the problems of low molecular weight, reduced polyamide yield, complexity, etc., and achieve the effects of reduced emissions, good mechanical properties, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

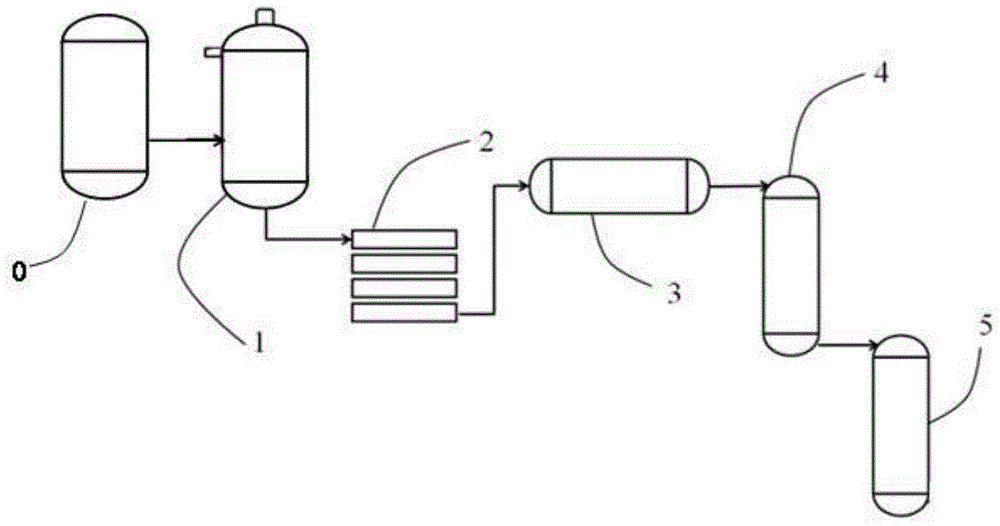

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing polyamide, comprising: preparing the polyamide by precondensing and polycondensing a raw material solution with a concentration of 75 to 100 wt% by weight; wherein, the raw material solution is 1, Nylon salt solution formed by 5-pentanediamine and dibasic carboxylic acid, or a mixture of 1,5-pentanediamine and dibasic carboxylic acid with a total concentration of 75 to 100 wt %; the dibasic carboxylic acid is selected from One or more of aliphatic dibasic acids.

[0021] The weight percentage concentration of raw material solution among the present invention refers to in nylon salt solution, and nylon salt accounts for the weight percentage in nylon salt solution, is expressed as with formula: m 尼龙盐 / m 尼龙盐溶液 ×100%; or in the mixed solution of 1,5-pentanediamine and dicarboxylic acid, the total mass of 1,5-pentanediamine and dicarboxylic acid accounts for the mass percentage of the mixed solution.

[0022] The obtained poly...

Embodiment 1

[0046] (1) After mixing 1,5-pentanediamine and adipic acid at a molar ratio of 1:1.02, they are fed into the salt-forming reactor at a flow rate of 1500kg / hr for salt-forming reaction. The salt-forming temperature is 80°C and the pressure is 0.15 MPa, prepare 1,5-pentamethylenediamine adipate solution of 80wt% (nylon salt accounts for the mass percentage of nylon salt solution);

[0047] (2) The 1,5-pentamethylenediamine adipate solution prepared in step (1) is pumped into a concentration tank for concentration through a supply pump at a temperature of 150°C and a pressure of 0.2MPa to obtain 90wt% of 1,5- Concentrated solution of pentamethylenediamine adipate;

[0048] (3) The above-mentioned concentrated solution of 1,5-pentamethylenediamine adipate was pumped to a parallel tubular reactor for prepolymerization. The prepolymerization temperature was 260°C, the prepolymerization pressure was 1 MPa, and the prepolymerization time was 45 minutes. get prepolymer;

[0049] (4) ...

Embodiment 2

[0054] (1) After mixing 1,5-pentamethylenediamine and adipic acid at a molar ratio of 1:1.03, add 100ppm (relative to the weight of 1,5-pentamethylenediamine adipate) of Bruggemann H10 (Bruggolen H10 produced by Bruggolen, Germany) carries out a salt-forming reaction with a salt-forming temperature of 80°C and a pressure of 0.15MPa to make 75wt% 1,5-pentamethylenediamine adipate solution;

[0055] (2) The 1,5-pentamethylenediamine adipate solution prepared in step (1) is pumped to the concentration tank for concentration, the temperature is 160°C, the pressure is 0.3MPa, and 90wt% of 1,5 - concentrated solution of pentamethylenediamine adipate;

[0056] (3) Send the above-mentioned 1,5-pentamethylenediamine adipate concentrated solution to a parallel tubular reactor through a supply pump for prepolymerization. The prepolymerization temperature is 260°C, the pressure is 3MPa, and the time is 50min to obtain a prepolymer. ;

[0057] (4) Lead the prepolymer into a continuous re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com