Ink bottle for quantitatively injecting ink

An ink bottle and ink filling technology, applied to ink containers, printing, office supplies, etc., can solve the problems of inconvenient use of ink pens, and achieve the effect of convenient transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

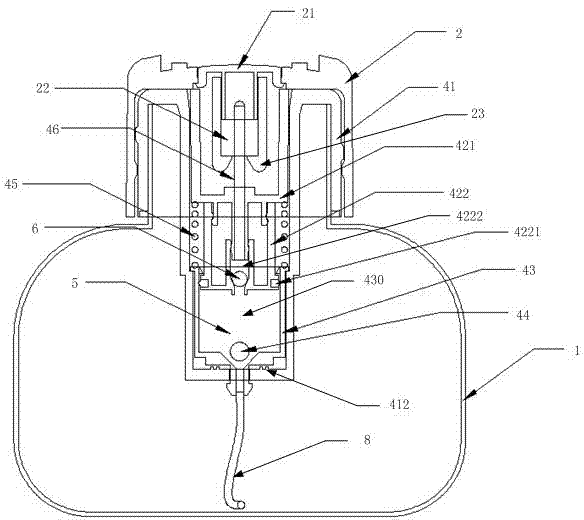

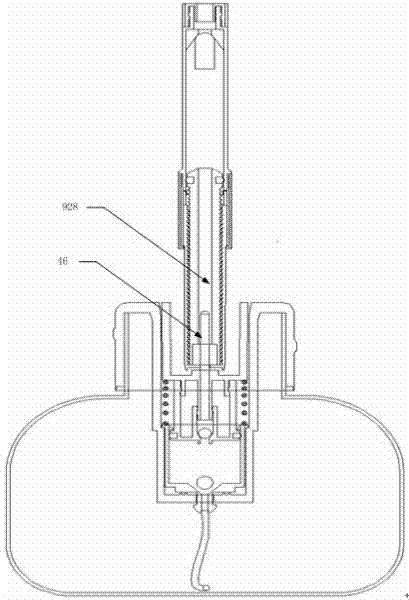

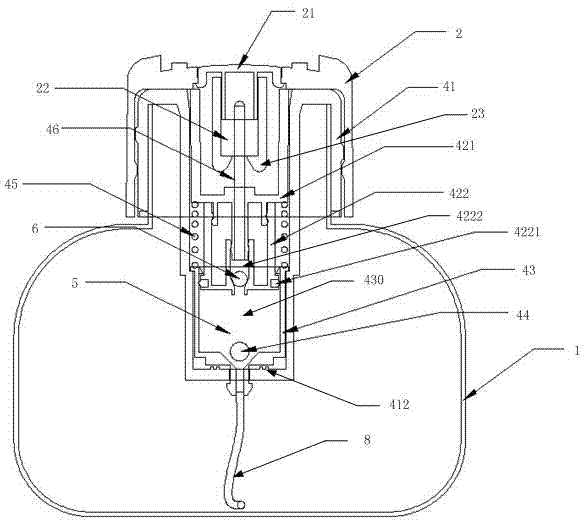

[0016] figure 1 A schematic structural diagram of an ink bottle for quantitative ink filling according to the first embodiment of the present invention is shown. Specifically, in this embodiment, the ink bottle for quantitative ink injection includes a bottle body 1, and also includes a pump body seat 41 connected to the bottle body 1, and a piston seat is sequentially arranged in the pump body seat 41 from top to bottom. , the pump body 43, and the ink delivery tube 8, wherein the piston seat includes a second one-way valve, a needle tube 46 and an ink injection channel 4222 that communicate with each other, and the chamber 430 of the pump body 43 passes through the second The one-way valve communicates with the ink injection channel 4222, the pump body 43 includes a first one-way valve, and the ink delivery pipe 8 communicates with the chamber 430 of the pump body 43 through the first one-way valve, so A spring 45 is connected between the piston seat and the pump body 43, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com