Practicalink bottle

An ink bottle, a practical technology, applied in the field of stationery, can solve the problems of increased manufacturing cost, waste, water level drop, etc., and achieve the effect of increased manufacturing cost, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

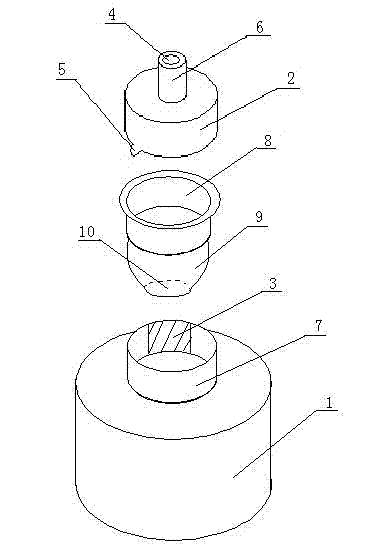

[0010] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment is a practical ink bottle, comprising a bottle body 1 and a bottle cap, characterized in that: the inner wall of the bottle mouth 7 of the bottle body 1 is provided with a sponge wipe pad 3, and the bottle cap includes an inner cover 8 and The outer cover 2, the upper part of the outer cover 2 is provided with a hollow tube 4 with a closed upper end; the edge of the outer cover 2 is provided with a diversion port 5; the outer wall of the tube 4 is provided with a sponge wiping pen layer 6. The lower end of the inner cover 8 is provided with a tapered rubber sleeve 9 , and the bottom of the tapered rubber sleeve 9 is provided with a pen through hole 10 . When the ink bottle of the present invention absorbs ink when there is more ink, the nib of the pen is put into the ink bottle to draw water. Dip into the ink; when the bottom of the ink cannot be sucked directly with a pen, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com