Ink bottle

An ink bottle and bottle body technology, applied in the field of school supplies, can solve the problems of excessive wall thickness, easy to get dirty, ink sucking, etc., and achieve the effect of small liquid level rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

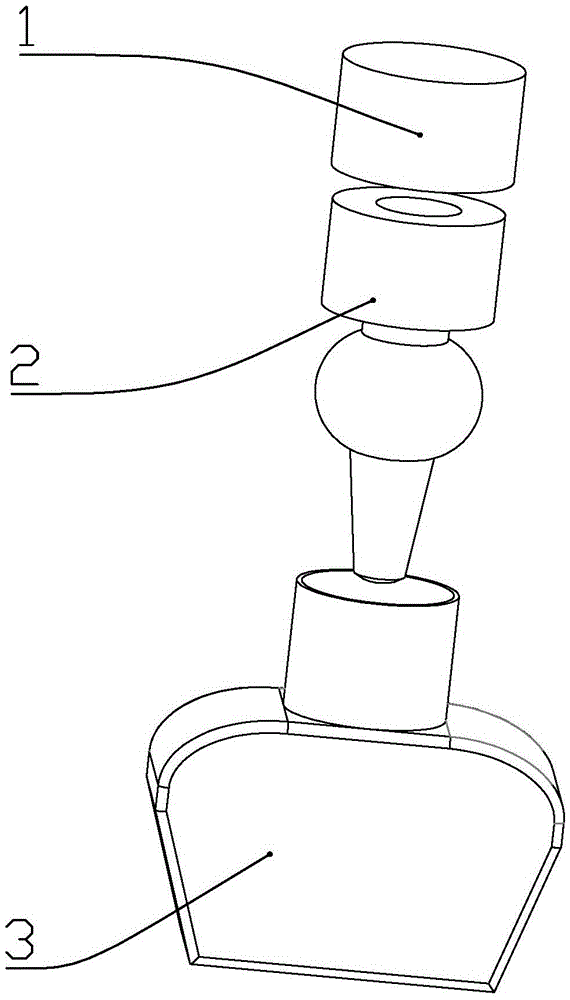

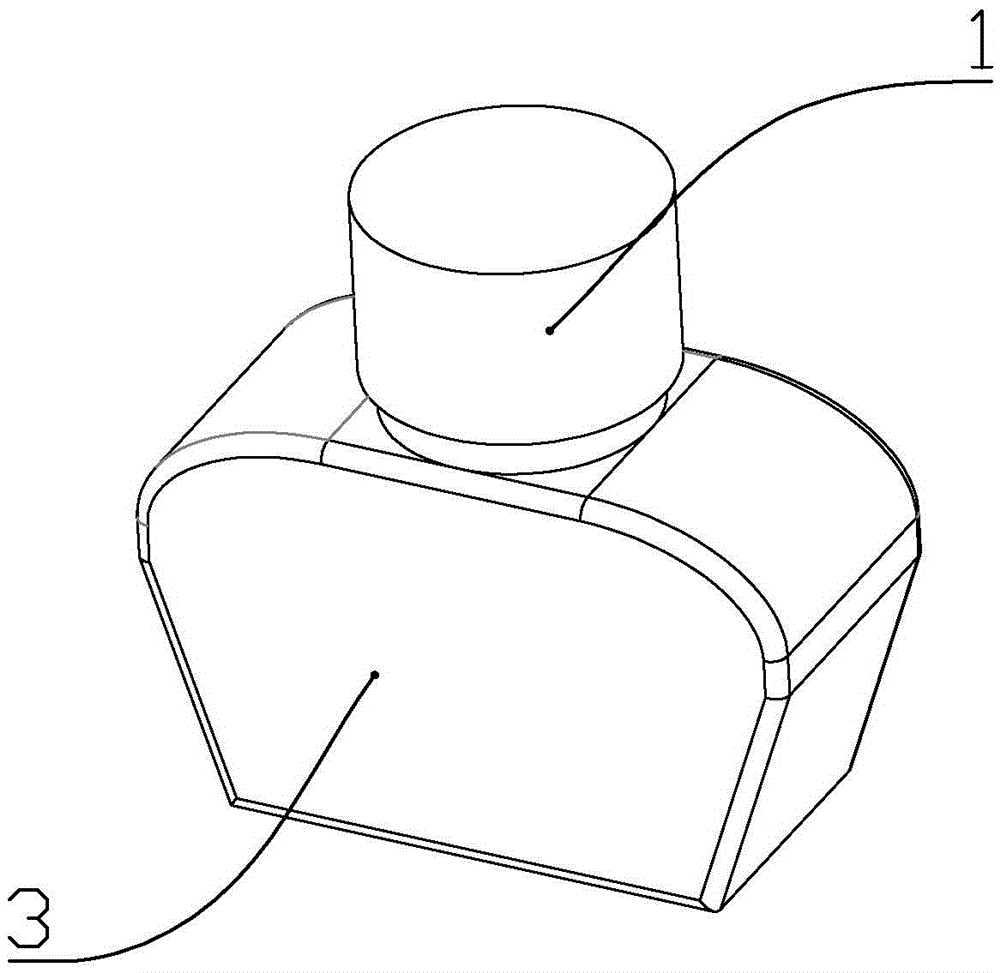

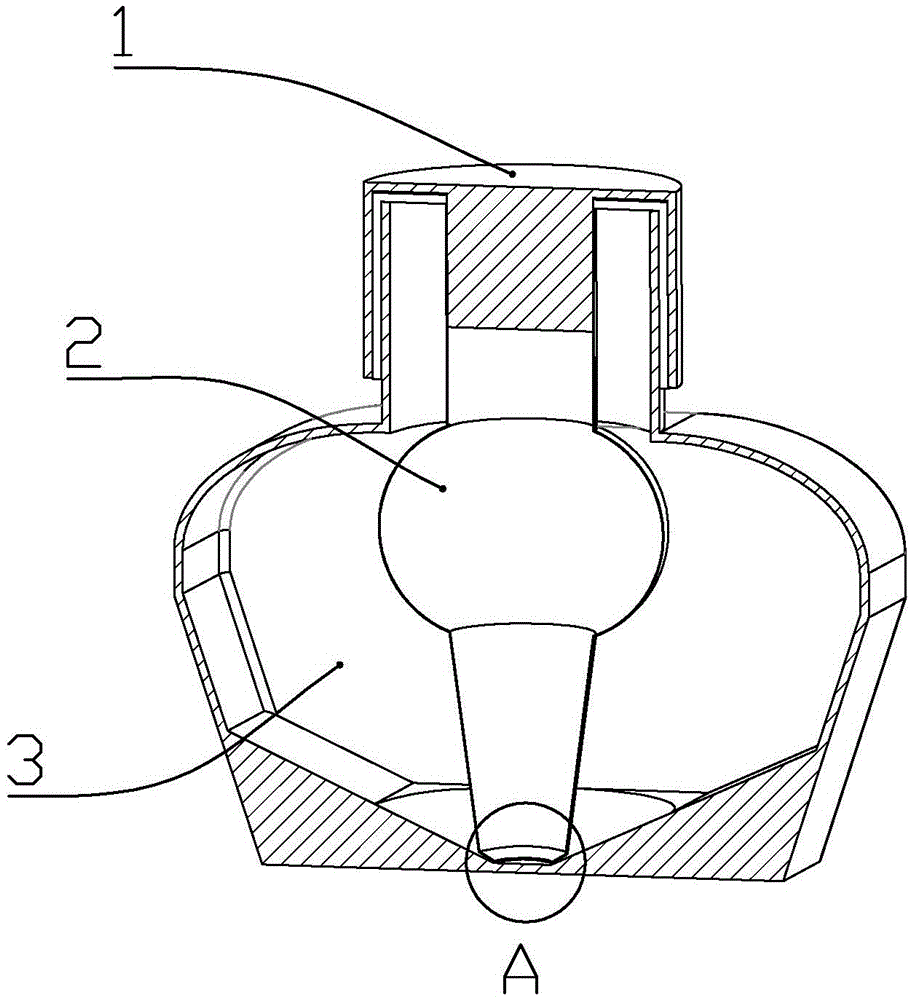

[0024] according to Figure 1 to Figure 8 As shown, an ink bottle described in this embodiment includes a bottle body 3, a bottle mouth 31 and a bottle cap 1 used in conjunction with the bottle mouth are formed on the upper part of the bottle body;

[0025] It also includes an inner bottle 2; the inner bottle is sequentially from top to bottom a bottle mouth matching part 21, a cavity A22, a spherical cavity 23, a cavity B24, and a flow blocking wall 25; the bottle mouth matching part and the bottle The mouth is connected by thread fit, and the cavity A is a cylindrical cavity as a whole, and its inner diameter is 16mm; the cavity A and the spherical cavity are connected with each other, and the radius of the spherical cavity is the radius of the cavity A. 2.3-3 times of that, the spherical cavity and the cavity B communicate with each other, and the cavity B as a whole is a circular platform with a large upper part and a smaller lower part. The radius of the upper bottom surf...

Embodiment 2

[0033] according to Figure 1 to Figure 6 , Figure 8 , Figure 9 As shown, an ink bottle described in this embodiment includes a bottle body 3, a bottle mouth 31 and a bottle cap 1 used in conjunction with the bottle mouth are formed on the upper part of the bottle body;

[0034] It also includes an inner bottle 2; the inner bottle is sequentially from top to bottom a bottle mouth matching part 21, a cavity A22, a spherical cavity 23, a cavity B24, and a flow blocking wall 25; the bottle mouth matching part and the bottle The mouth is used in conjunction with threads, and the cavity A is a cylindrical cavity as a whole, and its inner diameter is 16mm; the cavity A and the spherical cavity communicate with each other, and the radius of the spherical cavity is the radius of the cavity A 2.3-3 times of that, the inner lower part of the spherical cavity is formed with an annular protrusion 27, and the lower part of the annular protrusion is provided with at least 3 small holes;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com