Ink bottle

An ink bottle and bottle body technology, which is applied to ink containers, printing, office supplies, etc., can solve the problems of ink pen tube difficulty, ink difficult to enter the pen tube, pen detachment from the rubber stopper, etc., and achieve the effect of avoiding ink splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

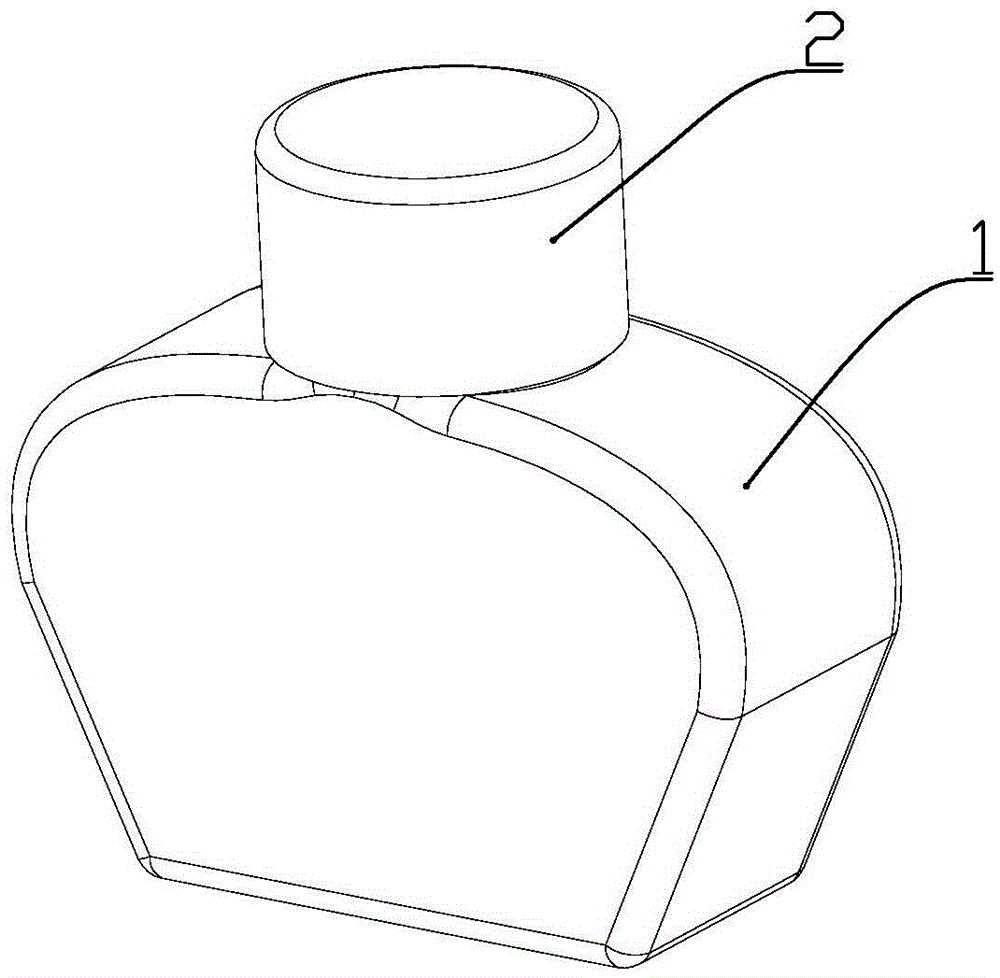

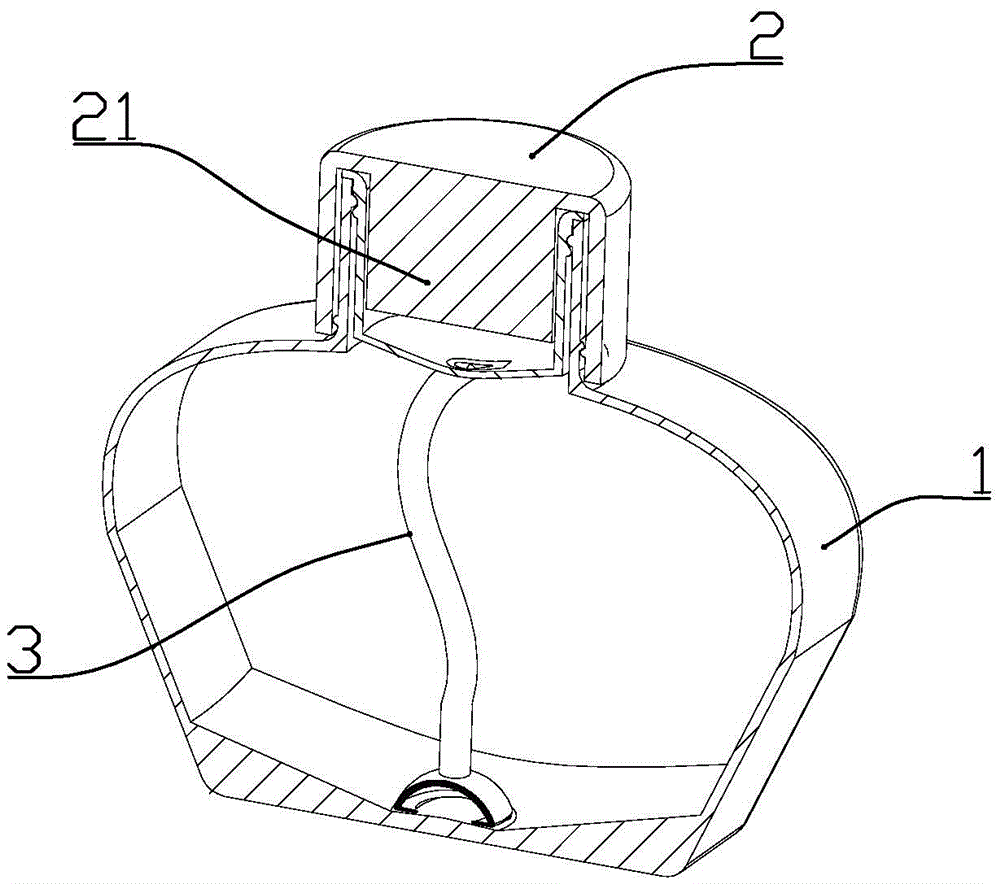

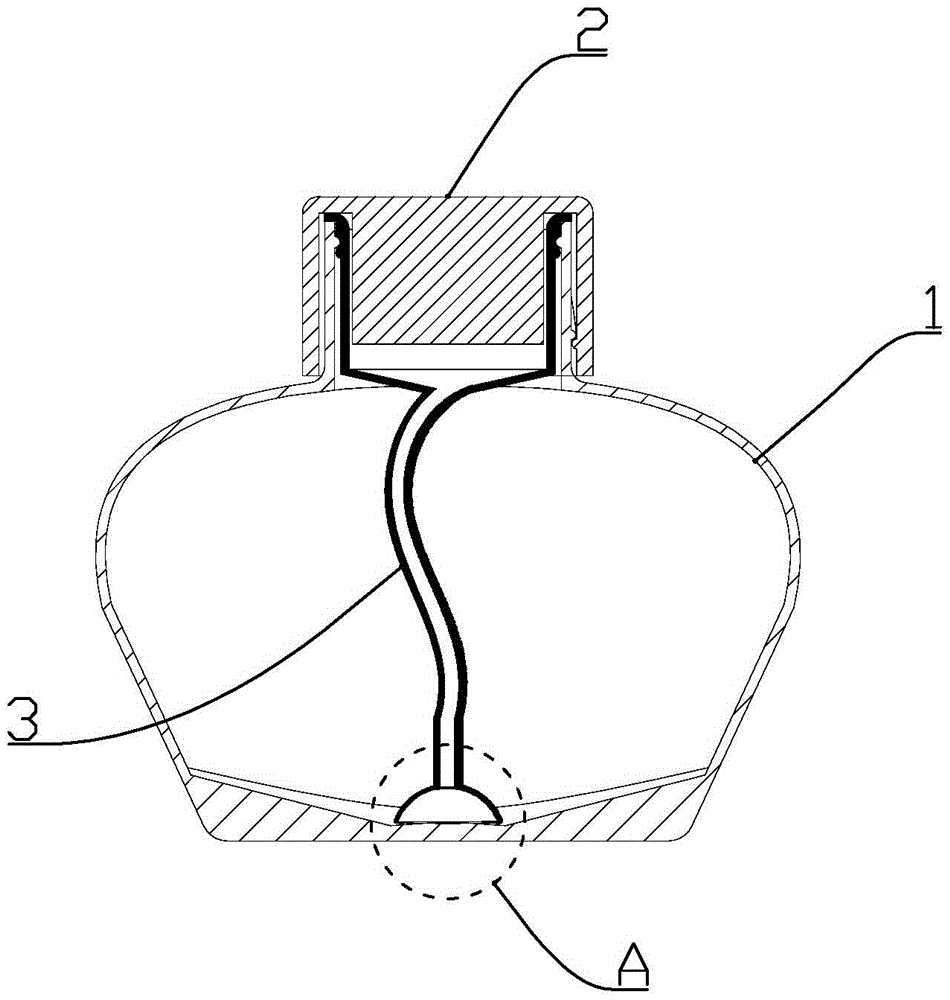

[0028] according to Figure 1 to Figure 8 As shown, the present embodiment is an ink bottle, including a bottle body 1, a rubber inner bottle 3 installed in the bottle body, and a cap body 2 screwed to the bottle mouth 11 on the upper part of the bottle body.

[0029] The inner wall of the mouth of the bottle is formed with more than one collar 13, and the inner bottom of the bottle is formed with a conical surface 15 with a middle height and a lower outer circumference. Low slope surface 14; the diameter of the conical surface is 22 mm, and the angle t between the generatrix of the conical surface and the horizontal direction is 8°.

[0030] The outer diameter of the bottle mouth is 30 mm, and the outer wall of the bottle mouth is formed with more than two sets of external threads 12, and the external threads include a first thread sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com