Electric vehicle charging pile spring cable

A spring cable, electric vehicle technology, applied in the direction of power cable including electronic control, power cable, power cable including electric communication line, etc., can solve the problem of poor flexibility of TPE material, high cost of charging station equipment, low cable safety factor, etc. problems, to achieve the effect of cost saving, good hand feel, and improved experience comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

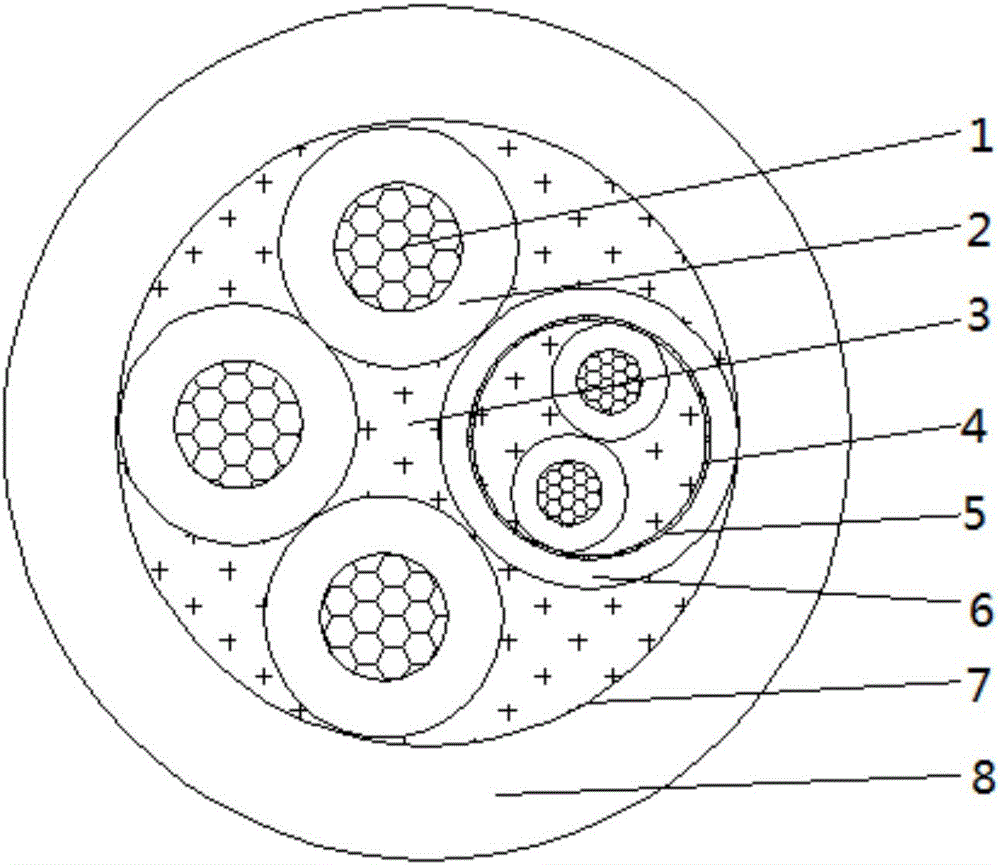

[0019] Please refer to figure 1 , the electric vehicle charging pile spring cable provided by the present invention includes 3 charging wires for electric energy transmission and grounding protection and shielding wires for charging connection confirmation, the charging wires and shielding wires are wrapped by non-woven fabric 7, and The charging wire, the shielding wire and the non-woven fabric are filled with nylon filaments, and the non-woven fabric 7 is extruded with a sheath layer 8 . During the production process, the cable adopts the coiling process to form a spring shape that can be freely stretched. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com