Patents

Literature

203results about "Ink stands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

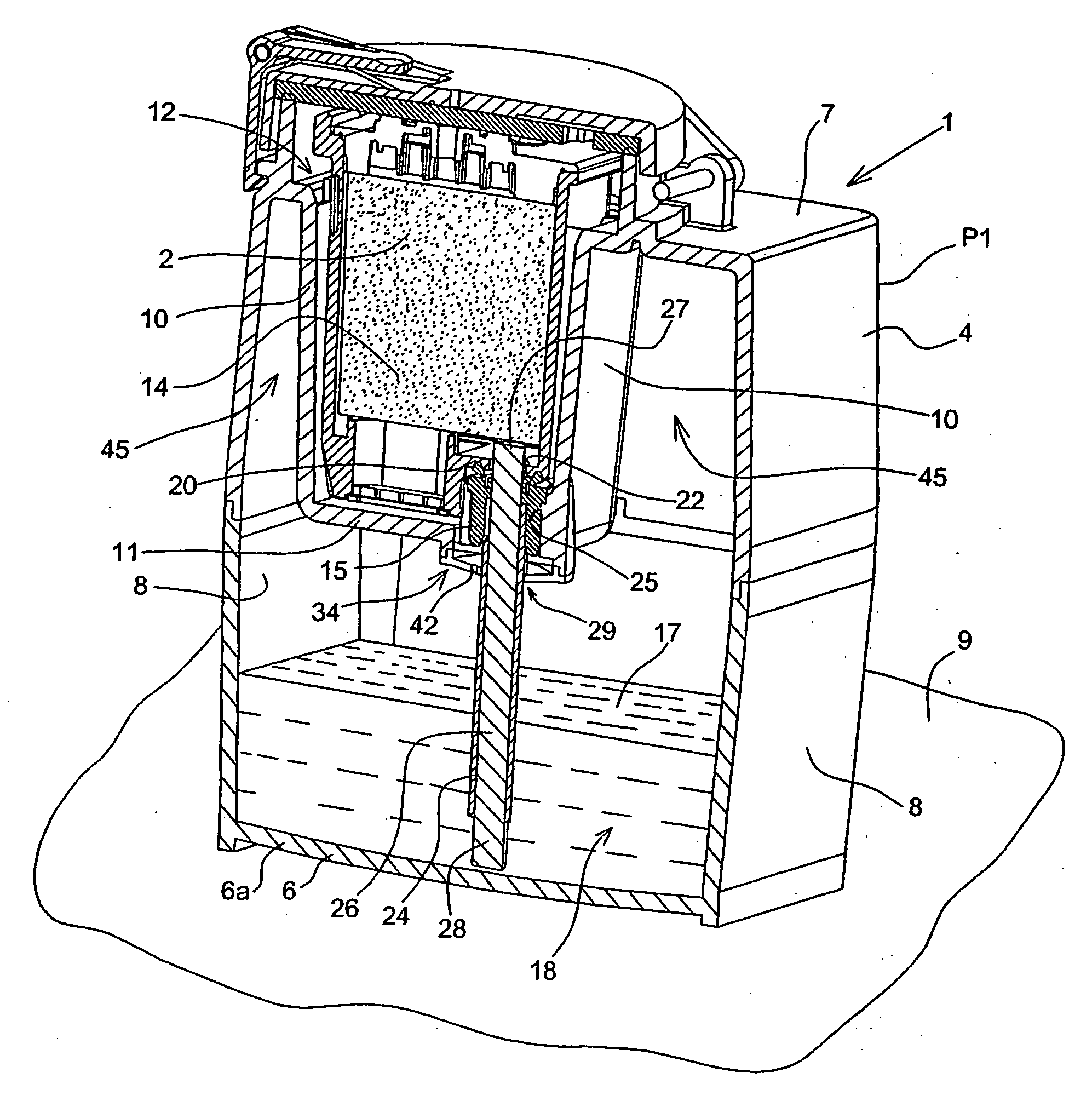

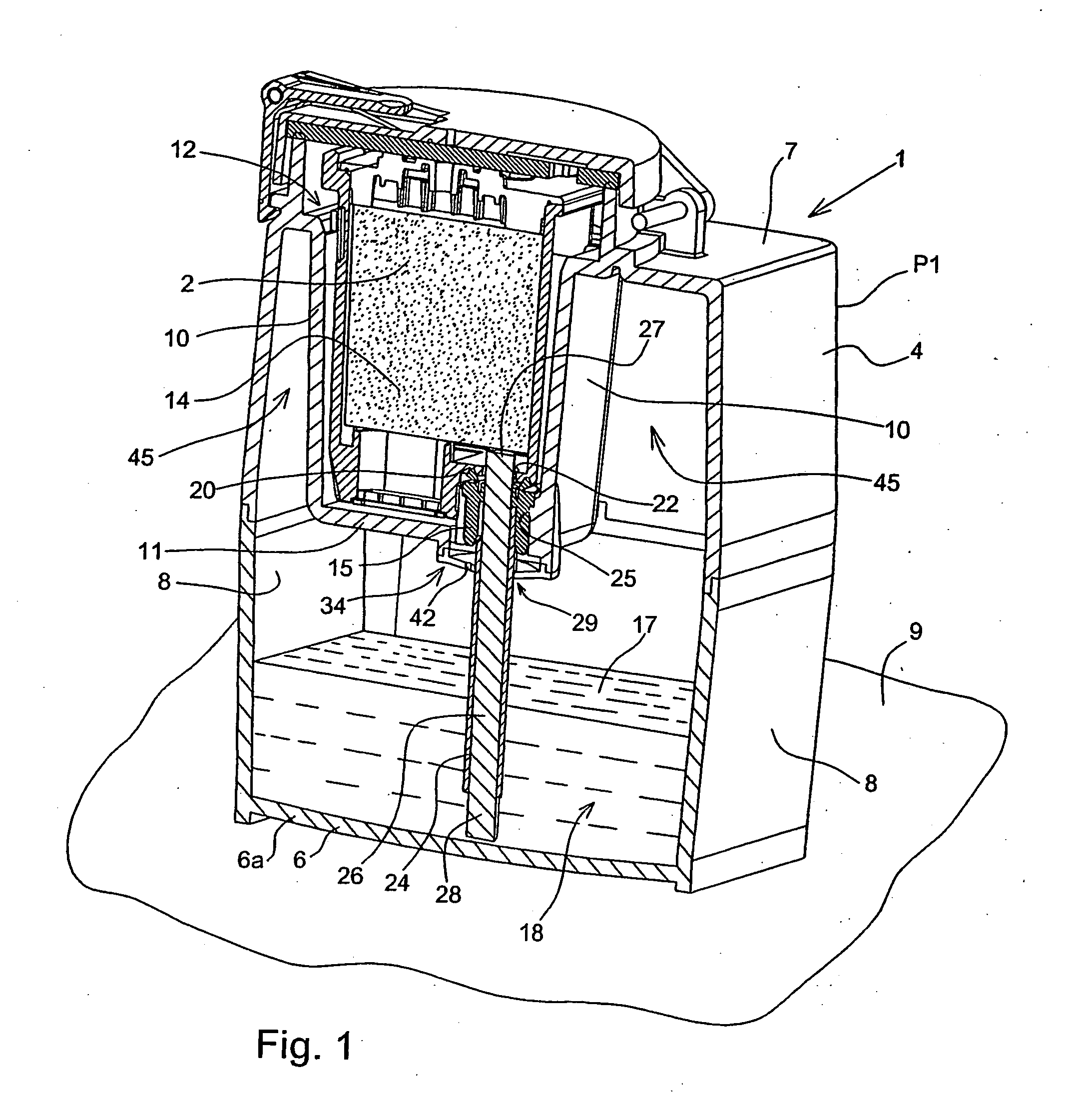

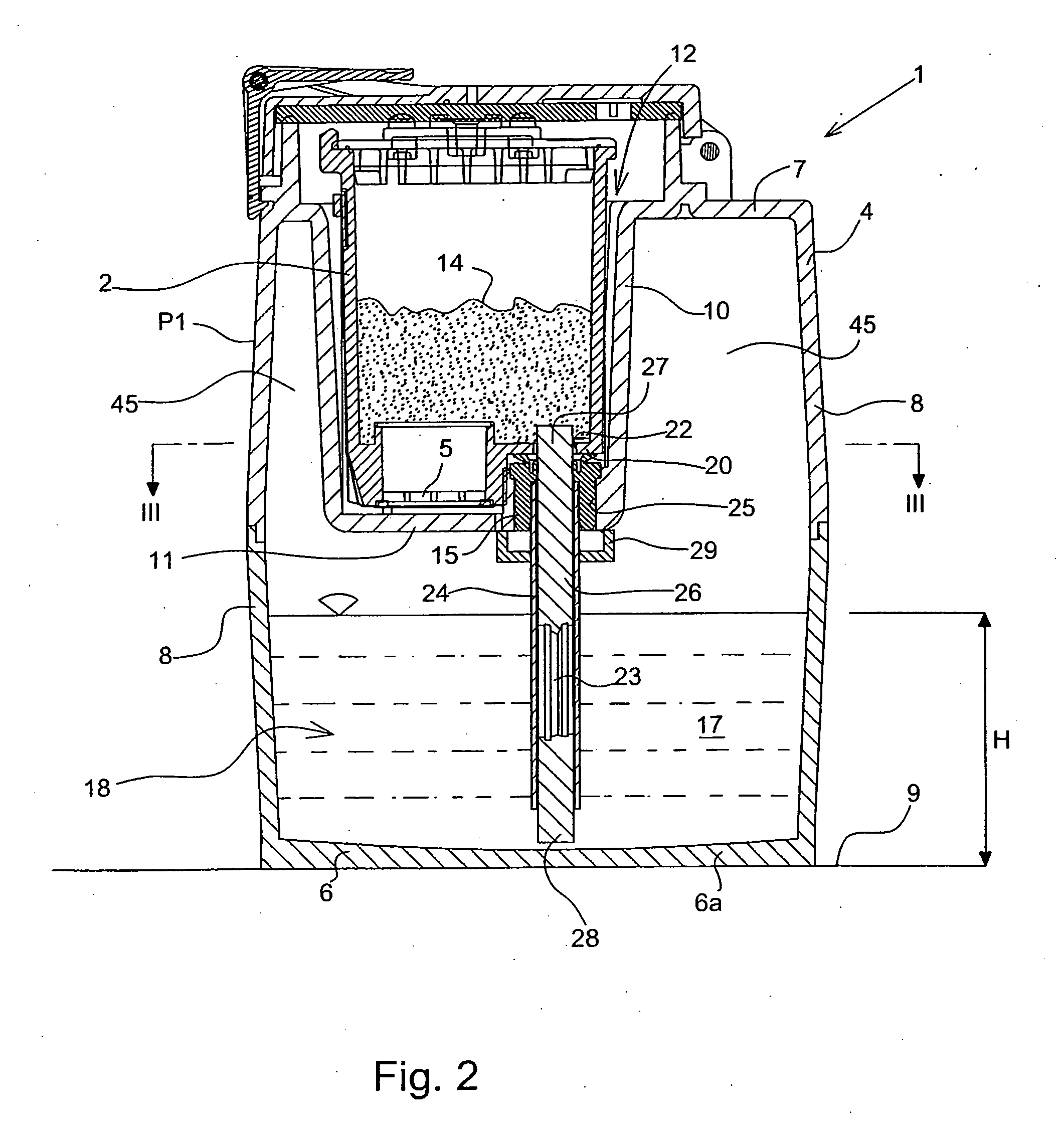

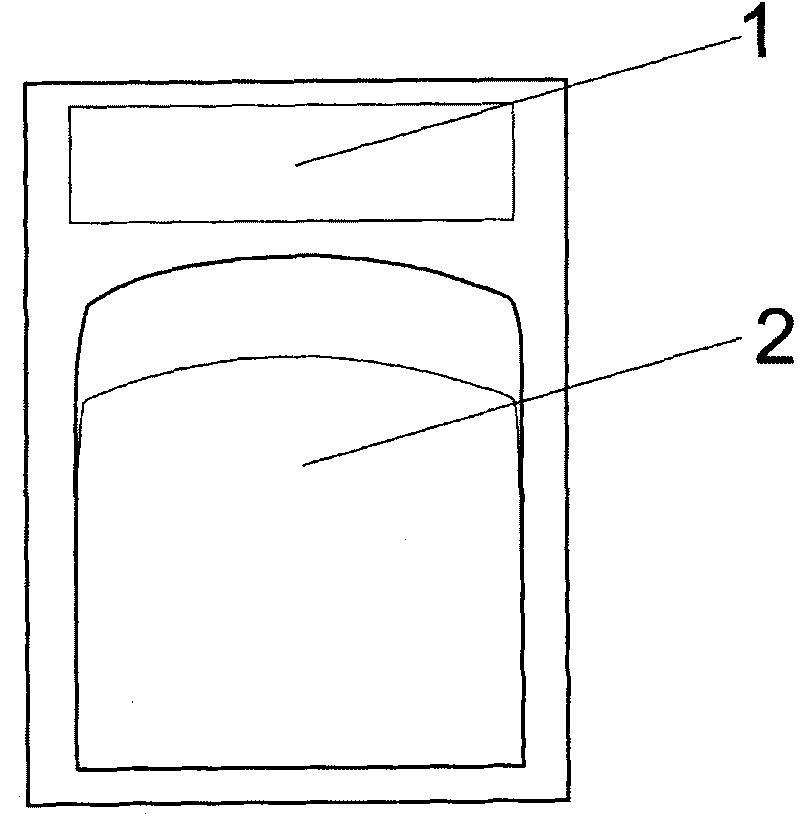

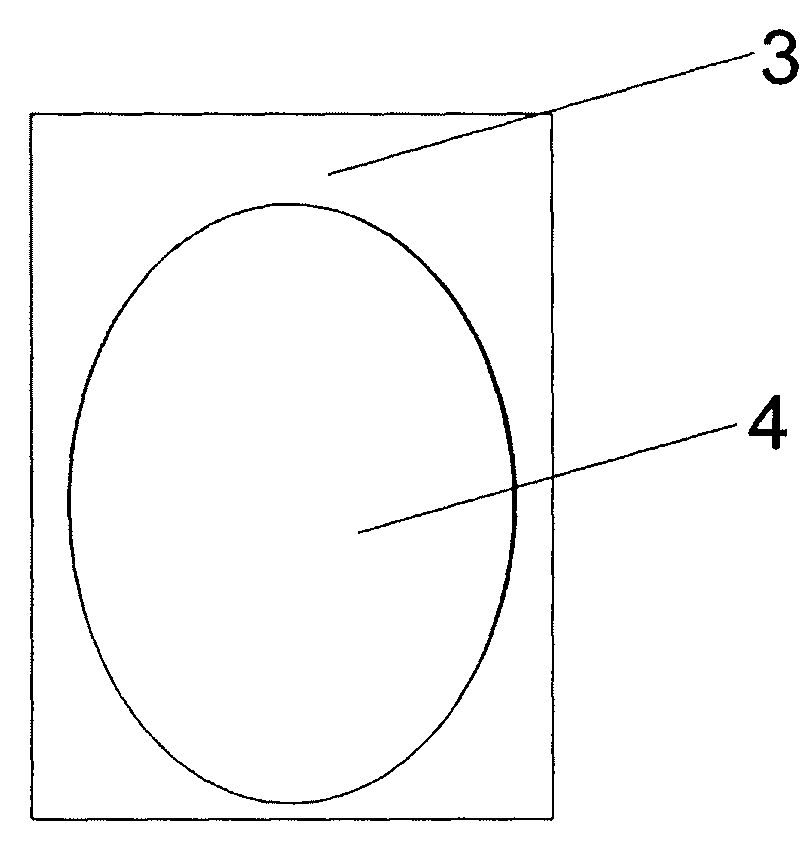

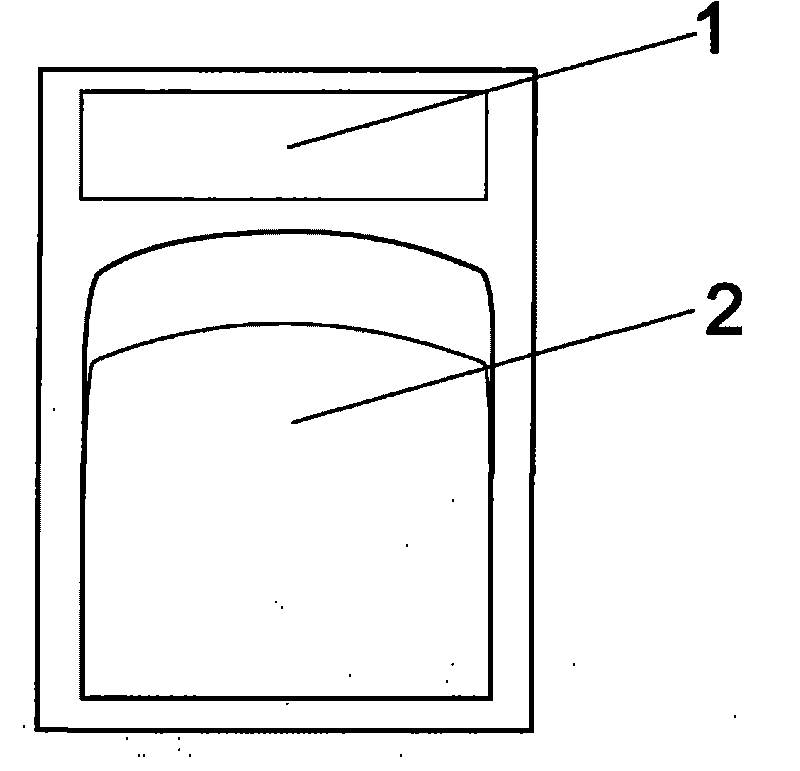

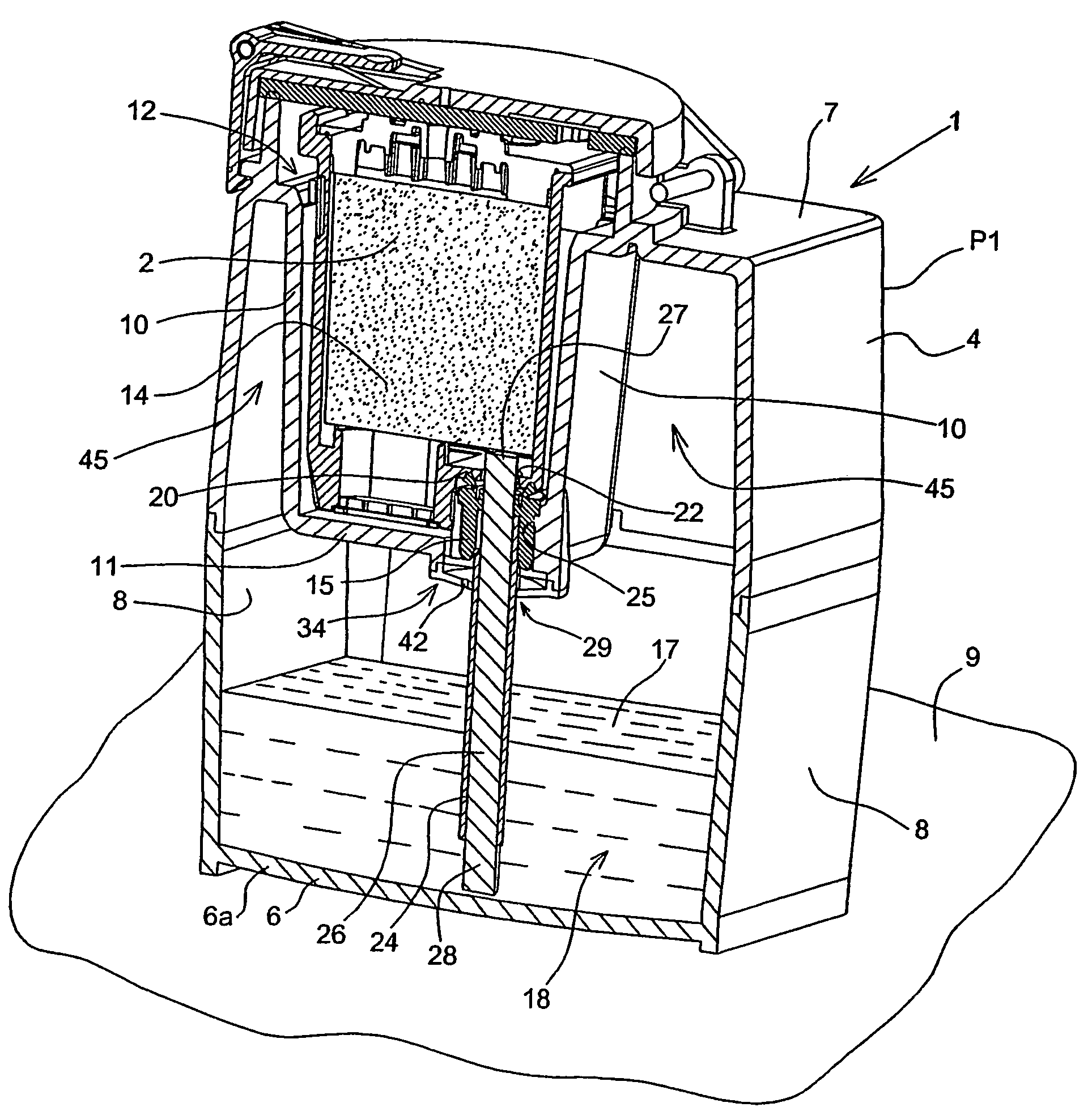

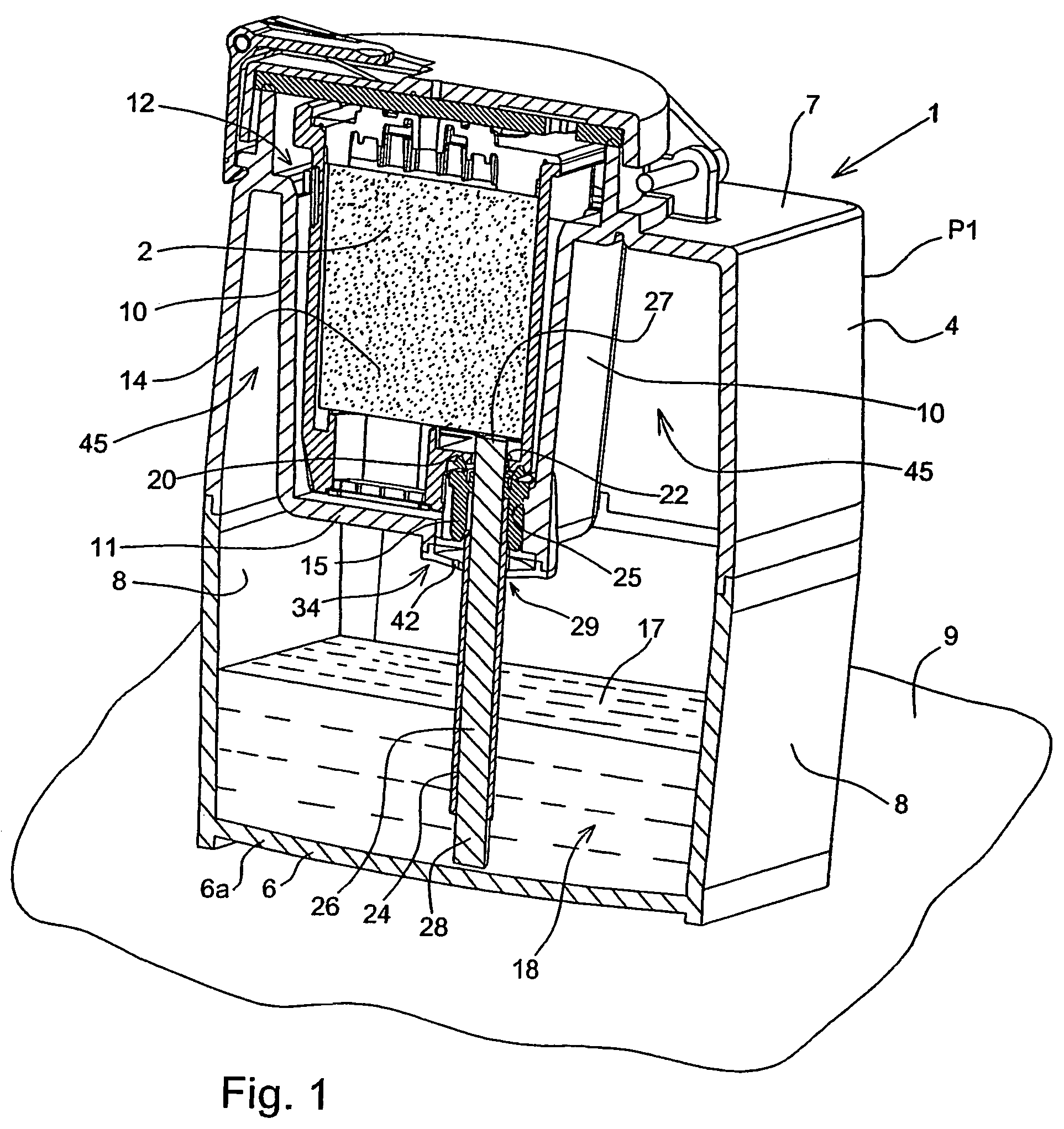

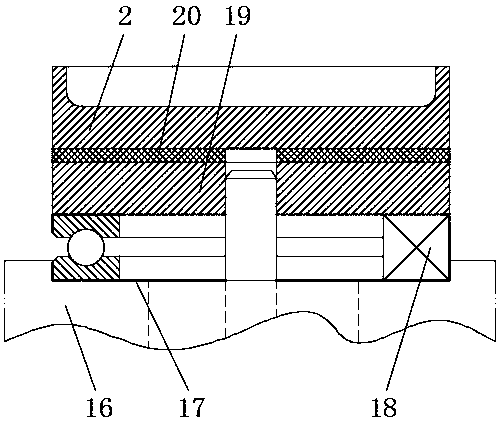

Storage and ink refilling station for a cartridge or a printhead

InactiveUS20070171264A1Avoid runningLiquid surface applicatorsWatering devicesMechanical engineeringCapillarities

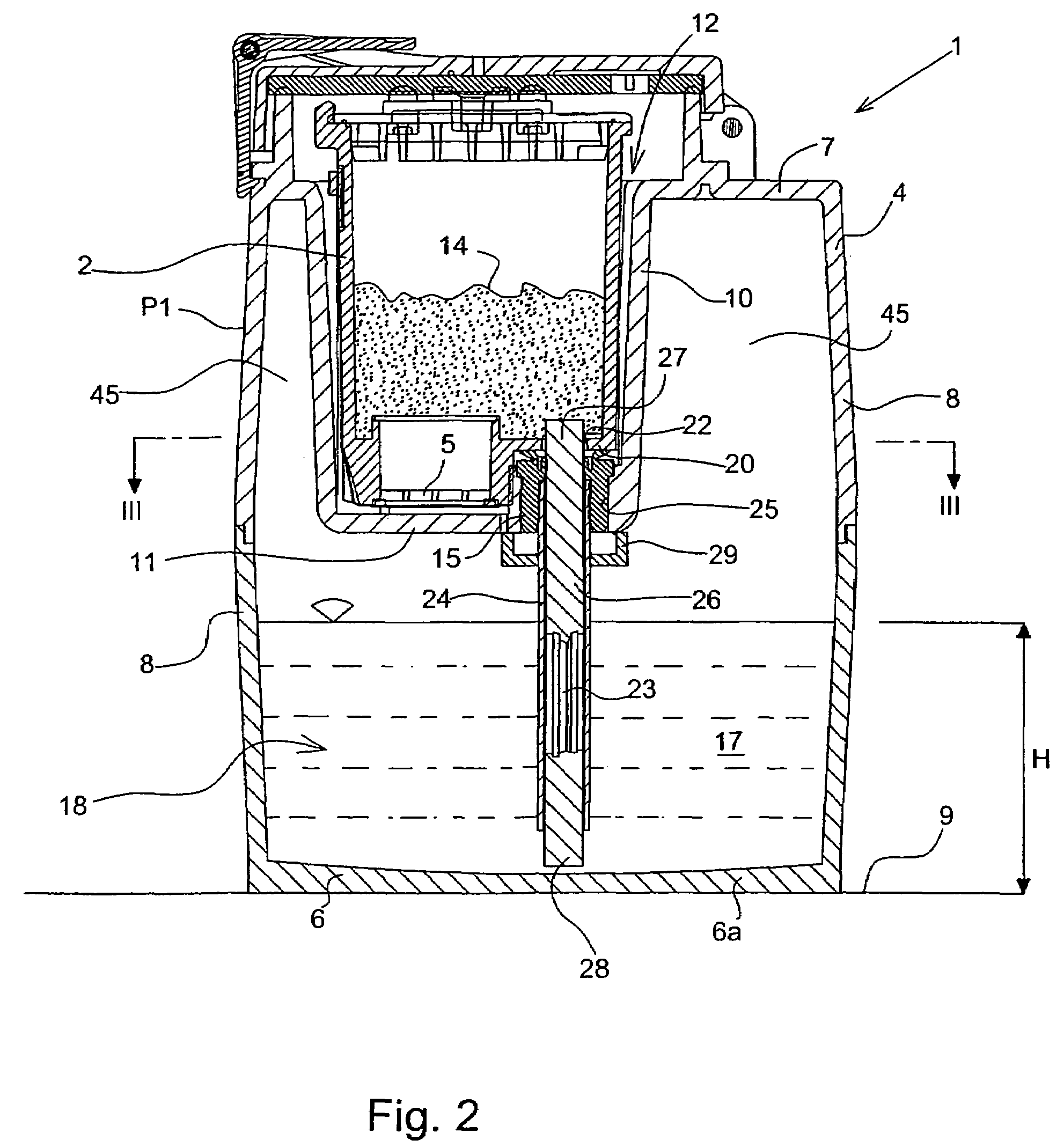

A station for storing and refilling a cartridge of a printhead has a container in which a seat is arranged for accommodating the cartridge to be refilled; the ink for refilling being contained in a collection chamber located in the bottom part of the container. The collection chamber communicates freely with a back-flow compartment located at the top, surrounding the housing and in free communication with the chamber. The feeding is effected by means of a capillary element contained inside an impermeable sheath extending vertically into the collection chamber and arranged centrally in a symmetrical position with respect to the base of the container. The capillary element penetrates into the housing in contact with the sponge of the cartridge to transfer the ink through capillarity. Feeding takes place solely and exclusively with the container in the vertical position whereas in any other position the ink flows into the back-flow compartment and the capillary element is no longer lapped against by the ink. In this way, any dripping and / or leakage of ink through the capillary element is avoided.

Owner:TELECOM ITALIA SPA

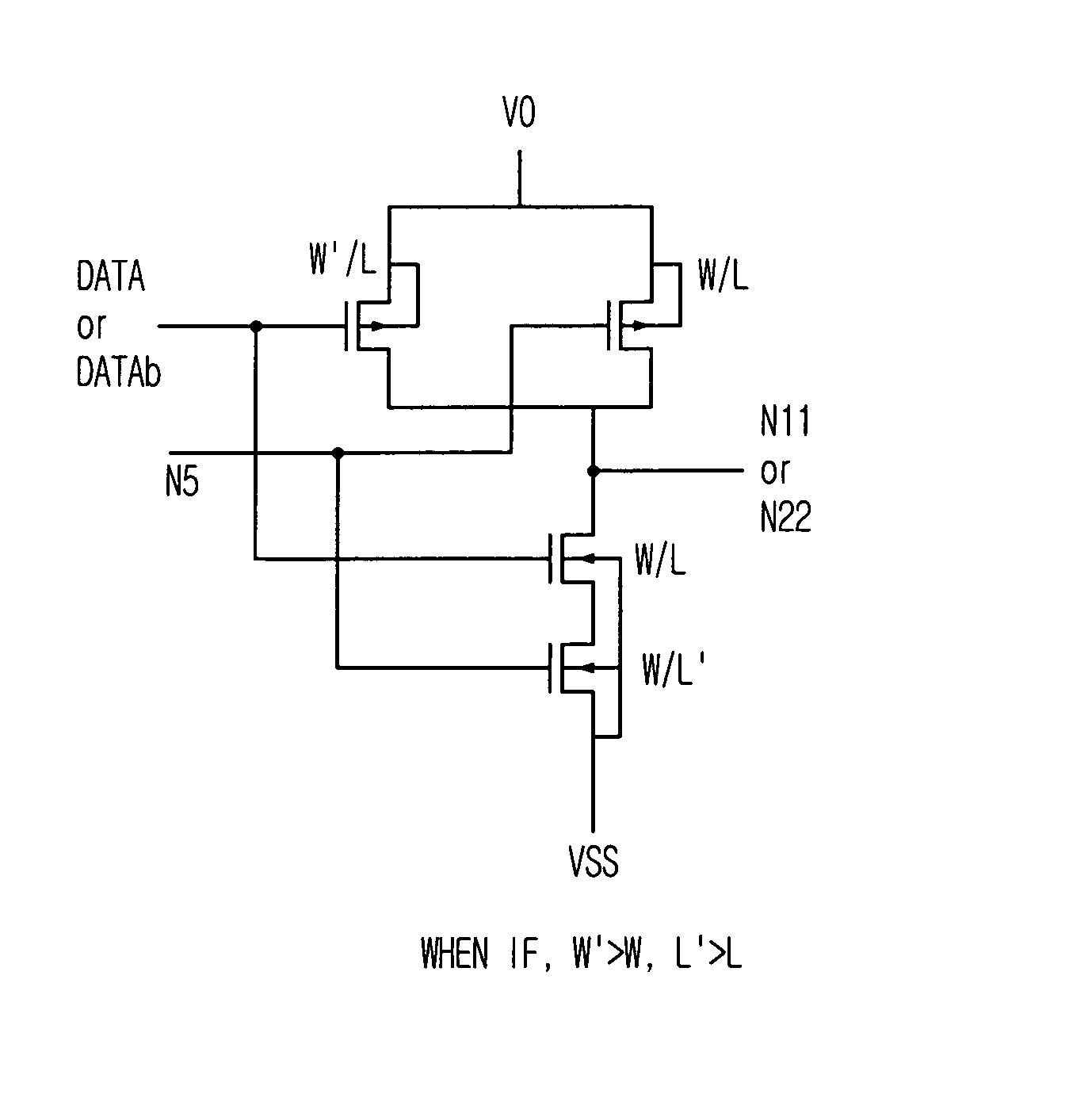

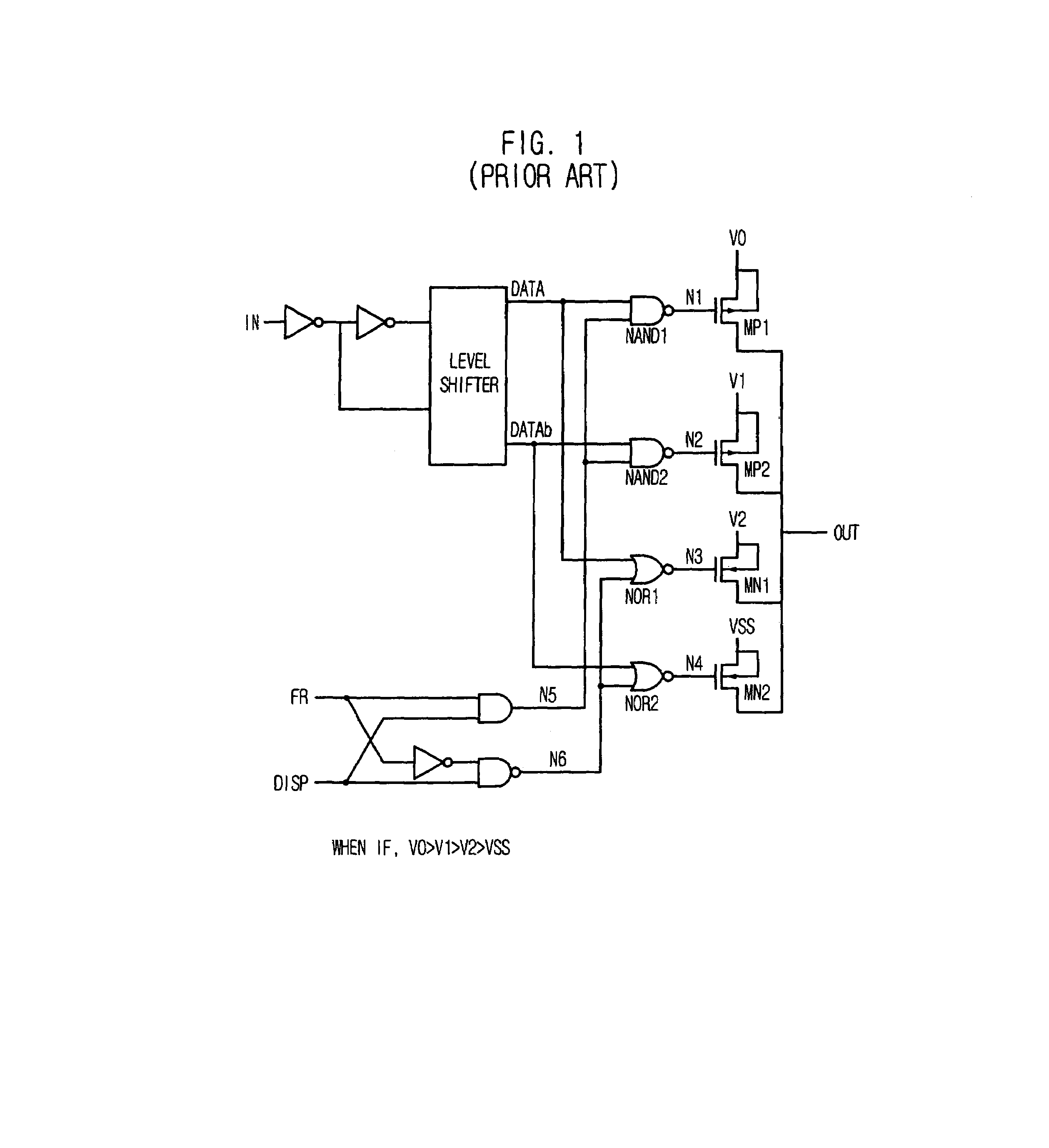

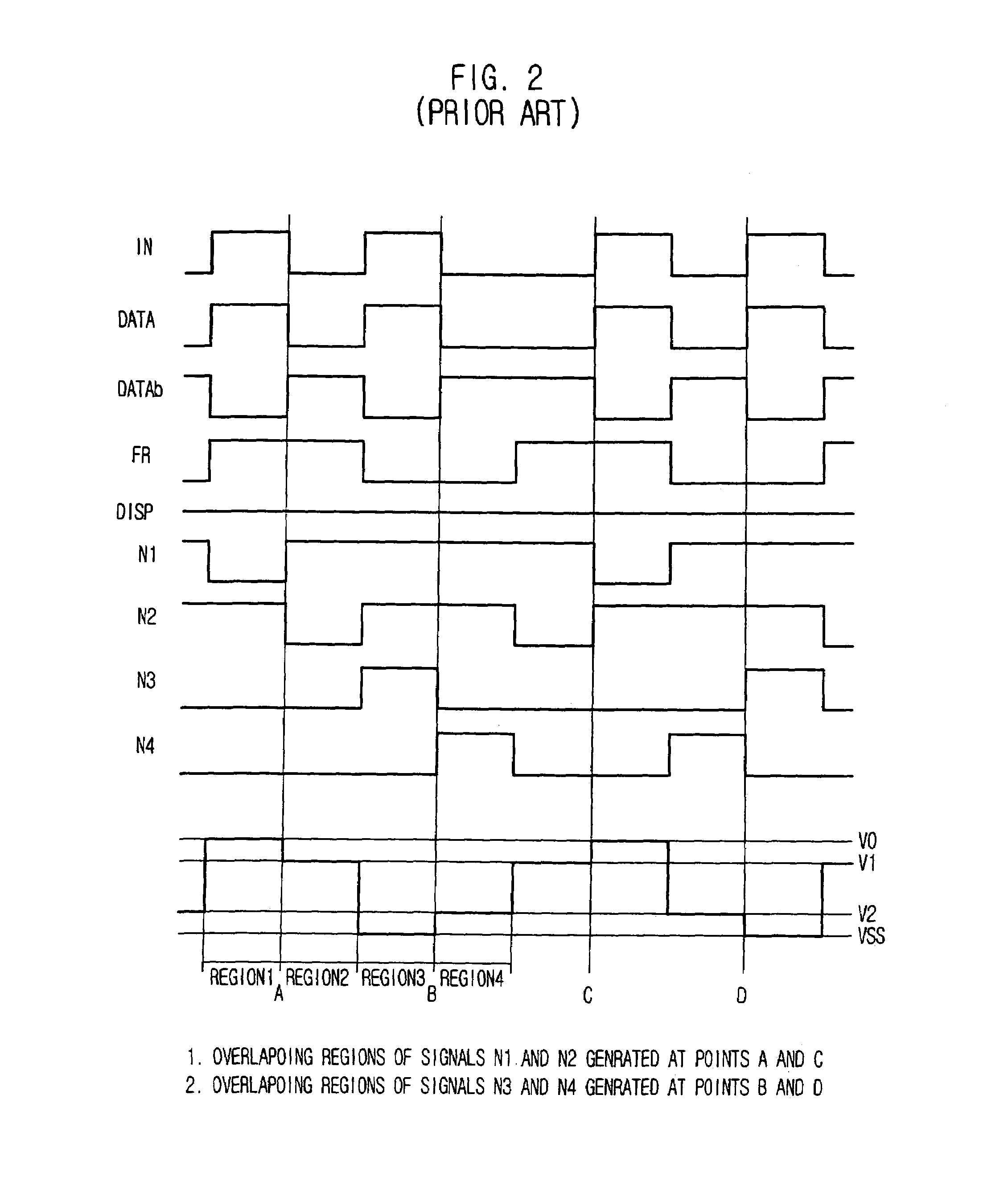

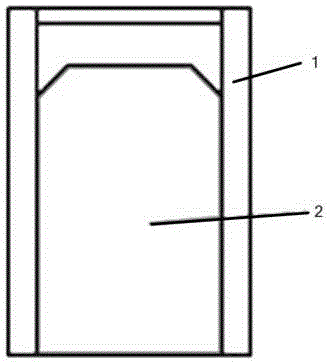

Multi-level voltage output control circuit and logic gate therefor

ActiveUS7068075B2Extended rise timeExtended fall timePower reduction in field effect transistorsStatic indicating devicesEngineeringLogic gate

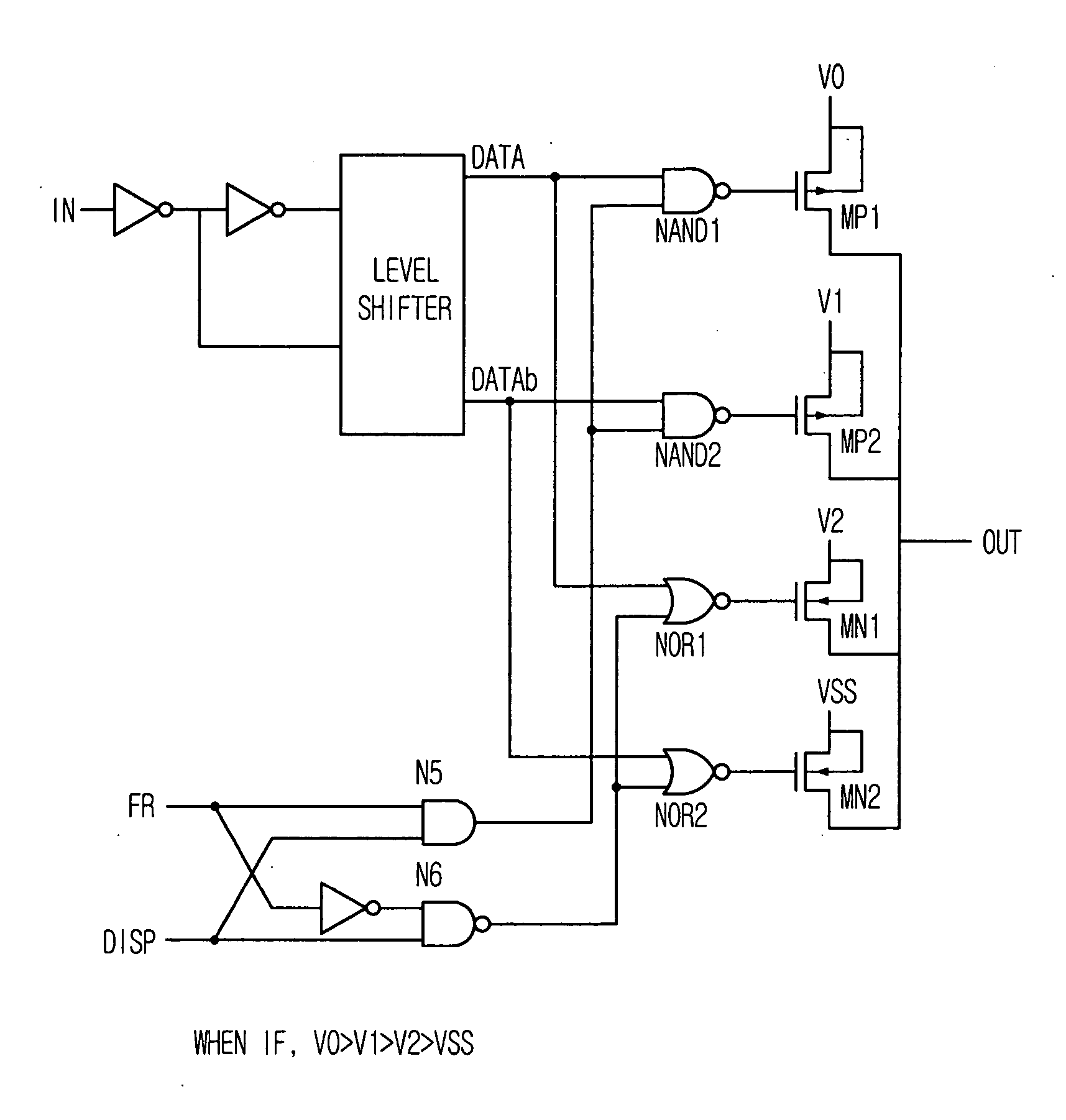

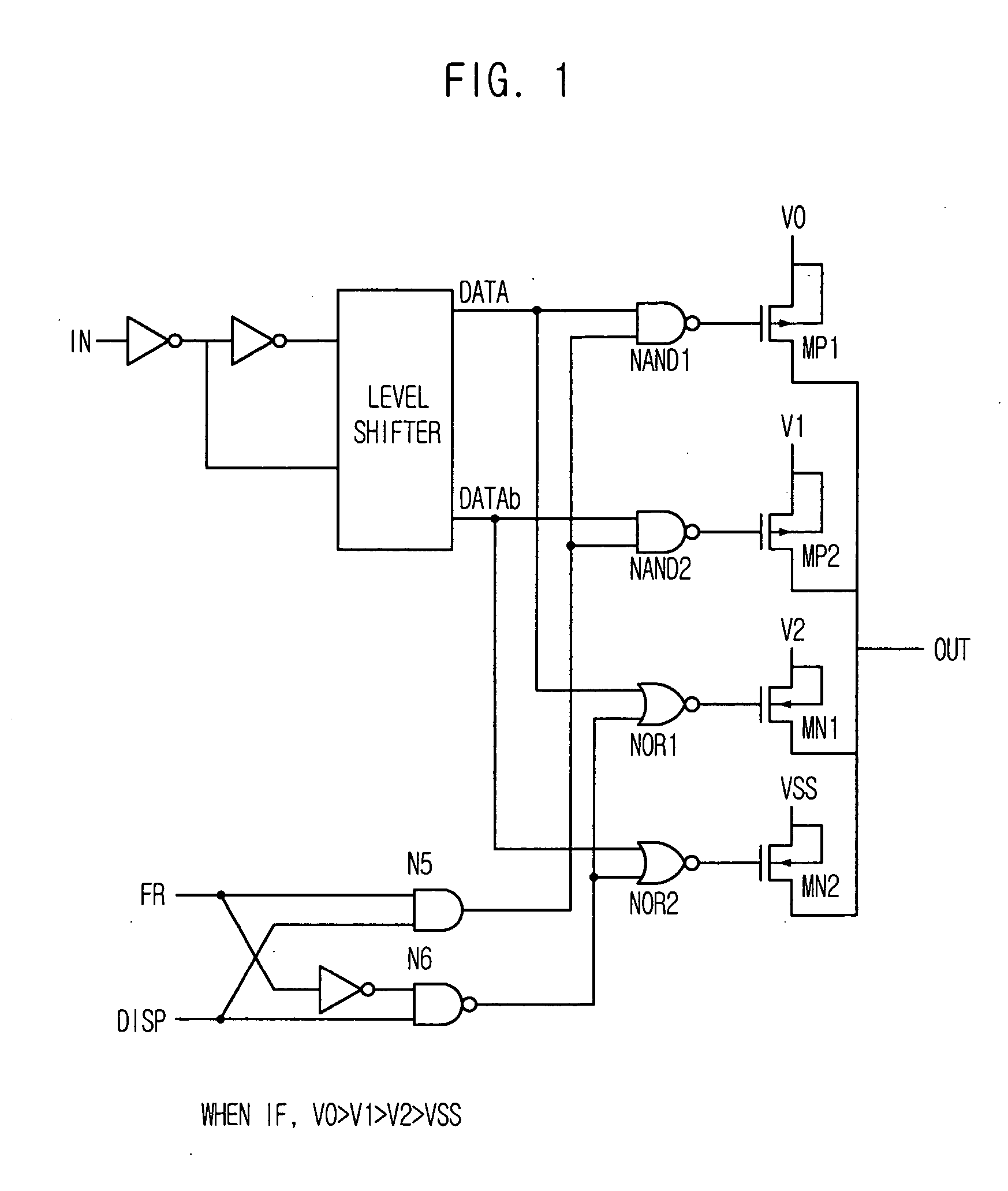

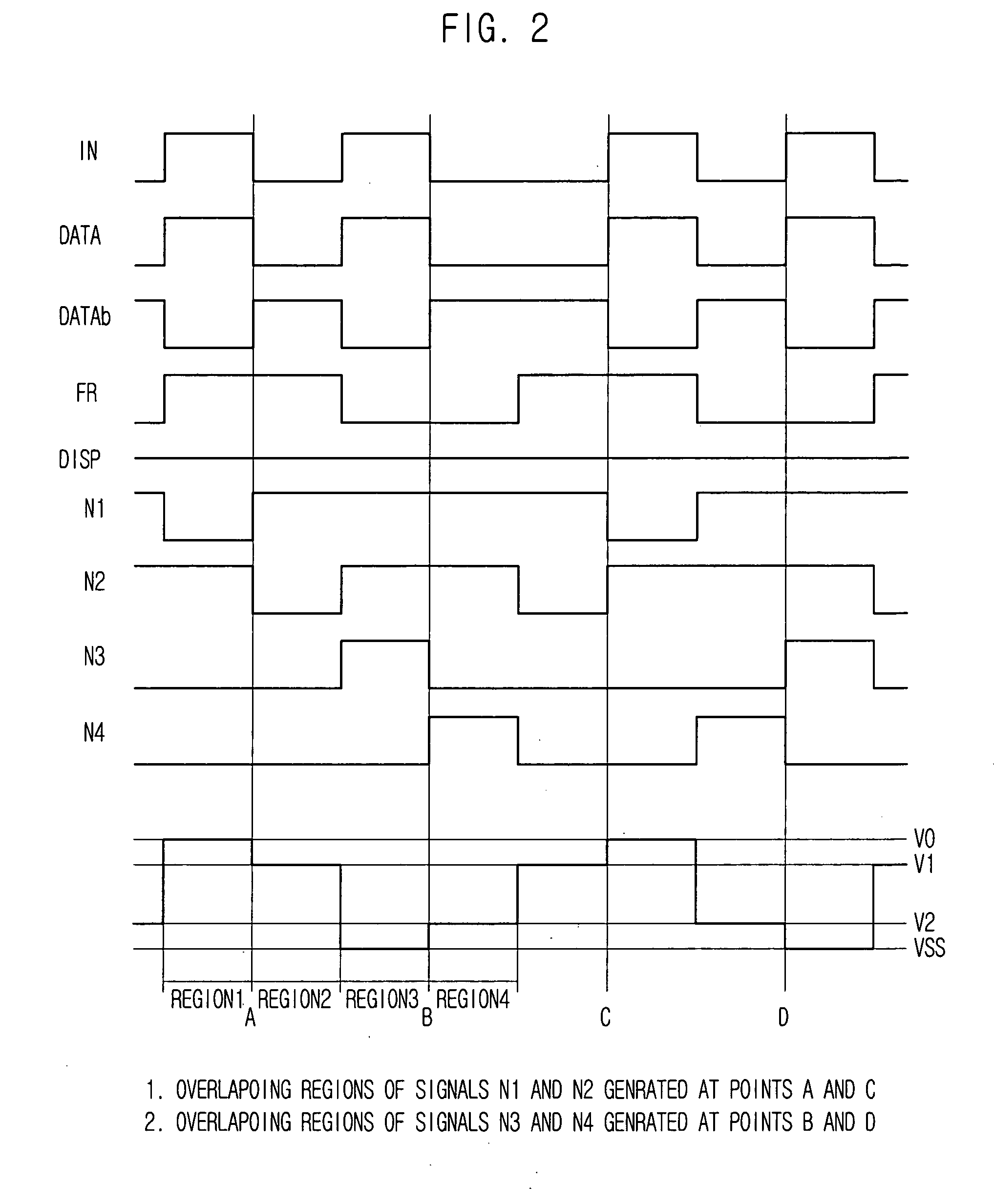

A multi-level voltage output control circuit selectively outputs one of multi-level power voltages by driving gates of two MOS transistors, which act as switching devices for the multi-level power voltages, with two output signals, the two output signals having complementary phases to each other and generated from two logic gates receiving two input signals which have an identical timing and complementary phases to each other, wherein the two logic gates advance or slow down a rising timing and / or a falling timing of the two output signals by differently adjusting a size of PMOS transistors and that of NMOS transistors, which construct the logic gates, thereby excluding a case in which the two output signals are in a same logic state at the same time.

Owner:MAGNACHIP SEMICONDUCTOR LTD

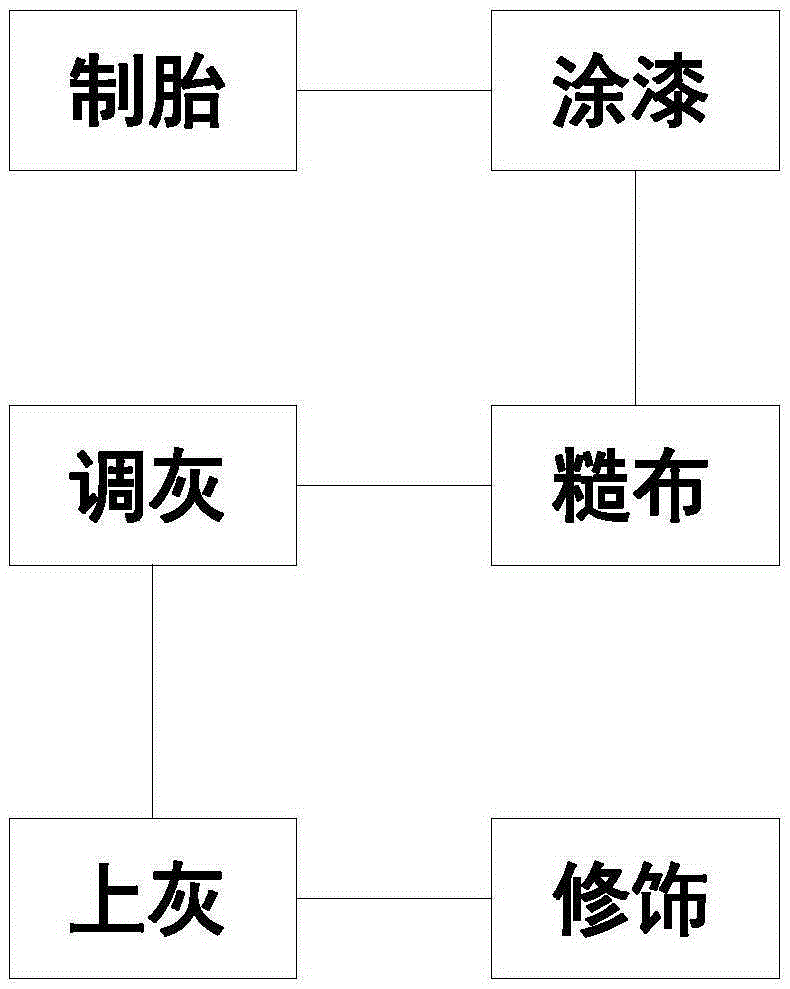

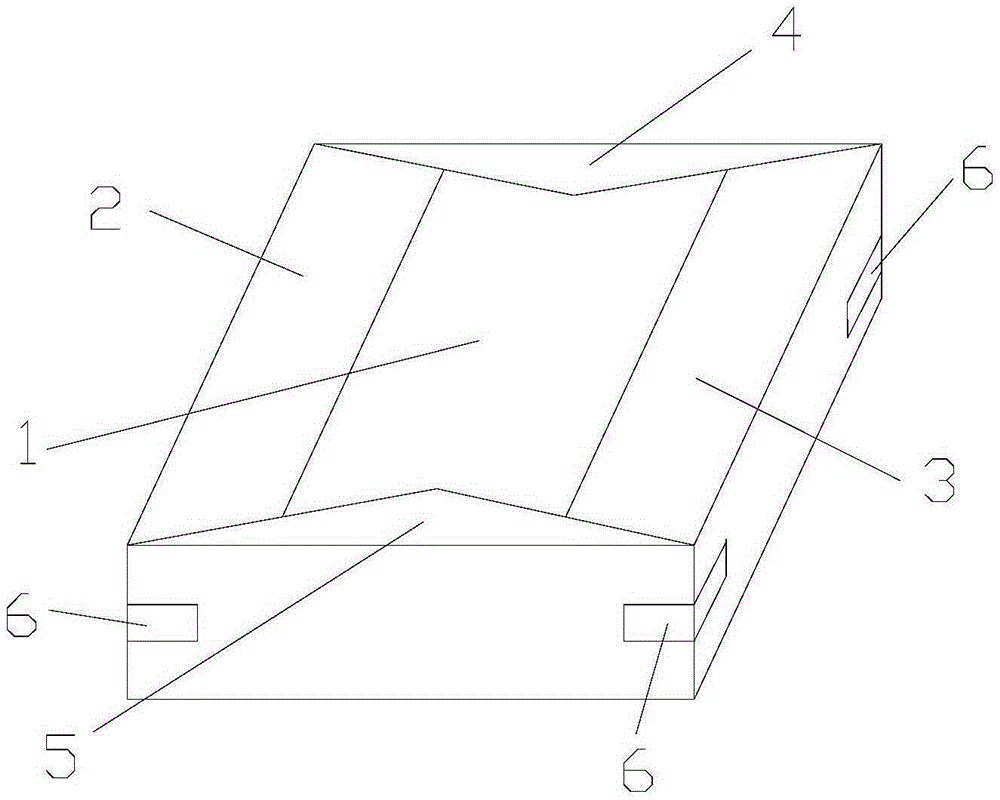

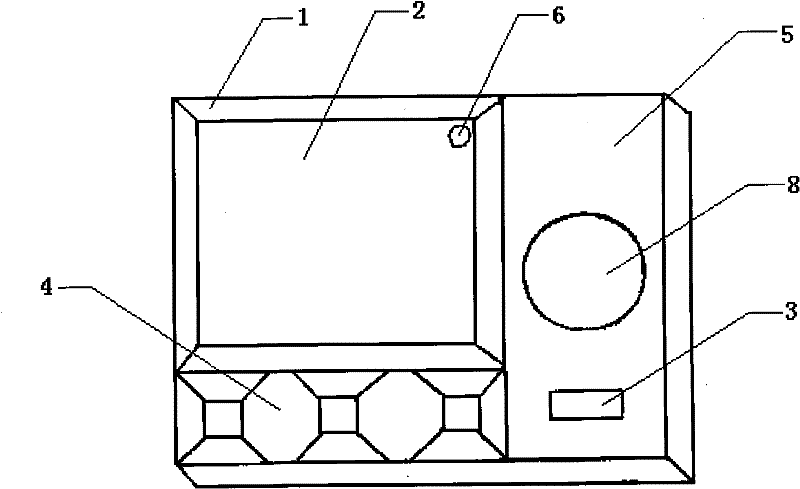

Paint-emery inkstone

ActiveCN105415473AComply with internal stress characteristicsShorten production timeWood working apparatusInk standsLacquerMaterials science

55. The invention discloses a paint-emery inkstone. A wood blank serves as a framework of the paint-emery inkstone. Raw lacquer, soil-stone powder or kaolin is blended with emery and other grinding materials for painting the outer surface of the paint-emery inkstone. The paint-emery inkstone has the advantages that a inkstone body is light, excellent in quality, free of damage to a brush head, ink grinding noise, deformation and cracks, beautiful and pratical; produced ink is glossy as oil. A preparation method for the paint-emery inkstone comprises the six steps of blank making, painting, rough cloth preparing, plaster mixing, plaster painting, and embellishing. By discovering the components of plaster, the thickness of the painted plaster, the mesh number of the grinding materials and the method of plaster painting in the processes of plaster mixing and painting, the quality of existing paint-emery inkstones is improved significantly, so that the parameters of ink abradability, ink productivity, ink concentration and the like of the paint-emery inkstone are increased substantially. According to the paint-emery inkstone, the technical problem which troubles personnel in the field for years is solved; the paint-emery inkstone is another significant development after the paint-emery inkstone technology is recovered.

Owner:ANHUI YUJINHAI LACQUERWARE CRAFT CO LTD

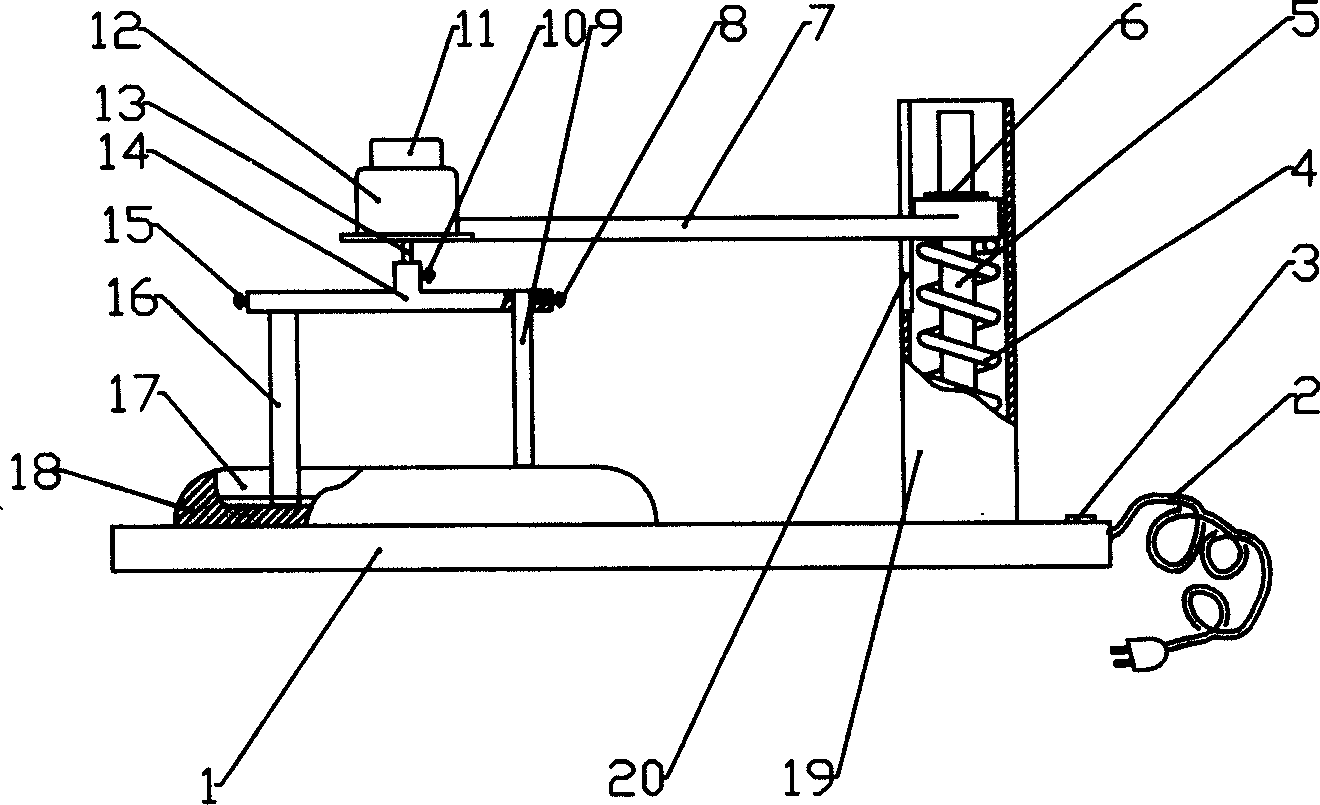

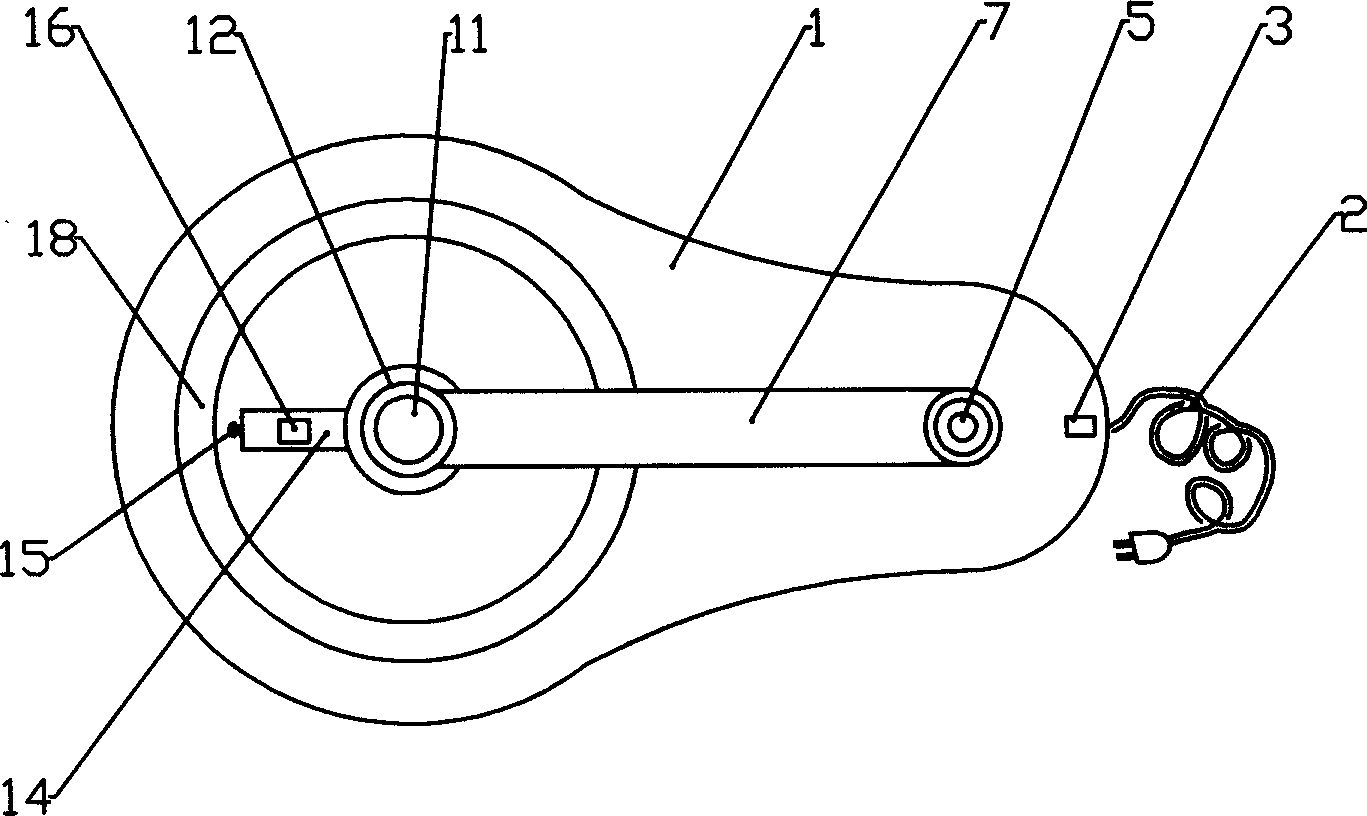

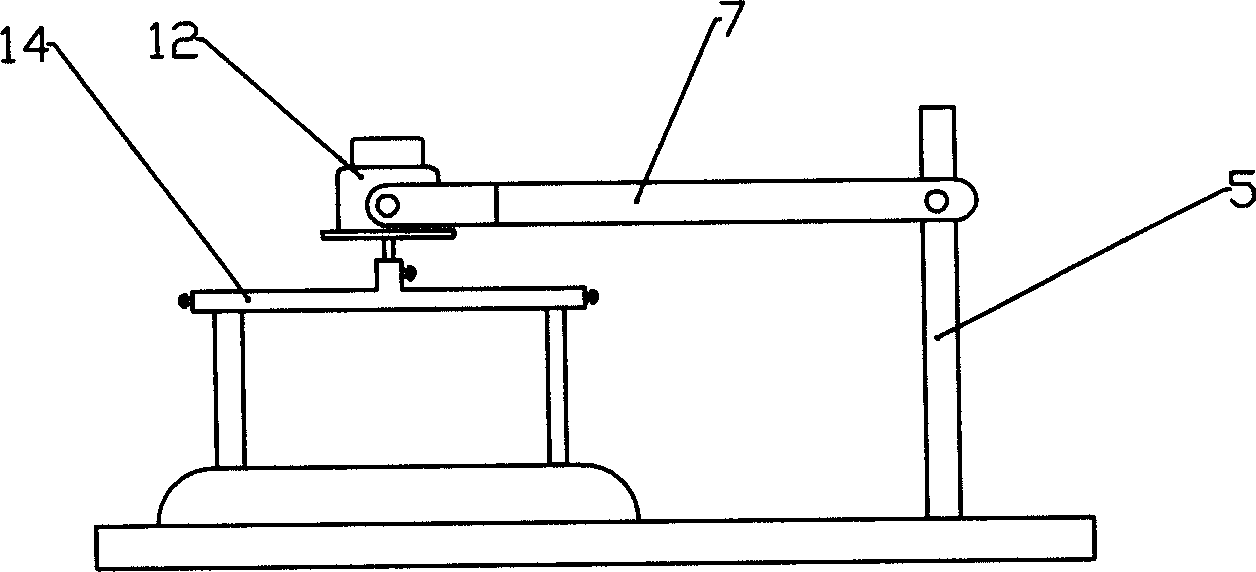

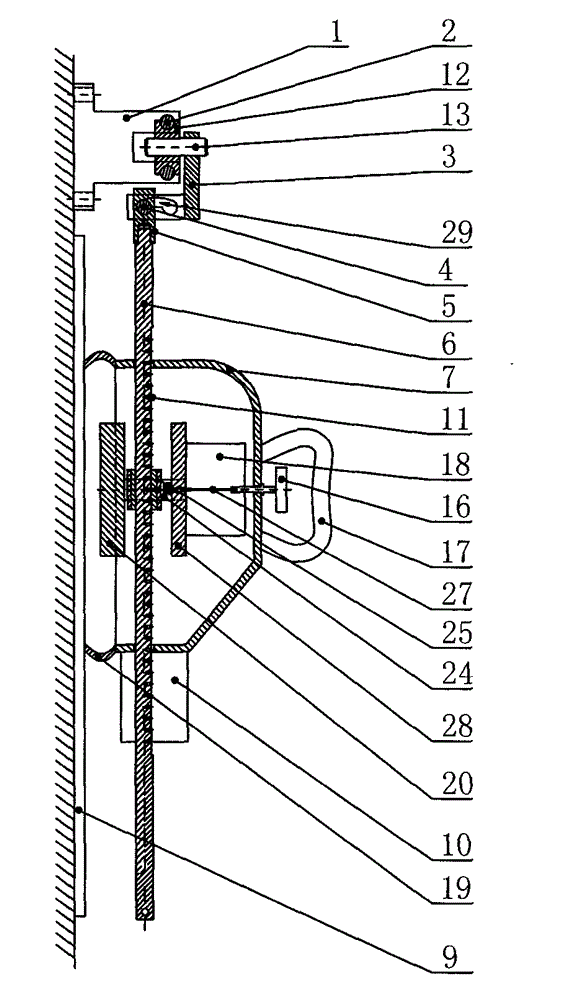

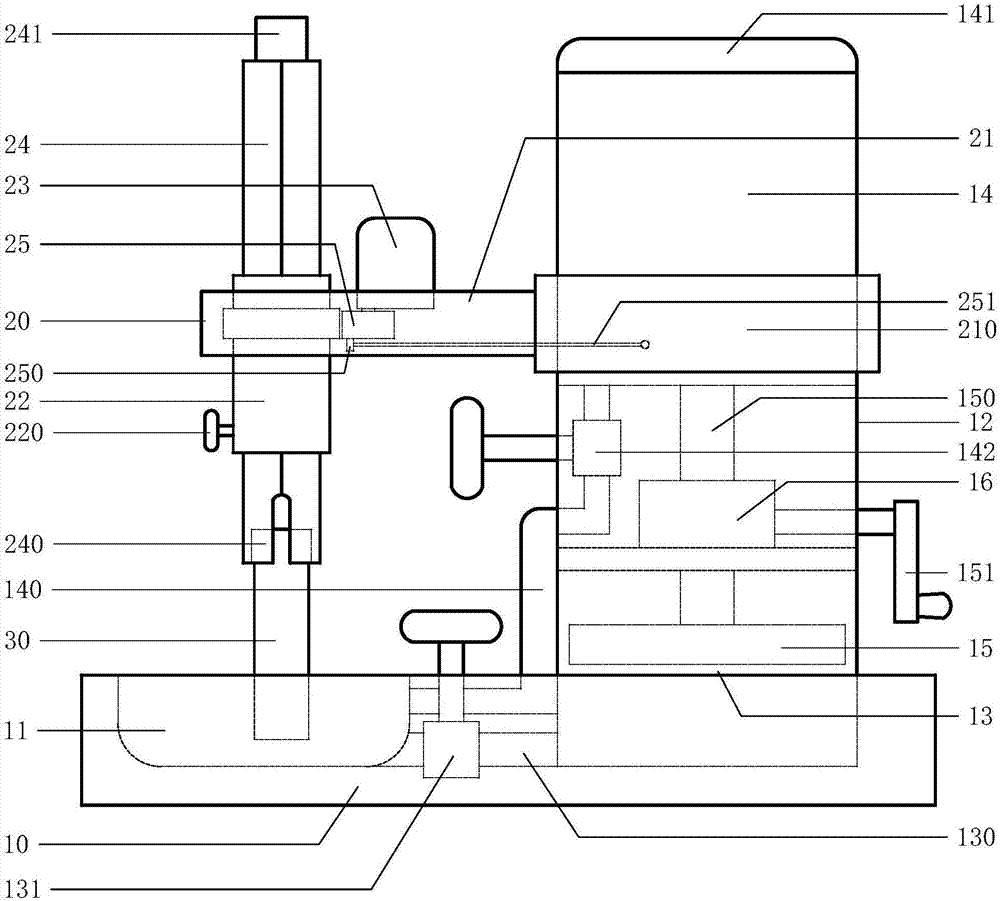

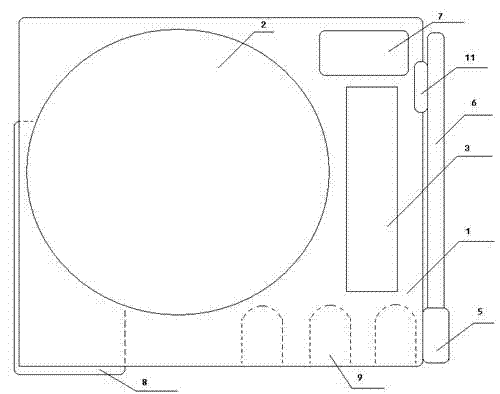

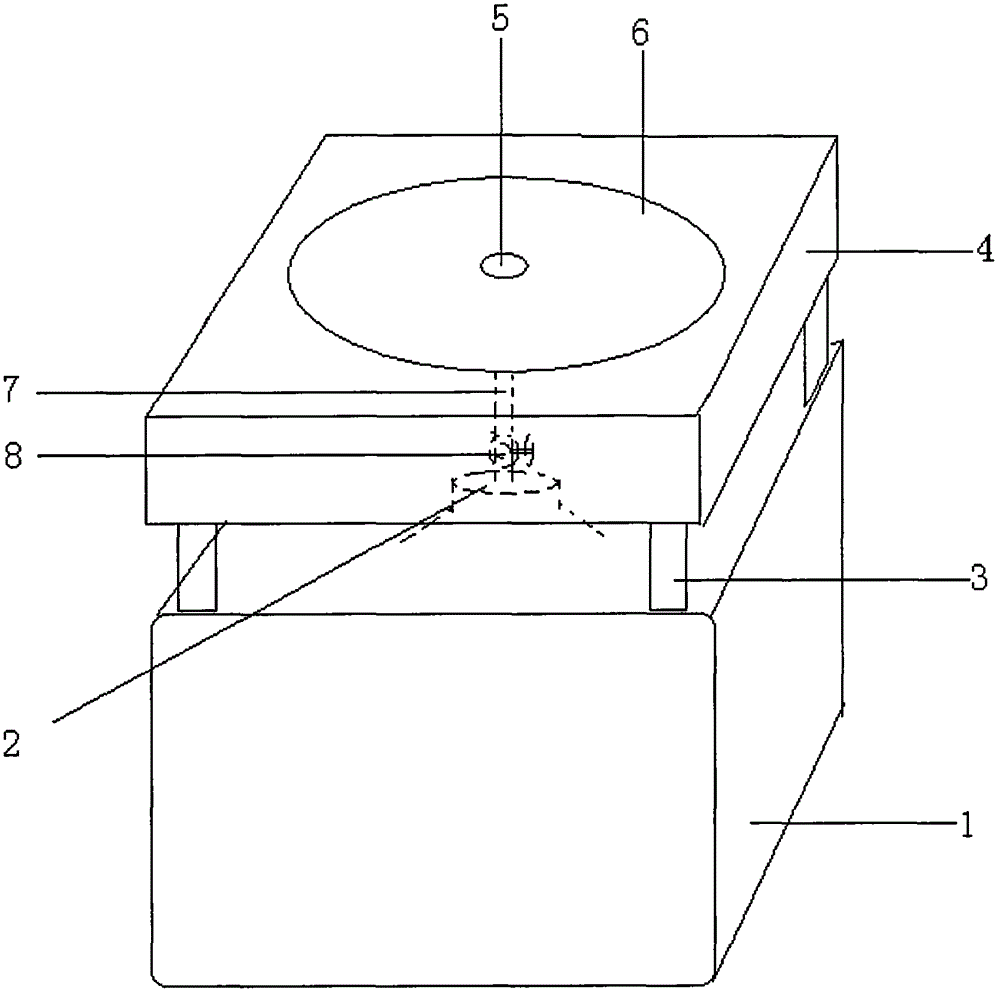

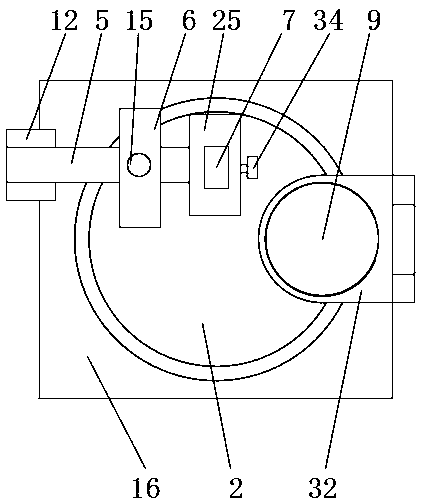

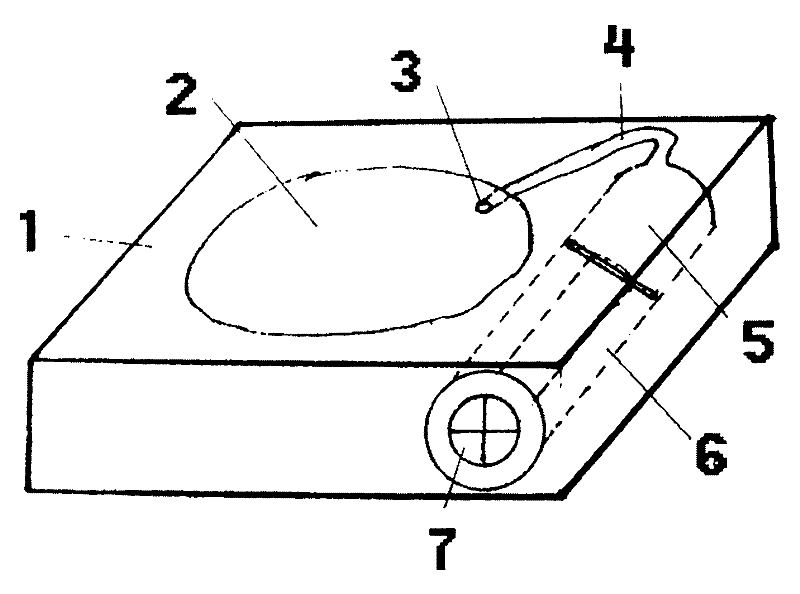

Automatic ink-grinding machine

The invention discloses a machine of the automatic grinding ink. It contains a batholith on which there is an inkstone. It installs an electromotor and an ink bar fixation frame which is driven and circumrotated by the electromotor. On the ink bar fixation frame there is an ink bar clamped equipment which is used in perpendicularly fixing the ink bar. The usage of the machine of the automatic grinding ink is convenient. It liberates the people from the hand-grinding ink operation and can grind the different concentration of the ink by the inkstone watering quantity, the length of the grinding time and the press.

Owner:杨国铵

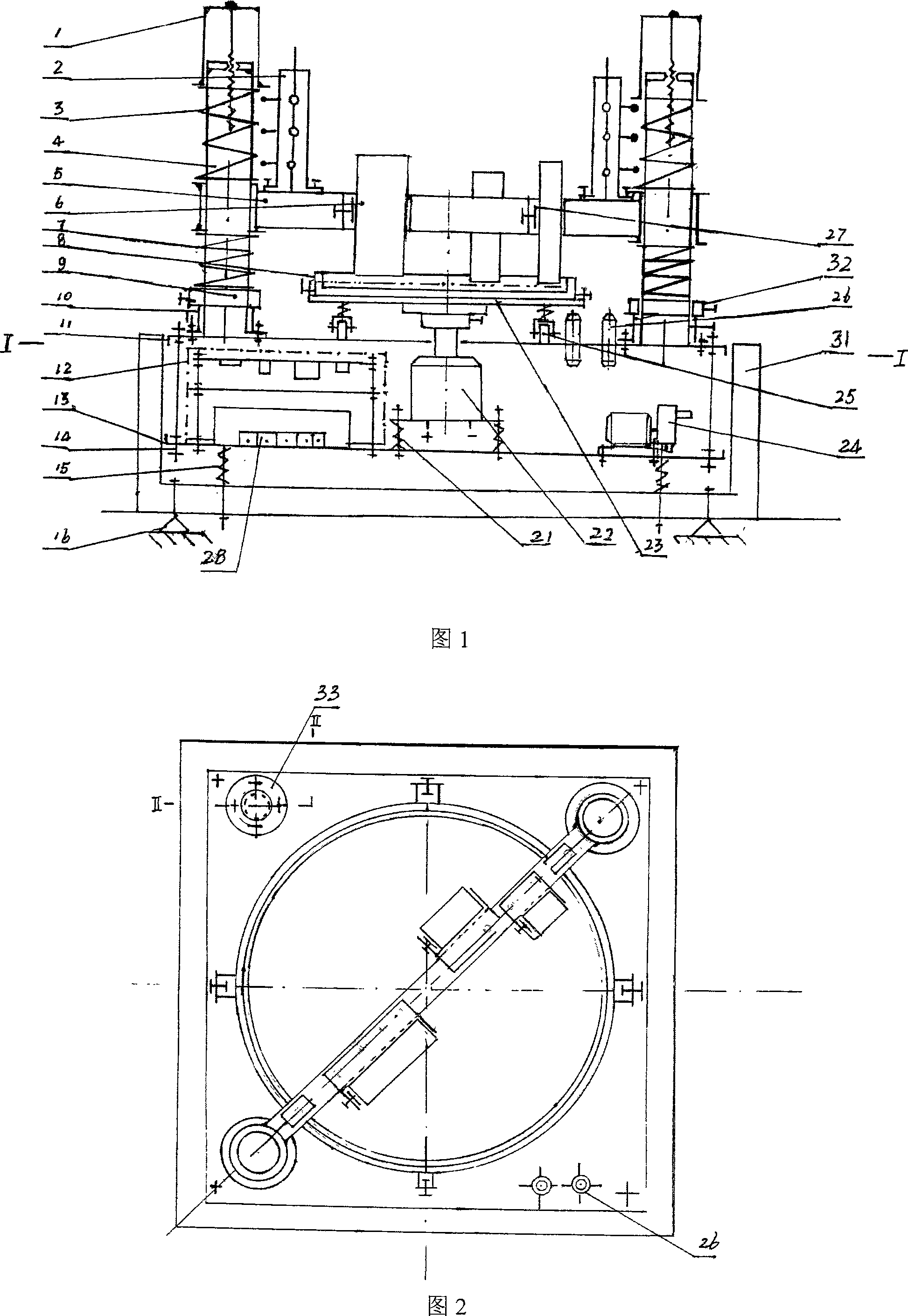

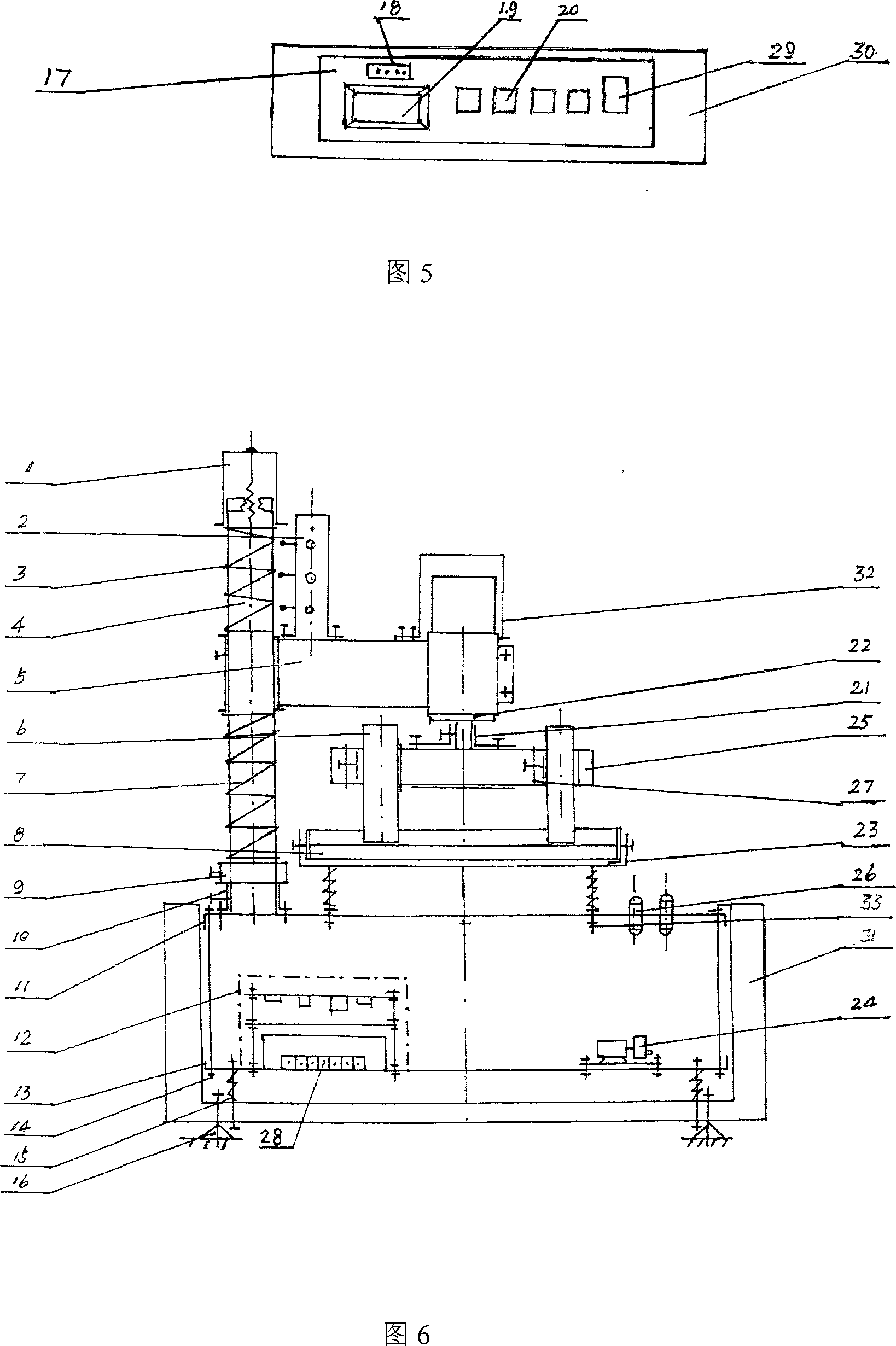

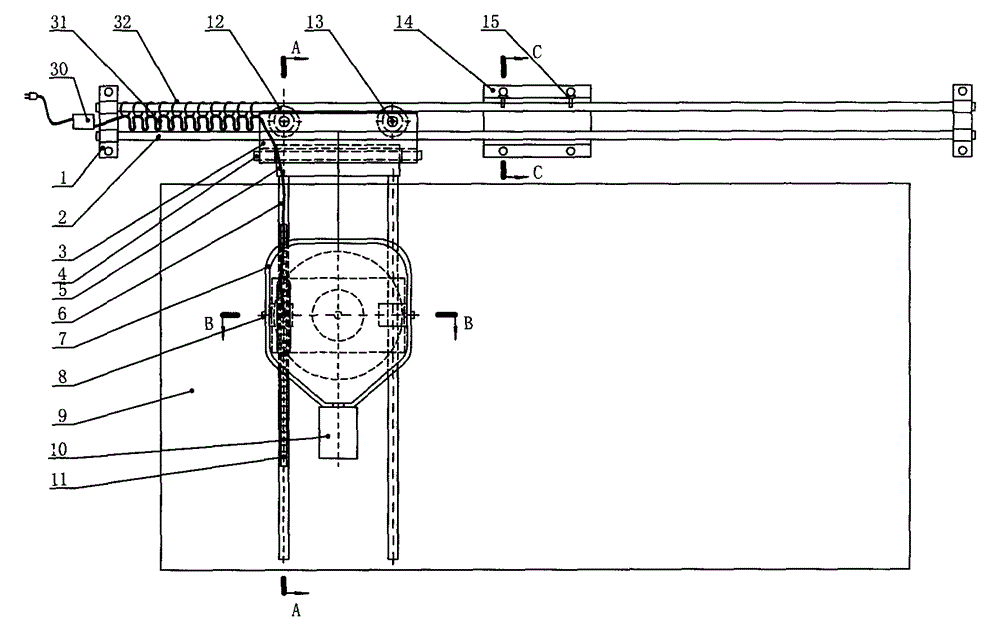

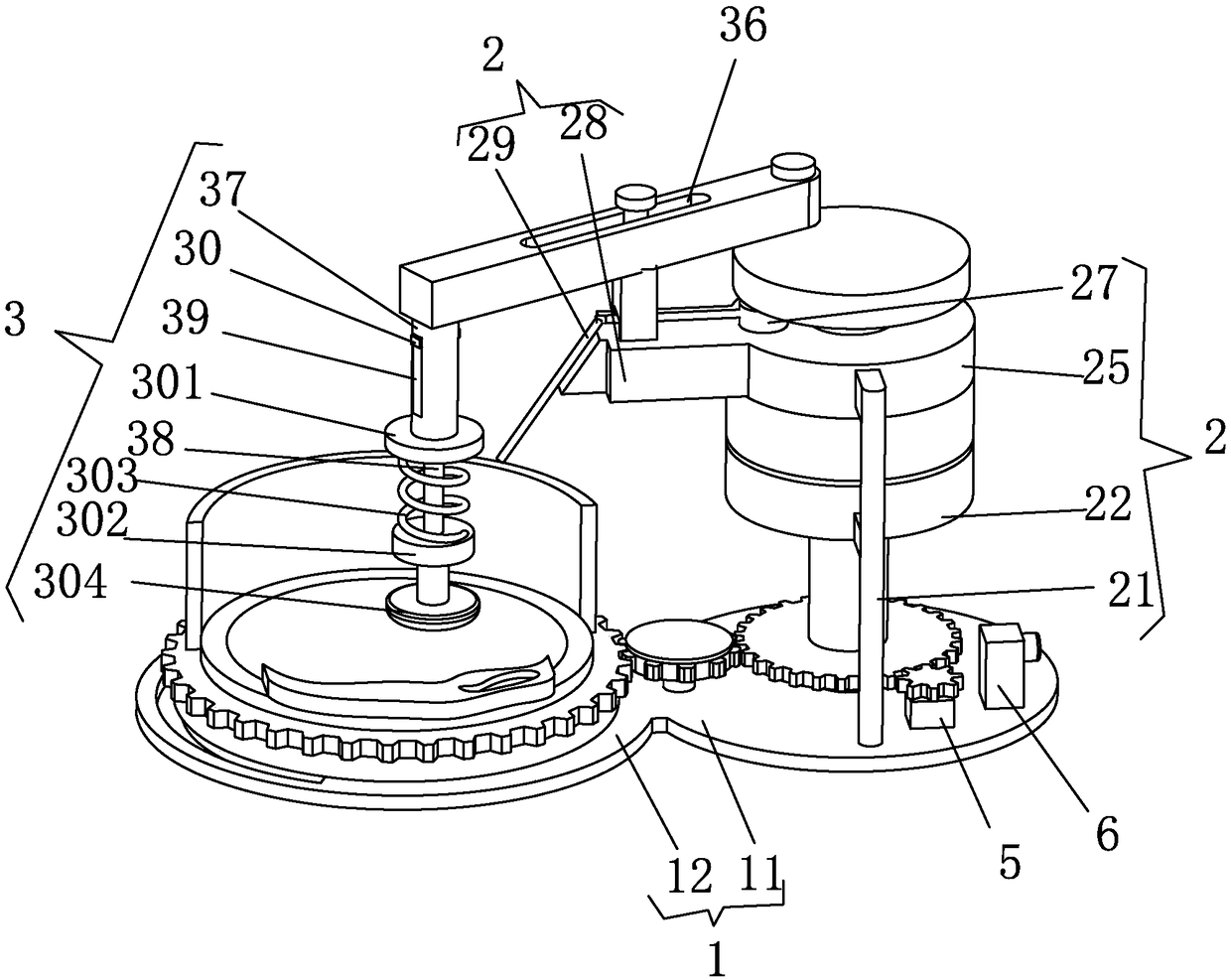

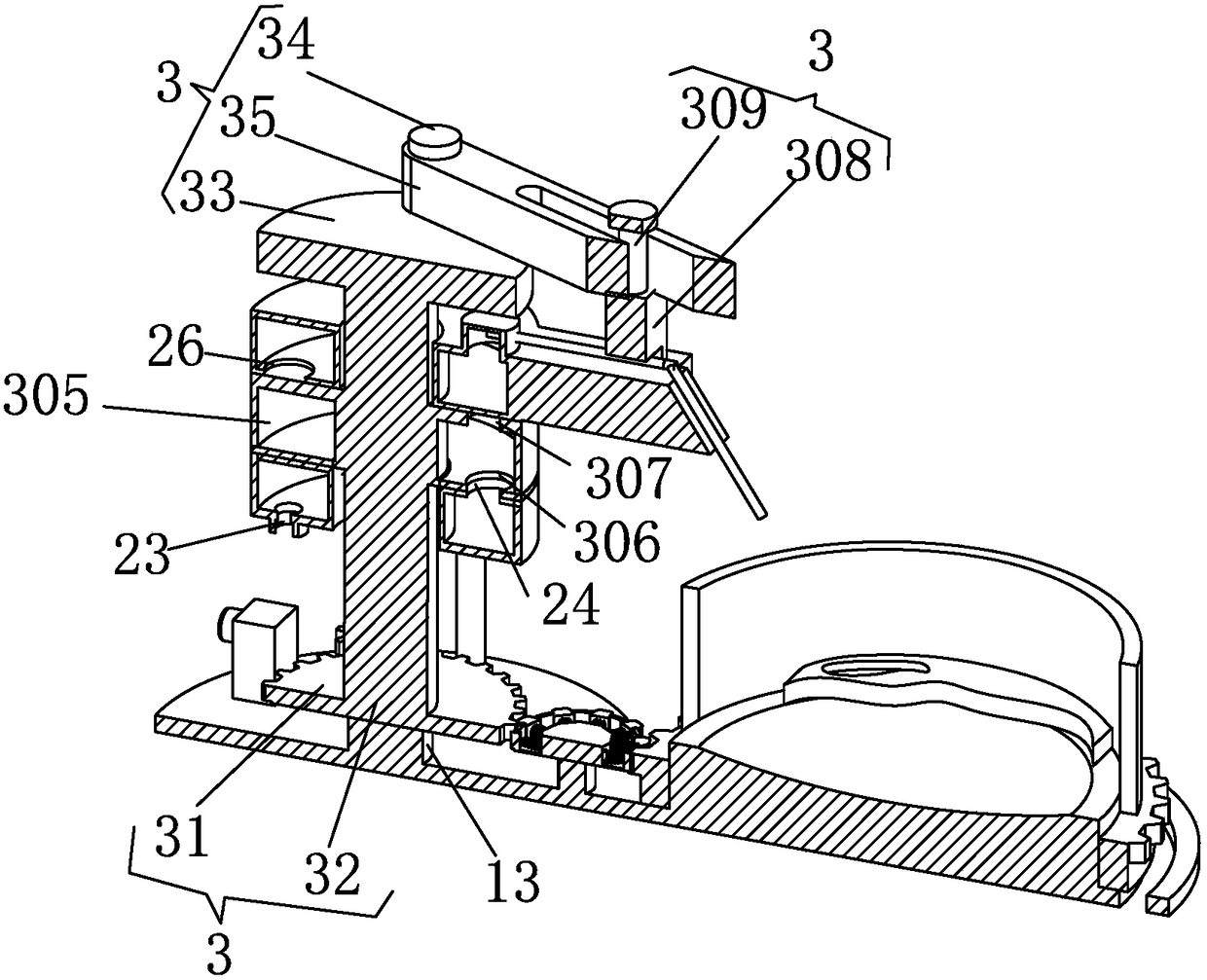

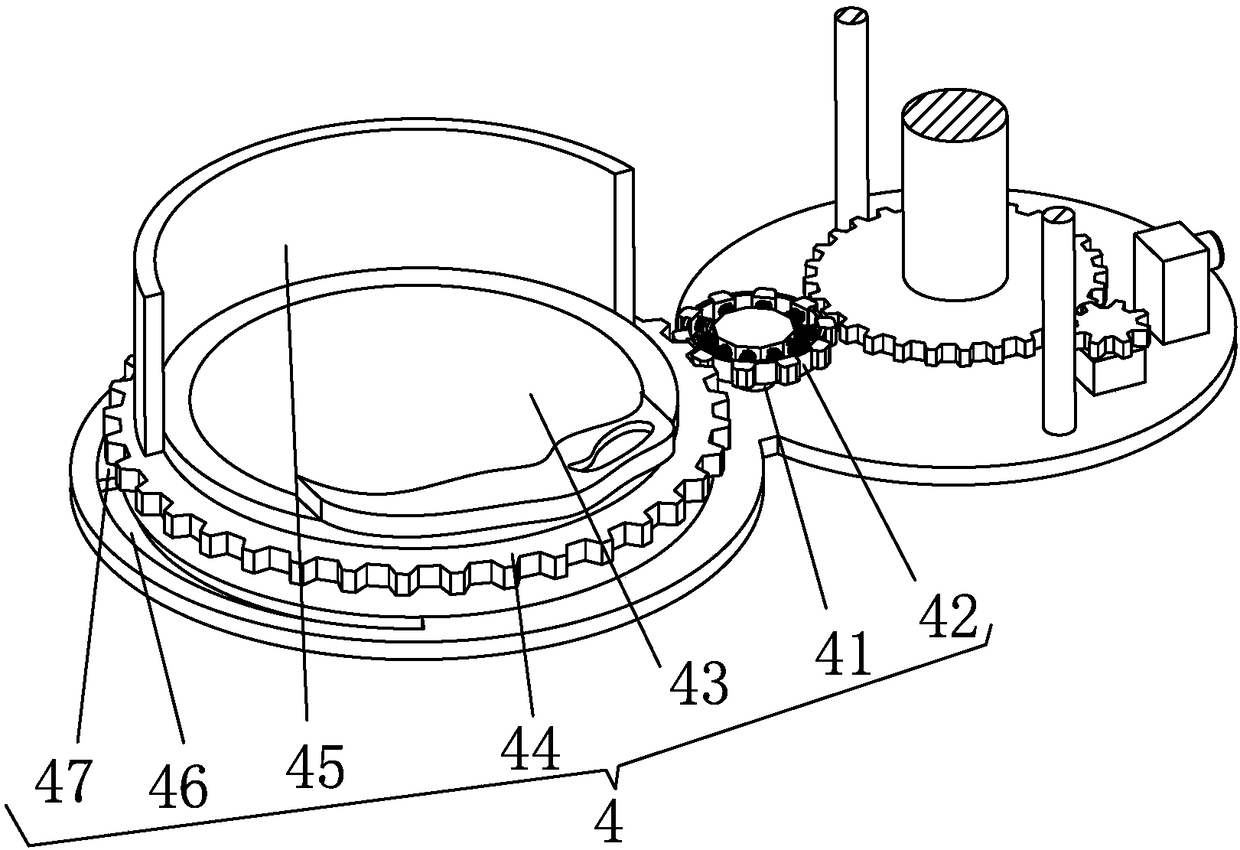

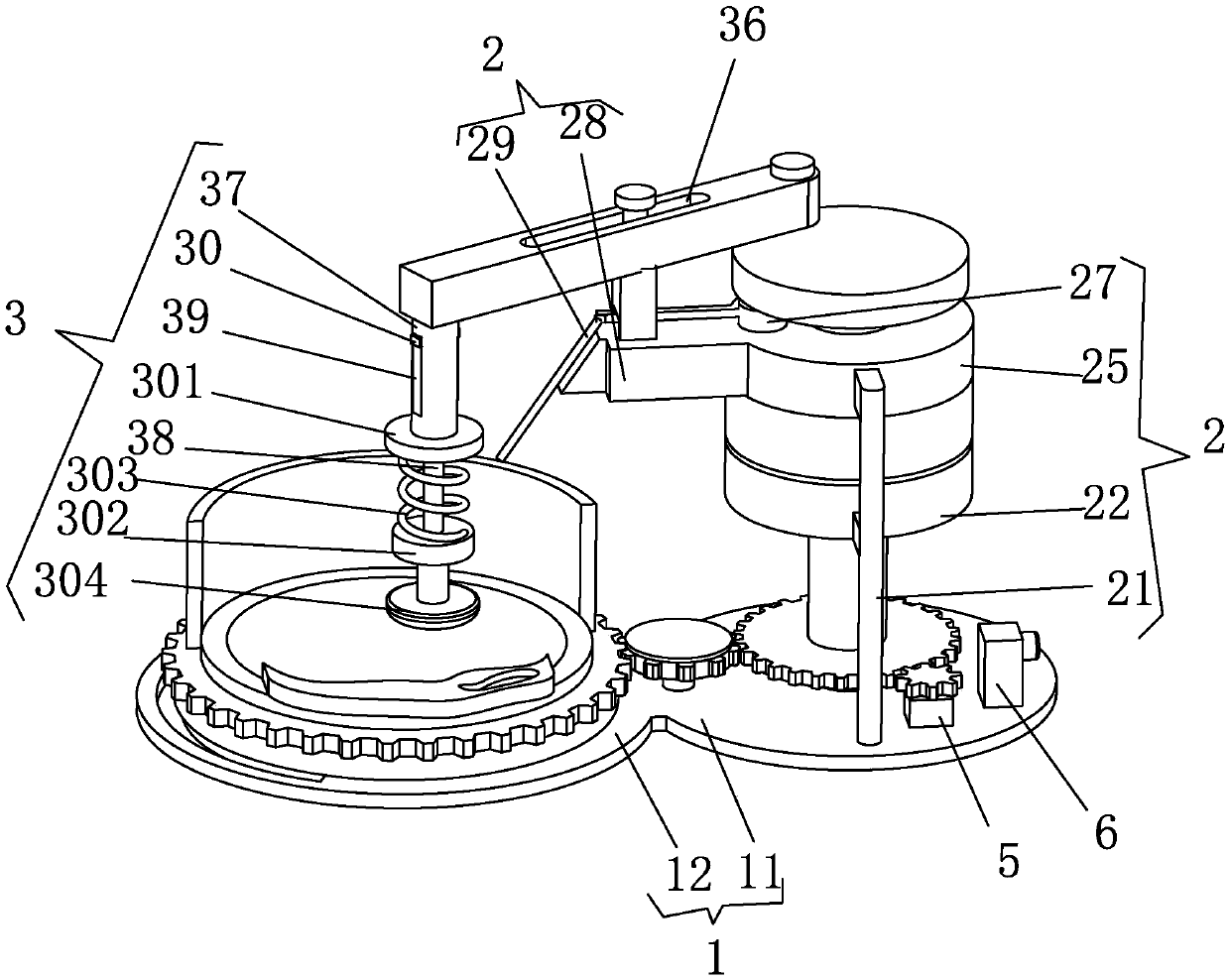

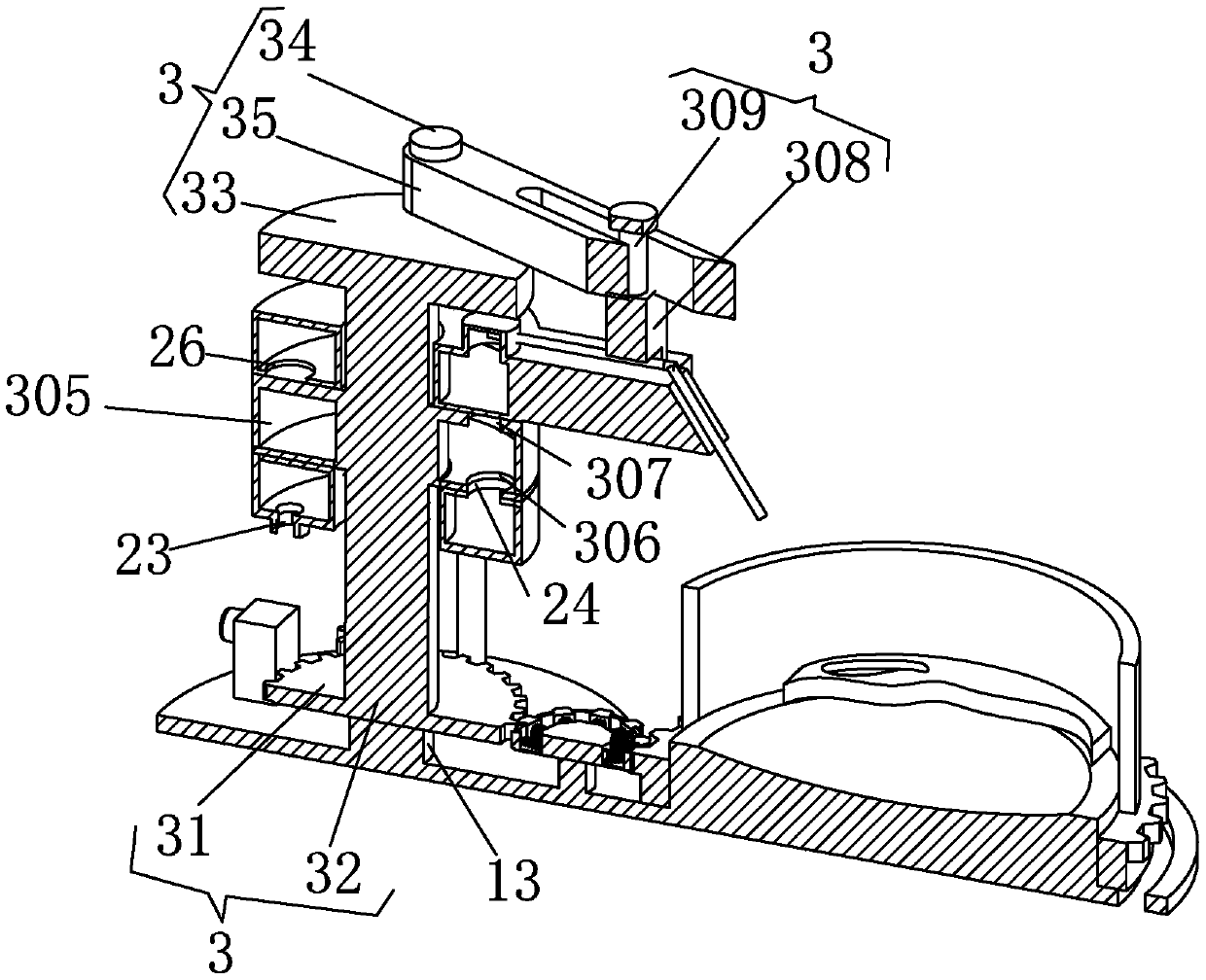

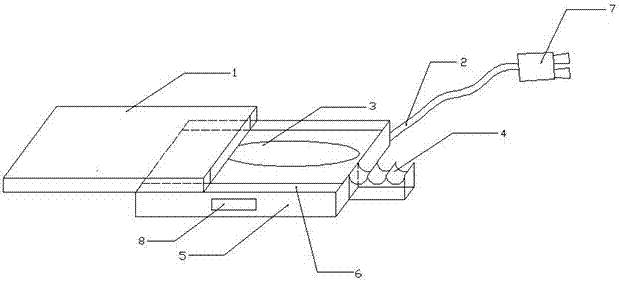

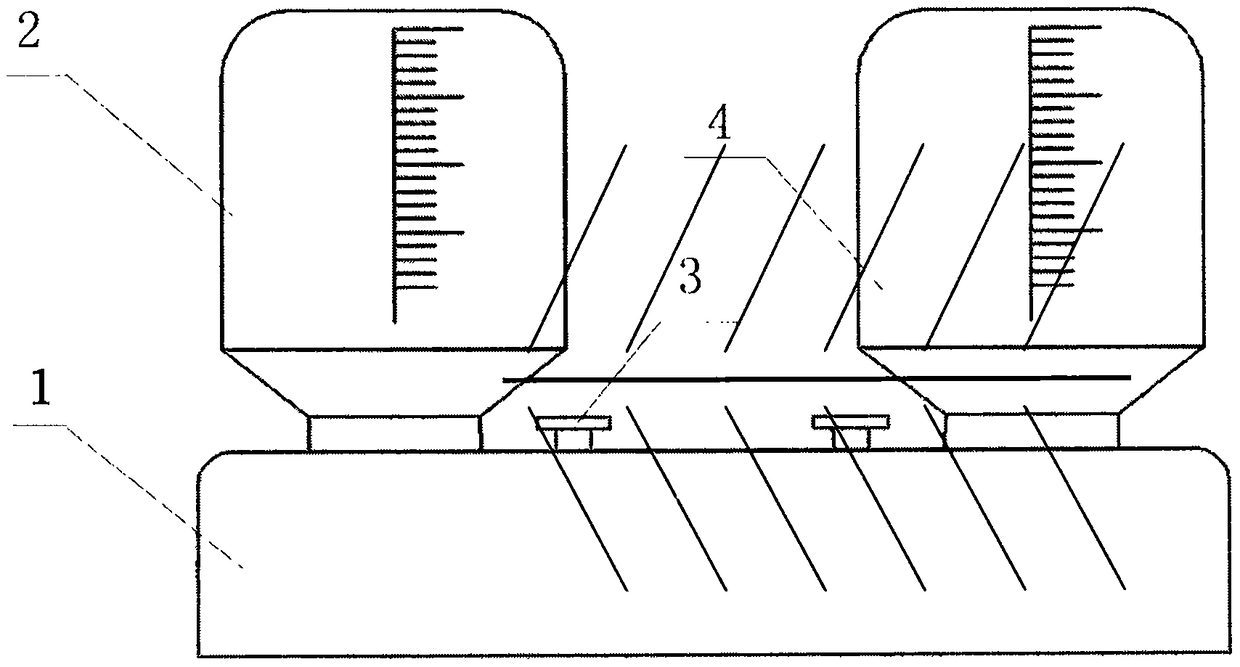

Dynamic pressure flexible simulation ink making machine

InactiveCN101195317AAchieve the doubling effect of grinding efficiencyTo achieve a multiplier effectInk standsMultiway switchingProgram instruction

The invention relates to a flexible simulation inks milling machine under dynamic pressure, which is composed of a mechanical portion driven by a motor and an electrical control portion using a main control circuit of a single chip computer as main body, wherein the mechanical portion is mainly composed of a rotatable guide spindle upright post (4), a seat of the guide spindle upright post (10), a augmented spring (3), a return spring (7), a tubular augmented bolt (1), a gate type beam (5) with a guide sleeve, or a sleeve seat of a rotatable motor with single back and a totatable beam (36), an ink-stone (8), an upper plate (11), a lower soleplate (13), a motor (22), a case (31), an ink sucking pump (24), an ink sucking pipe and the like, the single chip computer stores, calculates and controls the program data provided by each functional unit circuit of a main control panel, multiway switch power provides each functional unit circuit and the motor ink sucking pump with working voltage, preset program instructions for motor operation are executed by keys arranged on a keyboard with a liquid crystal display which complete display of instruction execution, an electrical pressure luminous beacon with independent power supply can indicate the selected pressure section with luminance in different colors. The invention achieves multiplication effect of ink-stone milling benefit, consumes a bit of ink-stone, completes and ensures reliable operation of flexible return of balance state of dynamic pressure, achieves aim of simulation, which saves time, increases benefit and is convenient and practical.

Owner:张继祖 +1

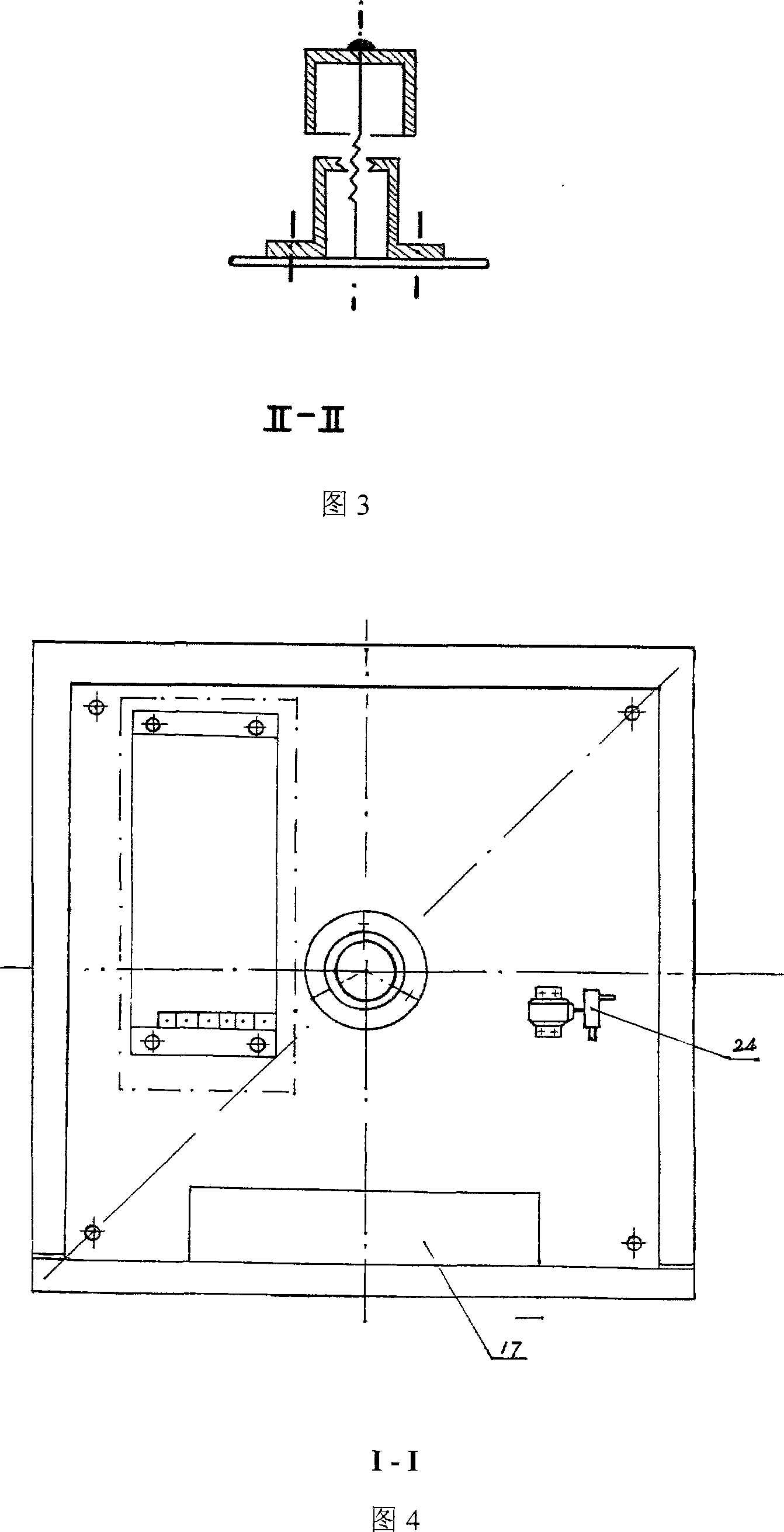

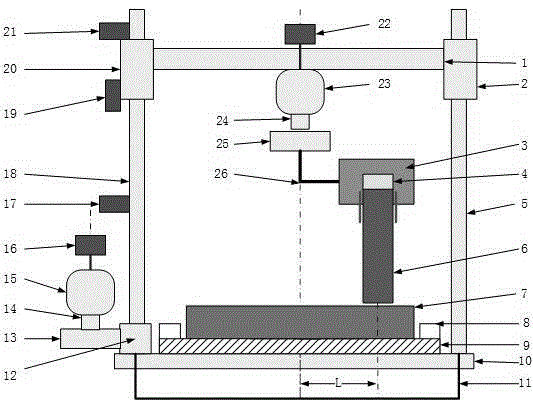

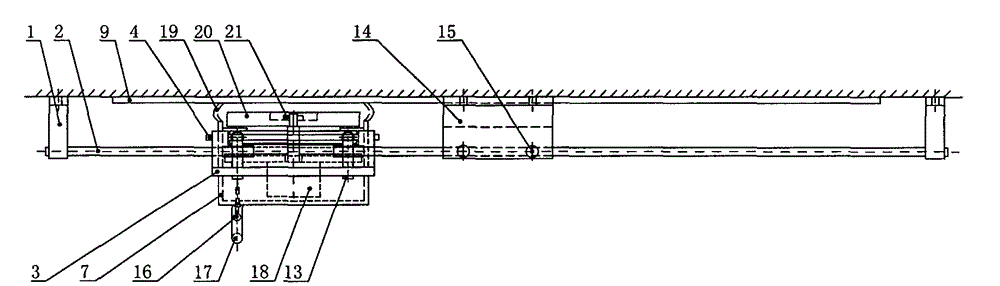

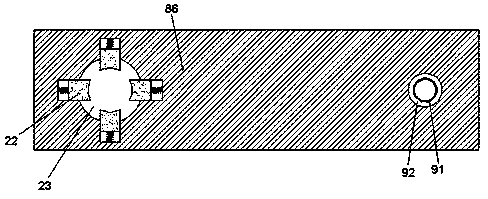

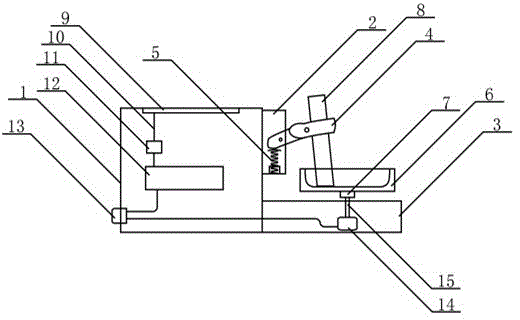

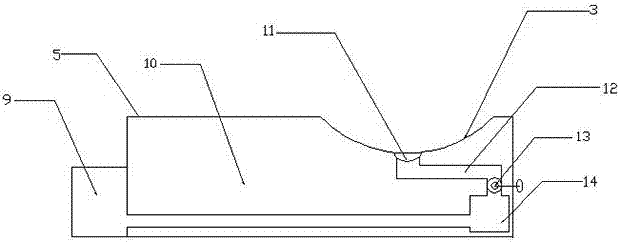

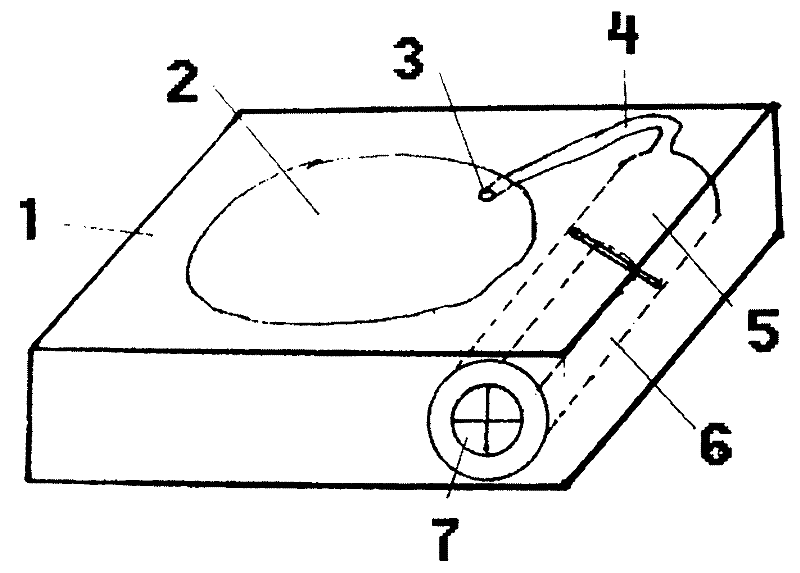

Special grinding device for detecting ink amount of ink stone

InactiveCN104924815AAccurately obtainedImprove detection efficiencyUsing mechanical meansInk standsTension compressionBall screw

The invention relates to a special grinding device, in particular to a special grinding device for detecting the ink amount of an ink stone. Two ball screws are vertically and symmetrically mounted on two sides of a base, a movable beam is respectively fixedly connected with two sliders, the two sliders are mounted on the two mutually parallel ball screws in a threaded manner respectively, the two ball screws are connected through a linkage shaft, a power device drives the ball screws to rotate, so that the two sliders vertically move along the ball screws and accordingly drive the movable beam to vertically move, a driving device for driving an L-shaped adjustable cantilever to rotate is arranged in the middle of the movable beam and connected with the L-shaped adjustable cantilever, the L-shaped adjustable cantilever is connected with an ink ingot fixture, an ink ingot is fixed onto the ink ingot fixture, the end face of the ink ingot vertically contacts with the surface of the ink stone, a tension-compression sensor is arranged between the ink ingot fixture and the ink ingot, a worktable is fixed in the middle of the base, and the ink stone is placed at the center of the worktable. The special grinding device has the advantages of parameter adjustability, simple structure, easiness in control and the like.

Owner:CHANGZHOU UNIV

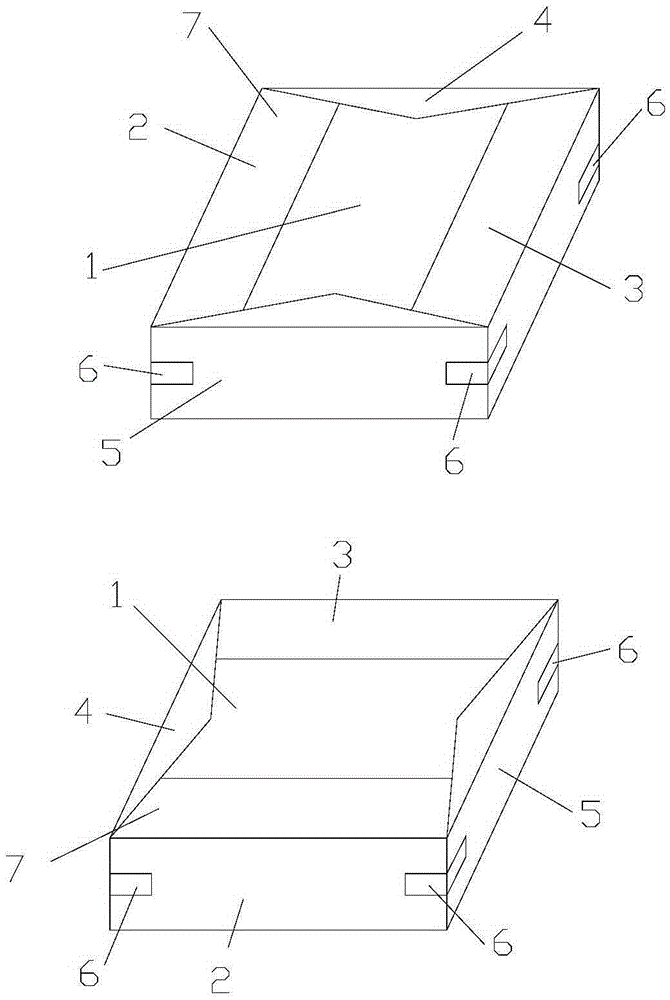

Inkstone and making method thereof

The invention discloses an inkstone and a making method thereof. The inkstone comprises an inkstone body made of inkstone material, an inkstone pond, an inkstone head and an inkstone bottom are arranged on the inkstone body, and carving layers are arranged on the inkstone bottom and the inkstone head. The inkstone is of strong artistic property and the invention can perfectly combine the Chinese element of pattern with the inkstone.

Owner:董鸣

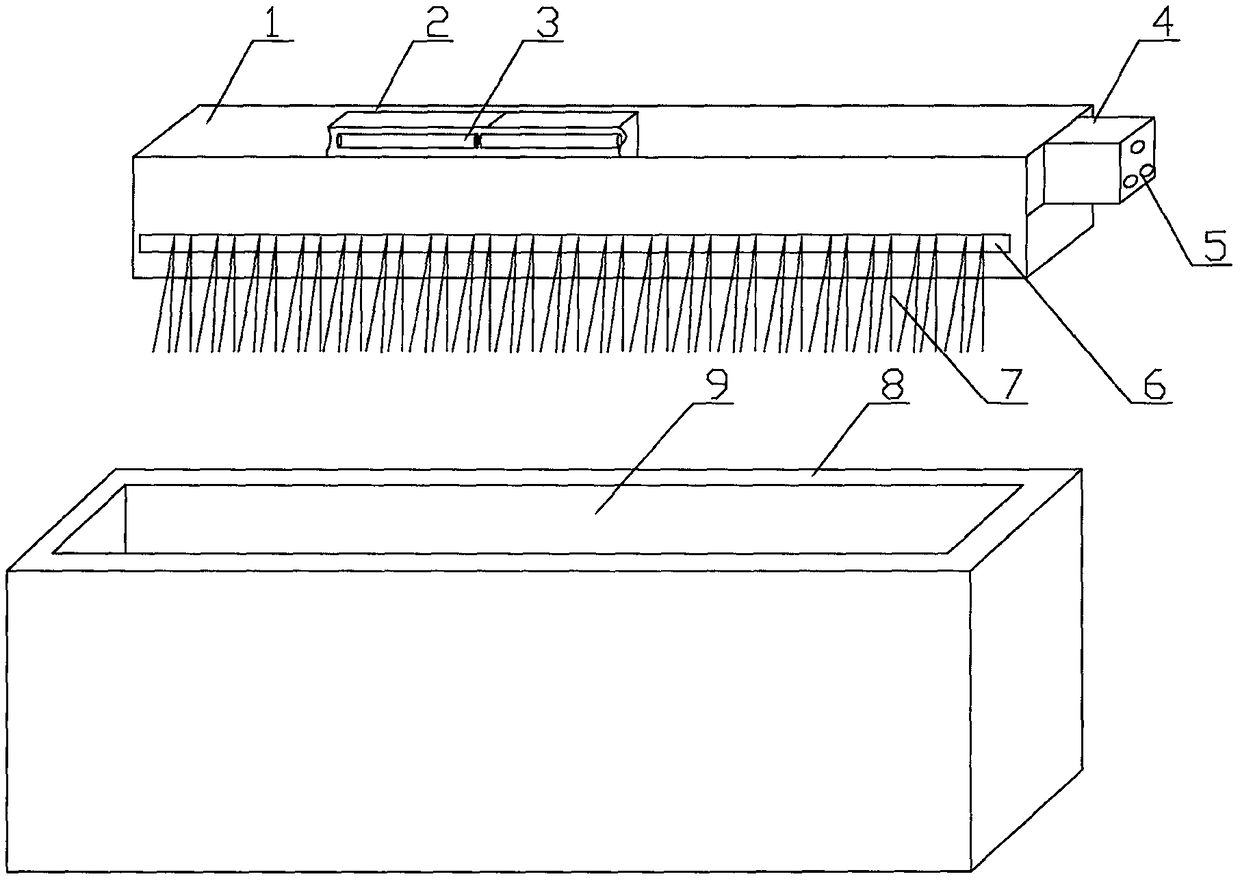

Handheld automatic blackboard eraser

InactiveCN102910010AFully automatedSimple structureBoard cleaning devicesInk standsEngineeringDust collector

The invention relates to a handheld automatic blackboard eraser which comprises a fixed and horizontal guide mechanism, a vertical guide and lock mechanism, a blackboard eraser subassembly, a dust collector, and a power supply and control mechanism, wherein the fixed and horizontal guide mechanism is fixedly connected to a wall body; the horizontal movement of the entire device is achieved through a guide wheel and a transverse guide rod, and the vertical guide and lock mechanism achieves free movement and reliable locking in the vertical direction through a vertical guide rod, a guide sleeve and a bolt locking mechanism. The combined movement in two directions can achieve erasing of a special area on the blackboard. The blackboard eraser subassembly drives the blackboard eraser to rotate so as to achieve the purpose of erasing handwriting through a motor, and the dust collector is fixedly connected with a housing of the blackboard eraser subassembly to collect dust. The handheld automatic blackboard eraser has the advantages that the automation of the action of erasing the blackboard can be achieved; the erasing area can be arbitrarily selected, and the handheld automatic blackboard eraser is simple in structure, small in volume, low in price, available in power failure, also suitable for a push-pull dual-layer blackboard, environment-friendly and healthy and wide in application prospect.

Owner:CHINA JILIANG UNIV

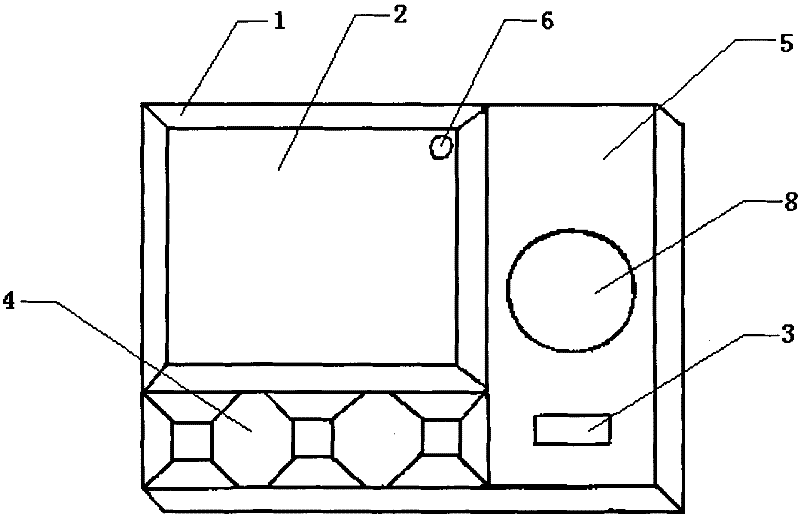

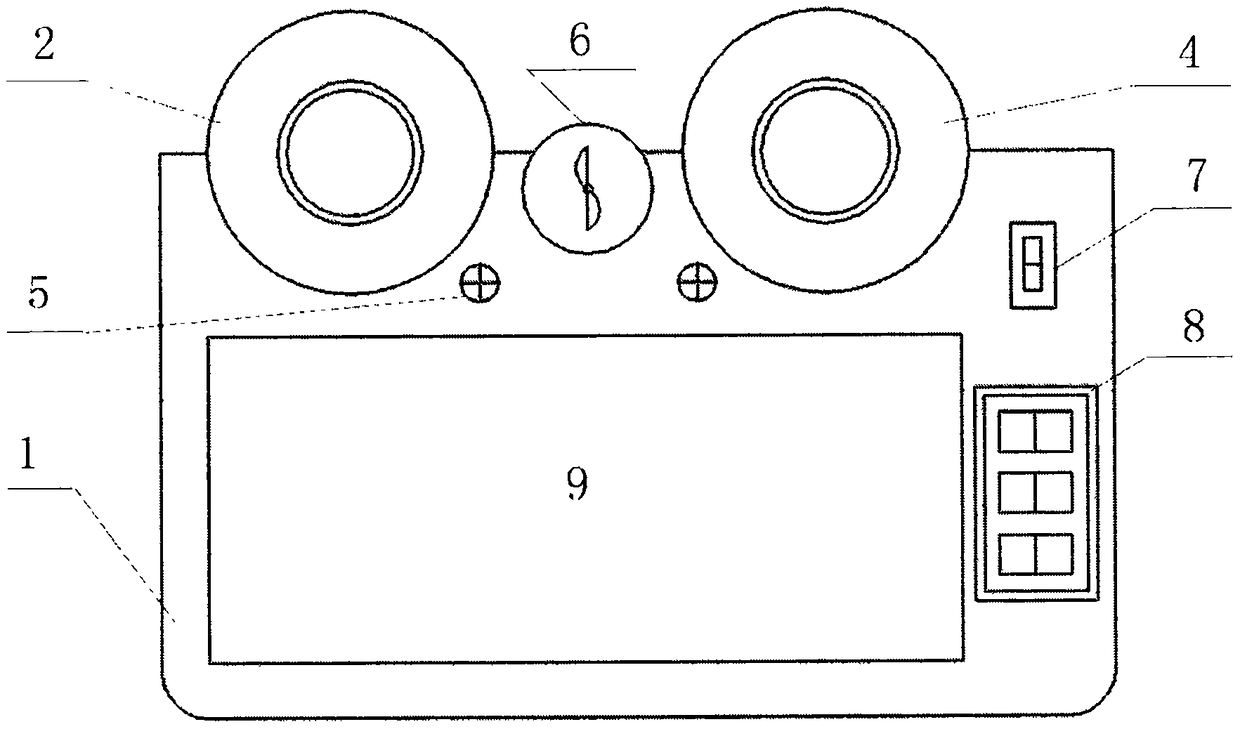

Multifunctional ink-stone

The invention relates to a multifunctional ink-stone. The multifunctional ink-stone comprises an ink-stone seat, an ink-stone plate and an ink ingot groove, wherein an ink box is arranged on the ink-stone seat; the ink box can be covered while the ink-stone is not in use; a small hole is arranged on the ink-stone plate to be connected with the ink-stone plate and the ink box; the small hole can be plugged by a hole plug; and the ink-stone can be made from both an ink-stone stone material and plastic. The multifunctional ink-stone provided by the invention has the following advantages that: the ink box can be prevented from being turned over; a space is available for placing the writing brush; the ink on the writing brush cannot drop to the desks, papers and hands; the dirt at the peripheral edge of the ink-stone and the bottle opening of the ink bottle can be avoided; and the ink is saved.

Owner:张永贵

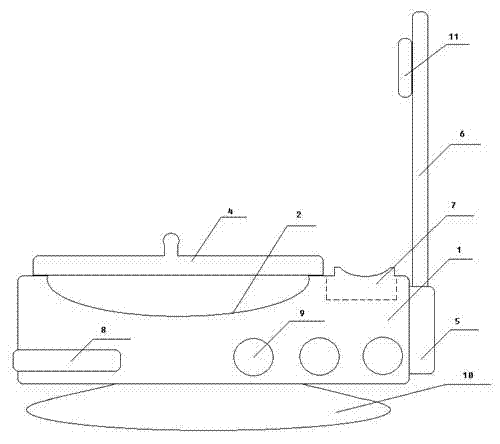

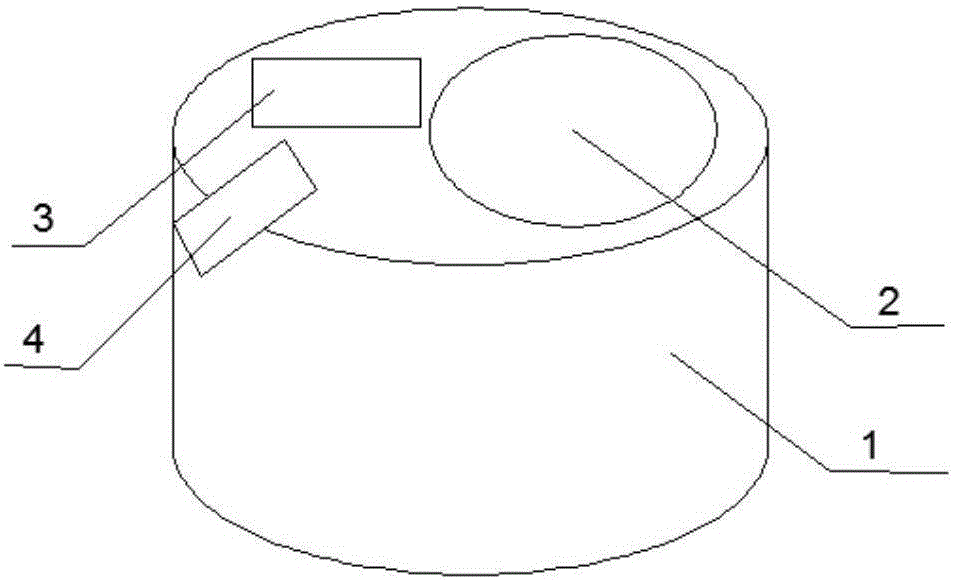

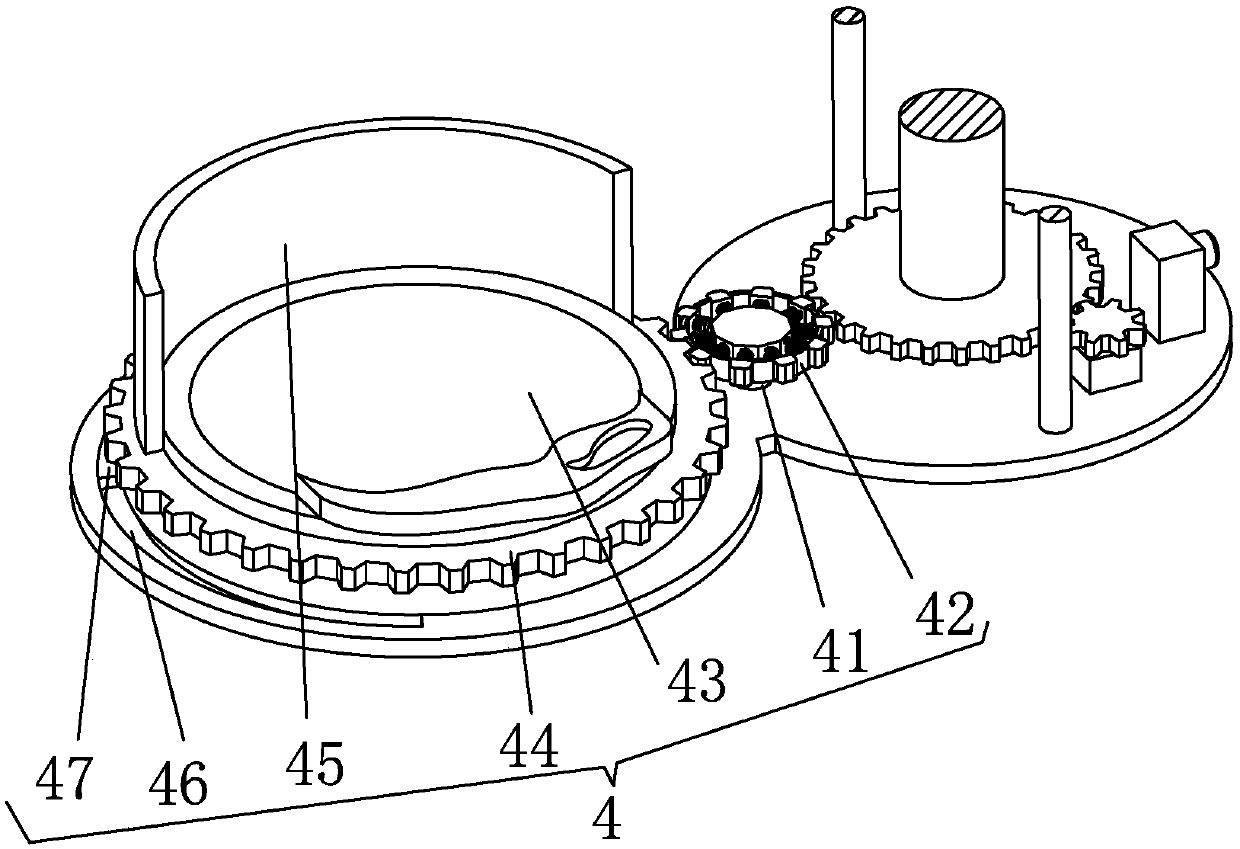

Motor-driven ink grinding device

A motor-driven ink grinding device comprises an inkstone-shaped base frame and a multiple-action ink grinding arm. An ink grinding ink pool is arranged on one side of the top surface of the inkstone-shaped base frame; a column-shaped box body is arranged on the other side of the top surface of the inkstone-shaped base frame; an ink box cabin is arranged at the bottom of the column-shaped box body; a clean water box cabin is arranged at the top of the column-shaped box body; the multiple-action ink grinding arm comprises an overhang arm frame, a rotating pipe sleeve, an arm rod rotating machine and an ink grinding arm rod; the overhang arm frame is connected with the column-shaped box body; the rotating pipe sleeve is arranged in a shaft seat of the end of the overhang arm frame; the ink grinding arm rod is mounted at the center of the rotating pipe sleeve in a sleeving mode; and an ink block clamping opening is formed in the lower end of the ink grinding arm rod. According to the motor-driven ink grinding device, the multiple-action ink grinding arm drives a strip-shaped ink block to conduct continuous ink grinding in the ink grinding ink pool in rotating and swinging modes, the ink grinding time is shortened, ink in the ink grinding ink pool is more even, and the ink box cabin can store the ink in the ink grinding ink pool, and can input the stored ink to the ink grinding ink pool to be directly used, and thus, the motor-driven ink grinding device is reasonable in structure and convenient to use.

Owner:宁津润科创投有限公司

Brush holder for writing brush storage

InactiveCN109367305AIngenious and reasonable structureEasy to useNib removersInk standsWater storageDrive motor

The invention discloses a brush holder for writing brush storage. The brush holder comprises a brush holder body, and a water storage slot formed in the brush holder body, wherein a water storage partis arranged in the water storage slot; a cleaning slot is formed in the right side of the water storage slot; a cleaning block which is fixedly connected with a water storage block in the water storage part is arranged in the cleaning slot; a water storage cavity is arranged in the water storage block; a water spraying mechanism which can drain water into the cleaning block is arranged in the water storage cavity; and a cleaning cavity is arranged in the cleaning block. The brush holder for writing brush storage disclosed by the invention is more reasonable and delicate in integral structure,is very convenient in use, further can automatically grind ink, can automatically clean and can moisturize a writing brush in addition to having a function of storing the writing brush, can control the cleaning part and the grinding part to work by single drive motor, is high in use safety, and has a relatively high use and popularization value.

Owner:金华佩特科技有限公司

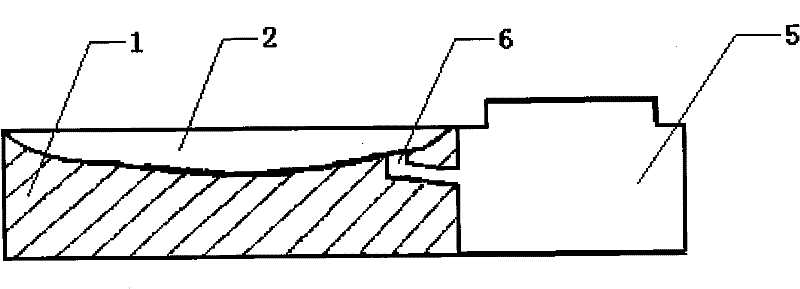

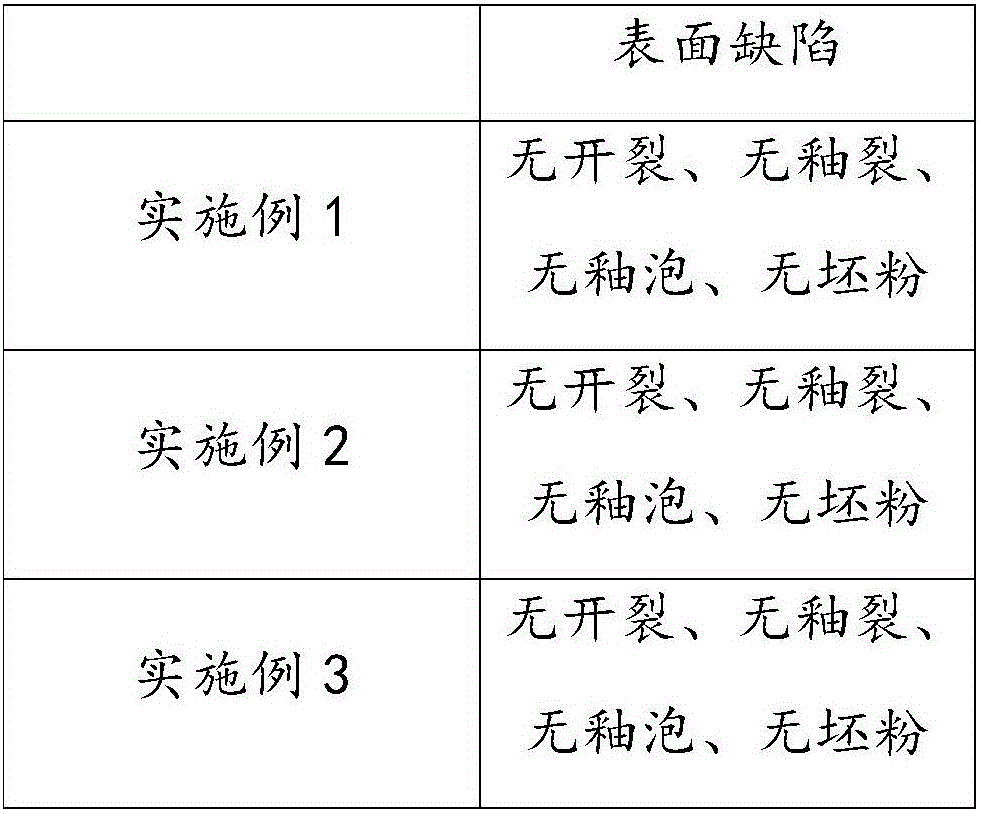

Ink slab with grinding layer and preparing method thereof

The invention provides an ink slab with a grinding layer and a preparing method thereof. A grinding area of the ink slab is arranged as an ink hall of the ink slab; the ink hall comprises an ink hall substrate and the grinding layer arranged on the ink hall substrate; and the grinding layer is integrated with the ink hall substrate. The invention also relates to the preparing method for the ink slab with the grinding layer. The preparing method comprises the following steps: 1, preparing a grinding layer material; 2, preparing the ink hall substrate; 3, adopting a hot-spraying method or high-temperature firing method for processing the grinding layer material on the surface of the ink hall substrate, thereby forming the grinding layer; and 4, polishing the grinding layer, thereby finishing the preparation. Aiming at the phenomena of abrasion, flaw, poor fineness and the like caused by long-term use of ceramic ink slabs, metal ink slabs, stone ink slabs and other ink slabs, a grinding layer structure made of the material different from the material of the ink hall substrate is additionally arranged to the ink slab, so that the ink slab has the advantages of long service life, good fineness, excellent toughness, high hardness, abrasion resistance, corrosion resistance, wide practical scope and better application prospect.

Owner:SHANGHAI WEIKAI CHEM

Ink grinding device

The invention discloses an ink grinding device. The ink grinding device comprises a base. The ink grinding device is characterized in that the upper side of the base is provided with a grinding devicecapable of continuously grinding an ink block. The grinding device is internally provided with a water adding device capable of outputting water intermittently along with continuous grinding of the grinding device. One side of the grinding device is provided with a blocking device capable of blocking the ink block along with start of the grinding device. The ink grinding device is simple in structure and convenient to use, water adding and grinding can be performed simultaneously just by pressing down a button, the blocking device can prevent ink from being splashed and hindering writing andpainting in the grinding process, the ink can be used while grinding is performed, two hands are liberated, and the ink grinding device has automaticity, convenience and the like.

Owner:GUANGDONG KNOWLEDGE CITY OPERATION SERVICES CO LTD

Inkstone

InactiveCN102765283ANot easy to knock overNot easy to polluteSlippage preventionInk standsAgricultural engineering

An inkstone comprises an inkstone seat, an inkstone disc and an ink stick groove. An inkstone cover is arranged on the inkstone disc, the side face of the inkstone seat is connected with a writing brush hanging rod through a rotary support rod, the rotary support rod is fixedly connected with the inkstone seat through a bolt, and a writing brush frame is arranged on the inkstone seat. The inkstone is convenient to use, not easy to pollute, simple in process and reasonable in design.

Owner:王大梦

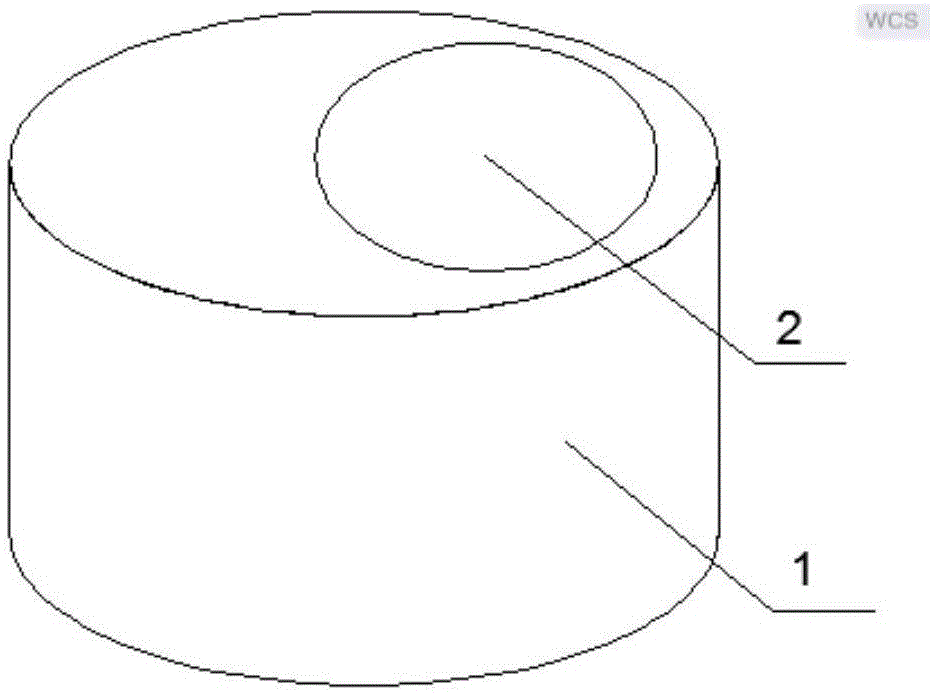

Inkstone and preparation method thereof

The invention provides an inkstone and a preparation method thereof. The inkstone includes a raw lacquer matrix base and an inkstone core embedded inside the base. The preparation method of the inkstone includes the steps that A, according to the shape of the base, an original matrix is manufactured; B, the outer surface of the original matrix is wrapped by cloth, and the surface of the cloth is coated with slurry containing raw lacquer and then dried in the shade; C, the step B is repeated one or more times until the thickness can meet the demand; D, the original matrix is detached and processed by ash coating and polishing to obtain the base; E, raw lacquer is used for embedding the inkstone core into the base, and then the inkstone core is dried in the shade. The inkstone is low in weight, stable and uneasy to deform and can be reinforced for shaping, the preparation method is simple in procedure, the operation conditions are mild, and high-temperature sintering conditions are not required.

Owner:王耀

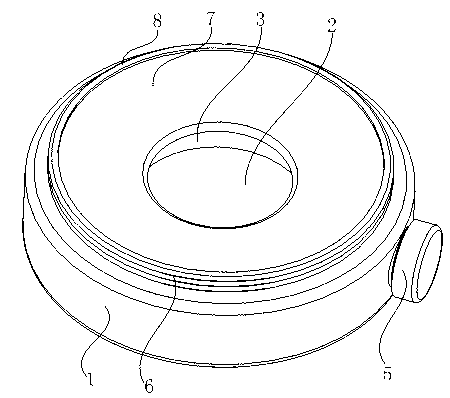

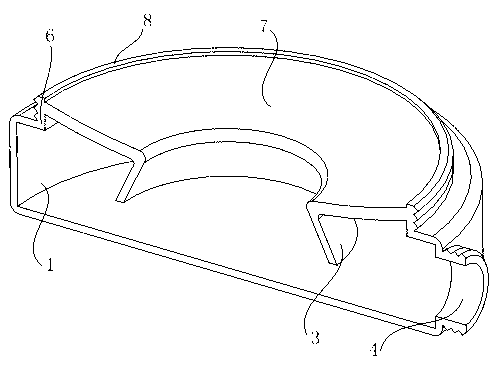

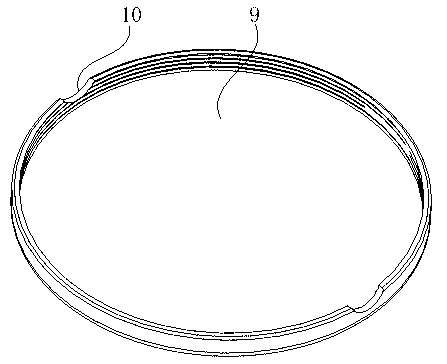

Anti-upsetting multifunctional ink stone box

The invention discloses an anti-upsetting multifunctional ink stone box. The multifunctional ink stone box comprises an ink box body, wherein an ink dipping hole is formed in the upper part of the ink box body and the ink box body is hollow; the cross section of the ink box body is of a central symmetry shape; the ink dipping hole is round and the circle center of the ink dipping hole and the center of the cross section of the ink box body are located on a same vertical straight line; the edge of the ink dipping hole is provided with an ink retaining plate in the shape of a bell with a small external part and a large internal part, and the ink retaining plate is located in the ink box body and is fixed with the ink box body to form a whole body; an ink outlet facilitating ink removing and cleaning is formed in the ink box body; an ink outlet cover is arranged on the ink outlet; and in order to increase the sealing performance of the ink outlet cover, the ink outlet cover is also internally provided with a sealing gasket. The multifunctional ink stone box is simple in structure and smart in conception; the ink in the ink stone box is effectively retained by the ink retaining plate which is specially arranged in the ink box body, so that the ink in the ink box body does not leak in any position states of the ink box body; simultaneously the ink stone box is provided with the special ink outlet and the special ink outlet cover which facilitate ink removing and cleaning; and the ink stone box is especially suitable for primary and secondary students to practice Chinese brush calligraphy.

Owner:王道林

Ink slab capable of recycling ink

The invention discloses an ink slab capable of recycling ink. Four slab legs are fixed at the bottom of the ink slab, a round bottom is arranged in the slab legs, an ink hole is formed in the center of the round bottom, the ink hole is connected with an ink pipe, the ink pipe extends out of the bottom of the ink slab, and a small valve is mounted at the bottom end of the ink pipe; the bottom ends of the slab legs are placed on an ink bottle, a bottle mouth is formed in the center of the ink bottle, and an outlet of the small valve is arranged in the bottle mouth; the heights of the slab legs are greater than the total height of the ink pipe and the small valve; both of the ink slab and the ink bottle are square, and the side lengths are equal. According to the ink slab disclosed by the invention, the bottom of the ink slab is made into a funnel type, the small valve is mounted at the mouth of the ink pipe at the bottom of the funnel, when the ink slab is used, the small valve is closed, and as the four slab legs are higher than the small valve, the ink slab can be flatly placed on a desk. After writing with a writing brush, the four slab legs of the ink slab are placed on the ink bottle, the outlet of the small valve is aligned to the bottle mouth of the ink bottle, the small valve is opened, and the residual ink flows back into the ink bottle, so that the ink cannot be wasted, and the purposes of hygiene and high convenience are achieved.

Owner:何羽丰

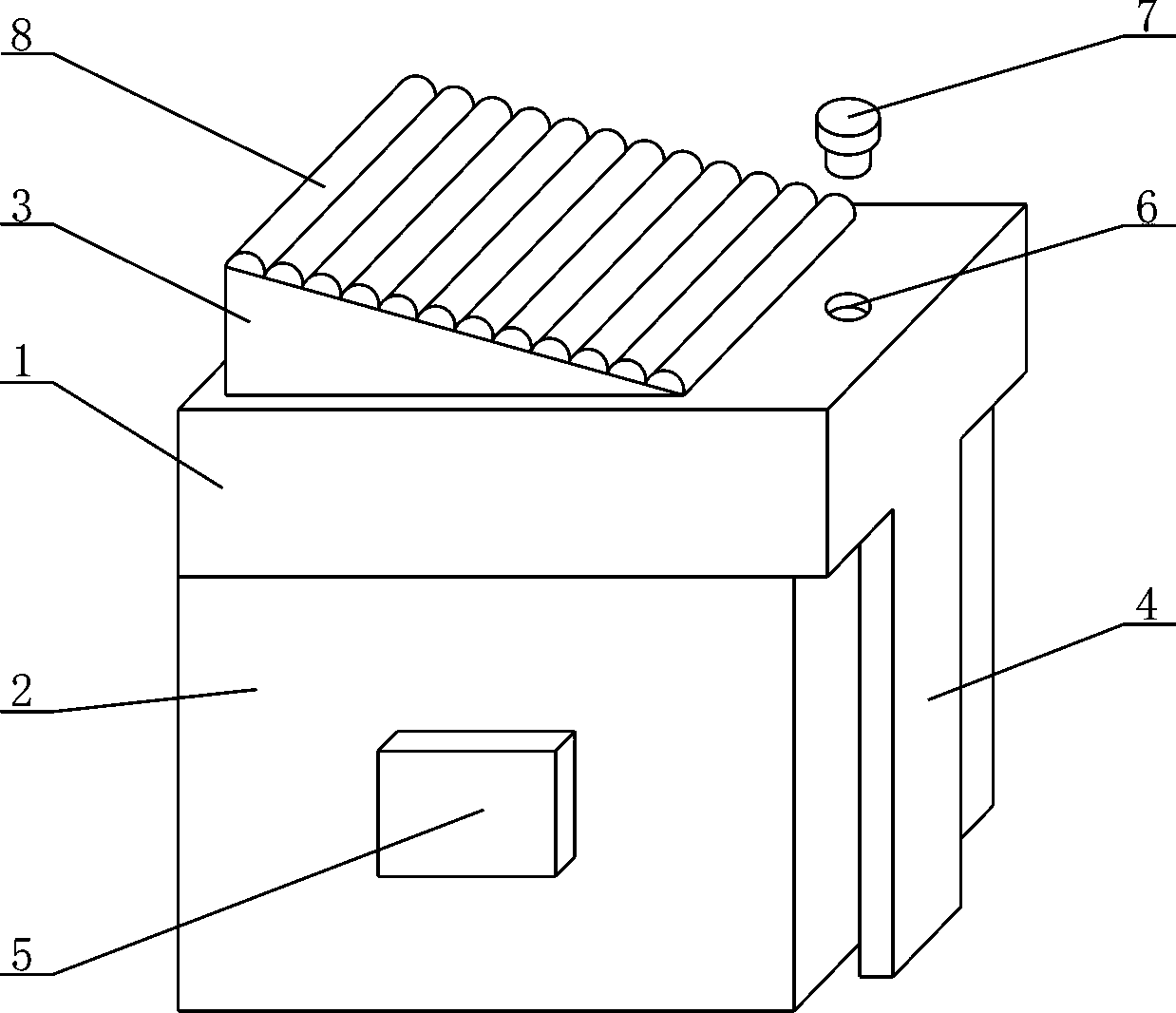

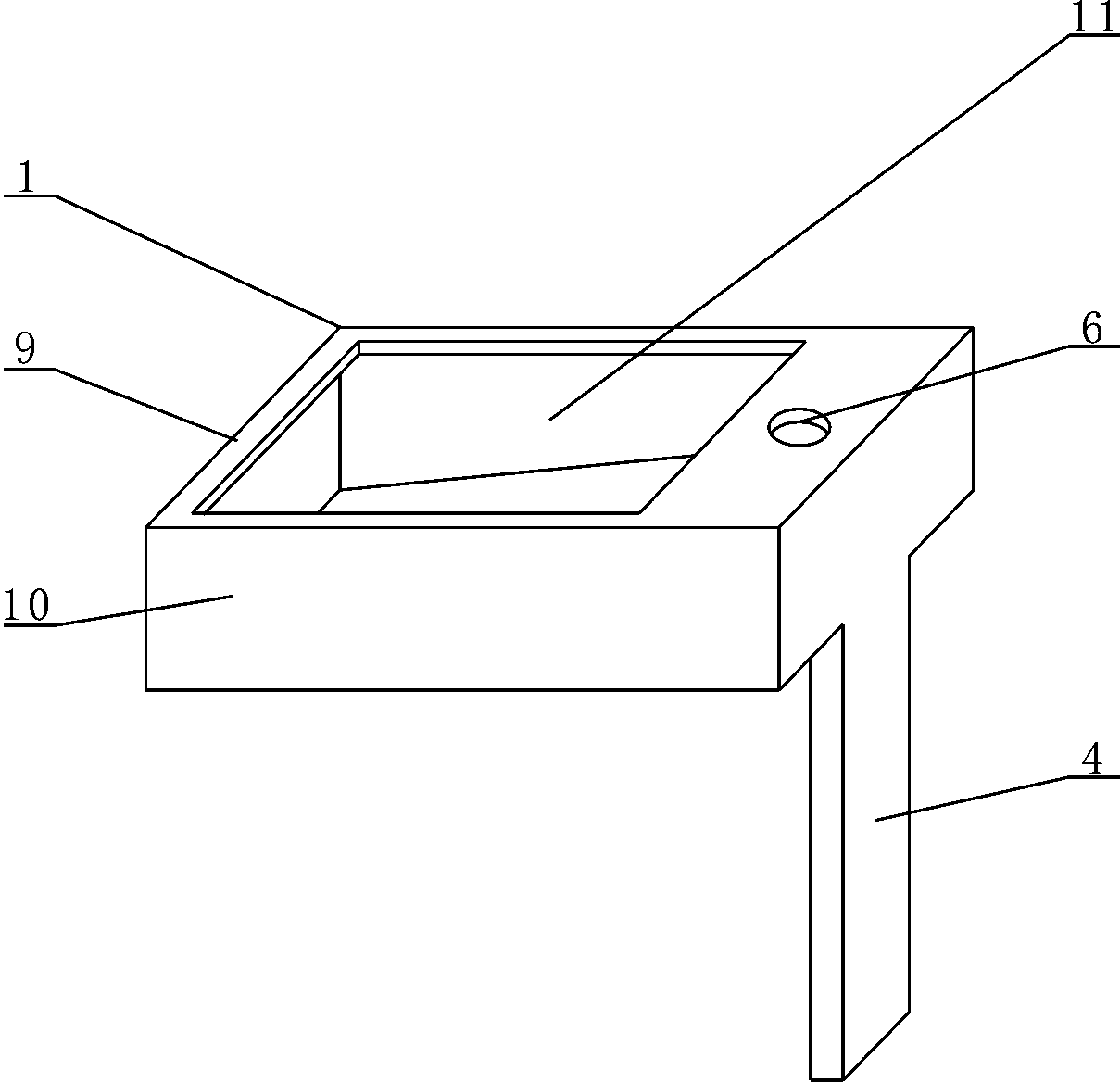

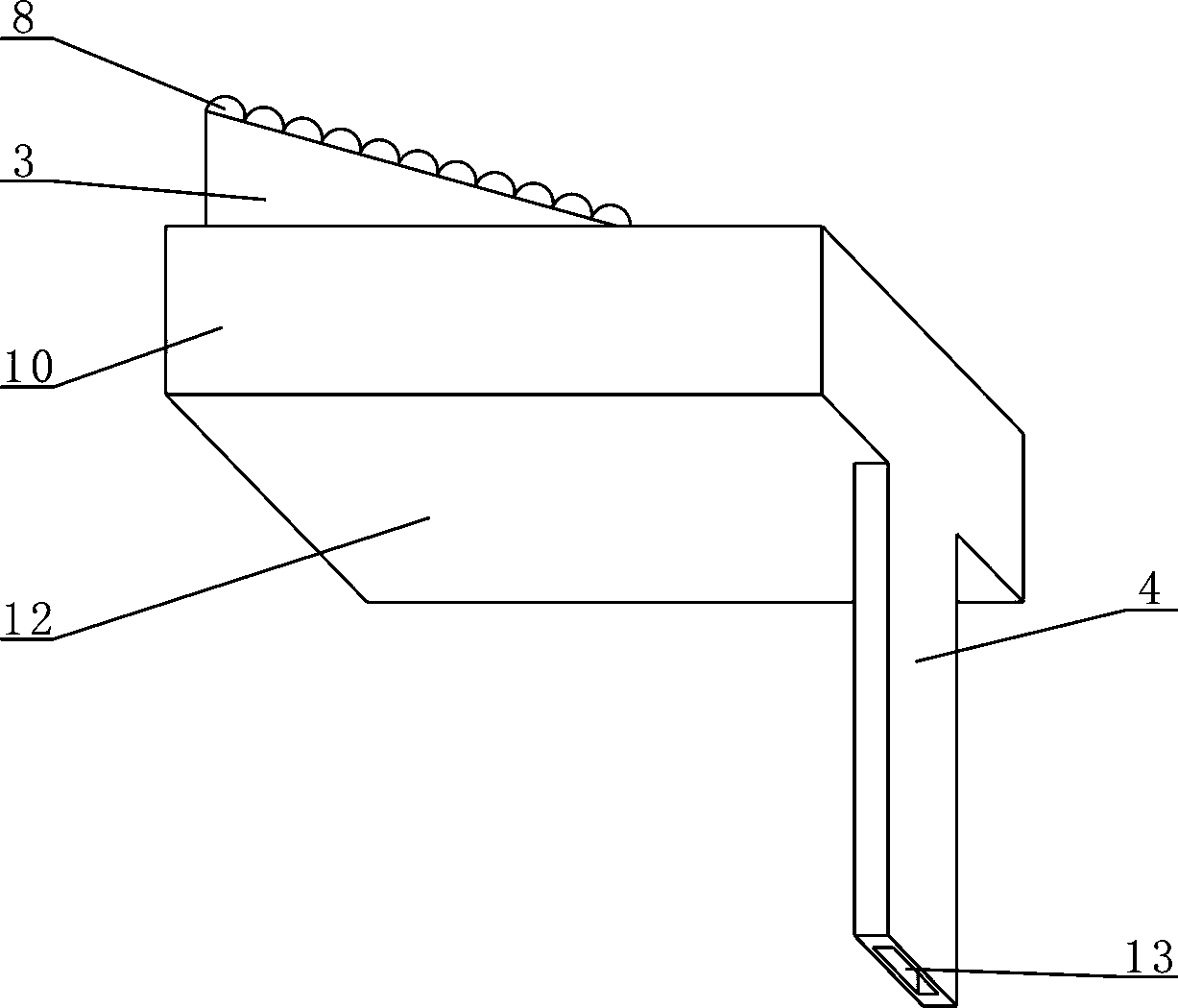

Electric ink grinding machine using photovoltaic power generation as power supply

The invention relates to an electric ink grinding machine using photovoltaic power generation as a power supply, and belongs to the application technical field of new energy resources. The electric ink grinding machine comprises a shell, an ink block clamp mounting box, an electric motor mounting box, an ink block clamp, a spring, an inkstone, a connecting device, an ink block, a solar cell, an electric wire, a controller, a storage battery, a switch, an electric motor and a power output shaft, wherein the solar cell generates currents under the irradiation of the sun; the currents are input into the controller to be adjusted through the electric wire, and are input into the storage battery to be stored; the ink block clamp is used for clamping the ink block; the ink block is supported against the inkstone pool bottom of the inkstone by the spring; a right amount of water is added into the inkstone pool of the inkstone, and the switch is pressed, a circuit between the storage battery and the electric motor is connected, the electric motor starts to work, the power output shaft drives the inkstone to rotate through the connecting device, grinding between the ink block and the inkstone pool bottom of the inkstone is generated, and the ink raw material in the ink block is released to be mixed with the water, so that ink is generated.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Production method for turquoise clear-mud inkstone

The invention discloses a production method for turquoise clear-mud inkstone, which solves problems that a production method for clear-mud inkstone is lost for years and colors of the inkstone cannot be manually controlled. The production method for turquoise clear-mud inkstone includes that ancient silt taken from the Hutuo river within the border of the Wutai county of Shanxi province is sun-dried, the dried ancient silt is placed in a water vat to be soaked for two hours, the soaked ancient silt is stirred to form mud, the mud is filtered, cattle bone powder with the weight of 5% of that of the mud is added into filtered mud, the mud is stirred again and filled in a cloth bag, water content in the mud is filtered out, the mud without the water content is beaten to form a mud pie, the mud pie is placed in a mold to make into a blank, the blank is placed in a fire-resistant box prior to being placed in a kiln, the temperature of the kiln is controlled to be in a range of 980 DEG C and 1050 DEG C, the blank is fired for 72 hours, and turquoise clear-mud inkstone is obtained. The production method has the advantages that the ancient technology is inherited while the production method is innovative, the production process, which is lost for a long time, for clear-mud inkstone is restored, and the produced clear-mud inkstone is excellent in quality and has advantages in terms of both the shape and the color.

Owner:WUTAI WENSHI CHENG MUD PROD

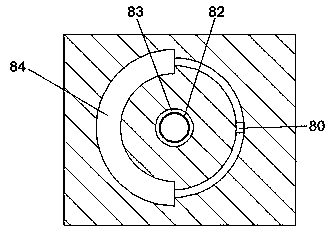

Storage and ink refilling station for a cartridge of a printhead

InactiveUS7513611B2Avoid runningLiquid surface applicatorsWatering devicesEngineeringMechanical engineering

A station for storing and refilling a cartridge of a printhead has a container in which a seat is arranged for accommodating the cartridge to be refilled; the ink for refilling being contained in a collection chamber located in the bottom part of the container. The collection chamber communicates freely with a back-flow compartment located at the top, surrounding the housing and in free communication with the chamber. The feeding is effected by means of a capillary element contained inside an impermeable sheath extending vertically into the collection chamber and arranged centrally in a symmetrical position with respect to the base of the container. The capillary element penetrates into the housing in contact with the sponge of the cartridge to transfer the ink through capillarity. Feeding takes place solely and exclusively with the container in the vertical position whereas in any other position the ink flows into the back-flow compartment and the capillary element is no longer lapped against by the ink. In this way, any dripping and / or leakage of ink through the capillary element is avoided.

Owner:TELECOM ITALIA SPA

Multi-level voltage output control circuit and logic gate therefor

ActiveUS20050218932A1Extended rise timeExtended fall timePower reduction in field effect transistorsStatic indicating devicesEngineeringLogic gate

A multi-level voltage output control circuit selectively outputs one of multi-level power voltages by driving gates of two MOS transistors, which act as switching devices for the multi-level power voltages, with two output signals, the two output signals having complementary phases to each other and generated from two logic gates receiving two input signals which have an identical timing and complementary phases to each other, wherein the two logic gates advance or slow down a rising timing and / or a falling timing of the two output signals by differently adjusting a size of PMOS transistors and that of NMOS transistors, which construct the logic gates, thereby excluding a case in which the two output signals are in a same logic state at the same time.

Owner:MAGNACHIP SEMICONDUCTOR LTD

Forming method for bodiless water-drop lacquer ware

The invention discloses a forming method for a bodiless water-drop lacquer ware. The forming method includes the following steps that firstly, a mold is made of gypsum after a water-drop model is molded; a china clay base is made of china clay in the gypsum mold through compression molding and is air-dried; a releasing agent is brushed on the china clay base two times, the china clay base is air-dried, and polished lacquer is painted three to five times; raw lacquer fine ash is scraped two times, and raw lacquer is made of flour through regulation, three pieces of silk are mounted by the raw lacquer, polishing is conducted after the raw lacquer fine ash is scraped two times again, and the polished lacquer is painted three times again; a gas feed hole and a water outlet of a base body are cut, the base body sinks in water and is soaked for a day, the china clay in the water-drop prototype base is completely washed away, painting is conducted on the water-drop prototype through a conventional technical skill, and the bodiless water-drop lacquer ware is manufactured. The manufactured water-drop lacquer ware is only provided with two small holes with the diameter smaller than 2 millimeters, and the one-time forming process is adopted; the china clay is used for making the base and can expand when encountering water, and the china clay can be easily washed away; and the water-drop china clay base is made through a female mold different from a traditional male mold.

Owner:黄文勇

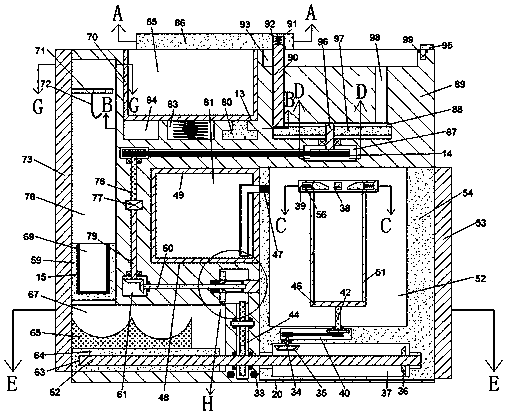

Water-adding ink-grinding device for teaching

InactiveCN108284691AImprove cleanlinessAdd water and grind ink accuratelyInk standsWater storageEngineering

The invention discloses a water-adding ink-grinding device for teaching and relates to the field of teaching of brush calligraphy. The water-adding ink-grinding device for teaching comprises a water storage box, an extruding device, a water adding pipe, a water bag, an ink box and an ink clamping box, wherein the extruding device, the water adding pipe and the ink box are arranged on the water storage box; the water bag is arranged in the water storage box; the ink clamping device is arranged on the ink box; the extruding device is composed of a pressure block, an anti-skid strip, a pressure plate, a rotating shaft and a spring; the anti-skid strip and the pressure plate are arranged on the pressure block; the rotating shaft and the spring are arranged on the pressure plate; the ink clamping device is composed of a baffle plate, a spring, a connecting rod, a clamping plate and an anti-skid layer; the connecting rod is arranged on the baffle plate; the spring and the clamping plate arearranged on the connecting rod; and the anti-skid layer is arranged on the clamping plate. The water-adding ink-grinding device for teaching disclosed by the invention is high in practicality and quite convenient to use and can add water the grind ink quantitatively and precisely at one time, and a writer keeps the hand grinding ink clean when grinding the ink, so that ink on the hand during laterstage writing is prevented from polluting written works.

Owner:LUOYANG GONGHANG MECHANICAL TECH CO LTD

Ink grinding device

The invention discloses an ink grinding device comprising a base. The ink grinding device is characterized in that: a grinding device capable of continuously grinding an ink stick is provided on a upper side of the base; a water adding device capable of intermittently discharging water in the continuous grinding process of the grinding device is provided in the grinding device; and a shielding device capable of blocking the ink block as the grinding device is activated is provided on one side of the grinding device. The ink grinding device is simple in structure and convenient to use. Water adding and grinding can be carried out synchronously, only by pressing a button, and the shielding device is used for protecting ink in the grinding from hindering the writing and painting due to splashing, so that the ink can be used while grinding, and the hands are freed, which is very automatic and convenient.

Owner:中山市锐炬科技有限公司

Intelligent ink-stone

The invention discloses an intelligent ink-stone. The intelligent ink-stone comprises an ink-stone body, wherein a rectangular ink slot is processed in the center of the ink-stone body; and a cleaningdevice is mounted inside the rectangular ink slot. The cleaning device comprises a cleaning box body, wherein bristles are mounted on the bottom of the cleaning box body; the bristles are mounted ona brush handle; the brush handle is matched with a gear rack mechanism; the gear rack mechanism can drive the brush handle to move back and forth, so that the bristles move back and forth inside the rectangular ink slot to clean; a gear of the gear rack mechanism is connected with a motor; the motor is connected with a power supply; and the power supply is connected with a charging device. The intelligent ink-stone can clean the table board of the ink-stone automatically, so that the defect that clothes are polluted in a cleaning process of a conventional ink-stone is avoided.

Owner:陈奕杨

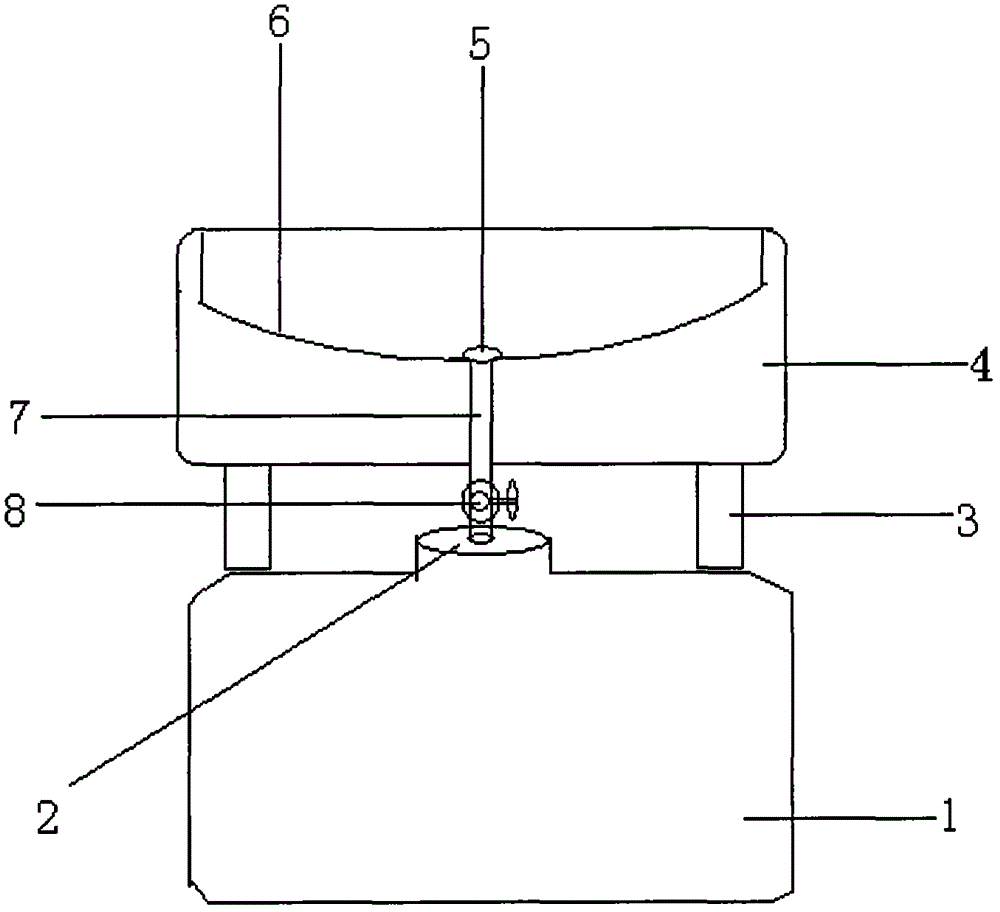

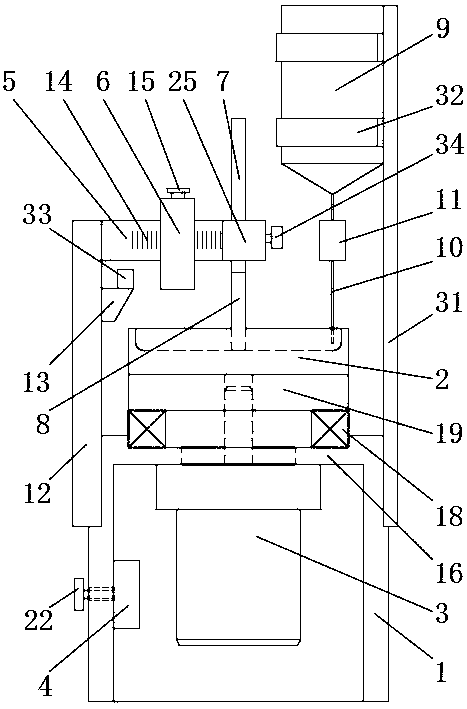

Inkstone grinder

The invention relates to the technical field of ink grinding, and discloses an inkstone grinder. The inkstone grinder comprises an underframe and an inkstone, wherein a frequency modulation motor anda frequency modulation controller are fixedly connected to the underframe, and the speed of the frequency modulation motor can be adjusted by the frequency modulation controller; an output shaft of the frequency modulation motor protrudes from the top of the underframe, and the top end of the output shaft is connected with the inkstone and is capable of controlling the inkstone to rotate; a crossbeam is arranged on the upper end of the underframe, the cross beam can rotate relative to the underframe in a vertical plane, a weight is arranged on the cross beam and can move in the length direction, an ink block assembly is installed on the end of the cross beam, the ink block assembly comprises an extension rod and an ink block, the upper end surface of the ink block makes contact with and is fixedly connected with the lower end surface of the extension rod, the ink block assembly is perpendicular to the cross beam and can be adjusted up and down relative to the cross beam, and the lowerend of the ink block makes contact with the grinding surface of the inkstone; and a water pot is arranged on the upper end of the underframe, a hose is connected to the bottom of the water pot, a drip control valve is arranged on the hose, and the bottom end of the hose is aligned with the grinding surface of the inkstone. The ink block can be effectively used, the waste is avoided, the ink grinding pressure and speed can be adjusted, and the ink concentration can be controlled.

Owner:米姿颖

Inkstone for ink recovery

The invention discloses an inkstone with recycled ink, which comprises an inkstone cover, an inkstone stand and an inkstone base. The side of the top of the inkstone base is correspondingly provided with a chute, and the inkstone cover and the chute are correspondingly slidably connected. An ink hole is fixed at the bottom of the ink hole, and the bottom end of the ink hole is fixedly connected to the micropump set in the inkstone base through a conduit. The micropump is electrically connected to the wire on the back of the inkstone base, and an ink container is provided , the micropump is flexibly connected with the ink container through the conduit. The present invention is novel in design and strong in practicability. The slider is more convenient to open and close by providing a chute on the inkstone base, and the normal use of the slider ensures the cleanliness of the inkstone and inkstand, which is conducive to neat writing; The pen stand is provided to facilitate the storage of the writing brush, and the clothes on the body are not easy to be soiled. The micro pump is provided, and the micro pump works, so that the remaining ink is conveniently extracted into the ink container, and the utility model is convenient for recycling.

Owner:朱石明

Method for manufacturing Chengni inkstone

InactiveCN103864400ATake advantage ofSolid textureInk standsClaywaresEngineeringManufacturing engineering

The invention discloses a method for manufacturing Chengni inkstone. The method comprises the following twenty-two process steps: selecting a stone, breaking the stone, ball-milling, cleaning, drying in the shade, corroding, forming, pressurizing, designing, shoveling the blank, carving, finely grinding, drying, roasting, finishing, drying finely, cooking in rice vinegar, fine and accurate grinding in water, maintaining, polishing, checking and packaging. The inkstone manufactured by the method is excellent in service performance and ink rising is easy.

Owner:惠东存

Inkstone capable of being filled with ink and storing ink conveniently

Disclosed is an inkstone capable of being filled with ink and storing ink conveniently. An inkstone body is organically combined with an injector, and the ink is stored in a space of the injector. A tube of the injector is communicated with the center of the bottom of the inkstone body, residual ink can be sucked into the injector again so as to be reused, and wastage is avoided. Simultaneously, the residual ink can be sucked into the injector or a recycling device by the aid of the injector or other sucking devices, the ink can be added, recycled and stored conveniently so as to be reused, wastage is avoided, and the inkstone also has functions of an ink box, and is convenient in use and carrying.

Owner:李唐路

Ink slab capable of mixing ink

The invention provides an ink slab capable of mixing ink. The ink slab capable of mixing the ink comprises an ink box used for containing well-mixed ink, an ink bottle containing ink and a water bottle containing clear water. The ink bottle and the water bottle are assembled on the ink box. The ink bottle and the water bottle are provided with control valves correspondingly, and ink and clear water are made to be mixed according to a certain ratio. The mixed ink at an appropriate concentration is placed in the ink box for writing. The ink bottle and the water bottle are provided with scales, and the use amount of the ink or the clear water can be controlled according to the scale values through the control valves. The ink slab is further provided with an ink stirring and mixing device which evenly mixes the ink with the clear water. The ink slab capable of mixing the ink can adjust the concentration of the ink according to actual use demands and has the advantages that ink use is convenient, and washing is easy.

Owner:石润坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com