Special grinding device for detecting ink amount of ink stone

A technology of ink volume and inkstone table, which is applied to ink table, measuring device, office supplies, etc., can solve the problems of inability to precisely control the grinding speed and grinding pressure, unreliable test results, time-consuming and laborious, etc., and achieves simple structure and easy control. , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

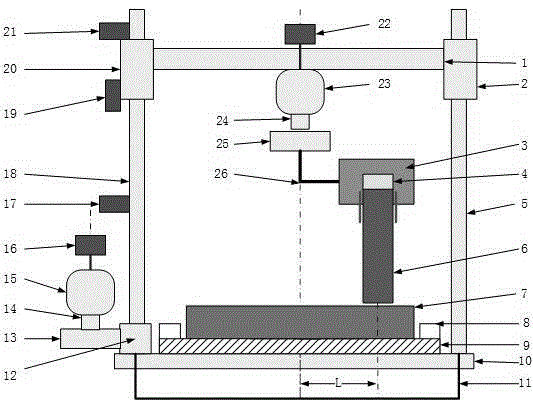

[0020] Such as figure 1 Shown: the above-mentioned special grinding equipment for inkstone ink output detection, the two ends of the moving beam 1 are fixedly connected with the first slider 2 and the second slider 20 respectively, the first slider 2 and the second slider 20 are respectively Installed respectively on the first ball screw 5 and the second ball screw 18 which are parallel to each other through threads, the first ball screw 5 and the second ball screw 18 are all vertically installed on the base 10; the workbench 9 is fixed on In the middle of the base 10, the inkstone 7 is freely placed in the center of the workbench 9 and clamped by the adjustable clamp 8; the first stepping motor 15 is connected with the first reducer 13 through the first coupling 14, and the first reducer 13 is connected with the gear transmission device 12 installed at the bottom of the second ball screw 18, the first ball screw 5 and the second ball screw 18 are connected through the linkage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com