Automatic ink-grinding machine

An ink grinder, automatic technology, applied in the direction of ink station, printing, office supplies, etc., can solve the problems of time-consuming, laborious, tasteless pen and ink, graying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

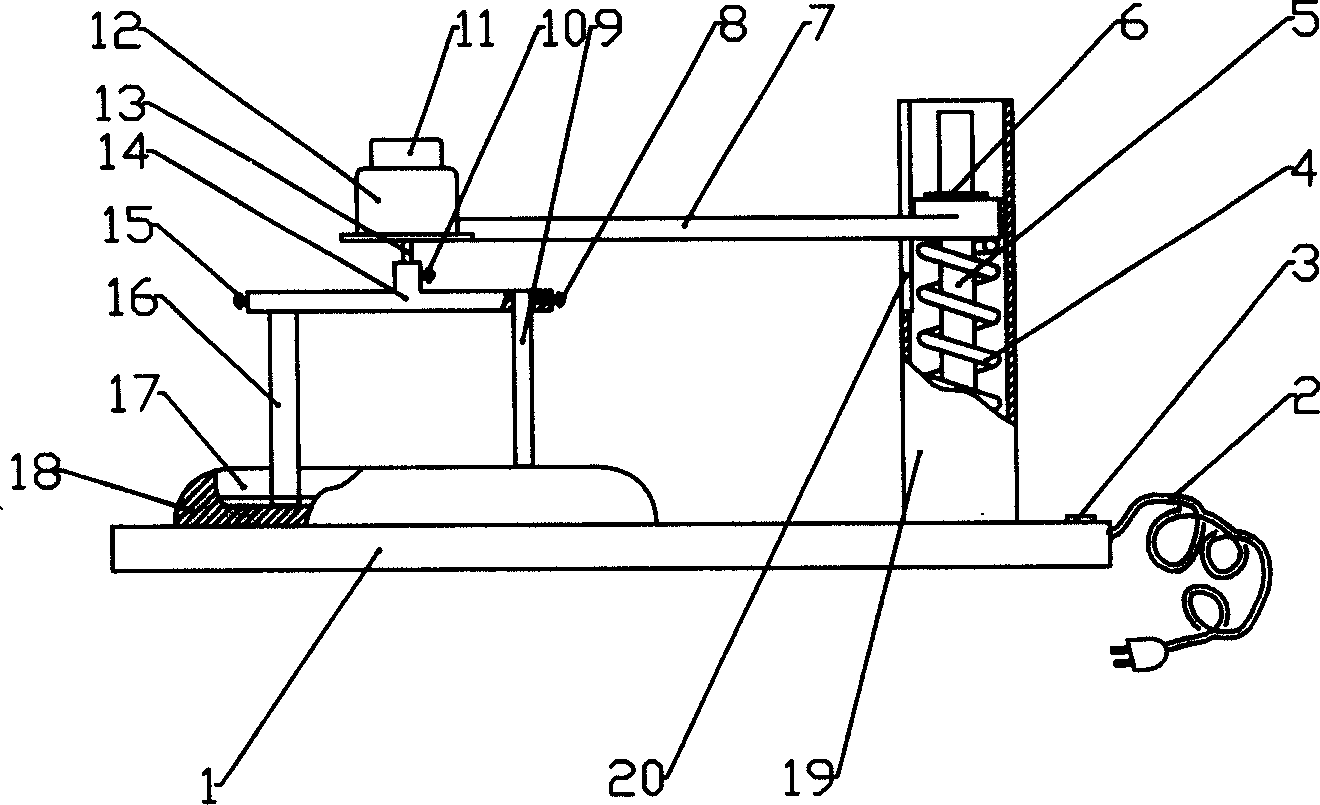

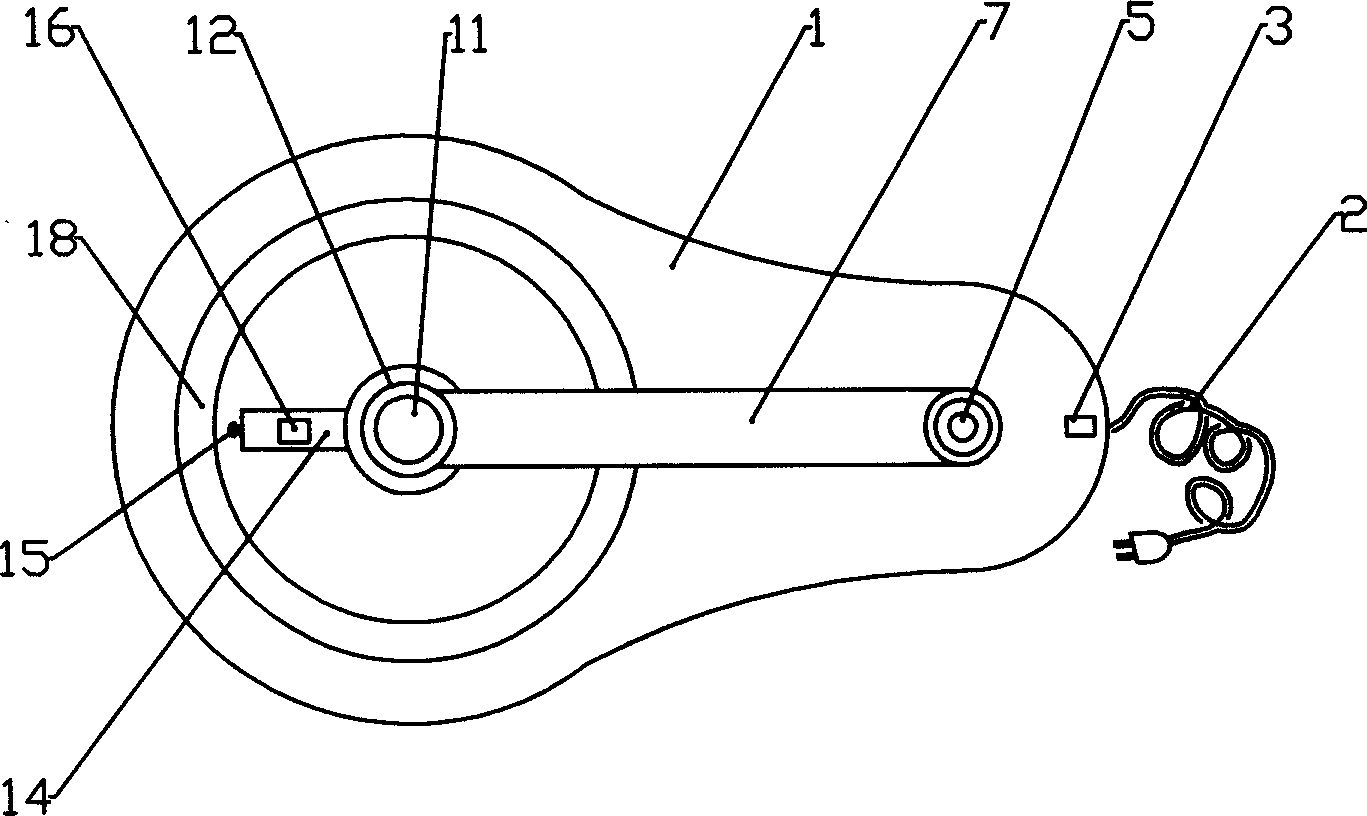

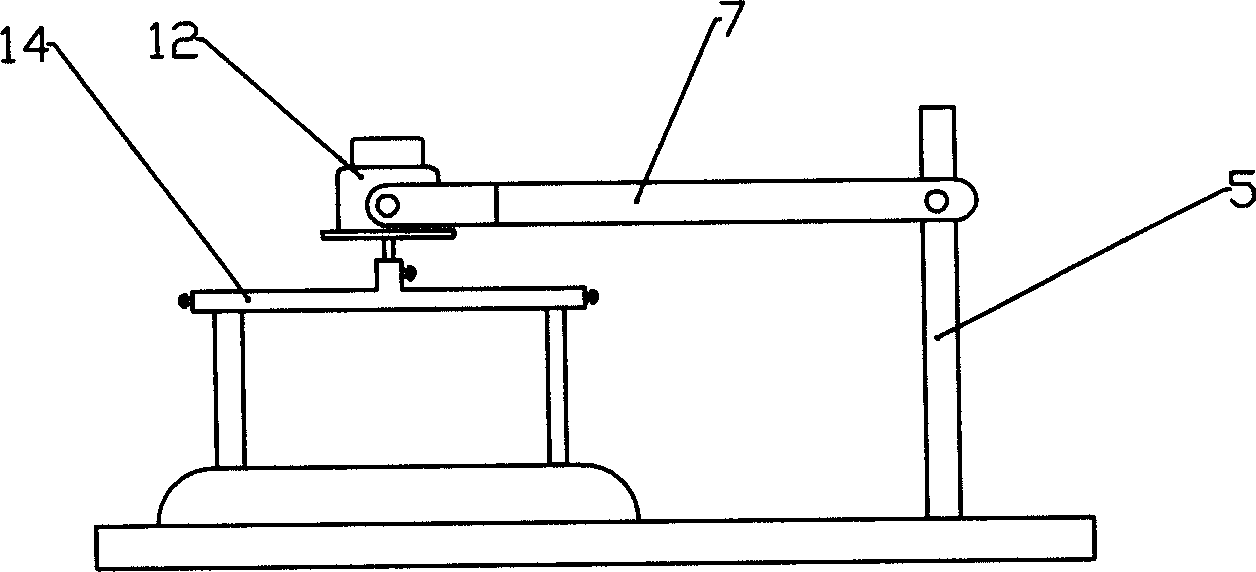

[0016] The automatic ink grinder of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0017] like figure 1 and figure 2 Shown is a schematic structural diagram of an automatic ink grinder, including a chassis 1 for placing an inkstone 18 and installing a landing bracket. like figure 2 As shown, the part of the chassis 1 used to place the inkstone is a relatively wide wide end, and the end where the landing bracket is installed is narrowed to become a narrow end, and a power switch 3 and a power cord plug 2 are arranged at the narrow end. The landing bracket is an assembly, consisting of a shaft 5 perpendicular to the chassis 1 and a connecting arm 7. The connecting arm 7 is installed on the shaft 5 through a steel ball bearing 6, and the inner diameter of the steel ball bearing 6 is inlaid with four rows of rolling steel balls (not shown in the figure). ) to ensure that the connecting arm 7 rises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com