Patents

Literature

51results about How to "Solid texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

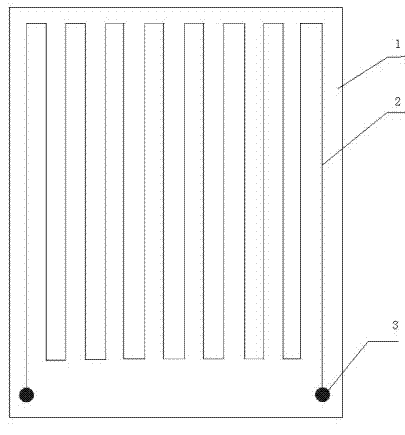

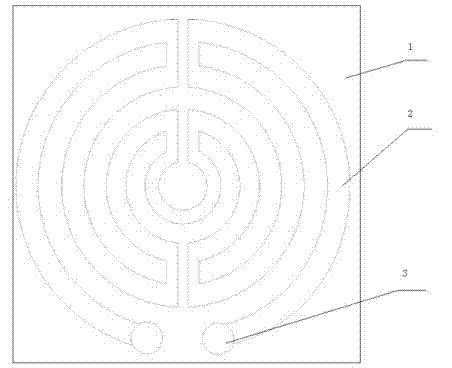

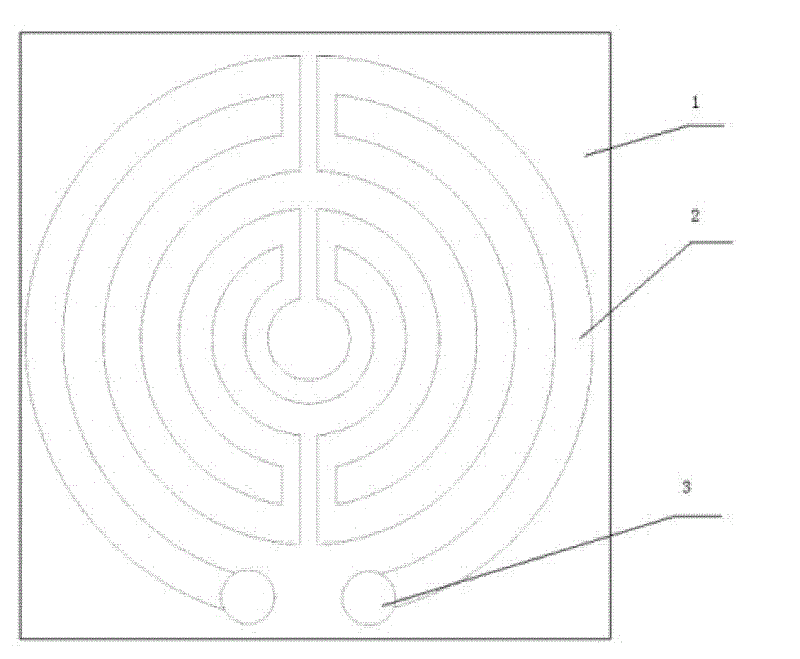

Heating flexible transparent thin film printed with silver paste and carbon paste and production method thereof

InactiveCN103209503AEvenly distributed by designNo corrosionHeating element materialsSilver pasteSoap solution

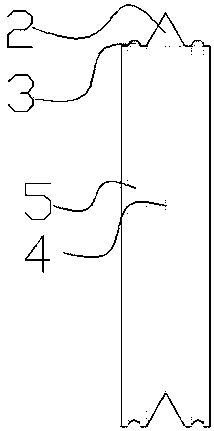

The invention relates to the technical field of heating thin films and discloses a heating flexible transparent thin film printed with silver paste and carbon paste and a production method thereof. The thermostatic heating flexible transparent thin film comprises a TIE (titanium ethylene) transparent plastic thin film, the conductive silver paste and the carbon paste, the TIE transparent plastic thin film is provided with a conductive heating thin film layer line which is printed with the conductive silver paste and the carbon paste, and the conductive heating thin film layer line is zigzag. The heating flexible transparent thin film printed with the silver paste and the carbon paste is applicable to high-technology applications in the agricultural and the medical fields. The line design of the conductive heating thin film layer is even; after the conductive heating thin film layer is powered for heating, the heat density is large, and the heat is even; the base material thin film is transparent, flexible and foldable; and the thickness can be from 0.02 to 0.05. The printed conductive heating thin film layer cannot drop even being soaked for 24 hours and cannot be eroded in an alkaline soap solution; and no broken line exists after carrying out a plurality of rub tests are carried out, so that the heating flexible transparent thin film printed with the silver paste and the carbon paste has the advantages of low pressure, low temperature, low manufacture cost, usage safety and convenience and , reliable quality and the like.

Owner:LUOYANG CLOUDS NET TECH

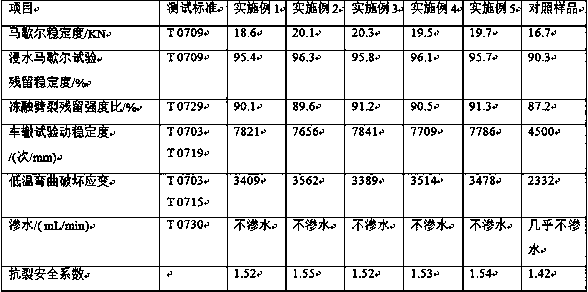

Rubber-asphalt concrete and preparation method thereof

The invention belongs to the field of building materials and particularly relates to rubber-asphalt concrete and a preparation method thereof. The rubber-asphalt concrete comprises, by weight, 50-60 parts of mineral powder fly ash, 20-30 parts of stone chips, 6-8 parts of limestone, 10-15 parts of cement, 5-10 parts of supermolecule rubber composite material, 6-10 parts of asphalt, 2-4 parts of glass fibers, 2-3 parts of sucrose diacetate hexaisobutyrate and 80-120 parts of water. The preparation method includes: using a method combining microwave and mechanical gridnign to regenerate waste rubber powder, performing grafting modification on the regenerated rubber powder, subjecting the limestone to high-temperature calcining, adding the supermolecule rubber composite material and the restof raw materials into the limestone, adding water, and evenly mixing to obtain the rubber-asphalt concrete. The rubber-asphalt concrete is good in performance such as high-temperature stability, low-temperature toughness, aging resistance, fatigue resistance and water damage resistance and capable of satisfying use requirements.

Owner:罗永山

Steamed pyramid-shaped dumpling of black glutinous rice wrapped in reed leaves and its production process

InactiveCN1403030ANourishing yin and nourishing kidneyHas the function of strengthening the spleen and protecting the liverFood preparationSpleenNutrient

The present invention relates to food production. The steamed pyramid-shaped dumping consist of pork, green mung and black glutinous rice wrapped in reed leaves. Compared with available technology, the present invention has the functions of nourishing Yin, invigorating kidney, invigorating spleen, protecting liver, nourishing blood and strengthening eyesight and is one kind of health food with rice nutrients.

Owner:梁伟明

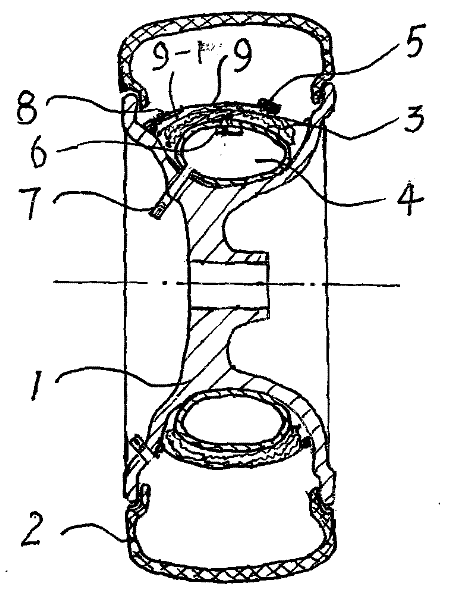

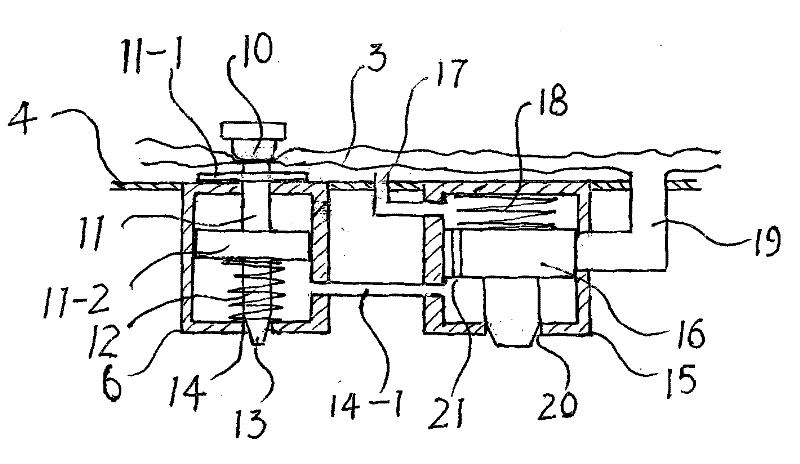

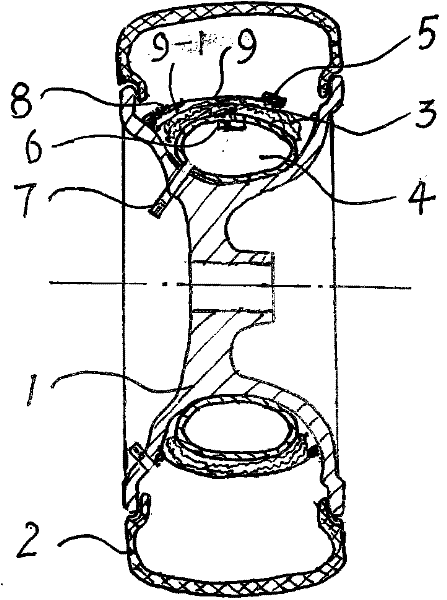

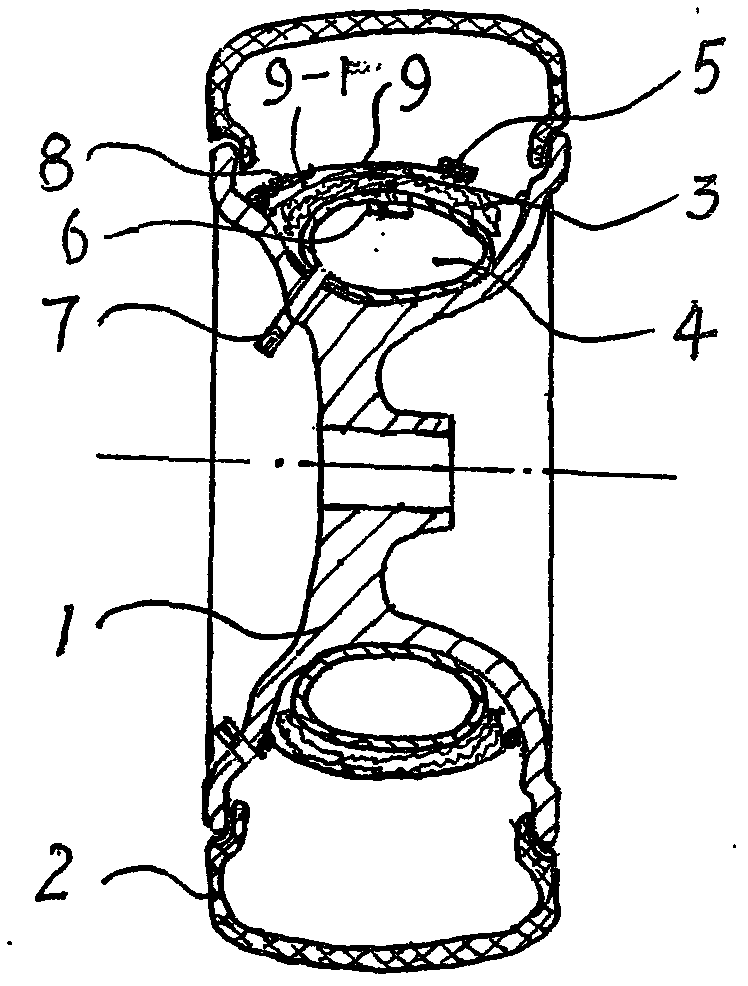

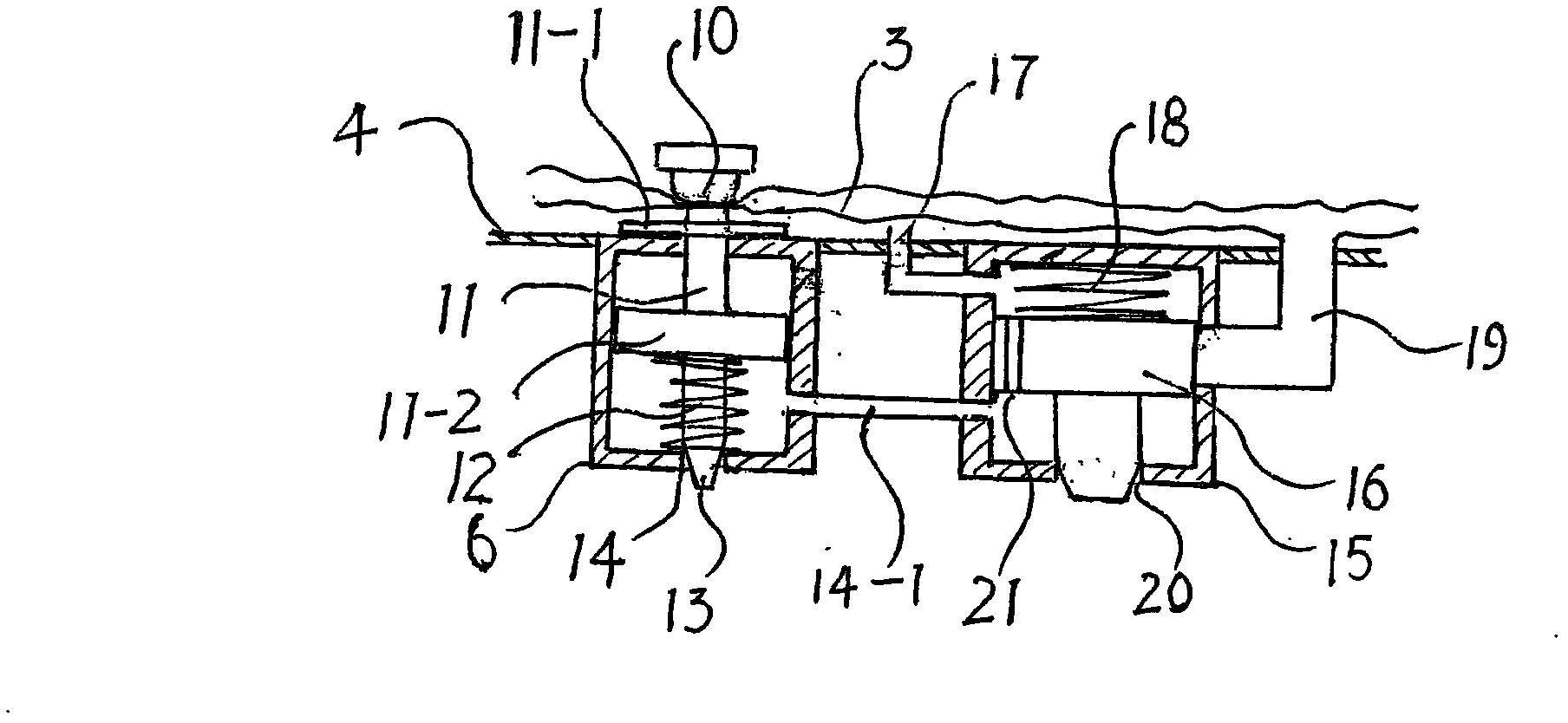

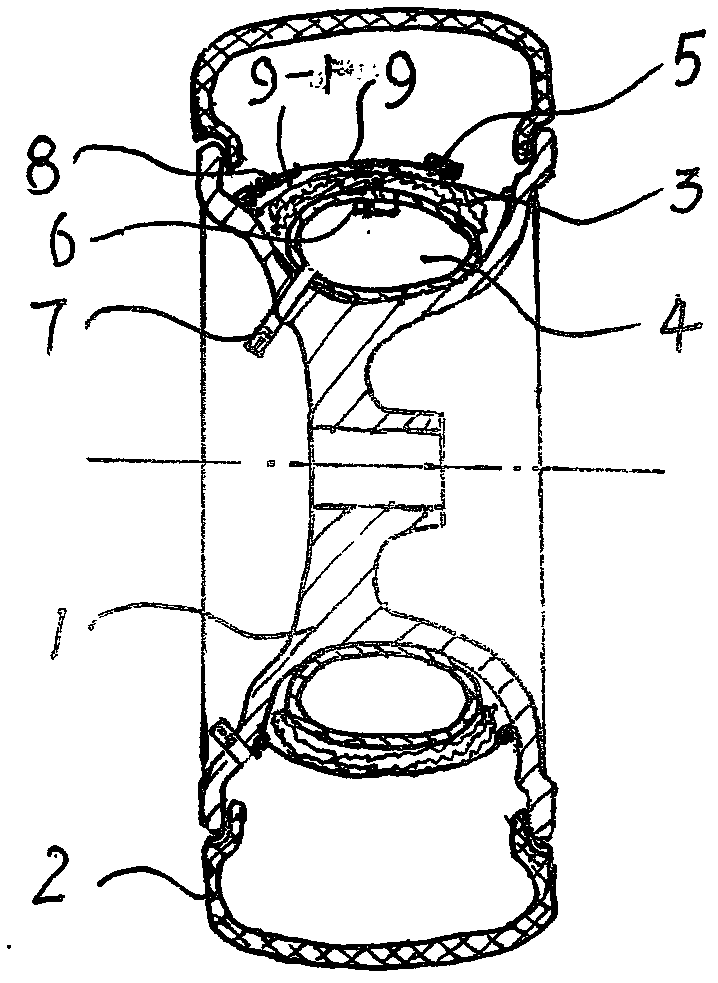

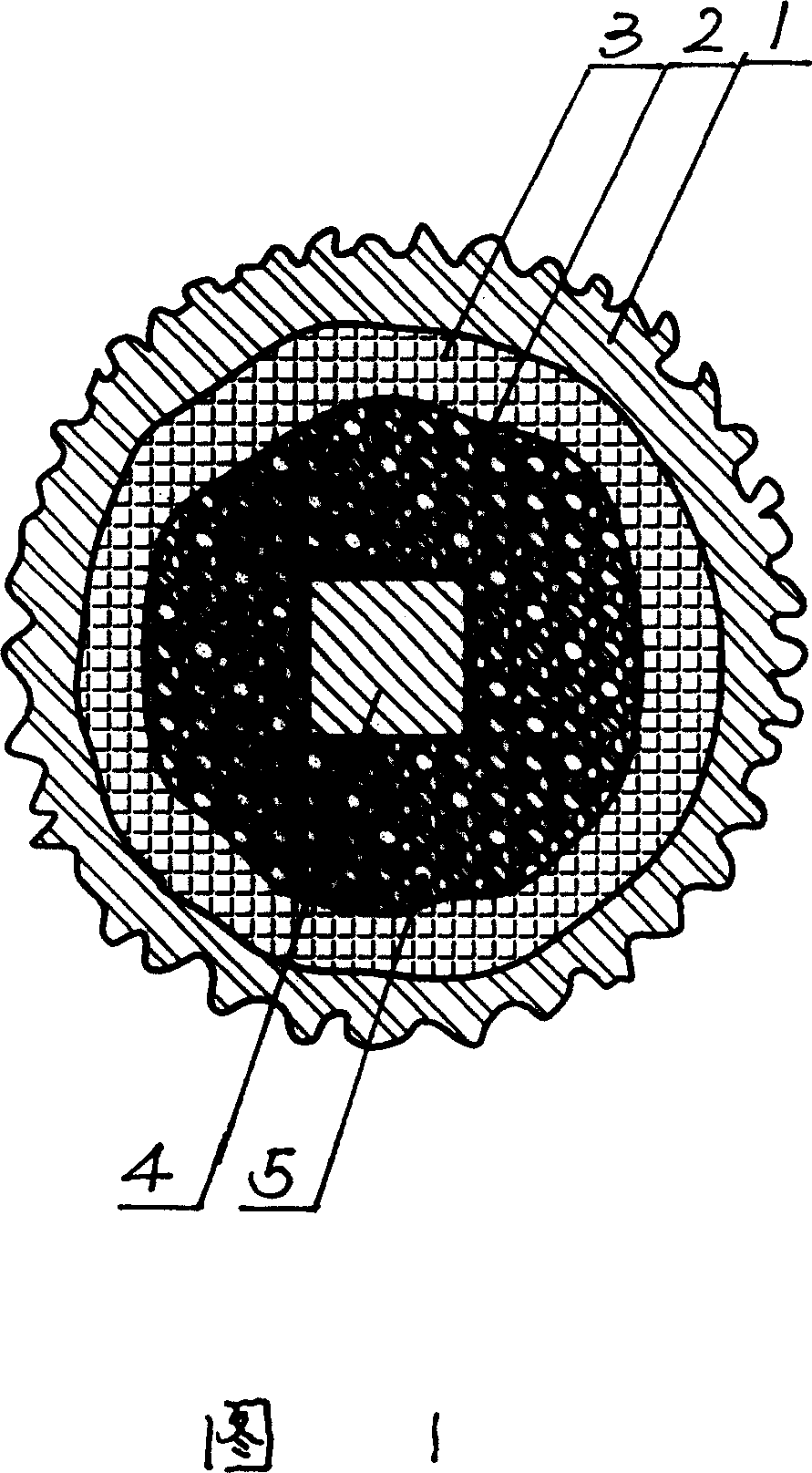

Tire airbag

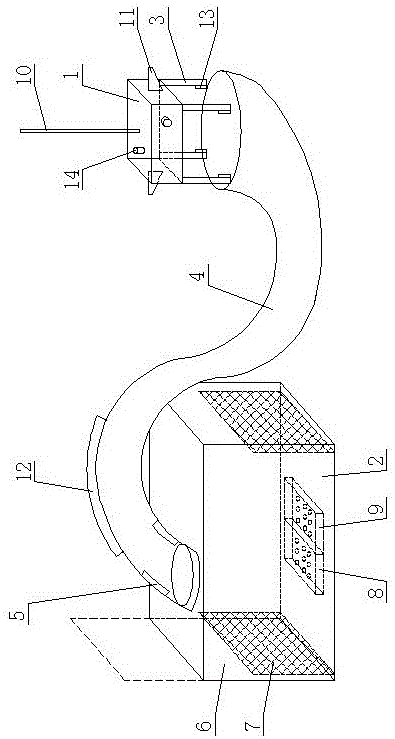

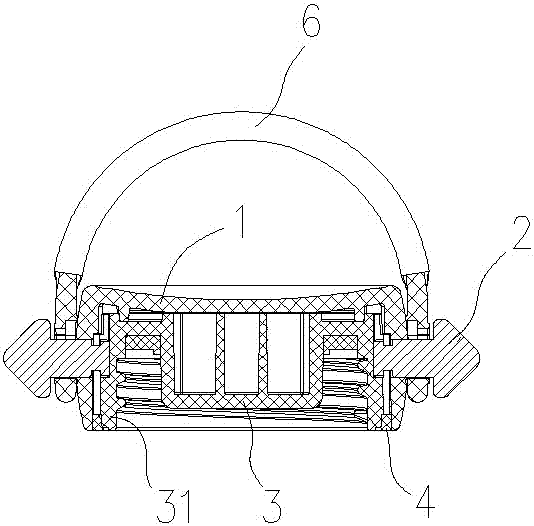

The invention discloses a tire airbag. An air bottle and an airbag are mounted in a rim, and a control valve and an air-release valve are connected between the air bottle and the airbag; the control valve is operated by a centrifugal hammer through a rocker arm, when vehicle tires rotate, under the action of centrifugal force, the control valve is opened, and a valve rod of the control valve is pressed by the air pressure in the tires so as to close the control valve, thus, the airbag is also in armed state; when a tire bursts suddenly and the air pressure in the tire sharply reduces, the tire still rotates at a high speed, and the centrifugal hammer is still not put down, the control valve is out of compression of the air pressure in the tire, under the action of spring force, a control air channel is opened, the air in the air bottle enters into the air-release valve through the control air channel to open the air-release valve, and by a large-caliber quick-release air channel, the high-pressure air in the bottle inflates the airbag instantaneously so as to support the tire, thus, the tire can recover the running function within a short time so as to improve the running safety.

Owner:宁波市镇海区职业教育中心学校

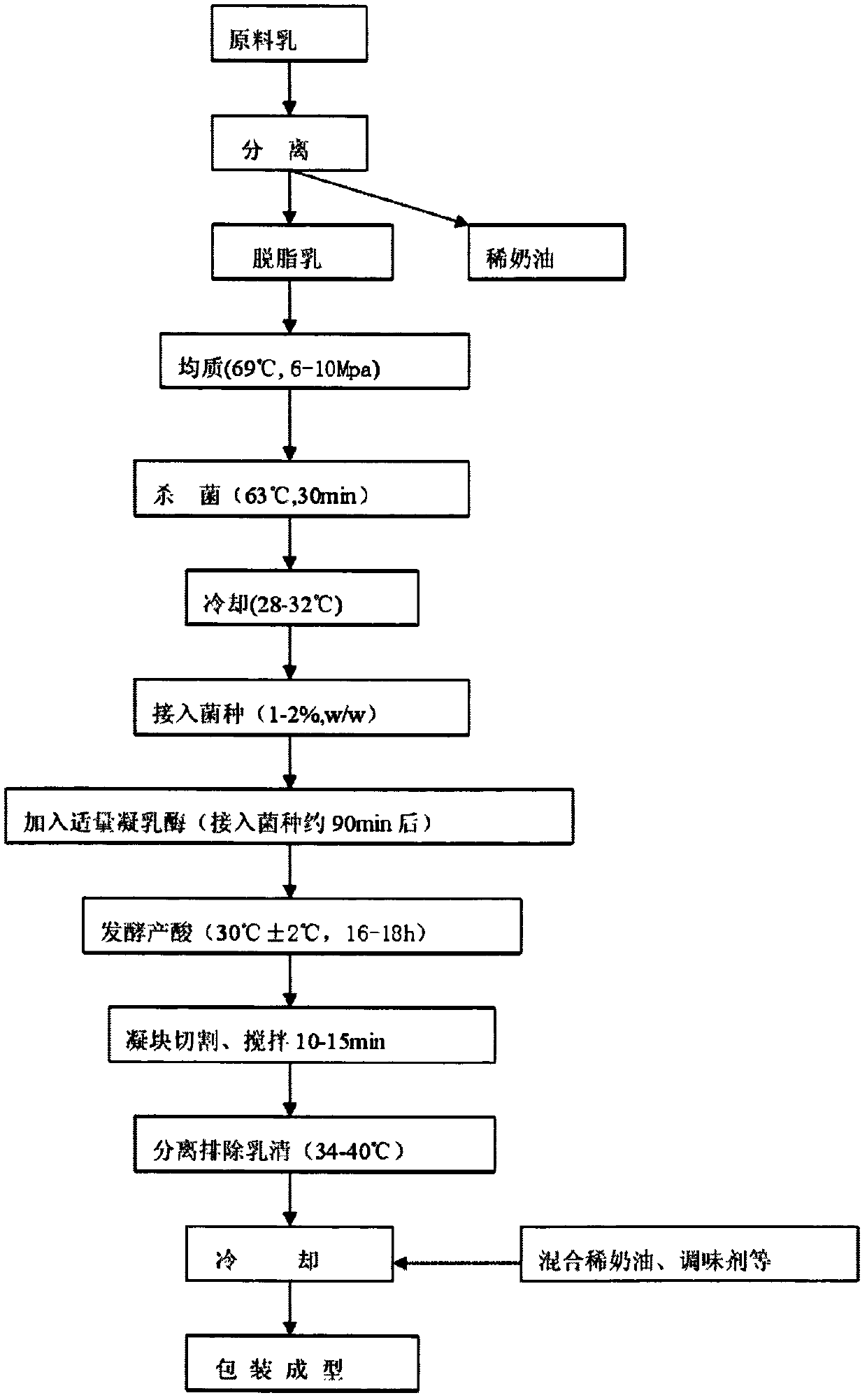

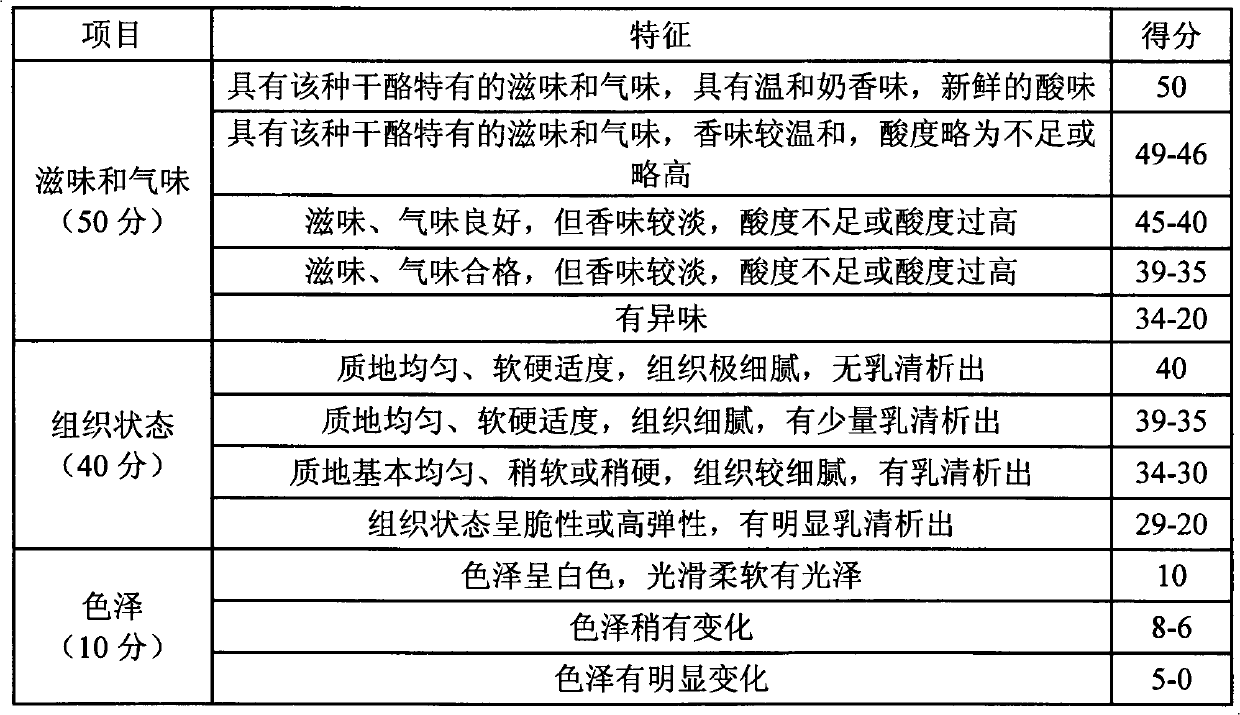

Quark-like cheese and manufacturing method thereof

ActiveCN103283855ASimple processAccelerate the process of localizationOther dairy technologyCheese manufactureProcess engineeringLactic bacteria

The invention discloses quark-like cheese and a manufacturing method thereof. The method comprises the following steps of: (1) concentrating raw material milk in vacuum at 40-50 DEG C until the protein is 6.0-8.0wt%, uniformly mixing with single cream, then homogenizing, then carrying out heat treatment at 90-95 DEG C for 5-10 minutes and then cooling to 30-34 DEG C to obtain treated milk; (2) inoculating the treated milk to a lactic acid bacteria starter for conventional quark-like cheese and fermenting at 30-34 DEG C for 90-120 minutes, wherein agitation conditions are as follows in a fermentation process: materials are agitated at a speed of 300-600rpm / min for 2-6 minutes and then the agitation is stopped for 5-15min and the agitation and the stopping are alternatively carried out; (3) filling: adding a chymosin water solution online in a filling process and then uniformly mixing, after filling, standing at 28-32 DEG C and fermenting until the pH (Potential of Hydrogen) value is 4.7-4.75 and then transferring a product into a refrigerated storage to be cooled for 8-12 hours. According to the quark-like cheese and the manufacturing method thereof disclosed by the invention, an existing technical blank is filled; existing equipment of a conventional dairy product processing plant is utilized and extra equipment investment is not needed to develop the production method of the quark-like cheese; the prepared product has flavor and textures which are similar with those of quark cheese, and the guarantee period is longer.

Owner:BRIGHT DAIRY & FOOD CO LTD

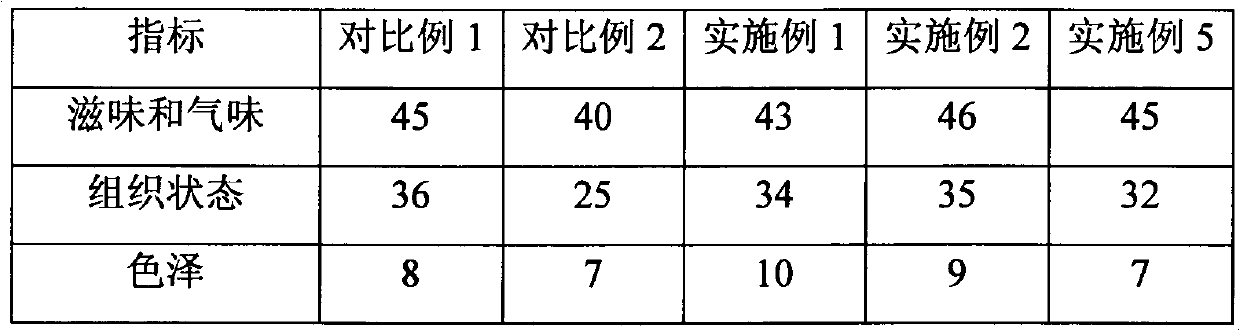

Method for making activated carbon by using wild peach pit shells

The invention discloses a method for making activated carbon by using wild peach pit shells. The method comprises the steps that the wild peach pit shells are dried for 12 hours at the temperature of 120DEG C to be dewatered, and are smashed to penetrate through a 40-mesh screen, the smashed wild peach pit shells are soaked in a 60% zinc chloride solution for 24 hours under the condition that the ratio of the wild peach pit shells to the zinc chloride solution is 1:2, then the soaked wild peach pit shells are transferred to a microwave oven with the microwave power ranging from 400W to 700W, and are processed for 10-30 minutes through irradiation, the processed wild peach pit shells are activated for 30-120 minutes at the temperature ranging from 400DEG C to 700DEG C, and then are processed through acid picking in a diluted hydrochloric acid solution which has the volume ratio of being 1:9 and is boiled for 30 minutes, cooling is conducted, the cooled wild peach pit shells are washed until the PH value ranges from six to seven, and are dried, and therefore the wild peach pit shell activated carbon can be obtained. The wild peach pit shell activated carbon made through the method has excellent adsorption performance.

Owner:姚雯楸

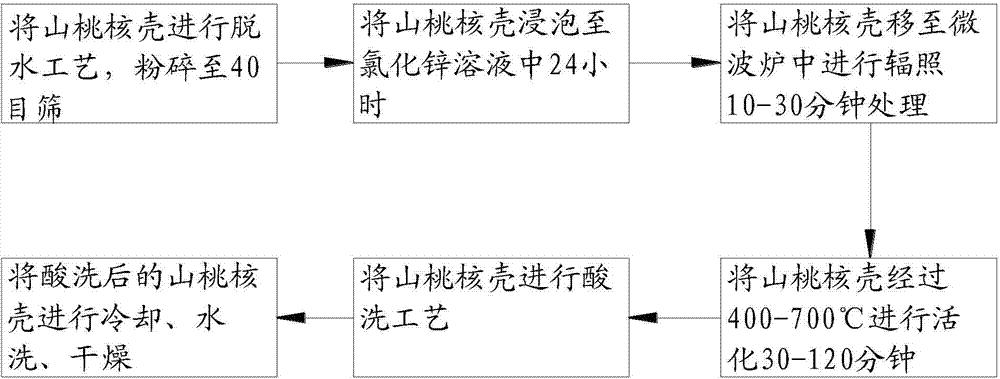

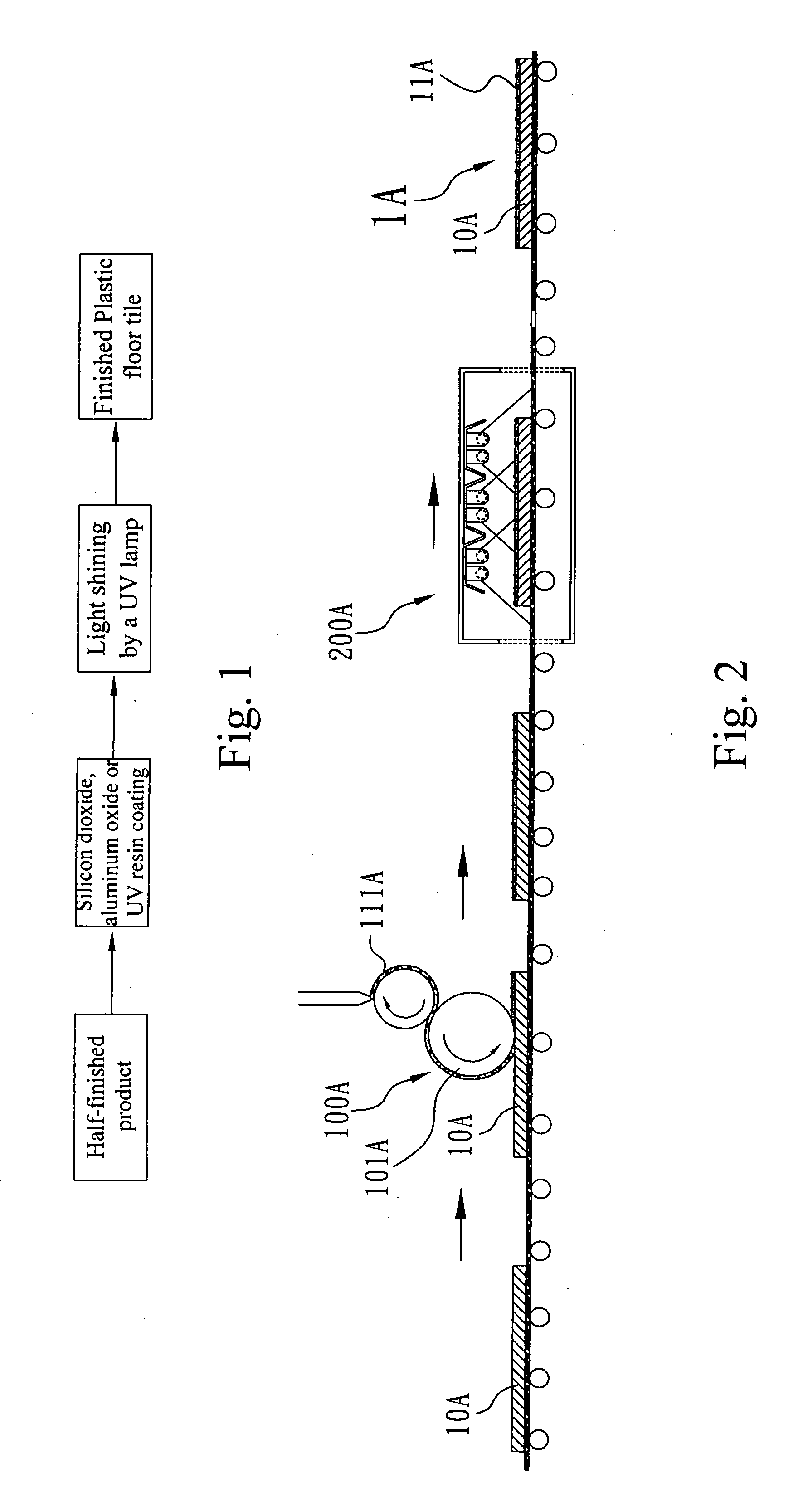

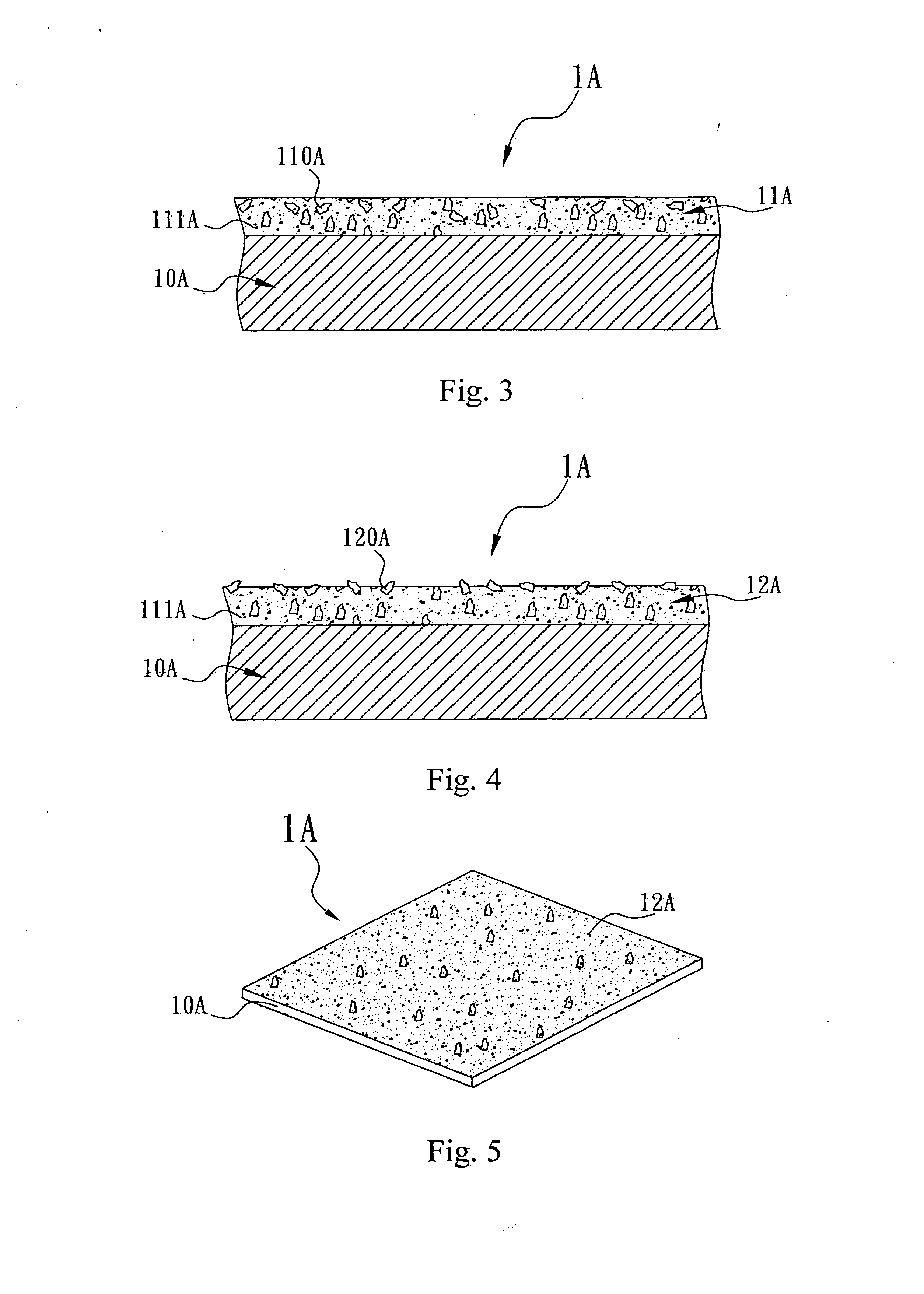

Coating process of aluminium oxide on the surface of plastic floor tiles

InactiveUS20050129866A1Excellent attachment propertySolid texturePretreated surfacesLiquid/solution decomposition chemical coatingOxideAluminium oxide

A coating process of aluminum oxide on the surface of a plastic floor tile includes plural steps consisting of a step of placing a half-finished plastic floor tile on a feeding table, two steps of coating two layers of UV photo-curing resin and a step of spraying a layer of aluminum oxide sand sandwiched between the two layers of UV photo-curing resin, and two steps of curing the two layers of UV photo-curing resin by light shining by one or more UV lamps, and a step of cooling the cured surface of a finished plastic floor tile and a last step of placing and storing a completely finished plastic floor tile on a receiving table.

Owner:CHUN SHIEN KO

Tire safe airbag

The invention relates to a tire safe airbag, which is characterized in that: an air cylinder and an airbag are arranged in a hub, and a control valve and an air release valve are connected between the air cylinder and the airbag; and the control valve is controlled by a centrifugal hammer through a rocker. When a car tire rotates, the control valve is turned on under the action of centrifugal force, and a valve rod is pressed by the air pressure in the tire, so that the control valve is in a turn-off state, and further the airbag is also in a standby state; when the tire bursts suddenly, the air pressure in the tire is plummeted, but the tire still rotates at high speed, the centrifugal hammer is not put down, and the control valve is not pressed by the air pressure in the tire any more; under the action of spring force, a control air channel is turned on, and the air in the air cylinder flows into the air release valve through the control air channel; and the air release valve is turned on, and high-pressure gas in the cylinder is instantaneously filled into the airbag to support the tire through a large-caliber rapid release air channel, so that the driving function of the tire is recovered in an extremely short time so as to improve the driving safety.

Owner:宁波市镇海区职业教育中心学校

Green ice cream and processing technology thereof

The invention relates to ice cream and a processing technology thereof, and concretely relates to green ice cream and a processing technology thereof, wherein the green ice cream has the advantages of good mouthfeel and abundant nutrition. A technical scheme adopted in the invention is that the green ice cream which treats mung bean and green tea as main raw materials comprises, by weight, 3-5% of mung bean, 41-43% of green tea water, 8-12% of waterless cream, 15-17% of white granulated sugar, 3-5% of fresh egg, 0.10-0.20% of CMC (carboxymethyl cellulose), 0.02-0.04% of carragheenan and 0.05-0.15% of citric acid. The technology of the green ice cream comprises steps of mung bean processing, green tea processing and ice cream making.

Owner:王晨

Method for manufacturing Chengni inkstone

InactiveCN103864400ATake advantage ofSolid textureInk standsClaywaresEngineeringManufacturing engineering

The invention discloses a method for manufacturing Chengni inkstone. The method comprises the following twenty-two process steps: selecting a stone, breaking the stone, ball-milling, cleaning, drying in the shade, corroding, forming, pressurizing, designing, shoveling the blank, carving, finely grinding, drying, roasting, finishing, drying finely, cooking in rice vinegar, fine and accurate grinding in water, maintaining, polishing, checking and packaging. The inkstone manufactured by the method is excellent in service performance and ink rising is easy.

Owner:惠东存

No-pollution glass fiber technology

InactiveCN105133129ASolid textureFlat surfaceFibre treatmentDry-cleaning apparatus for textilesPollutantTextile

The invention provides a no-pollution glass fiber technology. The technology comprises puffing and dispersing glass fibers, preparing original cloths, combining shafts, hot cleaning, fixing and demolding. The glass fiber prepared by the technology is smooth in surface and hard after being fixed, no pollutant emits out during preparation and no pollutant fills into a silencer of a vehicle exhaust pipe, the glass fiber does not volatilize pollutants, so a zero discharge effect can be achieved.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

Green ice cream and its preparation method

The invention relates to an ice cream and its preparation method, and specifically relates to a green ice cream and its preparation method. The green ice cream has good mouthfeel and abundant nutrition. A technical scheme adopted by the invention is characterized in that the green ice cream treats mung bean and a green tea as main raw materials, and mainly comprises 3-5wt% of the mung bean, 41-43wt% of green tea water, 8-12wt% of anhydrous cream, 15-17wt% of white granulated sugar, 3-5wt% of a fresh egg, 0.10-0.20wt% of CMC, 0.02-0.04wt% of carrageenan and 0.05-0.15wt% of citric acid. The preparation method comprises the steps of mung bean processing, green tea processing and ice cream making.

Owner:秦倩滢

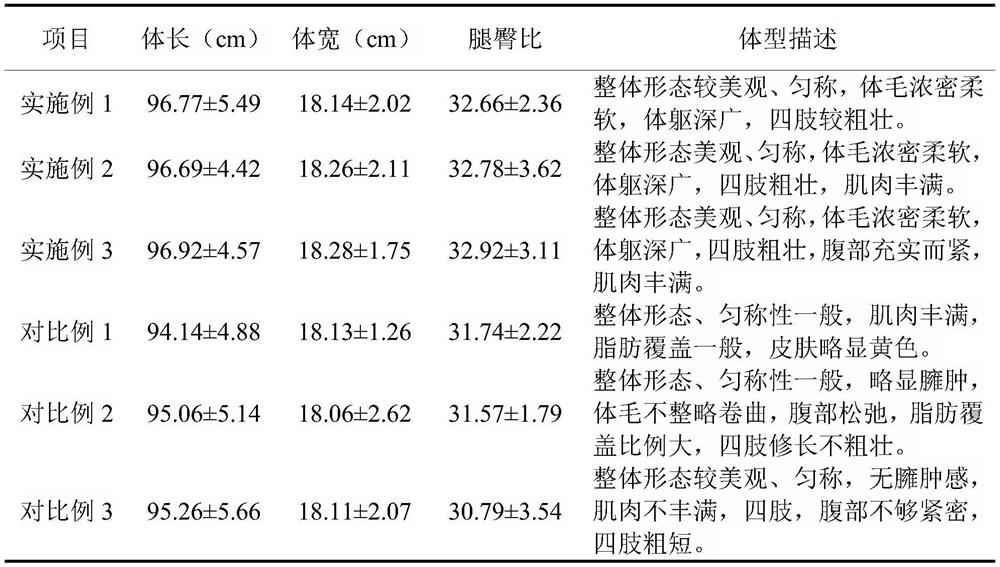

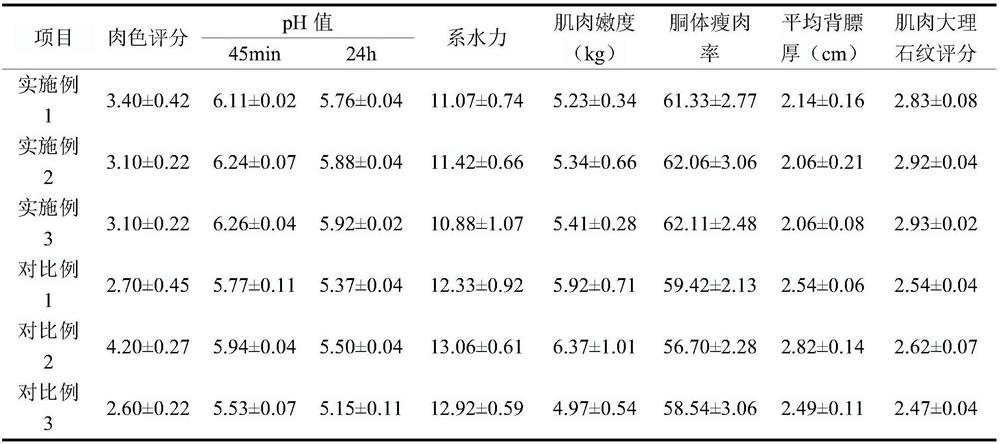

A late compound feed for improving the body shape and meat quality of fattening pigs and its processing method

The invention discloses a late compound feed for improving the body shape and meat quality of fattening pigs and a processing method thereof, belonging to the technical field of feed. The later stage feed is formulated with the following raw materials in mass percentage: 0.2-0.4% of betaine, 0.02-0.05% of chromium pyridine carboxylate, 0.01-0.02% of yeast selenium, 0.01-0.02% of vitamin E, and 0.01-0.03% of vitamin C , magnesium sulfate 0.06‑0.10%, potassium chloride 0.1‑0.2%, corn 64.0‑66.0%, soybean meal 20.0‑22.0%, oil bran 5.0‑6.0%, palm oil 0.8‑1.0%, coarse bran 4.0‑6.0%, Calcium hydrogen phosphate 0.38‑0.50%, stone powder 1.05‑1.20%, sodium chloride 0.40‑0.45%, antioxidant 0.05‑0.07, premix 1.0%.

Owner:WUHAN JIAJIALE FEED

Preparation method of natural plant pigment

PendingCN109320994ARaw materials are non-toxic and harmlessThe production process is simpleDead plant preservationArtist's paintsEpoxyPetal

The invention relates to a preparation method of a natural plant pigment, and belongs to the field of preparation of pigments. The preparation method of composite pigment comprises the following stepsof soaking tree leaves, vegetable leaves, fruit peels or flower petals and other raw materials of different colors into a fresh-keeping solution for 24h or longer; mixing the raw materials and wastepaper according to a volume ratio of 1 to (0.5 to 2), and stirring into crushed pieces with diameter of 1 to 5 mm by a stirring machine; uniformly mixing the crushed pieces, epoxy resin and a curing agent according to a volume ratio of 1 to (1 to 3) to (0.15 to 0.35), so as to obtain the composite pigment of different colors; sealing and storing under the light-shading condition. The preparation method has the advantages that the waste of resources and pollution to environment due to deliberate discard of waste articles can be avoided; the raw materials are poisonless and harmless, the preparation process is simple, and the preparation method is suitable for being popularized.

Owner:BEIJING UNIV OF TECH

Steamed pyramid-shaped dumpling of black glutinous rice wrapped in reed leaves and its production process

InactiveCN1242700CNourishing yin and nourishing kidneyHas the function of strengthening the spleen and protecting the liverFood preparationBiotechnologyNutrition

Owner:梁伟明

Novel lightweight wall

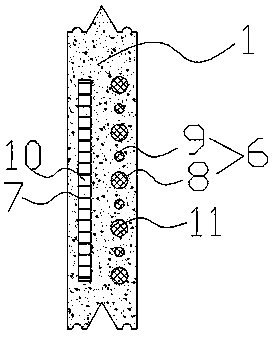

The invention discloses a novel lightweight wall. The novel lightweight wall comprises a wall formed by pouring of foamed concrete. The wall is square-shaped and provided with butt joint blocks and butt joint grooves. A heat-preserving tube and a sound absorption board are embedded into the wall. The heat-preserving tube is divided into large heat-preserving tubes and small heat-preserving tubes.The sound absorption board is a pinhole sound absorption board internally provided with multiple sound absorption cavities. The novel lightweight wall is simple in structure and reasonable in design.The wall is formed by pouring of foamed concrete so that the wall is firm in quality and low in weight. The large heat-preserving tubes and the small heat-preserving tubes are matched in an alternating manner so that the heat preservation effect is evident. Additionally, the pinhole sound absorption board is imbedded so that a sound absorption effect is acquired. Meanwhile, multiple lightweight walls are connected in an abutting manner through the butt joint blocks and the butt joint grooves. The integrating degree and flatness are improved. The bearing direction is the same.

Owner:镇江海利新材料科技有限公司

Chemical fertilizer special for coix seed and preparation method thereof

InactiveCN104311195APromotes robust growthFull grainCalcareous fertilisersMagnesium fertilisersCastor SeedAdditive ingredient

The invention discloses a chemical fertilizer special for coix seed and a preparation method thereof. The chemical fertilizer is prepared from the following ingredients in parts by mass: 26-28 parts of nitrogen fertilizer, 22-24 parts of phosphate fertilizer, 18-20 parts of potassium fertilizer, 15-17 parts of castor seed cake, 12-14 parts of rhizobium fertilizer, 9-11 parts of yeast fertilizer, 6-8 parts of vicia villosa green fertilizer, 2-4 parts of biogas waste fertilizer, 5-7 parts of monoammonium phosphate, 6-9 parts of magnesium sulfate, 3-5 parts of copper ammonium phosphate, 1-3 parts of calcium chloride, 4-6 parts of manganese chloride, 8-10 parts of organic complexing iron and 50-70 parts of water. The chemical fertilizer is rich in nutritional substances, can be prepared simply, has low cost, and can effectively promote strong growth of coix seed, and the coix seeds are full, white, smooth and tough in texture; and besides, the chemical fertilizer can improve the soil due to the vicia villosa green fertilizer in the formula, and can greatly improve the yield and the quality of the coix seed.

Owner:QINDAO BAOTANGXIN AGRI MACHINERY CO LTD

Heat insulating brick manufacturing method

InactiveCN100549339CGood smooth glossMild preparation conditionsRoof covering using tiles/slatesConstruction materialGlass fiberFoaming agent

The invention relates to a method for preparing a heat insulating brick, comprising the following steps: (a) preparing the outer layer of the heat insulating brick: taking the following materials according to the mass ratio, cement, water, sand, asbestos wool or glass fiber wool and brightener, and stirring Pour it into the mold evenly, and air-dry until the surface moisture is slightly dry after vibrating evenly; (b) prepare the raw materials of the heat-insulation brick insulation layer according to the mass ratio, cement, water, foam plastics and foaming agent; take cement and one of them Pour an appropriate amount of water into the mixer and stir into cement slurry, and pour the foaming agent into the rest of the water to stir and foam, then pour into the cement slurry and stir, then pour into the foam and stir evenly; (C) Prepare heat insulation Brick: Pour the heat insulation layer raw material obtained in the above step into the mold filled with the outer layer prepared in step (a), and vibrate the mold until the raw material is flat and compact. The preparation process adopts a semi-automatic technological process, and the operation at room temperature does not require high-temperature firing, the preparation conditions are mild, and the obtained heat-insulating brick has good flatness and gloss.

Owner:许聪勇

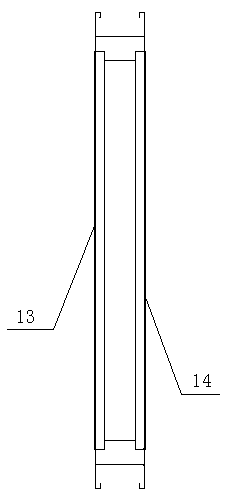

Integral device for fishing and loading of cultured aquatic products

InactiveCN106417198AGuaranteed fresh qualityKeep freshPisciculture and aquariaFishingWater flowAquatic product

The invention relates to an integral device for fishing and loading of cultured aquatic products. The device comprises an ultrasonic generator and a loading box, wherein a support is disposed on the lower end of the ultrasonic generator; a first end of a conveying pipe is connected to the support; a second end of the conveying pipe is connected to the loading box; a pressure pump is disposed on the second end of the conveying pipe; at least one side plate of the loading box is a slide side plate which can be slid up and down; a drainage net is disposed in the loading box on the inner side of the slide side plate; a cold accumulation room and a oxygen production room are disposed on the bottom inside the loading box; and the cold accumulation room and the oxygen production room communicate with the loading box via perforated holes on the top parts. According to the invention, the structural design is rational; use is convenient; the ultrasonic generator stimulates the hearing ability of the aquatic products, so that the aquatic products can be gathered and fished; and the pressure pump controls water flows, so that the aquatic products can enter the loading box via the conveying pipe, and the loading can be completed. In this way, time for the fishing and loading is shortened; efficiency of the fishing and loading is increased; labor force cost is reduced; and quality of the aquatic products can be maintained better.

Owner:SHANDONG INST OF COMMERCE & TECH

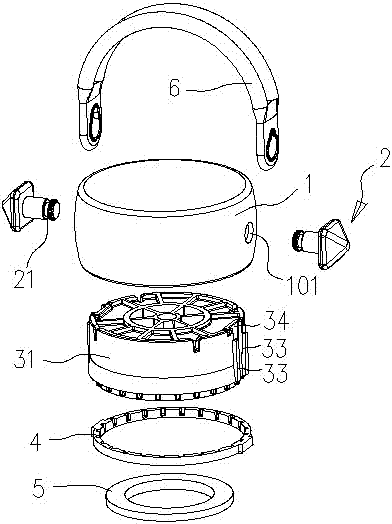

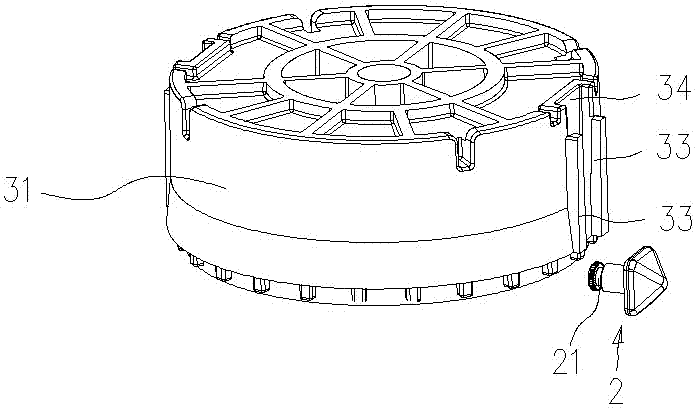

Portable cup cover and assembly method

The invention discloses a portable cup lid and an assembly method thereof. The portable cup lid comprises a cup body and a portable lid, wherein the portable lid comprises an outer lid and an inner lid, pin holes are formed in the left side and the right side of the outer lid, metal pegs are inserted into the two pin holes, ring slots of the metal pegs are clamped into vertical clamp strips, and a cup handle is arranged on the two metal pegs in a sleeving manner. The assembly method comprises steps as follows: the inner lid is fed towards a cavity of the outer lid under pressure, and when the vertical clamp strips reach the pin holes, pressure feeding is stopped; the metal pegs are inserted into the left pin hole and the right pin hole of the outer lid after penetrating into end holes of the cup handle, and then the whole inner lid is pressed into the cavity of the outer lid; secondary injection molding is performed in a gap between the lower end of a drum ring and the lower end of the outer lid. According to the portable cup lid, the gravity is uniform, the hands feel comfortable, when the cup is used for water drinking, a cup handle can be taken down from the cup body with the portable lid, and obstruction caused by the handle is avoided.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

Walnut health ball and fabricating method thereof

InactiveCN1311885CRealize comprehensive utilizationGood for healthElectrotherapyGymnastic exercisingInterior spaceSolid sphere

The invention relates to the amusement gymnasium equipment played in the hands, especially a walnut ball for health and its production method. The spherical shell is made of natural walnut shell, and its inner is filled with magnetic sphere that mixed by small block-shaped permanent magnet, iron dust and adhesive agent. The magnetic sphere is full in the inner space through glass cement, and coadunited with the inner surface of the spherical shell, to form the solid sphere of natural walnut shape. The invention make the abandoned walnut shell useful, adopt the chiropractic action of the hand acupuncture points by wooden outer surface's irregular scar of the natural walnut shell, fill the magnetic substance that good for human body's health. It not only aggravates the health ball's weight, satisfies the player's hand feeling demand, but also has the effect of magnetic health care and magnetic medical treatment. The texture of the walnut shell is solid and can be played for long. The invention is difficult to break even when it is fall to the ground.

Owner:索培力

Ruyao tea-dust glaze and preparation method thereof

InactiveCN109020219ASolid textureGlaze is smooth and crystal clearClaywaresAdditive ingredientCalcite

The invention relates to Ruyao tea-dust glaze and a preparation method thereof. The glaze is prepared from the following ingredients in parts by weight: 17 to 21 parts of calcite, 18 to 25 parts of blackrock, 10 to 16 parts of mica and 35 to 41 parts of purple marble. Each raw material uses the reasonable mass mixture ratio and is sequentially subjected to ball milling by a ball milling machine and is sieved; a biscuit blank is subjected to glaze soaking and trimming; the blank body is put into a kiln to be fired in oxidizing atmosphere and reducing atmosphere; the Ruyao tea-dust glaze can beobtained. The Ruci artwork prepared by using the recipe and the manufacturing process provided by the invention has the advantages that the glaze color is the tea dust color, is simple, beautiful andintriguing; the fired porcelain has the attractive appearance; the novel glaze color is increased for the Ruci; the economic benefits of the Ruci is improved.

Owner:汝州市宣和坊汝瓷有限公司

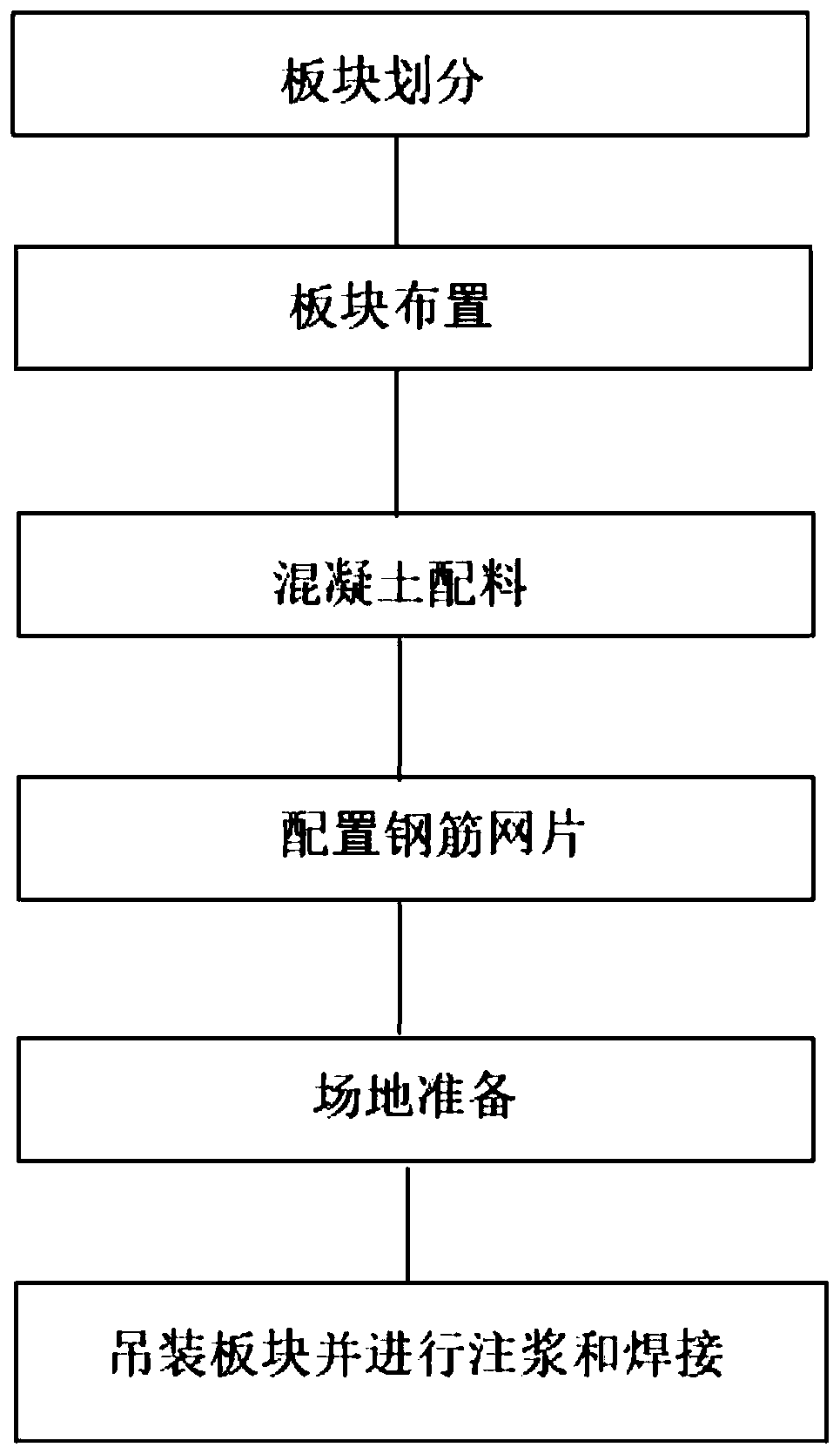

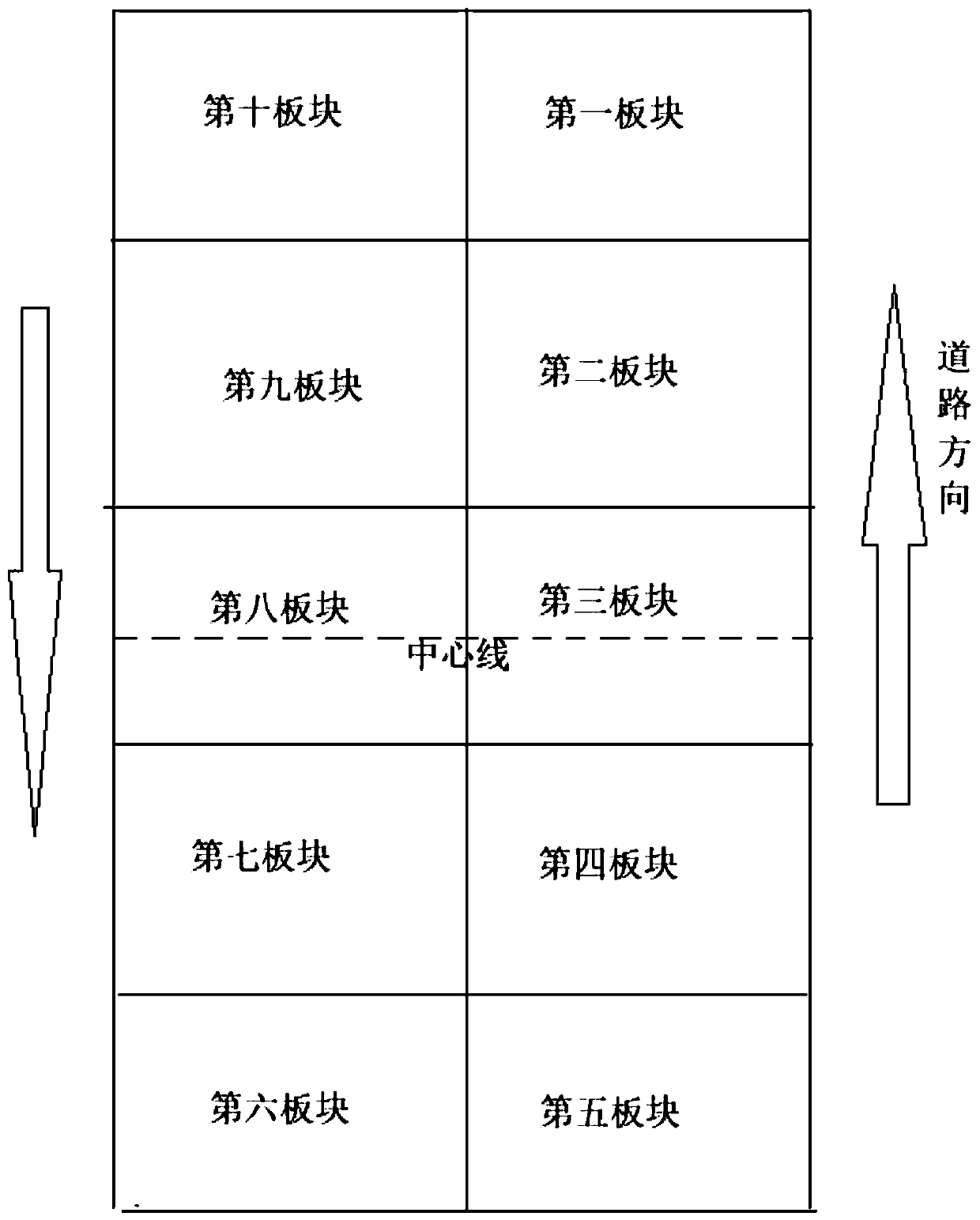

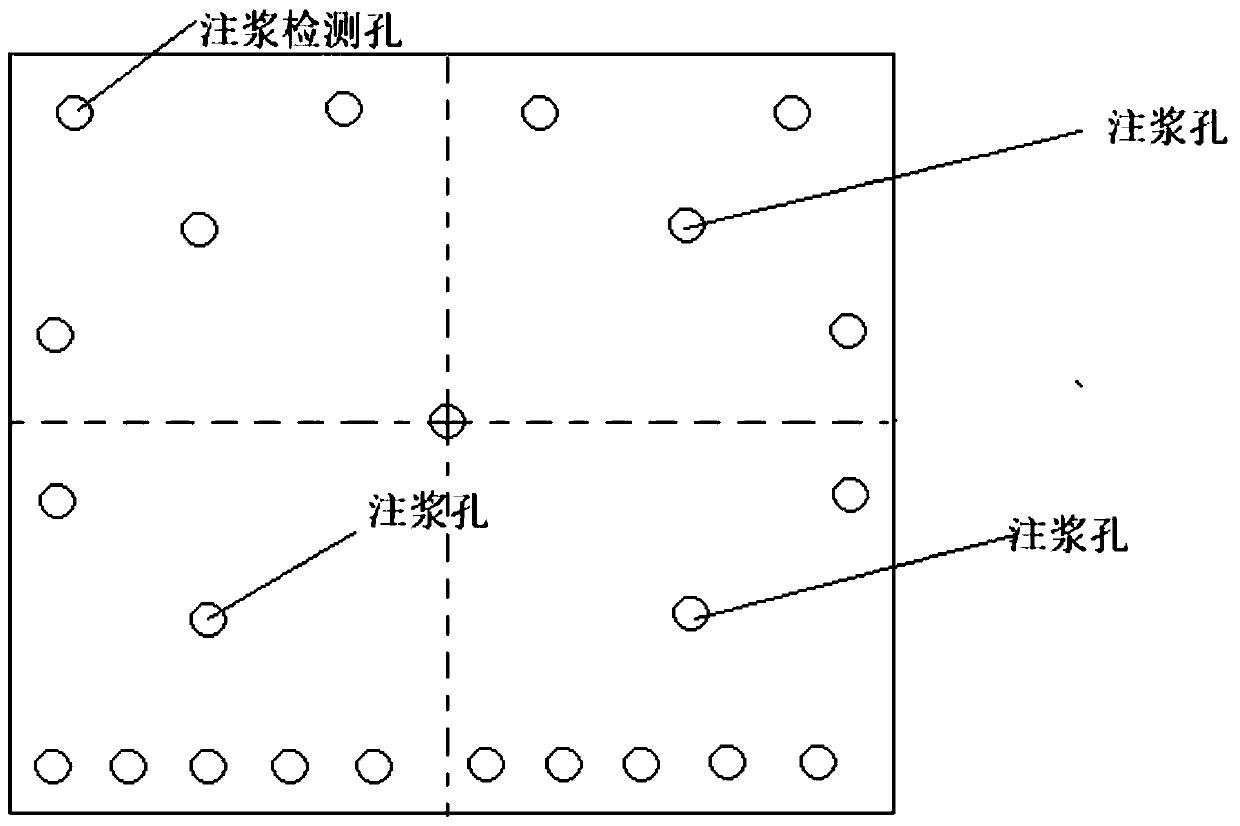

Prefabricated road process method with load monitoring module

InactiveCN111041921AHigh strengthEasy to shapeSingle unit pavingsClimate change adaptationHazardous substanceArchitectural engineering

The invention provides a prefabricated road process method with a load monitoring module. The prefabricated road with the load monitoring module is suitable for roads with large traffic flow and heavyload, plate division is carried out on the prefabricated road, and the prefabricated road surface construction method comprises the steps of plate division, plate arrangement, concrete batching, steel bar mesh configuration, site preparation, plate hoisting, grouting and welding. The method is suitable for roads with large traffic flow and heavy load, the roads are numbered from one to ten to facilitate monitoring, and in the selected materials for manufacturing the prefabricated plate, the coarse aggregate and the fine aggregate are good in particle shape, firm in texture, clean and free ofharmful substances, so that the strength of the manufactured prefabricated plate is high.

Owner:四川恒增装配式建筑科技有限公司

Low-energy consumption good-durability biomass briquette fuel and production method thereof

InactiveCN105969463AReduce contentReduce energy consumptionBiofuelsSolid fuelsEngineeringBULK ACTIVE INGREDIENT

The invention discloses a low-energy consumption good-durability biomass briquette fuel. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, finally, biogas residue is dried and crushed, and then is composited with an anti-slagging agent and an oxidant and other active ingredients for compression moulding under condition of 6MPa. The preparation method has the advantages of fast moulding and less required pressure, and is helpful for reducing equipment wearing. In the invention, magnesium carbonate is taken as the anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, waste diesel oil taking as an ignition-assisting agent is used for increasing the combustion efficiency and heat energy of the fuel, and the produced briquette fuel has the advantages of low energy consumption, high calorific value, firm quality, tight structure and good durability, easy initial ignition, less smoke, and long consumption time.

Owner:ANHUI DONGFANGJINHE PRECISION MACHINERY MFG

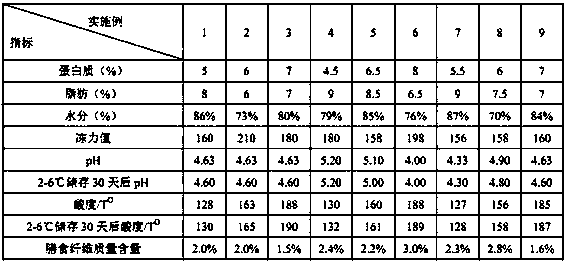

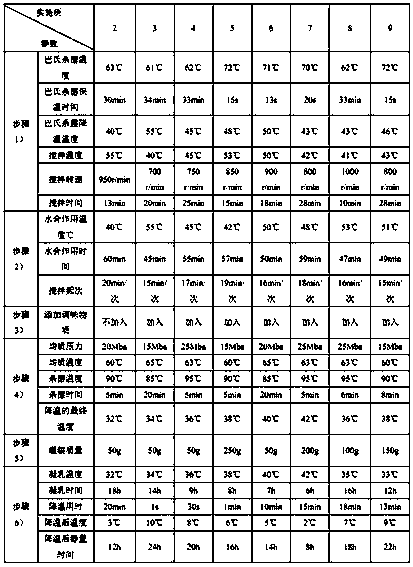

Soft green cheese containing dietary fiber and making method thereof

The invention belongs to the field of dairy product processing, and discloses soft green cheese containing dietary fiber, which is prepared from the active ingredients, including, by weight, 600-800 parts of milk, 40-80 parts of protein powder, 46-180 parts of cream, 40-60 parts of a sweetening material, 15-30 parts of dietary fiber, 0-60 parts of a flavoring material, 0.0001-0.1 part of rennet, 0.1-10 parts of fermentation bacteria, and which helps solve the problem that cheese cannot assist in digestion; the invention also discloses a making method of the soft green cheese containing dietaryfiber, which comprises the steps of mixing protein powder, cream and milk; allowing hydration to occur; adding the sweetening material and dietary fiber; homogenizing, sterilizing and cooling; addingthe fermentation bacteria and rennet; allowing to curdle and stand, and other steps; the making method helps solve the problem that discharged whey pollutes the environment. The soft green cheese contains dietary fiber and is beneficial to digestion; and the making method provided by the invention is environmentally friendly.

Owner:JUNLEBAO DAIRY GRP CO LTD

Indoor decoration daily use pure kieselguhr process brick and preparation method thereof

The invention provides an indoor decoration daily use pure kieselguhr process brick and a preparation method thereof, and relates to the technical field of decoration materials. The problems that theprocess of the existing kieselguhr water absorption pad product is complicated; the water absorption performance is poor; the powder falling can easily occur; bacteria easily grow are solved. The indoor decoration daily use pure kieselguhr process brick is prepared from the following ingredients in parts by weight:50 to 80 parts of first grade kieselguhr, 20 to 35 parts of binding agents and 15 to30 parts of dispersants. Ingredients possibly harmful to the human body such as plaster, paper pulp fiber and dye are not added in the production process; the process is simple; almost no waste is generated; after the powder body pressing shaping, high-temperature firing is performed; the materials can be used after being taken out and cooled; through the high-temperature firing process, possiblebacteria and organic matters can be removed together; the safety and the sanitation of the products are ensured; after the long-time use, no foreign smell is generated. Only the natural pure kieselguhr is used as raw materials, so that the weight of the finished product is light; meanwhile, the texture is hard and firm; powder falling cannot occur after the wiping and washing by force; the waterabsorption performance is obviously improved.

Owner:吉林省谊美生物科技有限公司

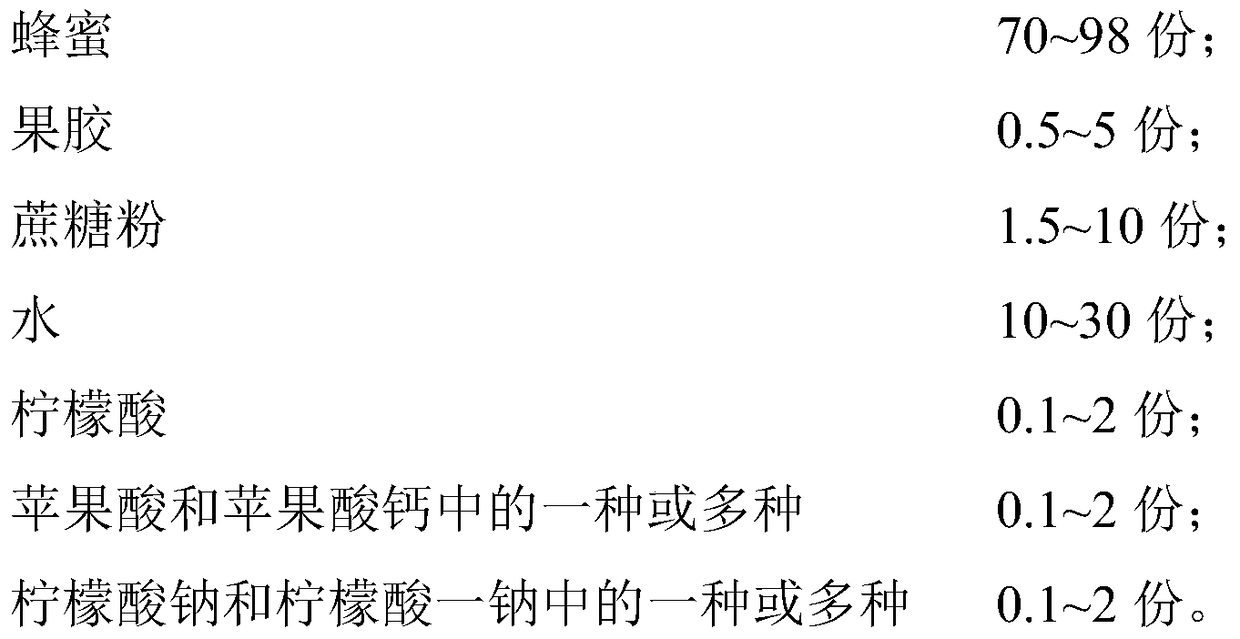

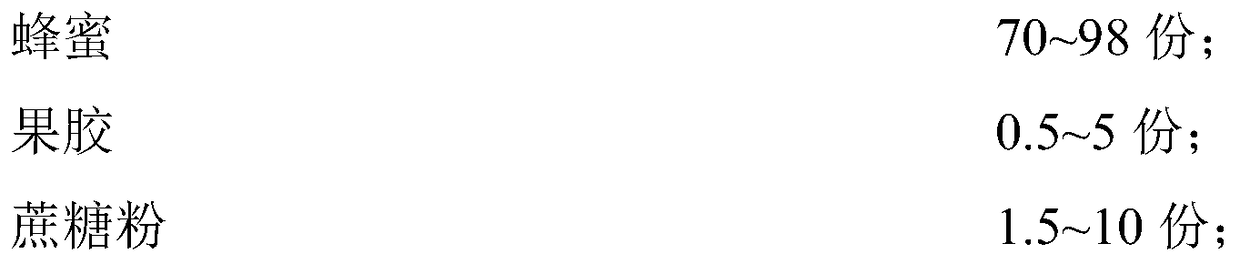

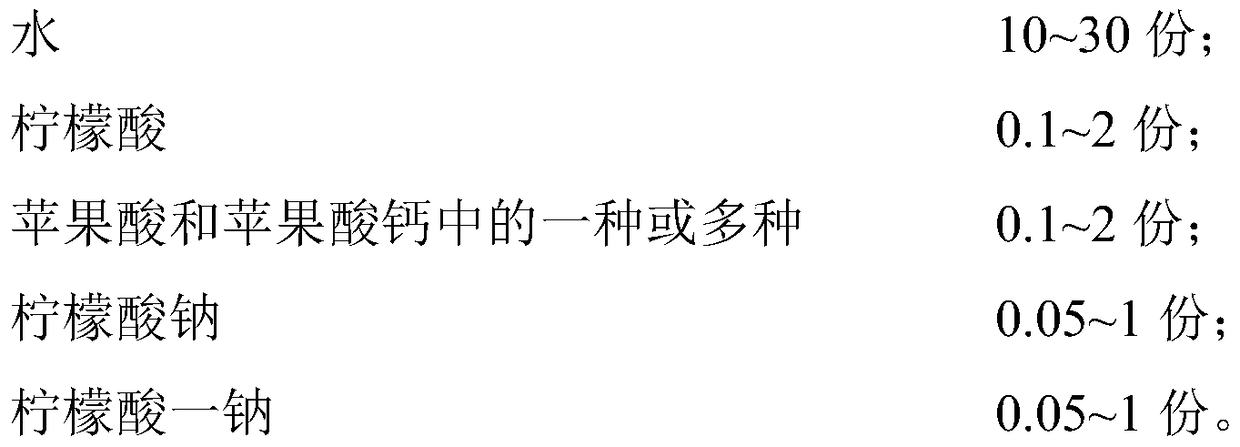

A kind of honey fudge and preparation method thereof

The invention discloses honeyed soft sweets and a preparation method thereof. The honeyed soft sweets contain the following ingredients in parts by weight: 70-98 parts of honey, 0.5-5 parts of pectin, 1.5-10 parts of sucrose powder, 10-30 parts of water, 0.1-2 parts of citric acid, 0.1-2 parts of one or more of malic acid and calcium malate and 0.1-2 parts of one or more of sodium citrate and monosodium citrate. The invention further provides the preparation method of the honeyed soft sweets. The honeyed soft sweets disclosed by the invention are high in honey content, good in product organoleptic properties, soft and delicate in mouth feel and moderate in elasticity, have a special strong honey flavor and have remarkable nutritional characteristics and biological activity. According to the honeyed soft sweets and the preparation method thereof, the process operation is simple, the cost is low, and project industrialization is easy to realize.

Owner:彭军

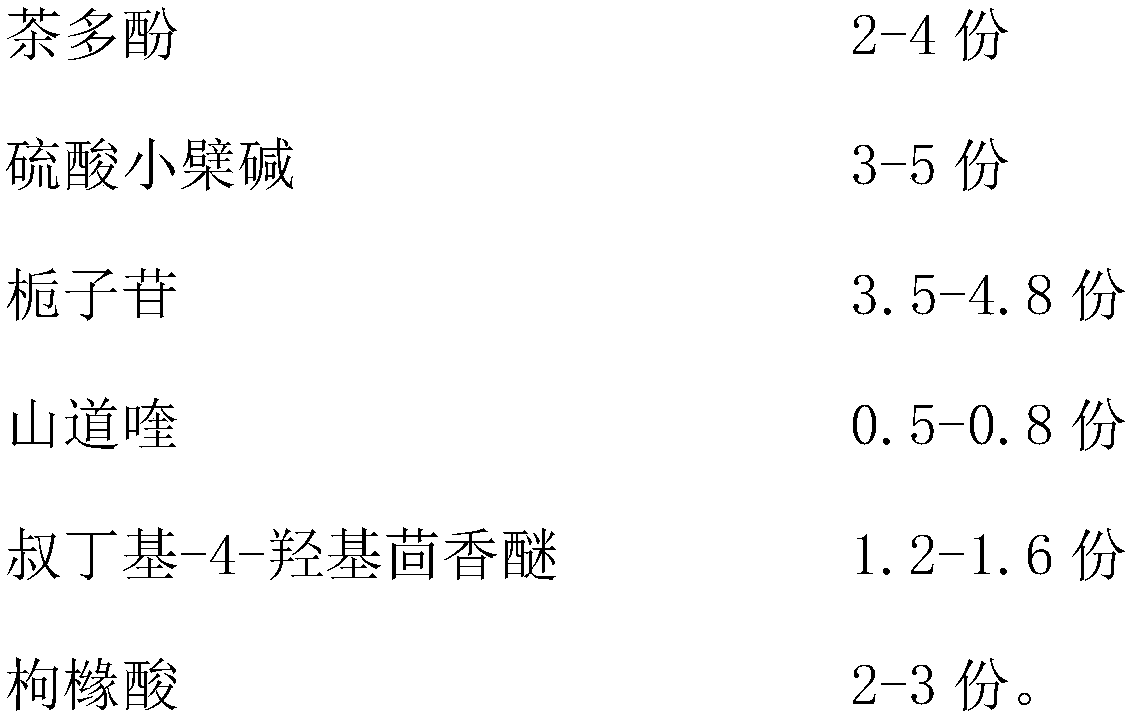

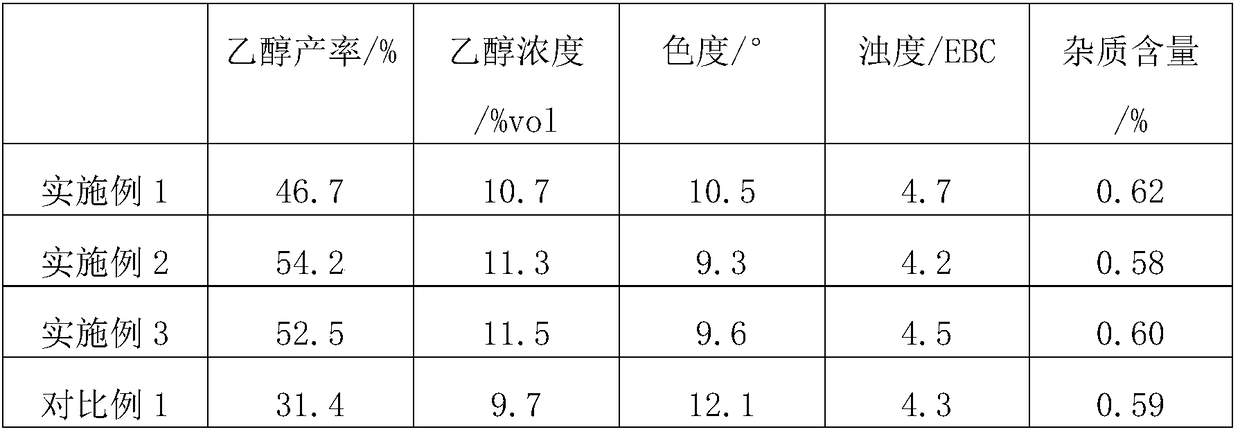

Method for producing ethanol, soap and feed from kitchen waste

InactiveCN108142661AImprove work efficiencyHigh yieldSoap detergents with organic compounding agentsFood ingredient as antioxidantDistillationResource utilization

The invention discloses a method for producing ethanol, soap and a feed from kitchen waste. The method comprises the following steps of step I, performing filtration; step II, performing crushing, andperforming saccharification; step III, performing fermentation, performing distillation, and performing rectification so as to obtain ethanol; step IV, performing refinement, performing decolorationand performing saponification; step V, adding methyl ethyl ketone peroxide and associative polyurethane to reach a precipitation and solidification state, so that soap is prepared; and step VI, mixinga feed additive with vinasse, and performing sterilization through ultraviolet radiation so as to obtain a feed, wherein the feed additive consists of tea polyphenols, berberine sulfate, jasminoidin,santoquin, butylated hydroxyanisole and citric acid. Through adoption of the method disclosed by the invention, the resource utilization rate of the kitchen waste is maximized, the produced ethanol can be used as fuel and an organic solvent, the produced soap has favorable functions of cleaning, emulsifying and sterilizing, the produced feed is high in safety, high in antioxidant ability and notliable to corrupt, the irritability resistance and the immune competence of animals are strengthened, and the yield is increased.

Owner:吴豪

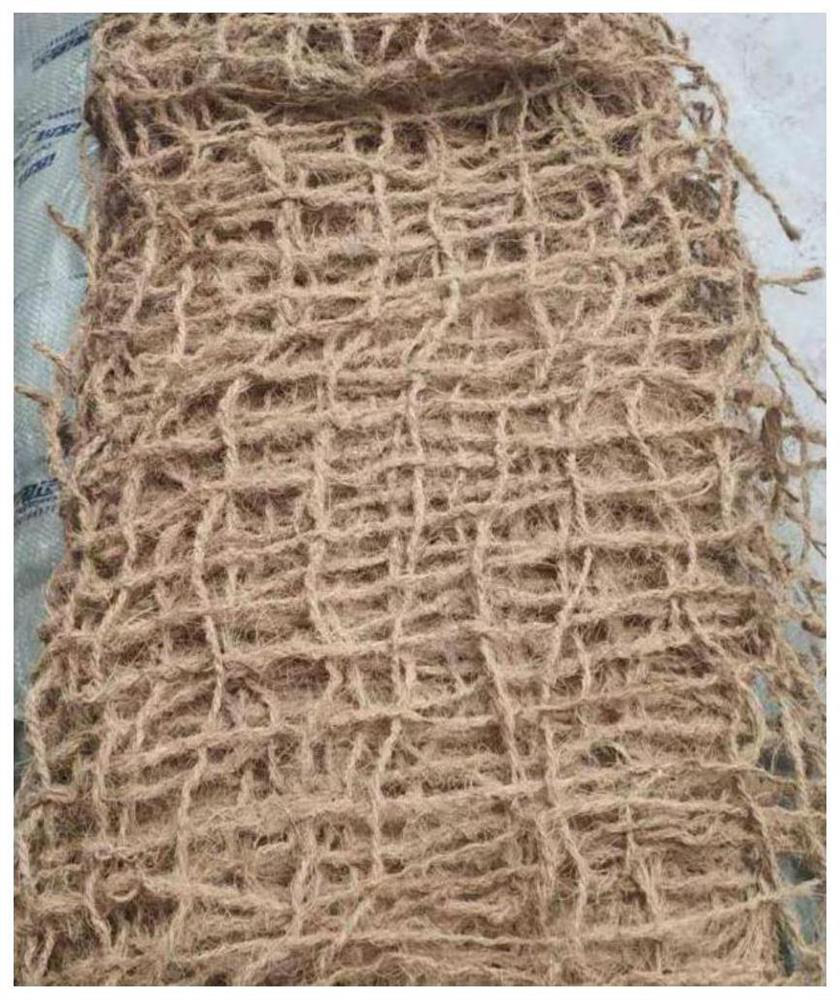

Ecological planting roll and preparation method and application thereof

InactiveCN112931147ASolid textureImprove wear resistanceClimate change adaptationCoastlines protectionFiberMicroorganism

The invention provides an ecological planting roll and a preparation method and application thereof, and belongs to the technical field of environmental ecological management. According to the ecological planting roll and the preparation method, the coconut fiber serves as a bank protection material to be used for the ecological planting roll, the coconut fiber has the advantages of being firm in texture, good in abrasion resistance and waterproofing, and the coconut fiber is excellent in elasticity and not prone to breaking; and meanwhile, the coconut fiber can resist denudation of microorganisms and long-term erosion of seawater, and it can be guaranteed that the bank protection effect is achieved. The ecological planting roll is simple in structure, easy to prepare, resistant to scouring, high in durability and good in ecological restoration effect, ecological transformation of a soil revetment and a hardened revetment can be achieved, the requirements for river water scouring resistance, biocompatibility, use durability and the like of a river bank in the river regulation process can be met, and high operability for improving the ecological environment quality of an urban water body is achieved.

Owner:BEIJING LVJINGXING TECH DEV CO LTD

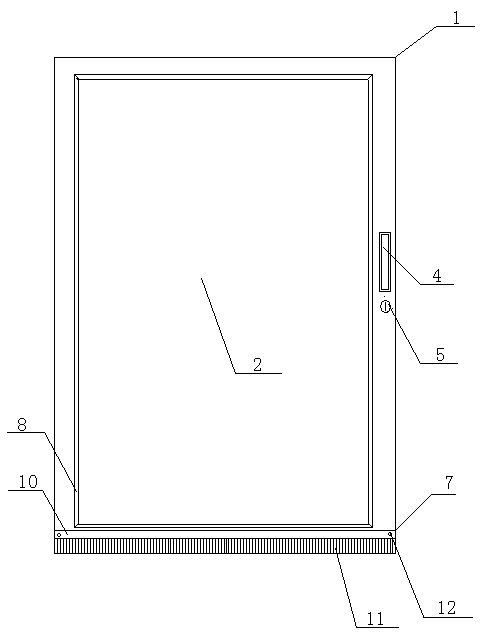

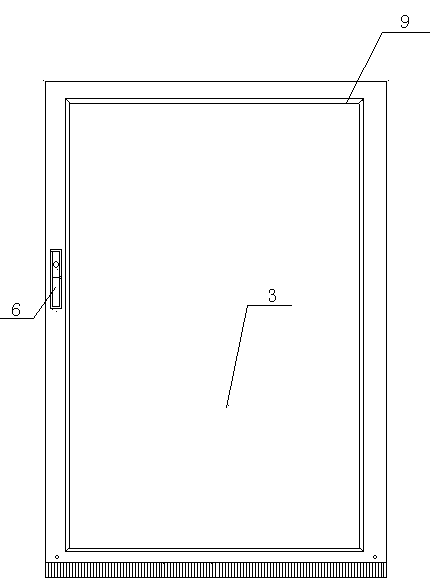

Improved double glass door

InactiveCN104343348AImprove antifouling performanceImprove dustproof effectSealing arrangementsWing framesEngineeringMechanical engineering

An improved double glass door comprises a double glass door frame. The double glass door glass frame is internally provided with outer glass and inner glass. A handle is arranged on the front right side of the double glass door frame. The lower portion of the handle is provided with a keyhole. A counter lock device is arranged on the back left side of the double glass door frame. The lower portion of the double glass door frame is provided with a dust prevention device. By means of the above improvement, the improved double glass door has the advantages of being good in dirt resistance, dust prevention effect and safety, not easy to scratch and solid in texture.

Owner:JIANGSU HAOTUO OFFICE FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com