Quark-like cheese and manufacturing method thereof

A manufacturing method and quark technology, applied in the field of quark-like cheese and its manufacture, can solve the problems such as difficult to realize the production of such products, and achieve the effect of consistent state, simple and feasible process, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

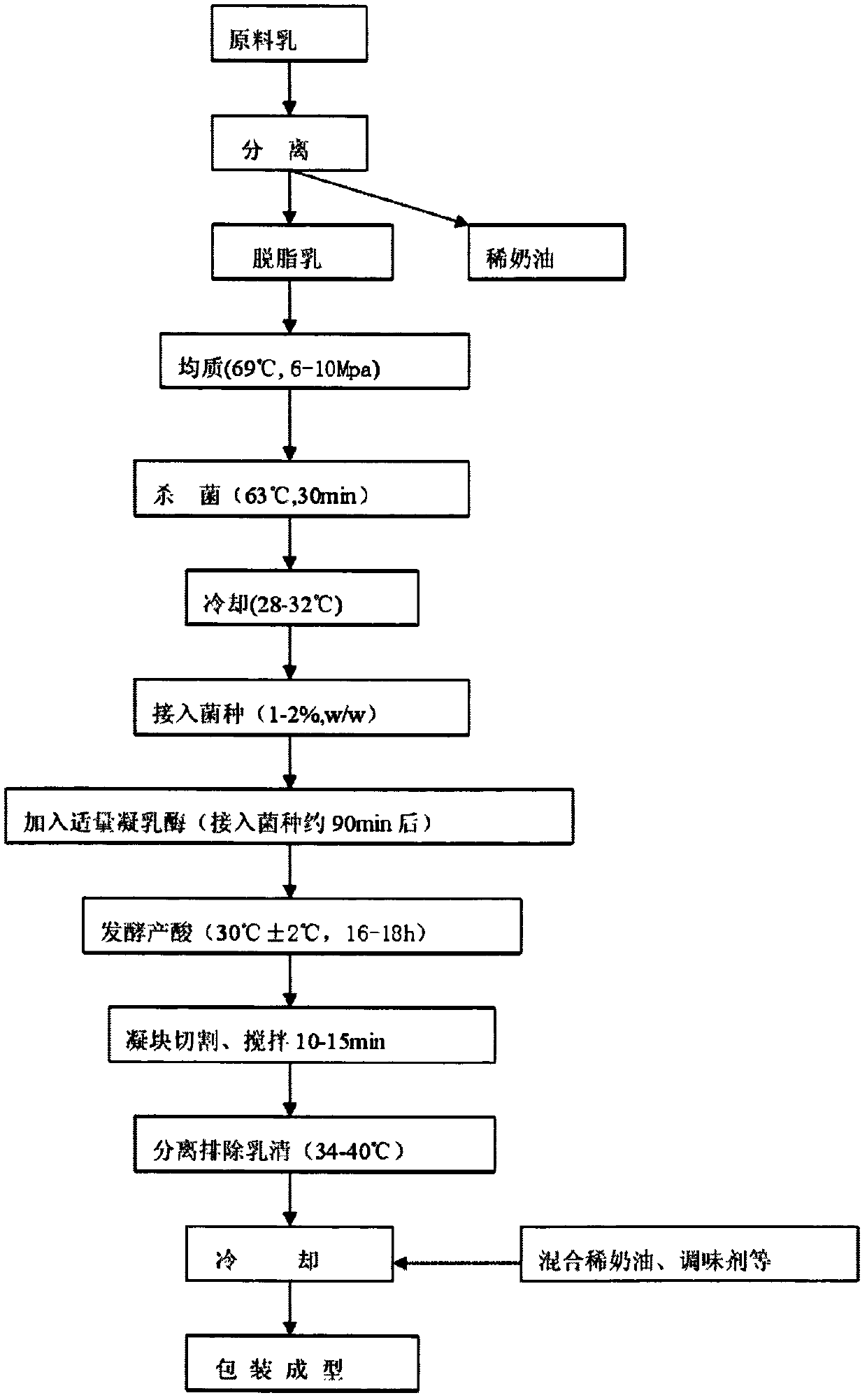

Method used

Image

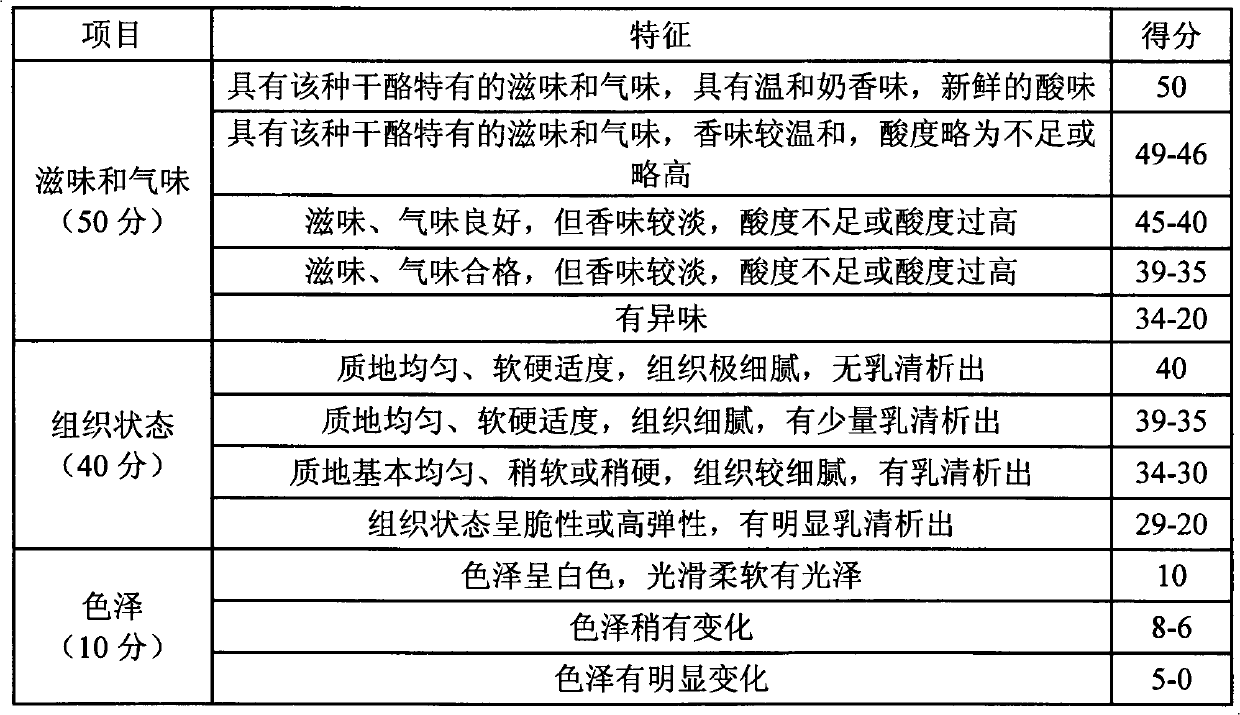

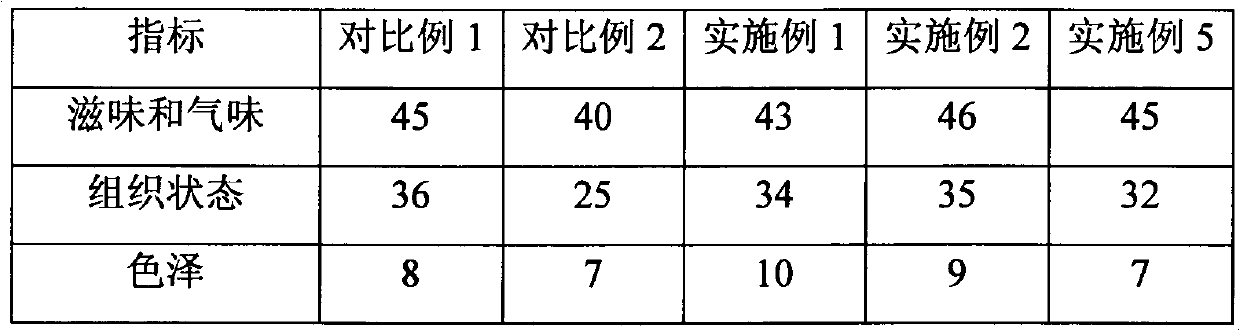

Examples

Embodiment 1

[0043] Concentrate raw milk in a single-effect falling-film evaporator (CNJM01-600) at 40°C in vacuum to 6.5% protein (mass percentage), mix it with 3wt% cream, and stir evenly. Two-stage homogenization, the homogenization pressure is 15MPa, and the temperature range is 65°C-75°C, followed by heat treatment at 95°C for 5 minutes, and cooling to 32°C to obtain treated milk.

[0044] In the fermenter, to the MA014 starter (Danisco company, bacterial classification is Lactococcus lactis subsp.lactis and Lactococcus lactis subsp.cremoris) that inserts processing milk 0.002wt%, stirring The speed is 300rpm / min, stirring for 6min, stopping for 10min, stirring and stopping alternately, after fermentation at 32°C for 120min, pumping to the filling equipment; calf rennet with an amount of 0.0005wt% is prepared with deionized water 2wt% aqueous solution, and keep it warm at 26°C for 20 minutes, then put it into the flavor tank of the filling equipment, and at the same time of filling, a...

Embodiment 2

[0046] The fresh milk was vacuum-concentrated in a double-effect falling-film evaporator (CNJM02-700) at 50° C. to protein 8.0% (mass percentage). Two-stage homogenization, the homogenization pressure is 18MPa, the temperature range is 65°C-75°C, and then heat treatment is carried out at 90°C for 10 minutes, and cooled to 32°C to obtain treated milk.

[0047] In the fermentor, add the R704 starter (Kerhansen company, bacterial classification is Lactococcus lactis subsp.lactis and Lactococcus lactis subsp.cremoris) that handles milk 0.003wt% in the fermentor, Stirring speed is 400rpm / min, stirring for 5min, stopping for 6min, stirring and stopping alternately, after fermentation at 32°C for 90min, pumped to filling equipment; calf rennet with an amount of 0.001wt% is prepared with deionized water into a 1wt% aqueous solution, and keep it warm at 28°C for 15 minutes, then put it into the essence tank of the filling equipment. At the same time of filling, add the rennet aqueous s...

Embodiment 3

[0049] Concentrate raw milk in a single-effect falling-film evaporator at 40°C in vacuum to 6.0% protein (mass percentage), mix it with 5wt% cream, and stir evenly. Two-stage homogenization, the homogenization pressure is 18MPa, and the temperature range is 65°C-75°C, followed by heat treatment at 95°C for 5 minutes, and cooling to 34°C to obtain treated milk.

[0050] In the fermenter, to insert the LL-50 starter (DSM company, bacterial classification is Lactococcus lactis subsp.lactis and Lactococcus lactis subsp.cremoris) of processing milk 0.002wt% to insert, Stirring speed is 600rpm / min, stirring for 2min, stopping for 5min, stirring and stopping alternately, after fermentation at 34°C for 100min, pumped to the filling equipment; calf rennet with an amount of 0.0008wt% is prepared with deionized water into a 1wt% aqueous solution, and keep it warm at 25°C for 20 minutes, then put it into the essence tank of the filling equipment. At the same time of filling, add the renne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com