Rubber-asphalt concrete and preparation method thereof

A rubber asphalt and concrete technology, applied in the field of building materials, can solve the problems of poor high temperature stability, easy cracking, poor fatigue resistance stability, etc., and achieve high skid resistance, enhanced pavement elasticity, high temperature stability and good water stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

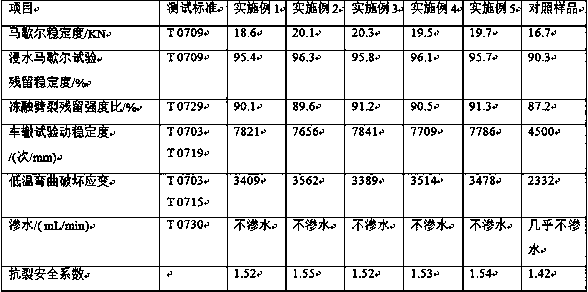

Examples

Embodiment 1

[0030] Preparation of regenerated waste rubber: Place 100 parts of waste rubber powder in a multi-mode resonant cavity microwave field, and process the waste rubber. Place the waste rubber powder in the grinder, add 12 parts of triphenylphosphine and 13 parts of di-n-butyl sodium phosphite for grinding, set the speed of the grinder to 360r / min, and the grinding time to 28min, and it will be regenerated after grinding waste rubber powder;

[0031] Graft modification of regenerated waste rubber powder: Add regenerated waste rubber powder into the reaction kettle, add 80 parts of tetrahydrofuran, and then raise the temperature to 74°C to fully dissolve the regenerated waste rubber powder in tetrahydrofuran, and then add polyethylene glycol function 58 parts of ionic liquid, 65 parts of hyperbranched polyamide, 21 parts of initiator, fully stirred and reacted for 24 hours, poured out the product after the reaction, added acetone for precipitation and separation, then washed the prec...

Embodiment 2

[0035] Preparation of regenerated waste rubber: 120 parts of waste rubber powder were placed in a multi-mode resonant cavity microwave field, and the waste rubber was processed. Place the waste rubber powder in the grinder, add 10 parts of triphenylphosphine and 12 parts of di-n-butyl sodium phosphite for grinding, set the speed of the grinder to 370r / min, and the grinding time to 20min, and it will be regenerated after grinding waste rubber powder;

[0036] Graft modification of regenerated waste rubber powder: Add regenerated waste rubber powder into the reaction kettle, add 60 parts of tetrahydrofuran, and then raise the temperature to 70°C to fully dissolve the regenerated waste rubber powder in tetrahydrofuran, and then add polyethylene glycol function 50 parts of ionic liquid, 60 parts of hyperbranched polyamide, 20 parts of initiator, fully stirred and reacted for 22 hours, poured out the product after the reaction, added acetone for precipitation and separation, then w...

Embodiment 3

[0040] Preparation of regenerated waste rubber: 105 parts of waste rubber powder were placed in a multi-mode resonant cavity microwave field, and the waste rubber was processed. Place the waste rubber powder in the grinder, add 13 parts of triphenylphosphine and 15 parts of di-n-butyl sodium phosphite for grinding, set the speed of the grinder to 400r / min, and the grinding time to 25min. After grinding, it will be regenerated waste rubber powder;

[0041] Graft modification of regenerated waste rubber powder: Add regenerated waste rubber powder into the reaction kettle, add 75 parts of tetrahydrofuran, and then raise the temperature to 71°C to fully dissolve the regenerated waste rubber powder in tetrahydrofuran, and then add polyethylene glycol function 52 parts of ionic liquid, 70 parts of hyperbranched polyamide, 25 parts of initiator, fully stirred and reacted for 20 hours, poured out the product after the reaction, added acetone for precipitation and separation, then wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com