Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

A manufacturing method and a technology for ceramic tiles, applied in the field of ceramic tiles, can solve the problems of inconspicuous three-dimensional effect on the surface of finished ceramic tiles, inconspicuous three-dimensional effect on the surface of ceramic tiles, shortening the service life of production equipment, etc. The effect of focusing, low glaze gloss and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

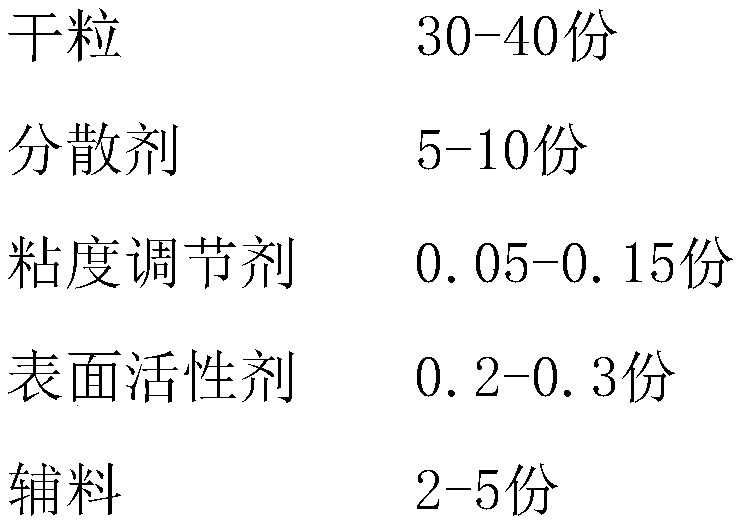

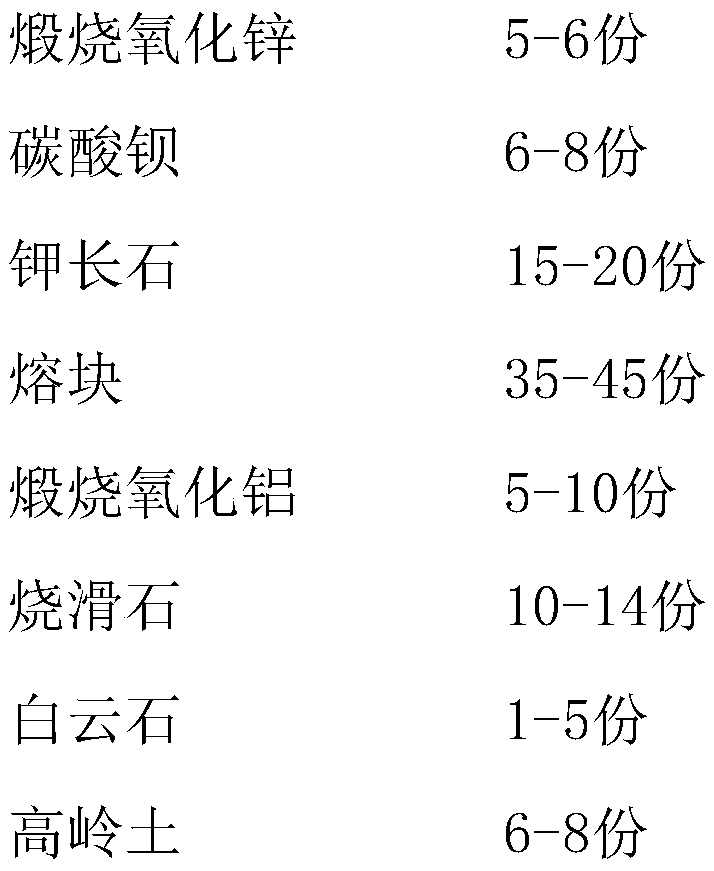

Method used

Image

Examples

Embodiment 1

[0062] A kind of manufacture method of ink-jet dry particle decorative ceramic tile, comprises the steps:

[0063] A. Bottom glaze decoration: Carry out bottom glaze decoration on the surface of the green body;

[0064] B, pattern decoration: control the temperature of the green body after the bottom glaze decoration in step A at 40°C, and then carry out pattern decoration on the bottom glaze surface of the green body;

[0065] C. Drying for the first time: drying the green body after the pattern decoration in step B for the first time;

[0066] D, dry particle decoration: spray dry particle ink on the body surface after the first drying in step C, carry out dry particle decoration, and then carry out second drying;

[0067] E, spray protective glaze: spray protective glaze on the body surface after step D is dried for the second time;

[0068] F. Firing: firing the body after spraying the protective glaze in step E to obtain a dry grain decorative ceramic tile with a three-...

Embodiment 2

[0085] A kind of manufacture method of ink-jet dry particle decorative ceramic tile, comprises the steps:

[0086] A. Bottom glaze decoration: Carry out bottom glaze decoration on the surface of the green body;

[0087] B. Pattern decoration: control the temperature of the green body after the bottom glaze decoration in step A at 45°C, and then carry out pattern decoration on the bottom glaze surface of the green body;

[0088] C. Drying for the first time: drying the green body after the pattern decoration in step B for the first time;

[0089] D, dry particle decoration: spray dry particle ink on the body surface after the first drying in step C, carry out dry particle decoration, and then carry out second drying;

[0090] E, spray protective glaze: spray protective glaze on the body surface after step D is dried for the second time;

[0091] F. Firing: firing the body after spraying the protective glaze in step E to obtain a dry grain decorative ceramic tile with a three-...

Embodiment 3

[0107] A kind of manufacture method of ink-jet dry particle decorative ceramic tile, comprises the steps:

[0108] A. Bottom glaze decoration: Carry out bottom glaze decoration on the surface of the green body;

[0109] B. Pattern decoration: control the temperature of the green body after the bottom glaze decoration in step A to 50°C, and then carry out pattern decoration on the bottom glaze surface of the green body;

[0110] C. Drying for the first time: drying the green body after the pattern decoration in step B for the first time;

[0111] D, dry particle decoration: spray dry particle ink on the body surface after the first drying in step C, carry out dry particle decoration, and then carry out second drying;

[0112] E, spray protective glaze: spray protective glaze on the body surface after step D is dried for the second time;

[0113] F. Firing: firing the body after spraying the protective glaze in step E to obtain a dry grain decorative ceramic tile with a three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com