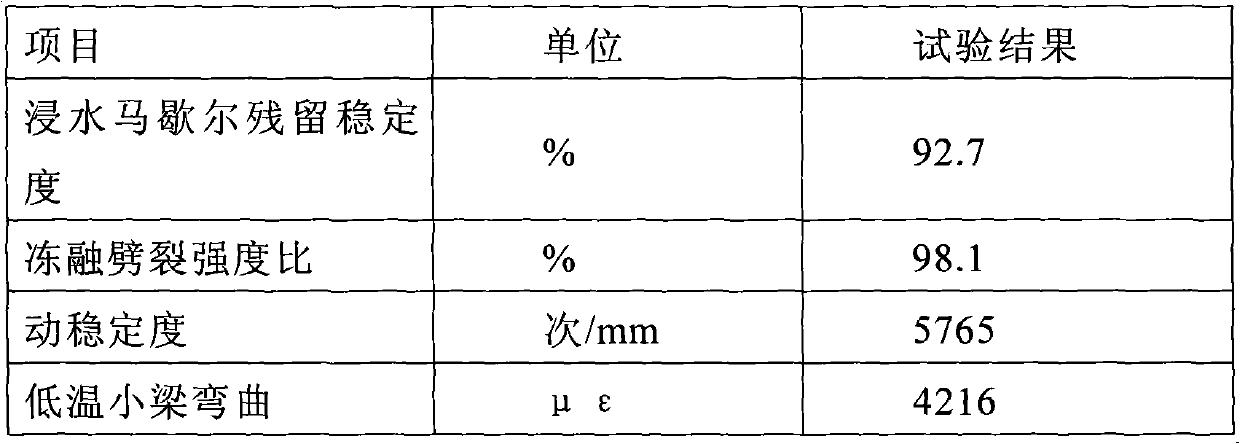

Patents

Literature

769 results about "Rubberized asphalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubberized asphalt concrete (RAC), also known as asphalt rubber or just rubberized asphalt, is noise reducing pavement material that consists of regular asphalt concrete mixed with crumb rubber made from recycled tires. Asphalt rubber is the largest single market for ground rubber in the United States, consuming an estimated 220,000,000 pounds (100,000,000 kg), or approximately 12 million tires annually.

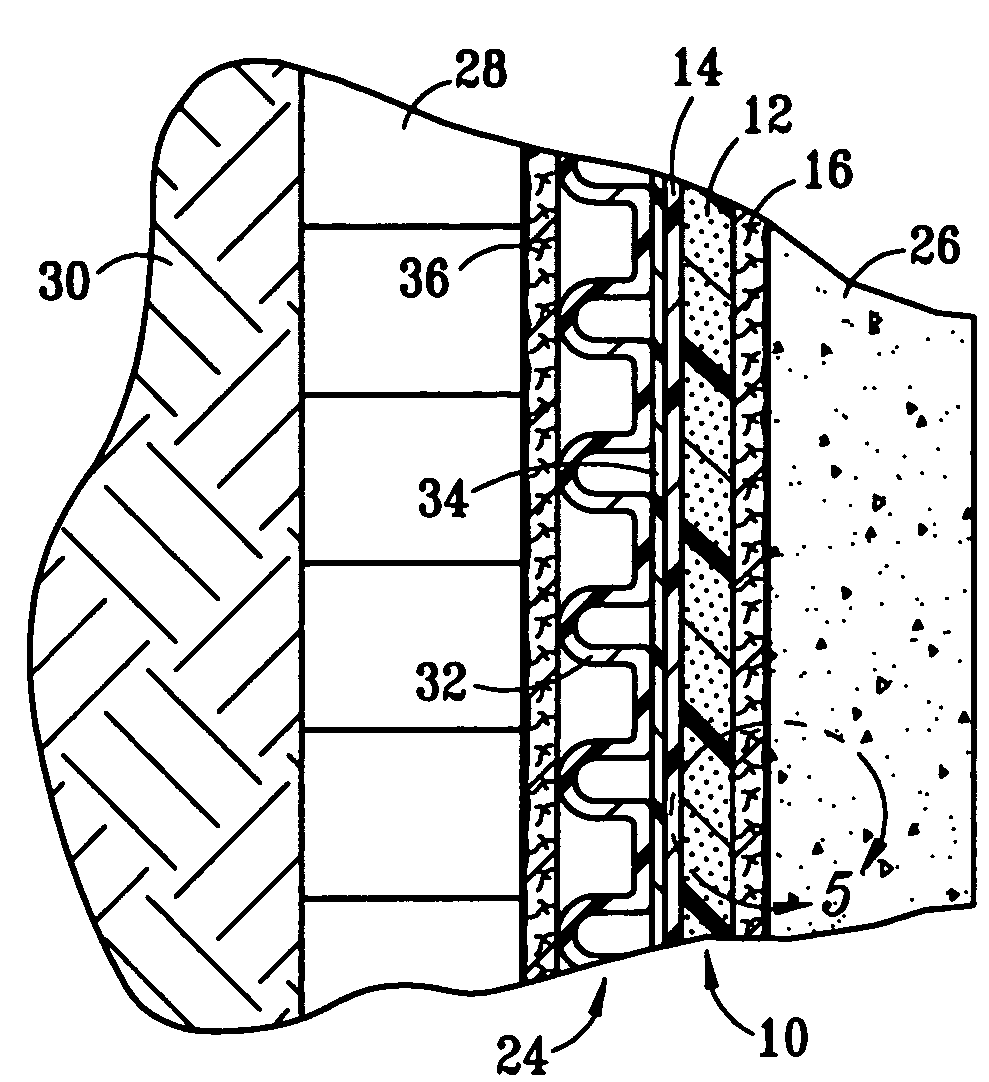

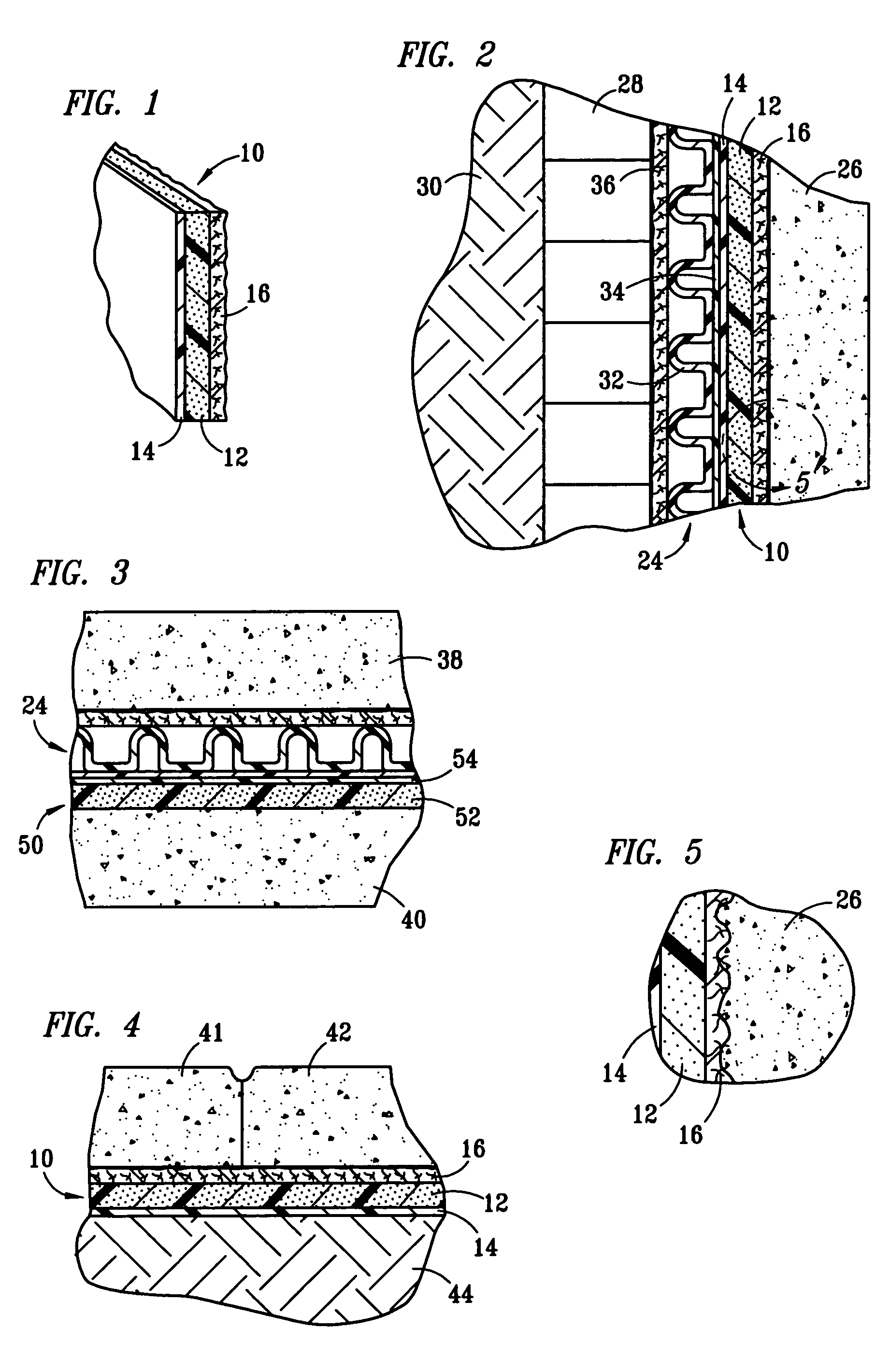

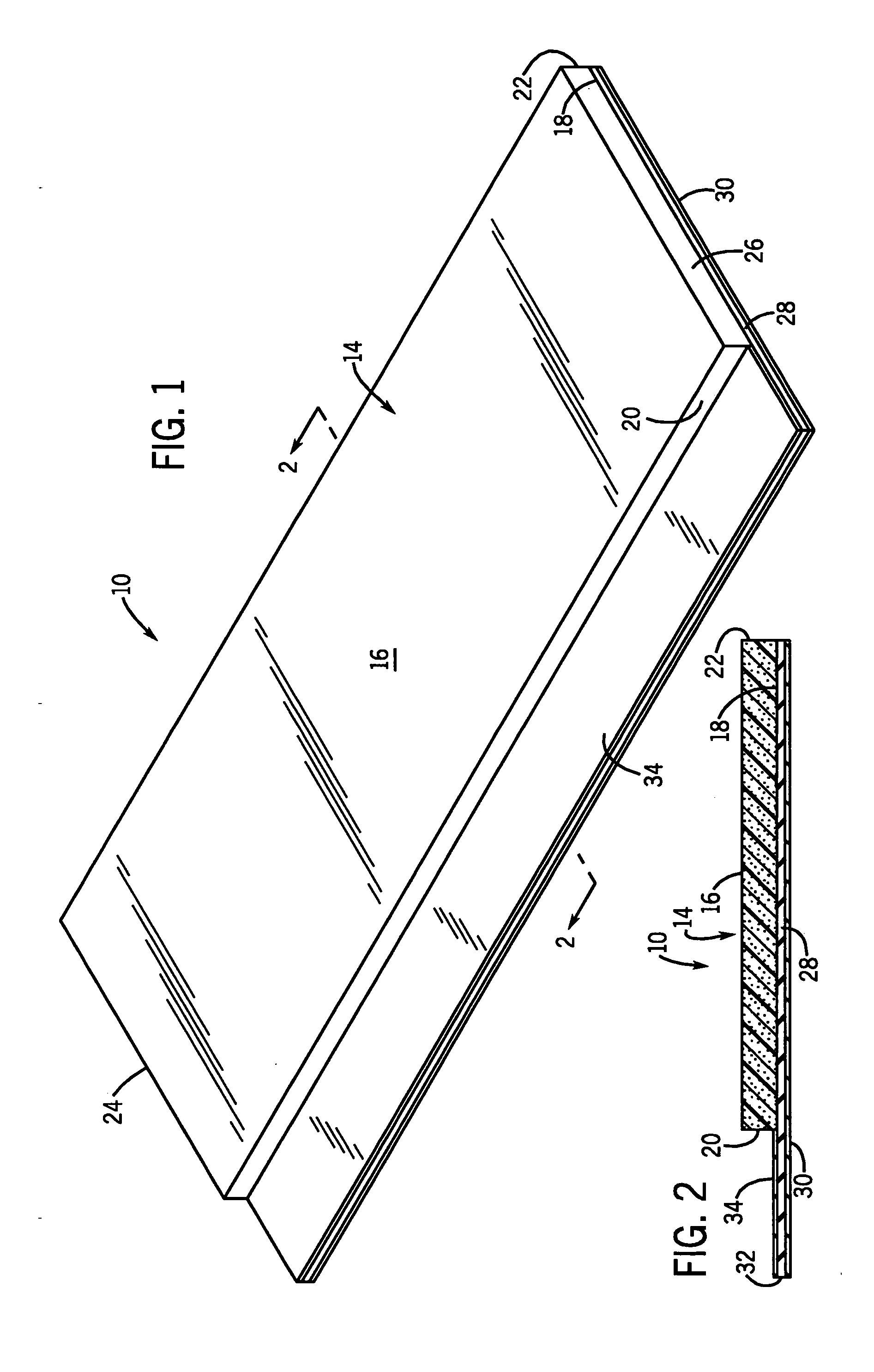

Stress-relieving barrier membrane for concrete slabs and foundation walls

ActiveUS7488523B1Relieve pressureReduce crack formationPaving reinforcementsIn situ pavingsStress relievingToxic material

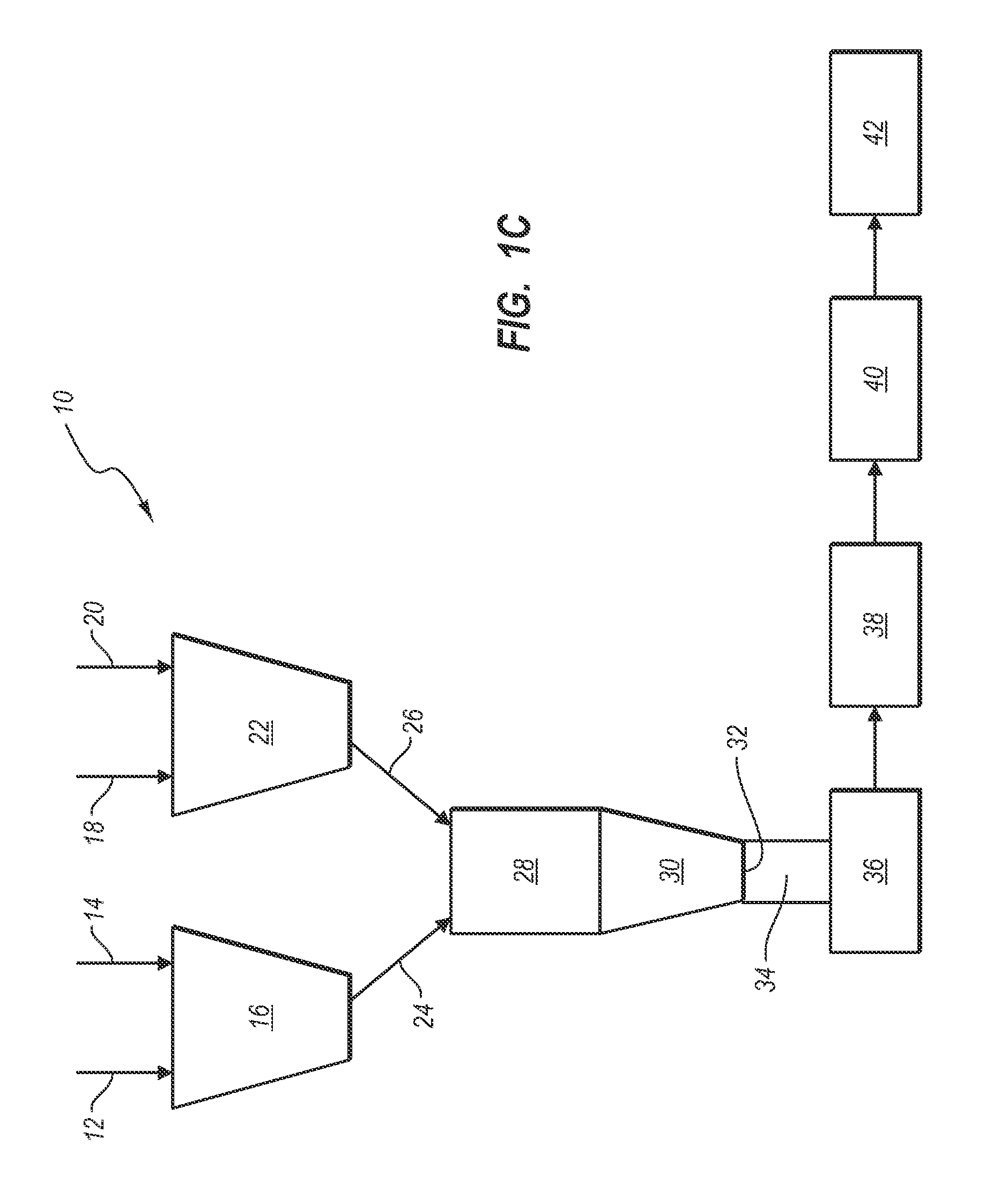

A composite membrane comprising a layer of rubberized asphalt having a heavy duty plastic film layer continuously bonded to one side and, optionally, a layer of nonwoven geotextile continuously bonded to the other side. The membrane can be used in vertical or horizontal applications, and is particularly useful for its stress-relief properties that resist crack formation and propagation in concrete walls and slabs in addition to serving as a barrier to moisture, toxic substances and insects. An appropriate composite membrane of the invention can be advantageously utilized in positive side, blindside, underslab or split slab applications. The thickness of the composite membrane preferably ranges from about 30 mils to about 150 mils.

Owner:POLYGUARD PRODS

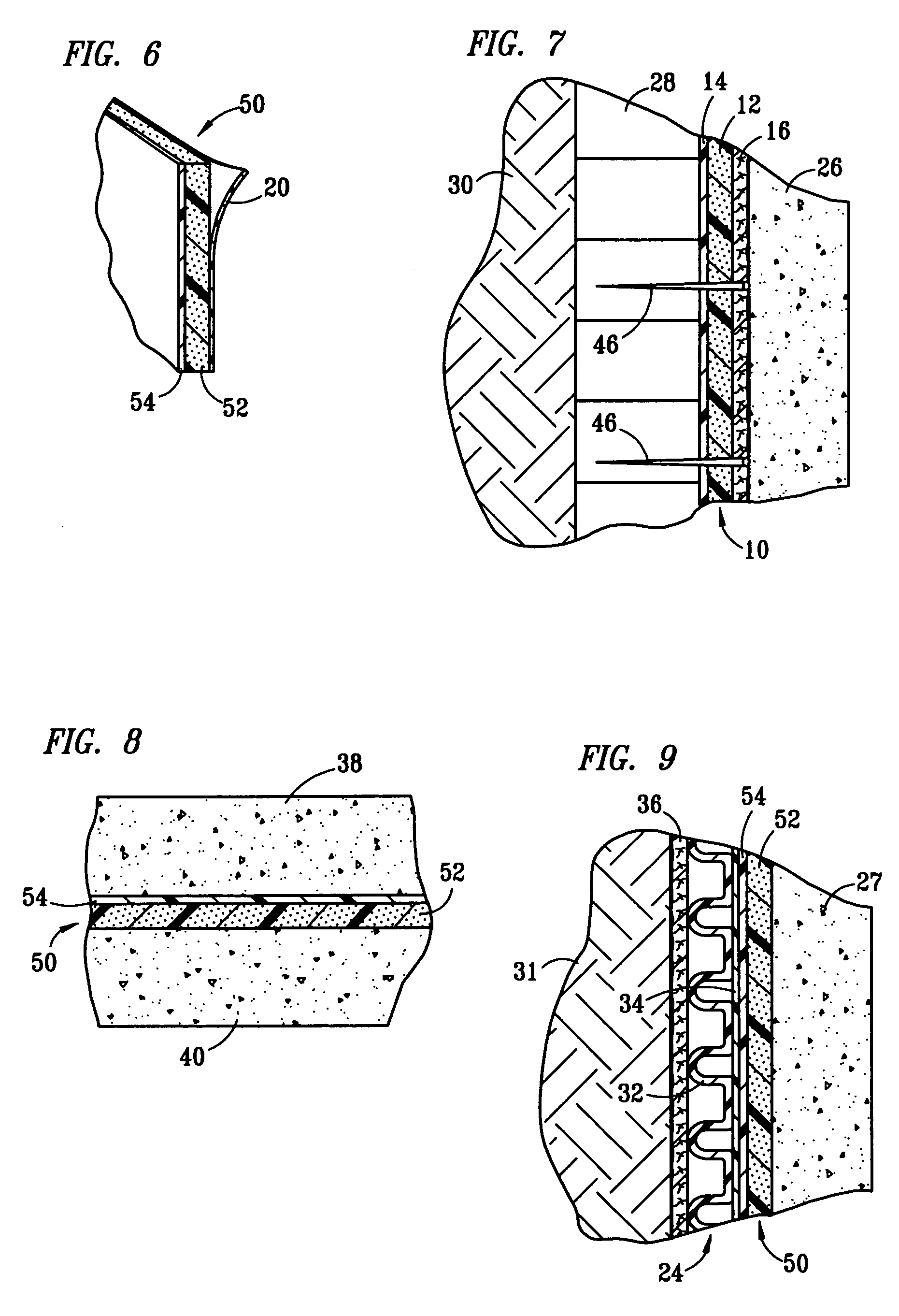

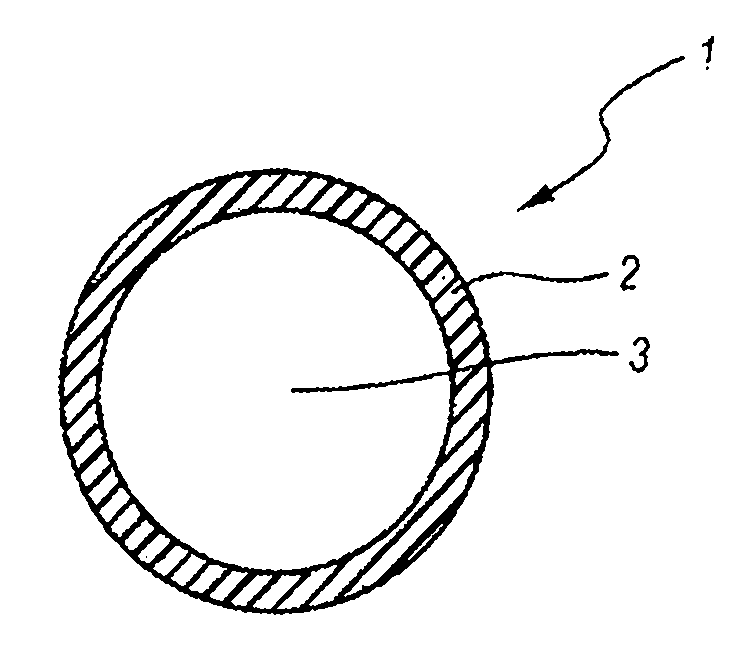

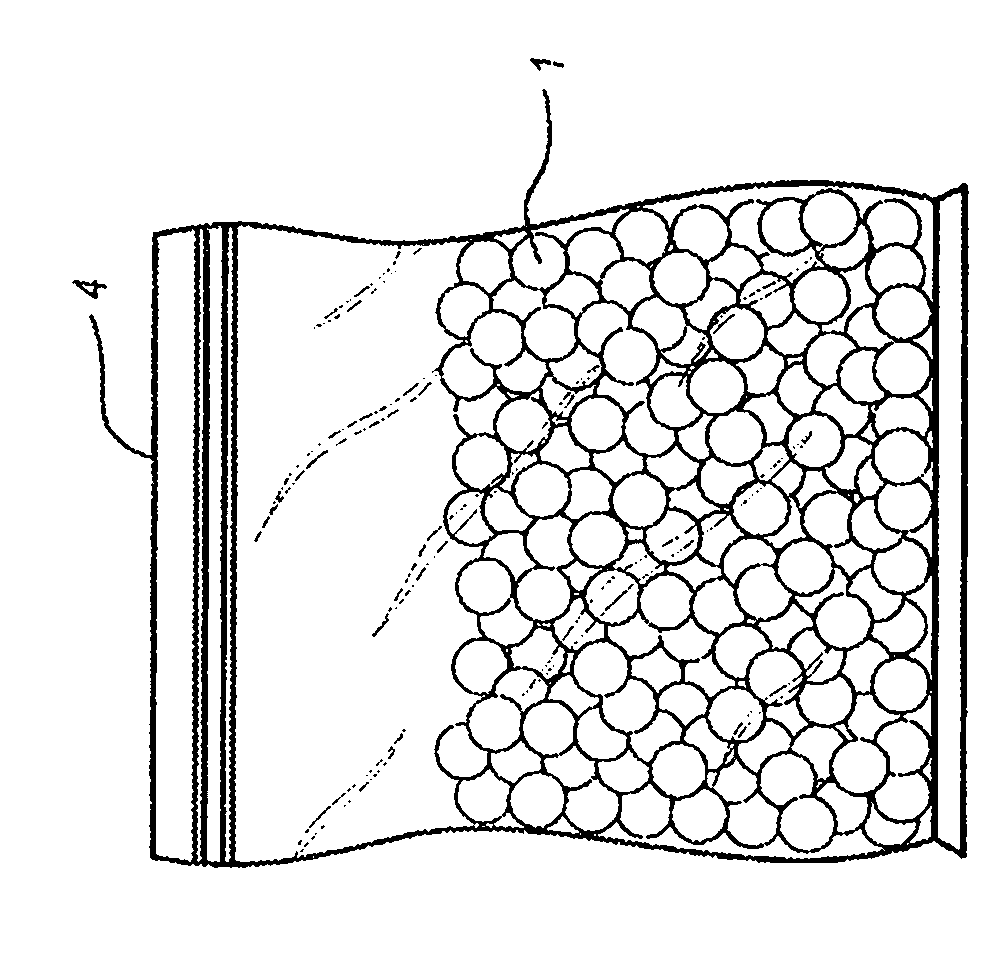

Rubberized asphalt pellets

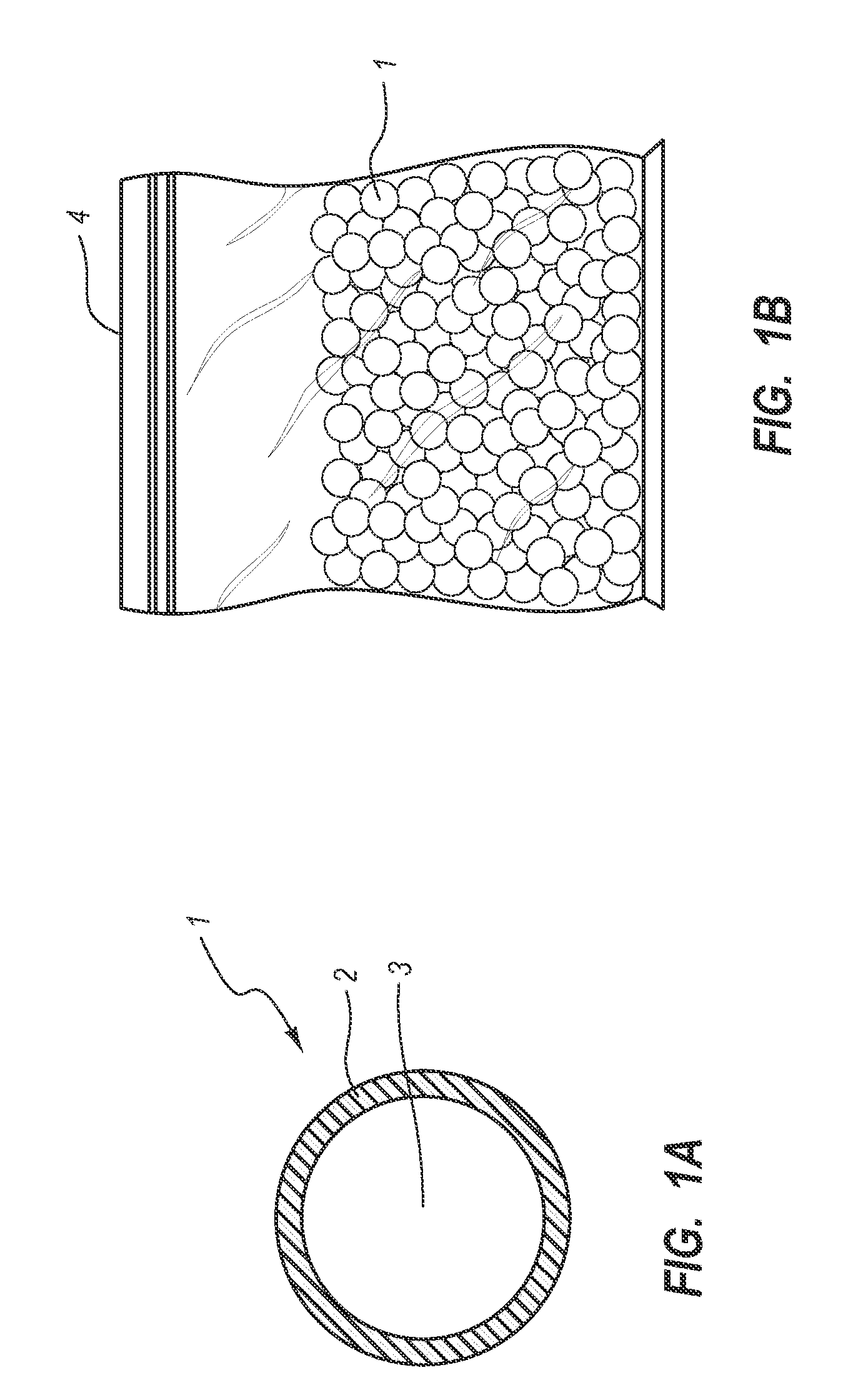

A storage-stable rubberized asphalt paving pellet can include fines in the core. The core can be an asphalt-based binder at about 70% to about 95% by weight of the core. The asphalt-based binder can include: ground tire rubber from about 15% to about 30% by weight of the asphalt-based binder, and pavement grade asphalt from about 85% to about 70% by weight of the asphalt based binder. The core can include fines at about 30% to about 1% by weight of the core. The shell coating the core can provide the pellet with a maximum dimension of about 1 / 16 inch to about 2 inches. The shell can include a water-resistant polymer or wax, or a coating of fines. In one aspect, the fines are lime fines or ground asphalt pavement fines. Optionally, the fines can be mineral or rock fines as described herein.

Owner:BILLIAN I P

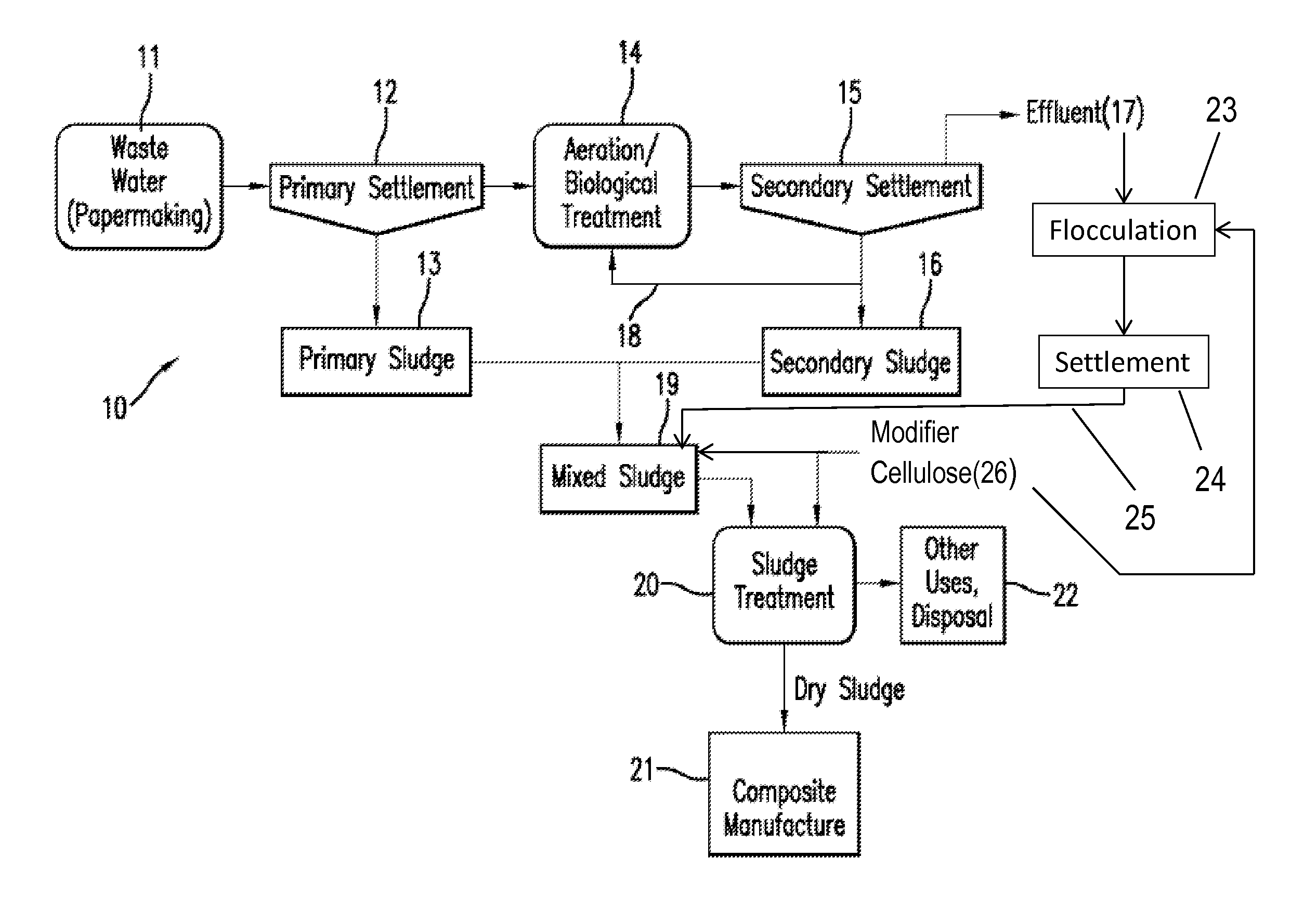

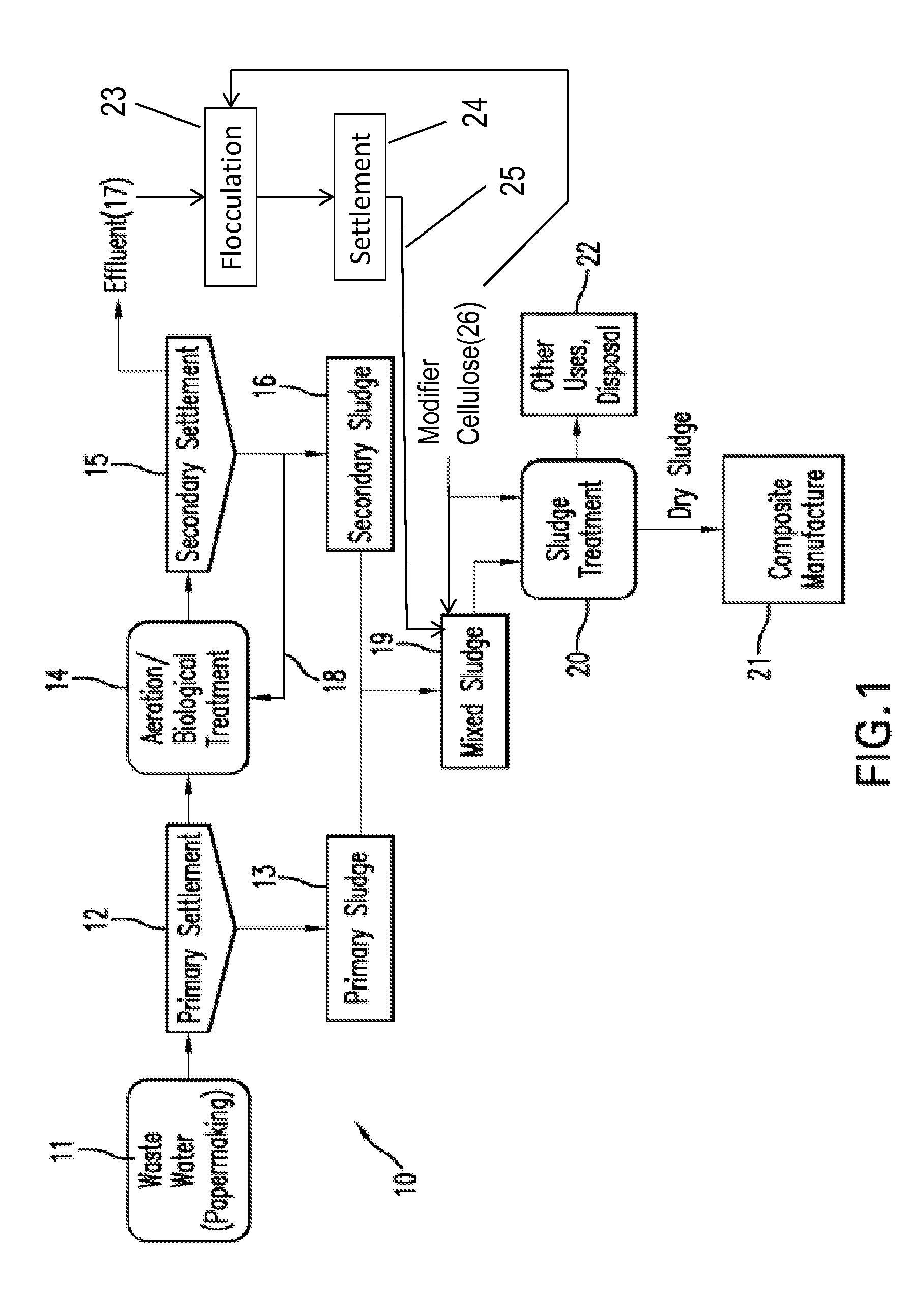

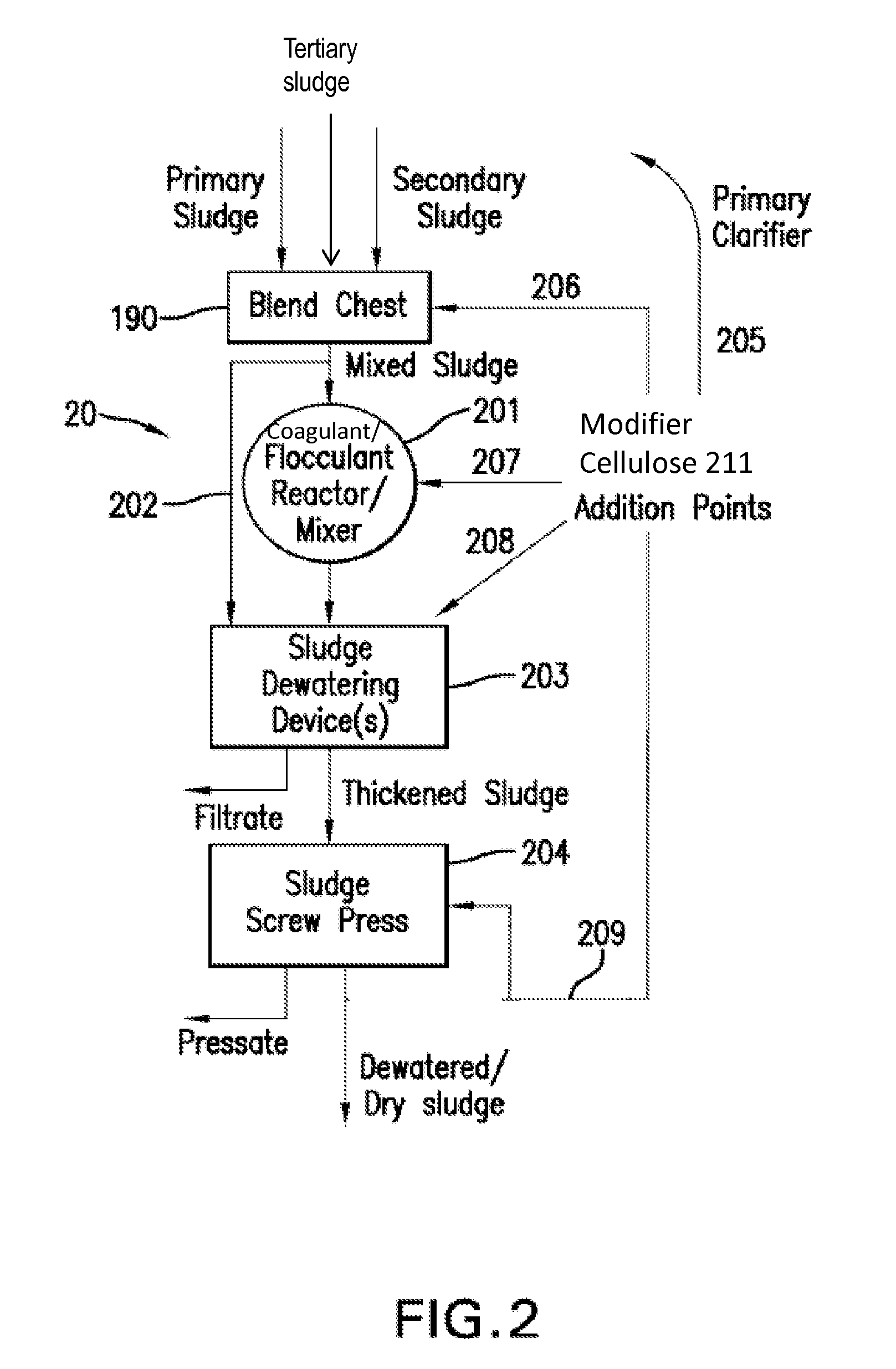

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

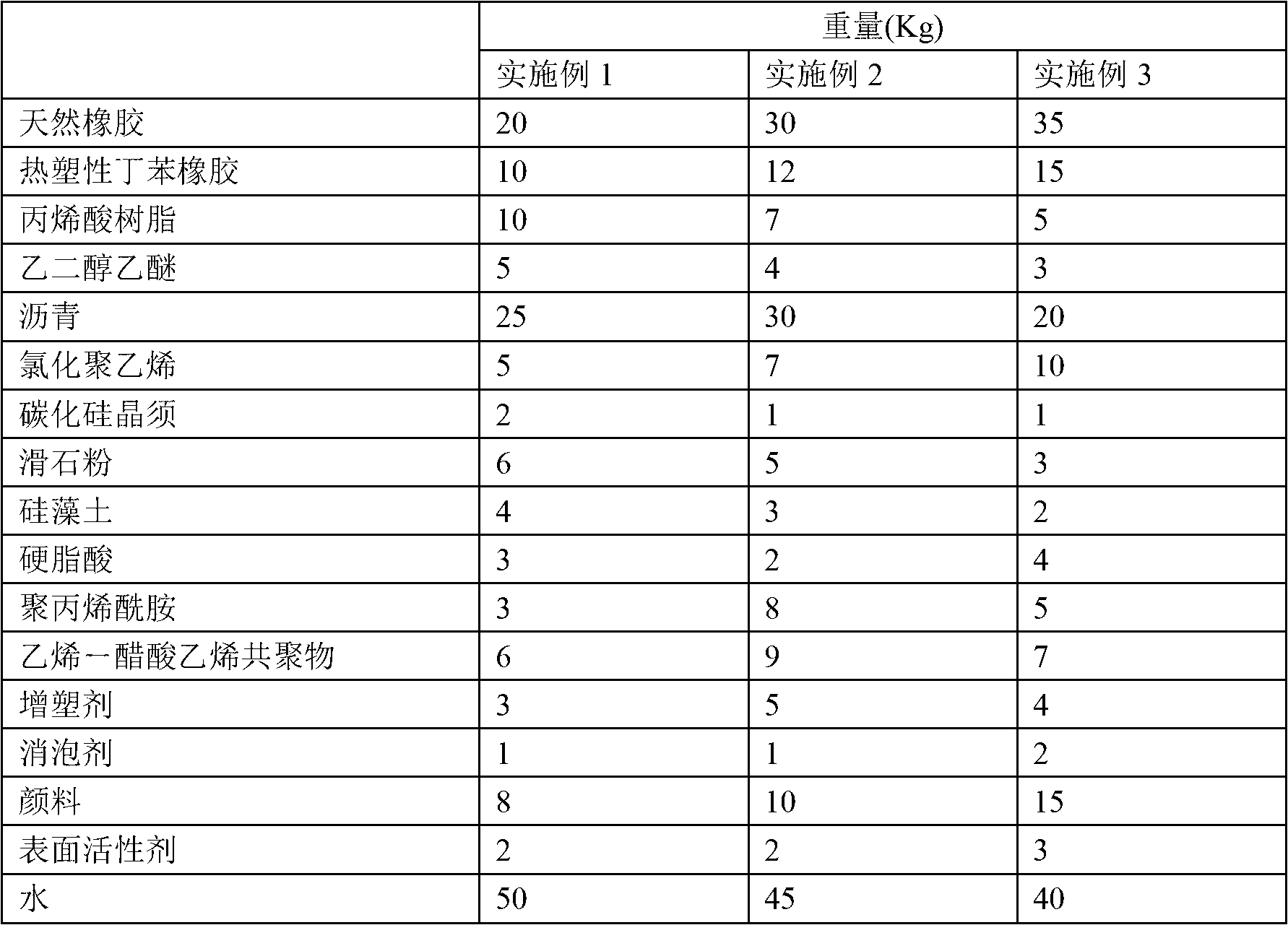

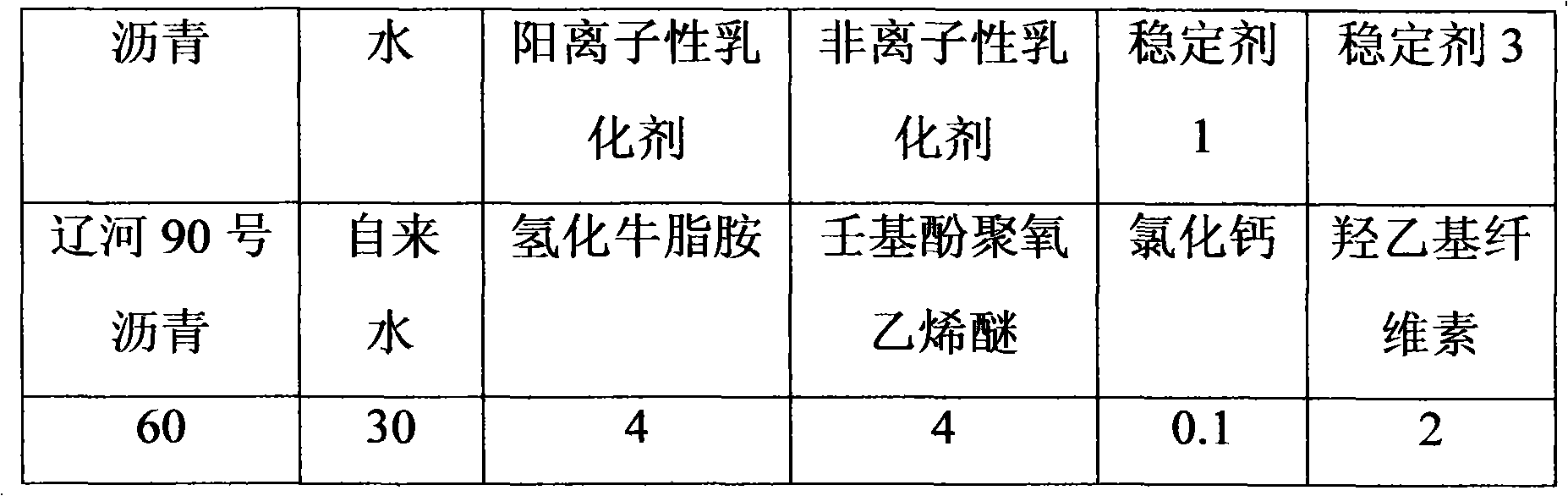

Asphalt rubber waterproof coating material

ActiveCN102936460AUniform procedure is goodNot easy to embrittleConjugated diene hydrocarbon coatingsNatural rubber coatingsAcrylic resinStearic acid

The present invention provides a rubber asphalt waterproof coating material, and belongs to the technical field of coating materials. The coating material is prepared from the following raw materials, by weight, 20-35 parts of a natural rubber, 10-15 parts of a thermoplastic styrene-butadiene rubber, 5-10 parts of acrylic resin, 3-5 parts of ethylene glycol ethyl ether, 20-30 parts of asphalt, 5-10 parts of chlorinated polyethylene, 1-2 parts of silicon carbide crystal whiskers, 3-6 parts of talc powder, 2-4 parts of diatomite , 2-4 parts of stearic acid, 3-8 parts of polyacrylamide, 6-9 parts of an ethylene-vinyl acetate copolymer, 3-5 parts of a plasticizer, 1-2 parts of a defoaming agent, 8-15 parts of a pigment, 2-3 parts of a surfactant, and 40-50 parts of water. The waterproof coating material provided by the embodiments still has good watertightness and good mechanical property after high temperature and high humidity destruction.

Owner:武汉飞盛建设工程有限公司

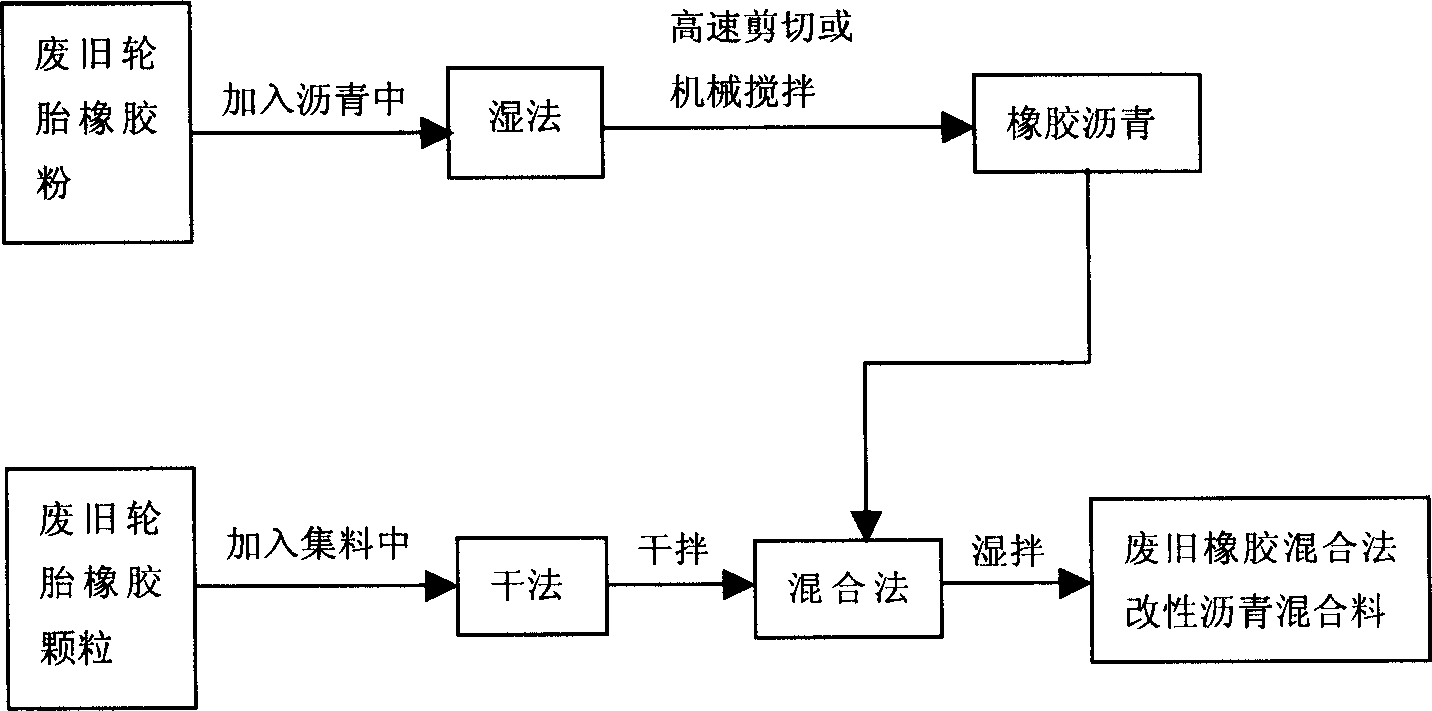

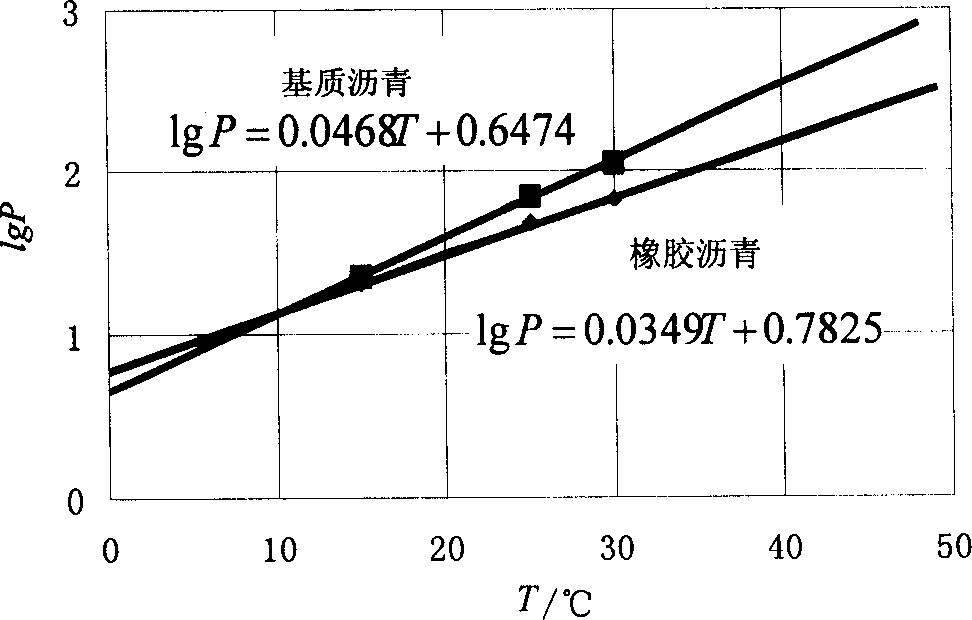

Method for preparing modified asphalt mixture using waste and old tyre and hybrid method

InactiveCN1807514AExtended service lifeReduce pollutionIn situ pavingsBuilding insulationsTraffic noiseEngineering

This invention relates to the field of engineering material technical, and it is specificly related to the method for preparing a kind of modified bituminous mixture with worn tyre. It is made as follows: mill worn tyre to powder, mix the owder with base bitumen and agitate to get rubber bitumen; gap-graded aggregate, screen the aggregates and get coarse, fine aggregates; mix rubber particles with the coarse and fine aggregates, agitate, then add rubber bitumen and agitate, lastly add powdered ore and mix to get needed production. This invention blends dry and wet processes together to exert each advantage sufficiently, and attained both the aims of consumping much worn tyre and improve pavement performance. With this invention, we can greatly improve high and low temperature behavior of bitumen and its mixture, we can longer pavement life and abate environmental pollution. The pavement paved by this mixture has the behavior of lowering traffic noise. Popularization of this achievement is economic, society, environmental and engineering benefit.

Owner:TONGJI UNIV

Non-cured asphalt mastic

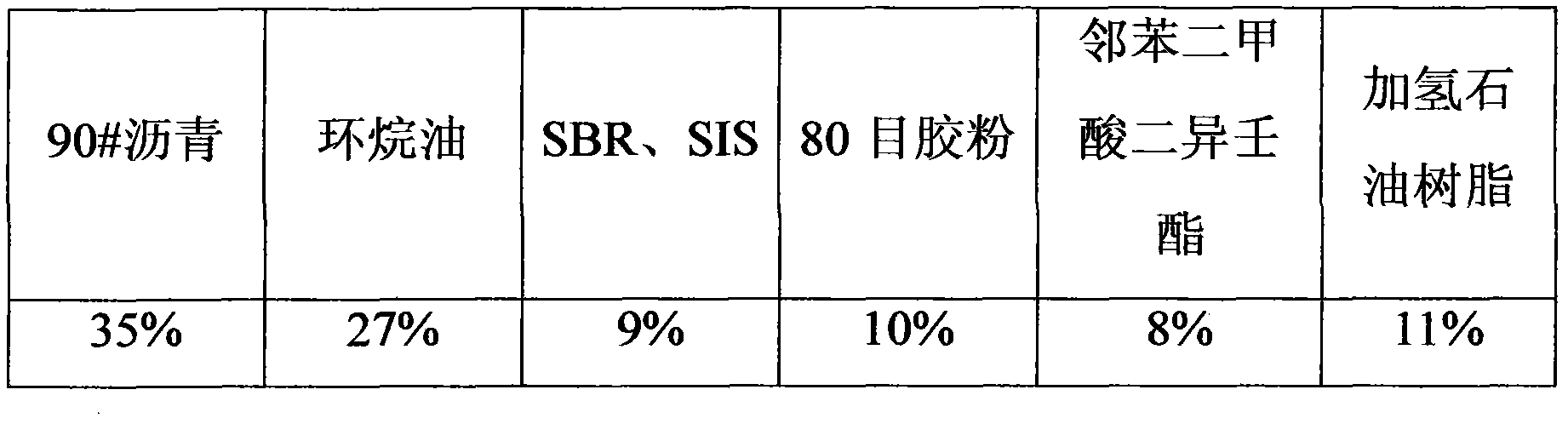

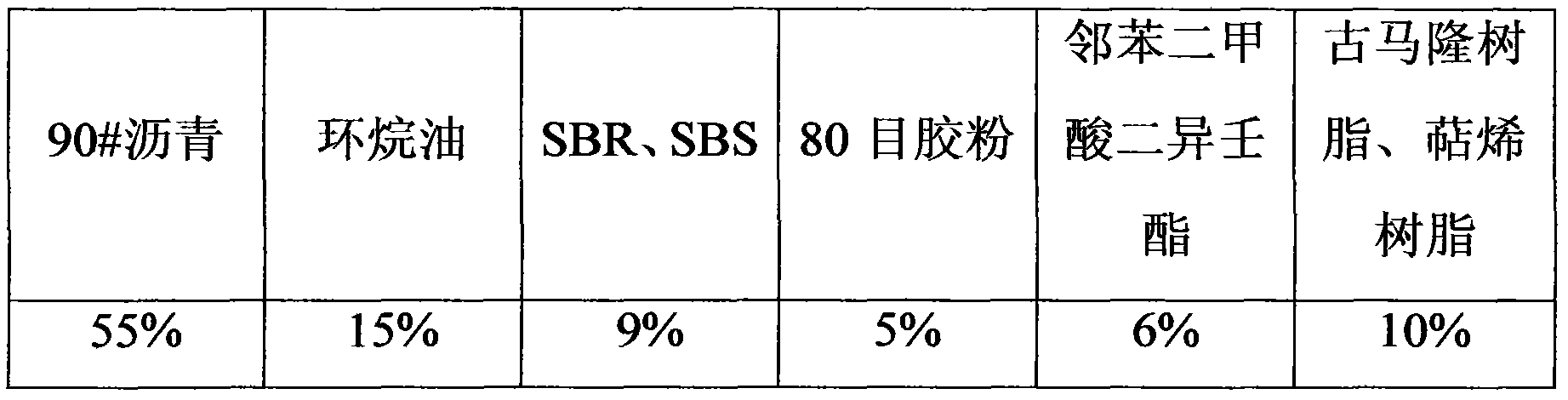

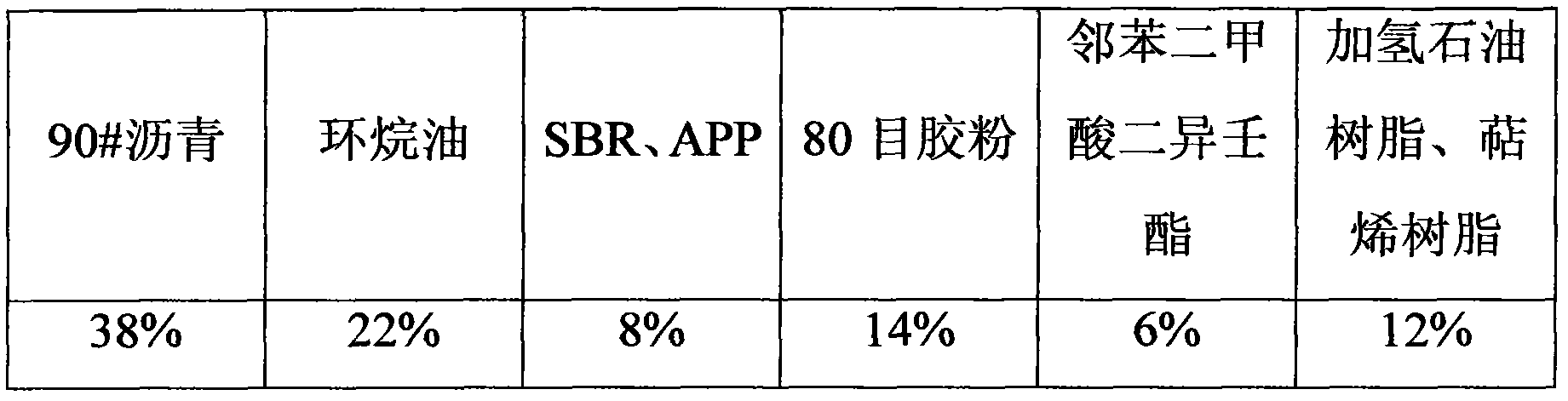

The invention requests to protect non-cured asphalt mastic comprising the following components in percentage by weight: 35-55 asphalt, 15-30 naphthenic oil, 3-10 polymer modifying agent, 55-20 gelatin powder, 3-10 diisononyl phthalate and 10-20 tackifying resin. The non-cured asphalt mastic can be independently used or can be used with the matched coil to form a waterproof system and can effectively solve the problem of water leakage caused by the crack of a waterproof layer due to the deformation of a base layer.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Low-temperature resistant self-adhesive rubber asphalt waterproofing coiled material

ActiveCN101126014AChange the defects that cannot be constructed below 5°CImprove adhesionOther chemical processesRoof covering using flexible materialsBituminous waterproofingPolymer science

The invention provides a rubber bitumen waterproof roll with low temperature resistance and auto-cohesive performance. Modified bitumen layer contains calcium carbonate and more than two kinds of adhesive, which solves the problem that the prior auto-cohesive rubber bitumen waterproof roll can not work under temperature below 5 DEG C, while the invention has good cohesive performance and can work well even under the temperature 10 DEG C under zero, and the stripping intensity is as high as 1.0N / mm.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

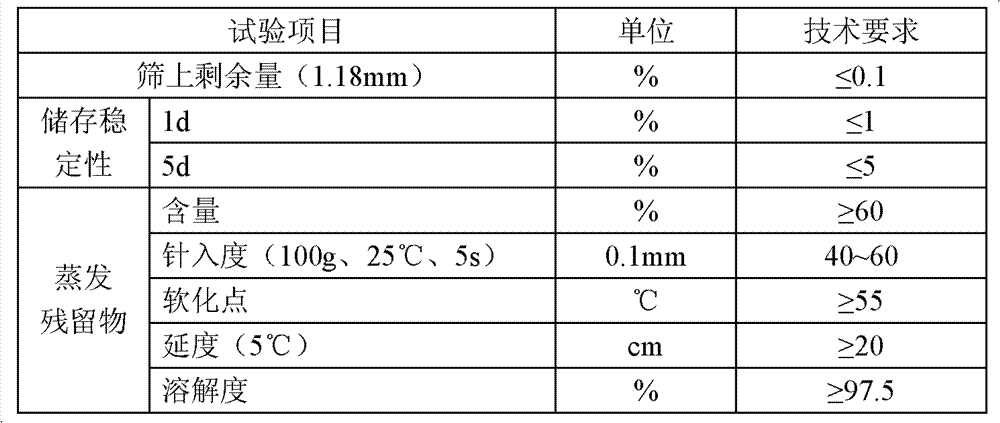

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

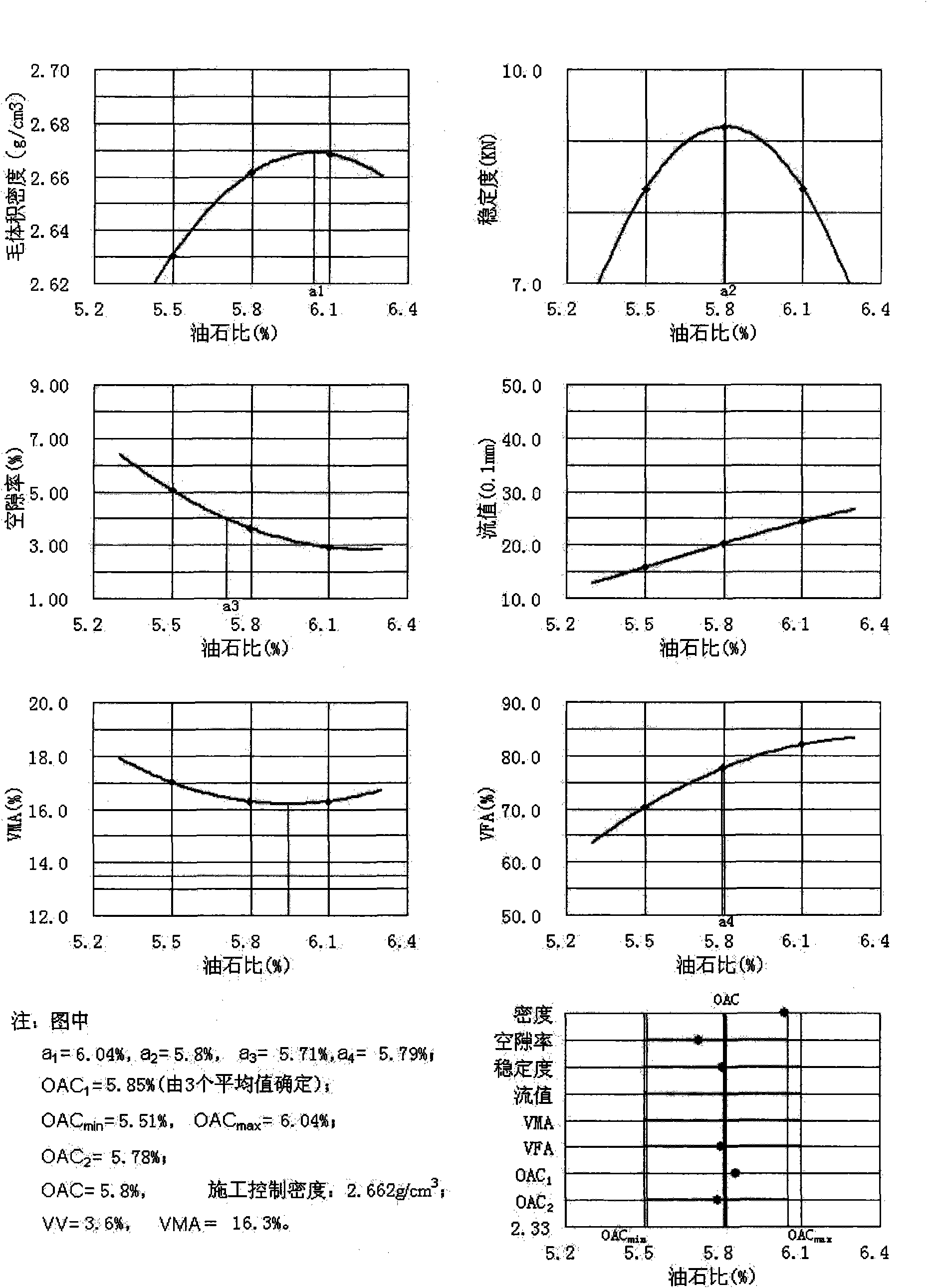

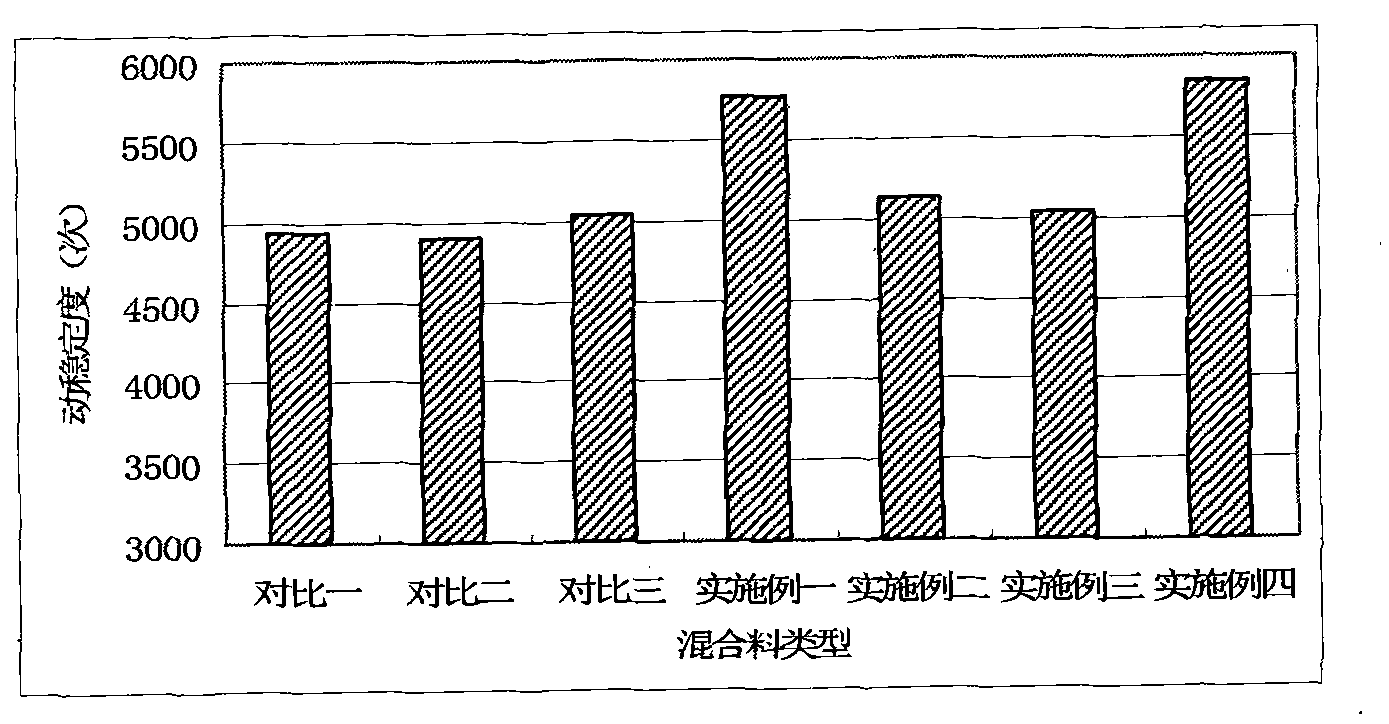

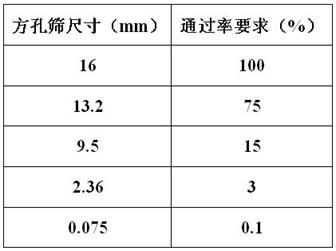

Steel slag and rubber asphalt concrete and preparation method thereof

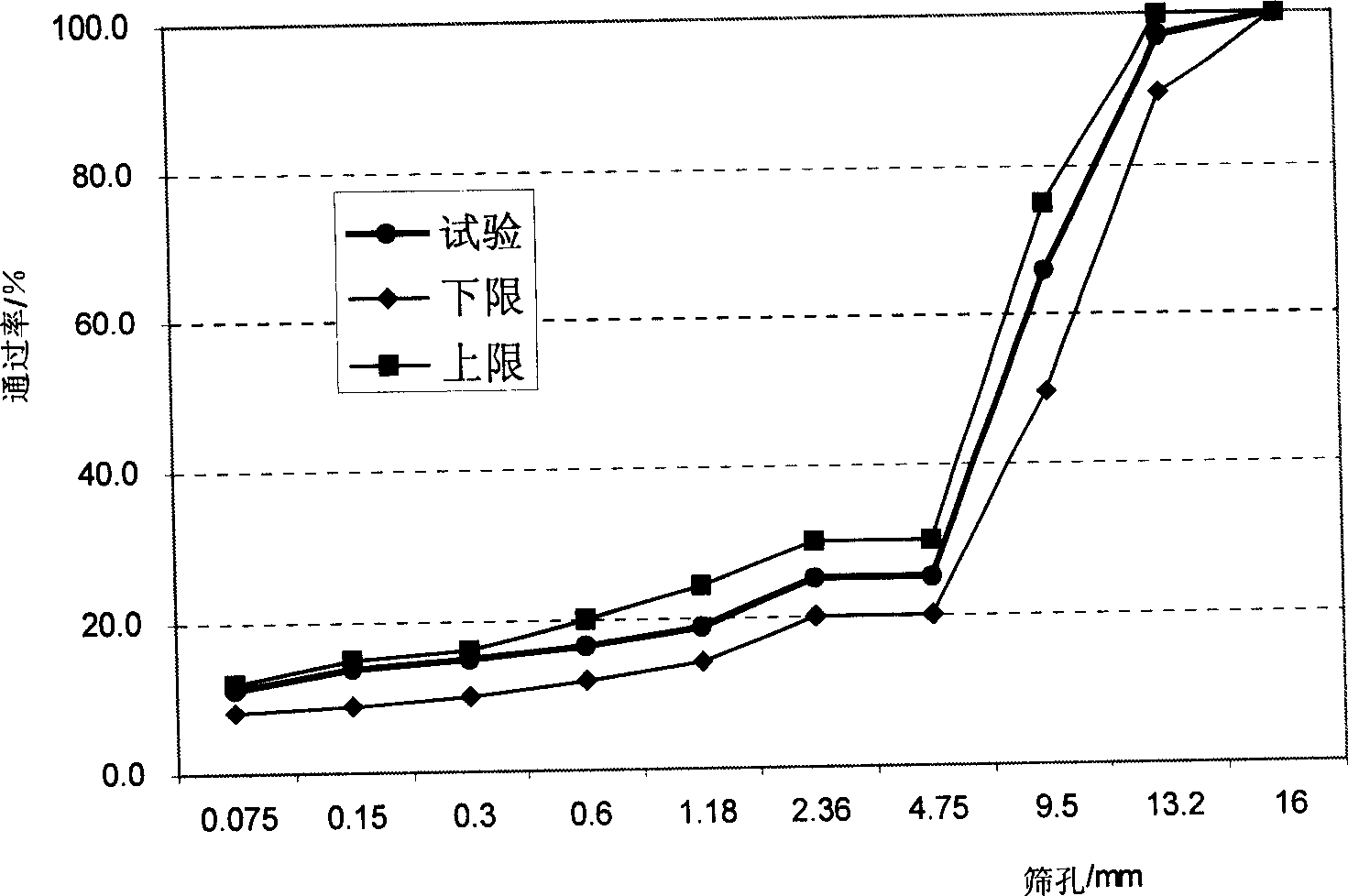

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

Non-curing rubber asphalt waterproof paint

ActiveCN103937407AStir wellHigh solid contentConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceTackifier

The invention relates to a non-curing rubber asphalt waterproof paint. The technical proposal adopted is that: the non-curing rubber asphalt waterproof paint comprises the following raw materials by weight: 45%-60% of asphalt, 10%-25% of rubber, 5%-15% of a dispersing agent, 5%-10% of a tackifier and 5%-20% of filler. The preparation method is as follows: proportionally taking the raw materials, heating the asphalt to 140-160DEG C; adding the dispersing agent and the tackifier to the asphalt, stirring for about 30 minutes; adding the rubber for mixing; adding the filler, mixing evenly, and discharging. The non-curing rubber asphalt waterproof paint does not cure, and is low temperature resistant, does not flow at high temperature, and good in waterproof performance.

Owner:SHENYANG GUOJIAN XINTEC TECH DEV

Rubber modified asphalt mixture and preparation and construction methods thereof

The invention relates to a modified asphalt mixture and preparation and construction methods thereof, particularly relates to rubber modified asphalt and preparation and construction methods thereof and belongs to the technical field of engineering. The rubber modified asphalt and the methods solve the construction problem that the mixture is thick and sticky by adding trans-polyoctenamer rubber (TOR) into the asphalt mixture, further reduce the stirring temperature of the rubber asphalt mixture, reduce processing equipment, improve production process, and are favorable for preventing water damage by a design method of continuous dense gradation. The preparation process of the mixture improves the using performance of the rubber asphalt mixture. The rubber modified asphalt and the methodshave the advantages of promoting the comprehensive utilization of waste tires by paving asphalt pavements with waste rubber powder modified asphalt, reducing great environment stress brought by blackpollution, saving resources, improving the pavement performance of the asphalt mixture, improving the service quality of the pavement, prolonging the service life of the pavement, reducing cost, and improving performance of products. Compared with the conventional modified asphalt production process, the preparation and construction methods have the advantages of energy saving and environmental protection and are convenient for construction.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

High-temperature resistant spray fast-setting rubber asphalt waterproof coating

ActiveCN102965016ANo pollutionExtended service lifeConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceSpray coating

The invention relates to a high-temperature resistant spray fast-setting rubber asphalt waterproof coating which is a high-temperature resistant water-based spray coating prepared proportionally by adding a vulcanizing agent and a composite reinforcing agent into liquid rubber asphalt mastic emulsion prepared from modified emulsified asphalt and high-molecular polymer rubber latex and then mixing with a coagulating agent. The high-temperature resistant spray fast-setting rubber asphalt waterproof coating provided by the invention is a novel spray fast-setting rubber asphalt environment-friendly waterproof material which is nontoxic, tasteless and pollution-free and can be subjected to cold construction at normal temperature; and meanwhile, the high-temperature resistant spray fast-setting rubber asphalt waterproof coating has good heat resistance (160 DEG C), high elongation at break (greater than 1,000%), high elasticity recovery rate (greater than 90%), high bonding strength (greater than 0.5MPa), excellent low temperature resistance (without breakage at -30 DEG C) and excellent ageing resistance, acid / alkali resistance, cohesiveness and shear resistance, and can prevent structural damage caused by water penetration so as to prolong the service life of highway bridges.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Self-hardening rubber asphalt paint

InactiveCN102108257AEliminates prone to low cloud point problemsLow densityConjugated diene hydrocarbon coatingsNatural rubber coatingsEmulsionSpray coating

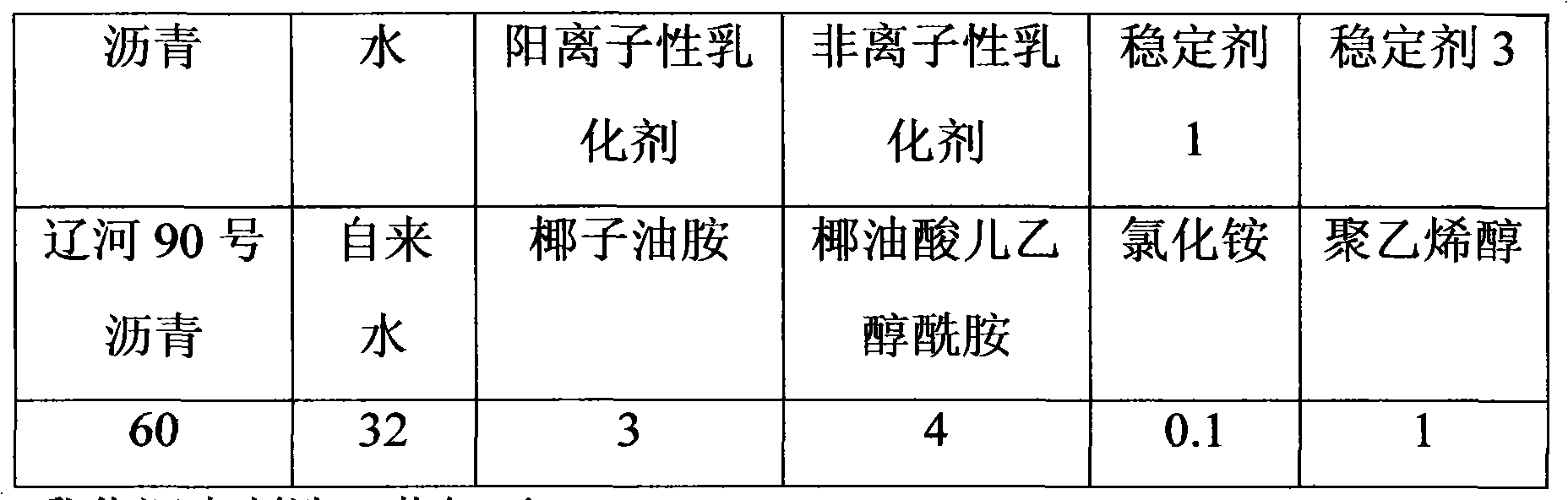

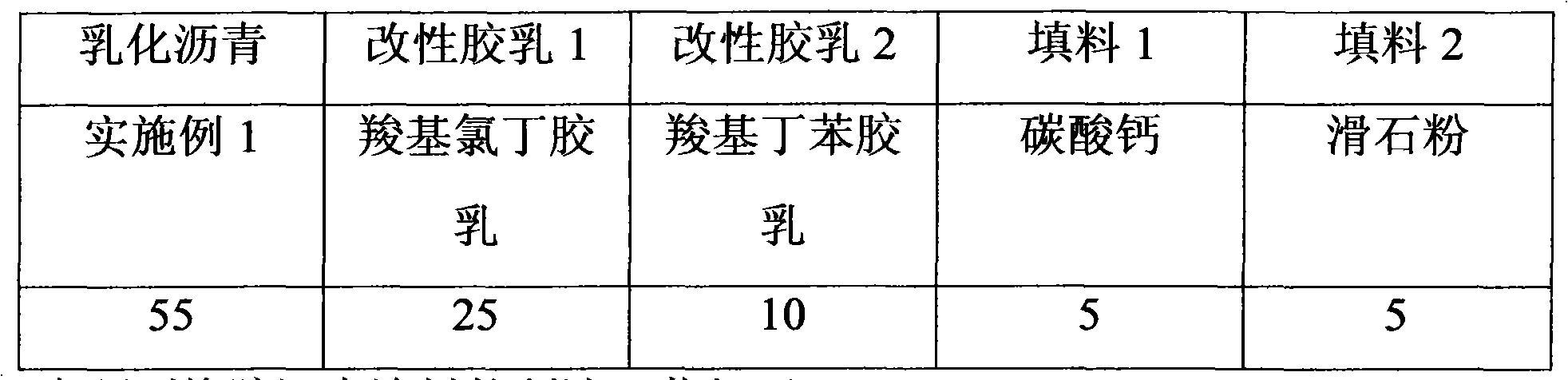

The invention provides self-hardening rubber asphalt paint which comprises the following components by weight percent: 50%-65% of asphalt, 3%-6% of cationic emulsifier, 3%-6% of nonionic emulsifier, 25%-35% of modified latex, 1%-3% of stabilizer and 5%-10% of filler. The invention further provides a preparation method of the self-hardening rubber asphalt paint, the rubber asphalt paint is modified through normal-temperature self-crosslinking emulsion, has the prominent characteristics of normal temperature spray coating, manual scrape-coating, instant shaping, perfect joint, high elastic force, zero joints and the like, and can fundamentally solve the technical difficulty of leakages at side angles, gaps and junction of irregular structures and the like, thereby thoroughly updating the traditional construction process and the method of waterproof material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

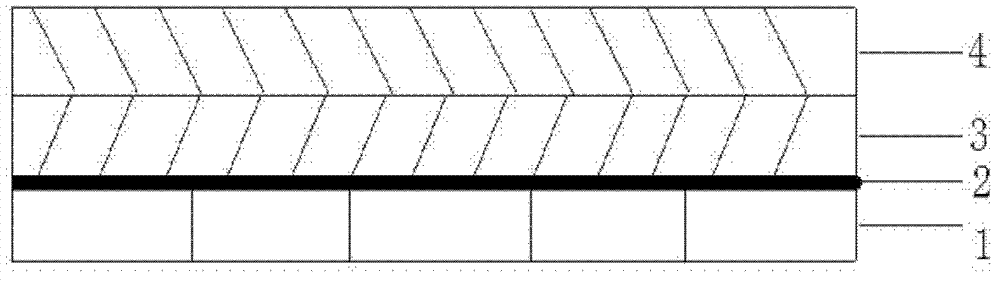

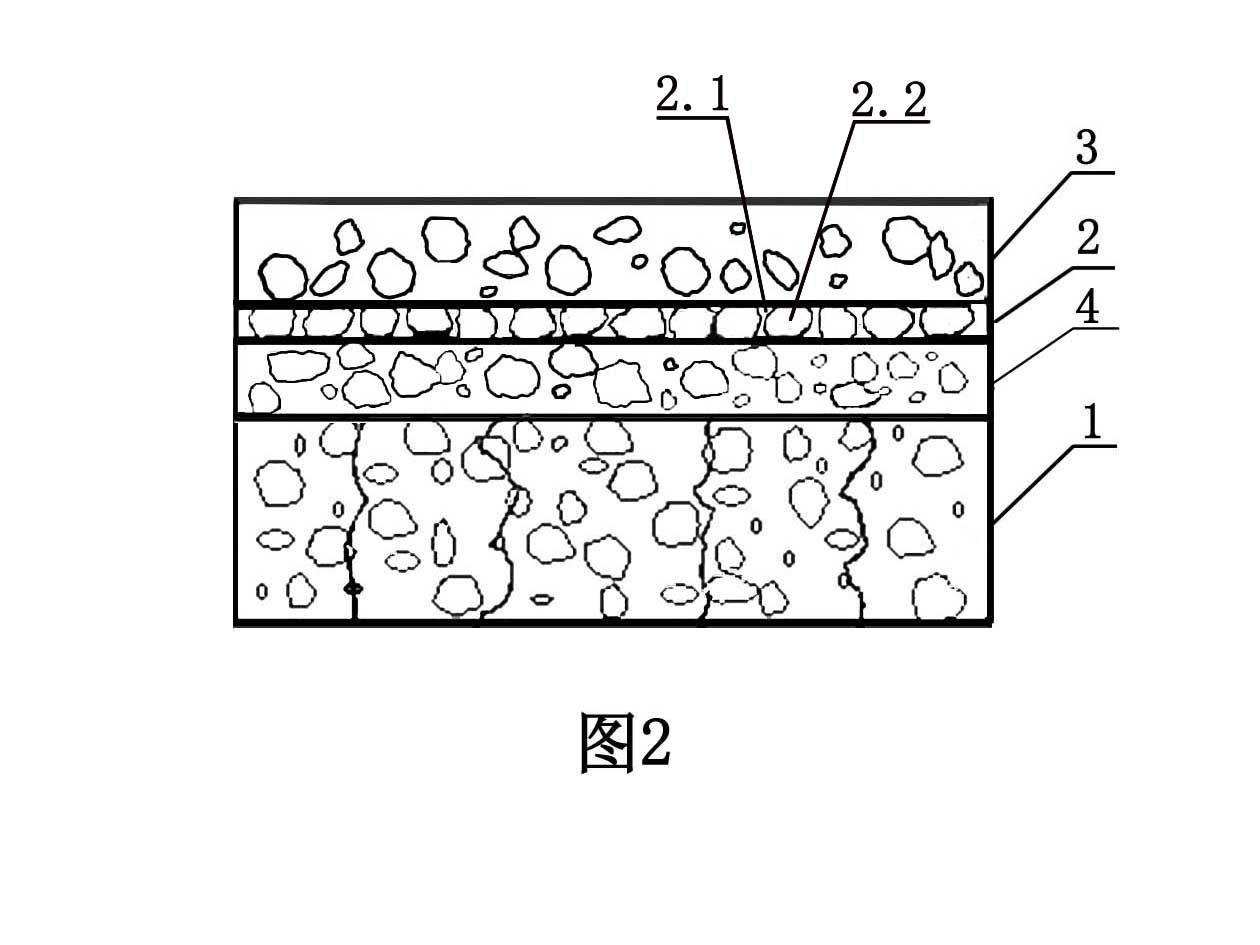

Double-layer rubber asphalt concrete structure for inhibiting reflection cracks of pavement and pavement method

ActiveCN102733284AGuaranteed against ruttingGuaranteed fatigue and other permanent deformation problemsIn situ pavingsCement boardRoad surface

The invention discloses a double-layer rubber asphalt concrete structure for inhibiting reflection cracks of a pavement, from the bottom up comprising a treated old cement concrete pavement, an anti-cracking tack coat, a lower surface adopting a special modified asphalt mixture, and an upper surface adopting a rubber asphalt mixture. The invention simultaneously discloses a pavement method of the double-layer rubber asphalt concrete structure, comprising the following steps: (a) firstly pasting an anti-cracking belt on the junction of adjacent cement boards, and then spraying modified emulsified asphalt tack coat oil with the thickness of 0.8-1.0 mm to form the anti-cracking tack coat; (b) then paving the special modified asphalt mixture with the paving thickness of 4-8 cm to form the lower surface; and (c) finally paving the rubber asphalt mixture to form the upper surface. According to the invention, the generation and extension of the reflection cracks can be effectively inhibited, and the service life and service condition of the pavement structure can be improved.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Hot-distribution rubber bituminous pavement and construction method thereof

InactiveCN101982610AImprove adhesionAvoid enteringIn situ pavingsSolid waste managementInter layerChipseal

The invention discloses hot-distribution rubber bituminous pavement and a construction method thereof. The construction method comprises the following steps: 1, cleaning a lower bearing layer; 2, preparing rubber asphalt; 3, distributing the rubber asphalt, namely, uniformly distributing a rubber asphalt layer on the lower bearing layer, wherein the distribution amount of the rubber asphalt is 2.2 to 2.6 kg / m<2>, and the distribution temperature is 180 to 190 DEG C; 4, distributing broken stone with an amount which is 60 to 70 percent based on the distribution area of the rubber asphalt, wherein the distribution temperature of the broken stone is not lower than 80 DEG C; and 5, rolling and forming, namely, rolling and forming a rubber asphalt waterproof adhesive layer by a rubber-tire pavement roller following a broken stone distribution vehicle, wherein the rubber-wire pavement roller rolls the pavement once to twice back and forth. The construction method of the invention can enhance the inter-layer adhesive performance, prevent water penetration, effectively absorb and eliminate inter-layer stress and reduce reflection cracks caused by the conventional bituminous pavement, and can be applied to the projects of building and rebuilding bituminous pavement, pavement of bituminous concrete bridge floor, bituminous overlaying of cement concrete pavement and the like.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP +2

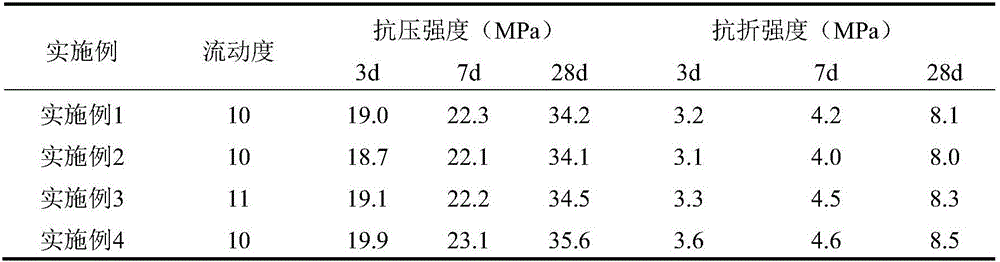

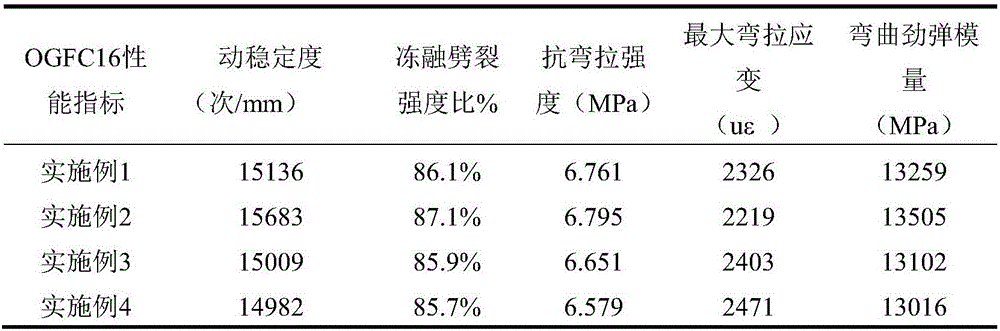

Semi-flexible pavement material, preparation method therefor and semi-flexible pavement

InactiveCN106587842AImprove crack resistanceImprove adhesionIn situ pavingsPolymer scienceCrack resistance

The invention discloses a semi-flexible pavement material, a preparation method therefor and a semi-flexible pavement. The semi-flexible pavement material is prepared from the raw materials, i.e., a cement grouting material and an asphalt mixture in parts by mass, wherein the cement grouting material contains 15-20 parts of cement, 8-10 parts of emulsified asphalt, 0.03-0.06 part of water reducing agent, 0.06-0.2 part of polypropylene fibers, 10-15 parts of mineral powder, 30-35 parts of sand, 8-10 parts of fly ash, 0.06-0.12 part of expanding agent and 0.03-0.06 part of interface modifier. According to the semi-flexible pavement material disclosed by the invention, the cement grouting material is added with the emulsified asphalt, the fly ash, the polypropylene fibers, the mineral powder, the water reducing agent, the expanding agent and the interface modifier which are mutually compounded and are in synergism, so that the cement grouting material can be easily subjected to dry shrinkage, the condition that the interfacial adhesion performance of cement-asphalt concrete is poor is improved, and thus, the crack resistance is improved. In addition, asphalt of the asphalt mixture is rubber asphalt, so that the crack resistance and adhesion property of the asphalt mixture are improved.

Owner:江苏北极星交通产业集团有限公司

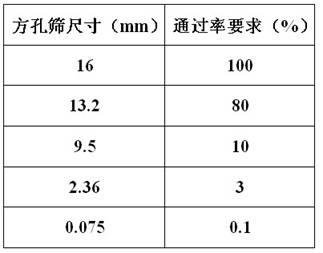

Rubber bituminous mixture partially using slag as coarse aggregate

InactiveCN101948272AImprove long-term road performanceLow costSolid waste managementCrack resistanceSlag

The invention belongs to the technical field of building materials used in road engineering, particularly relating to a high-strength wear-resisting rubber bituminous mixture partially using slag as coarse aggregate. The mixture comprises slag coarse aggregate, natural stone coarse aggregate, fine aggregate, filler and rubber asphalt, wherein part of coarse aggregate is the slag; part of coarse aggregate is basalt, diabase or limestone; the fine aggregate is limestone, diabase or basalt; the filler is cement or a mixture of limestone mineral powder and slaked lime; and the rubber asphalt is produced by selecting waste cart tire rubber powder with a granularity greater than or equal to 20 meshes and lower than or equal to 40 meshes. The invention fully utilizes the slag, waste tires and other waste materials and turns waste into wealth, thereby effectively relieving environmental pollution caused by the slag and the waste tires. The mixture is a dense grade bituminous mixture using the slag as the coarse aggregate and using the rubber asphalt as a matrix, which has good high-temperature stability, low-temperature crack resistance, normal-temperature fatigue resistance and other performances, and is applicable to various traffic road engineering.

Owner:上海佳砼新材料科技发展有限公司

Rubberized asphalt pellets

Owner:威廉·R·拜莱

Road asphalt prepared by adding plant asphalt to petroleum asphalt and production method thereof

The invention relates to a road asphalt prepared by adding plant asphalt to petroleum asphalt and a production method thereof, belonging to the field of communications and transportation. The road asphalt is prepared from the following raw materials in parts by weight: 100 parts of petroleum asphalt, 20-100 parts of plant asphalt, cellulose or starch, and rosin, wherein the ratio of cellulose or starch to plant asphalt is 0.01-0.1, and the ratio of rosin to plant asphalt is 0.01-0.03. The plant asphalt and petroleum asphalt (or rubber asphalt, rubber modified asphalt) have favorable compatibility under the actions of the stabilizer and tackifier, thereby improving the service performance of the asphalt and asphalt mixture; and thus, the invention provides a new way and new method for substituting for part of petroleum asphalt. The road asphalt provided by the invention has high viscosity and high softening point; and the on the premise of good mix design, the asphalt mixture has certain high-temperature stability, and can enhance the rutting deformation resistance of an asphalt concrete pavement with high temperature and heavy-load traffic.

Owner:吉林省交通规划设计院

High-performance rubber asphalt pouring sealant and preparation method thereof

InactiveCN103421467AReduce pollutionImprove performanceMineral oil hydrocarbon copolymer adhesivesOther chemical processesCrack resistanceProcess engineering

The invention discloses high-performance rubber asphalt pouring sealant and a preparation method thereof. The high-performance rubber asphalt pouring sealant is made from rubber powder, modifier, petroleum asphalt, tackifier, cosolvent, and stabilizer. The preparation method includes: heating the asphalt to 150-160 DEG C, adding the modifier, stirring to obtain liquid, adding the cosolvent and mixing for 30 minutes, heating to 190-200 DEG C, slowly adding the rubber powder, mixing for 30 minutes, adding the tackifier and the stabilizer, and mixing for 15 minutes to produce high-performance rubber asphalt pouring sealant. The rubber powder of waste tires is utilized, and accordingly product performance is improved, product cost is reduced and environmental pollution is reduced; the modifier, the rubber powder and the asphalt are mixed into stable, even mixture through the cosolvent, so that resin groups, rubber powder groups and asphalt groups can form a stable interlinked structure; through the modifier, route performance of the sealant can be improved, for example, softening point is increased and low temperature cracking resistance is improved; new cracks can be prevented effectively.

Owner:XIYUEFA INT ENVIRONMENTAL PROTECTION NEW MATERIALS CO LTD

Modified rubber asphalt and preparing method thereof

The invention discloses modified rubber asphalt and a preparing method thereof. The modified rubber asphalt is prepared from, by weight, 100 parts of asphalt base materials, 20-40 parts of rubber powder, 10-25 parts of modified graphene oxide, 5-15 parts of resin, 5-15 parts of fibers and 5-15 parts of a stabilizing agent. By adding the modified graphene oxide, the resin, the fibers and the stabilizing agent, the compatibility between the rubber powder and the asphalt base materials is enhanced, and therefore the modified rubber asphalt has the advantages that the modified rubber asphalt has good adhesivity, stability, high-temperature rut resistance, construction stability and the like.

Owner:NANJING TONGAN ROAD ENG

Low-temperature environment-friendly rubber asphalt and preparation method thereof

ActiveCN101747637AAchieve mild plasticizationStrong shear forceBuilding insulationsPolymer scienceSulfur

The invention discloses a low-temperature environment-friendly rubber asphalt, which is characterized in that: after rubber powder and auxiliaries are mixed, the mixture is subjected to mixed plasticization and granulation through a screw extruder to form plasticized particles; after the plasticized particles are mixed with a reaction crosslinker, the mixture is added and mixed with asphalt to prepare the rubber asphalt at the temperature of between 140 and 170 DEG C; the rubber powder is fine powder prepared by processing and grinding waste rubber products, and the mesh number is 5 to 60 meshes; the auxiliaries are a softening agent, an activating agent and a bonding granulating agent, wherein the softening agent is engine oil, pine tar oil and aromatic oil, the activating agent is a mixture of waste engine oil and alkylphenol disulfide, and the bonding granulating agent is reclaimed polyethylene; and the crosslinker is a mixture of sulfur and an accelerator, namely 2-benzothiazolethiol. The low-temperature environment-friendly rubber asphalt has the advantages of low investment, energy conservation and environmental protection.

Owner:沈阳三鑫集团有限公司 +2

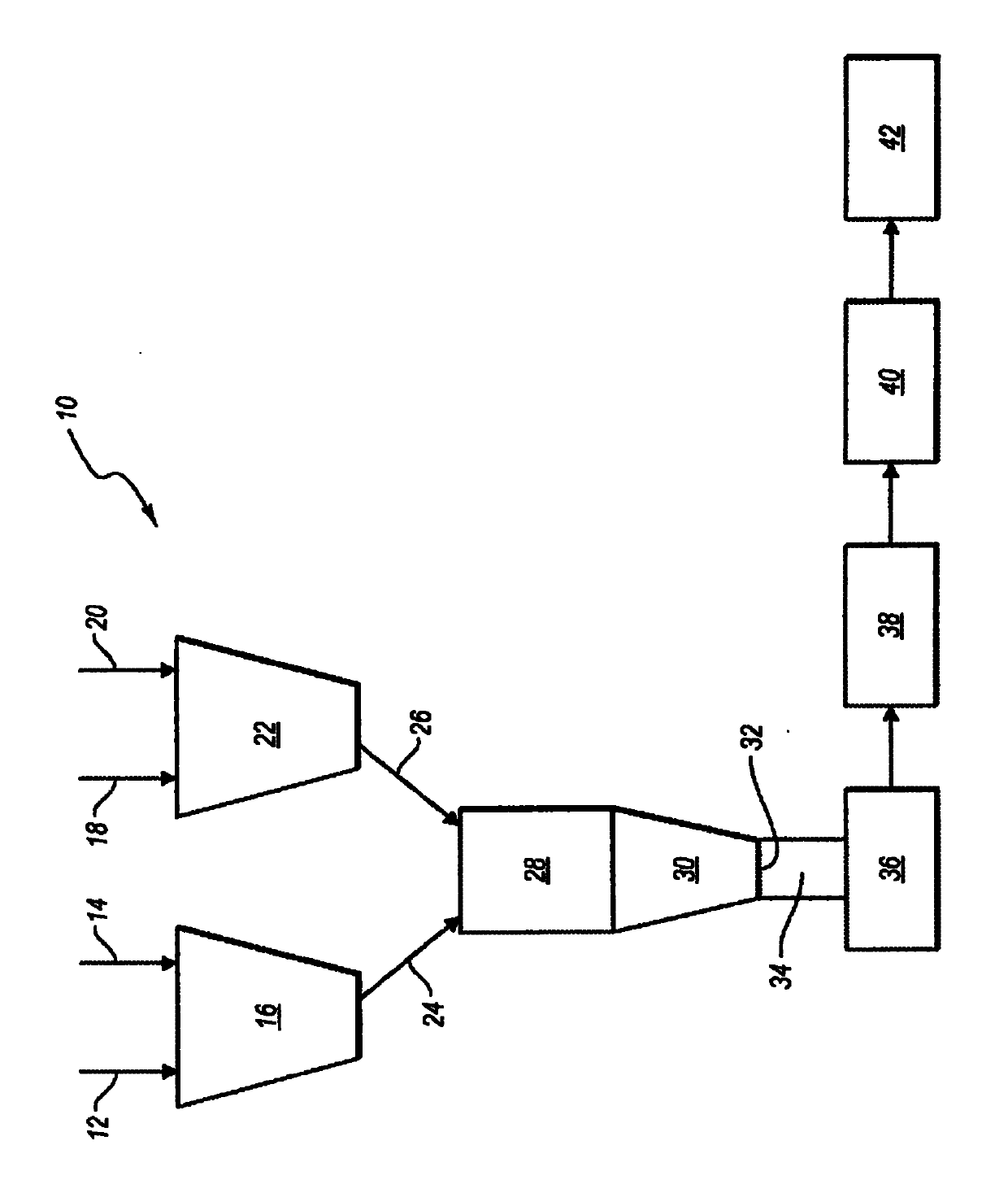

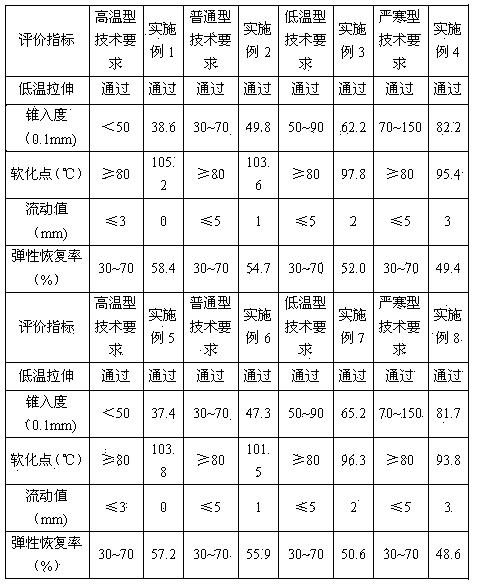

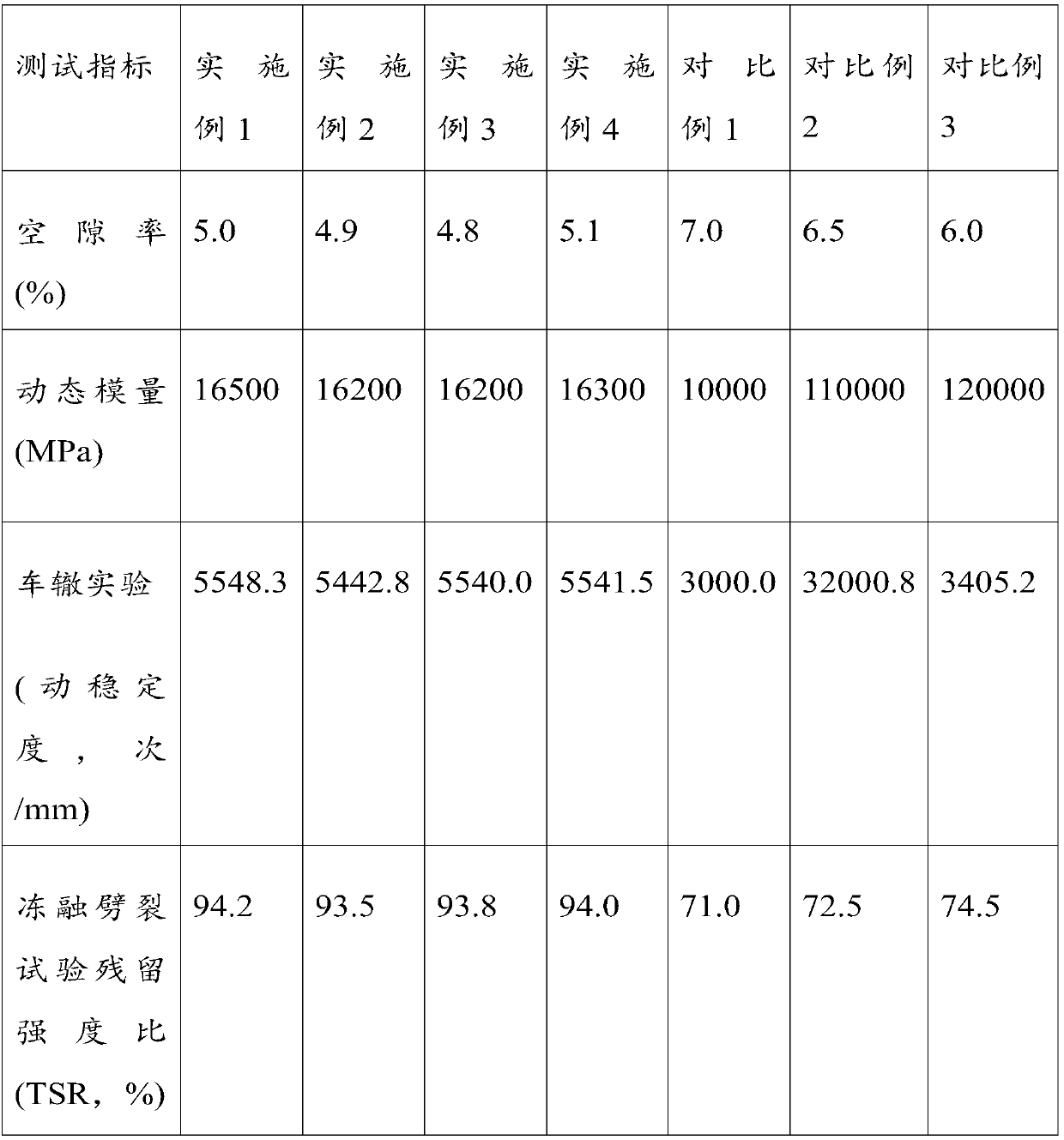

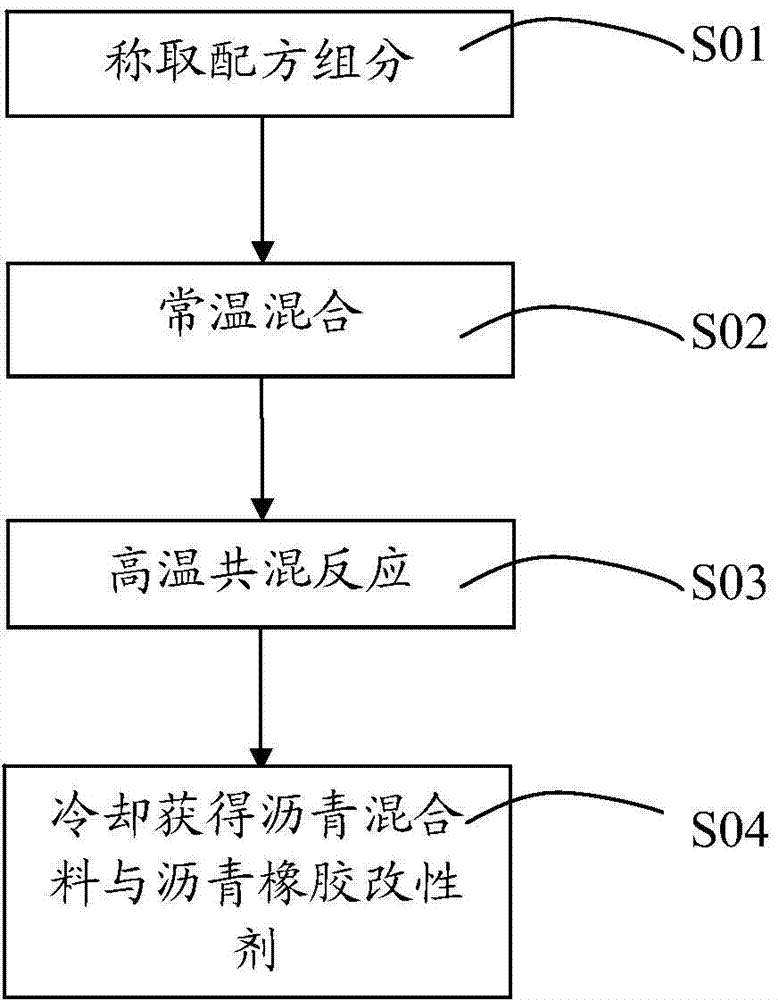

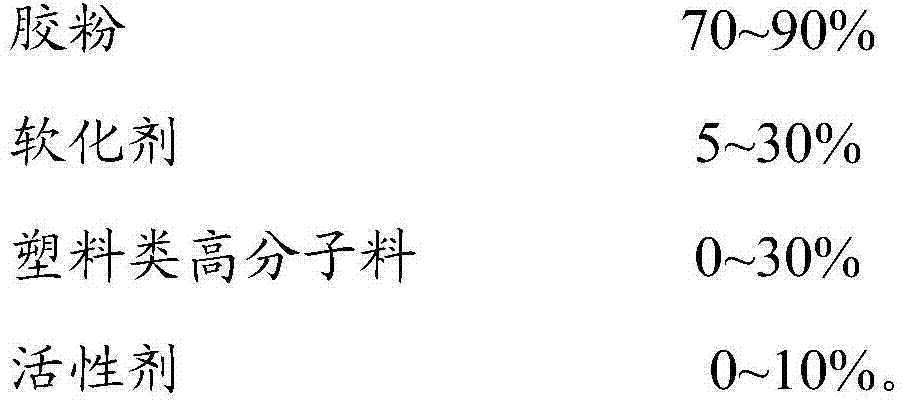

Rubber modifier, preparation method of rubber modifier, rubber asphalt mixture and rubber asphalt

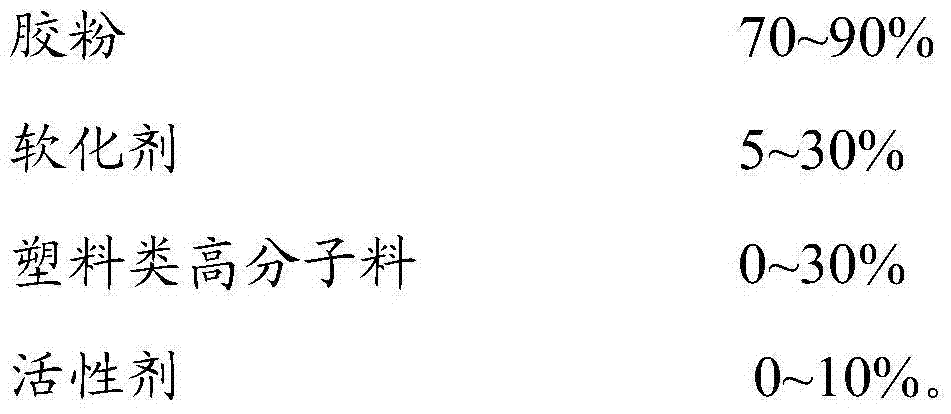

The invention relates to a rubber modifier and an application method thereof. The rubber modifier comprises the following components by mass percent: 70-90% of rubber powder, 5-30% of softener, 0-30% of plastic polymer materials and 0-10% of active agent. The rubber modifier works together with no less than 70% of rubber powder to consume a large quantity of waste rubber; since the softener is added to the rubber powder, rubber material becomes soft and the rubber powder and / or plastic polymer materials can be better swelled and dispersed into the asphalt mixture or asphalt; the rubber powder, the softener and / or the plastic polymer materials, and the active agent generate synergistic effects; the rubber modifier disclosed by the invention has excellent ageing resistance and low viscous flow temperature, can be used for preparing the rubber asphalt mixture by a dry method and also can be used for preparing the rubber asphalt by a wet method; the heating temperature of the asphalt and the asphalt mixture can be reduced. Thus, high-temperature aging of the asphalt is prevented and energy consumption and carbon emission are greatly reduced. The product disclosed by the invention is easy to store; the blending. Transportation and storage costs are effectively saved and the production cost is greatly reduced.

Owner:翁晓娜

Flame-retardant spraying quick-settling rubber asphalt waterproof paint

ActiveCN102965019AFlame retardantImprove performanceFireproof paintsConjugated diene hydrocarbon coatingsPolymer scienceBituminous waterproofing

The invention relates to flame-retardant spraying quick-settling rubber asphalt waterproof paint, which achieves a flame retardant effect by adding certain flame retardant components on the basis of the conventional quick-settling rubber asphalt waterproof paint, and has excellent performance. The waterproof paint is water-based spraying paint and is prepared in proportion by the steps of: compounding superfine, suspended and micro-emulsion modified emulsified asphalt and macromolecule polymer rubber latex to obtain components of liquid rubber asphalt mastic emulsion and mixing the emulsion with coagulating agent components. Compared with the conventional waterproof paint, the flame-retardant spraying rubber waterproof paint provided by the invention is higher in elongation at break and bonding strength and has the outstanding characteristic of flame retardance. The flame-retardant spraying quick-settling rubber asphalt waterproof paint effectively makes up the shortage of flame retardance of the conventional waterproof paint, has the advantages of convenience in construction, aging resistance, long service life, flame retardance and the like, and can be widely applied to water prevention of roofs of various buildings.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

Spraying rapid-hardening rubber asphalt water proofing material for drinking water pond

InactiveCN102964929AEnsure safetyGuaranteed reliabilityConjugated diene hydrocarbon coatingsNatural rubber coatingsBitumen emulsionLiquid rubber

The invention provides a spraying rapid-hardening rubber asphalt water proofing material for a drinking water pond. According to the spraying rapid-hardening rubber asphalt water proofing material, emulsified asphalt and high-molecular polymer rubber latex are prepared into liquid rubber asphalt emulsion component in the ratio by the latest technology, and then the liquid rubber asphalt emulsion component is mixed with a coagulating agent in the ratio so as to obtain a water-based spraying material; the emulsified asphalt, the latex and the chemical stabilizer and the like in the prescription are all the non-volatile organic compounds and organic solvents; the construction is mainly carried in a chemical spraying way, wherein a film can be generated after spraying for 30 seconds; and the formed elastic film has the characteristics of high elongation (more than 1000%) and high elastic recovery rate (more than 90%), so that the spraying rapid-hardening rubber asphalt water proofing material has the water proofing effect greater than that of conventional material. The spraying rapid-hardening rubber asphalt water proofing material for the drinking water pond is produced, constructed and used without organic solvents, so that the spraying rapid-hardening rubber asphalt water proofing material is nonpoisonous and tasteless, zero-waste, and free from exhaust emission and pollution; and the spraying rapid-hardening rubber asphalt water proofing material for the drinking water pond is constructed at normal temperature without being heated and adopting open fire, so that the safety and the reliability can be ensured.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

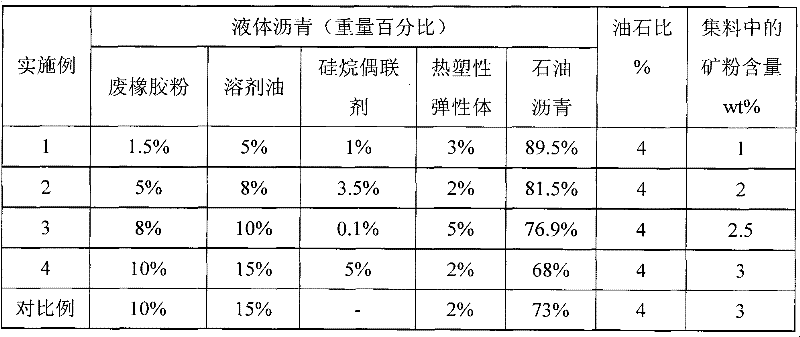

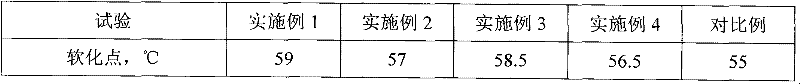

Hot-mix cold-lay rubber asphalt mixture

InactiveCN102329103ASolving Segregation ProblemsImprove loose stateSolid waste managementPolymer scienceNaphtha

The invention provides a hot-mix cold-lay rubber asphalt mixture. The mixture is characterized in that: the mixture comprises rubber asphalt and an aggregate; the aggregate comprises a coarse aggregate, a fine aggregate and ore powder; and the rubber asphalt comprises the following components, by weight, 1.5-10% of rubber powder, 5-15% of solvent naphtha, 0.1-5% of a silane coupling agent, 2-5% of a thermoplastic elastomer, and the balance petroleum asphalt. The silane coupling agent, which is added to rubber powder modified asphalt in the invention, allows a separation problem of the rubber powder and asphalt to be effectively solved. The obtained hot-mix cold-lay rubber powder modified asphalt mixture can keep a good loosened state for several months and all performances are stable in normal temperature conditions.

Owner:上海道柯特沥青科技有限公司

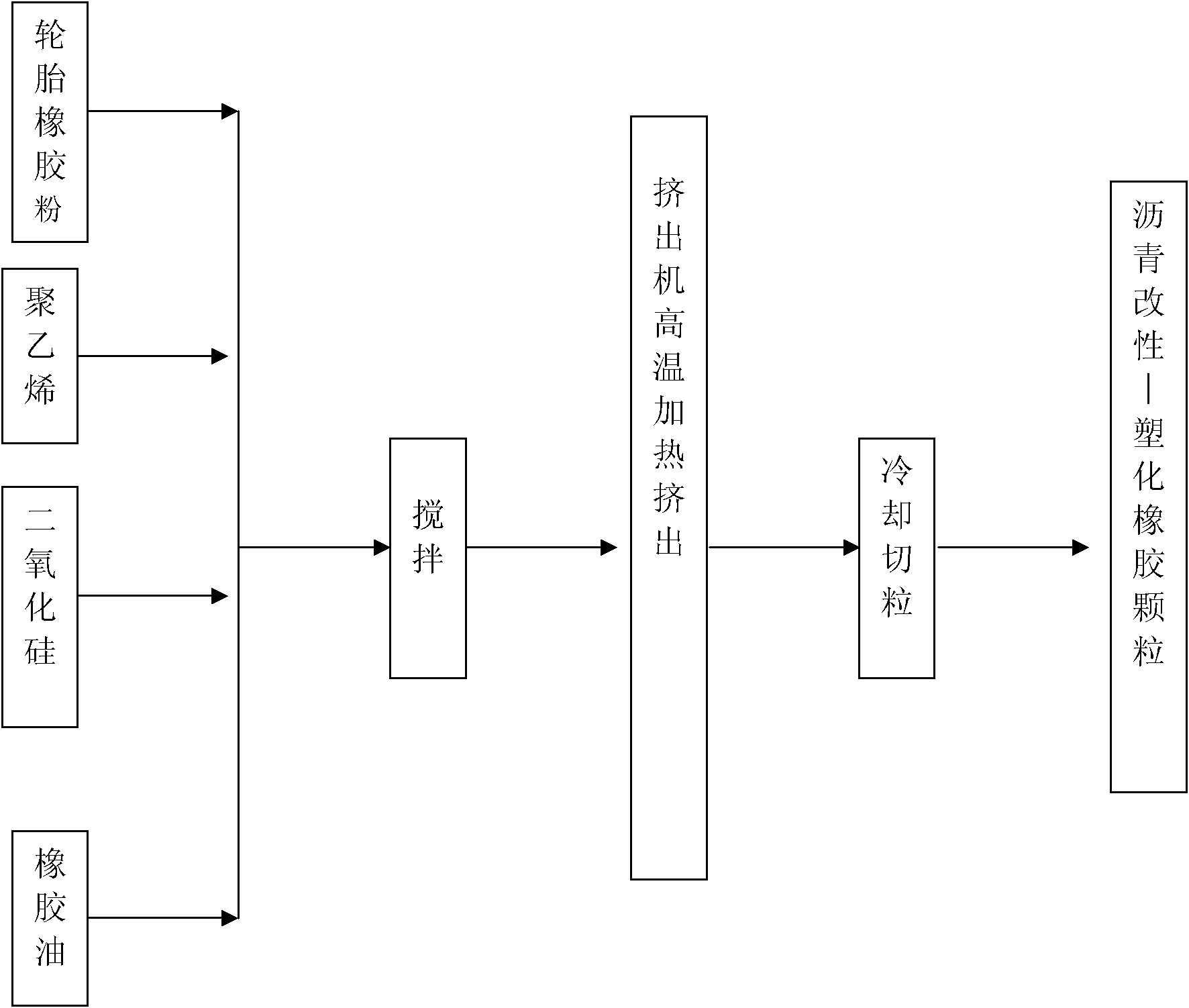

Asphalt modifier and preparation method thereof

InactiveCN101979440AGood compatibilityGood dispersionIn situ pavingsBuilding insulationsPolymer scienceSilicon dioxide

The invention aims to provide an asphalt modifier and a preparation method thereof, which overcome the disadvantages of nonuniform modification, serious pollution and hidden danger caused by adding rubber powder into asphalt and solve the technical problem of the modification and prefabrication of the rubber powder. The invention provides the asphalt modifier. The asphalt modifier is characterized by comprising the following components of: tire rubber powder, polyethylene, silicon dioxide and rubber oil, wherein the components are stirred, heated, extruded, cooled and cut to obtain plasticized rubber sticky particles, namely the asphalt modifier. The plasticized rubber sticky particle product of the invention greatly reduce high-temperature processing and pollution of rubber asphalt; the produced rubber asphalt sticky particles are a directly thrown type novel internal modification material and can be directly thrown into the asphalt and stones for mixing; and the asphalt modifier is odorless, can reduce secondary pollution, and has better meltability than that of rubber powder modified asphalt. The rubber asphalt particles are black sticky particles and are easy to package and transport.

Owner:无锡市同义路面新材料有限公司 +1

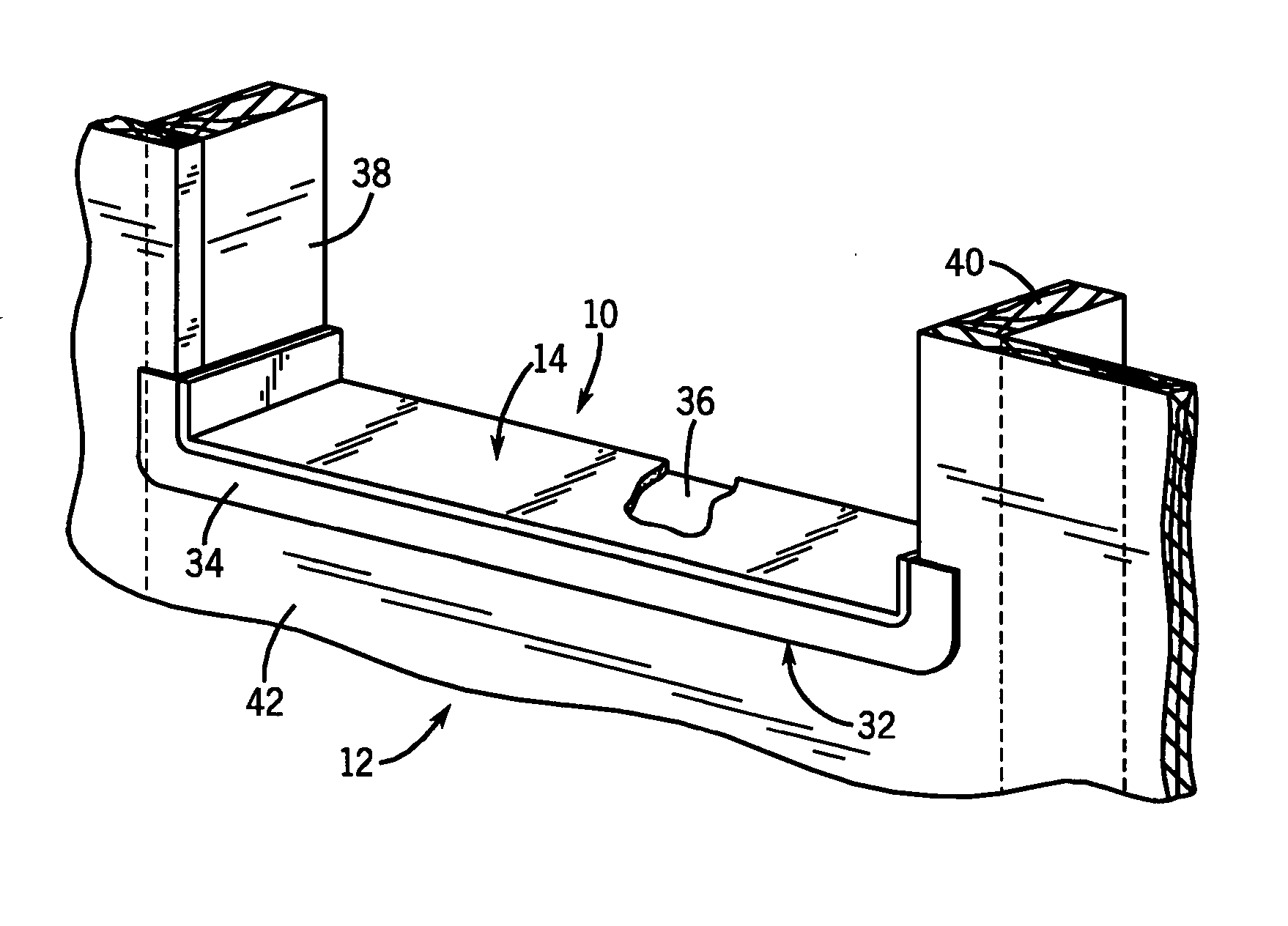

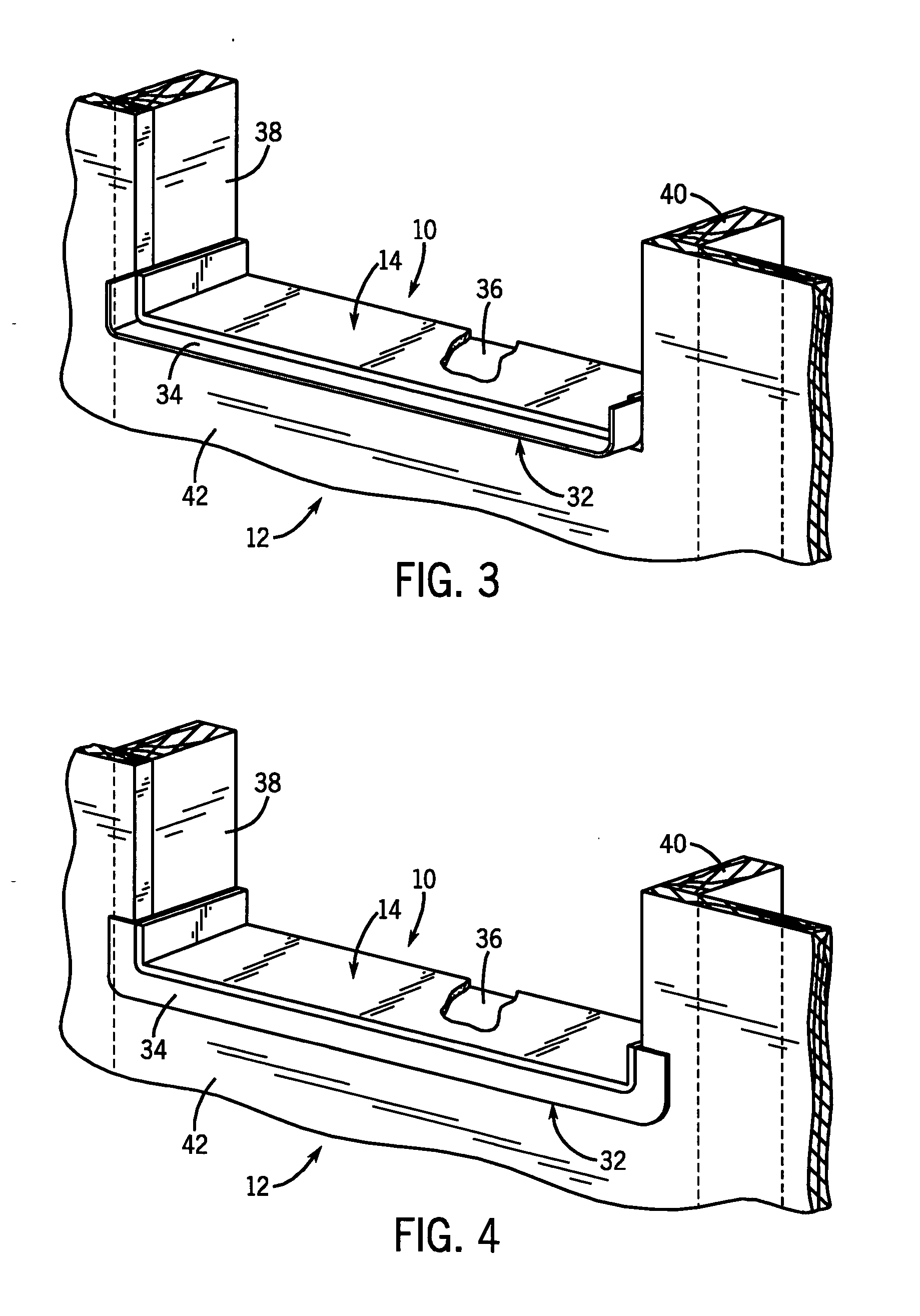

Door and window sill gasket

InactiveUS20050252131A1Prevent moisture infiltrationFloorsSills/thresholdCompressible materialWindow sill

A door and window sill gasket is adapted to seal the frame of doors and windows against moisture, air and insects. The gasket includes a water resistant compressible material having an upper surface, a lower surface and at least one edge. The lower surface of the compressible material is attached to an adhesively-coated top face of a rubberized asphalt sealing membrane providing an air / water infiltration barrier and having an adhesively-coated lower face covered by a removable release liner. The membrane includes a flexible, covered flange extending outwardly from the at least one edge of the compressible material.

Owner:BUSHBERGER ENTERPRISES

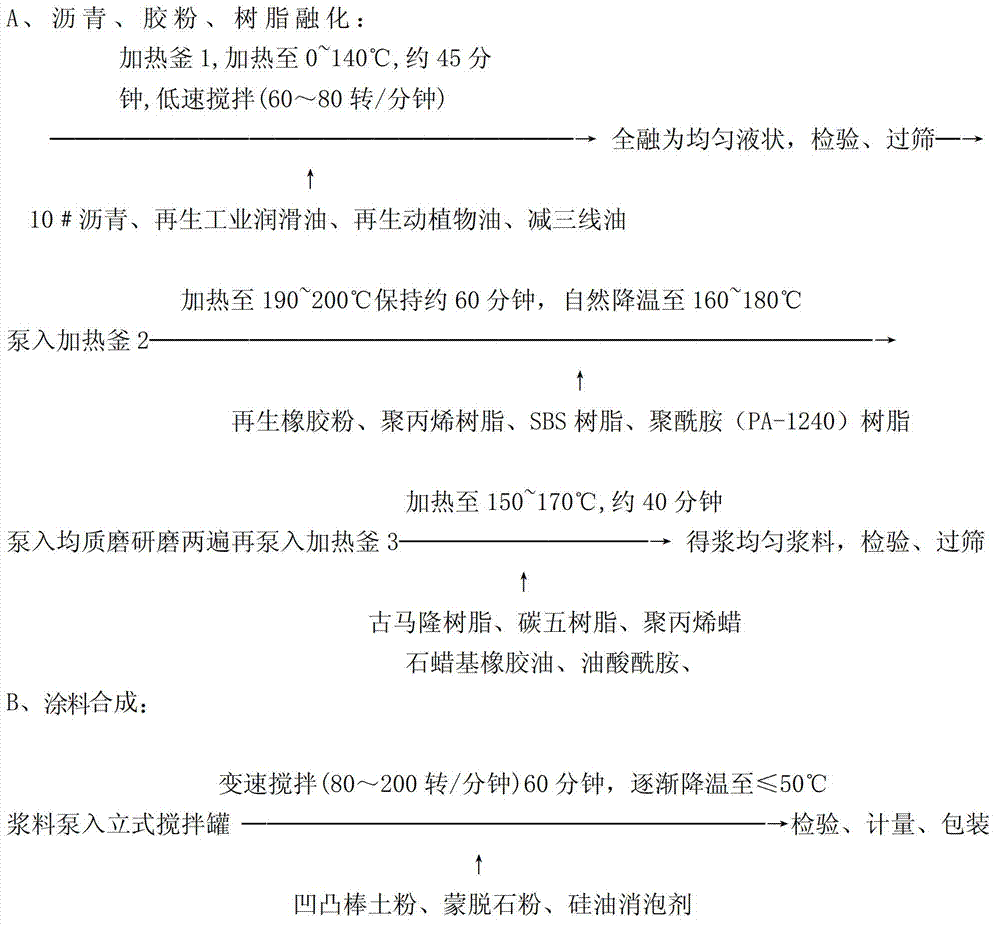

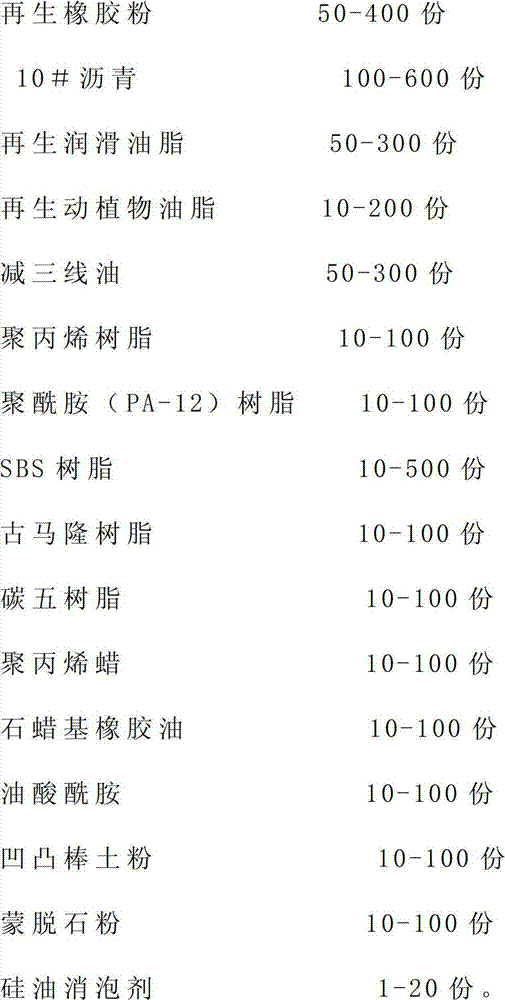

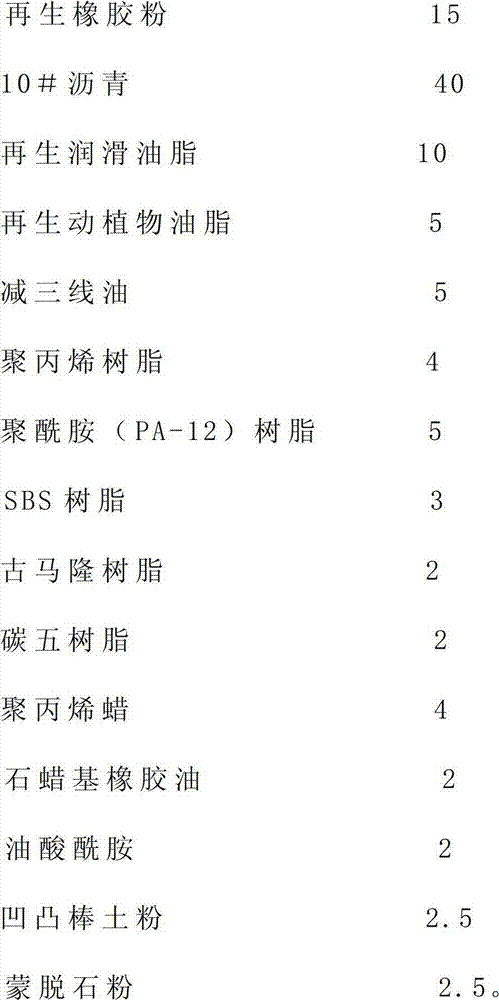

Non-solidifying rubber asphalt building waterproof coating

InactiveCN102925058AReduce pollutionImprove stabilityReclaimed rubber coatingsPolyamide coatingsDistilled oilFlora

The invention discloses a non-solidifying (wriggling) rubber asphalt building waterproof coating and belongs to the field of chemical material building. The coating is prepared by processing the following raw materials: 50-400 parts of regenerated rubber powder, 100-600 parts of 10# asphalt, 50-300 parts of regenerated lubricating grease, 10-200 parts of regenerated flora and fauna grease, 50-300 parts of tertiary-distilled oil, 10-100 parts of polypropylene resin, 10-100 parts of polyamide (PA-12) resin, 10-500 parts of styrene butadiene styrene (SBS), 10-100 parts of coumarone resin, 10-100 parts of carbon 5 resin, 10-100 parts of polypropylene wax, 10-100 parts of paraffin base rubber oil, 10-100 parts of oleamide, 10-100 parts of attapulgite powder, 10-100 parts of smectite and 1 part to 20 parts of silicone oil defoamer. Inspections show that technical indexes of the non-solidifying (wriggling) rubber asphalt building waterproof coating are superior to JC / T864-2008 national material building industry standard of the 'polymer emulsion building waterproof coating', and stability and aging resistance of the coating are greatly improved.

Owner:刘力

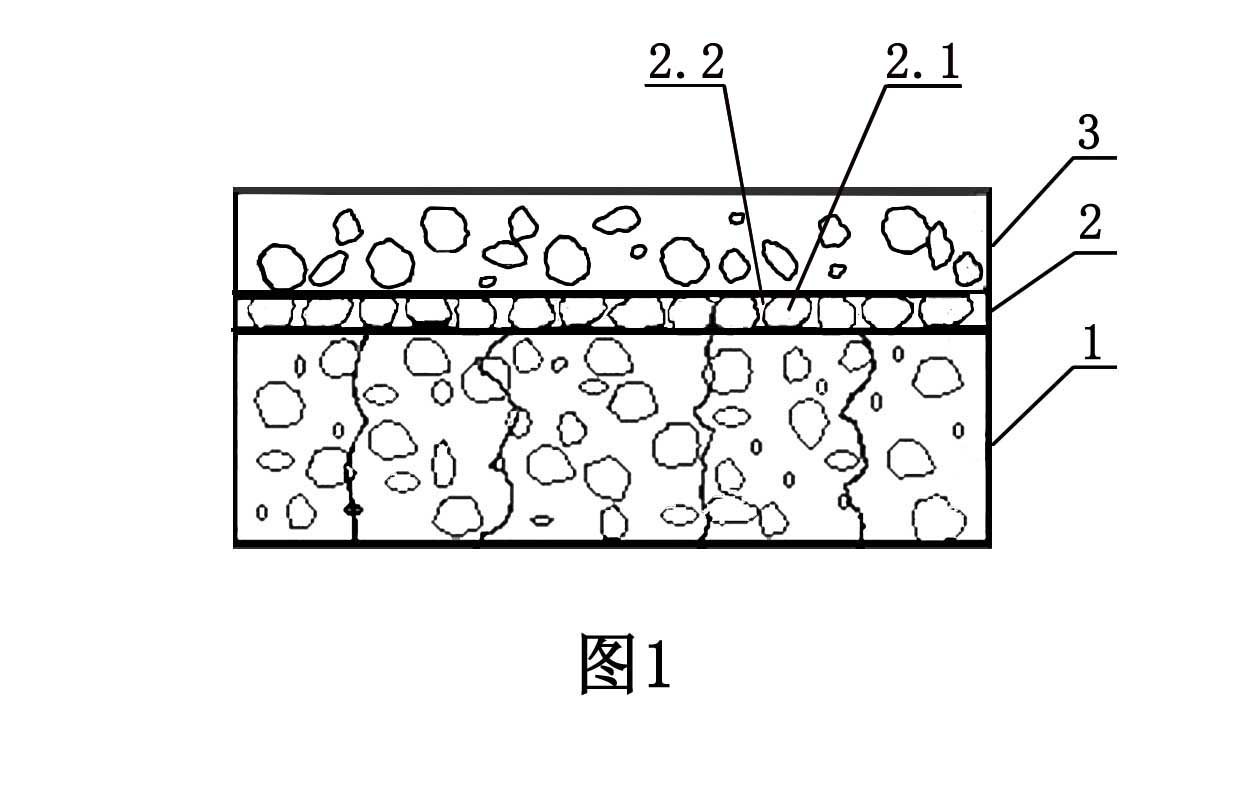

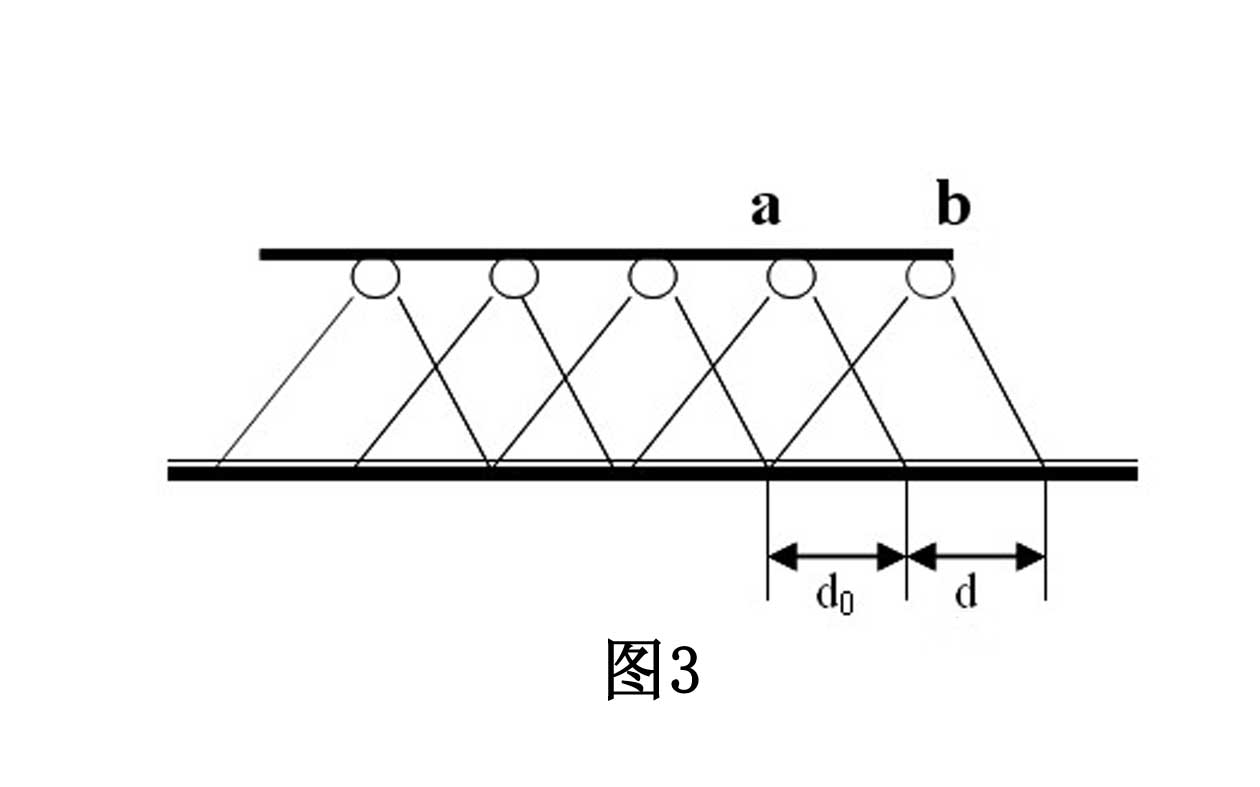

Fiber-reinforced rubber asphalt stress absorbing layer and construction method thereof

The invention provides a fiber-reinforced rubber asphalt stress absorbing layer and a construction method thereof. The fiber-reinforced rubber asphalt stress absorbing layer per square meter comprises the following components: 0.2-1.0 kg of SBS (styrene butadiene styrene) modified emulsified asphalt, 70-150 g of glass fibers, 1.5-3.0 kg of rubber asphalt and 10-20 kg of broken stones. The construction method comprises the following steps of: spraying an SBS modified emulsified asphalt layer and spreading the glass fibers sequentially on the clean and dry surface of a lower supporting layer; after the SBS modified emulsified asphalt breaks emulsion, spraying the rubber asphalt and spreading the broken stones; and finally, rolling a road surface, and controlling the time from the spraying of the rubber asphalt to the completion of the rolling within 10-20 minutes. The rubber asphalt stress absorbing layer prepared by the invention is firmly adhered to the lower supporting layer, can prevent the oil bleeding phenomenon of an asphalt surface layer and the generation of the reflection crack of the asphalt surface layer, improves the anti-cracking performance of the rubber asphalt stress absorbing layer, and prolongs the service life of the road surface.

Owner:广州大象超薄路面技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com