Rubber modifier, preparation method of rubber modifier, rubber asphalt mixture and rubber asphalt

A rubber modifier and asphalt mixture technology, which is applied in building insulation materials, building components, construction, etc., can solve the problems of inability to produce high-quality asphalt mixture, limited use of waste rubber, and obstacles to the promotion of rubber asphalt , to achieve the effect of preventing high temperature aging, simple method and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

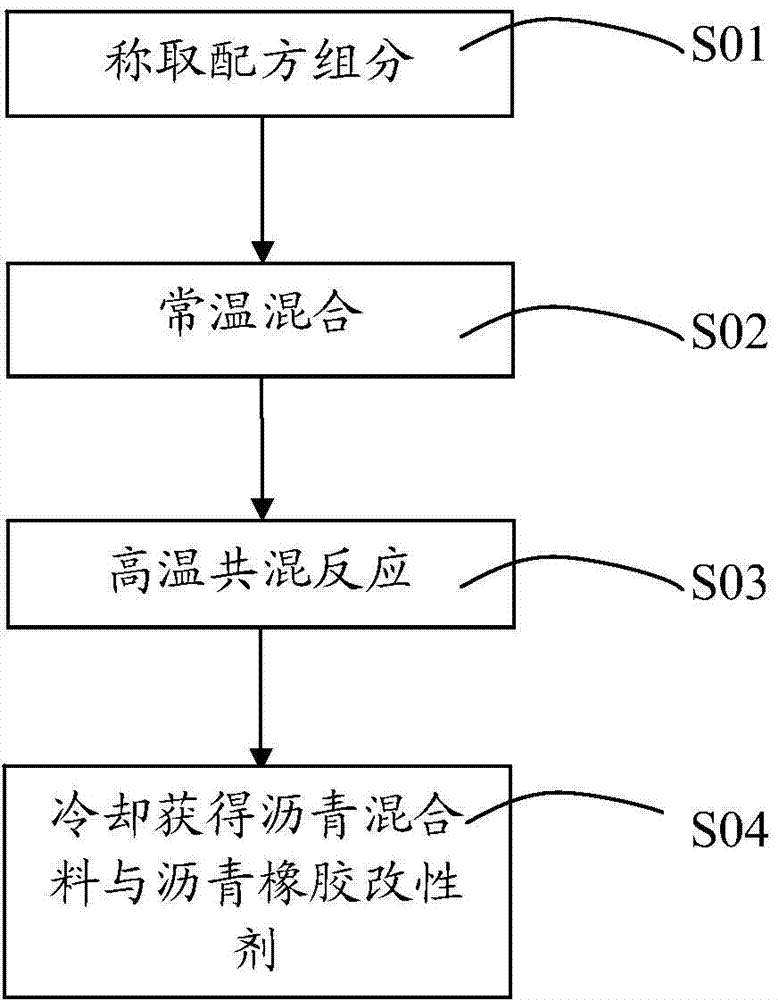

[0028] Correspondingly, the embodiment of the present invention also provides the preparation method of the above rubber modifier. The process flow diagram of the method is as figure 1 As shown, the method includes the following steps:

[0029] S01. Weighing the formula components: each component of the above-mentioned rubber modifier;

[0030] S02. Mixing: mixing the components of the rubber modifier weighed in step S01 to form a uniformly mixed mixture;

[0031] S03. High-temperature blending reaction: heating the mixture obtained in step S02 at a temperature of 220-260° C. for 0.5-1 hour;

[0032] S04. cooling to obtain a rubber modifier.

[0033] Specifically, in the above step S01, the formula for weighing the components of the rubber modifier is as described above, and will not be repeated here.

[0034] Further, in this step S01, when the source of rubber powder is waste rubber products, since waste rubber products generally contain non-rubber skeleton materials suc...

Embodiment 1

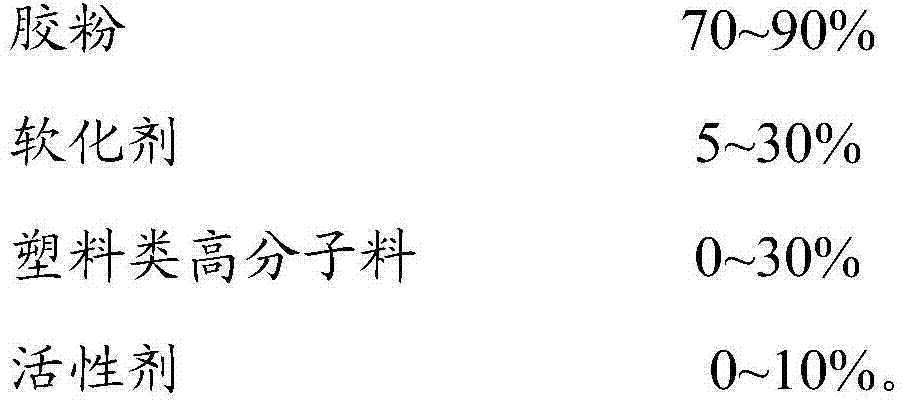

[0051] A rubber modifier, which comprises the following components by mass percentage:

[0052]

[0053] The preparation method of this rubber modifier is as follows:

[0054] S11. each component is weighed by the formula of above-mentioned rubber modifier;

[0055] S12. Mixing: Mix the components of the rubber modifier weighed in step S11 in a high-speed mixer for 10 minutes to obtain a uniformly mixed mixture;

[0056] S13. High-temperature blending reaction: heating the mixture obtained in step S12 at 240° C. for 1 hour, and melting to reach a uniform mixed reaction state;

[0057] S14. Obtain a rubber modifier: the density of the rubber modifier is 1.15kg / m 3 , the melting point is 120°C, the particle size is 40-70 mesh, the ash content is less than 8%, the moisture content is less than 1%, and the metal content is less than 0.3%.

Embodiment 2

[0059] A rubber modifier, which comprises the following components by mass percentage:

[0060]

[0061] The preparation method of this rubber modifier is as follows:

[0062] S21. The formula of the above-mentioned rubber modifier is weighed for each component;

[0063] S22. Mixing: Mix the components of the rubber modifier weighed in step S21 in a high-speed mixer for 7 minutes to obtain a uniformly mixed mixture;

[0064] S23. High-temperature blending reaction: heating the mixture obtained in step S22 at 235° C. for 1.5 hours, and melting to reach a uniform mixed reaction state;

[0065] S24. Obtain a rubber modifier: the density of the rubber modifier is 1.20kg / m 3 , the melting point is 140°C, the particle size is 40-70 mesh, the ash content is less than 8%, the moisture content is less than 1%, and the metal content is less than 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com