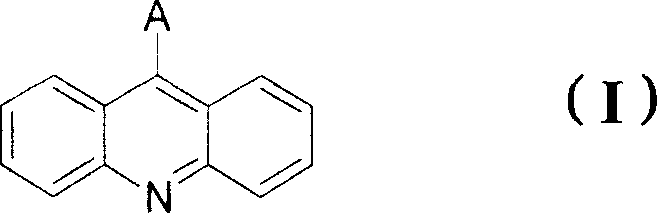

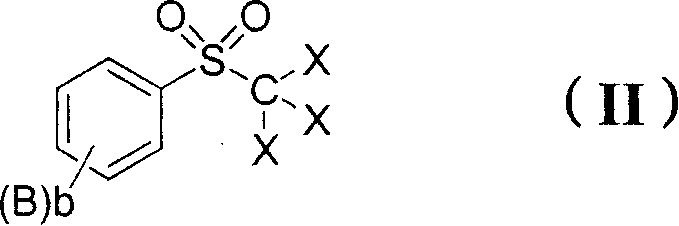

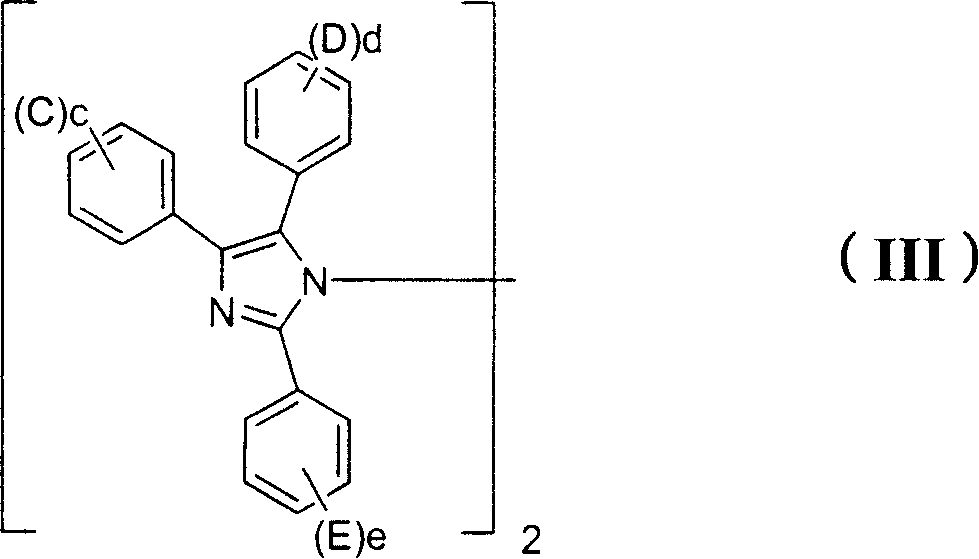

Photosensitive resin composition and laminating article thereof

A technology of photosensitive resin and composition, applied in photosensitive material processing, optics, opto-mechanical equipment, etc., can solve problems such as short circuit and pipeline blockage in developing tank, and achieve excellent dispersion stability, good etching solution resistance, resolution good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] Hereinafter, the preparation method of the evaluation sample of the Example and the comparative example, and the evaluation method and evaluation result with respect to the obtained sample are demonstrated.

[0152] 1. Production of samples for evaluation

[0153] The photosensitive resin laminates in Examples and Comparative Examples were produced as follows.

[0154]

[0155] Prepare the compounds shown in Table 1, uniformly stir and mix the photosensitive resin composition shown in Table 2, and use a bar coater to uniformly coat the polyterephthalic acid as a support with a thickness of 20 μm. The surface of the ethylene glycol film was dried in a dryer at 95° C. for 4 minutes to form a photosensitive resin layer. The thickness of the photosensitive resin layer was 40 μm.

[0156] In the composition of Table 1, MEK represents methyl ethyl ketone, and the parts by mass of P-1 to P-5 in Table 2 are values including MEK.

[0157] Then, on the surface of the photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com