Patents

Literature

122 results about "Developing tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A developing tank is a light-tight container used for developing film. A developing tank allows photographic film to be developed in a daylight environment. This is necessary because most film is panchromatic and therefore can not be exposed to any light during processing. Depending upon the size and type, a developing tank can hold one to many roll or sheet films. Famous brands include Paterson, Yankee, Jobo and Nikor.

Automatic developing apparatus and method of replenishing replenisher for developer for said apparatuses

InactiveUS6364544B1Reduce conductivityPrevent fluctuationsPhotosensitive material processingLiquid processing circulationDiluentEngineering

In order to compensate the reduction of a developing activity during working and / or stopped period, a replenisher and / or a diluent is added to the developer according to predetermined replenishing conditions, and also in order to compensate the reduction of the developing activity caused by processing photosensitive materials, the replenisher and / or the diluent is added to the developer. Then, in cases where the electric conductivity of the thus replenished developer exceeds a predetermined target value, the diluent is replenished to the developer tank until the electric conductivity of the developer falls below the target value.

Owner:FUJIFILM HLDG CORP +1

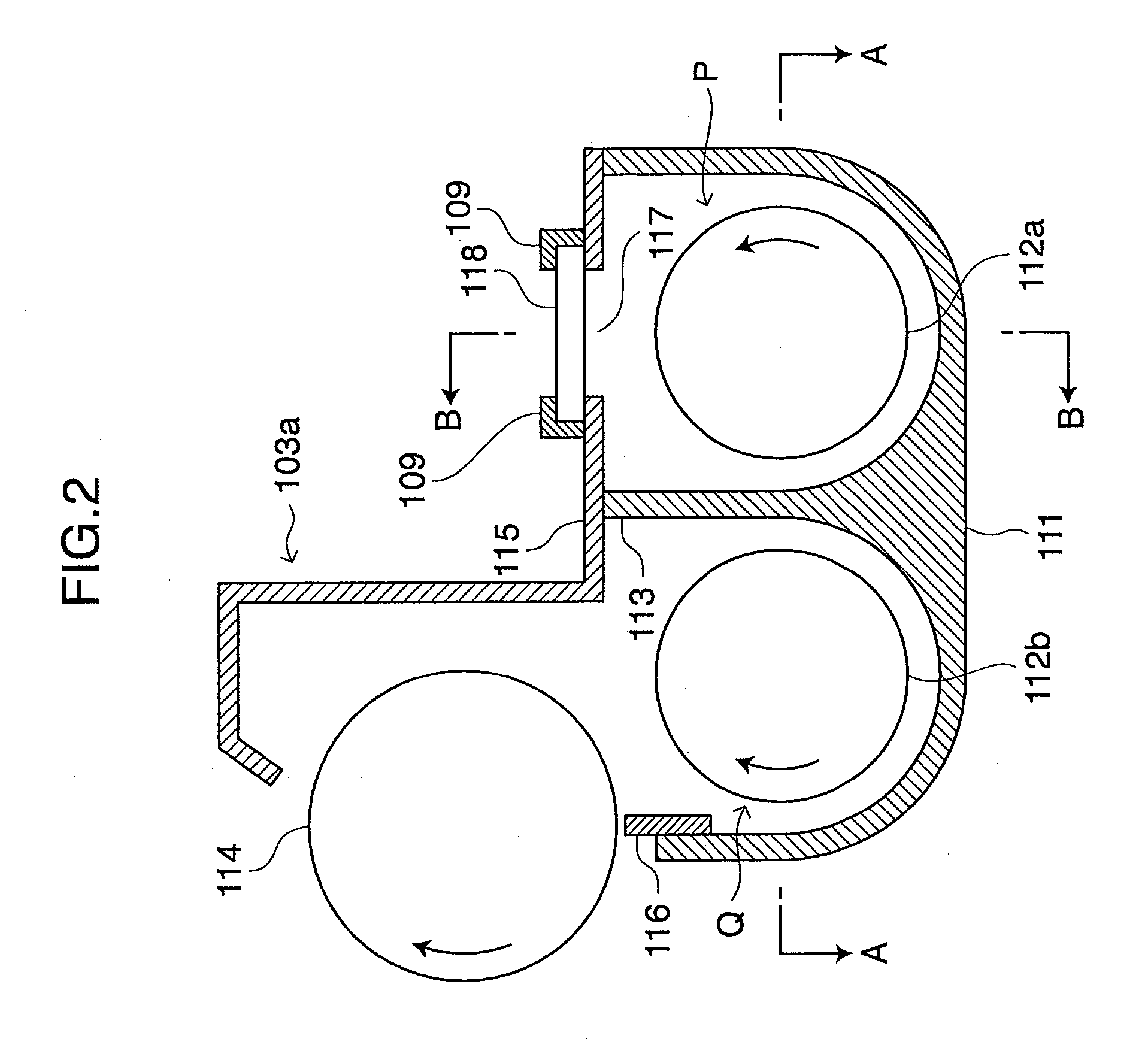

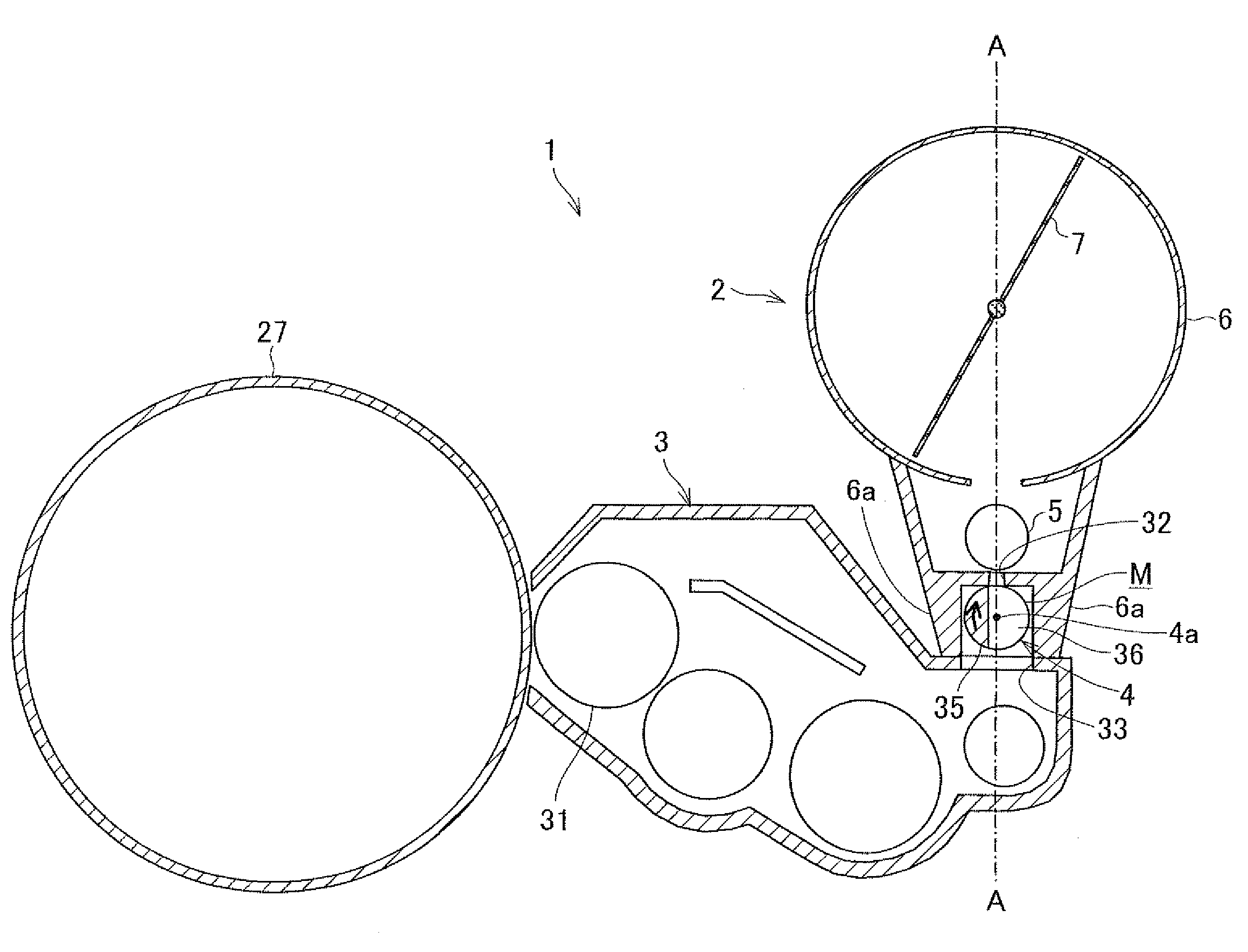

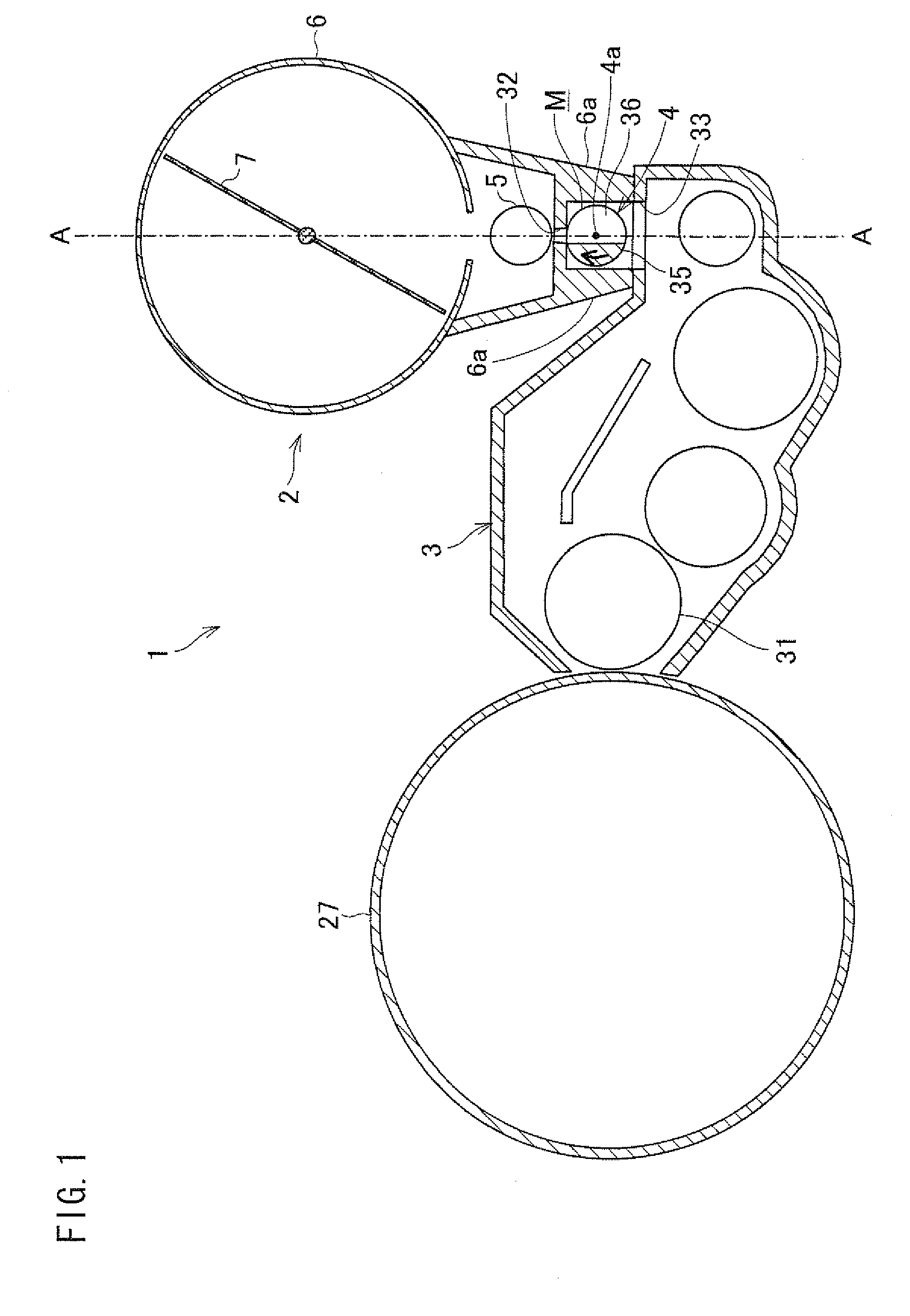

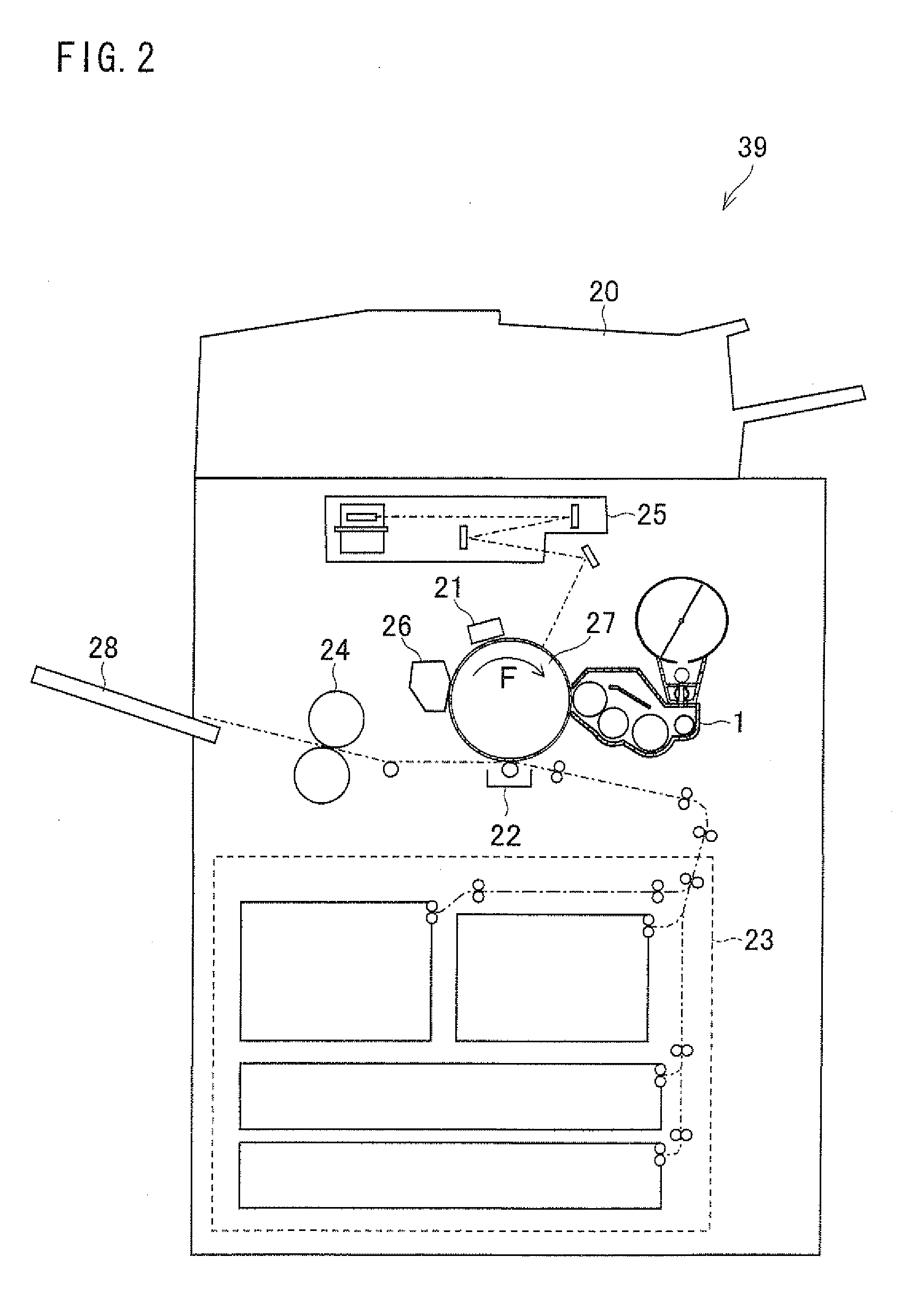

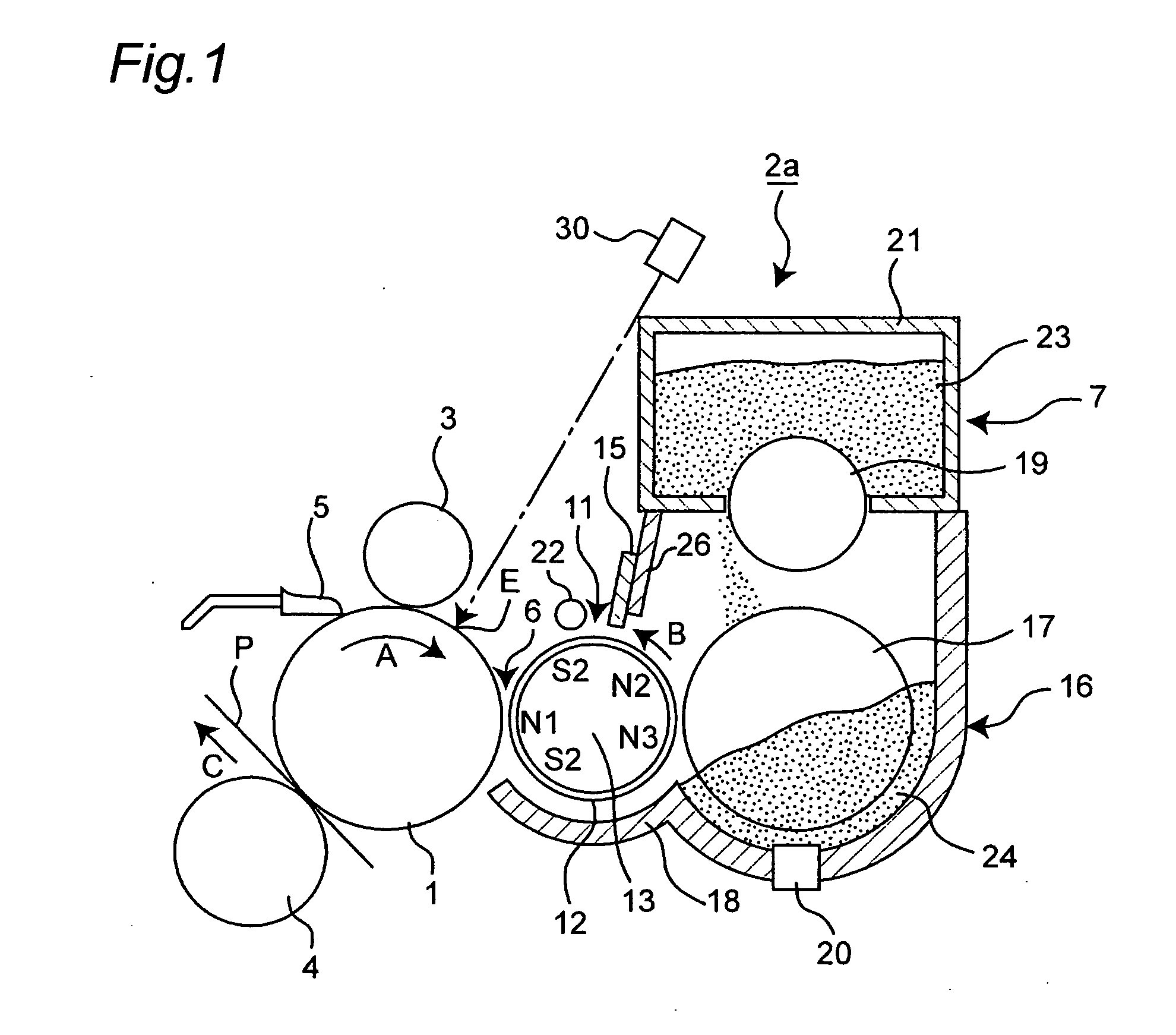

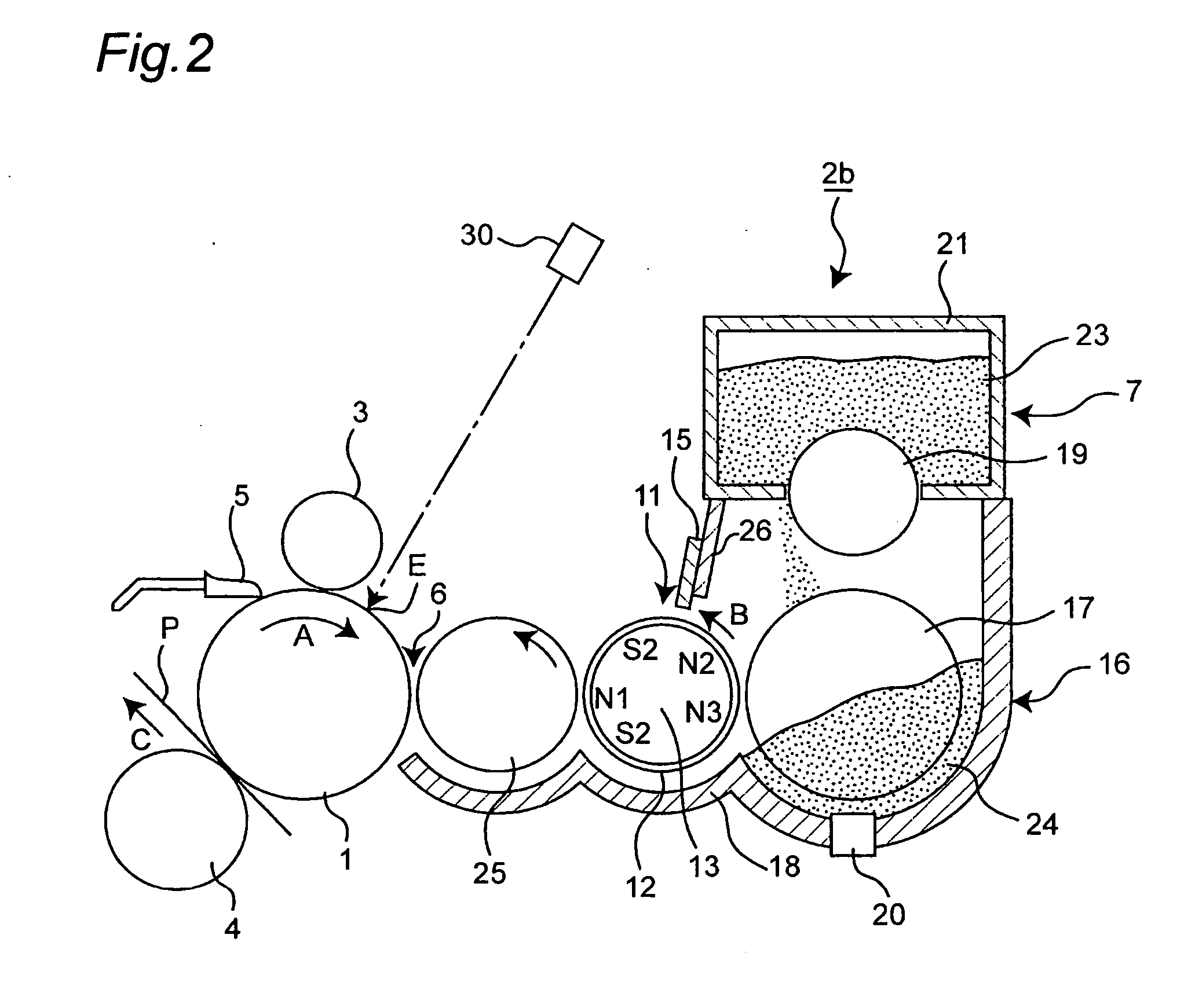

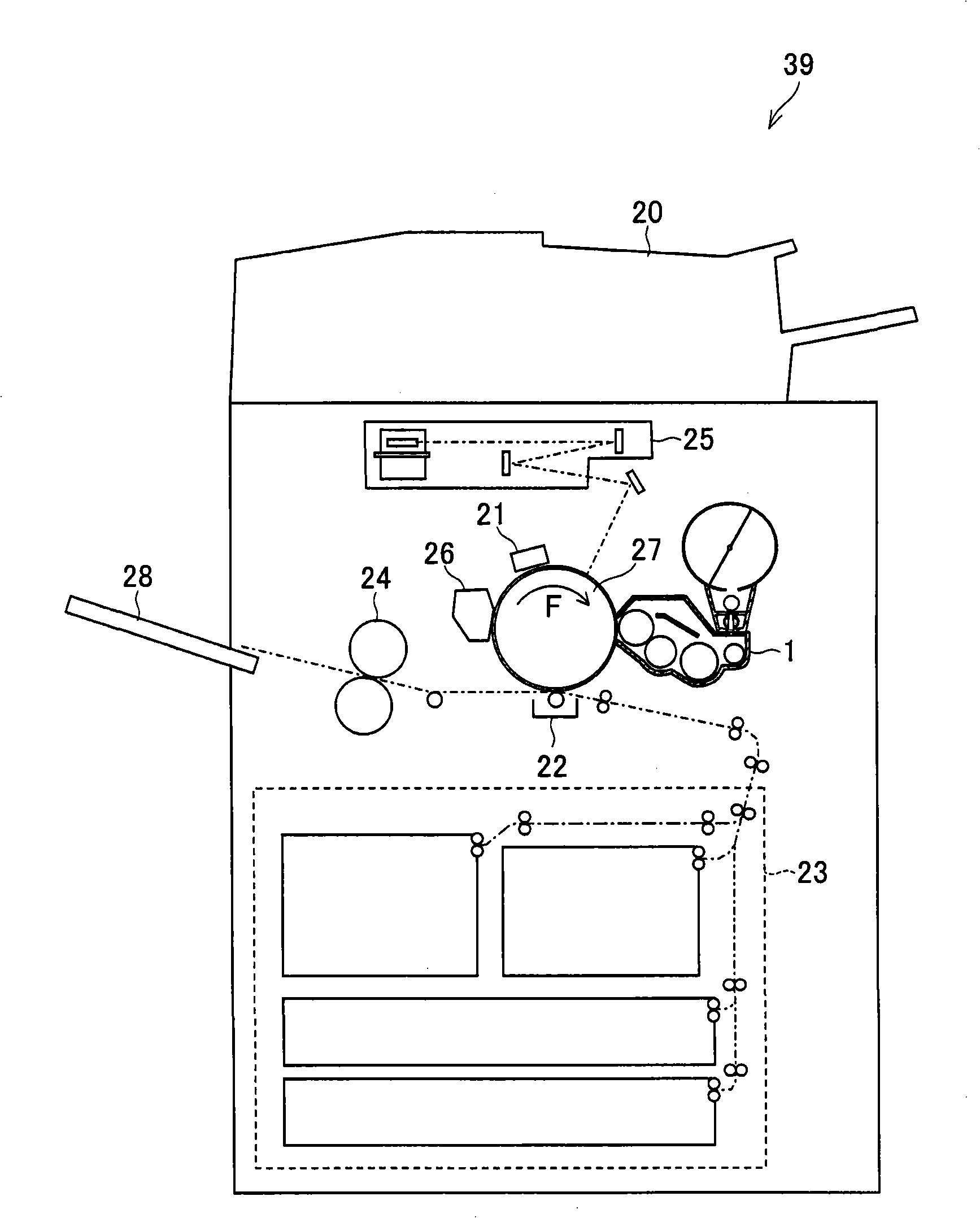

Developing apparatus using one-component toner

To prevent scattering of toner when an image forming operation is started and ended in a developing process using one-component toner, a rotatable developing roller in contact with a photosensitive member carrying a static latent image, which is used to carry and feed one-component toner, is provided in a developing tank containing one-component toner. Initially, toner is fed to a feed roller, then passed through a toner restricting member which is pressed against the developing roller to restrict the amount of toner to be fed, so that a layer of toner is formed at a fixed thickness and fed into a developing area in contact with the photosensitive member. Thus a static latent image is produced on the developing roller. In this process, a developing bias voltage Va is supplied to the developing roller, a restricting voltage Vb is supplied to the toner restricting member so as to fix the thickness of the toner layer, and a supply voltage Vc is supplied to the feed roller to control the supply of toner. Specifically, the developing bias voltage Va, restricting voltage Vb, and supply voltage Vc are applied to their respective objects before the developing roller begins rotating, thereby minimizing or preventing the scattering or blowing out of toner. Additionally, supply of those voltages Va, Vo, and Vc are stopped after the developing roller stops, which also helps to prevent excess scattering of toner.

Owner:SHARP KK

Cleaning agent for dry-film developing tank of printed circuit board (PCB) and preparation method of cleaning agent

InactiveCN102757871AShorten cleaning timeShorten the timeSurface-active non-soap compounds and soap mixture detergentsPhotosensitive material processingAcetic acidDeveloping tank

The invention relates to a cleaning agent for a dry-film developing tank of a printed circuit board (PCB). The cleaning agent comprises a solvent A and a solvent B, wherein the solvent A comprises the following components in percentage by weight: 15% to 20% of phosphoric acid, 4% to 10% of acetic acid and the balance of water; and with the solvent A as the basic quantity, the solvent B comprises the following components in percentage by weight: 3% to 6% of emulsifying agent, 0.5% to 1% of solubilizer, and 1% to 3% of surfactant. The cleaning agent for the dry-film developing tank of the PCB has the advantages of low cleaning temperature, short cleaning time and good cleaning effect.

Owner:瀚宇博德科技(江阴)有限公司

Determination method for saturated hydrocarbon, arene, colloid, asphalt content in oil product

InactiveCN1763522AHarm reductionImprove consistencyComponent separationData treatmentThin layer chromatogram

The invention discloses a detecting method of saturated hydrocarbon, aromatic hydrocarbon, colloid and asphaltene content in one oil, which comprises the following steps: diluting the 1-2 weight sample through 45-90 weight benzeneú” preheating for half a hour through thin-layer chromatograph to do blank scan; setting the drier temperature between 100 and 120 deg.c; extracting 1.0ª–l sample through microscale injector to drip on the chromarod for 5 times; moving the chromarod at the first, second and third developing tank; connecting the host and disposer to scan the chromarod on the hydrogen flame; displaying chromatogram, chromatogram peak area and hydrocarbon, aromatic hydrocarbon, colloid, asphaltene content on the data disposer automatically, which realizes the detection of single or mixing oil.

Owner:PETROCHINA CO LTD

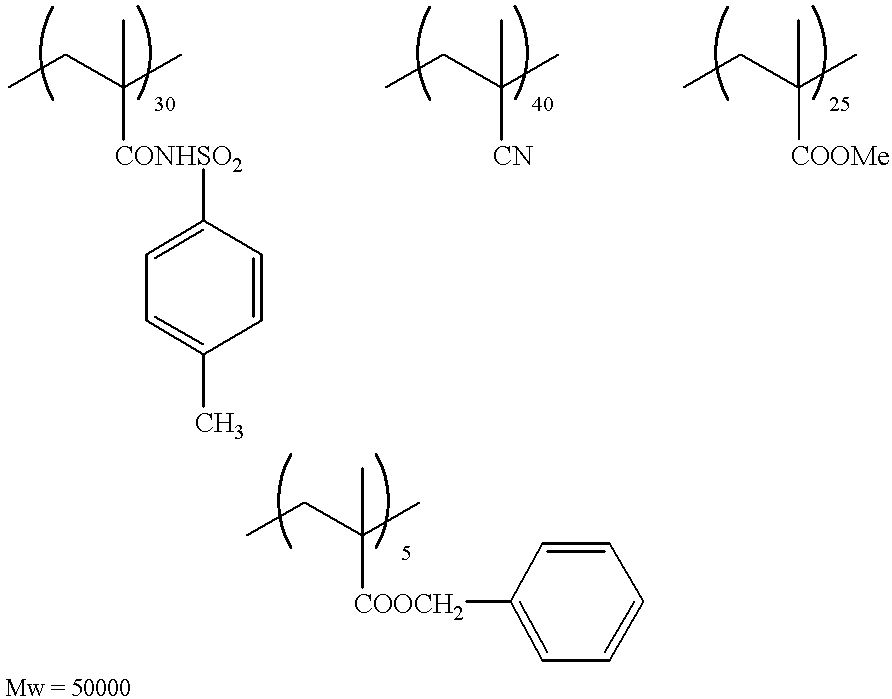

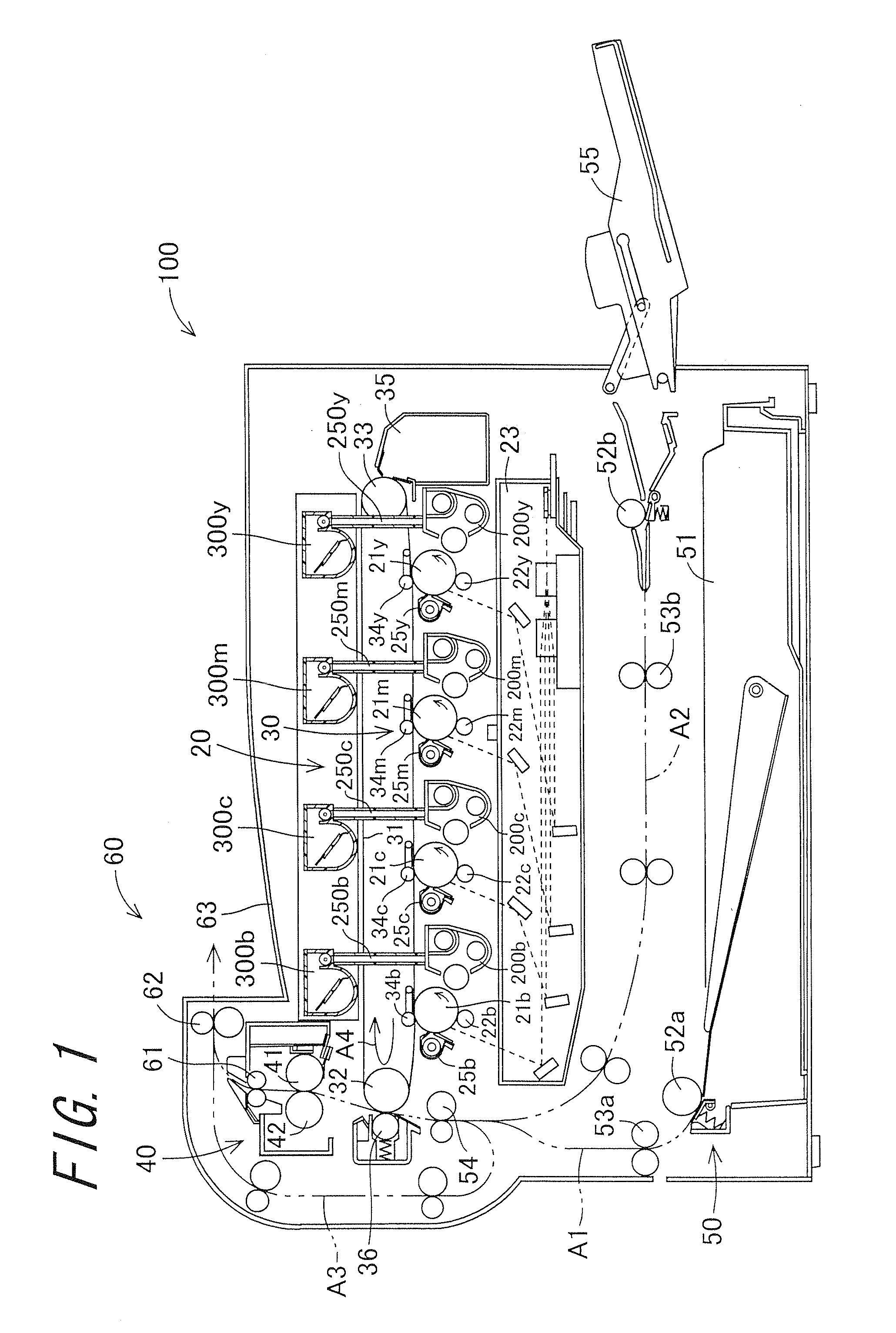

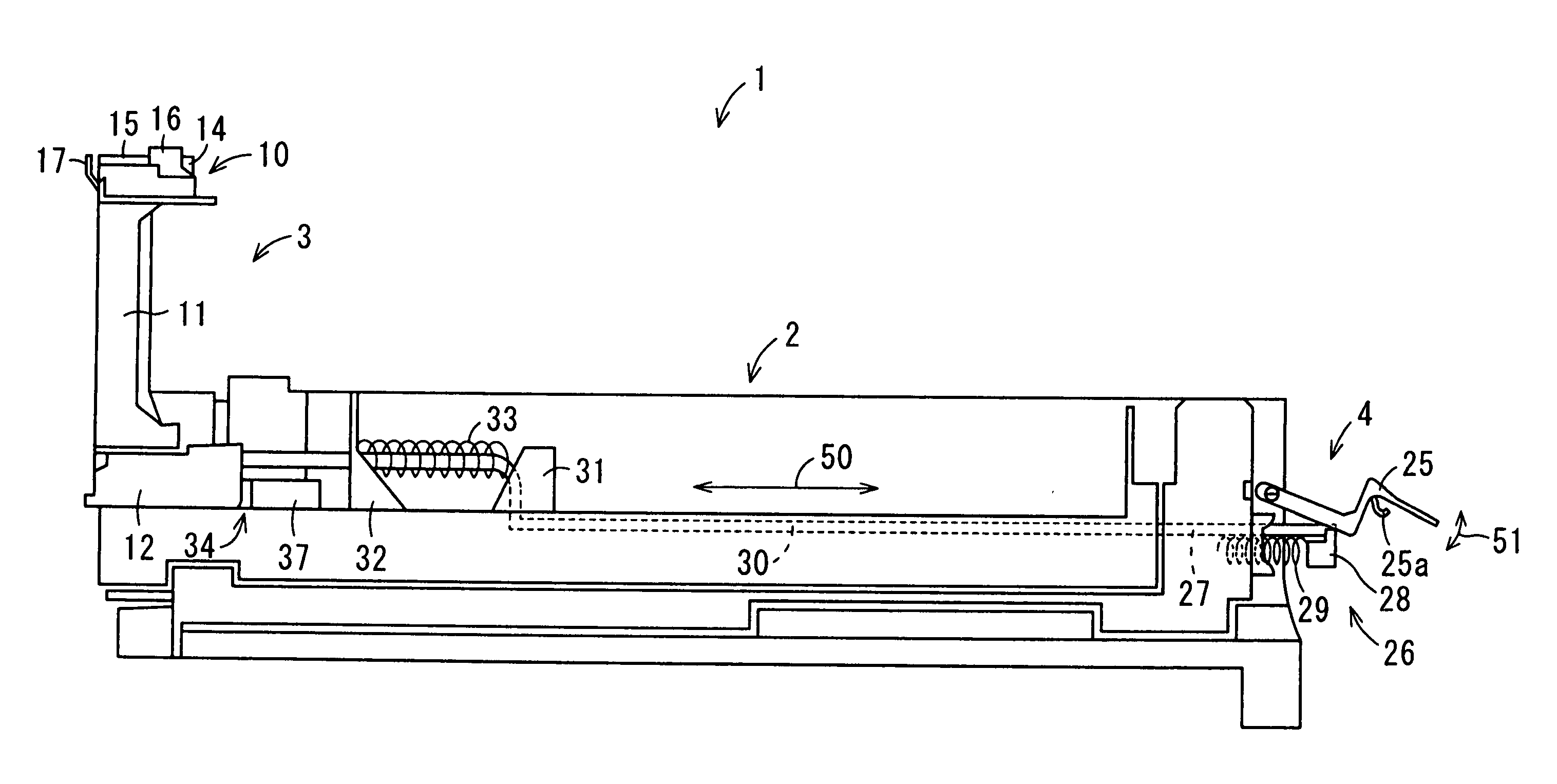

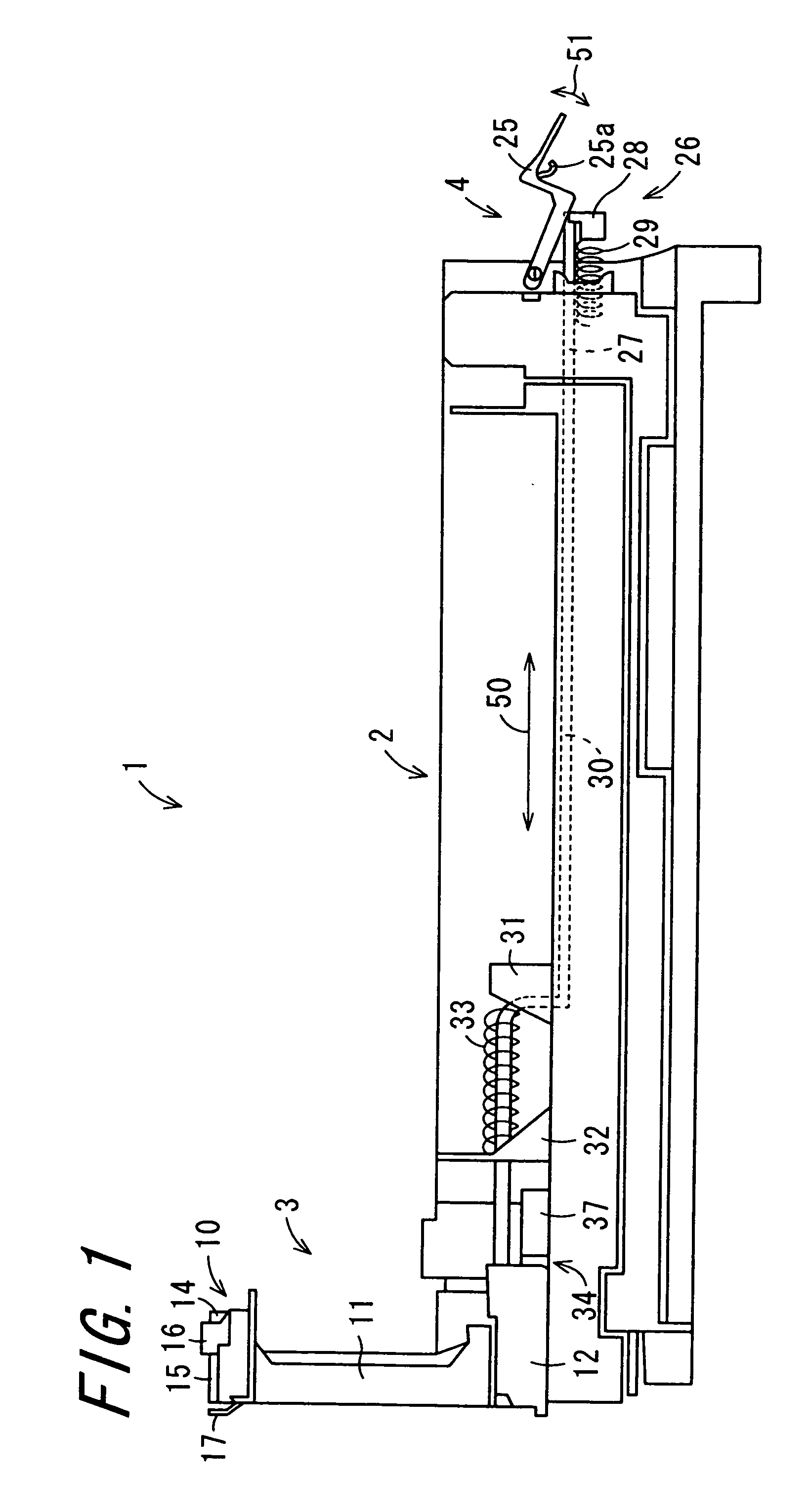

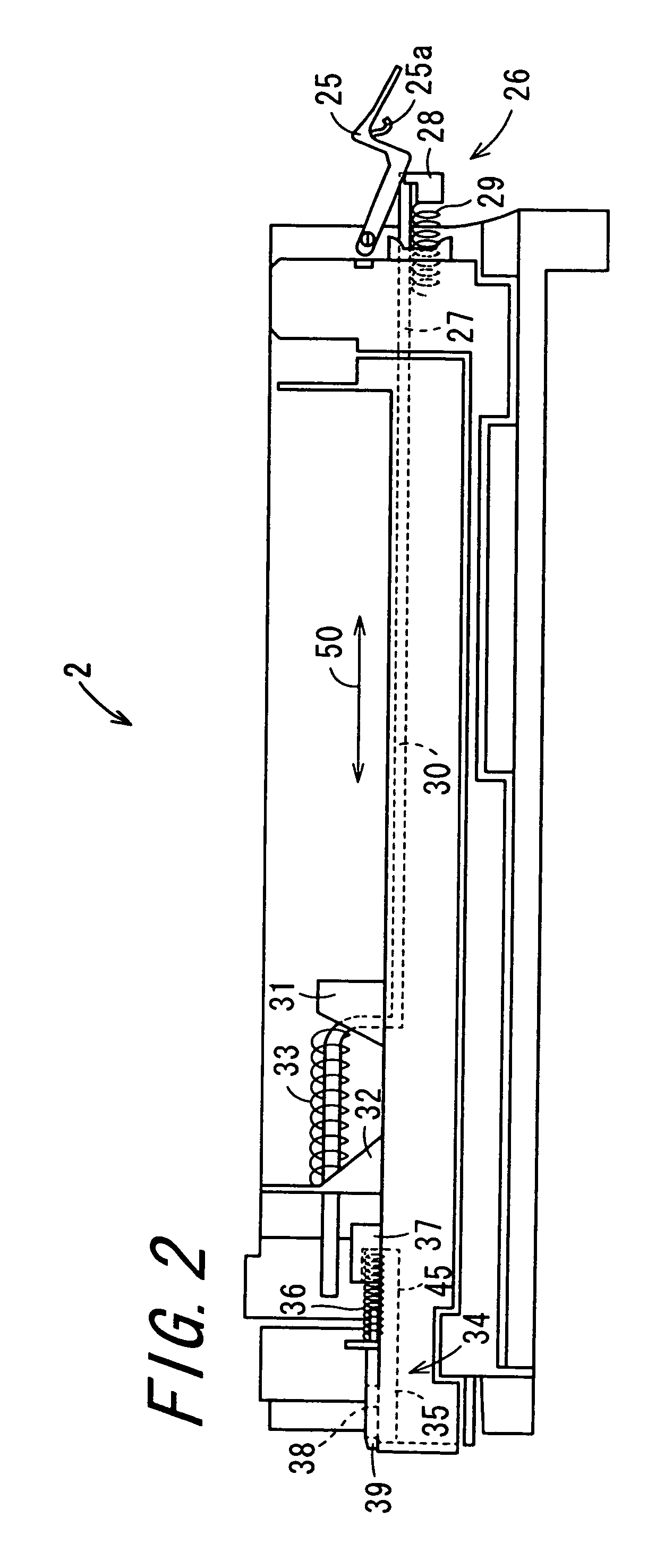

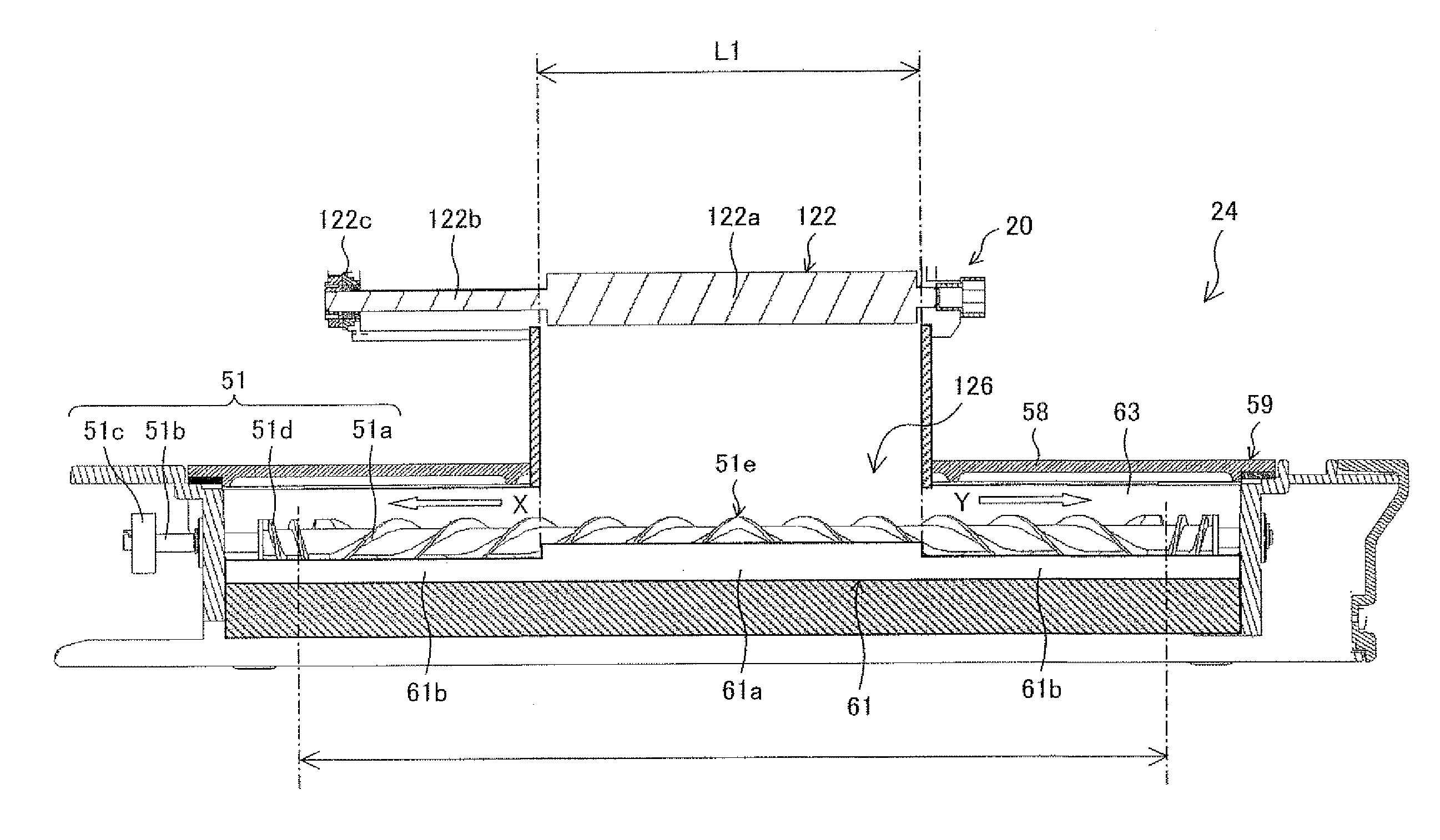

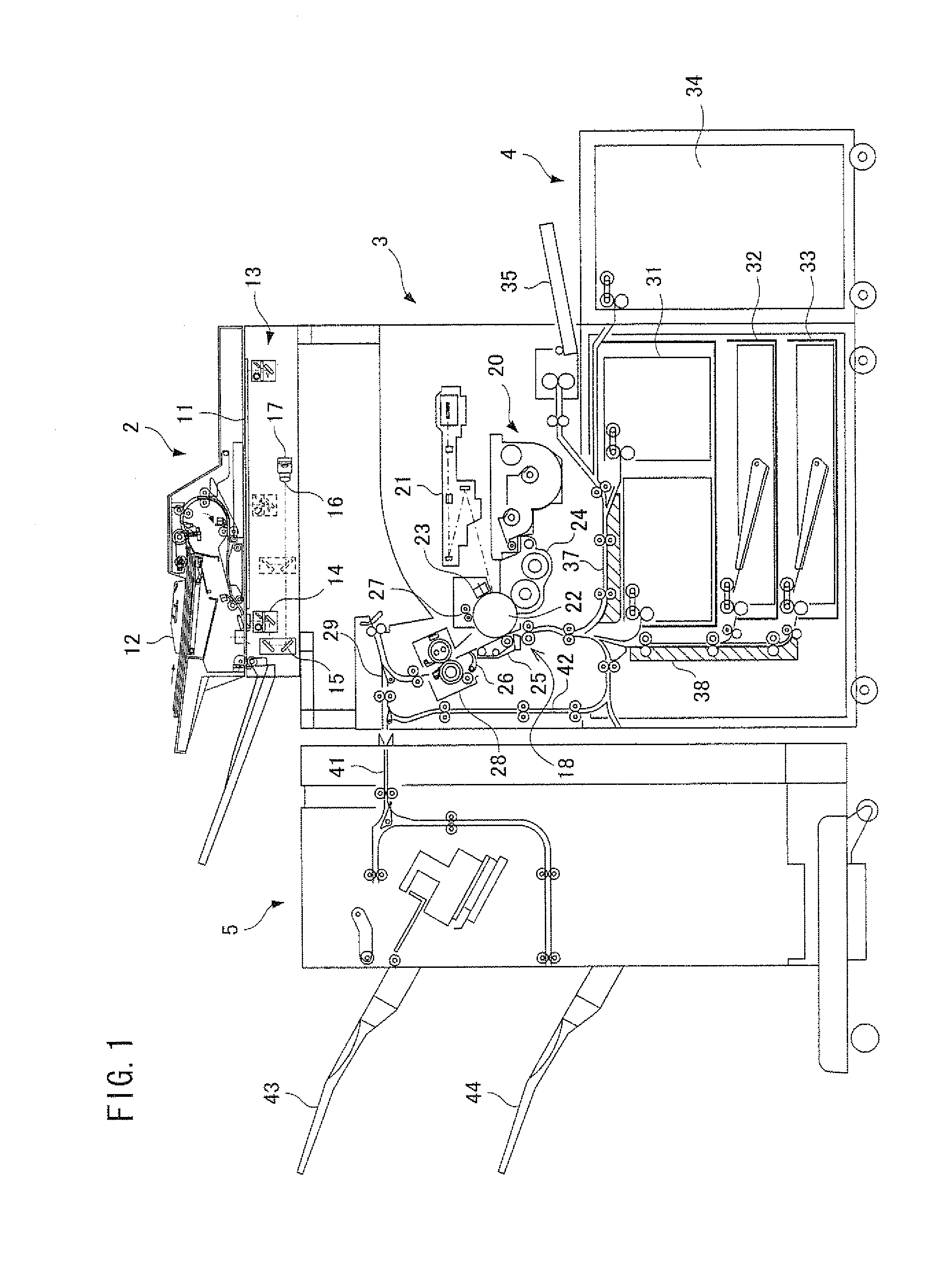

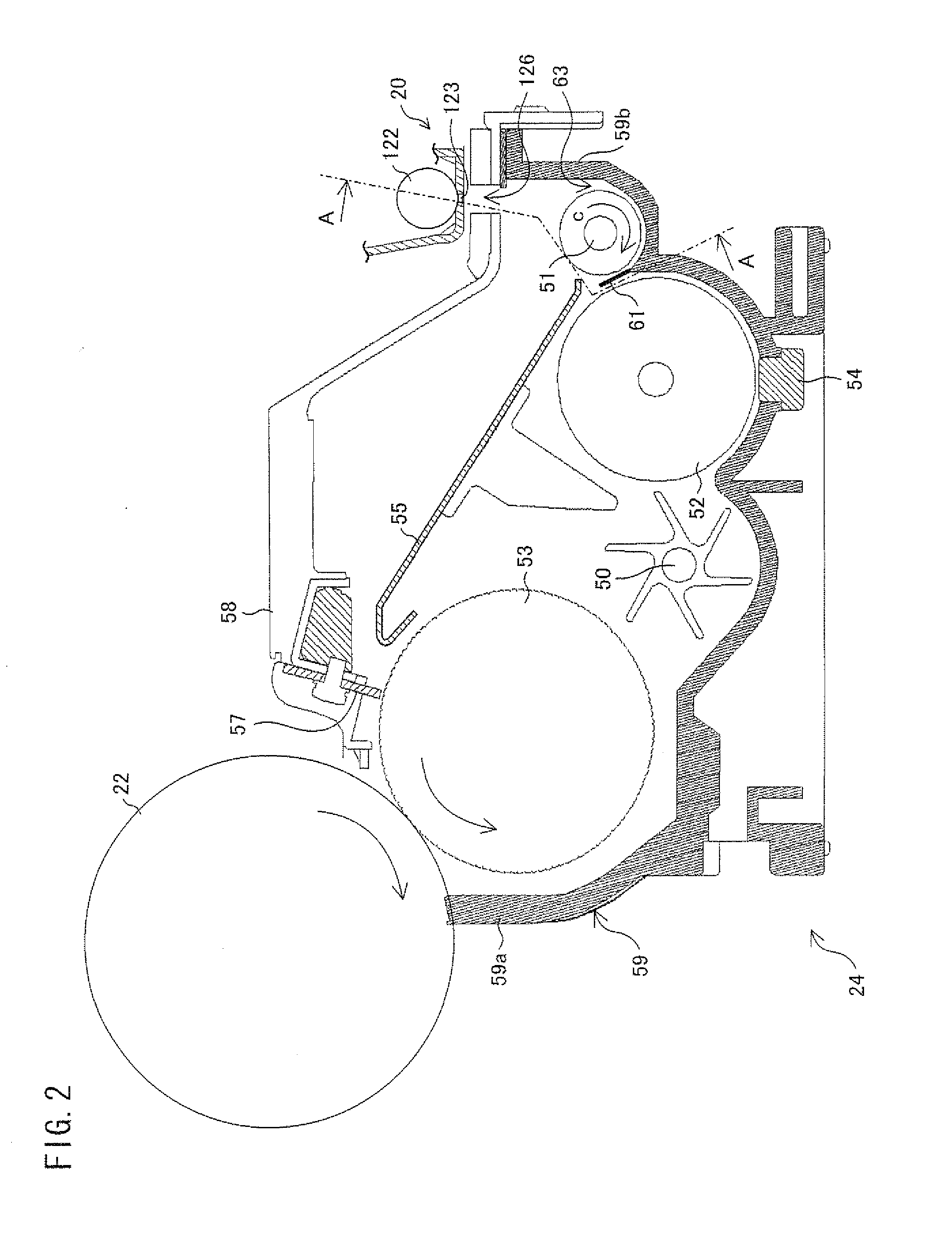

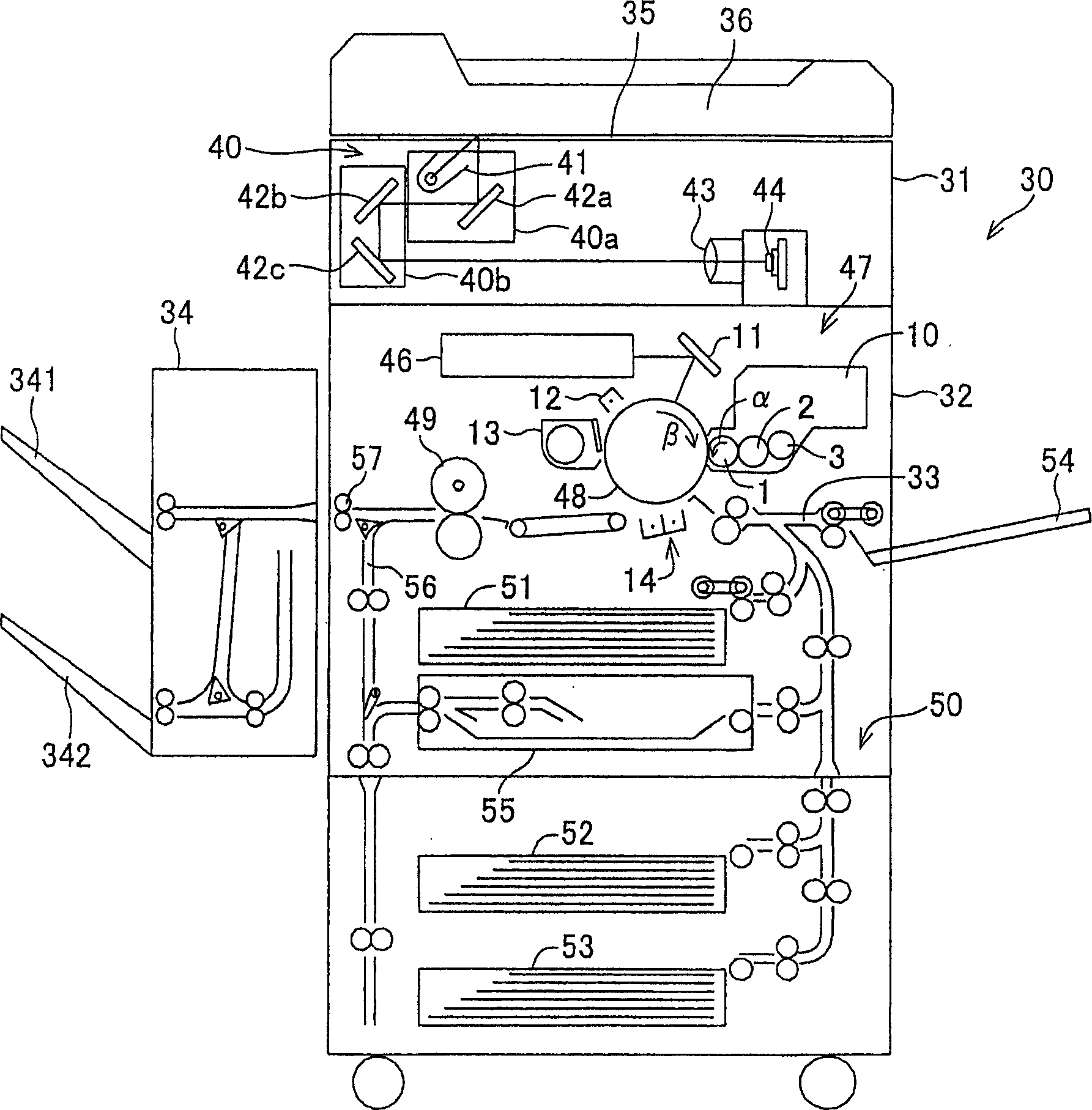

Developing device, image forming apparatus, developer agitating and conveying method

ActiveUS20120163872A1Reliable chargingEasy to chargeElectrographic process apparatusSpiral bladeDeveloping tank

A developing device includes a developer tank and a developing roller. An internal space of the developer tank is divided into an upper conveying path, a lower conveying path, a communication path, a main pumping conveying path section, and a developer supply path, by a partition wall. A developer pumping conveying section conveys a developer inside the main pumping conveying path section in a conveyance direction Z, and includes an inner spiral blade, a rotational tube, a first outer spiral blade, a second outer spiral blade, a pumping rotation shaft member, and a pumping gear. An attracting magnet is located in a position horizontally spaced from the rotational tube.

Owner:SHARP KK

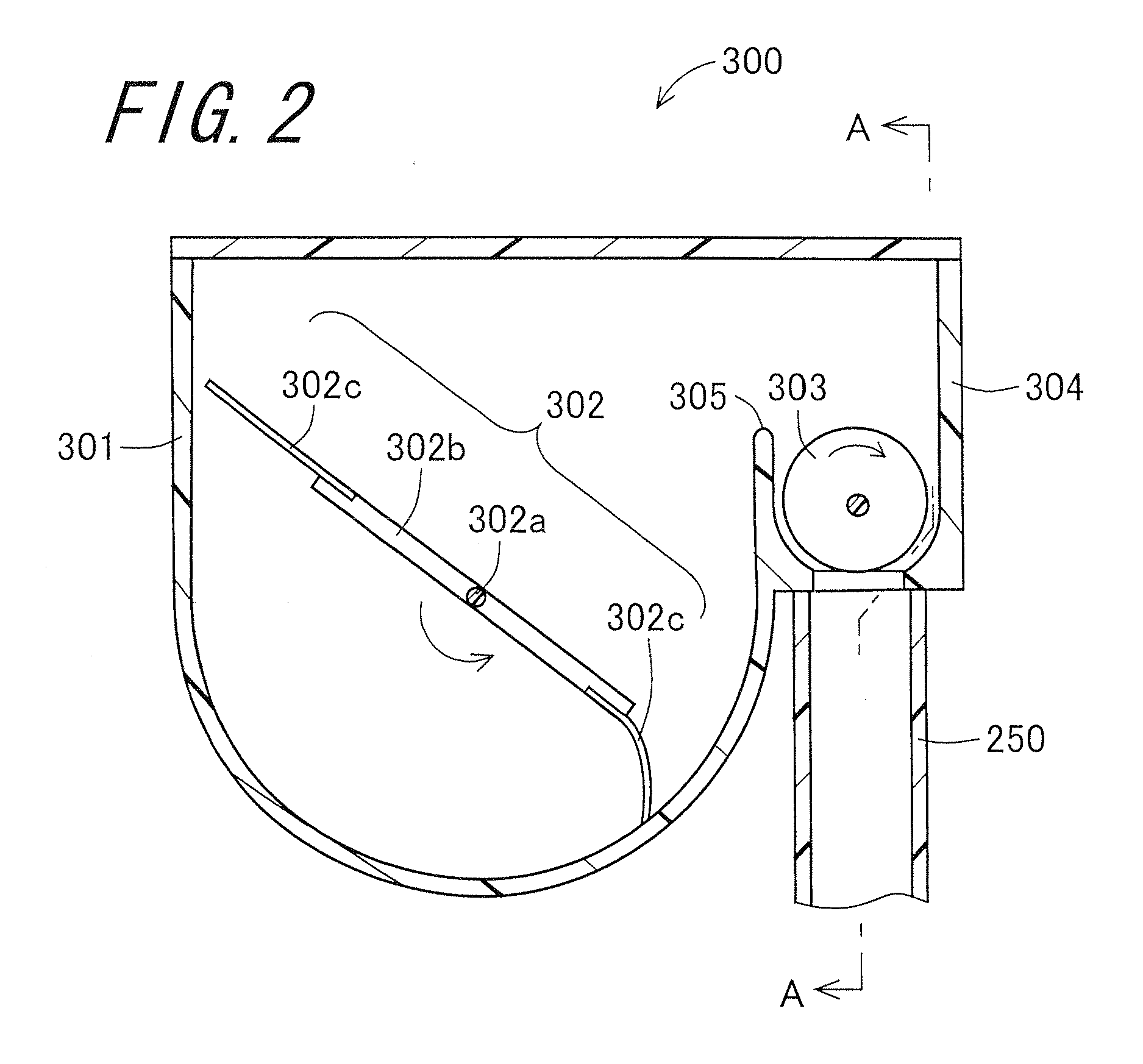

Developing cartridge and image forming apparatus using the same

ActiveUS20100092196A1Prevent leakageElectrographic process apparatusElectrical conductorLatent image

A developing cartridge includes: a developing roller for developing an electrostatic latent image of a photoconductor with a toner; and a developing tank for storing the toner to be supplied to the developing roller, the developing tank including: a toner receiving port for receiving the toner to be stored; a shutter having a function for sliding to open and close the toner receiving port, the shutter being adapted to be maintained in a closed state by an electrically-releasing adhesive; and a pair of conductive member for supplying an electric current to the electrically-releasing adhesive to open the shutter.

Owner:SHARP KK

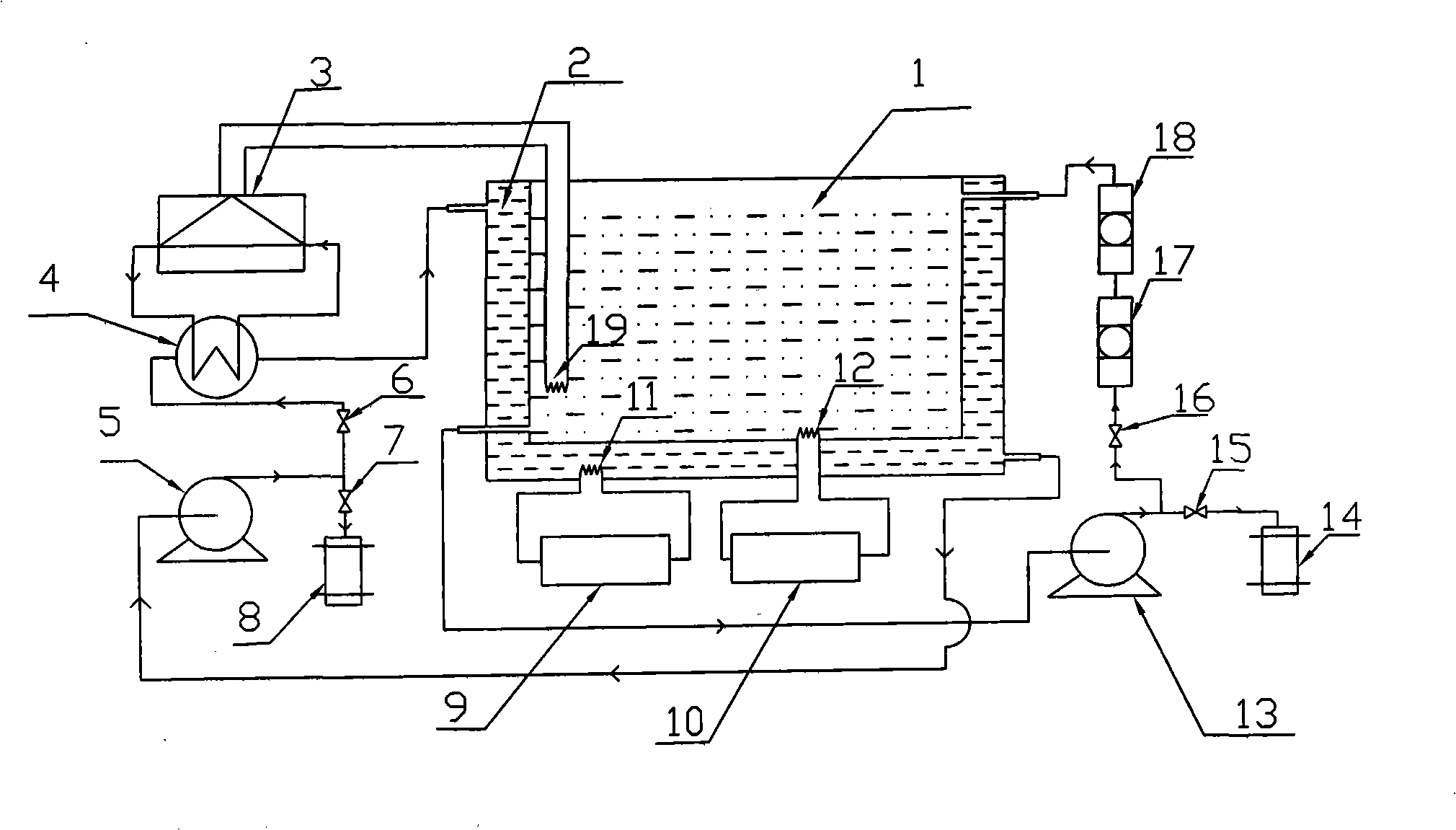

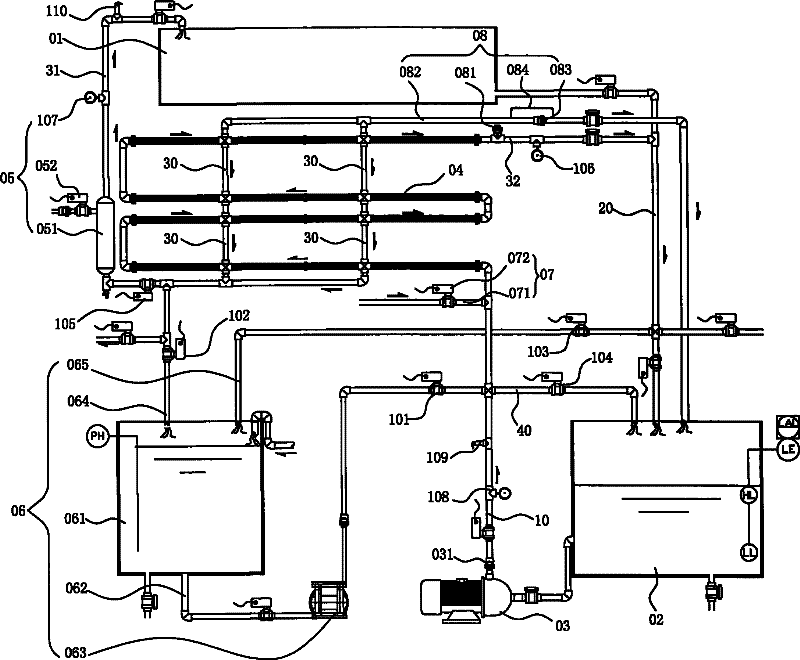

Constant temperature method and device for mask plate developing solution

ActiveCN101403868ASolve quality exceptionsHigh precisionTemperature control using electric meansPhotosensitive material processingWater bathsDeveloping tank

Owner:深圳清溢光电股份有限公司

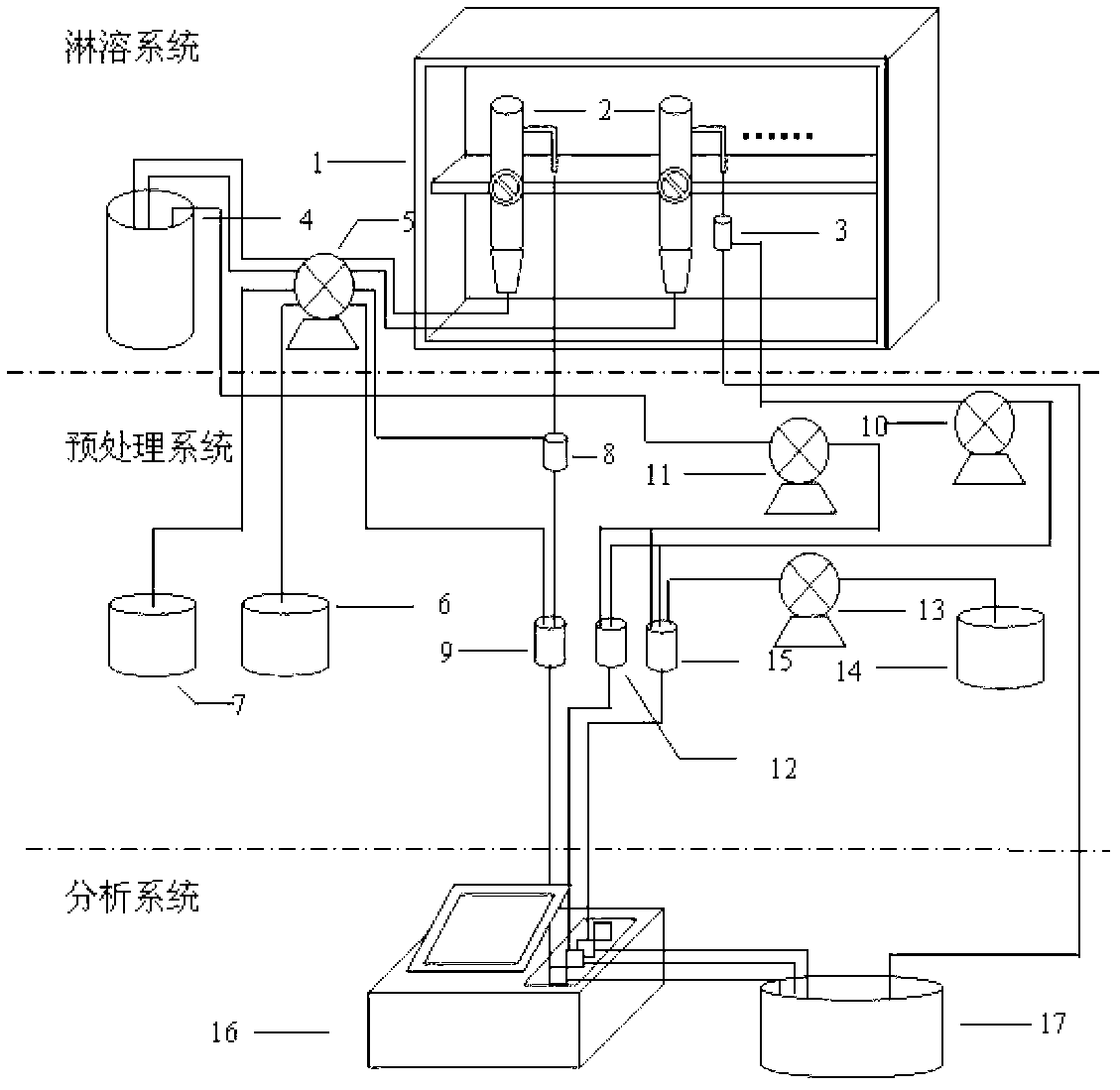

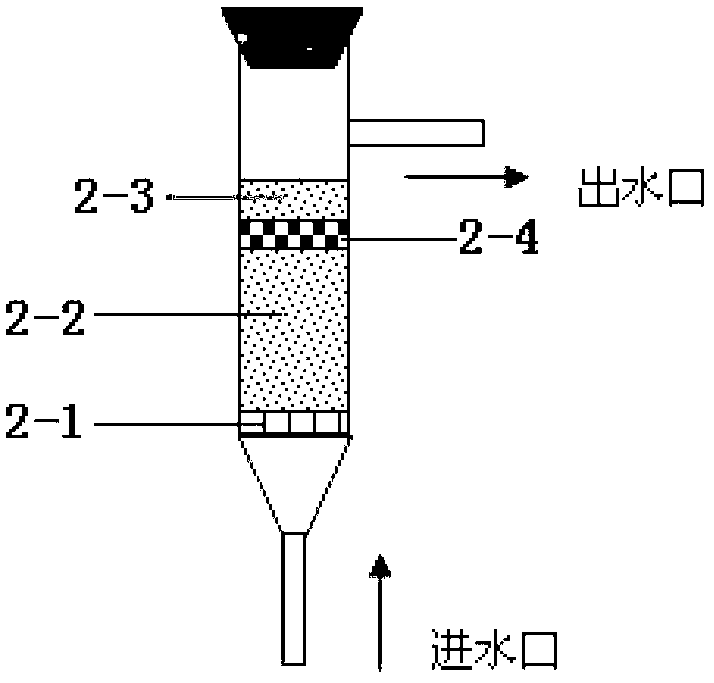

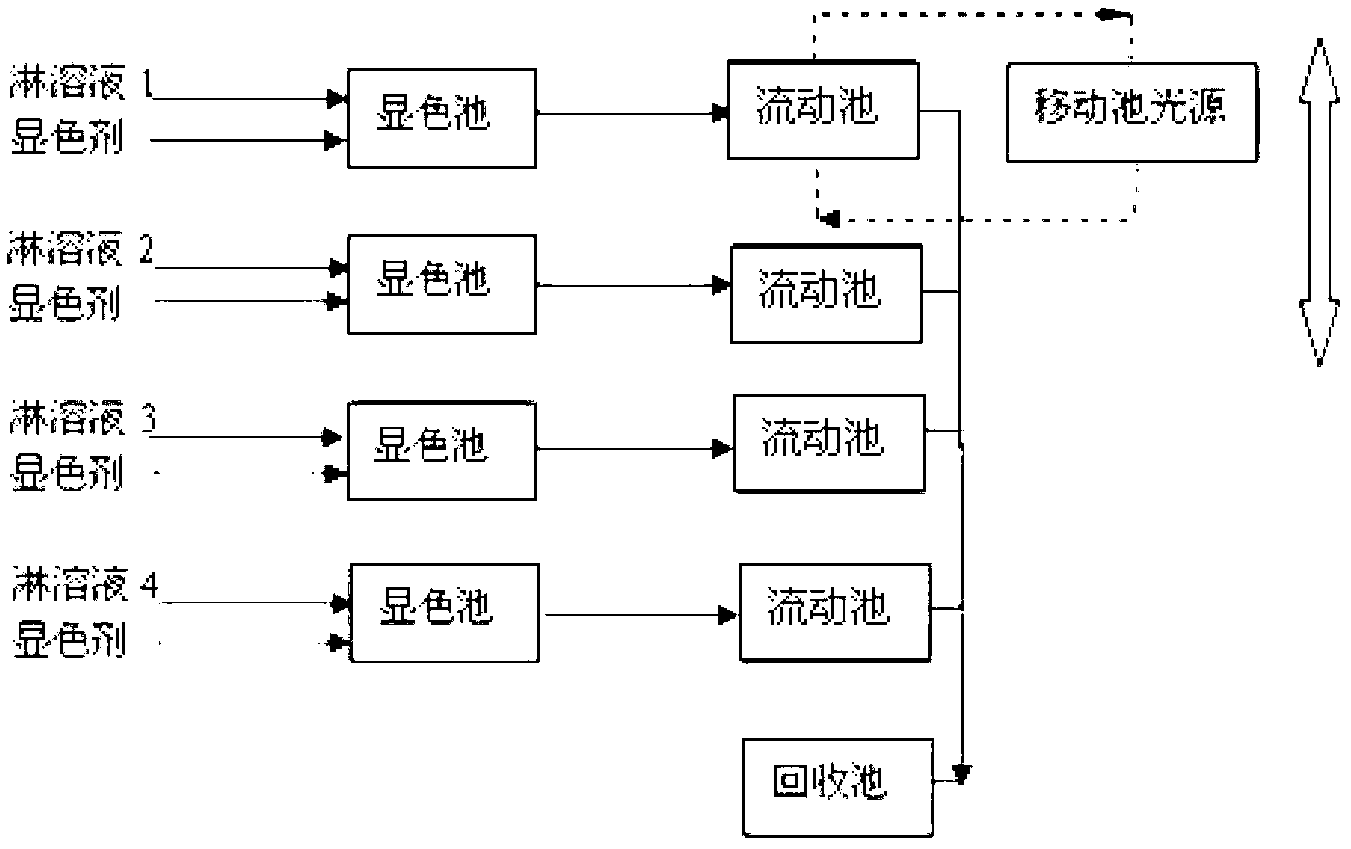

Online detection device of water dissolved-out nitrogen nutrients of chemical fertilizer

ActiveCN103217394AGood repeatabilityEasy to drawColor/spectral properties measurementsCompound (substance)Developing tank

The invention discloses an online detection device of water dissolved-out nitrogen nutrients of a chemical fertilizer. The online detection device comprises a leaching solution, a pre-treatment system and an analyzing system, wherein the leaching system is internally provided with a plurality of leaching pipes and adopts a leaching manner from bottom to top to leach a sample; outlet water of each leaching pipe of the pre-treatment system directly enters developing tanks or is automatically sampled and diluted and then enters the developing tanks; each developing tank is externally connected with a developing agent conveying pipeline to automatically develop; and the analyzing system is formed by a spectrophotometer which is provided with flowing tanks after being improved, and a recycling tank, and different wavelengths can be set according to a project to be detected of each flowing tank and rapid and alternative detection can be carried out through software control. According to the online detection device disclosed by the invention, online analysis of water dissolved-out concentration and quality is carried out on a plurality of the nitrogen nutrients in the same chemical fertilizer sample or the same nitrogen nutrient of the different chemical fertilizer samples.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Development device and image forming apparatus comprising same

InactiveUS20080219699A1Avoid dirtyFunction increaseElectrographic process apparatusDeveloping tankImage formation

The development device of the present invention has a rotating shutter supported rotatably between a supply opening formed on a toner supply device and a receiving opening formed on a developing tank. The rotating shutter has an open section extending in the axial direction of the roller-shaped main section as well as opened in the direction perpendicular to the axial direction thereof, opening and shutting the supply opening in conjunction with attachment and detachment operation of the developing tank. The rotating shutter shuts the supply opening by covering the supply opening with the outer surface of the roller-shaped main section, and opens the supply opening by communicating the supply opening and the receiving opening through the open section. Thus, it is possible to prevent the leakage of toner even after repetitively performing the attachment and detachment operation of the developing tank.

Owner:SHARP KK

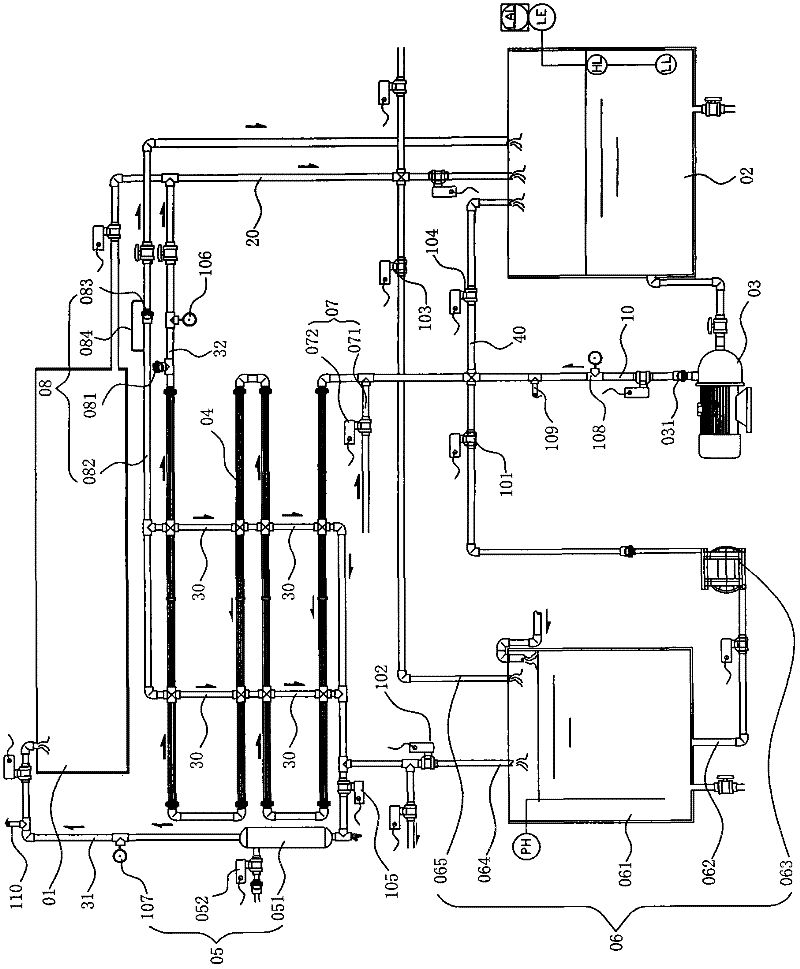

Cleaning system and cleaning method of developing solution circulation process equipment

ActiveCN102053507AGuaranteed filter functionProtection from cloggingPhotosensitive material processingCleaning using liquidsProcess equipmentPipe fitting

The invention discloses a cleaning system and a cleaning method of developing solution circulation process equipment. The cleaning system of the developing solution circulation process equipment comprises a developing tank, a concentration tank, a circulation power pump and a microfiltration film pipe fitting adopting cross filtration, wherein the developing tank is connected to the concentrationtank; the concentration tank is connected to the circulation power pump; the circulation power pump is connected to one end of the microfiltration film pipe fitting through the water outlet pipeline of the pump; the other end of the microfiltration film pipe fitting is connected to the concentration tank through a strong water return pipeline; and the microfiltration film pipe fitting is connected to the developing tank through a filter liquor return pipeline. Particularly, a back washing device, a medicine washing device and a water washing device are fully designed in the cleaning system for the cleaning of the microfiltration film pipe fitting, so as to prevent a microfiltration film from being blocked and maintain the optimum filtration function of the microfiltration film pipe fitting; and meanwhile, a film pipe protecting device is further arranged in the cleaning system, whether the microfiltration film pipe fitting needs cleaning is judged by a controller, and the corresponding cleaning mode is selected through the controller, so as to control the start-up of different cleaning devices.

Owner:GUANGDONG VICDI TECH

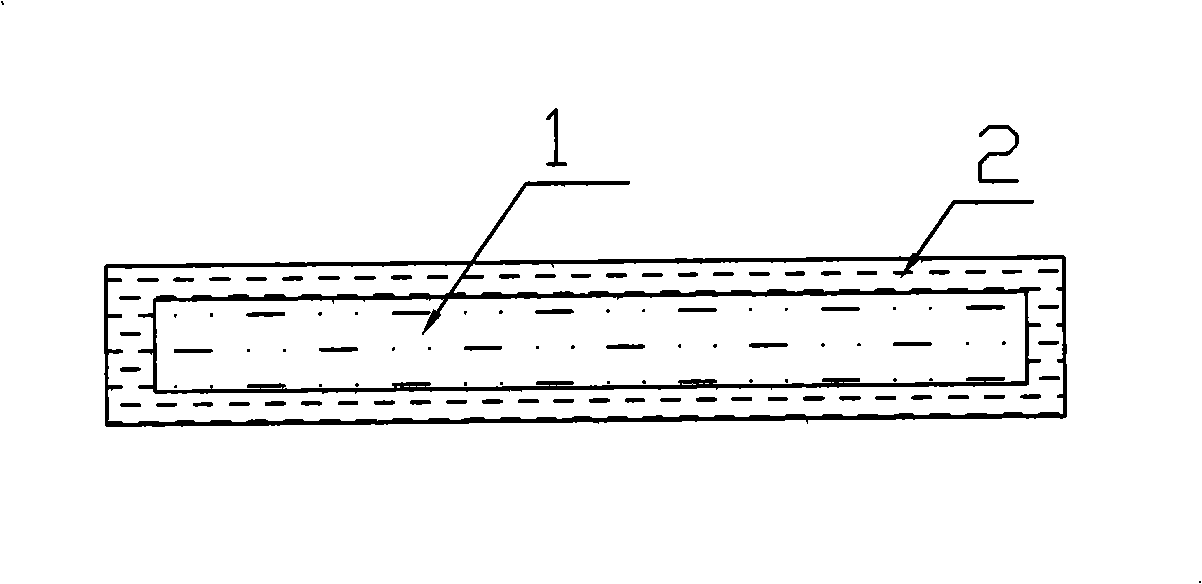

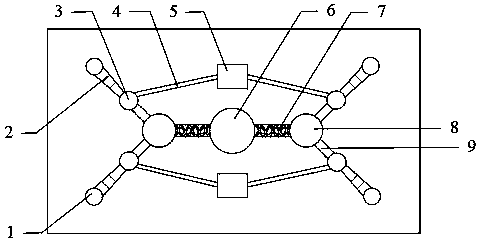

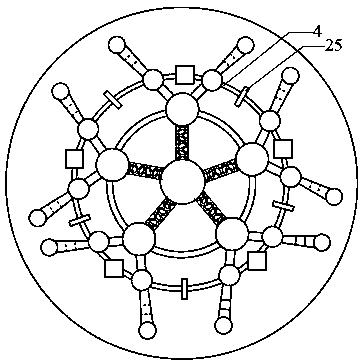

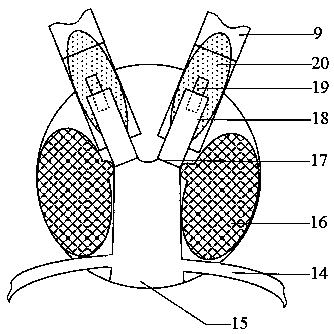

Paper-based micro-fluidic chip with multi-channel heavy metal ion detection function

ActiveCN109060793APrecise shuntSpeed up the flowMaterial analysis by observing effect on chemical indicatorGeneral water supply conservationPaper basedDeveloping tank

The invention provides a paper-based micro-fluidic chip with a multi-channel heavy metal ion detection function. The paper-based micro-fluidic chip is composed of a first layer of paper substrate, a second layer of paper substrate, a third layer of paper substrate and a bottom layer supporting substrate, and is characterized in that the chip is round or rectangular, and the three layers of paper substrates which are consistent in shape and size and are subjected to hydrophobic treatment are pasted together. The chip is provided with a color developing tank, a gradient channel, a reaction tank,a reagent channel, a reagent port, a sample port, a filter tank, a diversion tank, a diversion channel and a filtrate mutual channel with specific shapes and sizes. According to the chip, various functional components are arranged in a star shape by taking the sample port as a center. Or the sample port and the reagent port are taken as the center separately, and a left center and a right centerare formed, and the other functional components are arranged in the middle of the sample port and the reagent port. The paper-based micro-fluidic chip has the beneficial effects that the chip is disposable, the material adopts the low-price degradable filter paper, and the chip is environment-friendly and pollution-free, so that secondary damage to the environment is avoided; and continuous, real-time and rapid detection of heavy metal ions can be realized for environmental monitoring.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

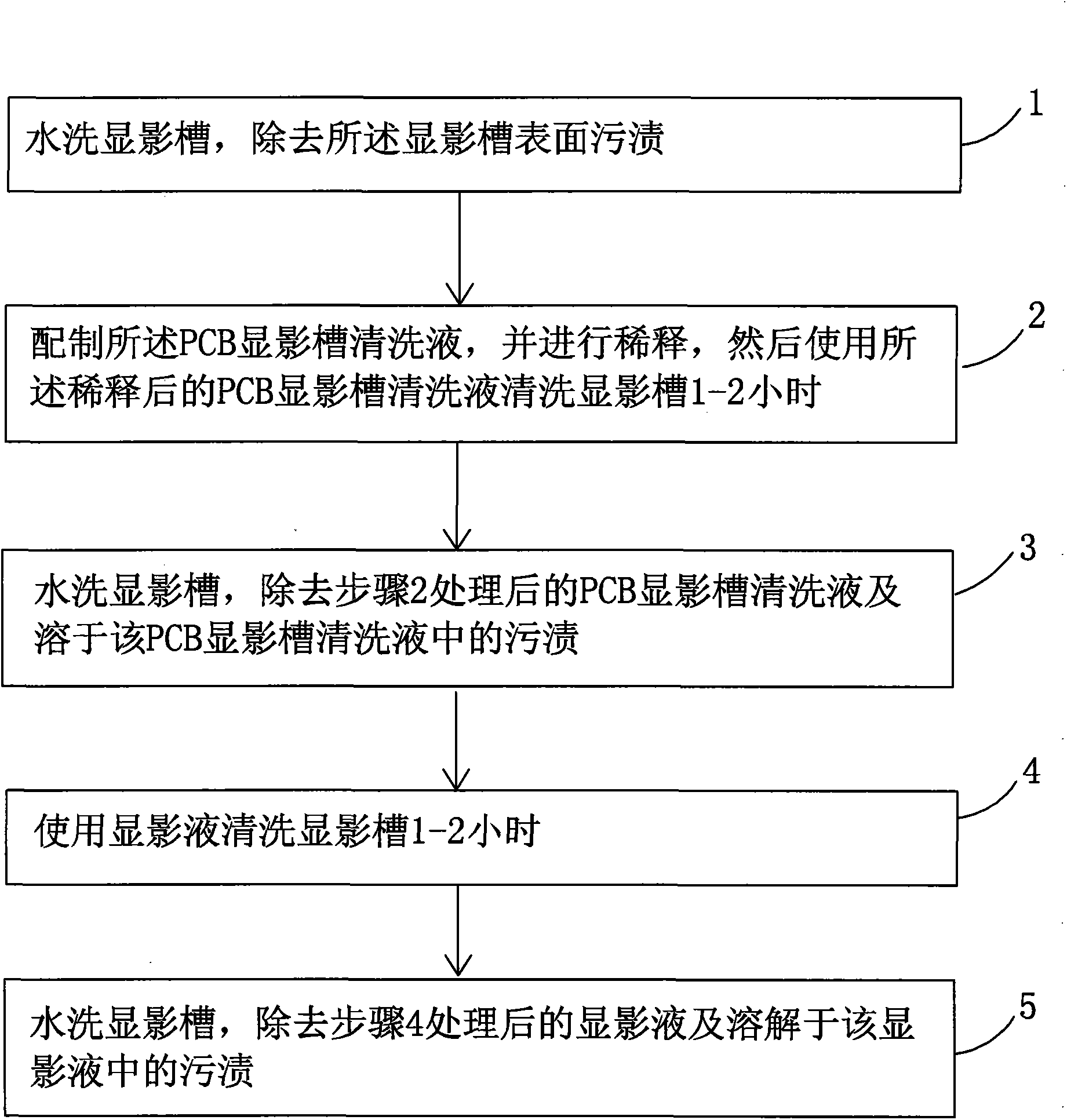

PCB developing tank cleaning solution and method for cleaning developing tank by using same

The invention provides a PCB developing tank cleaning solution and a method for cleaning a developing tank by using the same. The PCB developing tank cleaning solution comprises the following components in percentage by mass: 10-20% of ethylene glycol monobutyl ether, 15-30% of an emulsifying agent, 20-40% of acid and the balance of water. Ethylene glycol monobutyl ether is used as a bulking agent in the PCB developing tank cleaning solution to ensure that non-photosensitive solder resist ink is gradually dissolved into the PCB developing tank cleaning solution, beads formed by the solder resist ink are further decomposed into very fine particles by using emulsifying agent, a layer of milky substances is formed on the surfaces of the particles, and therefore, the non-photosensitive solder resist ink remained in a PCB developing tank is effectively cleaned under the combination action of acid and water; when the developing tank is cleaned by using the PCB developing tank cleaning solution, the PCB developing tank cleaning solution is not needed to be heated to very high temperature, the cleaning time is relatively short, and the cleaning effect is rather ideal.

Owner:SHENZHEN SHIRUITAI TECH

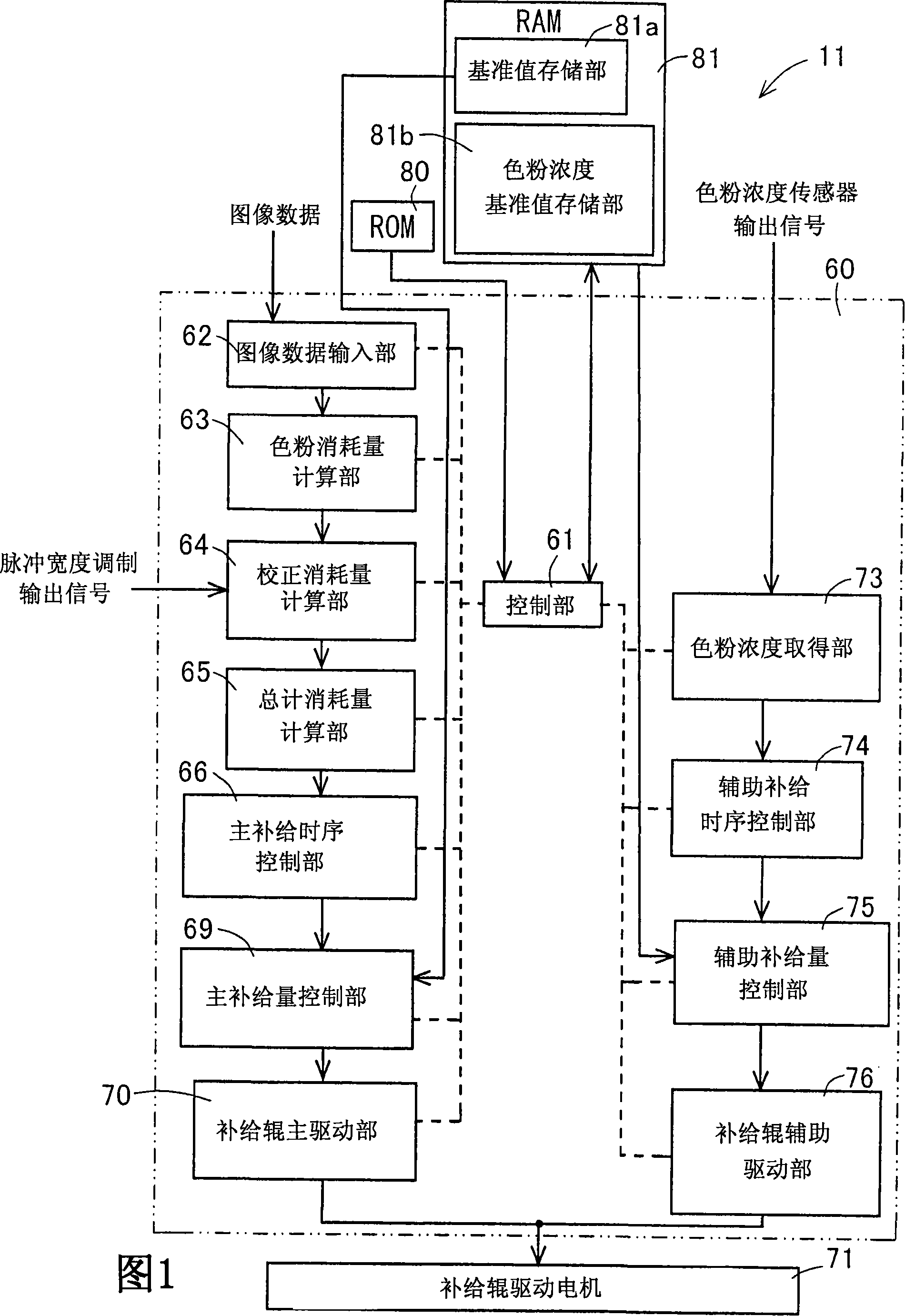

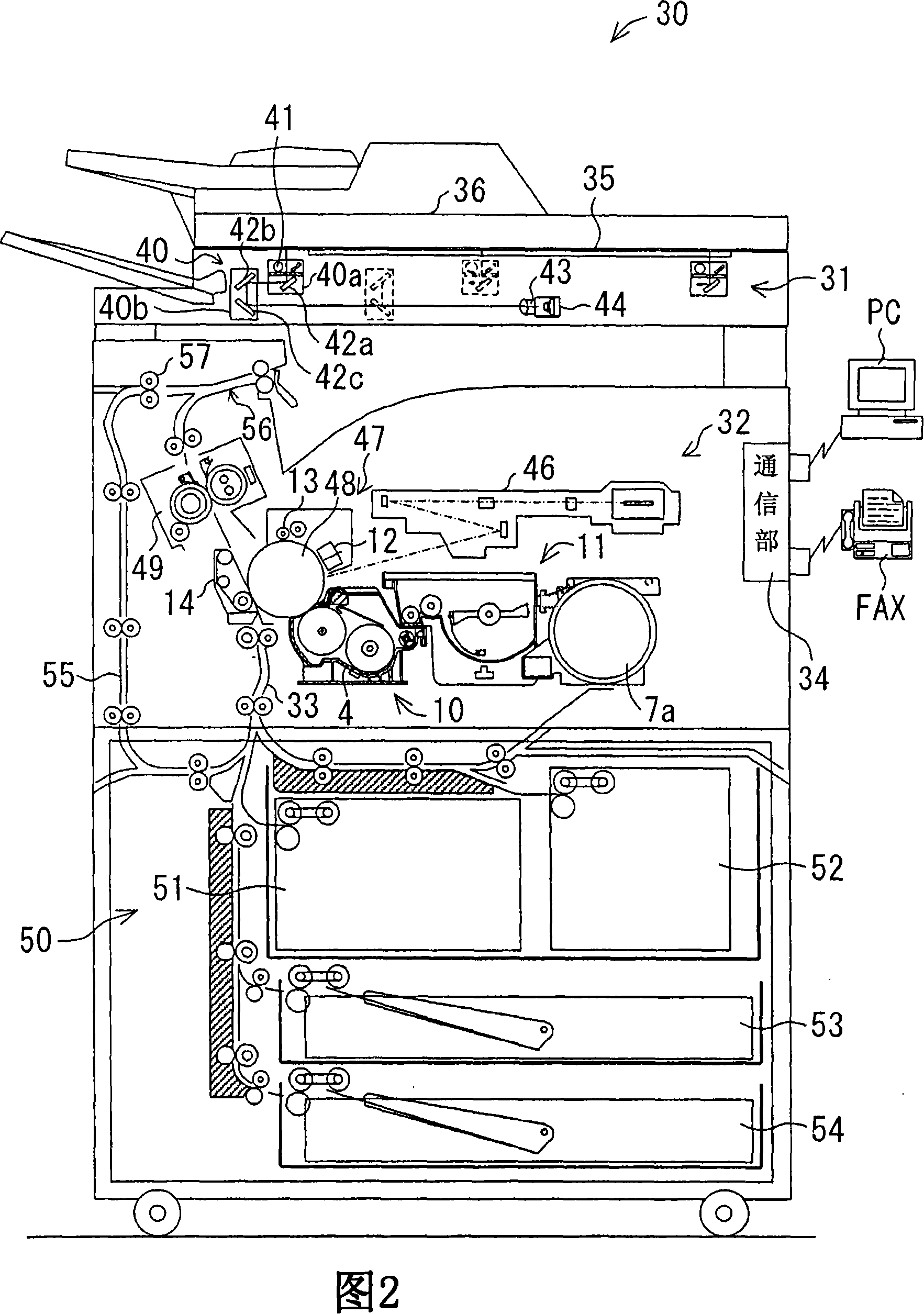

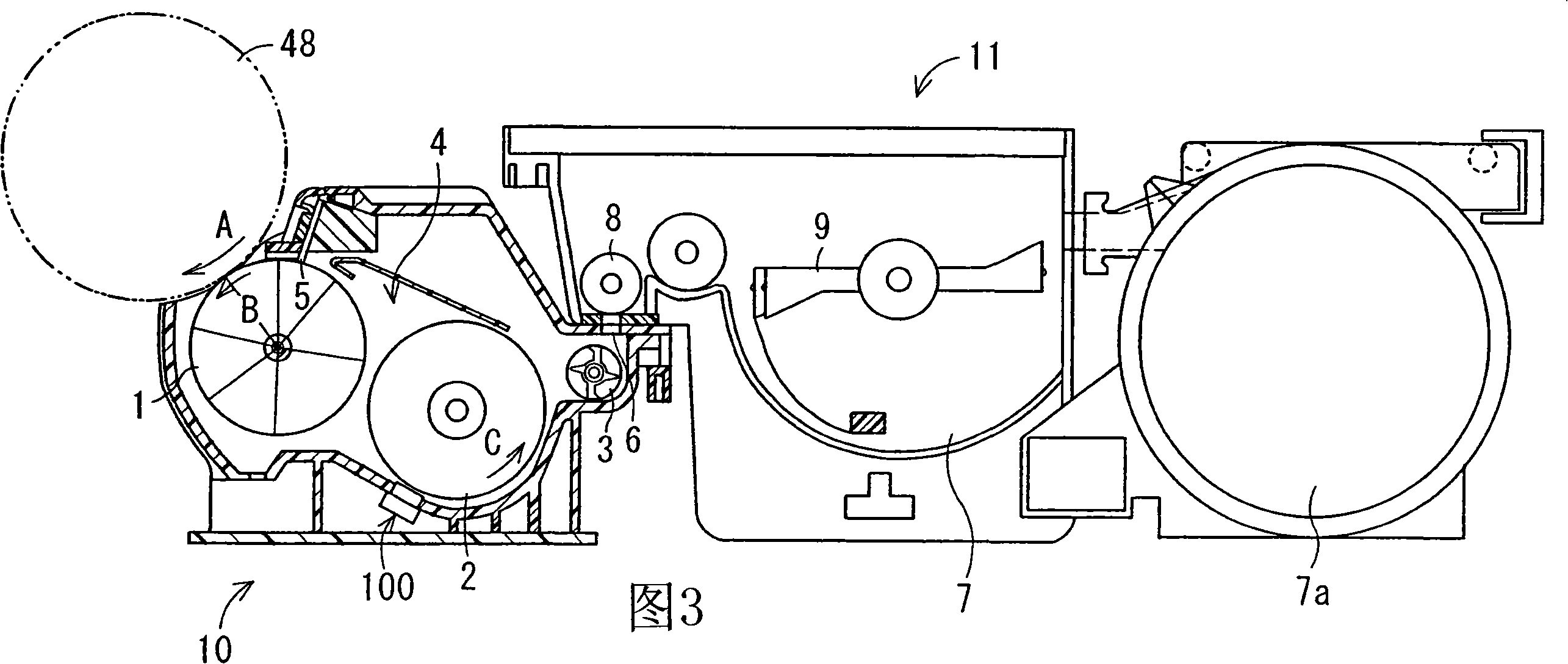

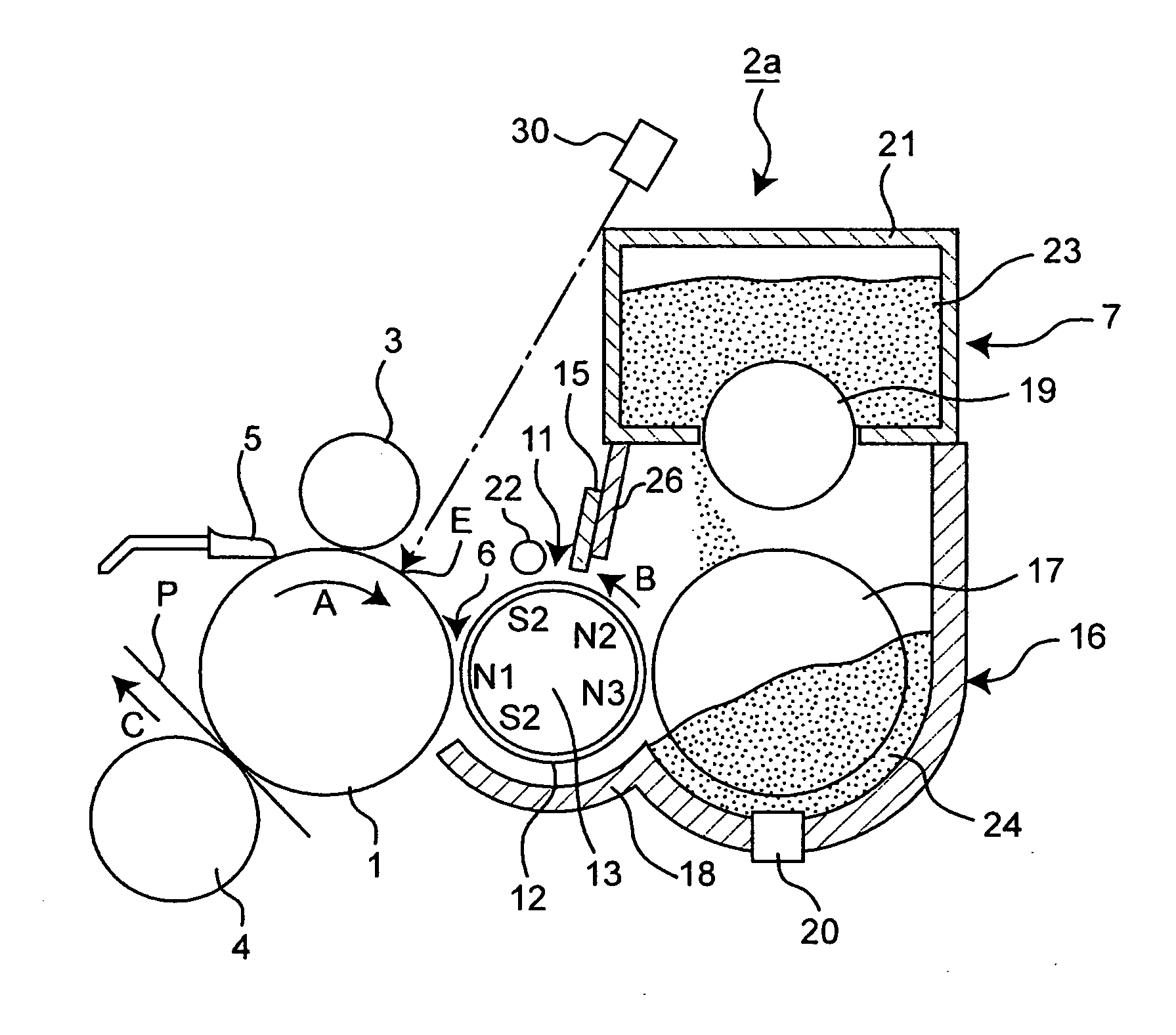

Toner replenishing device and image forming apparatus

Owner:SHARP KK

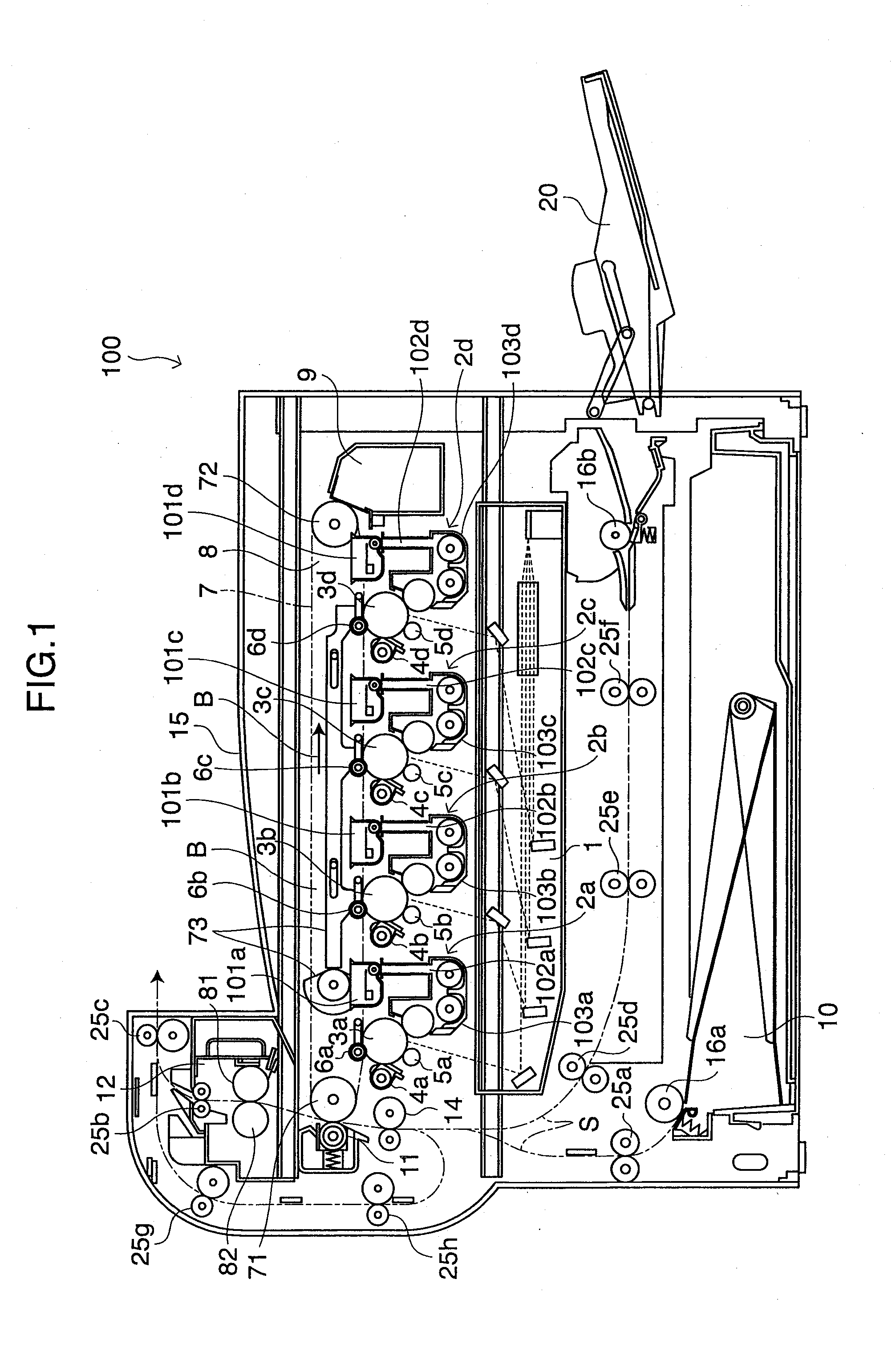

Developing device and image-forming apparatus

InactiveUS20070071506A1Reduce the impactEffective compensationElectrographic process apparatusImage formationDeveloping tank

Owner:KONICA MINOLTA BUSINESS TECH INC

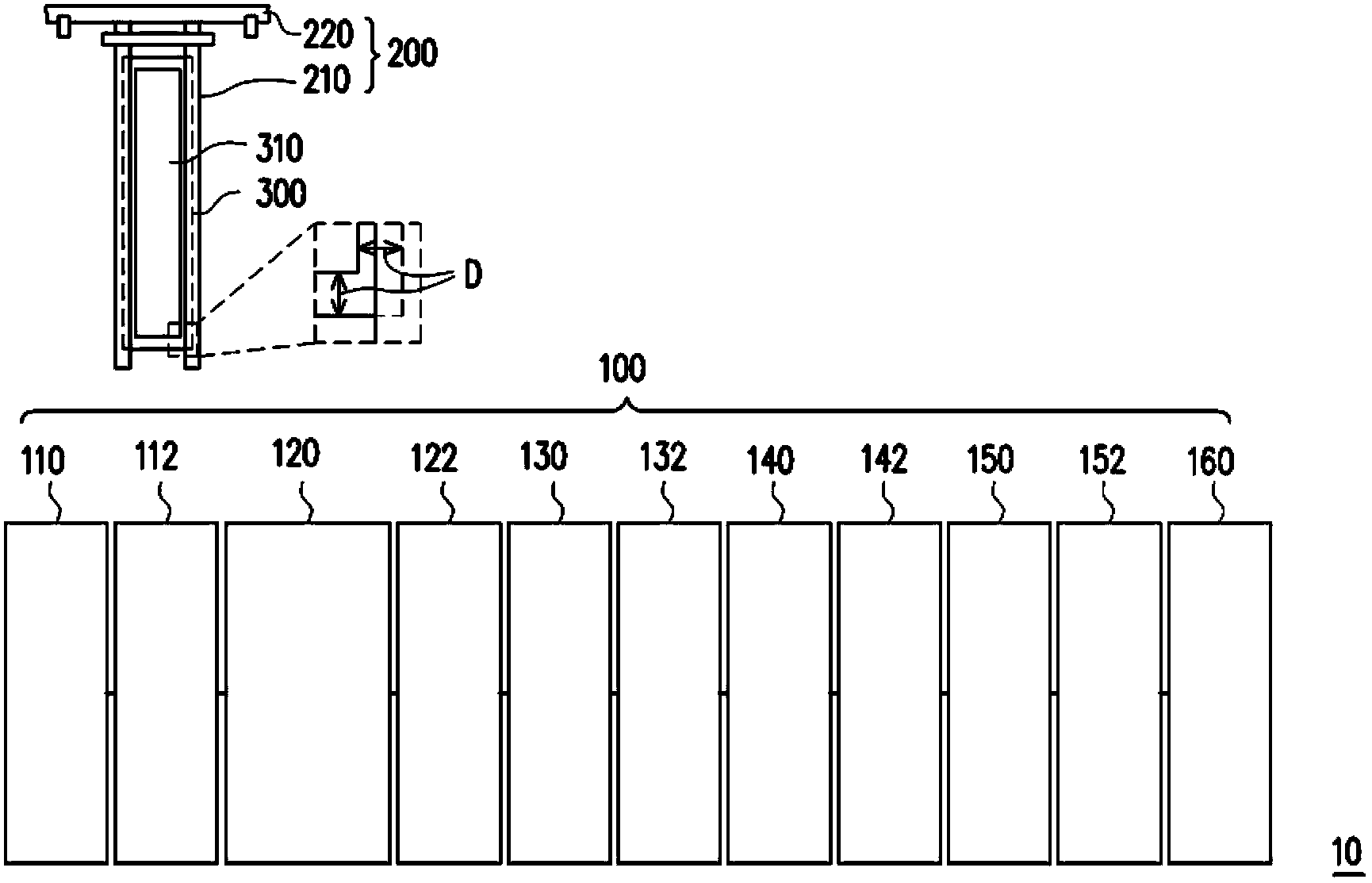

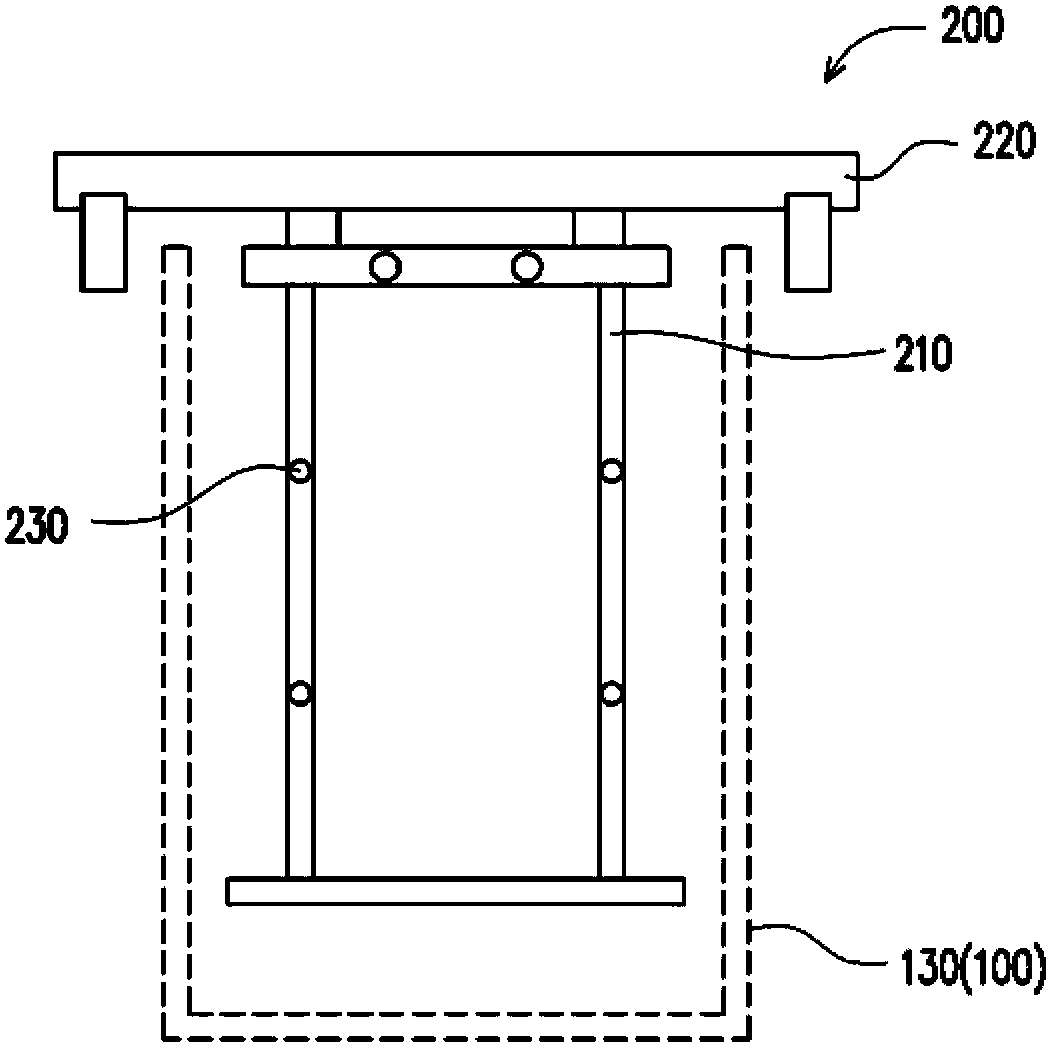

Circuit-board developing, electroplating and etching device

ActiveCN103491715AImprove yieldReduce the influence of external environmental factorsConductive material chemical/electrolytical removalDeveloping tankAcid washing

The invention discloses a circuit-board developing, electroplating and etching device suitable for carrying out manufacturing processes of developing, electroplating and etching on an exposed circuit board. The circuit-board developing, electroplating and etching device comprises a plurality of tank units and a moving unit. The tank units comprise a developing tank, a first water washing tank, an acid washing tank, a second water washing tank, an electroplating tank, a third water washing tank, a stripping tank, a fourth water washing tank, an etching tank, a fifth water washing tank and a drying tank, wherein the tanks are connected with one another in sequence. The moving unit clamps the exposed circuit board and enables the exposed circuit board to pass through the developing tank, the first water washing tank, the acid washing tank, the second water washing tank, the electroplating tank, the third water washing tank, the stripping tank, the fourth water washing tank, the etching tank, the fifth water washing tank and the drying tank in sequence, and therefore the manufacturing processes of developing, electroplating and etching are completed.

Owner:TRIPOD WUXI ELECTRONICS

Developing apparatus and image forming apparatus

InactiveUS20070059045A1Guaranteed uptimeAvoid distractionElectrographic process apparatusDeveloping tankImage formation

In the developing apparatus including a developing bath and a toner transport pipe for supplying toner to the developing bath, a toner supply portion opening / closing mechanism is provided, that includes a shutter member for opening and closing a toner supply port of the toner transport pipe that is contained in a base portion of the toner transport pipe, a shaft for moving the shutter member back and forth in a longitudinal direction of the developing bath, a second spring member provided such that the shaft is inserted therein, a first spring member for supporting the shaft detachably to the shutter member through its extension and contraction, and a lever member for extending and contracting the first spring member through its releasing and closing.

Owner:SHARP KK

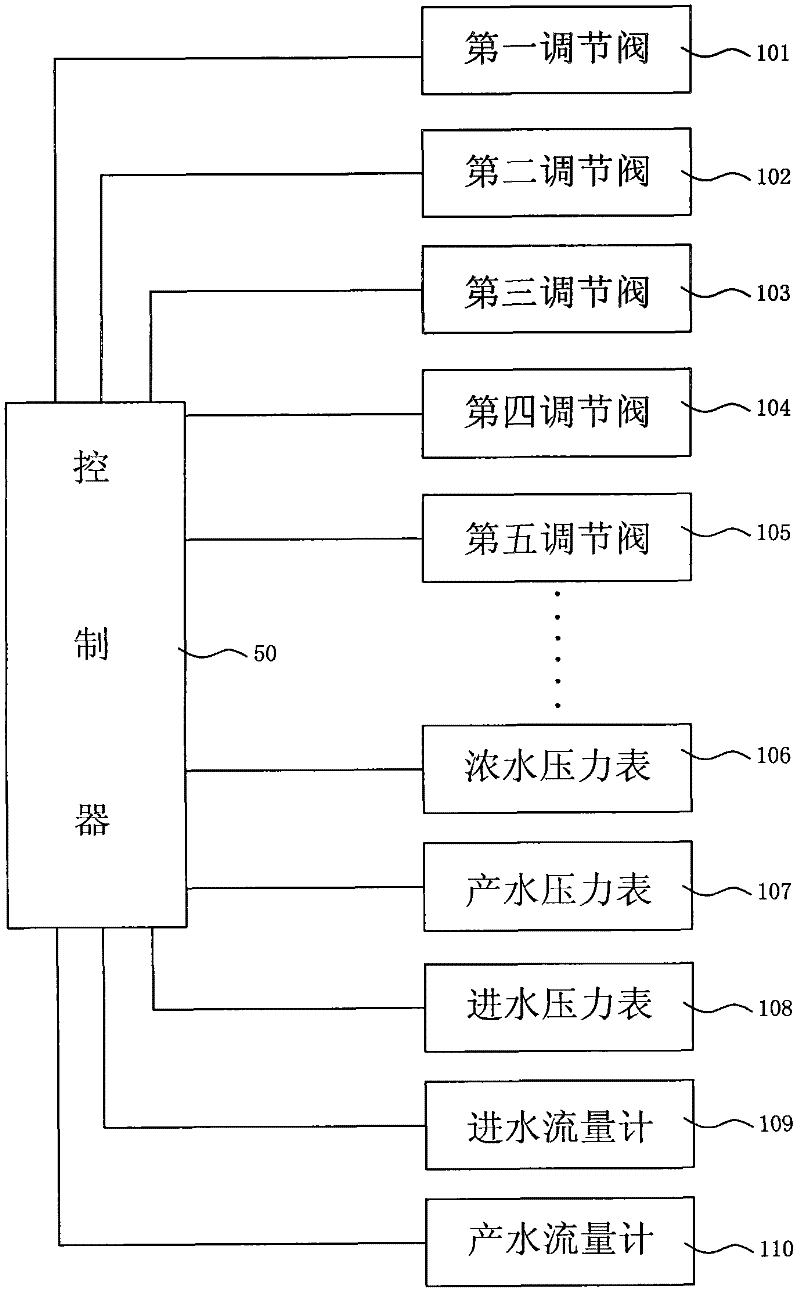

Printing developer concentration adjusting and control device

InactiveCN104122905ADensity automatic adjustmentGuaranteed stabilityControlling ratio of multiple fluid flowsColor/spectral properties measurementsMeasuring instrumentDeveloping tank

The invention provides a printing developer concentration adjusting and control device which comprises a developer tank, electric conductivity measuring instrument and the signal input end of the developing liquid storage tank is connected, effective detection of developer concentration tank, ultraviolet absorption signal input end of the light detecting unit is respectively connected with the developer tank and conductivity measuring instrument, the through the analysis of developer concentration of effective constituents in the storage tank calibration conductivity meter, conductivity meter and ultraviolet absorption signal output end of the optical detection unit and a computer display and control unit is connected; servo pump is arranged between the developer tank and chemical and water supply unit, servo pump is connected with a relay, the computer display and control output signal unit to the relay, the relay to control the servo pump to the developing tank add water or thick developer, when required, the computer display and control unit sends a stop command, servo pump stop adding. So as to ensure the stability of developer concentration, achieve the purpose of automatic adjustment of developer concentration.

Owner:TIANJIN DEBAO PRINTING

Developing device adjustment method

InactiveUS20070217802A1Improve image qualityElectrographic process apparatusLatent imageDeveloping tank

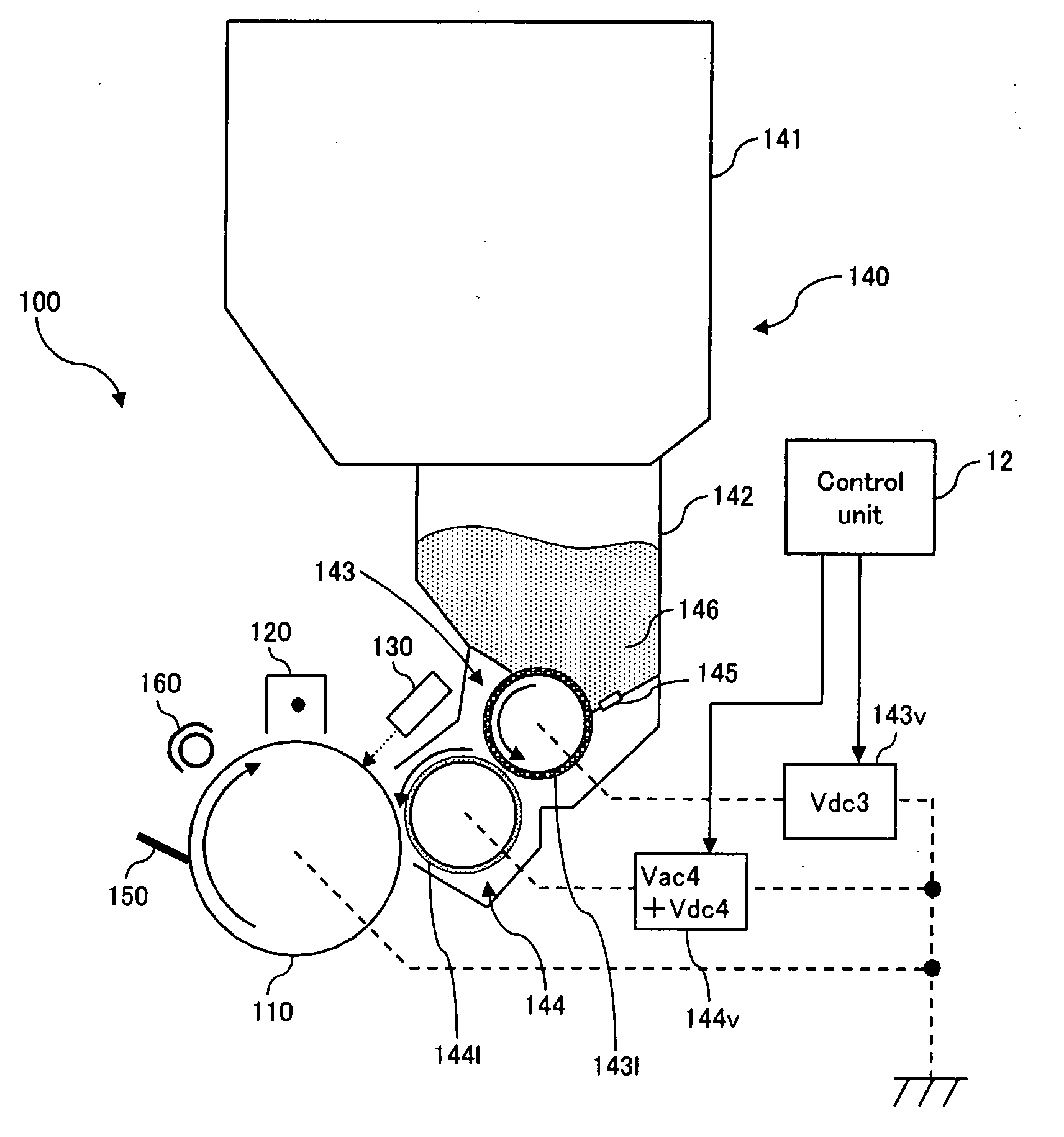

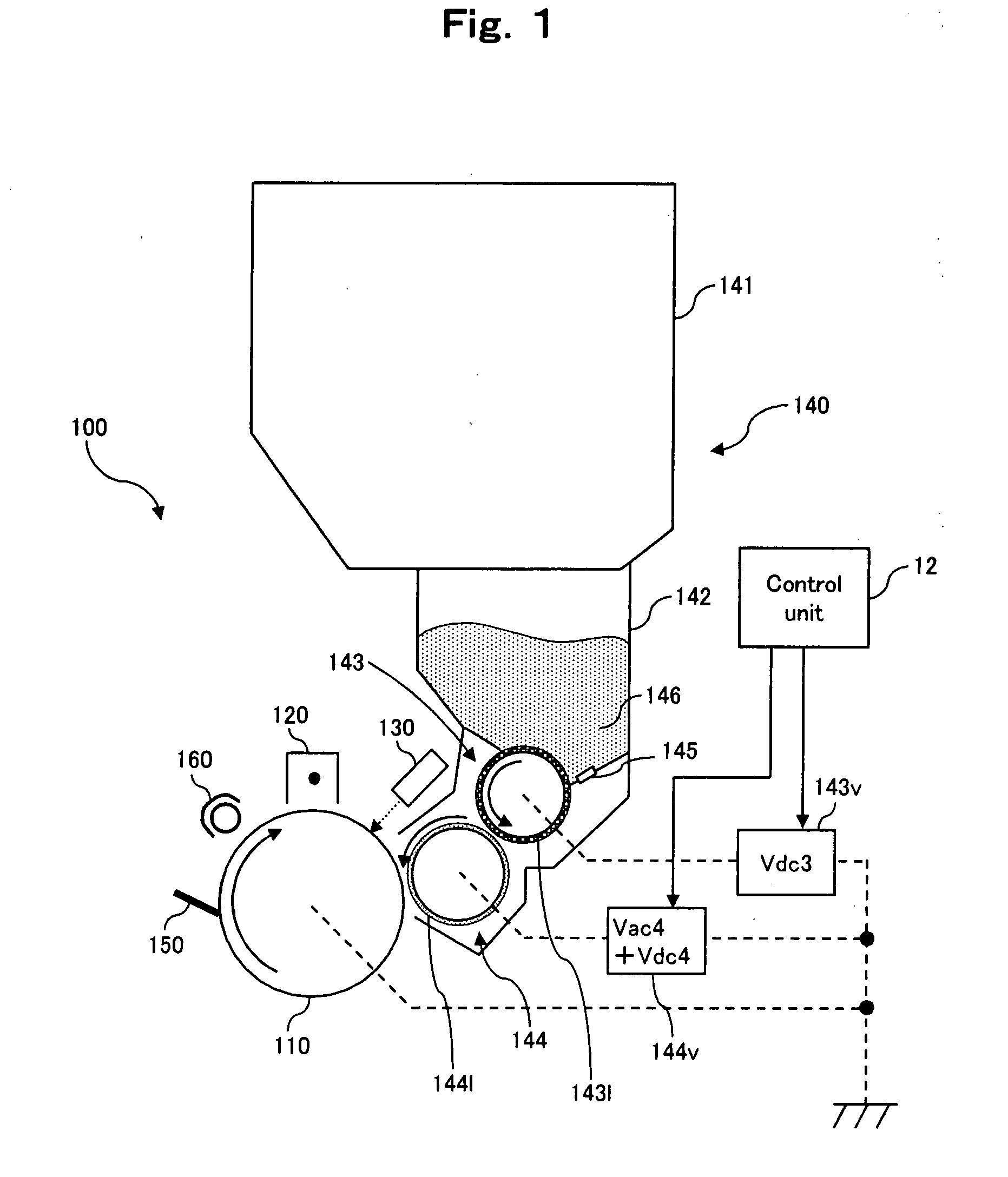

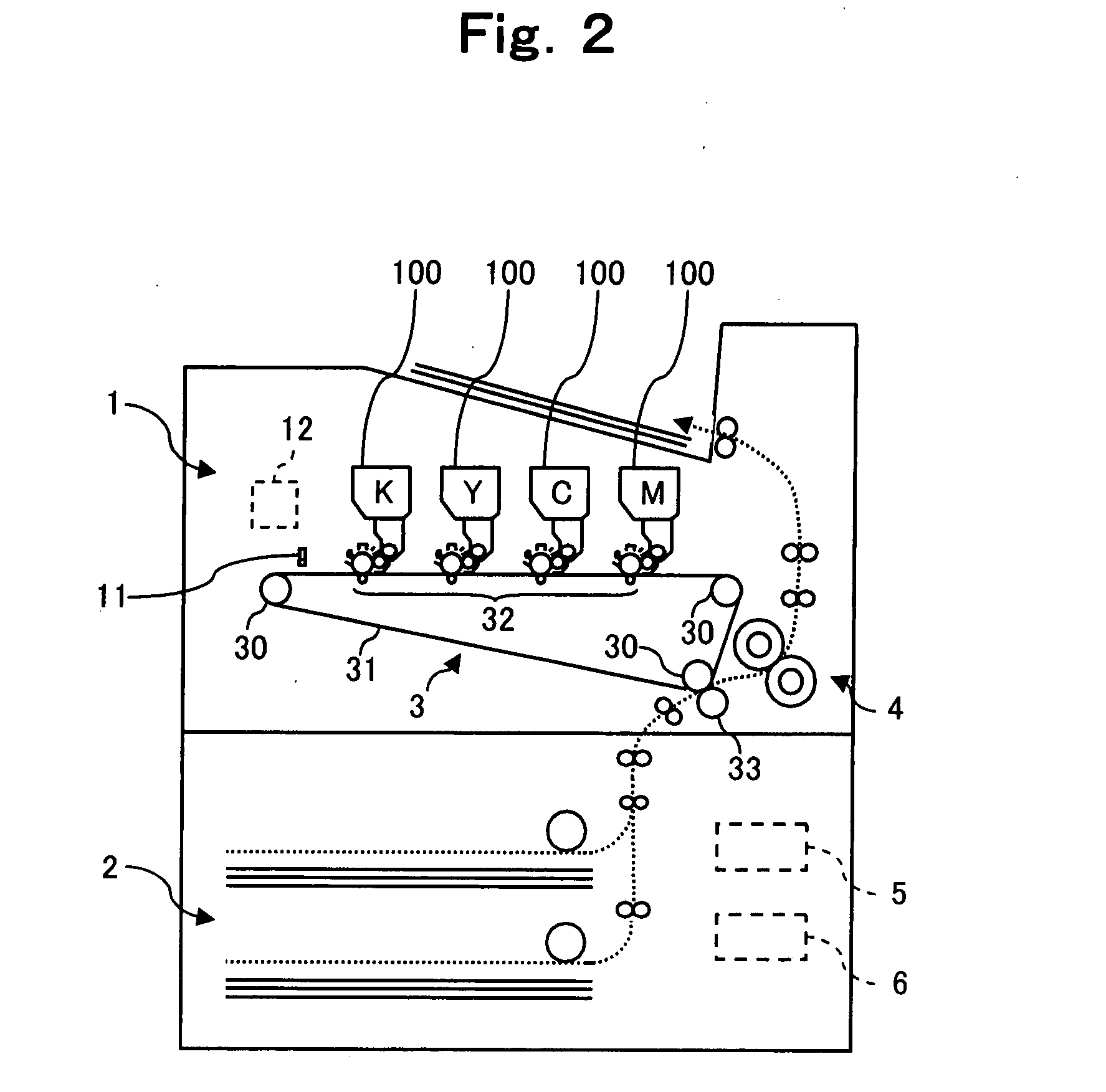

Provided is a method for adjusting a developing device including a magnetic roll (143) for holding a two-component developer (146) composed of a carrier and toner filled in a developing tank (142) in a brush state, and a developing roll (144) for developing an electrostatic latent image formed in an image carrier (110) by holding toner conveyed from the magnetic roll (143), having a bias voltage adjustment step for adjusting a conveyance amount of toner from the magnetic roll (143) to the developing roll (144) by an adjustment of bias voltages (Vdc3, Vdc4) applied to the magnetic roll (143) and the developing roll (144) respectively, and a mixing ratio adjustment step for adjusting a conveyance amount of the toner by an adjusting a mixing ratio of the two-component developer (146).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Method for removing fluorescent liquid in aero-engine compressor casing

ActiveCN104438176AAvoid overwashingAvoid misjudgmentCleaning using gasesCleaning using liquidsCold airWater vapor

The invention discloses a method for removing fluorescent liquid in an aero-engine compressor casing. The method is used for carrying out fluorescent flaw detection on blades of the 3-7-stage compressor casing and cleaning away penetrating liquid. Cold air and a water vapor spraying gun are adopted for purging a blade installation groove in the upper end face of the 4-7-stage part of the compressor casing and a stopping block installation site in the 3-stage part of the compressor casing so that the penetrating liquid can flow out from a casing gap or the other stopping block installation site; hot water is adopted for cleaning in winter, redundant penetrating liquid on the surface is cleaned away, and to prevent excessive cleaning, only the water vapor spraying gun and hot water can be adopted for cleaning rather than cold air is directly adopted for purging; the casing is placed in a developing tank for development after being dried. Post-cleaning is carried out on the casing after a flaw detection result shows that the casing is up to standard, and because a small amount of penetrating liquid which does not influence flaw detection quality remains in the gap, cleaning after flaw detection is necessary. The casing is placed in the hot water to be soaked, compressed air and the water vapor spraying gun are adopted for purging the blade installation groove in the upper end face of the 4-7-stage part of the compressor casing and the stopping block installation site in the 3-stage part of the compressor casing till no penetrating liquid flows out of the gap, and the casing is dried through a fan or an oven. By means of the method, the cost is lowered, the production cycle is shortened, and the production quality is improved.

Owner:中国航发贵州航空发动机维修有限责任公司

Environment-friendly developing tank dirt scavenging agent as well as preparation method and application method thereof

InactiveCN109234036AShort cleaning timeOvercoming volatileInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsDiethylene glycol monobutyl etherIsobutanol

The invention discloses an environment-friendly developing tank dirt scavenging agent as well as a preparation method and an application method thereof. The environment-friendly developing tank dirt scavenging agent is prepared from the following raw materials: acid liquid, a solubilizing agent, a surfactant and de-ionized water, wherein the acid liquid is obtained by mixing one or more of components including sulfuric acid, hydrochloric acid, nitric acid, acetic acid, glycollic acid, citric acid and the like according to the equal mass ratio; the solubilizing agent is obtained by mixing one or more of components including ethanol, propylene glycol, isopropanol, butanediol, isobutanol, ethylene glycol monobutyl ether, diethylene glycol monobutyl ether and the like; and the surfactant is glycerin fatty acid ester. The preparation method of the environment-friendly developing tank dirt scavenging agent comprises the following steps: adding water; adding a sulfuric acid solution into a stirring tank added with the de-ionized water; adding the hydrochloric acid into the stirring tank; adding the glycollic acid; adding the ethanol, the ethylene glycol monobutyl ether and the diethyleneglycol monobutyl ether; adding the surfactant; and finally, adding the de-ionized water to make the volume constant, and sufficiently stirring.

Owner:珠海特普力高精细化工有限公司

Device for maintaining developing solution stability

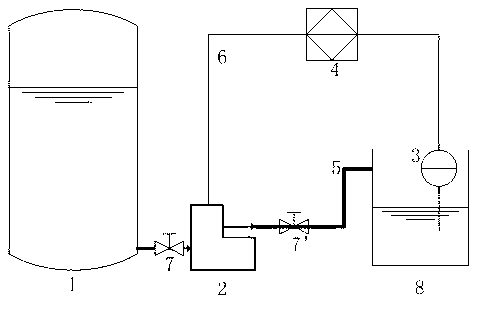

InactiveCN103207542ASolve the difficulty of manual maintenanceSolve time-consuming and laborious problemsPhotosensitive material processingProgrammable logic controllerDeveloping tank

The invention relates to a device used for maintaining the stability of a developing solution. The device comprises a developing tank 8, a developing solution addition tank 1, a metering pump 2, a pH meter 3, a programmable logic controller (PLC) 4, a pipeline 5, a signal lien 6, and valves 7 and 7'. The valve 7 is connected at a water outlet of the developing solution addition tank 1. The valve 7' is arranged at a water outlet of the metering pump 2. The pipeline 5 is used for delivering the developing solution. The pH meter 3 is a continuous-measuring on-line pH meter. The PLC 4 is used for receiving pH meter real-time monitoring signals and controlling the starting and working times of the metering pump. The signal line 6 is used for collecting and transmitting the signals of the PLC 4. With the device used for maintaining the stability of the developing solution, the developing solution can be subjected to intelligent real-time full-automatic monitoring and adjustment, and can be added automatically. Therefore, labor intensity is reduced, and production efficiency is improved.

Owner:KUN SHAN POWER STENCIL

Method for determining numerical value of homogenous self-radiating rays of MOX pellet

InactiveCN107464592ASolve the fragileSolve efficiency problemsNuclear energy generationNuclear monitoringStop bathTest sample

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

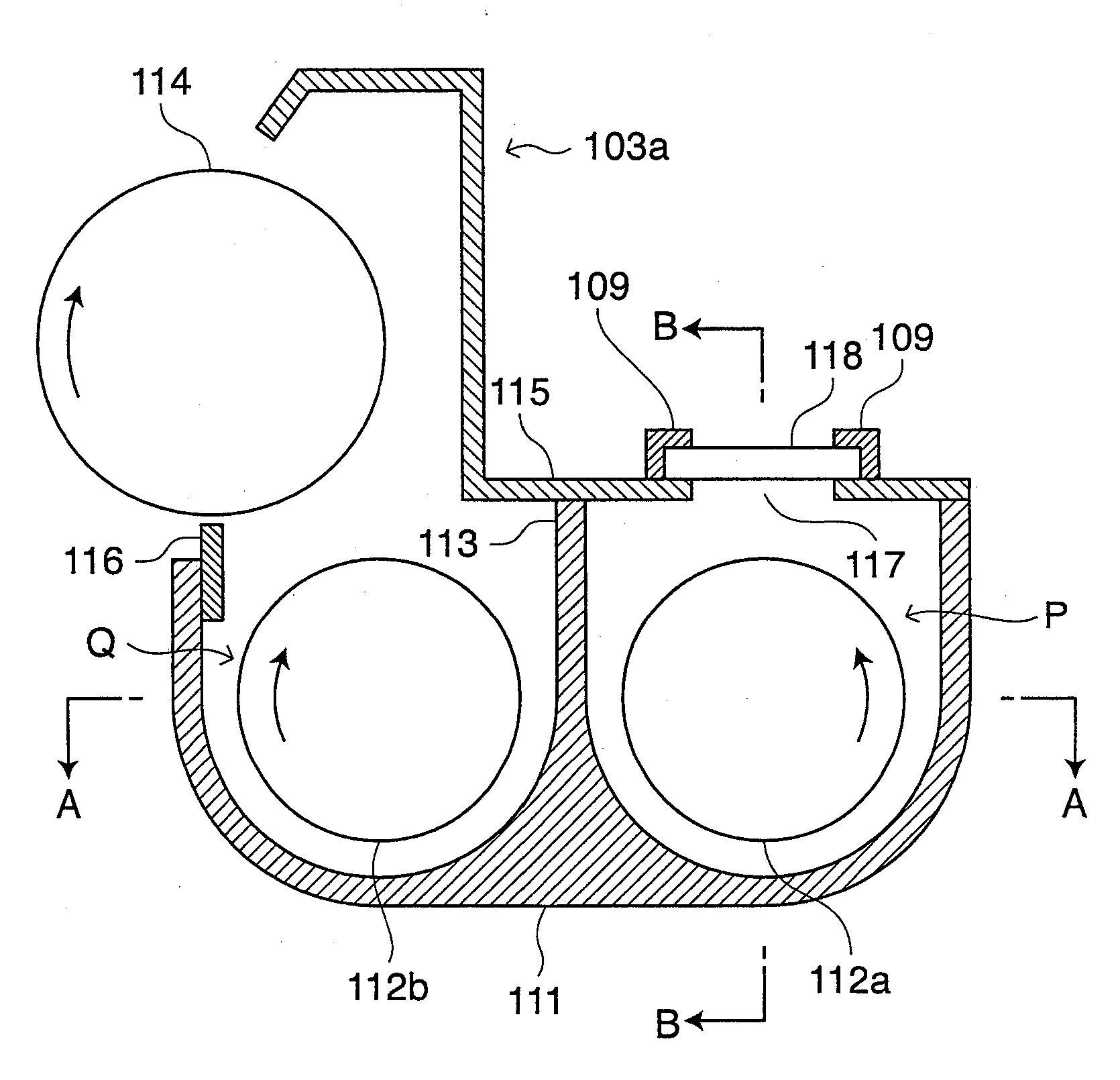

Developing device and image forming apparatus

InactiveUS20120057904A1Prevent unevenness of quantity of tonerAvoid unevennessElectrographic process apparatusDeveloping tankEngineering

A developing device includes a developing tank, a developing roller, a supply toner carrying path, and a supply toner diffusion screw. A partition board provided parallel to the developing roller in the developing tank has, in an axial direction of the supply toner diffusion screw, a first region and a second region lower than the first region. The first region is located so as to face a region perpendicularly below a toner supply opening, and the second region is located so as not to face the region perpendicularly below the toner supply opening.

Owner:SHARP KK

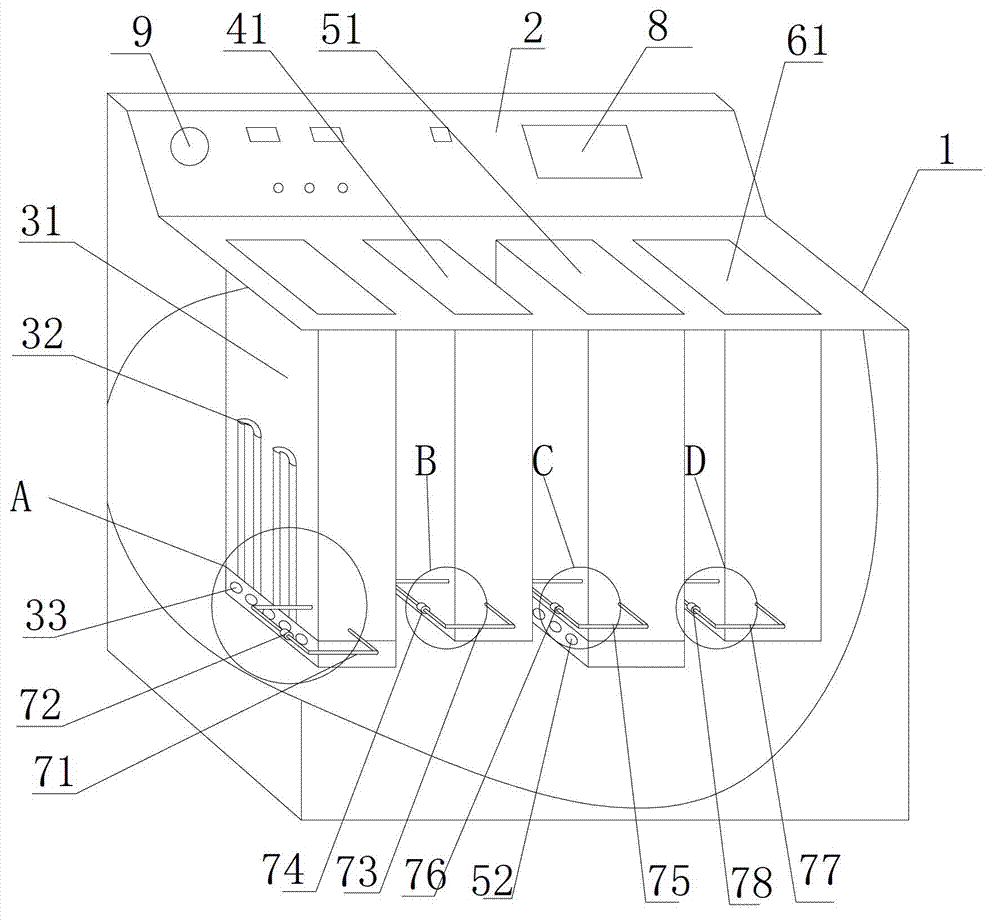

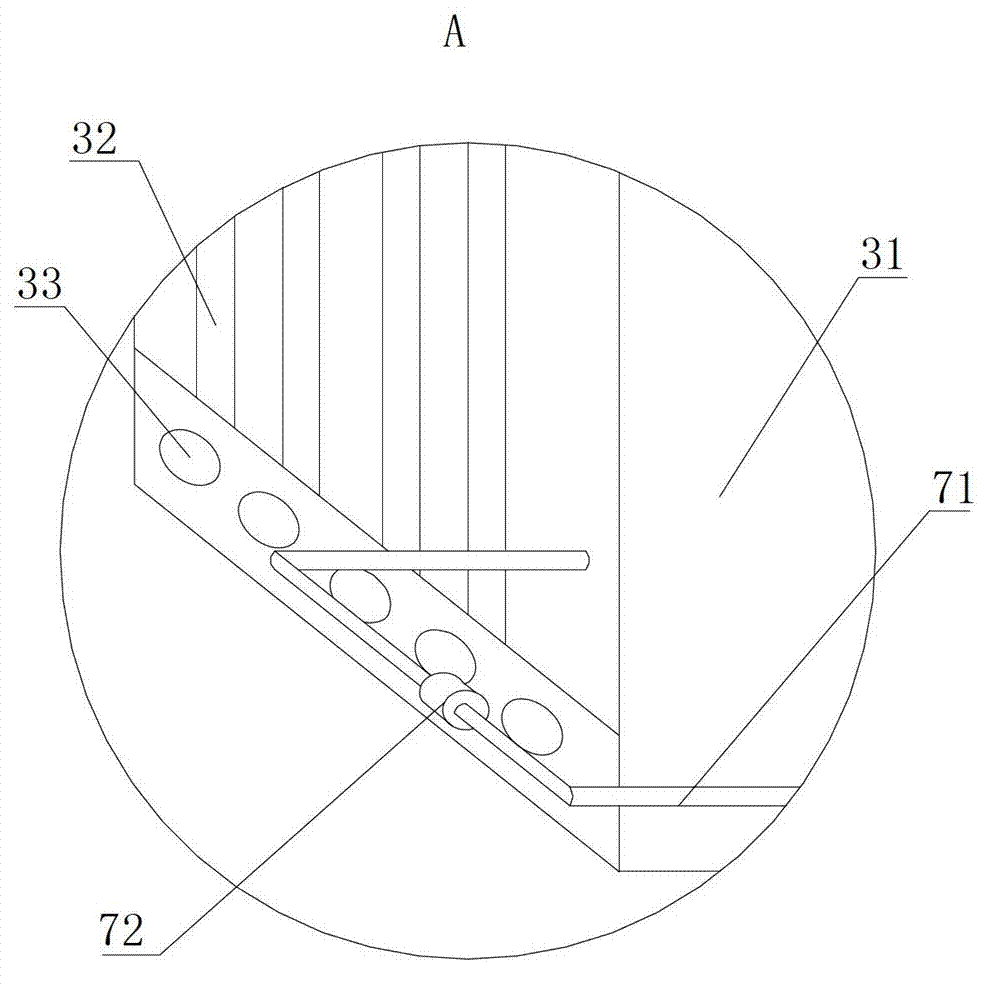

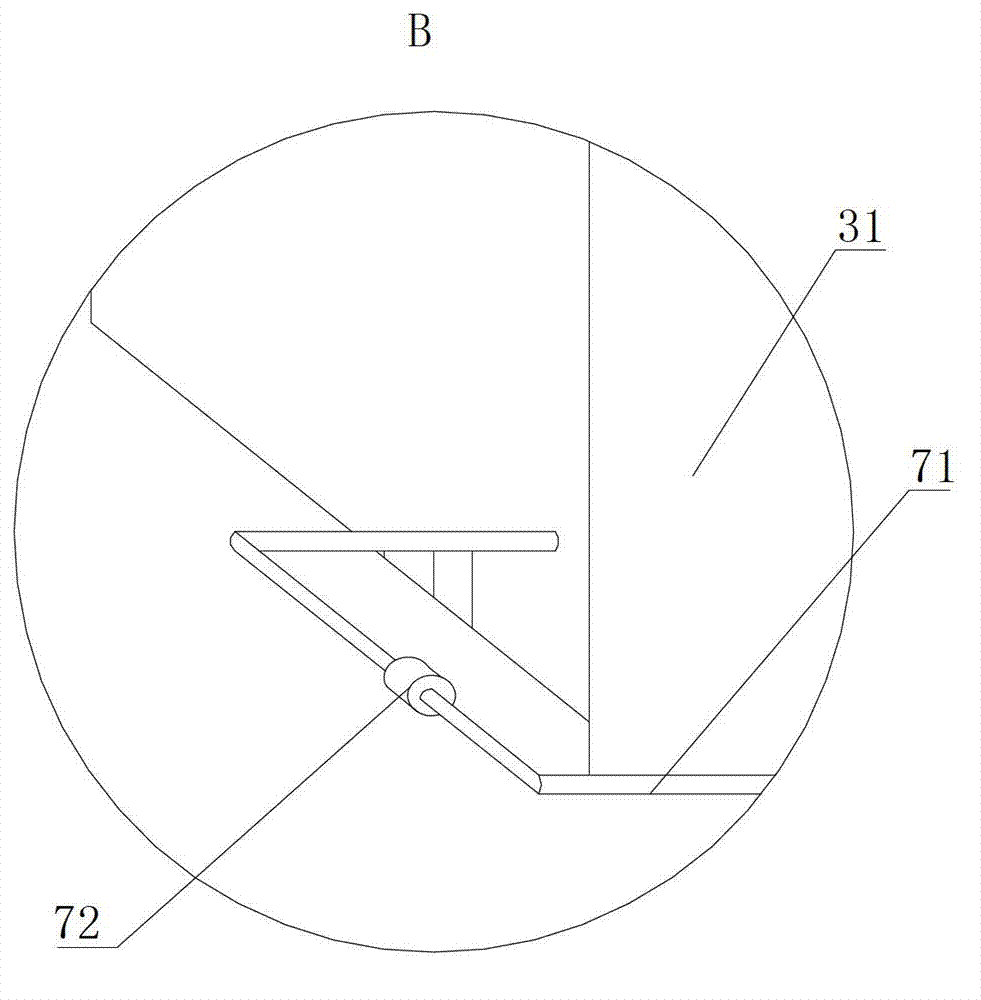

Industrial constant-temperature film developer

The invention discloses an industrial constant-temperature film developer which comprises a cuboid-shaped mainframe box, a console, a developing tank, a developing stop tank, a fixing tank, a rinsing tank, a film viewing illuminator and a darkroom red lamp, wherein the console is arranged on the upper end surface of the mainframe box, the film viewing illuminator and the darkroom red lamp are arranged on the console, the developing tank comprises a developing box body, a cooling tube arranged on the side wall of a first box body and a first heating tube arranged at the bottom of the developing box body, the developing stop tank comprises a second box body, the fixing tank comprises a third box body and a second heating tube arranged at the bottom of the third box body, the rinsing tank comprises a fourth box body, the first heating tube can be heated to the highest temperature of 120 DEG C, the lowest cooling temperature of the cooling tube is -40 DEG C, and the highest heating temperature of the second heating tube is 120 DEG C. According to the industrial constant-temperature film developer, the film viewing illuminator and the darkroom red lamp are additionally arranged on the console, the operation steps are simplified, and the production efficiency is improved; in addition, the temperature regulation scope is wide, so as to meet various film developing requirements.

Owner:WUJIANG HYPERD NDT MATERIAL

Development device and image forming apparatus comprising same

ActiveCN101261476ANo pollutionLong-term effective closureElectrographic process apparatusDeveloping tankImage formation

The development device of the present invention has a rotating shutter supported rotatably between a supply opening formed on a toner supply device and a receiving opening formed on a developing tank. The rotating shutter has an open section extending in the axial direction of the roller-shaped main section as well as opened in the direction perpendicular to the axial direction thereof, opening and shutting the supply opening in conjunction with attachment and detachment operation of the developing tank. The rotating shutter shuts the supply opening by covering the supply opening with the outer surface of the roller-shaped main section, and opens the supply opening by communicating the supply opening and the receiving opening through the open section. Thus, it is possible to prevent the leakage of toner even after repetitively performing the attachment and detachment operation of the developing tank.

Owner:SHARP KK

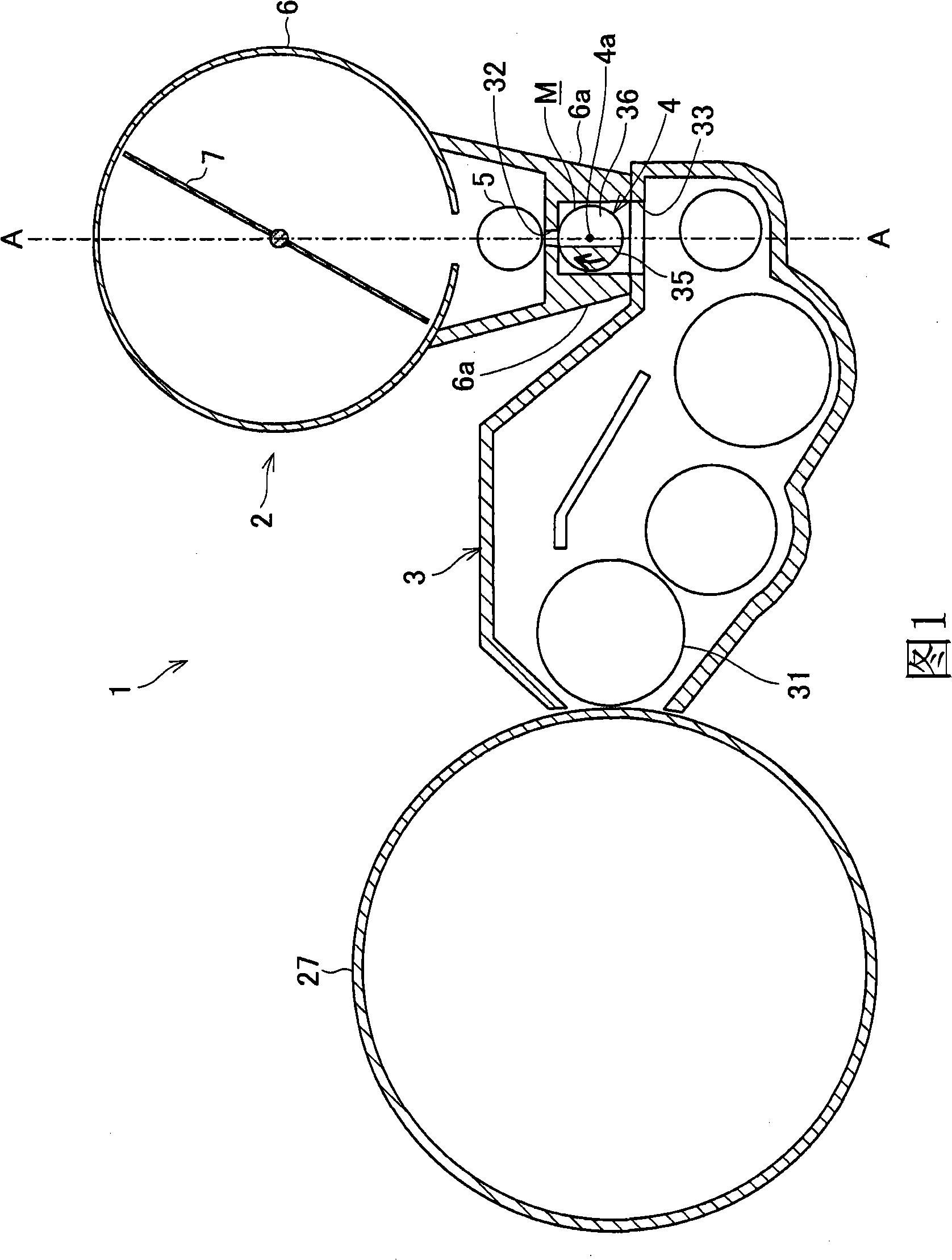

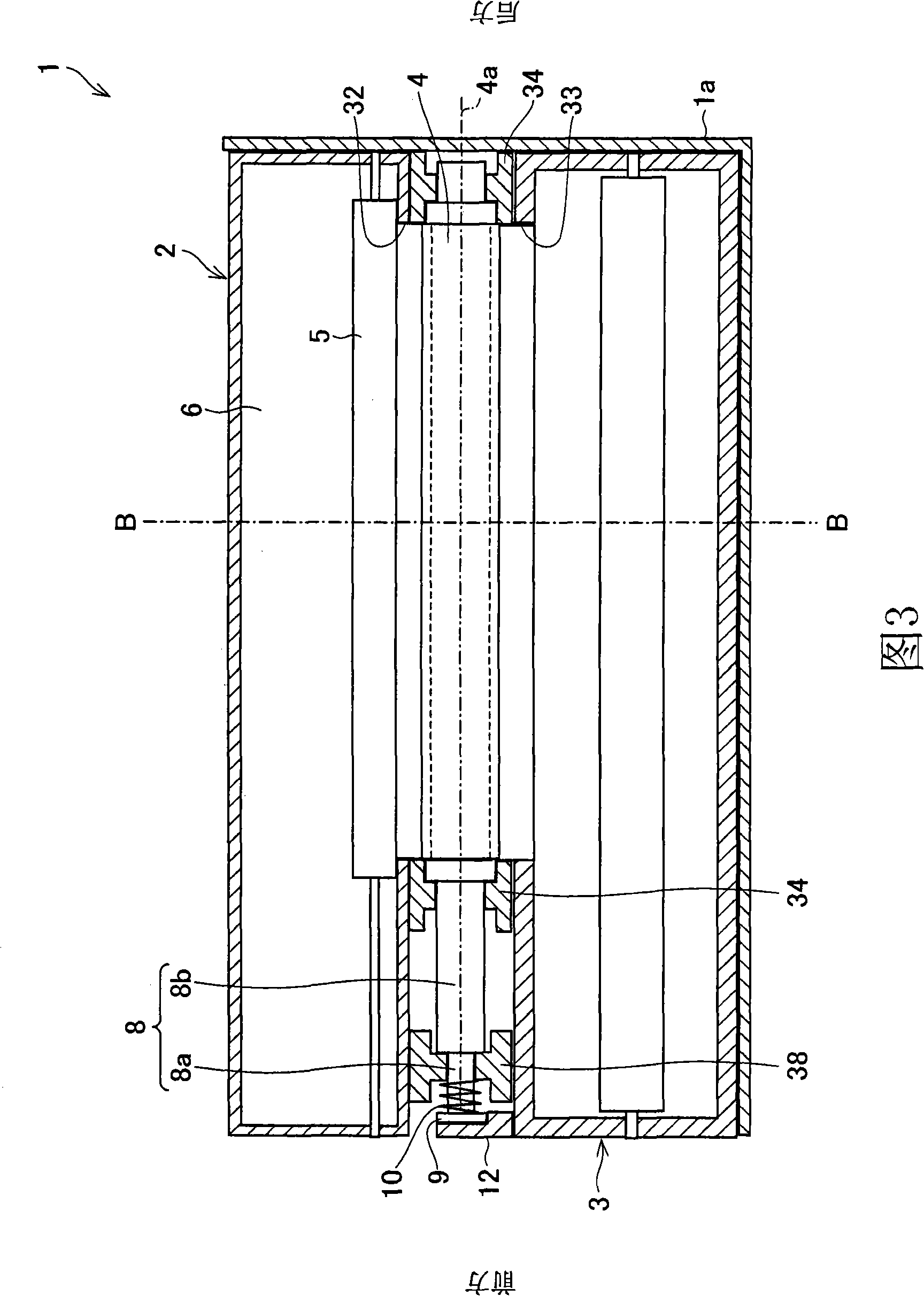

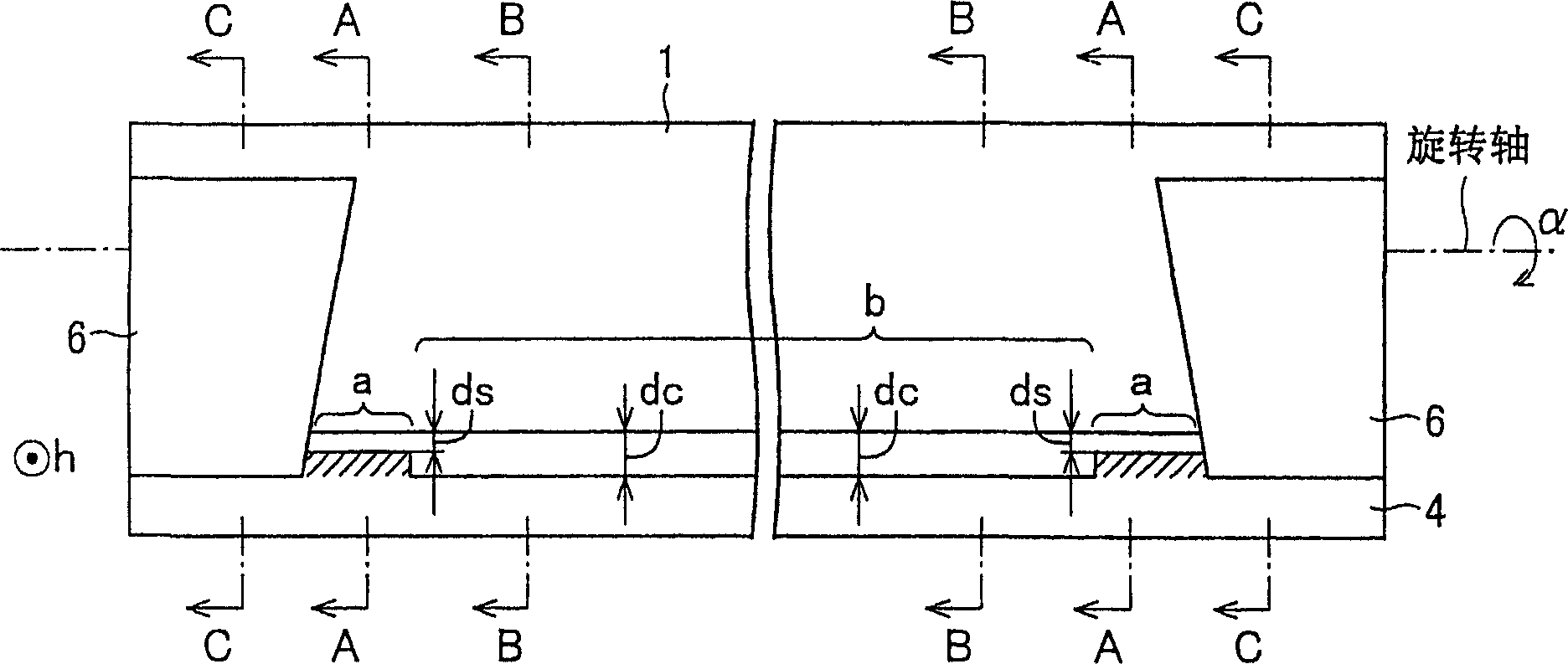

Developing device and image forming apparatus provided with same

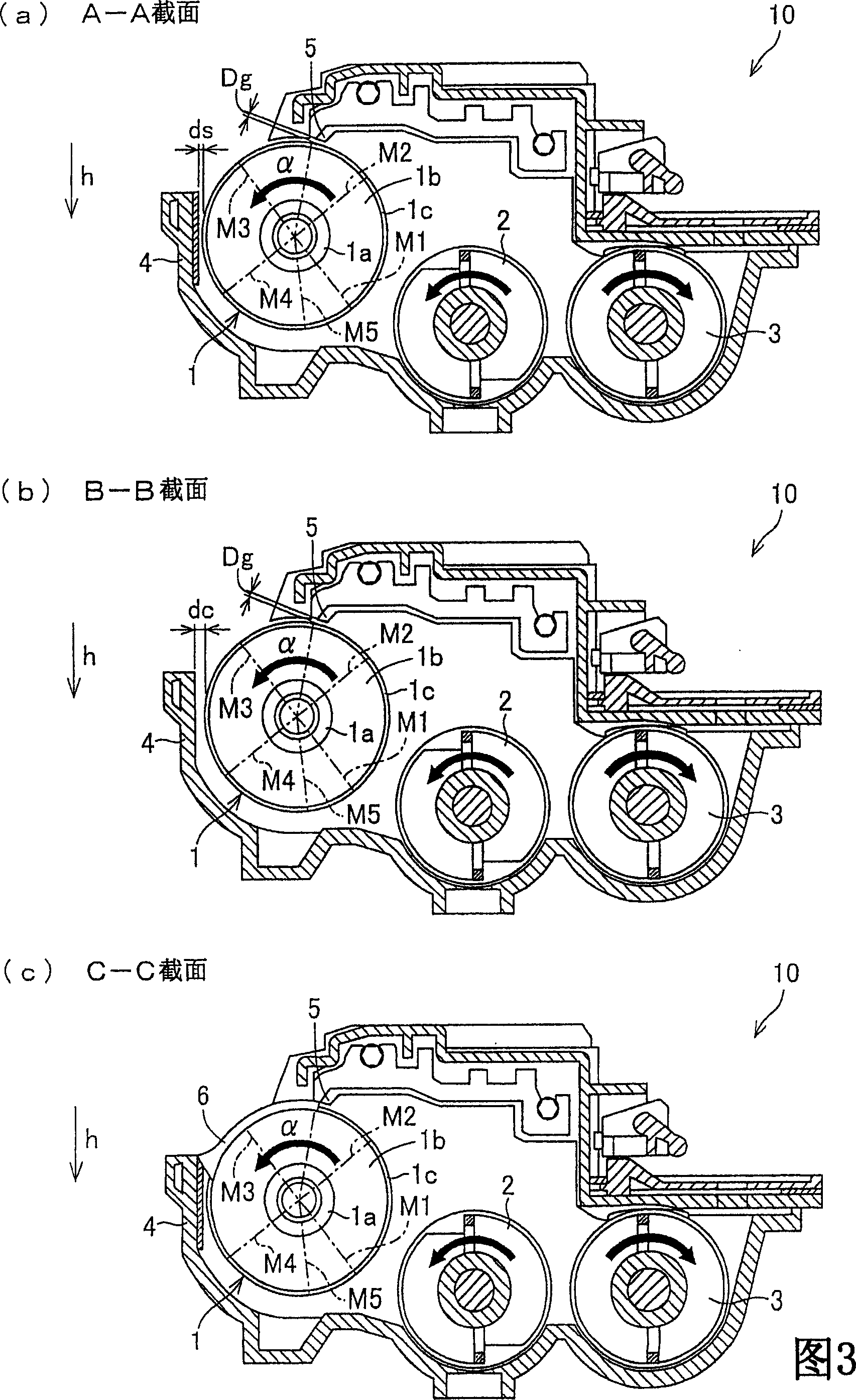

The invention appropriately prevents toner scattering in a developing device using a two-component developer containing toner and a carrier. Gaps ds between a developing tank 4 and both ends a in a direction of a rotating shaft of a developing roller 1 on a downstream side in the transporting direction of the developing roller 1 are each set within a range of Dg G03G 15 / 08 G03G 15 / 00 4 18 2 2005 / 10 / 17 1760769 2006 / 4 / 19 100454165 2009 / 1 / 21 2009 / 1 / 21 2009 / 1 / 21 Sharp KK Japan Nagata Tsutomu Kimura Takahiko zhong qiang xie lina 11219 Japan 2004 / 10 / 15 2004-302214

Owner:SHARP KK

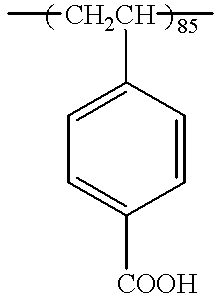

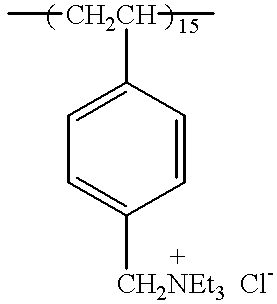

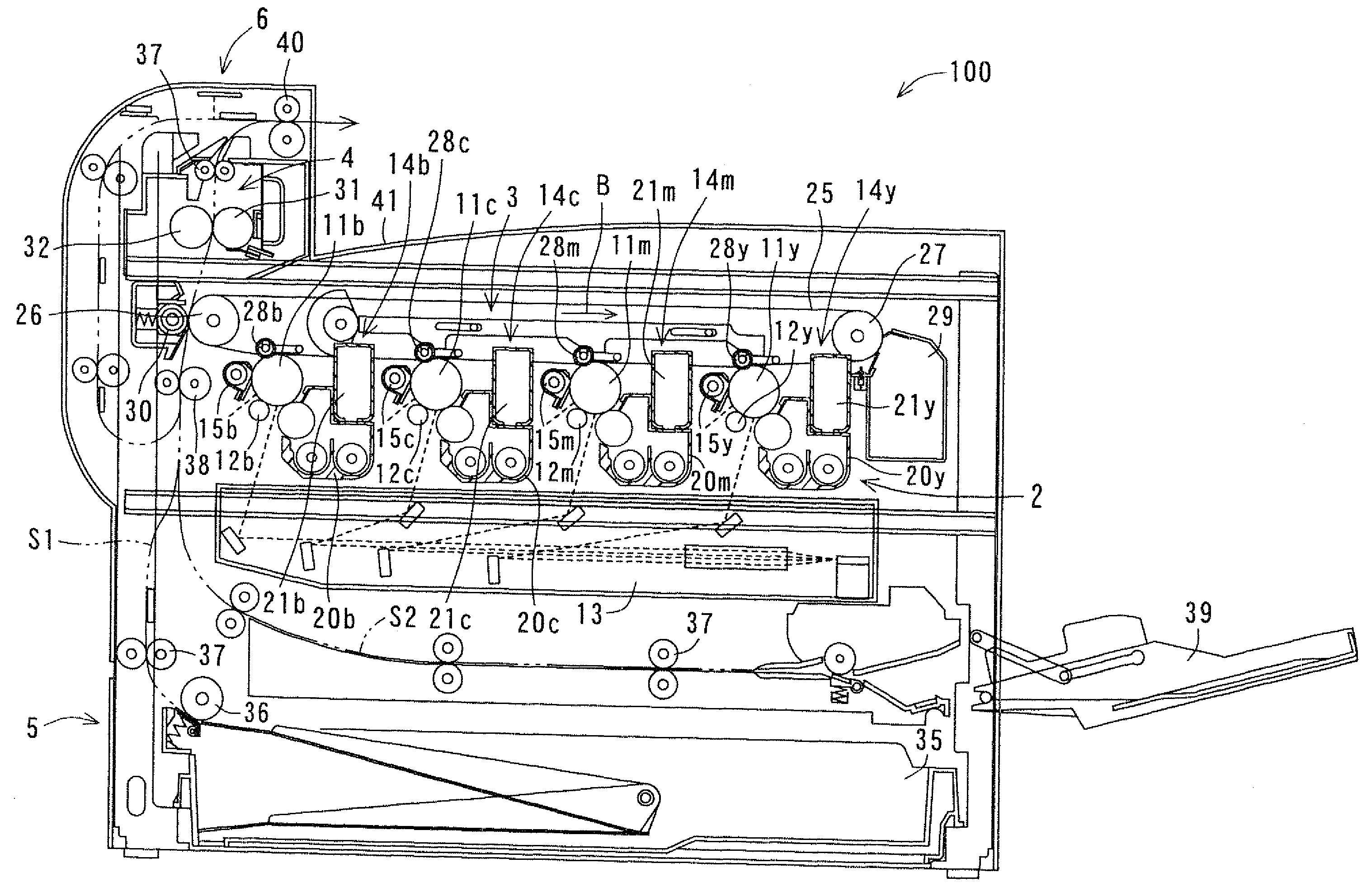

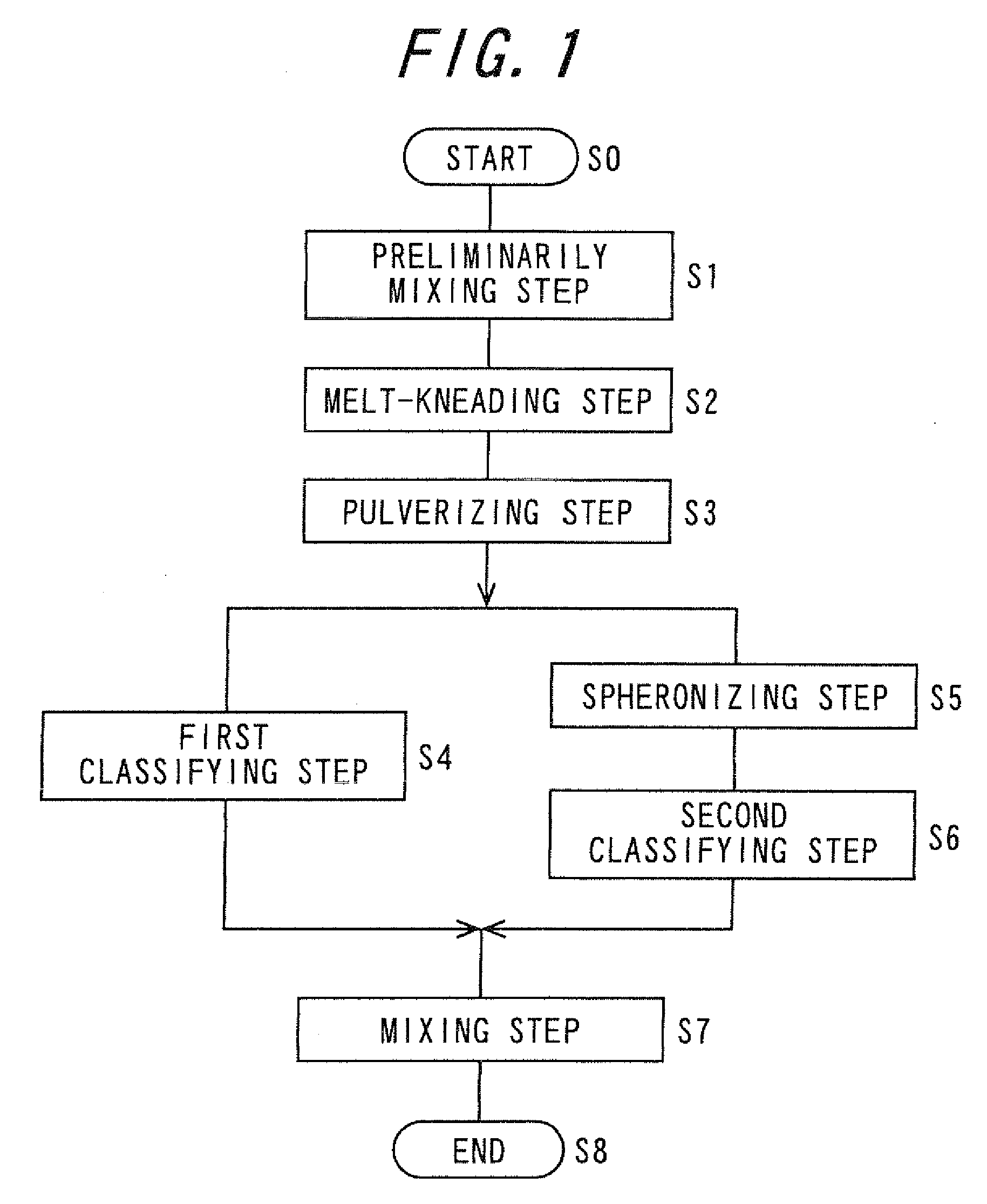

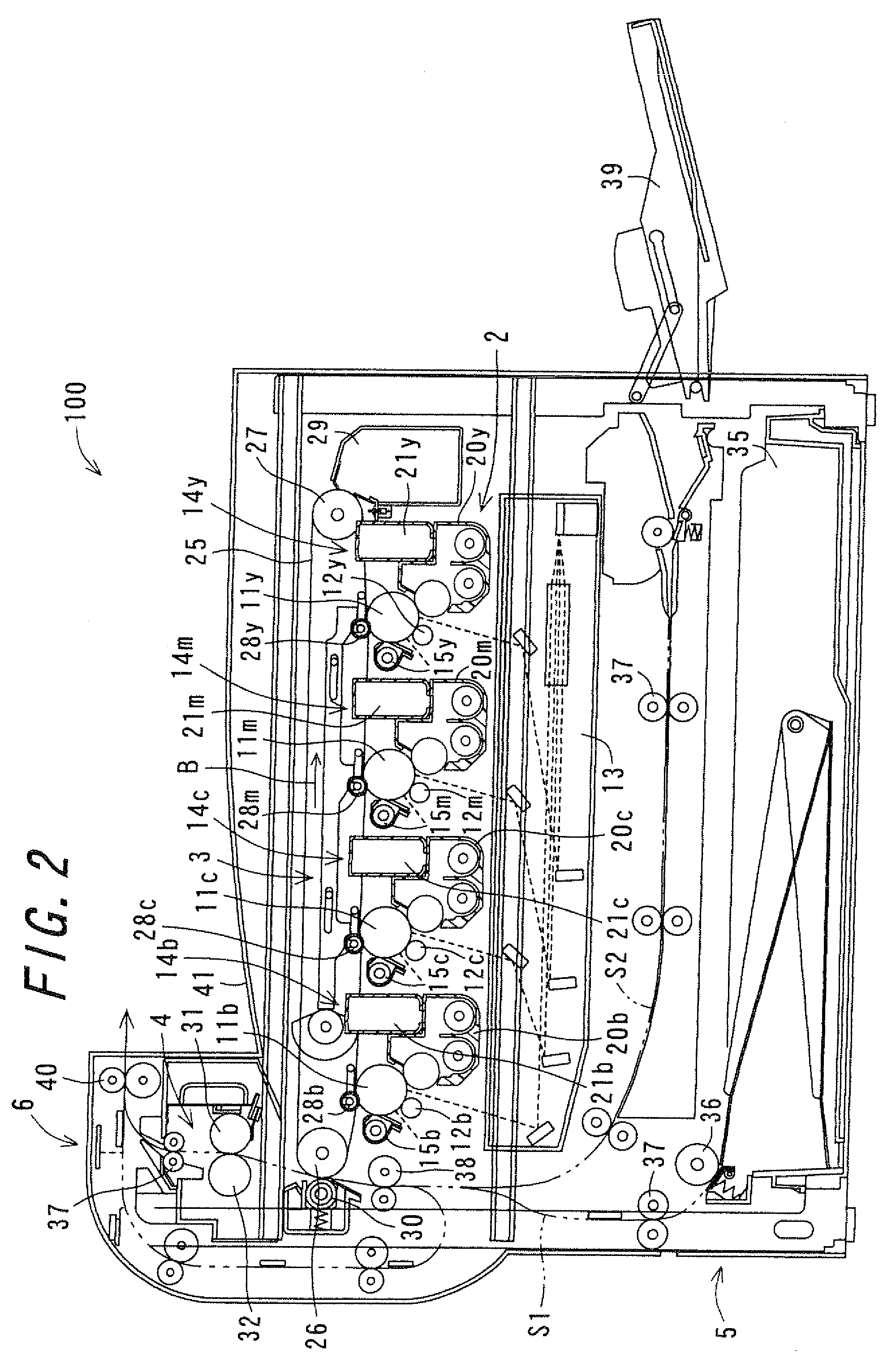

Toner, method of manufacturing toner, developer, two-component developer, developing device, and image forming apparatus

ActiveUS20090214264A1Flowability is restrainedHigh resolutionDevelopersElectrographic process apparatusImage formationAcid value

A toner, a developer, a two-component developer, a developing device and an image forming apparatus are provided. In the image forming apparatus, images are formed with a developer that fills a developing tank of the developing device. The developer includes the toner containing at least a binder resin, a colorant, and a release agent, the release agent having an acid value of less than 4 mgKOH / g and in which an amount of the release agent exposed on a surface of toner is 0.5% by weight or more and 2.5% by weight or less of a total amount of the toner.

Owner:SHARP KK

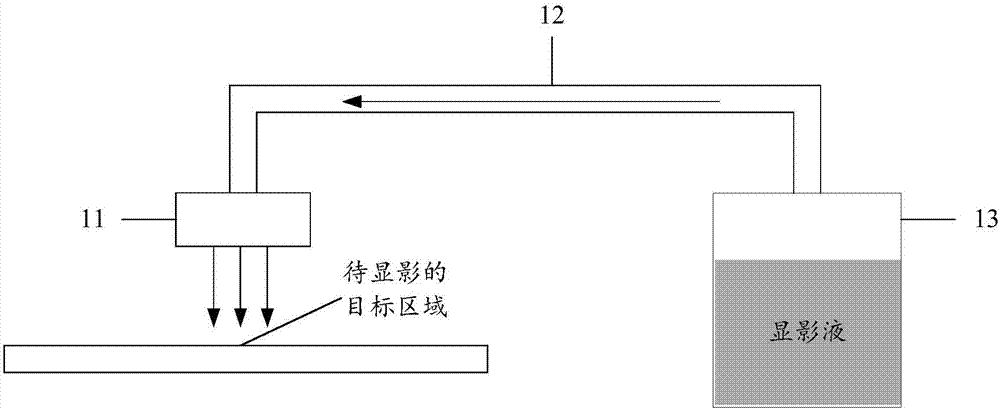

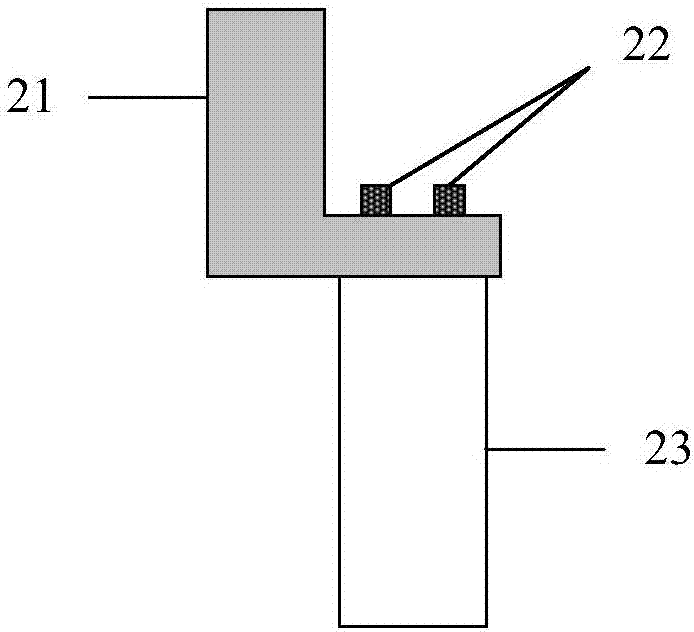

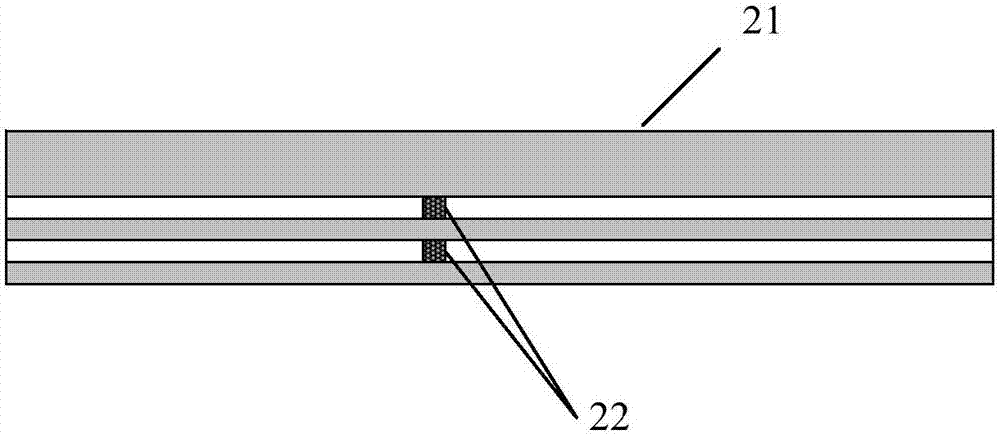

Developing device and developing processing method

InactiveCN106873318AAdjustable positionFlexible development processPhotosensitive material processingGraphicsSpray nozzle

The application discloses a developing device and a developing processing method. The developing device comprises a developing nozzle, a connecting pipeline and a developing tank, wherein the developing tank is used to hold the developing liquid; the connecting pipeline is used to communicate with the developing nozzle and the developing tank and to convey the developing liquid to the developing nozzle; and the developing nozzle is used to spray the developing liquid to a target region to be developed, and the location of the developing nozzle is adjustable. Thereby, when the developing device is used for developing the target region to be developed to realize the compensation for the size of TFT graphics, as the location of the developing nozzle for spraying the developing liquid in the developing device is adjustable, the target region to be developed can be more flexibly developed, and thus the size of the TFT graphics can be effectively compensated, the dimensional difference of the TFT graphics can be reduced, and the yield of products can be increased.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

New LED photoetching development process

InactiveCN103792799AEasy to operateControl the development processPhotosensitive material processingTetramethylammonium hydroxideBiochemical engineering

The invention relates to a new LED photoetching development process which is characterized by comprising the following steps: filling a developing tank with developing solutions: two parts of 0.8% sodium hydroxide solution and two parts of 2.38% tetramethyl ammonium hydroxide aqueous solution; setting the parameters of a developer and swinging a swing arm of the developer up and down; placing wafers on a flower basket, putting the flower basket full of the wafers on the swing arm of the developer, and shaking in the developing solution; developing the N electrode with the 0.8% sodium hydroxide solution; developing ITO with 0.8% sodium hydroxide solution; developing the P and N electrodes with 2.38% tetramethyl ammonium hydroxide aqueous solution; taking the wafer out of the developing tank and cleaning with deionized water in a cleaning tank so that the water resistance reaches 5M(omega)*cm; and drying with a hot nitrogen dryer. The process disclosed by the invention is simple to operate, controls the developing process accurately and can effectively reduce the phenomenon of halfway or excessive developing.

Owner:马阁华

Cleaning solution for dry plate developing tank and cleaning method thereof

ActiveCN101859074AImprove qualityEfficient removalLiquid processingPhotosensitive material processingPhosphateDeveloping tank

The invention relates to a cleaning solution for a dry plate developing tank and a cleaning method thereof. The cleaning solution comprises the components of cerium ammonium nitrate, perchloric acid and de-ionized water; the ratio of the cerium ammonium nitrate, the perchloric acid and the de-ionized water is 1-13g:1-20ml:25-2000ml. The cleaning method for the developing tank comprises the following steps of: (1) draining the waste developing solution in the developing tank, cleaning the developing tank by the de-ionized water, and draining the waste solution after the cleaning operation is finished; (2) injecting the cleaning solution of the dry plate developing tank to the developing tank, cleaning the developing tank and recycling the waste cleaning solution after the cleaning operation is finished; and (3) adding the phosphate-free cleaning agent to the developing tank and washing the developing tank by the de-ionized water till no foam exists. The cleaning solution for the dry plate developing tank, provided by the invention, can rapidly and effectively remove black silver ions and strong oxidizing residues, thereby preventing black type or mildew type defects on the surface of the dry plate in the developing process.

Owner:SHENZHEN NEWWAY PHOTOMASK MAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com