Industrial constant-temperature film developer

A technology of film processor and constant temperature, which is applied in processing equipment, liquid processing equipment, optics, etc., can solve the problems of cleaning droplets falling on the console, affecting the cleanliness of the working environment, and tedious operation, achieving a large temperature control range, The effect of meeting the development requirements and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

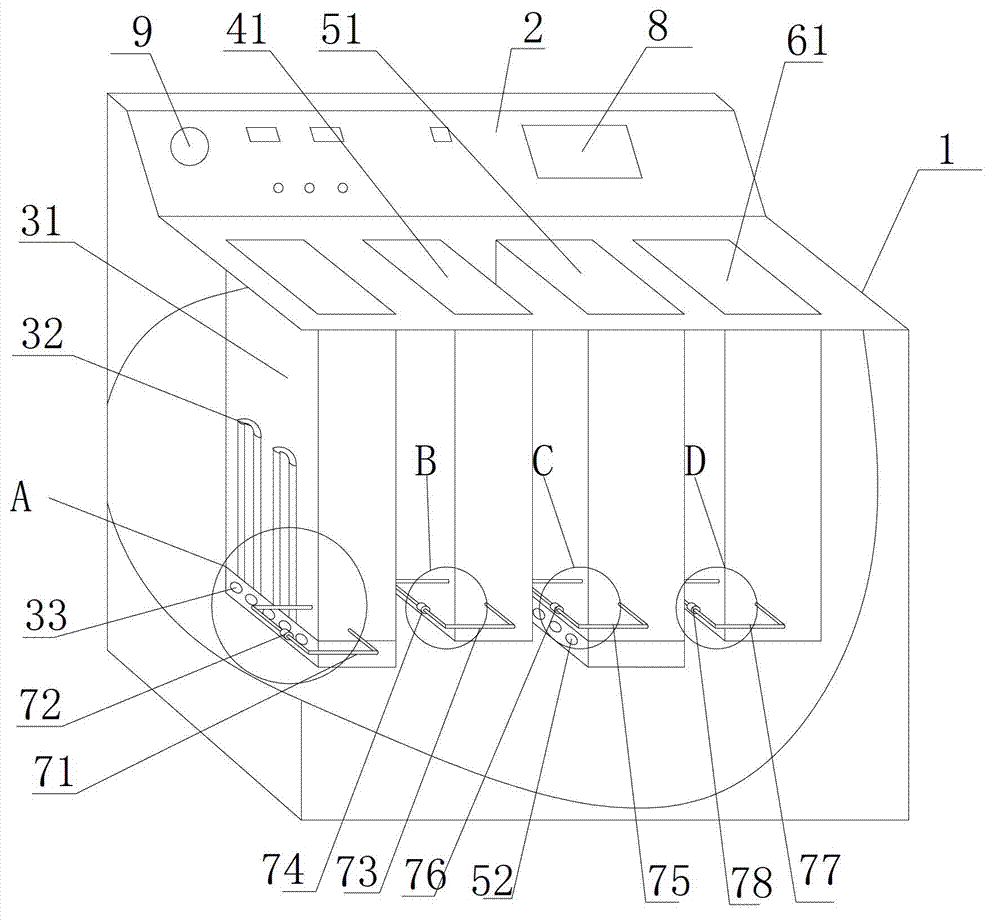

[0024] Attached below figure 1 , 2 The present invention is described in detail below.

[0025] The industrial constant temperature film developing machine includes a cuboid main box 1, a console 2 arranged on the upper surface of the main box 1, a developing tank, a stop developing tank, a fixing tank, a cleaning tank, and a viewing light installed on the console 2. 8 and the red light in the dark room 9, the temperature display screen installed on the console 2, the developing tank, the stop developing tank, the fixing tank, and the cleaning tank are embedded in the main cabinet 1 in sequence along the length direction of the upper end surface of the main cabinet 1.

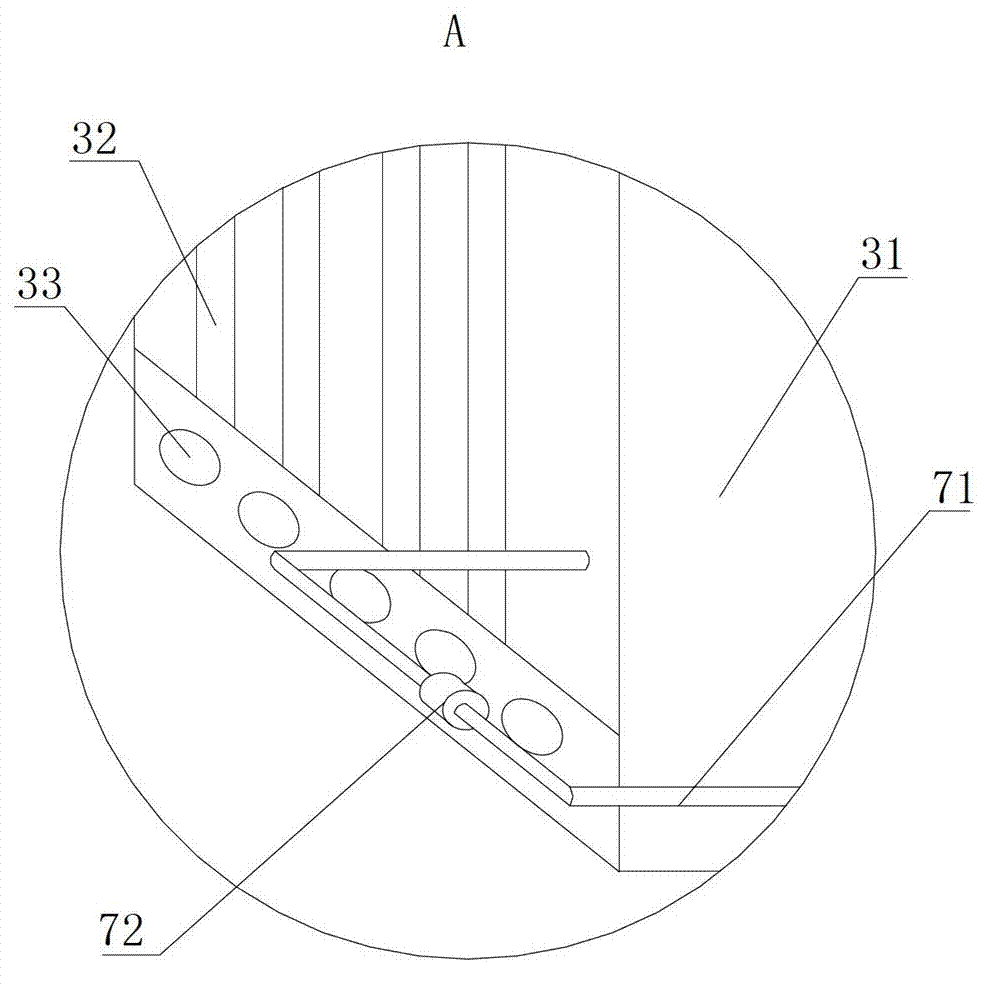

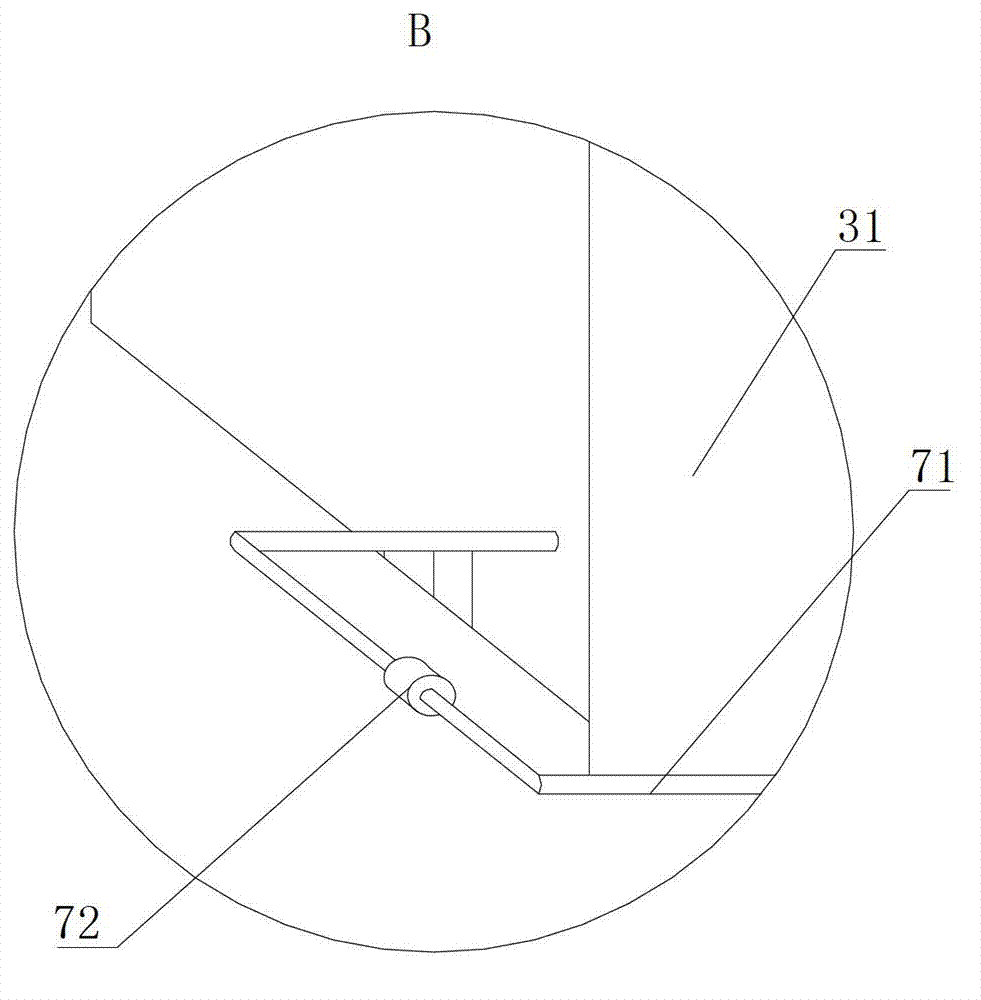

[0026] The developing tank includes a developing tank 31, a cooling tube 32 arranged on the side wall of the first tank 31, a first heating tube 33 arranged at the bottom of the developing tank 31, and the stop developing tank includes a second tank body 41, the fixing tank includes a third box body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com