Printing developer concentration adjusting and control device

A technology of regulating device and developing solution, which is applied in various fluid ratio control, color/spectral characteristic measurement, material resistance, etc., and can solve problems such as unresponsive developer concentration and low concentration of active developing solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

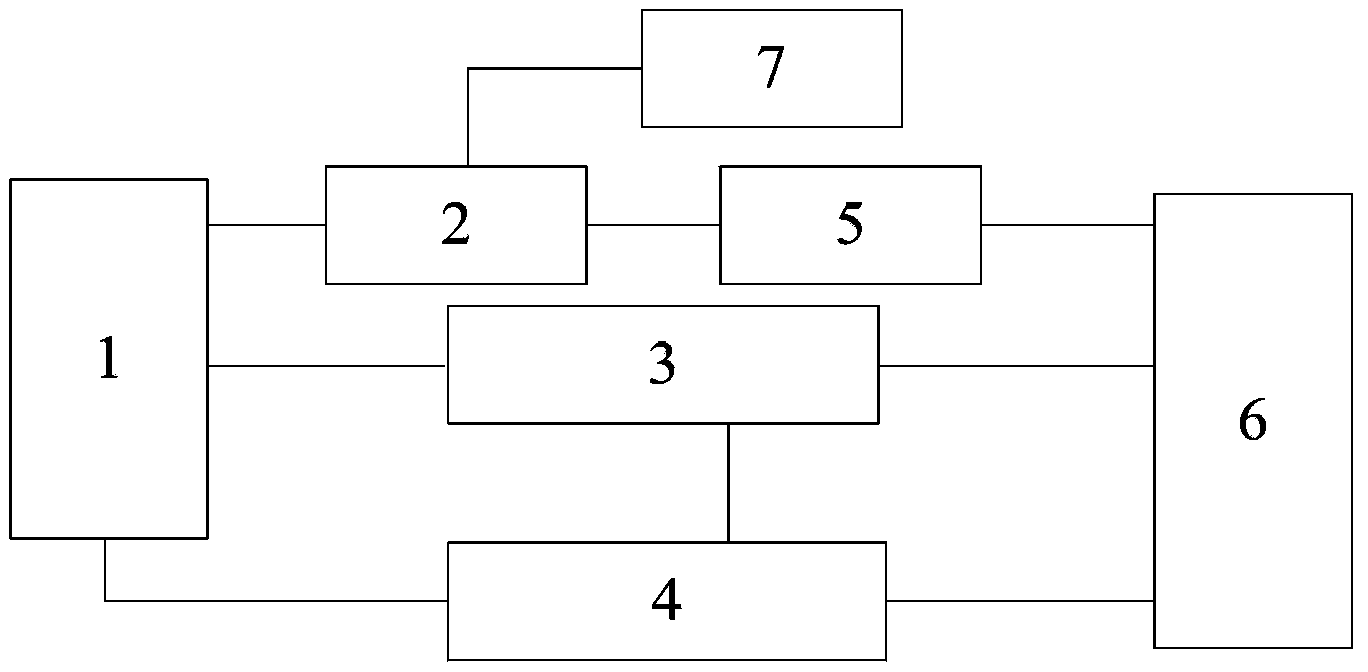

[0009] A developer concentration control device for printing, which includes a developer storage tank 1, the signal input end of the conductivity measuring instrument 3 is connected to the developer storage tank 1, and the effective concentration of the developer in the developer storage tank 1 is detected, and the ultraviolet light is absorbed. The signal input end of the detection unit 4 is respectively connected to the developing solution storage tank 1 and the conductivity measuring instrument 3, which calibrates the conductivity measuring instrument 3, the conductivity measuring instrument 3 and the ultraviolet light absorption by analyzing the concentration of the effective components of the developing solution in the developing solution storage tank 1 The signal output end of the detection unit 4 is connected to the computer display and control unit 6; a servo pump 2 is arranged between the developer storage tank 1 and the chemical and water supply unit 7, and the servo p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com