Patents

Literature

861 results about "Tetramethylammonium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

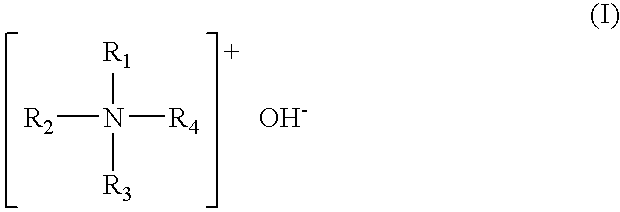

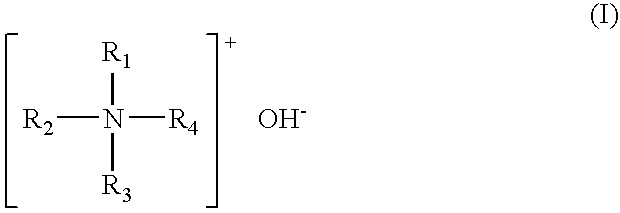

Tetramethylammonium hydroxide (TMAH or TMAOH) is a quaternary ammonium salt with the molecular formula N(CH₃)₄⁺ OH⁻. It is commonly encountered as concentrated solutions in water or methanol. The solid and solutions are colorless, or yellowish if impure. Although TMAH has virtually no odor when pure, samples often have a strongly fishy smell from the trimethylamine which is a common impurity. TMAH has numerous and diverse industrial and research applications.

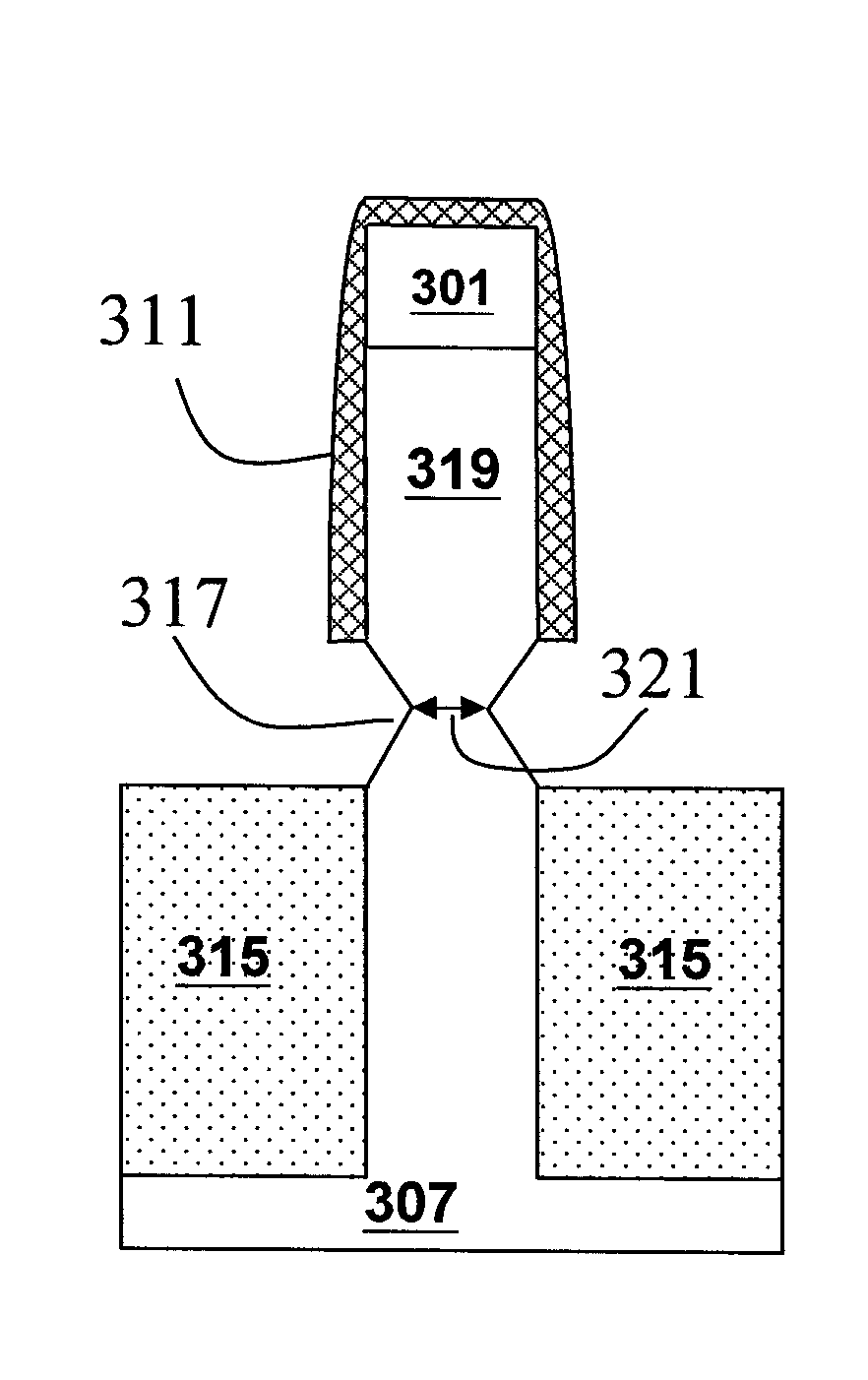

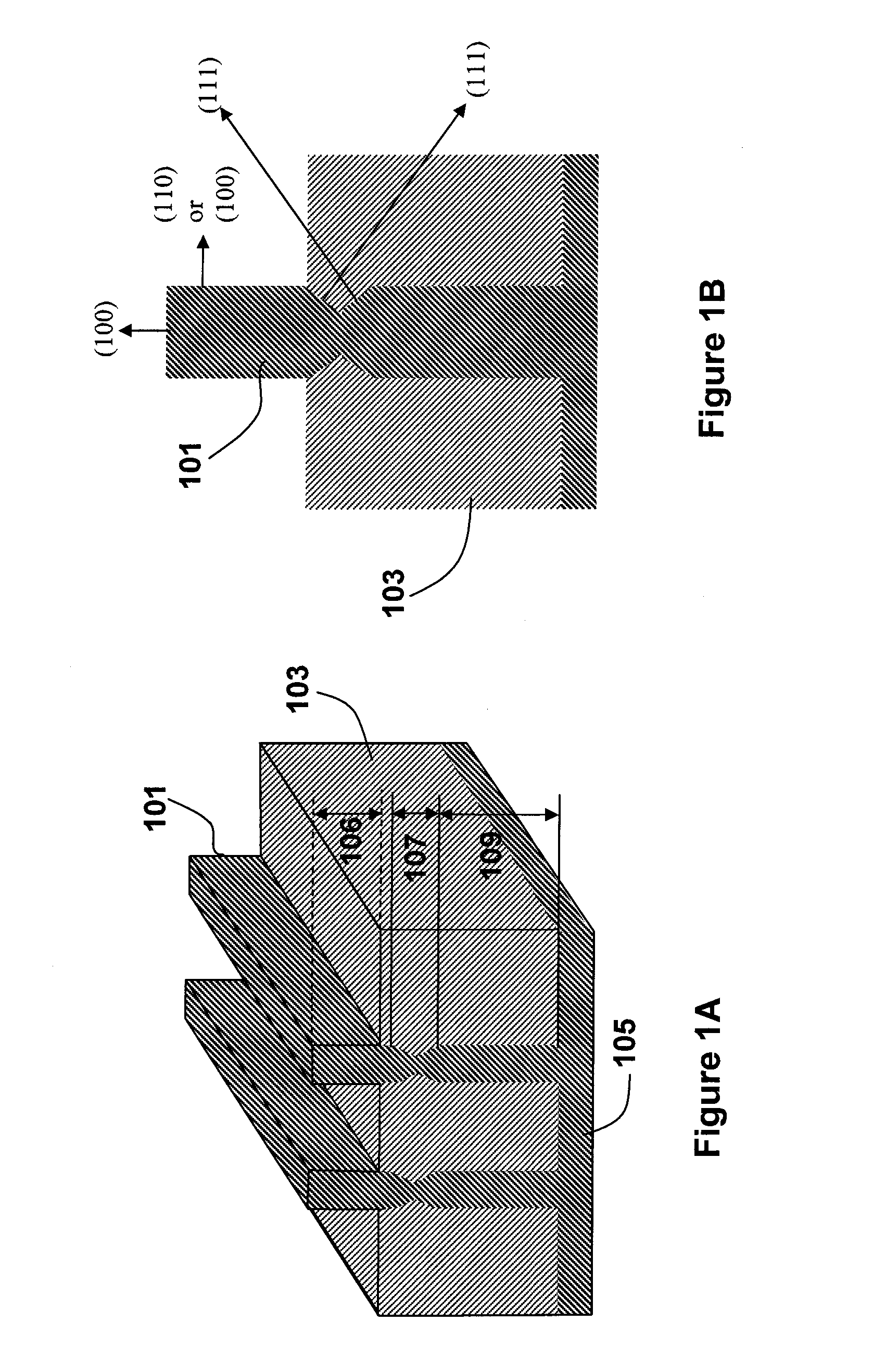

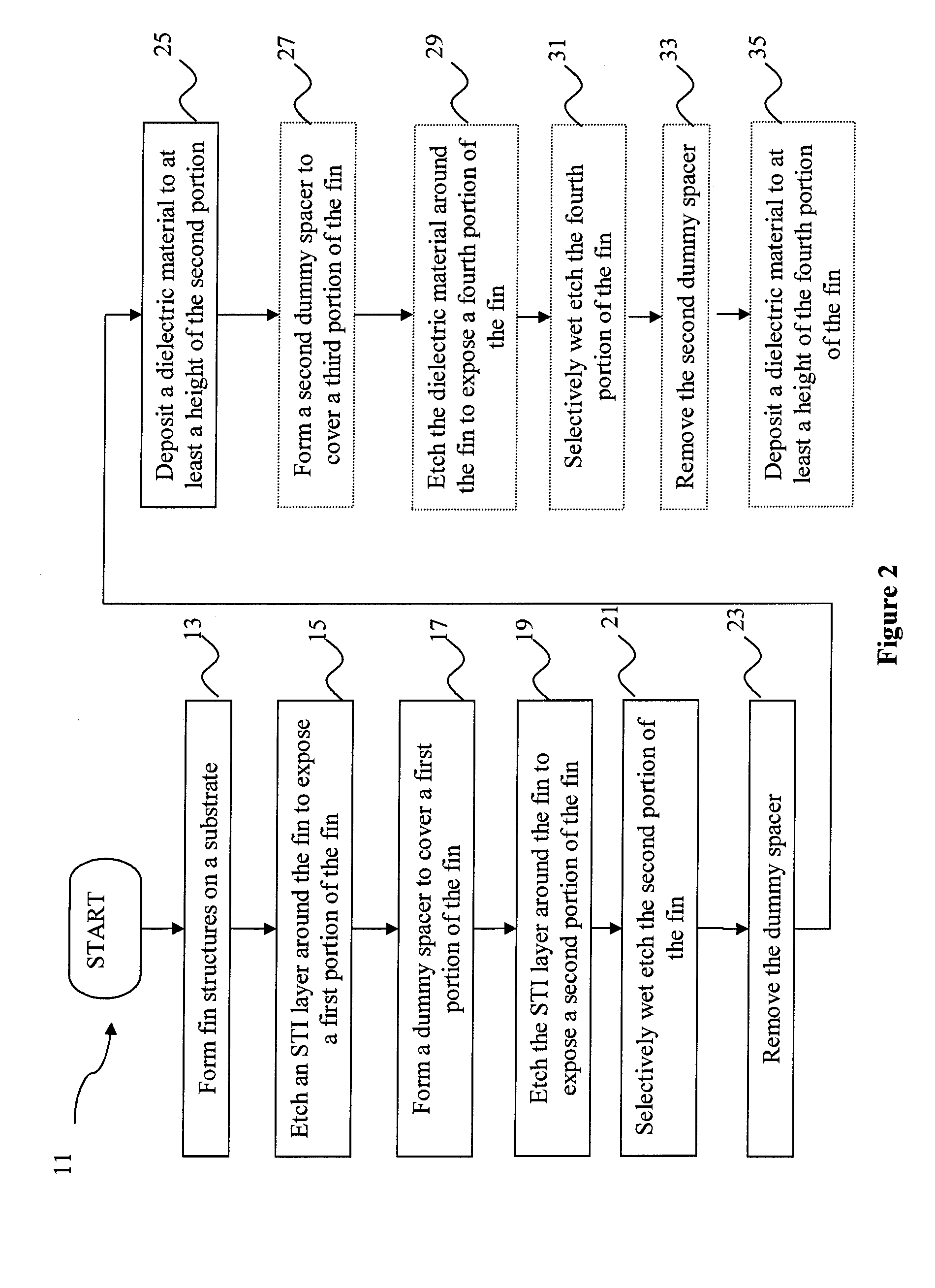

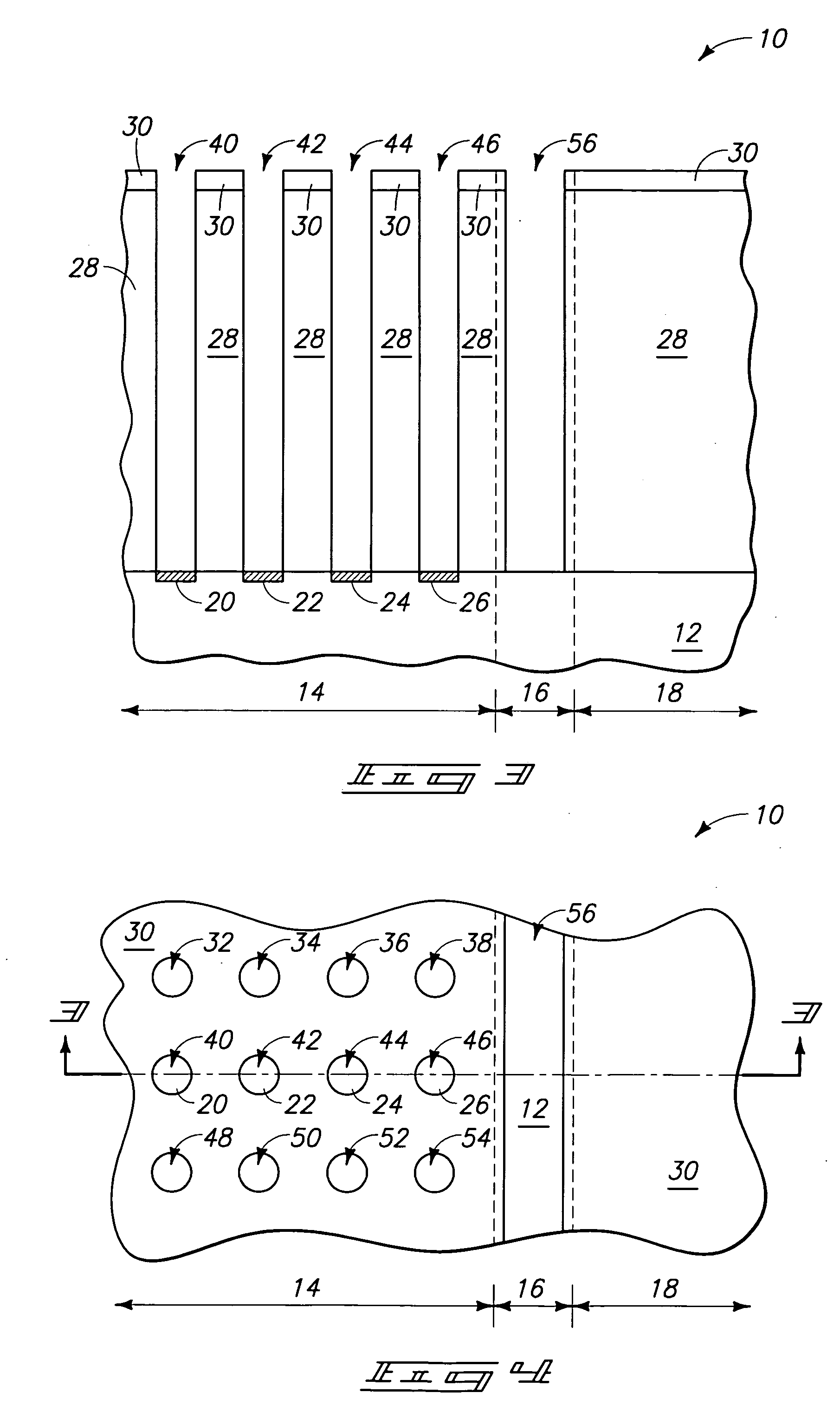

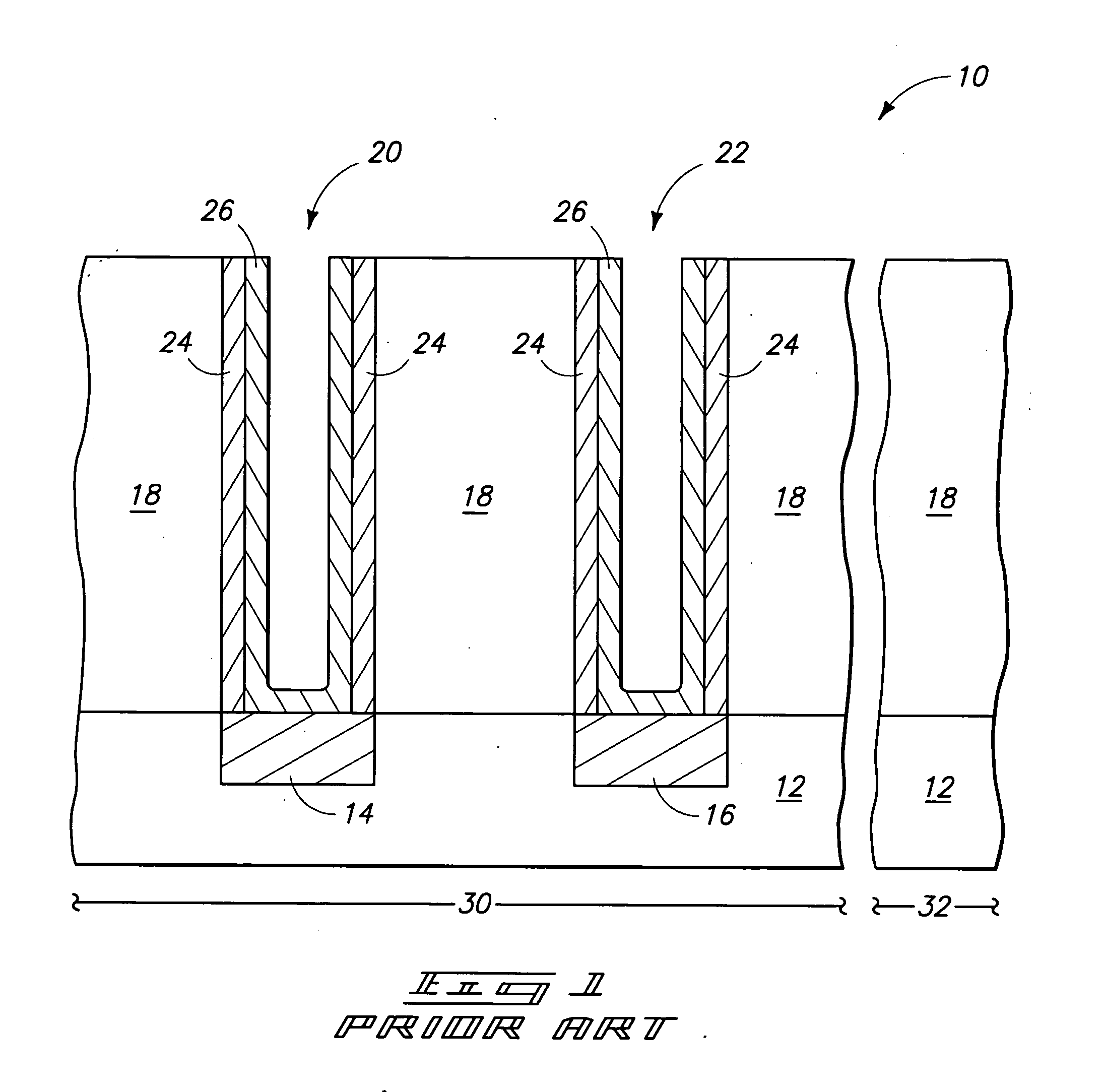

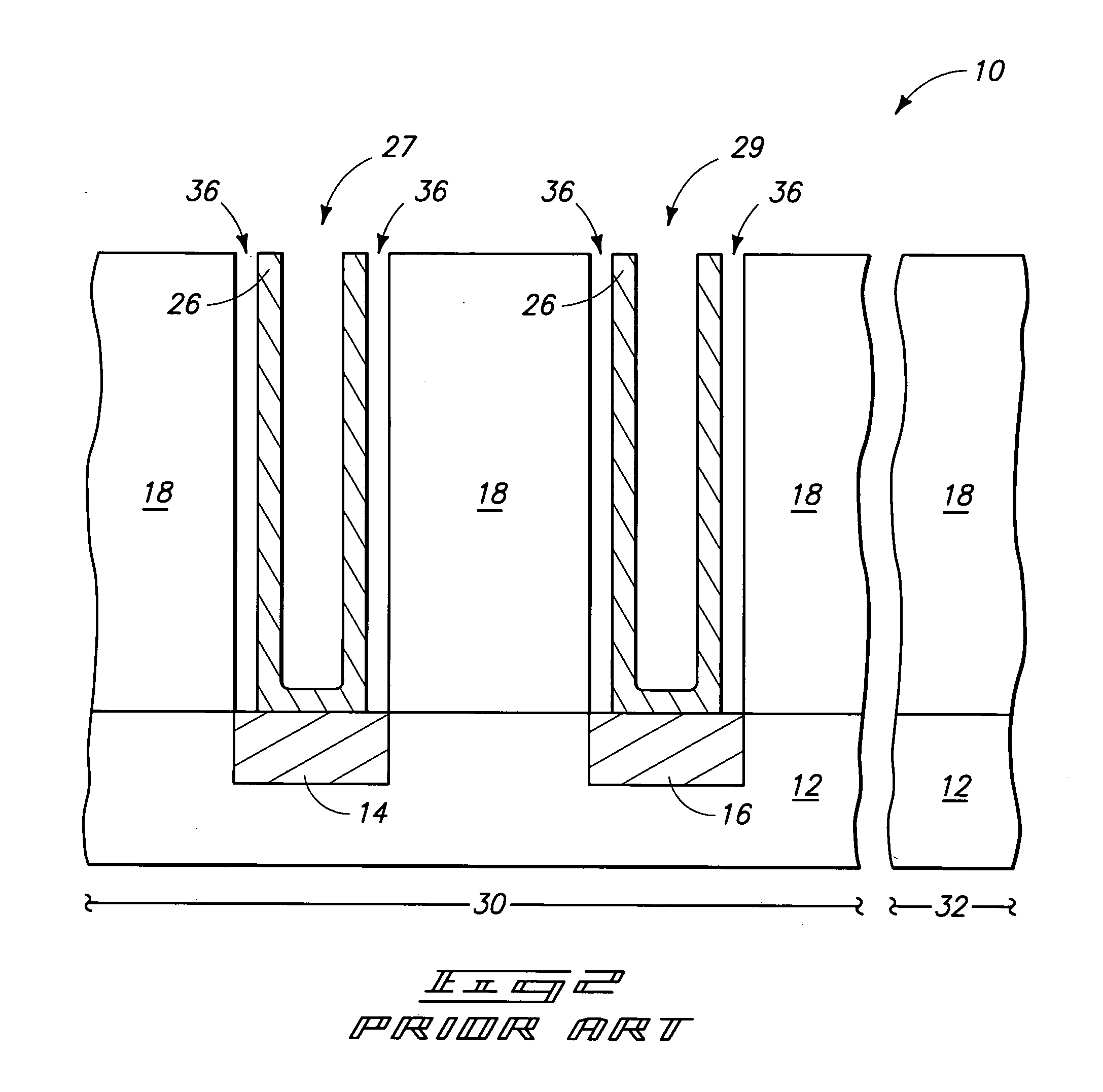

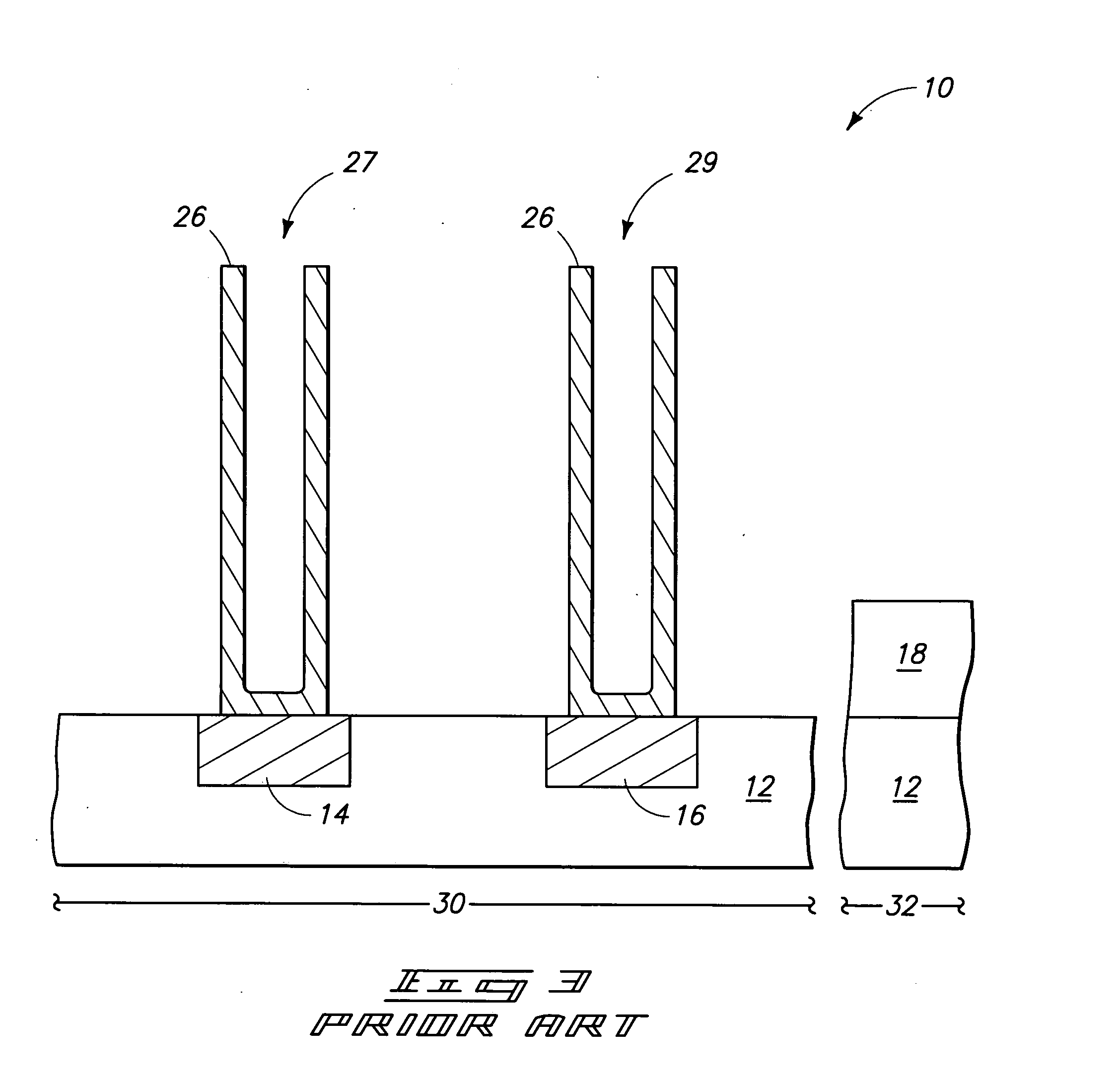

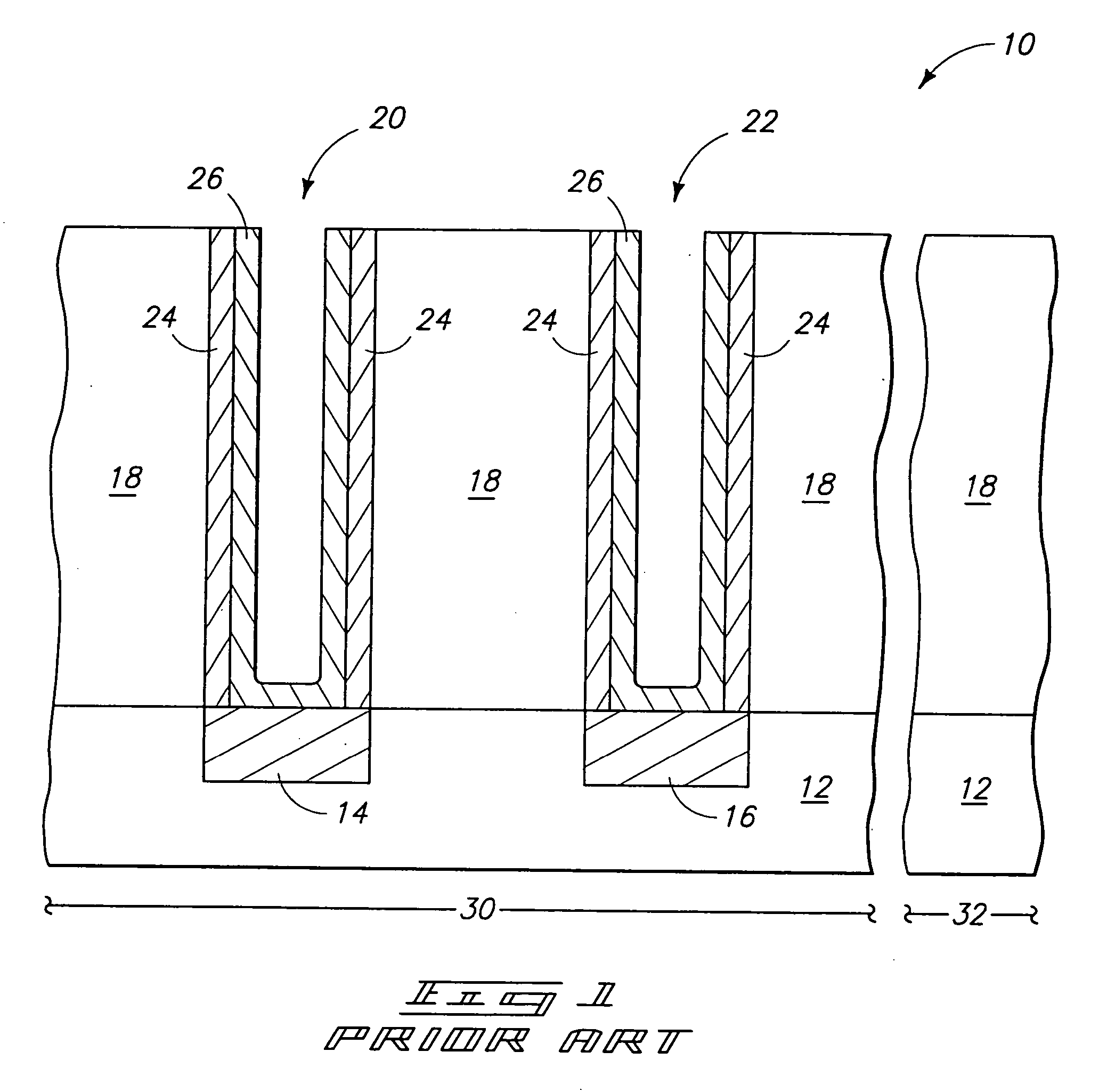

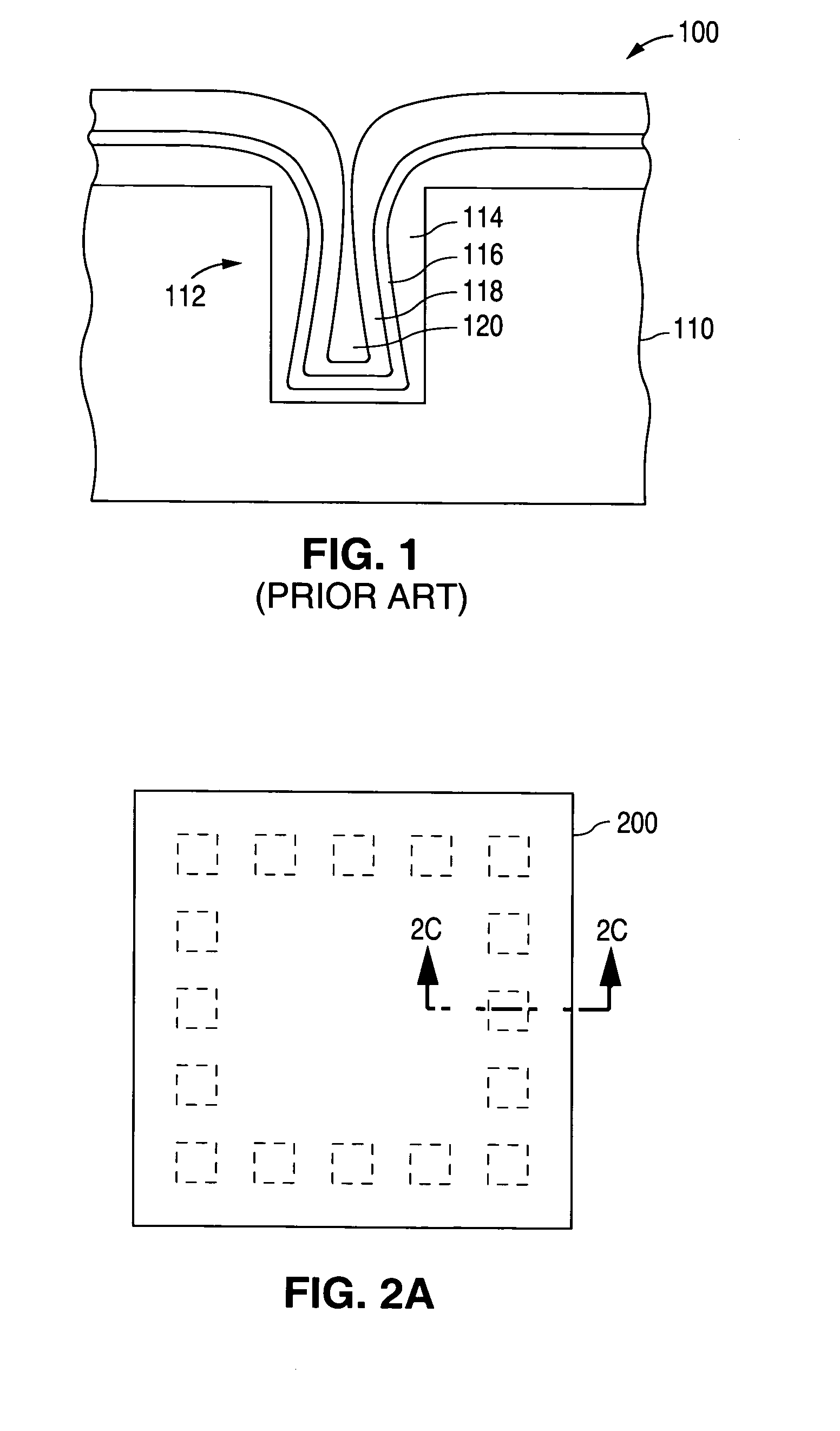

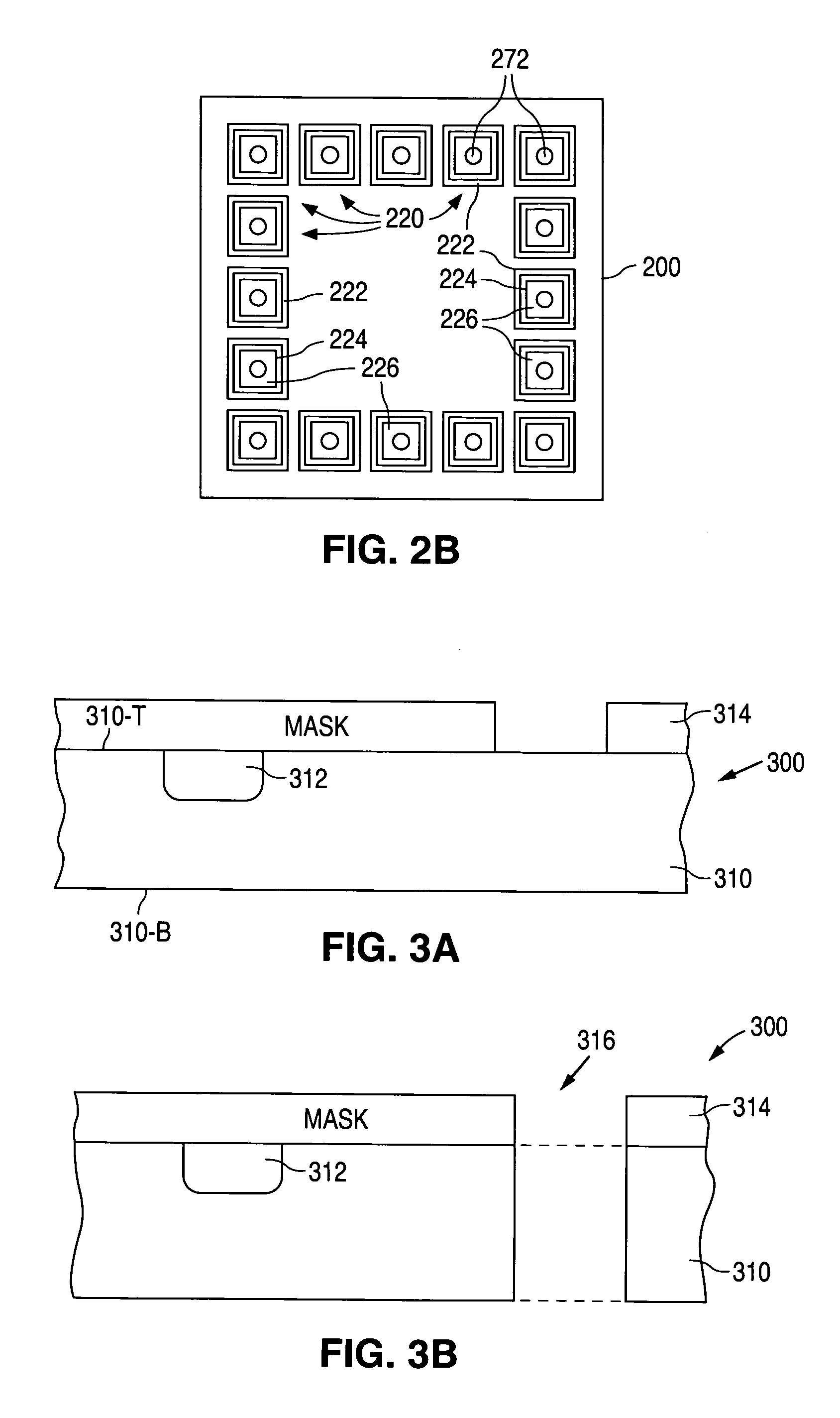

Transistor having notched fin structure and method of making the same

ActiveUS20120086053A1Semiconductor/solid-state device manufacturingSemiconductor devicesTetramethylammonium hydroxideEtching

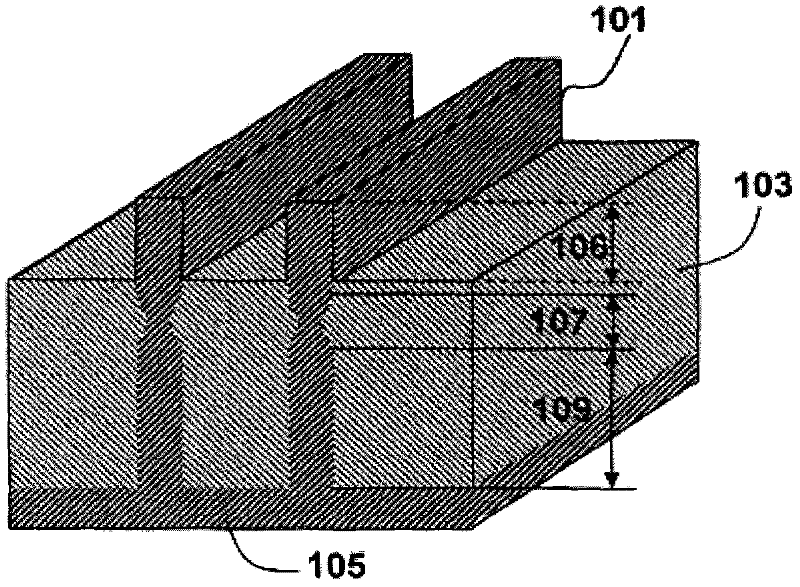

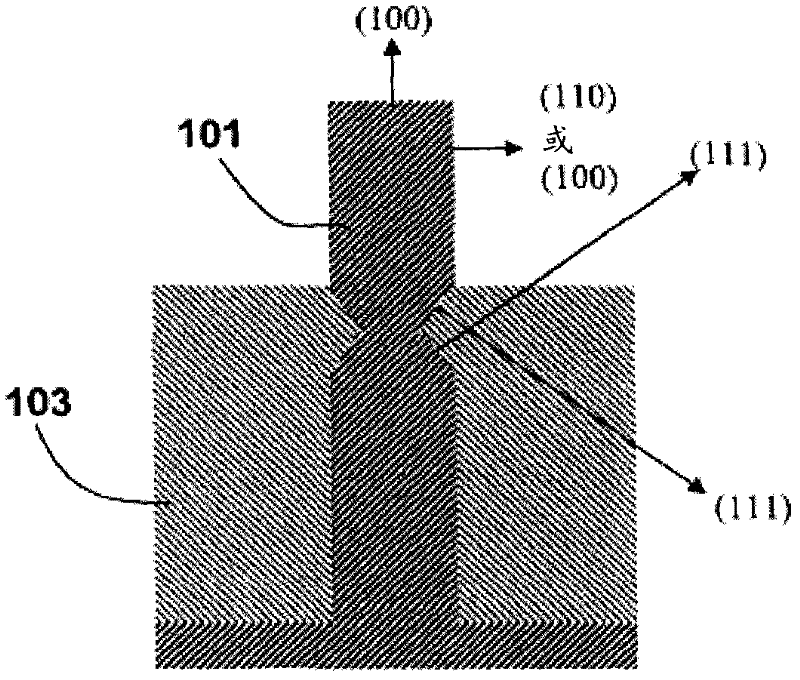

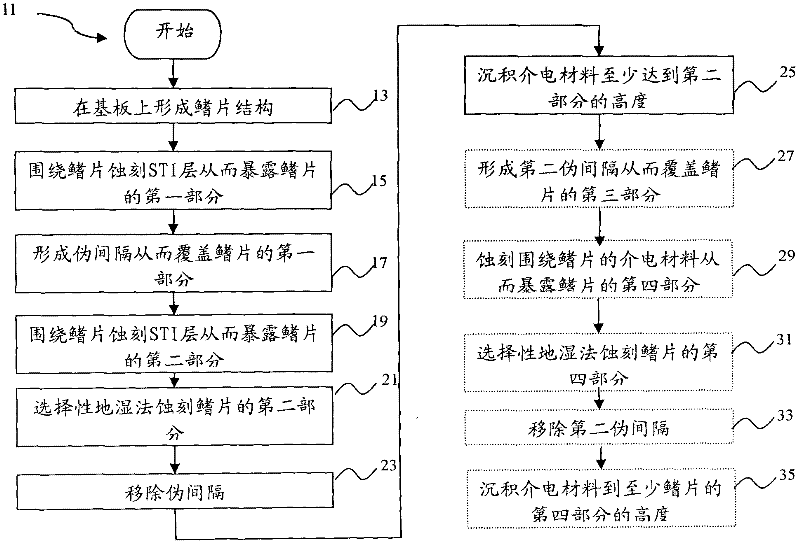

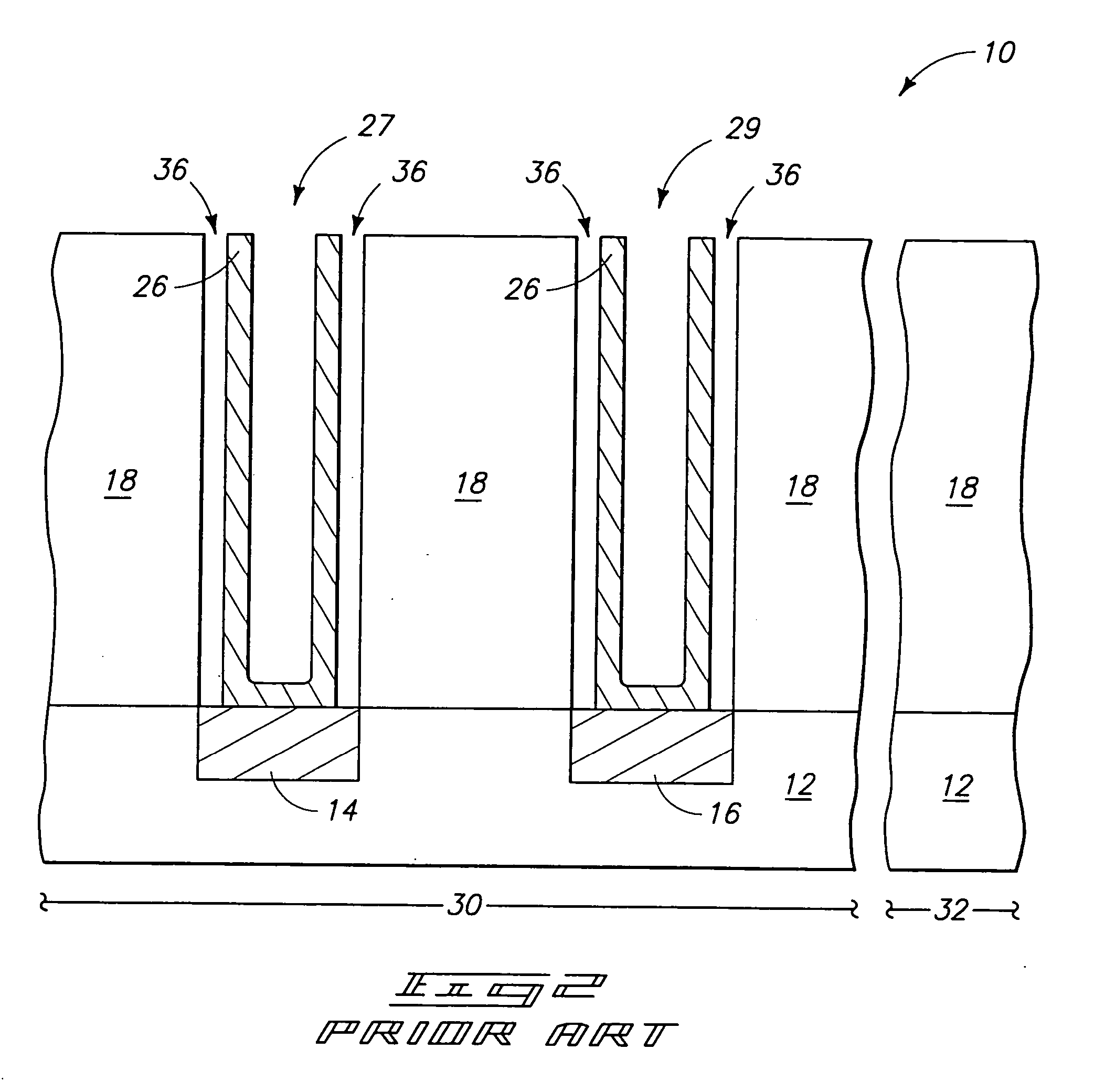

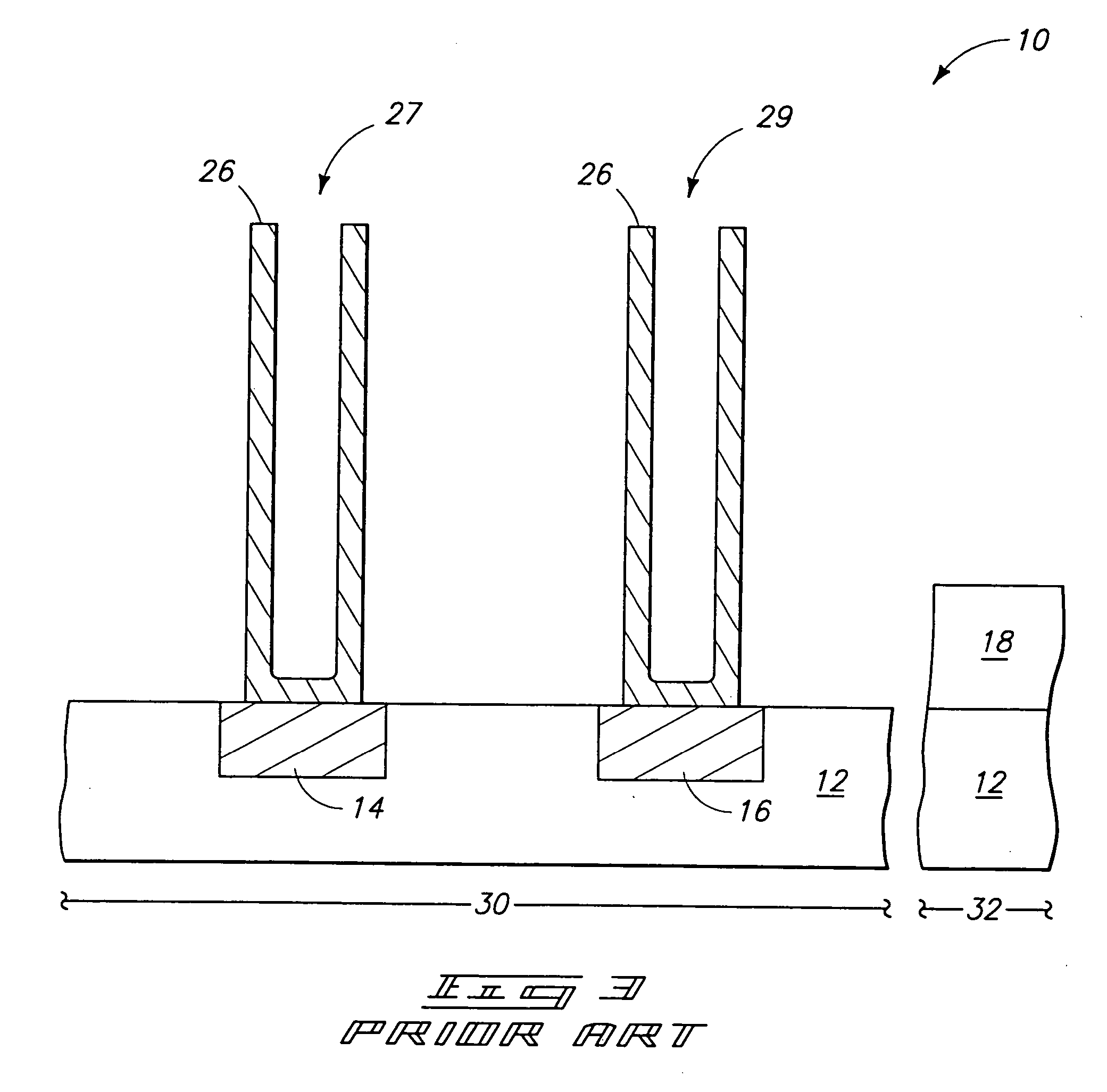

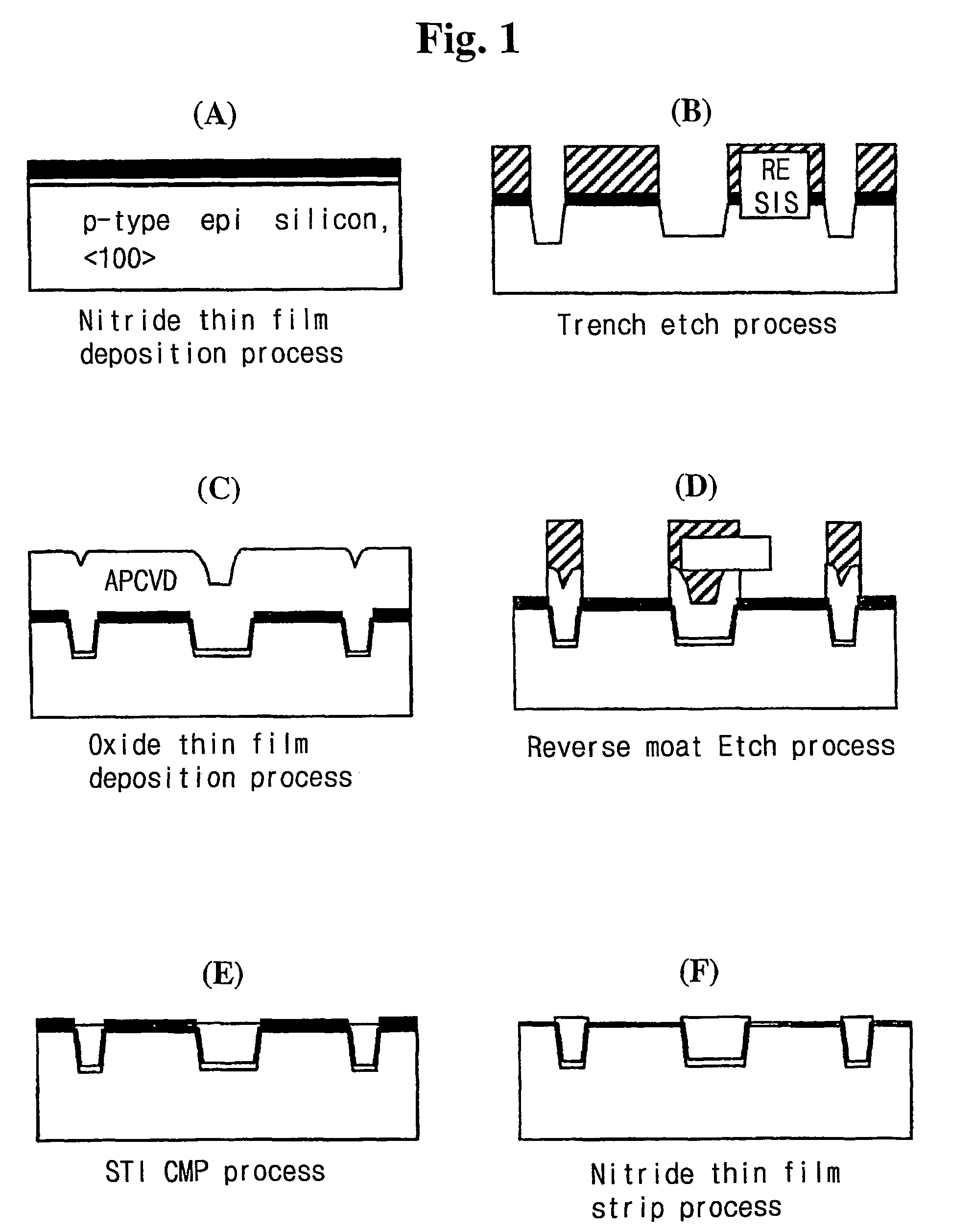

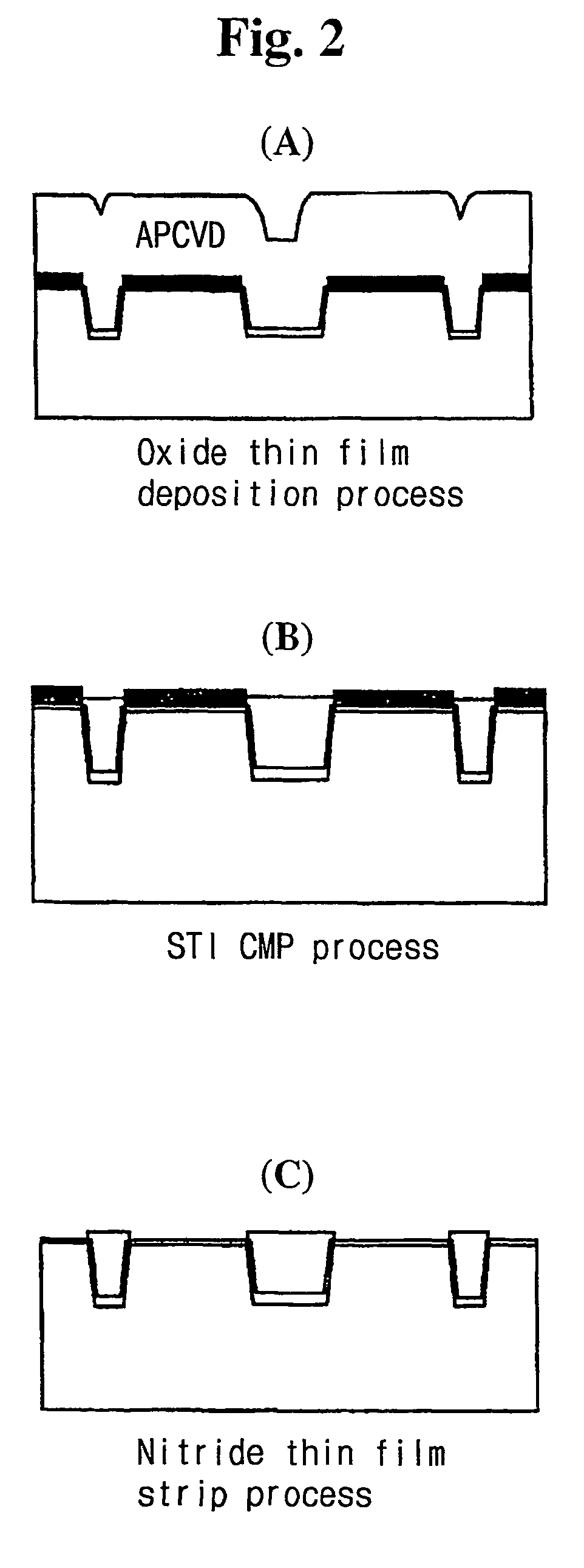

A transistor includes a notched fin covered under a shallow trench isolation layer. One or more notch may be used, the size of which may vary along a lateral direction of the fin. In some embodiments, The notch is formed using anisotropic wet etching that is selective according to silicon orientation. Example wet etchants are tetramethylammonium hydroxide (TMAH) or potassium hydroxide (KOH).

Owner:TAIWAN SEMICON MFG CO LTD

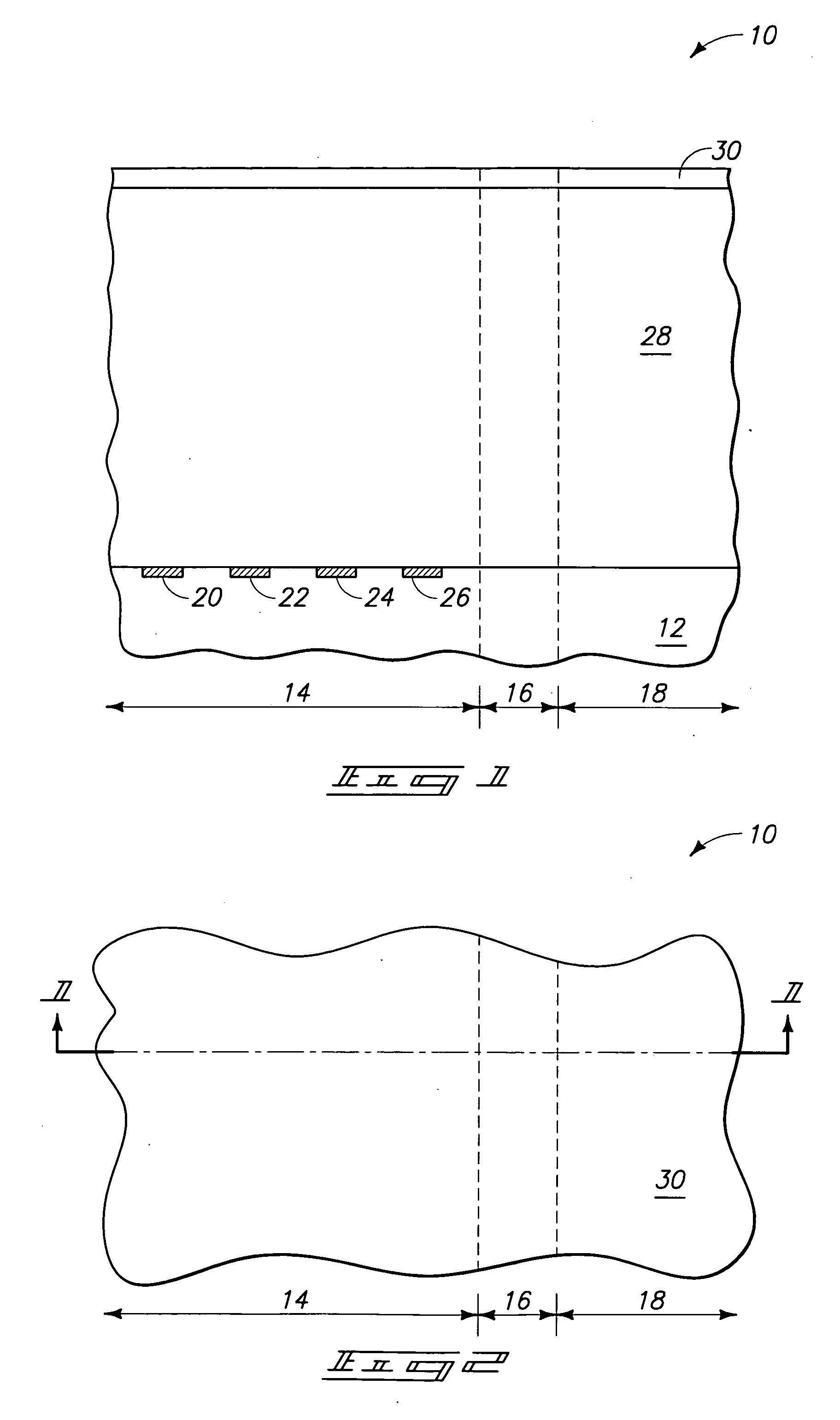

Methods of forming semiconductor constructions and capacitors

InactiveUS20070048976A1Solid-state devicesSemiconductor/solid-state device manufacturingTetramethylammonium hydroxideOxygen compound

The invention includes methods in which silicon is removed from titanium-containing container structures with an etching composition having a phosphorus-and-oxygen-containing compound therein. The etching composition can, for example, include one or both of ammonium hydroxide and tetra-methyl ammonium hydroxide. The invention also includes methods in which titanium-containing whiskers are removed from between titanium-containing capacitor electrodes. Such removal can be, for example, accomplished with an etch utilizing one or more of hydrofluoric acid, ammonium fluoride, nitric acid and hydrogen peroxide.

Owner:MICRON TECH INC

Polishing composition and polishing method

InactiveUS20050205837A1Suitable for useOther chemical processesDecorative surface effectsColloidal silicaTetramethylammonium hydroxide

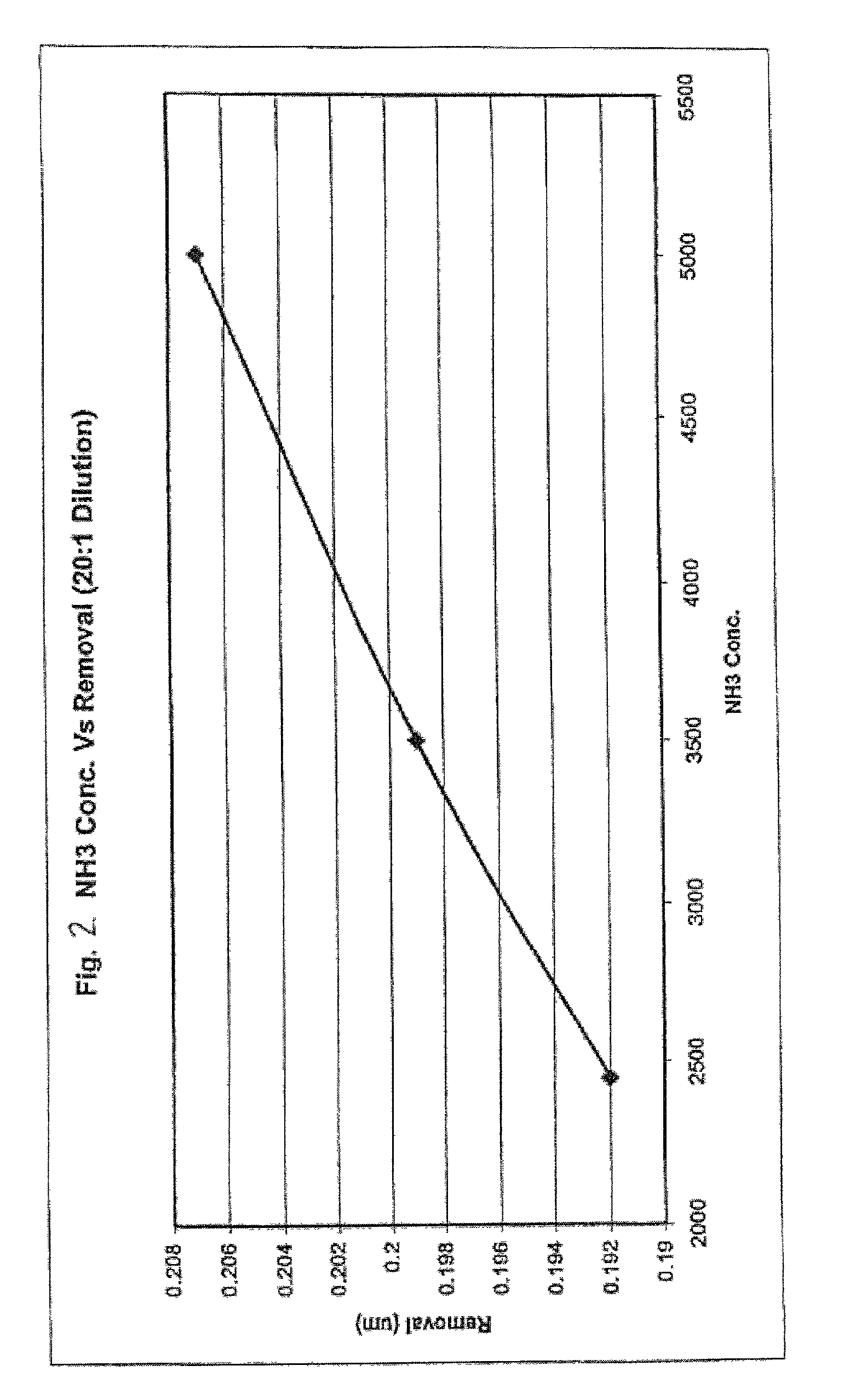

A polishing composition includes silicon dioxide, an alkaline compound, an anionic surfactant, and water. The silicon dioxide is, for example, colloidal silica, fumed silica, or precipitated silica. The alkaline compound is, for example, potassium hydroxide, sodium hydroxide, ammonia, tetramethylammonium hydroxide, piperazine anhydride, or piperazine hexahydrate. The anionic surfactant is at least one selected from a sulfonic acid surfactant, a carboxylic acid surfactant, and a sulfuric acid ester surfactant. The polishing composition can be suitably used in applications for polishing a silicon wafer.

Owner:FUJIMI INCORPORATED

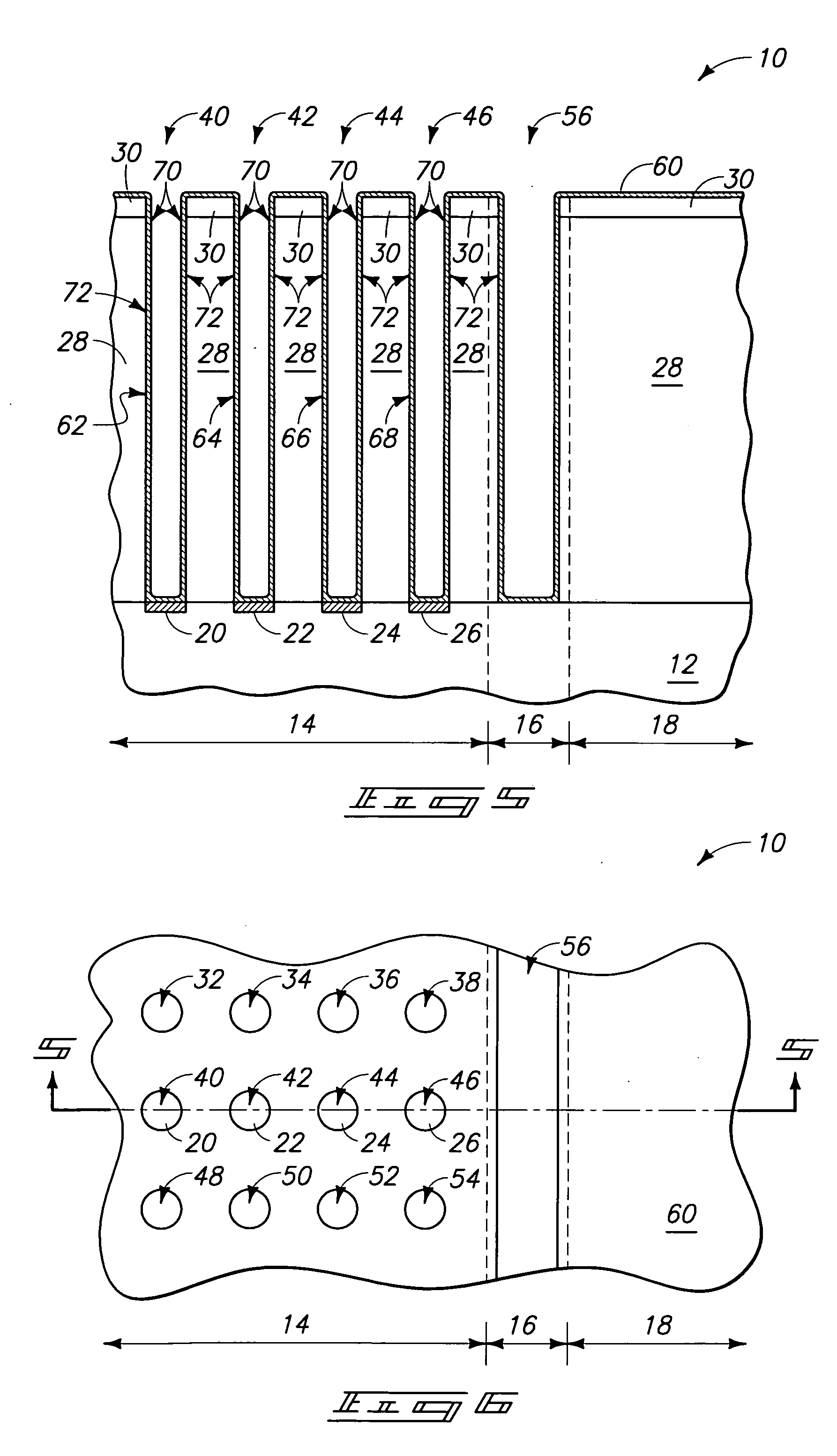

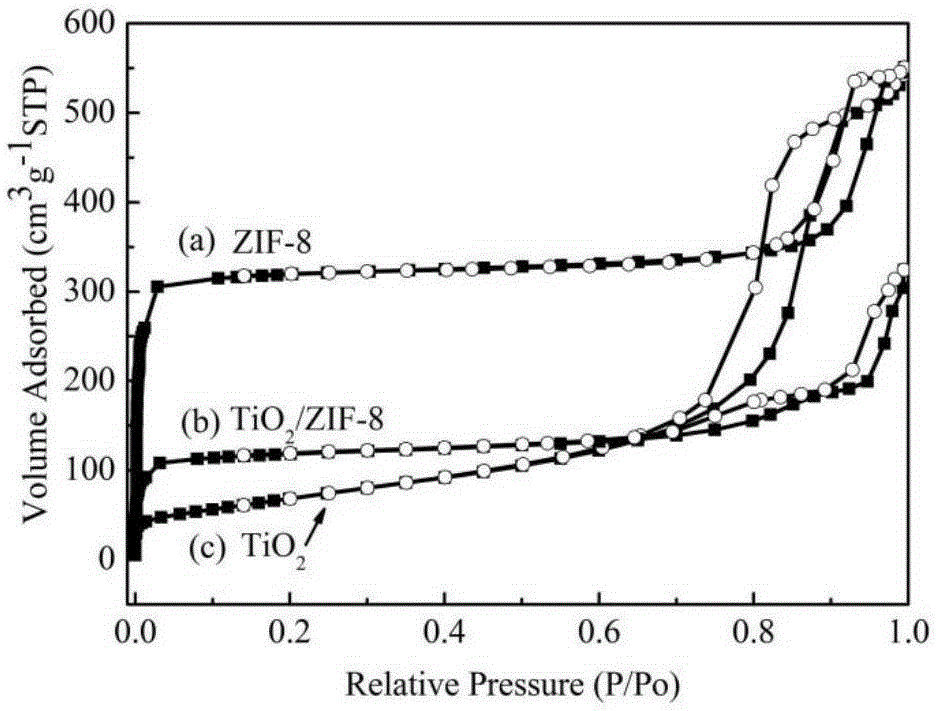

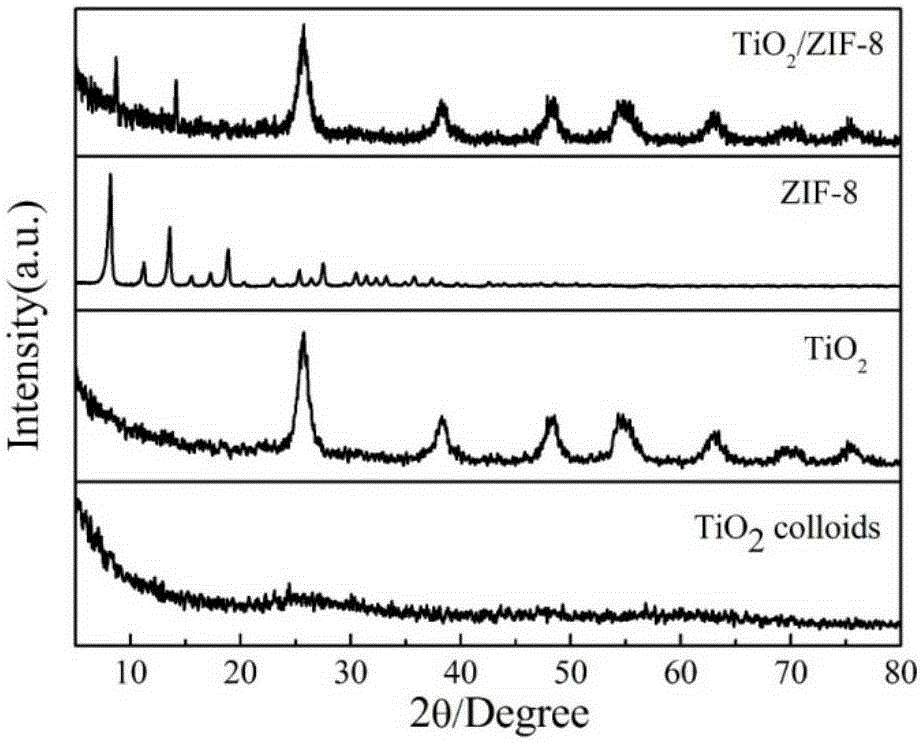

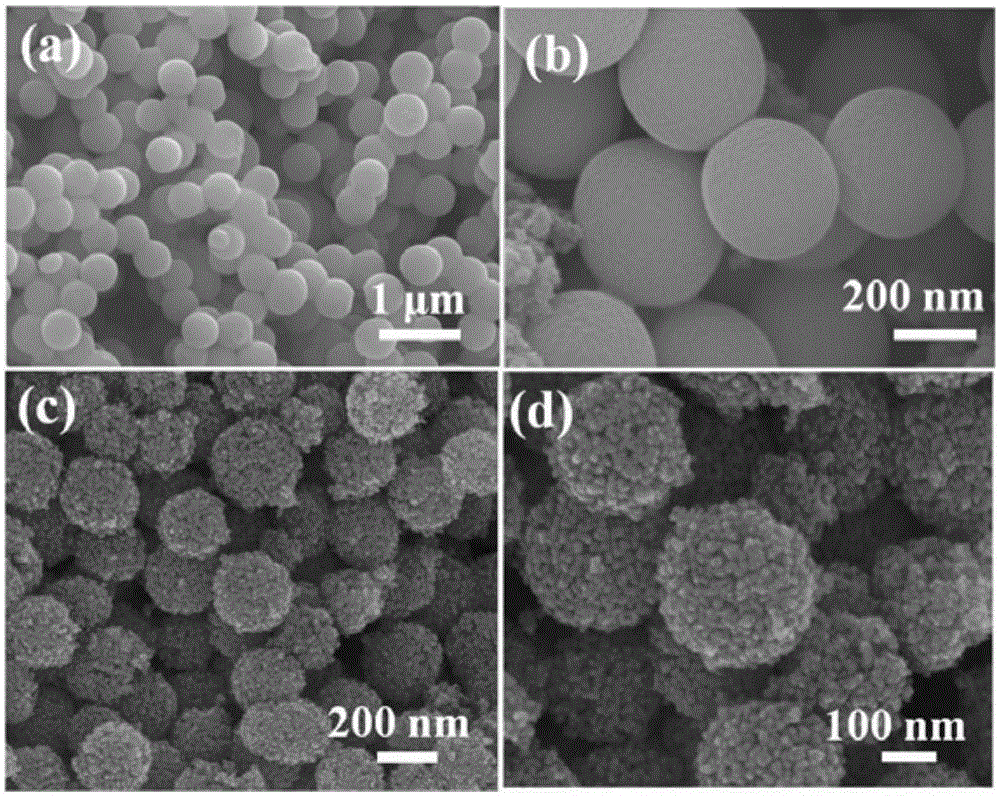

TiO2/ZIF-8 nanocomposite with core-shell structure and preparation method of TiO2/ZIF-8 nanocomposite

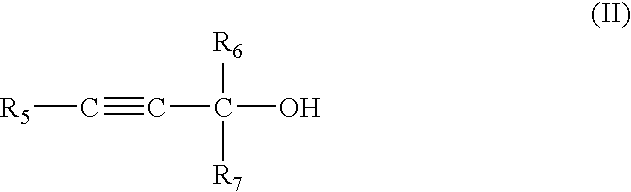

ActiveCN105170097AMild preparation conditionsSimple processOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsTetramethylammonium hydroxideMeth-

Owner:WUHU ALDOC TECH CO LTD

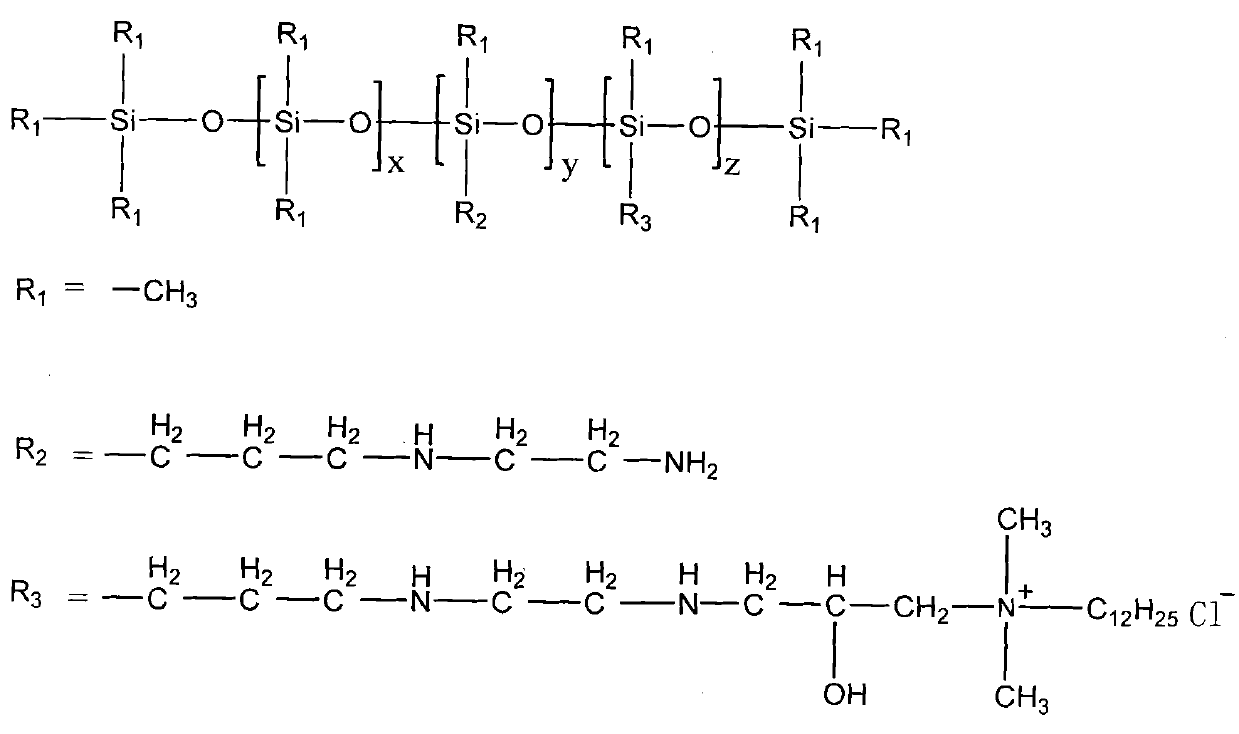

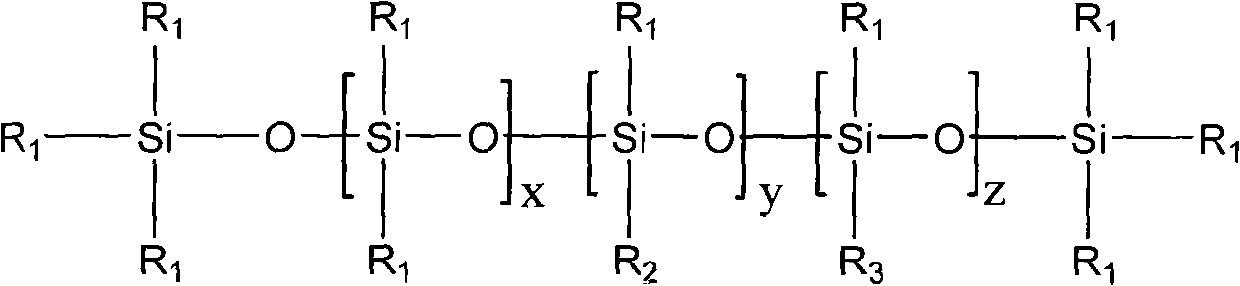

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

Aqueous cleaner with low metal etch rate comprising alkanolamine and tetraalkylammonium hydroxide

ActiveUS7365045B2Cationic surface-active compoundsOrganic detergent compounding agentsTetramethylammonium hydroxideAmmonium hydroxide

A cleaning solution is provided for cleaning metal-containing microelectronic substrates, particularly for post etch, via formation and post CMP cleaning. The cleaning solution consists of a quaternary ammonium hydroxide, an organic amine, and water. A preferred cleaning solution consists of tetramethylammonium hydroxide, monoethanolamine, and water. The pH of cleaning solution is greater than 10.

Owner:ENTEGRIS INC

Aqueous cleaner with low metal etch rate

InactiveUS20060148666A1Anionic surface-active compoundsNon-surface-active detergent compositionsTetramethylammonium hydroxideGallic acid ester

A cleaning solution is provided for cleaning copper-containing microelectronic substrates, particularly for post etch, post-CMP or Via formation cleaning. The cleaning solution comprises a quaternary ammonium hydroxide, an organic amine, a corrosion inhibitor, and water. A preferred cleaning solution comprises tetramethylammonium hydroxide, monoethanolamine, gallic acid, and water. The pH of cleaning solution is greater than 10.

Owner:ADVANCED TECH MATERIALS INC

Polishing composition

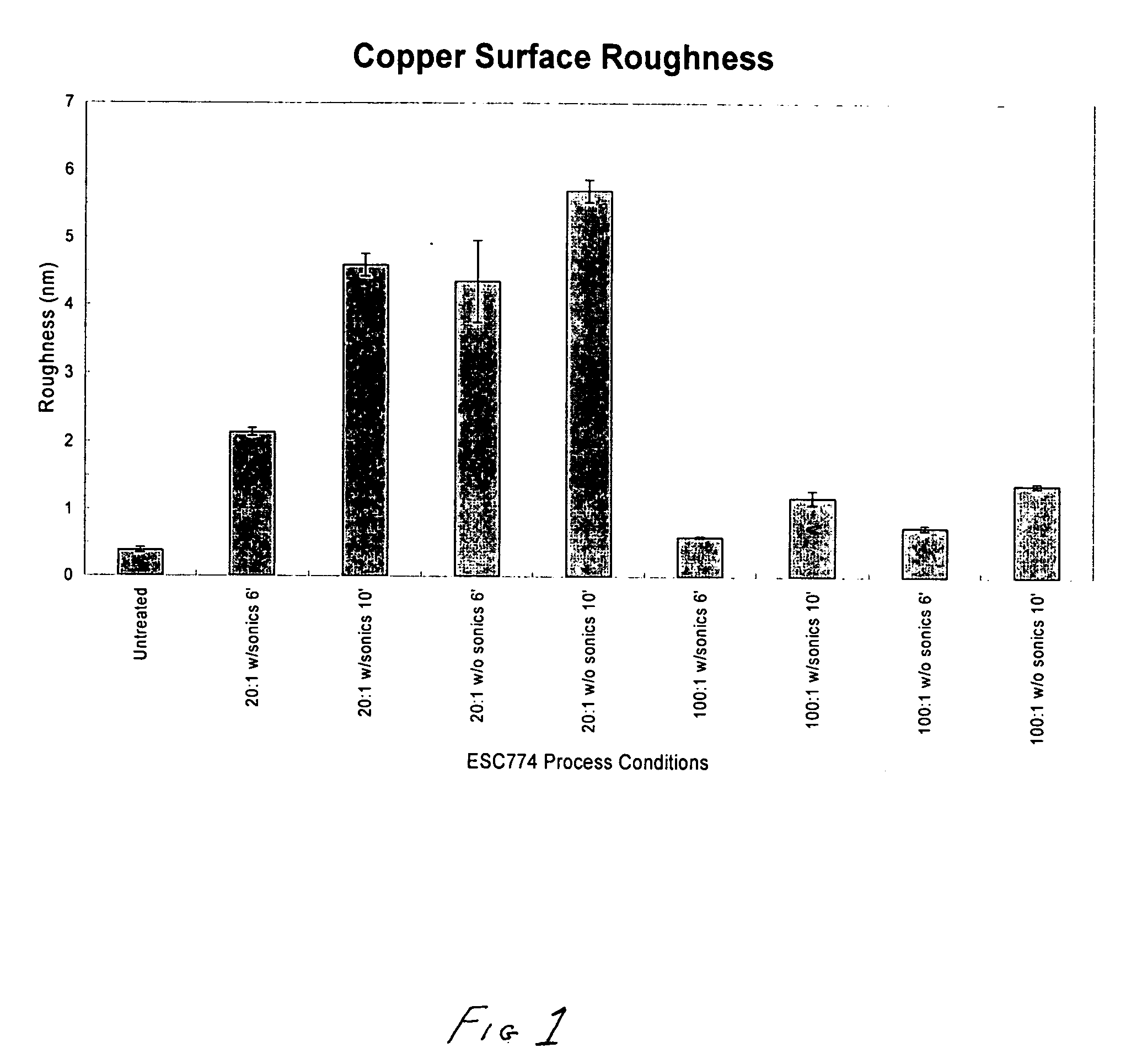

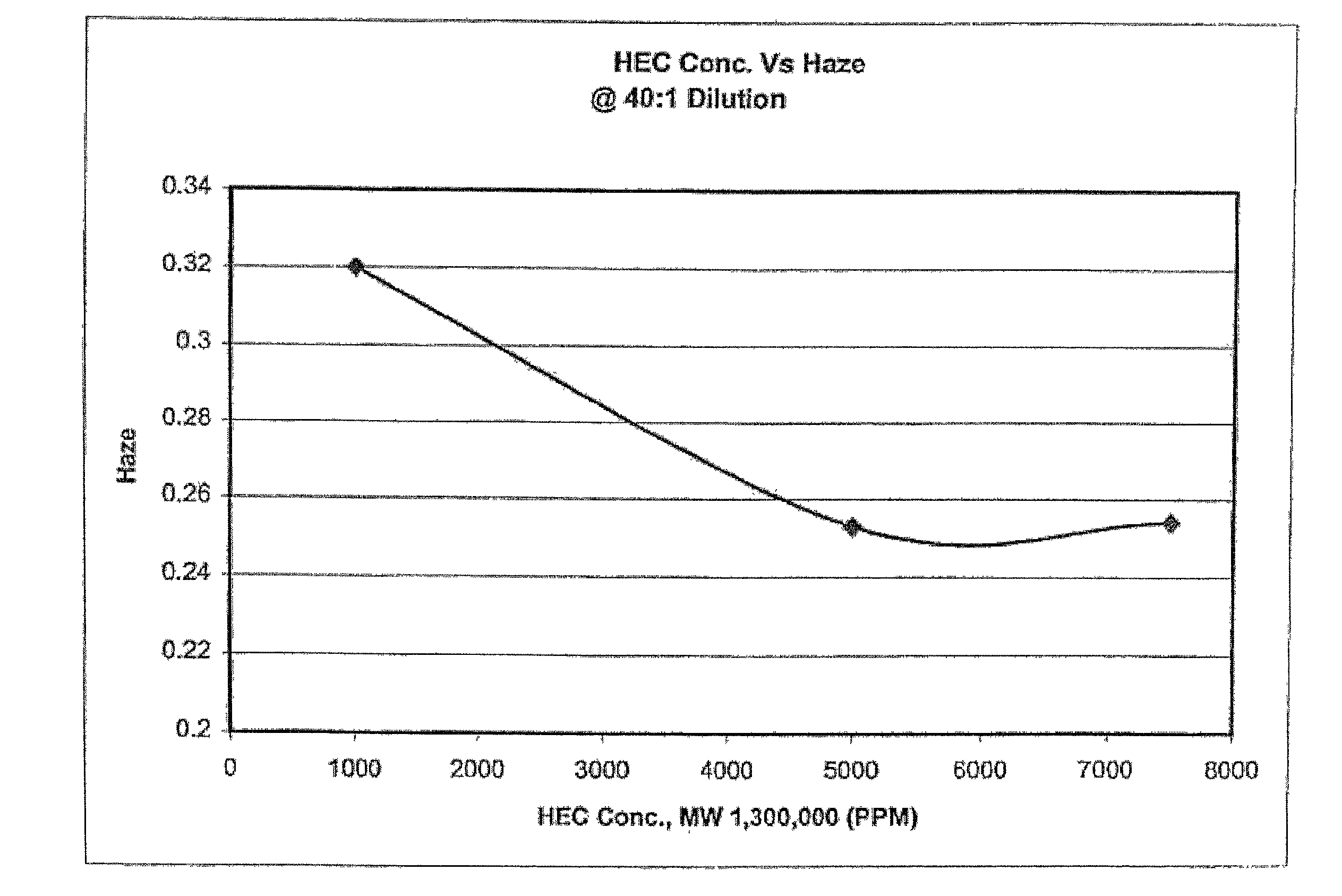

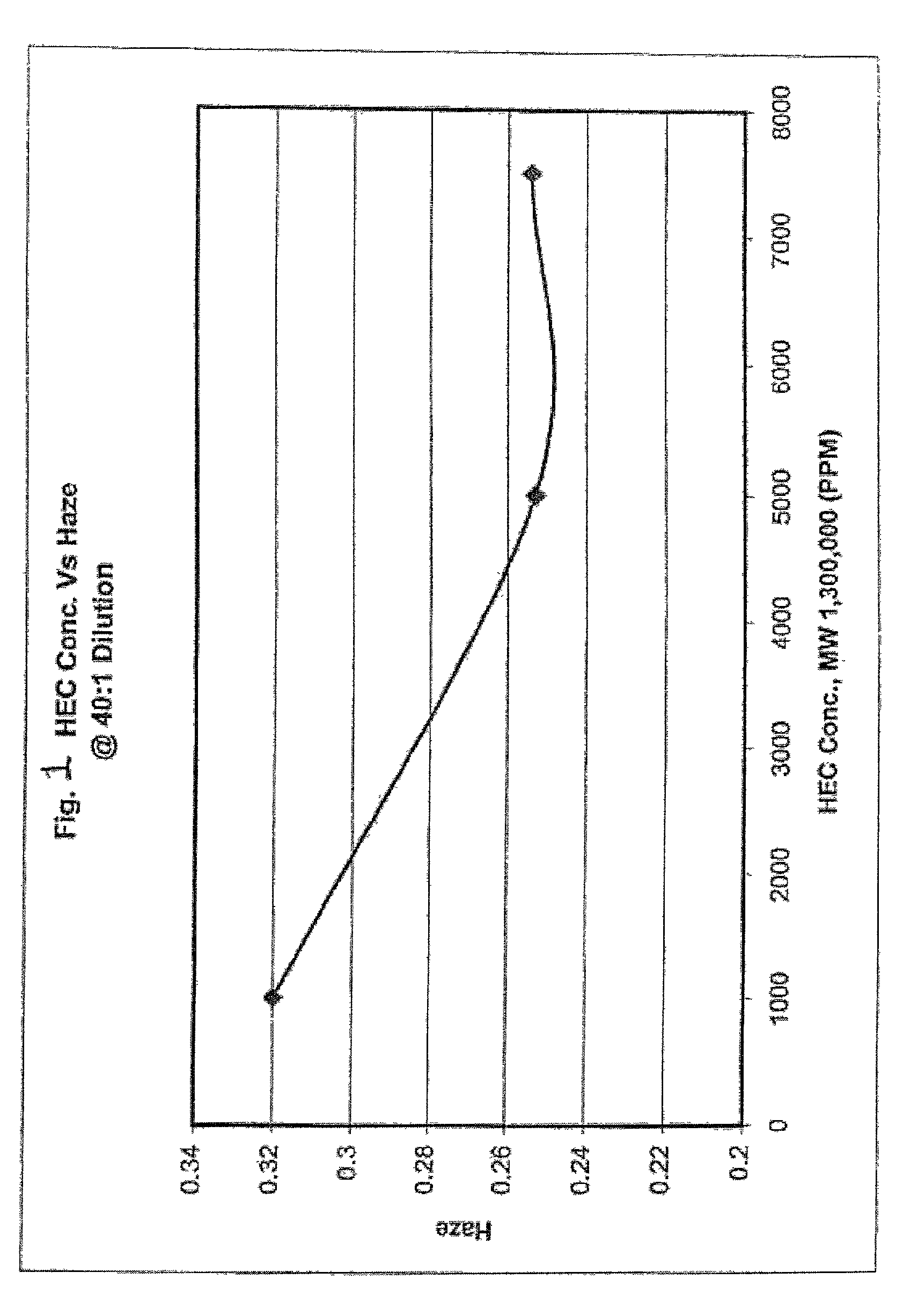

InactiveUS20030154659A1High polishing removal rateLow hazePigmenting treatmentOther chemical processesCelluloseColloidal silica

A polishing composition for polishing a semiconductor wafer includes comprises water, an abrasive that is preferably colloidal silica, water-soluble cellulose having a molecular weight of at least about 1,000,000 and an alkaline compound that is preferably ammonia. Tetra methyl ammonium hydroxide may also be added to the polishing composition.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Transistor having notched fin structure and method of making the same

ActiveCN102446972ASemiconductor/solid-state device manufacturingSemiconductor devicesTetramethylammonium hydroxideEtching

A transistor includes a notched fin covered under a shallow trench isolation layer. One or more notch may be used, the size of which may vary along a lateral direction of the fin. In some embodiments, The notch is formed using anisotropic wet etching that is selective according to silicon orientation. Example wet etchants are tetramethylammonium hydroxide (TMAH) or potassium hydroxide (KOH).

Owner:TAIWAN SEMICON MFG CO LTD

Methods of removing metal-containing materials

InactiveUS20050250339A1Semiconductor/solid-state device manufacturingCapacitorsTetramethylammonium hydroxidePersulfate

Various methods for selectively etching metal-containing materials (such as, for example, metal nitrides, which can include, for example, titanium nitride) relative to one or more of silicon, silicon dioxide, silicon nitride, and doped silicon oxides in high aspect ratio structures with high etch rates. The etching can utilize hydrogen peroxide in combination with ozone, ammonium hydroxide, tetra-methyl ammonium hydroxide, hydrochloric acid and / or a persulfate. The invention can also utilize ozone in combination with hydrogen peroxide, and / or in combination with one or more of ammonium hydroxide, tetra-methyl ammonium hydroxide and a persulfate. The invention can also utilize ozone, hydrogen peroxide and HCI, with or without persulfate. The invention can also utilize hydrogen peroxide and a phosphate, either alone, or in combination with a persulfate.

Owner:MICRON TECH INC

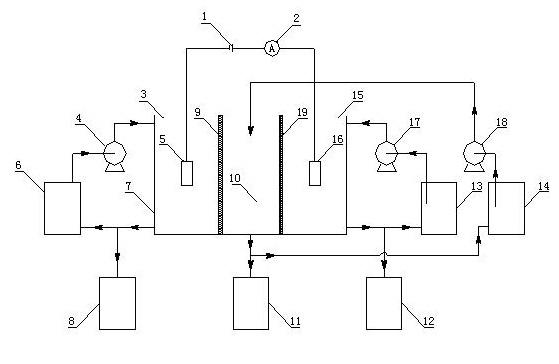

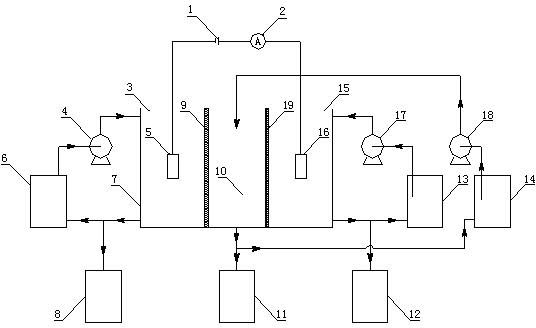

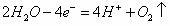

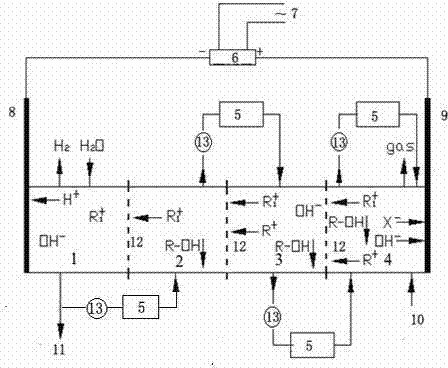

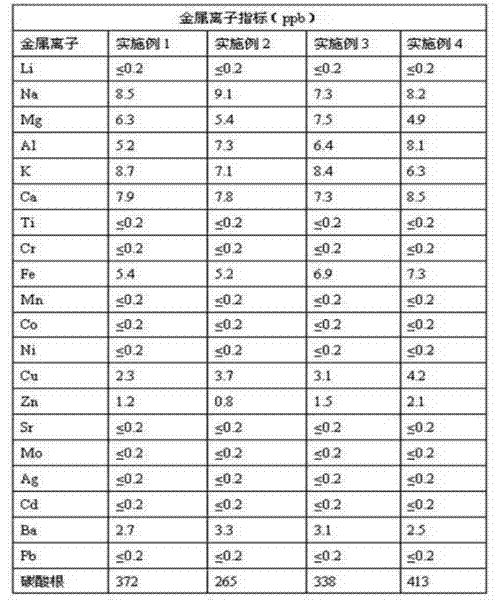

Method for preparing electronic-grade tetramethylammonium hydroxide (TMAH)

InactiveCN102206832ASimple processImprove current efficiencyElectrolysis componentsElectrolytic organic productionTetramethylammonium hydroxideBuffer tank

The invention discloses a method for preparing electronic-grade tetramethylammonium hydroxide (TMAH), belonging to the field of electrochemistry. In the method, tetramethylammonium bicarbonate is used as a raw material for electrolysis, a dual-film electrolyzer is used for preparing the electronic-grade TMAH, and the whole electrolyzer implements cyclic stirring of the electrolyte in the electrolytic process in an external cycle mode. The electrolytic conditions are as follows: the cathode tank uses a 0.2-0.5 mol / L TMAH solution; the buffer tank uses a 1.0-3.0 mol / L TMAHCO3 solution; the anode tank uses a 0.2-0.6 mol / L Na2SO4 solution; the temperature for electrolysis is 40-60 DEG C; and the current density is 400-1000 A / m<2>. The invention has the advantages of simple technological process, low raw material cost, high product yield (the content of metallic ions in the product is lower than 4ppm, achieving the standard for electronic-grade TMAH), high electrolytic-current efficiency (up to 80-90%), environmental protection, no pollution and high production safety.

Owner:ZHENGZHOU UNIV

Photoresist stripping solution and a method of stripping photoresists using the same

InactiveUS20050084792A1Effective protectionEfficient strippingPhotography auxillary processesSemiconductor/solid-state device manufacturingTetramethylammonium hydroxideResist

A photoresist stripping solution which comprises (a) a salt of hydrofluoric acid with a base free from metal ions, (b) a water-soluble organic solvent, (c) a mercapto group containing corrosion inhibitor, and (d) water, and a method of stripping photoresists with the use of the same are disclosed. In case of using ammonium fluoride as component (a), the photoresist stripping solution may further contain (e) a salt of hydrofluoric acid with a quaternary ammonium hydroxide, such as tetramethylammonium hydroxide, tetrapropylammonium hydroxide, etc., and / or an alkanolamine. The photoresist stripping solution of the present invention has an excellent effect of protecting both Al- and Cu-based metal wiring conductors from corrosion, of efficiently stripping photoresist films and post-ashing residues, and is free from the precipitation of the corrosion inhibitor.

Owner:YOKOI SHIGERU +1

Method for directly synthesizing mesoporous material coated heteropolyacid functionalized MOF material

InactiveCN104338556AMild reaction conditionsHigh reaction yieldOrganic chemistryOrganic compound preparationTetramethylammonium hydroxideHeteropoly acid

The invention discloses a method for directly synthesizing a mesoporous material coated heteropolyacid functionalized MOF material, and relates to a method for a mesoporous material coated polyacid modified metal organic framework material, wherein a mesoporous molecular sieve, phosphorus molybdenum heteropoly acid, tetramethylammonium hydroxide, 1,3,5-trimesic acid, and Cu(NO3)2.3H2O are adopted as raw materials, a hydrothermal synthesis method is adopted, and water is adopted as a solvent to carry out one step synthesis at a temperature of 90-230 DEG C to obtain the target material. The catalysis material synthesized by the method is applied in the benzene hydroxylation reaction, wherein the good stability performance of the material is presented under the mild reaction conditions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

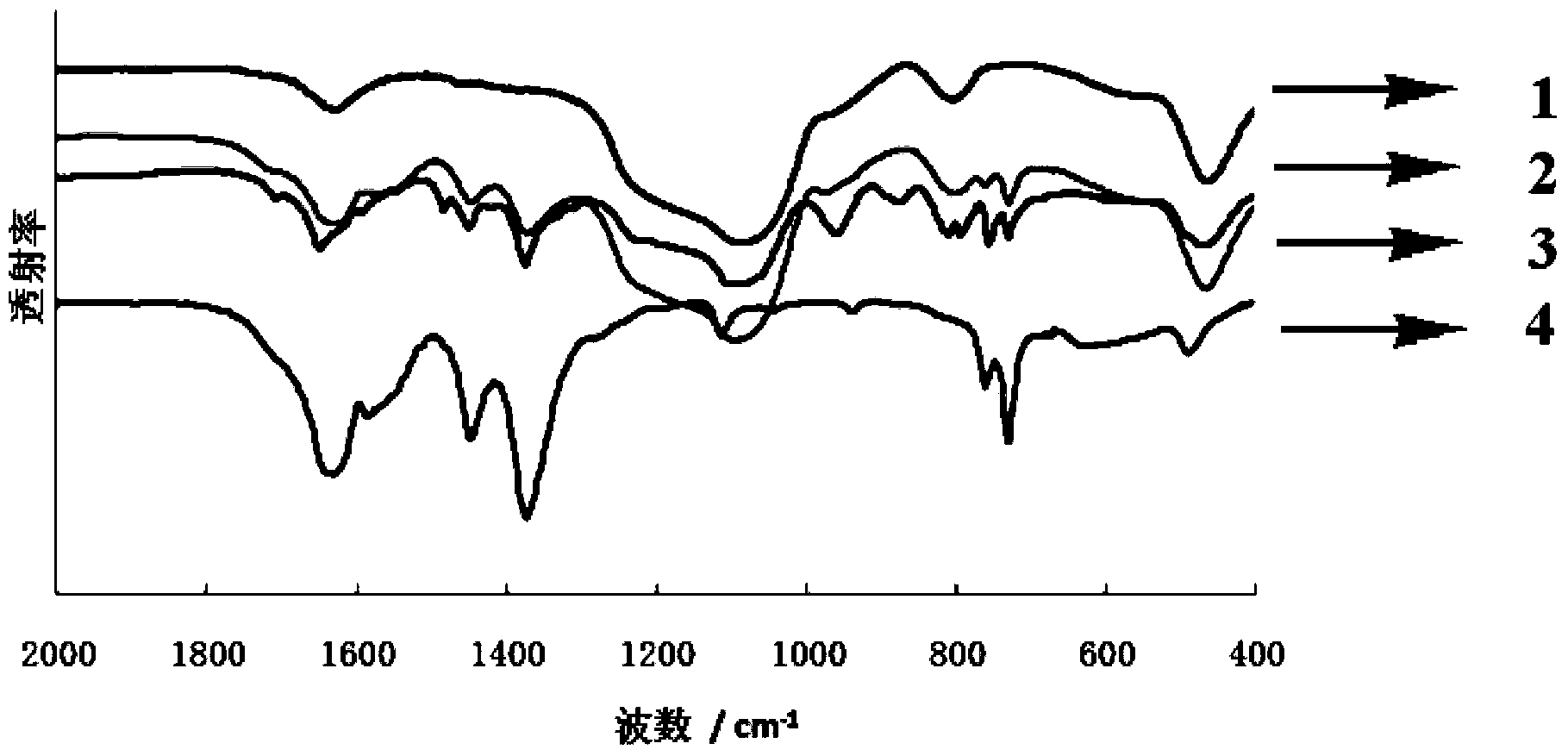

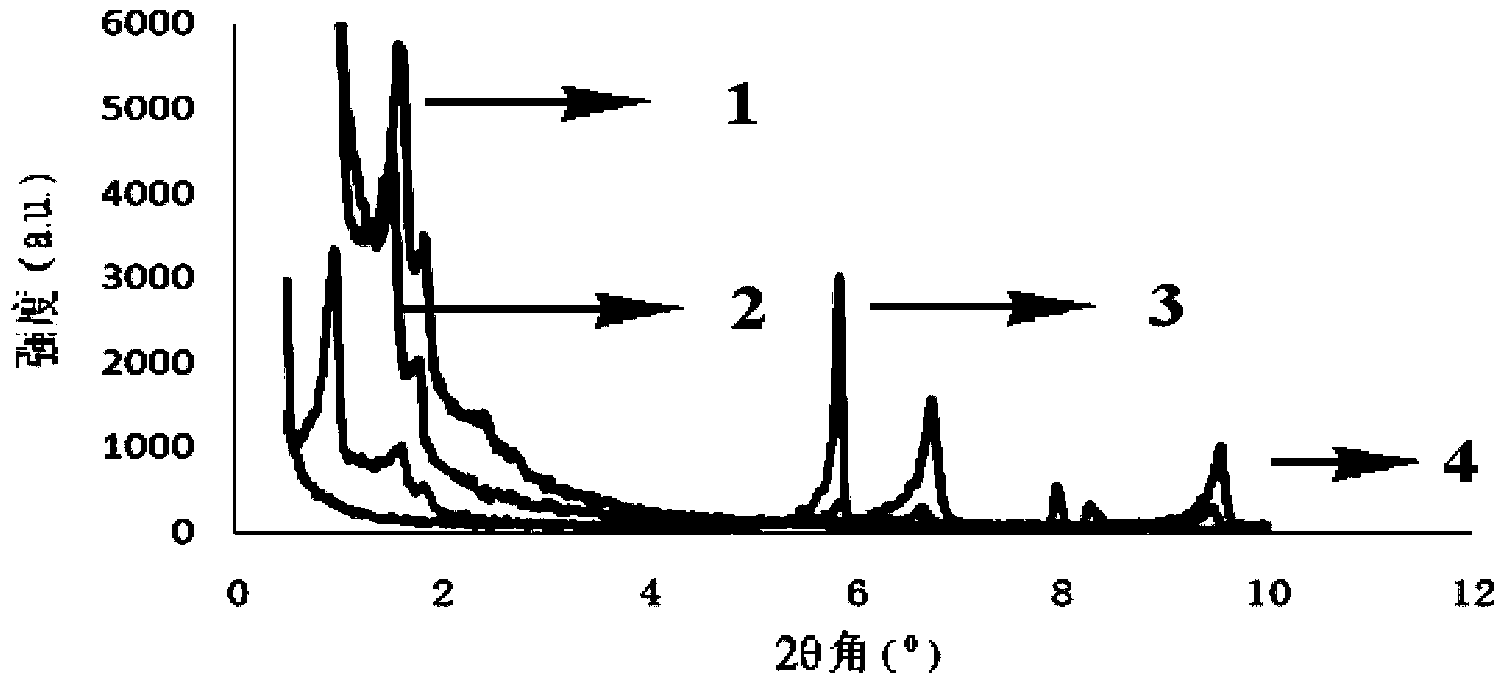

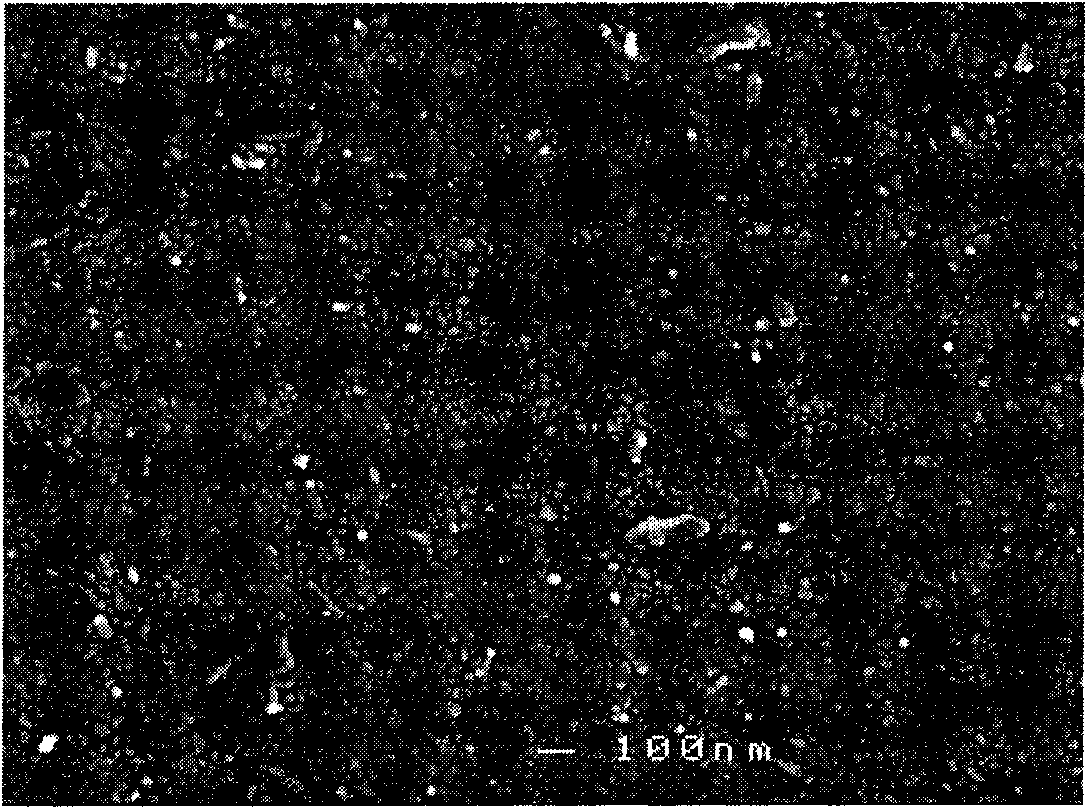

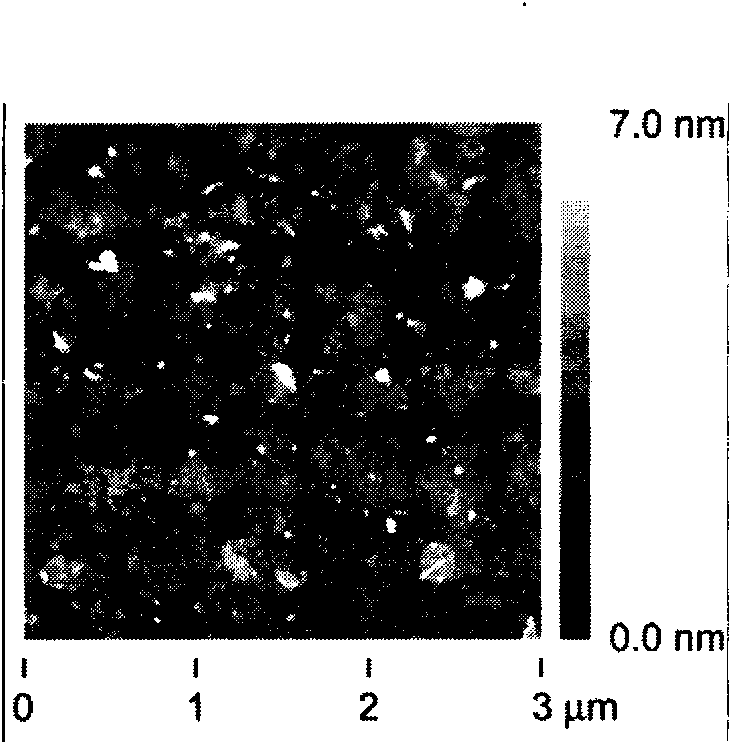

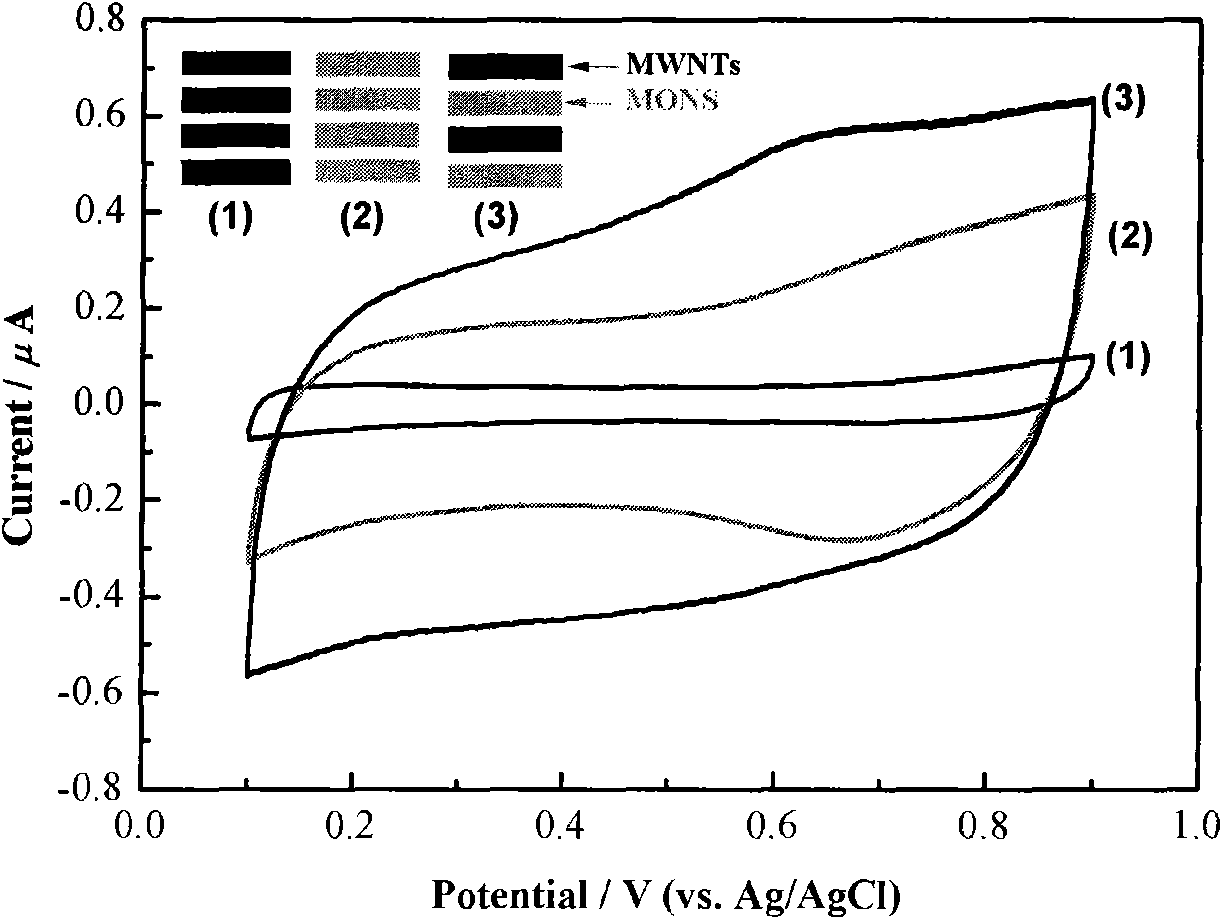

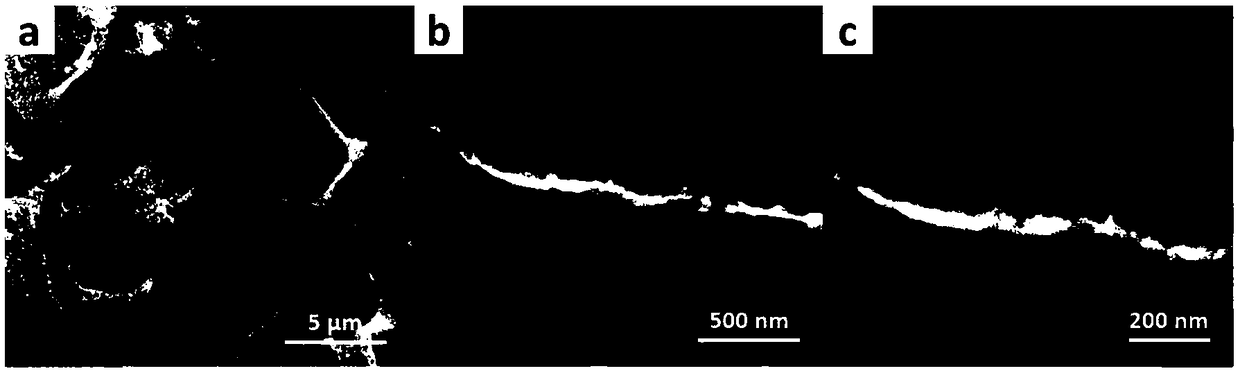

Preparation method of monolayer manganese dioxide nano-plates

InactiveCN101585555AFacilitate post-processing preparationImprove electrochemical performanceElectrolytic capacitorsManganese oxides/hydroxidesTetramethylammonium hydroxideSynthesis methods

The invention discloses a preparation method of monolayer manganese dioxide nano-plates, including the following steps: (1) manganese nitrate is reacted with sodium hydroxide or potassium hydroxide with the existence of oxidant to produce NaxMnO2 or KxMnO2 having ordered laminated structure; (2) the NaxMnO2 or KxMnO2 having ordered laminate structure is added to sodium hydroxide aqueous solution, OHxMnO2 is obtained by hydro-thermal synthesis method, and the obtained OHxMnO2 is fully acid-cleaned to obtain HxMnO2; (3) tetrabutylammonium hydroxide or tetramethylammonium hydroxide is used for reacting with laminated HxMnO2, and the tetrabutylammonium hydroxide or tetramethylammonium hydroxide is inserted inside the laminated HxMnO2 so that the laminated HxMnO2 is dispersed into monolayer manganese dioxide nano-plates. The manganese dioxide nano-plates obtained in the invention have monolayer with the thickness of just 0.3 to 0.8 nm; and as electrode material, the chemical performance of manganese dioxide nano-plate electrode is obviously higher than that of carbon nanotube electrode.

Owner:ZHEJIANG UNIV OF TECH

Semiconductor fabrication processes

InactiveUS20060177988A1Semiconductor/solid-state device manufacturingCapacitorsTetramethylammonium hydroxidePersulfate

Various methods for selectively etching metal-containing materials (such as, for example, metal nitrides, which can include, for example, titanium nitride) relative to one or more of silicon, silicon dioxide, silicon nitride, and doped silicon oxides in high aspect ratio structures with high etch rates. The etching can utilize hydrogen peroxide in combination with ozone, ammonium hydroxide, tetra-methyl ammonium hydroxide, hydrochloric acid and / or a persulfate. The invention can also utilize ozone in combination with hydrogen peroxide, and / or in combination with one or more of ammonium hydroxide, tetra-methyl ammonium hydroxide and a persulfate. The invention can also utilize ozone, hydrogen peroxide and HCl, with or without persulfate. The invention can also utilize hydrogen peroxide and a phosphate, either alone, or in combination with a persulfate.

Owner:MICRON TECH INC

Process for the preparation of zeolites having CHA structure

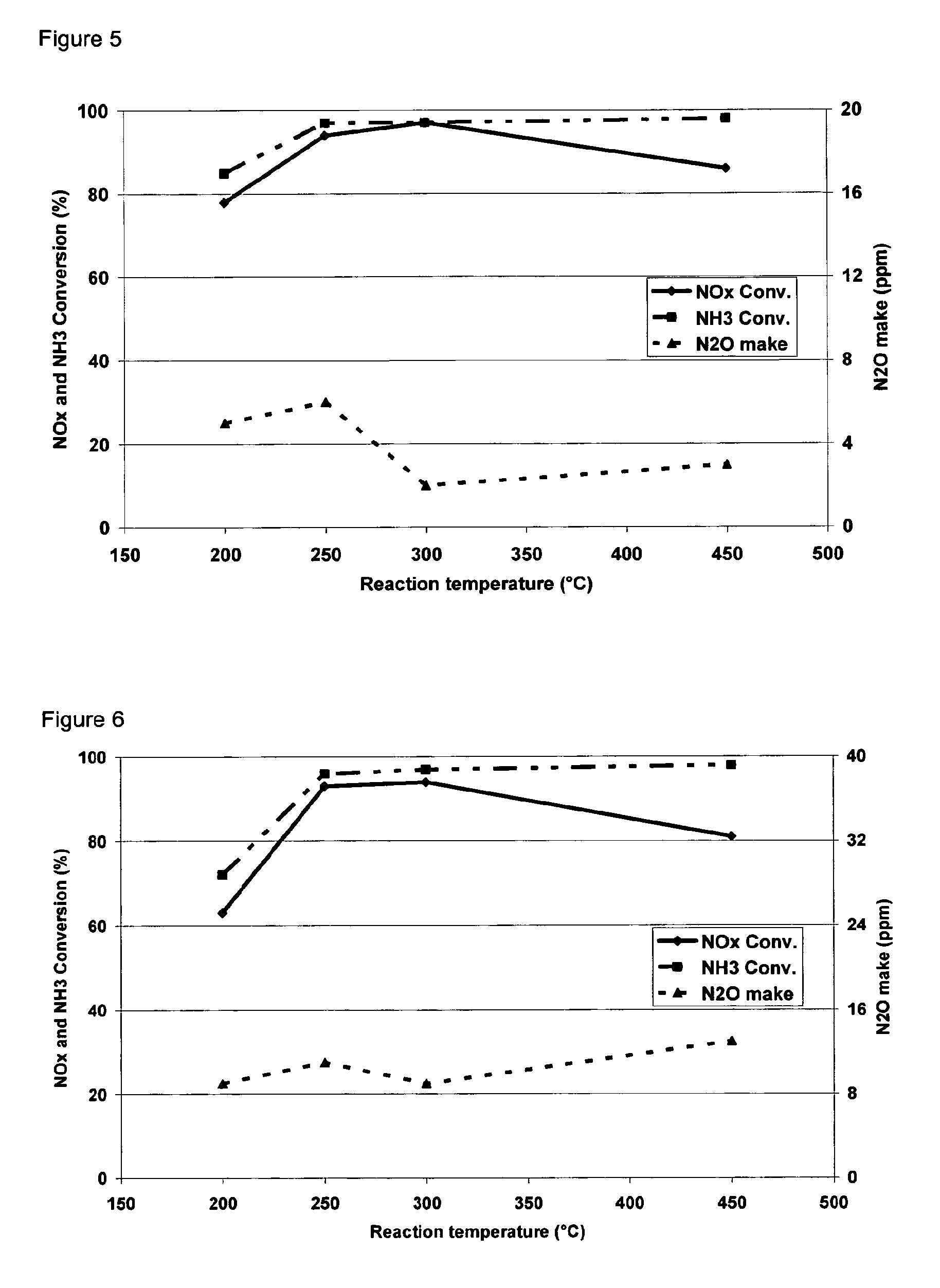

ActiveUS8883119B2Nitrous oxide captureAluminium compoundsTetramethylammonium hydroxideOrganic structure

A process for the preparation of zeolites having CHA framework structure and a composition comprising the molar ratio (n Si02):X203, wherein X is a trivalent element, and wherein n is at least 10, the process comprising (i) preparation of an aqueous solution containing at least one source for X203, wherein X is selected from Al, B, Ga, and a mixture of two or more, and at least one source for Si02, at least one organic structure directing agent (SDA) other than Tetramethylammonium hydroxide (TMAOH), acting as a template for the CHA structure, and Tetramethylammonium hydroxide (TMAOH), wherein the SDA or mixtures thereof are employed in such amounts that the aqueous solution in (i) exhibits a molar ratio of SDA:TMAOH of 0.01 to 5; (ii) hydrothermal crystallization of the aqueous solution according to (i); wherein the aqueous solution of (i) contains copper in an amount less than 0.005 Cu:((n O2):X2O3) where n is in the range of 10 to 50.

Owner:BASF AG

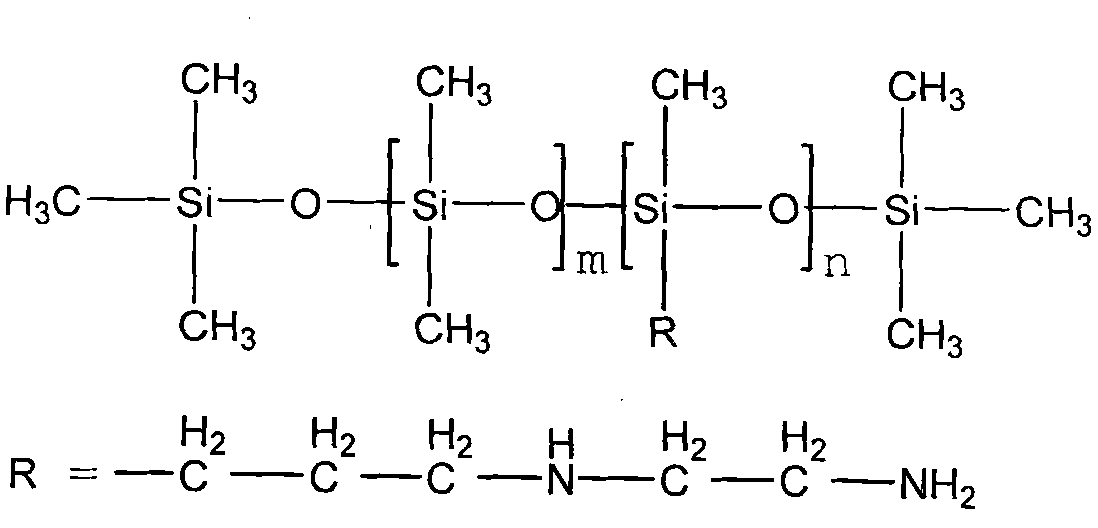

Preparation method for high-viscosity 107 glue

ActiveCN102558563AHigh yieldSimple preparation processAdhesivesTetramethylammonium hydroxideBoiling point

The invention relates to a preparation method for high-viscosity 107 glue. The preparation method comprises the following steps of: adding a certain amount of DMC (Dimethyl Carbonate) and 107 glue of which the viscosity is 100-1,500 cs or a certain amount of DMC into a reactor provided with a stirrer, a thermometer and a condensation reflowing pipe, starting stirring, heating to a certain temperature, and adding an alkali catalyst, wherein the alkali catalyst comprises one of potassium hydroxide, tetramethylammonium hydroxide pentahydrate, tetrabutyl phosphorus oxychloride or silicon alkoxidealkali gel of the alkalis; undergoing a balanced reaction at the temperature for certain hours, and directly neutralizing or heating for decomposing the alkali catalyst; and adding a phosphoric acid or silanol hydrochloric acid gel neutralizing agent of which the mass is equal to that of the catalyst under the condition that neutralization is performed, or directly heating for decomposing the alkali catalyst under the condition that neutralization is not performed, continuously stirring for 1 hour, and removing low-boiling-point substances. The high-viscosity 107 glue prepared with the methodhas the advantages of simple preparation process, stable viscosity, high product yield and capability of meeting production requirements.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Silicon solar cell front face electrode lead-free silver paste and preparing method thereof

InactiveCN104157332AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureTetramethylammonium hydroxidePotassium

The invention discloses silicon solar cell front face electrode lead-free silver paste and a preparing method thereof. The silicon solar cell front face electrode lead-free silver paste is characterized in that inorganic glass powder is not contained in the silver paste, and the silver paste comprises, by mass, 75-85 percent of conductive silver powder, 1-5 percent of antireflective film corrosive, 10-20 percent of organic vehicle and 1-5 percent of additive; the conductive silver powder is formed by mixing micro silver powder and nano silver powder with the mass ratio of 10:1-2; the antireflective film corrosive comprises one or more of potassium fluotitanate, potassium fluoroaluminate, potassium fluosilicate and potassium fluoborate; the additive comprises one or more of ethanol amine, diethanol amine, triethanol amine, tetramethylammonium hydroxide, tetraethylammonium hydroxide and tetramethylammonium hydroxide. According to the silicon solar cell front face electrode lead-free silver paste and the preparing method thereof, lead-free silver paste printing and antireflective film removing are conducted in one step, sintering can be conducted at a low temperature, the compactness and the smoothness of a silver electrode film are improved, and the photoelectric conversion efficiency of a silicon cell piece is improved.

Owner:TIANJIN VOCATIONAL INST

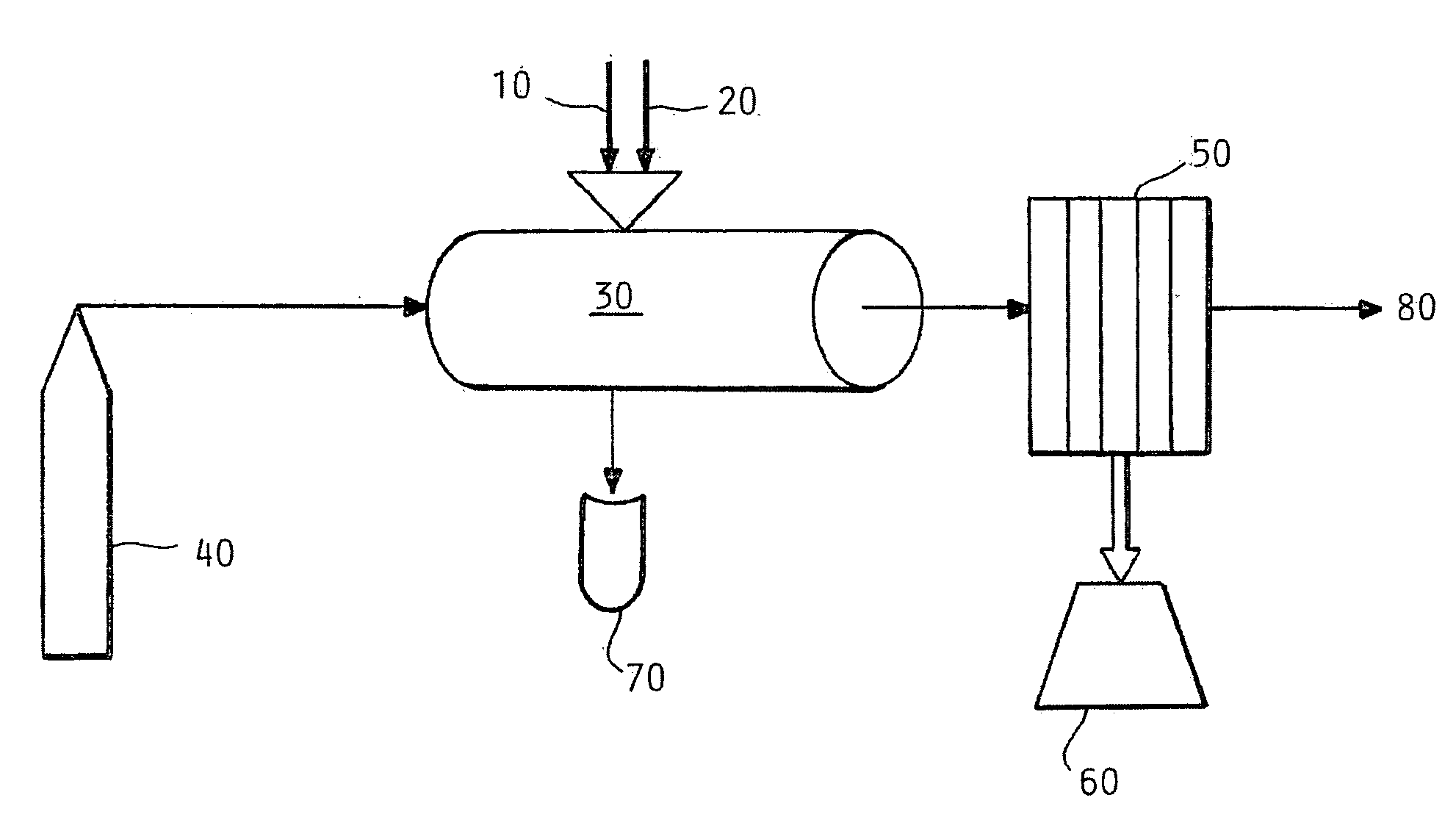

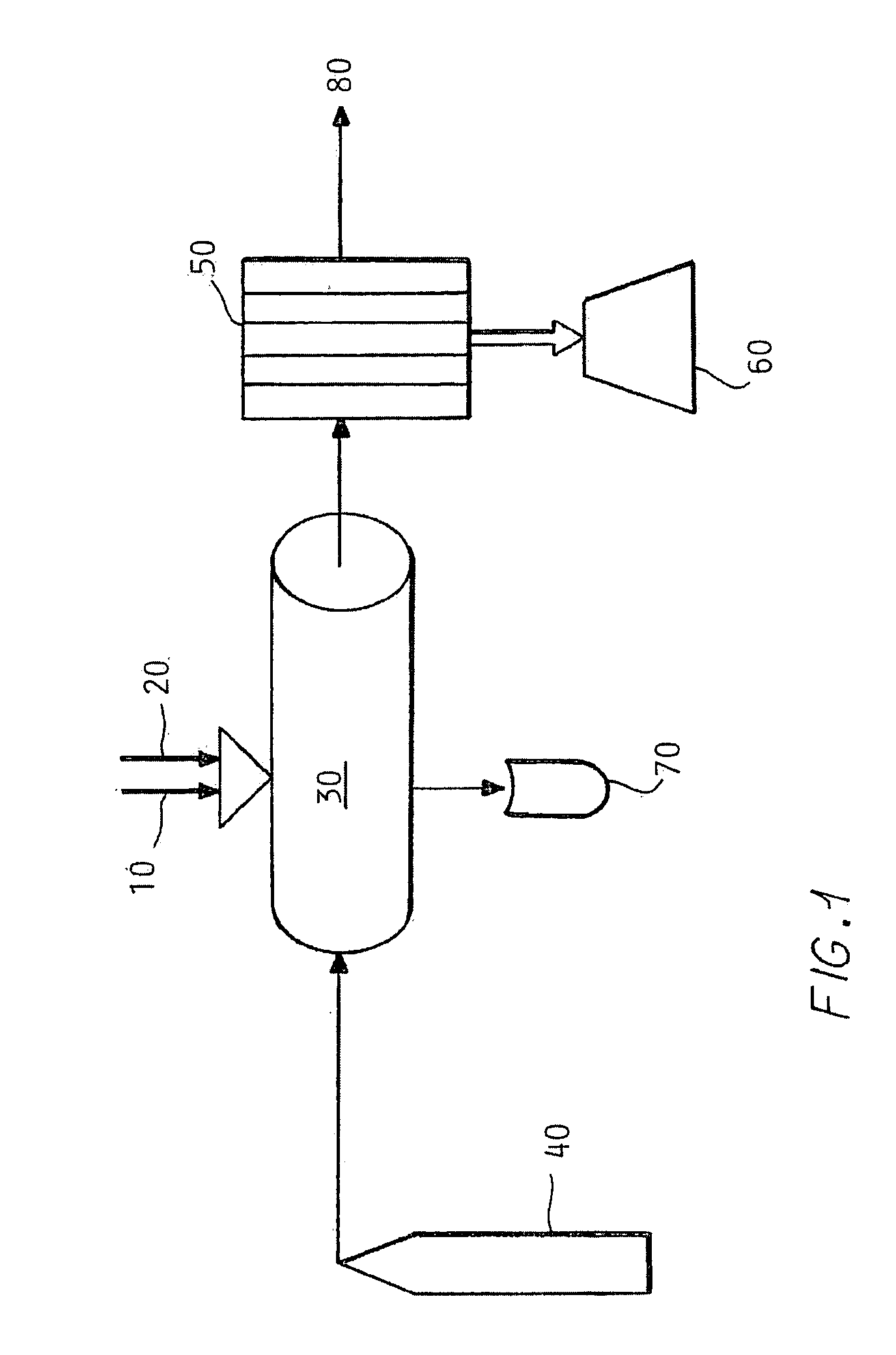

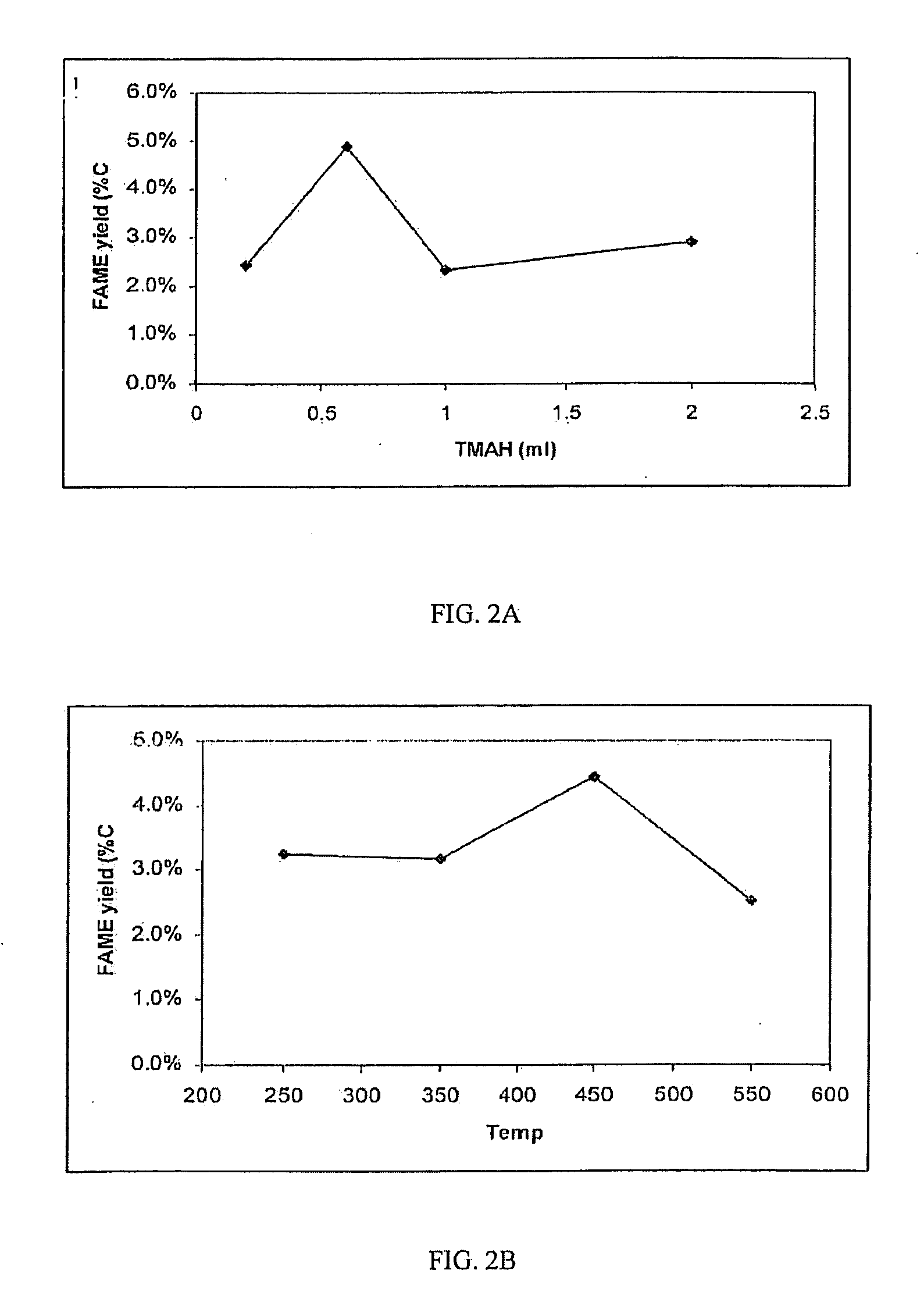

Direct Conversion of Biomass to Biodiesel Fuel

ActiveUS20090158638A1Fatty acid esterificationOrganic compound preparationAlkyl transferTetramethylammonium hydroxide

Disclosed is the direct conversion process for producing biodiesel from a biomass. The direct conversion process for producing biodiesel from a biomass comprises reacting a feed stock comprising a biomass and an alkylation reagent in a substantially oxygen free environment at a temperature sufficient to hydrolyze one or more lipid glycerides in the biomass and alkylated one or more fatty acids in the reaction. The process may comprise reacting a feed stock comprising an algal biomass and tetramethylammonium hydroxide in a substantially oxygen free environment at a temperature between 250° C. and 500° C. The direct conversion process for producing biodiesel may further comprise reacting oil containing lipid glycerides with an alkylation reagent at a sufficient temperature to esterify the oil. The fatty acid alkyl esters produced from the reacted feed stock are recovered. The recovered fatty acid alkyl esters, as an essential component of biodiesel, may be formulated into biodiesel.

Owner:OLD DOMINION UNIVERSITY RESEARCH FOUNDATION

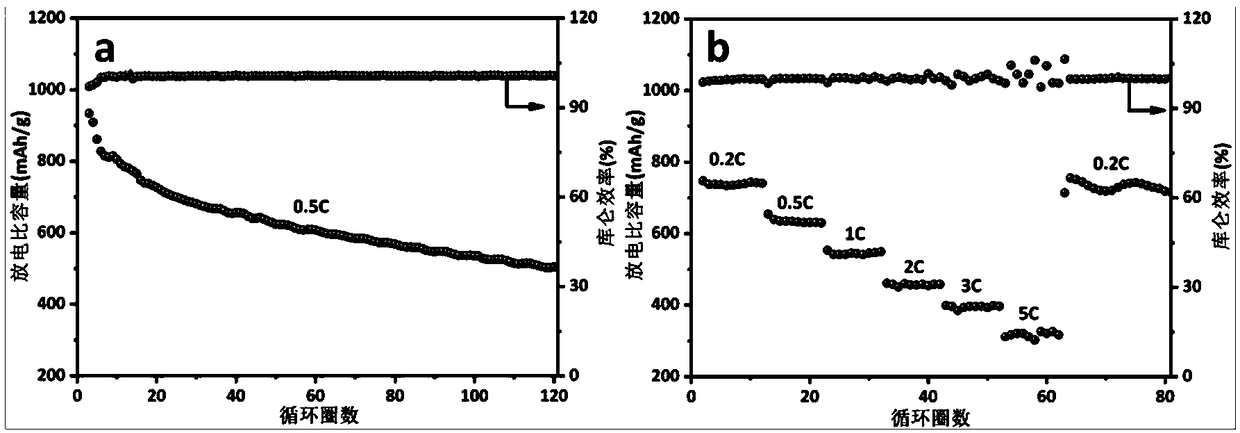

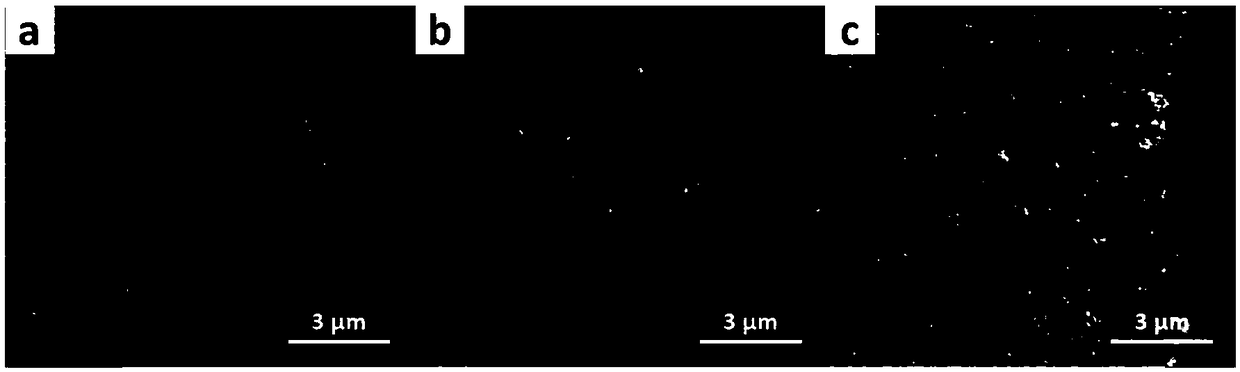

A method for prepare a nitrogen doped carbon nanotube three-dimensional composite material by in-situ growth of a small lay of titanium carbide

InactiveCN109167066AImprove conductivityAchieve controlled growthCell electrodesTetramethylammonium hydroxideFreeze-drying

The invention belongs to the technical field of preparation of nano-functional materials, in particular to a method for preparing a nitrogen doped carbon nanotube three-dimensional composite materialby in-situ growth of a few layers of titanium carbide, immersing ternary layered Ti3AlC2 ceramic powder in hydrofluoric acid solution, heating and stirring, centrifugally cleaning with ultrapure waterand absolute ethanol, drying to obtain two-dimensional layered titanium carbide nano-powder, adding it into tetramethylammonium hydroxide solution, heating and stirring, centrifuging with deionized water to obtain a few layers of titanium carbide nano-sheet dispersion; Adding cobalt salt into a dispersion of a few layers of titanium carbide nano-sheets for reaction, adding dicyandiamide, heatingand stirring until dicyandiamide is completely dissolved, freezing, and freeze-drying to obtain precursor powder; Nitrogen-doped carbon nanotubes (CNTs) three-dimensional composites were prepared by in-situ growth of a few layers of titanium carbide after grinding the precursor powder and heat treatment. A three-dimensional composite material is prepared by a simple pyrolysis method using a few layers of titanium carbide as a carrier, cobalt as a catalyst, dicyandiamide as a carbon and nitrogen source, and the electrochemical performance of the few layers of titanium carbide can be improved.

Owner:UNIV OF JINAN

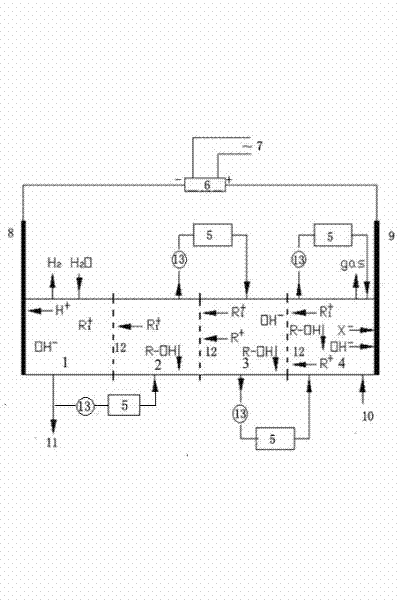

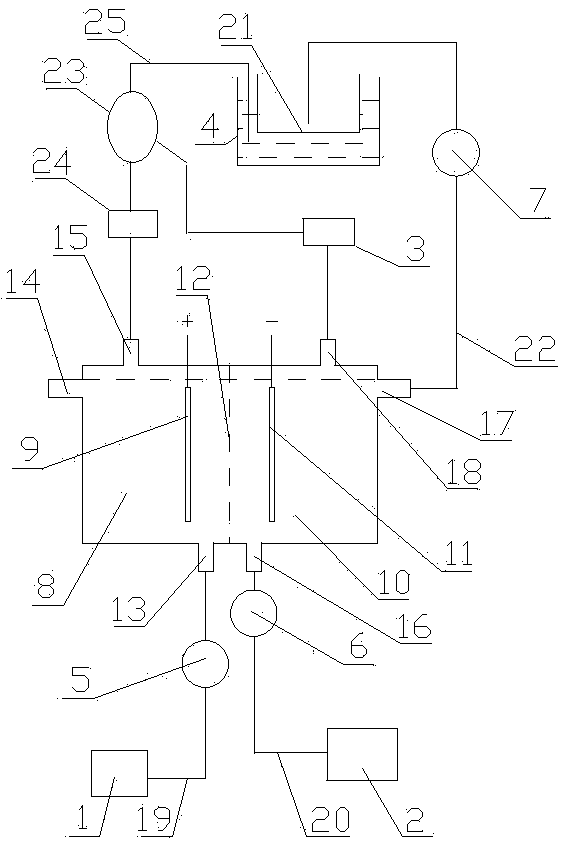

Method for preparing electronic grade tetramethylammonium hydroxide by continuous method

ActiveCN102400173AReduce generationSolve productivityCellsElectrolytic organic productionTetramethylammonium hydroxideCirculator pump

The invention discloses a method for preparing electronic grade tetramethylammonium hydroxide by a continuous method. The method comprises the following steps of: sequentially dividing an electrolytic cell into a cathode chamber, a first cathode middle chamber, a second cathode middle chamber and an anode chamber, wherein the two adjacent chambers are partitioned by a cation exchange membrane and connected by using a circulating pump and a filter connected in series, and the anode chamber is connected with the circulating pump and the filter connected in series; putting a 5 to 50 percent aqueous solution of a tetramethyl ammonium salt into the anode chamber, wherein (CH3)4N<+>, H<+> and metal cation R<+> in the solution enter the two cathode middle chambers and the cathode chamber through the cation exchange membranes; and removing the sediment generated by partial metal cation R<+> and OH<-> by using the filter, pumping the filtrate for reaction by using the circulating pump, and discharging the 5 to 30 percent tetramethylammonium hydroxide from the cathode chamber, wherein the concentration of each metal ion is less than 10ppb, the concentration of each anion is less than 500ppb, and the tetramethylammonium hydroxide has high purity. The current efficiency of the tetramethylammonium hydroxide is 70 to 80 percent, the tetramethylammonium hydroxide has high utilization rate, and the method has no pollution and can be used for large-scale production.

Owner:镇江润晶高纯化工科技股份有限公司

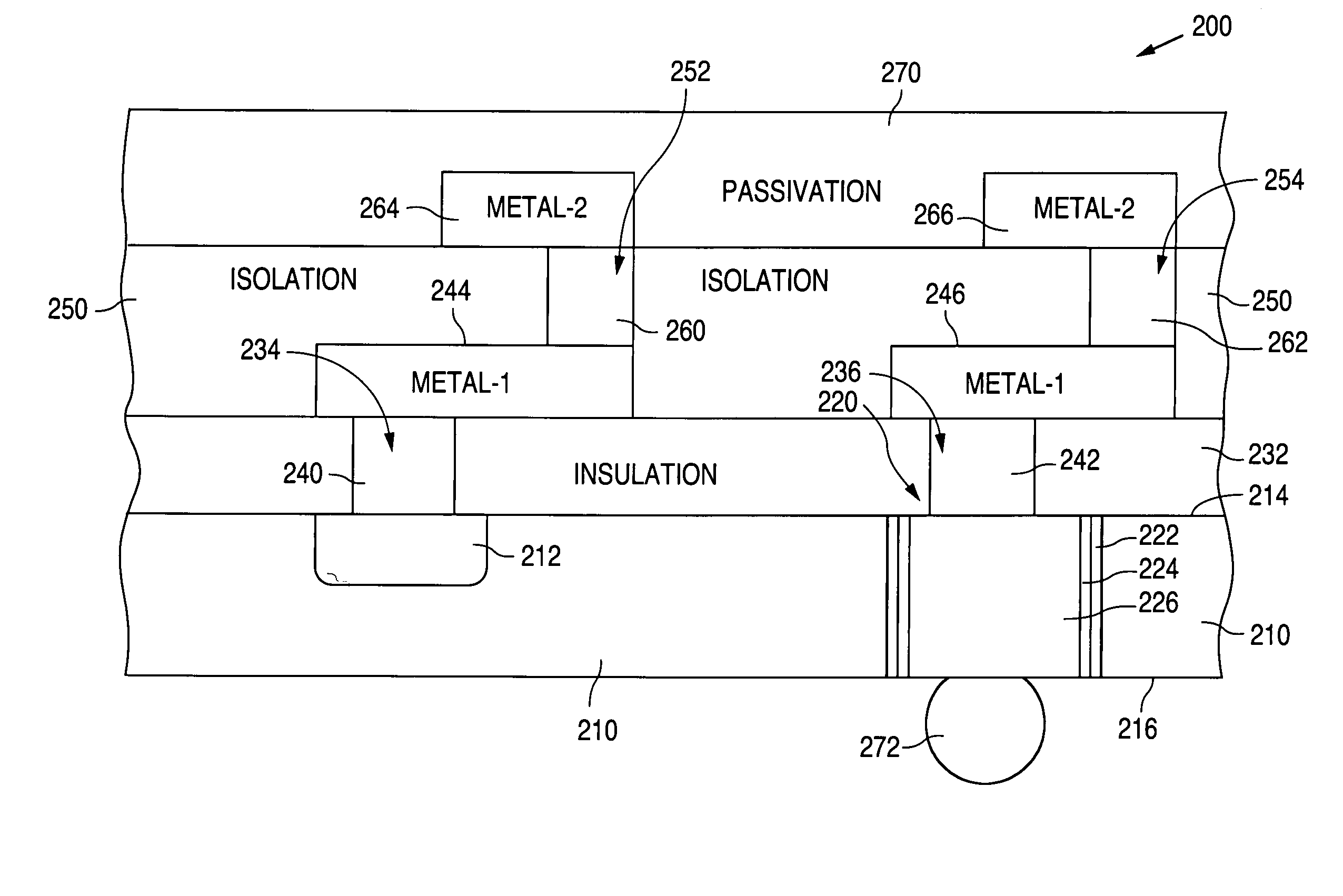

Method of forming through-the-wafer metal interconnect structures

ActiveUS7005388B1Semiconductor/solid-state device detailsSolid-state devicesTetramethylammonium hydroxideMetal interconnect

A semiconductor die is formed in a process that forms a hole through the wafer prior to the formation of the contacts and the metal-1 layer of an interconnect structure. The through-the-wafer hole is formed by using a wafer with a <110> crystallographic orientation and a wet etch, such as with ethanol (KOH) or tetramethylammonium hydroxide (TMAH).

Owner:NAT SEMICON CORP

Polishing composition and polishing method

InactiveCN1670115AOther chemical processesDecorative surface effectsTetramethylammonium hydroxideColloidal silica

A polishing composition includes silicon dioxide, an alkaline compound, an anionic surfactant, and water. The silicon dioxide is, for example, colloidal silica, fumed silica, or precipitated silica. The alkaline compound is, for example, potassium hydroxide, sodium hydroxide, ammonia, tetramethylammonium hydroxide, piperazine anhydride, or piperazine hexahydrate. The anionic surfactant is at least one selected from a sulfonic acid surfactant, a carboxylic acid surfactant, and a sulfuric acid ester surfactant. The polishing composition can be suitably used in applications for polishing a silicon wafer.

Owner:FUJIMI INCORPORATED

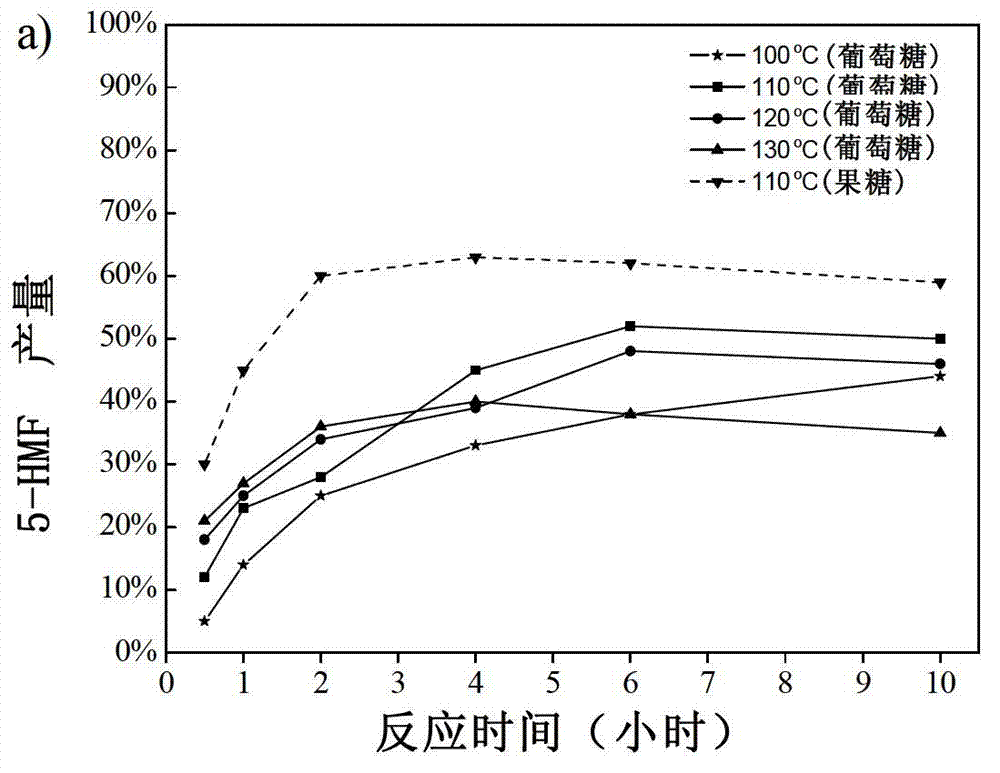

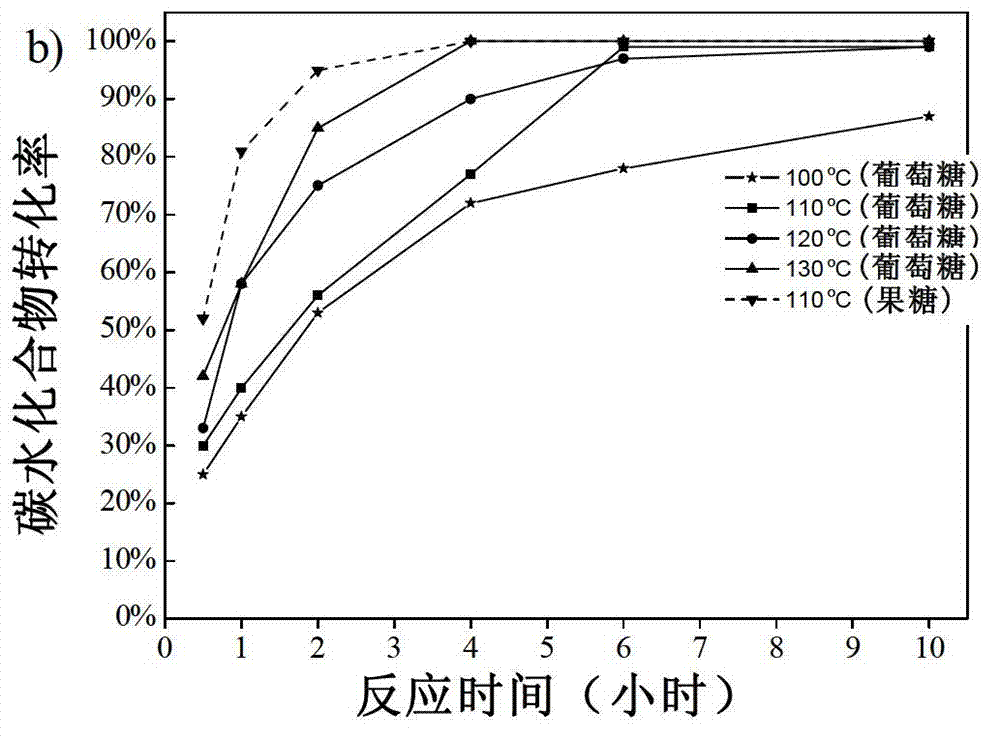

Preparation method and application of solid acid catalyst

InactiveCN102814189AEfficient conversionHigh selectivityOrganic chemistryMolecular sieve catalystsTetramethylammonium hydroxideSolid acid

The invention discloses a preparation method and application of a solid acid catalyst. The preparation method of the solid acid catalyst comprises the following steps: (1) mixing a silicon source, an alkali source, a metallic compound and a template, and carrying out hydrothermal reaction to obtain a reaction product 1; (2) filtering the reaction product 1 to obtain a solid, and drying at 60-120 DEG C for 12-36 hours to obtain a reaction product 2; and (3) calcining the reaction product 2 at 500-600 DEG C for 3-10 hours to obtain the solid acid catalyst. The silicon source is selected from hydrophilic nano silicon oxide, sodium silicate and tetraethyl orthosilicate; the alkali source is selected from tetramethylammonium hydroxide, alkali metal hydroxide and ammonia water; the metallic compound is selected from tin tetrachloride, zirconium sulfate, sodium silicate, chromic nitrate, nickel nitrate and tetrabutyl titanate; and the template is cetyl trimethyl ammonium bromide. The solid acid catalyst disclosed by the invention can be used for preparing 5-hydroxymethylfurfural.

Owner:UNIV OF SCI & TECH OF CHINA

CMP slurry composition and a method for planarizing semiconductor device using the same

InactiveUS7029509B2Improve efficiencyGood polishing performancePigmenting treatmentOther chemical processesTetramethylammonium hydroxidePhosphate

The present invention relates to a CMP (chemical mechanical polishing) slurry composition and a method for planarizing a semiconductor device. The CMP composition comprises fumed silica, tetramethyl ammonium hydroxide, phosphates, fluorine compounds and deionized water. The method of planarizing comprises the steps of etching, subsequently laminating and polishing a semiconductor device by said CMP slurry composition.

Owner:DONGBU HITEK CO LTD

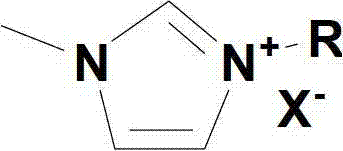

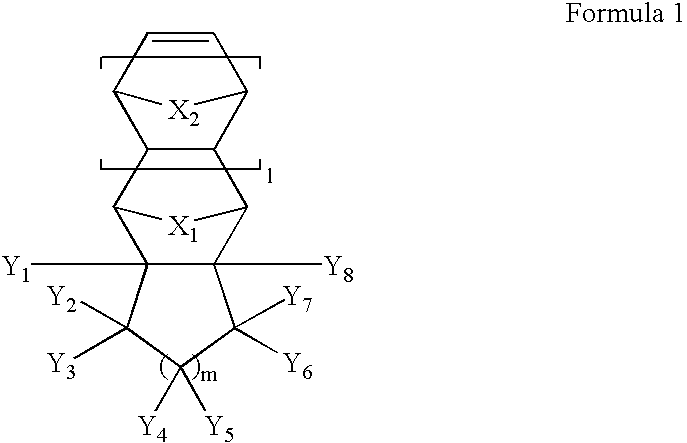

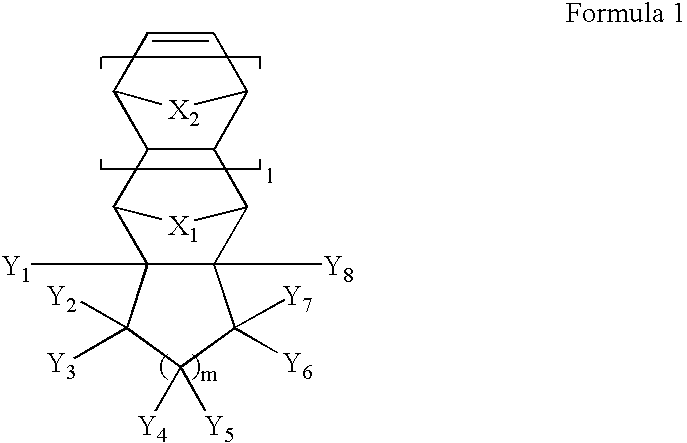

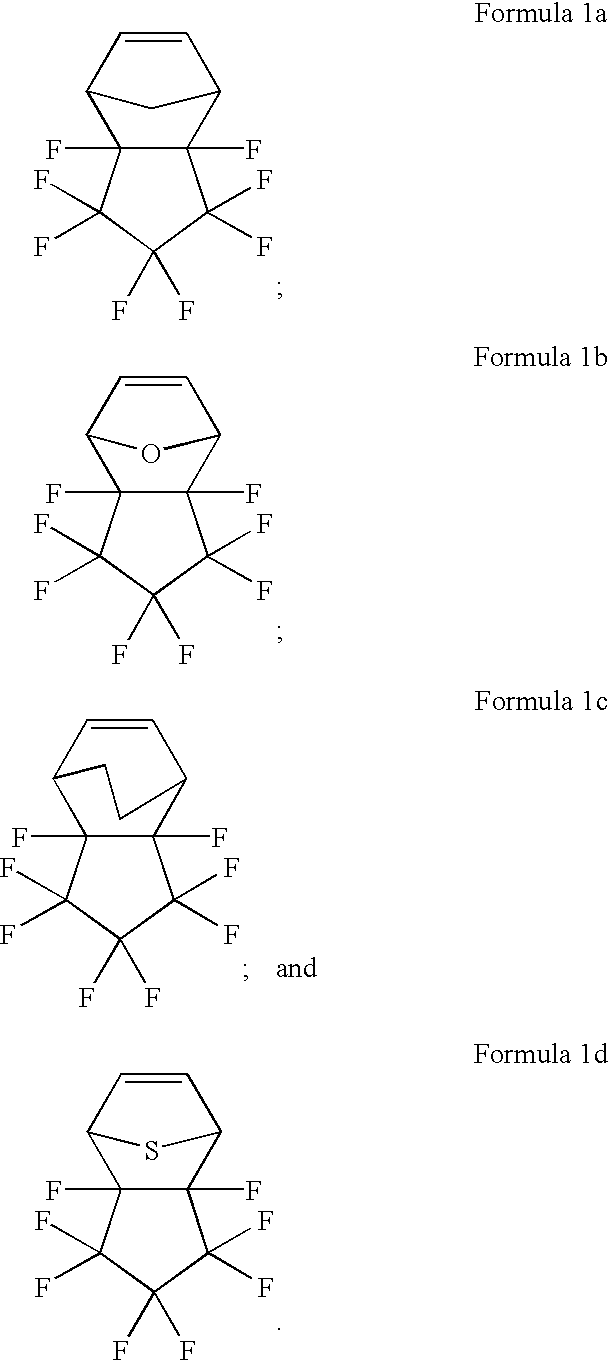

Photoresist monomers, polymers thereof and photoresist compositons containing the same

InactiveUS20030003379A1Photosensitive materialsSemiconductor/solid-state device manufacturingResistTetramethylammonium hydroxide

Photoresist monomers of following Formula 1, photoresist polymers thereof, and photoresist compositions containing the same. The photoresist composition has excellent etching resistance, heat resistance and adhesiveness to a wafer, and is developable in aqueous tetramethylammonium hydroxide (TMAH) solution. In addition, the photoresist composition has low light absorbance at 157 nm wavelength, and thus is suitable for a photolithography process using ultraviolet light sources such as VUV (157 nm) in fabricating a minute circuit for a high integration semiconductor device. wherein, X1, X2, Y1, Y2, Y3, Y4, Y5, Y6, Y7, Y8, l and m are as defined in the specification of the invention.

Owner:SK HYNIX INC

Anisotropic etching agent composition used for manufacturing of micro-structures of silicon and etching method

InactiveUS20070175862A1Reduce processing timeIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingMicro structureTetramethylammonium hydroxide

An anisotropic etching agent composition for manufacturing of micro-structures of silicon comprising an alkali compound and hydroxylamines; an anisotropic etching method with the use of the etching agent composition. The alkali compound is preferably tetramethylammonium hydroxide, and the hydroxylamines is preferably at least one kind selected from the group consisting of hydroxylamine, hydroxylamine sulfate, hydroxylamine chloride, hydroxylamine oxalate, dimethyl hydroxylamine hydrochloride and hydroxylamine phosphate. An anisotropic etching property whose etching rate is different in crystal face orientation especially relating with etching technology with the use of manufacturing of micro-structures of silicon used as Micro Electro Mechanical Systems (MEMS) parts, semiconductor materials, etc is provided.

Owner:MITSUBISHI GAS CHEM CO INC

Device and method for continuously preparing tetramethylammonium hydroxide

ActiveCN103388155AHigh purityReduce manufacturing costCellsChemical industryTetramethylammonium hydroxideIon exchange

The invention discloses a device and method for continuously preparing tetramethylammonium hydroxide, aiming to solve the problems of high production cost and high impurity content of the existing tetramethylammonium hydroxide production methods. The device comprises an ion exchange column, an electrolytic cell, an anode material tank, a cathode material tank, a cathode gas storage tank, an anode gas storage tank, a boiler, a heating trough, a first liquid pump, a second liquid pump, a third liquid pump, a first pipeline, a second pipeline, a third pipeline and a fourth pipeline. In the method, a tetramethyl ammonium bicarbonate aqueous solution is taken as anode liquor, a tetramethyl ammonium hydroxide dilute solution is taken as cathode liquor, through the mutual cooperation of the production device and a process, the process flow can be effectively shortened, and the production cost can be significantly reduced. The device and method disclosed by the invention are short in process flow, simple in operation and low in production cost, and prepared products are high in purity and high in yield, so that the energy efficiency is effectively reduced, and the defects of high power consumption and low current efficiency existing in the prior art are overcome, therefore, the device and method disclosed by the invention can adapt to the needs of industrial production.

Owner:自贡天龙化工有限公司

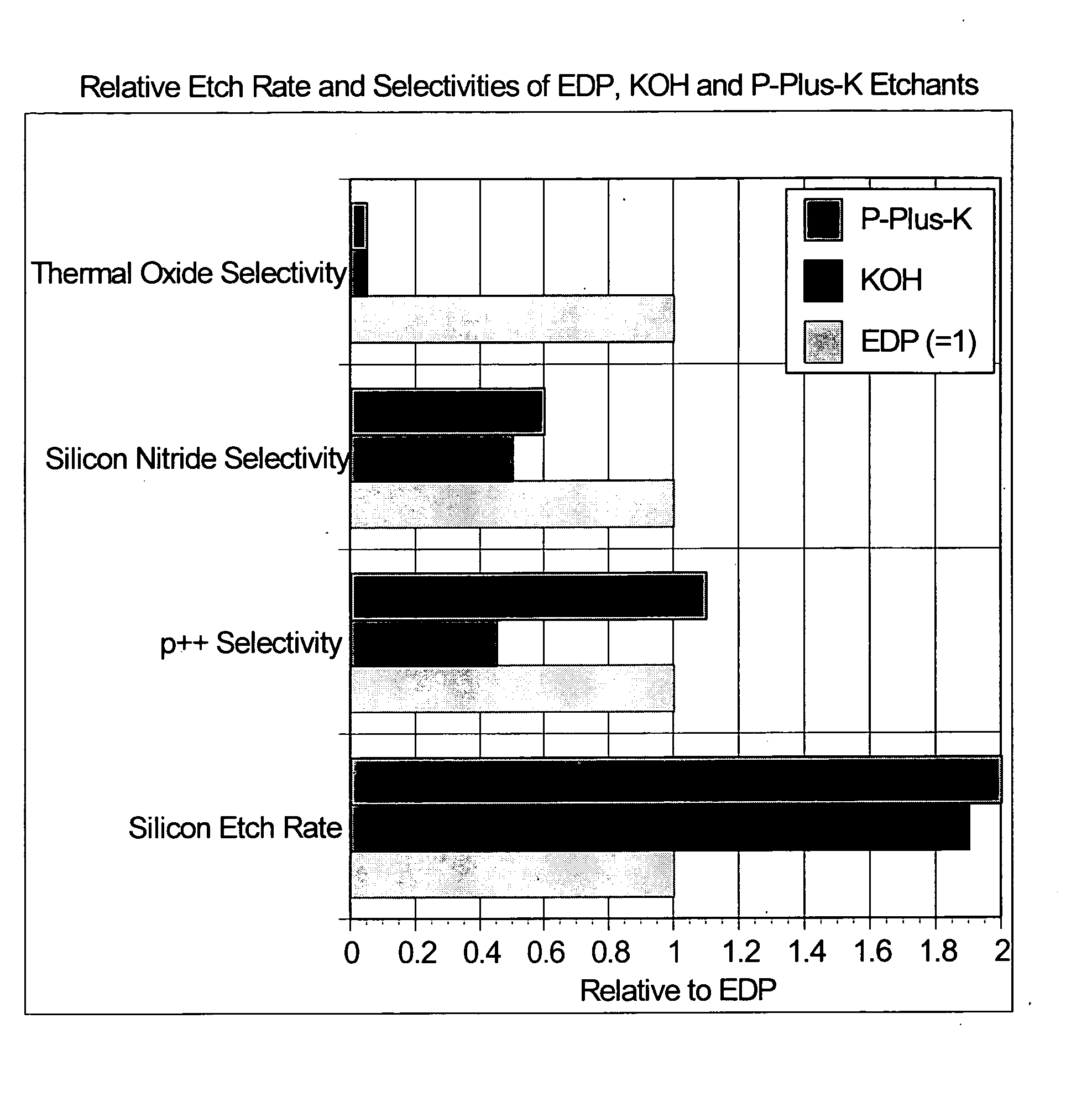

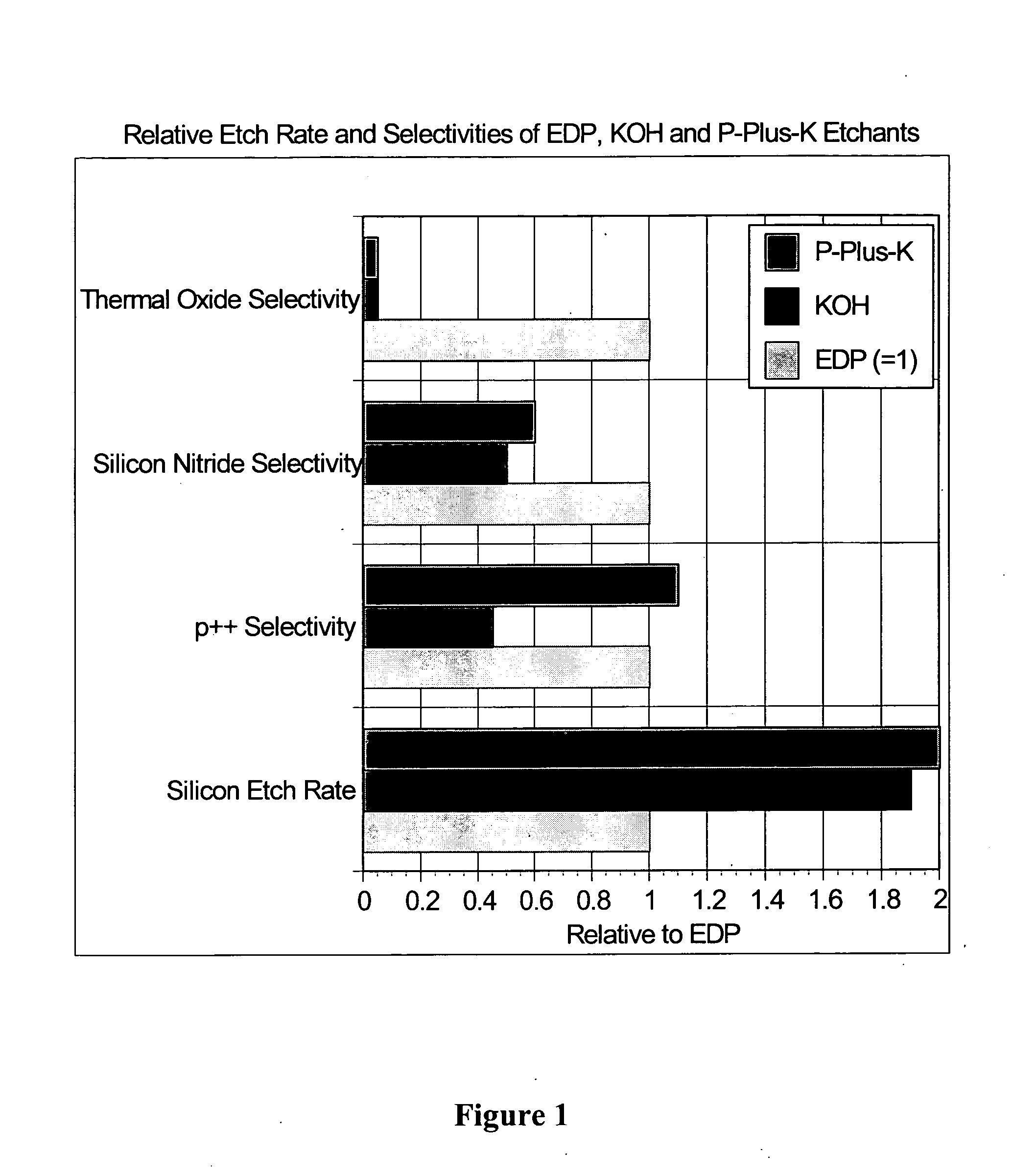

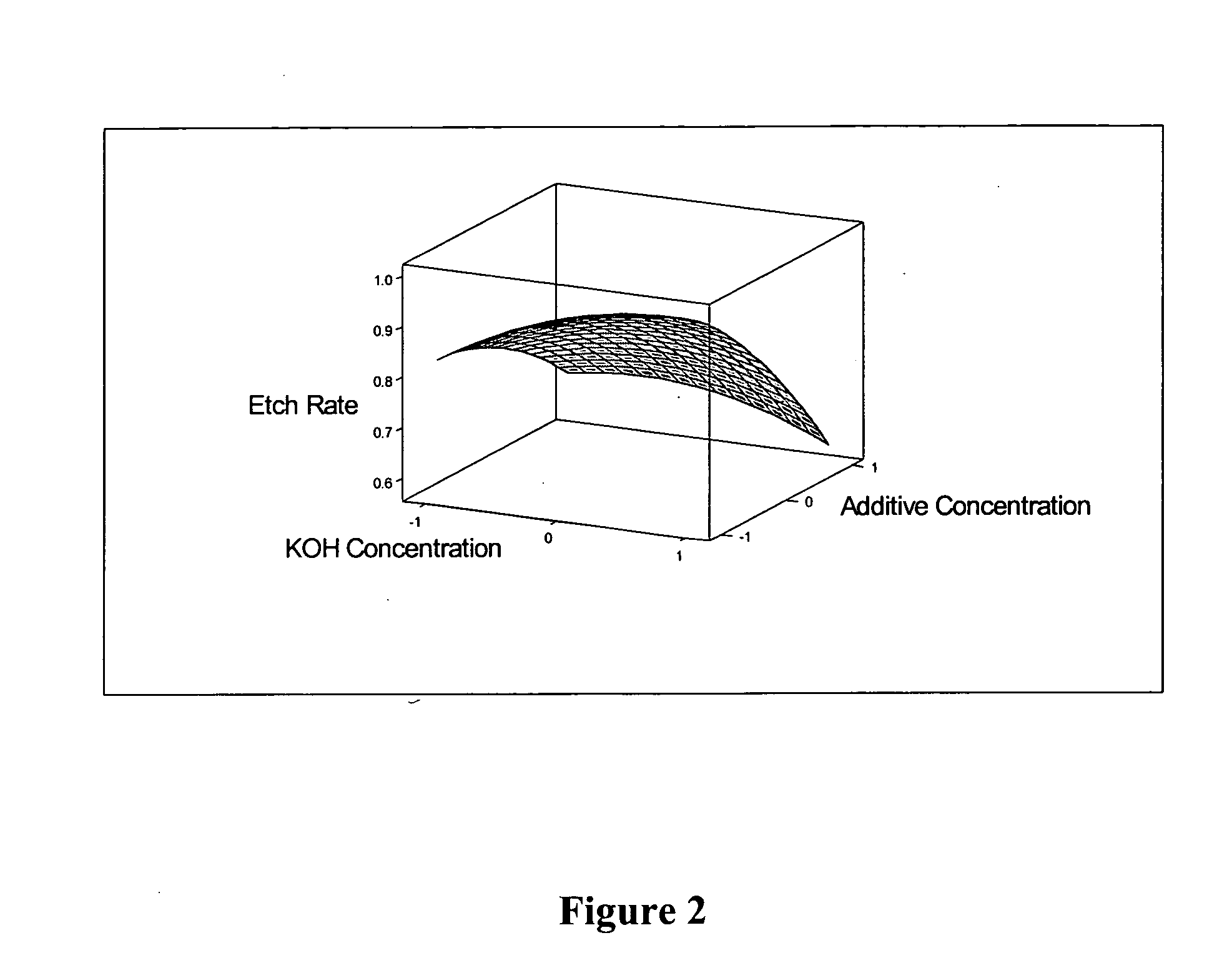

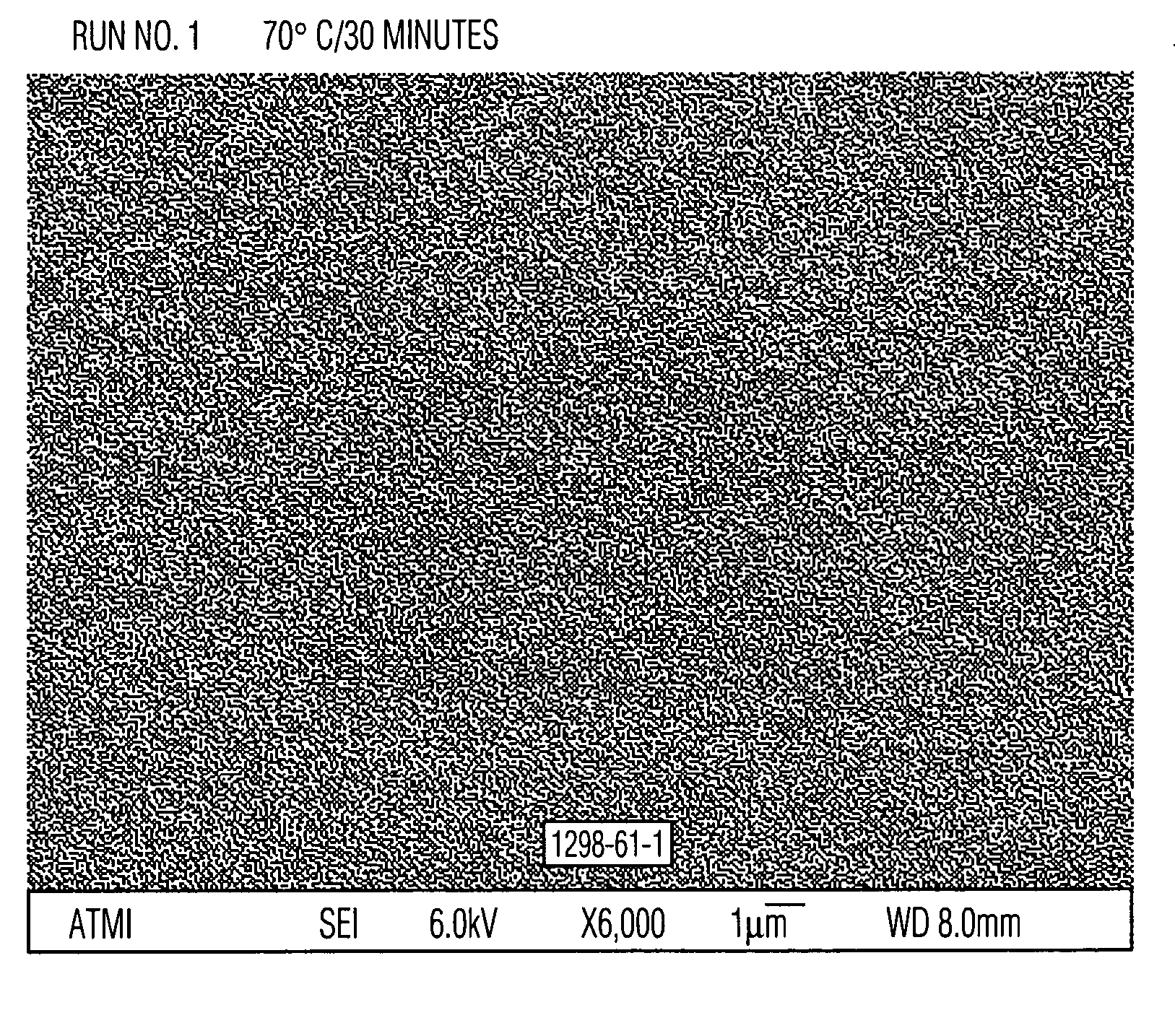

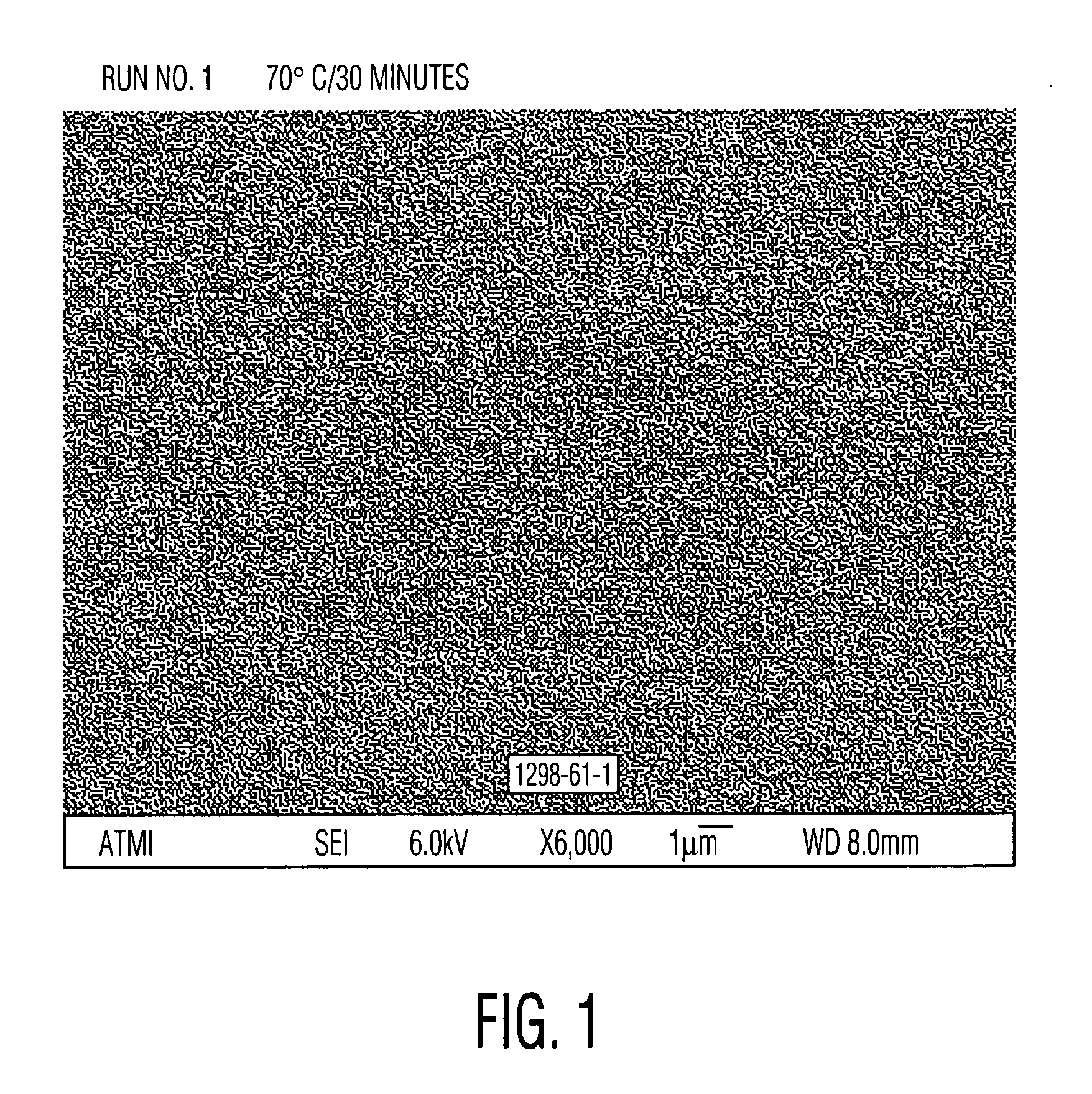

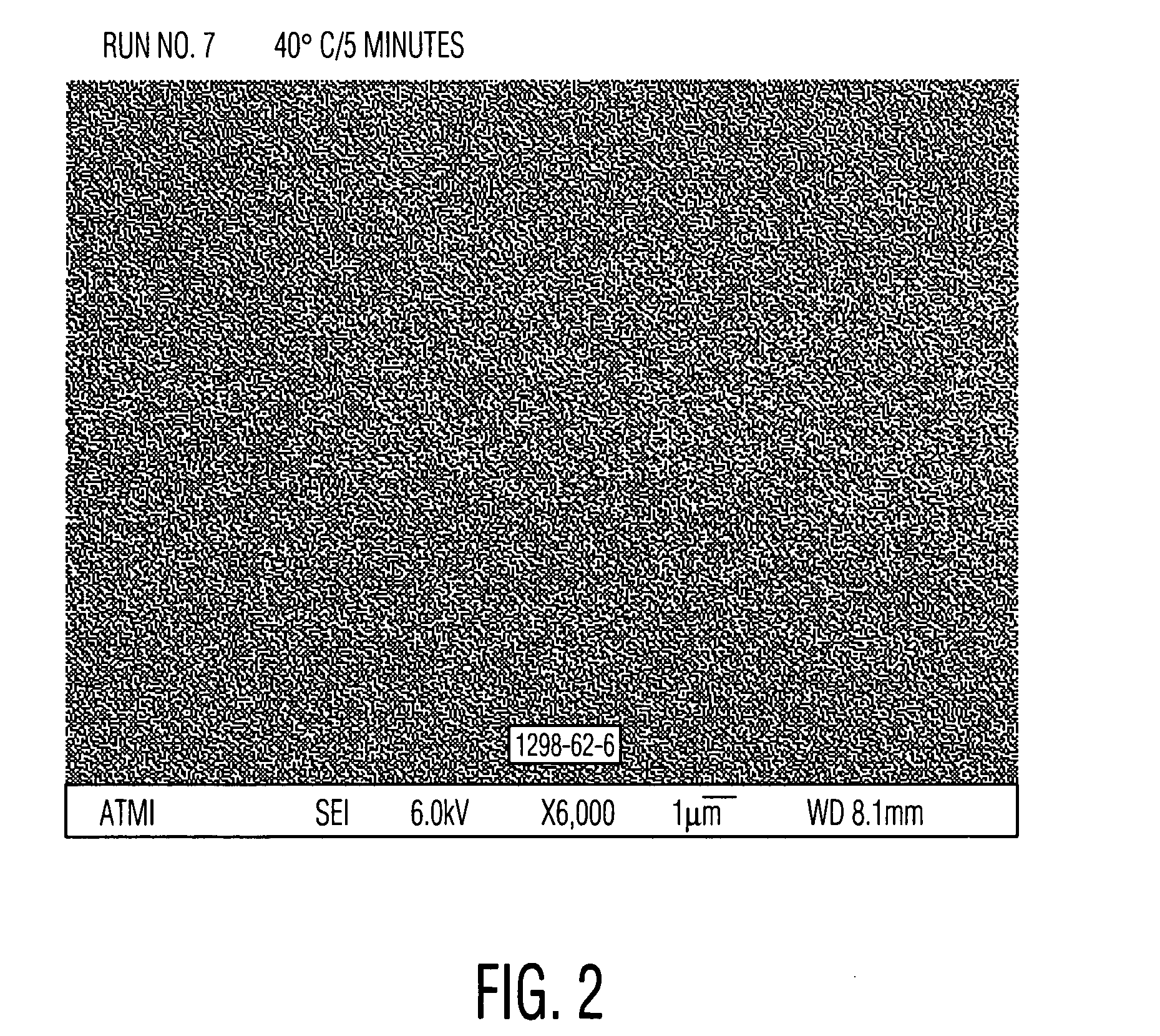

Selective silicon etch chemistries, methods of production and uses thereof

InactiveUS20050065050A1Surface-active detergent compositionsDetergent mixture composition preparationTetramethylammonium hydroxidePotassium hydroxide

Silicon etchants described herein are aqueous solutions that comprise at least one of potassium hydroxide or tetramethyl ammonium hydroxide; at least one additive, wherein the additive comprises at least two of the following physical properties: water-soluble, non-volatile and non-flammable; and an aqueous environment that comprises at least one solvent or solvent blend. Methods of producing a selective silicon etchant include: a) providing at least one of potassium hydroxide or tetramethyl ammonium hydroxide; b) providing at least one additive, wherein the additive comprises at least two of the following physical properties: water-soluble, non-volatile and non-flammable; c) providing an aqueous environment that comprises at least one solvent or solvent blend; and d) blending the at least one potassium hydroxide or tetramethyl ammonium hydroxide with the at least one additive in the aqueous environment in order to form a solution that can be utilized as a selective silicon etchant.

Owner:HONEYWELL INT INC

Aqueous cleaner with low metal etch rate

ActiveUS20060229221A1Organic detergent compounding agentsDetergent mixture composition preparationTetramethylammonium hydroxideAmmonium hydroxide

A cleaning solution is provided for cleaning metal-containing microelectronic substrates, particularly for post etch, via formation and post CMP cleaning. The cleaning solution consists of a quaternary ammonium hydroxide, an organic amine, and water. A preferred cleaning solution consists of tetramethylammonium hydroxide, monoethanolamine, and water. The pH of cleaning solution is greater than 10.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com