Patents

Literature

43results about How to "High polishing removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acidic chemical and mechanical polishing composition

ActiveCN102585706AEasy to polishBoost rateOther chemical processesPolishing compositions with abrasivesColloidal silicaOrganic film

The invention provides an acidic chemical and mechanical polishing composition. The pH value of the acidic chemical and mechanical polishing composition is 2-7, and the acidic chemical and mechanical polishing composition comprises 1-20% by weight of abrasive material, 0.5-10% by weight of oxidant, 0.1-10% by weight of complexing agent, 0.001-1% by weight of corrosion inhibitor, 0.001-5% by weight of organic film-forming auxiliaries and the balance of pH regulator and deionized or distilled water, wherein the abrasive material is of colloidal silica sol after modification in the special step, and the average particle size is of 10-200nm. According to the chemical and mechanical polishing composition provided by the invention, the abrasive material is refined and modified; by using the method, the stability of the abrasive material in polishing slurry can be effectively upgraded, and polishing removal rate and surface roughness degree are respectively optimized to a certain extent; and the unique adding effect of the organic film-forming auxiliaries can well balance the strength of chemical corrosion action and the strength of mechanical grinding action, and achieve the effects of improving polishing removal efficiency and performing global planarization.

Owner:TSINGHUA UNIV

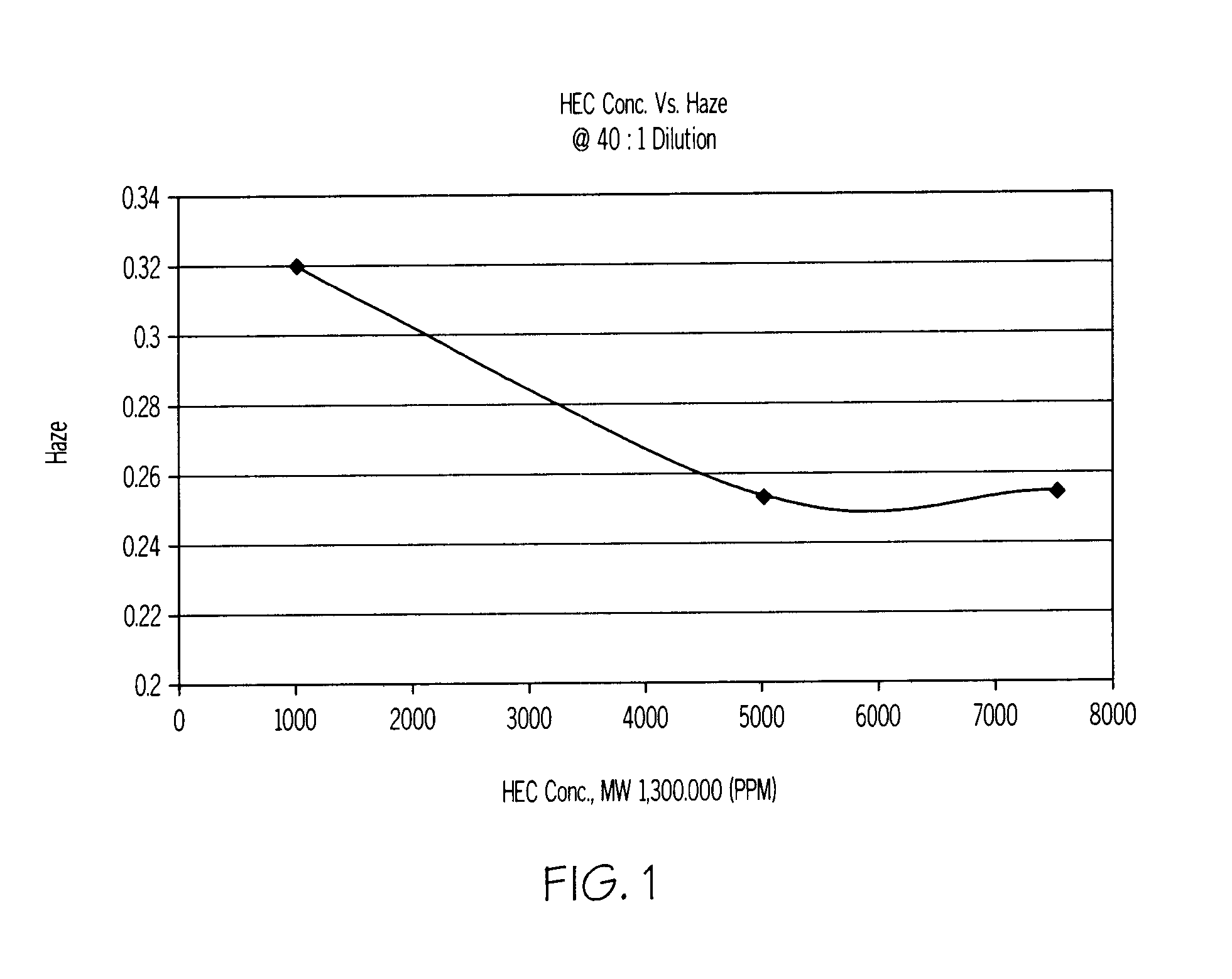

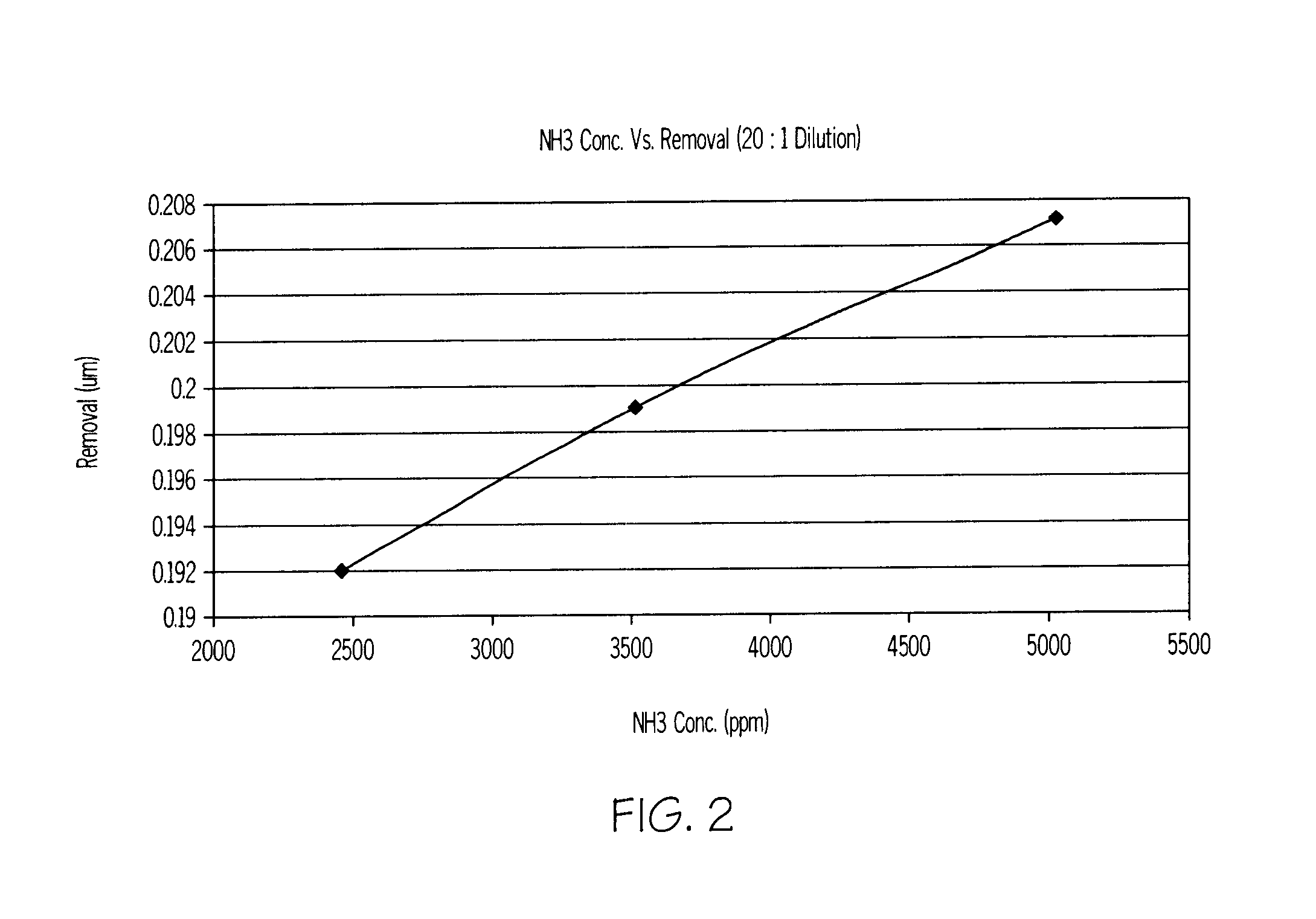

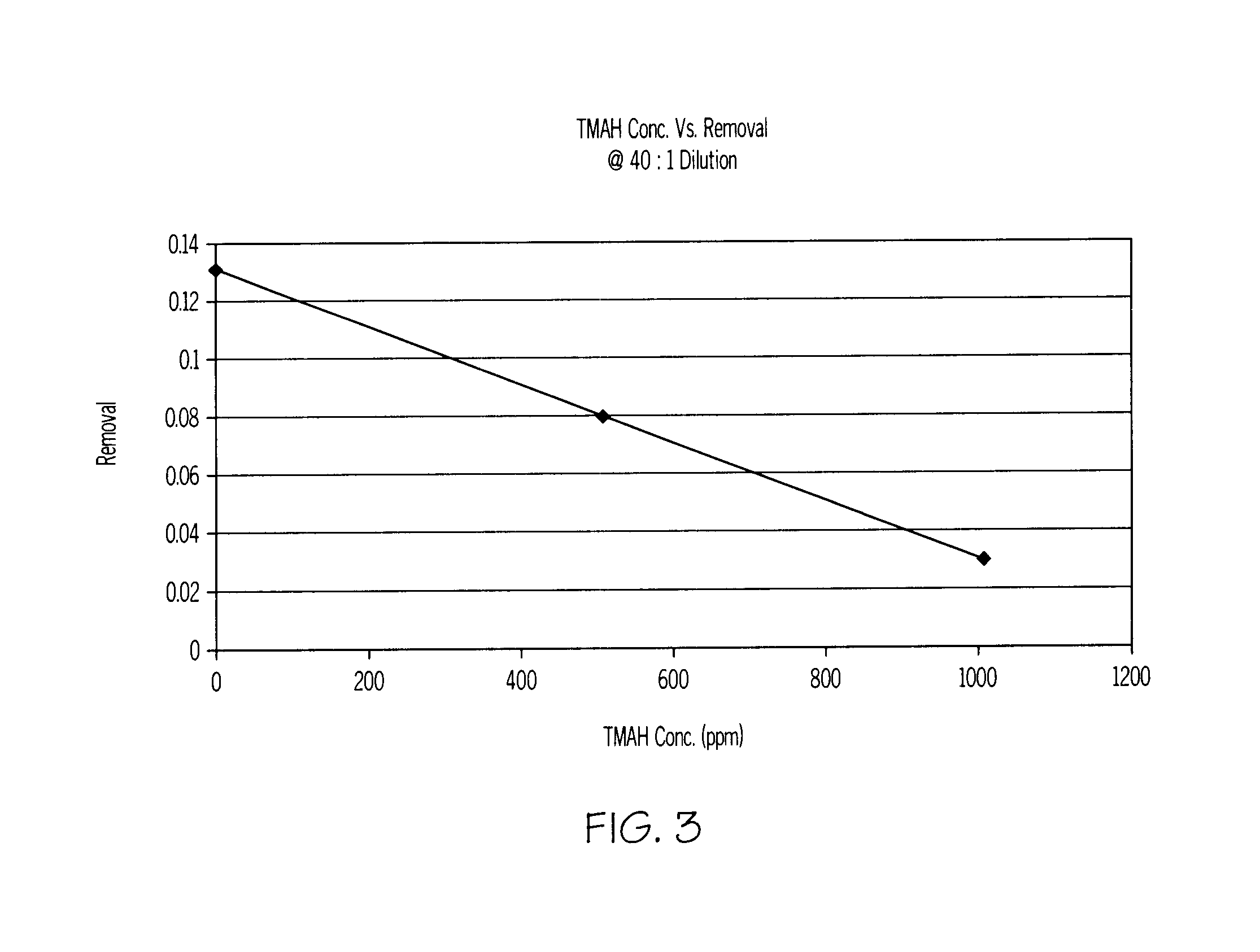

Polishing composition

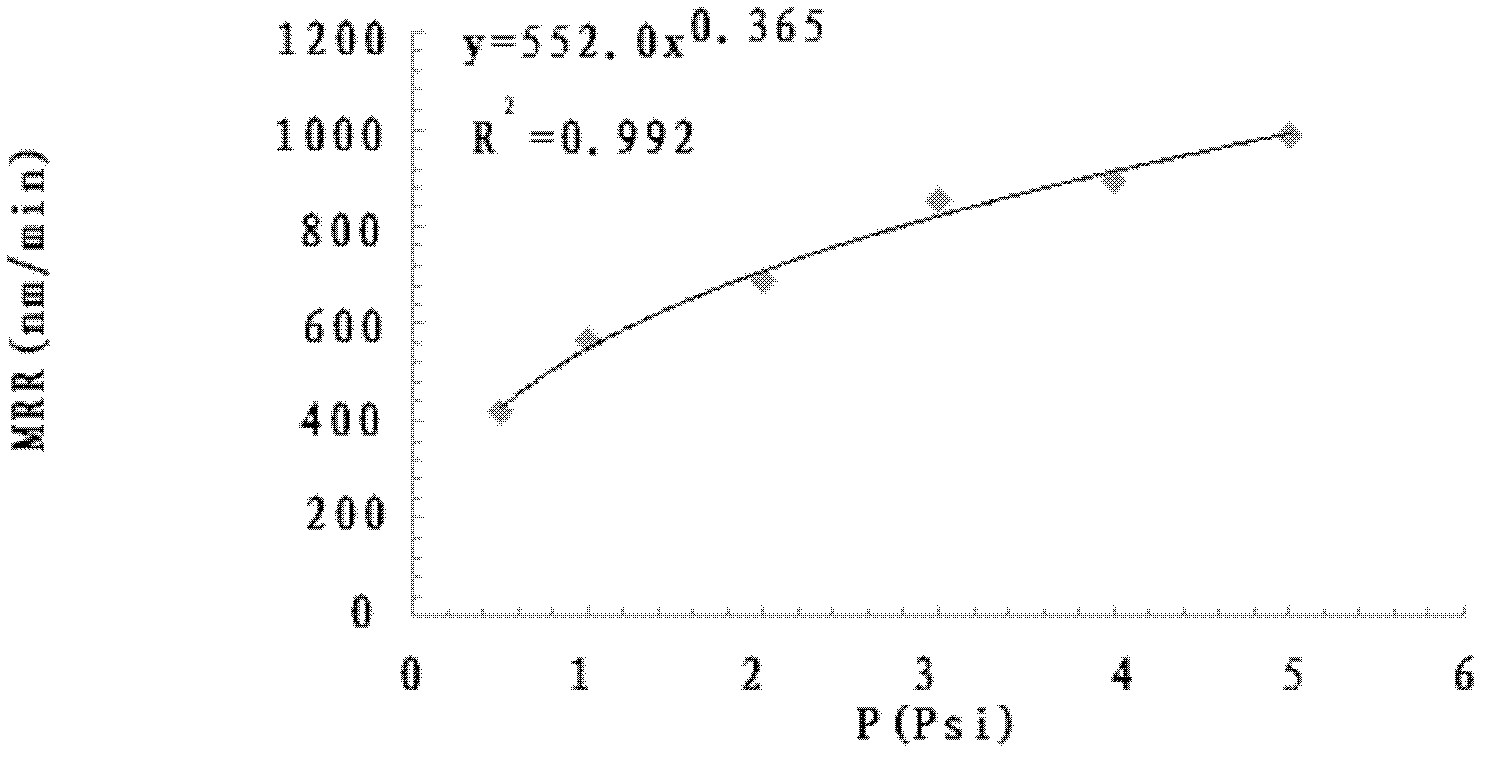

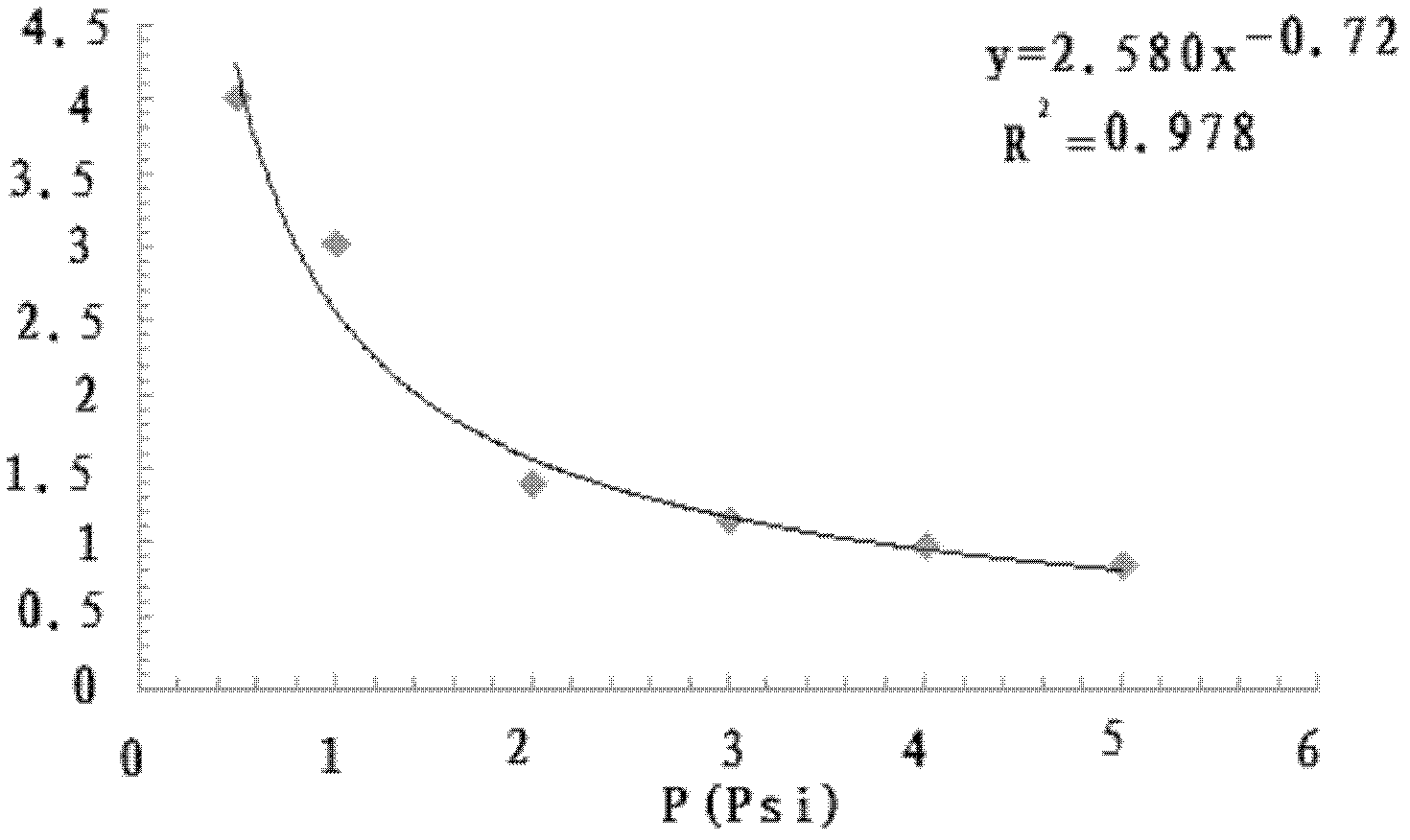

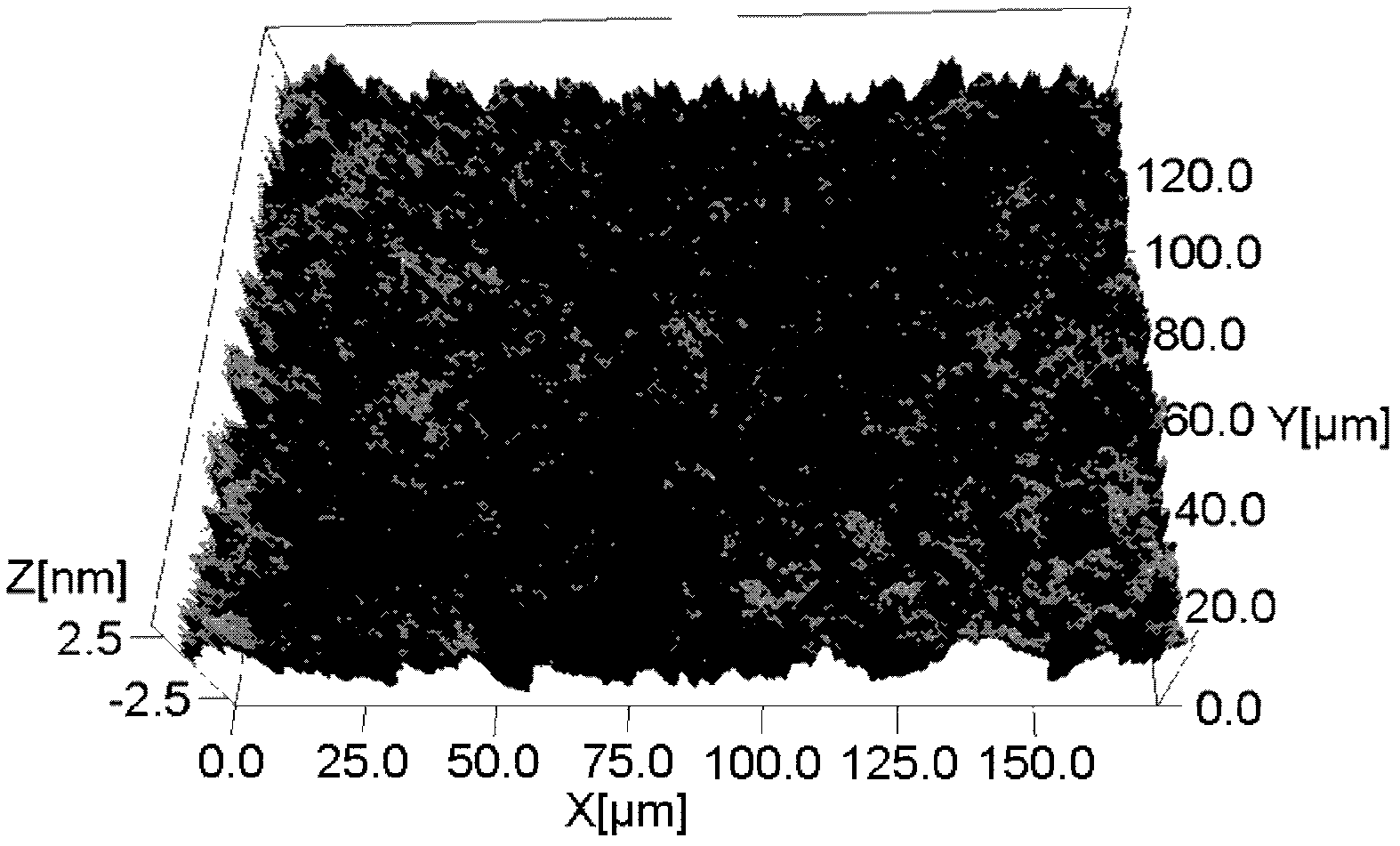

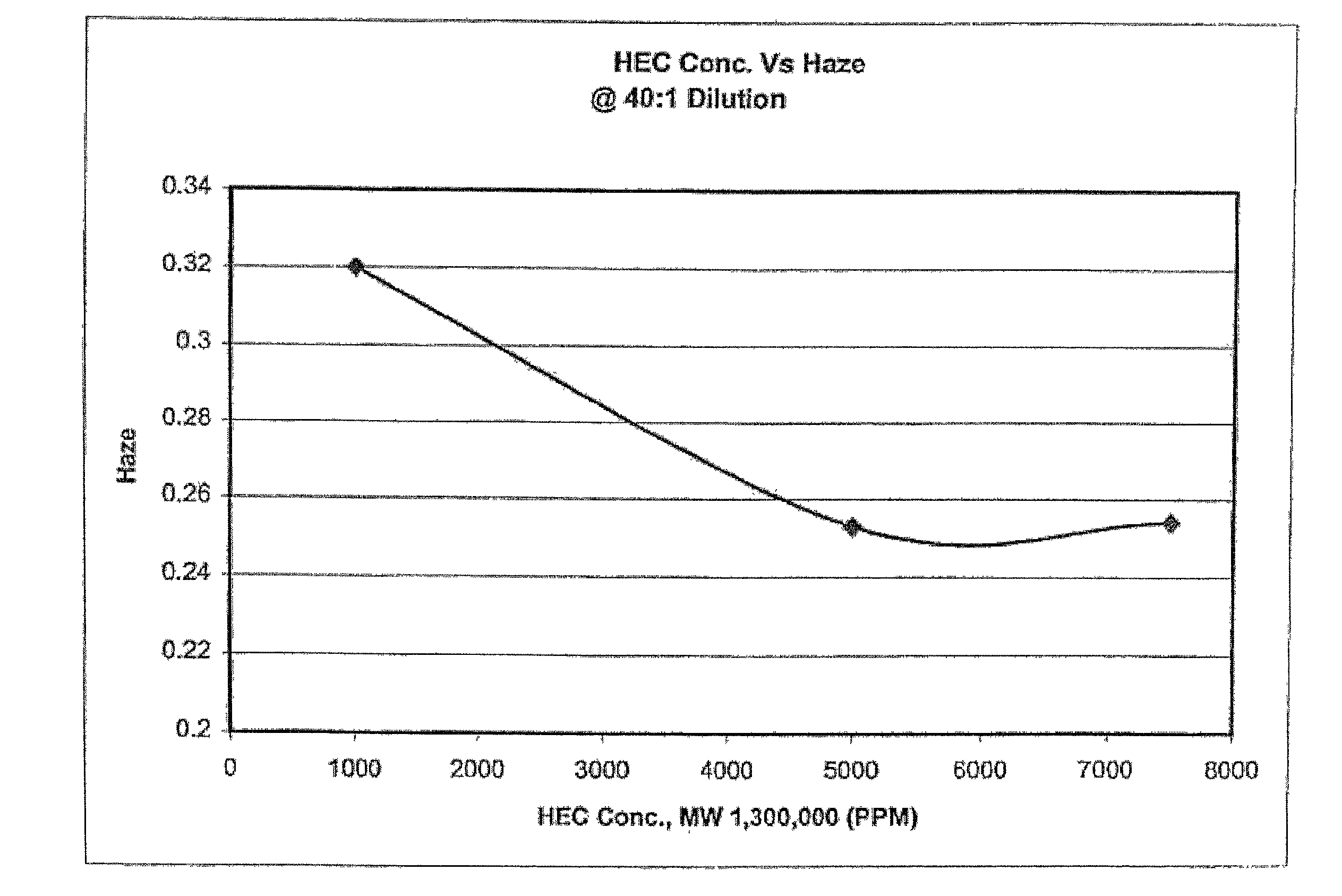

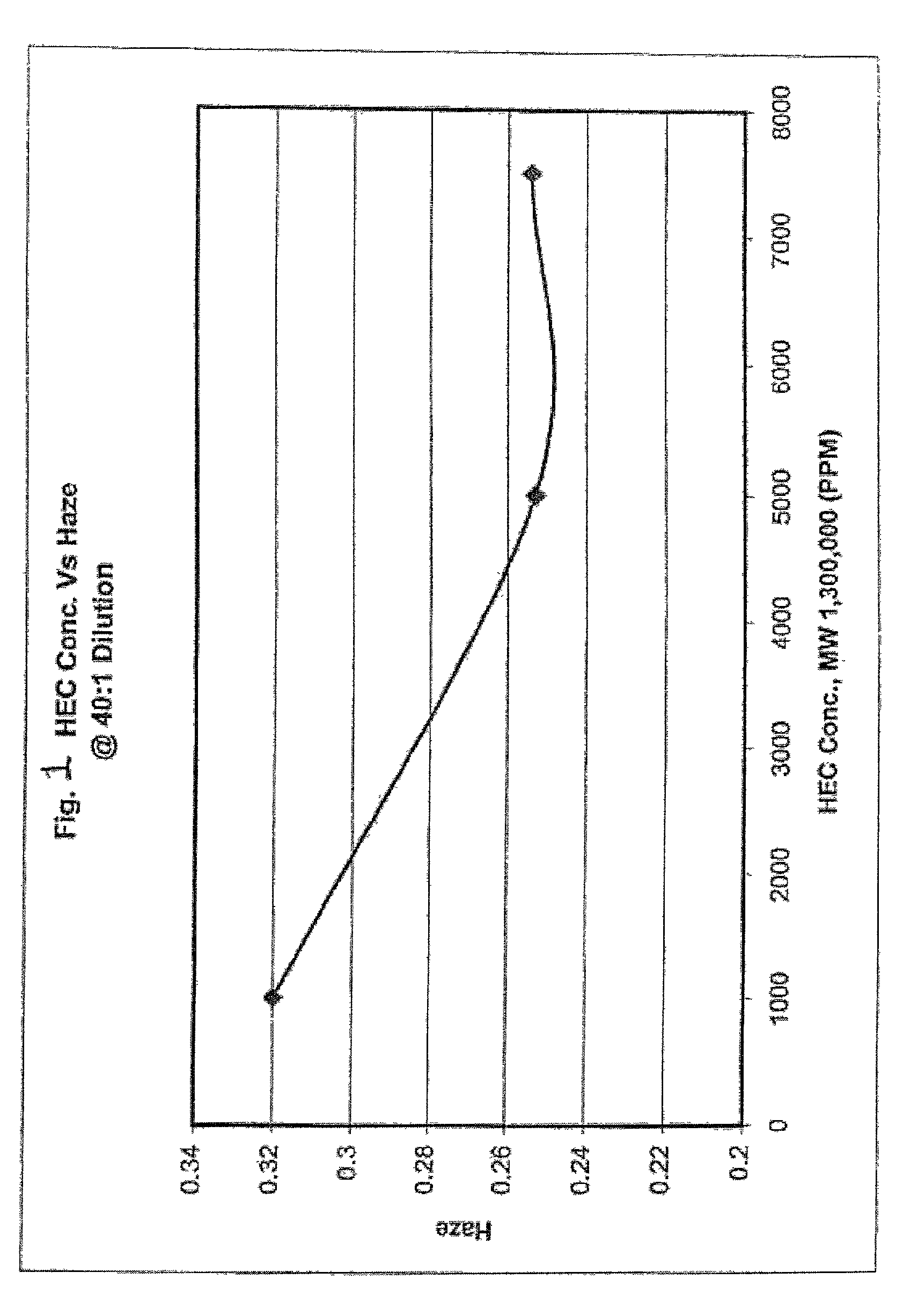

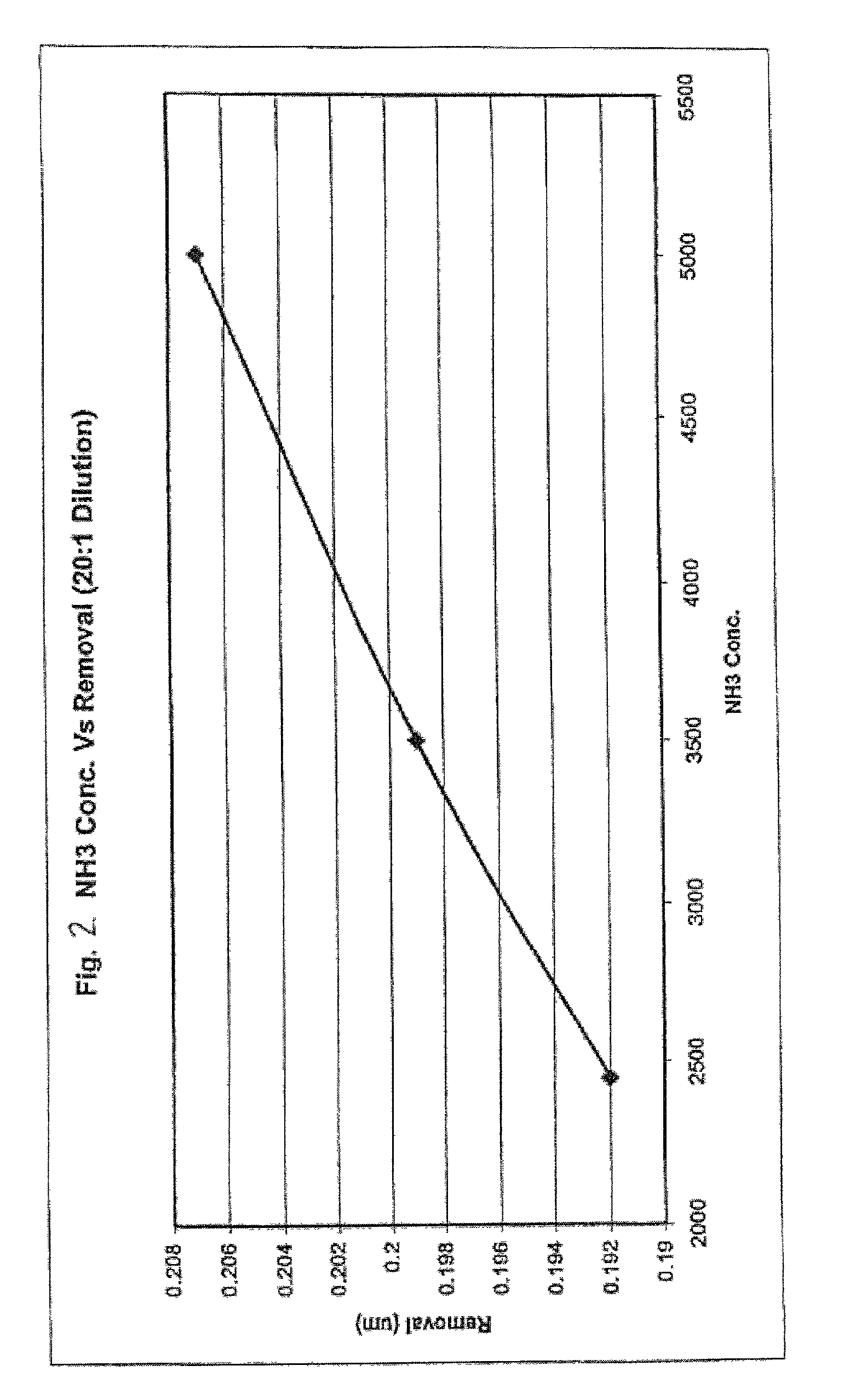

InactiveUS20030154659A1High polishing removal rateLow hazePigmenting treatmentOther chemical processesCelluloseColloidal silica

A polishing composition for polishing a semiconductor wafer includes comprises water, an abrasive that is preferably colloidal silica, water-soluble cellulose having a molecular weight of at least about 1,000,000 and an alkaline compound that is preferably ammonia. Tetra methyl ammonium hydroxide may also be added to the polishing composition.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

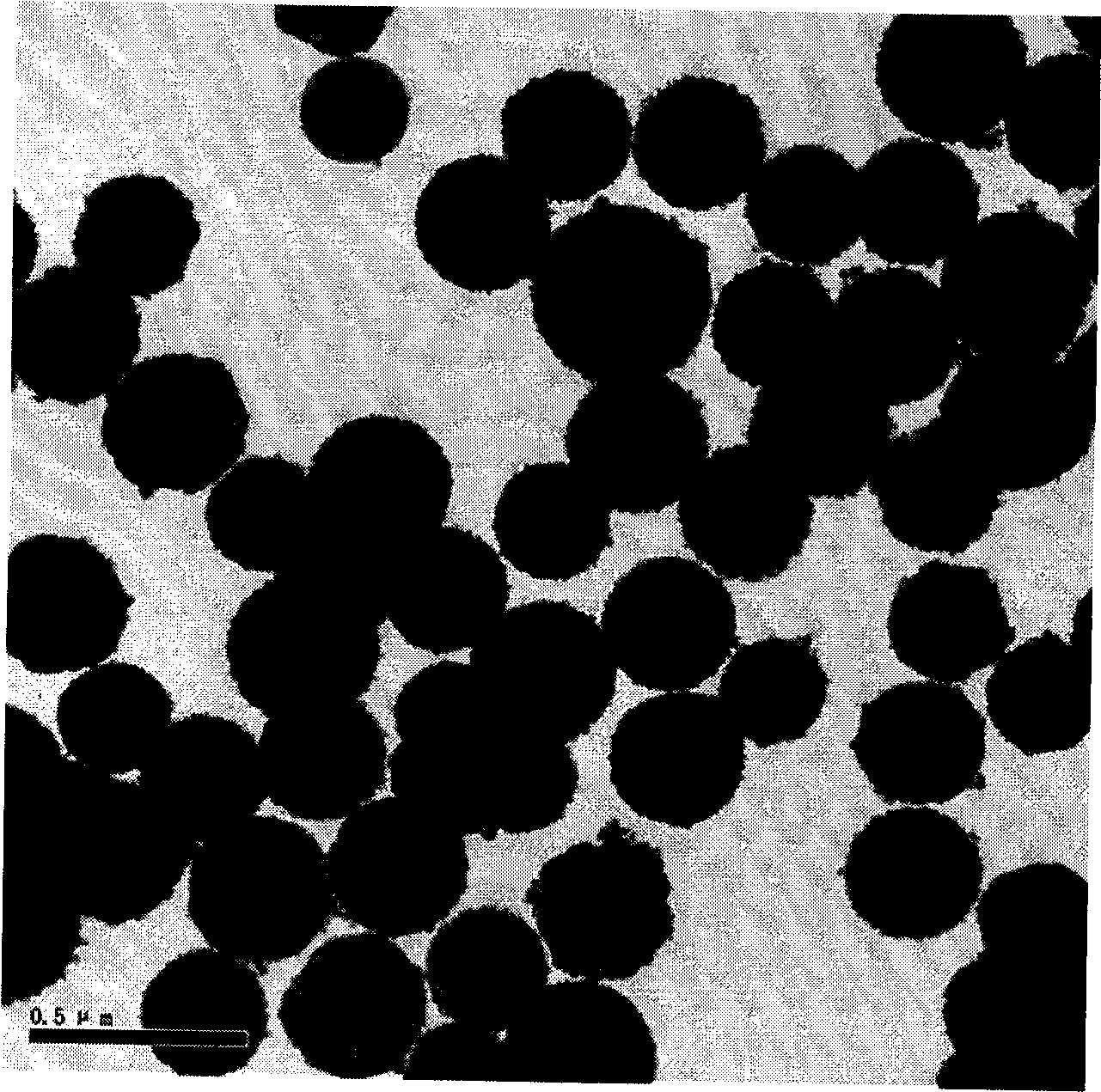

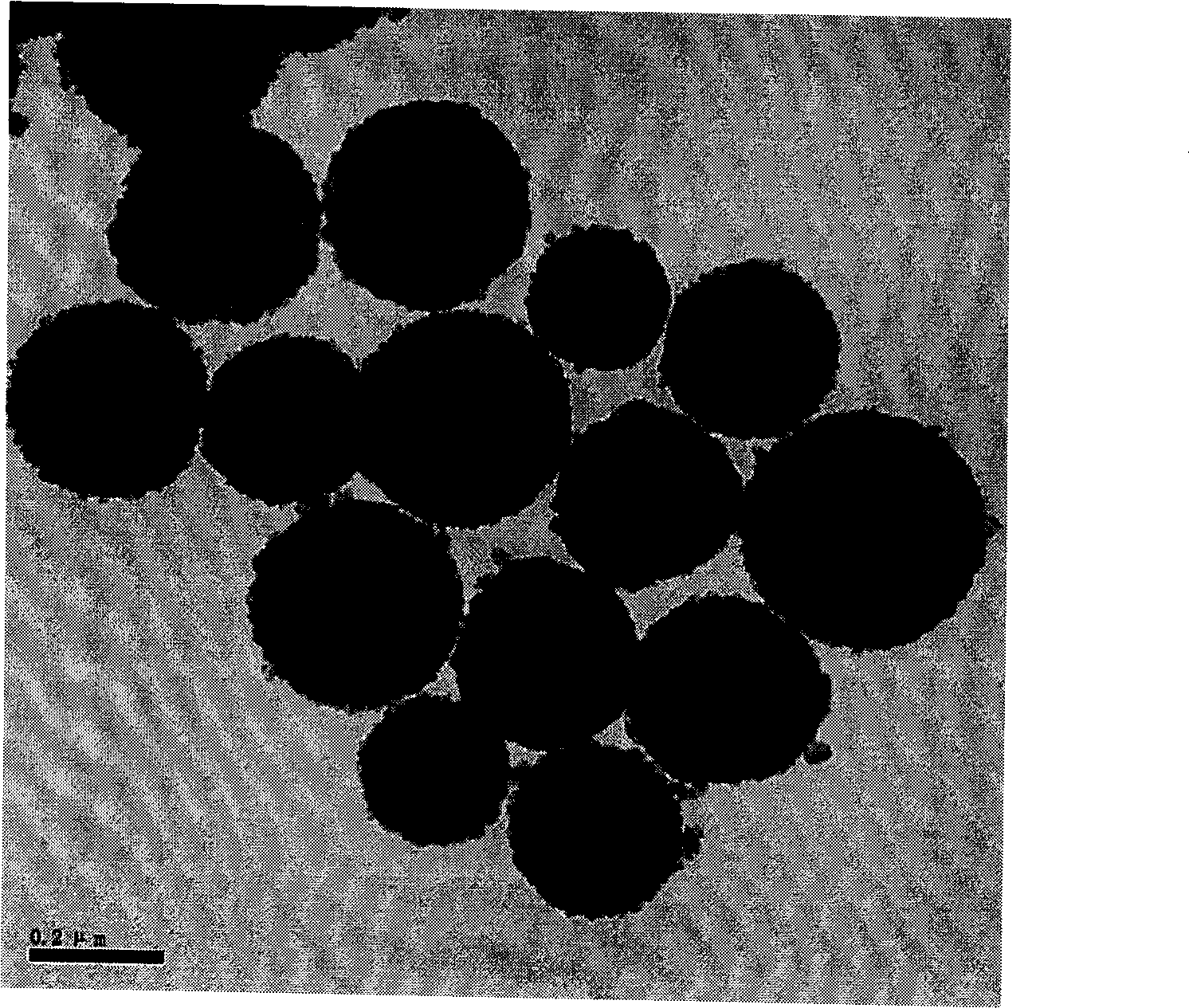

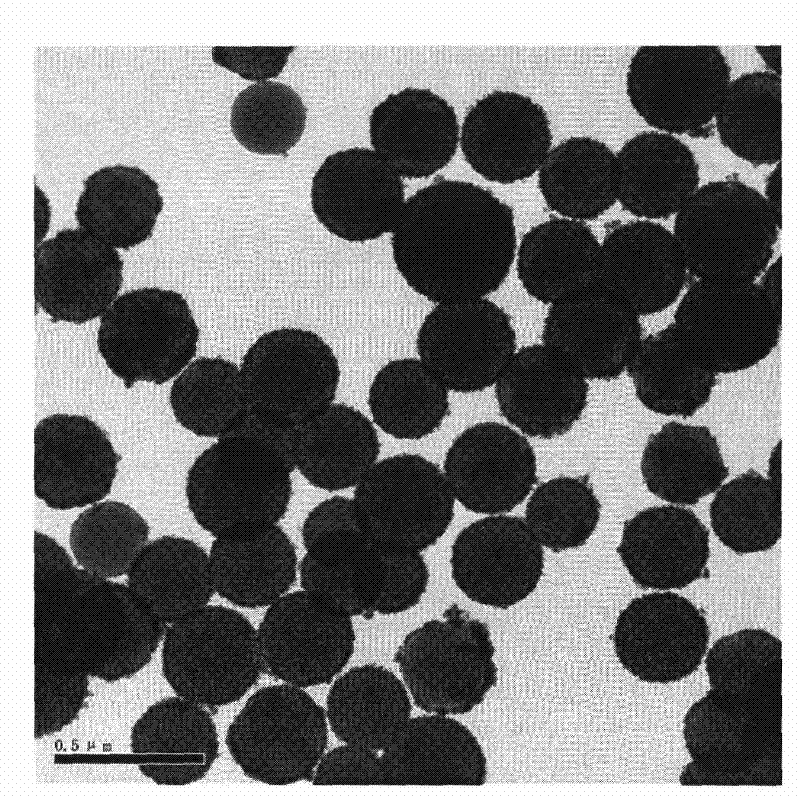

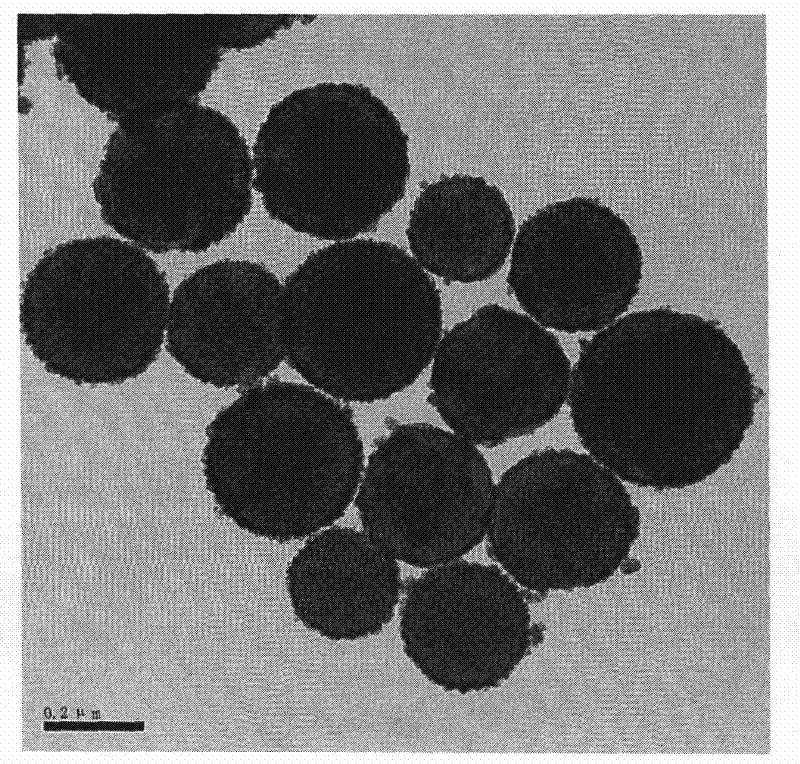

Preparation and use of cerium oxide / silicon oxide compound abrasive

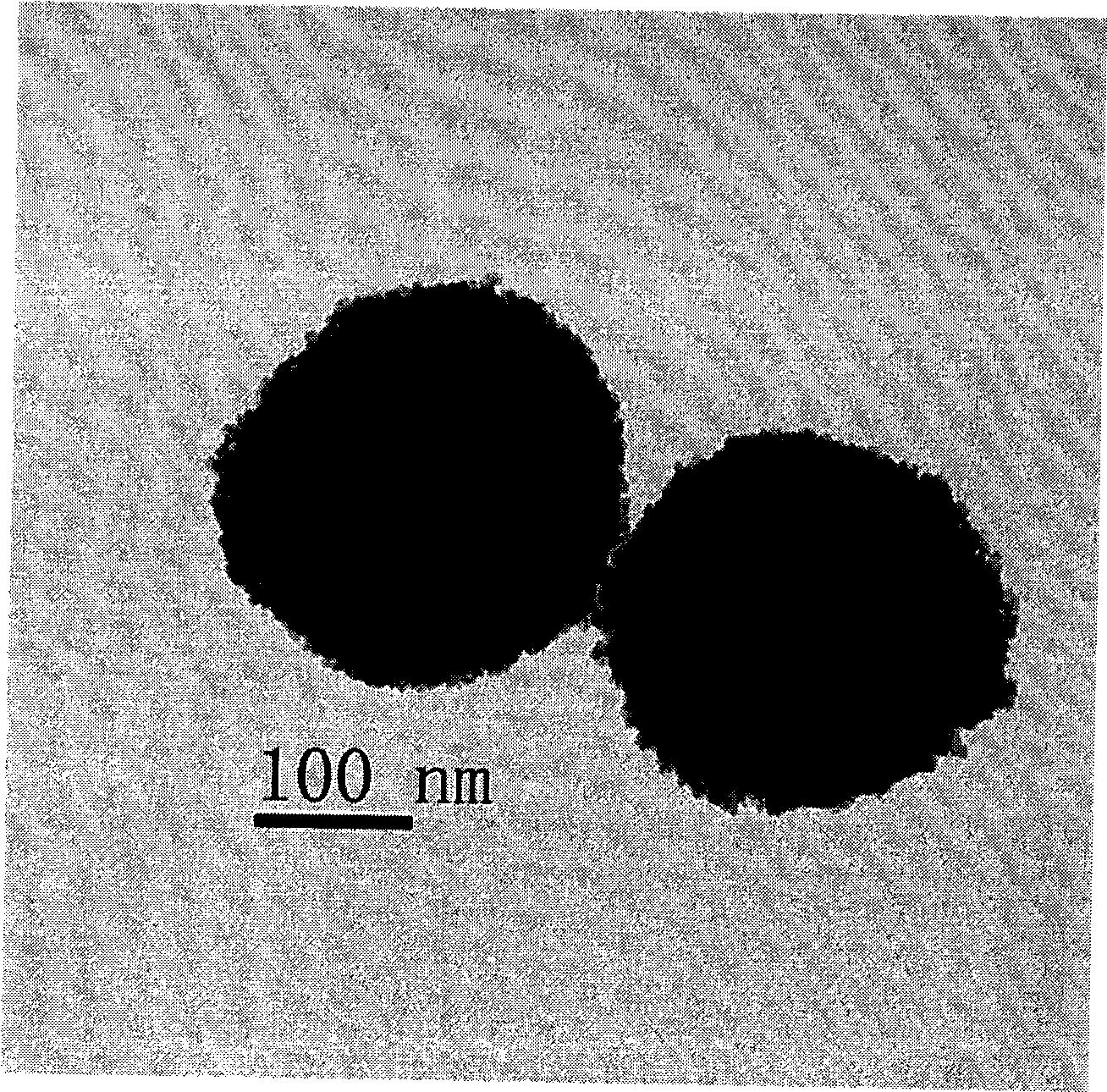

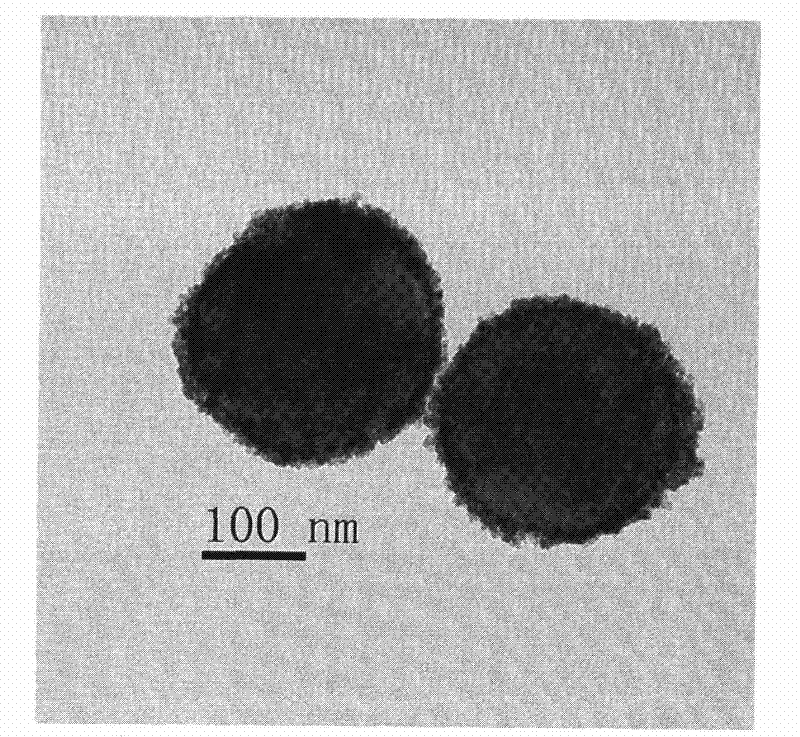

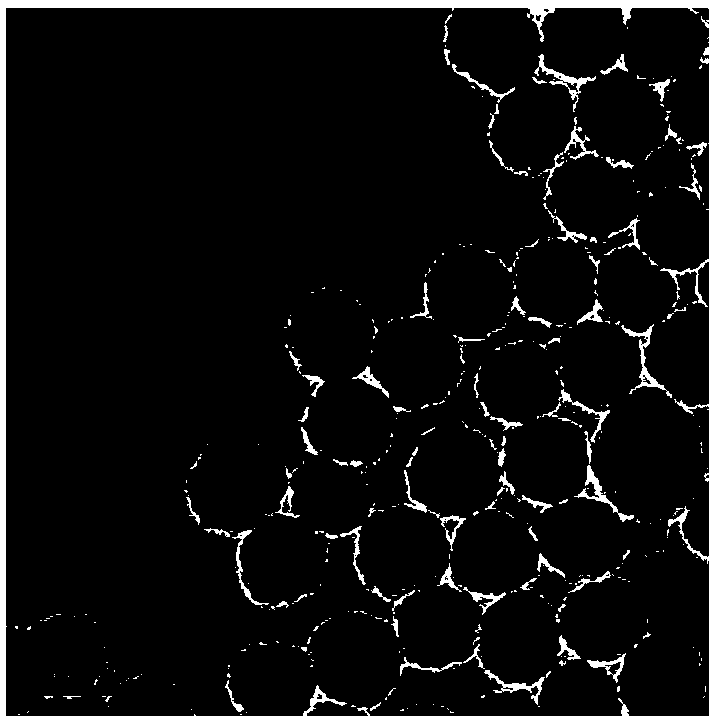

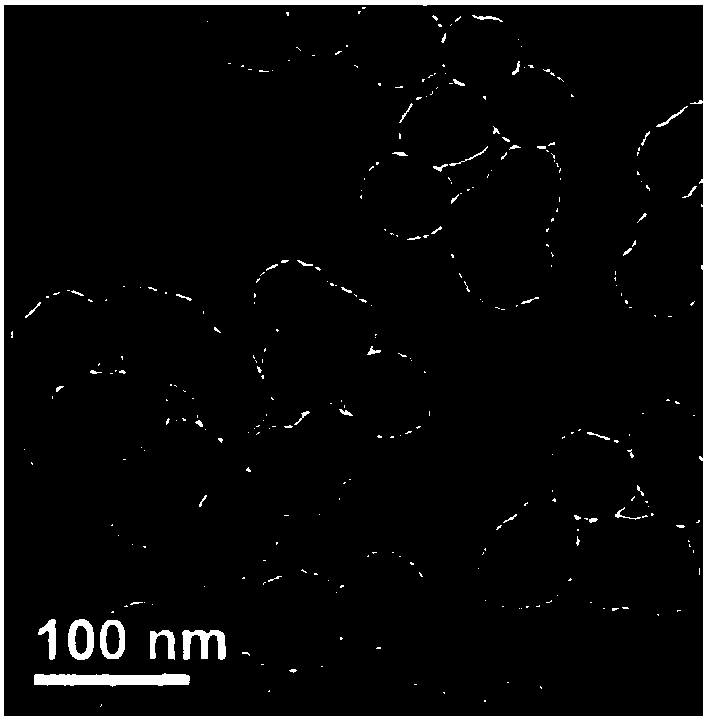

ActiveCN101475791ACoated evenlyGood monodispersityOther chemical processesHexamethylenetetramineCerium

The invention relates to a method for preparing a ceria / monox compounded abrasive, and application of the compounded abrasive. The method uses monodisperse spherical monox as a kernel of a coating type compounded abrasive, hexamethylenetetramine (HMT) as a precipitator and cerium salt as a raw material, and adopts an even precipitation method process to synthesize the ceria / monox compounded abrasive. Through the optimization of process parameters, such as the use amount ratio of monox master particles to the cerium salt, the molar ratio of the HMT to the cerium salt, and reaction and calcination temperature, the method controls the covering amount, the shape and the distribution state of ceria particles on the surface of the monox, thereby preparing the ceria / monox compounded abrasive of which the nanometer-level ceria particles evenly cover on the surface of the monox and which has good monodispersity; the method does not need complex equipment; and the needed chemical materials have less varieties, cheap prices and good experiment repeatability. The ceria / monox compounded abrasive is prepared into polishing slurry for chemical mechanical polishing of a gallium arsenide chip so as to obtain the polishing surface with the roughness in sub-nanometer magnitude and further improve polishing speed, reduce polishing pass and improve efficiency.

Owner:溧阳常大技术转移中心有限公司

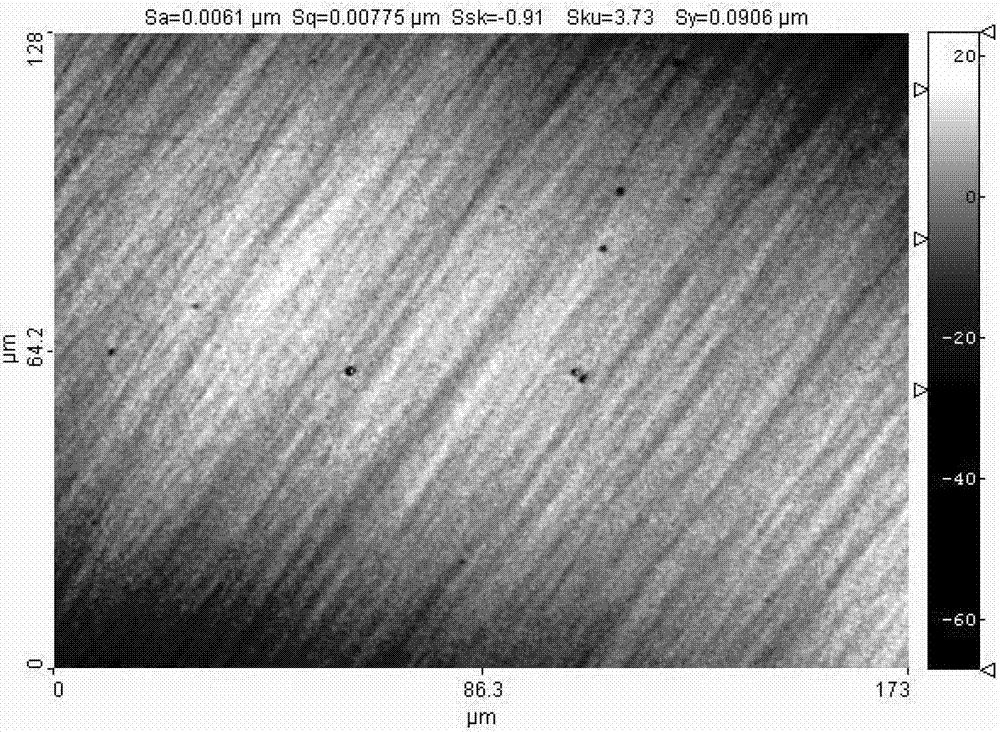

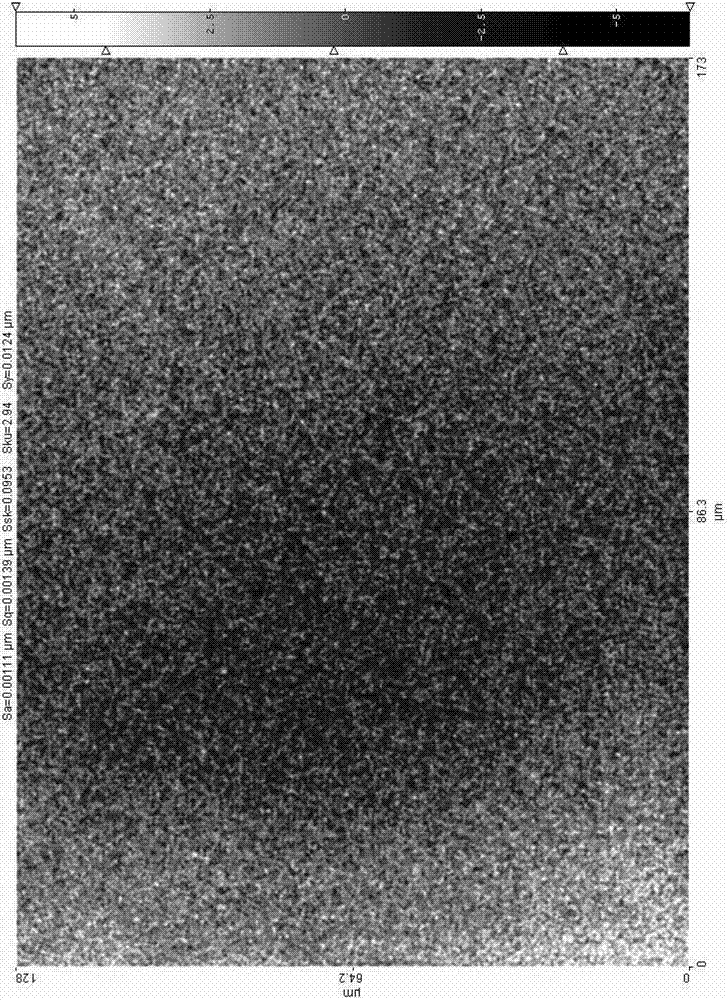

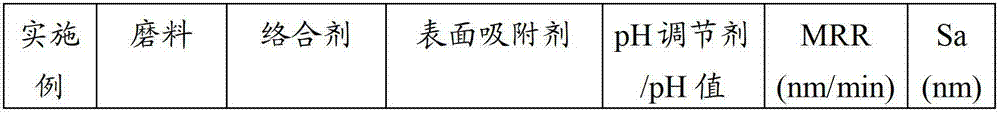

Barium titanate chemico-mechanical polishing aqueous composition and its application

ActiveCN102786879AImprove removal rateReduce concentrationPolishing machinesPolishing compositions with abrasivesBarium titanateSorbent

The invention relates to a barium titanate chemico-mechanical polishing aqueous composition and its application. Specifically, the barium titanate chemico-mechanical polishing aqueous composition comprises: 1-20 wt%, preferably 8-15 wt% of an abrasive; 0.5-10 wt%, preferably 1-3 wt% of a complexing agent; and 0.01-5 wt%, preferably 0.1-1 wt% of a surface adsorbent, wherein the barium titanate chemico-mechanical polishing aqueous composition has a pH value of 8.0-12.0, preferably 10.0-11.5. The barium titanate chemico-mechanical polishing aqueous composition provided in the invention can be effectively applied to a barium titanate substrate chemico-mechanical polishing process, thereby being able to effectively obtain a polished barium titanate layer with a high polishing rate and high surface quality.

Owner:TSINGHUA UNIV

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

Polishing composite for hard disk substrate

InactiveCN101463230AReduce scratchesHigh polishing removal ratePolishing compositions with abrasivesManufacturing technologySurface roughness

The invention discloses a polishing composition for hard disk substrates, belonging to the technical field of manufacturing memory hard disks of a computer. A polishing composition for the hard disk substrates includes grinding materials and water, and further includes a polishing accelerating agent and a lubricating agent, the contents thereof based on weight percent are as below: the grinding materials: 0.5-20%, the polishing accelerating agent:0.01-10%; the lubricating agent: 0.00001-5%, the rest is water. The polishing composition further includes a pH regulator. The pH value of the polishing composition is 0.5-5. The polishing composition provided by the invention is mainly suitable for the polishing process in manufacturing the hard disk substrates, and has the characteristic of high polishing removal rate, the polished disk substrate is less in scratches on the surface and free from recesses, protrusions and the like, as well as has smooth surface and the average surface roughness that can reach 3 angstroms or below.

Owner:TSINGHUA UNIV +1

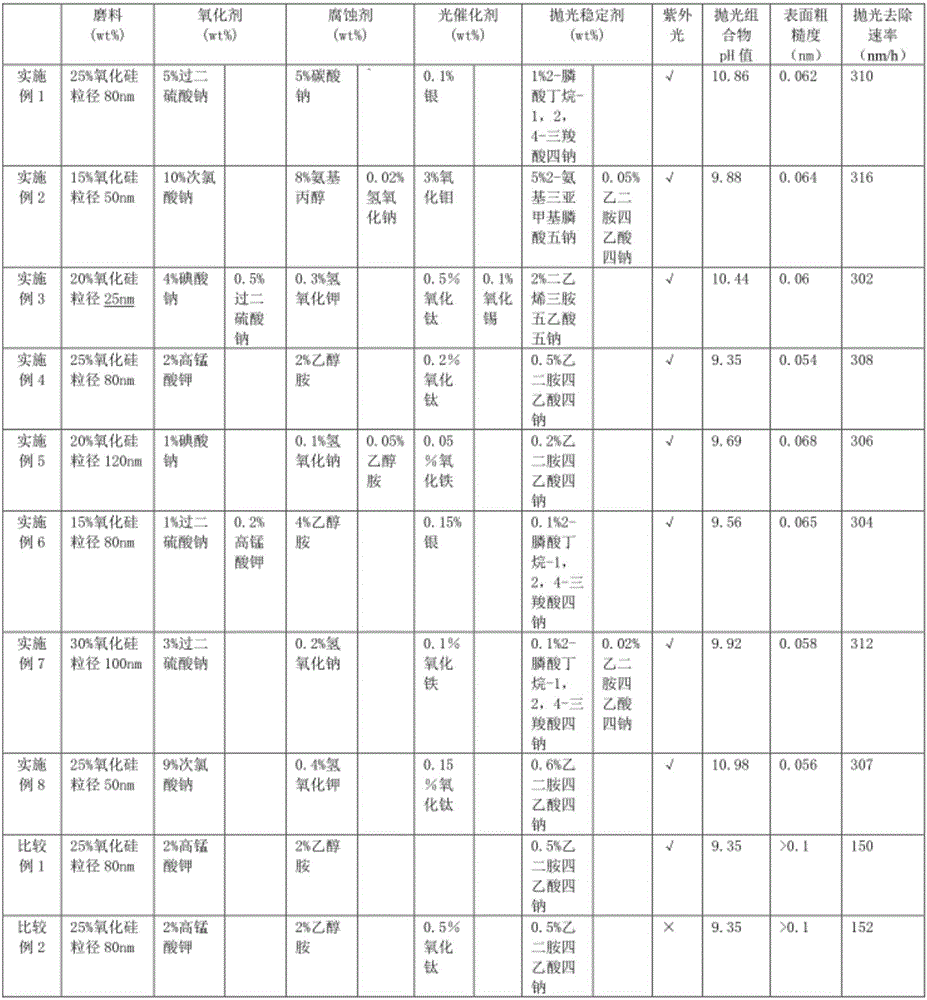

Polishing composition, and preparation and polishing methods thereof

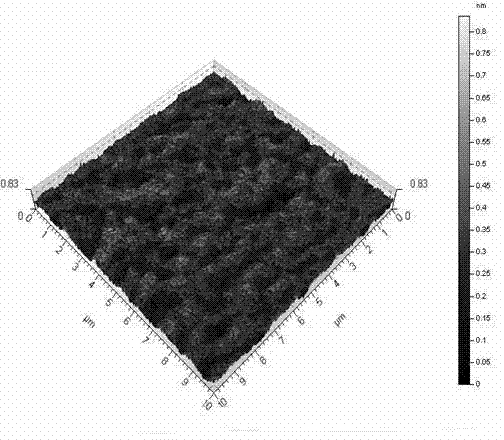

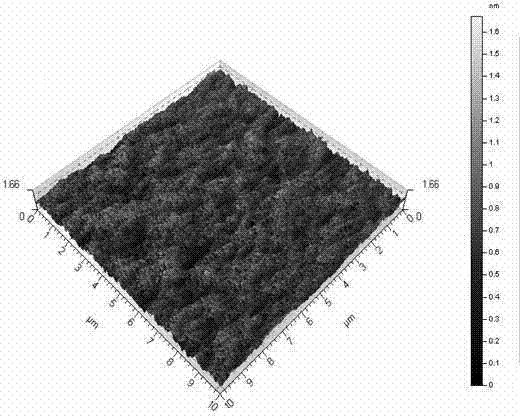

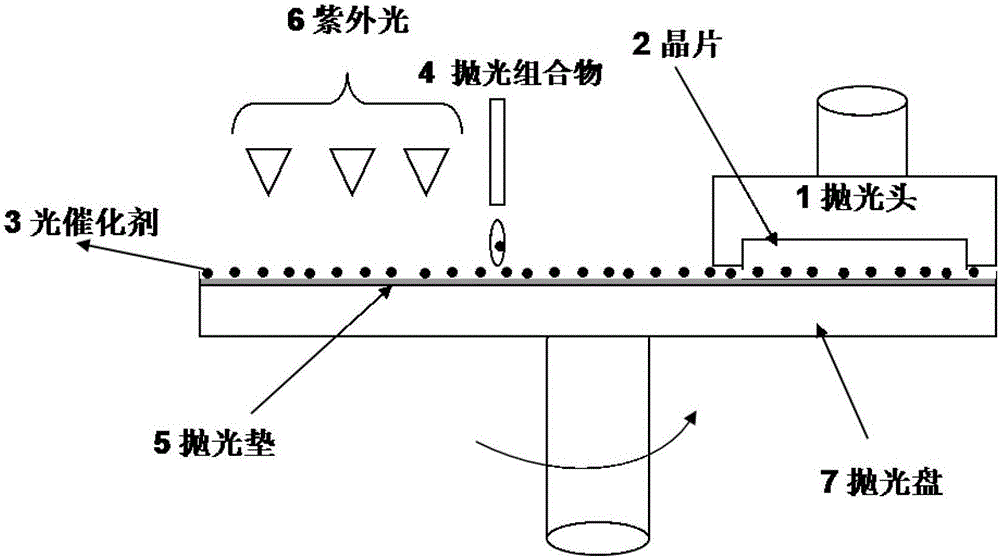

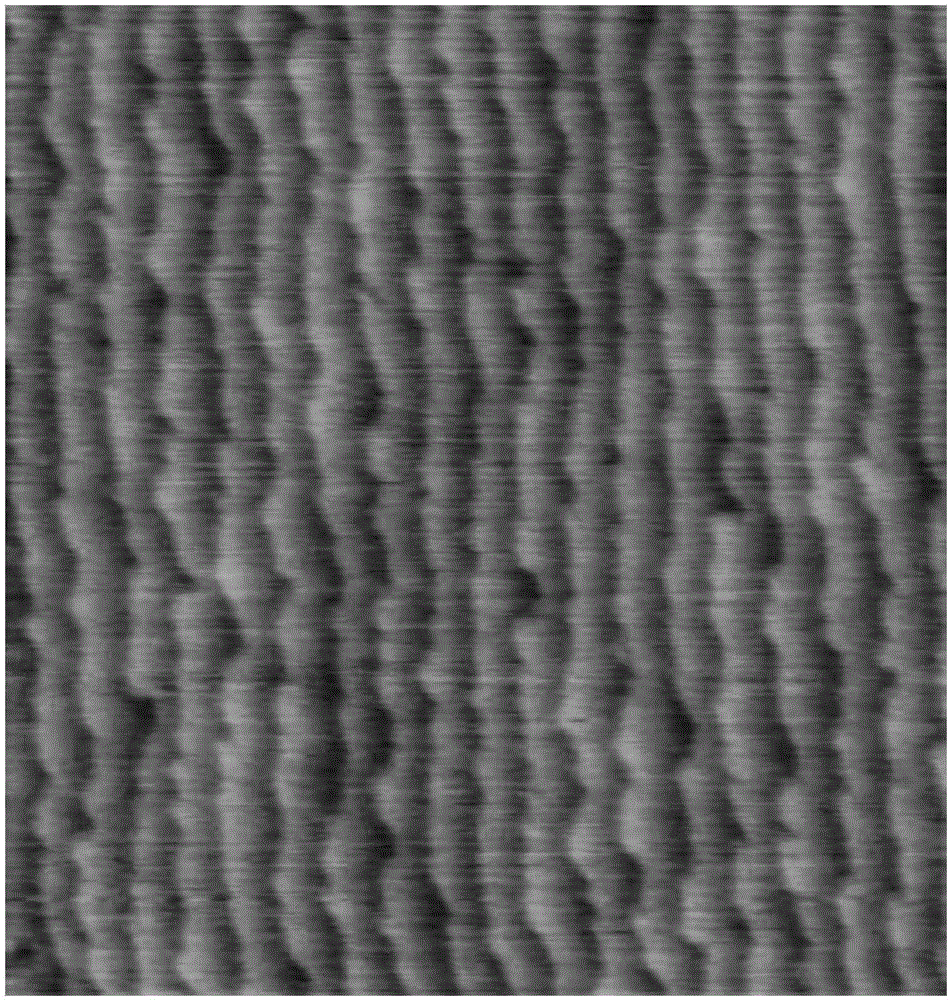

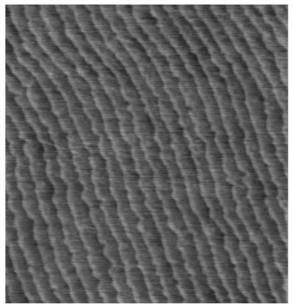

InactiveCN106189872ALow surface roughness RaHigh polishing removal rateLapping machinesPolishing compositions with abrasivesSurface roughnessUltraviolet lights

The invention relates to a polishing composition, and preparation and polishing methods thereof, belongs to the technical field of microelectronic manufacturing and especially relates to the technical field of ultra-precision machining of ultra-hard materials. The polishing composition comprises polishing particles, an oxidizing agent, a photo-catalyst, a corrosive agent, a polishing stabilizer and water according to the ratio of 10-30 wt% of the polishing particles, 0.5-15 wt% of the oxidizing agent, 0.01-10 wt% of the corrosive agent, 0.001-5 wt% of the photo-catalyst, 0.1-10 wt% of the polishing stabilizer and the balanced being water. The polishing composition containing the photo-catalyst is used for polishing a silicon carbide wafer under irradiation of ultraviolet light. The polishing composition significantly increases removal rate and has good cyclic polishing stability. The polished silicon carbide wafer has a super-smooth surface, has no surface defects such as scratches, pits and the like, is low in surface roughness, and can present clear and regular atom step morphology.

Owner:TSINGHUA UNIV +1

Polishing composition

InactiveUS6685757B2High polishing removal rateLow hazePigmenting treatmentOther chemical processesTetramethylammonium hydroxideCellulose

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Chemical mechanical polishing aqueous composite and chemical mechanical polishing process of titanium substrate

ActiveCN102796458AImprove performanceStay decentralizedPolishing compositions with abrasivesTitanium metalCompound (substance)

The invention relates to a chemical mechanical polishing aqueous composite and a chemical mechanical polishing process of a titanium substrate. The chemical mechanical polishing aqueous composite comprises: 1-20wt%, preferably 4-6wt% of abrasive material, 0.5-10wt%, preferably 0.9-3wt% of oxidant, 0.01-10wt%, preferably 0.1-2wt% complexing agent, and 0.1-10wt%, preferably 1-5wt% corrosion-inhibition film forming agent, wherein a pH value of the chemical mechanical polishing aqueous composite is 1.0-7.0, preferably 1.5-4.0. The chemical mechanical polishing aqueous composite disclosed by the invention can be effectively applied to a chemical mechanical polishing process of the titanium substrate so as to be capable of effectively obtaining a polished titanium metal layer with high polishing speed and high surface quality.

Owner:TSINGHUA UNIV

Polishing solution for chemically mechanical polishing single-crystal magnesium oxide substrate

InactiveCN101760138AReduce surface roughnessLow costAfter-treatment detailsPolishing compositions with abrasivesOrganic acidSurface roughness

The invention relates to a polishing solution for chemically mechanical polishing single-crystal magnesium oxide substrate, belonging to polishing solution used for chemically mechanical polishing, in particular to the field of the polishing solution for chemically mechanical polishing single-crystal magnesium oxide. The polishing solution has the pH value of 1.5-7.0 and comprises the components as follows by weight percent: 0.5-30% of grinding material, 0.0001-1% of inhibitor, 0.001-10% of complexing agent and balance deionized water, wherein the grinding material of the polishing solution has the grain diameter of 10-500nm and is selected from SiO2, ZrO2, Al2O3, TiO2, MgO or CeO2 hydrosol; the complexing agent of the polishing solution is selected from organic acid, organic acid salt, inorganic acid or inorganic acid salt which contains phosphorus oxygen double bonds; and the inhibitor of the polishing solution is selected from compound containing five-membered ring. The polishing solution has high material removing rate and low surface roughness of a polished sample, and ensures the polished sample not to have the defects of scratch, pits and the like on the surface; and furthermore, the polishing solution is simple and convenient for preparation and low in cost.

Owner:DALIAN UNIV OF TECH

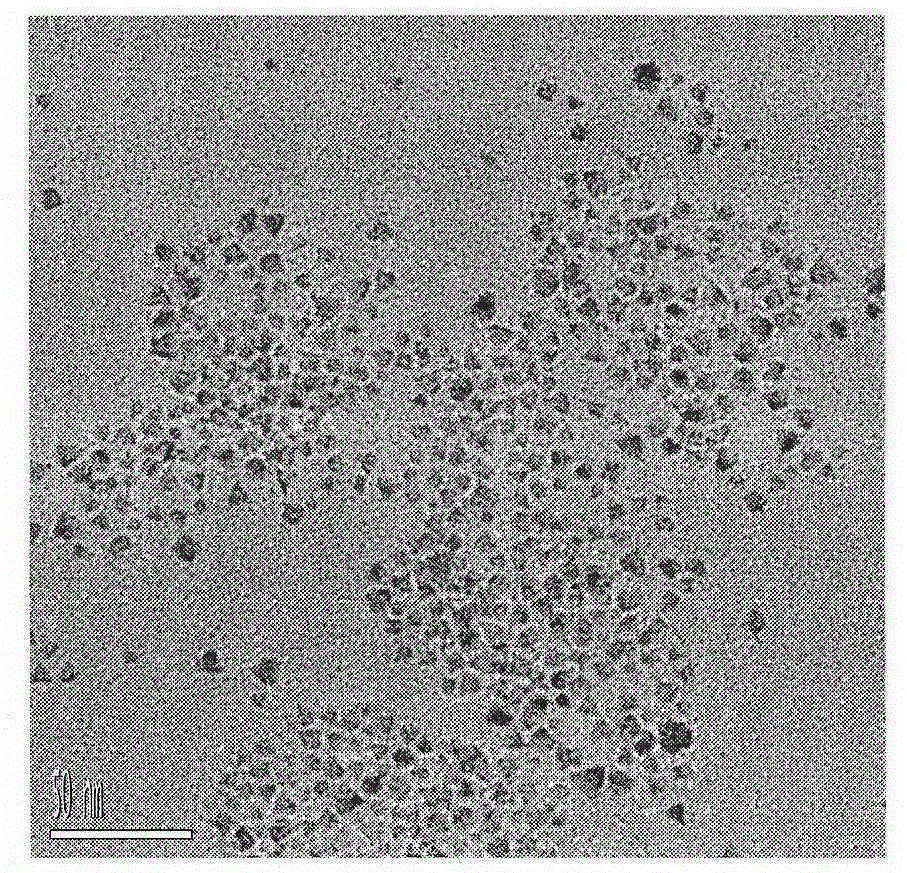

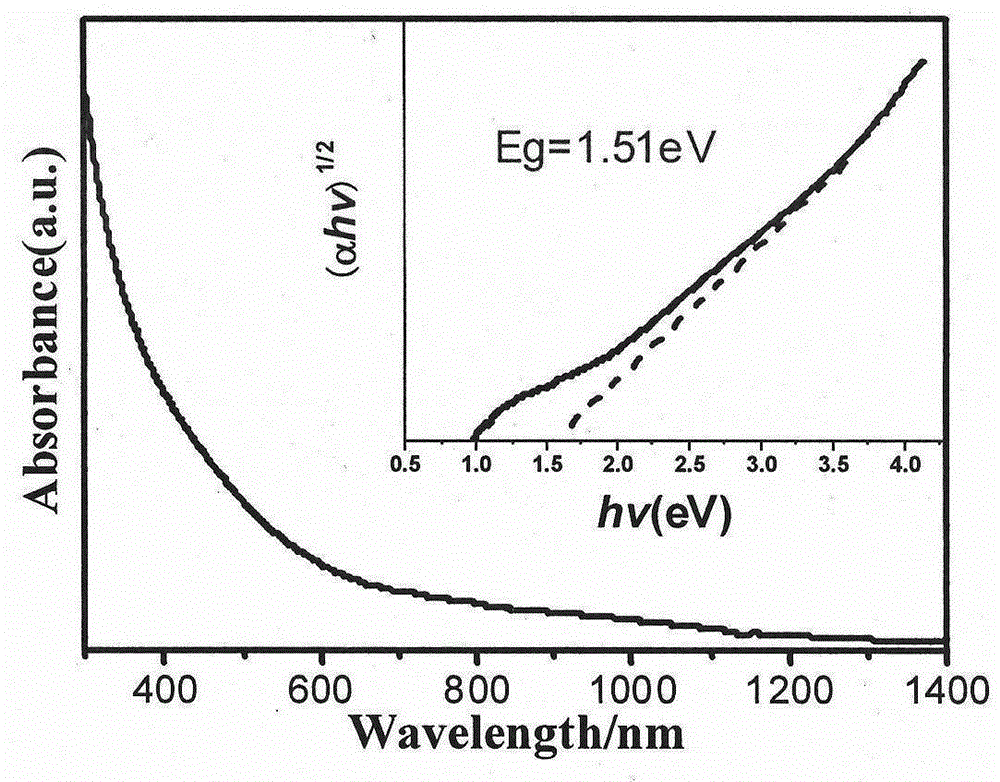

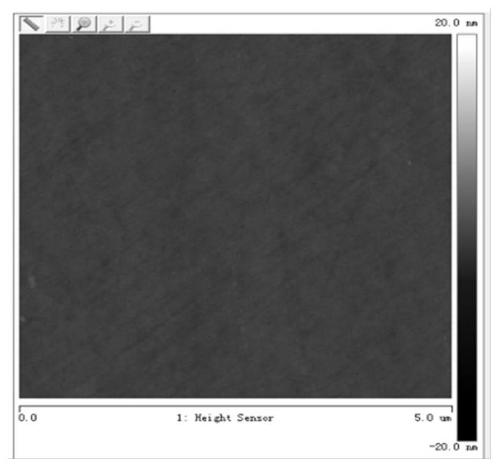

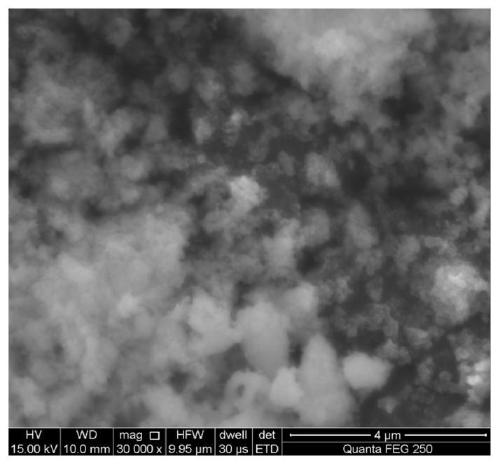

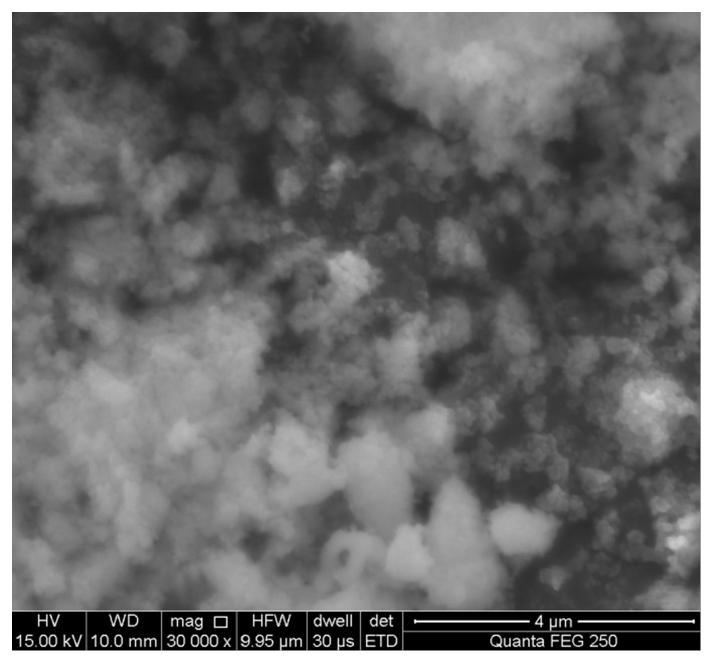

Preparation method and application of nano-semiconductor photocatalyst

InactiveCN105727996AEasy to prepareLow costMaterial nanotechnologyPhysical/chemical process catalystsSemiconductorNanotechnology

A preparation method and an application of a nano-semiconductor photocatalyst. The invention relates to the nano-semiconductor photocatalyst used for surface planarization, and the preparation method and the application thereof. In the method, with toxic-free and low-cost precursor raw materials, nano-semiconductor particles, which have uniform particle size and good stability, are synthesized through a simple thermal injection method. The nano-semiconductor photocatalyst has wide application in the surface planarization.

Owner:TSINGHUA UNIV +2

Preparation method of silicon-aluminum composite polishing powder

ActiveCN111073518AHigh polishing removal rateImprove polishing ratePolishing compositions with abrasivesSilicic acidAluminum ammonium sulfate

The invention discloses a preparation method of silicon-aluminum composite polishing powder. The method comprises the following steps: (1) stirring and reacting an ammonium bicarbonate solution and analuminum ammonium sulfate solution to prepare an aluminum oxide precursor solution; (2) dropwise adding tetraethoxysilane into the aluminum oxide precursor solution under high-speed stirring, and aging after stirring reaction to obtain an aged solution; (3) filtering the aging solution, collecting filter residues, drying and crushing to obtain a silicon-aluminum compound precursor; (4) uniformlymixing the silicon-aluminum compound precursor with a calcining accelerator, and calcining to obtain a silicon-aluminum compound; and (5) carrying out water washing, ball milling, water flow grading and spray drying on the silicon-aluminum compound to obtain the silicon-aluminum composite polishing powder. SiO2 and Al2O3 in the silicon-aluminum composite polishing powder obtained by the preparation method are chemically bonded, so that the silicon-aluminum composite polishing powder has the advantages of high polishing removal rate, good polishing stability, high polishing rate (up to 8.5-9.5mu m / h) and the like, and meanwhile, the polishing yield can also be improved.

Owner:湖南景翌湘台环保高新技术开发有限公司 +1

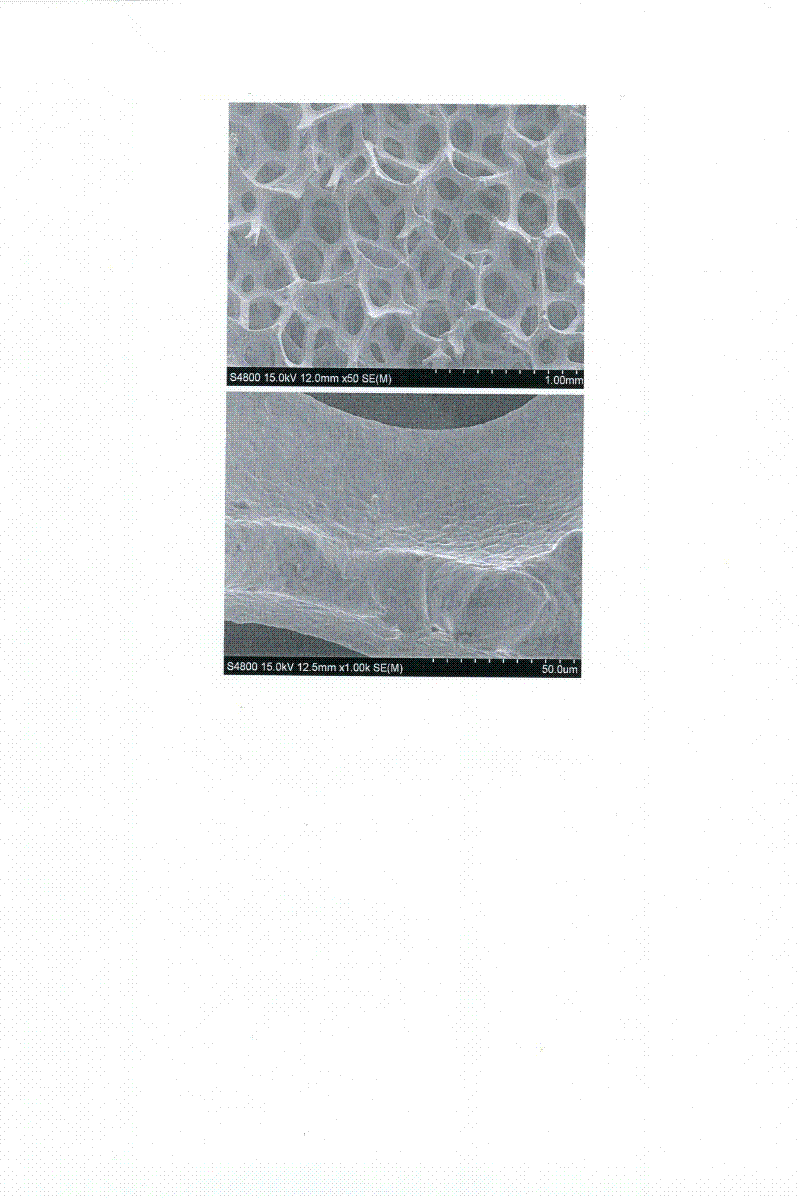

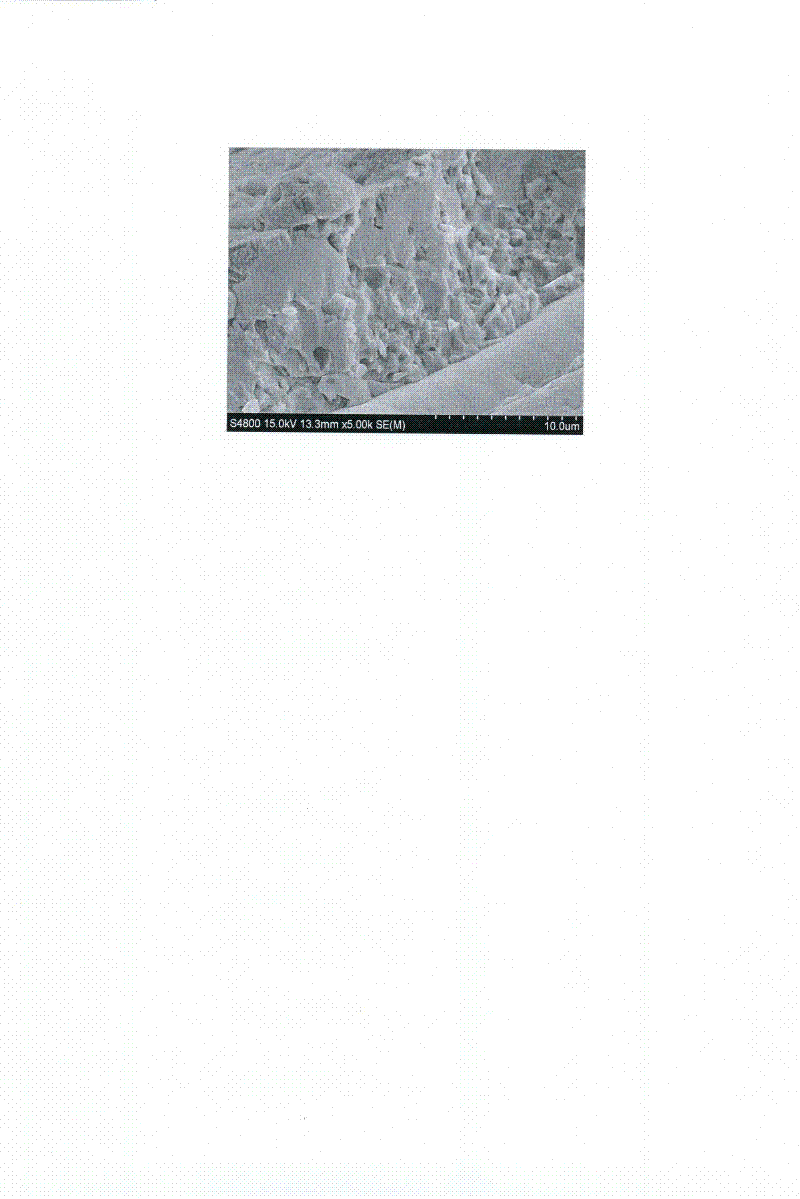

Method for manufacturing porous polishing and grinding tool

InactiveCN102517580AReliable qualityHigh polishing removal rateElectrophoretic coatingsLiquid/solution decomposition chemical coatingElectrophoretic depositionUltrasonic oscillation

The invention discloses a method for manufacturing a porous polishing and grinding tool. The method mainly comprises the following steps of: performing ultrasonic oscillation on ethanol, micro-powder diamond and sodium dodecyl benzene sulfonate to obtain a suspension; placing a foaming nickel sheet as an anode and a nickel sheet as a cathode in the suspension, performing electrophoretic deposition for 1 to 10 minutes, and drying the foaming nickel on which the diamond micro-powde is deposited for 10 minutes at 70 DEG C; suspending the foaming nickel in chemical nickel plating liquid, 3 to 5 hours later, cleaning the foaming nickel sheet, drying the foaming nickel sheet in vacuum, annealing the foaming nickel sheet at 250 to 300 DEG C for 2 to 4 hours to eliminate stress, wherein the increased weight of the nickel layer is up to 80 to 100 percent; and repeating the processes of electrophoretic deposition, chemical nickel plating and annealing for 4 to 10 times, so that the increased weight of the nickel layer is up to 300 to 800 percent. The polishing and grinding tool manufactured by the method is uniform and controllable in porosity, and the probability of manufacturing the polishing and grinding tool with big pores and high porosity is provided; and a grinding material is uniformly distributed, so the utilization rate of the grinding material in a polishing and grinding process is improved.

Owner:YANSHAN UNIV

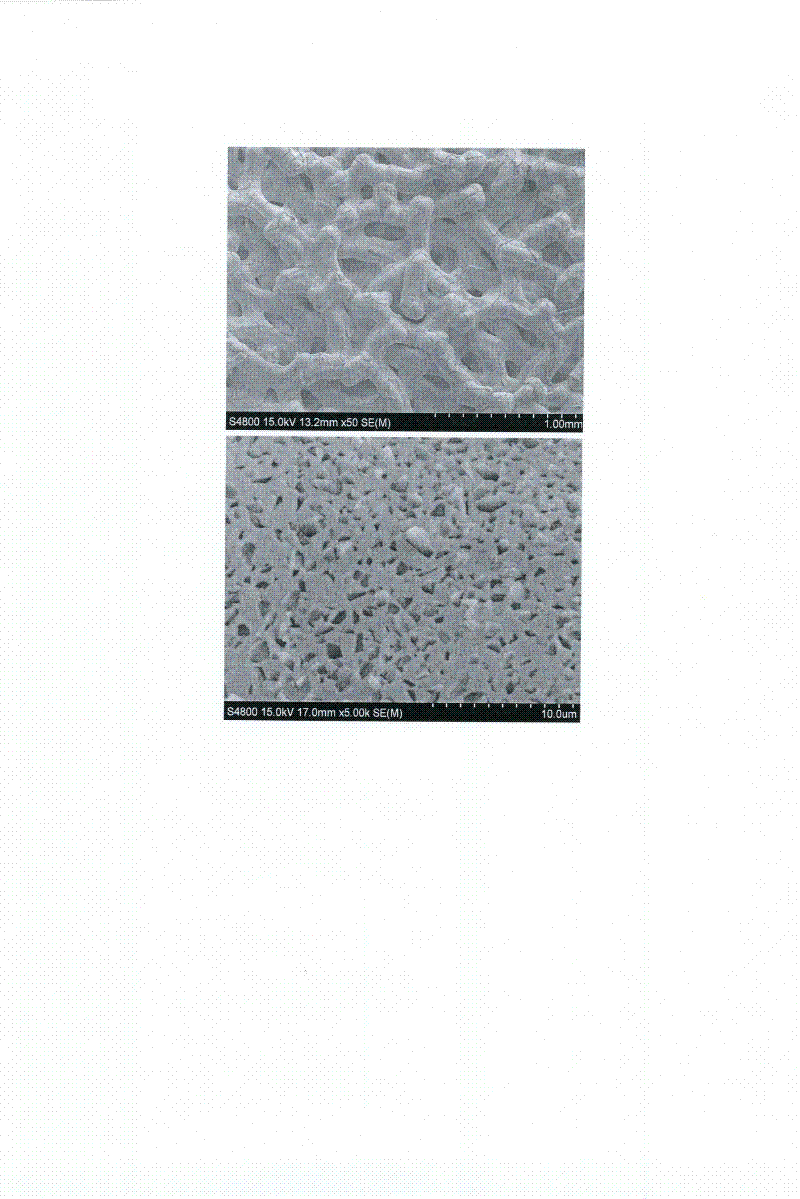

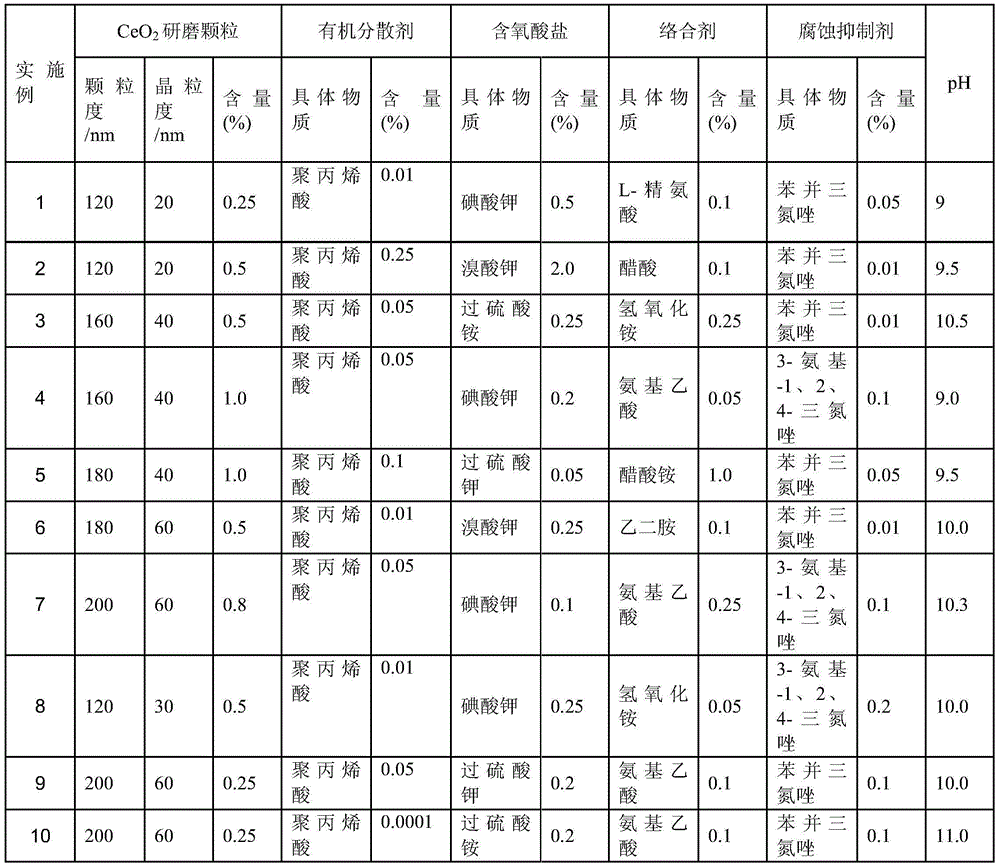

A chemical-mechanical polishing solution and applications thereof

InactiveCN104650736AAdjustable polishing rateHigh polishing removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCerium oxideCorrosion inhibitor

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Sapphire polishing solution with high surface evenness, and polishing technology thereof

InactiveCN108485532AMeet the requirements of high polishing removal rateMeet the requirements of polishing removal ratePolishing compositions with abrasivesEthylenediamineHigh surface

The invention relates to a sapphire polishing solution with the high surface evenness, and a polishing technology thereof. The sapphire polishing solution with the high surface evenness is prepared from a rough polishing solution and a finish polishing solution, wherein the rough polishing solution is prepared from the following components in percentage by weight: 20 to 50 percent of alumina nanoparticle, 3 to 10 percent of sodium methylate, 0.1 to 1 percent of disodium methylene dinaphthalenesulfonate, 0.5 to 2 percent of sodium iminodisuccinate, and the balance of solvent; the finish polishing solution is prepared from the following components in percentage by weight: 20 to 50 percent of hydrophilic silicon dioxide nanoparticle, 0.1 to 1 percent of nonionic surfactant fatty alcohol-polyoxyethylene ether, 0.5 to 2 percent of sodium polyacrylate, 0.2 to 1.5 percent of hydroxyethyl ethylenediamine, and the balance of solvent. The sapphire polishing solution with the high surface evenness provided by the invention not only can meet the requirement on a high polishing removal rate, but also can form a sapphire surface with high evenness and ultralow roughness; the polishing solution is low in cost, a polishing process is easy to control, the production yield is high, and the product quality is stable; a polishing method of combining the rough polishing and the finish polishing canbe used, so that not only can fast production with a high removal rate be realized, but also the precision polishing requirements on high evenness and low surface roughness can be met.

Owner:江苏金琥珀光学科技股份有限公司

Polishing agent and method for polishing gallium antimonide wafer by employing polishing agent

ActiveCN106590439AHigh polishing removal rateNo chippingSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesGallium antimonideEngineering

The invention discloses a polishing agent and a method for polishing a gallium antimonide wafer by employing the polishing agent. The polishing agent is high in speed of polishing and removing a gallium antimonide material; the polished wafer surface is glabrous and smooth; edge breakage and scaling off do not exist; the polishing technology is simple, artificial control factors are relatively few, the availability ratio is greatly improved, and the polishing agent and the method are beneficial to cost reduction.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Polishing composition

ActiveUS20190112506A1High removal rateReduce scratchOther chemical processesSemiconductor/solid-state device manufacturingAbrasiveMaterials science

The present invention provides a polishing composition for use in polishing a material having a Vickers hardness of 1500 Hv or higher. The polishing composition comprises an alumina abrasive and water. The alumina abrasive has an isoelectric point that is below 8.0 and is lower than the pH of the polishing composition.

Owner:FUJIMI INCORPORATED

Chemical mechanical polishing aqueous composite and chemical mechanical polishing process of titanium substrate

ActiveCN102796458BImprove performanceStay decentralizedPolishing compositions with abrasivesTitanium metalCompound (substance)

Owner:TSINGHUA UNIV

Polishing liquid for sapphire substrate, and preparation method thereof

InactiveCN105017970AGuaranteed stabilitySolve the speed problemSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesEthylenediamineActive agent

The invention discloses a polishing liquid for a sapphire substrate. The polishing liquid is composed of the following components, by weight: 50-70 parts of deionized water, 20-40 parts of nano-grade silica hydrosol, 4-6 parts of graphene microchip, 4-6 parts of an active agent, 3-5 parts of stearic acid, 3-5 parts of glycol, 0.1-0.3 parts of tungstate, 1-2 parts of theophylline, 1.5-2.5 parts of flatting micro-powder wax, 4-6 parts of nano-grade titanium carbide, 1.5-2.5 parts of epoxy soybean oil, 2-4 parts of diphenyl silandiol, 2-4 parts of potassium phosphotungstic, 1-2 parts of methyl methacrylate, 0.4-0.6 parts of ethylenediamine, 0.4-0.6 parts of malonic acid, and 0.2-0.5 parts of polyvinylpyrrolidone. According to the polishing liquid, graphene microchips are added into a traditional silica sol, such that polishing removing rate can be effectively improved, and polishing liquid pH stability is ensured. With the polishing liquid, technical problems of low polishing rate and low efficiency of traditional polishing liquids are solved, and the polishing liquid is more environment-friendly.

Owner:ANHUI DENUO CHEM CO LTD

Polishing material for polishing hard surfaces, media including the material, and methods of forming and using same

ActiveUS20160001417A1High polishing removal rateUniform material removalOther chemical processesAbrasion apparatusMetallurgyMaterials science

Polishing materials suitable for polishing hard surfaces, media including the polishing material, and methods of forming and using the polishing materials and media are disclosed. Exemplary polishing materials have a relatively high hard segments:soft segments ratio and exhibit relatively high removal rates and / or relatively high process yields.

Owner:JH RHODES CO INC

Polishing composition

PendingUS20210017423A1Improve surface qualityHigh polishing removal rateOther chemical processesSemiconductor/solid-state device manufacturingAluminium oxideAbrasive

The present invention provides a means capable of polishing an object to be polished at a high polishing removal rate and further improving a surface quality of a surface of the object to be polished.The present invention is a polishing composition used for polishing an object to be polished, containing an alumina abrasive and a dispersion medium, in which the alumina abrasive contain only an α-alumina A having an α conversion rate of 80% or more and an α-alumina B having an α conversion rate of less than 80% as crystalline alumina, and an average particle size of the α-alumina A is smaller than an average particle size of the α-alumina B.

Owner:FUJIMI INCORPORATED

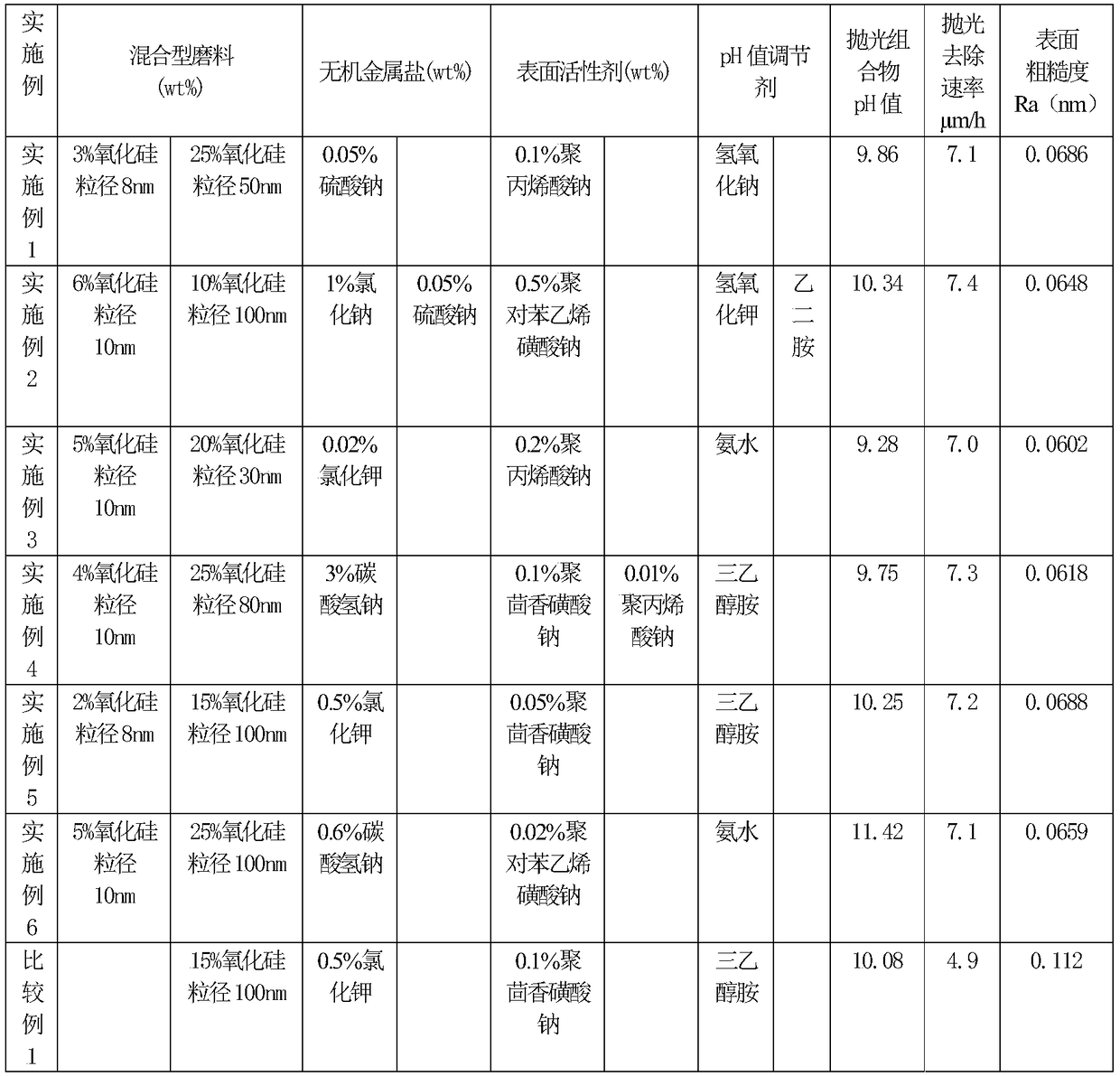

a polishing composition

ActiveCN106349945BImprove surface qualityHigh polishing removal ratePolishing compositions with abrasivesSilicon oxideSapphire wafer

The invention belongs to the technical field of chemically mechanical polishing of ultra-hard materials for electronic manufacture and relates to a polishing composition. The polishing composition comprises a mixed grinding material, inorganic metal salt, a surfactant, a pH value adjusting agent and water, and the mixed grinding material is composed of silicon oxide being 0.1-10nm in particle size and other grinding materials. A pH value of the composition is 9.0-12.0 and suitable for polishing of sapphires. The polishing composition is capable of not only evidently increasing sapphire polishing removal rate but also improving surface quality of sapphire wafers, and the polished sapphire wafers are smooth in surface and free of surface defects such as scratches and pits.

Owner:TSINGHUA UNIV +1

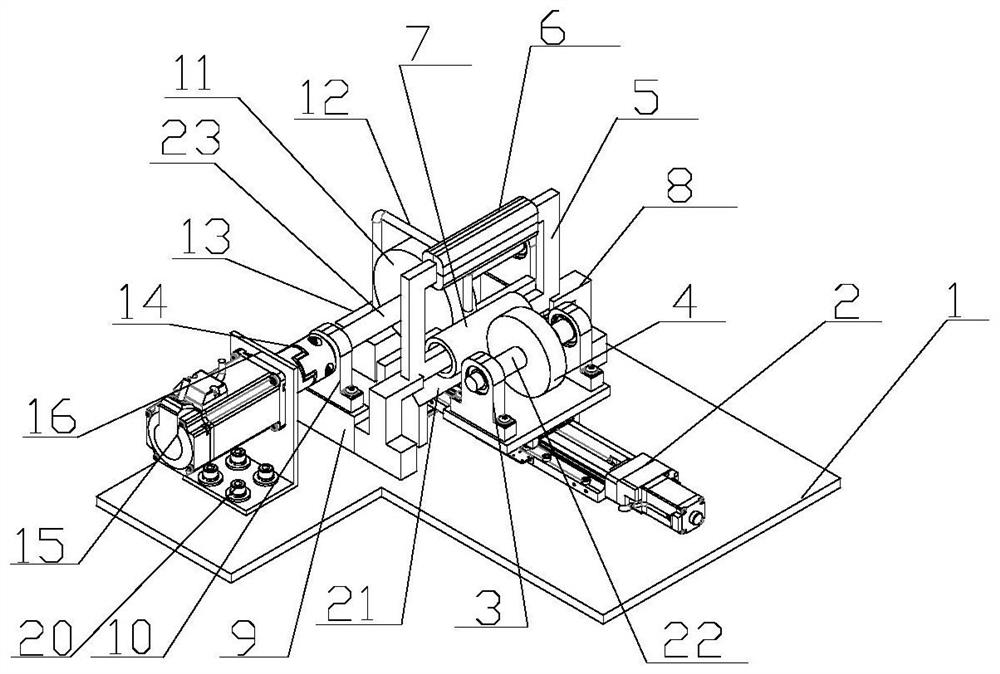

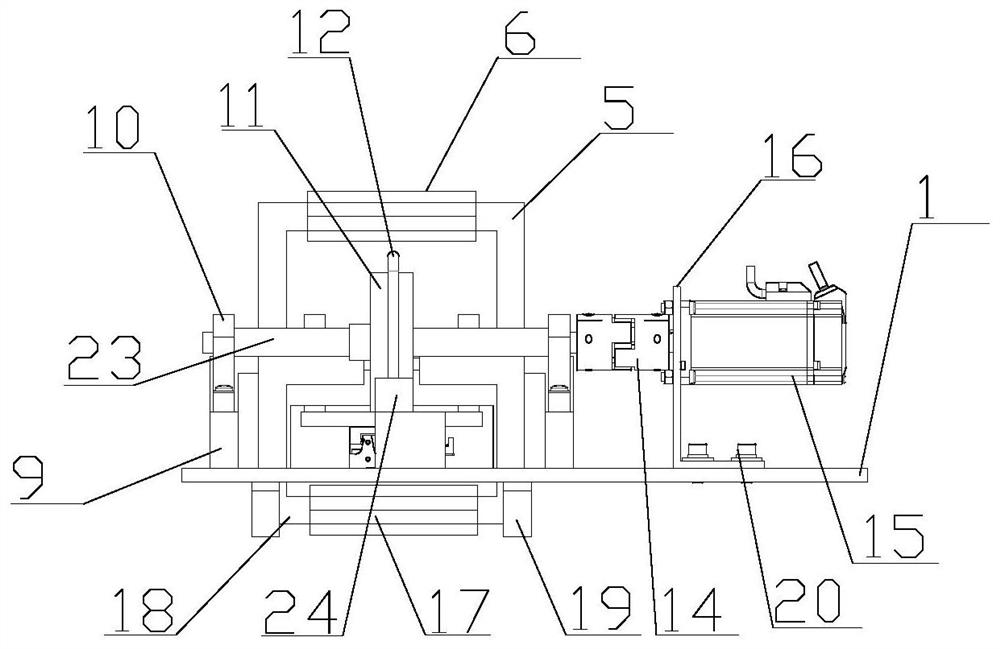

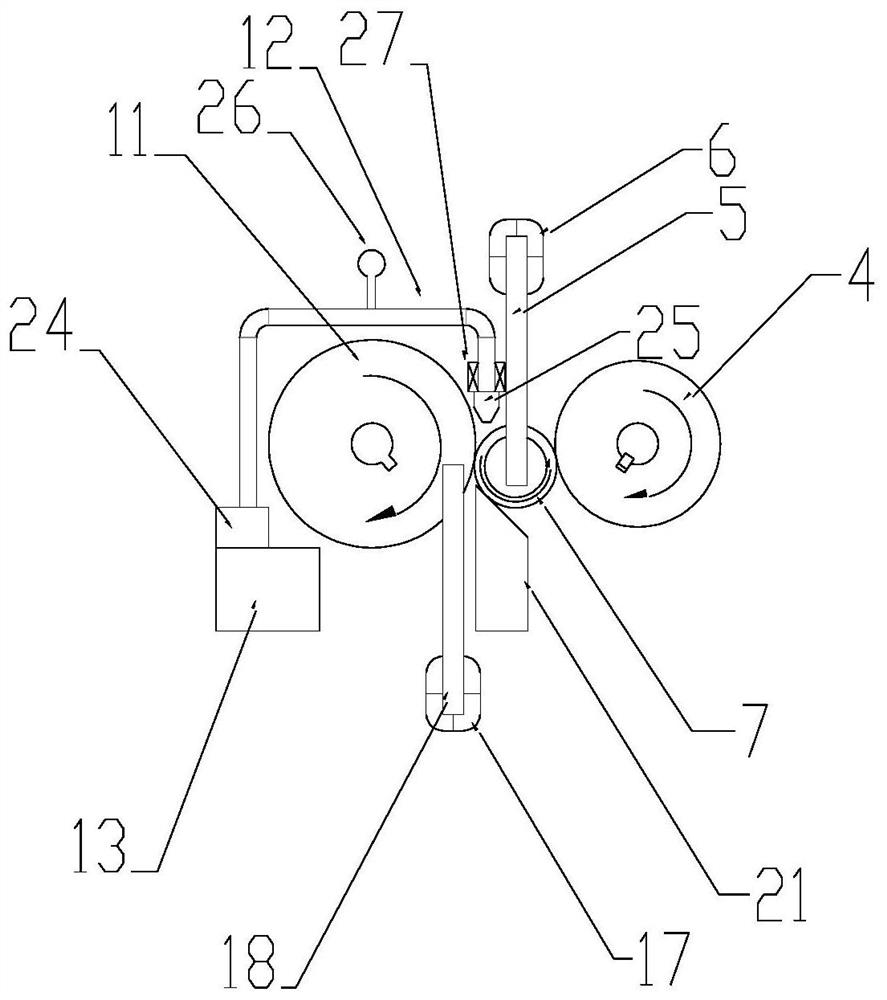

Polishing device and method for variable-stiffness grinding wheel assisted by magneto-rheological jet flow

PendingCN113084609AReduce heatControl removal rateRevolution surface grinding machinesGrinding/polishing safety devicesLiquid jetElastomer

The invention relates to the technical field of ultra-precision machining, in particular to a polishing device and method for a variable-stiffness grinding wheel assisted by magneto-rheological jet flow. The polishing device comprises a bottom plate, a sliding guide rail module, a first bearing seat, a guide wheel, a first iron core, a first coil, a workpiece, an iron core support, a second bearing seat base, a second bearing seat, a magneto-rheological elastomer grinding wheel embedded with abrasive particles, a guide pipe, a magneto-rheological polishing solution storage box, a coupler, a motor, a motor support, a second coil, a second iron core, a base, a bolt, a workpiece support, a first shaft, a second shaft, a pump, a nozzle, a pressure sensor and a third coil. Mechanical polishing and magneto-rheological polishing liquid jet flow polishing for controlling the rigidity of the magneto-rheological elastomer grinding wheel embedded with the abrasive particles through the magnetic field are carried out at the same time, and good surface machining quality and machining efficiency are achieved.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of stainless steel polishing agent and preparation method and application thereof

The invention relates to the technical field of materials, and specifically discloses a stainless steel polishing agent and a preparation method thereof. A kind of stainless steel polishing agent, by weight, its preparation raw material comprises at least, abrasive material 8-15 parts, corrosive acid 10-18 parts, oxidizing agent 1-4 parts, lubricant 3-6 parts, surfactant 2-5 parts , 45‑60 parts of water. Compared with the traditional polishing process, the polishing time can be greatly shortened. In addition, the polishing liquid prepared by the invention not only has a high polishing removal rate, but also can make the stainless steel material higher in quality and smoother. The preparation method of the polishing liquid is simple, the cost is low, the polishing process is easy to control, the productivity is high, the product quality is stable, and the invention has great development potential.

Owner:新华手术器械有限公司

Preparation and use of cerium oxide / silicon oxide compound abrasive

ActiveCN101475791BGood monodispersityIncrease the absolute value of zeta potentialOther chemical processesHexamethylenetetramineGallium arsenate

Owner:溧阳常大技术转移中心有限公司

A kind of preparation method of silicon-aluminum composite polishing powder

ActiveCN111073518BHigh polishing removal rateImprove polishing rateOther chemical processesPolishing compositions with abrasivesSilicic acidAluminum ammonium sulfate

Owner:湖南景翌湘台环保高新技术开发有限公司 +1

Polishing composition

ActiveUS20220017782A1High polishing removal rateImprove surface qualityOther chemical processesSemiconductor/solid-state device manufacturingPhysical chemistryHigh surface

Owner:FUJIMI INCORPORATED

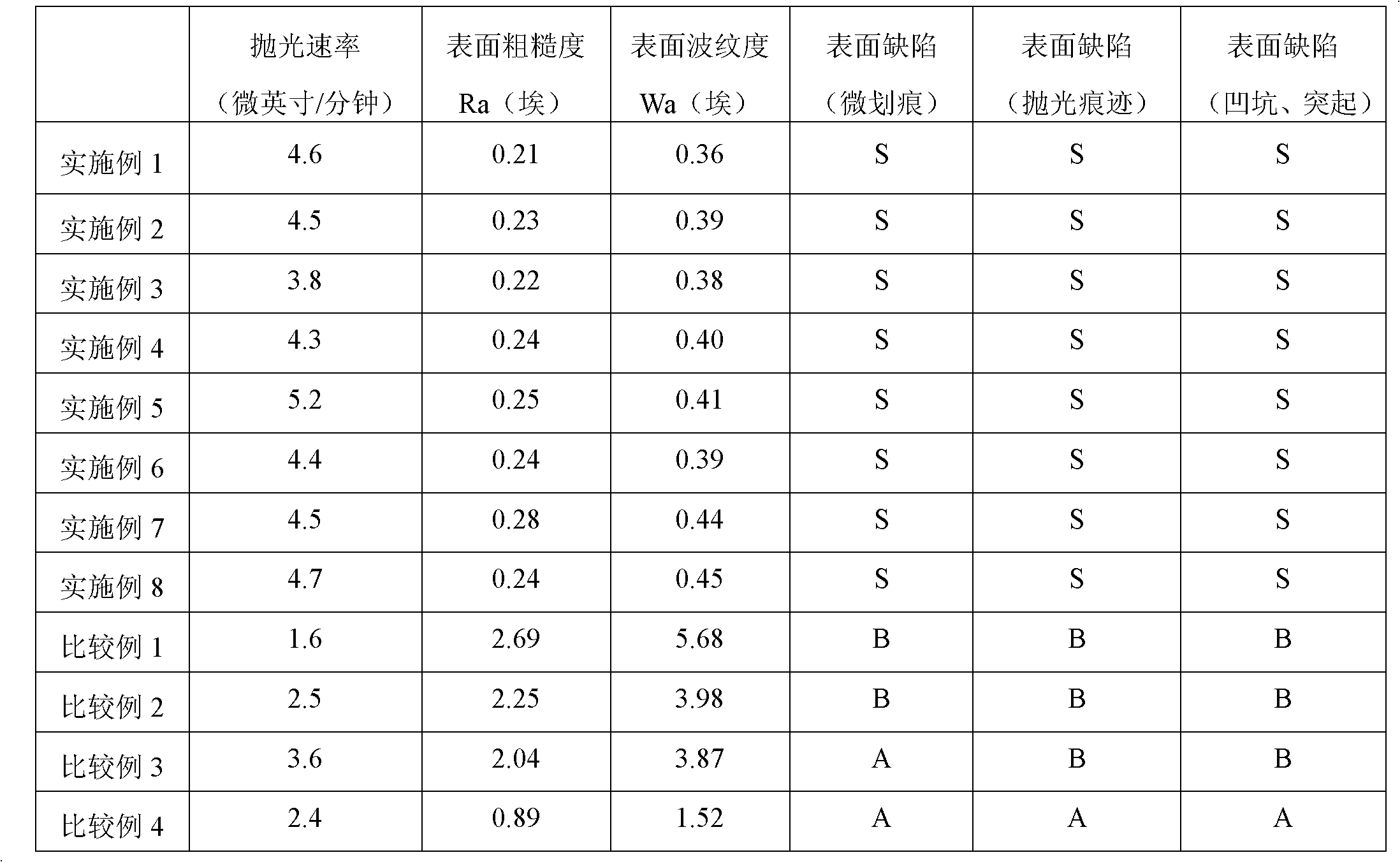

Polishing composition for ultra-precision surface manufacture of hard disk substrate

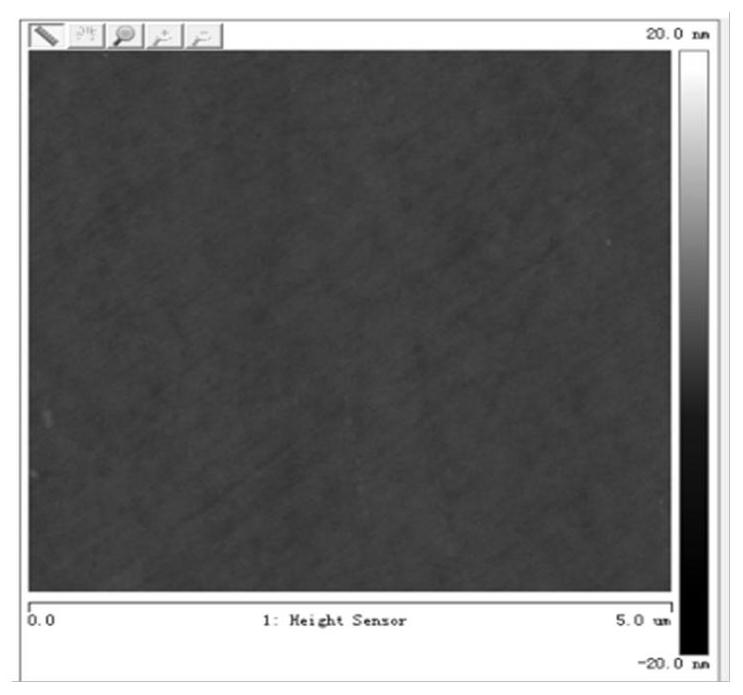

InactiveCN102358824BEliminate surface micro-scratchesEliminate polishing marksPolishing machinesOther chemical processesAlloy substrateMetallic Nickel

The invention discloses a polishing composition for ultra-precision surface manufacture of a hard disk substrate, and belongs to the technical field of computer memory hard disk manufacture. The polishing composition comprises an abrasive, one or more corrosive agents, one or more oxidizing agents and water. The polishing composition is characterized in that the polishing composition also comprises one or more stabilizing agents, one or more polishing promoters and one or more polishing poising agents; the polishing promoters are inorganic salts; and the polishing poising agents are organic acidic salts. The polishing composition provided by the invention is mainly suitable for ultra-precision polishing in hard disk substrate manufacture, and has the characteristic of a high polishing removal rate. A hard disk substrate treated by the polishing composition has a smooth surface, does not have the defect of pit and protrusion formation, and has surface roughness below 0.3 angstroms and surface waviness below 0.5 angstroms. The polishing composition can effectively eliminate micro-defect such as surface micro-scratch, polishing traces and the like. The polishing composition is suitable for ultra-precision surface manufacture of a nickel and phosphor plated aluminum alloy substrate, a glass substrate and the like of a hard disk.

Owner:TSINGHUA UNIV +2

A kind of water-soluble polymer coated special-shaped silica sol, preparation method and application

ActiveCN106590530BReduce roughnessRoughness Ra reducedOther chemical processesPolishing compositions with abrasivesPolyacrylamideMaterials science

The invention relates to water-soluble polymer coated special-shaped silica sol, a preparation method and an application. The special-shaped silica sol is prepared from raw materials in percentage by weight as follows: 0.01wt%-1wt% of polyalcohol with molecular weight of 200-20,000, 0.01wt%-5wt% of water-soluble polymers with molecular weight of 10,000-500,000, 5wt%-50wt% of a silica sol raw material and the balance of deionized water. A physical structure of the special-shaped silica sol is irregularly special-shaped and is formed by the water-soluble polymers through coating. According to a polishing solution prepared from the silica sol, a protective film can be formed on the surface of a chip through addition of the water-soluble polymers including polyacrylamide, sodium polyacrylate and polyacrylic acid, microdefects of the surface of the chip in a polishing process are effectively reduced, so that the surface roughness of the chip is obviously reduced, and a relatively high polishing removal rate can be guaranteed.

Owner:HEBEI UNIV OF TECH

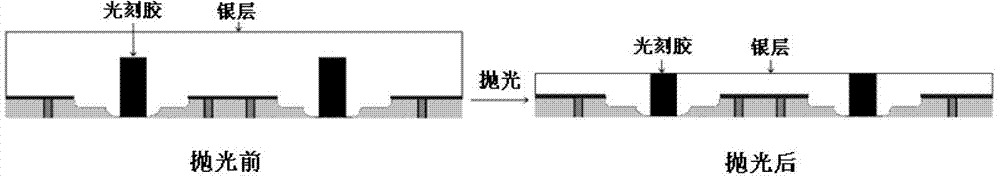

Aqueous chemical mechanical polishing composition and use thereof

ActiveCN103194148BEasy to prepareStrong applicabilitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesIntegrated circuitEnvironmental chemistry

The invention discloses a chemical-mechanical polishing aqueous composition and a chemical-mechanical polishing process method of an integrated circuit silver interconnecting sliver layer, wherein the chemical-mechanical polishing aqueous composition comprises the following components in percentage by weight: 1%-20%, preferably 4%-8% of abrasive materials, 0.1%-10%, preferably 0.5%-5% of complexing agent, and 0.1%-10%, preferably 1%-3% of lubricating agent, wherein the pH value of the chemical-mechanical polishing aqueous composition is 8.0-11.0, preferably 9.5-10.5. The chemical-mechanical polishing aqueous composition can be effectively applied to the chemical-mechanical polishing process of the integrated circuit silver interconnecting sliver layer and can be used for effectively realizing high-flatness high-speed initial polishing and optimizing the low-speed final polishing of surface crudeness, so that a nanometer-level polishing sliver layer surface with extremely low surface defects can be obtained.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com