Preparation method of silicon-aluminum composite polishing powder

A composite polishing, silicon-aluminum composite technology, applied in polishing compositions containing abrasives, etc., can solve the problems of increasing processing costs and reducing production yield, and achieves guaranteed yield, excellent properties, and good reproducibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

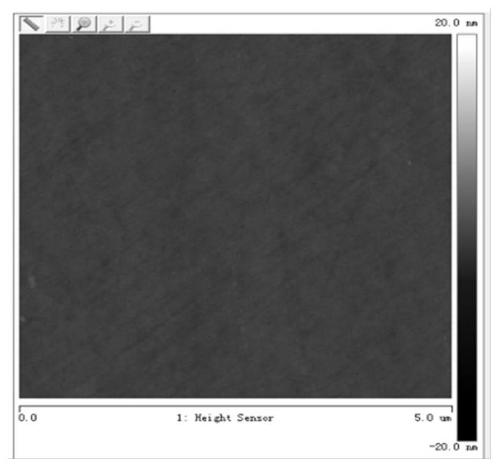

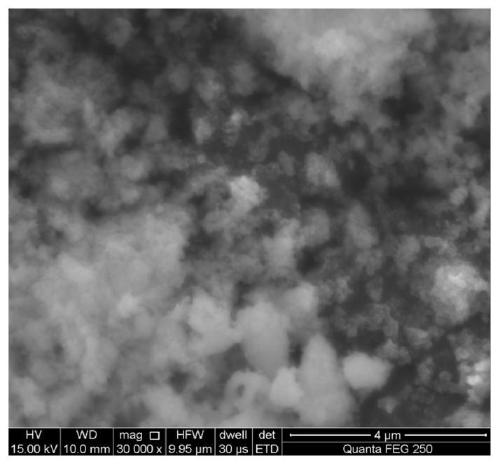

Image

Examples

Embodiment 1

[0031] A preparation method of silicon-aluminum composite polishing powder, comprising the following steps:

[0032] (1) Take 1000 parts of 2.0mol / L ammonium bicarbonate and add 1 part of polyethylene glycol (molecular weight 2000) and 50 parts of ammonium hydroxide as a mother liquor and put them into a round bottom flask, then add 2000 parts of 0.2mol / L aluminum sulfate The ammonium solution was added dropwise at a speed of 20 parts / min while stirring at a high speed, keeping the reaction temperature at 60°C, and aging for 6 hours after the dropwise addition was completed to obtain an alumina precursor solution;

[0033] (2) Take another 30 parts of tetraethyl orthosilicate solution and drop it into a round bottom flask at a speed of 1 part / min while stirring at high speed, keep the reaction temperature at 30°C, and wait for 6 hours after the dropwise addition to obtain aging liquid;

[0034] (3) After the aging liquid is filtered by suction, the filter residue is washed wi...

Embodiment 2

[0040] A preparation method of silicon-aluminum composite polishing powder, comprising the following steps:

[0041] (1) Take 1000 parts of 2.0mol / L ammonium bicarbonate, add 5 parts of sodium hexametaphosphate and 30 parts of ethanolamine as a mother liquor and put it into a round bottom flask, then put 2000 parts of 0.2mol / L ammonium aluminum sulfate solution at 20 parts / The speed of min is dropped while stirring at a high speed, keeping the reaction temperature at 60°C, and aging for 6 hours after the dropwise addition is completed to obtain the alumina precursor solution;

[0042](2) Take another 30 parts of tetraethyl orthosilicate solution and drop it into a round bottom flask at a speed of 1 part / min while stirring at high speed, keep the reaction temperature at 30°C, and wait for 6 hours after the dropwise addition to obtain aging liquid;

[0043] (3) After the aging liquid is filtered by suction, the filter residue is washed with ultrapure water or distilled water, ...

Embodiment 3

[0047] A preparation method of silicon-aluminum composite polishing powder, comprising the following steps:

[0048] (1) Take 1000 parts of 2.0mol / L ammonium bicarbonate and add 1 part of polyethylene glycol (molecular weight 2000) and 50 parts of ammonium hydroxide as a mother liquor and put them into a round bottom flask, then add 2000 parts of 0.2mol / L aluminum sulfate The ammonium solution was added dropwise at a speed of 20 parts / min while stirring at a high speed, keeping the reaction temperature at 60°C, and aging for 6 hours after the dropwise addition was completed to obtain an alumina precursor solution;

[0049] (2) Take another 30 parts of tetraethyl orthosilicate solution and drop it into a round bottom flask at a speed of 1 part / min while stirring at high speed, keep the reaction temperature at 30°C, and wait for 6 hours after the dropwise addition to obtain aging liquid;

[0050] (3) After the aging liquid is filtered by suction, the filter residue is washed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com