Polishing composition for ultra-precision surface manufacture of hard disk substrate

A polishing composition and ultra-precise technology, which are applied to polishing compositions containing abrasives, machine tools for surface polishing, manufacturing tools, etc. The surface quality is not obvious enough to achieve the effect of eliminating surface micro-scratch, reducing surface micro-defect and high polishing removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

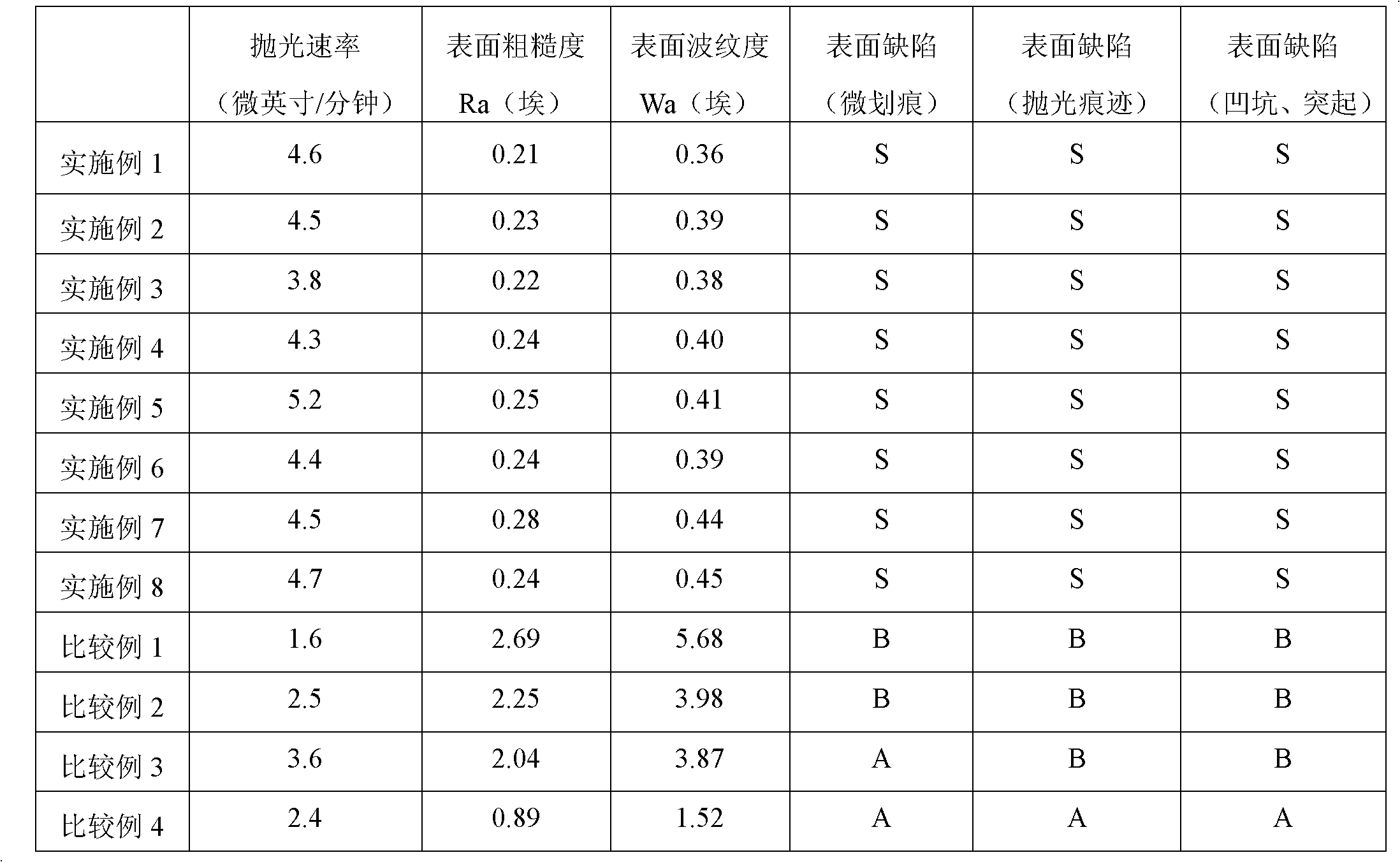

Examples

Embodiment 1

[0024] A kind of polishing composition that is used for the manufacture of the ultra-precision surface of the hard disk disc substrate, by weight percentage, the corrosive agent sulfuric acid is 2wt%, the oxidant hydrogen peroxide is 2wt%, the polishing accelerator potassium sulfate is 0.5wt%, the polishing balancer 0.5 wt% tetrasodium 2-phosphonic acid butane-1,2,4-tricarboxylate, 1 wt% stabilizer succinic acid, 5 wt% abrasive silicon oxide (average particle size 20nm), and the rest is water.

[0025] Under the condition of mechanical stirring, add corrosive agent, oxidant, polishing accelerator, polishing balancer, and stabilizer into deionized water according to the above ratio, mix thoroughly, then add abrasive, stir and mix evenly, and prepare a polishing composition, the pH of which is 1.59.

[0026] The prepared polishing composition is used for the polishing of the hard disk substrate, and the polishing conditions are as follows:

Embodiment 2

[0055] A kind of polishing composition that is used for the manufacture of ultra-precision surface of hard disk disc substrate, by weight percent, corrosive agent phosphoric acid is 2.5wt%, oxidant hydrogen peroxide is 1.5wt%, polishing accelerator dipotassium hydrogen phosphate is 1wt%, The polishing balancer sodium citrate is 1wt%, the stabilizer lactic acid is 0.5wt%, the abrasive silica (average particle size is 20nm) is 5wt%, and the rest is water.

[0056] Under the condition of mechanical stirring, add corrosive agent, oxidant, polishing accelerator, polishing balancer, and stabilizer into deionized water according to the above ratio, mix thoroughly, then add abrasive, stir and mix evenly, and prepare a polishing composition, the pH of which is 1.74.

Embodiment 3

[0058] A polishing composition used for the manufacture of ultra-precision surfaces of hard disk substrates, in terms of weight percent, the corrosive agent hydrochloric acid is 1wt%, the oxidizing agent hydrogen peroxide is 0.5wt%, the polishing accelerator potassium chloride is 0.5wt%, and the polishing The balancing agent tetrasodium aminotrimethylene phosphonate is 1wt%, potassium citrate is 0.1wt%, the stabilizer salicylic acid is 3wt%, the abrasive silica (average particle size is 20nm) is 5wt%, and the rest is water.

[0059] Under the condition of mechanical stirring, add corrosive agent, oxidant, polishing accelerator, polishing balancer, and stabilizer into deionized water according to the above ratio, mix thoroughly, then add abrasive, stir and mix evenly, and prepare a polishing composition, the pH of which is 1.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com