Aqueous chemical mechanical polishing composition and use thereof

A water-based composition, chemical mechanical technology, applied in the direction of polishing composition containing abrasives, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems that need to be improved, reduce the generation of volatilization and irritating odor, improve Polishing environment, strong applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Influence of oxidizing agent type on polishing effect in the initial polishing process of embodiment 1

[0044] With reference to the aforementioned general method, according to the conditions described in the following experimental groups and control groups, carry out the initial polishing experiment of the silver layer of integrated circuit silver interconnection respectively, and then compare the polishing effects of each group:

[0045] 1. Grouping and processing methods

[0046] Experimental group 1:

[0047] Add 5 grams of ethanolamine, 5 grams of ammonia water, 10 grams of glycerol and 10 grams of lactic acid into 700 grams of deionized water in sequence, stir to dissolve, and after uniformity, slowly stir and add 200 grams of 30% 15nm silica hydrosol.

[0048] Before polishing, add 16.7 grams of 30% oxidant hydrogen peroxide solution to the above mixture, and use KOH to calibrate the pH value to 10.5, and finally add water to make up 1000 grams and stir evenl...

Embodiment 2

[0064]Influence of complexing agent kind on initial / finish polishing effect in the polishing composition of embodiment 2

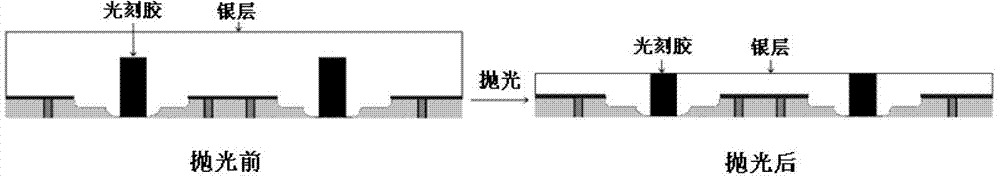

[0065] With reference to the aforementioned general method, according to the conditions described in the following experimental group and control group, carry out the initial / final polishing experiment of the silver layer of integrated circuit silver interconnection respectively, then compare the polishing effect of each group, wherein, first adopt the initial polishing liquid to The silver layer of integrated circuit silver interconnection is polished at a high rate. After removing most of the silver layer until the photoresist is slightly exposed, the final polishing solution is used for final polishing at a low rate until it reaches the figure 1 The effect shown. specifically:

[0066] 1. Grouping and processing methods

[0067] Experimental group 1:

[0068] Initial liquid preparation: add 5 grams of ethanolamine, 5 grams of ammonia water, 10 gram...

PUM

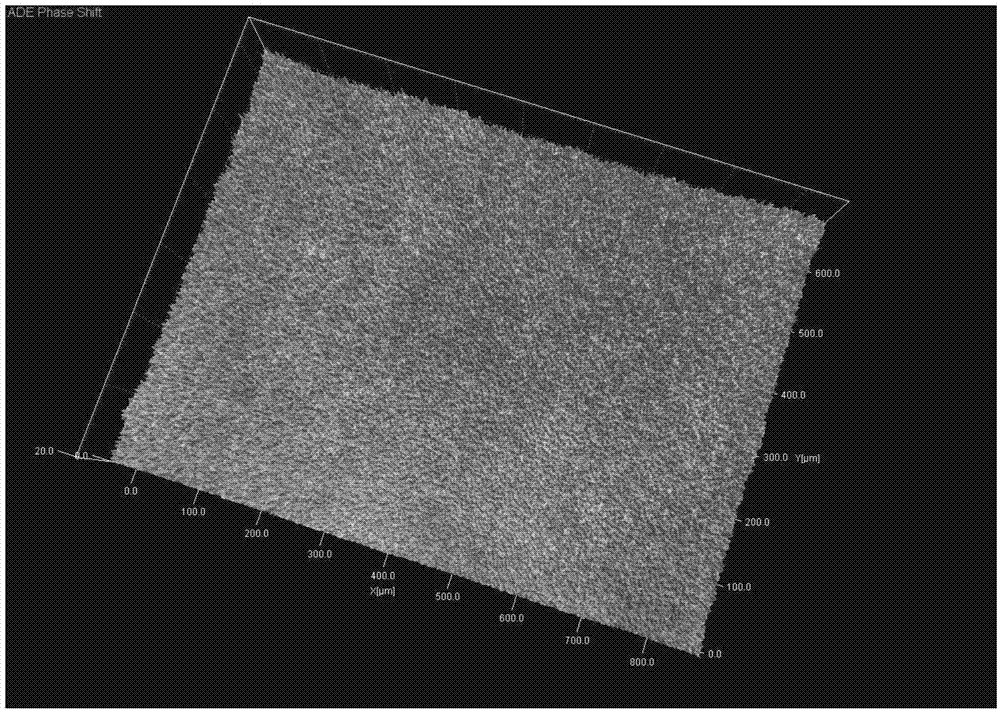

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com