Patents

Literature

260 results about "Aluminum ammonium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

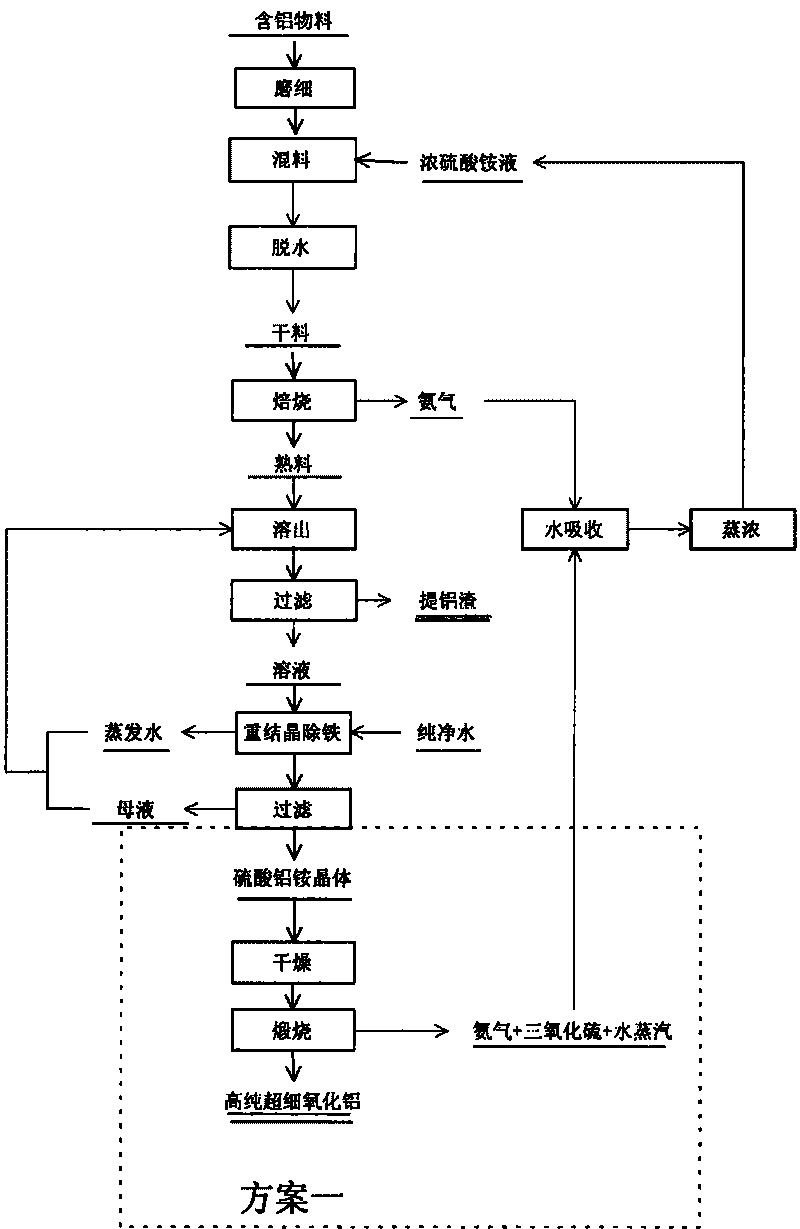

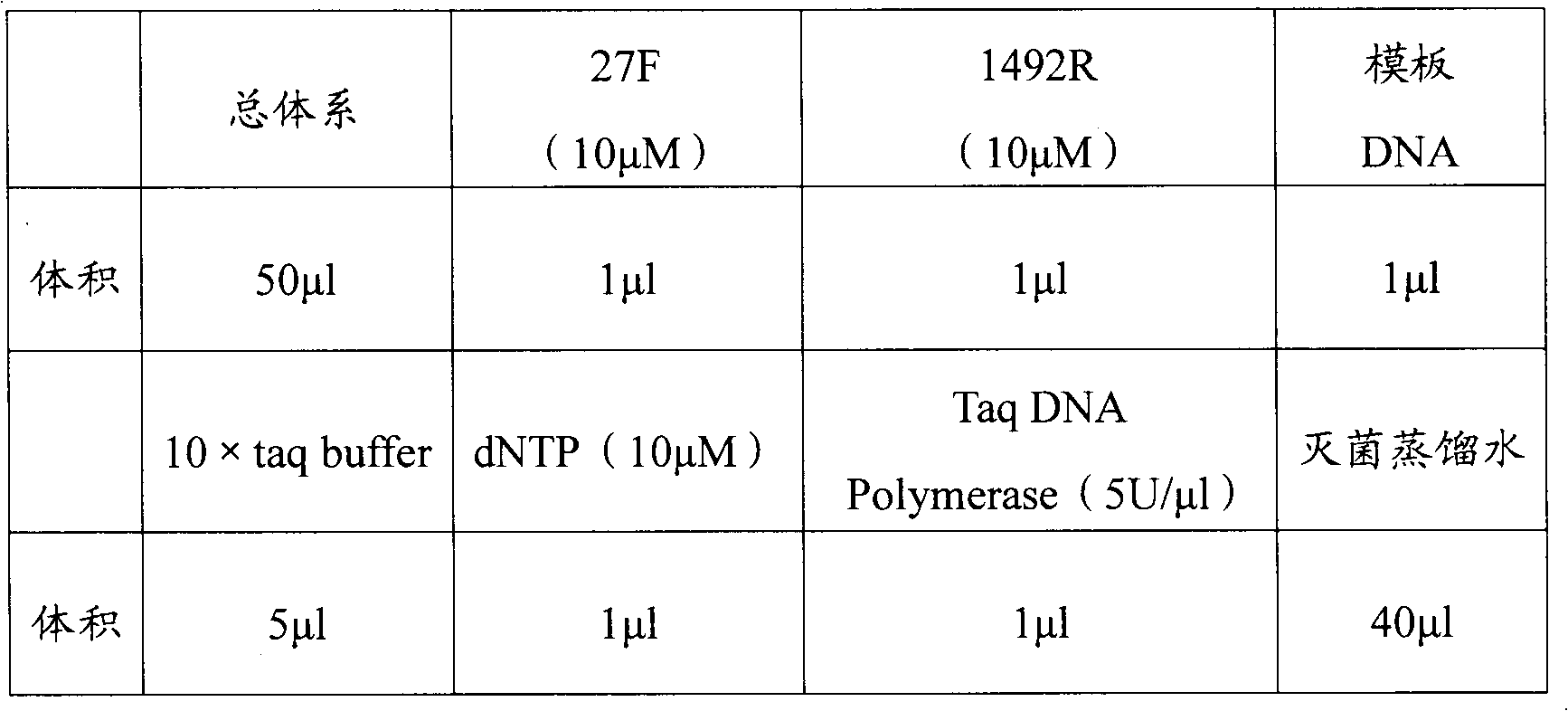

Method for preparing aluminum oxide from aluminiferous material

InactiveCN101734698AHigh value-added comprehensive utilizationCause secondary pollutionAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum ammonium sulfateAlunite

The invention provides a method for preparing aluminum oxide and other products from aluminiferous materials such as bauxite, high iron bauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like. The method comprises the following steps: (1) crushing, grinding and mixing the aluminiferous materials with ammonium sulfate and then roasting; (2) dissolving the roasted product (clinker aggregate) in water, and filtering to obtain aluminum ammonium sulfate solution and filter residues; (3) carrying out deferrization, aluminum deposition or recrystallization on the aluminium ammonum sulfate solution with ammonia to prepare aluminum oxide, and meanwhile, recycling the ammonium sulfate; (4) preparing silicon dioxide from the filter residues, and taking the remaining residues containing ferrum as the raw material for ironmaking. The method is suitable for treating various aluminiferous materials, has the advantages of simple technical process, simple equipment, no emission of solid, liquid and gas wastes, and no secondary pollution, and realizes the high-added-value green complex utilization of the aluminiferous materials such as bauxite, high ironbauxite, alunite, kaoline, alumina, fly ash, coal gangue, aluminum ash, nepheline, clay and the like.

Owner:NORTHEASTERN UNIV

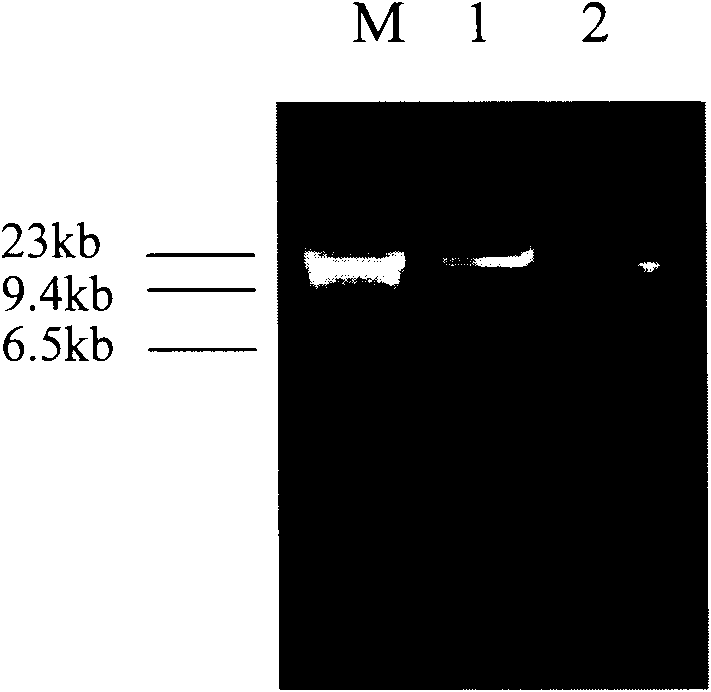

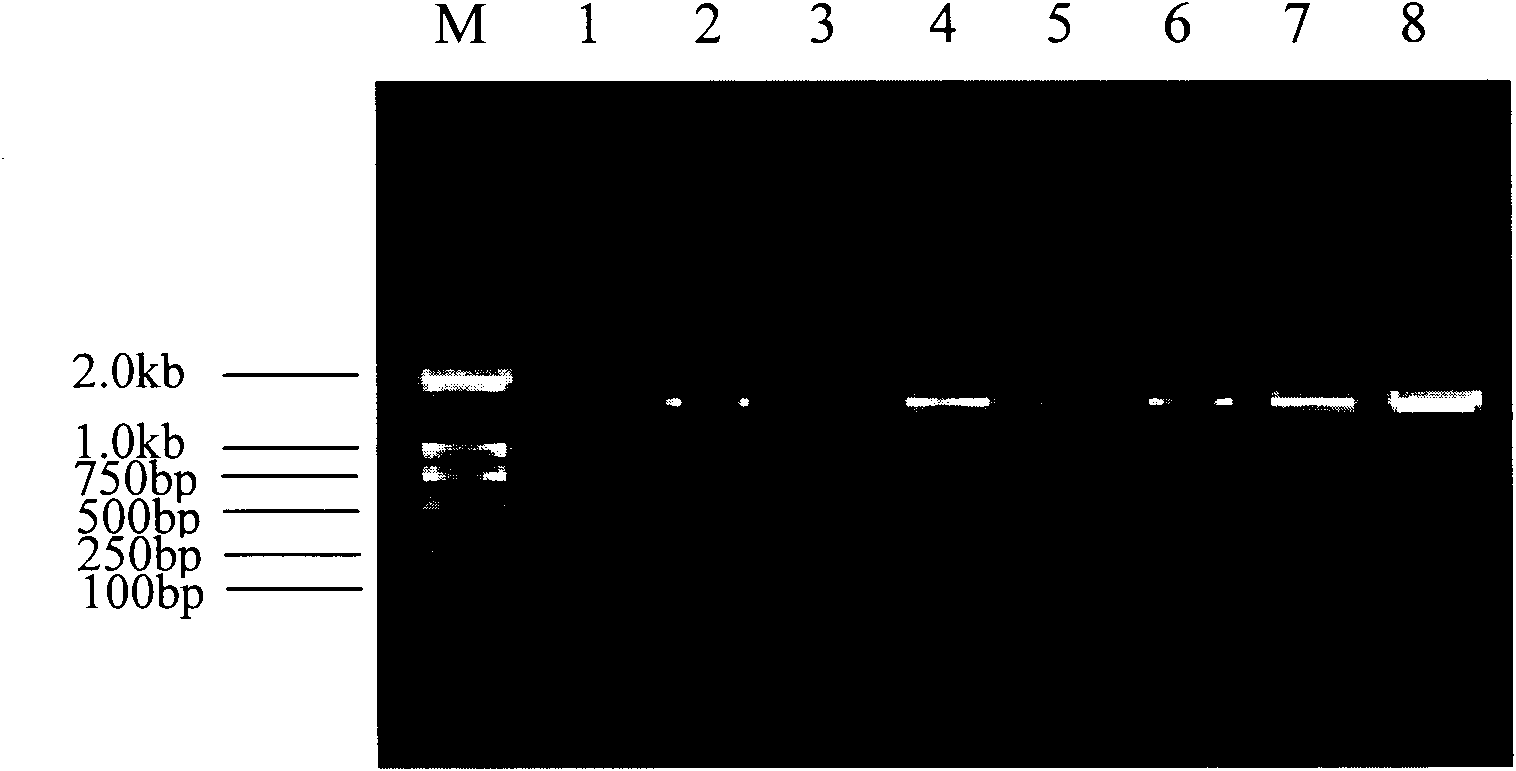

Kit and method for extracting microbial DNA

ActiveCN101935647AImprove bindingReduce adsorptionDNA preparationSodium acetateAluminum ammonium sulfate

The invention relates to the field of molecular biology and discloses a kit and a method for extracting microbial DNA. The kit comprises lysis solution, inhibitor removal solution and binding solution, wherein the lysis solution comprises 50 to 200mM of Tris-HCl, 50 to 150mM of EDTA, 0.5 to 3M of NaCl, 0.5 to 2 percent of CTAB, 0.5 to 2 percent of PVP and 0.5 to 2 percent of SDS; the inhibitor removal solution comprises 100 to 300mM potassium acetate, sodium acetate or ammonium acetate and 50 to 200mM aluminum sulfate, ammonium sulfate or aluminum ammonium sulfate; and the binding solution comprises 3 to 6M guanidine hydrochloride, 10 to 50mM Tris-HCl and 5 to 50 percent isopropanol. The kit and the method for extracting the microbial DNA have the advantages of high purity, high universality, high extraction speed, direct use for a downstream experiment, and application to extracting DNA from a microbe-containing sample.

Owner:中生方政生物技术股份有限公司

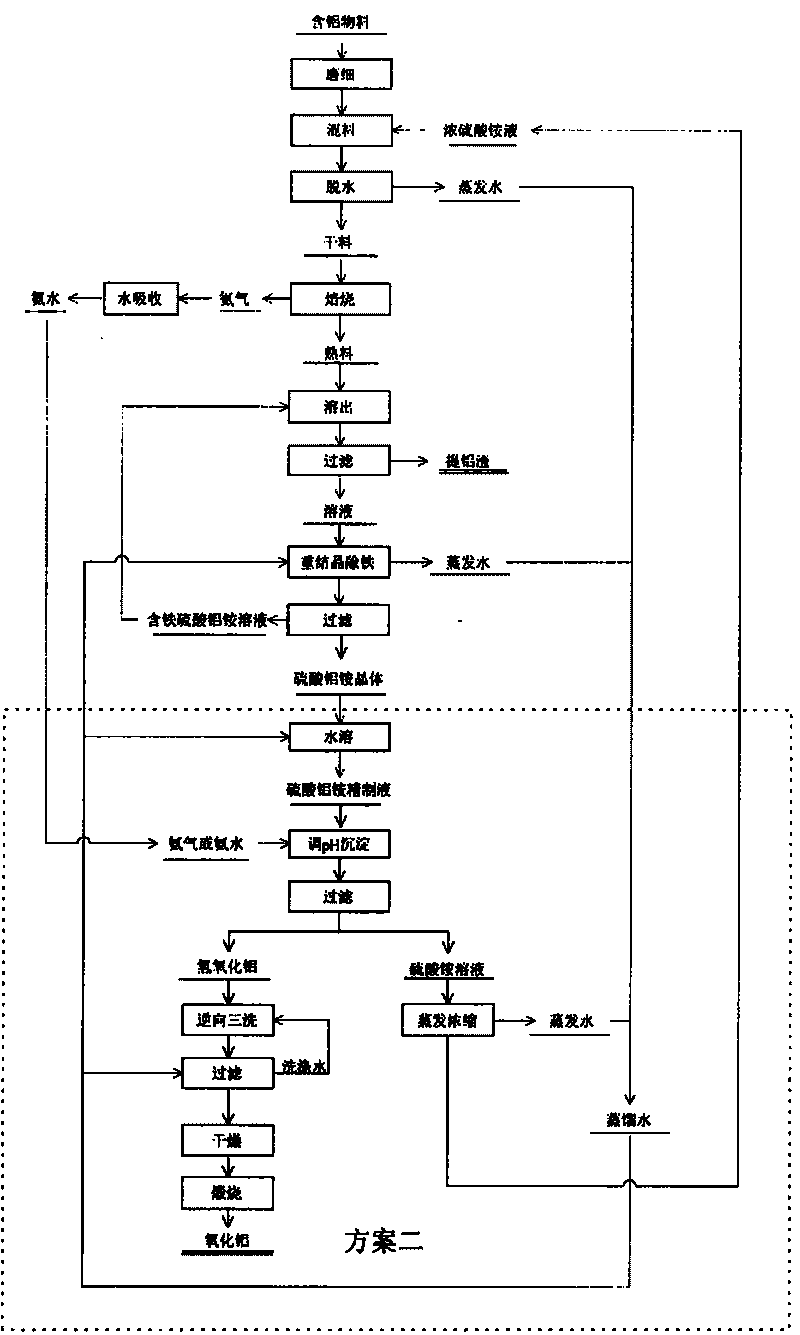

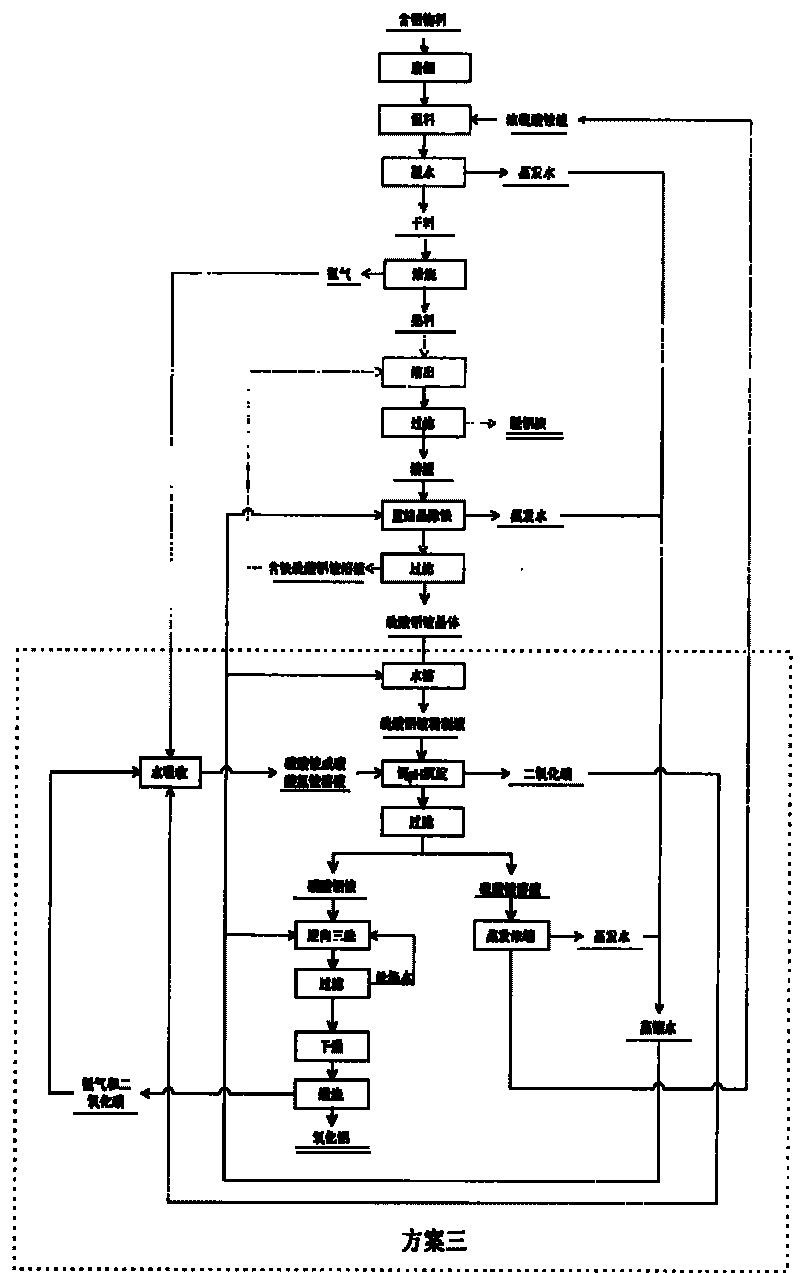

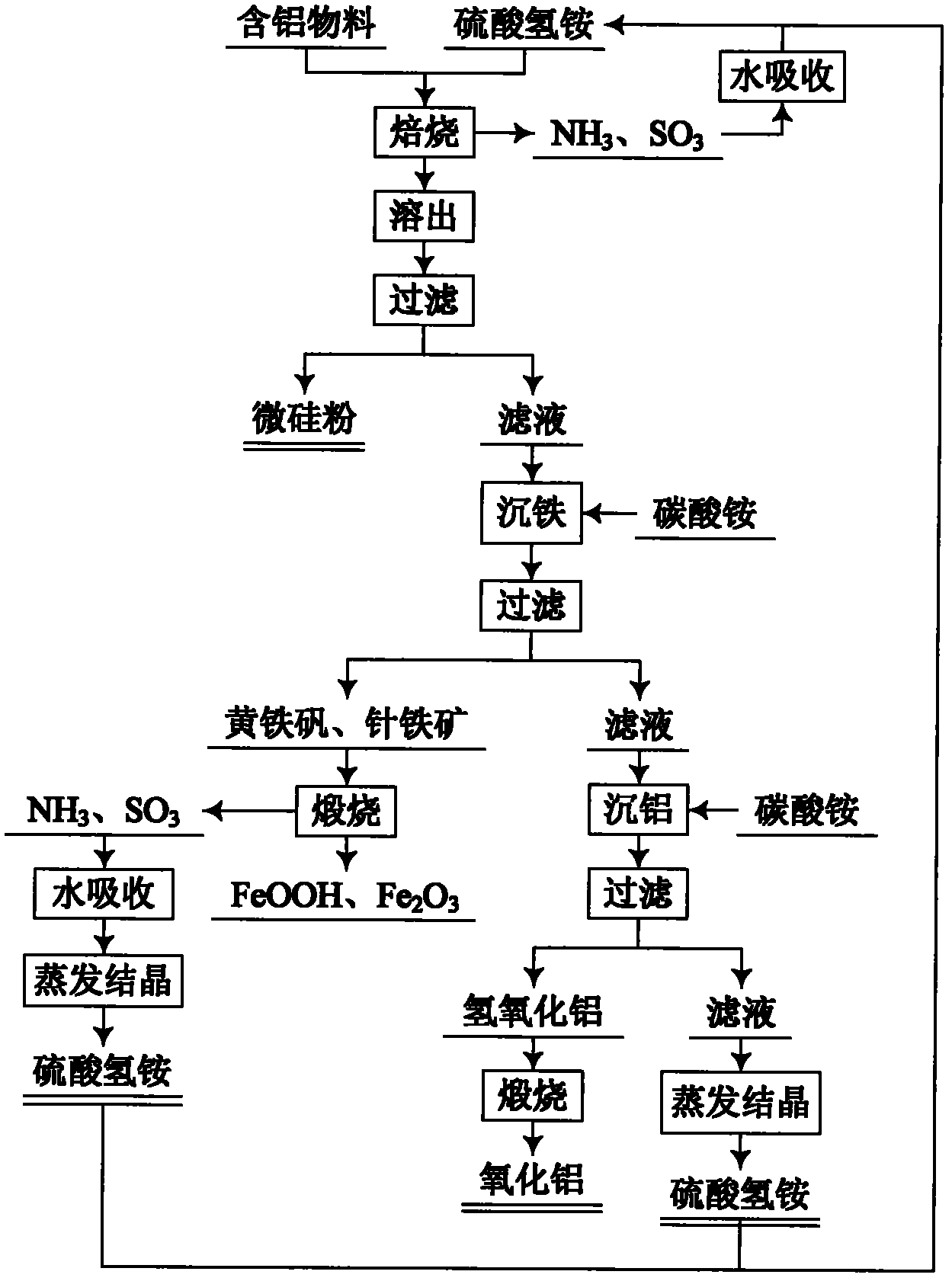

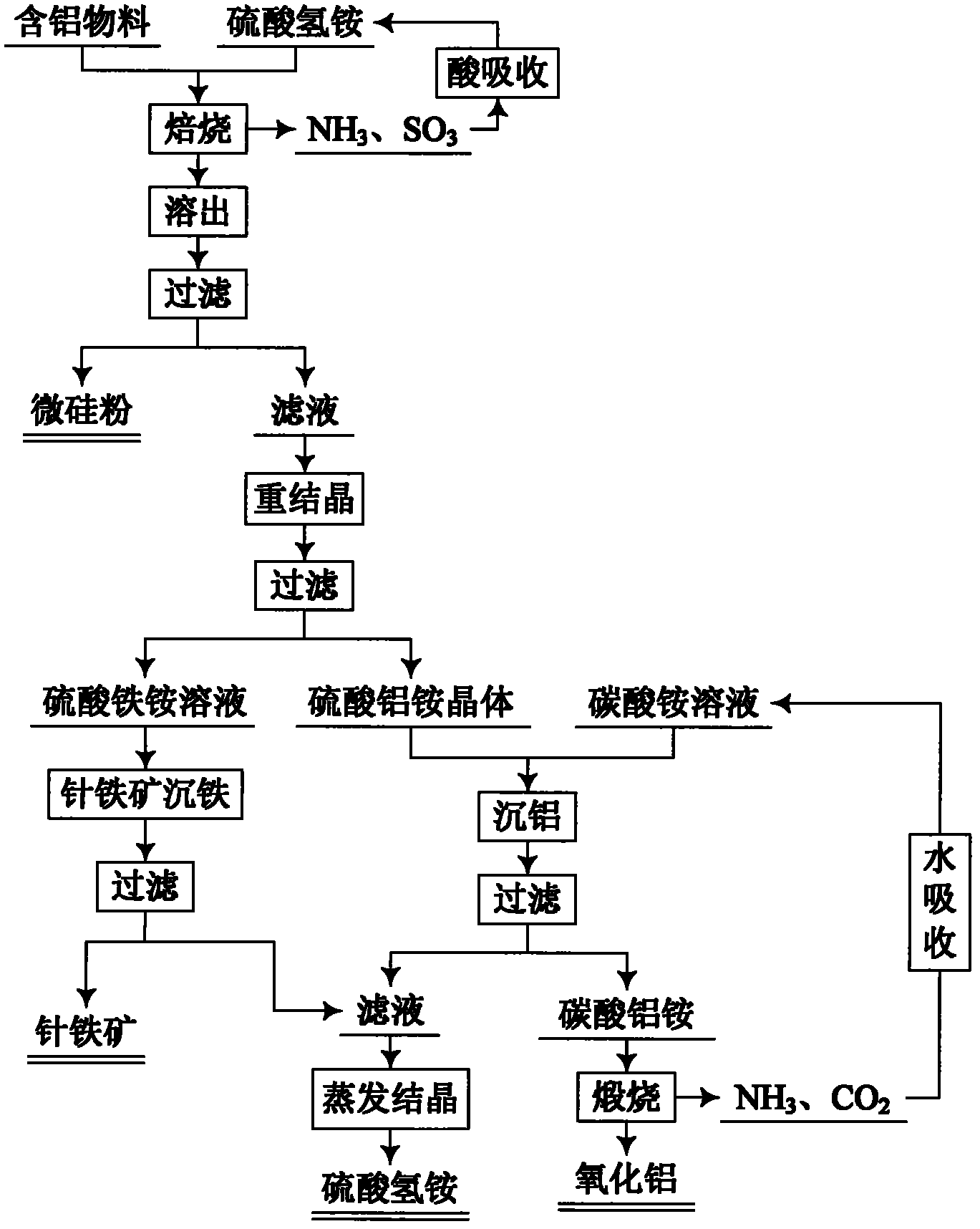

Method for comprehensive utilization of aluminum-containing material

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

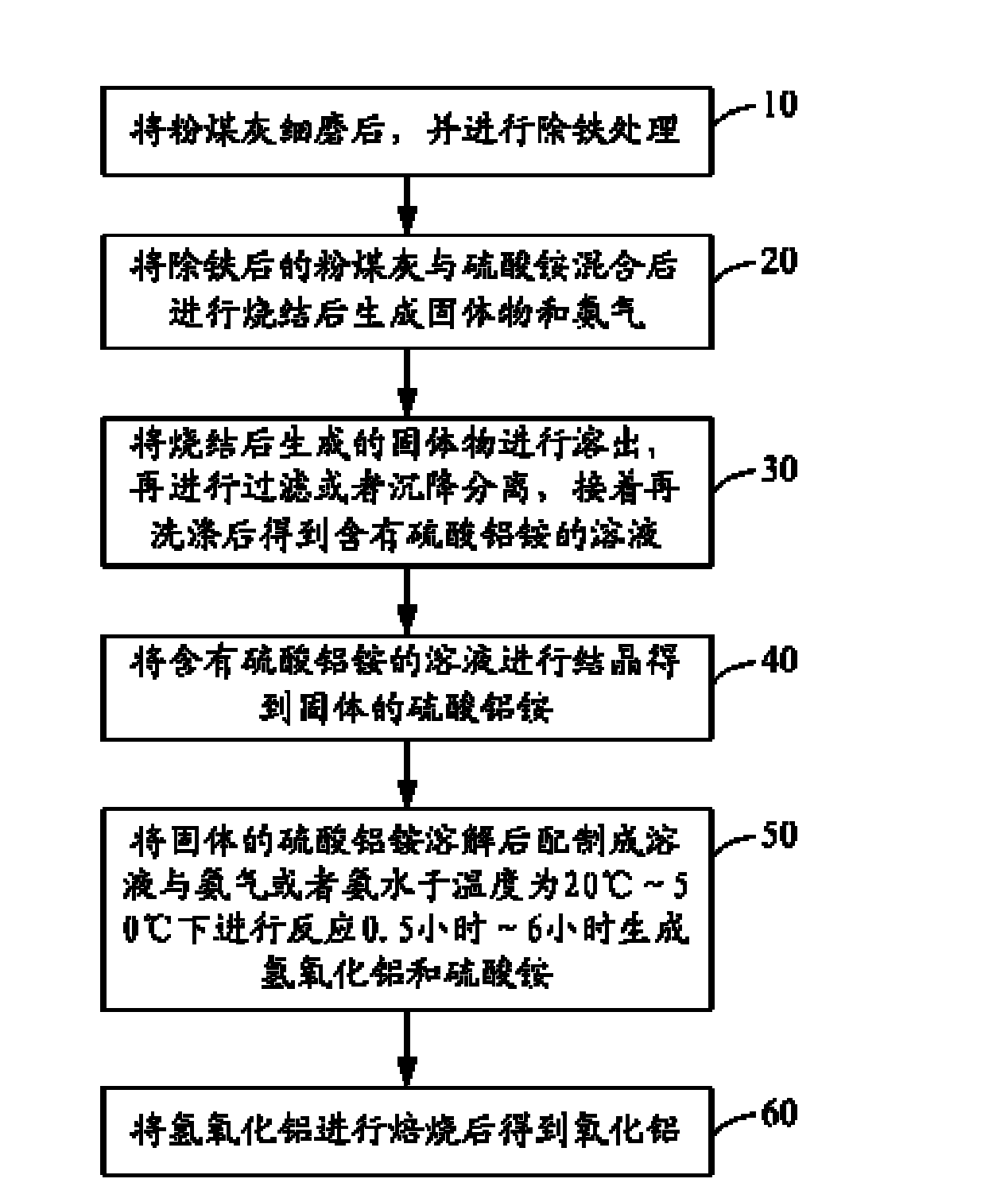

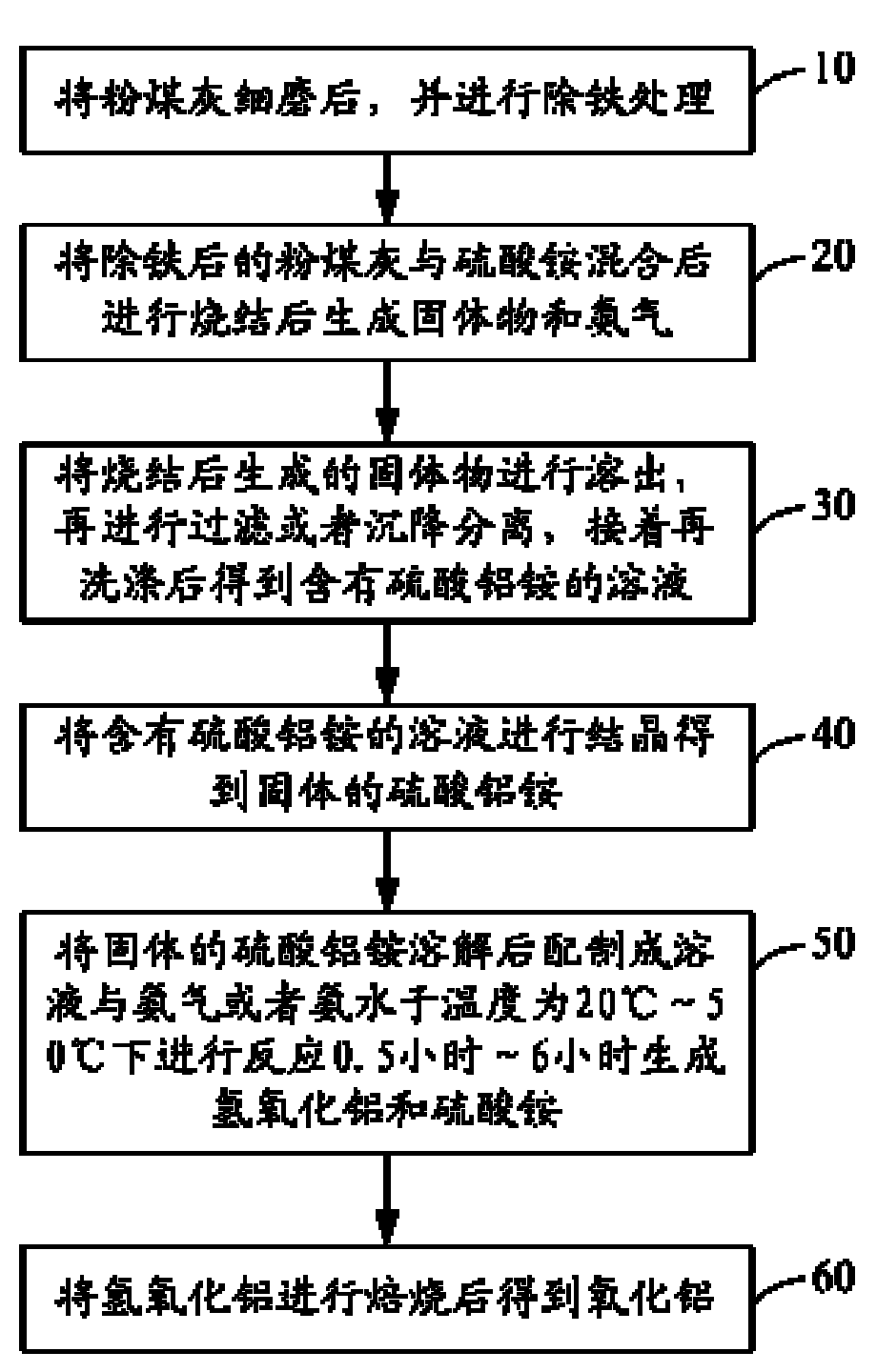

Method for extracting aluminum oxide from pulverized flue ash

ActiveCN102120593ALess corrosiveLess residueAluminium oxides/hydroxidesAluminium hydroxideAluminum ammonium sulfate

The invention relates to a method for extracting aluminum oxide from pulverized flue ash. The method comprises the following steps of: finely grinding the pulverized flue ash, and deironing; mixing the deironed pulverized flue ash and ammonium sulfate and then sintering to generate solid and ammonia gas; dissolving out the solid generated through sintering, then filtering or settling out, washing to obtain a solution containing aluminum ammonium sulfate; crystallizing the solution containing the aluminum ammonium sulfate to obtain solid aluminum ammonium sulfate; dissolving the solid aluminum ammonium sulfate, then preparing into a solution which reacts with the ammonia gas or ammonia water for 0.5-6h at a temperature of 20-50 DEG C to generate aluminum hydroxide and ammonium sulfate; roasting the aluminum hydroxide to obtain the aluminum oxide. The method for extracting the aluminum oxide from the pulverized flue ash is simple, ensures that less byproduct is produced and is easy to realize industrial application.

Owner:北京世纪地和控股有限公司

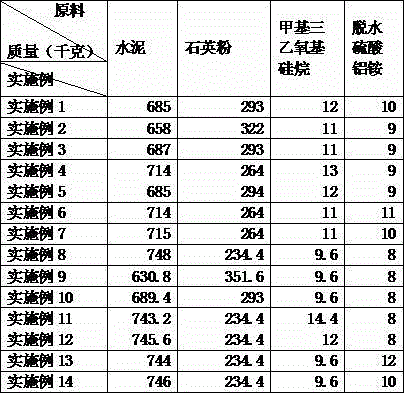

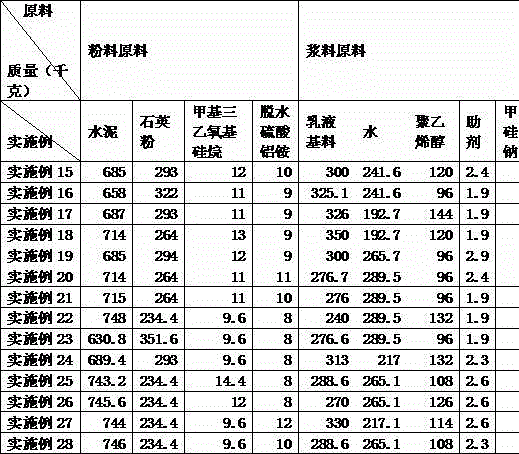

Cement-based capillary crystalline waterproof coating and preparation method thereof

The invention discloses a cement-based capillary crystalline waterproof coating. A preparation method of the cement-based capillary crystalline waterproof coating comprises the steps of taking 630.8-748 parts of cement, 234.4-351.6 parts of quartz powder, 9.6-14.4 parts of methyl triethoxysilane, 8-12 parts of dehydrated ammonium aluminum sulfate, 240-350 parts of an emulsion binder, 192.7-289.5 parts of water, 96-144 parts of polyvinyl alcohol, 1.9-2.9 parts of an assistant and 2.4-3.6 parts of sodium methyl silicate; mixing the cement, the quartz powder, methyl triethoxysilane and dehydrated ammonium aluminum sulfate and stirring to obtain a powder material; mixing the emulsion binder, water, polyvinyl alcohol, the assistant and sodium methyl silicate and stirring to obtain a slurry; and mixing the powder material, the slurry and water according to a mass ratio of 6-6.5:4-4.5:4-4.5, and thus a cement-based capillary crystalline waterproof coating capable of being used instantly is obtained. The cement-based capillary crystalline waterproof coating can form a cement crystalline layer on building cement, so that self-waterproof cement concrete can be obtained.

Owner:王福刚

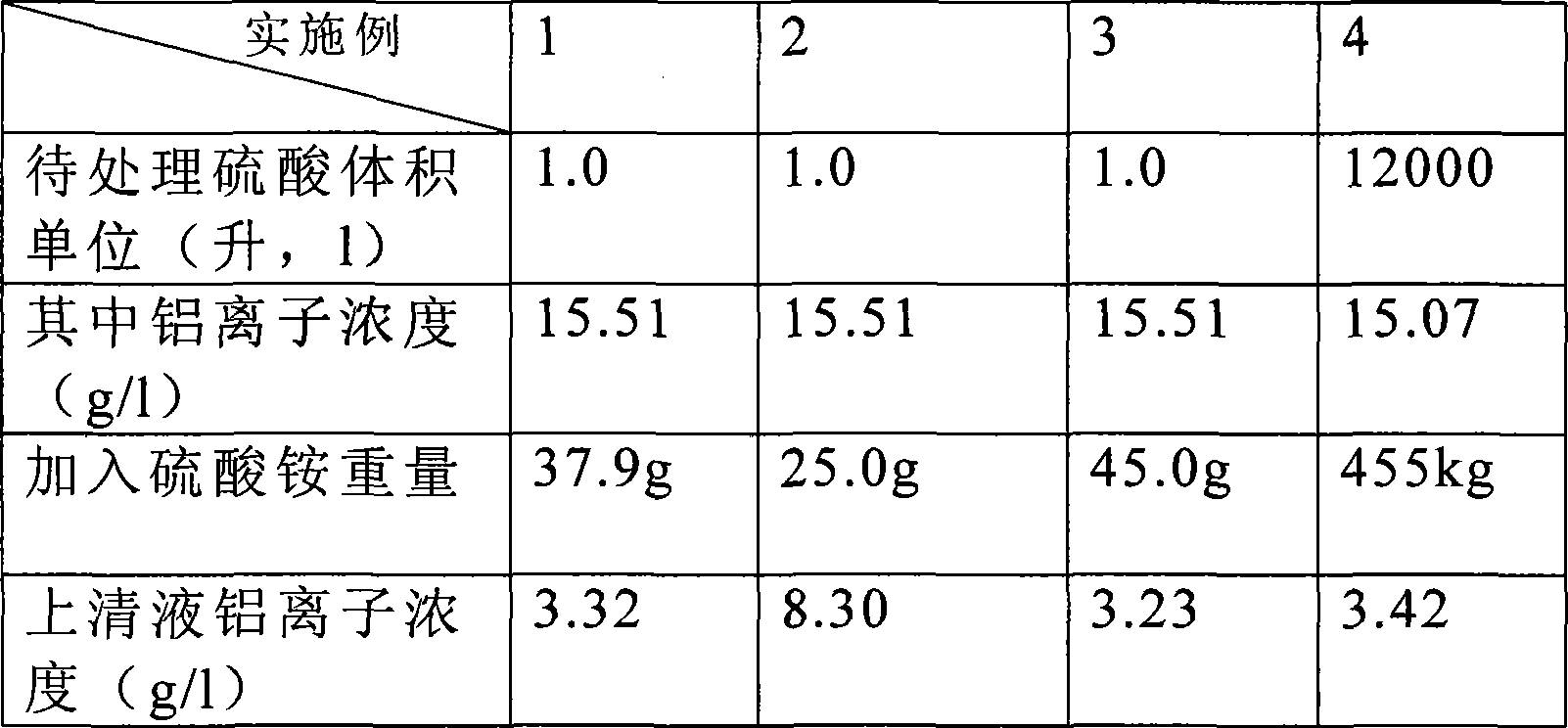

Method for reclaiming waste sulfuric acid in hard anode oxidation process

ActiveCN101186282BPromote precipitationReduce processing costsSulfur-trioxide/sulfuric-acidAluminium sulfateAfter treatment

Owner:ZHEJIANG SUPOR CO LTD

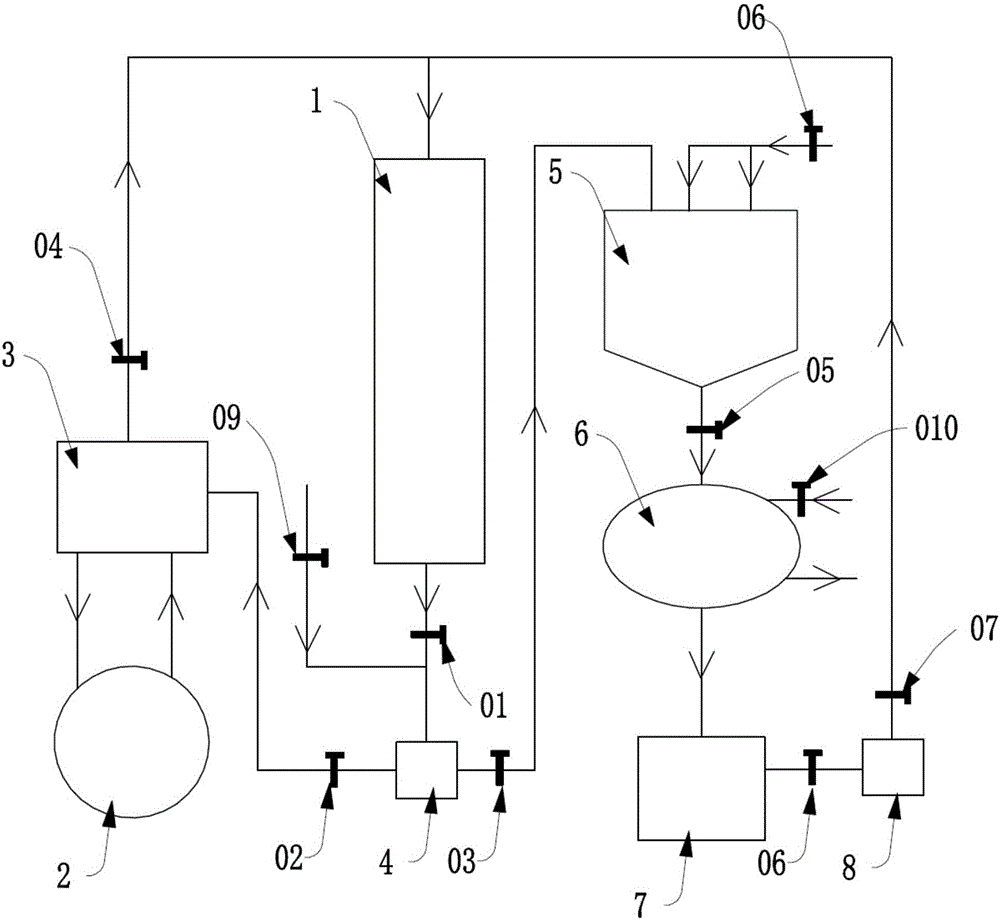

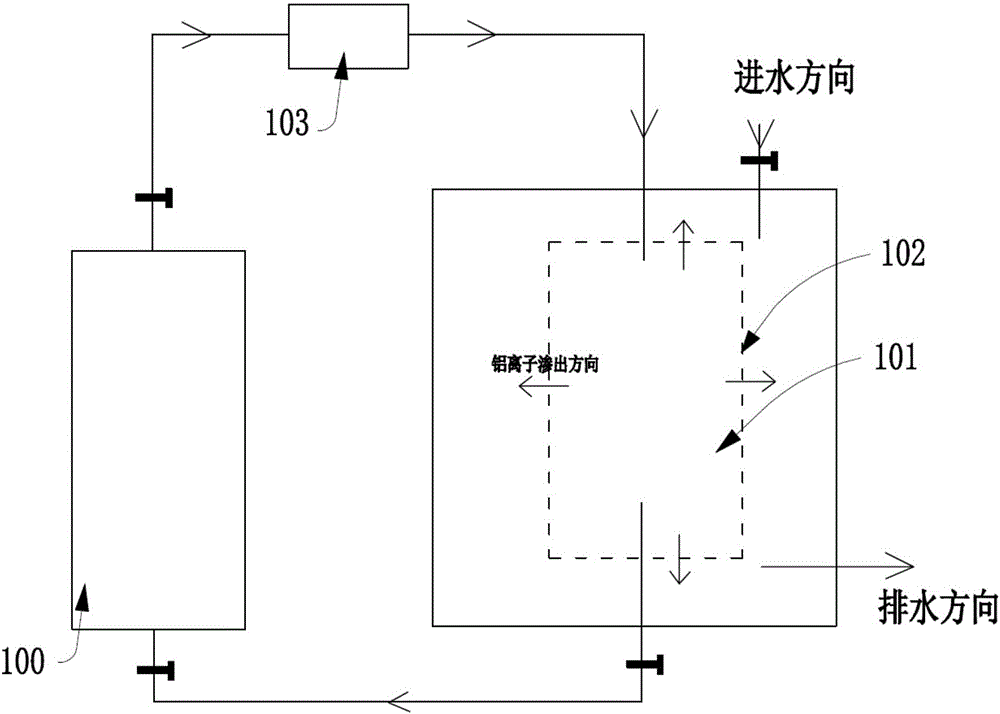

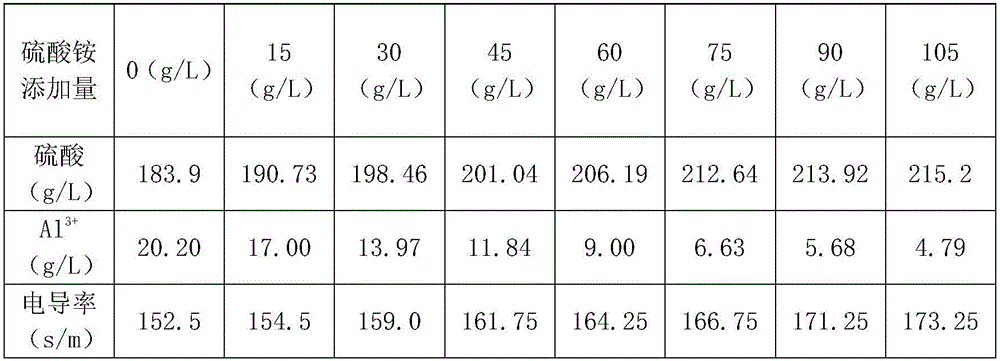

Energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition

ActiveCN106757258ALower resistanceReduce the amount of dissolutionCellsAnodisationAmmonium sulfateAluminium salts

The invention discloses an energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition. The process comprises an oxidization liquid cyclic cooling step, an aluminum ion crystal product recycling step, a sulfuric acid oxidization liquid recycling step, a gas stirring step and a defrosting step; the aluminum ion crystal product recycling step includes that oxidization liquid is guided into a reaction tank, ammonium aluminum sulfate crystals are precipitated out after ammonium sulfate is added into the reaction tank, and then materials in the reaction tank are guided into a centrifugal machine to be centrifuged so that solid and liquid after solid-liquid separation can be acquired; and the sulfuric acid oxidization liquid recycling step includes that oxidization liquid after crystallization treatment is collected, and is conveyed to an anodic oxidization tank to be cyclically used after being subjected to regeneration treatment. The energy-saving device and process for oxidation tank aluminum ion and sulfuric acid recycling and oxidation liquid corrosion inhibition are provided, by extracting aluminum in the oxidization liquid, sulfuric acid is recycled, the resistance of the oxidization liquid is reduced, a corrosion inhibition agent is added in the oxidization liquid, oxidization energy conservation is achieved by reducing the dissolving amount of an oxidization film, and more than 20% of energy is saved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

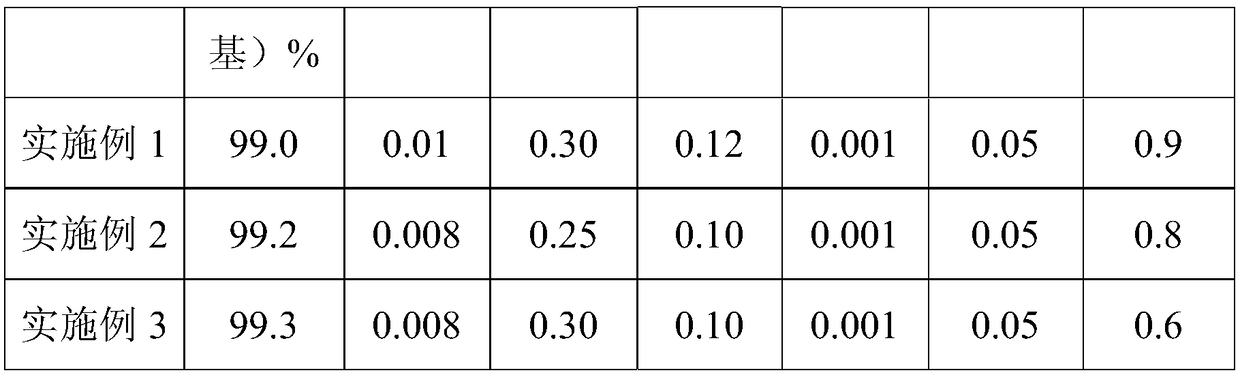

Production method of high-purity aluminum oxide

InactiveCN103241754ASimple production processPurity is easy to controlAluminium oxides/hydroxidesAluminium hydroxideWater vapor

The invention discloses a production method of high-purity aluminum oxide. The production method comprises the steps of preparing aluminum ammonium sulfate, recrystallizing the aluminum ammonium sulfate, producing high-purity aluminum oxide, collecting tail gas and regenerating ammonium sulfate, i.e., firstly preparing the aluminum ammonium sulfate from aluminum hydroxide and sulfuric acid; secondly, recrystallizing the aluminum ammonium sulfate to prepare high-purity aluminum ammonium sulfate; thirdly, implementing low-temperature dehydration and intermediate-temperature decomposition calcination to produce gamma-Al2O3; decomposing and removing all ammonia gas, sulfur trioxide and water vapour; finally, grinding the gamma-Al2O3, screening the ground gamma-Al2O3, molding and pressing the screened gamma-Al2O3 by a molding press, and sintering the gamma-Al2O3 by a high temperature furnace, thereby obtaining alpha-Al2O3. In the whole production process, the tail gas is collected effectively and the waste gas is recycled effectively. The production method of the high-purity aluminum oxide is simple in production technology, free from pollution and low in cost; and the purity of the high-purity aluminum oxide is easy to control.

Owner:GUIYANG YIJINGXIANG PHOTOELECTRIC TECH

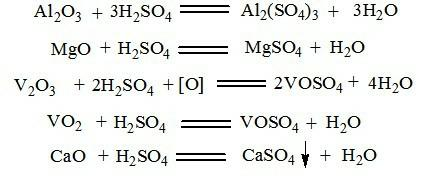

Preparation method of vanadium containing solution

ActiveCN108359815AHigh recovery rateSolve the pollution of the environmentVanadium oxidesCeramic materials productionResource utilizationAluminum ammonium sulfate

The invention provides a preparation method of a vanadium containing solution. The preparation method comprises the following steps that vanadium containing lixivium is subjected to silicon removal and dealumination to obtain the vanadium containing solution and silicon removal waste residues; the silicon removal waste residues are leached through concentrated sulfuric acid to obtain an acid leaching solution; after the acid leaching solution is precisely filtered, silicon residues and an aluminum sulfate solution are obtained; and the aluminum sulfate solution and an ammonium sulfate solutionare mixed, recooling crystallization is carried out after reacting, aluminum ammonium sulfate crystals and crystallization mother liquor are obtained through second solid-liquid separation, and the crystallization mother liquor is used for replacing part or all of aluminum salt to be mixed with a silicon-chrome-silicon containing solution for silicon removal. According to the method, the siliconremoval waste residues can be subjected to resource utilization, and an aluminum ammonium sulfate product high in additional value can be obtained; meanwhile, the consumption of the aluminum salt canbe reduced, high-purity ammonium metavanadate can be prepared continuously and stably, and therefore a high-purity vanadium pentoxide product with the purity not smaller than 99.9% is prepared, and the vanadium recovery rate is increased; and the process is simple, the cost is low, and energy consumption is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing copper base composite material by chemical precipitation method to obtain composite powder

The process of preparing copper base composite material with composite powder prepared through chemical precipitation includes the following steps: dropping ammonium bicarbonate into mother liquid comprising copper sulfate and aluminum ammonium sulfate at 25-30 deg.c to obtain settled NH4Al(OH)2CO3-Cu2(OH)2CO3 sol, ageing for 8 hr and centrifuging to obtain NH4Al(OH)2CO3 -Cu2(OH)2CO3 gel, washing the gel with anhydrous alcohol, centrifuging to eliminate alcohol and stoving and grinding at 50deg.c to obtain NH4Al(OH)2CO3-Cu2(OH)2CO3 precursor, igniting the precursor at 1100-1200 deg.c to obtain composite Al2O3-CuO powder, reducing the composite Al2O3-CuO powder in reducing methanol or hydrogen atmosphere at 350 deg.c for 0.5-1 hr to obtain composite Al2O3-Cu powder; cold pressing the composite Al2O3-Cu powder at 100 kN pressure to form blank, and final at 800-850 deg.c. The present invention has precisely controlled Al2O3 content for required wear resistance and conductivity.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

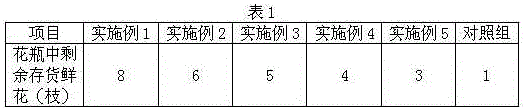

Flower preservative and preparation method thereof

InactiveCN105746499AGood fresh-keeping effectImprove the preservation effectDead plant preservationSucroseAluminum ammonium sulfate

The invention provides a flower preservative and a preparation method thereof.The flower preservative is prepared from, by weight, 2-8 parts of zinc gluconate, 2-6 parts of iron gluconate, 3-5 parts of sucrose, 1-5 parts of borax, 2-4 parts of aluminium potassium sulfate, 3-6 parts of aluminum ammonium sulfate, 1-5 parts of chitosan, 2-5 parts of chitin, 3-6 parts of magnesium sulfate, 1-4 parts of traditional Chinese medicine extracts, 2-5 parts of 6-benzyladenine, 1-4 parts of forchlorfenuron, 2-4 parts of gibberellins, 1-5 parts of 2,4-dichlorphenoxyacetic acid, 2-6 parts of salicylic acid, 3-8 parts of 8-hydroxyquinoline citrate, 1-6 parts of inositol hexaphosphate, 1-5 parts of ethylene glycol and 8-12 parts of deionized water.The flower preservative is simple to prepare and excellent in preservation effect.

Owner:LIANYUNGANG XIUJING LANDSCAPING ENG CO LTD

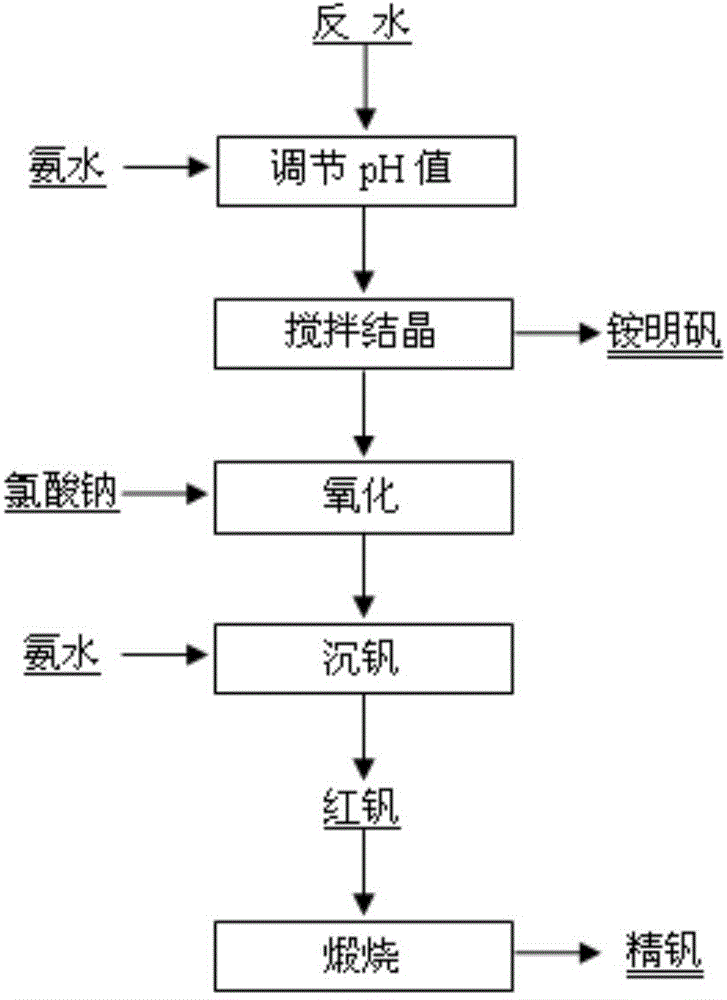

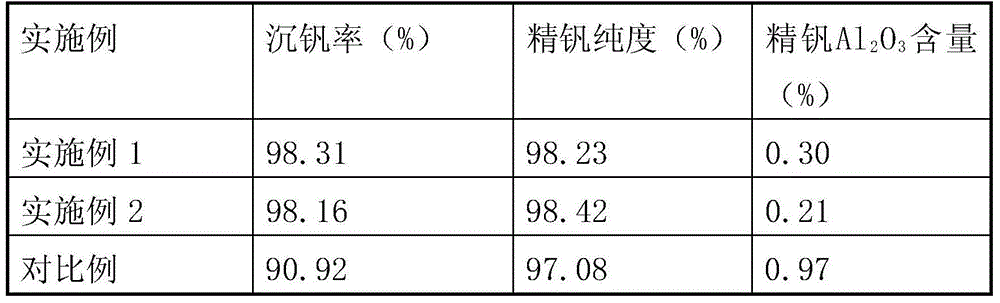

Method for precipitating vanadium from high-aluminum vanadium-containing solution

InactiveCN104131180AHigh purityHigh vanadium deposition rateProcess efficiency improvementSal ammoniacSodium chlorate

The invention provides a method for precipitating vanadium from a high-aluminum vanadium-containing solution. The method comprises the following steps: carrying out extraction and back extraction on a vanadium-containing acidic leaching solution so as to obtain backwater, adding ammonium hydroxide into the backwater, stirring and crystallizing so as to separate out aluminum ammonium sulfate; adding low-valence vanadium ions oxidized by sodium chlorate into a tail liquid obtained during crystallization, adding the ammonium hydroxide into an oxidized liquid, stirring and precipitating the vanadium; and drying and calcining a red cake so as to obtain a refined vanadium product. According to the method, the problems of influences of impurities Al<3+> in the backwater on the vanadium precipitating rate and the purity of the refined vanadium are solved via a process of firstly crystallizing the aluminum ammonium sulfate and then precipitating the vanadium by fully aiming at the characteristic of high content of aluminum in the backwater obtained by precipitating the vanadium from stone coal type vanadium ores or vanadium-containing coal ash, and the byproduct aluminum ammonium sulfate is obtained at the same time. The method is low in running cost, high in vanadium precipitating rate and high in refined vanadium purity, and can be widely applied to industrial production.

Owner:西安西北有色地质研究院有限公司 +1

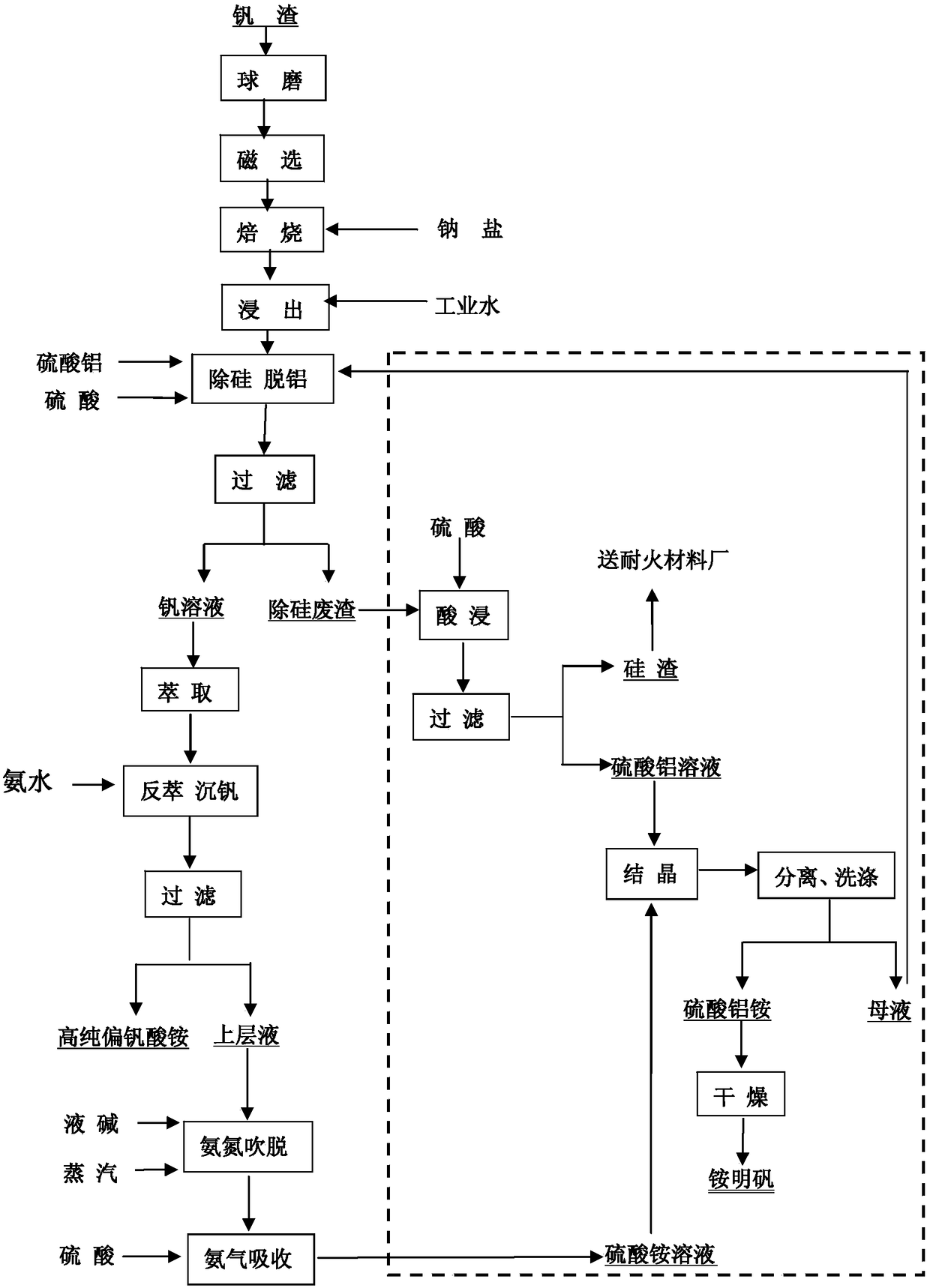

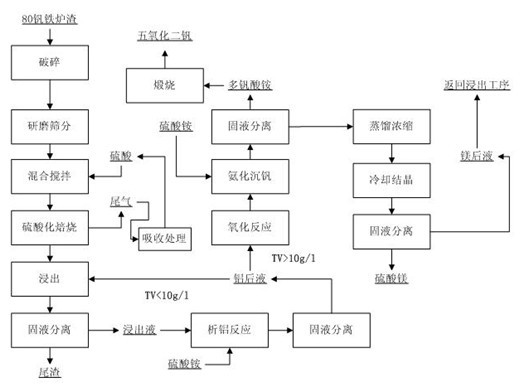

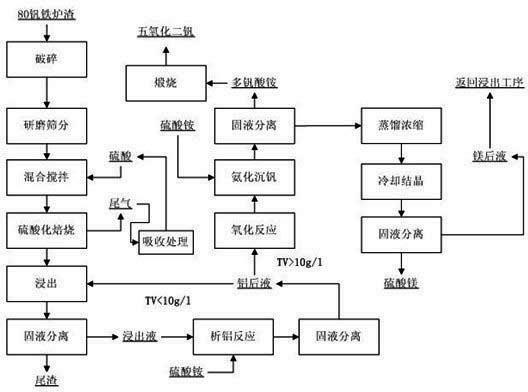

Resource recycling method for 80 ferrovanadium slag

ActiveCN102616851AFewer separation stepsEfficient recyclingSolid waste disposalMagnesium sulfatesSlagAluminum ammonium sulfate

The invention discloses a resource recycling method for 80 ferrovanadium slag, which adopts the following steps: (1) sulfating roasting: mixing the ferrovanadium slag and sulfuric acid, stirring, and then conducting sulfating roasting to obtain roasting slag; (2) leaching: mixing the roasting slag and deionized water or diluted acid, stirring and leaching, and then filtering to obtain leaching liquid; (3) enriching vanadium: adding ammonium sulfate into the leaching liquid, heating and dissolving, and then cooling, crystallizing, and filtering to obtain aluminum ammonium sulfate crystal and crystallization post liquid; (4) oxidizing and sinking vanadium: adding oxidant into the crystallizing post liquid to conduct oxidizing, converting all V3+ and V4+ in the crystallizing post liquid into V5+, then dropwise adding ammonia water, stirring and filtering to obtain ammonium polyvanadate sediment and filtrate, and roasting ammonium polyvanadate to obtain vanadium pentoxide; and (5) magnesium separating reacting: distilling and concentrating the filtrate, cooling, and filtering to obtain magnesium sulfate crystal. The method has the advantages of being simple in technology process, low in energy consumption and friendly in environment.

Owner:HEBEI IRON AND STEEL

Industrial waste water treatment agent and preparation method therefor

InactiveCN106564977AWide variety of sourcesThorough treatmentWater contaminantsWater/sewage treatment by sorptionCelluloseSodium Bentonite

The invention discloses an industrial waste water treatment agent. The industrial waste water treatment agent is mainly prepared from the following raw materials in parts by weight: 15-30 parts of aluminum sulfate, 15-30 parts of ferric sulfate, 1-5 parts of polyacrylamide, 1-5 parts of microorganisms, 15-30 parts of corn starch, 3-13 parts of chitosan, 7-17 parts of bentonite, 5-10 parts of sodium cellulose, 4-11 parts of montmorillonite powder, 20-40 parts of modified pelelith, 10-20 parts of calcium hydroxide, 10-20 parts of activated carbon, 5-15 parts of polymeric aluminum, 1-5 parts of aluminum ammonium sulfate, 3-7 parts of 3-chloro-2-hydroxypropyl-trimethylammonium chloride, 5-15 parts of barium sulfide and 5-20 parts of lignin. The manufacturing raw materials of the industrial waste water treatment agent are wide in source, pollutants in the waste water can be effectively removed, the sewage treatment is thorough, the treatment cost is low, and the treatment agent is non-toxic and pollution-free; the treated waste water satisfies the requirements of national sewage comprehensive discharge standard. Moreover, the preparation method of the industrial waste water treatment agent is simple and the industrial waste water treatment agent is convenient to produce.

Owner:广西新六合环保有限责任公司

Concrete shrinkage compensating pumping agent

InactiveCN106145745ASmall shrinkageCompensation for shrinkageSuperplasticizerAluminum ammonium sulfate

The invention belongs to the technical field of concrete additives, and particularly relates to a concrete shrinkage compensating pumping agent. The concrete shrinkage compensating pumping agent is prepared from, by weight, 45-65 parts of polycarboxylate superplasticizer, 10-22 parts of aluminum ammonium sulfate, 6-14 parts of coco fatty acid diethanol amide, 2-8 parts of sepiolite, 5-13 parts of sodium citrate, 1-8 parts of sodium glucoheptonate, 1.2-2 parts of zinc stearate and 45-65 parts of water. The concrete shrinkage compensating pumping agent can compensate for concrete shrinkage and also can meet the pumping agent performance requirement and the pumping construction demand.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

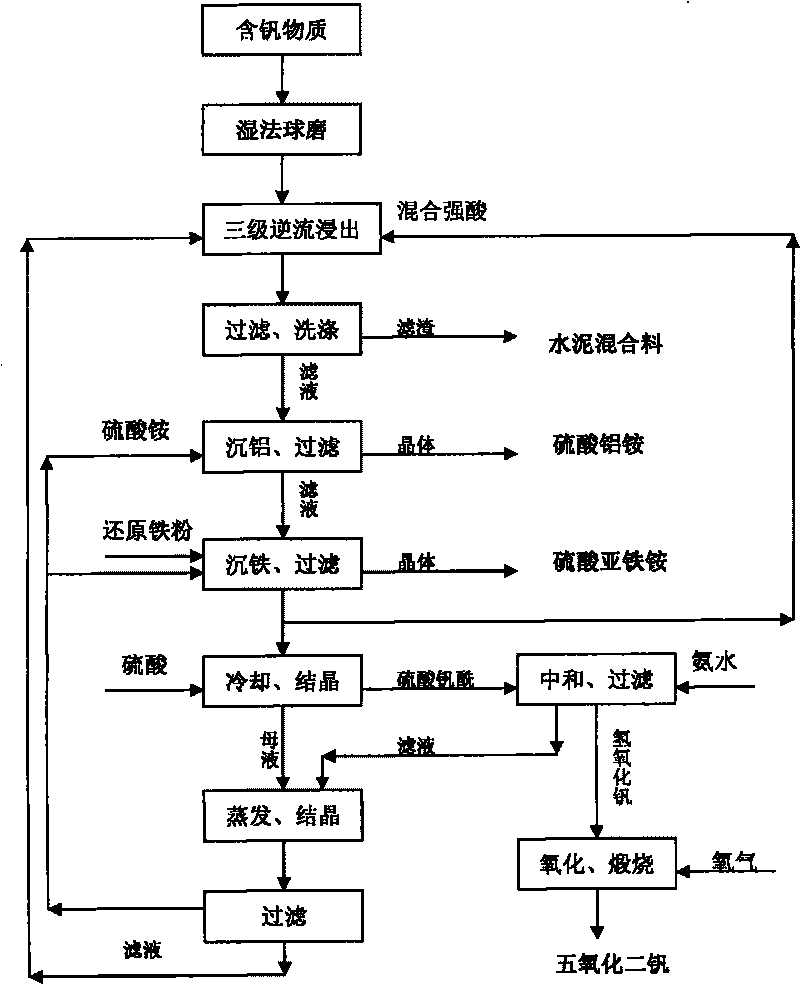

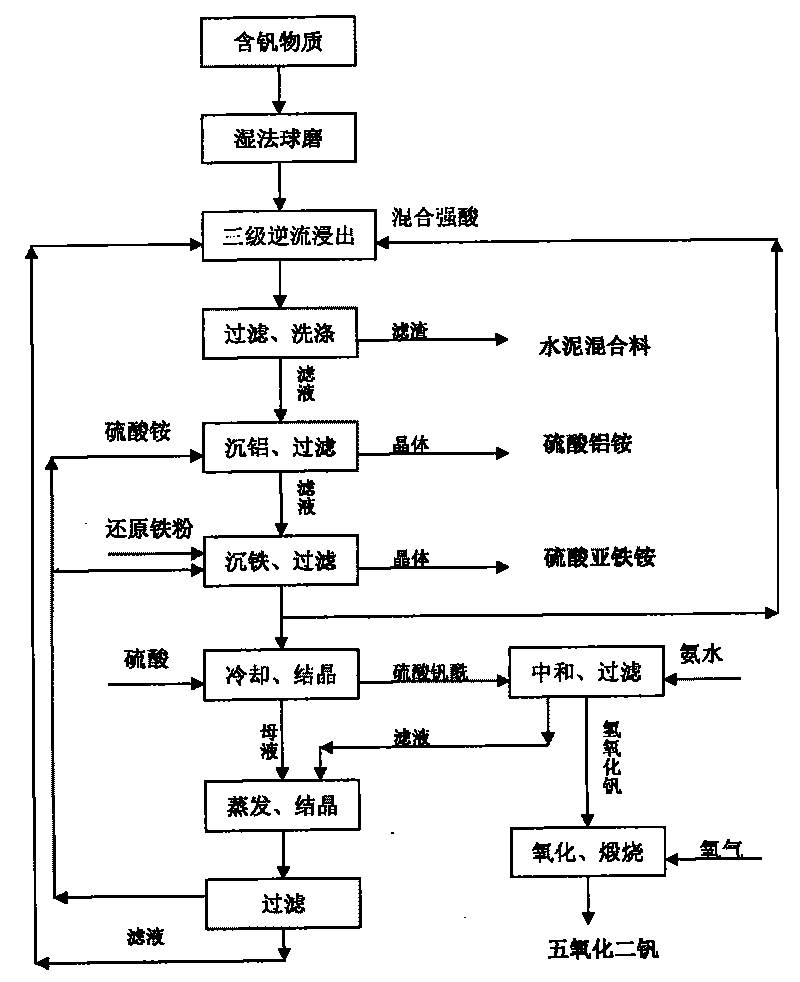

Method for cleanly extracting vanadium pentexide from vanadium containing material

ActiveCN101723458AHigh yieldRealize comprehensive utilizationVanadium oxidesPhosphateAluminum ammonium sulfate

The invention relates to a method for cleanly extracting vanadium pentexide from a vanadium containing material. The method is characterized in that: the vanadium containing material is milled by the wet method, and then mixed with a certain weight amount of sulfuric acid, vanadic acid, water, sulfuric acid or phosphoric acid salt having certain association; under conditions of set temperature and set time, performing three-stage reflux leaching reaction of the mixture; adding ammonia sulfate and reducing iron powder to reaction leach solution in sequence to obtain aluminum ammonium sulfate crystals and ammonium ferrous sulfate crystals respectively; adding sulfuric acid to the solution in which aluminum and iron are separated out, cooling the solution for crystallization to obtain vanadium sulfate acyl crystals, and returning the mother liquor to extract vanadium ores; performing the neutralization reaction of the vanadium sulfate acyl crystals and ammonia water to obtain a precipitate of vanadium hydroxide, and returning the solution of ammonia sulfate to precipitate the aluminum and iron; and calcining the vanadium hydroxide and oxygen gas at a high temperature of over 300 DEG C to obtain the vanadium pentexide. The method has the advantages of short process flow, less energy consumption, high vanadium yield, low production cost, environmental protection, and comprehensive utilization of valuable metallic elements in ores.

Owner:河南龙宇钒业有限公司

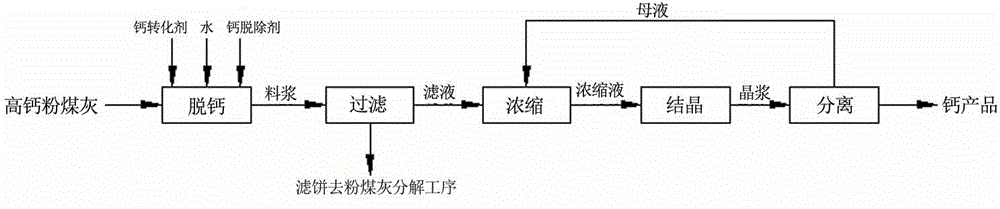

Method for treating calcium in high-calcium fly ash

ActiveCN104876253ARealize comprehensive utilizationReduce the amount of secondary residueCalcium/strontium/barium chloridesCalcium/strontium/barium nitratesAluminum ammonium sulfateAlkaline hydrolysis

The invention discloses a method for treating calcium in high-calcium fly ash, which comprises the steps of phase inversion reaction, decalcification reaction and calcium compound preparation. The technique principle comprises the following steps: converting calcium sulfate in fly ash into calcium compounds capable of reacting with hydrochloric acid and nitric acid by a phase inversion process, treating the fly ash with hydrochloric acid or nitric acid to convert the calcium compounds in the fly ash into soluble calcium chloride or calcium nitrate, and separating to collect a calcium chloride or calcium nitrate solution and a decalcified fly ash filter cake; and concentrating the calcium chloride or calcium nitrate solution, and crystallizing to collect the calcium chloride or calcium nitrate product. The decalcified fly ash filter cake is sent to a subsequent procedure and subjected to acid hydrolysis and alkaline hydrolysis, the acid leach solution is used for preparing aluminum ammonium sulfate, aluminum oxide, cryolite, aluminum fluoride, high-purity iron oxide or iron oxide red, the water glass is used for preparing silica white other silicon compounds, and the decomposition residues are mixed with coal to be used as a boiler fuel.

Owner:河南省睿博环境工程技术有限公司

Textile fabric coloring agent

The invention discloses a textile fabric coloring agent. The textile fabric coloring agent is prepared from the following raw materials in parts by weight: 8 to 12 parts of cobaltous sulfate, 7 to 10 parts of aluminum ammonium sulfate, 3 to 7 parts of butyl methacrylate, 2 to 5 parts of ethyl acetate, 3 to 6 parts of trimethylolpropane, 7 to 9 parts of camphor tree leaf extract liquor, 6 to 8 parts of ferrous sulfate, 5 to 10 parts of aluminum sulfate, 3 to 7 parts of glycerol, 2.5 to 3.2 parts of hydroxypropyl methyl cellulose, 1 to 4 parts of imidazoline, 1.2 to 2.4 parts of 2-naphthol and 12 to 26 parts of modified starch. The textile fabric coloring agent has the beneficial effects of high colorability, prevention of fading, bright color and harmlessness to human bodies.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

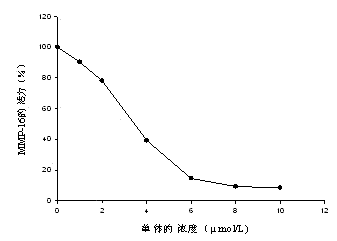

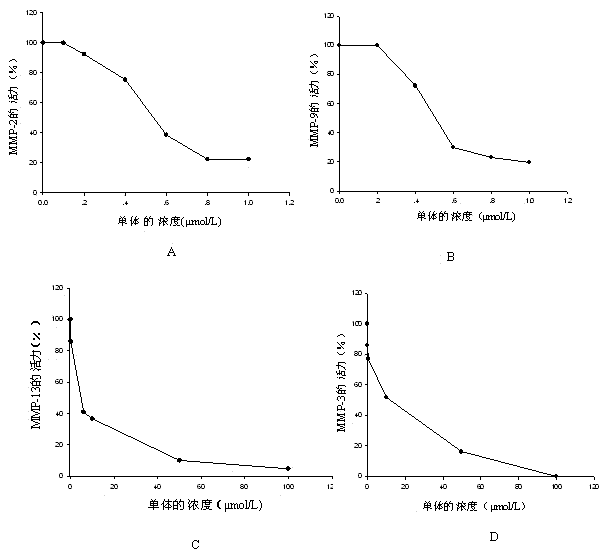

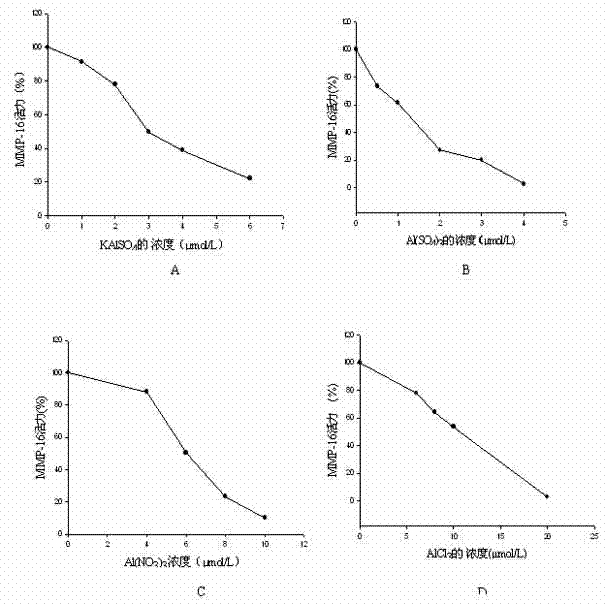

Application of aluminum ammonium sulfate dodecahydrate in preparation of antitumor matrix metal protease inhibitors

InactiveCN102813672AStrong inhibitory activitySimple structureAluminium/calcium/magnesium active ingredientsAntineoplastic agentsAluminum ammonium sulfateProtease

The invention discloses an application of AlNH4(SO4)2.12H2O in the preparation of antitumor matrix metal protease inhibitors. Compared with previous MMPs inhibitors, the AlNH4(SO4)2.12H2O disclosed in the invention has the advantages of strong inhibition activity to the MMPs, simple structure, low price and convenient obtaining.

Owner:NORTHWEST UNIV(CN)

Method for preparing high-pure aluminum oxide

InactiveCN102910657AAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesOrganic acidAluminium sulfate

The invention relates to a method for preparing high-pure aluminum oxide. The method comprises the following steps: organic acids such as ammonium sulfate and tartaric acid are added in purified industrial aluminum sulfate to remove iron, so as to obtain an aluminum ammonium sulfate solution; the aluminum ammonium sulfate is reacted with refined hydrochloric acid; the obtained crystal is washed, dried, fired and milled, and finally the high-pure aluminum oxide is obtained. The method is simple in production technology; and the obtained aluminum oxide has high purity which can reach 99.999% even 99.9999 spectrum purity.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Anti blocking biomembrane

An antiadhesion iomembrane for wound and operation is prepared from carboxymethyl cellulose, carboxymethylchitosan, aluminium ammonium sulfate, glutaraldehyde glycerine and water.

Owner:SHANGHAI HAOHAI BIOLOGICAL TECH +2

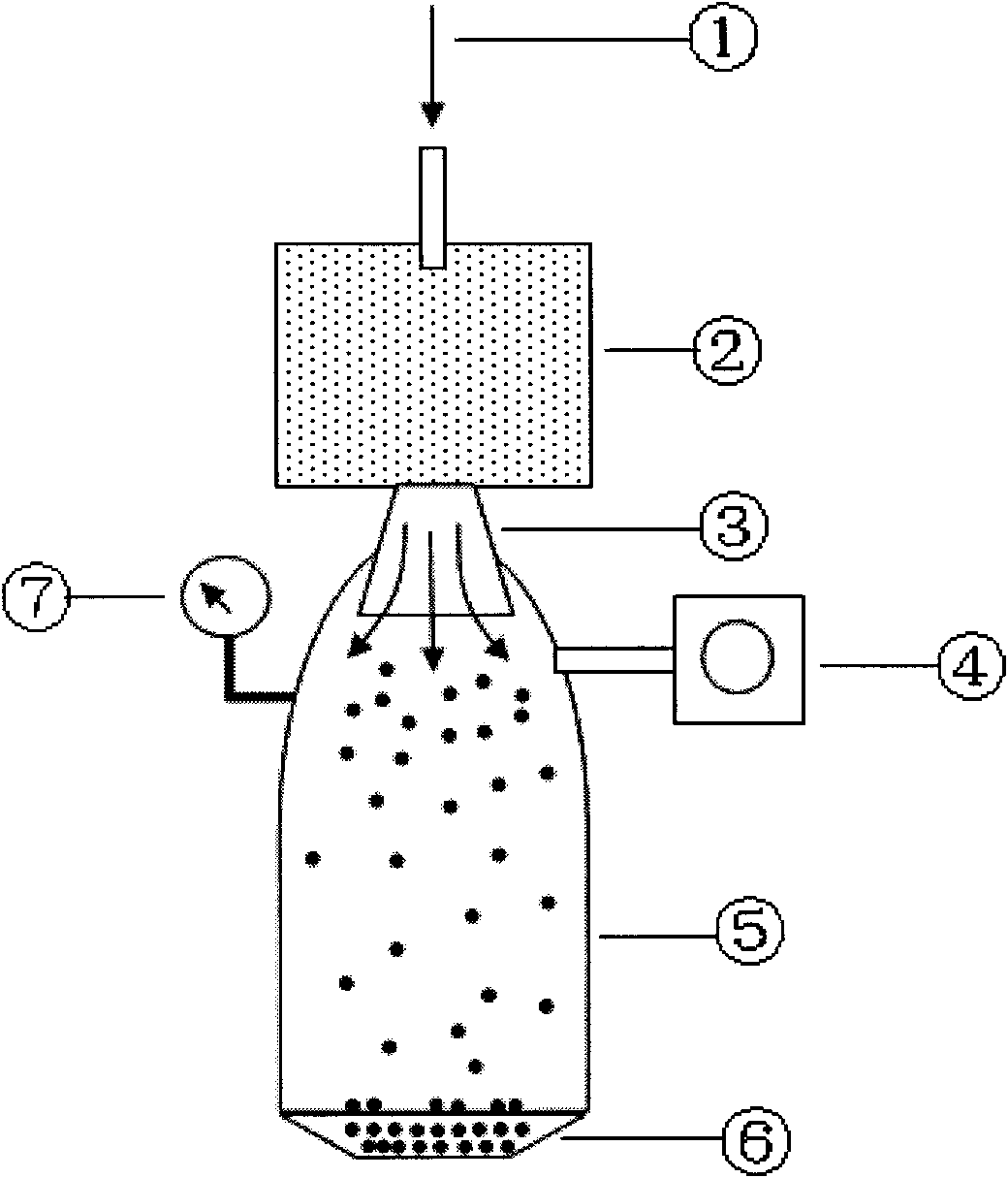

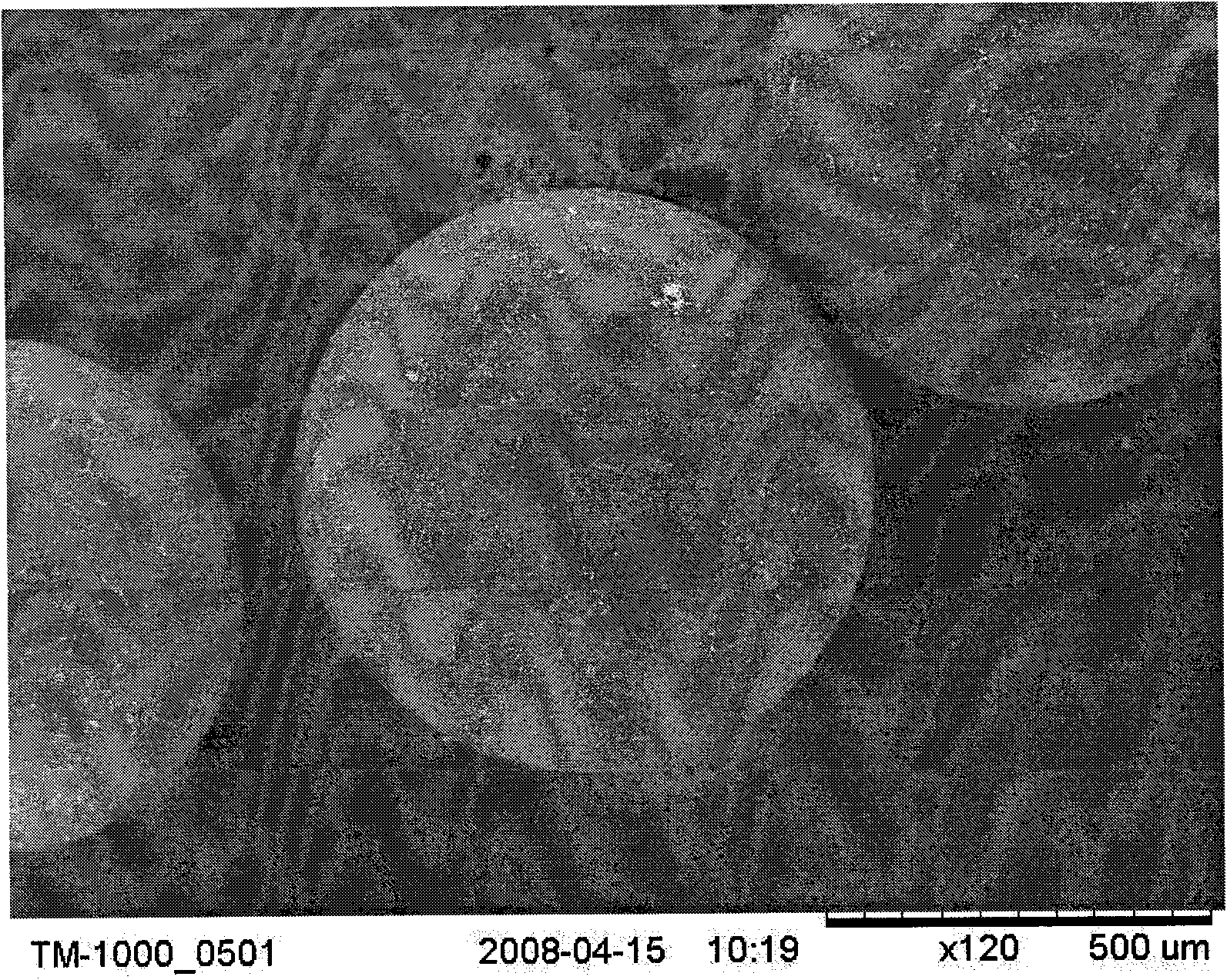

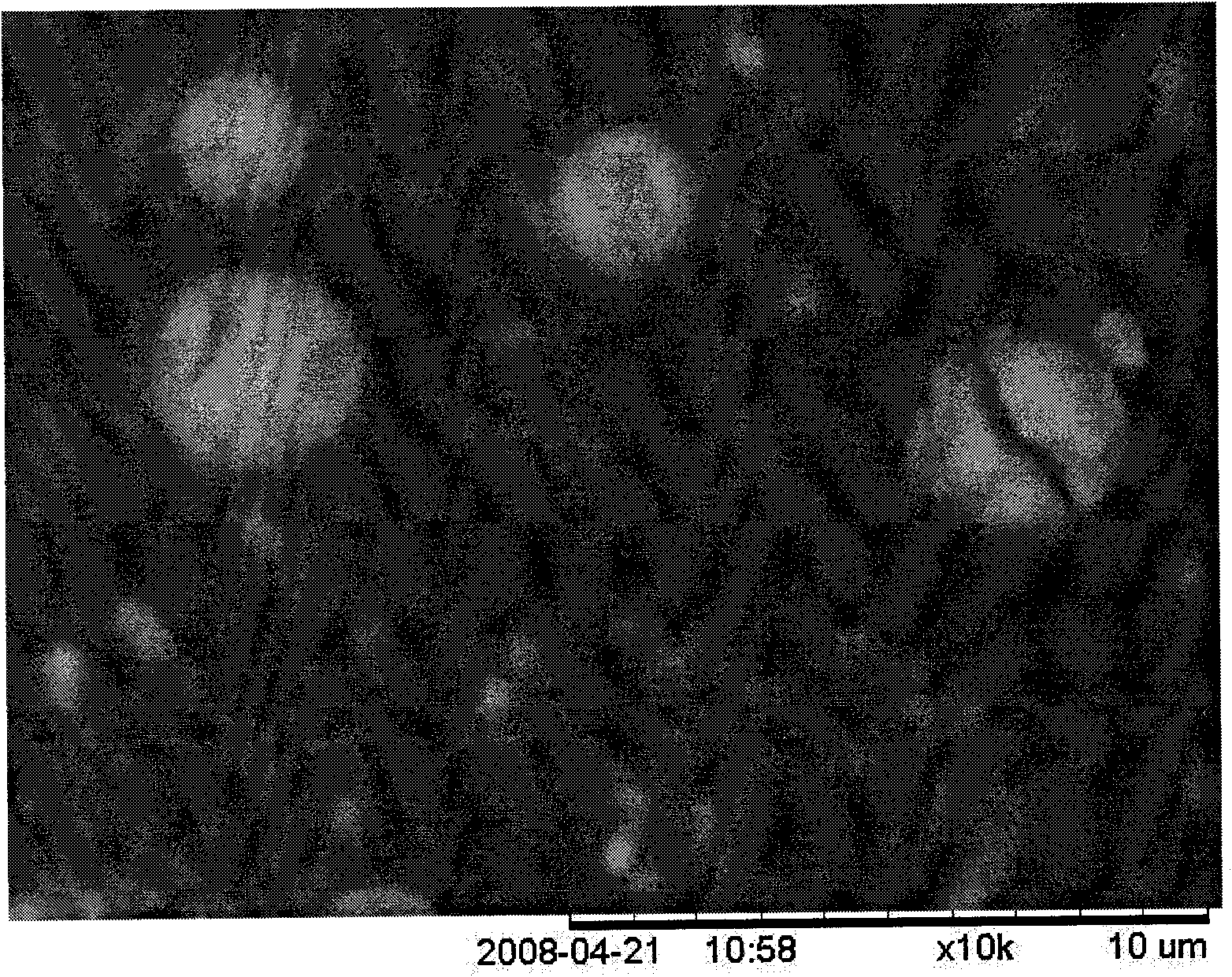

Method for preparing hollow aluminum oxide microspheres

InactiveCN101885502AThe process is simple and reliableLow costAluminium oxide/hydroxide preparationMicrosphereAluminum ammonium sulfate

The invention discloses a method for preparing hollow aluminum oxide microspheres, which relates to material technology. The method comprises the following steps of: a) placing analytically pure aluminum ammonium sulfate [(NH4)2Al2(SO4)4.24H2O] into a flour mill for milling, and sieving the milled aluminum ammonium sulfate with a sieve of 800 meshes for later use; b) preheating a vacuum sintering furnace; c) filling the aluminum ammonium sulfate powder obtained by the milling into an atomizer for atomization; d) blowing the atomized aluminum ammonium sulfate powder into the vacuum sintering furnace by using compressed air; e) maintaining the temperature in the vacuum sintering furnace to be over 1,000 DEG C, keeping the air pressure in the vacuum sintering furnace lower than the atmospheric pressure, vigorously decomposing the aluminum ammonium sulfate powder to form porous aluminum oxide powder which falls under the action of gravity, exhausting produced gases by an exhaust pump, and arranging a filter screen of 12,500 meshes at the front end of an inlet pipe of the exhaust pump to prevent the solid powder from being sucked in; and f) keeping the temperature for 1 hour when the temperature in the vacuum sintering furnace is 1,000 DEG C so as to sinter the porous powder into hollow ceramic microspheres, stopping heating, injecting air into the vacuum sintering furnace and obtaining the hollow aluminum oxide microspheres when the temperature is reduced to the room temperature. The method of the invention has the advantages of simple and reliable process, low cost and high yield.

Owner:SOUTHWEAT UNIV OF SCI & TECH

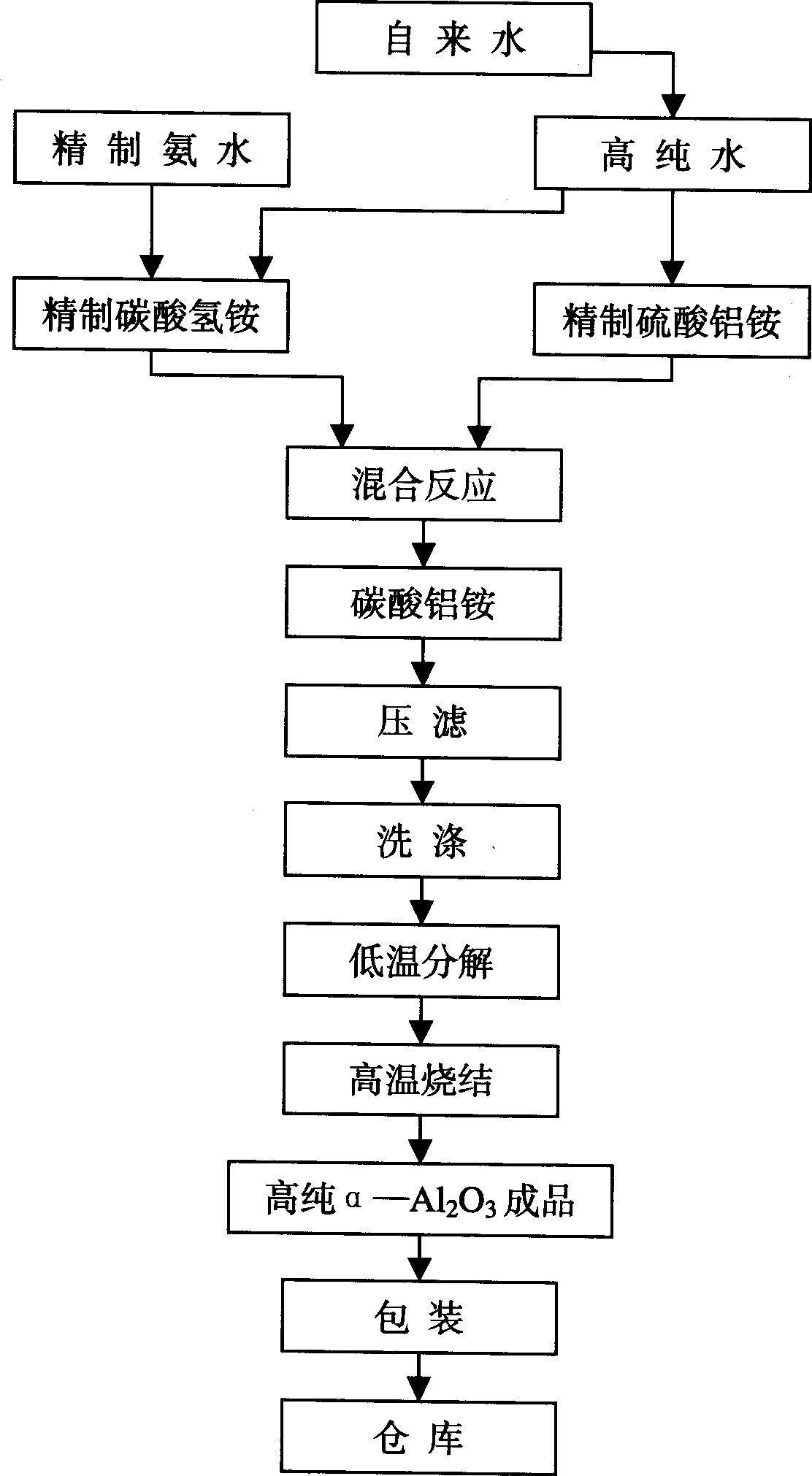

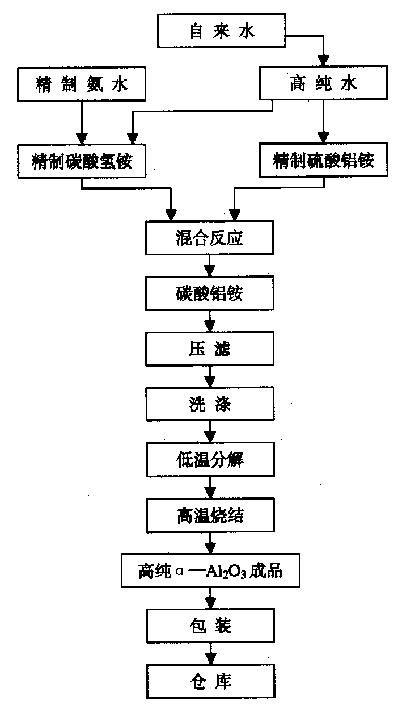

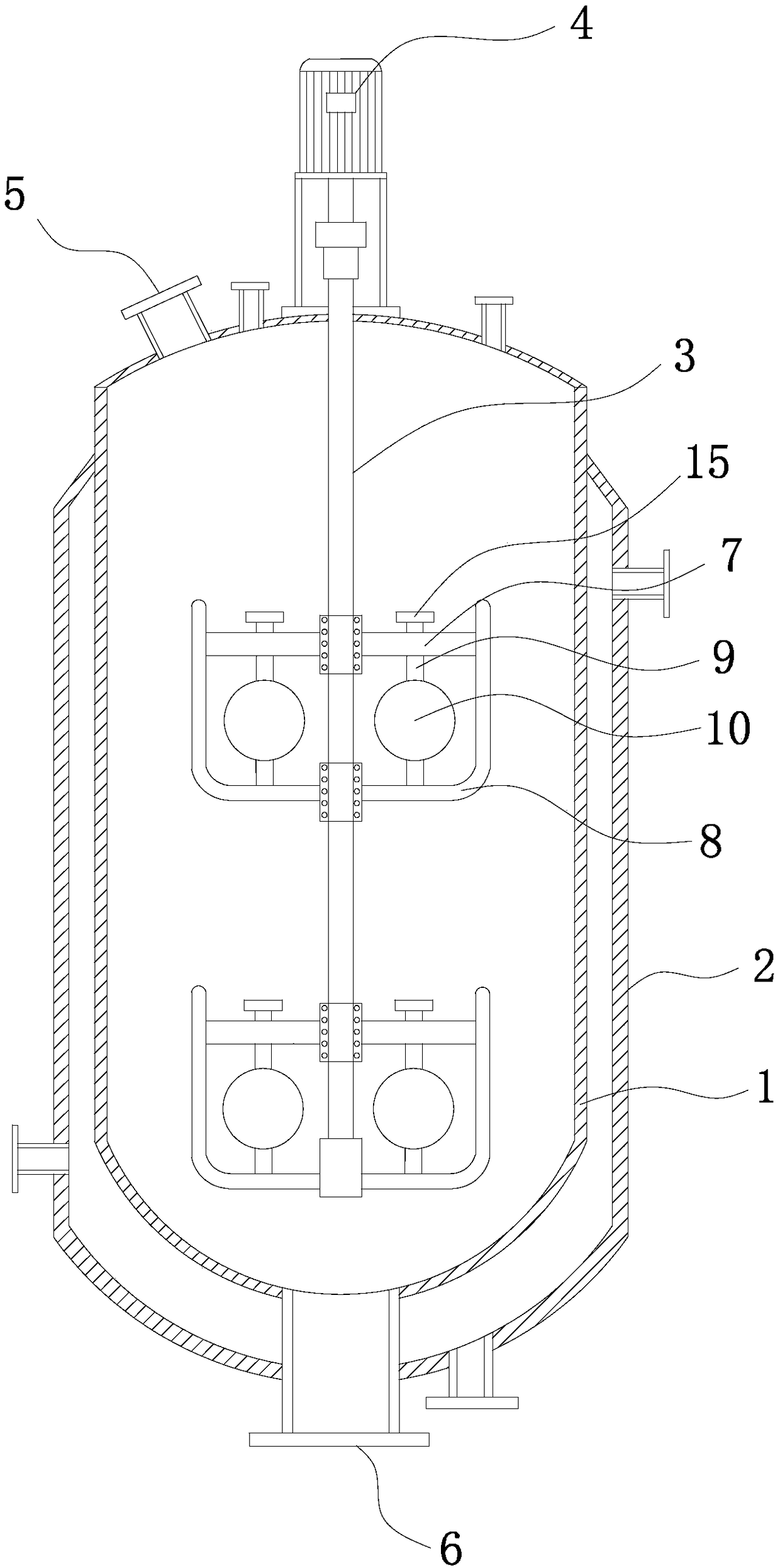

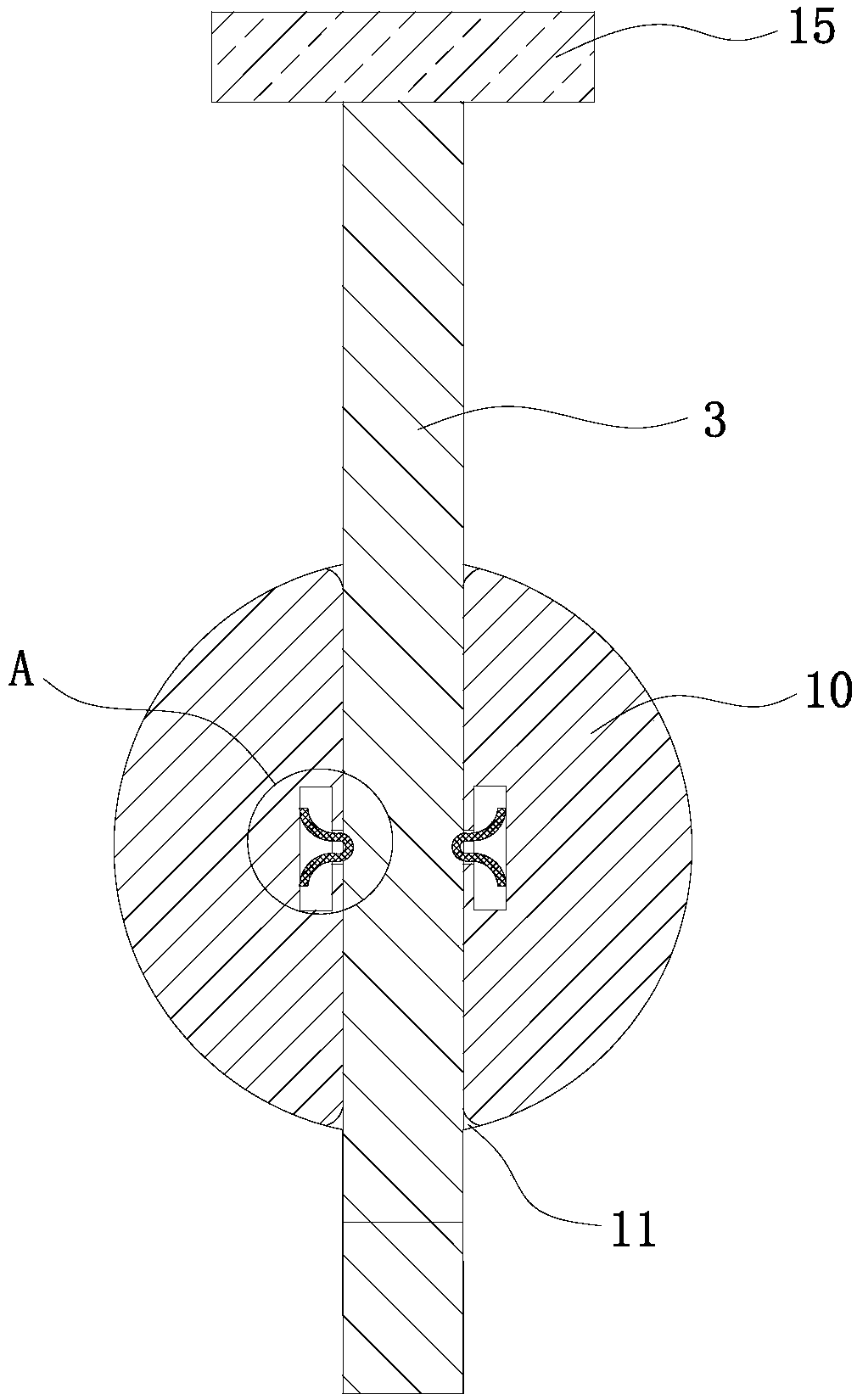

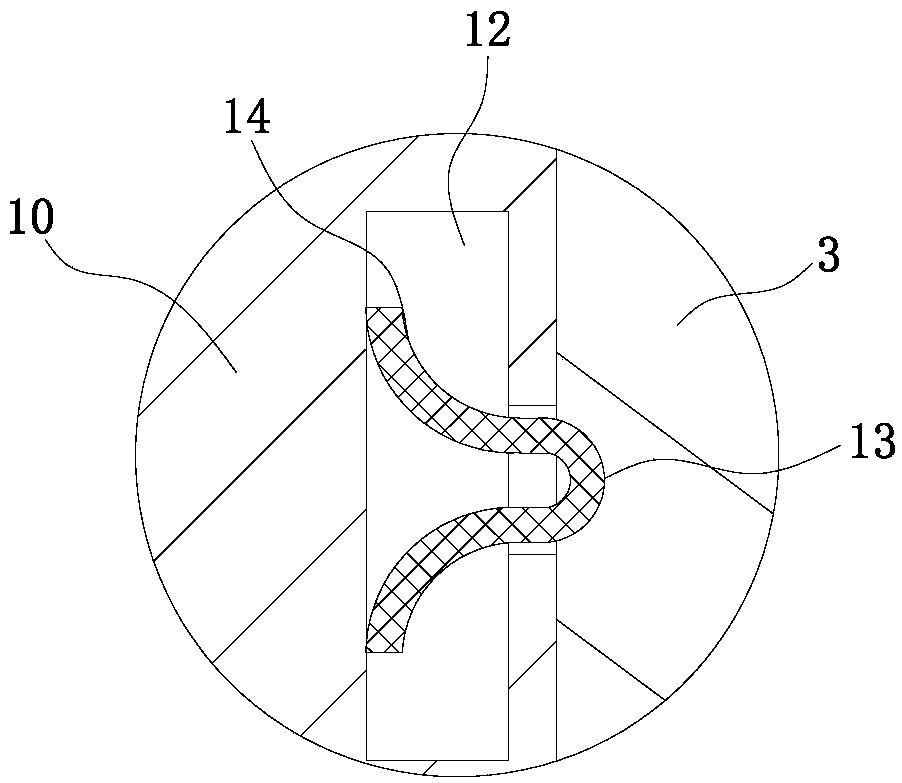

Production process of high-purity superfine alpha-aluminium oxide powder

InactiveCN1432529AInhibition releaseWill not polluteAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesGranularityAluminum ammonium sulfate

The present invention discloses a production process of high-purity superfine alpha-aluminum oxide powder. Refined ammonium bicarbonate and aluminum ammonium sulfate is first mixed with pure water toprepare solution, refined ammonia water is added into the solution of ammonium bicarbonate to produce micro reaction, and the product is filtered, washed and sintered in tunnel kiln. The said production process can result in alpha-Al2O3 content up to 99.99, D50 granularity of 0.1-5 microns, BET specific surface area of 2-20 sq m / g, true density of 3.80-3.97 g / cu cm bulk density of 0.3-0.5 g / cu cm, densified density of 0.6-1.3 g / cu cm, sintered density of 3.92-3.96 g / cu cm and alpha-Al2O3 phase converting rate greater than 95%.

Owner:XINXIANG HI TECH CERAMIC MATERIAL

Preparation method of super-purity aluminum oxide

The invention discloses a preparation method of a super-purity aluminum oxide, characterized by comprising the specific process steps as follows: (1) dissolving an industrial aluminum sulfate, stirring and heating to 60-95 DEG C, cooling concentrated solution, filtering, crystallizing and drying, removing impurity from filtrate, and recycling; (2) dissolving industrial senior ammonium sulfate in deionized water, and filtering to obtain clarified filtrate; (3) dissolving the dried crystallized aluminum sulfate solution, adding the ammonium sulfate while stirring continuously, then adding ammonium tartrate, heating the solution, filtering when the solution is hot and the crystal is to be separated out, concentrating the filtrate, cooling and crystallizing, recrystallizing for twice, and recycling the mother solution for reuse; (4) adding the deionized water to dissolve the recrystallized aluminum ammonium sulfate, filtering, adding hydrochloric acid until aluminum trichloride is completely separated out; crystallizing and drying, using the hydrochloric acid to wash the surface of the crystal; and (5) placing the high-purity AlCl3 in a muffle furnace to burn for 3-6 hours at 550-800 DEG C, crushing, grinding, and sieving to obtain the high-purity aluminum oxide powder.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing aluminium oxide and phosphorus-containing fertilizer from methanol-to-olefin waste catalyst

ActiveCN109455747AAchieve recyclingReduce pollutionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminum ammonium sulfateALUMINUM PHOSPHATE

The invention relates to the technical field of silicon-aluminum-phosphate molecular sieve recycling, and particularly discloses a method for preparing aluminium oxide and phosphorus-containing fertilizer from a methanol-to-olefin waste catalyst. The method comprises the following steps: calcining and decomposing the waste catalyst, and then recovering by adopting an aluminum ammonium sulfate decomposing method to obtain the high-purity aluminium oxide, and performing acidolysis and curing to obtain a silicon-phosphorus-nitrogen compound fertilizer. The method disclosed by the invention is simple in processing steps, is stable and controllable in process, is high in operability, can prepare high-purity Al2O3 of which the purity is higher than 99% and the silicon-phosphorus-nitrogen compound fertilizer of which the content of effective nutrients is larger than 30% synchronously, realizes the recycling of the methanol-to-olefin waste catalyst, reduces the pollution of the waste catalystto the environment, and has great significance for developing coal chemical industry in China.

Owner:陕西好一化工科技有限公司

Method for molding high-purity alumina for LED sapphire single crystal

ActiveCN104250017AGuaranteed single crystal qualityPurity is not contaminatedAluminium oxide/hydroxide preparationAluminum ammonium sulfateSingle crystal

The invention relates to a method for molding high-purity alumina for an LED sapphire single crystal. The method comprises the following steps: (1) carrying out high-temperature and heat-preservation calcination of high-purity aluminum ammonium sulfate, cooling with circulating water after discharging from a furnace, and allowing a sintered alumina coarse powder to have the alpha-Al2O3 phase content of 60-65% and the gamma-Al2O3 phase content of 35-40%; (2) crushing the sintered alumina coarse powder with an airflow crushing device to obtain an alumina ultrafine powder; and (3) directly carrying out one-time stamping molding on the alumina powder, to obtain a high-purity alumina round cake green body. The method has no addition of any adhesion agent, adopts direct dry pressing molding, ensures the purity of the molded-shaped alumina is not polluted, and ensures the single crystal quality of the produced LED sapphire single crystal; and the molded-shaped alumina is an ideal raw material for replacing high-purity alumina imported from abroad in the LED sapphire single crystal growth field.

Owner:长沙国瓷新材料有限公司

Preparation method of chicken manure fermented organic fertilizer

InactiveCN104402545AGreat tasteShorten the timeBio-organic fraction processingClimate change adaptationSodium bicarbonateWater vapor

The invention belongs to chicken manure fermented organic fertilizer and discloses chicken manure fermented organic fertilizer which has low water content and storage resistance. The chicken manure fermented organic fertilizer comprises 3000kg of chicken manure, 400-600kg of domestic fungus waste residue, 100-200kg of soybean meal, 2-3kg of a composite raising agent and 20-30kg of yeast powder. The preparation method comprises the following steps of mixing the raw materials to obtain a uniform mixture, carrying out fermentation by a short stack with a triangular section for 7-10 days until water vapor basically disappears, and then carrying out fermentation by a high stack for 1-2 months to obtain a finished product. The chicken manure fermented organic fertilizer only utilizes chicken manure, is free of any fertilizer raw materials, and utilizes the composite raising agent containing aluminum ammonium sulfate and sodium bicarbonate, and yeast powder. Through heating and foaming agent-based chicken manure treatment, more oxygen enters into the fermented chicken manure in microbial fermentation so that fermentation is full, a heat yield is large and water in chicken manure is volatilized fast.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

Novel compound emulsifier for food

The invention discloses a novel compound emulsifier for a food. The novel compound emulsifier comprises the following components in parts by weight: 20-40 parts of glycerin monostearate, 30-50 parts of sucrose fatty acid ester, 10-30 parts of propylene fatty acid ester, 4-10 parts of calcium stearoyl lactylate, 20-40 parts of wheat germ powder, 2-6 parts of ascorbic acid, 2-6 parts of sorbitol, 10-20 parts of tween-60, 2-8 parts of aluminum ammonium sulfate and 3-9 parts of sodium bicarbonate. The novel compound emulsifier has a good emulsifying effect, a making process of the food is simplified and the making cost of the food is reduced.

Owner:ZHEJIANG XIAOERHEI FOOD

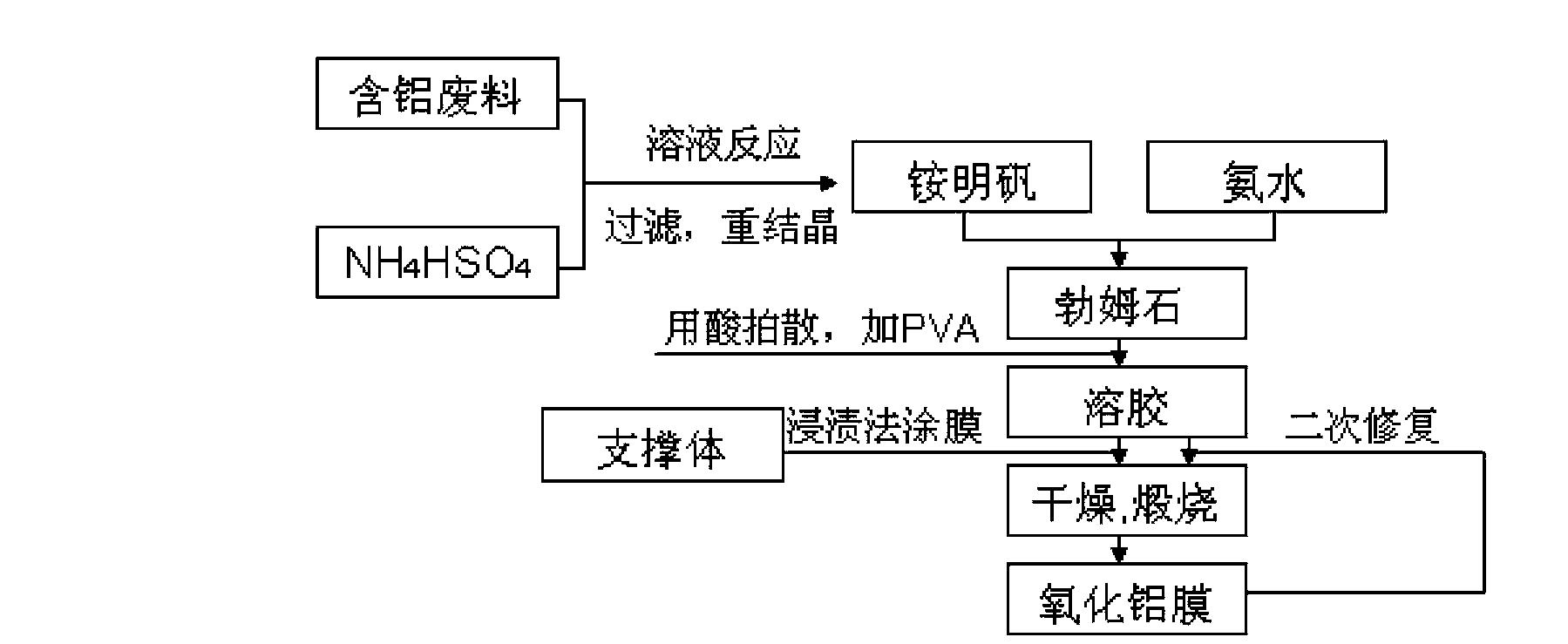

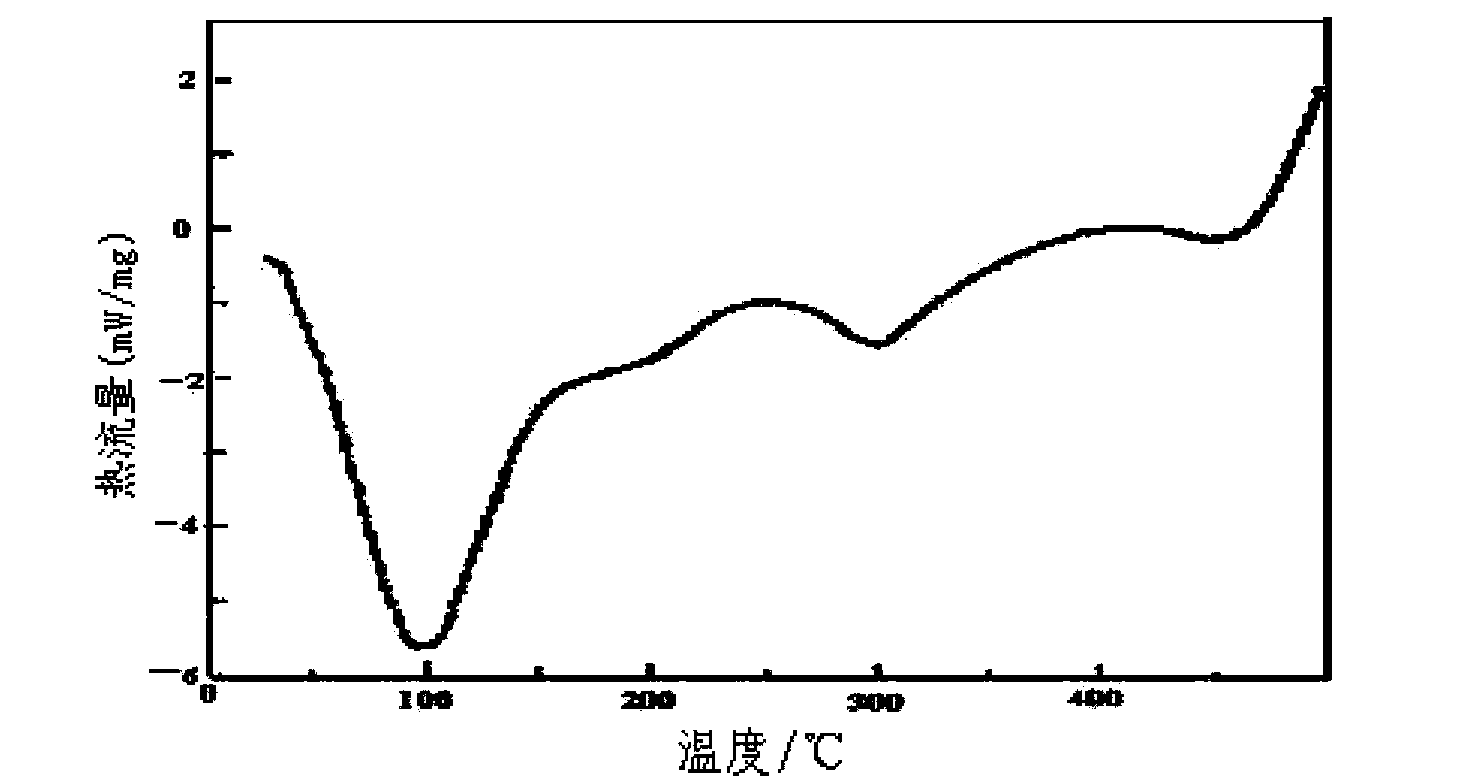

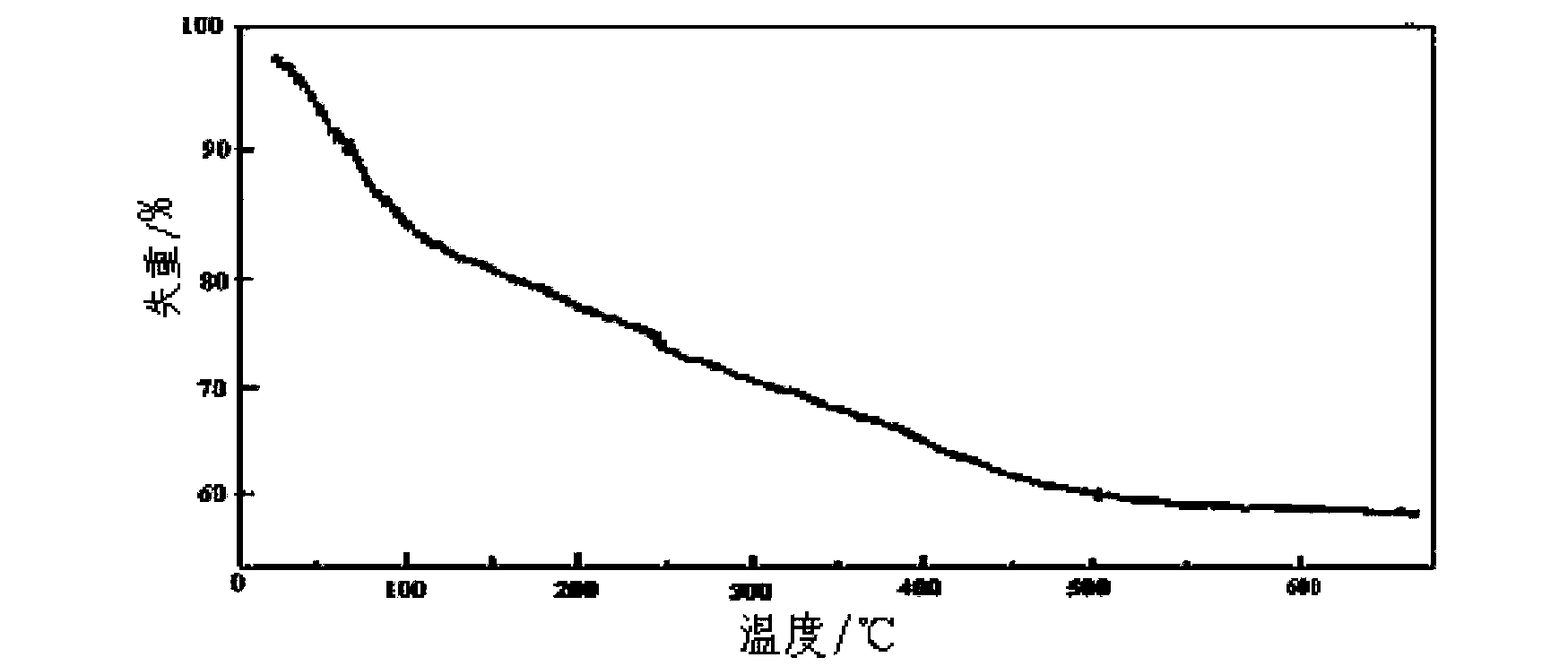

Low-cost nano aluminum oxide film preparation method and nano aluminum oxide film

InactiveCN103449493ALow costImprove the natural environmentAluminium oxide/hydroxide preparationWater bathsPolyvinyl alcohol

The invention discloses a low-cost nano aluminum oxide powder preparation method which comprises the following steps: 1. preparing an aluminum ammonium sulfate crystal from an aluminum oxide spent catalyst or aluminum scrap turnings; 2. dissolving aluminum ammonium sulfate in water, taking aqua ammonia, dropwisely adding the aluminum ammonium sulfate solution into the aqua ammonia while stirring to obtain a precipitate, filtering, adding a hydrochloric acid solution, heating in a water bath while stirring, sufficiently reacting, adding polyvinyl alcohol, and cooling to room temperature to obtain a boehmite sol; and 3. immersing a pretreated support base into the boehmite sol, slowly lifting, drying at room temperature, transferring into a furnace, heating to 550 DEG C, keeping for 2 hours, and carrying out furnace cooling to obtain the nano aluminum oxide film on the support base. By using waste as the raw material, the preparation method disclosed by the invention has the advantages of cost saving, simple production technique and not need of adding complex equipment, and can easily implement industrial production.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Preparation method of high-purity aluminum oxide

InactiveCN103288114ALess impuritiesHigh purityAluminium oxide/hydroxide preparationAluminium hydroxideAluminum ammonium sulfate

The invention discloses a preparation method of high-purity aluminum oxide. The preparation method comprises the following steps of: with industrial Al2(SO4)3.18H2O and (NH4)2SO4 solids as raw materials, preparing an aluminum ammonium sulfate crystal by utilizing a recrystallization method; adding ammonia water to the obtained aluminum ammonium sulfate crystal to obtain an aluminum hydroxide gel; purifying with an aluminum-type mixed resin to obtain a high-purity aluminum hydroxide gel; distilling the obtained aluminum hydroxide gel at reduced pressure to obtain aluminum hydroxide colloidal particles; roasting the aluminum hydroxide colloidal particles for 1 to 2 hours at 1,000 to 1,200 DEG C through a muffle so as to obtain aluminum oxide powder. According to the preparation method, the aluminum ammonium sulfate crystal is prepared by utilizing the recrystallization method, so that the crystal has less impurity; and the prepared aluminum hydroxide sol is purified by the ion exchange resin to obtain the high-purity aluminum hydroxide gel, and then the high-purity aluminum hydroxide gel is roasted to obtain the aluminum oxide which is high in purity.

Owner:RUGAO CITY LEHENG CHEM COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com