Method for preparing hollow aluminum oxide microspheres

A technology of alumina hollow and hollow microspheres, applied in the field of materials, can solve problems such as complex processes, and achieve the effects of simple and reliable process, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

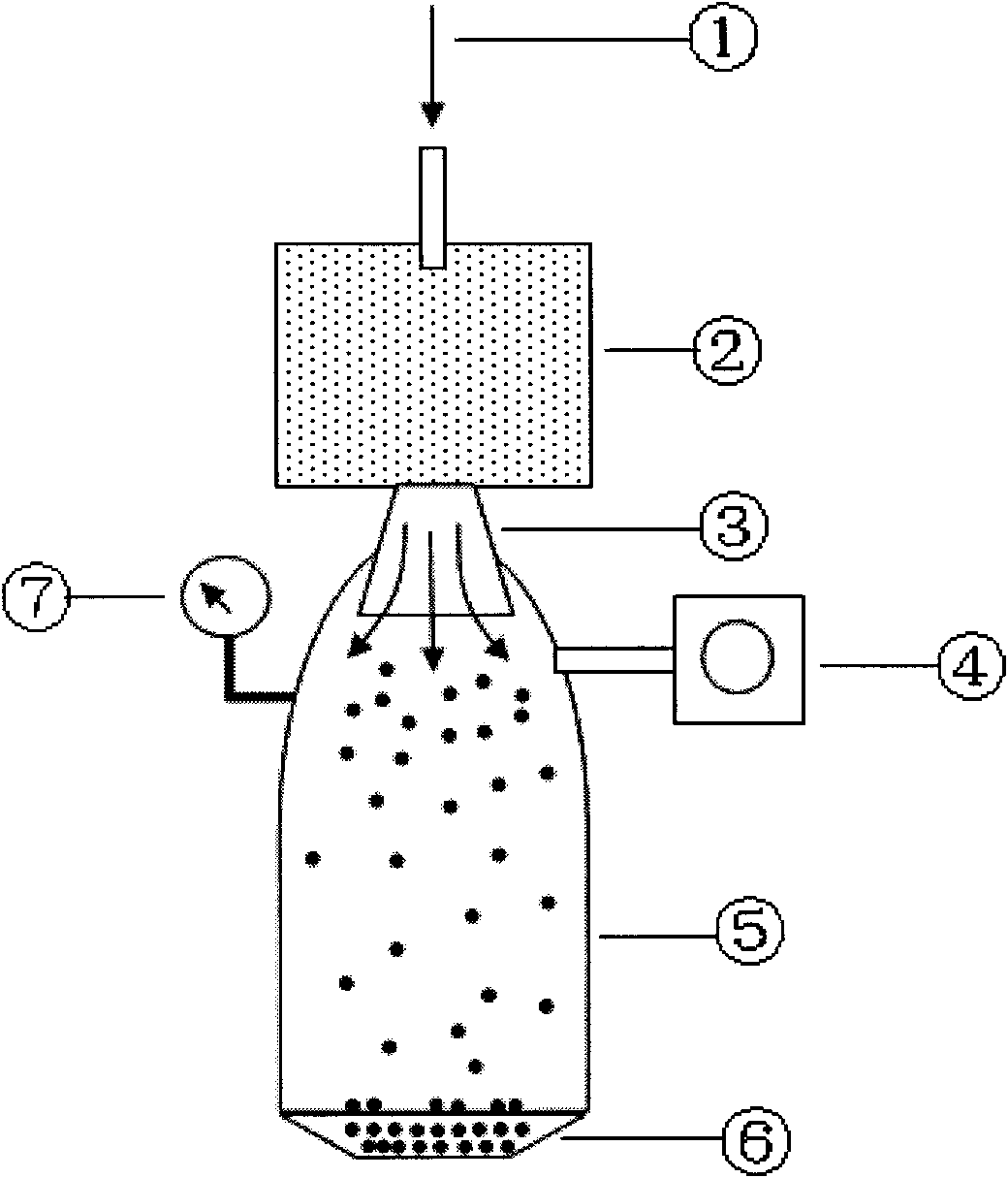

[0017] see figure 1 .

[0018] The present invention uses ammonium aluminum sulfate [(NH 4 ) 2 al 2 (SO 4 ) 4 24 hours 2 O] as raw material, the main preparation equipment is mill, sprayer, vacuum sintering furnace and so on. The specific process is to first heat the vacuum sintering furnace to 1000°C-1200°C and keep the pressure in the furnace at a negative pressure (1kPa-5kPa), then place the aluminum ammonium sulfate powder in the sprayer, atomize and spray it into the vacuum sintering furnace through the sprayer, The atomized aluminum ammonium sulfate is rapidly decomposed in the vacuum sintering furnace to discharge gas, and the volume expansion is calcined at high temperature to form alumina hollow microspheres.

[0019] The specific steps are:

[0020] a) Analytical pure aluminum ammonium sulfate [(NH 4 ) 2 al 2 (SO 4 ) 4 24 hours 2 O] be placed in the pulverizer and grind finely, and cross 800 mesh sieves for subsequent use;

[0021] b) will figure 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com