Beneficiation reagent for separating lead zinc ores from lead zinc sulphide ores containing carbon and beneficiation method

A mineral processing method and sulfide ore technology, applied in solid separation, flotation, etc., can solve the problems of poor separation effect, poor separation effect, and complicated process of the mineral processing process, and achieve low cost, easy operation, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

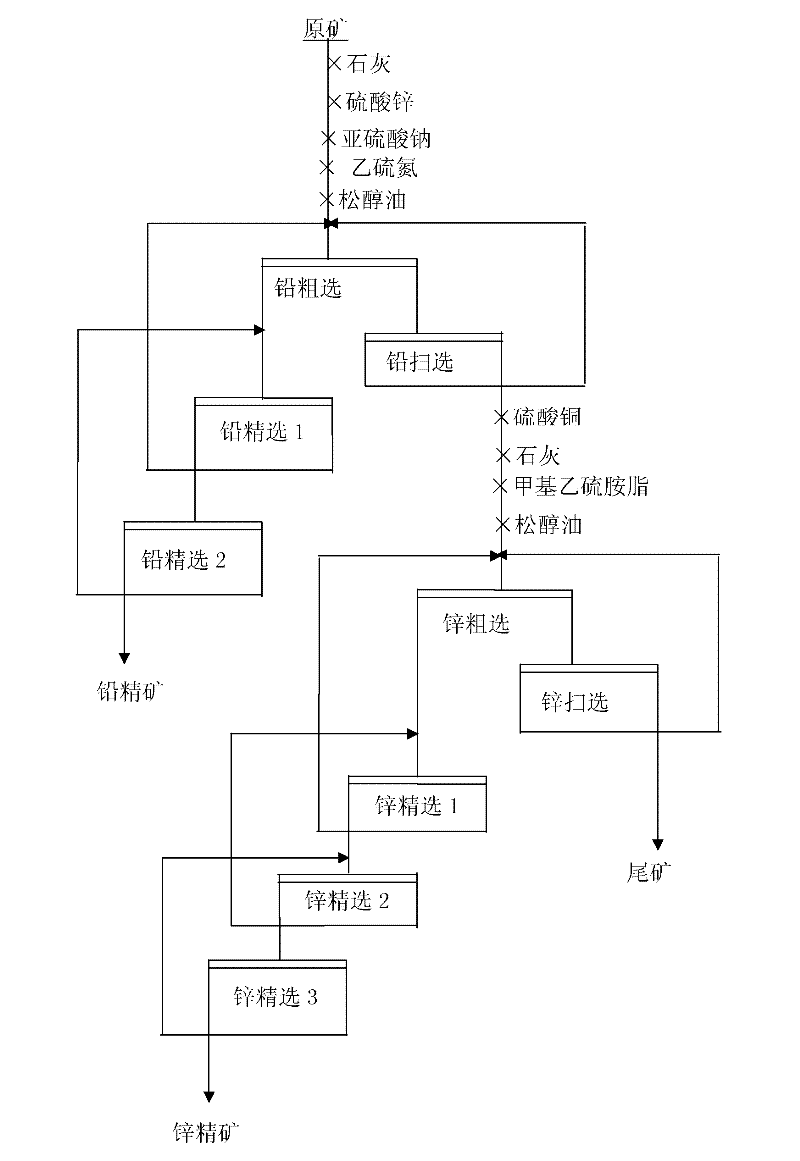

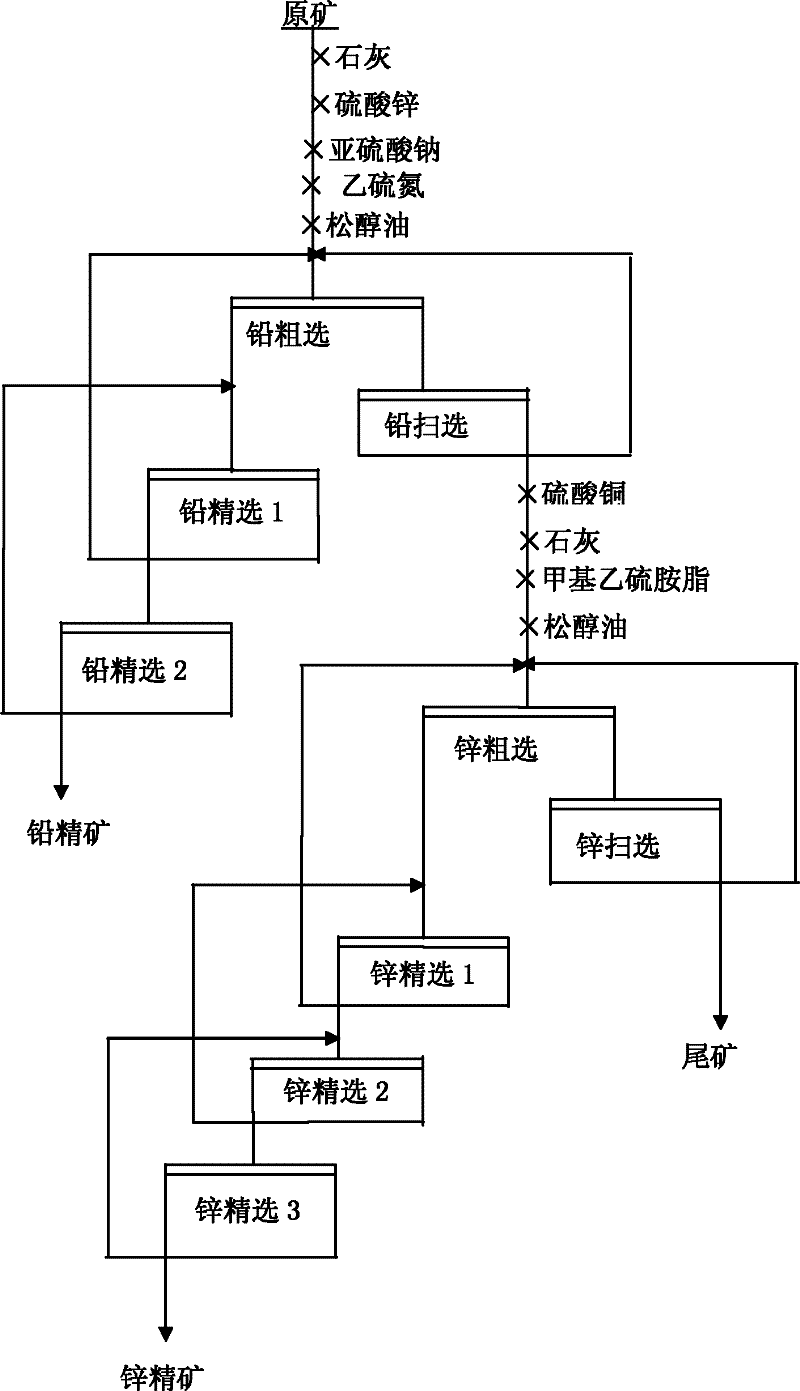

[0031] The mineral dressing agent of the present invention includes lime+zinc sulfate+sodium sulfite as a regulator, ethionyl as a collector for lead selection, copper sulfate as an activator for zinc selection, methyl ethylthiamine grease as a collector for zinc selection, pinitol Oil is a foaming agent.

[0032] The mineral dressing agent of the present invention is to add 4kg / t of lime, 1500g / t of zinc sulfate, 500g / t of sodium sulfite, 80g / t of ethion, 700g / t of copper sulfate, 70g / t of methyl ethanethiamine, and pine alcohol per ton of raw ore. Oil 10g / t. The total amount of lime mentioned above is 4kg / t, including 3kg / t when lead is selected and 1 kg / t when zinc is selected.

[0033] Such as figure 1 Shown, the beneficiation method of separating lead-zinc ore from carbon-containing lead-zinc sulfide ore comprises the following sequential steps implemented at normal temperature:

[0034] (a) Lead roughing: put the raw ore of carbon-containing lead-zinc sulfide ore afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com