Patents

Literature

38results about How to "Adjust gap size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

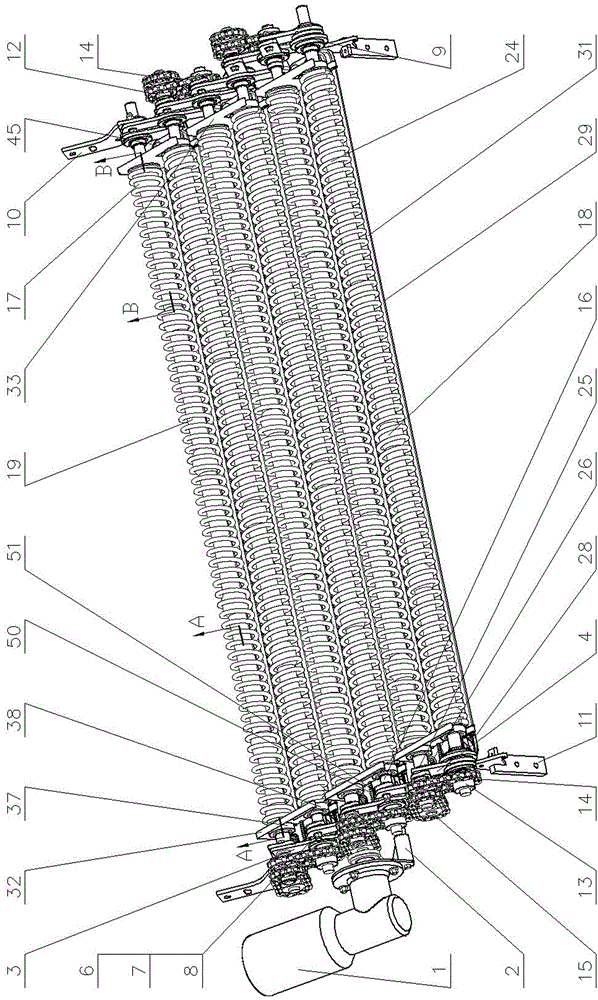

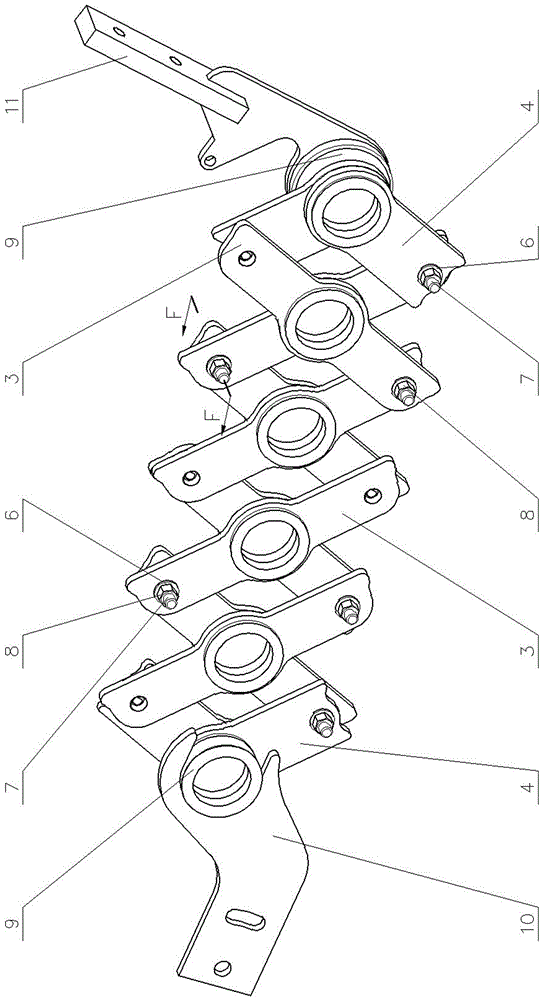

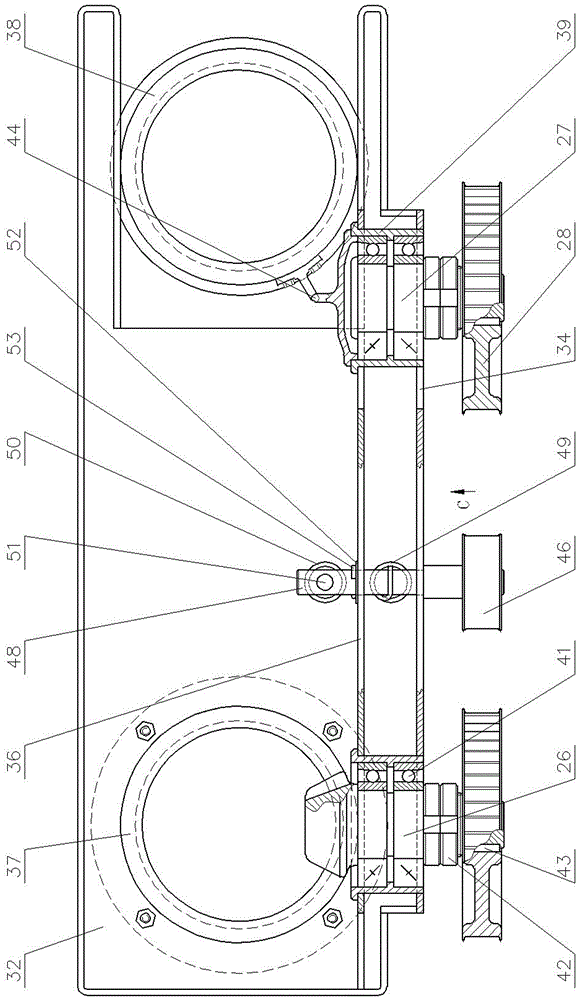

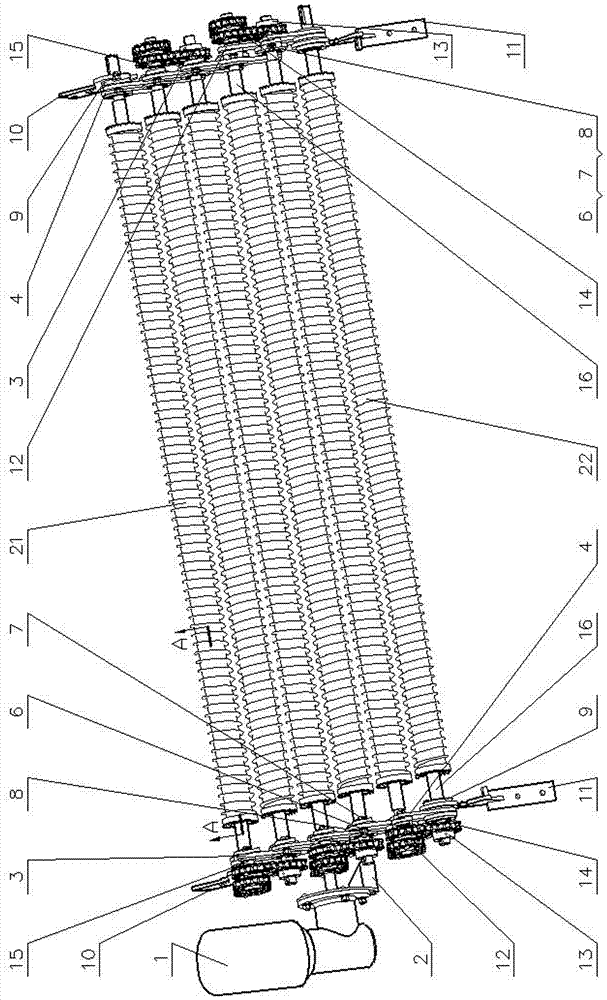

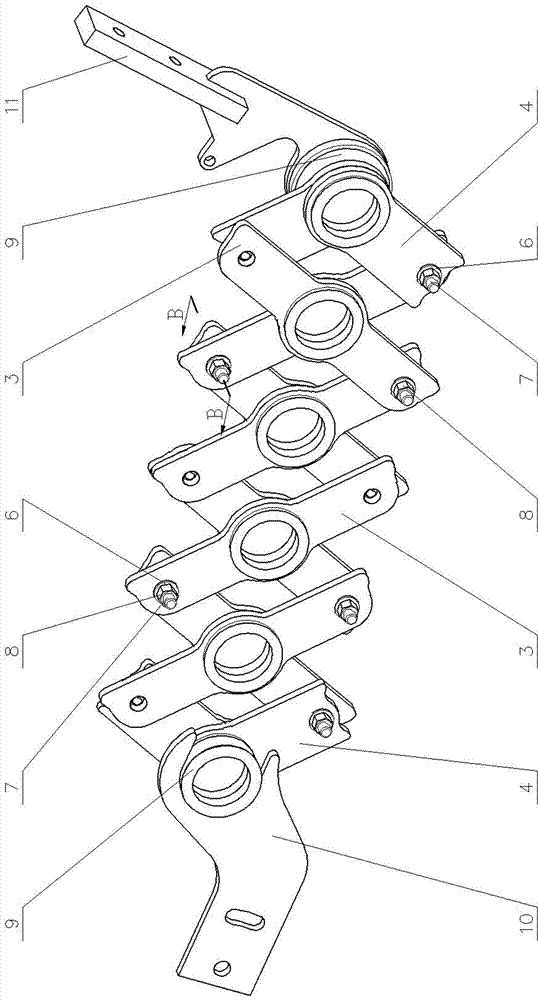

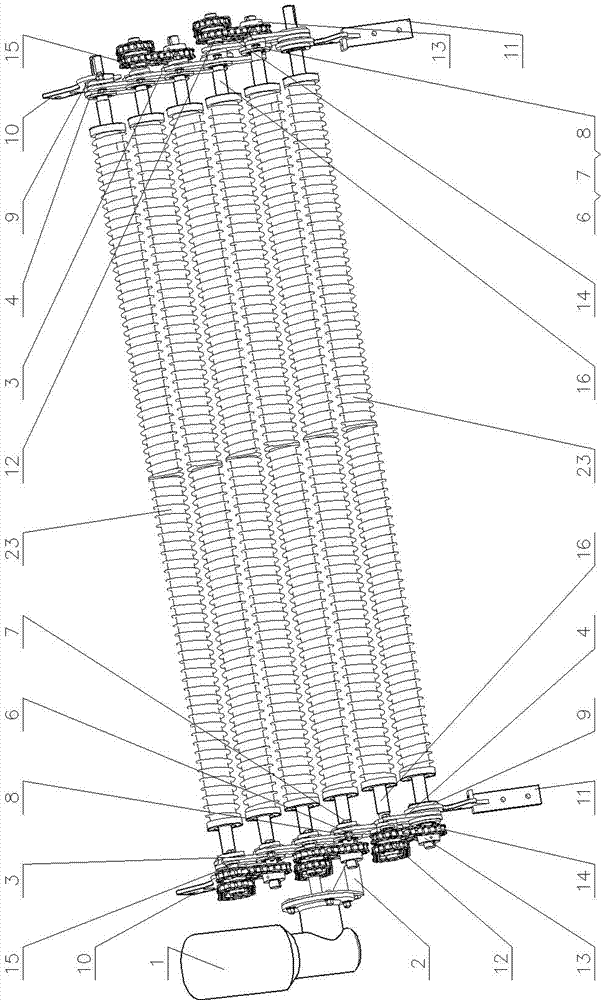

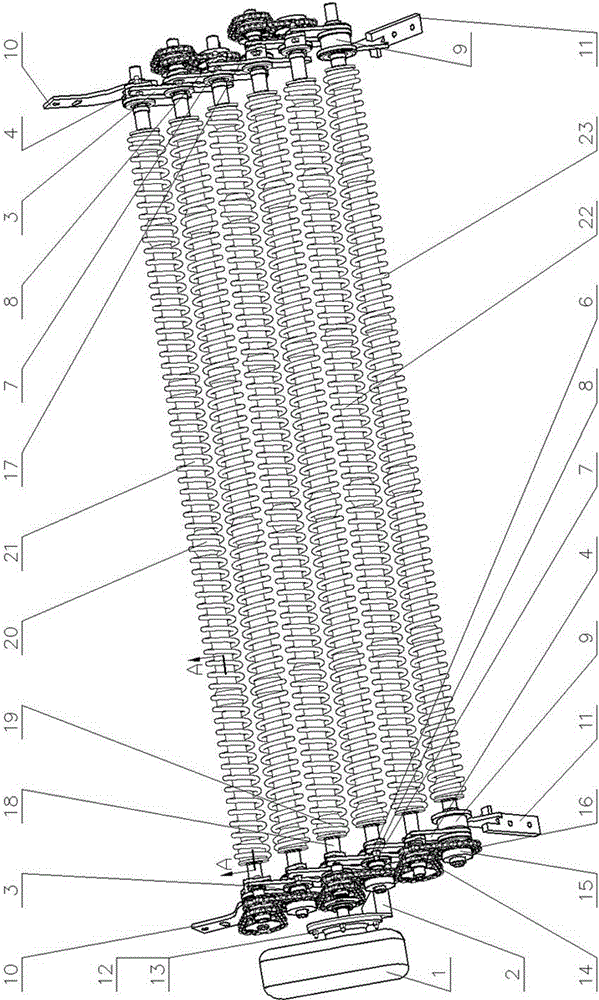

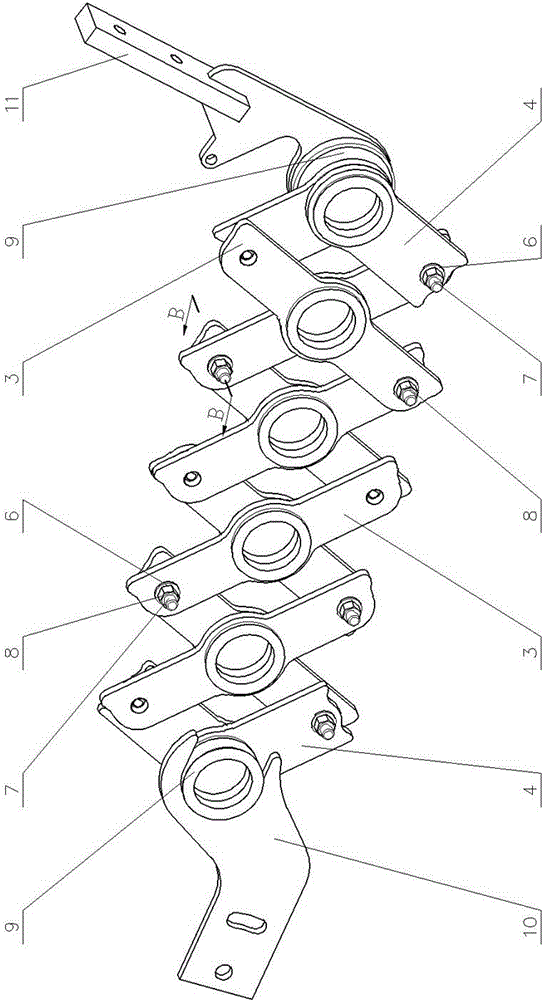

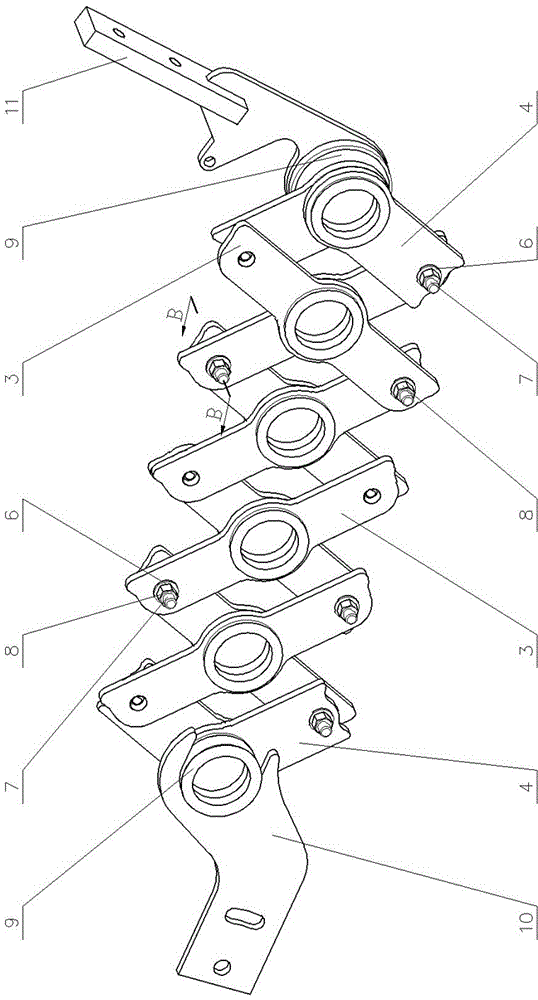

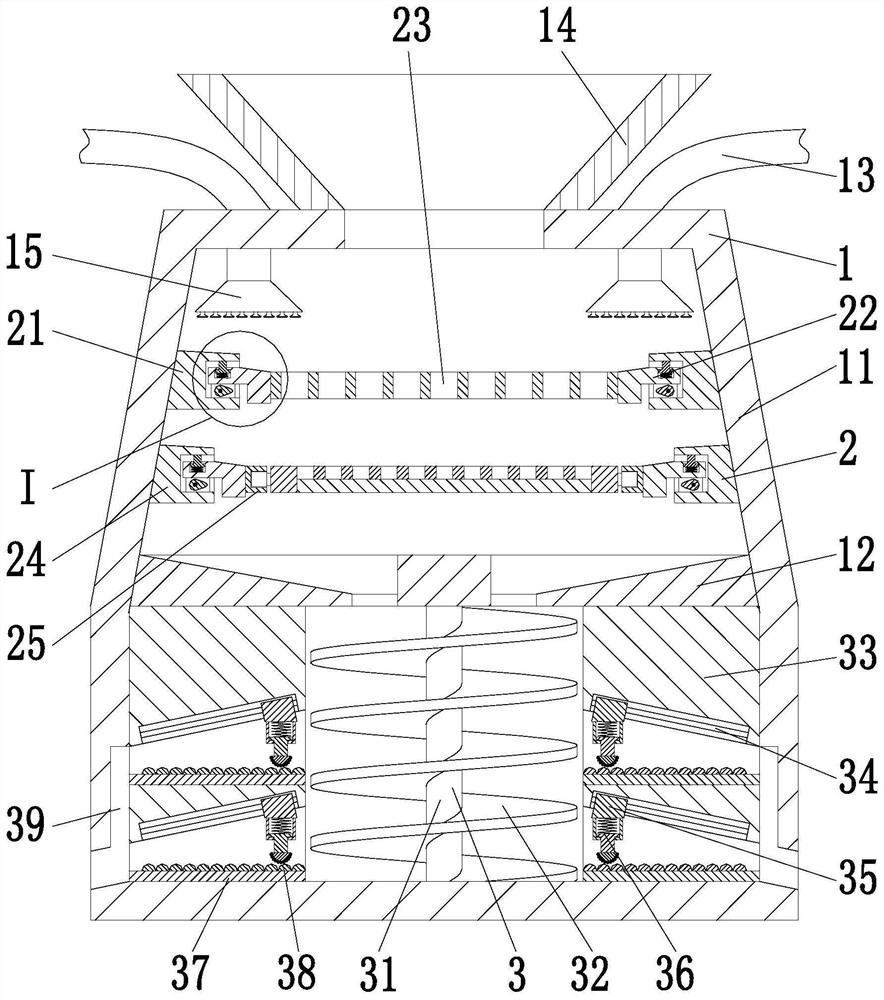

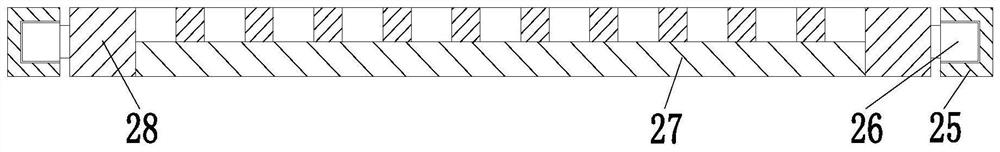

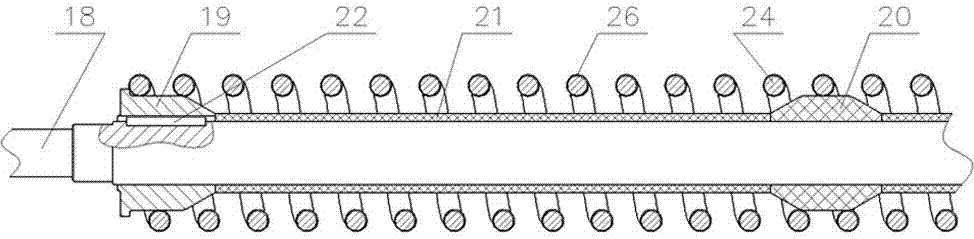

Sorting device provided with impurity-clearing mechanisms used for potato cleaning and sorting machine

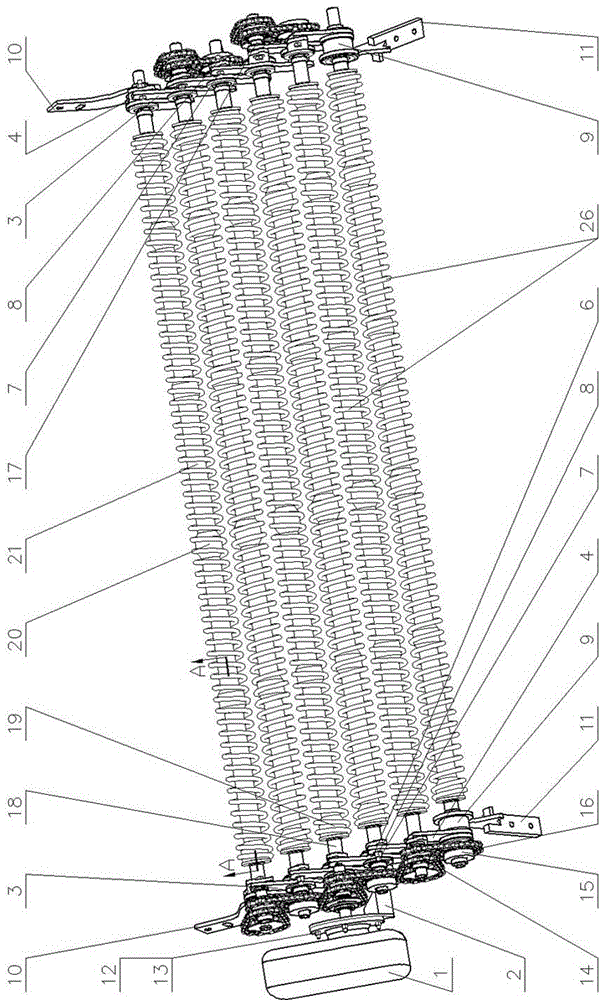

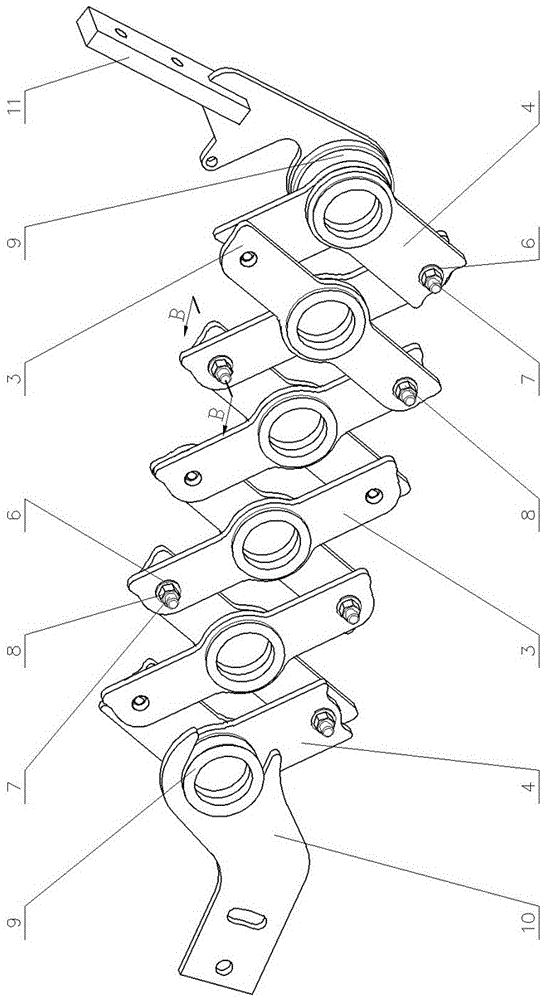

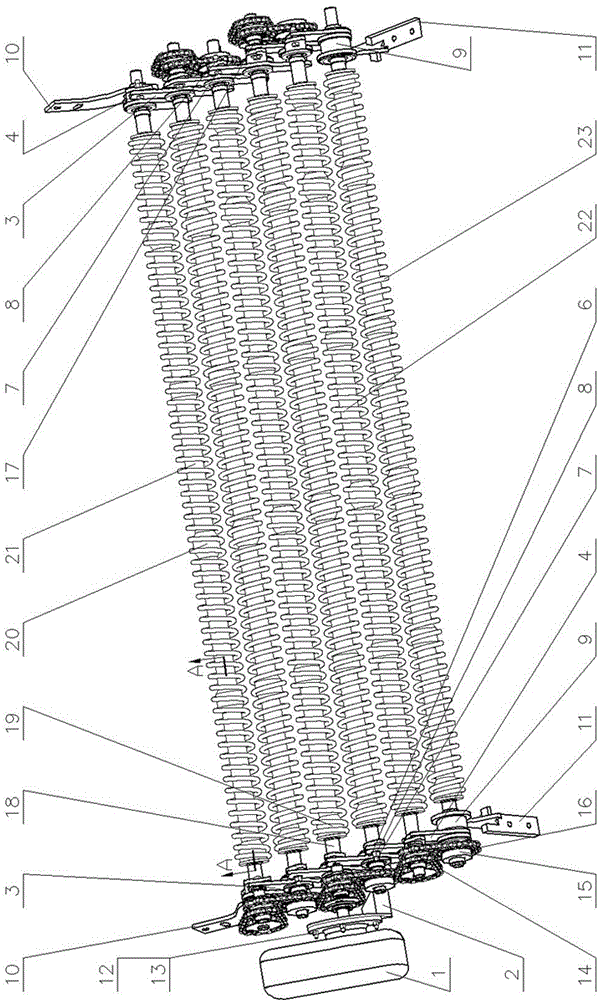

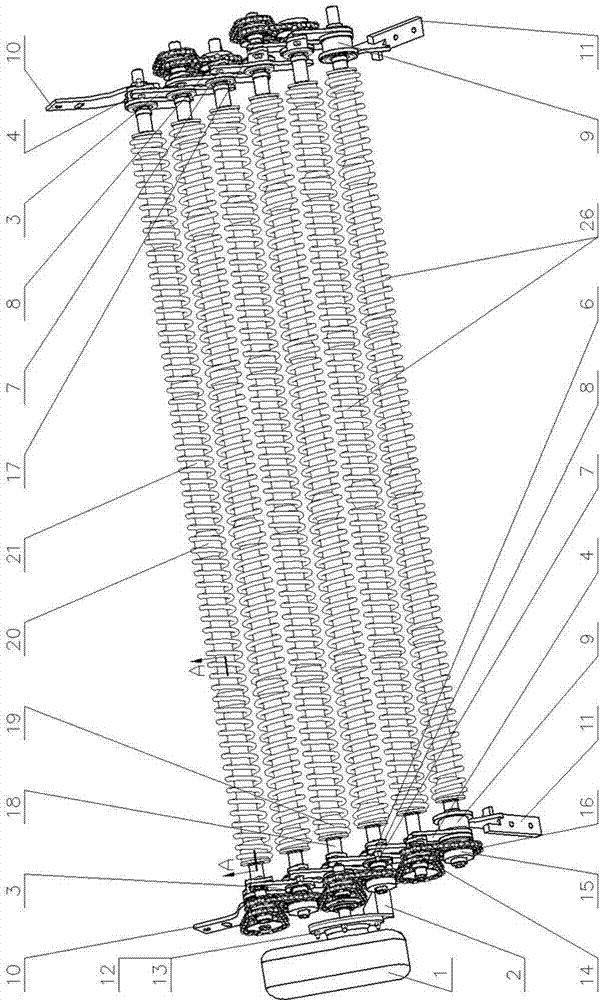

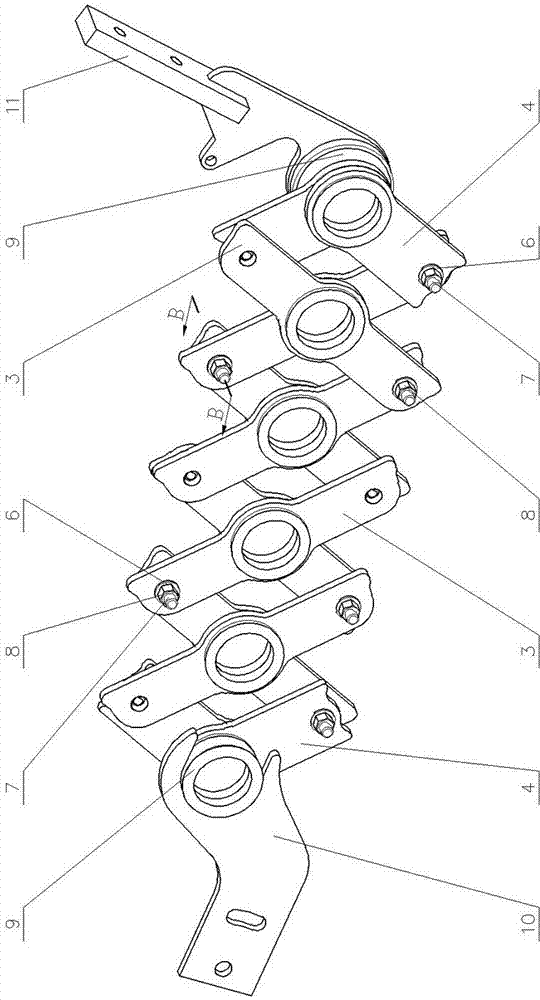

The invention provides a sorting device provided with impurity-clearing mechanisms used for potato cleaning and sorting machine. The sorting device is characterized in that serial numbers of five rhombuses of an expansion bracket are I, II, III, IV and V; a motor frame is mounted on a hinged part of the end part of a long connecting piece with the III rhombus; a gear motor mounted on the motor frame drives each sorting roller on the expansion bracket to rotate through a transmission mechanism; the two ends of each sorting roller which passes through the expansion bracket are connected to a single row of chain wheels; one end of the sorting roller which passes through the rhombus II and the rhombus III is connected to the gear motor; a protective sleeve is arranged on the external circle of each sorting roller in a sleeved manner; the end part, towards the gear motor, of each sorting roller is provided with a impurity-clearing frame I of each clearing mechanism, and the other end of the corresponding sorting roller is provided with a impurity-clearing frame II; a bevel gear shaft is driven by a bevel gear mounted on the sorting roller I to operate; and a plurality of impurity-clearing cones are driven by a synchronous belt which is hung on four synchronous belt wheels of each group of impurity-clearing mechanisms to operate along a rail. The sorting device can be used for conveniently grading the cleaned potatoes and timely clearing mud and impurities, is low in potato damage rate, and is uniform and thorough in sorting.

Owner:SHANDONG UNIV OF TECH +1

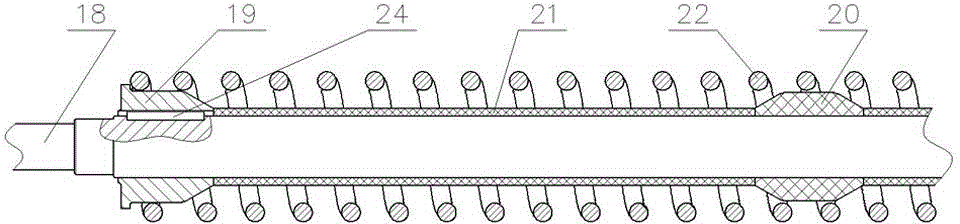

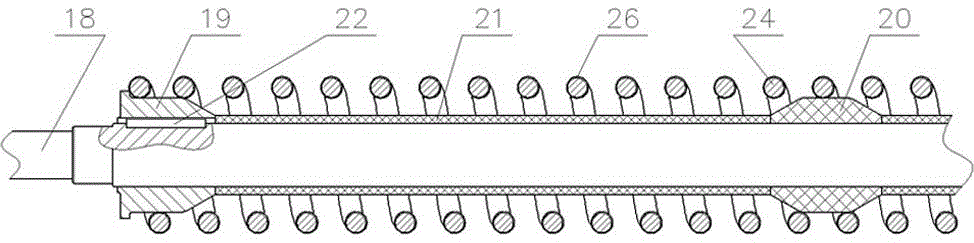

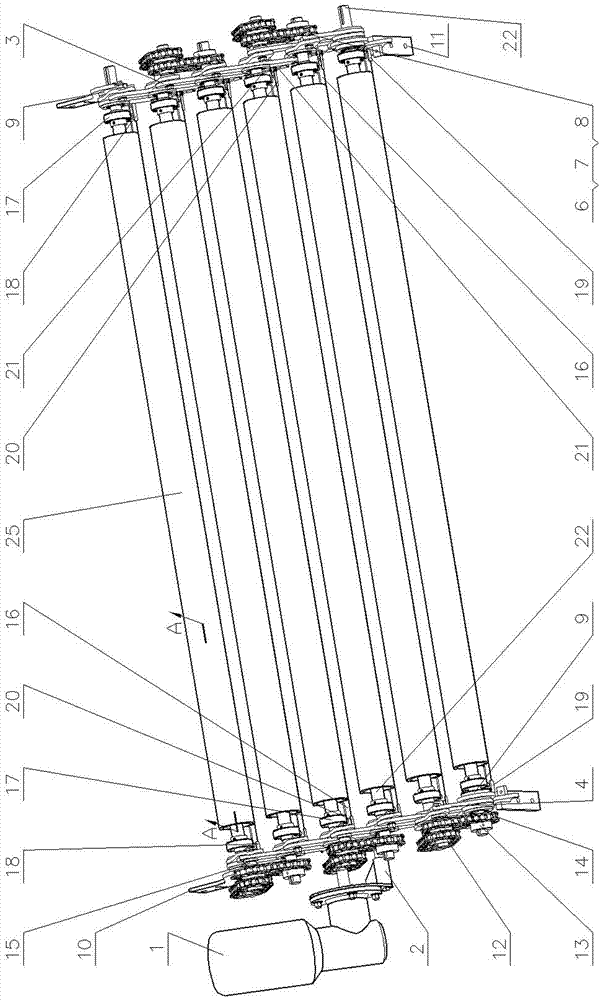

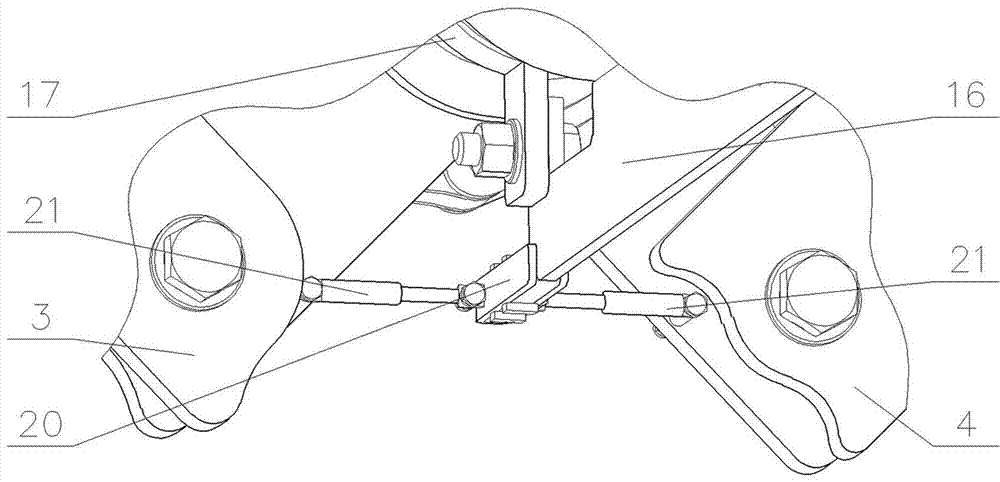

Elastic sorting device of potato separator

The invention provides an elastic sorting device of a potato separator. The device is characterized in that long and short connecting pieces of an extension frame are overlapped and connected to form five rhombuses with sequence numbers of I, II, III, IV and V; a motor frame is mounted in the hinged place of end parts of the long connecting piece of the rhombus III; a speed reducing motor is connected with a flange of the motor frame, and drives each elastic sorting roller, supported on the extension frame by two ends, to rotate through a transmission device; after two ends of one elastic sorting roller I and one elastic sorting roller II respectively penetrate through circular holes in short connecting piece bosses of the rhombuses I and V, extension ends in the direction of the speed reducing motor are connected with single-row chain wheels; the extension ends, penetrating through the extension frame, of the rest elastic sorting rollers are all connected with the single-row chain wheels, and penetrate through the single-row chain wheels in the hinged place of the rhombuses II and III; and the extension ends towards the speed reducing motor are connected with the speed reducing motor. The device can conveniently classify cleaned potatoes, and is low in skin breakage rate, stable and reliable in work, uniform and thorough in sorting and wide in application range.

Owner:山东希成农业机械科技有限公司 +1

Potato cleaning conveyer sorting device

The invention provides a potato cleaning conveyer sorting device. The potato cleaning conveyer sorting device is characterized in that long connecting pieces and short connecting pieces of a retractable frame are connected in an overlapped mode to form five diamond shapes with sequence numbers of I, I, III, IV and V; a motor rack is mounted on the hinged position of the end portion of the long connecting piece of the diamond shape III; the reducing motor is connected with the flange of the motor rack and drives sorting rollers to rotate, wherein both ends of every sorting roller are supported inside the corresponding round holes of the retractable frame; both ends of a sorting roller I and a sorting roller II penetrate the round holes of the bosses of the short connecting pieces of the diamond shape I and the diamond shape V respectively, and then the extending ends of the sorting roller I and the sorting roller II, which face towards a reducing motor, are connected with single-row chain wheels; the others sorting rollers penetrate the retractable frame, and then the extending ends of the others sorting rollers are connected with the single-row chain wheels; after penetrating the single-row chain wheels at the hinged positions of the diamond shape II and the diamond shape III, the extending ends of the others sorting rollers, which face towards the reducing motor, are connected with the reducing motor. The potato cleaning conveyer sorting device can conveniently sort cleaned potatoes and meanwhile, is even and thorough in sorting, wide in application range and reliable in working.

Owner:山东思代尔农业装备有限公司 +1

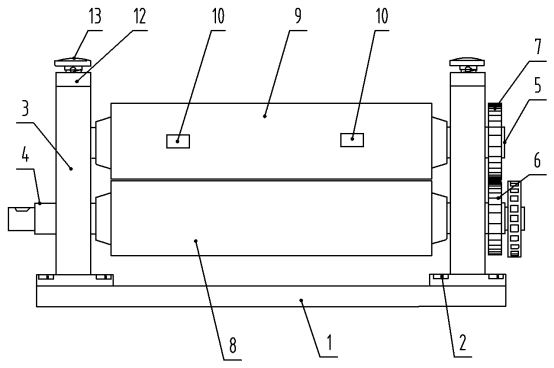

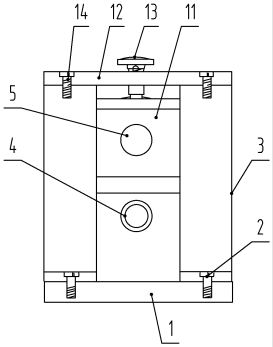

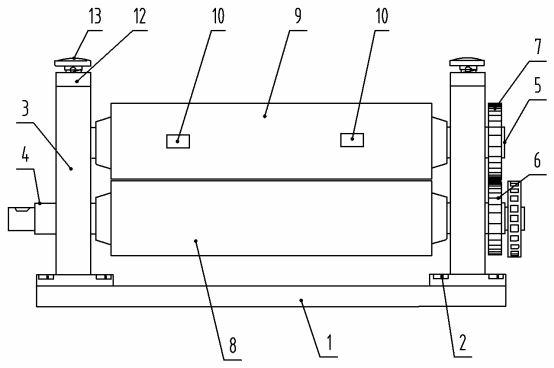

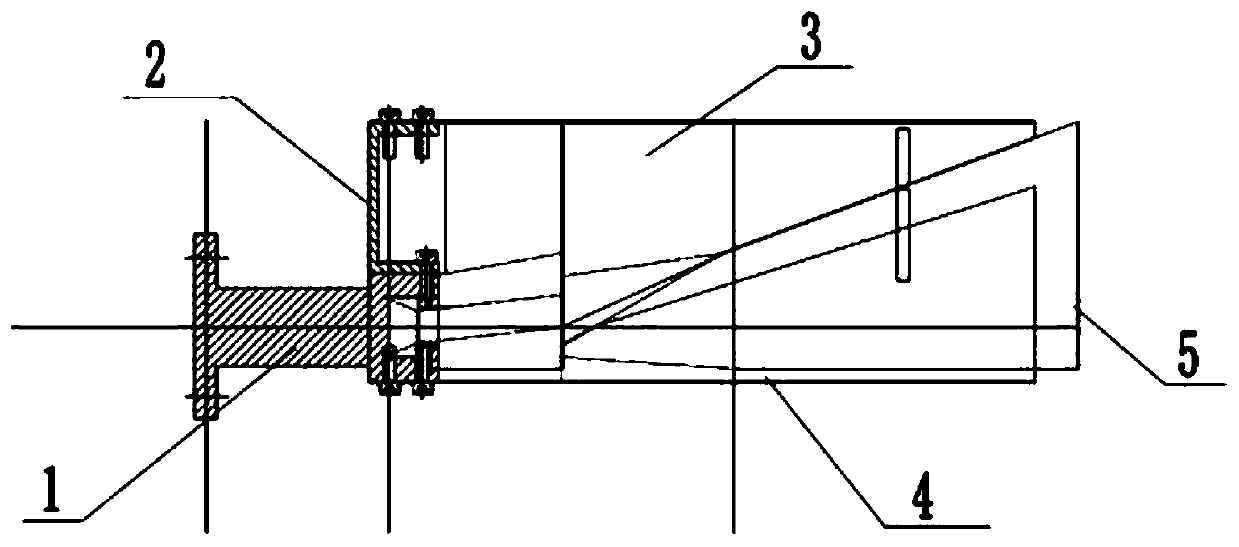

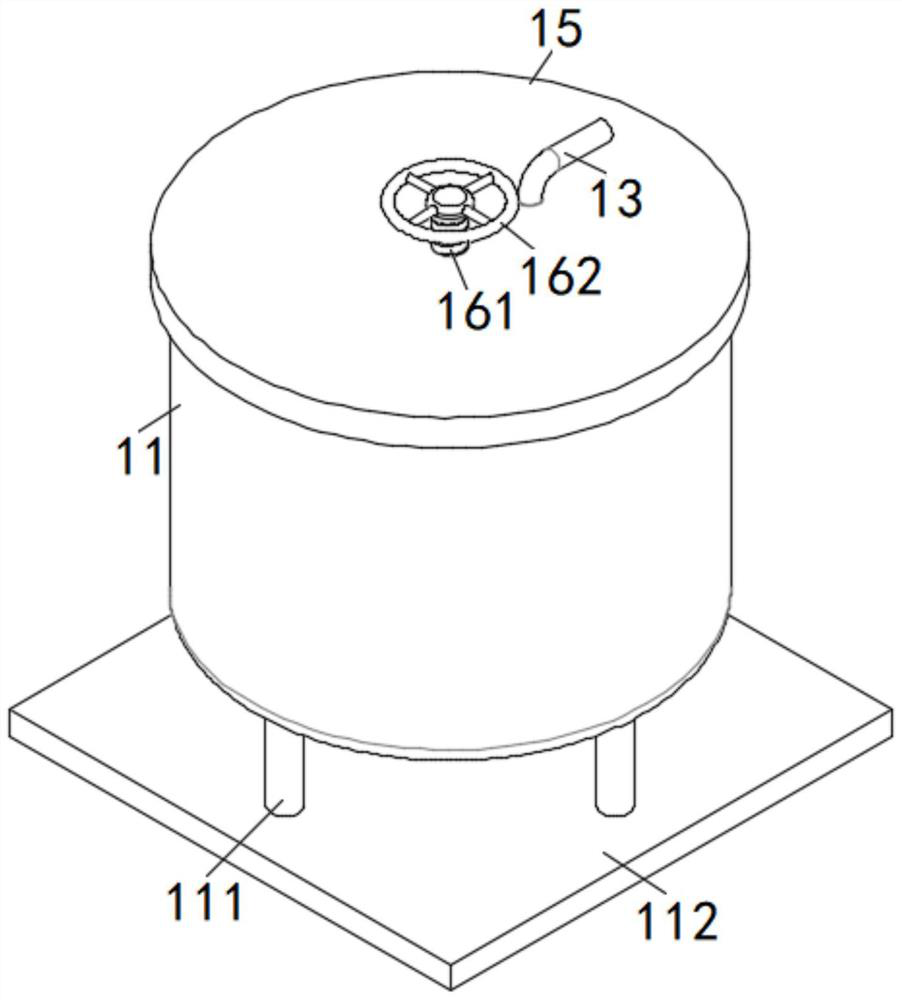

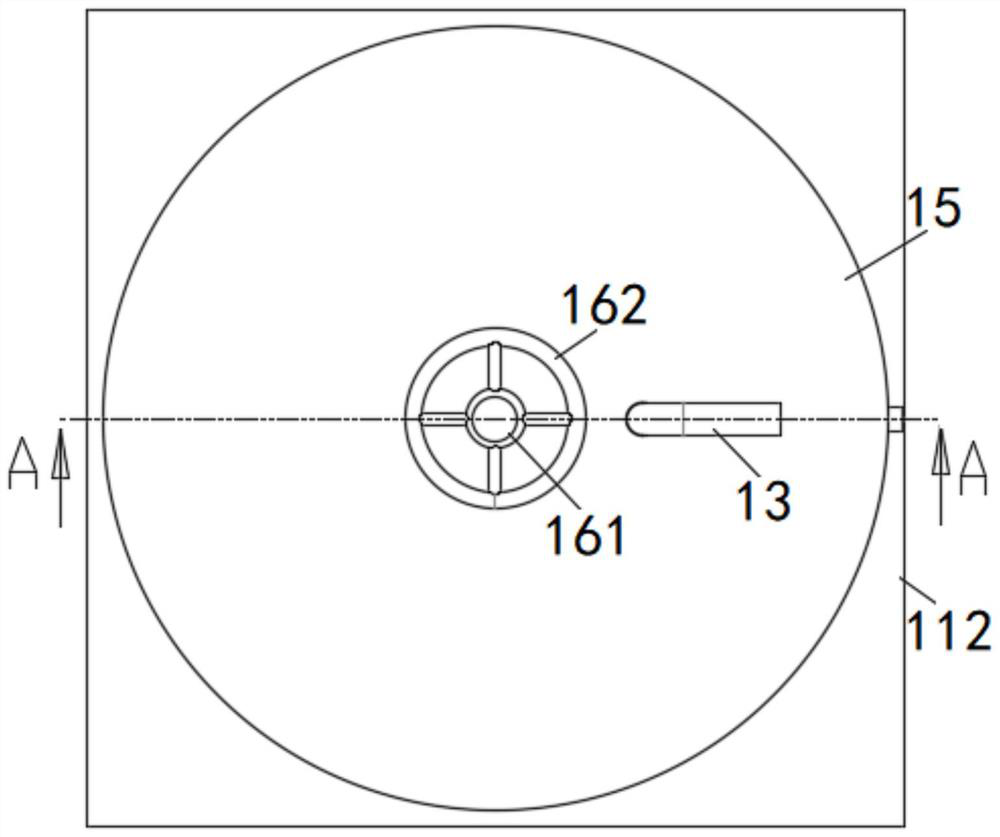

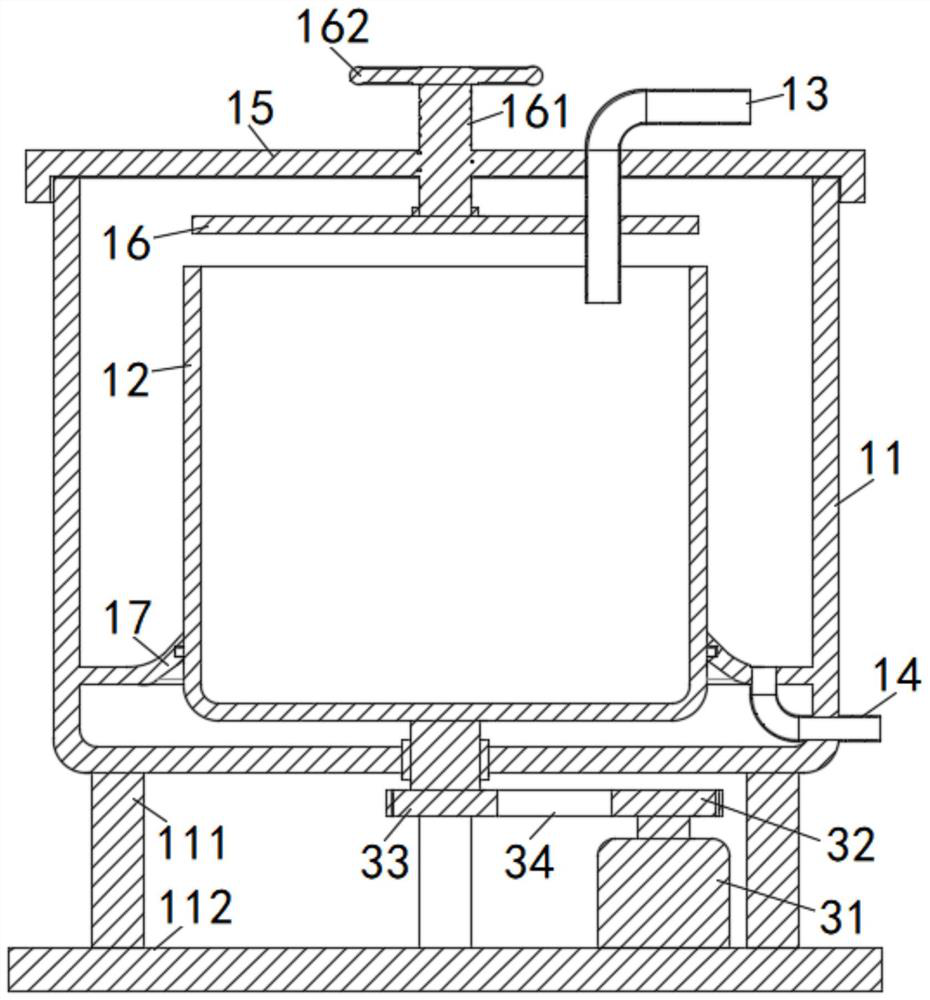

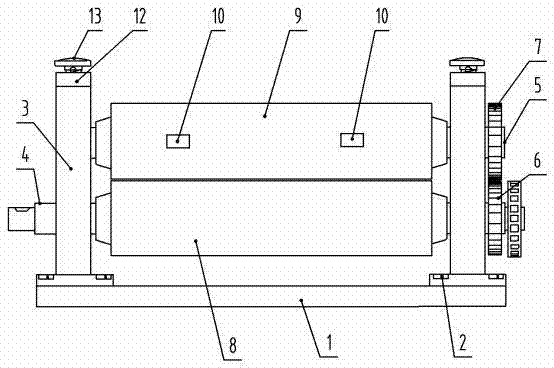

Damping rubber plate molding machine

InactiveCN102069588AAdjust gap sizeFulfil requirementsDomestic articlesStampingMolding machineDrive shaft

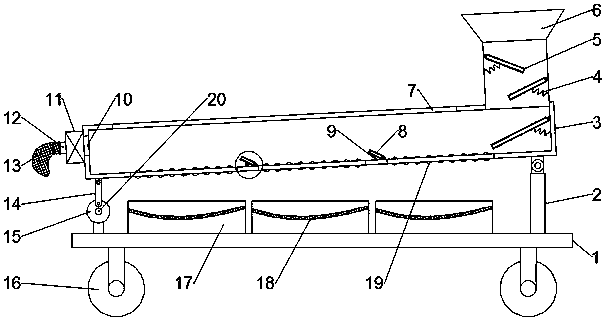

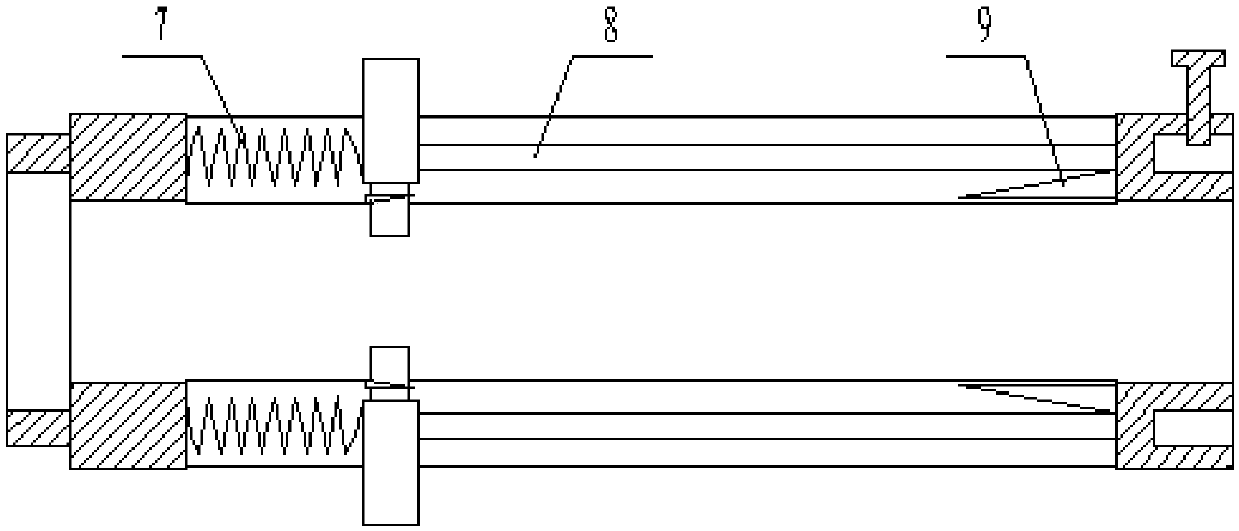

The invention discloses a damping rubber plate molding machine, which comprises a base, and a frame arranged on the base. A driving shaft and a driven shaft are arranged on the frame; the same end of the driving shaft and the driven shaft is provided with a driving gear and a driven gear in engaged transmission respectively; a compression roller is arranged on the driving shaft and the driven shaft respectively; the frame comprises two movable plates which are rotationally connected with two ends of the driven shaft, and two fixing plates which are positioned above the movable plates and are arranged on the top of two sides of the frame; and an adjusting hand wheel of which the lower end is fixedly connected with the movable plates is screwed on each fixing plate respectively. The dampingrubber plate molding machine is simple in structure, easy to manufacture, easy and convenient to operate, low in cost, diversified in function, high in practicality and easy for popularization and application.

Owner:ZHENGZHOU LEDA IND

Sorting device with protection sleeves of potato cleaner

The invention provides a sorting device with protection sleeves of a potato cleaner. The sorting device is characterized in that long connecting sheets and short connecting sheets of telescopic frames are overlapped and connected to form five rhombuses, and the sequence numbers of the rhombuses are I, II, III, IV and V; a motor rack is mounted at the hinged position of the ends of the long connecting sheets of the rhombus III; a gear motor is connected with a flange of the motor rack; sorting rollers with the two ends borne on the telescopic frames are driven by a transmission device to rotate; the outer circle of a spring wire of each spring is sleeved with one corresponding protection sleeve; after the two ends of one sorting roller I and the two ends of one sorting roller II penetrate round holes in bosses of the short connecting sheets of the rhombus I and the rhombus V, the stretching ends, in the direction of the gear motor, of the sorting roller I and the sorting roller II are connected with single-row chain wheels; and the stretching ends, penetrating the telescopic frames, of the rest of the sorting rollers are all connected with single-row chain wheels, and after penetrating single-row chain wheels at the hinged position of the rhombus II and the rhombus III, the stretching ends, facing the gear motor, of the rest of the sorting rollers are connected with the gear motor. The sorting device can classify thoroughly-cleaned potatoes conveniently, and is low in potato damage rate, even and thorough in sorting and wide in application range.

Owner:SHANDONG UNIV OF TECH

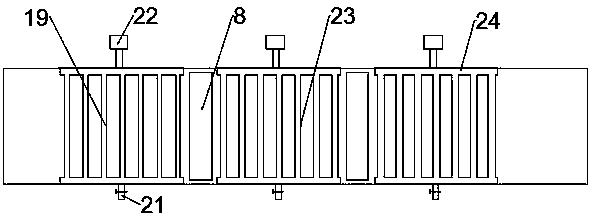

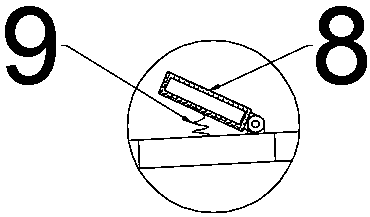

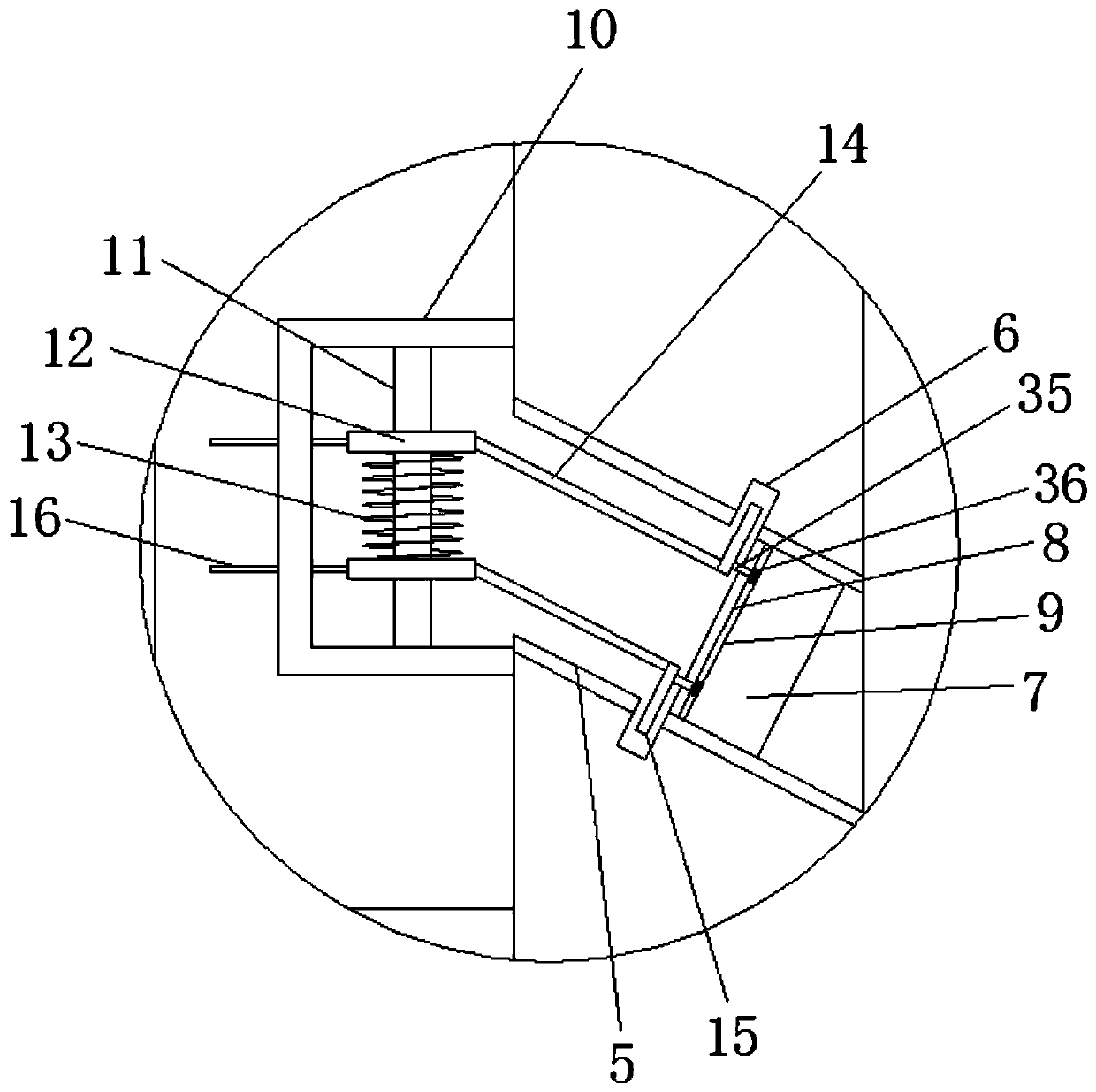

Adjustable multi-stage fruit sorting device

InactiveCN108940872AAdjust gap sizeFast sortingSievingGas current separationCircular discMotor drive

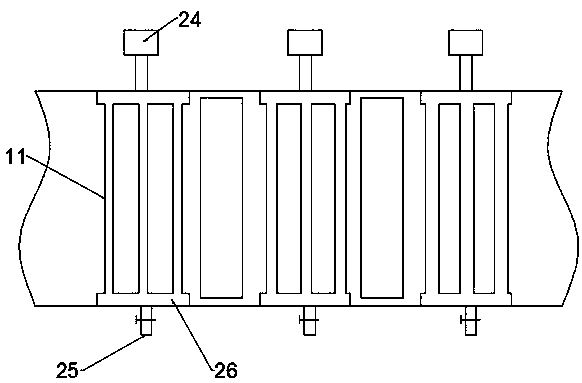

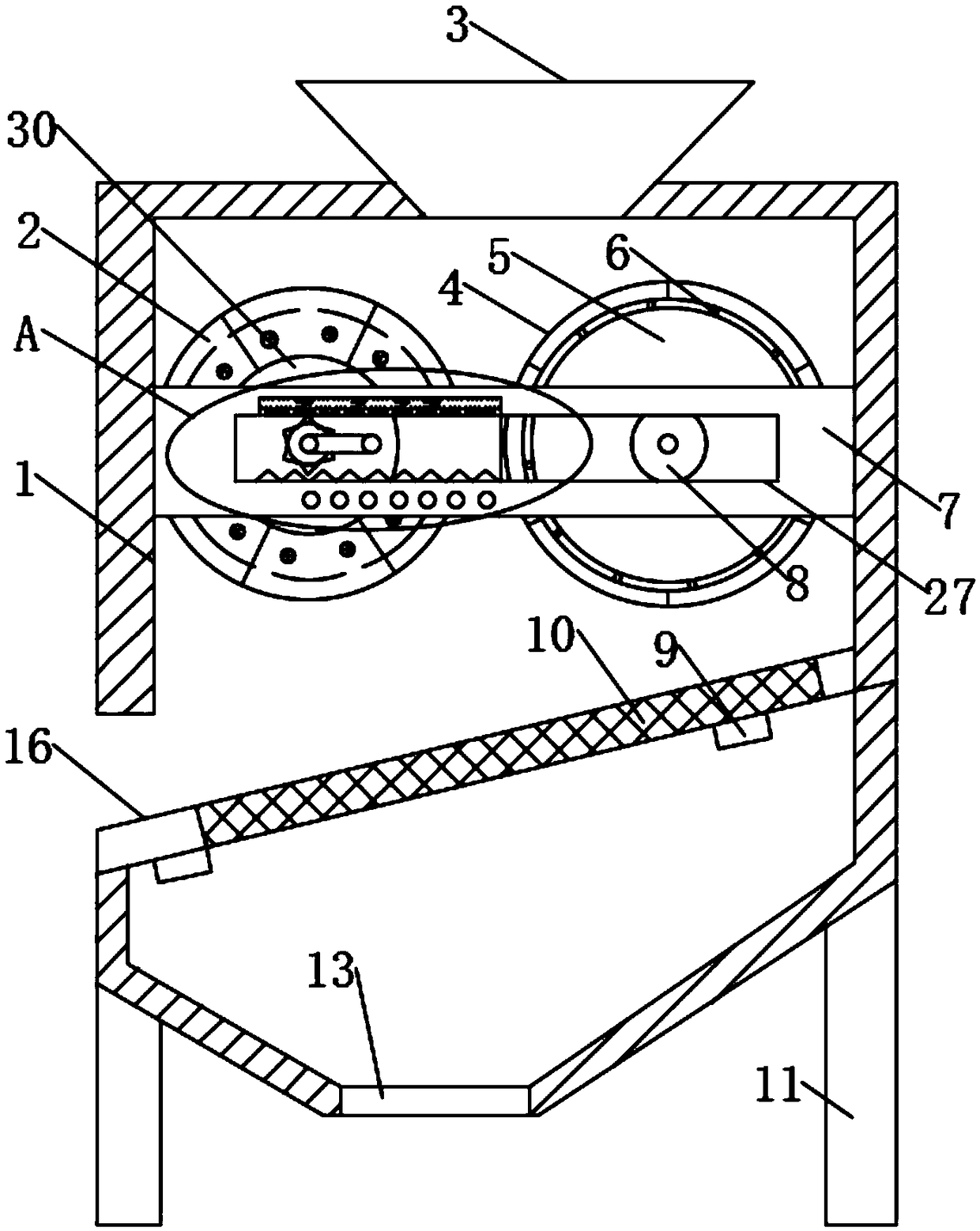

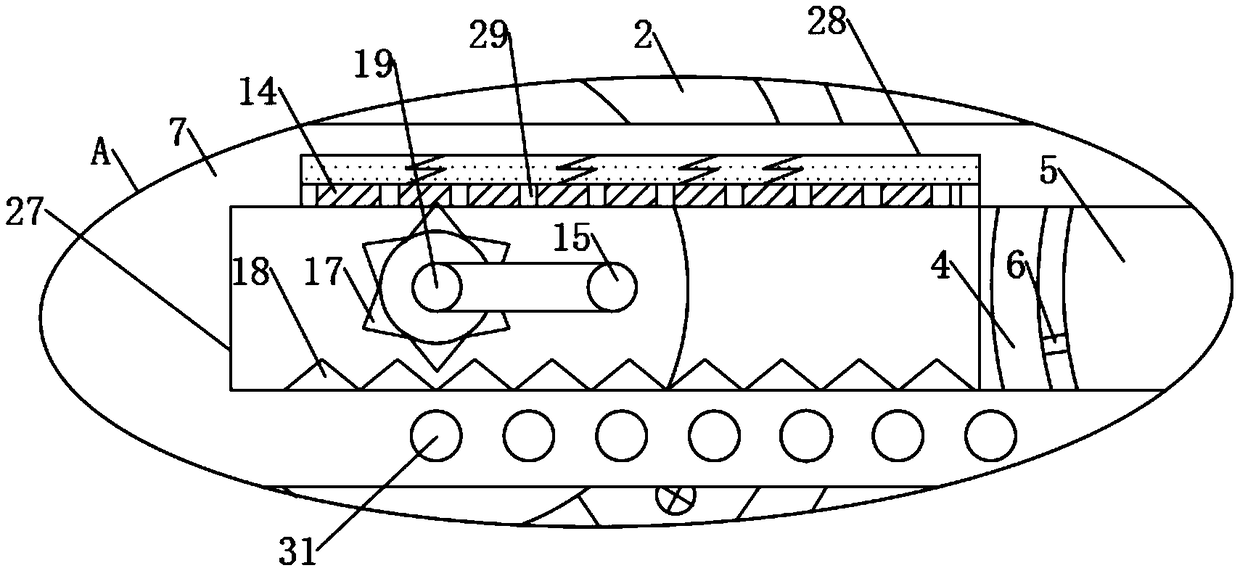

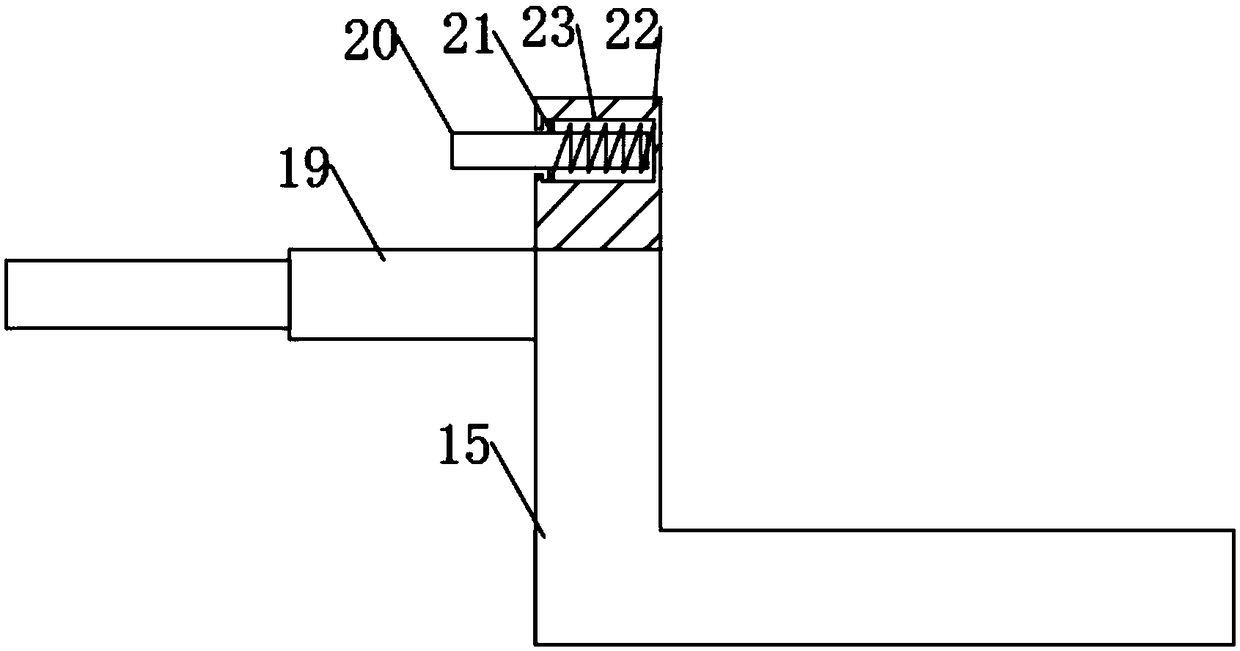

The invention discloses an adjustable multi-stage fruit sorting device. The adjustable multi-stage fruit sorting device comprises a bottom plate, a sorting box, a supporting rod, a motor, a disc, a connection rod, first buffer plates, first buffer springs, a sorting pipeline, an air pump, an air escape valve, second buffer plates and collecting frames. The adjustable multi-stage fruit sorting device is provided with the supporting rod, the motor, the disc and the connection rod, the motor drives the disc to rotate, the disc drives the sorting box to continuously swing around the top end of thesupporting rod through the connection rod, accordingly, fruits can continuously roll down advantageously, the sorting speed is advantageously increased, and the sorting efficiency is improved; the adjustable multi-stage fruit sorting device is provided with the air pump, the sorting pipeline and the air escape valve, sorting branch pipes can be subjected to air inflation or air escape through theair pump and the air escape valve, accordingly, the gap between every two adjacent sorting branch pipes can be adjusted, and the adjustable multi-stage fruit sorting device can sort different fruitsand is high in applicability; and the adjustable multi-stage fruit sorting device is provided with the an exhaust fan and a compact mesh bag, the exhaust fan works, and leaves in the fruits can be sucked into the compact mesh bag.

Owner:陈国柱

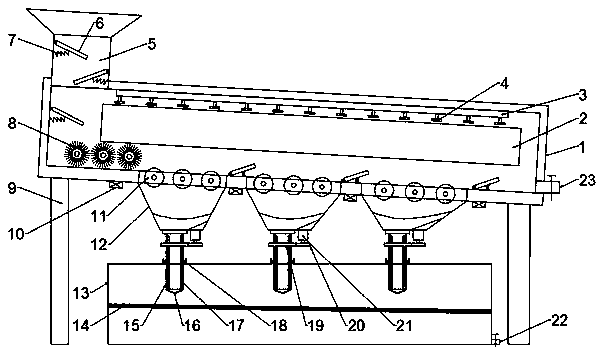

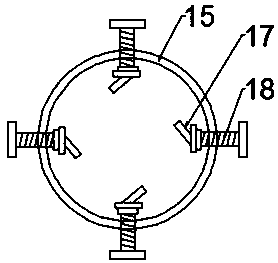

Fruit and vegetable automatic cleaning and peeling device

InactiveCN109090635AEasy to cleanAdjust gap sizeVegetable peelingFood treatmentEngineeringThreaded rod

The invention discloses a fruit and vegetable automatic cleaning and peeling device. The device comprises a box body, a plurality of soft brushing rollers are installed at the lower portion of the left side of an inner cavity of the box body side by side, collecting hoppers are arranged on the portions, at the lower portions of all screening areas, at the bottom of the box body, discharging pipesare arranged on the collecting hoppers, multiple threaded rods equidistantly penetrate through the side walls of the discharging pipes in circumferential direction, installing plates are rotatably installed on the parts, located on one ends of the interiors of the side walls of the discharging pipes, of the threaded rods, and blades are installed on the installing plates through screws. By arranging the soft brushing rollers, hard water pipes and nozzles, fruits and vegetables can be brushed and washed, the screening areas, the discharging pipes, threaded rods and the blades are arranged, andthe position of the blades can be adjusted through the threaded rods to allow the blades to mutually get close to or away from the centers of the discharging pipes to peel fruits with different sizes;an air pump, a screening pipeline and a deflating valve are arranged, the interiors of screening branch pipes can be inflated or deflated, and therefore the size of the gap between the adjacent screening branch pipes can be adjusted to screen different fruits.

Owner:山东润品源食品有限公司

Crusher with screening device for producing building waste recycled aggregates

InactiveCN108654734AAdjust gap sizeAdjust the broken particle sizeGrain treatmentsLeft halfWear resistant

The invention discloses a crusher with a screening device for producing building waste recycled aggregates. A supporting plate is arranged in a case, a horizontal sliding groove is formed in the supporting plate, a horizontal straight gear is arranged on the inner side of the bottom of the left half part of the horizontal sliding groove, the horizontal straight gear is in meshed transmission witha circular gear, located in the horizontal sliding groove, the center of the back face of the circular gear is in transmission connection with a left roller cylinder through a rotating rod, the outersurface of a left roller is provided with a U-shaped wear-resistant plate, the two side plates of the U-shaped wear-resistant plate are fixed on the side wall of the left roller through screws, the front center of the circular gear is fixedly connected with a telescopic rod, the end of the telescopic rod is fixedly connected with an L-shaped handle, an arc-shaped wear-resistant plate is arranged on the surface of a right roller through a screw rod, and an inclined filter screen is arranged in the case, below the left roller and the right roller. According to the crusher, the gap between the left roller and the right roller can be adjusted through the position movement of the left roller, so that the crushing granularity can be adjusted; and the inclined filter screen can be used for screening crushed coarse aggregates and fine aggregates.

Owner:石卫阳

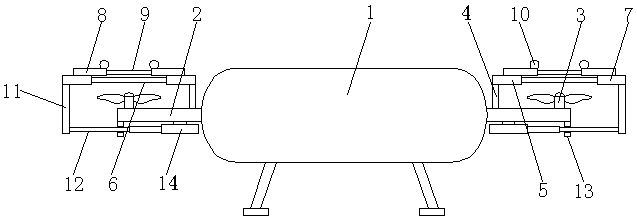

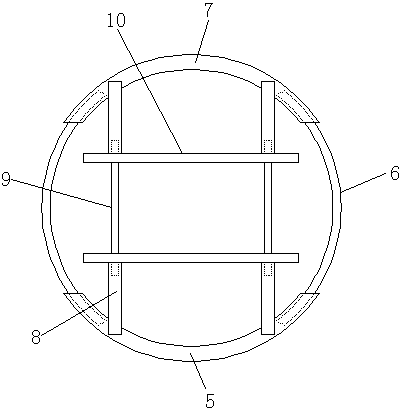

Unmanned aerial vehicle flight collision-prevention device

InactiveCN109353517AImprove securityAvoid occlusionAircraft indicatorsAircraftsForeign objectUncrewed vehicle

The invention discloses an unmanned aerial vehicle flight collision-prevention device and aims to solve the problem that in the prior art, there are not protective measures for blades during flight ofan unmanned aerial vehicle and accordingly collision with tree branches possibly occurs to cause damage. Currently, the following scheme is proposed that the unmanned aerial vehicle flight collision-prevention device comprises a device body, the outer wall of the device body is arrayed and welded with four horizontally arranged installing rods, the sides, away from the device body, of the tops ofthe installing rods are provided with blades, the sides, close to the device body, of the tops of the installing rods are welded with supporting rods arranged in the vertical direction, the tops of the supporting rods are welded with first casing pipes, each first casing pipe is movably sleeved and connected with two first movable rods, the ends, away from the first casing pipes, of the first movable rods are movably sleeved and connected with second casing pipes, the tops of the first casing pipes and the tops of the second casing pipes are both welded with two sleeves. The unmanned aerial vehicle flight collision-prevention device is novel in design, simple in structure and capable of making adjustment to prevent baffles and fixing rods from blocking the blades, accordingly can preventcollision between foreign objects and the blades and improve the safety of the blades.

Owner:郑州浩普航空科技有限公司

Smooth roll sorting device for potato cleaning and sorting machine

The invention provides a smooth roll sorting device for a potato cleaning and sorting machine. The smooth roll sorting device is characterized in that long connecting plates and short connecting plates of each stretching frame are in overlapped connection, forming five rhombuses, and the sequence numbers are I, II, III, IV and V; a motor frame is mounted at the hinge joint of the ends of the long connecting plates of one rhombus III, and a speed reduction motor is connected with a flange of the motor frame and drives smooth roll sorting rollers with two ends supported on the stretching frames to rotate through a transmission device; the two ends of two smooth roll sorting rollers penetrate through round holes in bosses of the short connecting plates of the rhombuses I and the rhombuses V and then stretching-out ends, facing the speed reduction motor, of the two smooth roll sorting rollers are connected with single-row chain wheels, and stretching-out ends of the rest of the smooth roll sorting rollers penetrating through the stretching frames are connected with single-row chain wheels; after penetrating through the single-row chain wheels at the hinge joints of the rhombuses II and the rhombuses III, the stretching-out ends facing the speed reduction motor are connected with the speed reduction motor; and soil scrapers are arranged under the smooth roll sorting rollers. The smooth roll sorting device can conveniently carry out classification on potatoes subjected to preliminary soil removing, the skin breaking rate is low, the sorting rollers are not prone to adhering to soil, and work is stable and reliable.

Owner:山东希成农业机械科技有限公司 +1

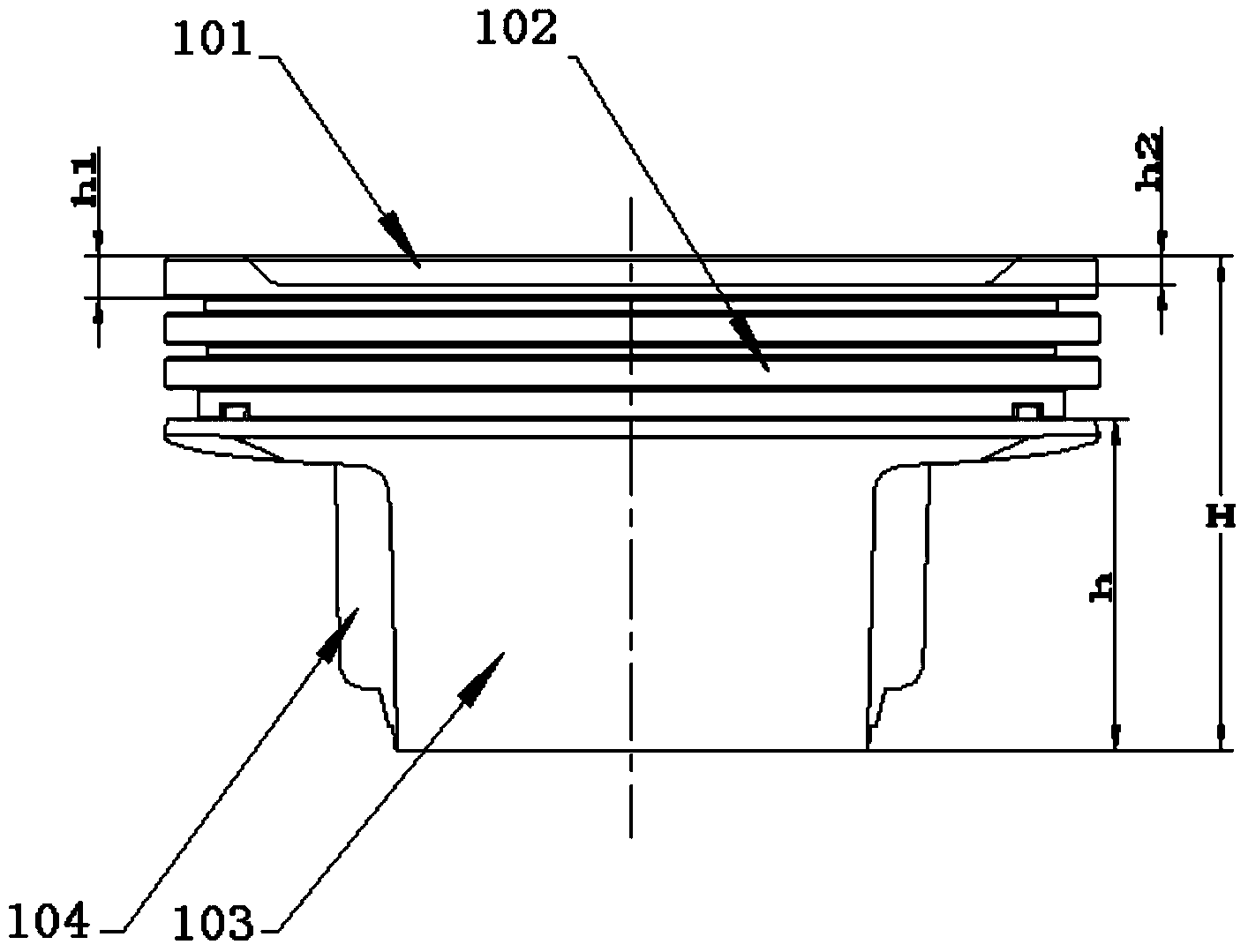

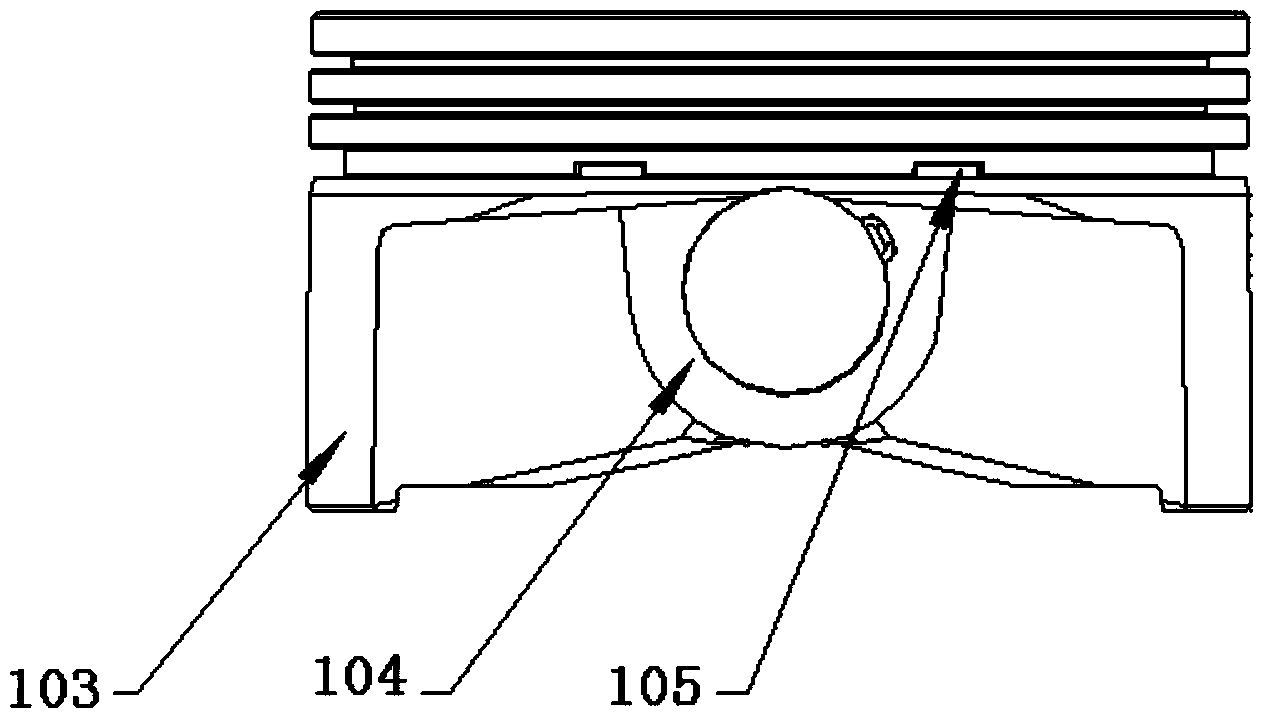

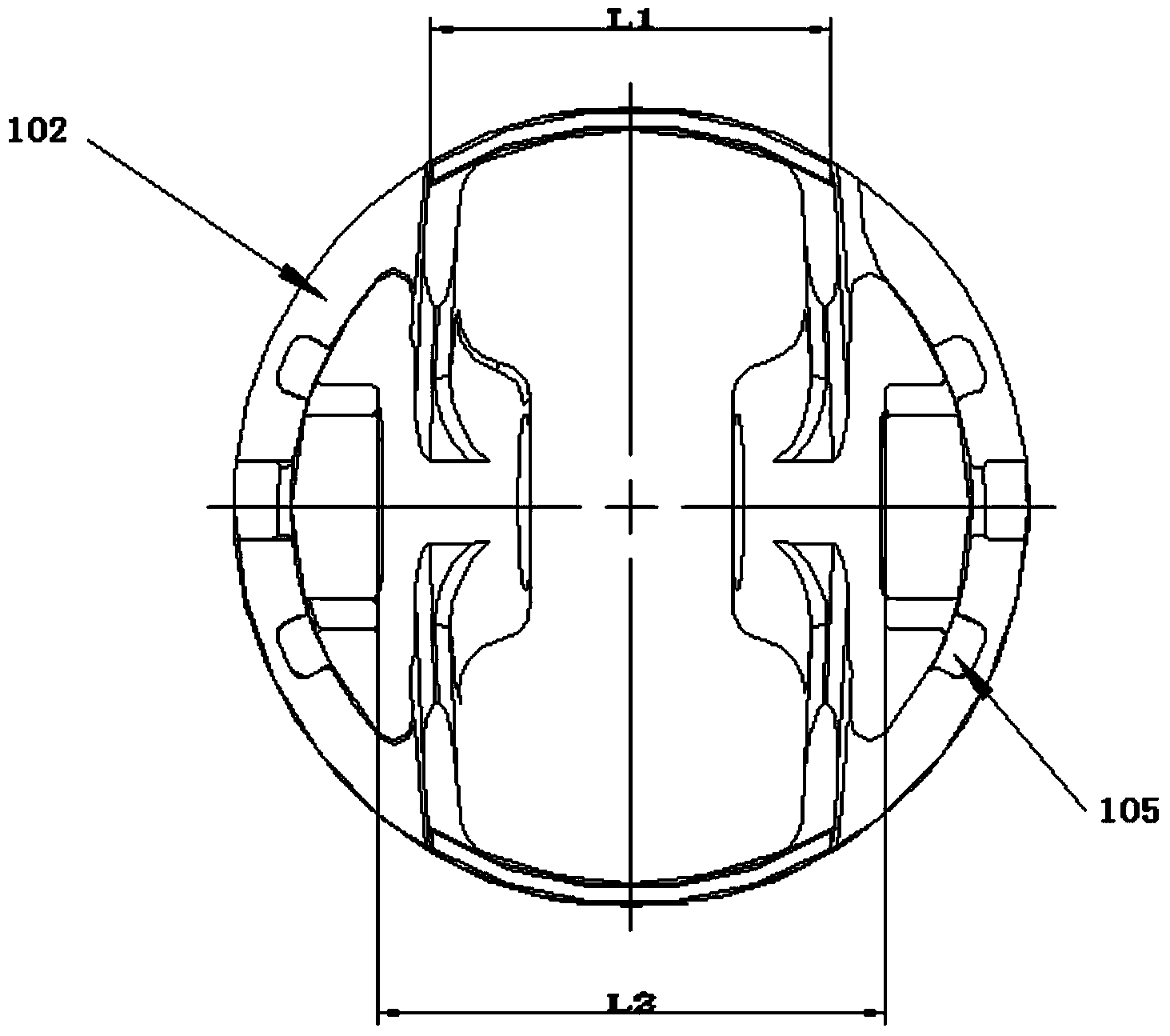

Gasoline engine

ActiveCN103867296AImprove mechanical efficiencyReduce friction workValve arrangementsInternal combustion piston enginesGasolineEngineering

The invention relates to a gasoline engine, which comprises a piston, a combustion chamber and a fuel-oil supplying system, wherein the piston is formed by a piston top, a head, a pin seat and a skirt, wherein the ratio of the height of the skirt to the total height formed by the head and the skirt is 0.6 to 0.7, and the ratio of the chord length of the projection of the molded line of the skirt on a plane on the piston top to the diameter of a cylinder is 0.5 to 0.6; the combustion chamber is hemispheric and is jointly formed by a cylinder head, the piston top, a cylinder-head gasket and one part of a box body, and the surface-to-volume ratio delta of the combustion chamber is 0.15 to 0.25; the fuel-oil supplying system comprises a gasoline pump, a ventilating pipe and a negative-pressure pipe, wherein a negative-pressure impulse-type gasoline pump is adopted as the gasoline pump, the ventilating pipe is arranged on a cylinder head cover, one end of the negative-pressure pipe is connected with the ventilating pipe of the cylinder head cover, and the other end of the negative-pressure pipe is connected with the negative-pressure impulse-type gasoline pump. Through the improvement on structures, such as the piston, a connecting rod, a rocker and the like, the frictional work is reduced, and therefore the mechanical efficiency of the gasoline engine is greatly enhanced.

Owner:ZHEJIANG YAOFENG POWER TECH

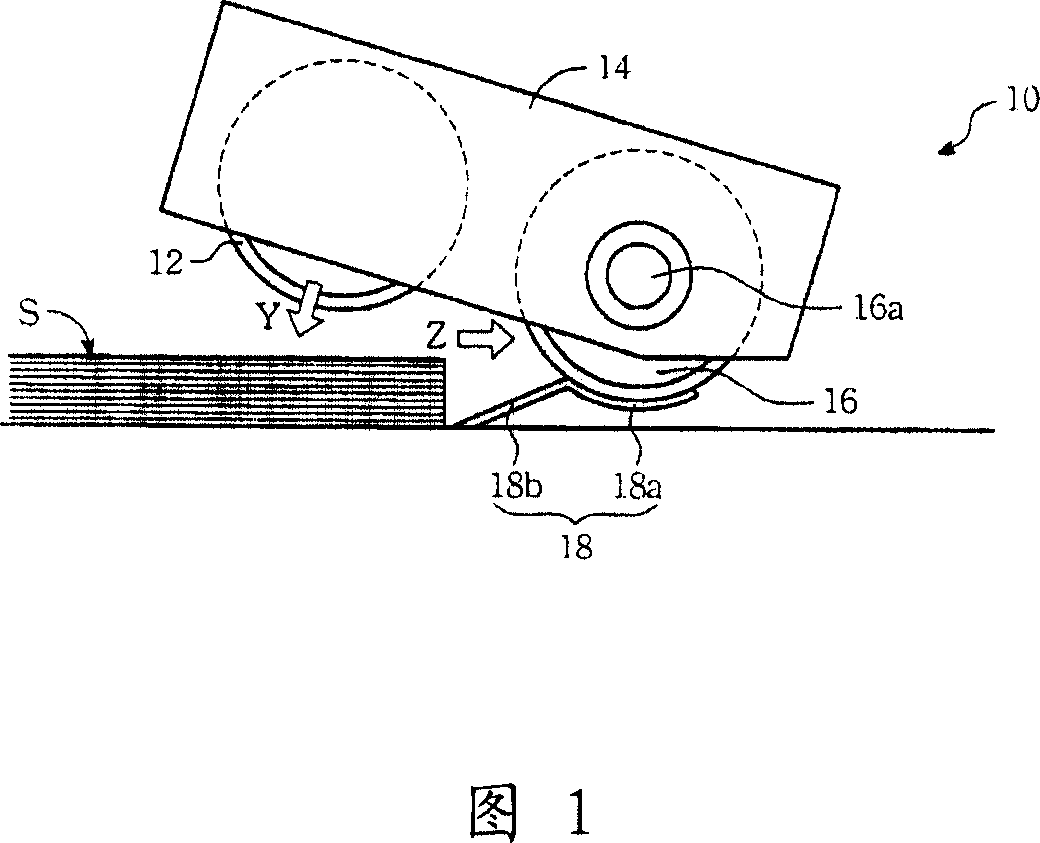

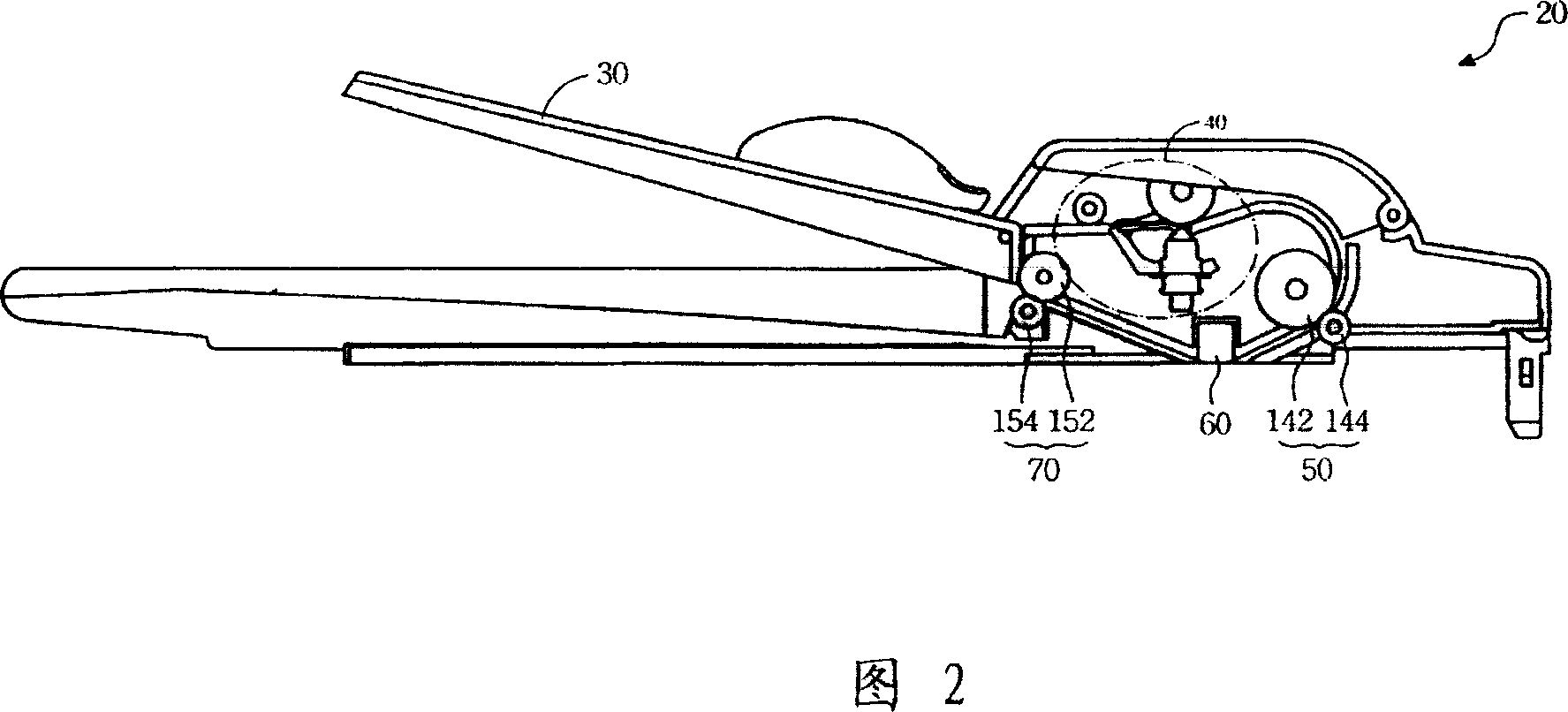

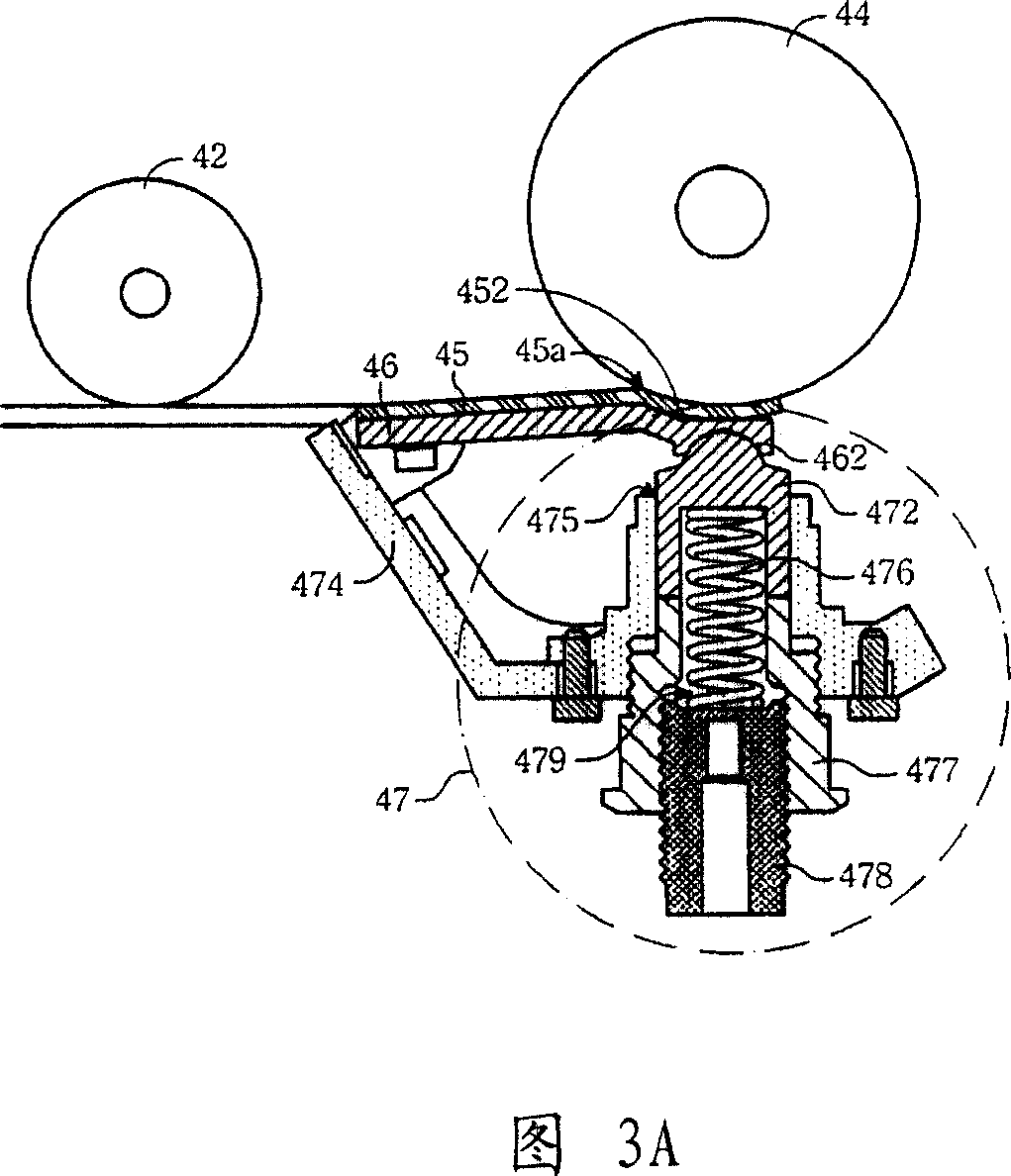

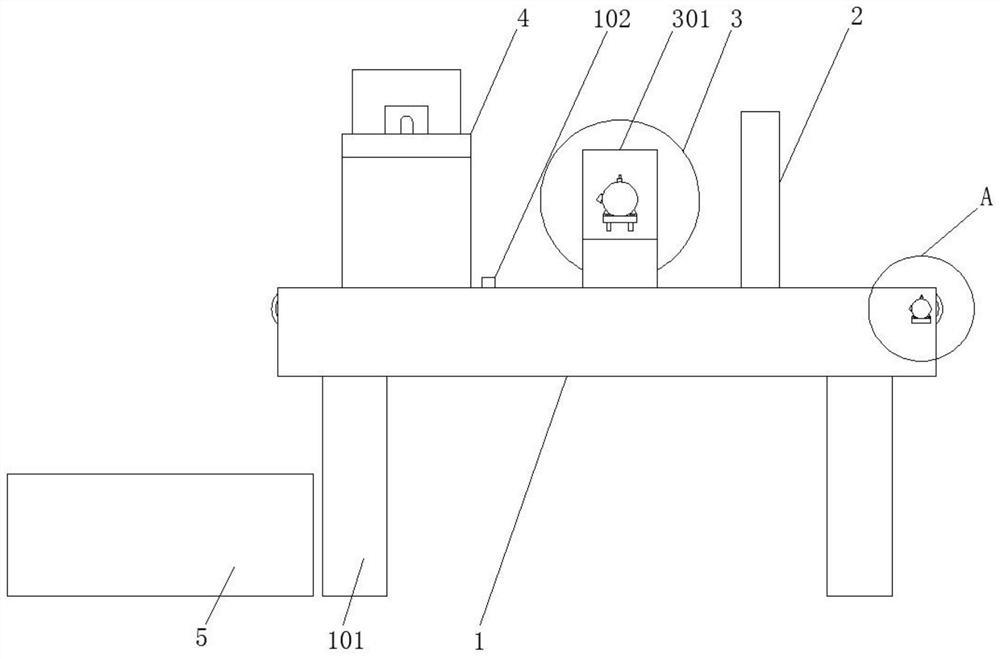

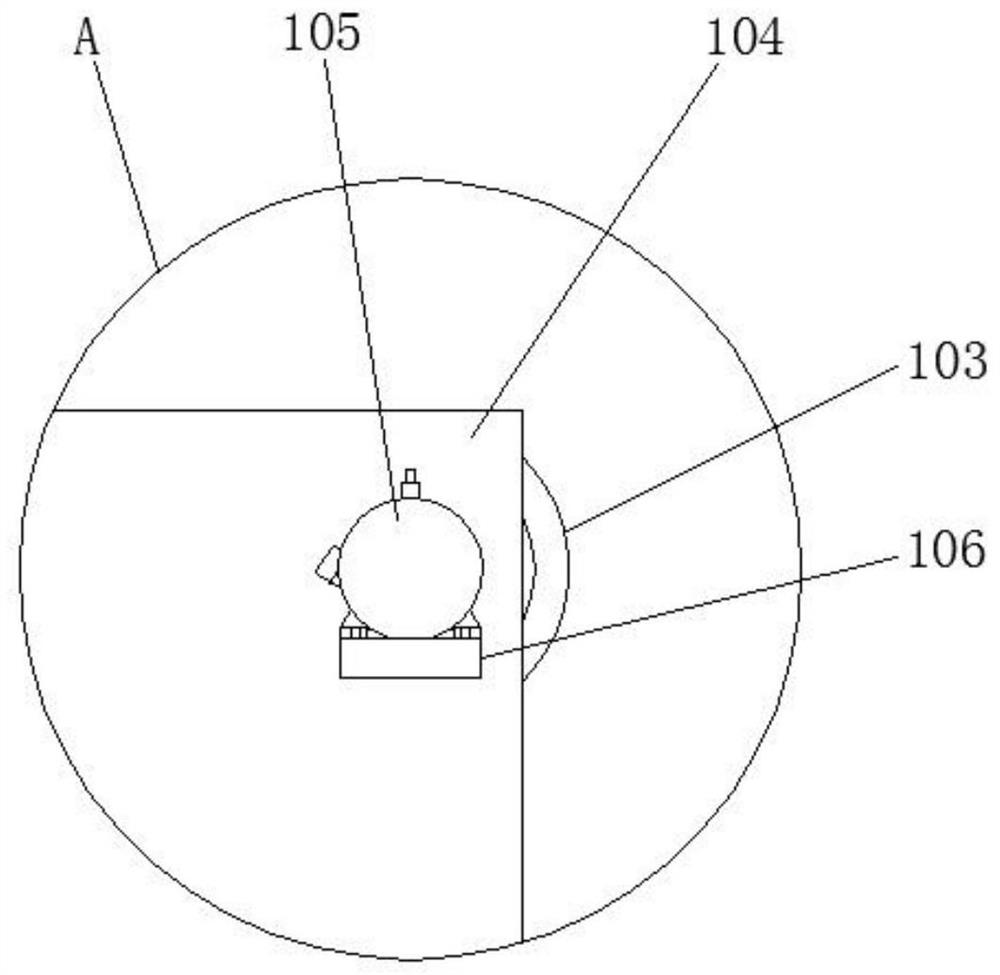

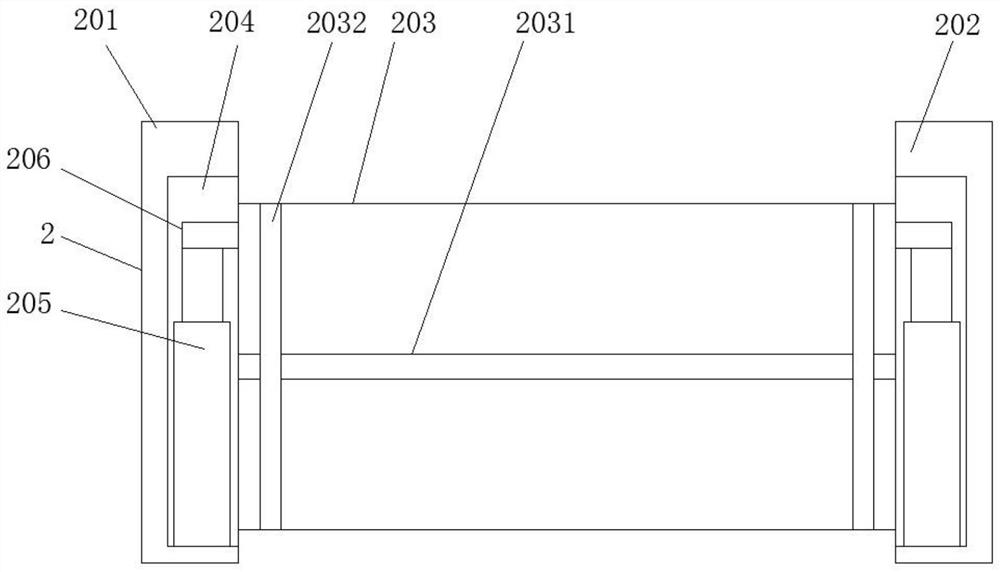

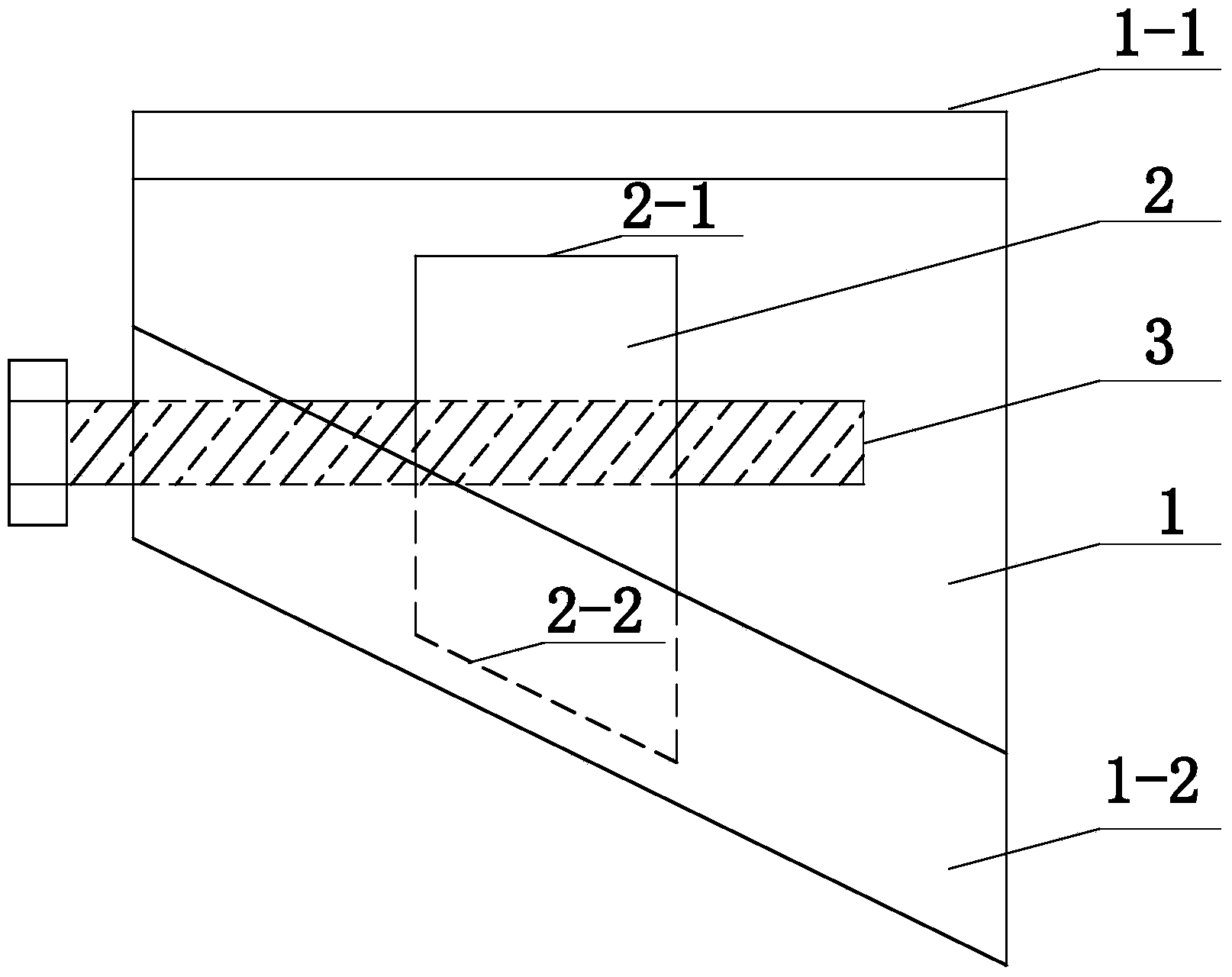

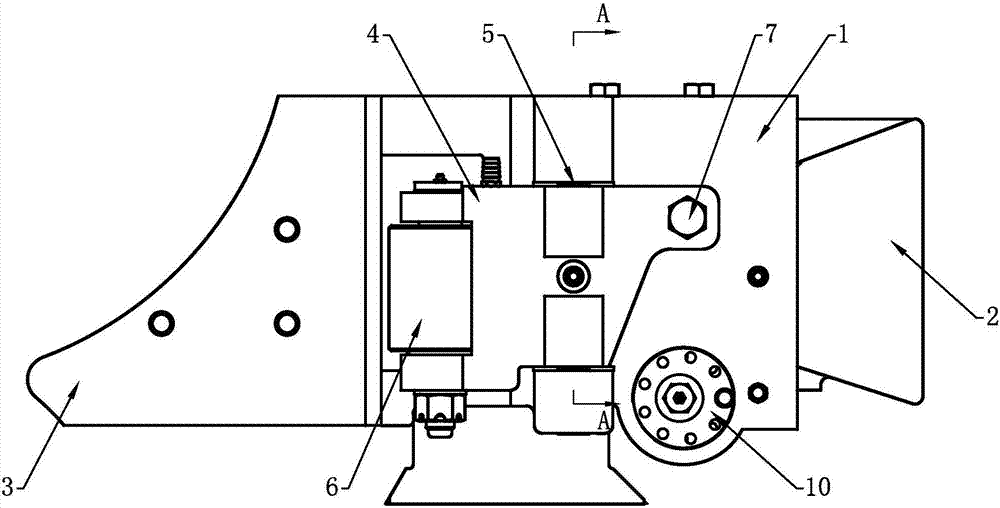

Paper-feeding mechanism against tilt

InactiveCN1939822AAccurate positioning and assemblyAvoid skewArticle separationEngineeringPulp and paper industry

A paper feeding mechanism able to prevent the skew of fed paper is composed of a paper advancing roller, a paper separating roller at the downstream of paper advancing roller, a paper separating plate close to said paper separating roller and with an arc paper-separating part, a pressure regulating unit with a pressure-applying spherical part, and a pressing plate of paper-separating plate with a recess on its back for matching with said pressure-applying spherical part.

Owner:BENQ CORP

Potato cleaning conveyor sorting device

The invention provides a potato cleaning conveyer sorting device. The potato cleaning conveyer sorting device is characterized in that long connecting pieces and short connecting pieces of a retractable frame are connected in an overlapped mode to form five diamond shapes with sequence numbers of I, I, III, IV and V; a motor rack is mounted on the hinged position of the end portion of the long connecting piece of the diamond shape III; the reducing motor is connected with the flange of the motor rack and drives sorting rollers to rotate, wherein both ends of every sorting roller are supported inside the corresponding round holes of the retractable frame; both ends of a sorting roller I and a sorting roller II penetrate the round holes of the bosses of the short connecting pieces of the diamond shape I and the diamond shape V respectively, and then the extending ends of the sorting roller I and the sorting roller II, which face towards a reducing motor, are connected with single-row chain wheels; the others sorting rollers penetrate the retractable frame, and then the extending ends of the others sorting rollers are connected with the single-row chain wheels; after penetrating the single-row chain wheels at the hinged positions of the diamond shape II and the diamond shape III, the extending ends of the others sorting rollers, which face towards the reducing motor, are connected with the reducing motor. The potato cleaning conveyer sorting device can conveniently sort cleaned potatoes and meanwhile, is even and thorough in sorting, wide in application range and reliable in working.

Owner:山东思代尔农业装备有限公司 +1

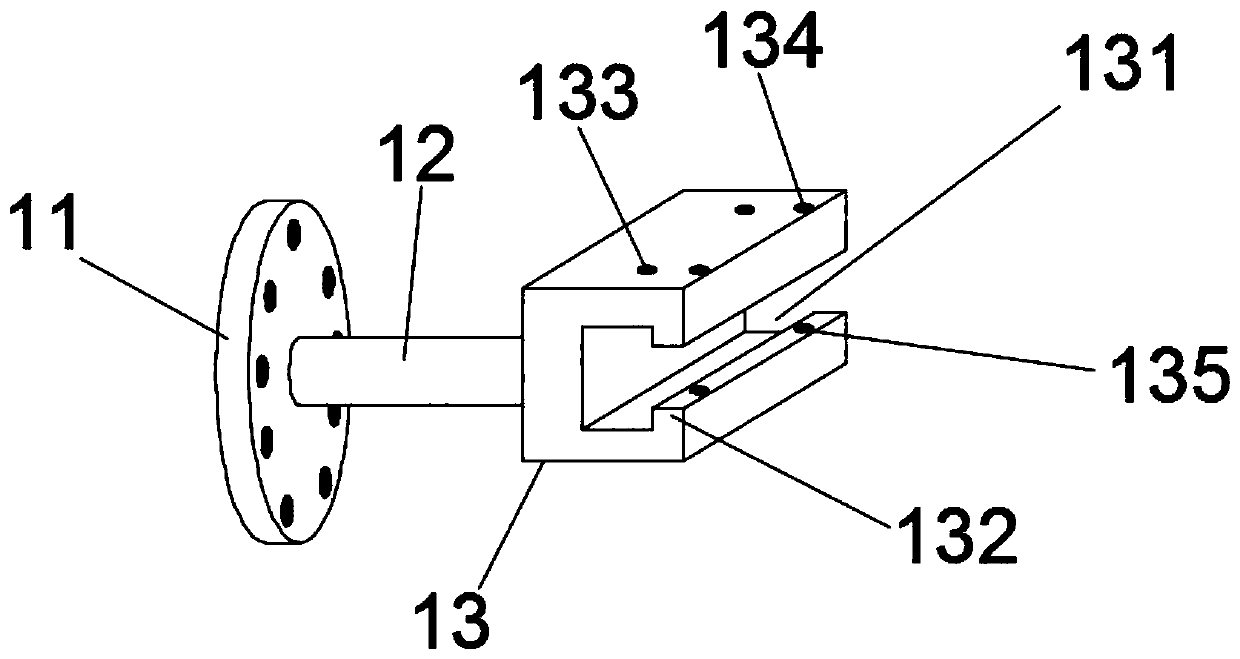

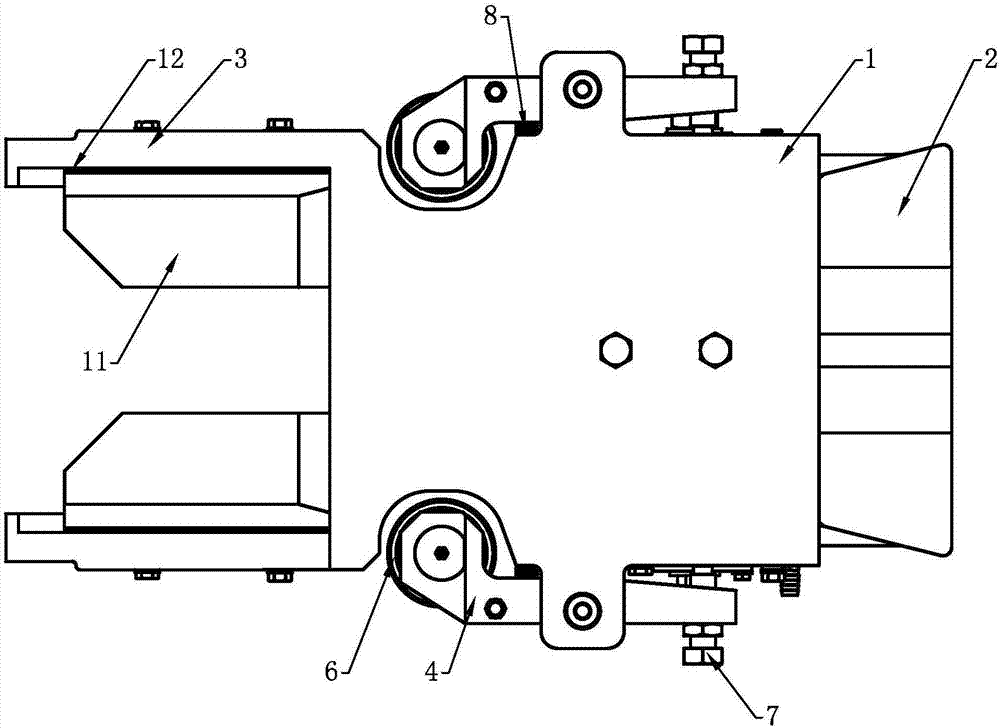

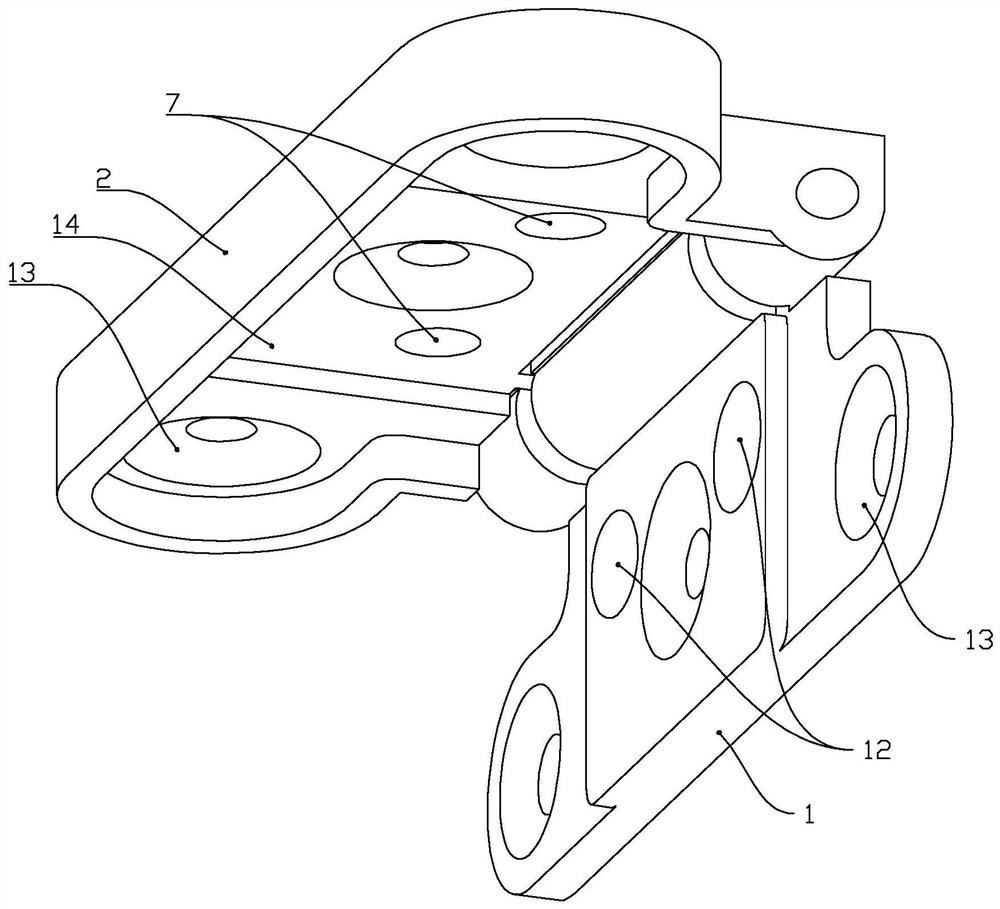

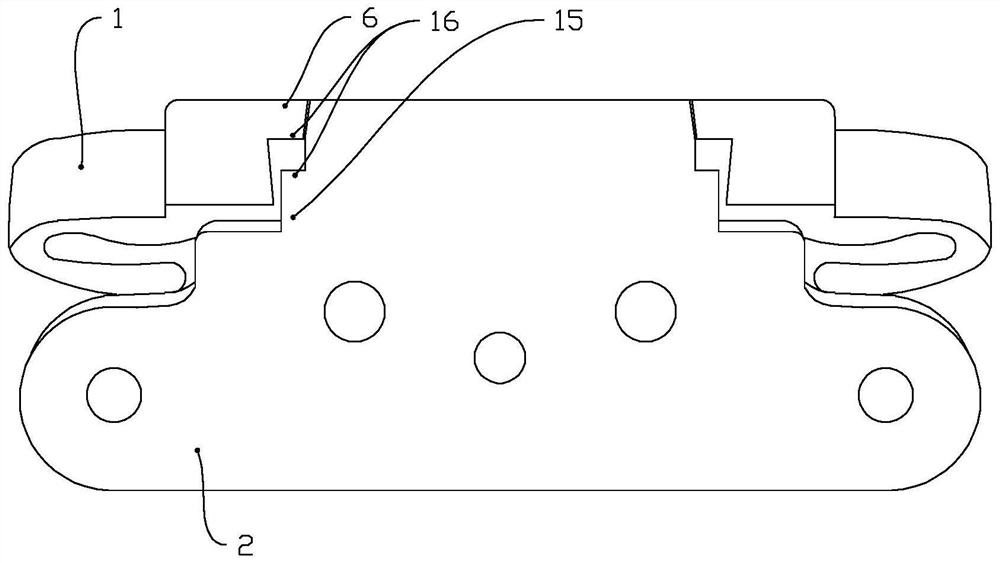

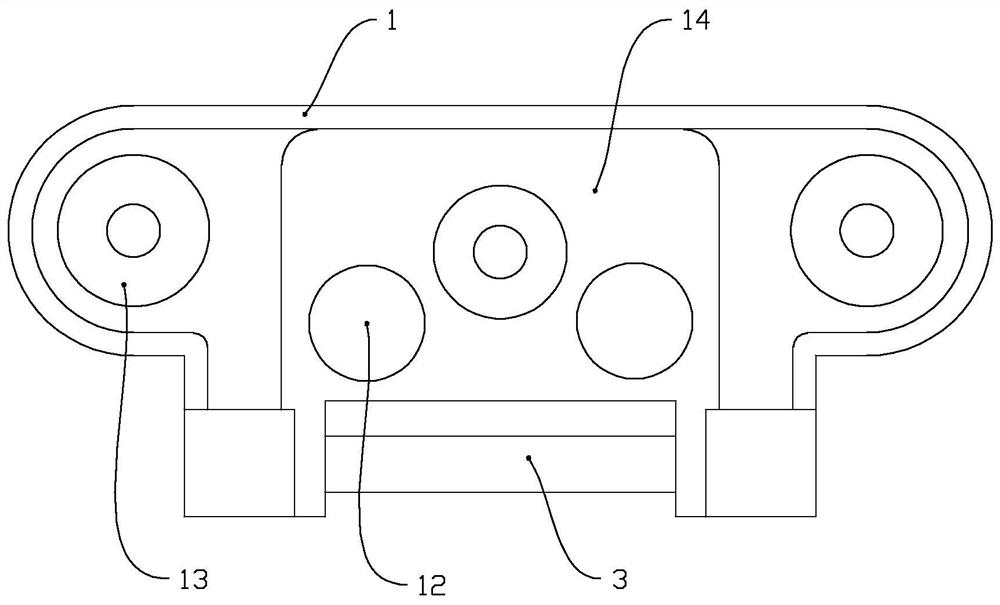

Clamp for preparing coating on selective surface area of blade and preparation method of coating

ActiveCN111575671AGuaranteed fatigue strengthReduce erosion damageVacuum evaporation coatingSputtering coatingTurbine bladeStructural engineering

The invention discloses a clamp for preparing a coating on the selective surface area of a blade and a preparation method of the coating. The clamp comprises a blade fixing shaft, a cover plate bracket, an upper cover plate and a lower cover plate, wherein the blade fixing shaft is connected with the cover plate bracket, the upper cover plate is mounted on the upper end face of the cover plate bracket, the lower cover plate is mounted on the lower end face of the blade fixing shaft, and the upper cover plate and the lower cover plate are connected in a staggered clamping manner. The blade canbe clamped and fixed by using the clamp when a hard coating is sprayed on an engine blade or a turbine blade, the coating meeting the requirements of erosion and fatigue performance is prepared on thesurface of the blade by using a zonal coating process, the requirement for locally spraying the hard coating on the engine blade or the turbine blade is met, the erosion damage of the surface of theblade is reduced, and the fatigue strength of the blade is ensured. The clamp has the advantages of being simple in structure, convenient to use and reasonable in design.

Owner:AIR FORCE UNIV PLA

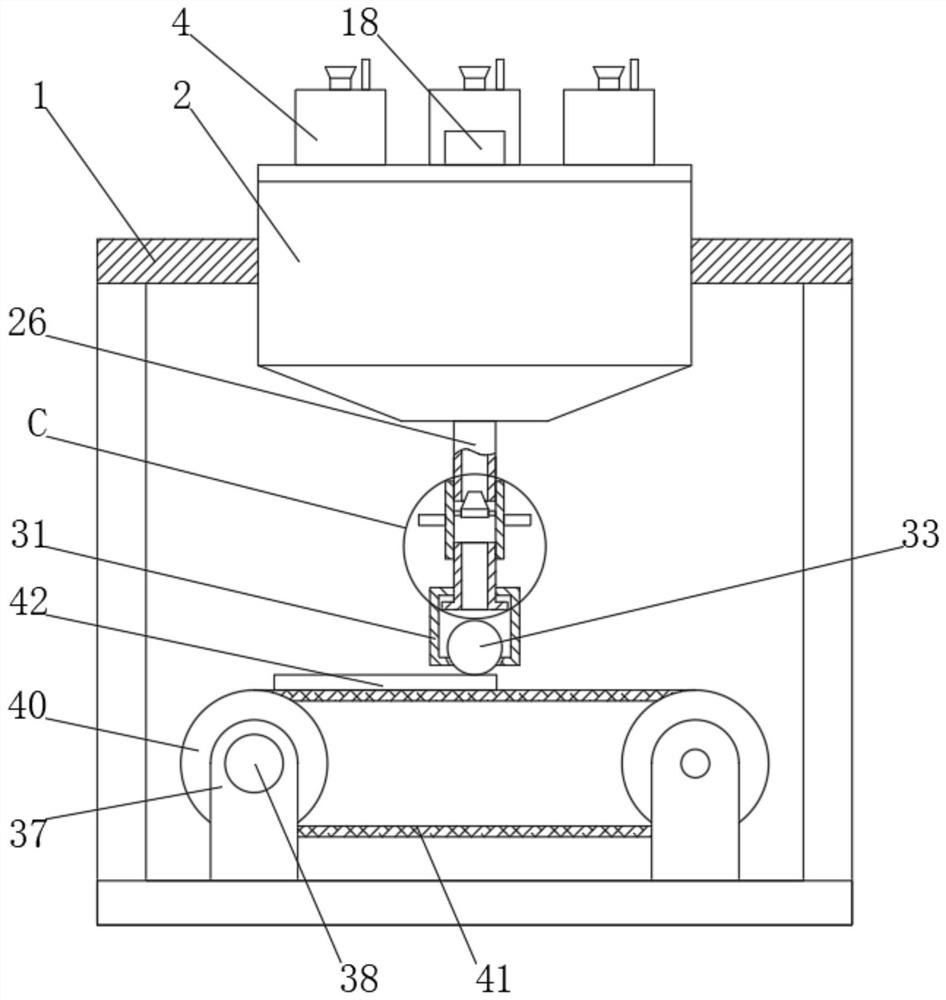

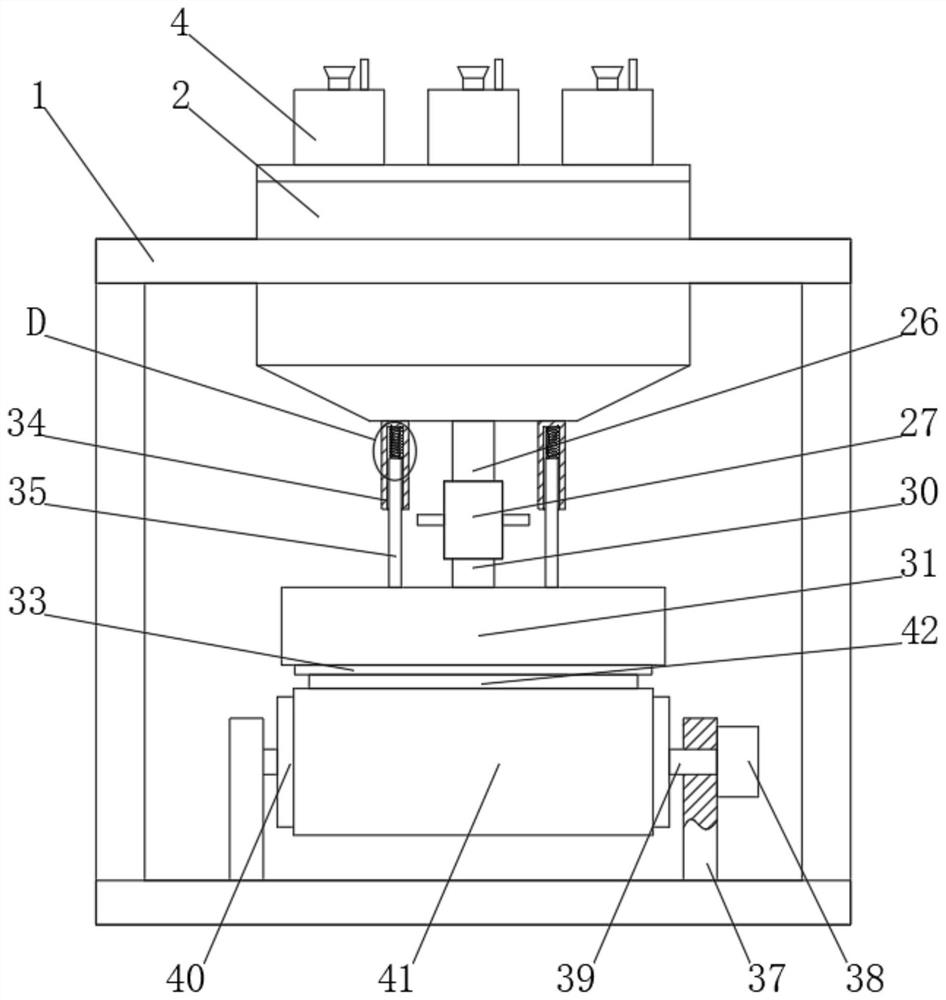

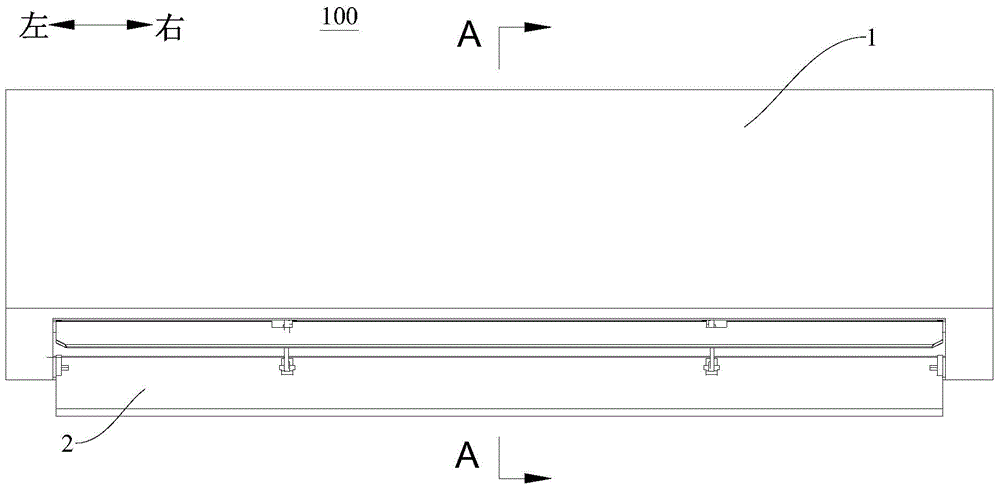

Gradient printing equipment and printing process thereof

PendingCN112810308AWell mixedEasy to adjust the feeding speedInking apparatusRotary pressesDrive shaftElectric machinery

Owner:深圳市旺博科技有限公司

Printing device with pre-pressing function for carton processing

ActiveCN113459658AGood preloading effectAvoid bad printingRotary pressesOther printing apparatusCartonElectric machinery

The invention discloses a printing device with a pre-pressing function for carton processing. The printing device comprises a conveying structure, a material blocking assembly, a pre-pressing roller and a printing frame, side baffles are arranged on the front portion and the rear portion of the conveying structure, the material blocking assembly is arranged on the right side of the top of the conveying structure, and the pre-pressing roller is arranged in the middle of the top of the conveying structure; and an upper supporting plate and a lower supporting plate are arranged at the front end and the rear end of the pre-pressing roller correspondingly, a second driving motor is installed at the front end of the upper supporting plate through a second motor base, a second inner cavity is formed in the lower supporting plate, and the printing frame is arranged on the left side of the top of the conveying structure. The pre-pressing roller is arranged, the pre-pressing roller is driven by the second driving motor to rotate, paper boxes conveyed on a conveying belt are pre-pressed, the poor printing effect caused by the fact that the corners of the paper boxes tilt is avoided, the pre-pressing roller can ascend and descend under the action of a second hydraulic rod, then the paper boxes with different thicknesses can be pre-pressed conveniently, and the application range of the device is widened.

Owner:宿迁海宇包装有限公司

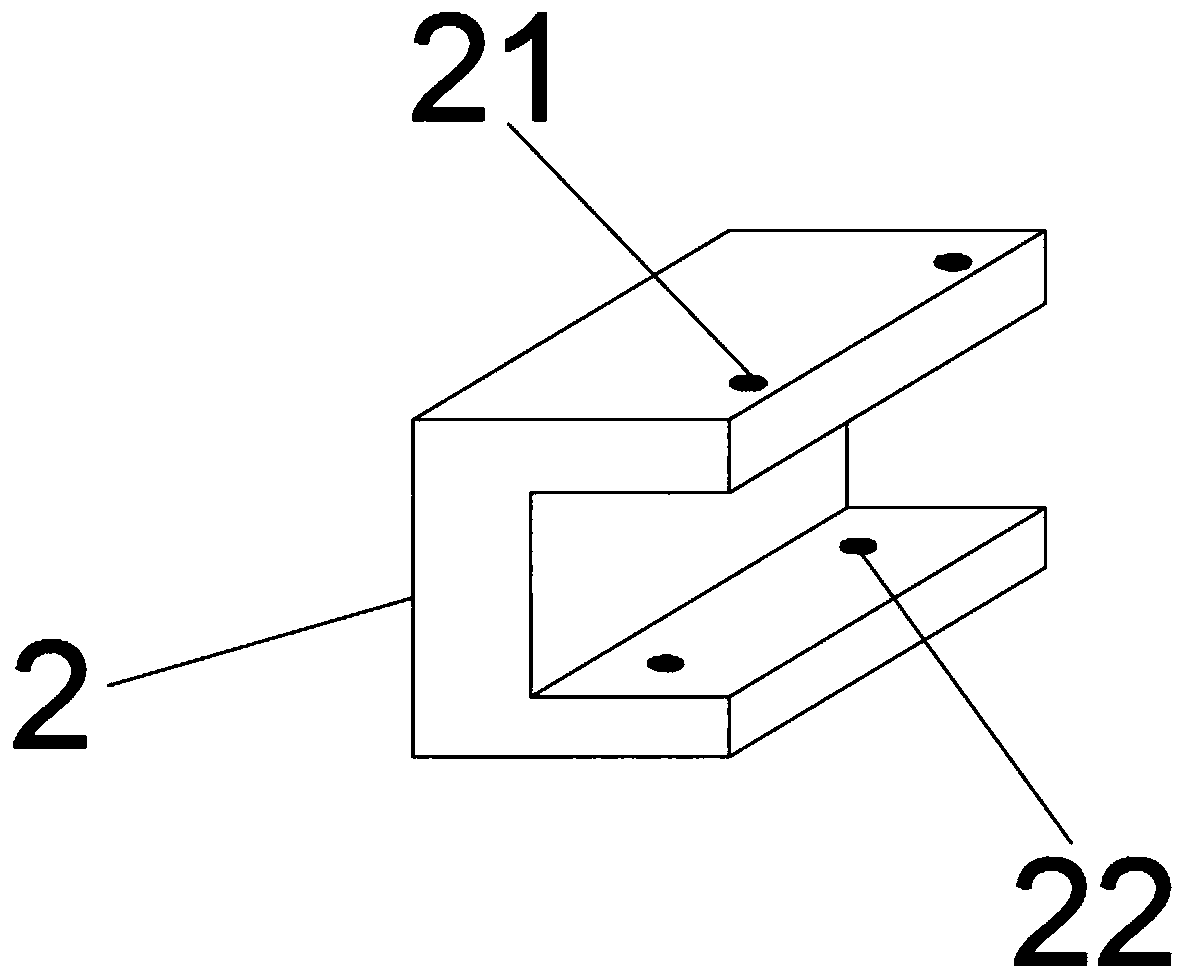

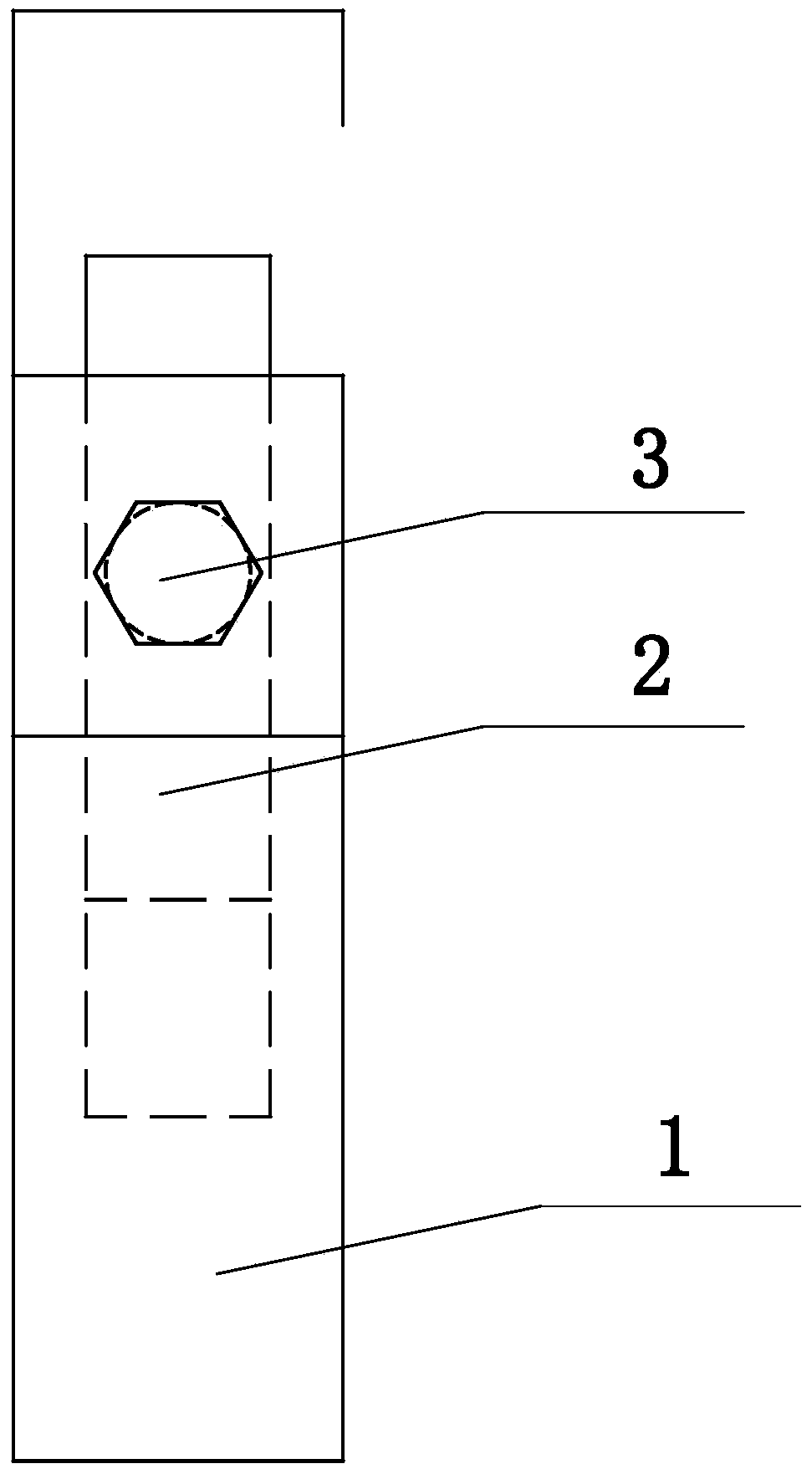

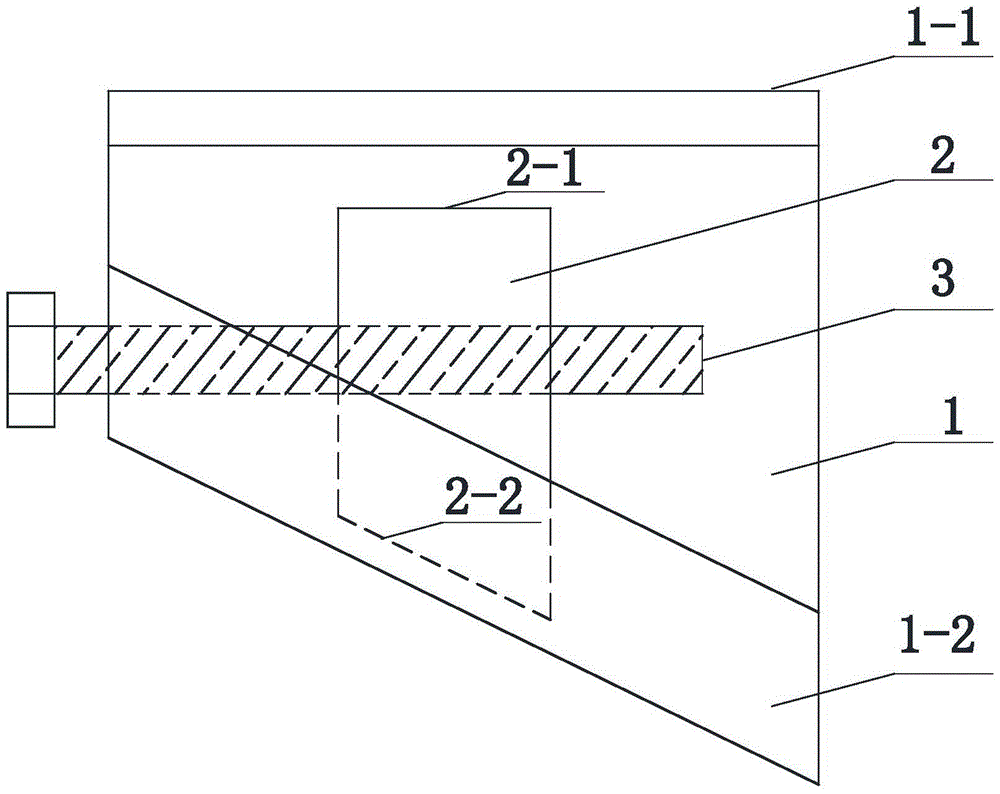

Inclined plane type air duct flange fastener and using method thereof

ActiveCN104344119AAchieving a sealed connectionAdjust Gap SizeDucting arrangementsFlanged jointsControl systemEngineering

The invention relates to an inclined plane type air duct flange fastener and a using method thereof, belongs to the technical field of an ventilation air conditioning and smoke control system and aims at the problem that in the mounting process of existing air ducts, a mounting operation space at the joint of flanges is narrow and fastening of flange bolts cannot be completed so as to cause the condition that the air ducts cannot be effectively abutted. The inclined plane type air duct flange fastener comprises a right trapezoid shell and a right trapezoid sliding block, wherein the inclined edge of the shell is provided with a slide; the sliding block is arranged in the slide of the shell; the sliding block is connected with the shell by a bolt; the straight edge of the shell is in parallel to that of the sliding block; the inclined edge of the sliding block is arranged in the slide, and thus, rotation of the bolt drives the sliding block to slide along the slide so as to regulate the size of a gap between the straight edge of the shell and the straight edge of the sliding block. The using method comprises the following steps: firstly, buckling a gap between the straight edge of the shell and the straight edge of the sliding block between two outer flanges; then rotating the bolt to gradually reduce the gap until fastening of the two outer flanges is completed, so that a first air duct and a second air duct are connected in a sealing manner.

Owner:SHANGHAI INSTALLATION ENG GRP

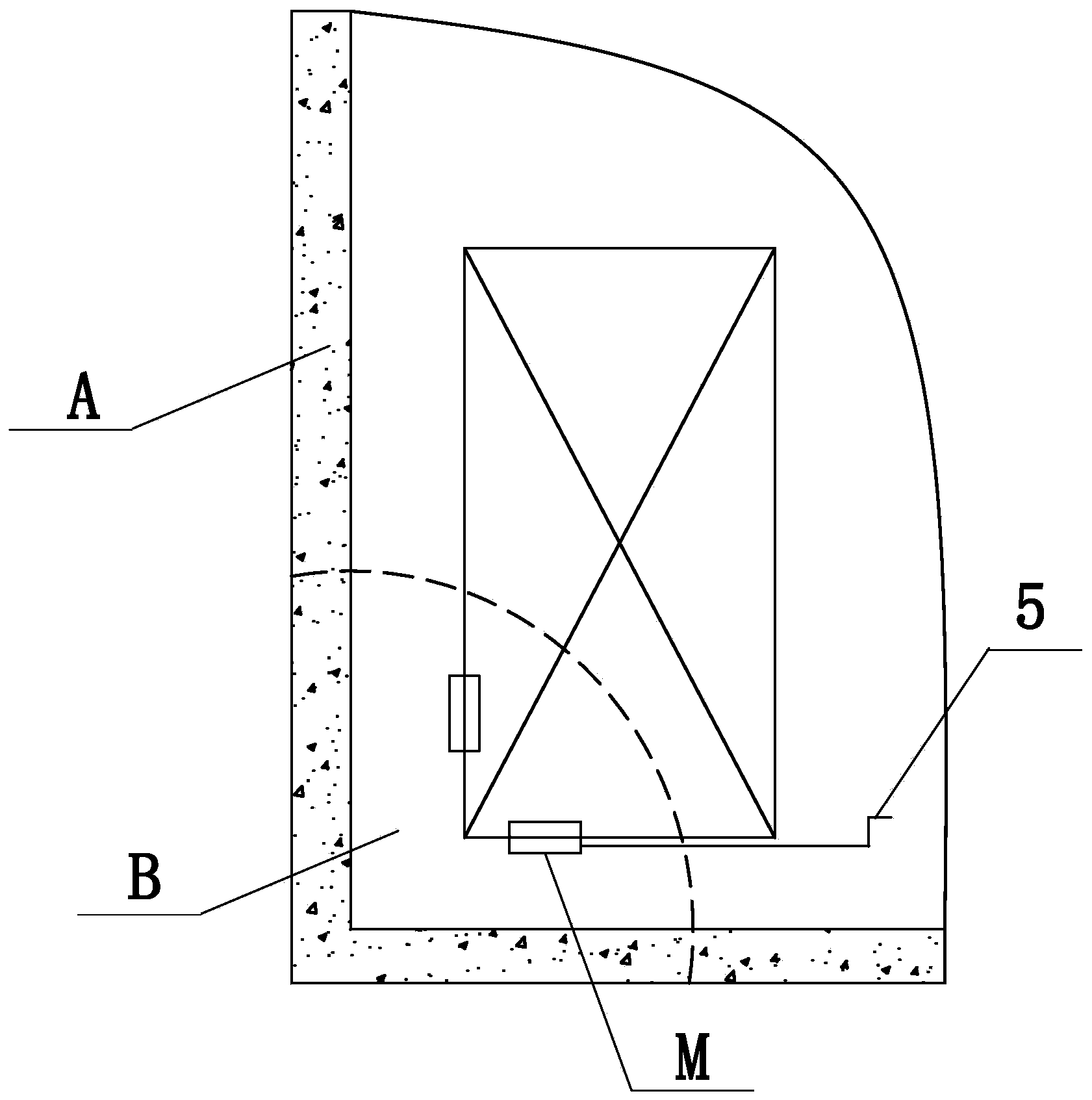

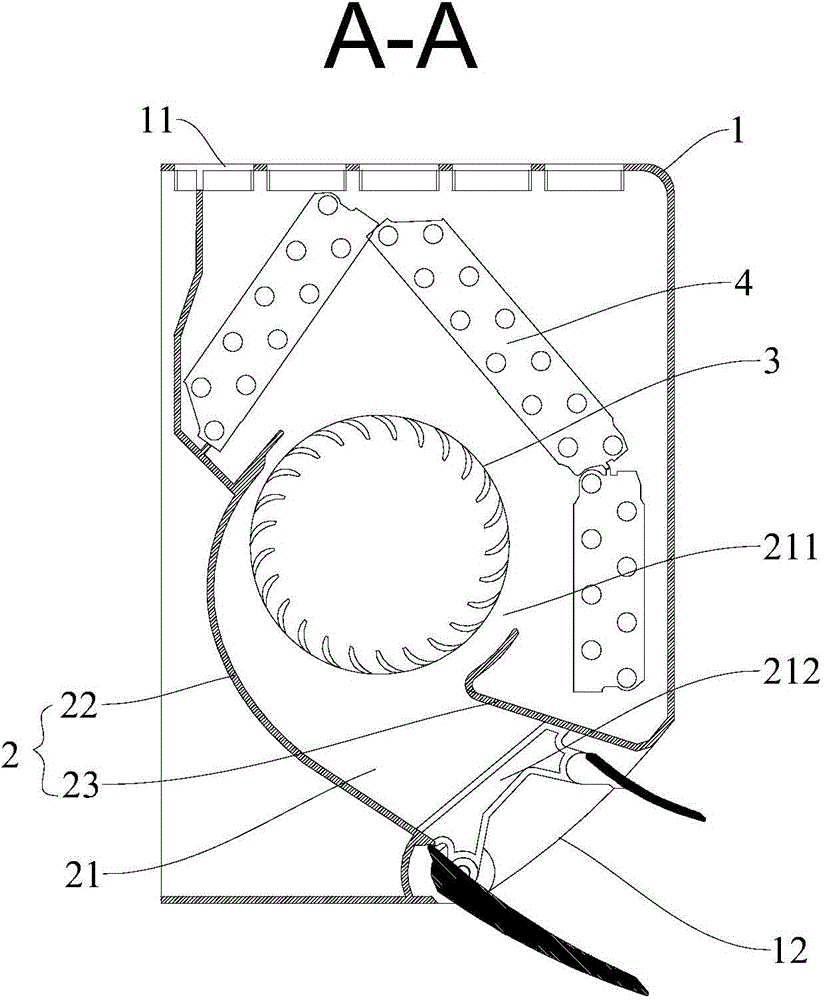

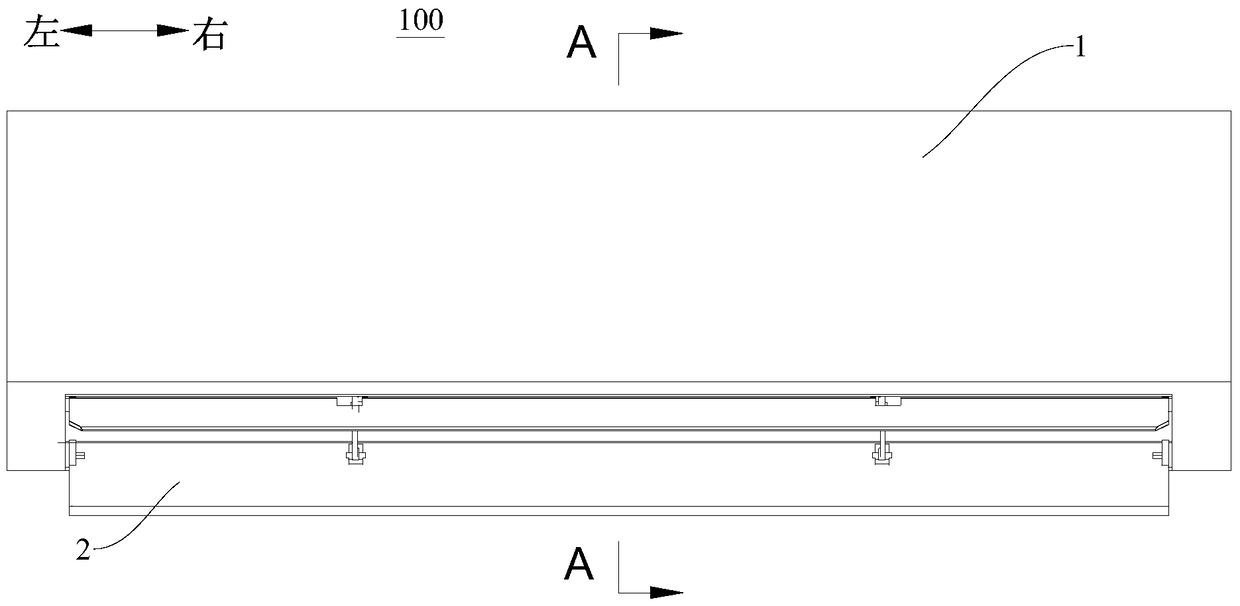

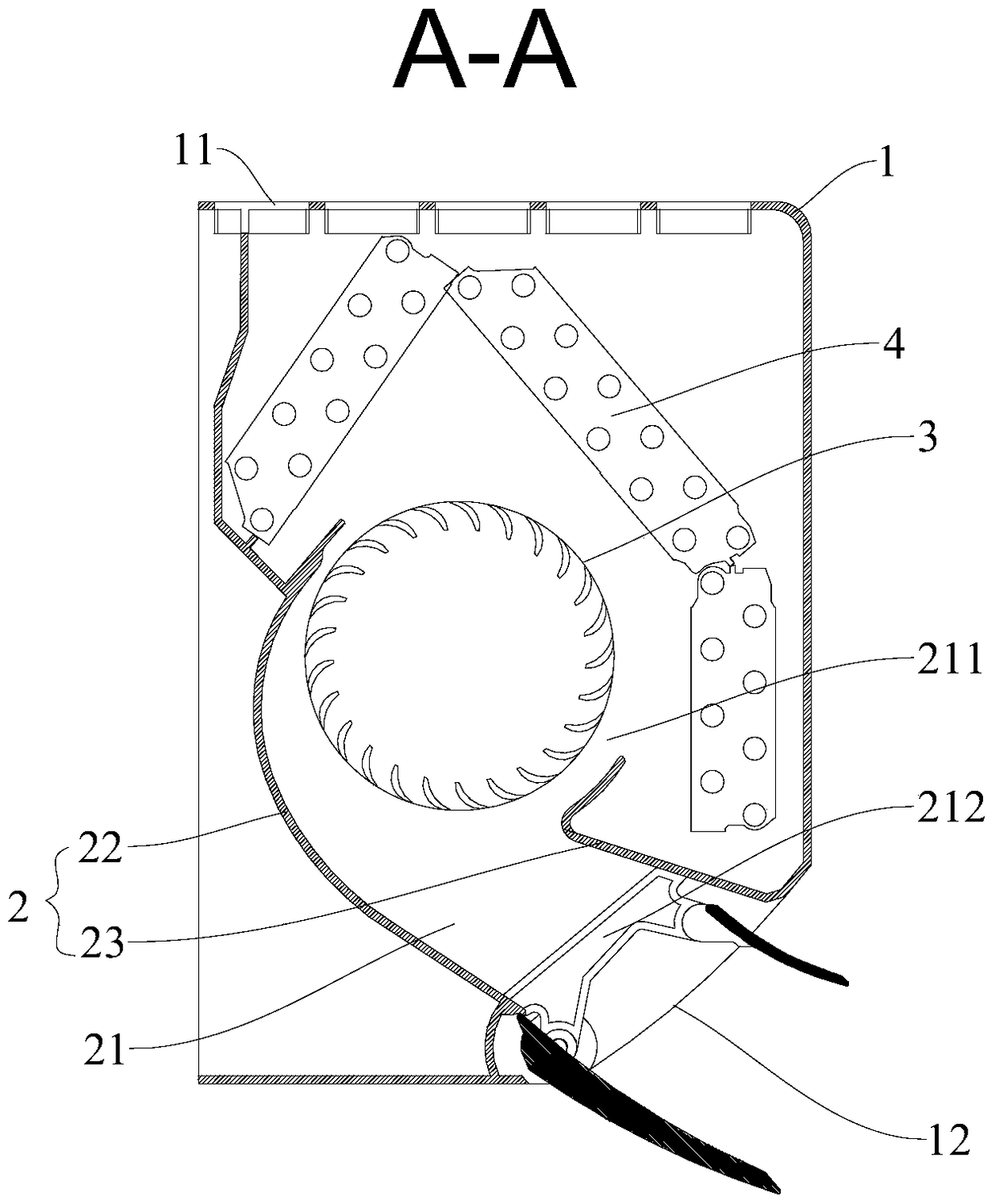

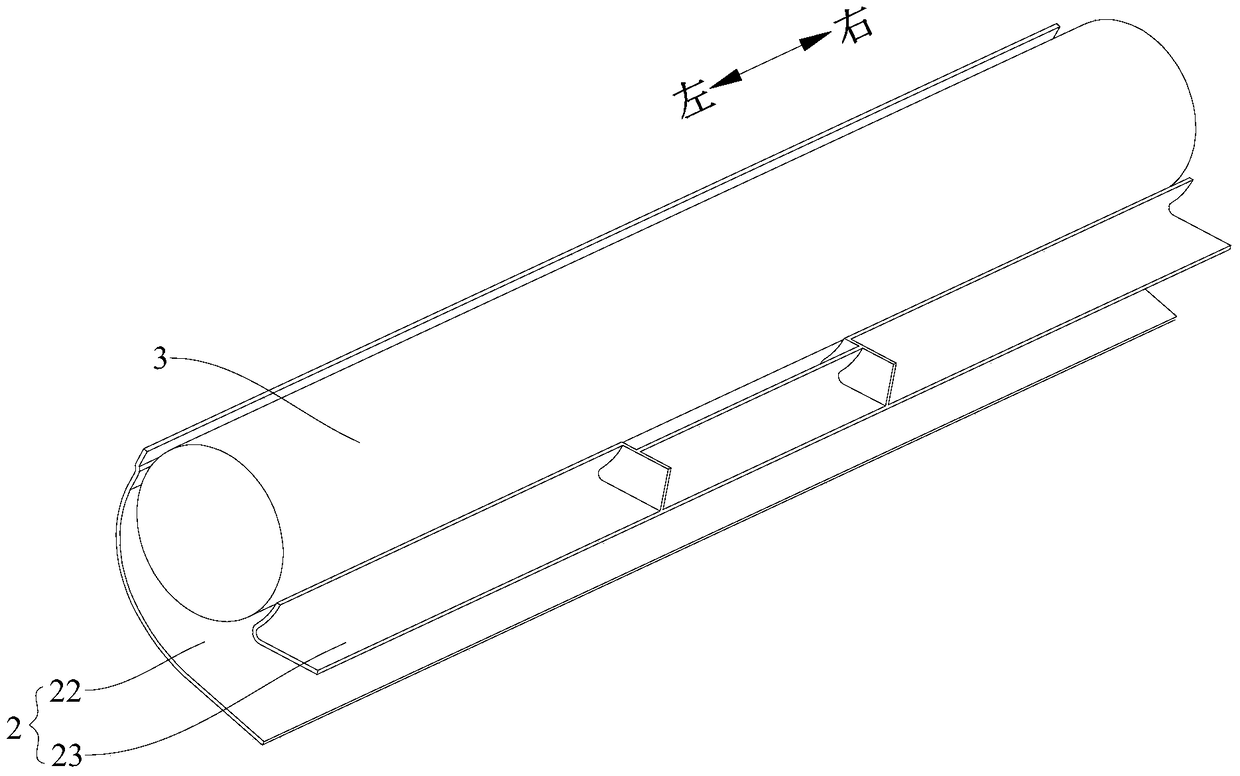

Indoor unit of air conditioner

ActiveCN105276678AImprove comfortSimple structureLighting and heating apparatusAir conditioning systemsIndustrial engineering

The invention discloses an indoor unit of an air conditioner. The indoor unit comprises a machine shell, an air guiding assembly and a through-flow air wheel. The machine shell is provided with an air inlet and an air outlet. The air guiding assembly is arranged in the machine shell, and an air passage is limited in the air guiding assembly. The air passage is provided with an air passage inlet and an air passage outlet. The air passage inlet is communicated with the air inlet. The air passage outlet is communicated with the air outlet. The widths of the air passage inlet are not equal in the length direction of the air guiding assembly. The through-flow air wheel is arranged at the air passage inlet. According to the indoor unit of the air conditioner, due to the fact that the widths of the air passage inlet are not equal in the length direction of the air guiding assembly, air supply of the indoor unit of the air conditioner has diversity; the comfortability of air supply can be improved, and different needs of users can be met.

Owner:MIDEA GRP CO LTD

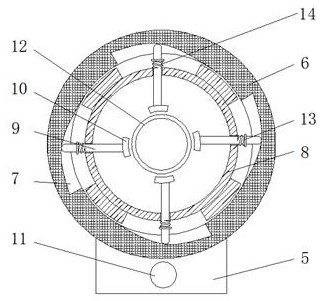

Oil-scrap separating and oil cooling centrifugal device

PendingCN113976334AGuaranteed flow rateGuaranteed cooling effectRotary centrifugesThermodynamicsCooling effect

The invention discloses an oil-scrap separating and oil-cooling centrifugal device, which belongs to the technical field of oil-scrap separating and cooling, and comprises an oil-scrap separating mechanism and an oil-cooling mechanism, the oil-scrap separating mechanism comprises a centrifugal machine shell, a centrifugal machine rotary drum, an oil inlet pipe and an oil outlet pipe. The centrifuge drum is rotationally mounted on the inner bottom surface of the centrifuge shell; the centrifuge drum is driven by driving equipment to rotate; a sealing cover covers the top end of the centrifugal machine shell; an oil baffle is movably mounted on the inner bottom surface of the sealing cover; the oil cooling mechanism comprises an oil cooling box, an oil cooler and an oil cooler pump. The driving equipment drives the centrifuge drum to rotate, so that oil in the centrifuge drum is separated from abrasive dust, the abrasive dust is precipitated at the bottom in the centrifuge drum, and the oil flows out from the open end of the centrifuge drum and is stored in the oil storage cavity; the oil in the oil storage cavity flows into the oil cooling box from the oil outlet pipe and is cooled by the oil cooler so as to be recycled, and the cost is reduced while the flow speed and the cooling effect of the cooling oil are ensured.

Owner:南京睿鑫智能制造有限公司

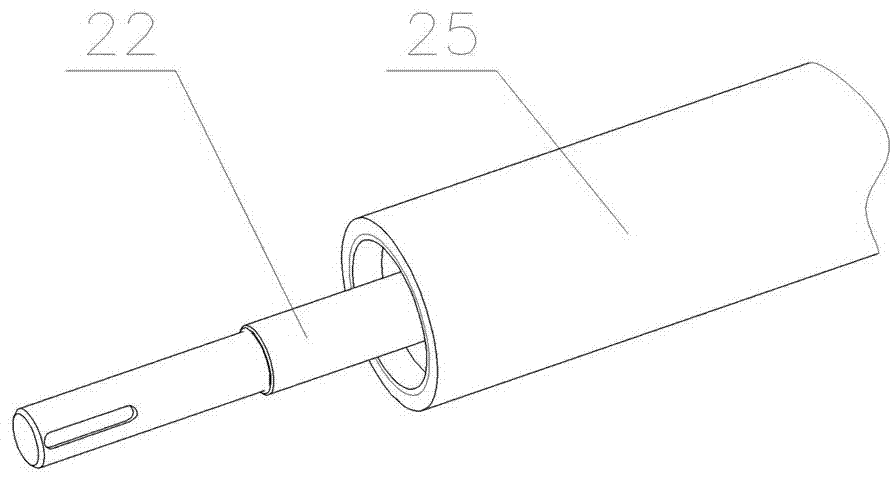

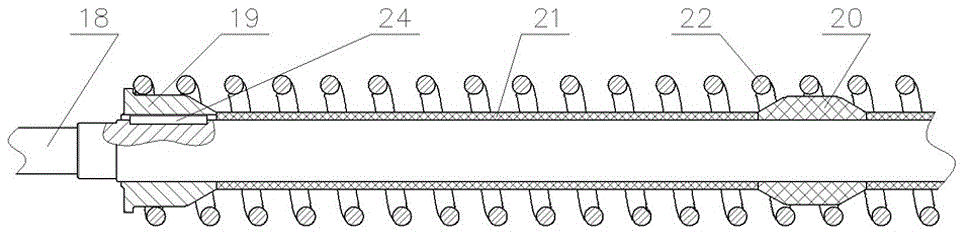

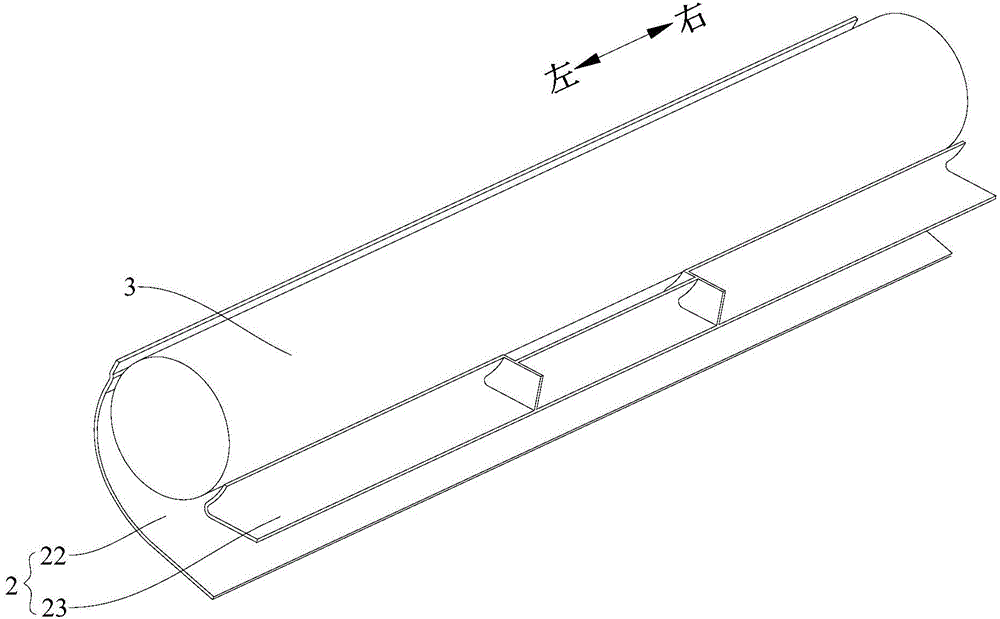

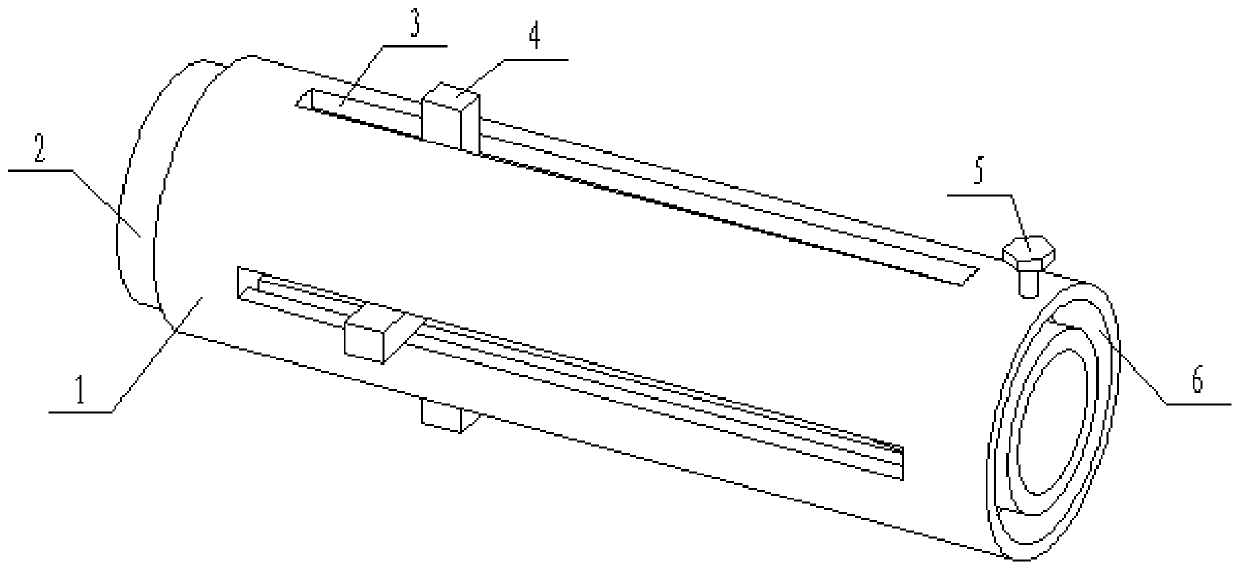

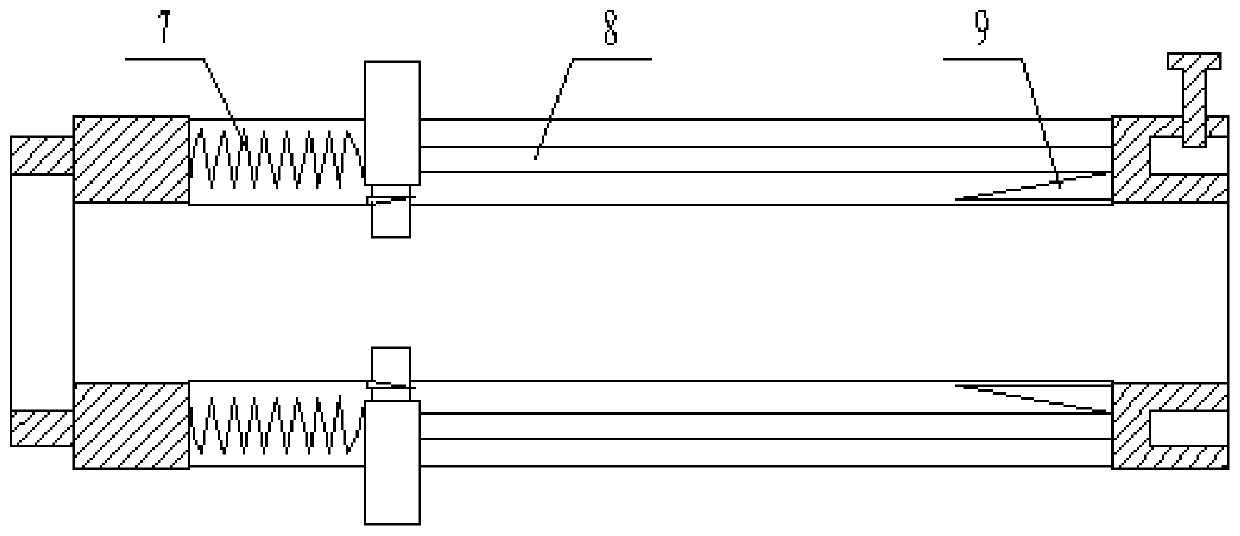

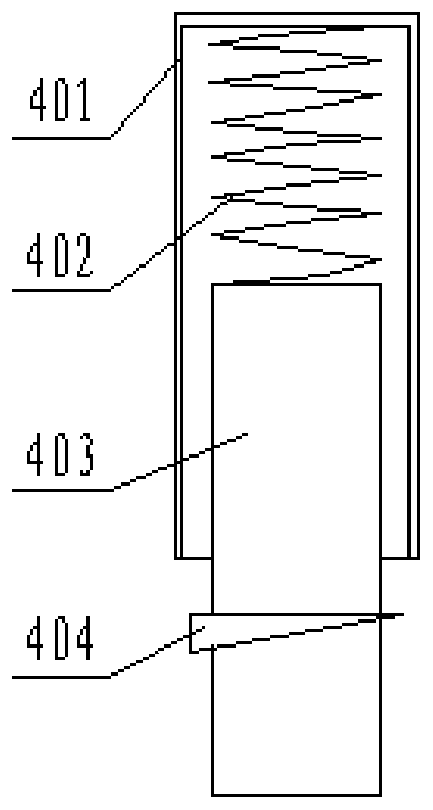

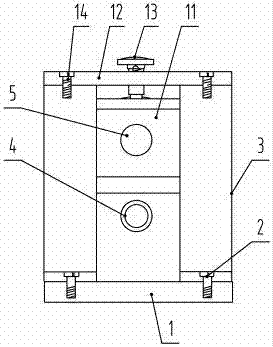

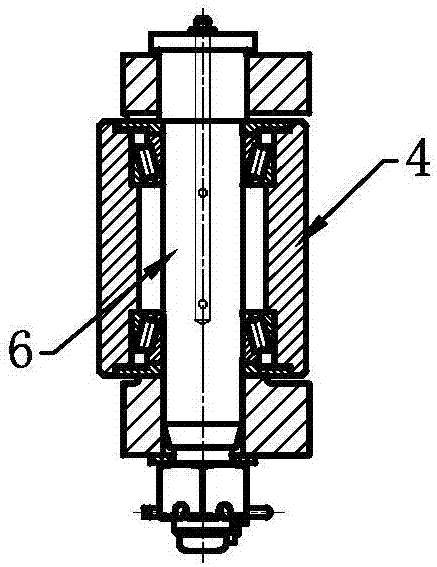

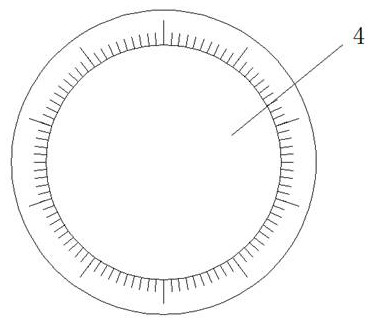

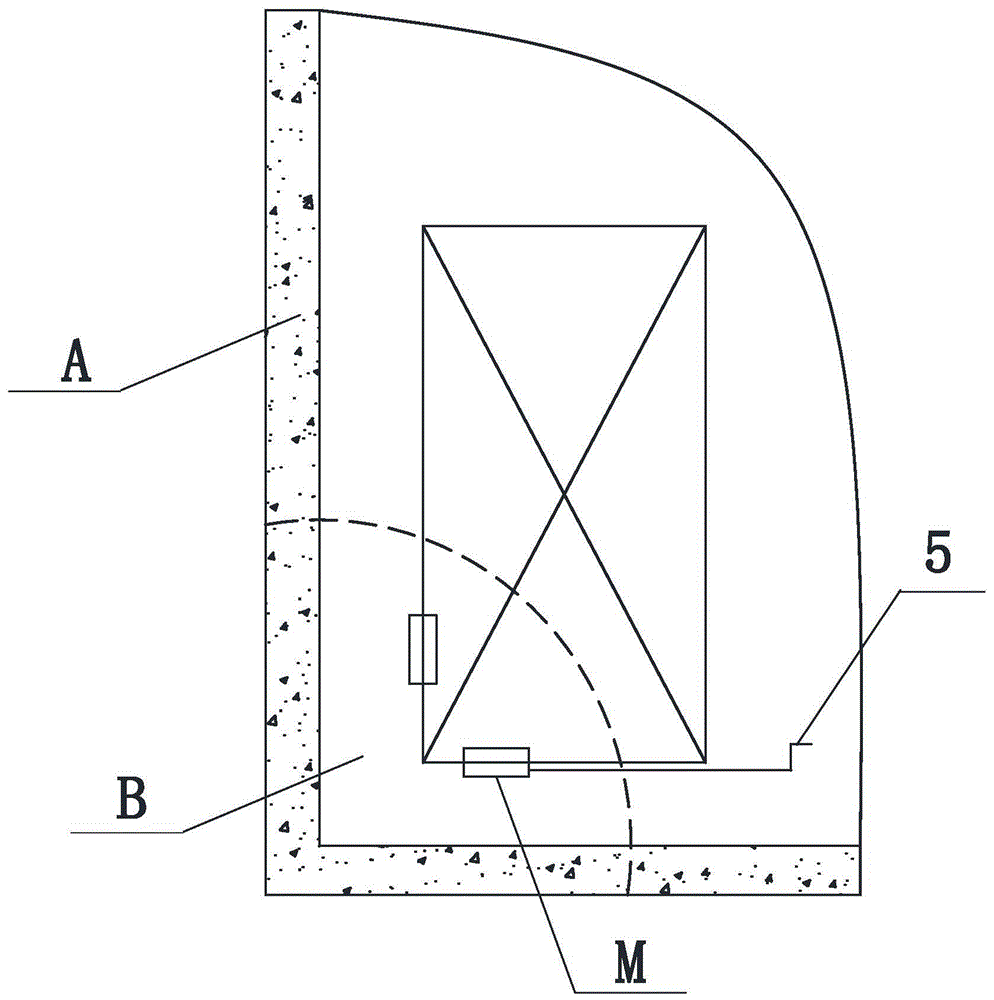

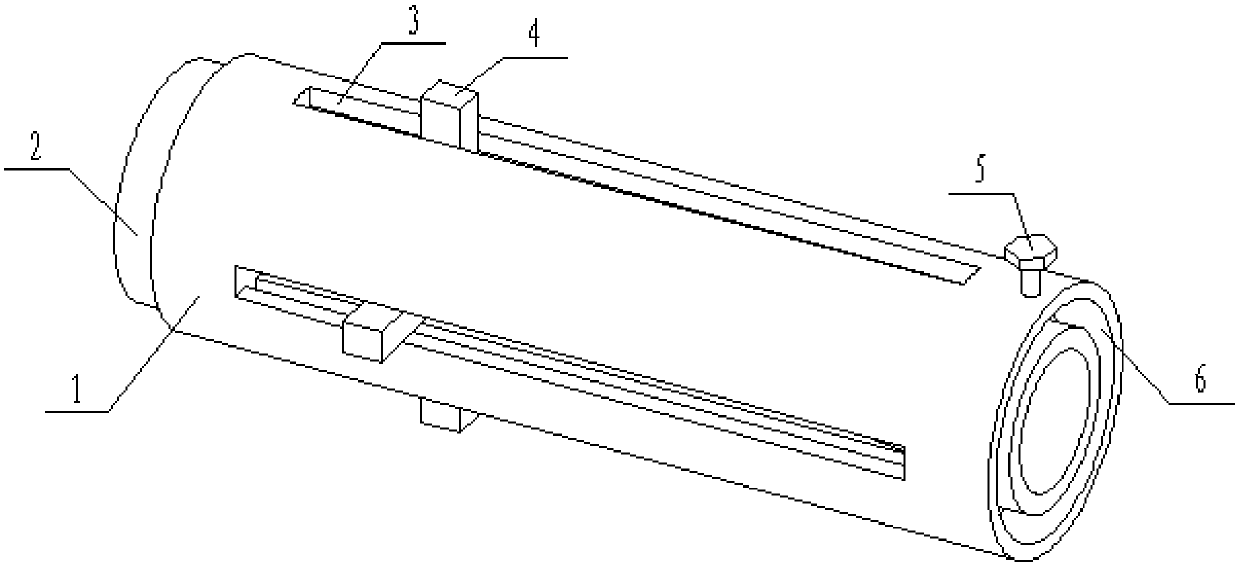

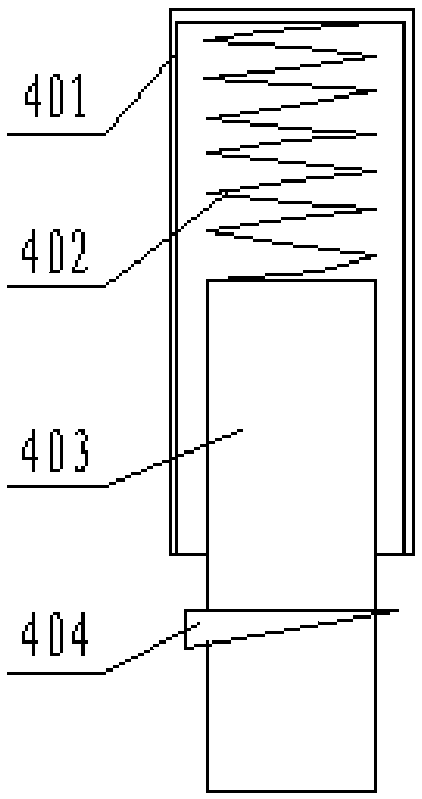

A mold for stabilizing the welding quality of optical fiber stainless steel casing

The invention discloses a mold for stabilizing the welding quality of optical fiber stainless steel sleeves. The mold comprises a cylinder; a connecting ring and a connecting groove are respectively arranged at the two ends of the cylinder; a fastening bolt is mounted at one end of the cylinder, and is inserted in the connecting groove; an opening groove is formed in the outer side of the cylinder; slide rail grooves are formed in the two sides of the opening groove; stop devices are slidingly mounted in the slide rail grooves, and are connected with one end of the opening groove through tension springs; and a limiting block is arranged at the other end of the opening groove. The mold has the following beneficial effects: self elasticity of the tension springs is used for cooperating withlifting of stop rods to apply resistance to wound steel strips, so that gaps are adjusted, unified gap sizes are guaranteed, and the welding line quality is guaranteed; the splicing installation of devices can be realized through the connecting ring and the connecting groove; and the devices are freely combined according to the lengths of sleeves to meet production of the sleeves with different lengths.

Owner:CHENGDU TECH UNIV

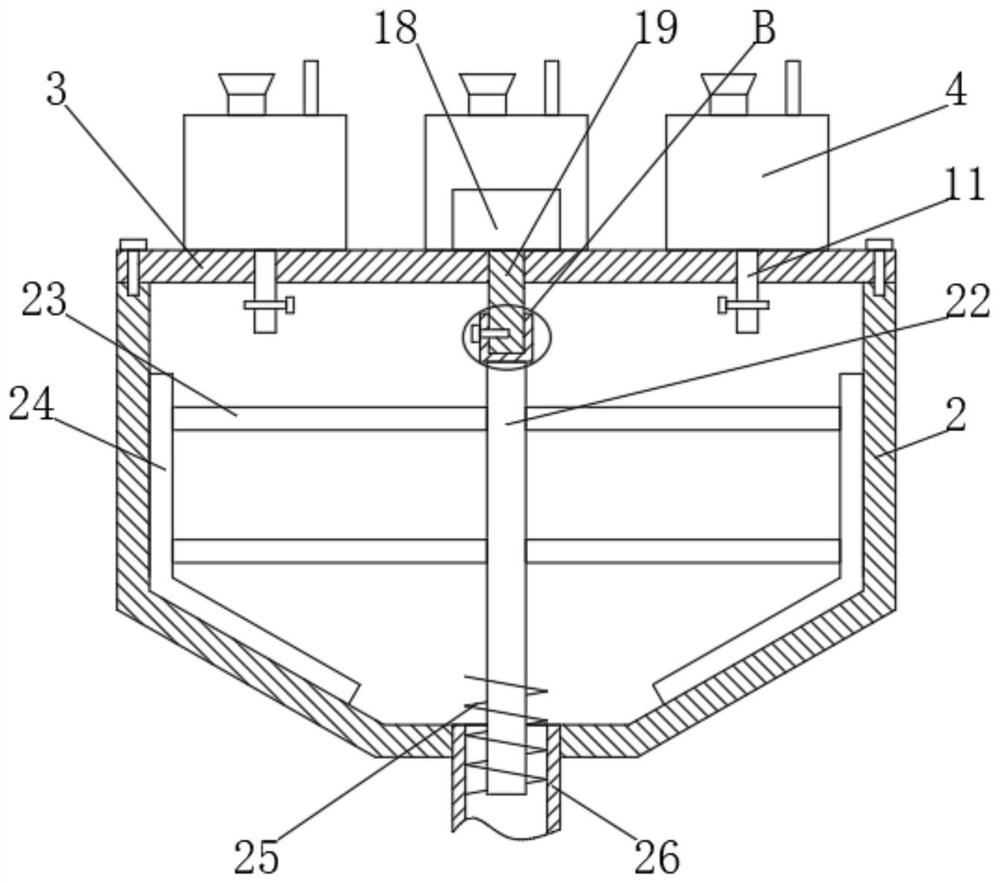

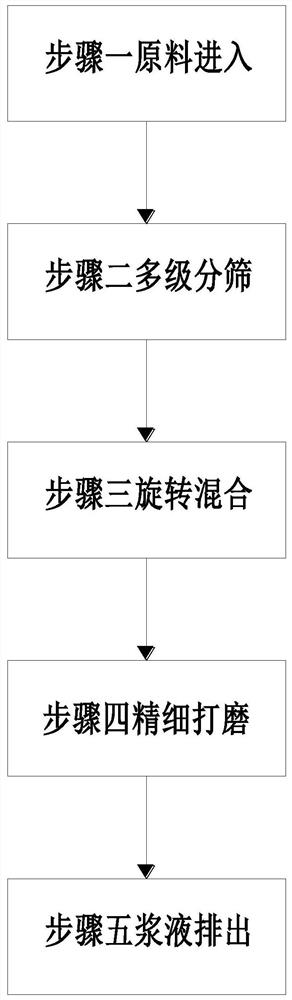

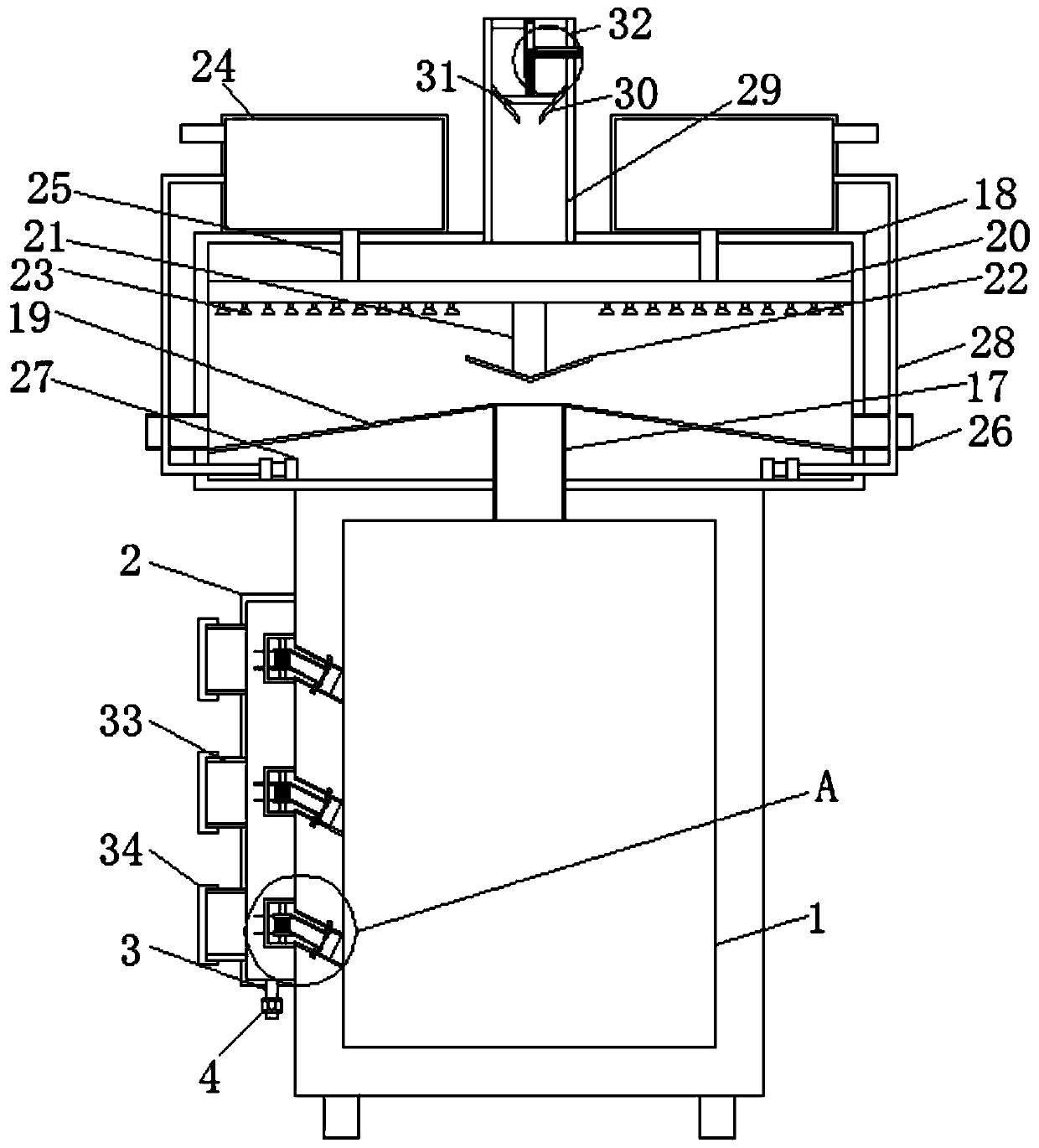

A kind of preparation method of lost foam casting coating

ActiveCN111185570BAdjust Gap SizeImprove screening efficiencyFoundry mouldsFoundry coresLost-foam castingMaterials science

The present invention relates to a preparation method of lost foam casting paint, the preparation method of lost foam casting paint adopts the following paint processing equipment, the paint processing equipment includes a support spray device, a multi-stage vibrating screen device and a rotary grinding device; the described The supporting spraying device has a hollow structure, a multi-stage vibrating screen device is installed on the upper side of the supporting spraying device, and a rotary grinding device is installed on the lower side of the supporting spraying device. The invention can solve the problem that the existing equipment only performs one screening process when preparing the lost foam casting coating, the screening efficiency is low, and the size of the screen holes is fixed, which cannot meet the requirements for different screening particle sizes, and the existing When the equipment is used to prepare the coating for lost foam casting, it uses one-time grinding treatment, and the grinding fineness is not high, which leads to problems such as the decline in the quality of subsequent coatings.

Owner:徐州卓越新材料科技有限公司

Damping rubber plate molding machine

InactiveCN102069588BAdjust gap sizeFulfil requirementsDomestic articlesStampingDrive shaftMolding machine

The invention discloses a damping rubber plate molding machine, which comprises a base, and a frame arranged on the base. A driving shaft and a driven shaft are arranged on the frame; the same end of the driving shaft and the driven shaft is provided with a driving gear and a driven gear in engaged transmission respectively; a compression roller is arranged on the driving shaft and the driven shaft respectively; the frame comprises two movable plates which are rotationally connected with two ends of the driven shaft, and two fixing plates which are positioned above the movable plates and are arranged on the top of two sides of the frame; and an adjusting hand wheel of which the lower end is fixedly connected with the movable plates is screwed on each fixing plate respectively. The damping rubber plate molding machine is simple in structure, easy to manufacture, easy and convenient to operate, low in cost, diversified in function, high in practicality and easy for popularization and application.

Owner:ZHENGZHOU LEDA IND

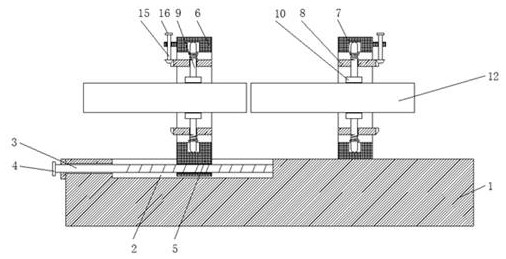

Angle steel rolling guide device

PendingCN107185975AAccurateAdjust gap sizeGuiding/positioning/aligning arrangementsStructural engineeringMechanical engineering

The invention relates to the field of steel rolling in the steel industry and discloses an angle steel rolling guide device. The angle steel rolling guide device comprises a guide box. Vertical plates and an inlet guide plate are arranged on the left side and the right side of the guide box, the inlet guide plate is in a horn mouth shape, the vertical plates are vertically arranged on the two sides of the guide box, and the vertical plates and the guide box are integrally formed. Two supporting arms are arranged on the front side and the rear side of the guide box correspondingly. The middle portion of each supporting arm is connected with the guide box through a rotation shaft. The supporting arms are provided with vertical guide rollers, and the vertical guide rollers on the two supporting arms can be used in cooperation. Compressing springs are arranged on the parts, between the vertical guide rollers and the rotation shafts, of the supporting arms, one end of each compressing spring is connected with the corresponding supporting arm, and the other end of each compressing spring is connected with the guide box. A flat guide roller is arranged on the bottom of the guide box and can provide support for displacement of a steel piece in the guide box. The angle steel rolling guide device can reduce the problems of surface scratches, scars and the like on rolling pieces, and precise centering can be achieved.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

a calciner

ActiveCN108302936BGuaranteed closureAvoid fireCharge treatment typeFurnace typesThermodynamicsFlue gas

The invention discloses a calcinator, and relates to the field of calcinators. Blocking grooves are formed in the tops and the bottoms of inner walls of observation holes, sealing plugs are arranged in inner cavities of the observation holes, blocking covers are arranged on the left sides of the observation holes, a compression spring is connected between every two movable sleeves, and the right side of each extension rod is connected with a check block. A spray pipe is installed on the upper side of an inner cavity of a purification box, the inner wall of a trapezoidal cover is in lap joint with a control panel, and a lifting mechanism is installed at the top of the control panel. The sealing plugs extend into the observation holes through sliding blocks connected with the check blocks, the sealing effect of the observation holes is guaranteed, the situation that the observation holes in the calcinator are on fire is prevented, the air pressure in an enclosing cover is approximate tothat in the calcinator, so that the situation of smoking from the observation holes is reduced, flue gas exhausted from the calcinator can absorb particles in the flue gas through water sprayed from the spray pipe, and the harm to a human body when the flue gas is discharged is reduced.

Owner:山东齐明炭素有限公司

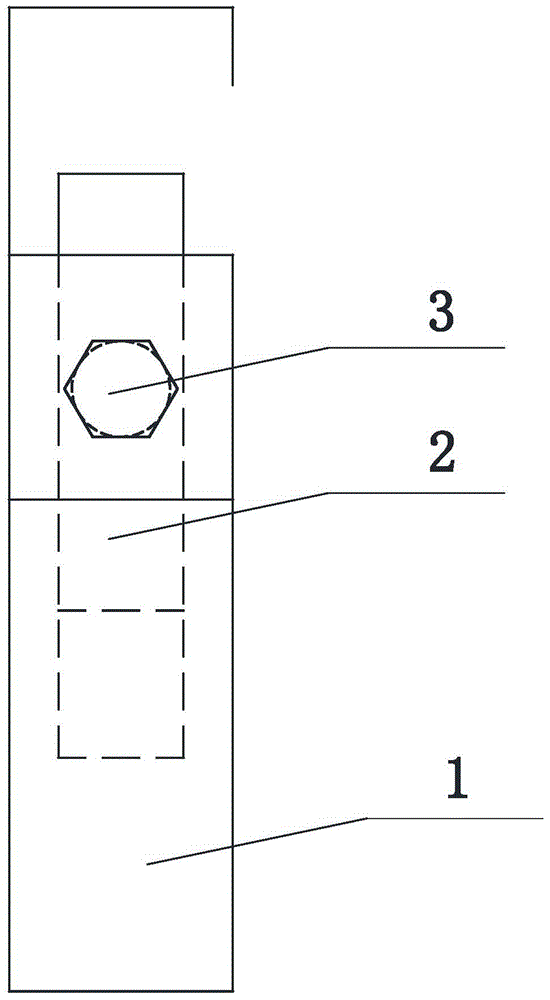

Anti-eccentric clamping device for circular hard alloy welding

InactiveCN112824009AAchieve the purpose of alignmentSimple structureWelding/cutting auxillary devicesAuxillary welding devicesAlloyCemented carbide

The invention relates to the technical field of welding, and discloses an anti-eccentric clamping device for circular hard alloy welding. The device comprises a workbench, a sliding groove is formed at the top of the workbench, a screw rod is movably connected to the left side of the workbench, a gap adjusting handle is fixedly connected to the left side of the screw rod, and a sliding seat is slidably connected to the interior of the sliding groove; and a disc body is fixedly connected to the top of the sliding seat, a fixing sleeve is slidably connected to the interior of the disc body, and an adjusting groove is formed in the inner wall of the disc body. Welding bodies are gradually clamped by a clamp at the end, close to the welding bodies, of a clamping rod, meanwhile, the axes of the welding bodies coincide with the axis of the disc body, the axes of the welding bodies at the two sides coincide with the axis of the disc body, the axes of the two welding bodies coincide, and therefore the purpose that the welding axes are aligned is achieved; and meanwhile, as the structure is simple and the axis alignment is not influenced by different diameters of the two welding bodies, the application range is wide.

Owner:HUNAN UNIV OF TECH

An inclined plane air duct flange fastener and using method thereof

ActiveCN104344119BAchieving a sealed connectionAdjust Gap SizeDucting arrangementsFlanged jointsControl systemEngineering

The invention relates to an inclined plane type air duct flange fastener and a using method thereof, belongs to the technical field of an ventilation air conditioning and smoke control system and aims at the problem that in the mounting process of existing air ducts, a mounting operation space at the joint of flanges is narrow and fastening of flange bolts cannot be completed so as to cause the condition that the air ducts cannot be effectively abutted. The inclined plane type air duct flange fastener comprises a right trapezoid shell and a right trapezoid sliding block, wherein the inclined edge of the shell is provided with a slide; the sliding block is arranged in the slide of the shell; the sliding block is connected with the shell by a bolt; the straight edge of the shell is in parallel to that of the sliding block; the inclined edge of the sliding block is arranged in the slide, and thus, rotation of the bolt drives the sliding block to slide along the slide so as to regulate the size of a gap between the straight edge of the shell and the straight edge of the sliding block. The using method comprises the following steps: firstly, buckling a gap between the straight edge of the shell and the straight edge of the sliding block between two outer flanges; then rotating the bolt to gradually reduce the gap until fastening of the two outer flanges is completed, so that a first air duct and a second air duct are connected in a sealing manner.

Owner:SHANGHAI INSTALLATION ENG GRP

Adjustable hinge

PendingCN111636783AAvoid damageReduce safety incidentsPin hingesClassical mechanicsStructural engineering

Owner:ZHEJIANG DAFENGFAN FURNITURE CO LTD

Mold for stabilizing welding quality of optical fiber stainless steel sleeves

The invention discloses a mold for stabilizing the welding quality of optical fiber stainless steel sleeves. The mold comprises a cylinder; a connecting ring and a connecting groove are respectively arranged at the two ends of the cylinder; a fastening bolt is mounted at one end of the cylinder, and is inserted in the connecting groove; an opening groove is formed in the outer side of the cylinder; slide rail grooves are formed in the two sides of the opening groove; stop devices are slidingly mounted in the slide rail grooves, and are connected with one end of the opening groove through tension springs; and a limiting block is arranged at the other end of the opening groove. The mold has the following beneficial effects: self elasticity of the tension springs is used for cooperating withlifting of stop rods to apply resistance to wound steel strips, so that gaps are adjusted, unified gap sizes are guaranteed, and the welding line quality is guaranteed; the splicing installation of devices can be realized through the connecting ring and the connecting groove; and the devices are freely combined according to the lengths of sleeves to meet production of the sleeves with different lengths.

Owner:CHENGDU TECHCAL UNIV

Sorting device with protective cover for potato cleaning machine

Owner:SHANDONG UNIV OF TECH

Air conditioner indoor unit

ActiveCN105276678BHave diversityAdjust gap sizeLighting and heating apparatusAir conditioning systemsEngineeringAir blower

The invention discloses an indoor unit of an air conditioner, comprising: a casing, the casing is provided with an air inlet and an air outlet; An air duct is defined in the assembly, the air duct has an air duct inlet and an air duct outlet, the air duct inlet communicates with the air inlet, the air duct outlet communicates with the air outlet, and the width of the air duct inlet is The length direction of the air guide assembly is not equal; and the cross-flow wind wheel is arranged at the inlet of the air duct. According to the indoor unit of the air conditioner in the embodiment of the present invention, since the width of the air duct inlet is not equal in the length direction of the air guide assembly, the air supply of the indoor unit of the air conditioner can be diversified, and the comfort of the air supply can be improved. And can meet the different needs of users.

Owner:MIDEA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com