Patents

Literature

63results about How to "Guaranteed fatigue strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

Method for preparing high-power AC transmission power car axle

InactiveCN101250665AGuaranteed mechanical propertiesGuaranteed fatigue strengthShaftsMetal-working apparatusChemical compositionEngineering

The invention relates to a method for manufacturing a vehicle shaft of a high-power alternating current electric locomotive, which comprises the following steps: utilizing European standard EN13261(2005 year edition) performance index to be standard, controlling chemical components of material in the process of smelting as follows, C 0.22%-0.29%, Cr 0.90%-1.20%, Mn 0.60-0.90%, Mo 0.15%-0.30%, Si<=0.40%, P<=0.020%, S<=0.015%, Cu<=0.20%, V<=0.06% and Ni<=0.25%. The process technique of the vehicle shaft of the high-power locomotive comprises the following steps: smelting bar material according to the above chemical component requirements, doing a series of forging for the bar material, shaping, guaranteeing horizontal mechanical property, machining and roughing bar material which is forged to shape, thermally processing the vehicle shaft of the high-power locomotive which is roughed, and finishing the vehicle shaft of the high-power locomotive which is thermally processed.

Owner:ZHUZHOU TIANLI FORGING IND

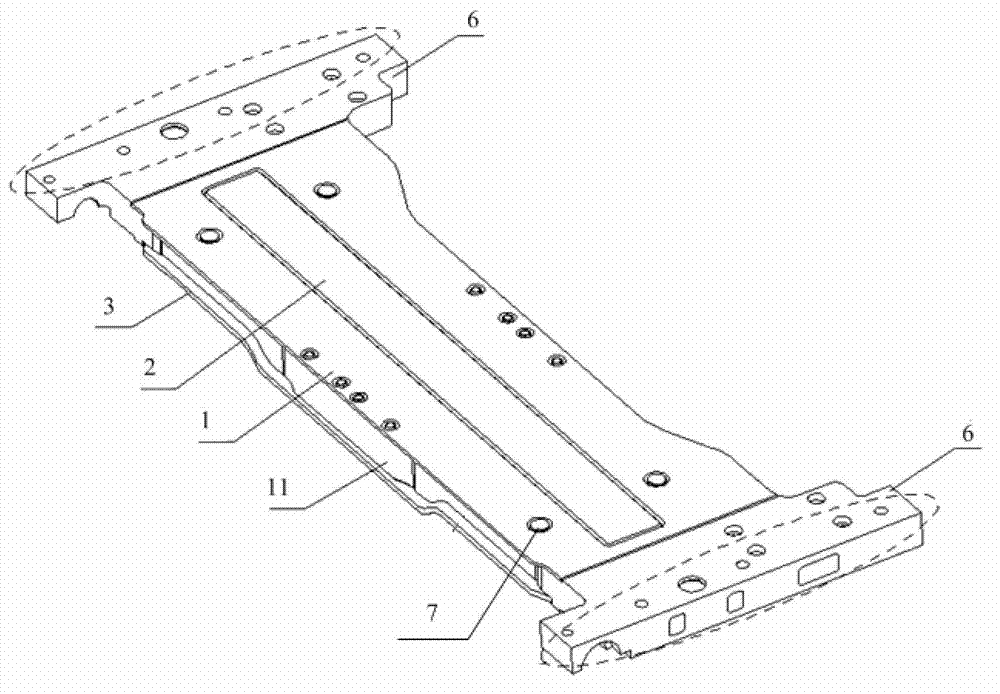

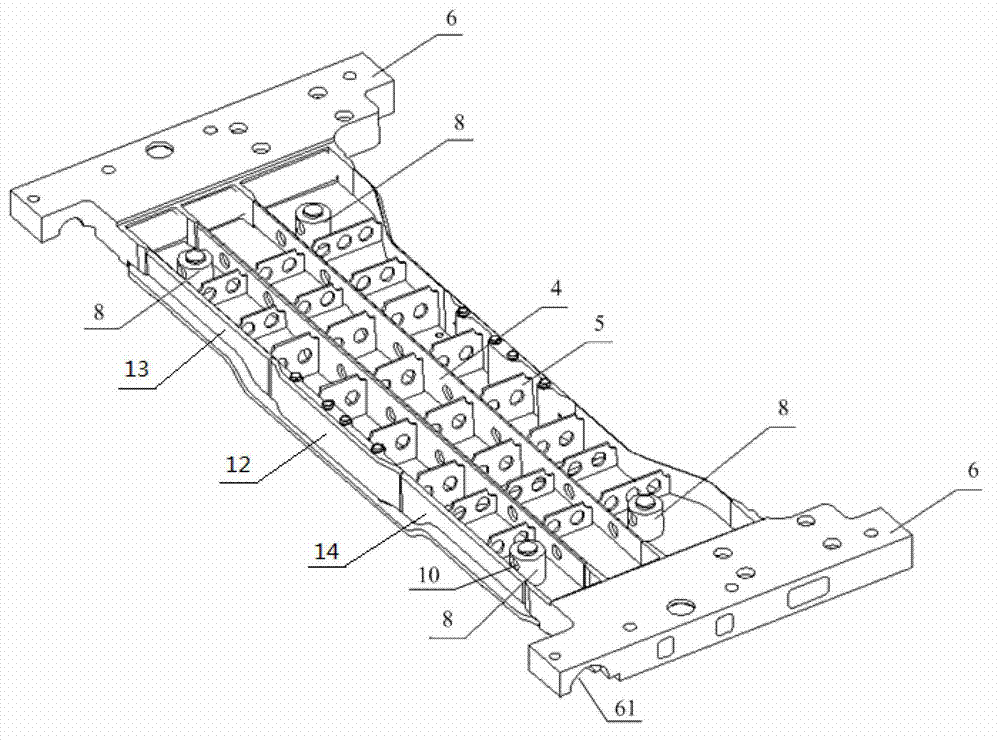

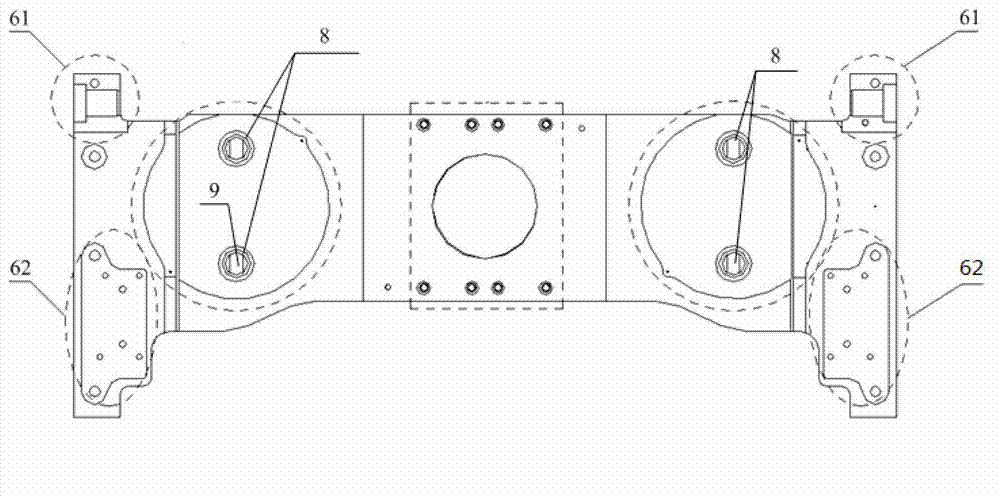

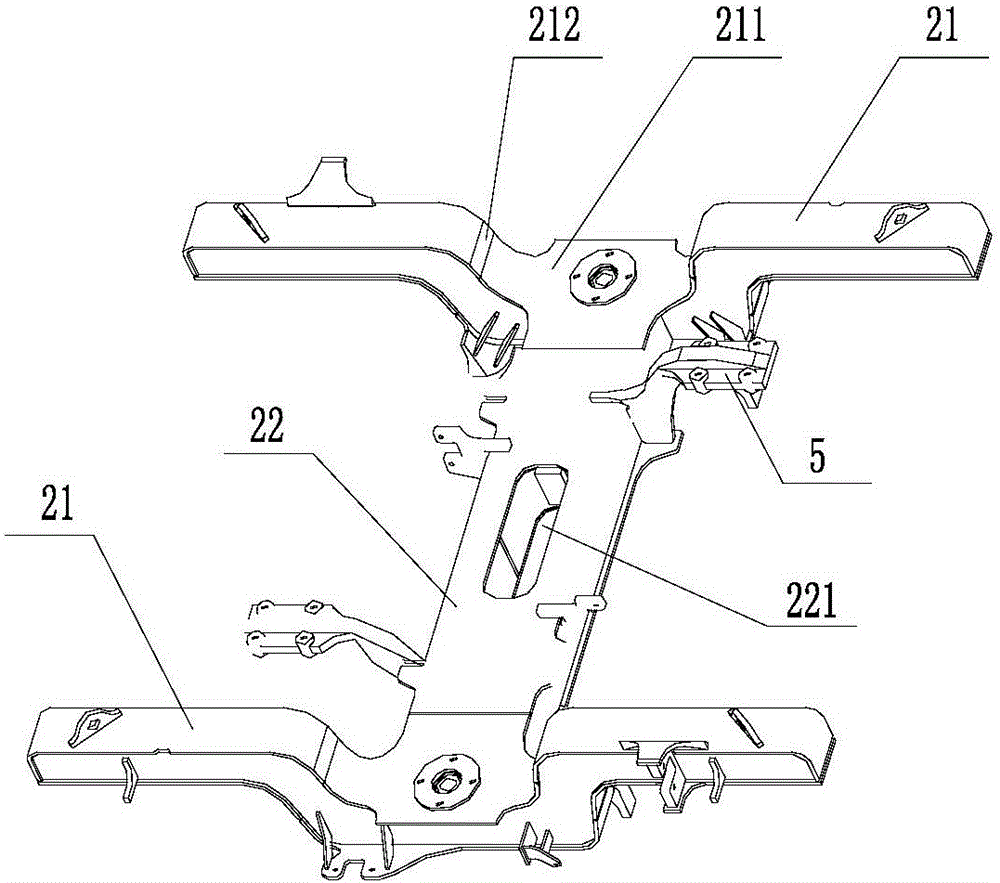

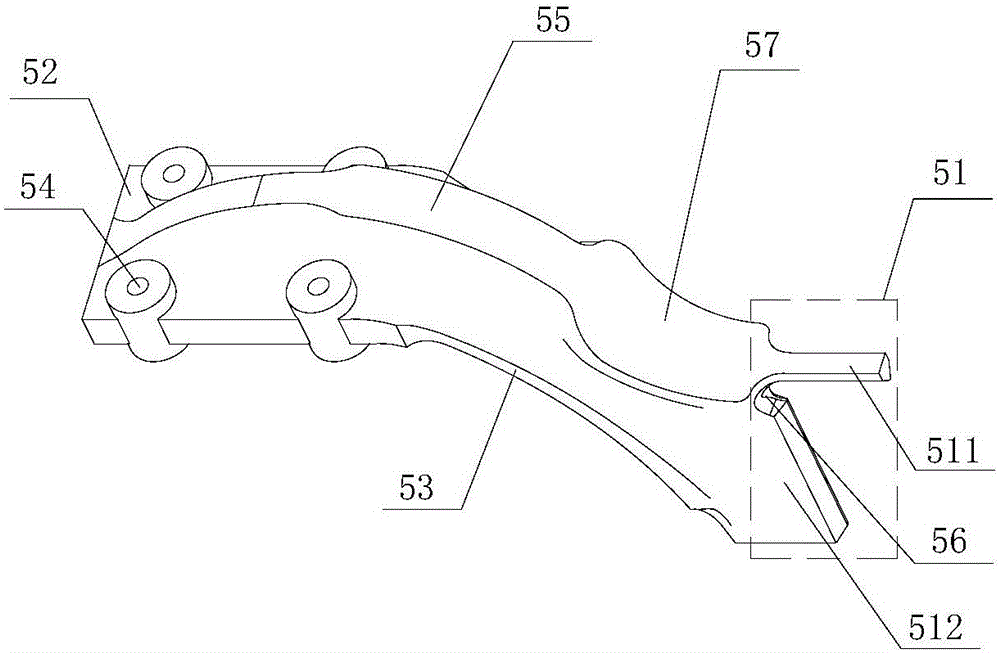

Steering frame contact sleeper beam and railway vehicle

ActiveCN103112468AGuaranteed fatigue strengthGuaranteed StrengthBogiesBogieArchitectural engineering

Owner:CRRC TANGSHAN CO LTD

Adjustable finishing broach of wheel disc and tenon slot combination surface

InactiveCN102717149AMaintain and improve geometric accuracyEliminate size deviationBroaching toolsTongue and grooveGas turbines

The invention discloses an adjustable finishing broach of wheel disc and tenon slot combination surface. The adjustable finishing broach comprises a mounting section, a cutting section and an adjusting section, wherein the cutting section consists of two halves of separate contour line blade elements and fixed on the mounting section through the adjusting section, and the adjusting section is a replaceable element to adjust the position of the contour line of the cutting section. According to the invention, the dimensional deviation of reground cutting edge can be removed; the geometric accuracy of precisely processed contour line is kept; the tool cost is reduced, and the service life of the tool is prolonged; and the adjustable finishing broach is suitable for broaching machining of the wheel disc and the tenon slot of a heavy gas turbine rotor.

Owner:SHANGHAI JIAO TONG UNIV

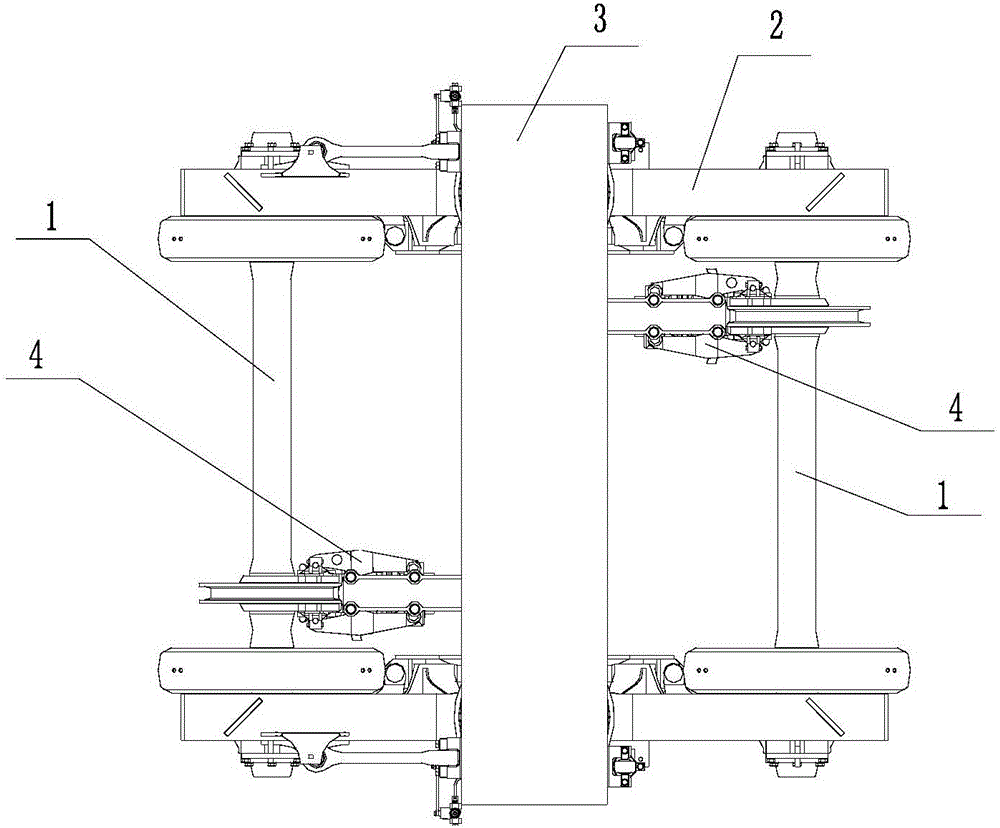

Power bogie and light rail vehicle

ActiveCN105151068AReduce frequencyGuaranteed fatigue strengthRail brake actuationBogiesBogieManufacturing technology

The invention provides a power bogie and a light rail vehicle, and relates to the technical field of vehicle manufacturing. The power bogie comprises power wheel pairs, a framework, a sleeper beam and basic brake devices. The framework comprises two parallel side beams and a cross beam connected with the side beams. The cross beam is in a plate shape. The two ends of the power wheel pairs are connected with the two side beams respectively. A center hole is formed in the middle of the cross beam. The middle of the sleeper beam is connected with the cross beam through a center pin. The cross beam is provided with brake hanging bases. The basic brake devices are arranged on the brake hanging bases. The basic brake devices are arranged on the cross beam, so that the self-frequency of nodding and sinking or floating of the bogie is reduced, and the overall fatigue strength of the bogie is guaranteed. Accordingly, the stability and safety of the vehicle are improved while the vehicle can run at a high speed.

Owner:CRRC TANGSHAN CO LTD

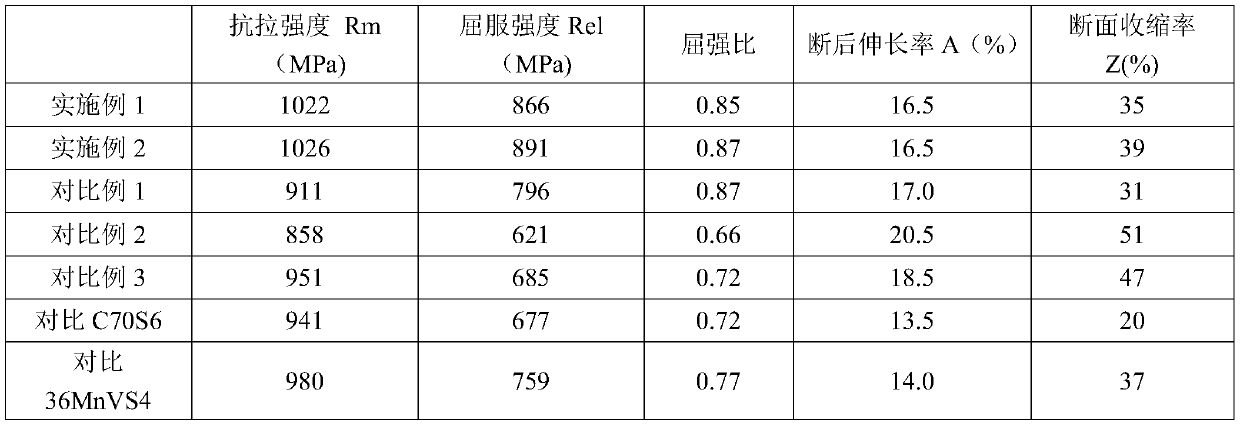

High-strength and high-yield-ratio non-quenched and tempered steel for automobile engine stretch-broken connecting rod and production method thereof

The invention discloses high-strength and high-yield-ratio non-quenched and tempered steel for an automobile engine stretch-broken connecting rod and a production method thereof. The steel comprises the following chemical components in percentage by weight, 0.40-0.50% of C, 0.40-0.60% of Si, 1.00-1.30% of Mn, 0.040-0.060% of S, 0.10-0.20% of V, 0.020-0.035% of Nb, 0.10-0.30% of Cr, 0.10-0.30% of Ni, 0.010-0.020% of N, and the balance Fe and impurity elements. Through the combination of the group distribution ratio and a controlled rolling and controlled cooling process, the mechanical propertyRel of the connecting rod material is greater than or equal to 850 MPa, the Rm is greater than or equal to 1000 MPa, and the yield ratio can reach more than 0.84, so that the light weight of an automobile engine is facilitated.

Owner:ZENITH STEEL GROUP CORP +1

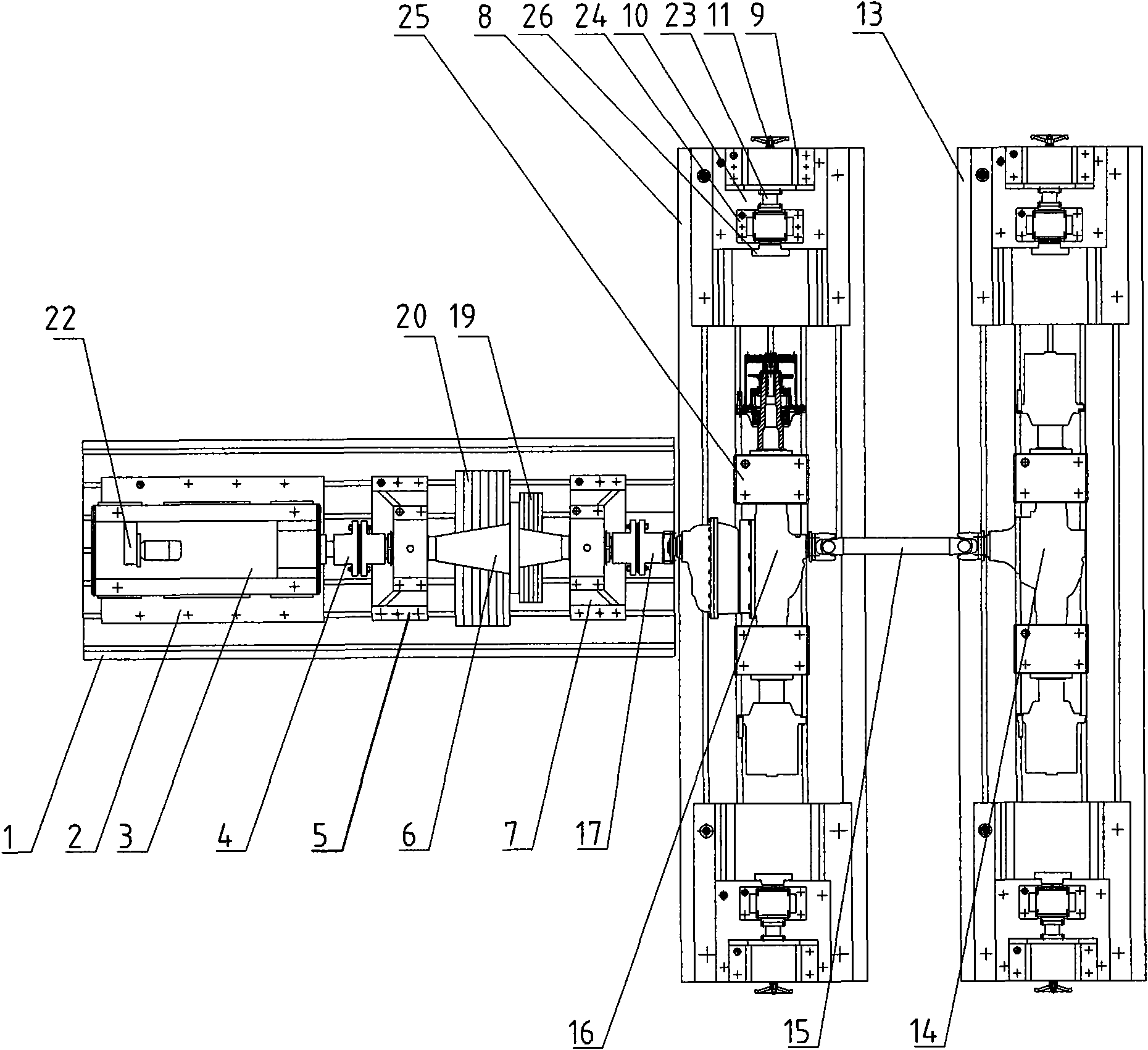

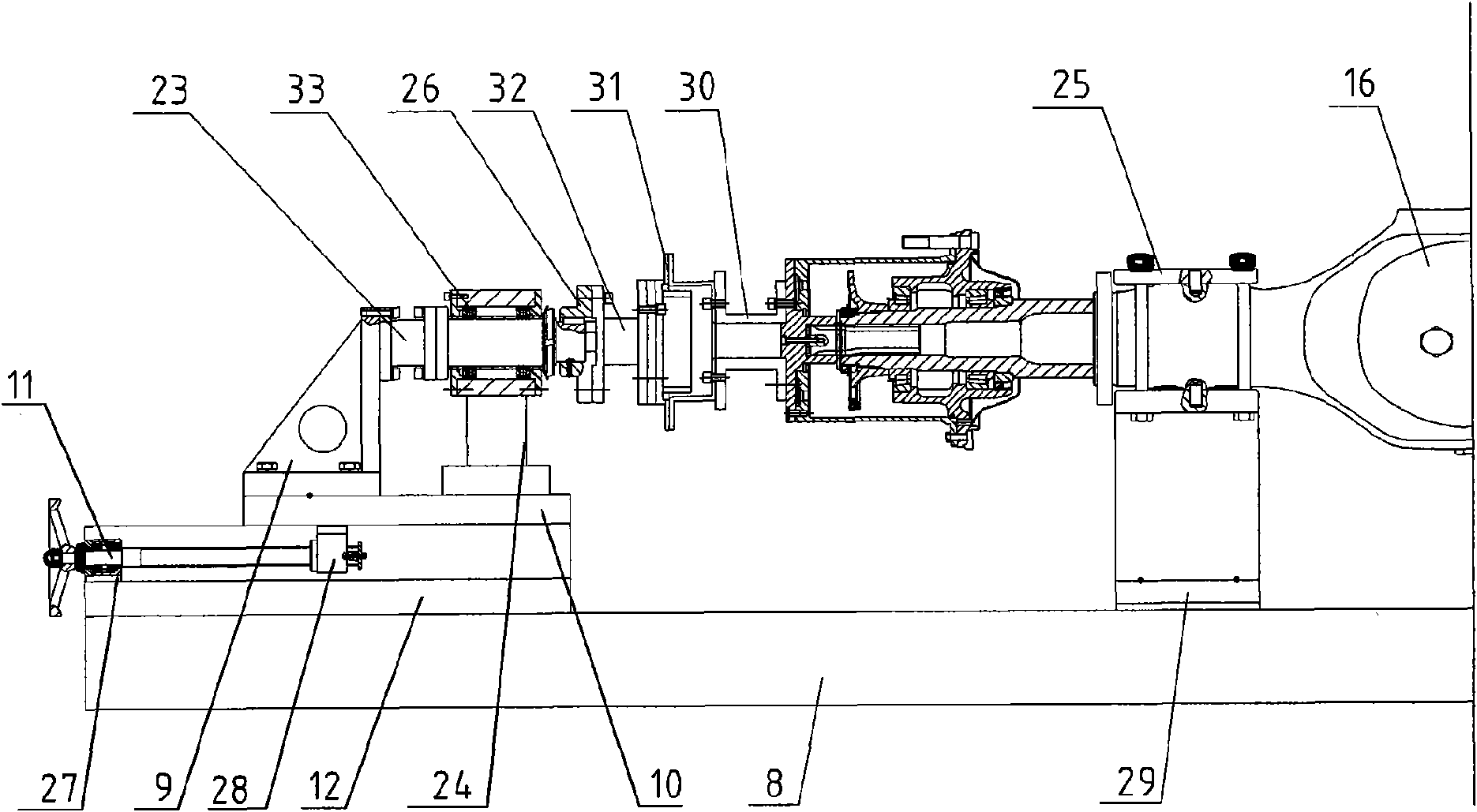

Passenger-vehicle four-end braking system test device

InactiveCN101608971AGuaranteed accuracyGuaranteed stiffness and fatigue strengthVehicle testingVelocity modulationDrum brake

A passenger-vehicle four-end braking system test device is characterized in that a DC (direct current) velocity modulation motor is fixedly arranged on a main bottom plate; an output shaft of the DC velocity modulation motor is connected with an inertial flywheel taper shaft through a coupling; the output end of the flywheel taper-shaft is connected with an input shaft of an intermediate axle through a coupling; the output end of the intermediate axle is connected with an input shaft of a rear axle through a transmission shaft; a drum brake clamp is respectively arranged on hub ends of the intermediate axle and the rear axle; a drum brake of a drum-style brake is mounted on the drum brake clamp and a brake shoe matched with the drum-style brake is arranged on a brake shoe clamp; and the brake shoe clamp is connected with a torque sensor through a mounting shaft. The invention adopts the motor to drive the flywheel to rotate and the flywheel can idle without power after the preset rotation speed is reached; and the braking to the whole test device can be realized by four-end brakes, the braking process of vehicles can be effectively simulated, and the four-ends brakes can be tested simultaneously in the braking process so as to provide evidence for both the performance test of the braking system and the research of the braking process.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

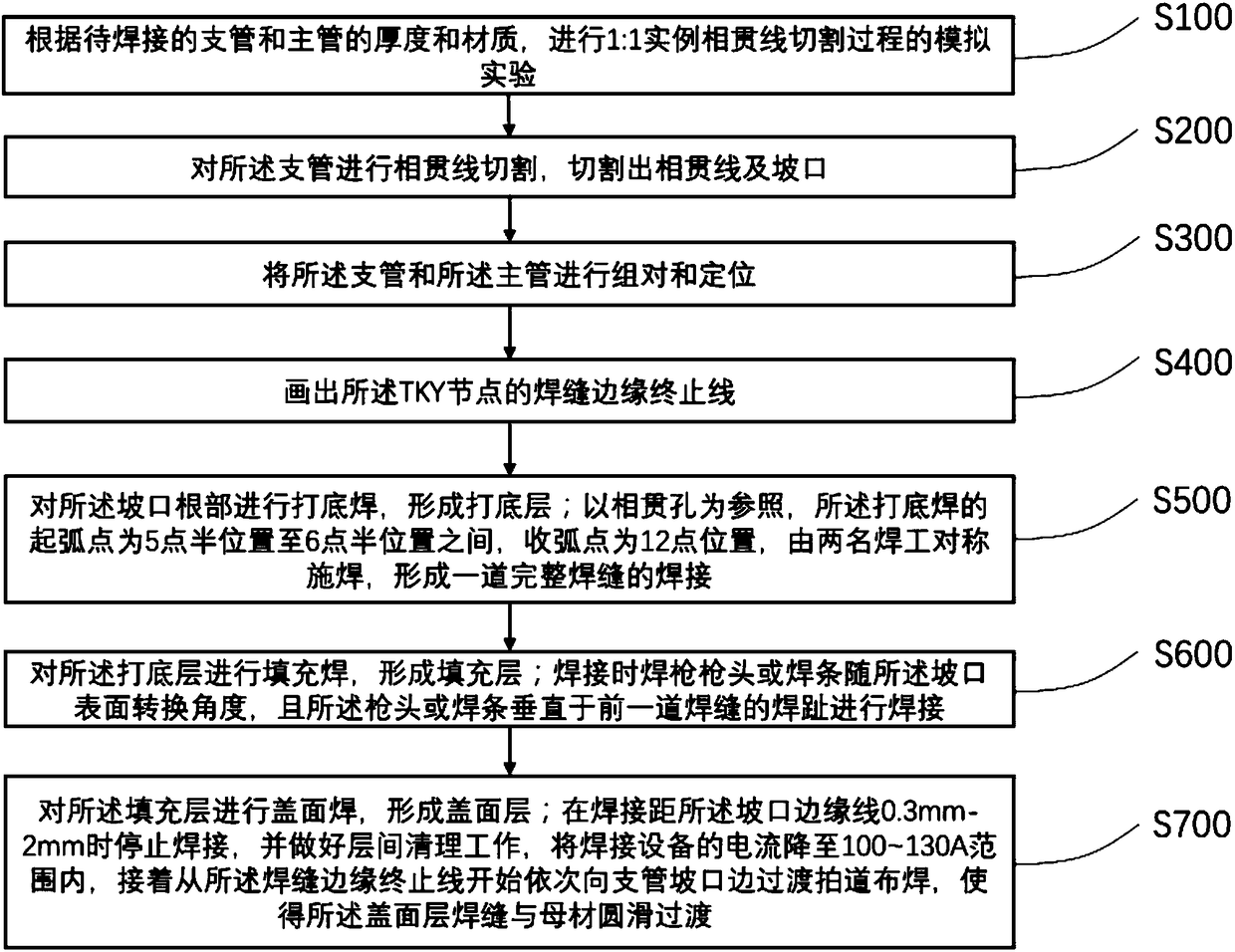

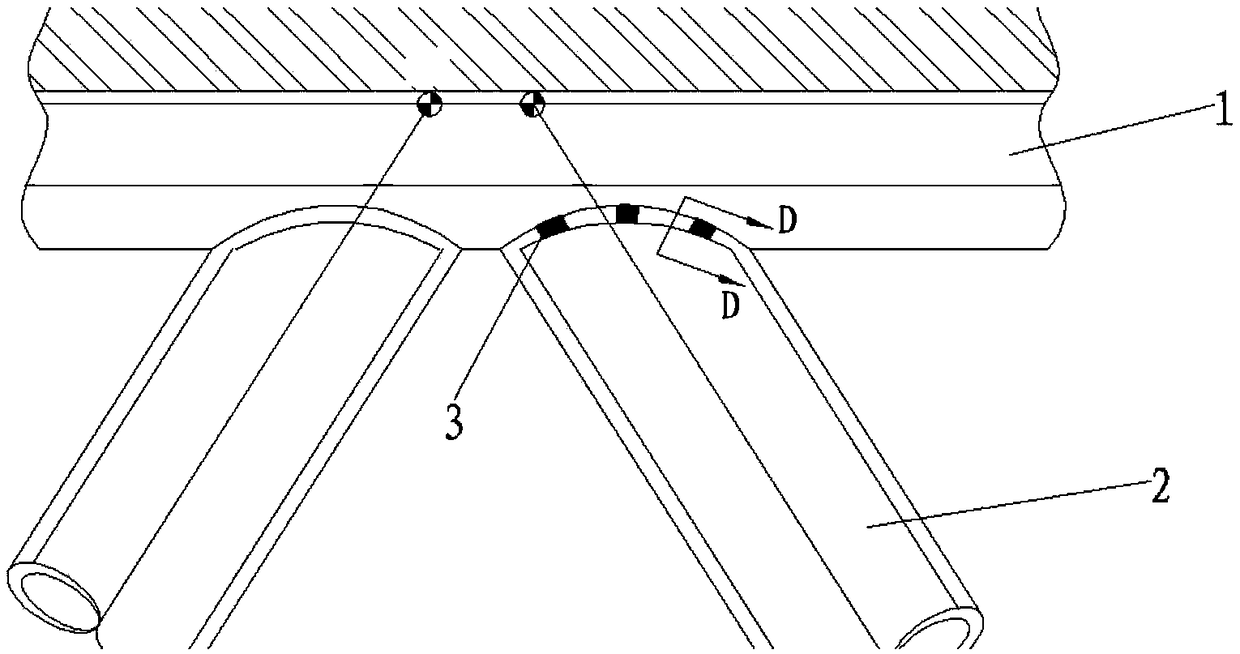

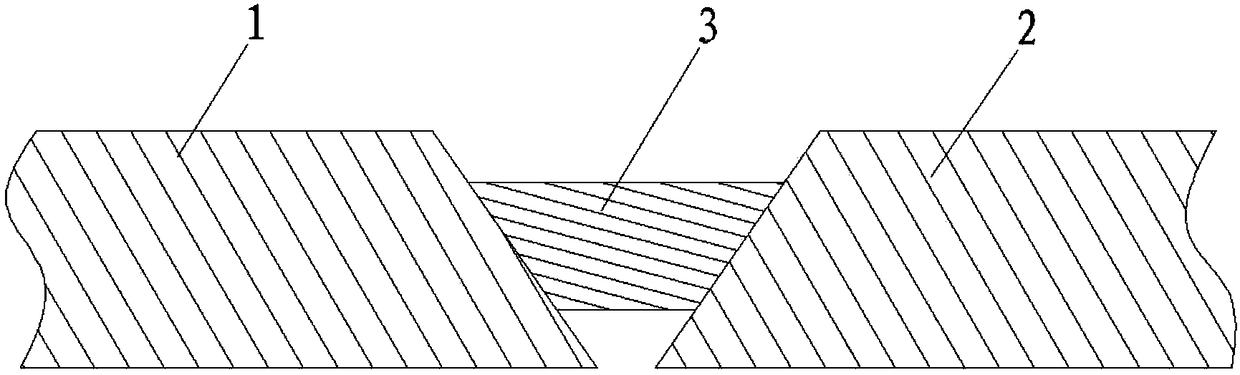

Welding method for TKY joints of steel structure

ActiveCN108453340AGuaranteed fatigue strengthReduce sandingGas flame welding apparatusPower flowEngineering

The invention discloses a welding method for TKY joints of a steel structure. The welding method includes the following steps that firstly, a 1: 1 example intersecting line cutting simulation test isperformed; secondly, intersecting line cutting is performed; thirdly, fitting up and positioning are performed; fourthly, weld joint edge terminated lines of the TKY joints are drawn; fifthly, backingwelding is performed to form a bottoming layer; sixthly, filling welding is performed to form a filling layer; and seventhly, surface covering welding is performed to form a surface covering layer, current of a welding device is decreased into the range of 100-130 A, welding stops when the distance from welding to a groove edge line is 0.3 mm to 2 mm, then from the weld joint edge terminated lines, arranging and welding are sequentially in transition to the groove edge of a branch pipe, and a surface covering layer weld joint and parent metal are made to be in smooth transition. The welding method guarantees that the fatigue strength and other mechanical performance of the TKY joints reach standards, one-time welding forming is performed, root portion defects are not likely to be caused,weld joint grinding is reduced, the labor intensity of workers and the production cost are lowered, and the production efficiency is improved.

Owner:上海拓直数字科技有限公司

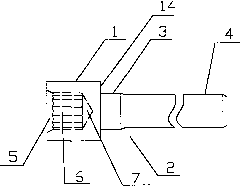

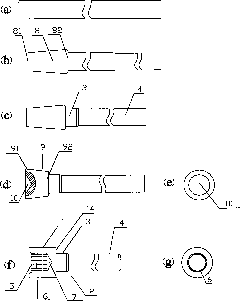

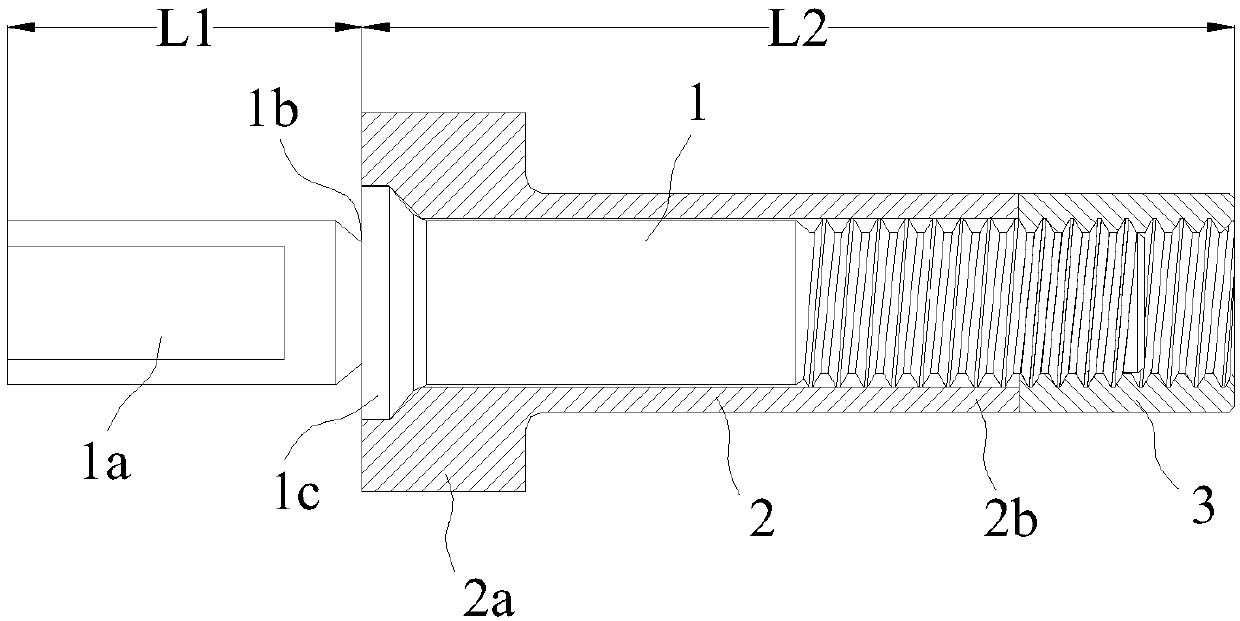

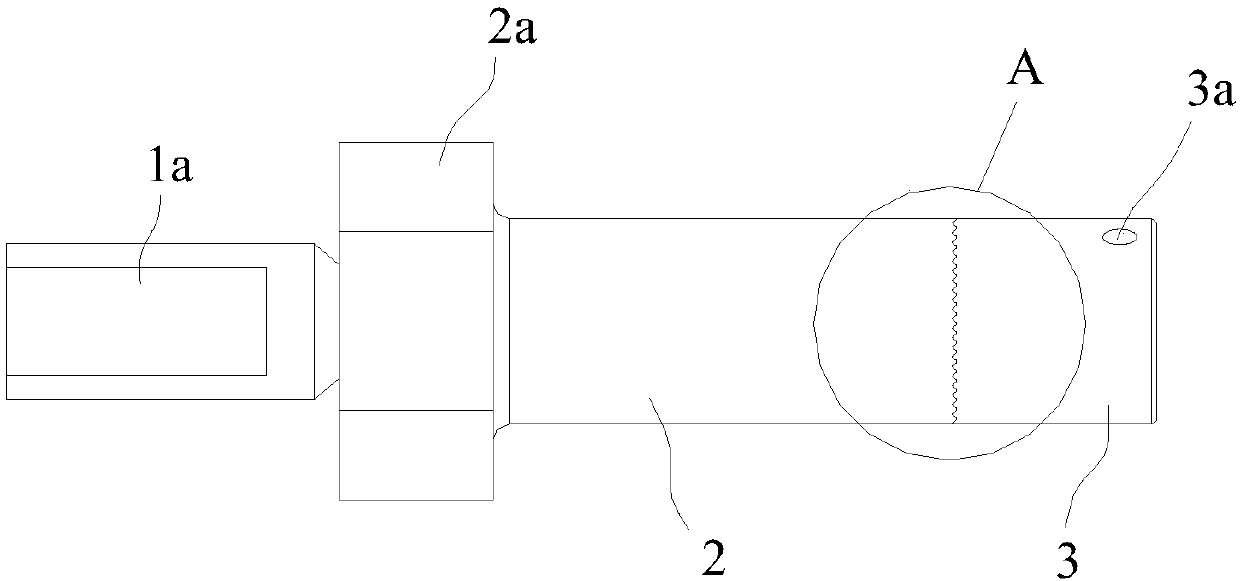

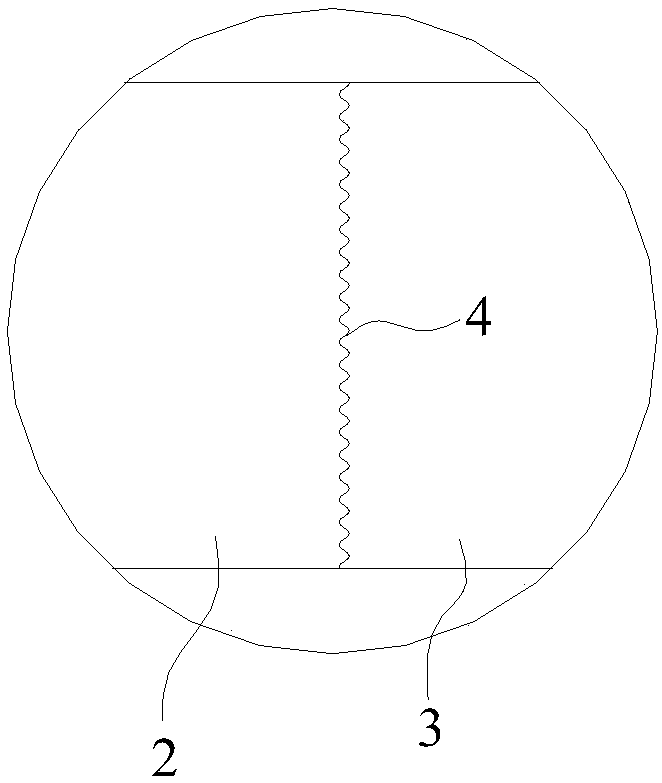

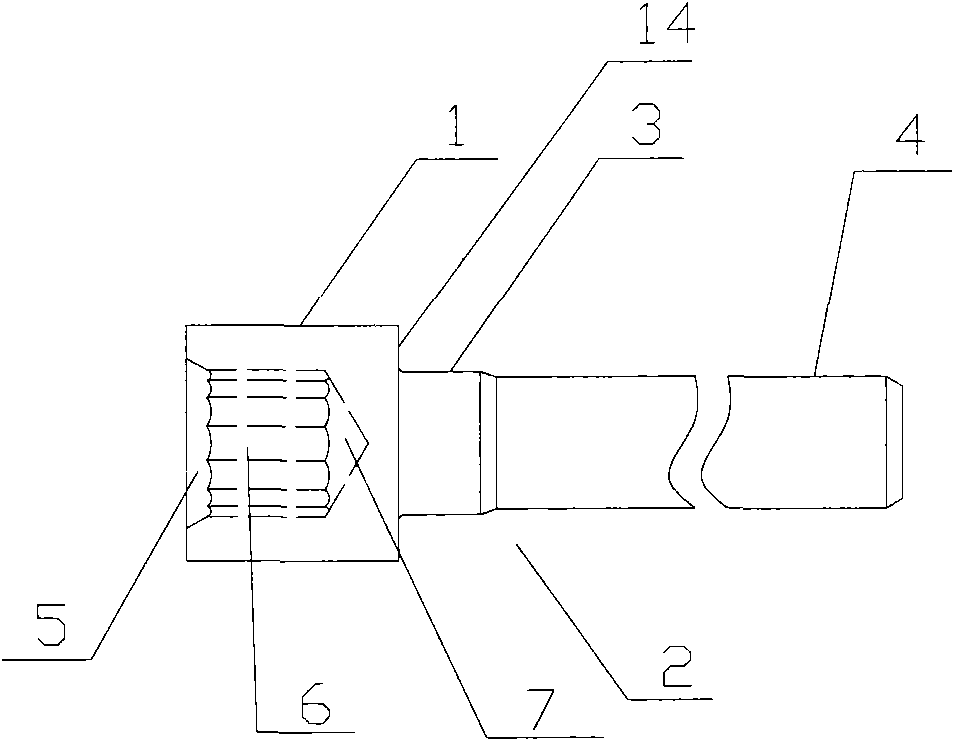

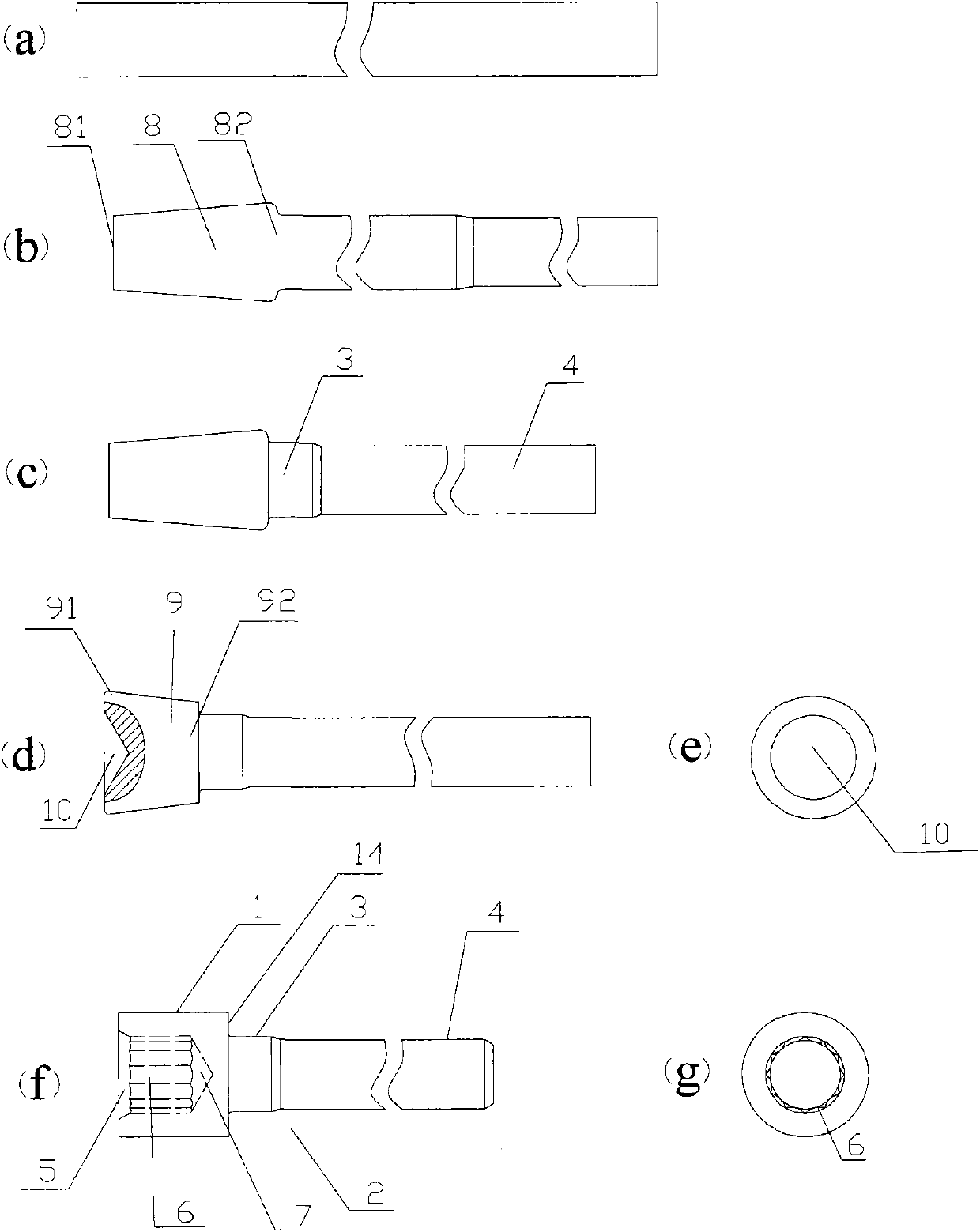

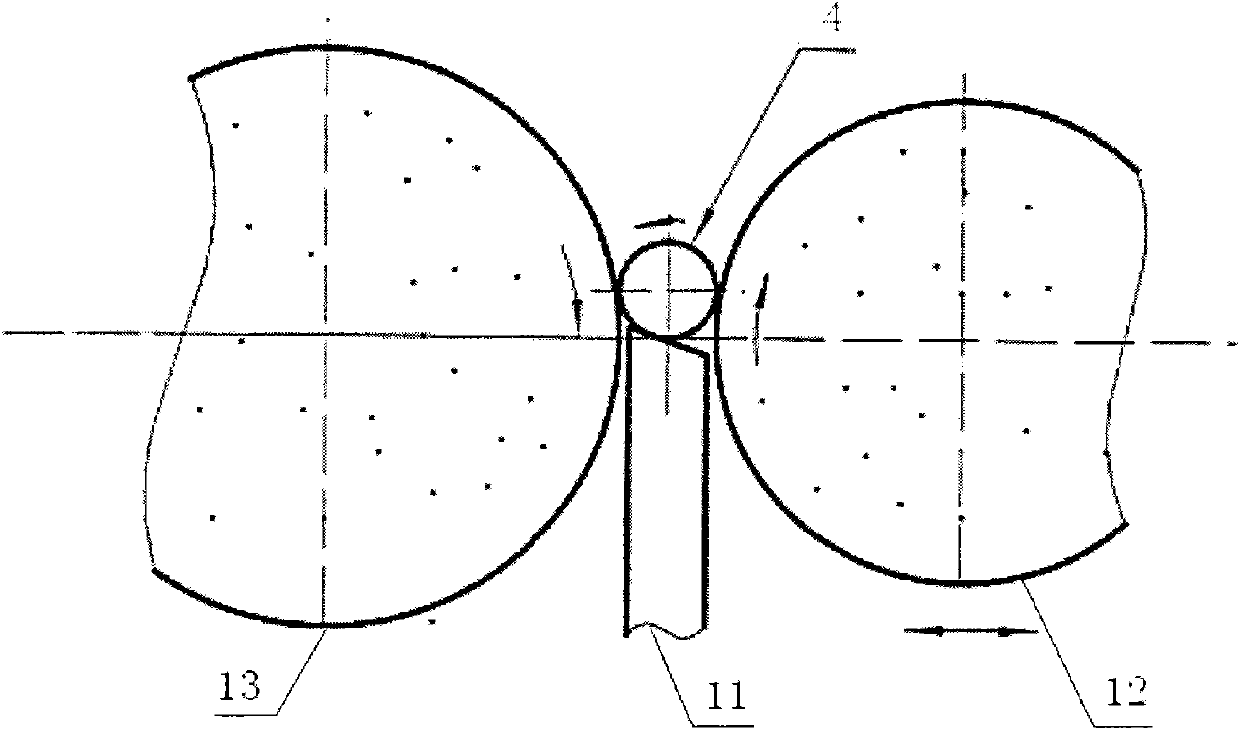

Thread core-pulling rivet and riveting method using same

PendingCN108050142AEasy to assembleReduce manufacturing costRivetsScrewsEngineeringUltimate tensile strength

The invention discloses a thread core-pulling rivet and a riveting method using the same. The thread core-pulling rivet comprises a rivet rod with a limiting cap, a driving ring mounted on the rivet rod in a threaded mode and a rivet sleeve arranged on the rivet rod in a sleeving mode and located between the limiting cap and the driving ring. A blocking head matched with the limiting cap in an abutting mode is arranged at one end of the rivet sleeve, and the other end of the rivet sleeve and the driving ring are matched circumferentially in a positioned mode. In riveting, the rivet rod rotatesrelative to the rivet sleeve, the driving ring and the limiting cap apply force to the rivet sleeve oppositely to enable the rivet sleeve to be deformed, and after riveting, a deformed part of the rivet sleeve and the blocking head abut against the two sides of a riveting part. The thread core-pulling rivet has high pre-tightening force, tensile strength and fatigue strength after being mounted and is easy to assemble, so that the manufacturing difficulty and cost are reduced.

Owner:RITAI SHANGHAI AUTO STANDARD COMPONENT

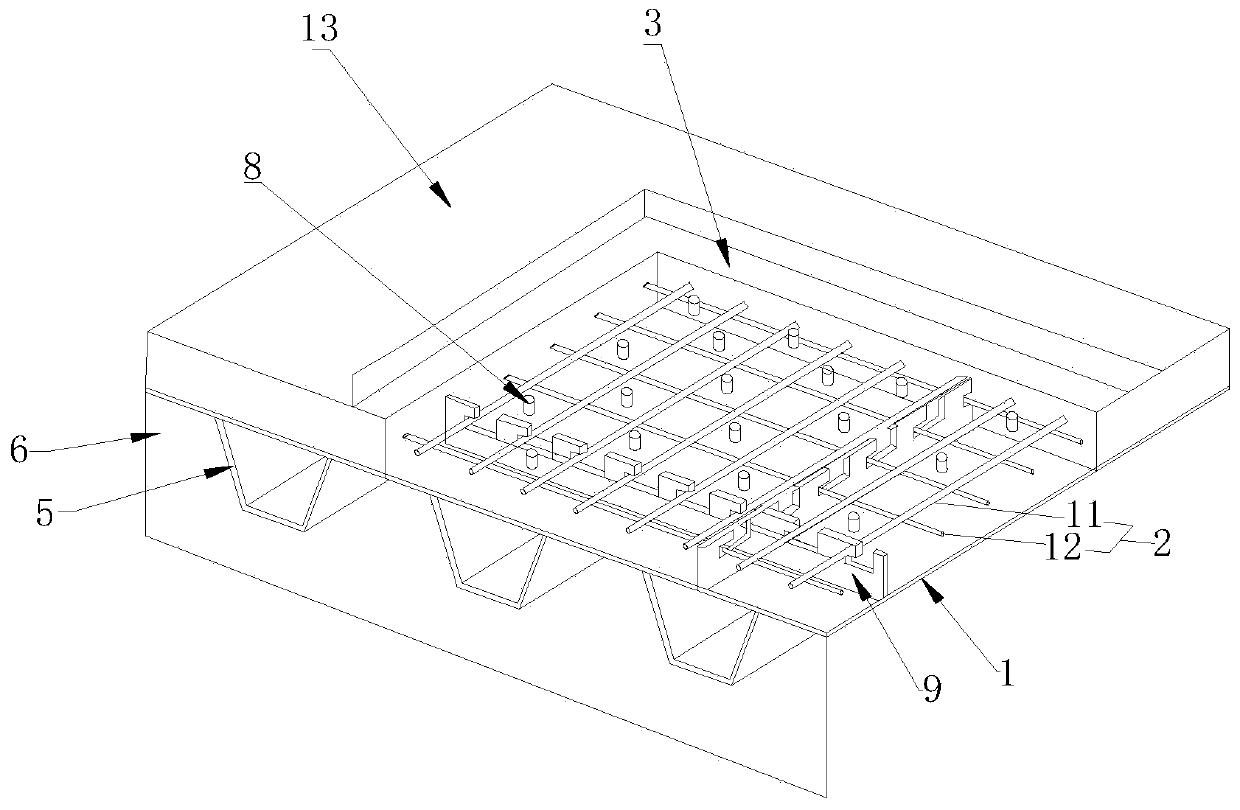

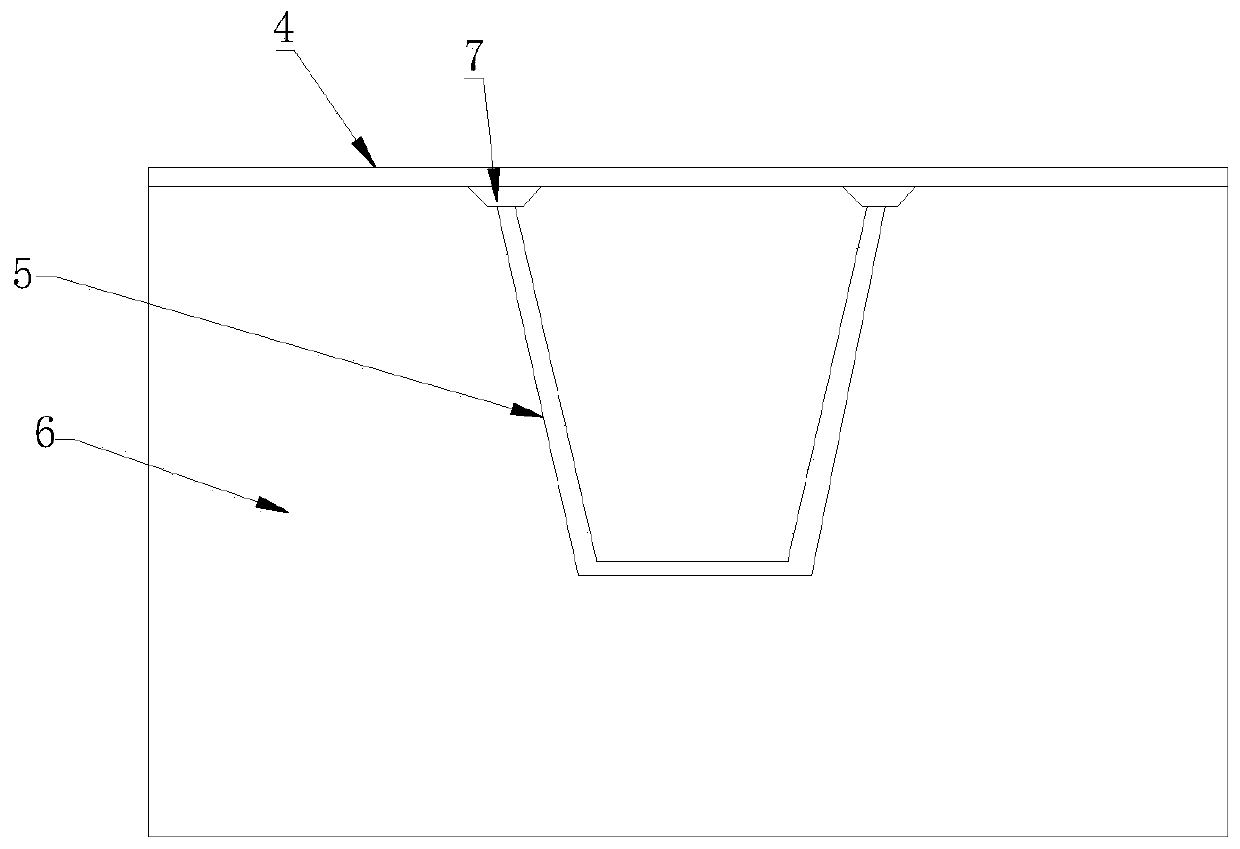

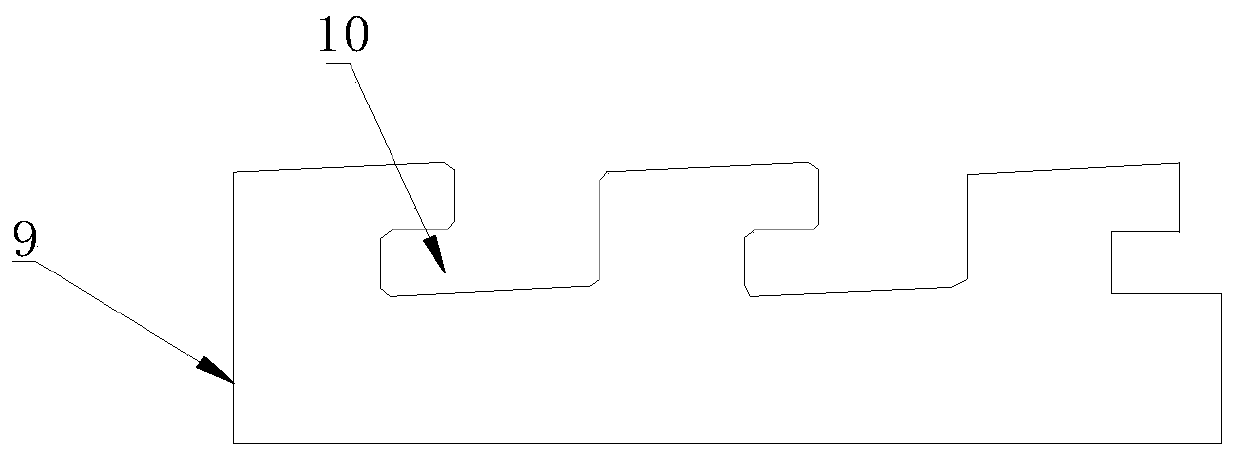

Orthotropic steel bridge deck ductile concrete composite structure and construction method

PendingCN111485491AIncrease stiffnessImprove mechanical performanceBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses an orthotropic steel bridge deck ductile concrete composite structure and a construction method, and relates to the technical field of bridge engineering. The key points of thetechnical scheme are as follows: the orthotropic steel bridge deck ductile concrete composite structure comprises an orthotropic steel bridge deck, a grid mesh and a tough concrete layer; a pluralityof longitudinal ribs are transversely arranged on the bottom surface of the steel bridge deck at intervals; shear nails are arranged on the top surface of the steel bridge deck; a plurality of criss-cross erecting rib perforated plates are arranged on the top surface of the steel bridge deck at equal intervals; and an SBS modified asphalt SMA pavement layer is paved on the top surface of the tough concrete layer. The combined structure can improve the overall rigidity of the steel bridge deck and improve the fatigue problem of the steel bridge deck system and has the advantages of light self-weight, high bearing capacity and simple structure, and can ensure that the steel bridge deck has a wide application range and good stress performance under various conditions; bridge construction cost is saved, and benefits are remarkable. The national key research and development plan subsidy is obtained, the subject name is the key technical research of the efficient construction of the combined structure urban bridge, and the subject number is 2017YFC070348.

Owner:中交三公局第一工程有限公司

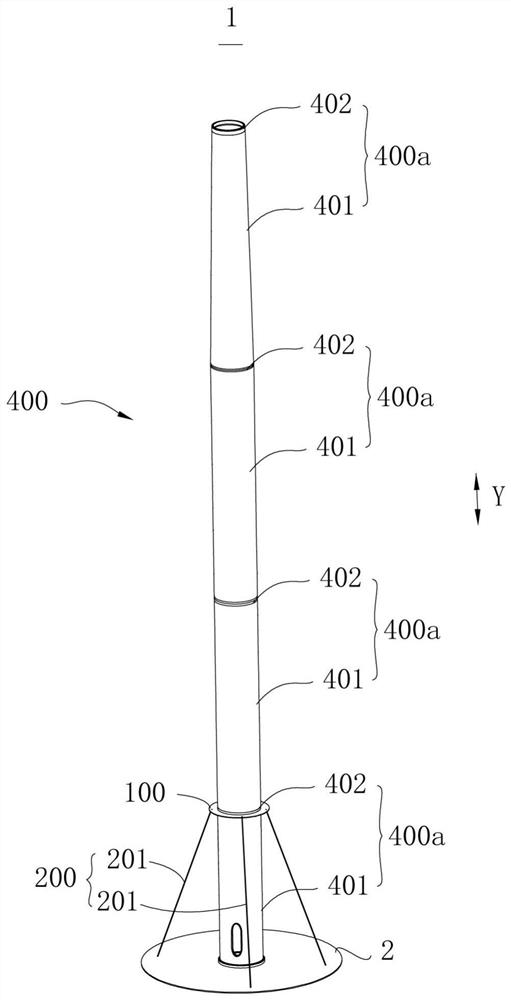

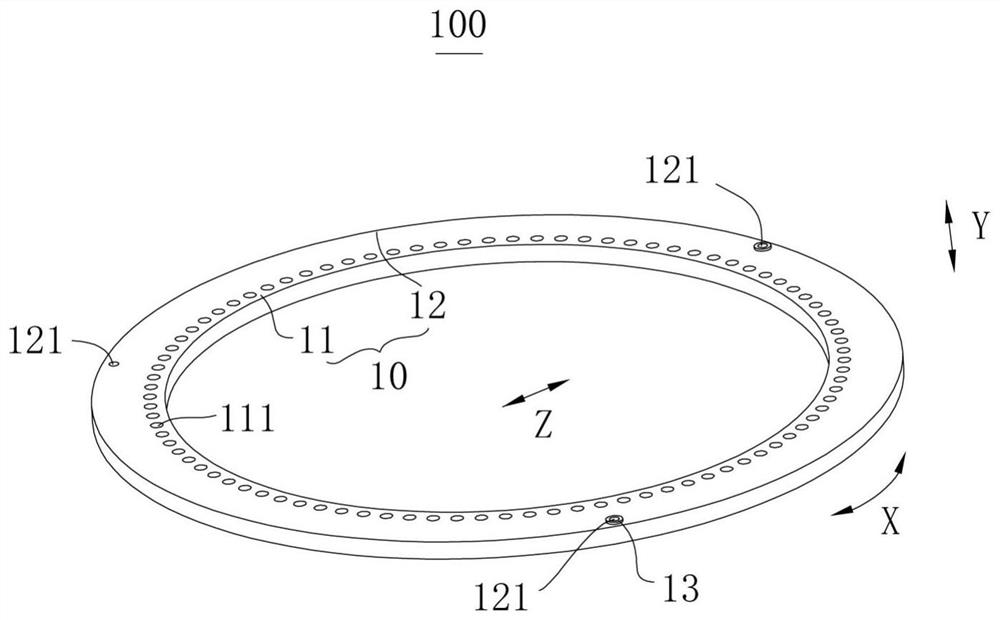

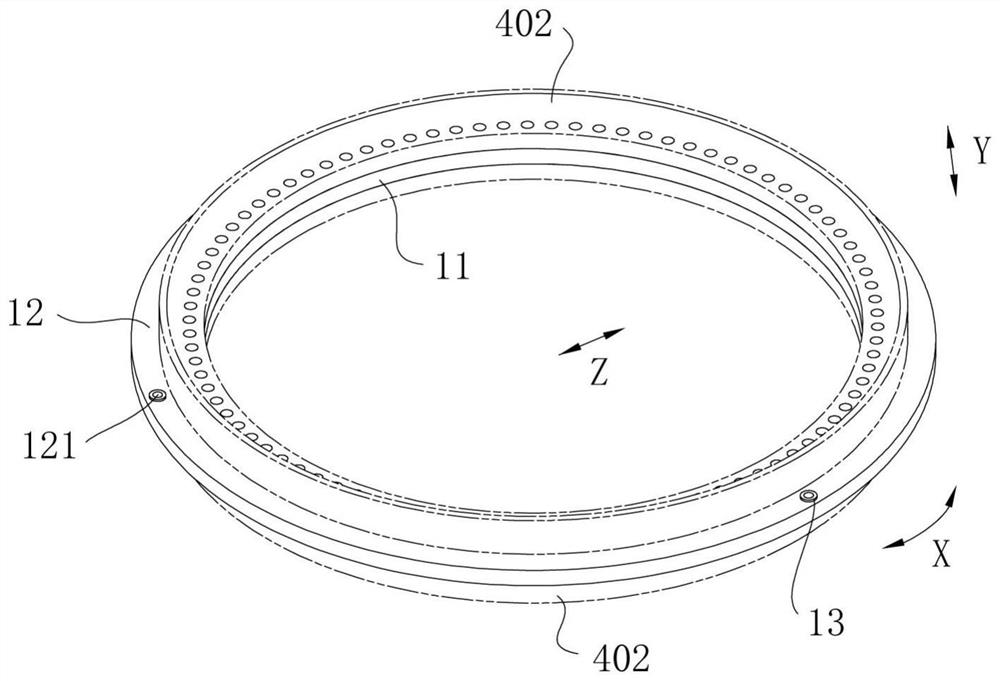

Anchoring device and tower

ActiveCN111720269AWon't hurtGuaranteed fatigue strengthFinal product manufactureWind motor supports/mountsTowerMechanical engineering

The invention relates to an anchoring device and a tower. The anchoring device is used for connecting an inhaul cable and a tower body, the anchoring device comprises an annular body, the annular bodycomprises a base body and a connecting body which are successively arranged in the radial direction of the annular body, the base body is provided with a plurality of installation holes penetrating in the axial direction of the annular body, the installation holes are formed in the circumferential direction of the annular body at intervals, the connecting body is connected with the inhaul cable through connecting positions, and the connecting body is provided with the plurality of connecting positions distributed at intervals in the circumferential direction so as to be connected with the inhaul cable. The embodiment of the invention provides the anchoring device and the tower, the anchoring device can be used for connecting the inhaul cable and the tower body, the weld joint length and the fatigue strength of the tower body cannot be affected, meanwhile, machining and manufacturing of tower barrel sections of the tower body cannot be affected, the cost is low, and the assembling efficiency of a wind generating set can be guaranteed.

Owner:XINJIANG GOLDWIND SCI & TECH

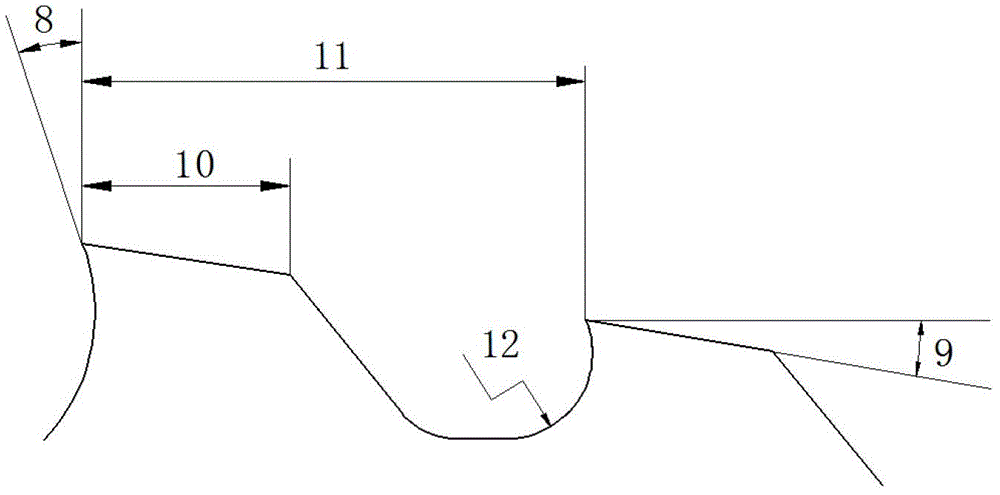

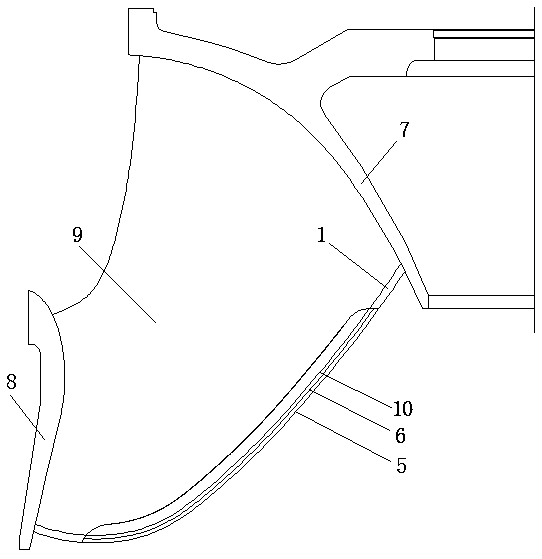

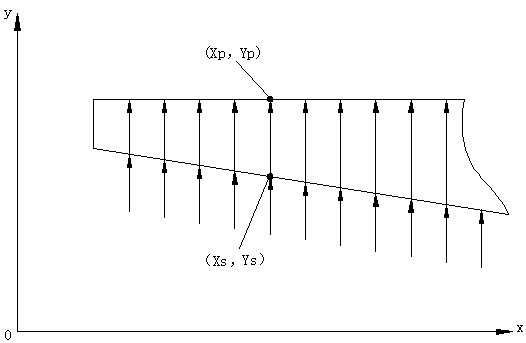

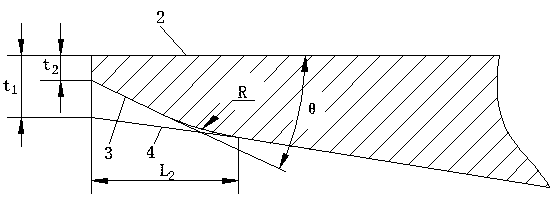

Mixed-flow water turbine runner blade outlet edge trimming method

ActiveCN108661840AGuaranteed mechanical strengthAvoid crackingHydro energy generationGrinding machinesMixed flowWater turbine

The invention discloses a mixed-flow water turbine runner blade outlet edge trimming method. The mixed-flow water turbine runner blade outlet edge trimming method comprises the following steps of: step a. cutting to obtain a blade wing profile, and determining a blade outlet edge trimming area; step b. enabling a molded line of the back of a blade after edge trimming and a molded line of the backof the blade before edge trimming to be in circular arc transition, wherein the radius R is 4-7 times of the thickness t1 of the outlet edge of the blade before edge trimming; step c. determining thefinal geometric dimension of the outlet edge trimming of the blade; step d. determining the sizes of a child-mother sample plate and a circular arc sample plate of the back of the blade, and integrally machining the child-mother sample plate and the circular arc sample plate of the back of the blade; step e. marking off on the outlet edge of the blade, and determining the final position of the back pressure edge of the outlet of the blade after trimming; step f. adjusting the angle of the outlet edge of the blade till the angle meets the size of the son-mother sample plate; and step g. grinding the circular arc of the black of the blade till the circular arc meets the size of the circular arc sample plate of the back of the blade. The mixed-flow water turbine runner blade outlet edge trimming method can prevent or eliminate water turbine squealing and blade cracks generated by blade hydraulic power elastic resonance induced by the Karman vortex street of a runner outlet, and improves the structure integrality of the mixed-flow water turbine runner and the operation safety of the water turbine.

Owner:DONGFANG ELECTRIC MACHINERY

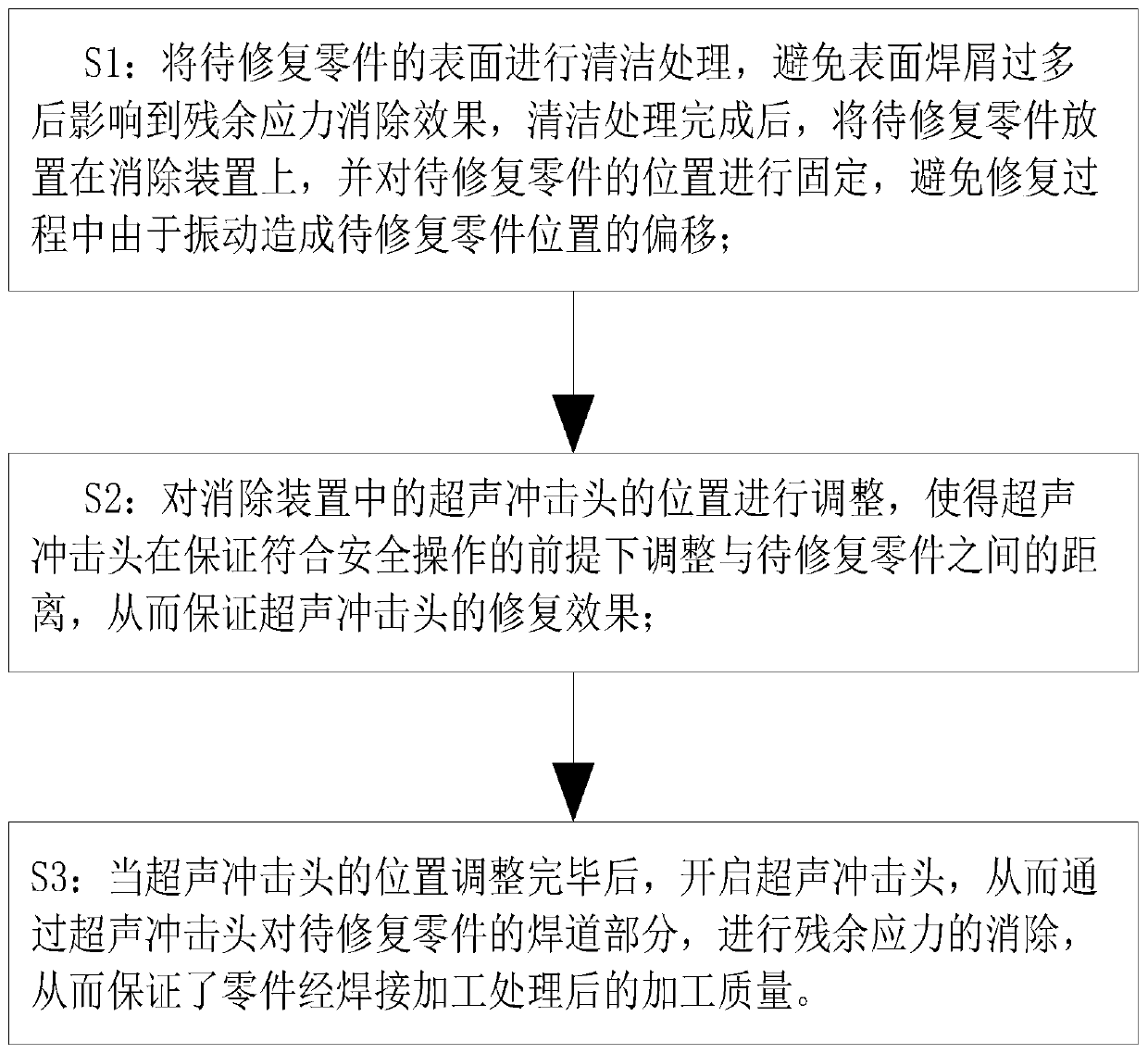

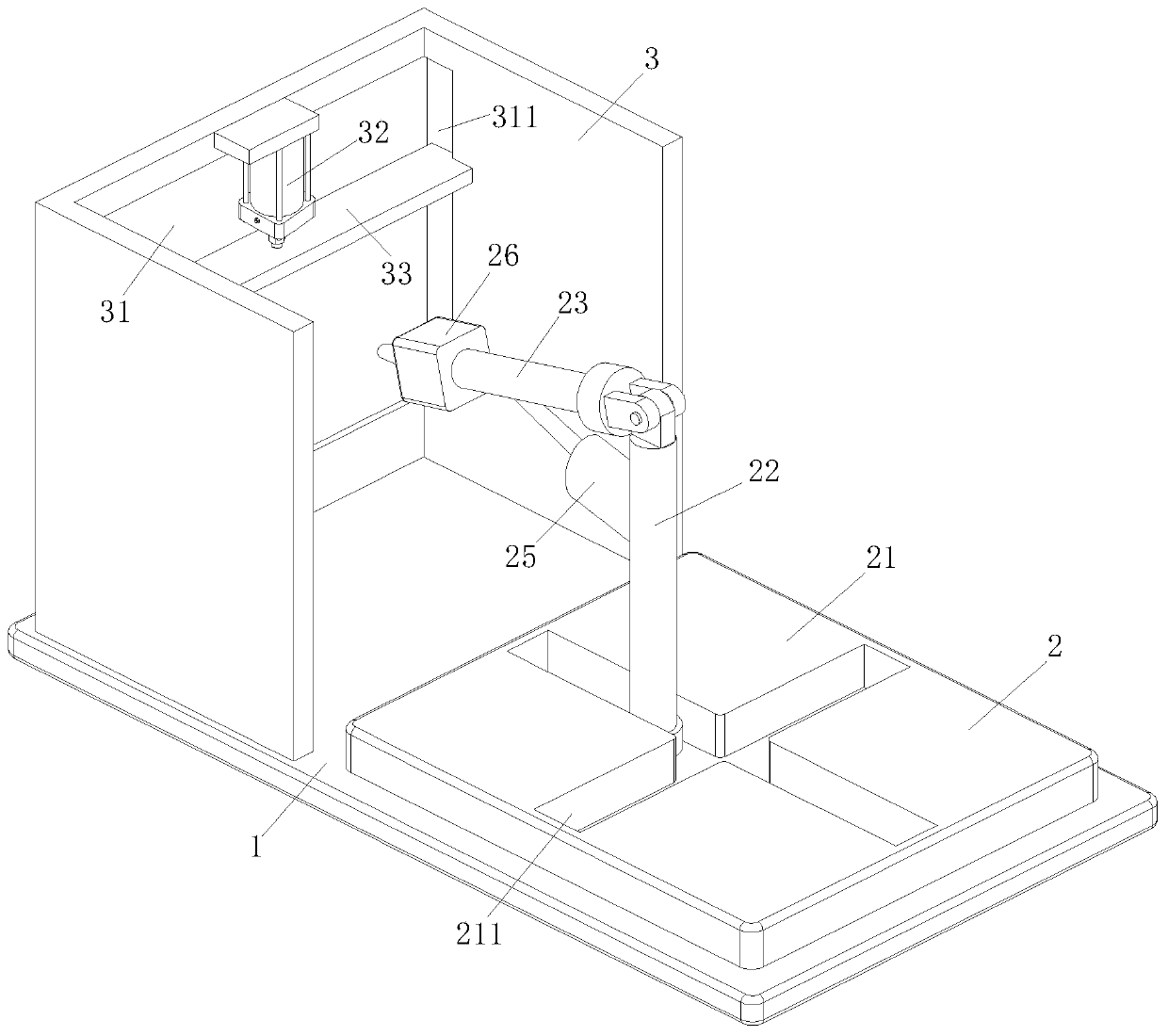

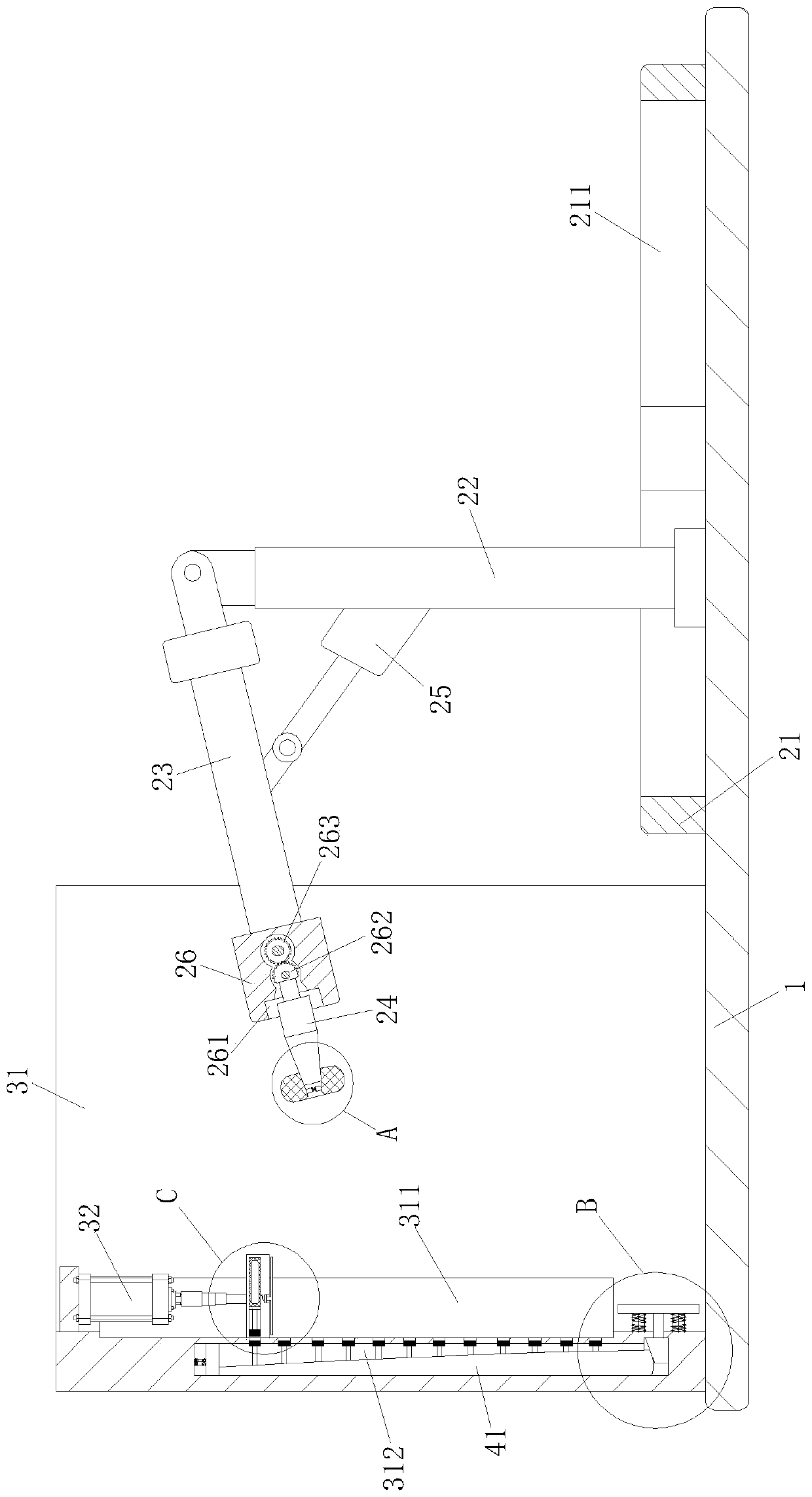

Weld bead residual stress eliminating device and method

InactiveCN110983026AReduce residual stressImprove welding process qualityProcess efficiency improvementCrack resistanceStress corrosion cracking

The invention belongs to the technical field of welding and particularly relates to a weld bead residual stress eliminating device and method. The device comprises a base, an eliminating unit and a fixing unit, wherein the eliminating unit is fixed to the base and comprises a guide rail plate, a first support, a second support and an ultrasonic impact head, the fixing unit comprises a fixing plate, a second air cylinder and a pressing plate, when a part is fixed, the first support is controlled to slide in the cross-shaped sliding groove to adjust the position, a swinging angle of the second bracket is controlled through extension and retraction of a first cylinder, when an ultrasonic impact head is close to the welding bead, the ultrasonic impact head is started, so the residual stress ofthe welding bead is eliminated, the residual stress of the part at the welding bead is reduced, the fatigue strength, brittle failure resistance, stress corrosion cracking resistance and high-temperature creep cracking resistance of a part structure are guaranteed, and the welding machining quality of the part is improved.

Owner:汪时

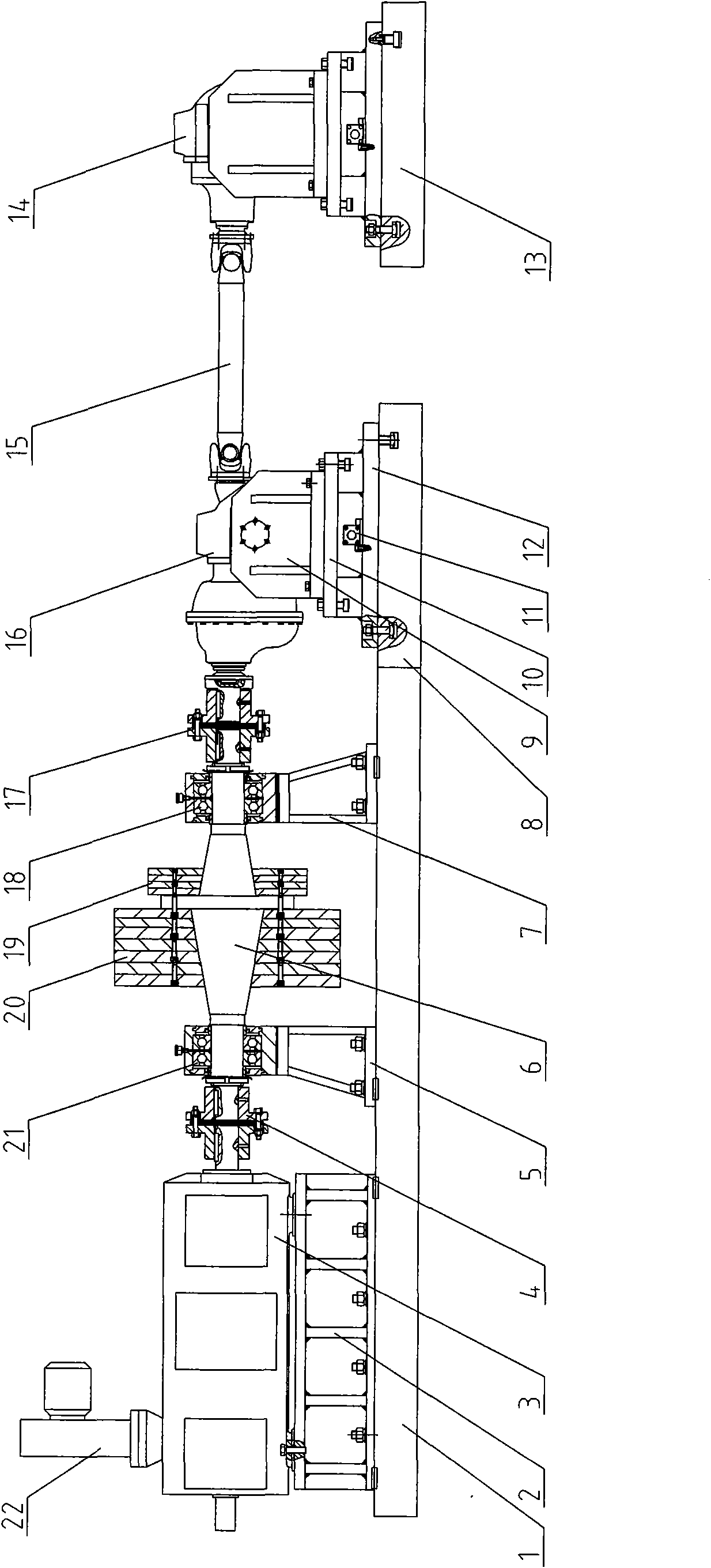

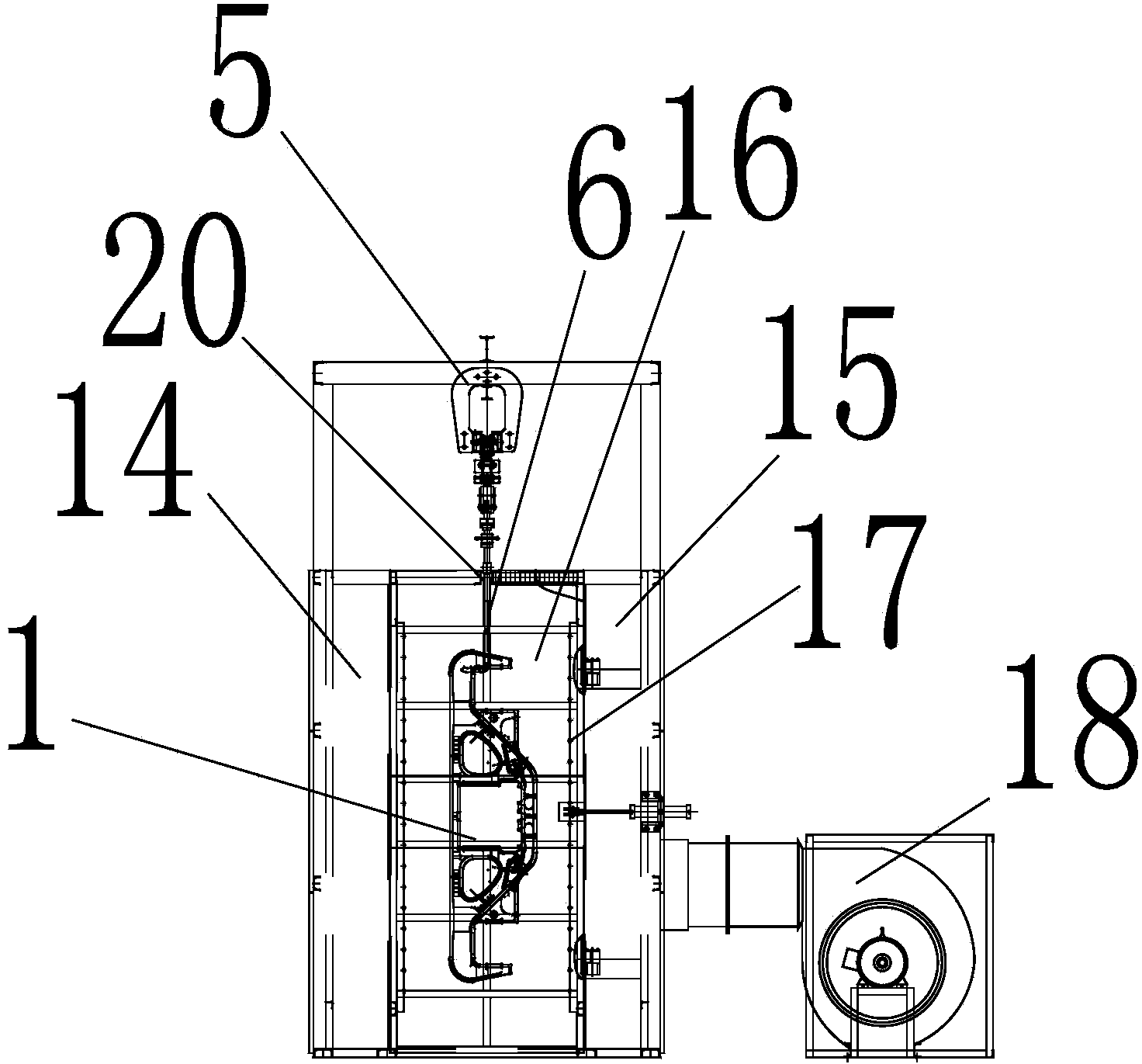

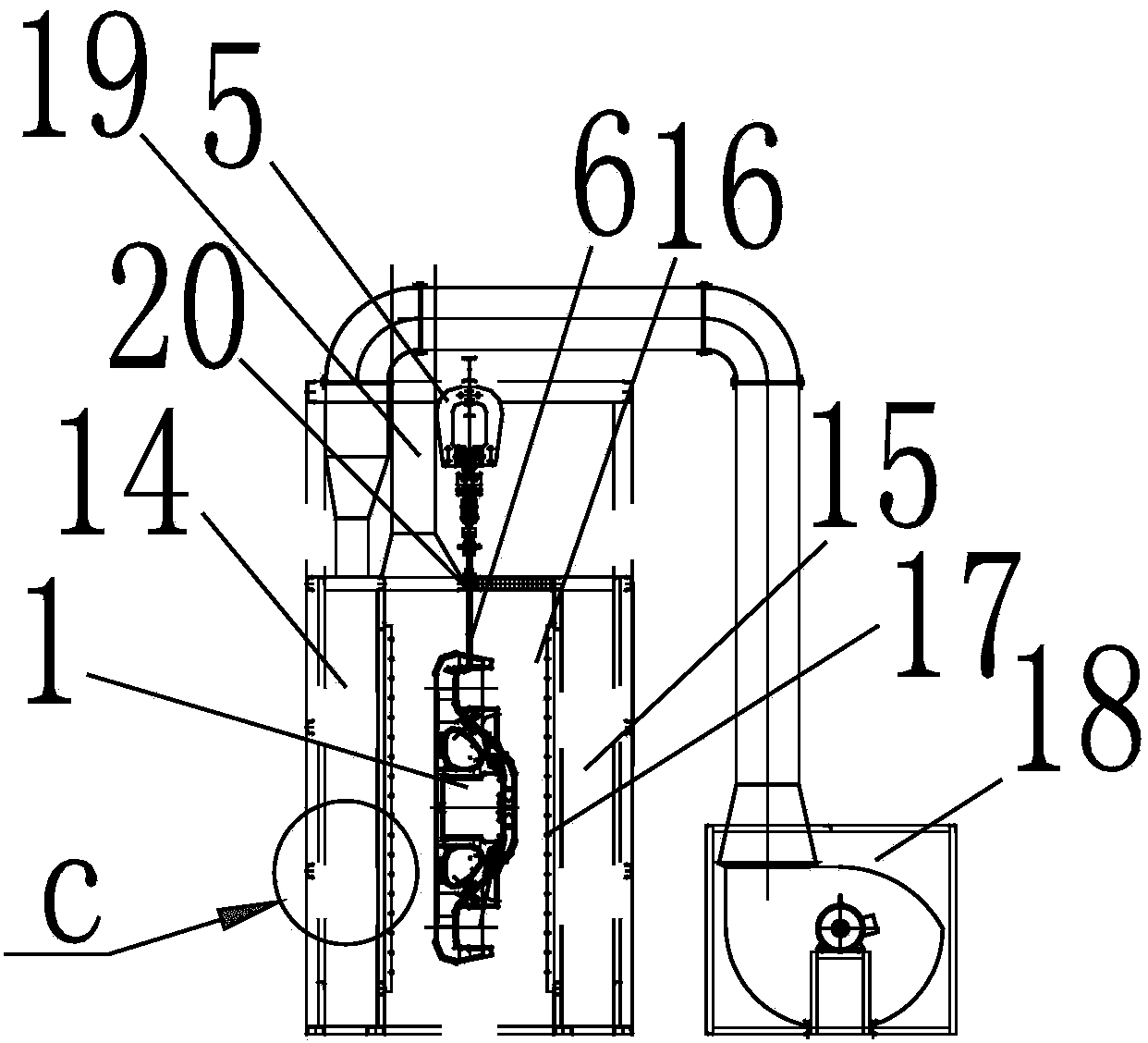

Railway wagon swing bolster and side frame cooling and cleaning method and system

The invention relates to a railway wagon swing bolster and side frame cooling and cleaning method and system. The railway wagon swing bolster and side frame cooling and cleaning method and system changes a traditional casting cleaning mode into a mode of hanging and transporting castings through accumulation suspension chains to on-line complete the steps such as casting cooling, casting head cutting, flaw clearing and abrasive blasting and accordingly to achieve clean casting processing. The railway wagon swing bolster and side frame cooling and cleaning method and system has the advantages of simple process, small space occupation, high production efficiency and low labor intensity.

Owner:CRRC YANGTZE CO LTD

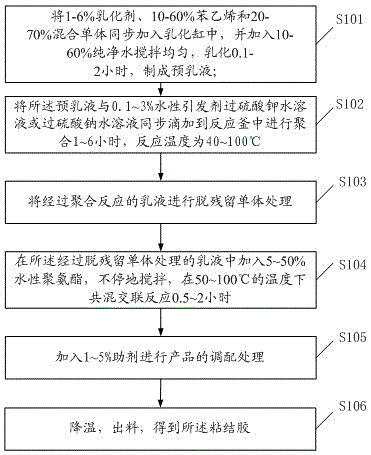

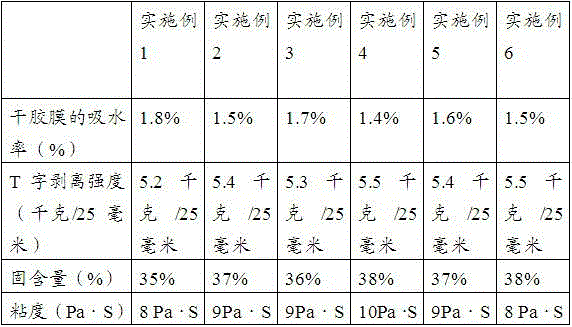

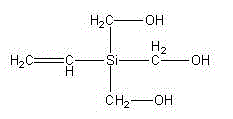

Bonding glue used for glass mosaics and preparation method thereof

ActiveCN103059794AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesEster polymer adhesivesEmulsionAlkylphenol

The invention discloses a bonding glue used for glass mosaics. The bonding glue is mainly prepared from the following raw materials by weight: 20-70% of a mixed monomer, 10-60% of styrene, 5-50% of water-based polyurethane, 1-6% of an emulsifier, and 0.1-3% of an initiator. The mixed monomer comprises acrylic ester, hydroxyethyl acrylate, acrylic acid and vinyl trimethoxysilane. The emulsifier is an emulsion prepared from vinyl alkylphenol polyoxyethylene ether sodium sulfate and anions. The initiator is a water-based initiator and / or a peroxide initiator. Correspondingly, the invention discloses a preparation method of the bonding glue used for glass mosaics. The method consists of: preparing a pre-emulsion, adding the initiator to conduct polymerization, removing residual monomers, adding the water-based polyurethane to perform blending crosslinking, carrying out dosing treatment, and performing cooling and discharging, thus obtaining the bonding glue. According to the invention, the bonding glue has an interpenetrating network (IPN) structure, and has the characteristics of excellent bonding effect, high strength, vibration resistance, and impact resistance.

Owner:FOSHAN HAITE CHEM TECH

Laser strengthening technology for surface of steel rail of railway

The invention discloses a laser strengthening technology for the surface of a steel rail of a railway. The laser strengthening technology includes the steps that the surface of the steel rail is quenched through lasers, and then a tempering technology is carried out on the steel rail through lasers. Microscopic structures of the steel rail are tempered martensite structures and are optimized with a laser processing technology, evenly-refined sorbite-or-troostite-similar tempered structures with the thickness of 0.8 mm to 1 mm can be obtained on the surface of the steel rail, high rigidity (HRC35-50) and high abrasion resistance are achieved, and meanwhile high bending strength and high fatigue strength are achieved; the sticking resistance, the creeping resistance, the squashing resistance, the side abrasion resistance and the corrugation resistance of the steel rail are improved accordingly. By means of the laser strengthening technology, corrugation, side abrasion and block falling of the steel rail are remarkably reduced on the premise that the mechanical performance such as bending strength, breaking tenacity and fatigue strength of the whole steel rail is guaranteed, the stability and the corrosion resistance of the steel rail are remarkably improved, the service life of the steel rail is remarkably prolonged, the replacement time of the steel rail is prolonged, the maintenance cost of the steel rail is saved, driving resistance is reduced, fuel is saved, and the service period of the steel rail of the railway is prolonged.

Owner:WUHAN TUANJIE DIANJIN LASER MFG TECH

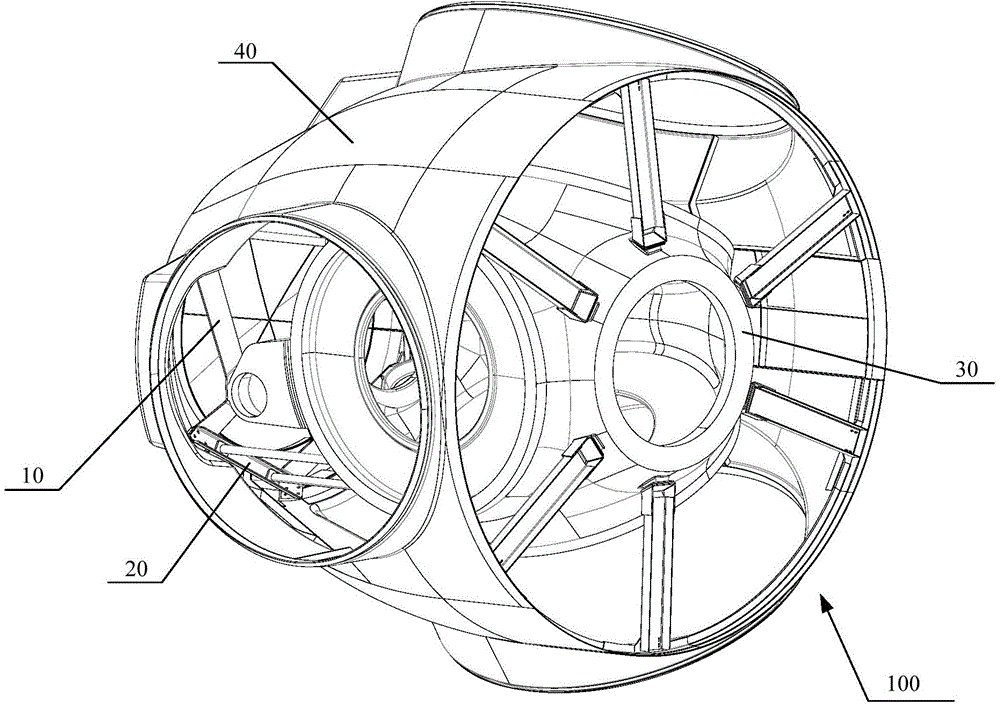

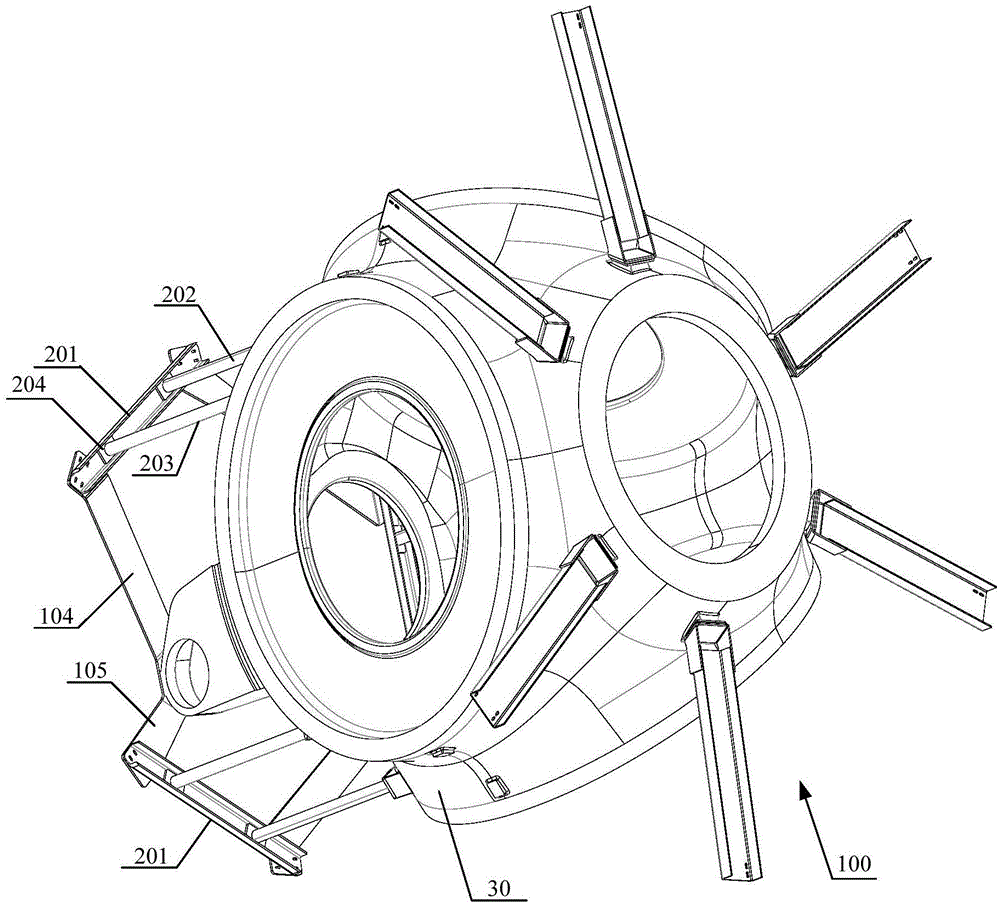

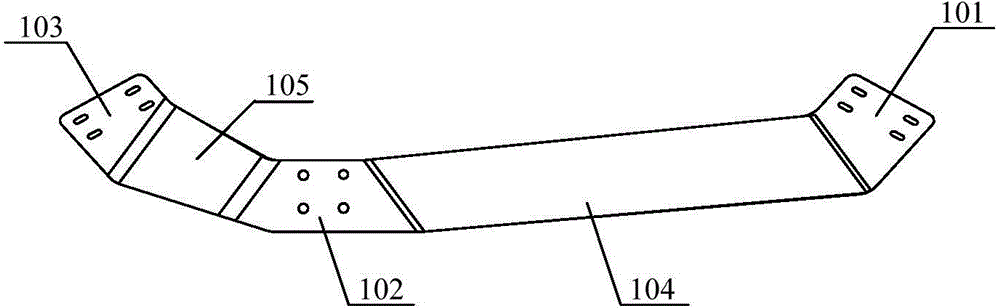

Wind turbine generator system and flow guide cover front support device thereof

ActiveCN104564539AImprove fatigue strengthGuaranteed fatigue strengthMachines/enginesWind energy generationEngineeringTurbine

The invention discloses a wind turbine generator system and a flow guide cover front support device thereof. The flow guide cover front support device comprises a flow guide cover, a hub, three groups of axial support frames and three groups of bent plates. The hub is arranged inside the flow guide cover; the three groups of axial support frames are arranged between the hub and the flow guide cover in a connected manner; the three groups of bent plates and the three groups of axial support frames are arranged at intervals, the bent plates are of integrally formed structures, two ends of each bent plate are connected onto the corresponding adjacent axial support frames, and the middle of each bent plate is connected onto the hub. The wind turbine generator system comprises the flow guide cover front support device. The wind turbine generator system and the flow guide cover front support device of the wind turbine generator system have the advantages of high rigidity and fatigue resistance.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Preparation method of rolling mill bearing steel

The invention discloses a preparation method of rolling mill bearing steel. The preparation method comprises the following steps: (1) smelting and alloying: performing electric furnace smelting and tapping, and adopting external refining and vacuum degassing treatment; (2) pouring: adopting die casting or continuous casting, controlling the superheat degree of the continuous casting tundish at 40-50 DEG C, and controlling the casting speed of the continuous casting at 1.1-1.3m / min to guarantee the quality of the casting billet; (3) rolling, wherein the soaking temperature of the billet in a heating furnace is 1,180-1,200 DEG C, the heating time is 2.5-3.5 hours, the initial rolling temperature is 1,110-1,130 DEG C, and the final rolling temperature is 820-840 DEG C; (4) cooling control, wherein the cooling speed of the rolled steel is 3-5 DEG C / min; (5) heat treatment: heating the billet to 960-980 DEG C, preserving heat for 1-2 hours and performing oil quenching, and then tempering, wherein the heating temperature in tempering is 180-190 DEG C, and the temperature is kept for 2-4 hours.

Owner:锡山区鹅湖慧盾机械厂

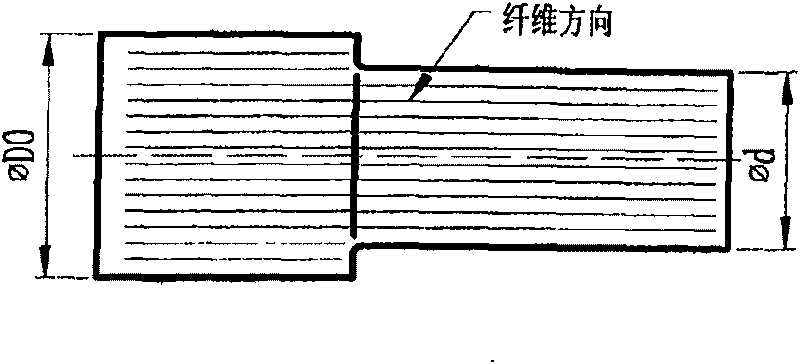

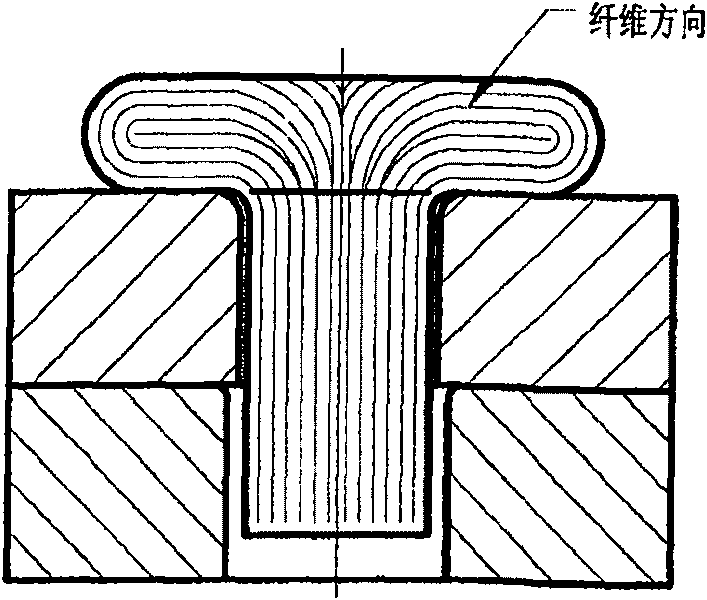

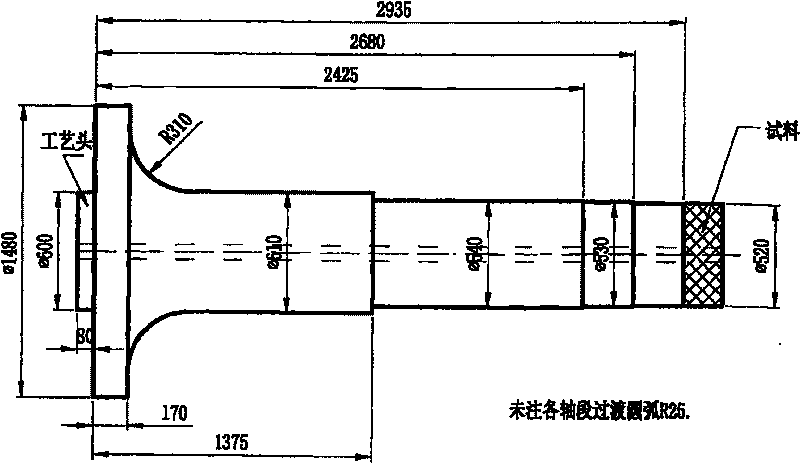

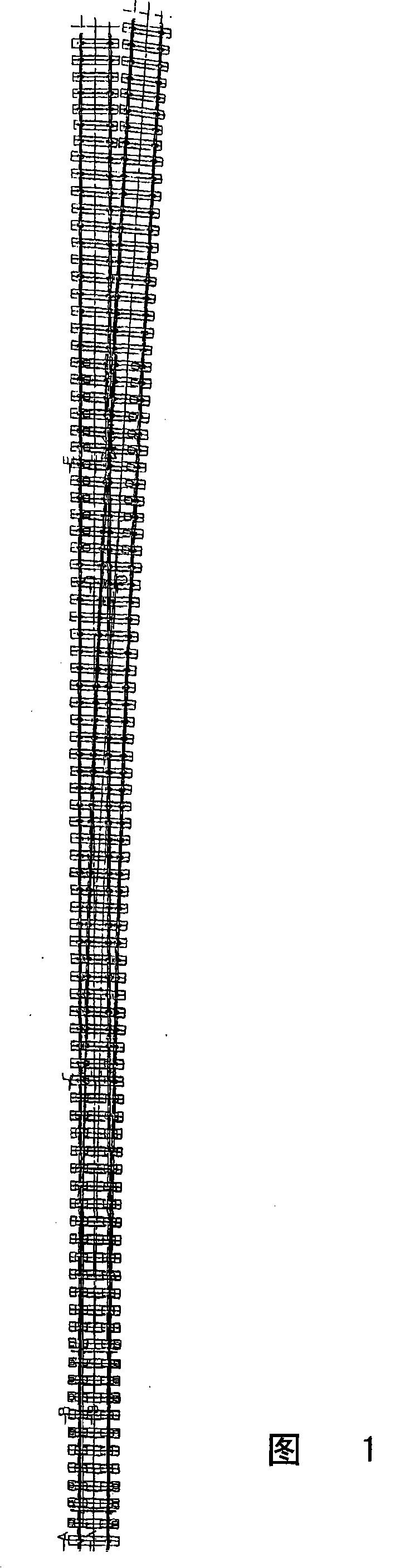

Method for producing wind-electricity principal axis by gathering stock full fibre upset forging

InactiveCN101314202BExtended service lifeGuaranteed fatigue strengthShaftsFurnace typesElectricityIngot

The invention relates to a method for producing a wind-power mainshaft by local continuous upsetting and all-fibre upset forging. The method comprises the following: step one, the heating of steel ingot; step two, forging; step three, first heat processing; step four, rough machining and ultrasonic inspection; step five, quenching and tempering and heat processing; step six, fine machining, wherein, during the step two, the forging comprises that: (1) a first fire, during which, a steel ingot is subject to upset forging at a forging temperature of between 1250 and 900 DEG C; firstly, the bottom of the steel ingot is sawed off, and the steel ingot is subject to capping and upset forging; (2) a second fire, during which, the steel ingot is stretched towards various directions, marked and subject to intermediate billet cogging; after a pole part is molded, scrap on a T end is chopped and removed; after the forging is finished, the steel ingot returns to a heating furnace for being reheated; (3) a third fire, during which, the steel ingot is subject to local continuous upsetting and all-fibre upset forging; (4) a fourth fire, during which, the steel ingot is subject to rolling and leveling; the pole part is stretched; the disc edge of a hub end on the head part of an intermediate billet material after the local continuous upsetting and all-fibre upset forging is subject to rollingoperation; after the rolling, the intermediate billet material is inserted into a leaking disc component again; the end face of the disc is pressed and leveled; after the shaping of the disc end is completed, a manipulator clamps the disc and stretches the pole part of the intermediate billet material to a dimension of a forgeable piece; thus, the mainshaft forging is completed. The method can improve the fatigue resisting strength of a wind-power mainshaft forging piece.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

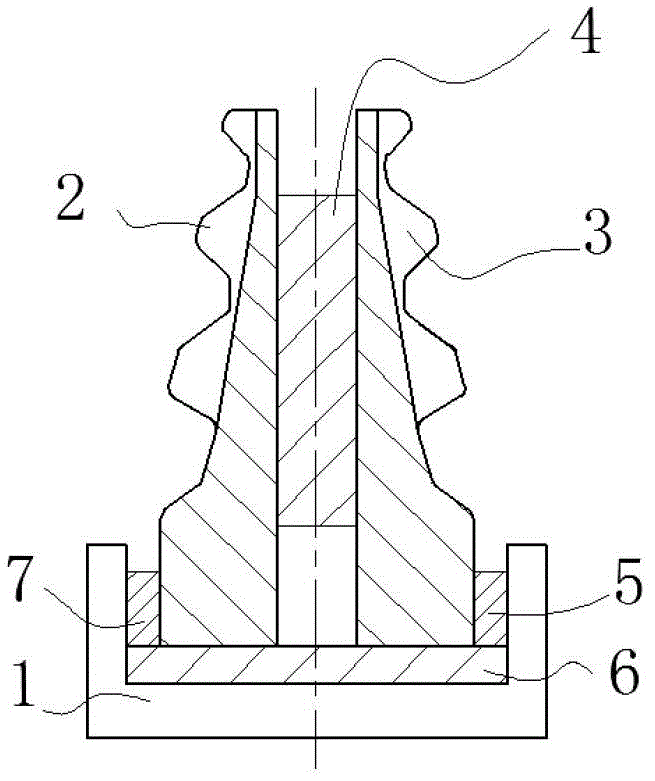

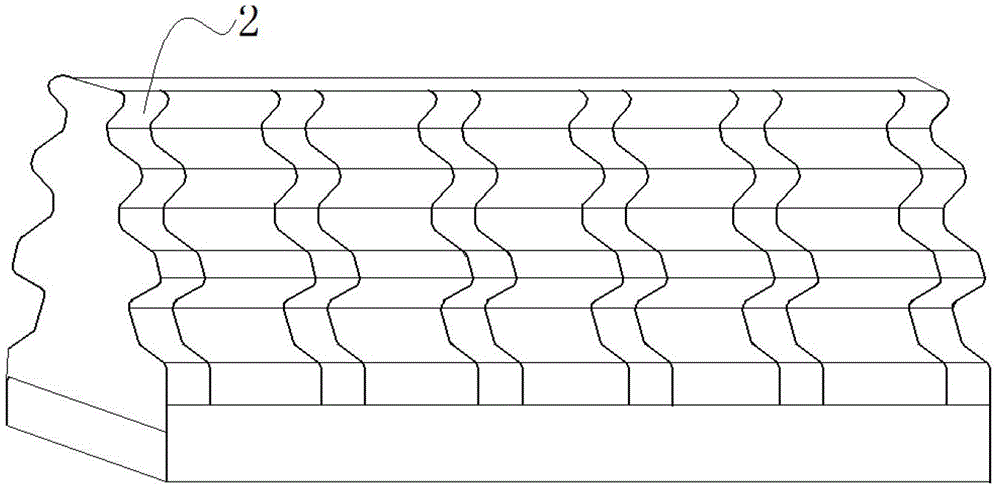

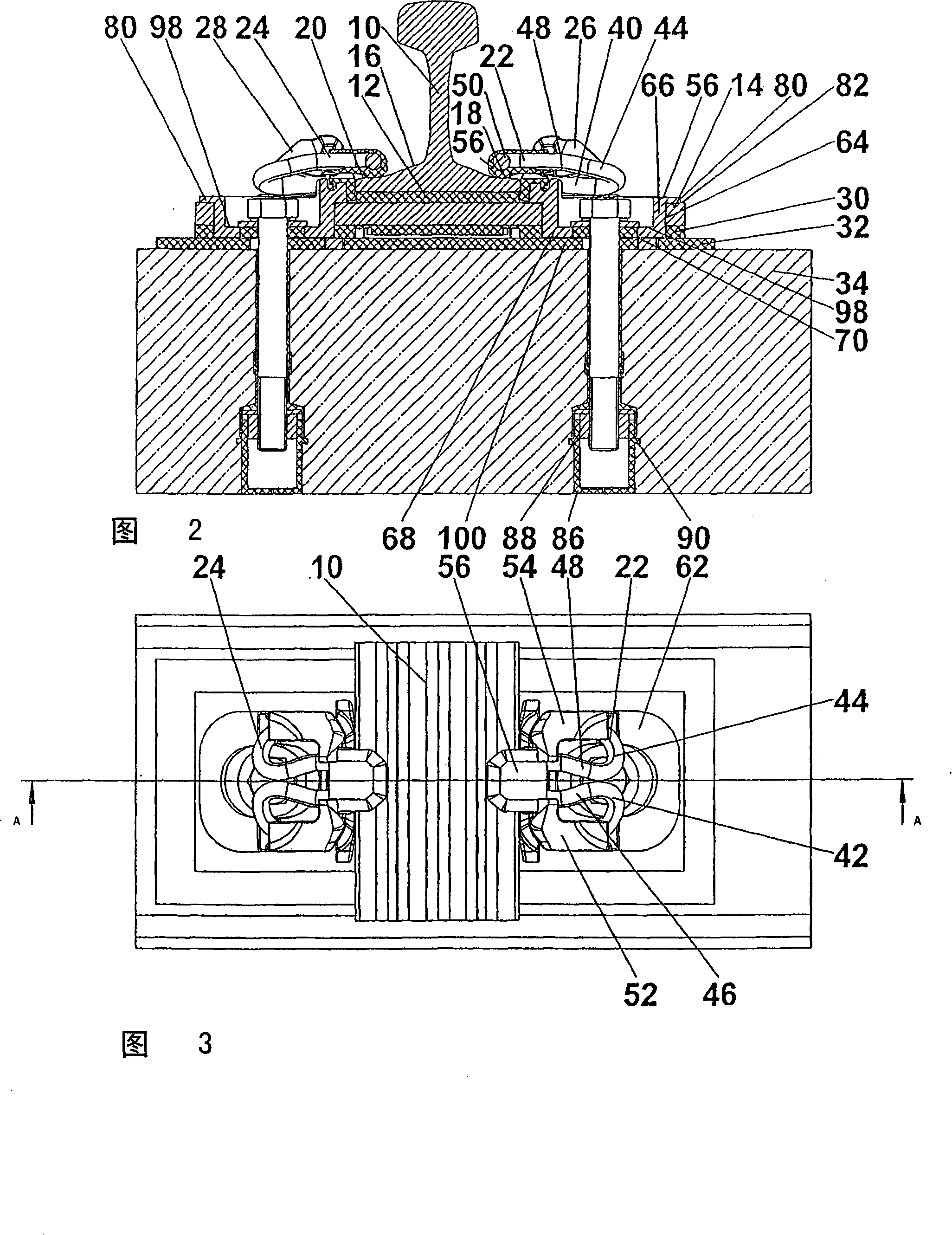

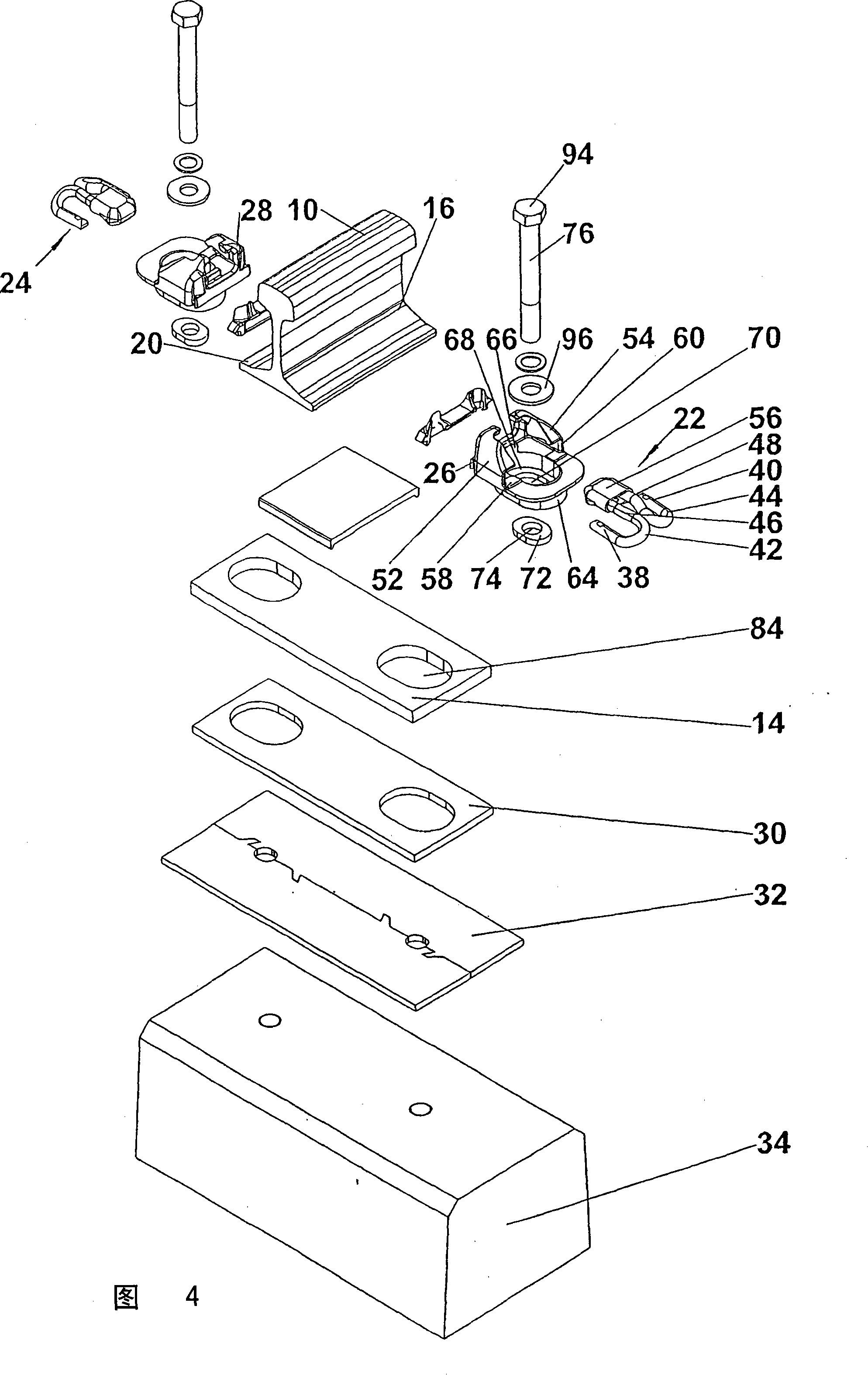

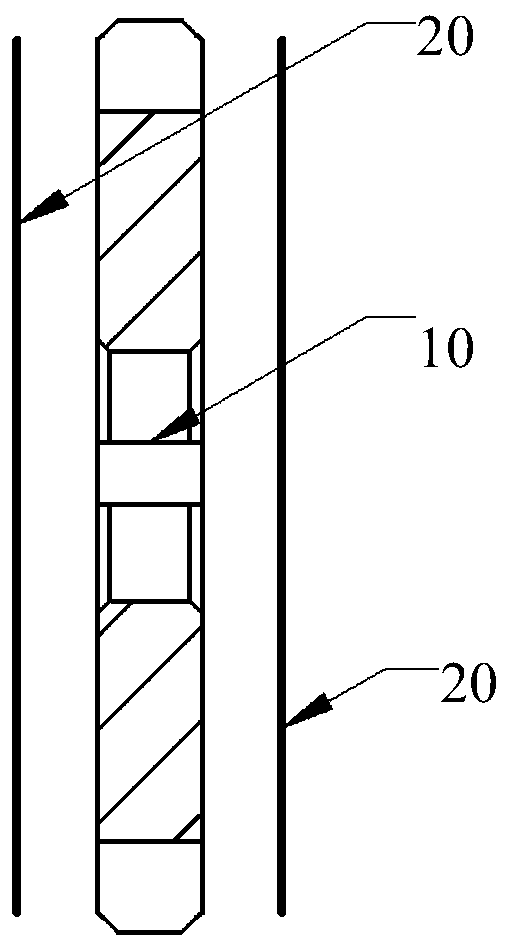

Rail fixing device

InactiveCN1981089BIncrease elasticityGuaranteed fatigue strengthRail fastenersBiomedical engineeringEngineering

Owner:BWG & K G +3

Composite microalloyed large-section non-quenched and tempered steel

ActiveCN102199731BHigh strengthImprove fatigue strengthTemperature control deviceMetal rolling arrangementsInduction hardeningUltimate tensile strength

The invention discloses composite microalloyed large-section non-quenched and tempered steel, specifically relates to large-section rolled non-quenched and tempered steel used for a half shaft of an automobile and non-quenched and tempered steel used for a half shaft of an engineering machinery. On one hand, the strength of the large-section non-quenched and tempered steel is increased through increasing C content, and on the other hand, grains are further refined through adding microalloy elements such as Nb, V and Ti, thus maintaining certain toughness while improving strength; in addition,the fatigue strength of the half shaft is improved through employing an induction hardening method, and the hardenability of steel is improved through adding B. The invention effectively solves the use strength requirement of the large-section non-quenched and tempered steel half shaft, guarantees the fatigue life of the half shaft, improves the performance of the half shaft, lowers the cost of the half shafts, saves energy and reduces heat treatment deformation.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

Piston ring and manufacturing method therefor

ActiveCN107636367AAvoid stickingImprove wear resistancePiston ringsCylinder headsPiston ringHigh pressure

The purpose of the present invention is to provide: a piston ring with which aluminum adhesion can be prevented over long periods even when used in a high temperature, high pressure environment and which exhibits excellent side surface abrasion resistance; and a manufacturing method therefor. By forming a nitride layer on the upper and / or lower side surface of the piston ring and then applying a phosphate chemical conversion treatment, the nitride layer is made to comprise granular and / or worm-shaped surface forms.

Owner:RIKEN CO LTD

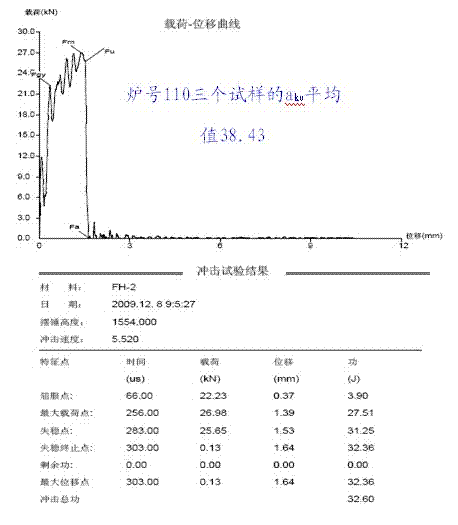

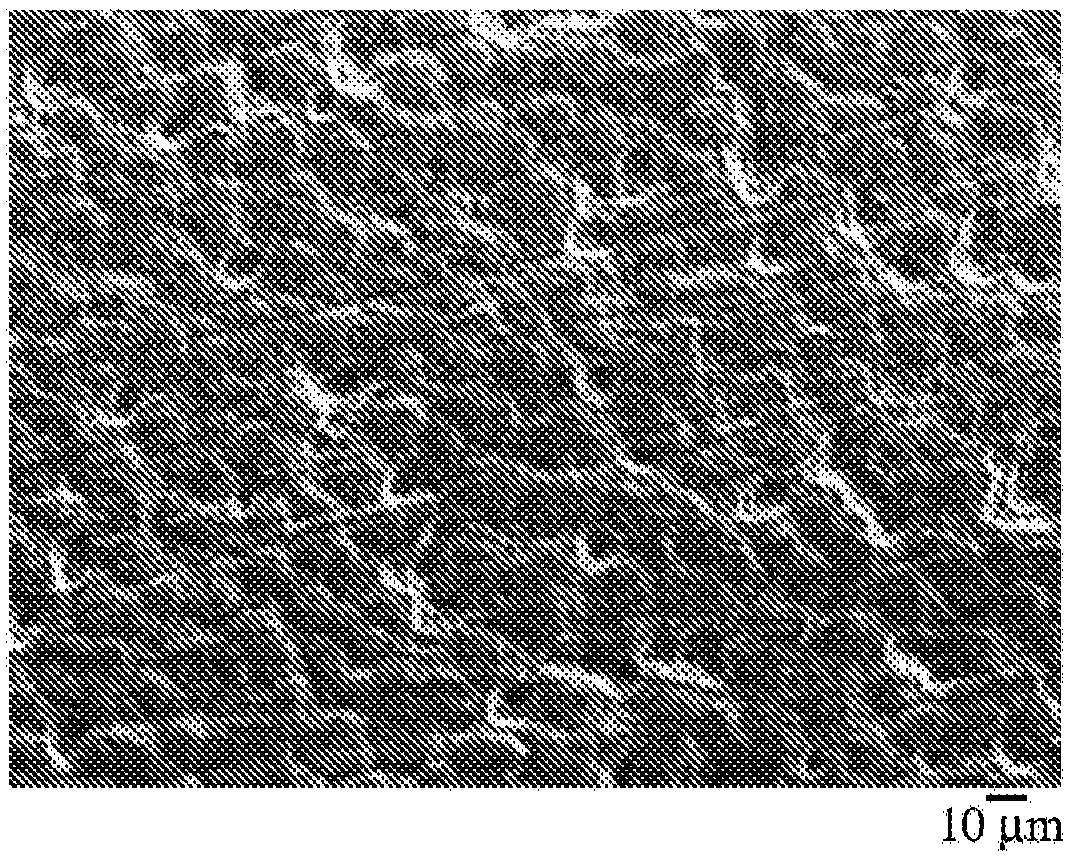

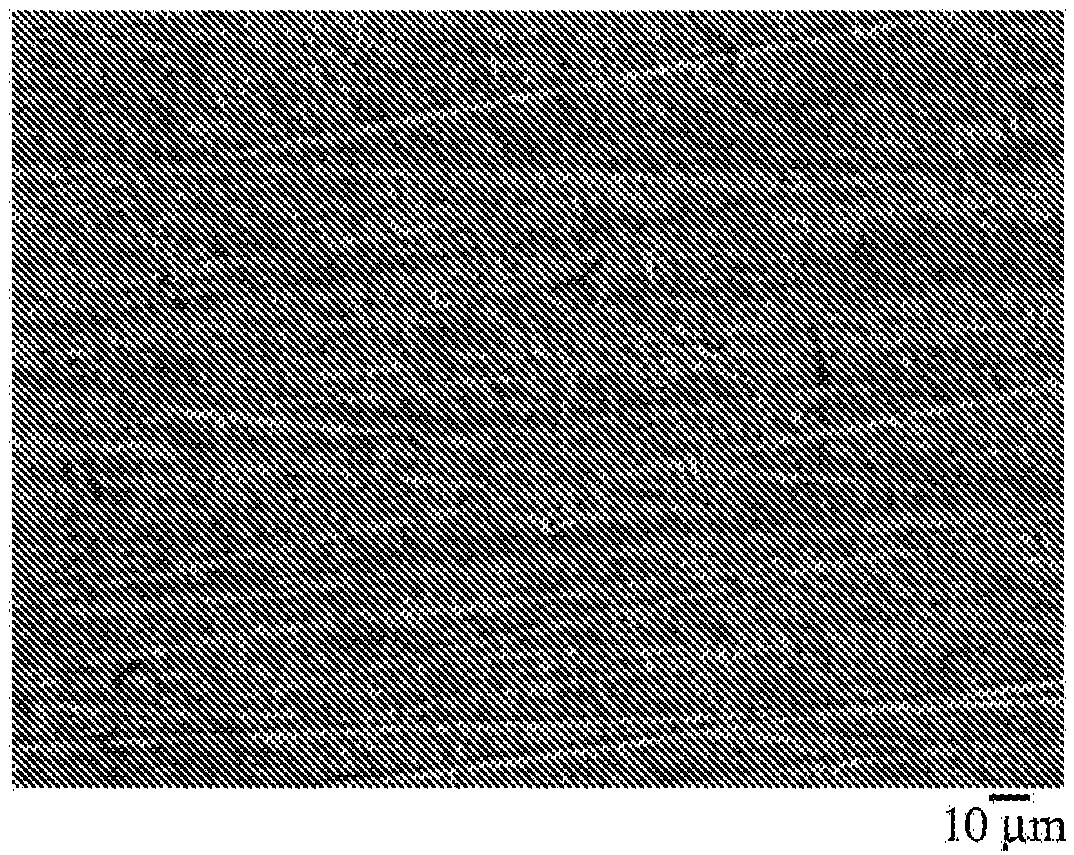

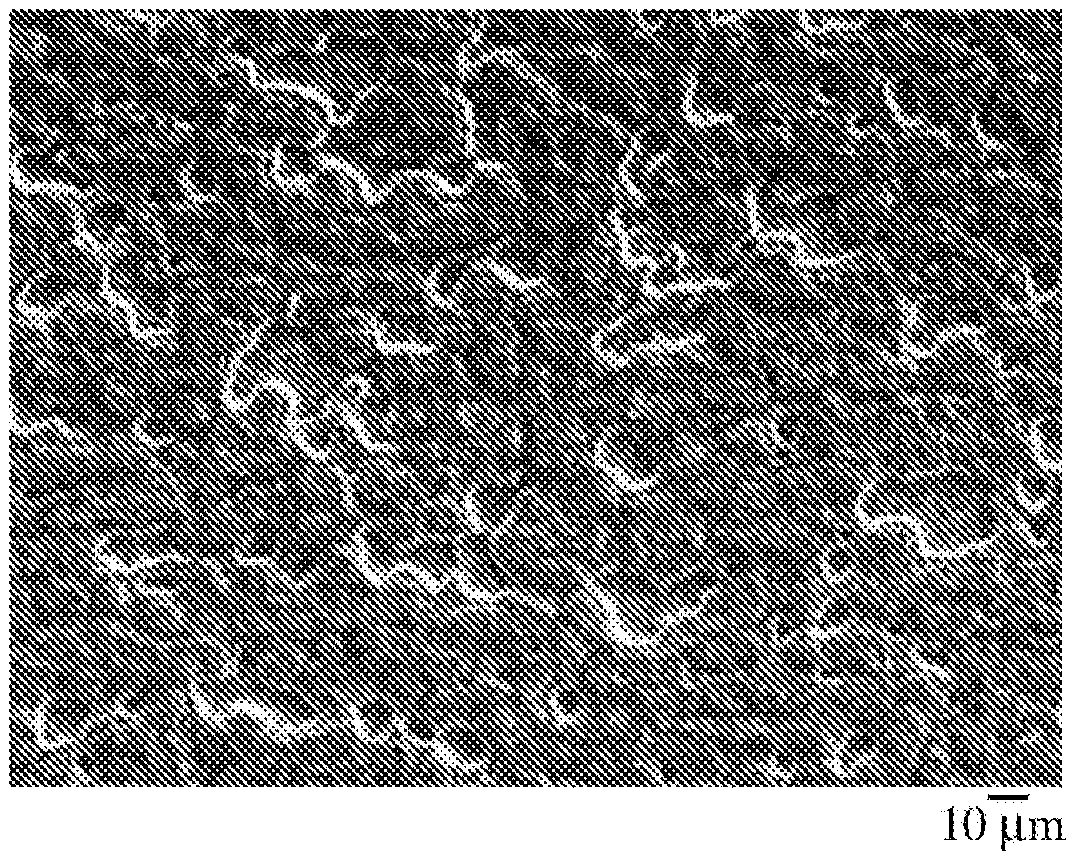

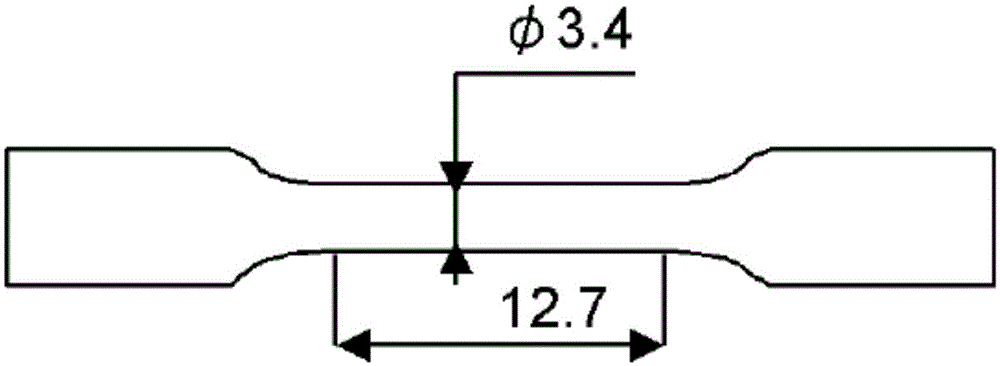

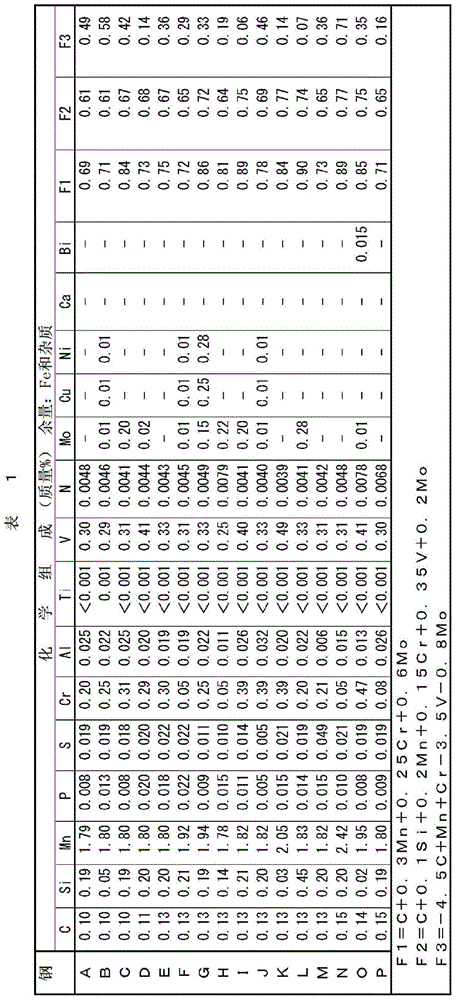

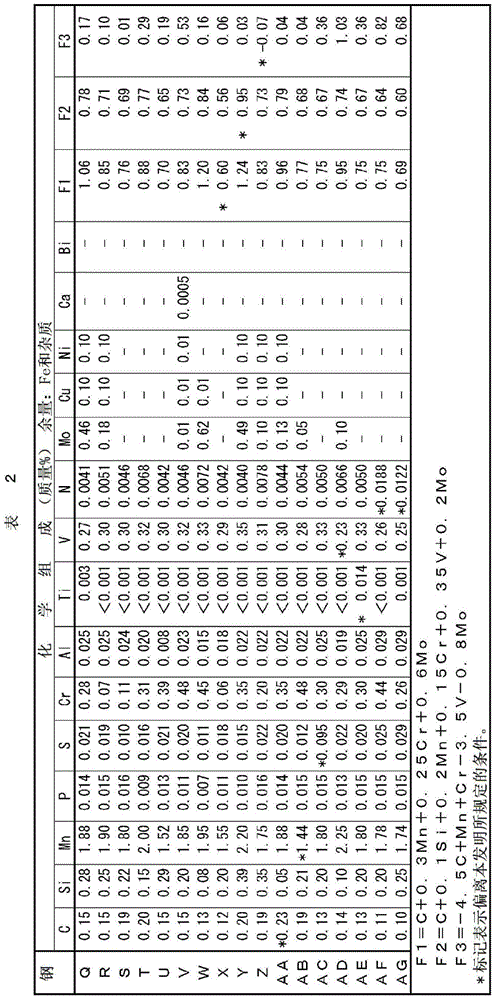

Age-hardening steel

ActiveCN105164297AGuaranteed fatigue strengthImprove toughnessFurnace typesHeat treatment furnacesMachine partsCharpy impact test

The invention provides age-hardening steel having a chemical composition containing 0.05 to 0.20% of C, 0.01 to 0.50% of Si, 1.5 to 2.5% of Mn, 0.005 to 0.08% of S, 0.03 to 0.50% of Cr, 0.005 to 0.05% of Al, 0.25 to 0.50% of V, 0 to 1.0% of Mo, 0 to 0.3% of Cu, 0 to 0.3% of Ni, 0 to 0.005% of Ca, 0 to 0.4% of Bi and a remainder made up by Fe and impurities, wherein the following formulae P <= 0.03%, Ti < 0.005% and N < 0.0080% are satisfied in the impurities, and the following formulae [C+0.3Mn+0.25Cr+0.6Mo >= 0.68], [C+0.1Si+0.2Mn+0.15Cr+0.35V+0.2Mo <= 0.85] and [-4.5C+Mn+Cr-3.5V-0.8Mo >= 0.00] are satisfied. The age-hardening steel has hardness of 290 HV or less before being subjected to an aging treatment, also has an amount of hardening of 25 HV or more and fatigue strength of 350 MPa or more when subjected to an aging treatment, and also has an absorption energy of 16 J or more at 20 DEG C after being subjected to an aging treatment as evaluated by a Charpy impact test that is carried out using a U-notched standard test specimen having a notch depth of 2 mm and a notch root radius of 1 mm. Therefore, the age-hardening steel is extremely suitable as a material for machine parts.

Owner:NIPPON STEEL CORP

Highway pavement construction method

InactiveCN107558339AHigh degree of mechanizationEasy to operate on siteIn situ pavingsRoads maintainenceLand levelingSubgrade

The invention discloses a highway pavement construction method, which comprises the following steps of primarily pressing a roadbed by adopting a vibrating road roller, then finishing repair of the roadbed, and eliminating all crushed matters, bulges and hollowing matters; laying self-made limestone soil on the roadbed to form a pavement bedding; spreading aggregates on the bedding layers by layers by adopting a crushed stone spreader according to a preset width and a preset thickness, fully rolling a laid crushed stone layer by adopting rolling equipment, performing leveling after rolling byadopting a land leveling machine, and uniformly spreading steel fiber reinforced self-compacting cement on the crushed stone layer according to a preset dosage by adopting a powder spreading vehicle;performing mixing to form a pavement base course by adopting a cold recycling machine; and constructing a seal course on the pavement base course, and then laying a pavement surface course. The highway pavement construction method is short in construction period, reduces pollution to environment while reducing the manpower and ensures the loading strength, the fatigue resistance, the compressive strength, the impact strength and the stability of a pavement.

Owner:NANCHANG INST OF TECH

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

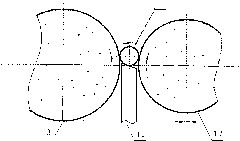

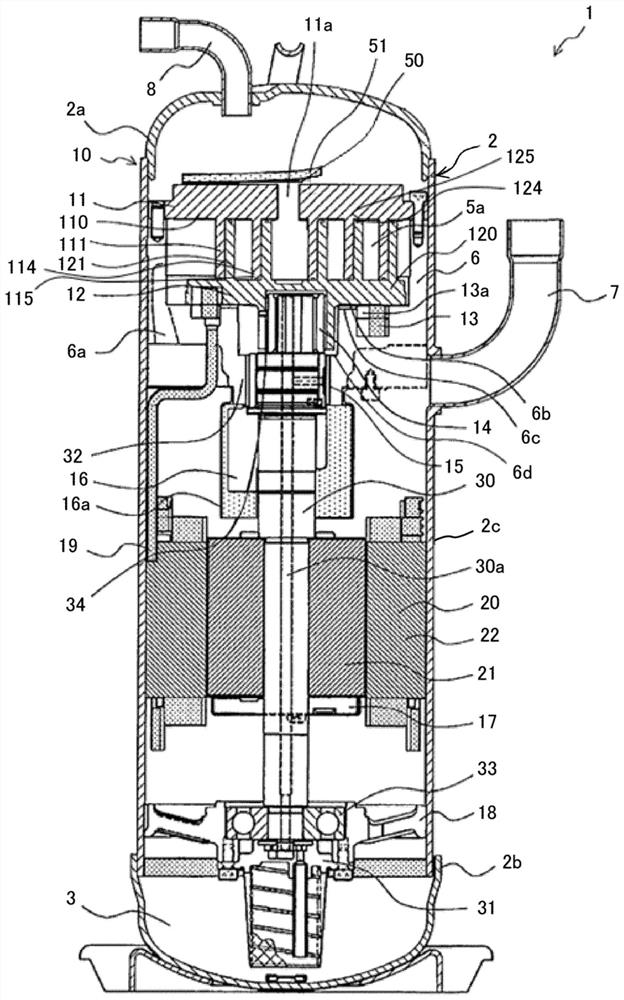

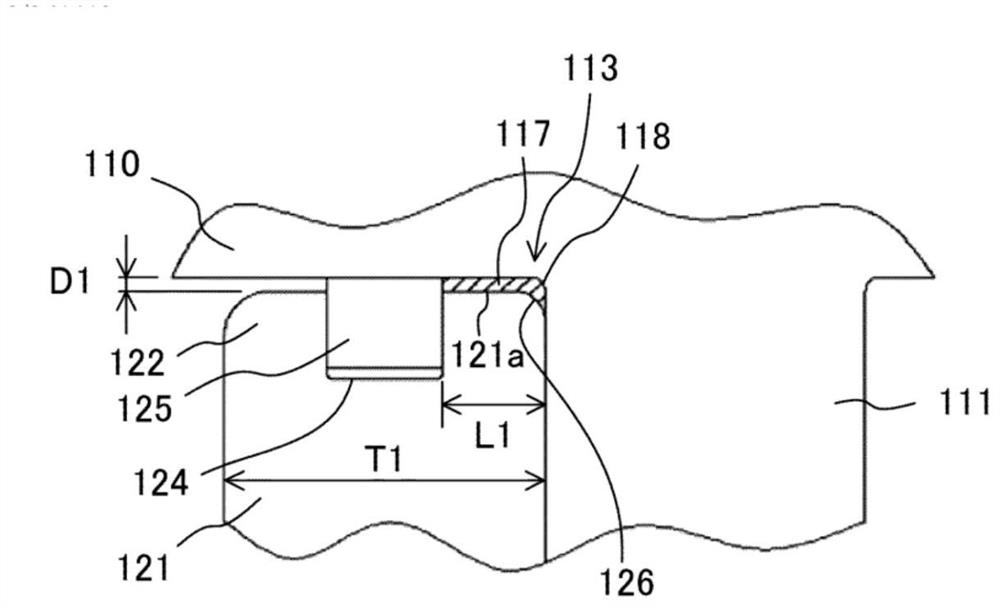

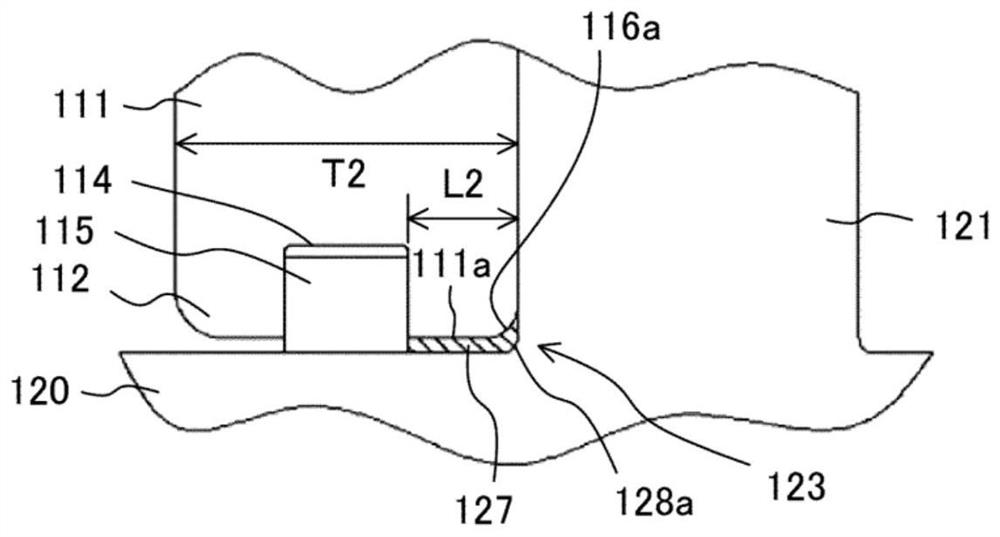

Scroll compressor

ActiveCN113994097ASmall radius of curvatureReduce leakageRotary piston pumpsRotary piston liquid enginesEngineeringRefrigerant

The present invention comprises: a fixed scroll in which a first fixed-side tooth tip curved section and a second fixed-side tooth tip curved section having a larger curvature radius than the foregoing first section are formed on a tooth tip of a scroll tooth, and in which a fixed-side root curved section is formed in a root section on a fixed table plate side of the scroll tooth; and a rocking scroll in which a rocking-side tooth tip curved section is formed on a tooth tip of the scroll tooth, and in which a first rocking-side root curved section and a second rocking-side root curved section having a larger curvature radius than that the foregoing first section are formed in a root section on a rocking table plate side of the scroll tooth. The second fixed-side tooth tip curved section and the second rocking-side root curved section are formed, in a scroll tooth of each scroll, in at least a part of or an entirety of a range including: a first arc section extending from a center-side end point of an outer involute curve toward a scroll center; and a second arc section extending from a center-side end point of an inner involute curve toward the scroll center. Due to this configuration, refrigerant leakage can be reduced while sufficiently ensuring fatigue strength at the center of the scroll tooth, and the compression efficiency can be improved while ensuring reliability.

Owner:MITSUBISHI ELECTRIC CORP

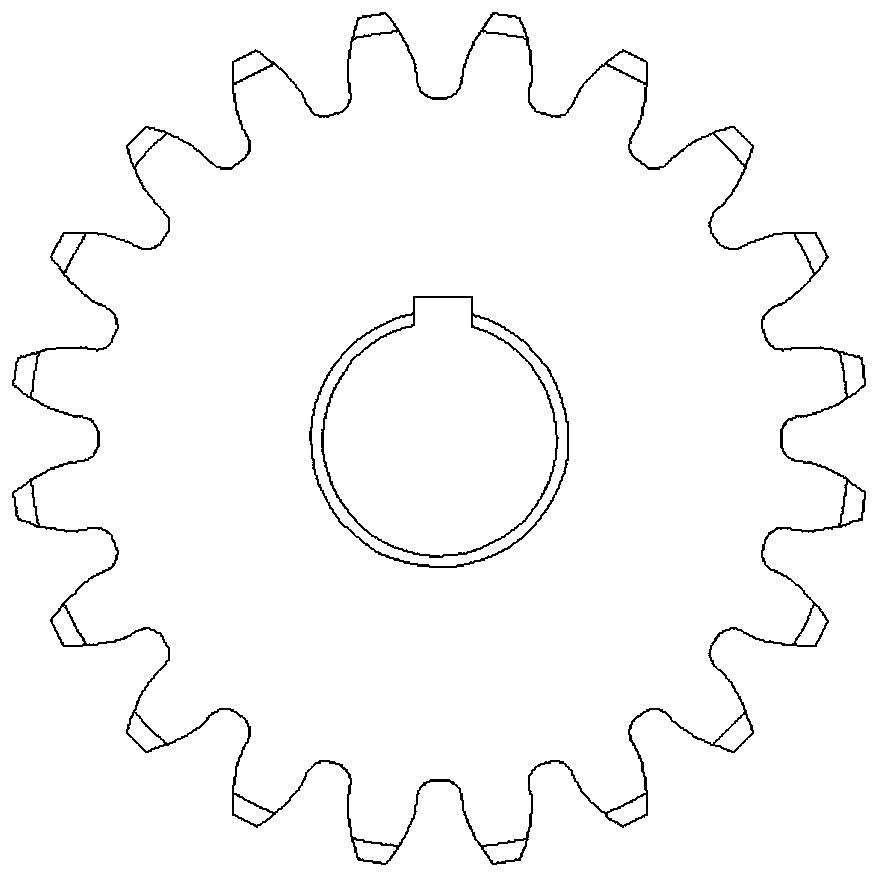

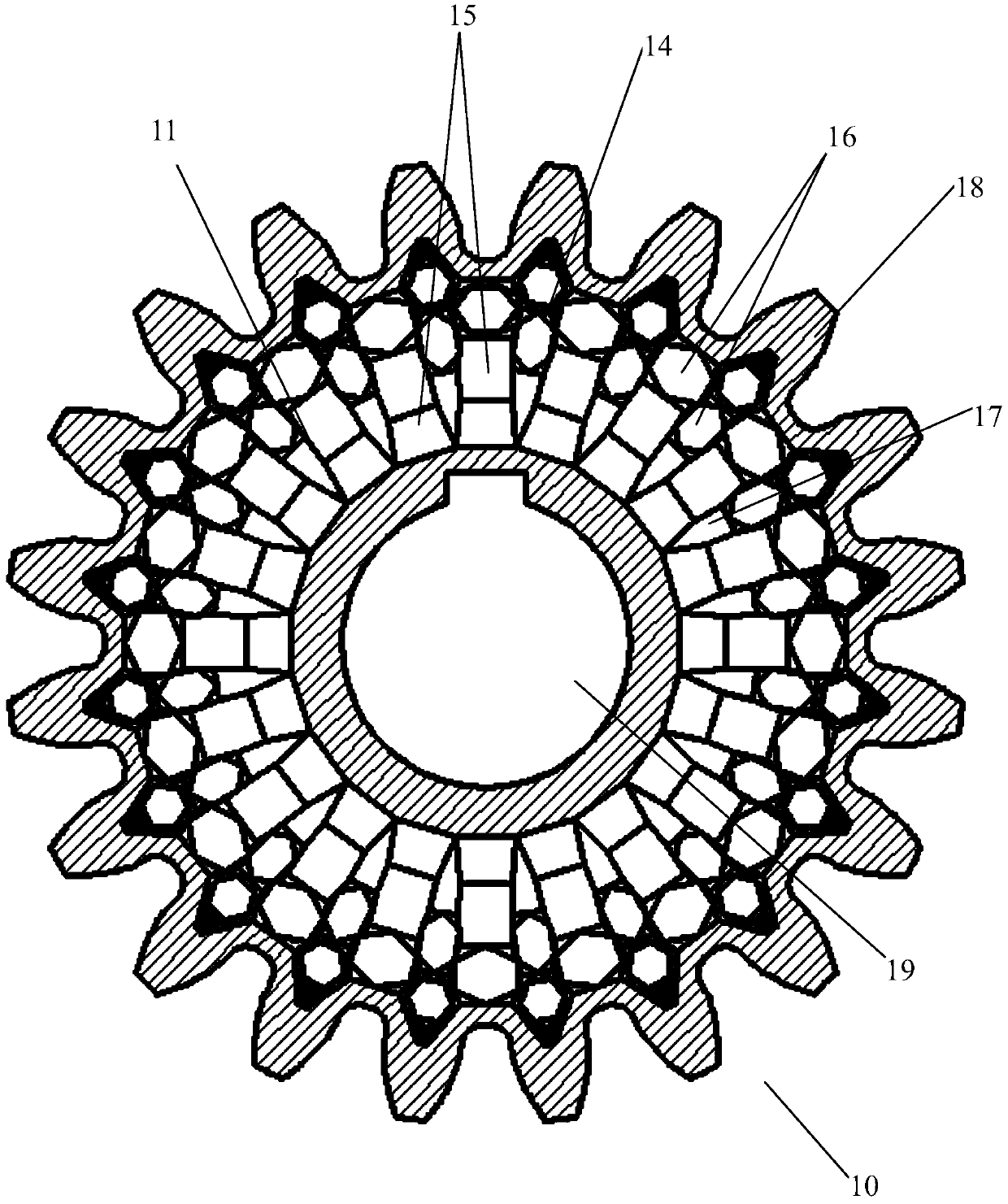

Lightweight fractal gradient gear

PendingCN111140639AImprove mechanical performanceGuaranteed fatigue strengthPortable liftingGearing elementsGear wheelManufacturing engineering

The invention discloses a lightweight fractal gradient gear. The lightweight fractal gradient gear comprises a gear body and is characterized by further comprising two plate bodies, wherein the platebodies are fixed to the two sides of the gear body; and the gear body is of a porous lightweight structure, wherein the porous lightweight structure at least is composed of a first-stage gradient holegroup, a second-stage gradient hole group and a third-stage gradient hole group which are constructed in a staggered mode. According to the lightweight fractal gradient gear, a honeycomb type multi-cell structure serves as a prototype, and gradient type, split type and multi-type design is carried out, so that the maximum lightweight of the gear is achieved, and manufacturing is convenient.

Owner:HUAQIAO UNIVERSITY

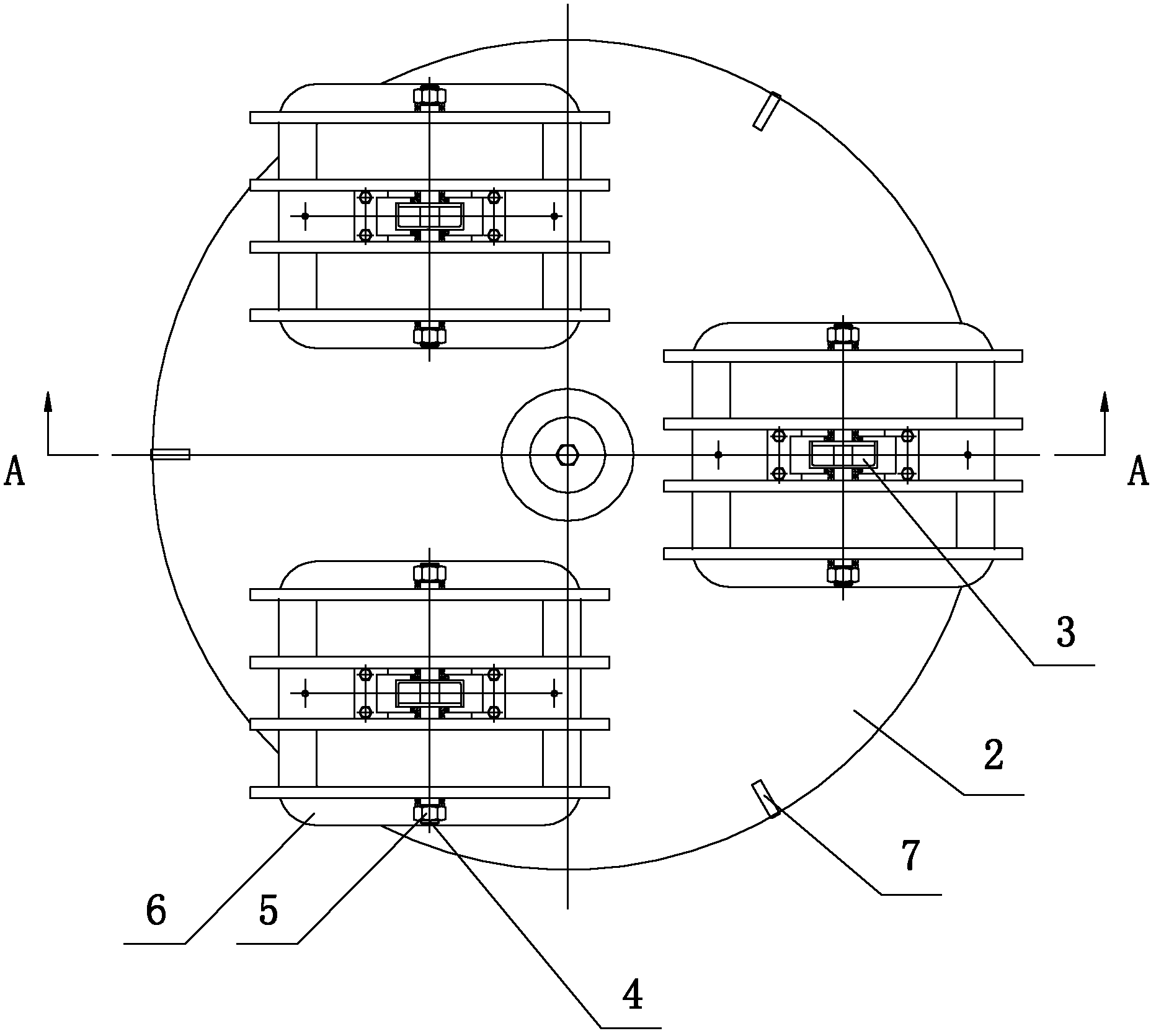

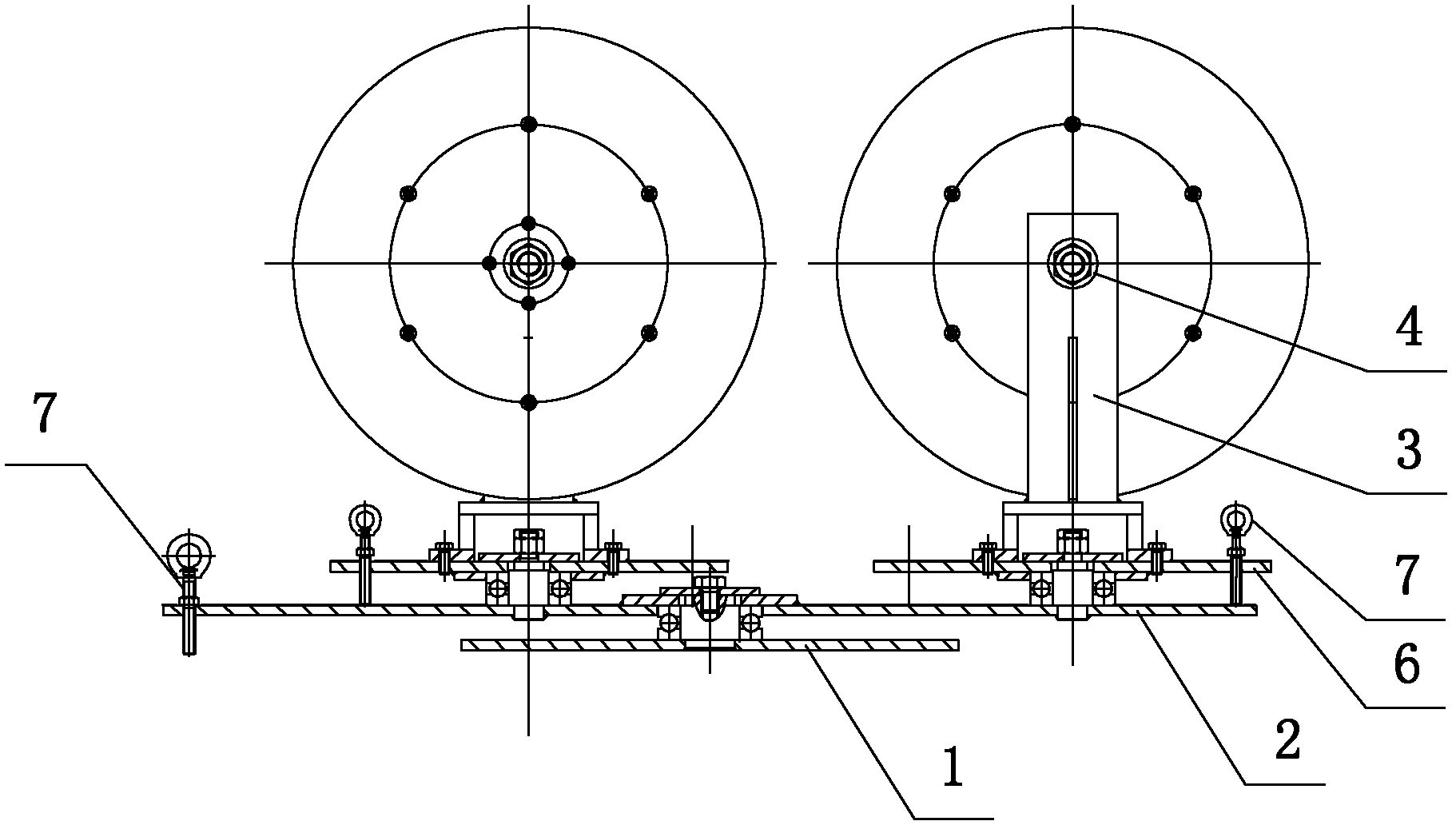

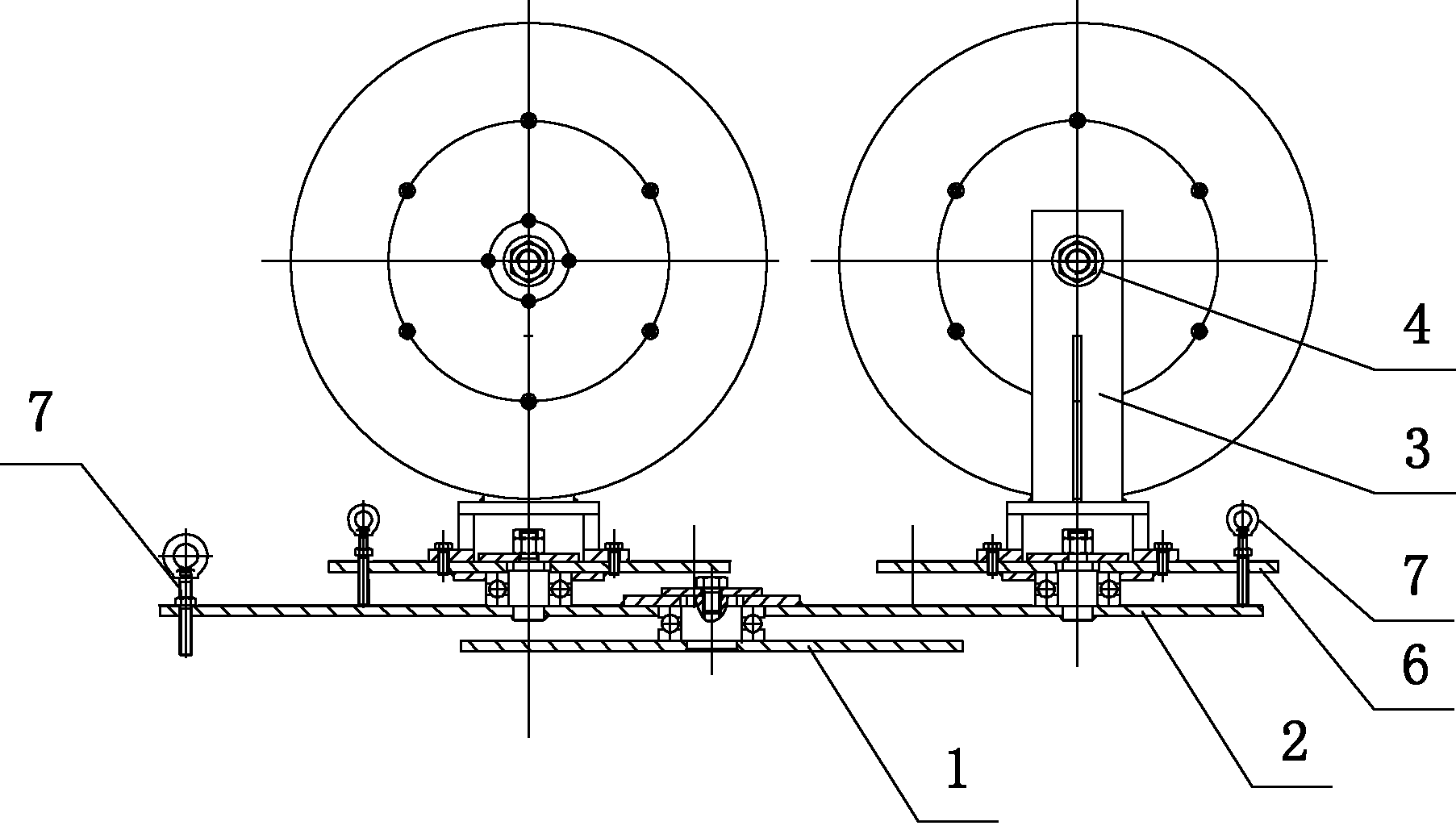

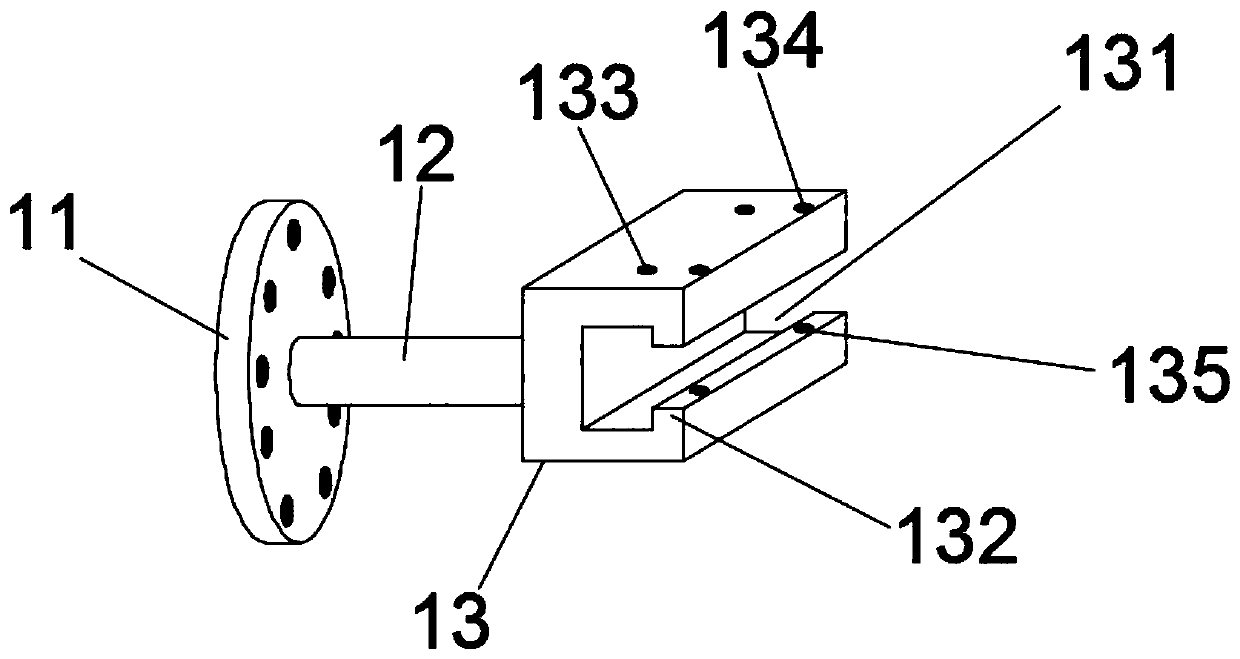

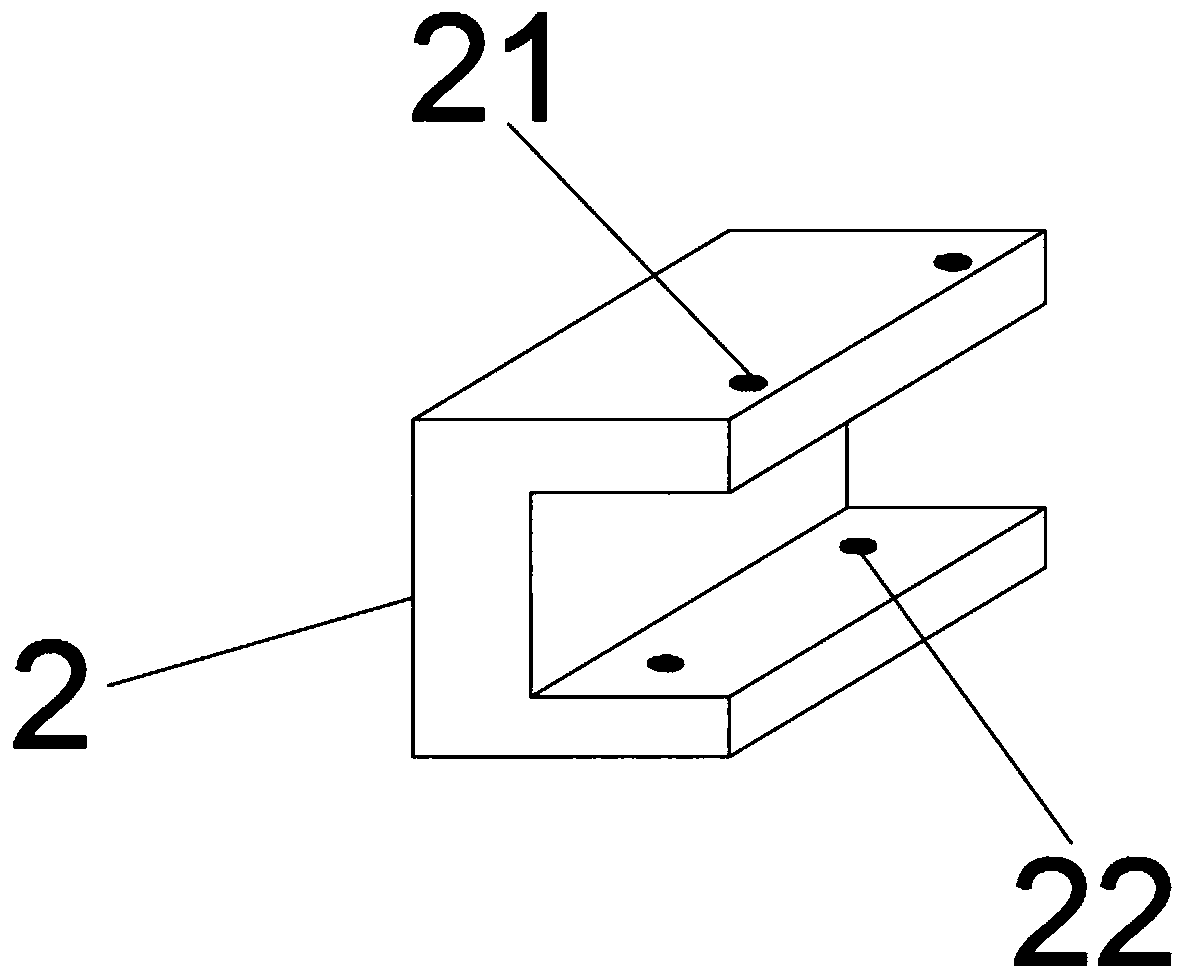

Non-joint wire embedding device for random-embedded windings of large-power motor stator and wiring method

ActiveCN102594059AHigh anti-halation effectGuaranteed fatigue strengthManufacturing dynamo-electric machinesConductor CoilPhase number

The invention discloses a non-joint wire embedding device for random-embedded windings of a large-power motor stator. The non-joint wire embedding device comprises a base, wherein a supporting plate is rotationally connected to the base; at least three wire releasing frames are rotationally connected to the first supporting plate; a horizontal wire releasing rod is arranged on each wire releasing frame and passes through the wire releasing frame; the middle of each wire releasing rod is rotationally connected with the corresponding wire releasing frame; and fixing devices are arranged at two ends of each wire releasing rod. The invention further discloses a wiring method, which sequentially comprises the steps as follows: variable-frequency enameled circular electromagnetic wires are wound on circular wire discs; a stator iron core is vertically placed on a rolling frame; two wire releasing devices are respectively placed on two sides of the stator iron core; the wire discs are evenly placed on the wire releasing rods of the wire releasing devices on the two sides of the stator iron core by phase number; the variable-frequency enameled circular electromagnetic wires are embedded into the stator iron core; and after the wires are embedded into the stator iron core, the end parts of coils are manually bent. The non-joint wire embedding device and the wiring method have the advantages that the wires are continuously and randomly embedded into the stator iron core, the insulating integrity of the windings is guaranteed, materials and production costs are saved, and the performance of the motor is improved.

Owner:浙江省金华市电机实业有限公司

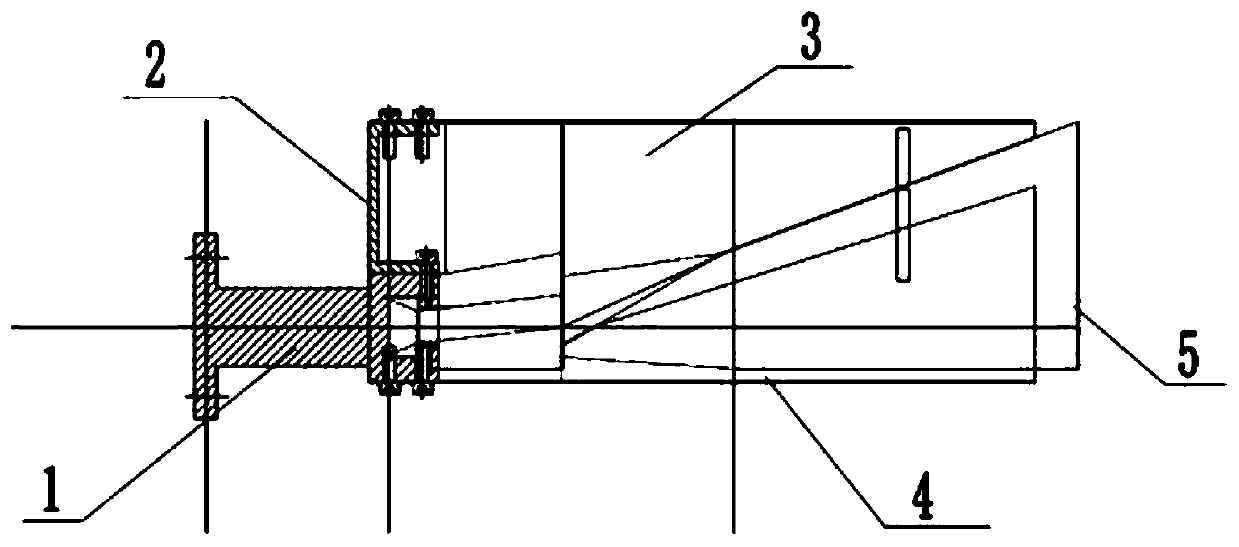

Clamp for preparing coating on selective surface area of blade and preparation method of coating

ActiveCN111575671AGuaranteed fatigue strengthReduce erosion damageVacuum evaporation coatingSputtering coatingTurbine bladeStructural engineering

The invention discloses a clamp for preparing a coating on the selective surface area of a blade and a preparation method of the coating. The clamp comprises a blade fixing shaft, a cover plate bracket, an upper cover plate and a lower cover plate, wherein the blade fixing shaft is connected with the cover plate bracket, the upper cover plate is mounted on the upper end face of the cover plate bracket, the lower cover plate is mounted on the lower end face of the blade fixing shaft, and the upper cover plate and the lower cover plate are connected in a staggered clamping manner. The blade canbe clamped and fixed by using the clamp when a hard coating is sprayed on an engine blade or a turbine blade, the coating meeting the requirements of erosion and fatigue performance is prepared on thesurface of the blade by using a zonal coating process, the requirement for locally spraying the hard coating on the engine blade or the turbine blade is met, the erosion damage of the surface of theblade is reduced, and the fatigue strength of the blade is ensured. The clamp has the advantages of being simple in structure, convenient to use and reasonable in design.

Owner:AIR FORCE UNIV PLA

Steel for rolling mill bearing

The invention discloses steel for a rolling mill bearing. The steel is composed of the following chemical components in percentage by weight: 1.05-1.15% of C, 0.3-0.5% of Si, 1.3-1.5% of Mn, 1.1-1.3% of Mo, 0.2-0.4% of V, 1.2-1.4% of Cr, 0.4-0.6% of Ni, 0.2-0.4% of Cu, less than or equal to 0.015% of S, less than or equal to 0.015% of P, 0.02-0.04% of Ti, less than or equal to 15*10<-4> of O, less than or equal to 2*10<-4> of H and the balance of Fe and unavoidable impurities.

Owner:锡山区鹅湖慧盾机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com