Thread core-pulling rivet and riveting method using same

A technology of blind rivets and threads, which is applied in the direction of screws, rivets, threaded fasteners, etc., can solve the problems of high dimensional accuracy and matching degree between nail sleeves and lock rings, and increase the difficulty of manufacturing, so as to achieve simple assembly, Reduce manufacturing cost and ensure the effect of preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The threaded blind rivet of the present invention will be described in detail below in conjunction with the accompanying drawings.

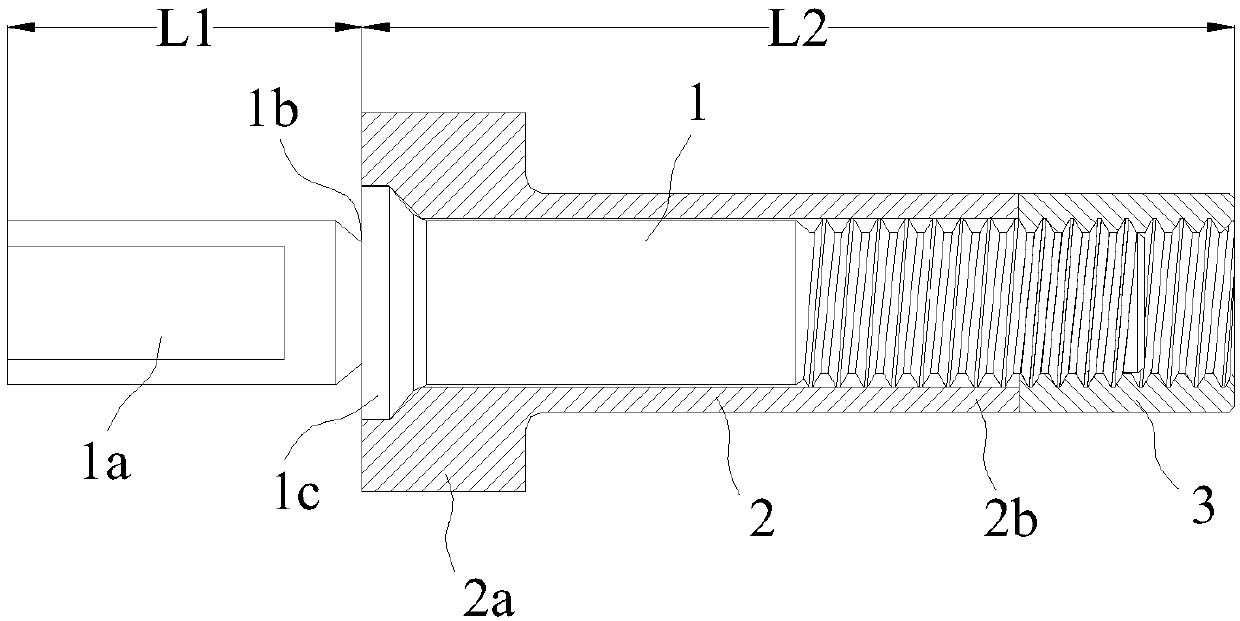

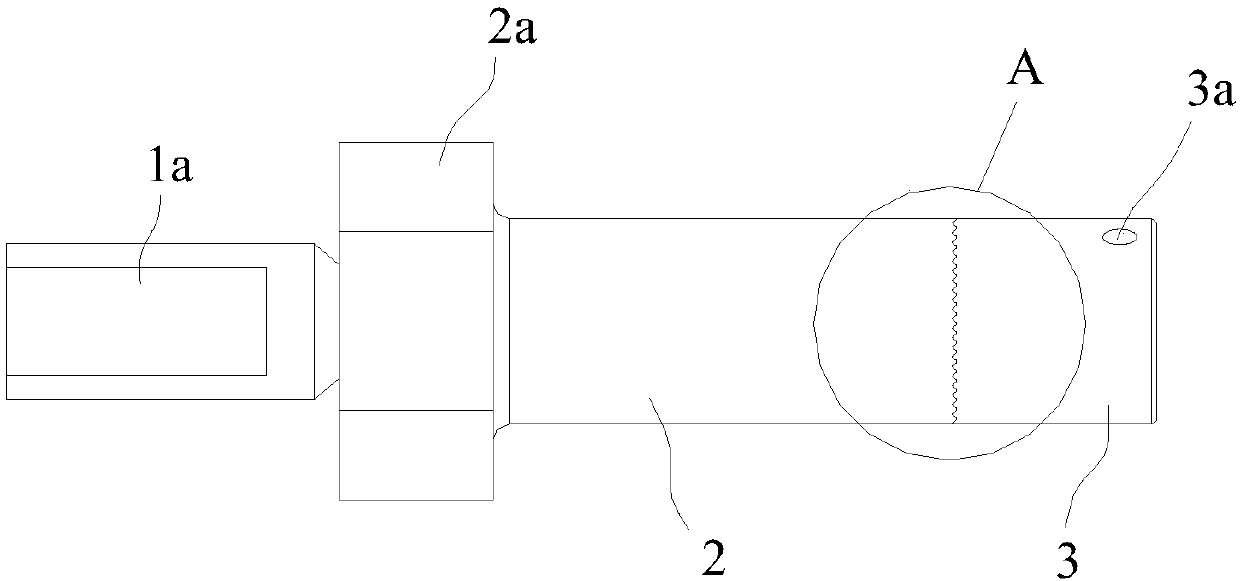

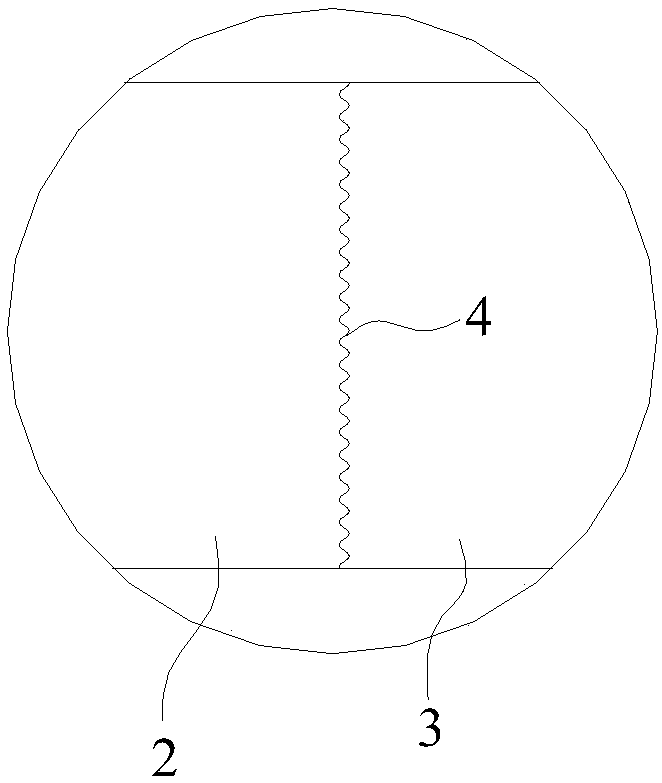

[0051] Such as figure 1 , figure 2 As shown, the threaded blind rivet includes: a nail shank 1 with a limit cap 1c, a drive ring 3 threaded on the nail shank 1, and a sleeve set on the nail shank 1 and located on the limit cap 1c and the drive ring 3 between nail sets 2.

[0052] Such as figure 1As shown, there is a broken neck groove 1b on the nail rod 1, and one side of the broken neck groove 1b is the driving section 1a twisted off after installation (the length of the driving section 1a is L1), and the other side is the riveting section (the length of the riveting section L2), the limit cap 1c is located on the riveting section and adjacent to the broken neck groove 1b, and the end of the riveting section away from the limit cap has an external thread that matches the drive ring 3 .

[0053] During the riveting process, the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com