Patents

Literature

60results about How to "Won't spring back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing technology of arc-shaped spring

ActiveCN102501009ASmall thermal relaxation rateLarge momentary torqueFurnace typesHeat treatment furnacesStress reliefMaterials science

The invention relates to a processing technology of a large-radian arc-shaped spring. The processing technology is characterized by comprising the following procedures of: spring coiling: primary stress relief annealing; spring grinding; spring bending into an arc-shaped spring; secondary stress relief annealing; shot blasting; hot-strong pressing; sorting; angular rigidity and torque test; fatigue life test; and surface antirust treatment. According to the forming technology of the arc-shaped spring provided by the invention, the arc-shaped spring with the free angle of being more than 45 degrees can be effectively formed, the thermal relaxation rate of the spring is less than 2%, the instantaneous torque is large, the fatigue life is 1 million times, and the technical problems of low finished product rate and incapability for normal use of the large-radian arc-shaped spring in the prior art are solved.

Owner:HANGZHOU FUCHUN SPRING

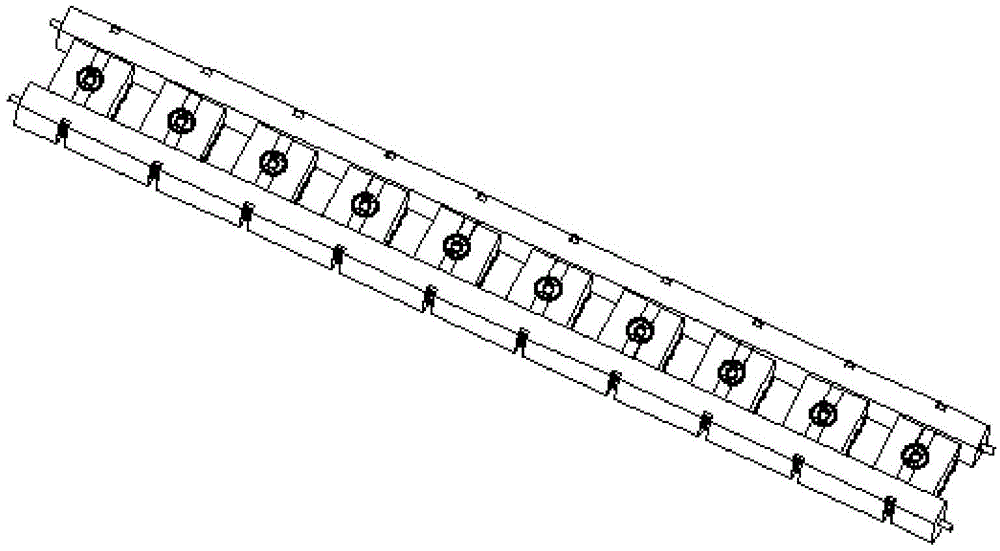

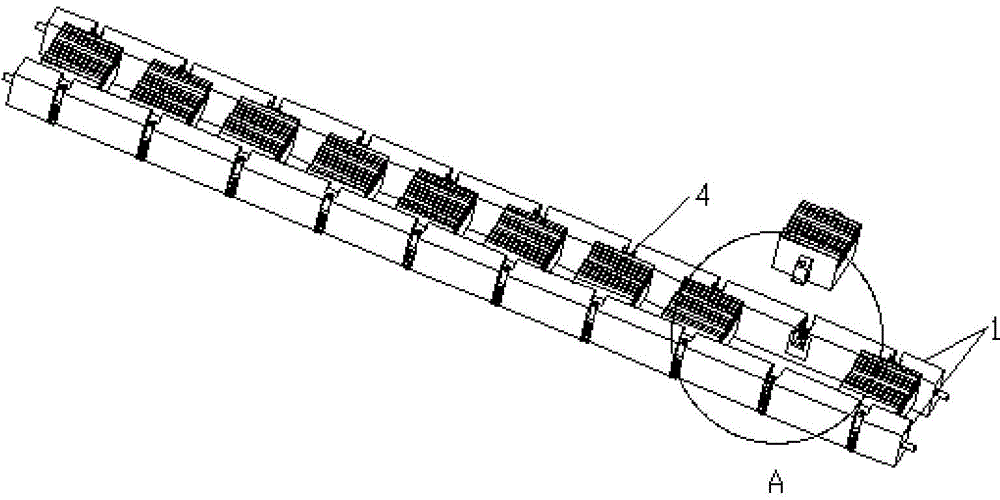

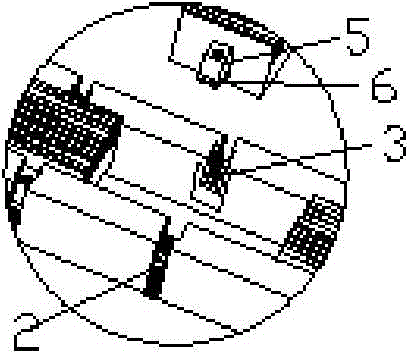

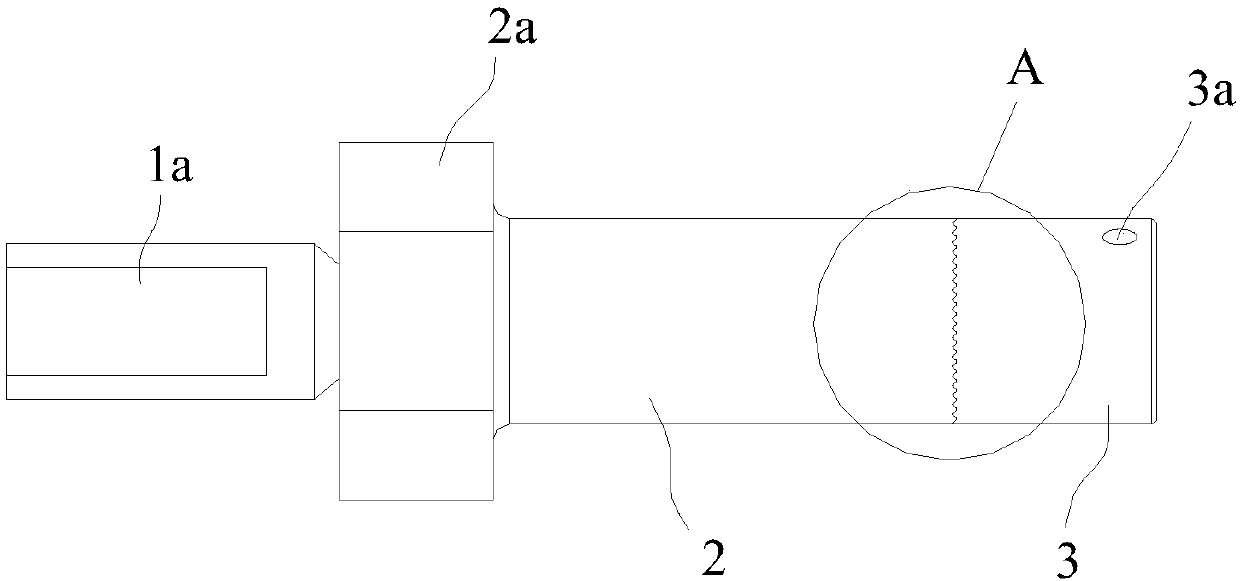

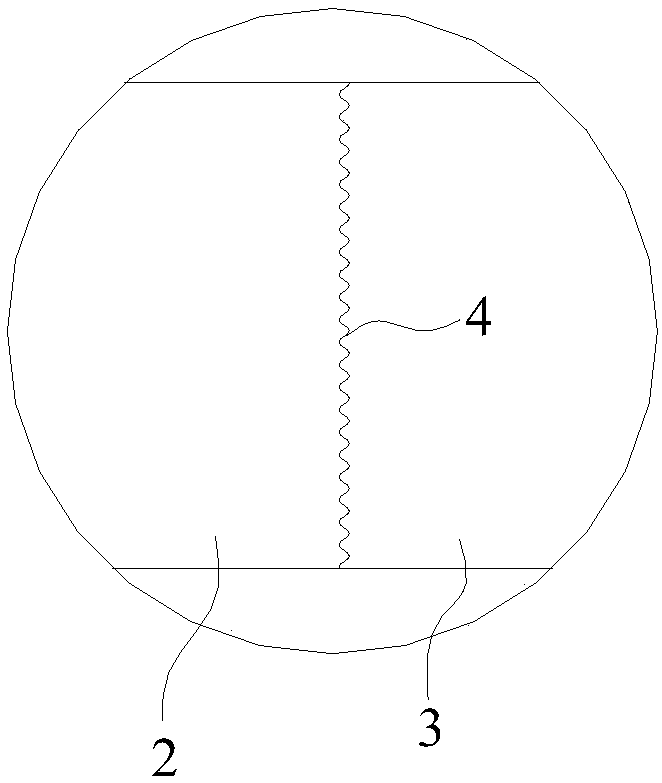

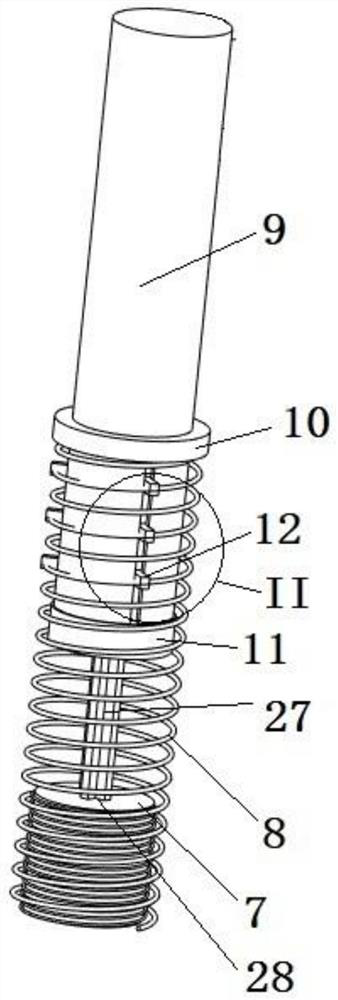

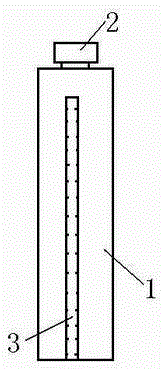

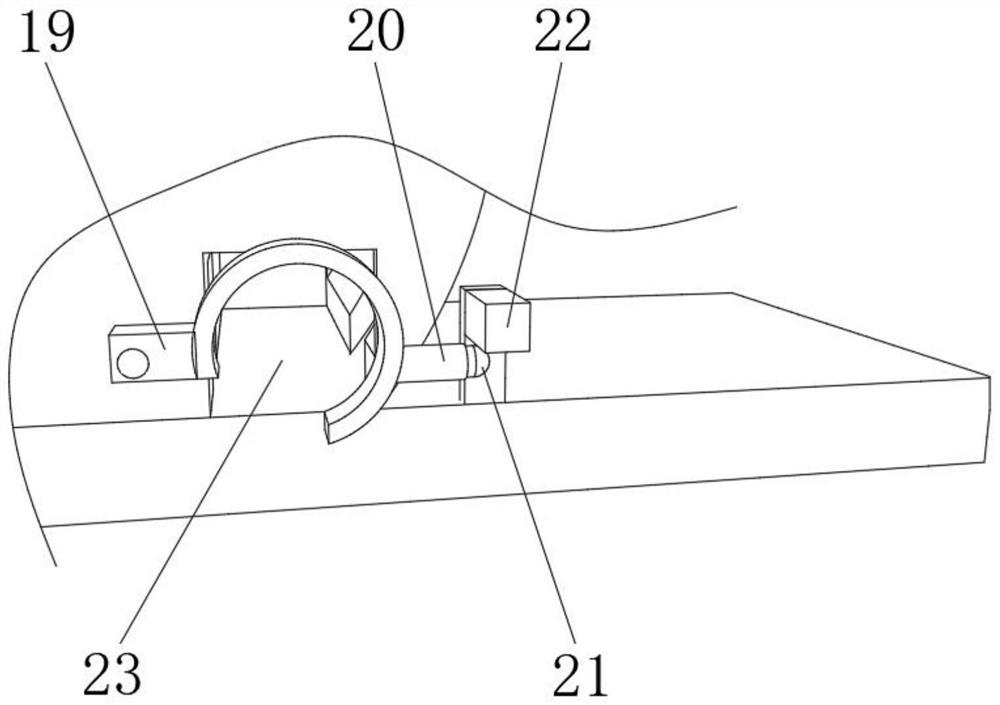

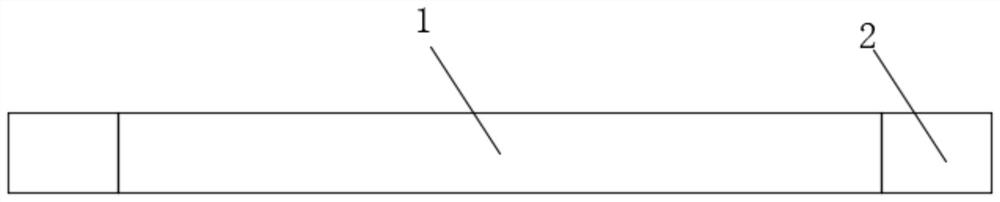

Bendable strip-shaped module lamp strip matched with pluggable LED (light emitting diode) metal lamp bulbs

ActiveCN104359037AWon't spring backEasy to plug and unplugPoint-like light sourceElongate light sourcesEngineeringLead Metal

The invention relates to the field of LED (light emitting diode) lamps, in particular to a bendable strip-shaped module lamp strip matched with pluggable LED metal lamp bulbs. The bendable strip-shaped module lamp strip comprises plastic lamp bulb strips and lamp bulbs, wherein the plastic lamp bulb strips and the lamp bulbs are plugged and fixed by a plugging assembly, and the plastic lamp bulb strips are connected by a connecting head to form a straight line shape, an L shape, a T shape and a cross shape. The bendable strip-shaped module lamp strip has the advantages that the strip-shaped module lamp strips can be bent into various shapes, the rebounding is avoided, the strip-shaped module lamp strip can be applied to structures with flat surfaces, annular surfaces, arc-shaped surfaces and spherical surfaces, and the plastic strips can also be cut into any length according to the structure of a lamp.

Owner:HUNAN YUEGANG MOOKRAY IND CO LTD

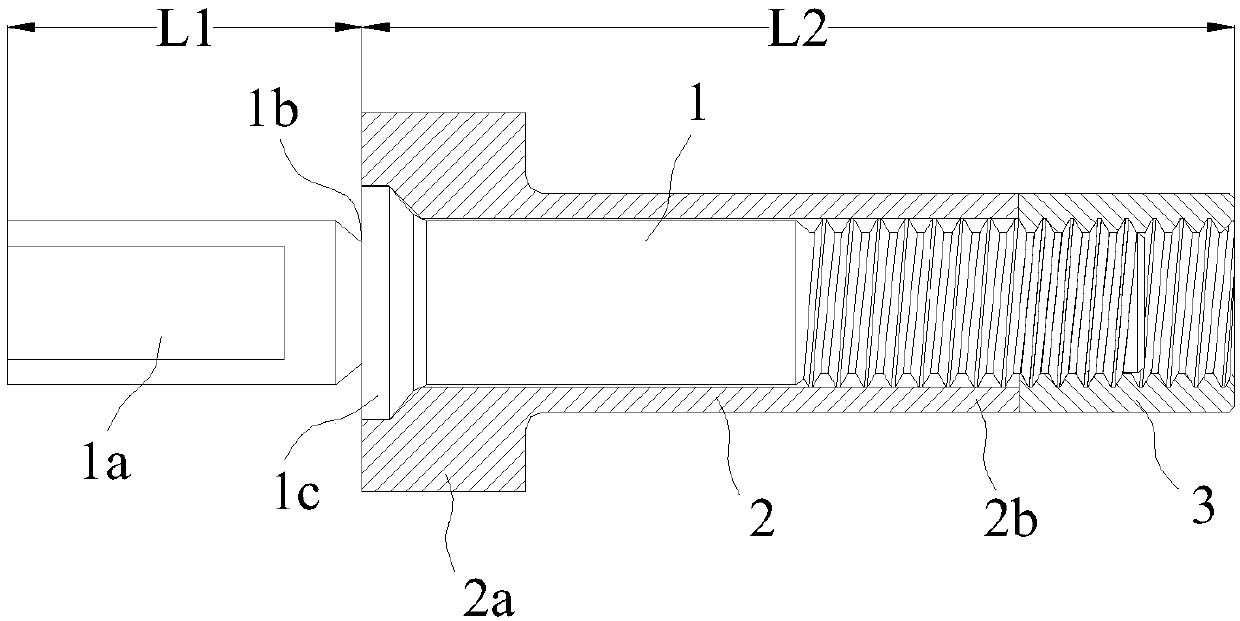

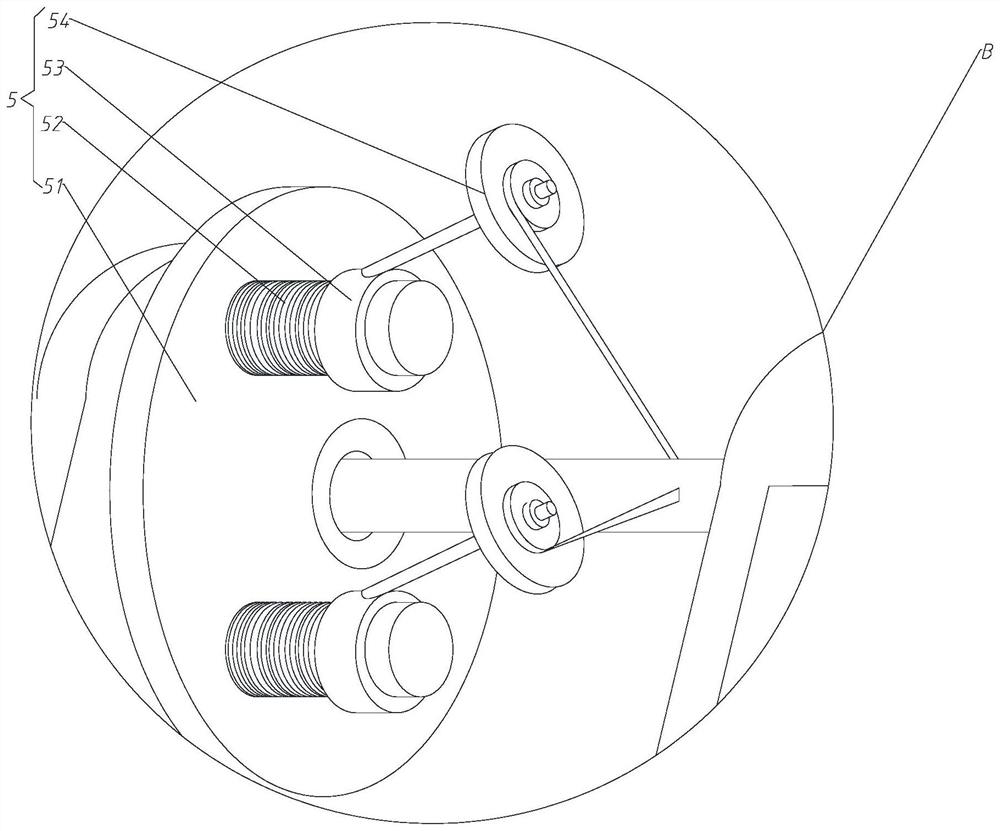

Thread core-pulling rivet and riveting method using same

PendingCN108050142AEasy to assembleReduce manufacturing costRivetsScrewsEngineeringUltimate tensile strength

The invention discloses a thread core-pulling rivet and a riveting method using the same. The thread core-pulling rivet comprises a rivet rod with a limiting cap, a driving ring mounted on the rivet rod in a threaded mode and a rivet sleeve arranged on the rivet rod in a sleeving mode and located between the limiting cap and the driving ring. A blocking head matched with the limiting cap in an abutting mode is arranged at one end of the rivet sleeve, and the other end of the rivet sleeve and the driving ring are matched circumferentially in a positioned mode. In riveting, the rivet rod rotatesrelative to the rivet sleeve, the driving ring and the limiting cap apply force to the rivet sleeve oppositely to enable the rivet sleeve to be deformed, and after riveting, a deformed part of the rivet sleeve and the blocking head abut against the two sides of a riveting part. The thread core-pulling rivet has high pre-tightening force, tensile strength and fatigue strength after being mounted and is easy to assemble, so that the manufacturing difficulty and cost are reduced.

Owner:RITAI SHANGHAI AUTO STANDARD COMPONENT

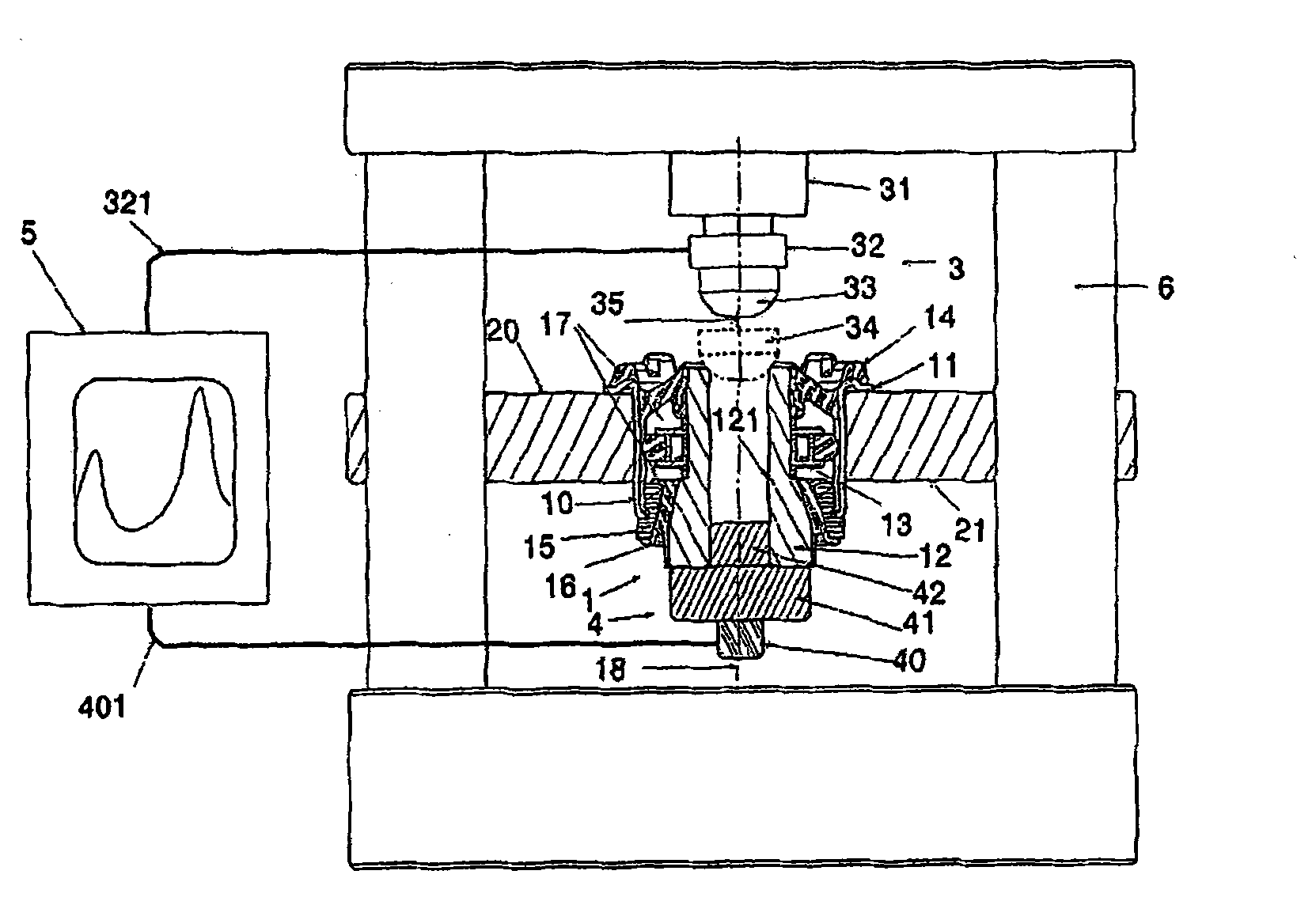

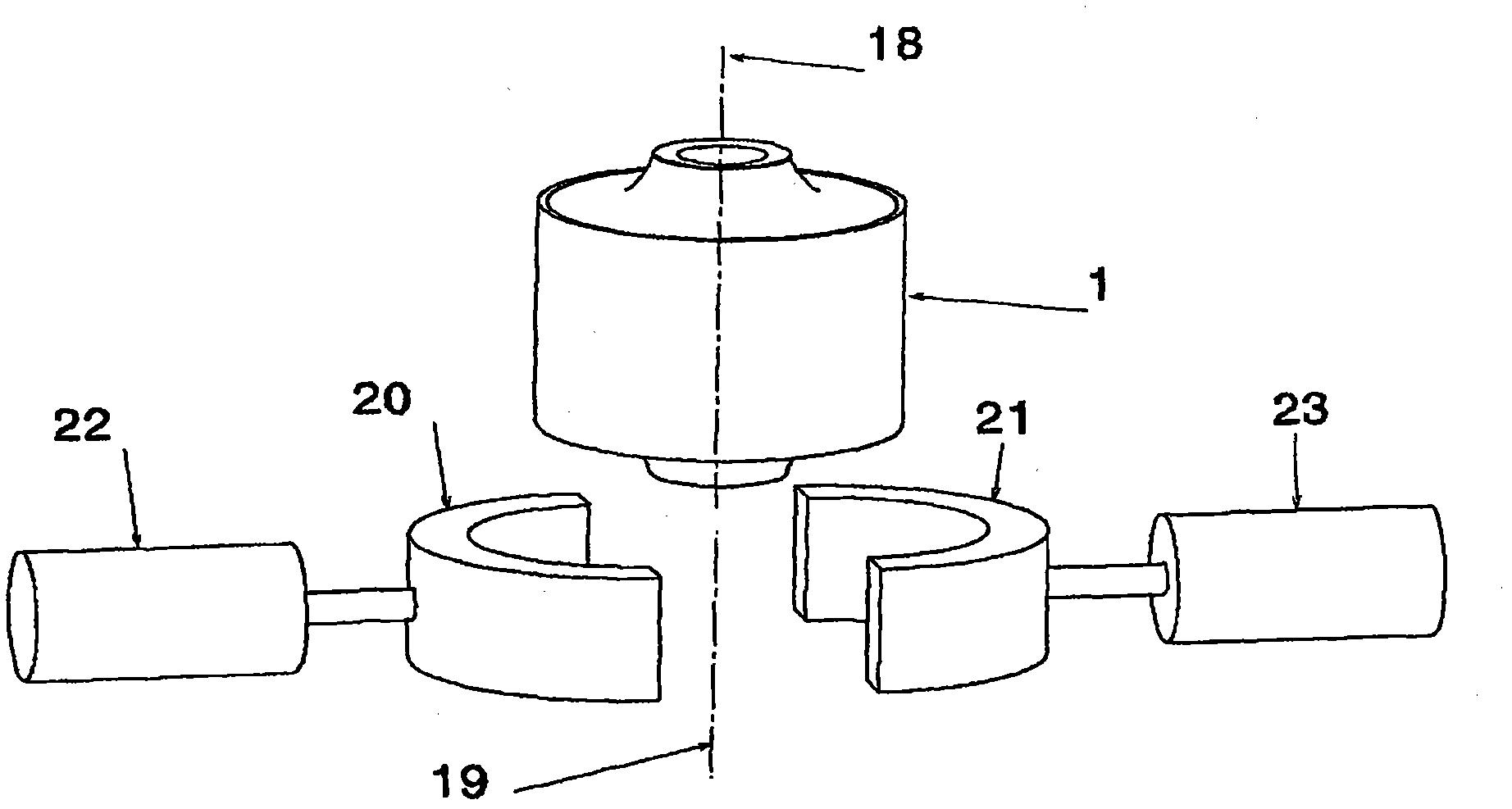

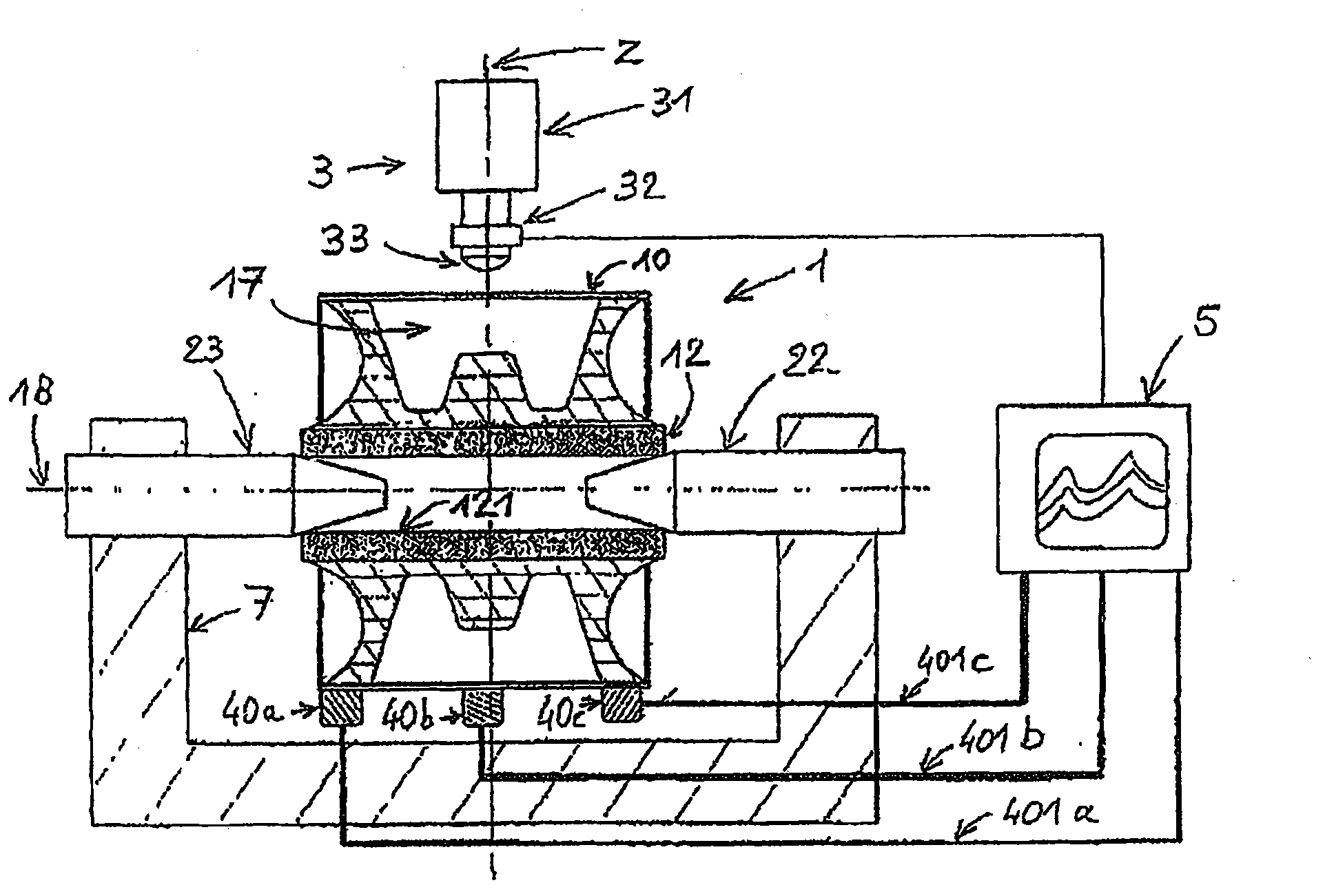

Method and device for monitoring the quality, particularly the stiffness and the phase, of a hydroelastic joint

InactiveCN102047091AControl impact processWon't spring backMachine part testingShock testingElastomerProduction line

Method for monitoring the quality, particularly the stiffness and the phase, of a joint intended to connect two other parts while filtering the transmission of vibrations between these other two parts, said joint being called on to work axially, radially or in torsion, optionally having one or more hydroelastic chambers and being composed of two concentric cylindrical reinforcements, the inner reinforcement being largely situated within the volume defined by the outer reinforcement, these two reinforcements being connected by a set of rubber or elastomer components and, where appropriate, plastic components and metal parts, said reinforcements themselves being respectively fastened to the other two parts that are connected by the joint, by applying an impact monitoring technique at the rate of the production line on which the joints are produced, that is to say less than 10 seconds of cycle time, in order to identify the good from the poor parts during a frequency analysis of the oscillation of the impacted joint region, characterized in that phase shift values of the frequency analysis are compared with an authorised phase shift bandwidth.

Owner:ANVIS SD FRANCE

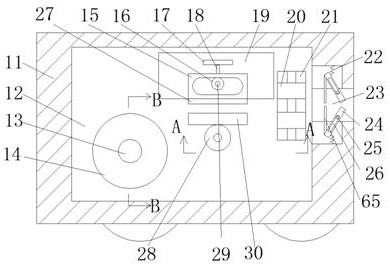

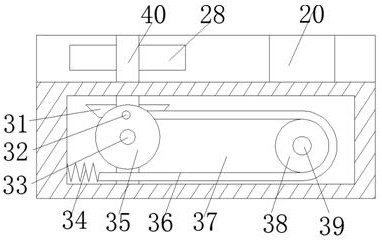

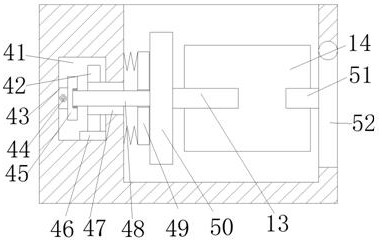

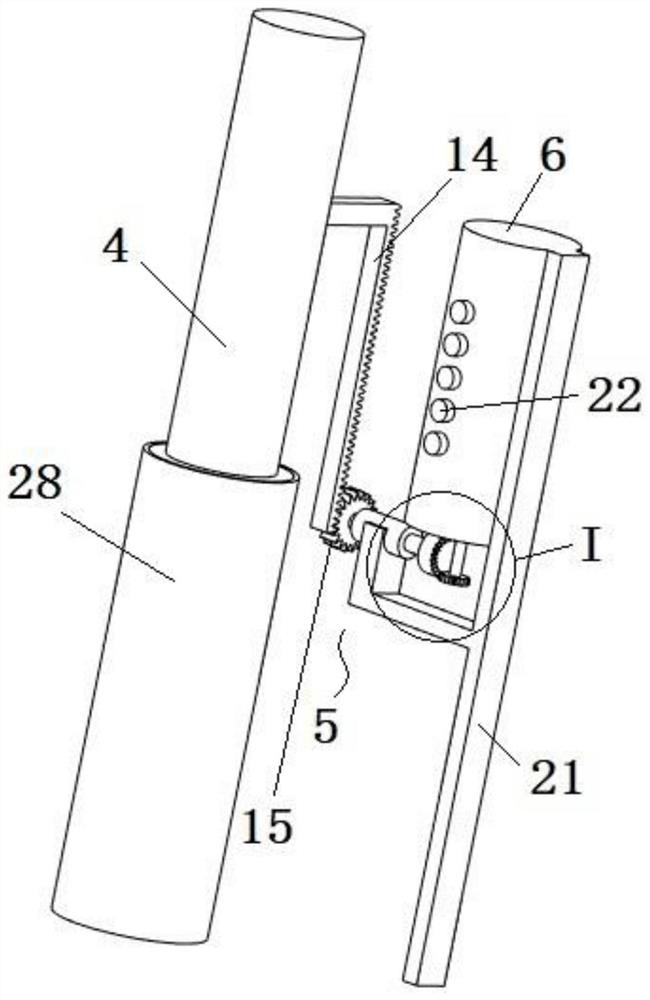

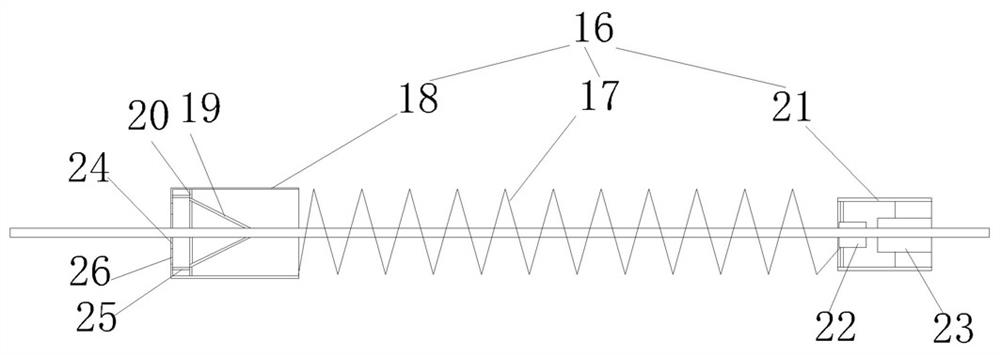

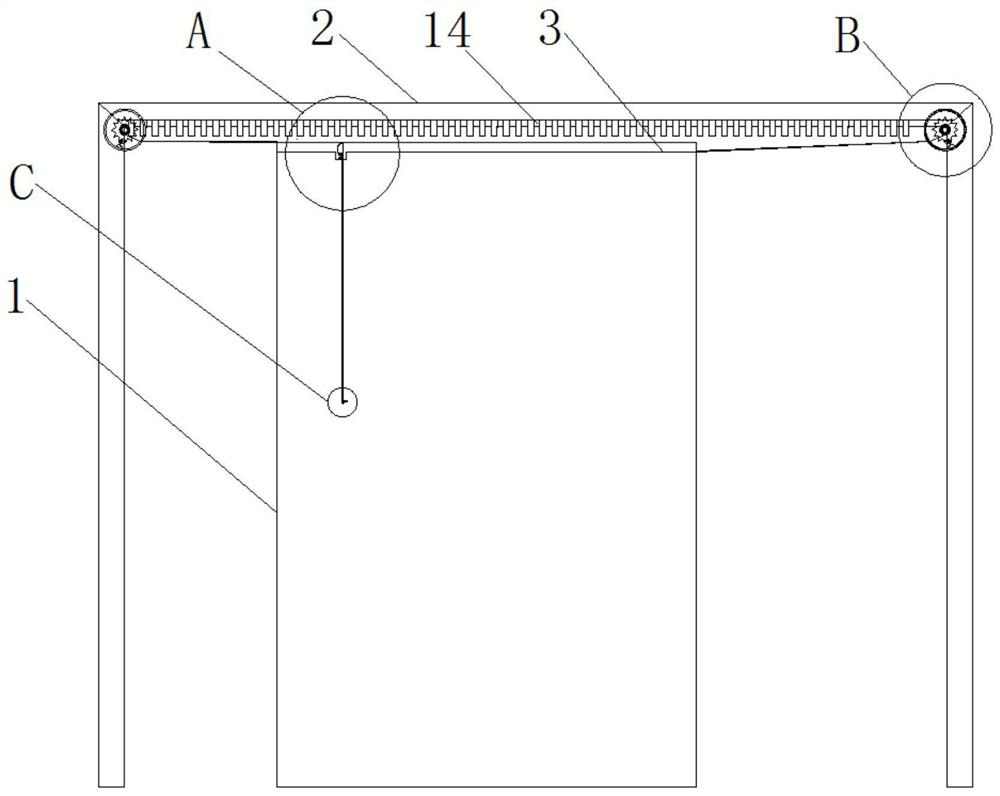

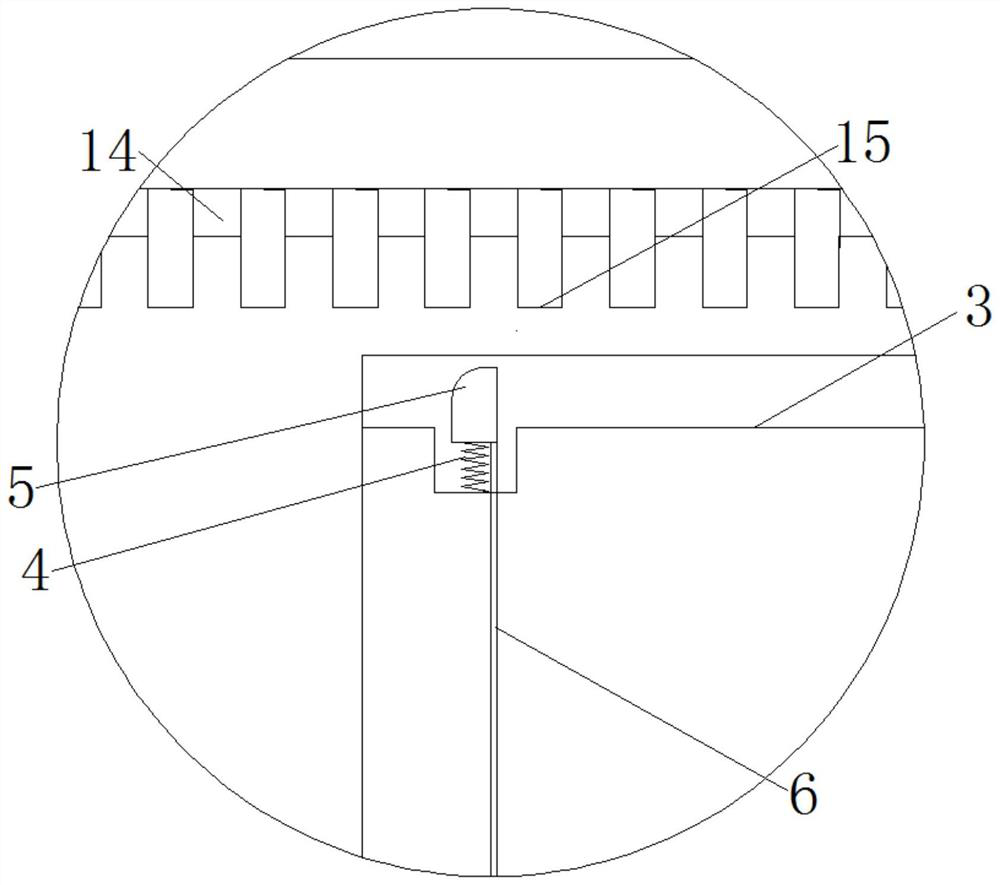

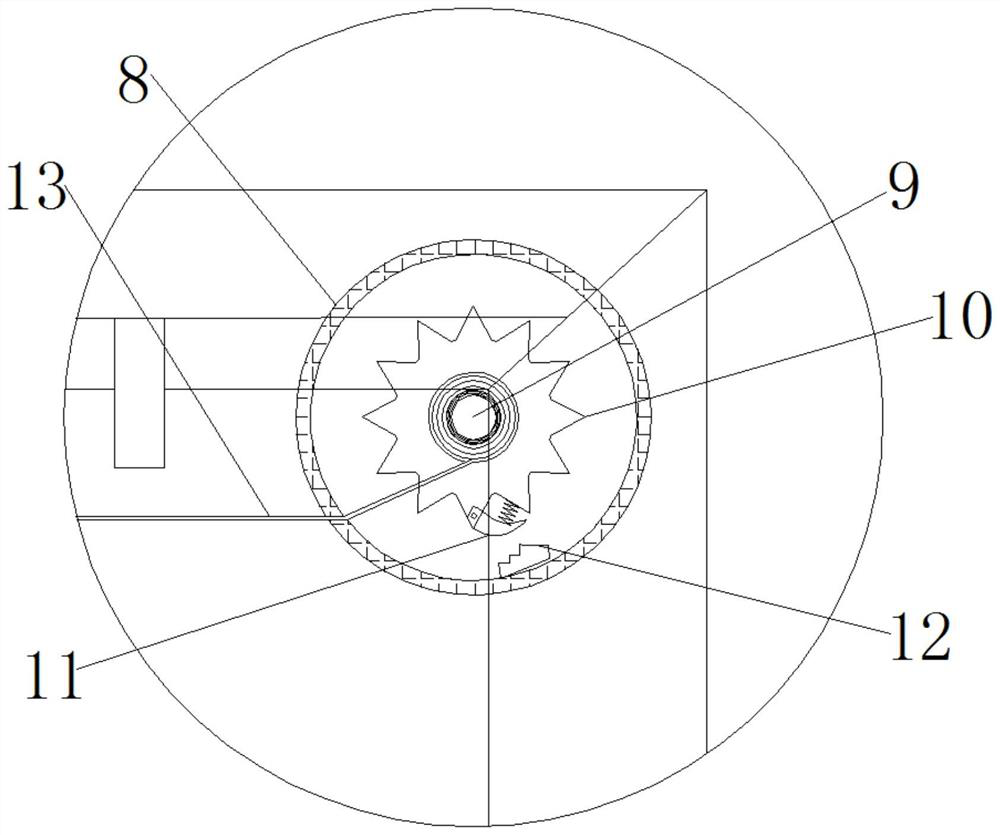

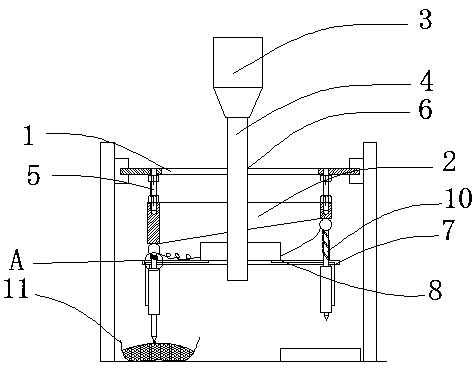

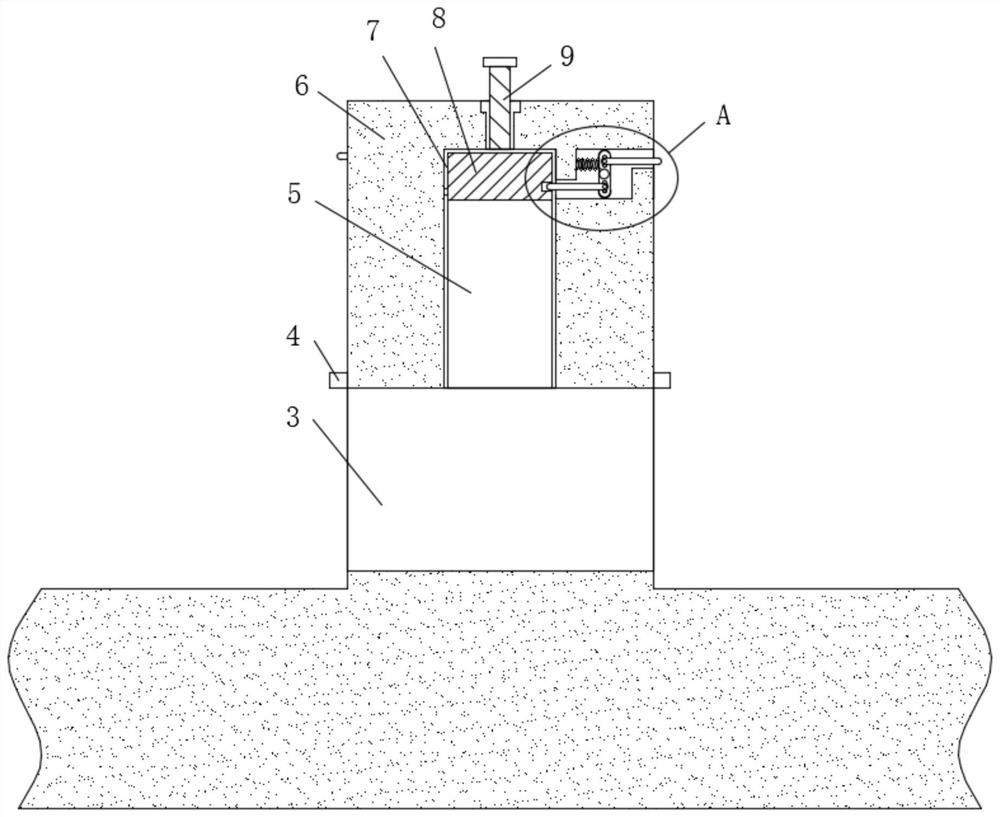

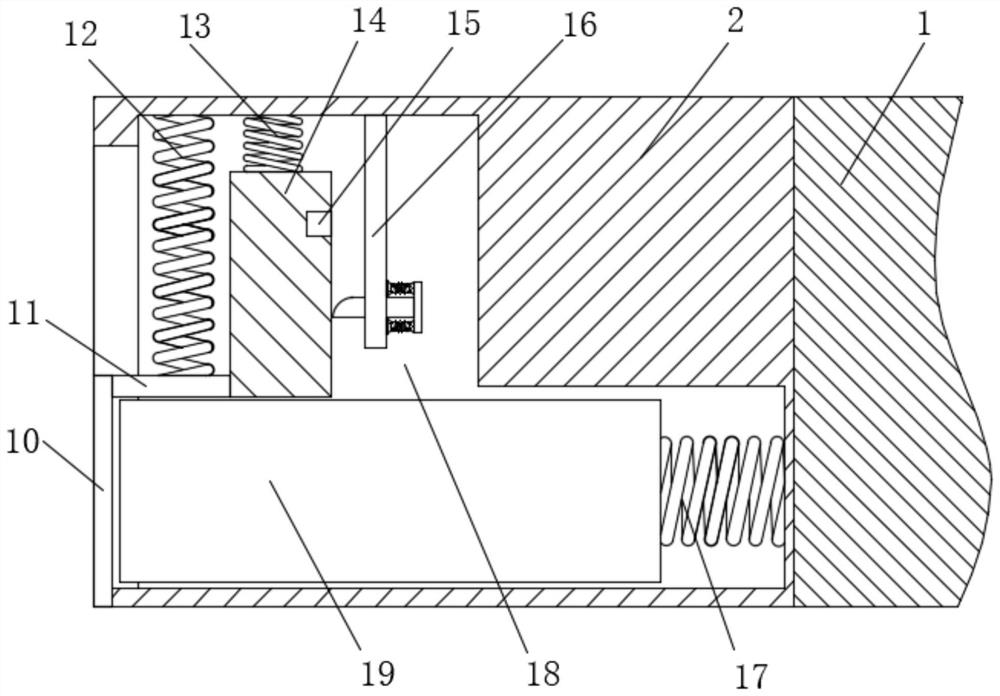

Threading construction auxiliary device for electrical engineering

The invention discloses a threading construction auxiliary device for electrical engineering. The threading construction auxiliary device comprises a vehicle body, wherein a working cavity is formed in the vehicle body; the right side wall of the working cavity is connected with a wire arrangement hole penetrating through the vehicle body; a wire releasing guide device is arranged in the wire arrangement hole; a connecting cavity is formed in the rear side wall of the working cavity; and a spline sleeve is rotationally mounted on a wall body between the connecting cavity and the working cavity. According to the device, a transmission shaft is matched with a one-way bevel gear, so that a pressing block only works when the transmission shaft rotates forwards, a cable is fixed, the cable is prevented from rebounding when the transmission shaft rotates reversely, and normal operation is guaranteed; and when the transmission shaft rotates reversely, a pawl rack drives a ratchet wheel to enable a material disc to rotate, the material disc rotates to release the cable, and the working efficiency is improved.

Owner:平潭县绵亘电子科技有限公司

Machining process of arc spring

InactiveCN108747218ASmall thermal relaxation rateLarge momentary torqueWire springsLife testingControl theory

The invention relates to a machining process for an arc spring. The machining process for the arc spring is characterized by comprising the following working procedures of spring coiling, first-time stress relieving, spring grinding, bending for the arc spring, second-time stress relieving, shot blasting, hot stressing, sorting, angle rigidity and torque testing, fatigue life testing and surface rust-proof treatment. The forming process of the arc spring is provided, and by means of the forming process, the arc spring with the free angle larger than 45 degrees can be effectively formed, it isguaranteed that the hot relaxation rate of the spring is smaller than 2 %, the instantaneous torque is large, and the fatigue life is one million times or above; and the technical problems that in theprior art, the yield of the large-angle arc spring is low, and the large-angle arc spring cannot be normally used are solved.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

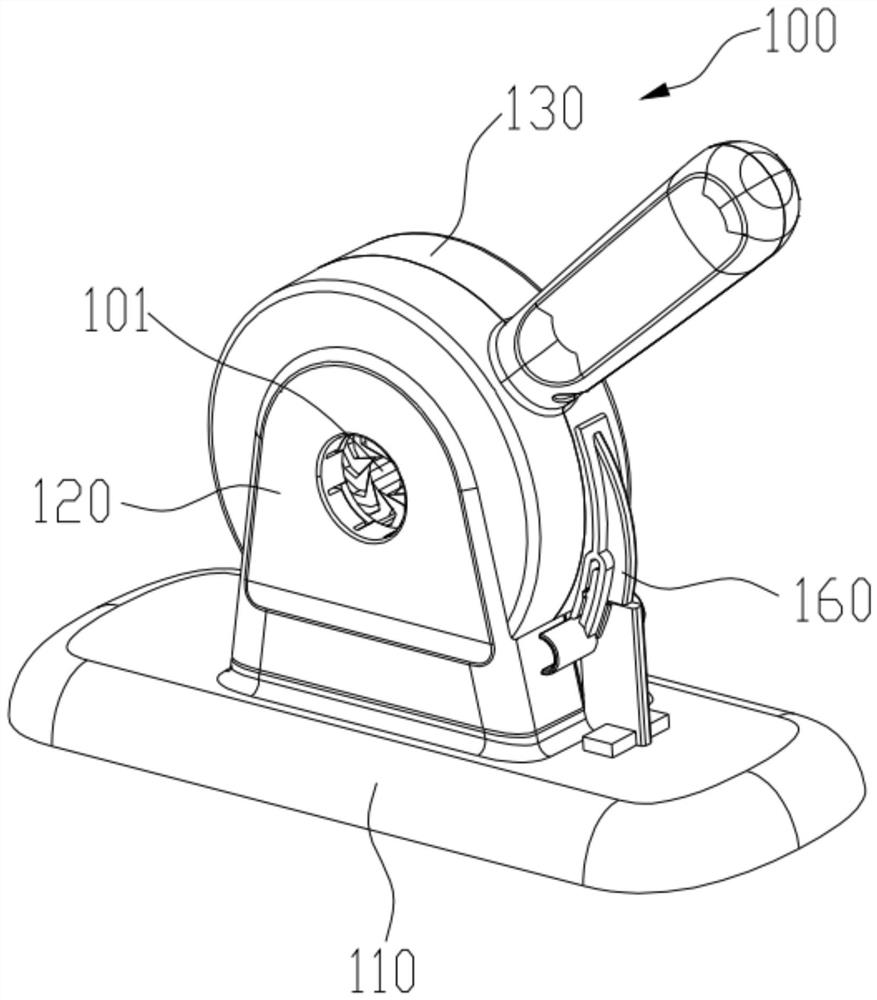

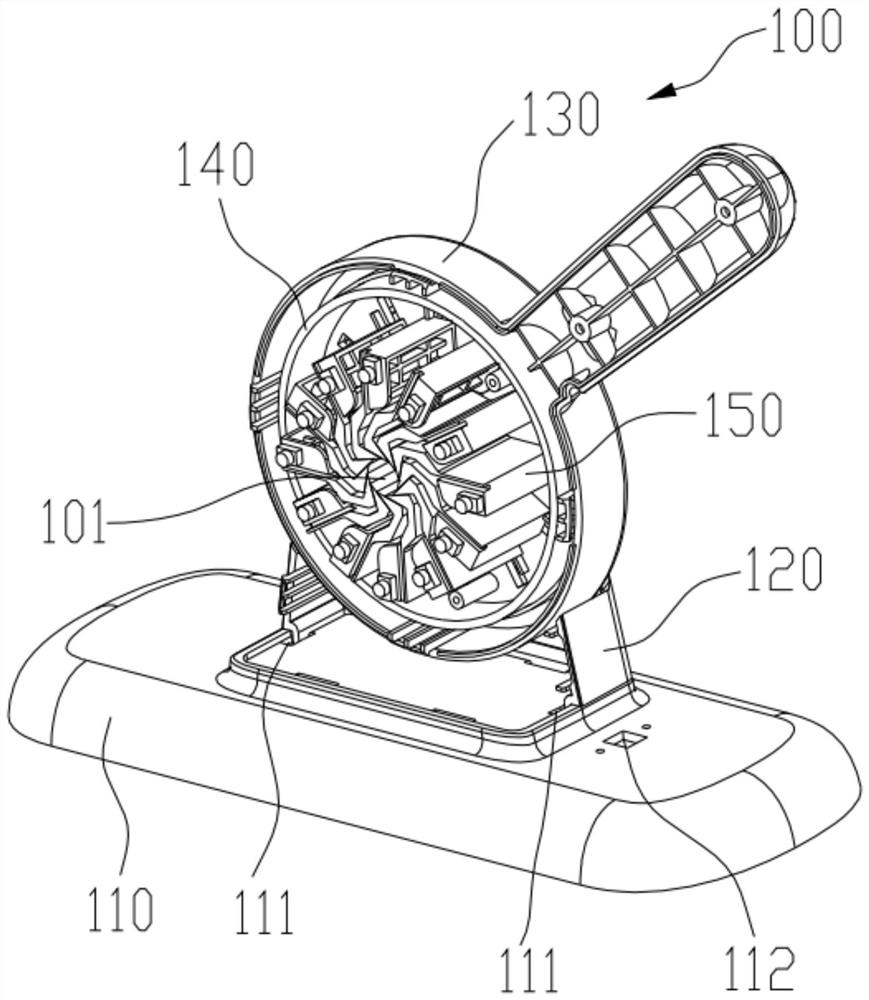

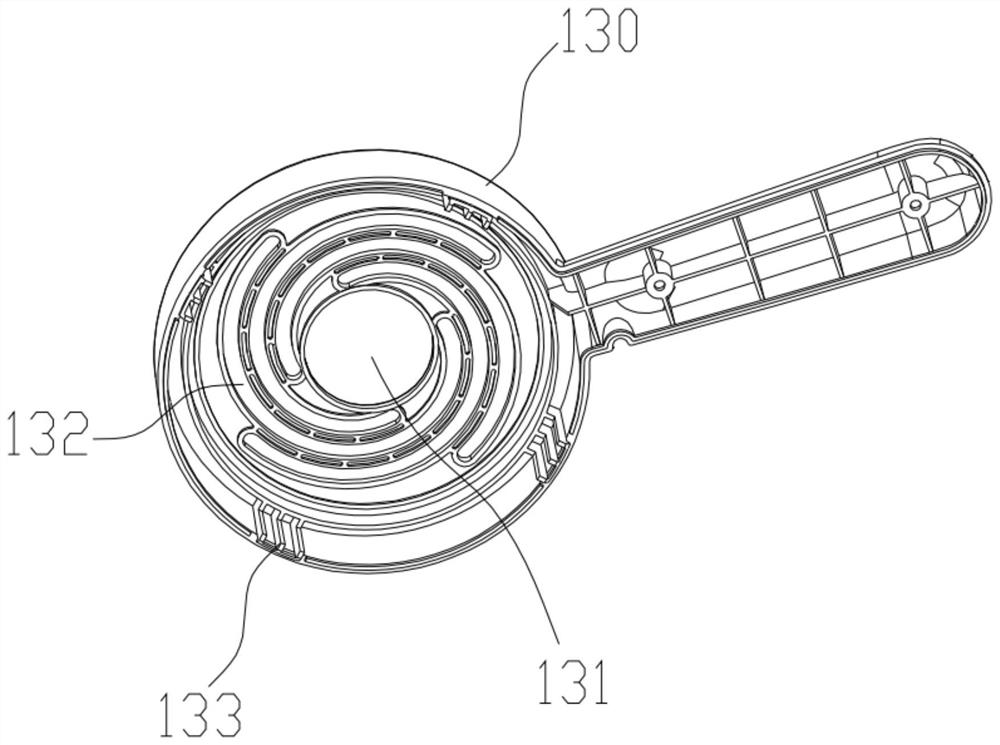

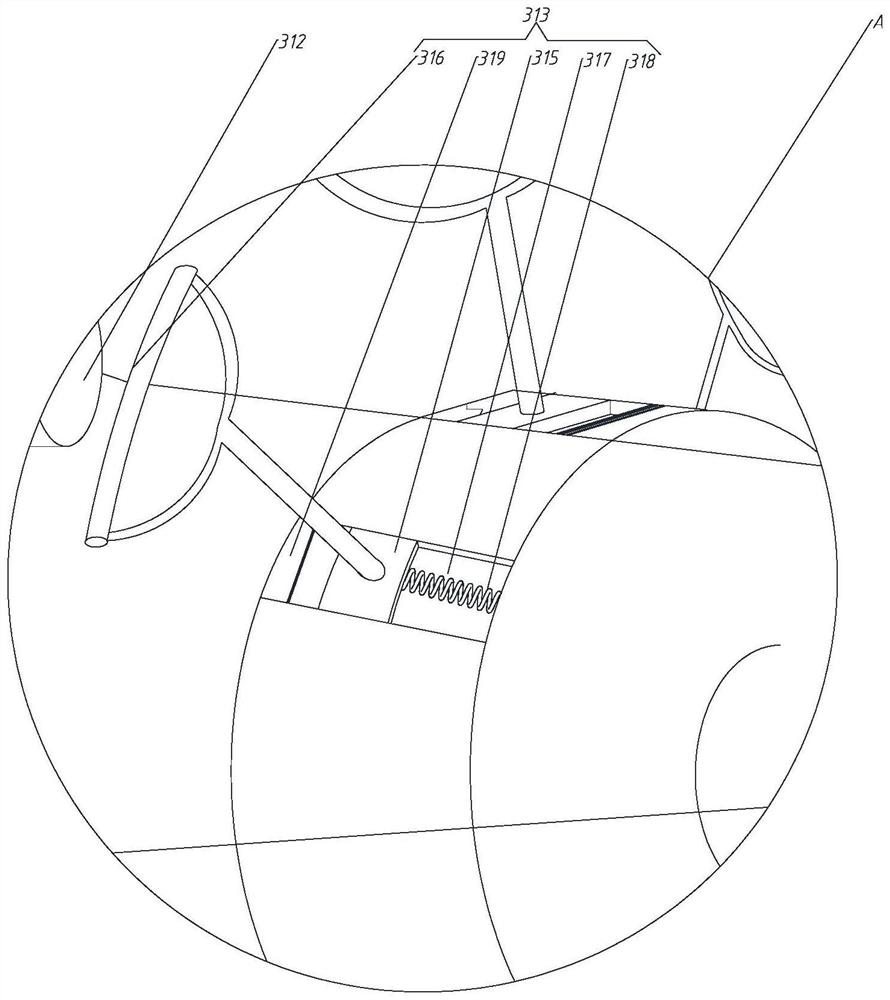

Press-holding system and press-holding method

ActiveCN111870395AAchieving a sustained gripWon't spring backHeart valvesEngineeringApparatus instruments

The invention relates to the technical field of medical instruments, and discloses a press-holding system and a press-holding method. The press-holding system comprises a valve press-holding machine,a handheld press-holding device, a conveyor, press-holding sponge and a press-holding film, wherein the valve press-holding machine is used for performing first-stage press-holding on a valve, and thehandheld press-holding device is used for performing second-stage press-holding on the valve; the press-holding sponge is used during first-stage press-holding, and adopts a cylindrical structure, and the valve is arranged in the press-holding sponge in a penetrating manner; and the press-holding film is used during second-stage press-holding, and adopts a cylindrical structure, the valve is arranged in the press-holding film in a penetrating manner after the first-stage press-holding is finished, and the handheld press-holding device is provided with a self-locking structure. According to the press-holding method, the valve press-holding machine is used for performing first-stage press-holding on the valve, and the handheld press-holding device is used for performing second-stage press-holding on the valve. The valve can be effectively prevented from being broken in the press-holding process, and the valve is prevented from rebounding after being pressed and held.

Owner:SHANGHAI NEWMED MEDICAL CO LTD

Production equipment of foam laminated packaging box blanks

Owner:汕头市万奇包装材料有限公司

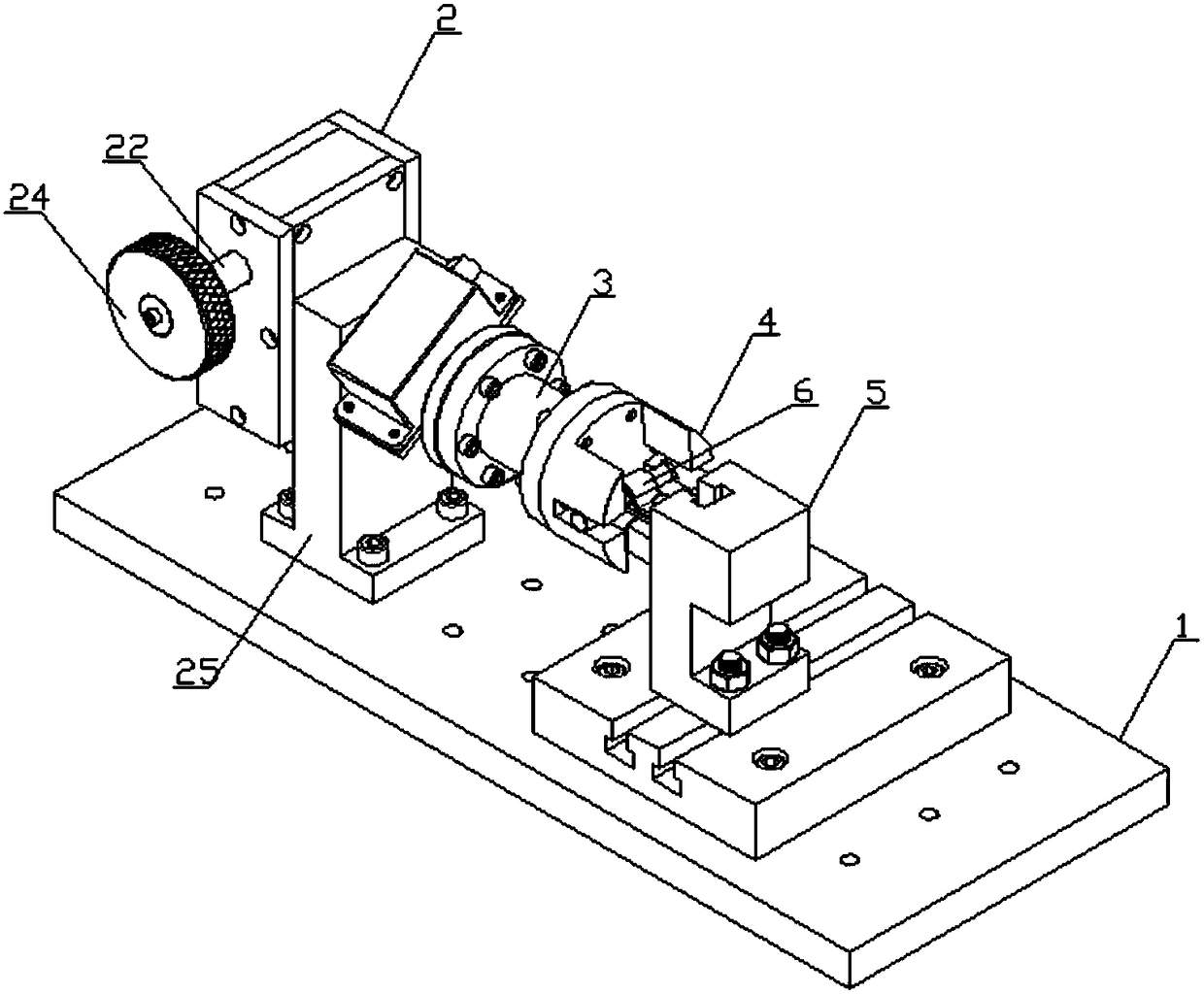

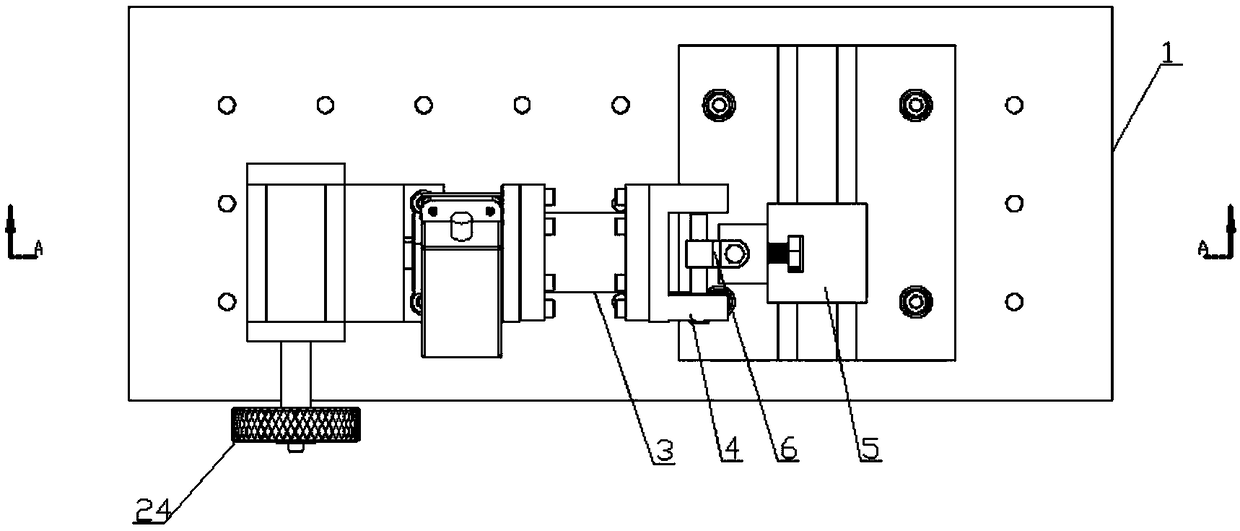

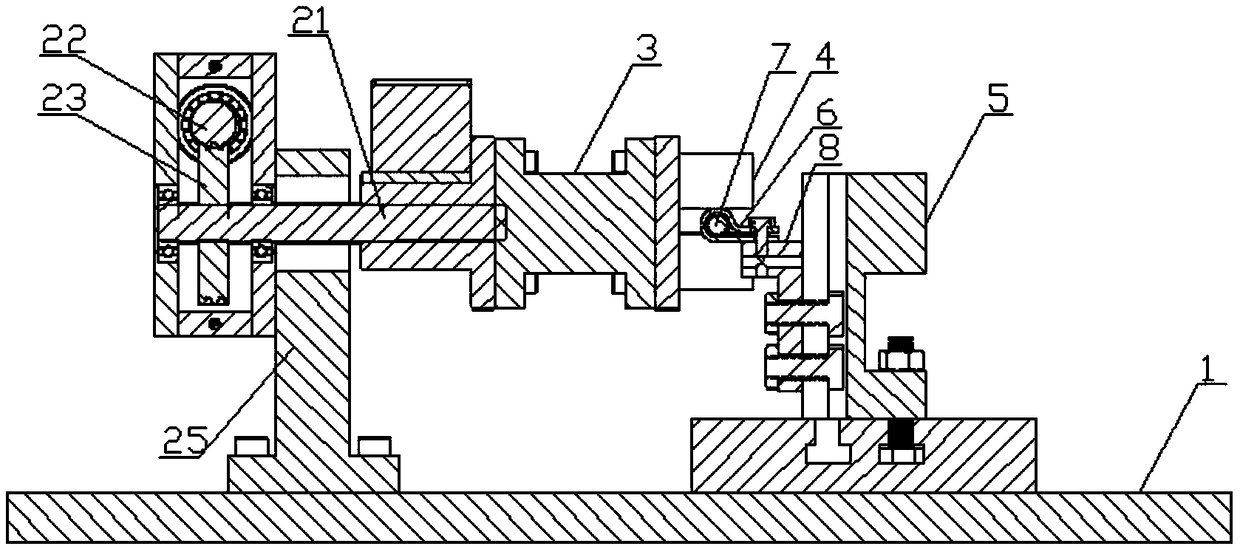

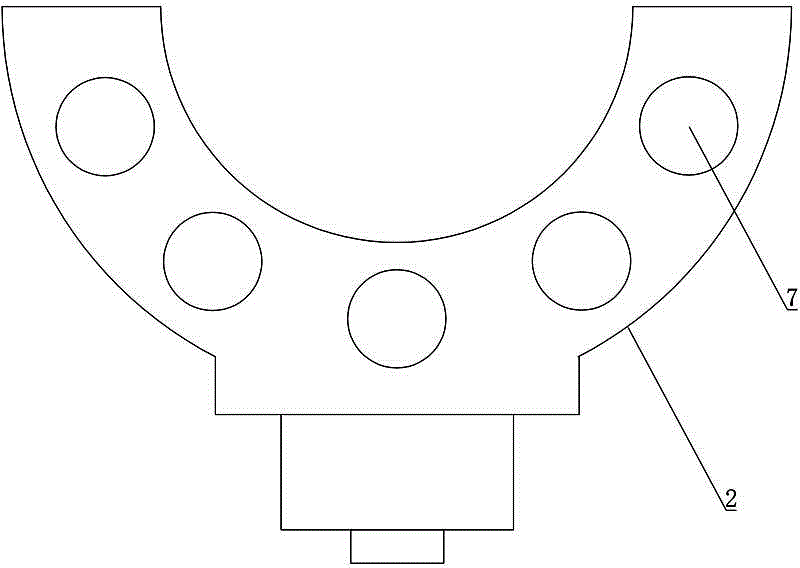

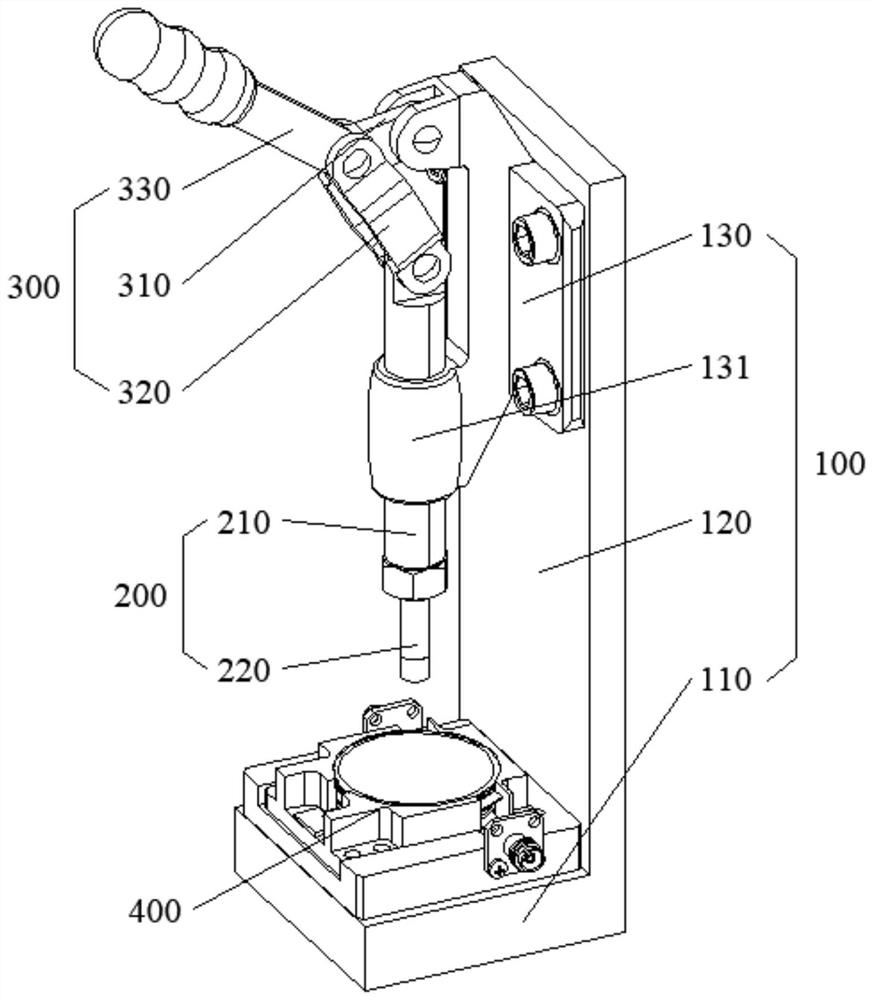

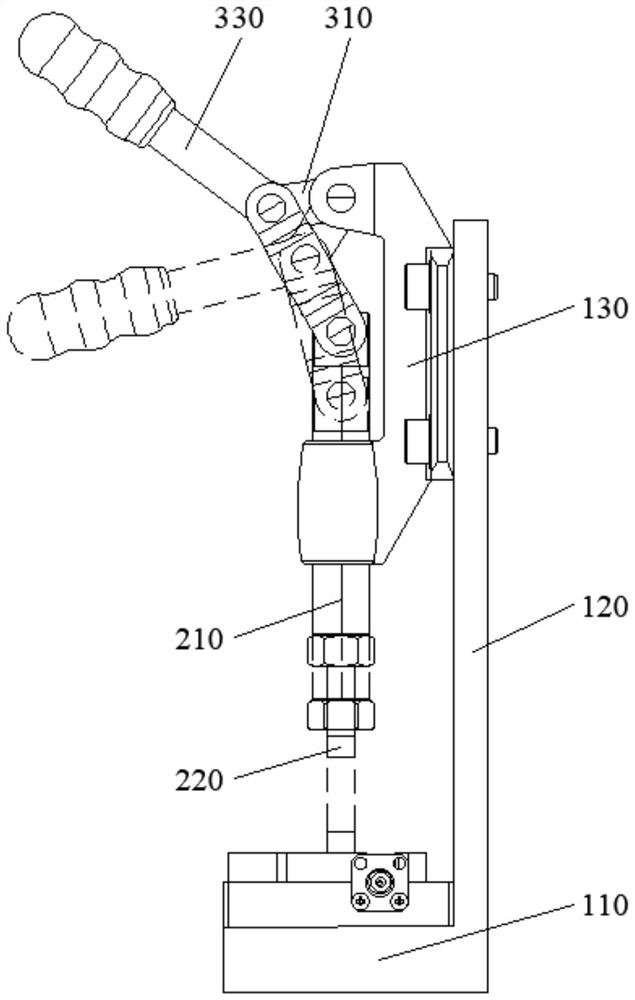

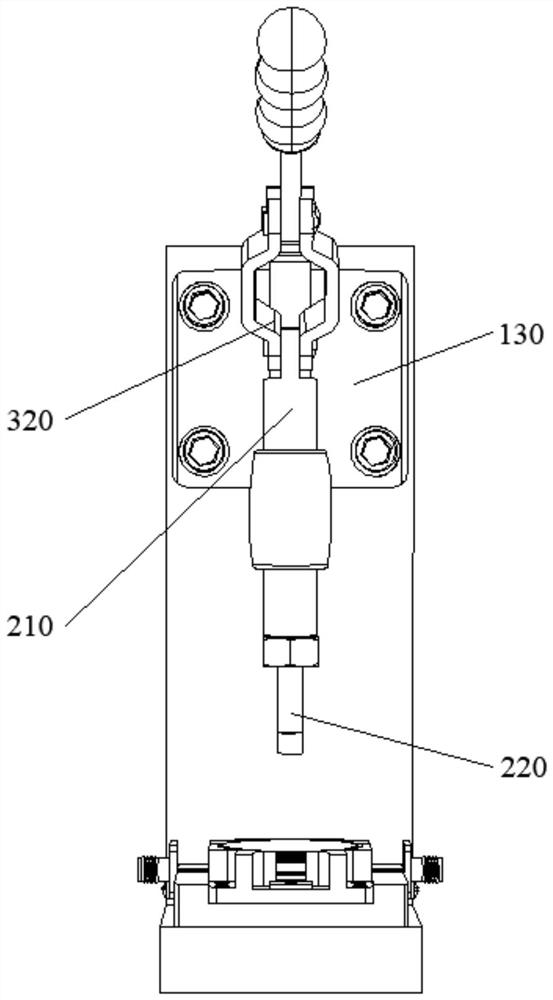

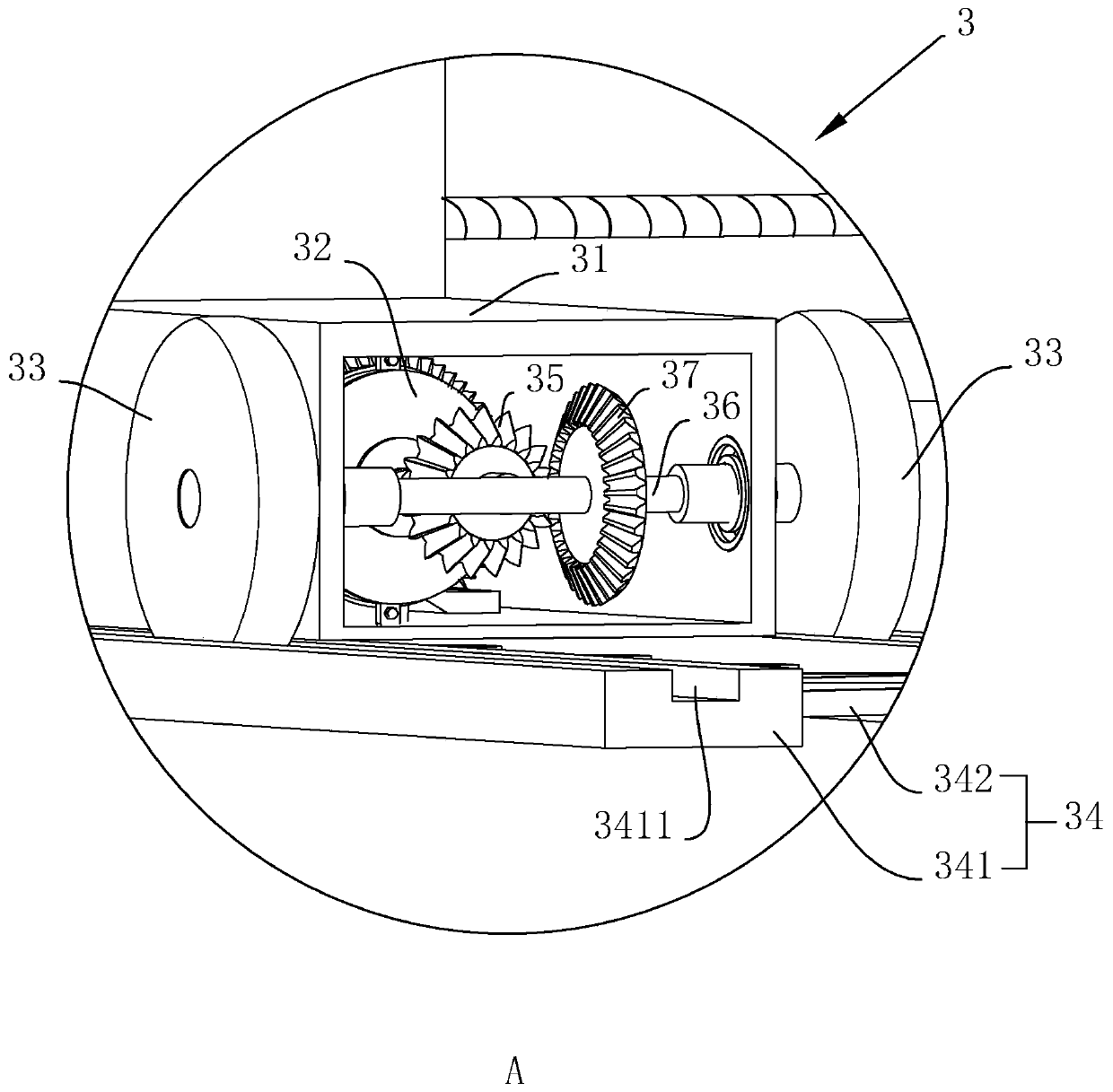

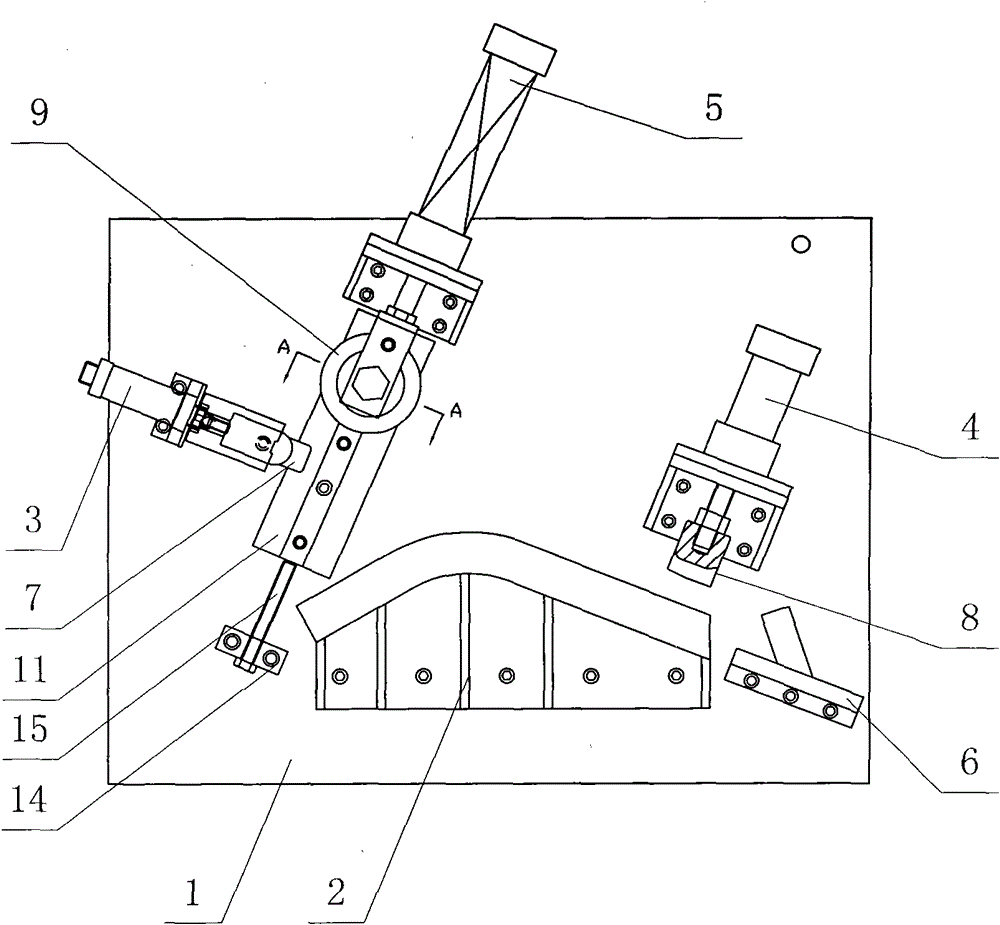

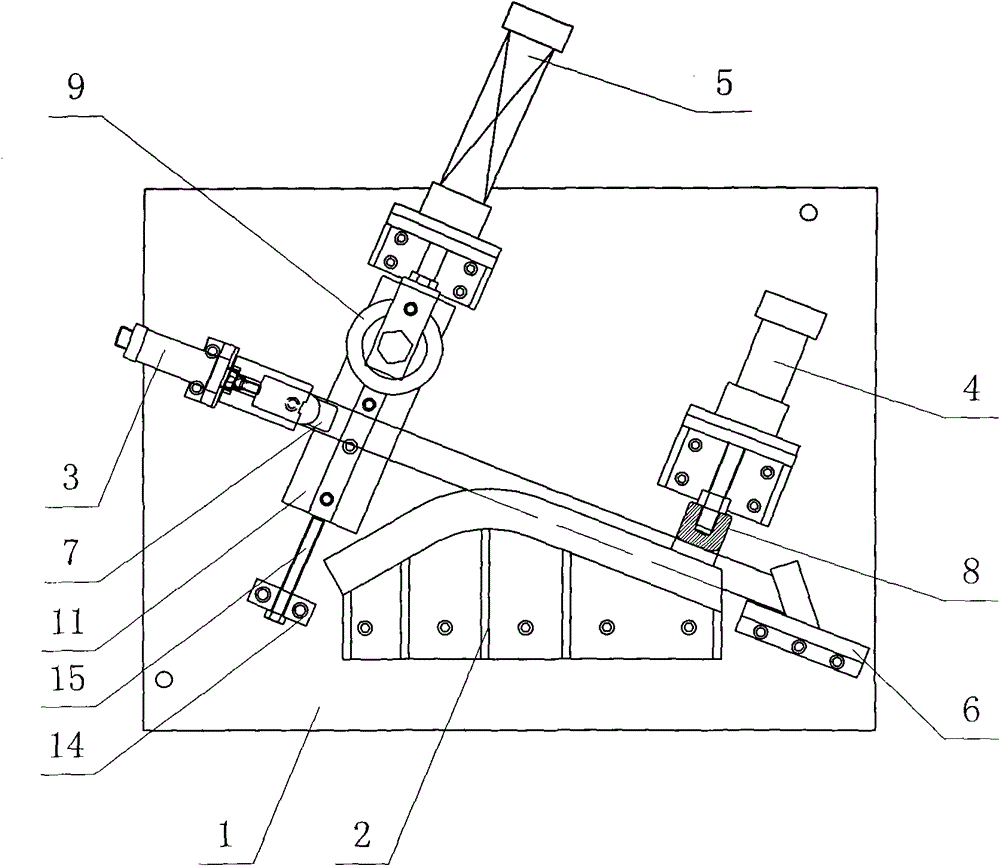

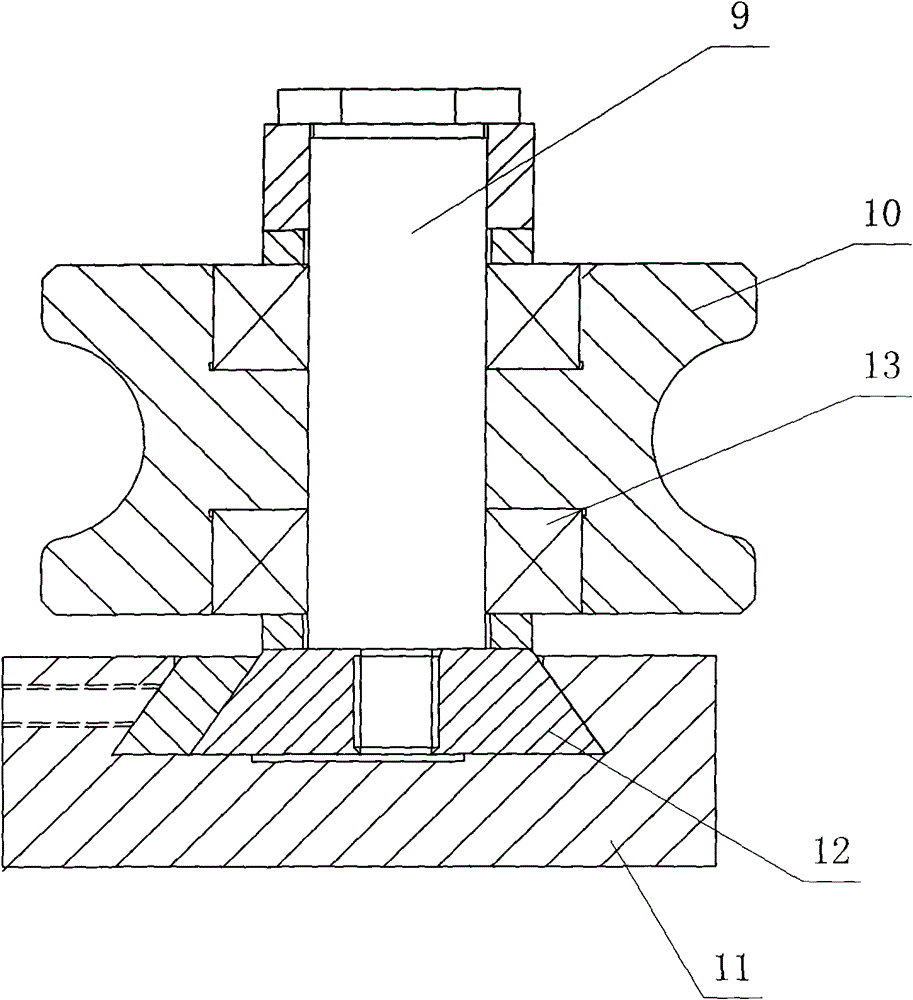

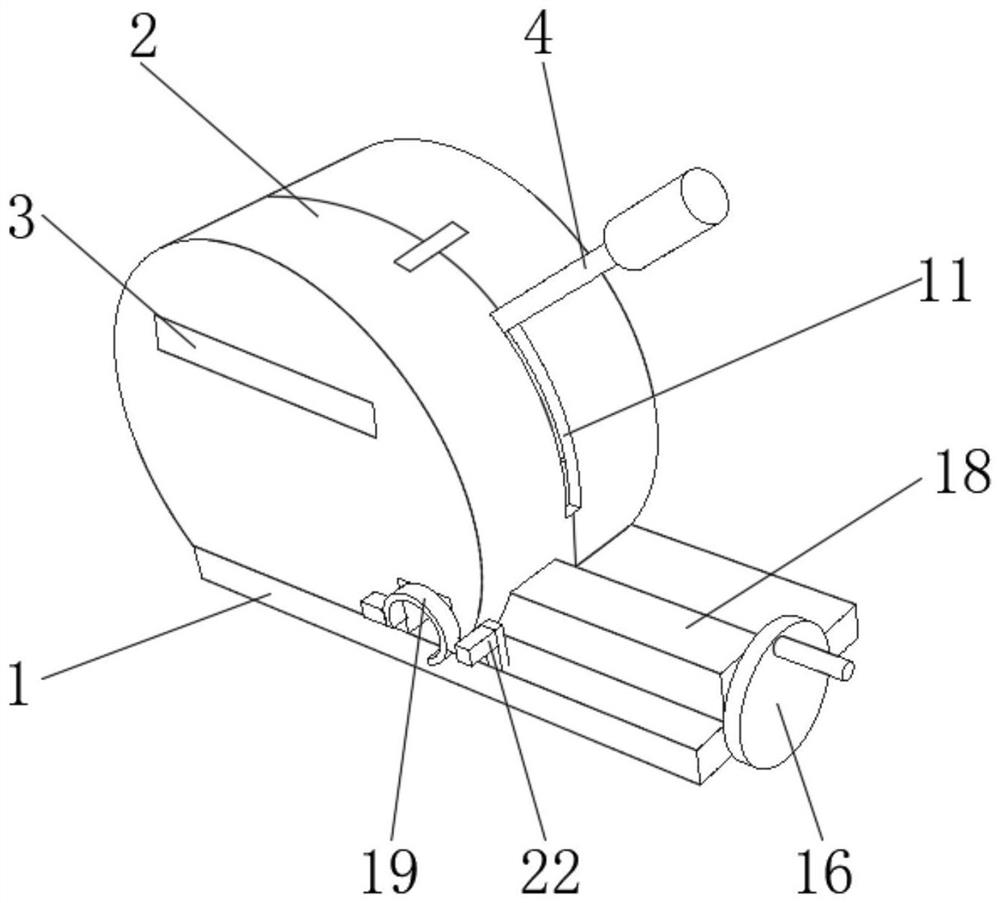

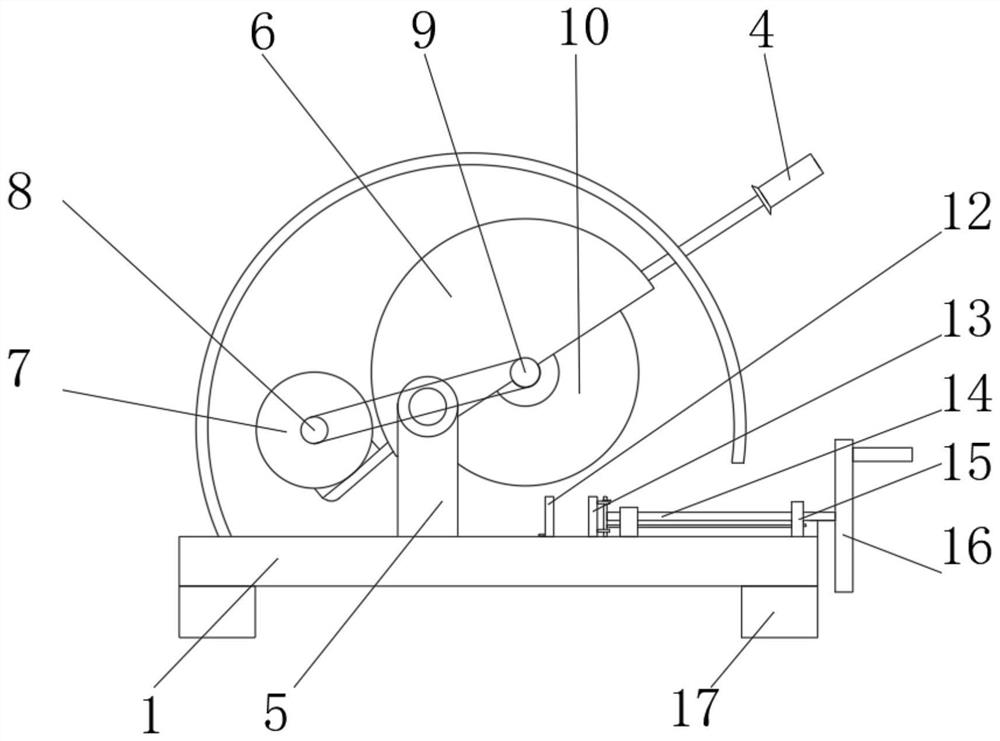

Accurate measuring device for angular rigidity of aero-engine clamp

The invention, which belongs to the technical field of test tooling, in particular relates to an accurate measuring device for the angular rigidity of an aero-engine clamp. The accurate measuring device comprises a base, a torque loading device, a torque sensor, a loading head and a clamp mounting seat; and the torque loading device and the clamp mounting seat are disposed on the base. The torqueloading device includes an output shaft, a worm, a worm wheel, and a hand wheel; the hand wheel is arranged on the worm and the worm wheel is arranged on the output shaft; the worm wheel and the wormare mutually meshed; and the two ends of the torque sensor are respectively connected with the loading head and the output shaft. According to the accurate measuring device, the torque loading deviceapplies forces to the clamp and loading is realized based on the worm wheel and the worm, so that the large-angle rotation of the operating head is ensured and small-angle deflection of the clamp is realized; the operation becomes convenient; the worm wheel and the worm can be locked by themselves; and no rebounding is caused during the loading process. And thus the running distance of the loadingrod is controlled precisely.

Owner:NORTHEASTERN UNIV

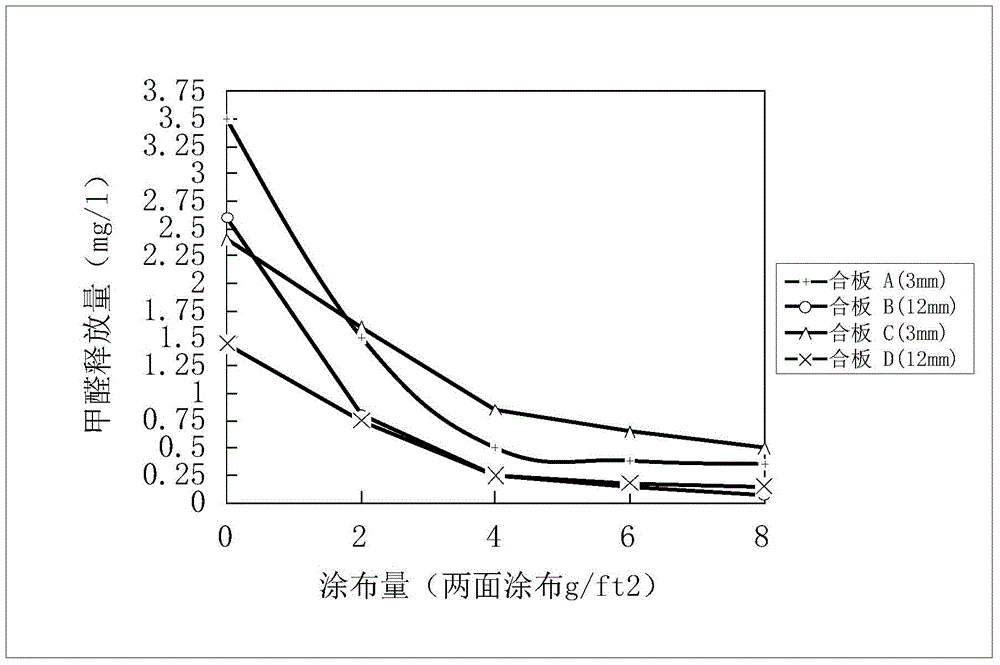

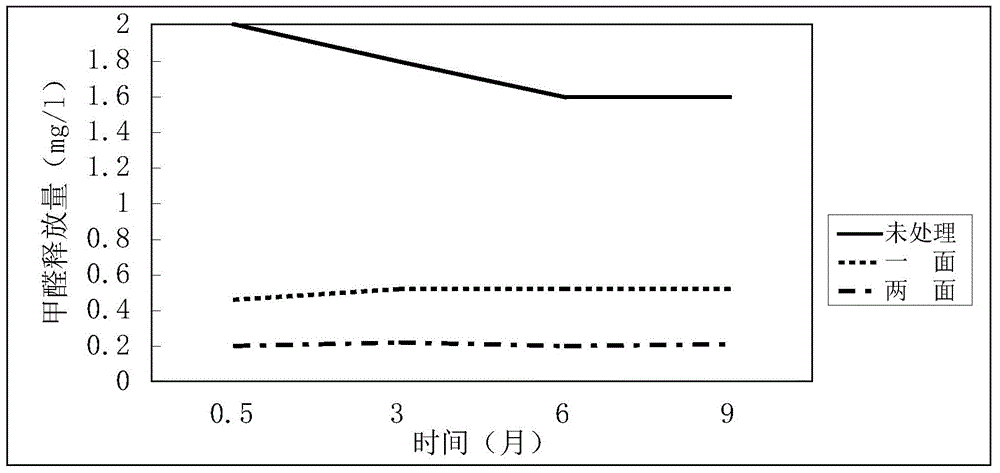

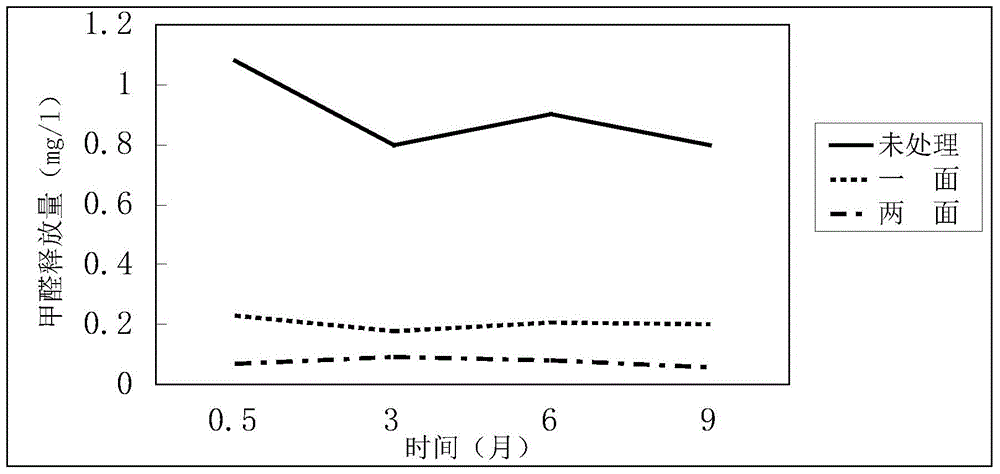

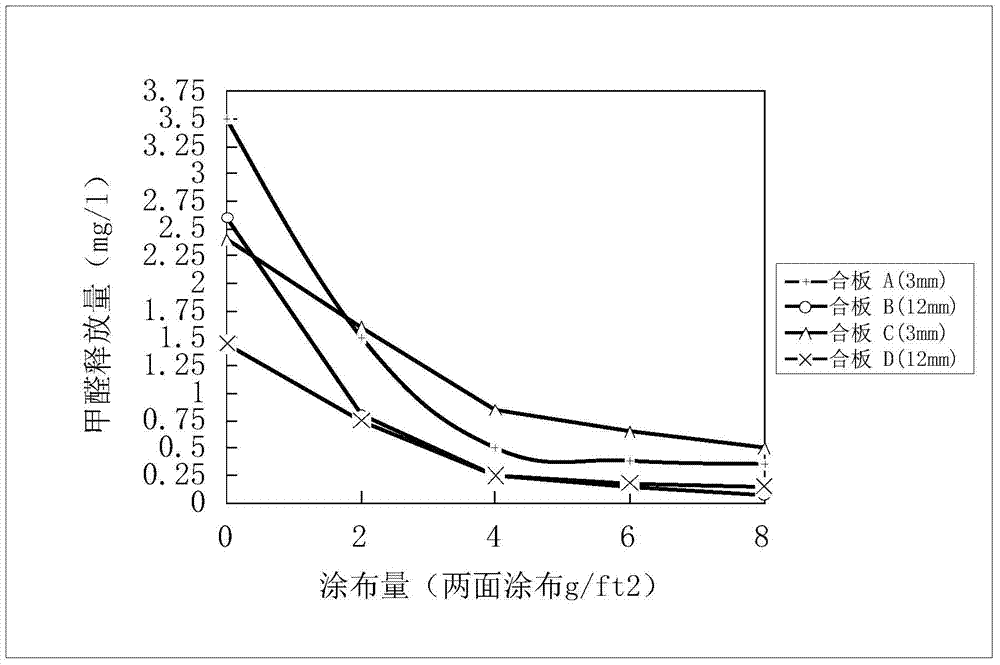

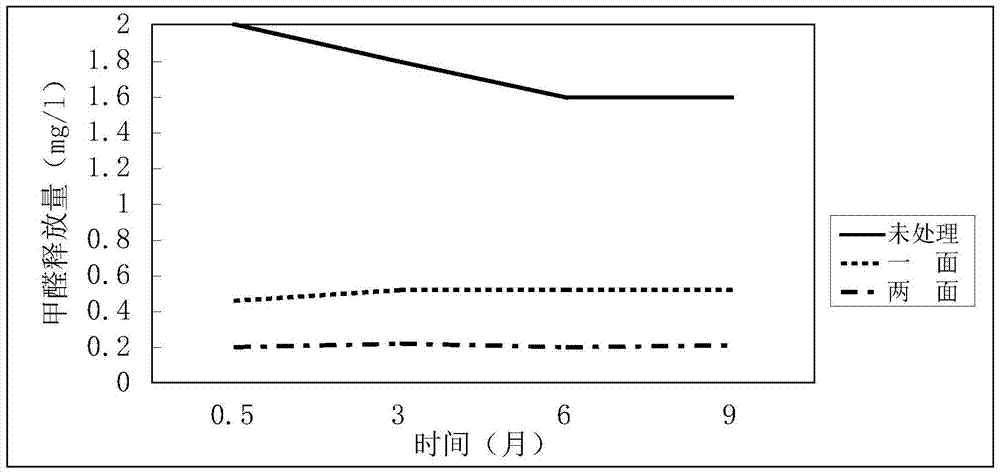

Formaldehyde elimination agent and preparation method thereof as well as adhesive, wooden product and artificial board

ActiveCN105131862ARespond completelyNo reverse reactionNon-macromolecular adhesive additivesWood treatment detailsUreaAdhesive

The invention relates to a formaldehyde elimination agent and a preparation method thereof as well as an adhesive, a wooden product and an artificial board. The formaldehyde elimination agent comprises the following ingredients in parts by weight: 64-92.9 parts of pure water, 5-20 parts of urea, 2-15 parts of hydrazide compound and 0.1-1 part of an anionic surfactant. The formaldehyde elimination agent can be added into the adhesive and can be also sprayed on the wooden product and the artificial board. The formaldehyde elimination agent has the benefits as follows: on the basis of reaction between urea and formaldehyde, the hydrazide compound is added, so that the technical effect of no reverse reaction after reaction is realized; since the anionic surfactant is added, the reaction between effective ingredients in the product and formaldehyde in the artificial board is reinforced; the pH of the formaldehyde elimination agent is 7-9, the color of the wood material is not changed after the formaldehyde elimination agent is sprayed on the wood material with a light color, and the contents of formaldehyde in the adhesive, the artificial board and the wooden product reach the national compulsorily-executed health standard level.

Owner:潘春尧

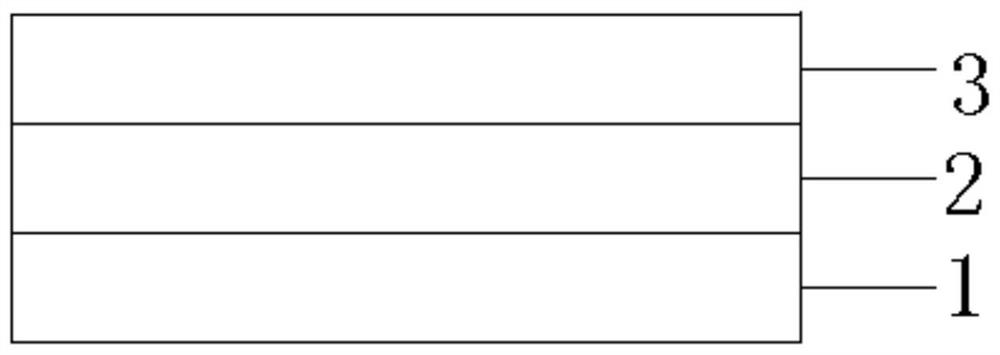

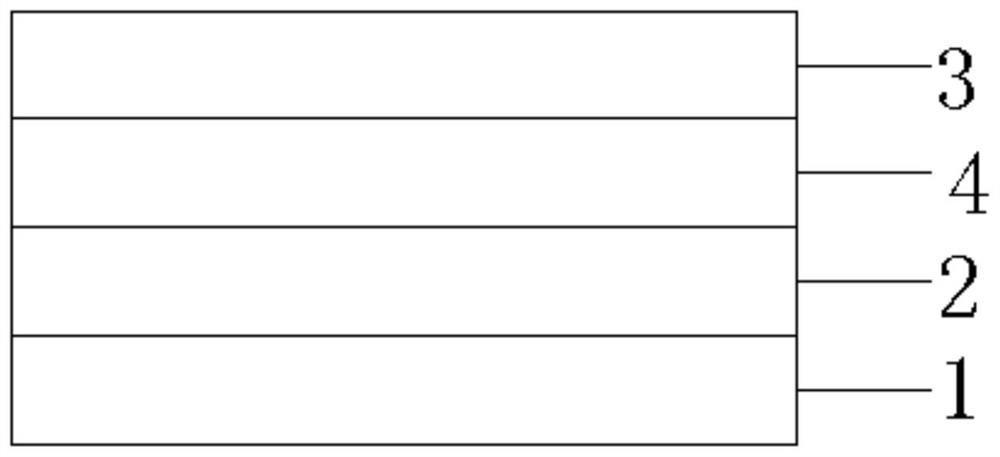

Composite material with holographic anti-counterfeiting effect and manufacturing method thereof

PendingCN113002212APrevent piracyHigh technology contentSpecial ornamental structuresInformation cardsUV curingNano structuring

The invention discloses a composite material with a holographic anti-counterfeiting effect and a manufacturing method thereof. The composite material comprises a holographic layer, a medium plating layer and a protective layer, wherein the holographic layer comprises a supporting layer and a holographic anti-counterfeiting micro-nano structure formed on the surface of the supporting layer; the transparent medium plating layer is formed on the holographic layer and covers the holographic anti-counterfeiting micro-nano structure; the protective layer is formed on the transparent medium plating layer; and the protective layer is formed by curing a UV curing coating layer and / or a thermosetting coating layer. In order to overcome the defects in the prior art and solve the problems in the prior art, the invention provides the composite material with higher physical strength and the holographic anti-counterfeiting effect and the manufacturing method thereof. The composite material is high in wear resistance and bending resistance, relatively high in anti-counterfeiting technical content level, significant in optical effect, easy to quickly identify the authenticity, and stable in product quality in long-term use. Meanwhile, the composite material with the holographic anti-counterfeiting effect is not prone to imitation, and not prone to information tampering.

Owner:SVG TECH GRP CO LTD

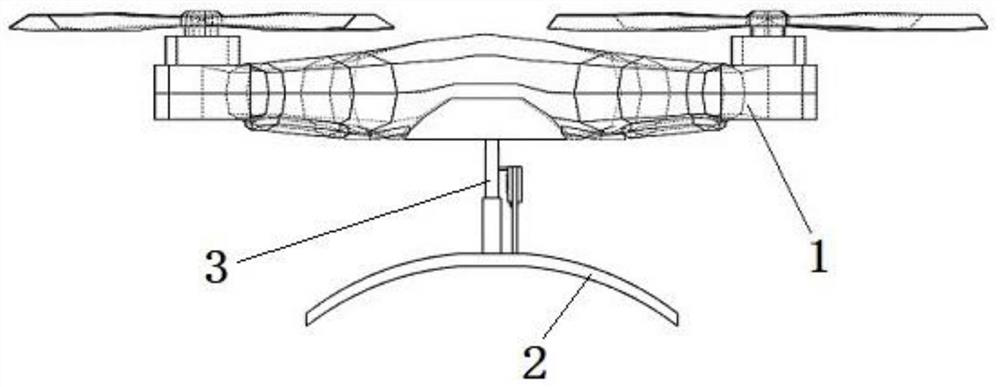

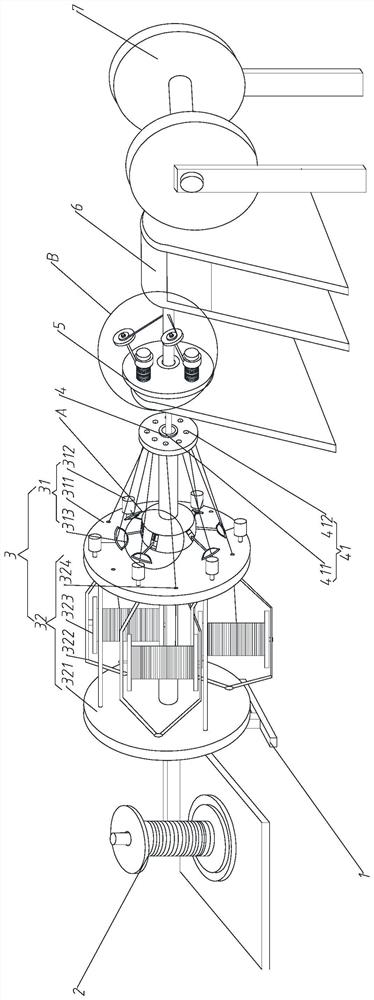

Unmanned aerial vehicle flight platform for intelligent geographic remote sensing surveying and mapping

InactiveCN111994272AImprove buffering effectWon't spring backAlighting gearAircraftsUncrewed vehicleRemote sensing

The invention relates to an unmanned aerial vehicle flight platform for intelligent geographic remote sensing surveying and mapping. The platform comprises an unmanned aerial vehicle body, a landing frame, a buffer mechanism, a bracket, a switching mechanism and a transmission mechanism. The landing frame is arranged below the unmanned aerial vehicle body. The buffering mechanism comprises a supporting column, an electromagnet, a permanent magnet and a spring. The switching mechanism comprises a power supply, an outer shell, an inner cylinder, a plurality of conductive columns, an output shaftand a plurality of blades, and the transmission mechanism is configured to transmit downward movement of the supporting column under the pushing of the unmanned aerial vehicle body to the output shaft and enable the output shaft to rotate for electric conduction. When the unmanned aerial vehicle flight platform for intelligent geographic remote sensing surveying and mapping lands, the reverse thrust repulsion intensity can be adaptively adjusted according to the descending speed of the unmanned aerial vehicle body when the unmanned aerial vehicle body lands, and the buffering effect of the unmanned aerial vehicle body during landing is improved. Preferably, the unmanned aerial vehicle body stops descending before the spring balance point, and at the moment, even if the repulsive force ofthe electromagnet is removed, the unmanned aerial vehicle body cannot rebound.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

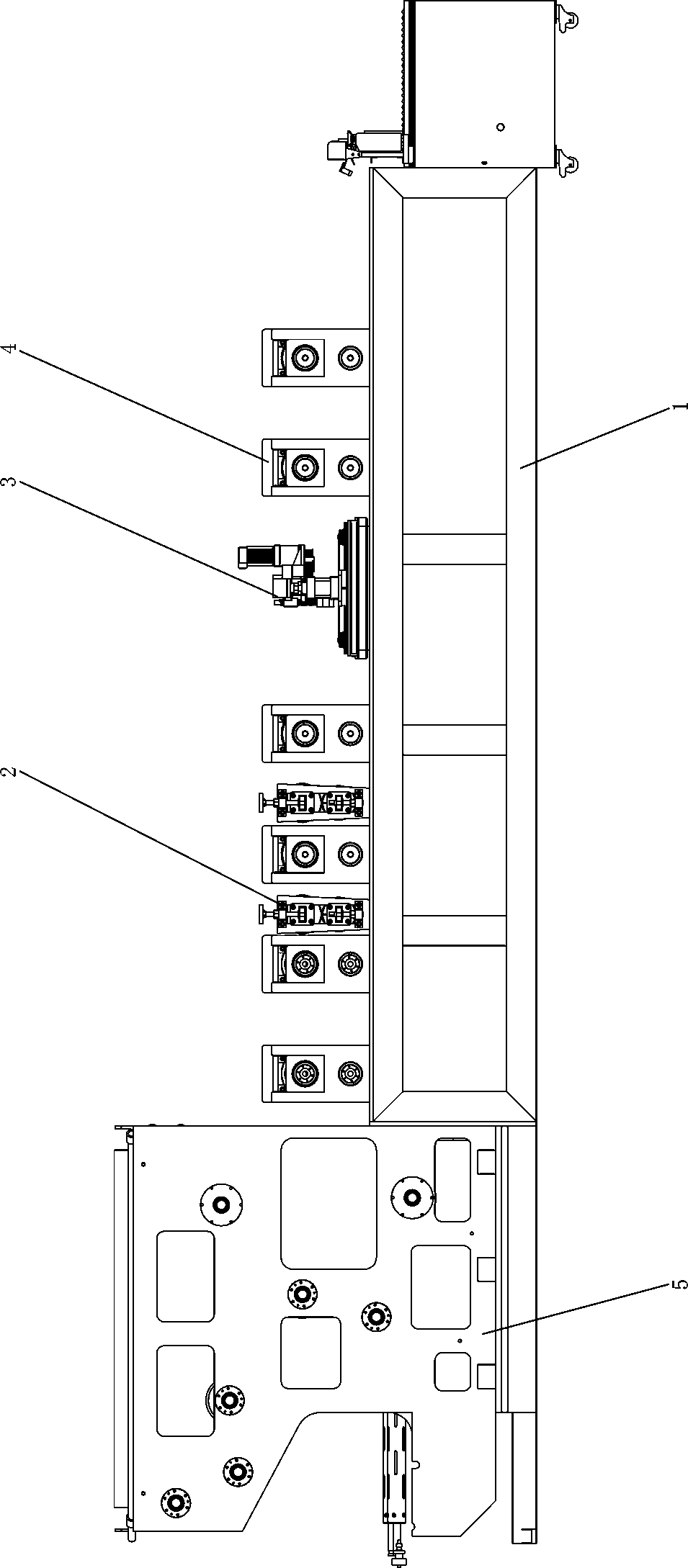

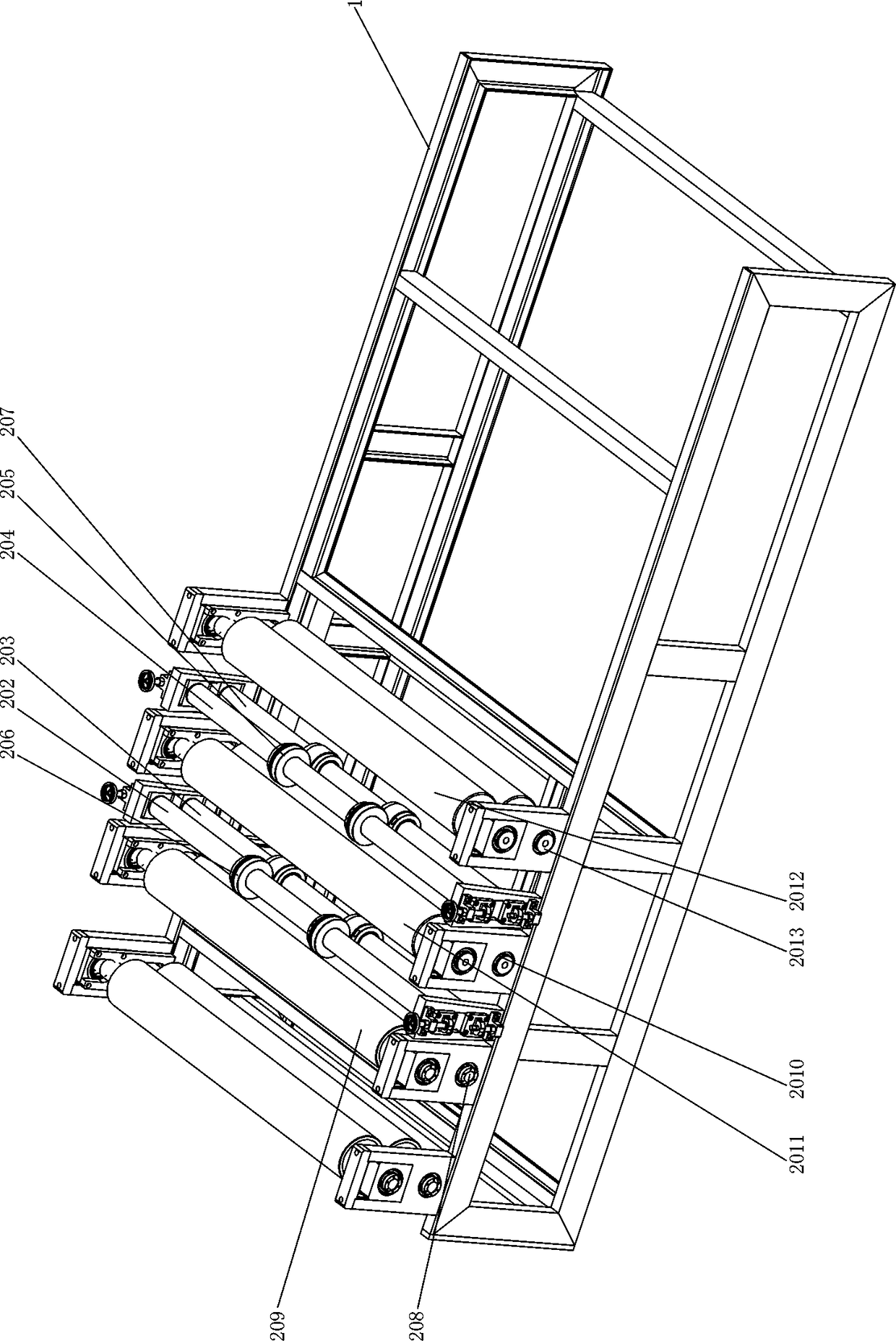

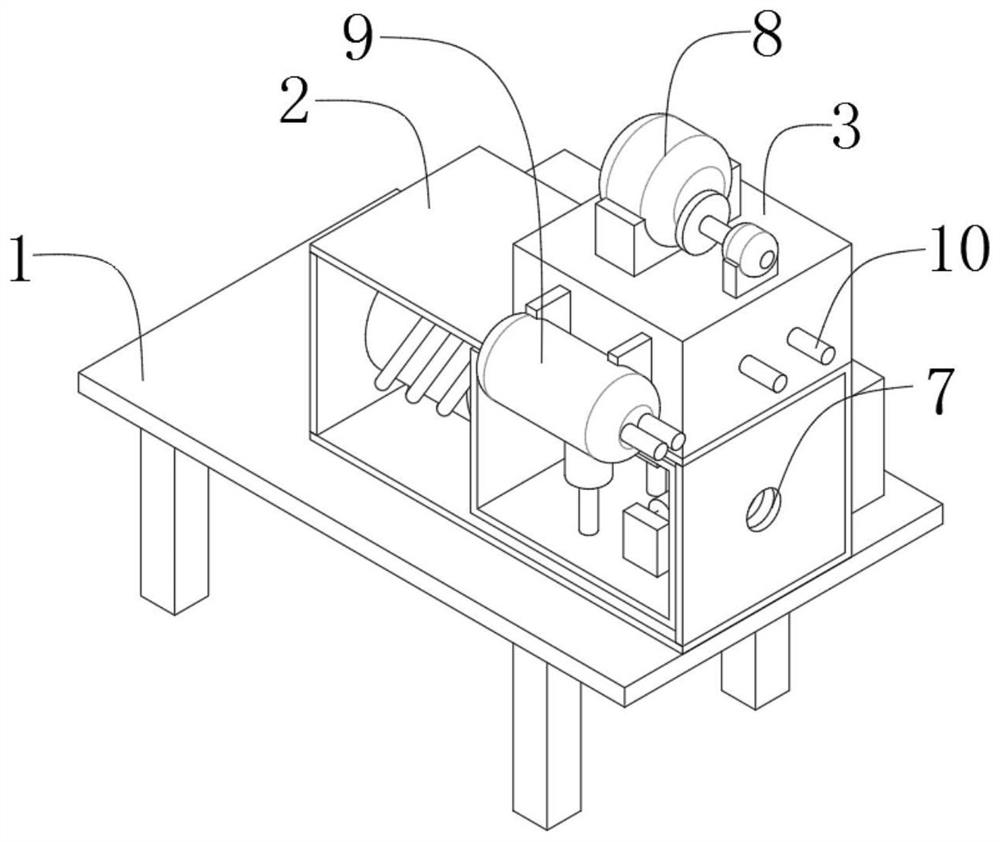

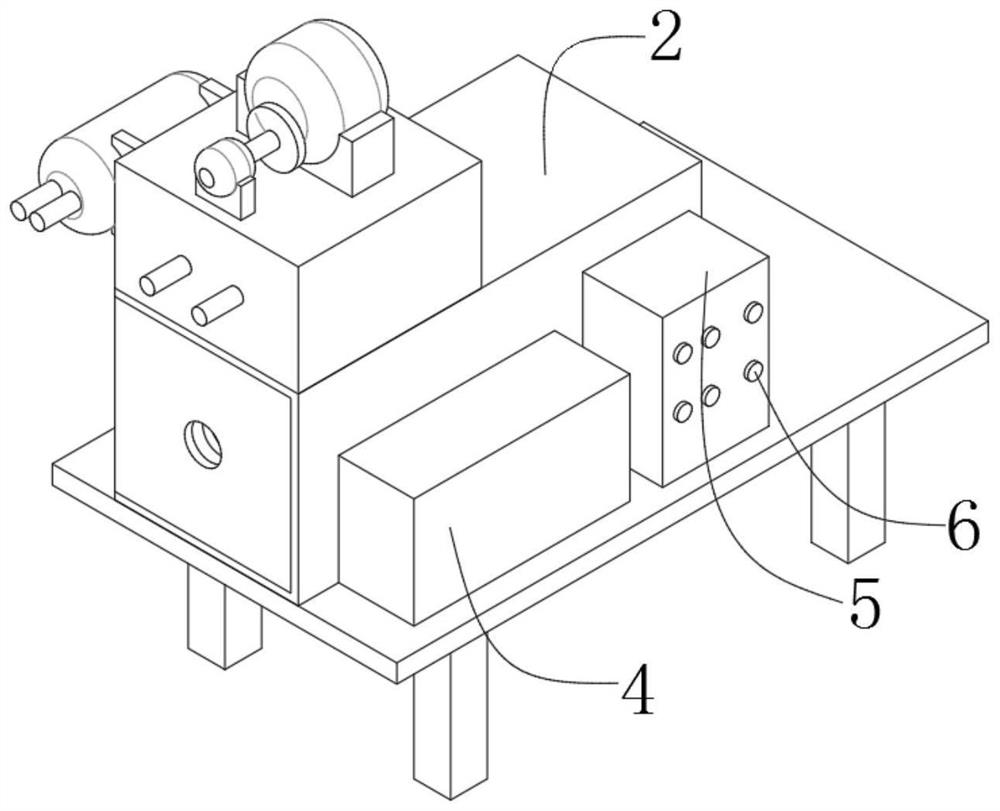

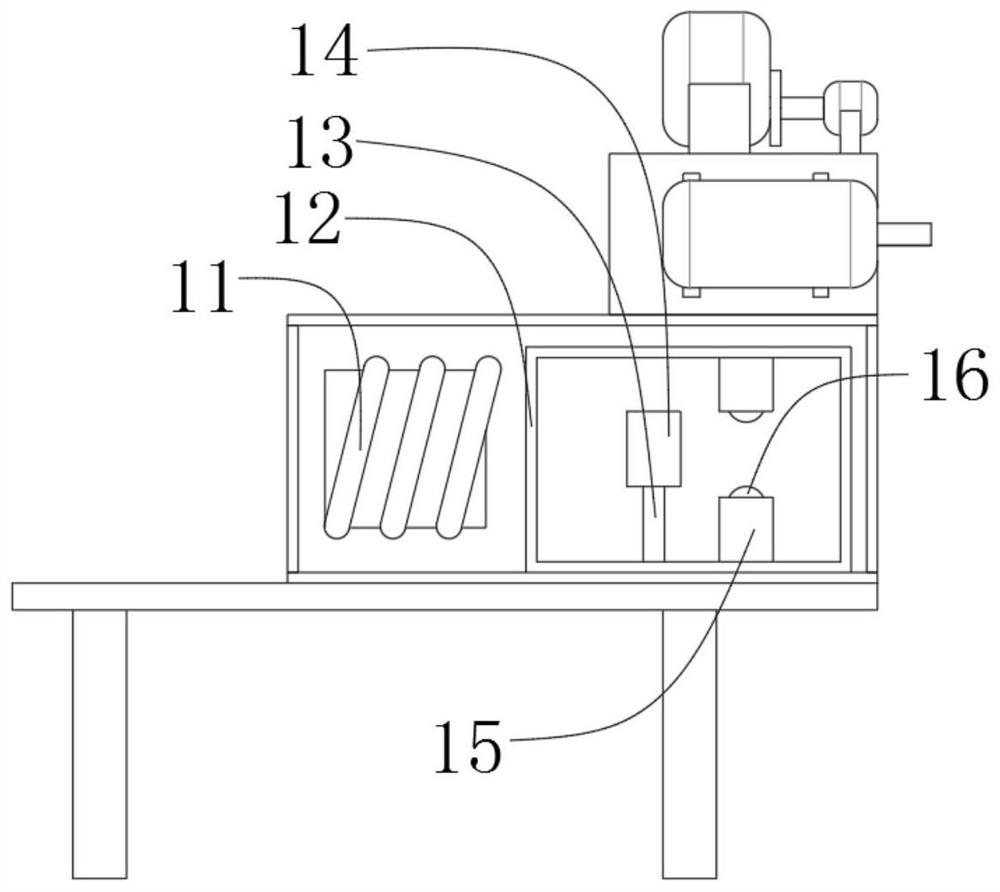

Straightening device for aluminum profile machining

InactiveCN112775214AWon't spring backImprove straightening effectShaping toolsMetal-working feeding devicesElectric machineryEngineering

The invention discloses a straightening device for aluminum profile machining, and belongs to the technical field of aluminum profile machining. The straightening device for aluminum profile machining comprises a workbench, a straightening box and a mounting box, wherein the straightening box is fixedly installed on the upper surface of the workbench; the mounting box is fixedly installed on the upper surface of the straightening box; a motor is fixedly installed on the upper surface of the mounting box; a liquid cooling tank is fixedly installed on the front end face of the mounting box; a distribution box and a control box are fixedly installed on the upper surface of the workbench; an electromagnetic heating coil is fixedly installed on the rear end face in the straightening box; and a straightening bin is fixedly installed on the lower surface in the straightening box. According to the straightening device for aluminum profile machining provided by the invention, by arranging the electromagnetic heating coil, an aluminum profile is heated before being straightened, so that the aluminum profile is softened to a certain degree, the elasticity of the aluminum profile is damaged, the straightened aluminum profile does not rebound, multiple sets of straightening rollers do not need to be arranged for continuous extrusion, the straightening effect is better, and meanwhile, the occupied area is smaller.

Owner:广东华昌集团有限公司

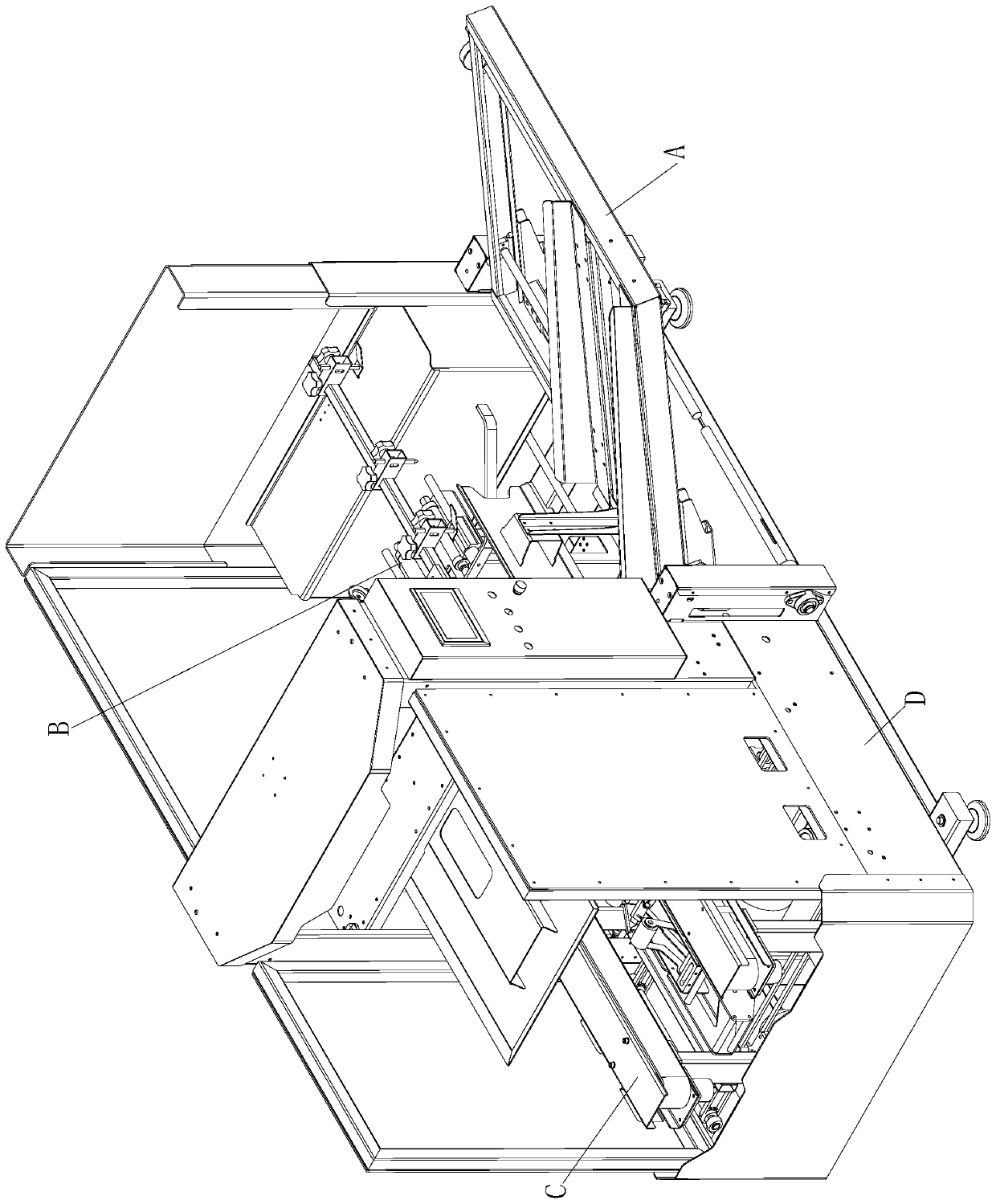

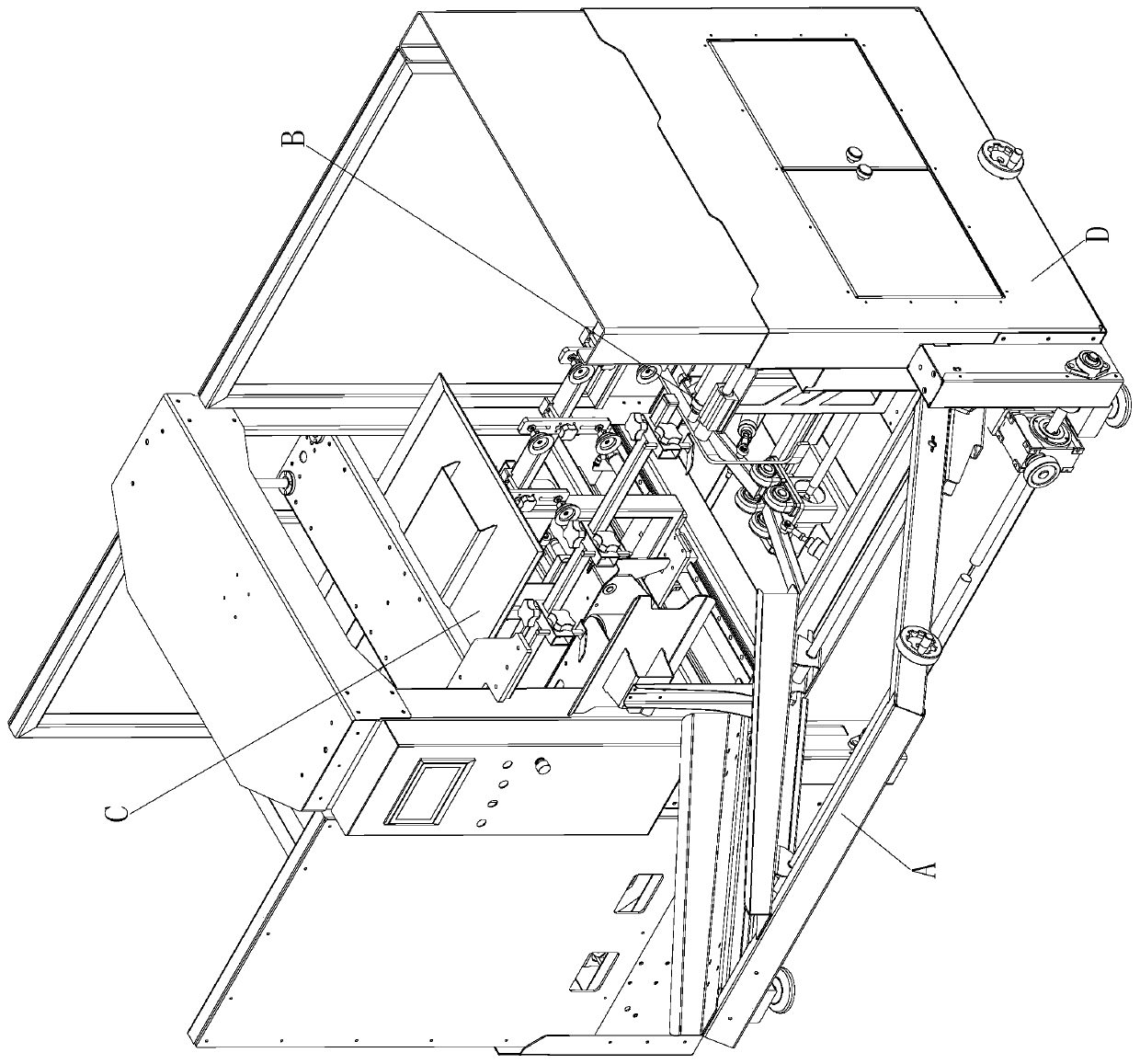

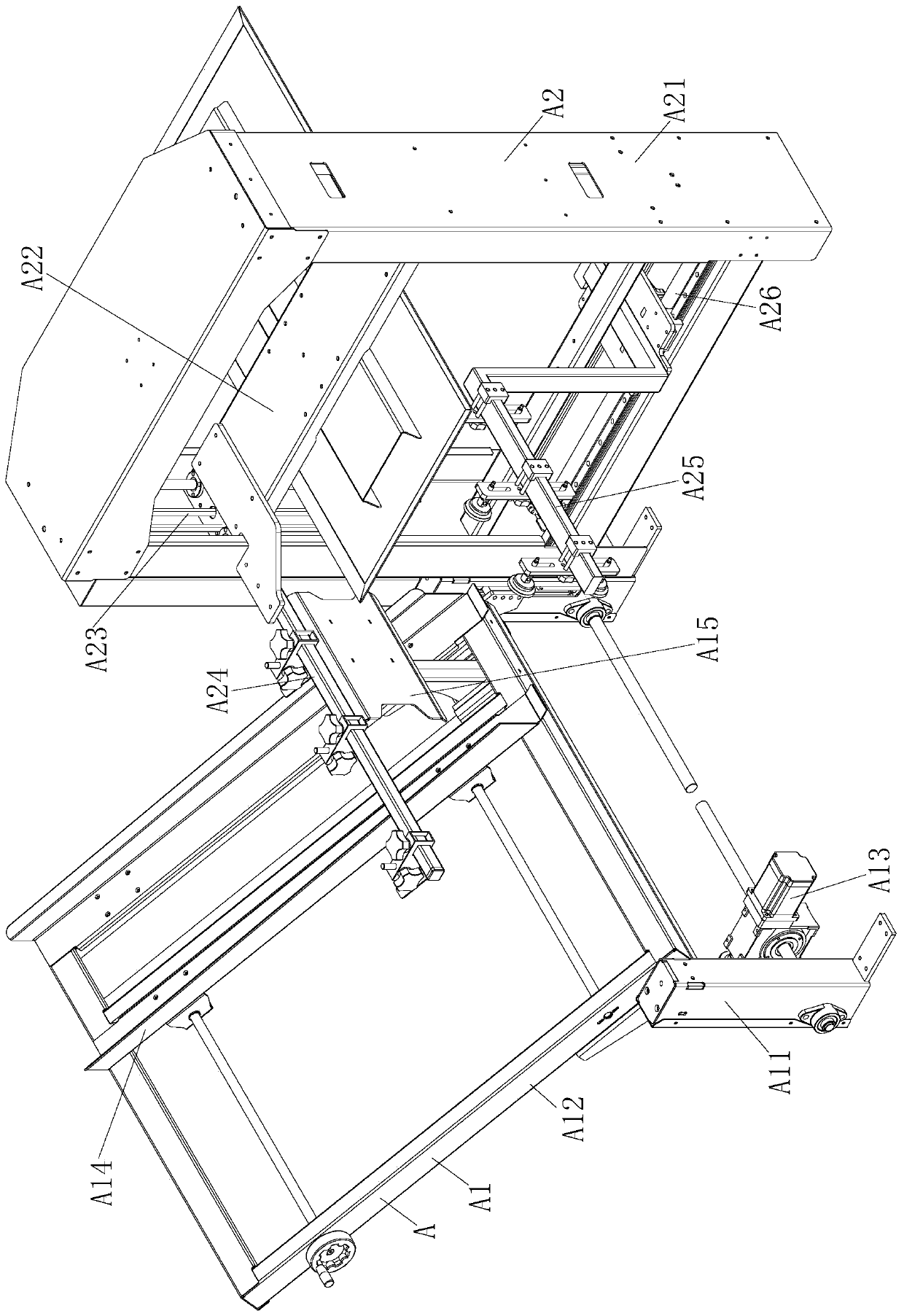

Automatic box-opening and bottom-sealing machine

The invention relates to an automatic box-opening and bottom-sealing machine, and belongs to the field of mechanical equipment. The equipment comprises a storage feeding device, a bottom-closing pushing device, a bottom-sealing discharging device and an equipment rack, the storage feeding device comprises a bracket assembly and a feeding assembly, the bracket assembly is matched with the feeding assembly, the bottom-closing pushing device comprises a bottom-closing assembly and a pushing assembly, the bottom-closing assembly is matched with the pushing assembly, the bottom-sealing dischargingdevice comprises a conveying assembly and a bottom-sealing assembly, and the conveying assembly is matched with the bottom-sealing assembly. The automatic box-opening and bottom-sealing machine can replace manual operation to seal the bottom of a paper box, the investment of labor cost is reduced, and the working efficiency is improved.

Owner:杭州申佳包装设备有限公司

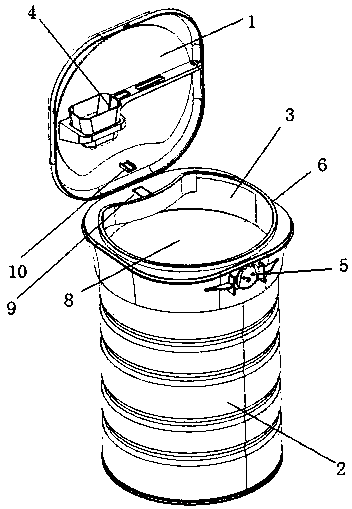

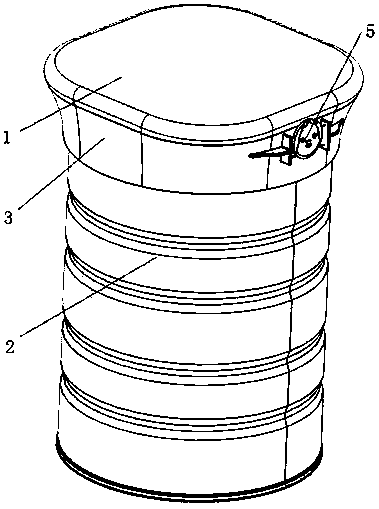

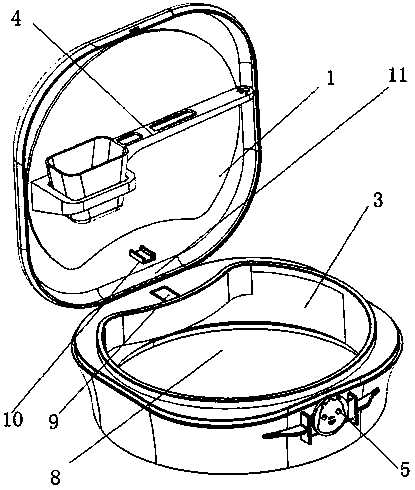

Multifunctional pot cover

PendingCN108016731AEasy to operateEasy to closeClosure with auxillary devicesNon-removalbe lids/coversEngineering

Owner:深圳市禾意创智包装设计有限公司

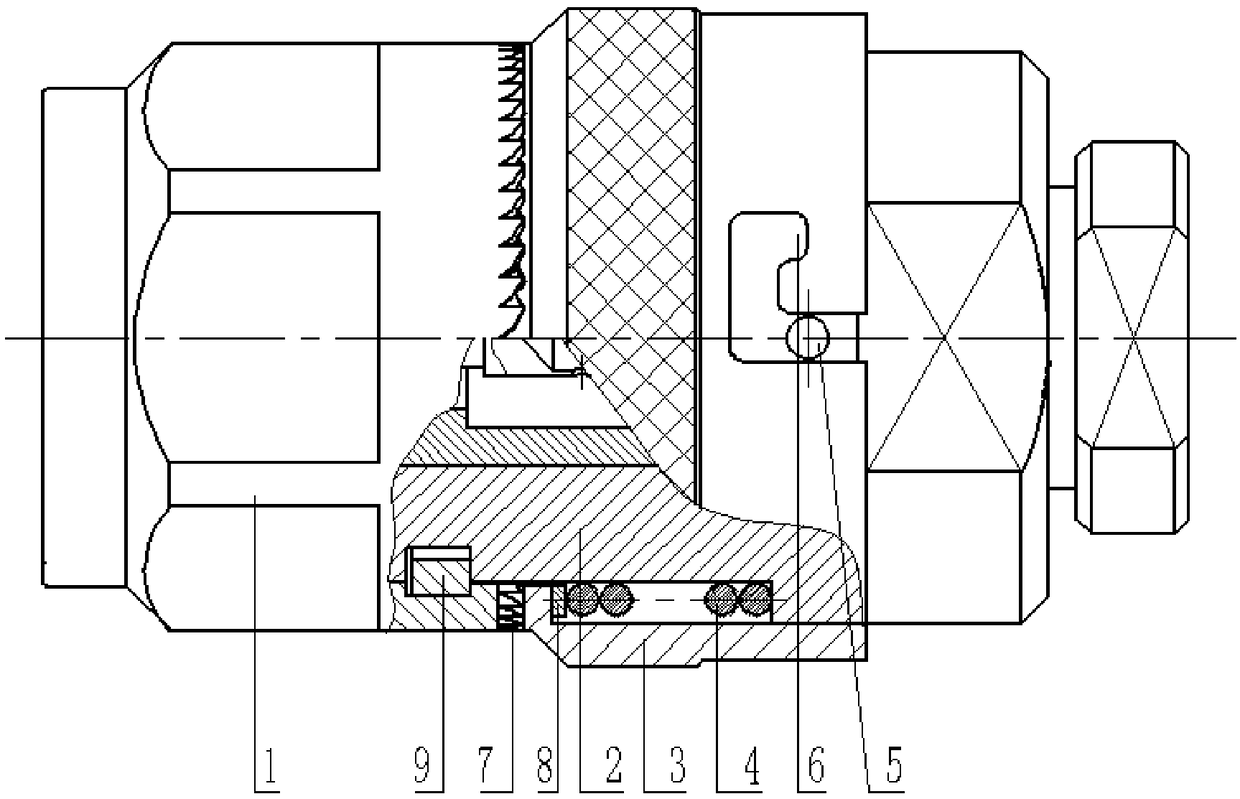

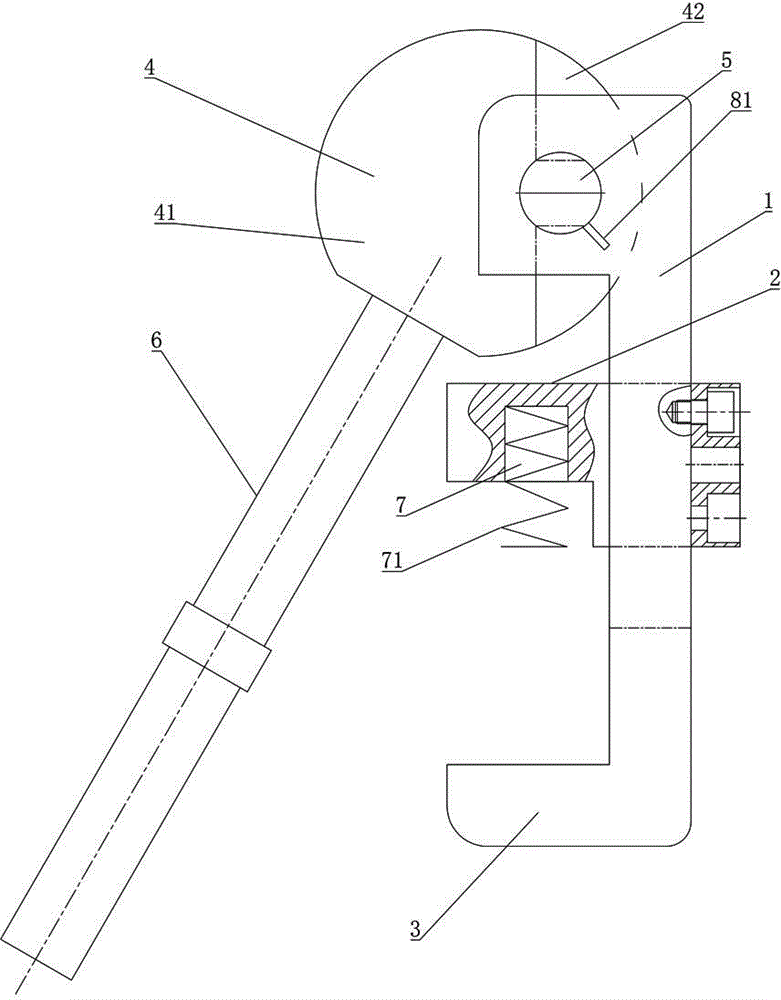

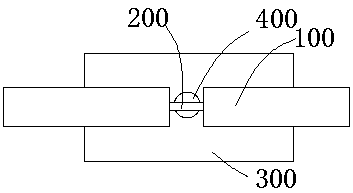

An external self-locking structure of a connector

PendingCN109066180AGuaranteed mesh stabilityIncrease contactEngagement/disengagement of coupling partsSelf lockingScrew thread

An external self-locking structure of a connector is disclosed. A housing connecting sleeve with an engaging groove sleeves the outer side of the housing, and a hanging pin groove is arrange on the connecting sleeve of the case to match with the hanging pin on the case so as to limit the circumferential position of the connecting sleeve of the case, the engagement groove of the housing connectingsleeve and the engagement teeth on the screw sleeve are engaged and locked, pressure is applied by means of a spring, so as to ensure the meshing stability of the housing connecting sleeve and the screw sleeve, Screw down the threaded sleeve, After tightening, and then pushing the hanging pin on the connector housing into the hanging pin slot through the spring in the housing, The sawtooth are fully engaged with the locked design, ensuring good contact of the inner center contact, After the external connection is locked, the sawtooth meshes tightly in the high-frequency vibration process, andthe hanging pin does not spring back in the hanging pin groove. The device has the advantages of simple structure, simple and convenient installation, saves installation space, and solves the problemof instantaneous breakage of microwave signal caused by poor internal contact caused by loose screw thread in the high-frequency vibration process.

Owner:CHANGZHOU WUJIN FENGSHI COMM EQUIP

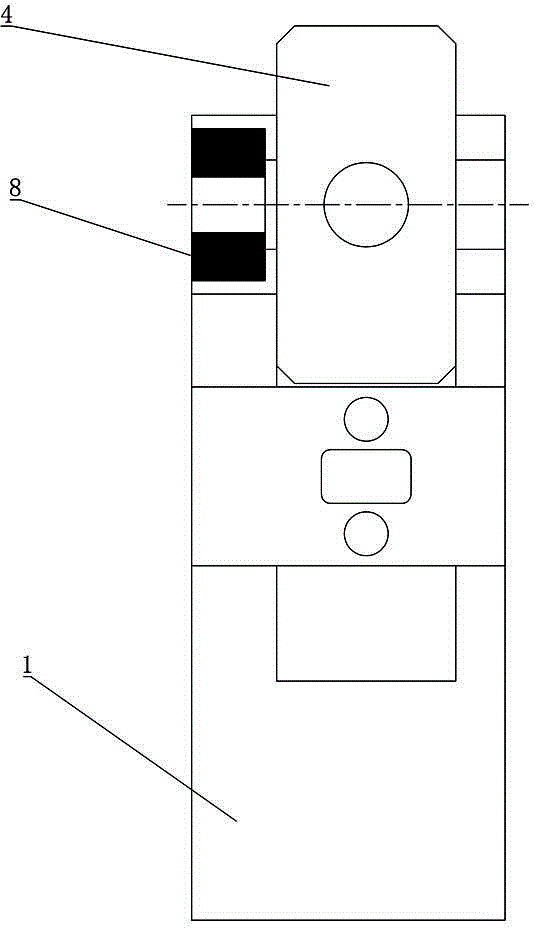

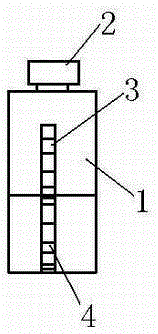

Circuit breaker gas-taking auxiliary device

ActiveCN105304397AEasy accessSimple structureHigh-tension/heavy-dress switchesAir-break switchesEngineeringCam

The invention discloses a circuit breaker gas-taking auxiliary device. The device comprises a rack, the rack is provided with a press block capable of sliding up and down along the rack, a cushion block matched with the press block is fixedly arranged on the bottom end of the rack, the top end of the rack is provided with a rotatable cam, when the cam rotates, the contour line of the cam is contacted with the press block and the cam drives the press block to slide up and down along the rack. The device disclosed by the invention has the advantages of being simple in structure, convenient and fast in operation and good in clamping effect.

Owner:STATE GRID CORP OF CHINA +2

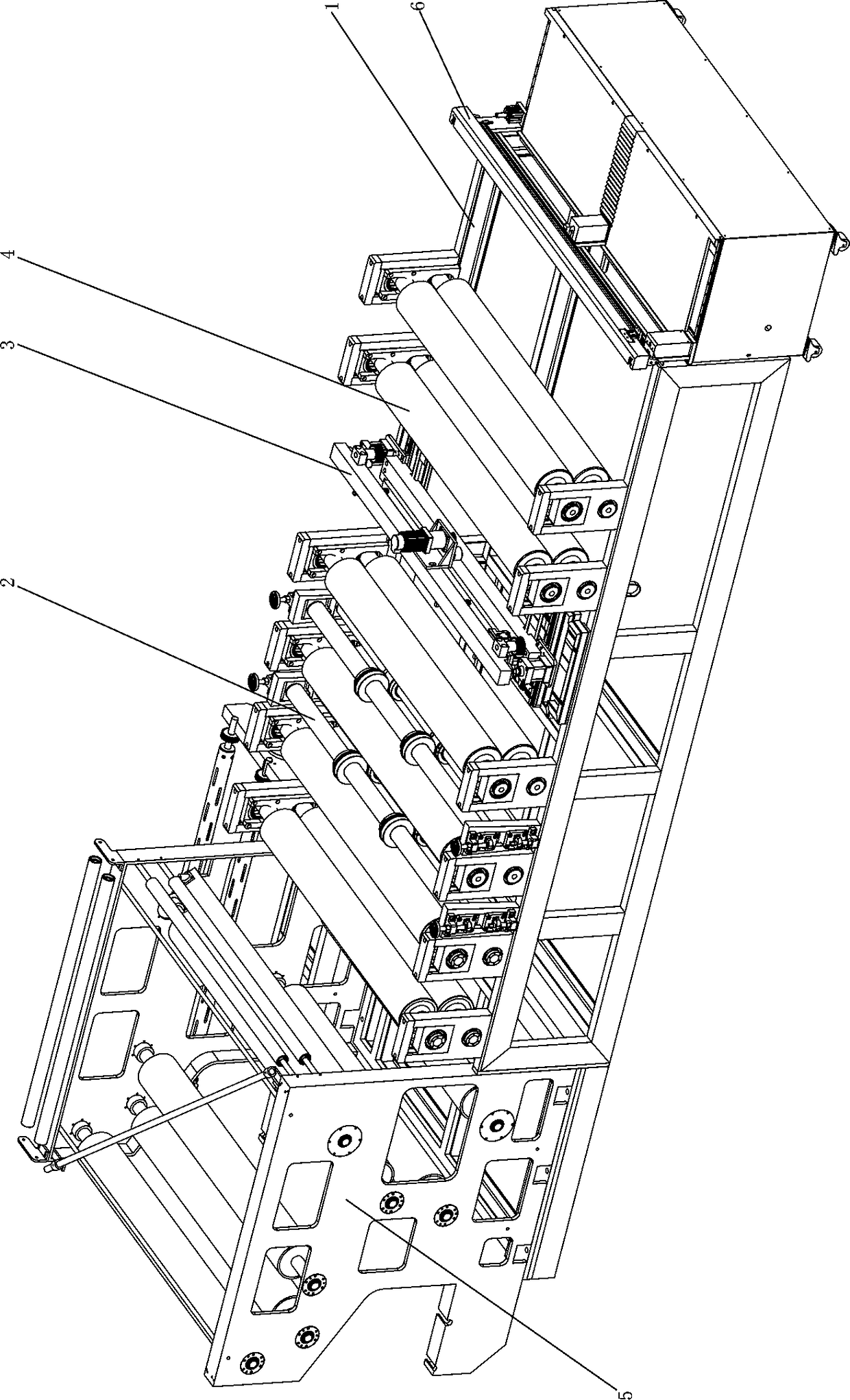

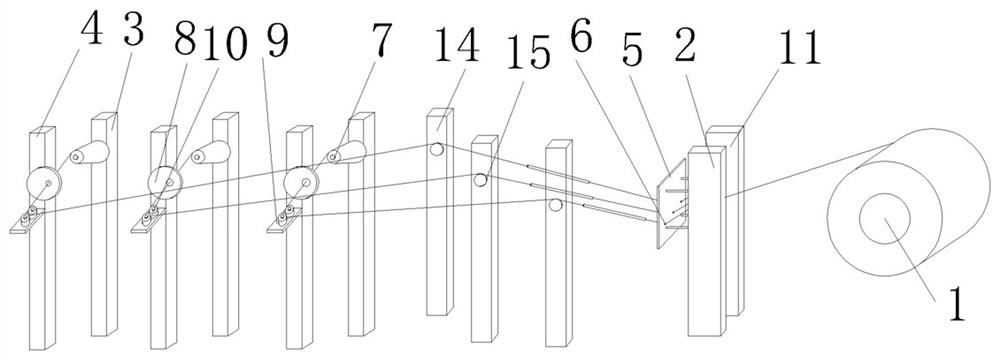

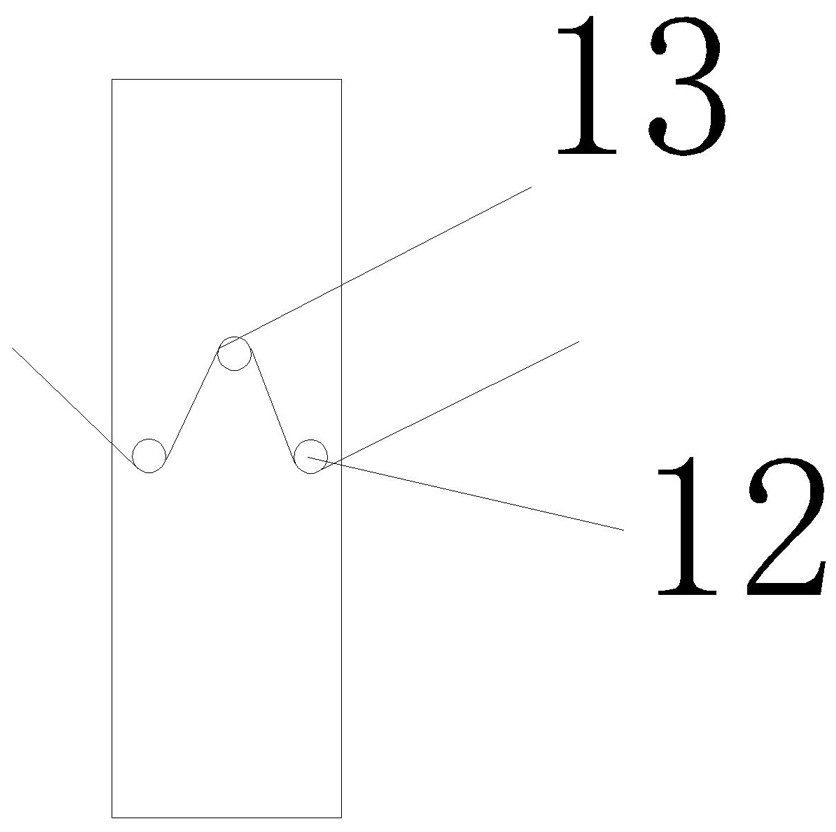

Cabling machine for cable production

PendingCN114203364AAvoid affecting productionPrevent springbackApparatus for heat treatmentCable machineEngineering

The invention relates to the technical field of cabling machines, and provides a cabling machine for cable production, which comprises a machine body, and a cable core discharging device, a branching discharging device, a doubling device, a skin winding device, a heat sealing device and a take-up device which are sequentially arranged on the machine body along the movement direction of a cable core, the doubling device comprises a disc body and a sliding sleeve, the disc body is rotationally arranged on the machine body, and the sliding sleeve is arranged on the disc body. A first through hole and a plurality of second through holes are formed in the disc body, the cable core penetrates through the first through hole, the wire core penetrates through the second through holes, the sliding sleeves are slidably arranged in the first through hole and the second through holes respectively, each sliding sleeve is provided with a sliding cavity, the cable core and the wire core penetrate through the sliding cavity, each sliding sleeve is provided with a one-way part, and the one-way parts are located in the sliding cavities. And each one-way part is in contact with the wire core or the cable core and prevents the wire core or the cable core from rebounding. By means of the technical scheme, the problem that in the prior art, after cables are collected, the cables can rebound due to tensioning force is solved.

Owner:河北万方线缆集团有限公司

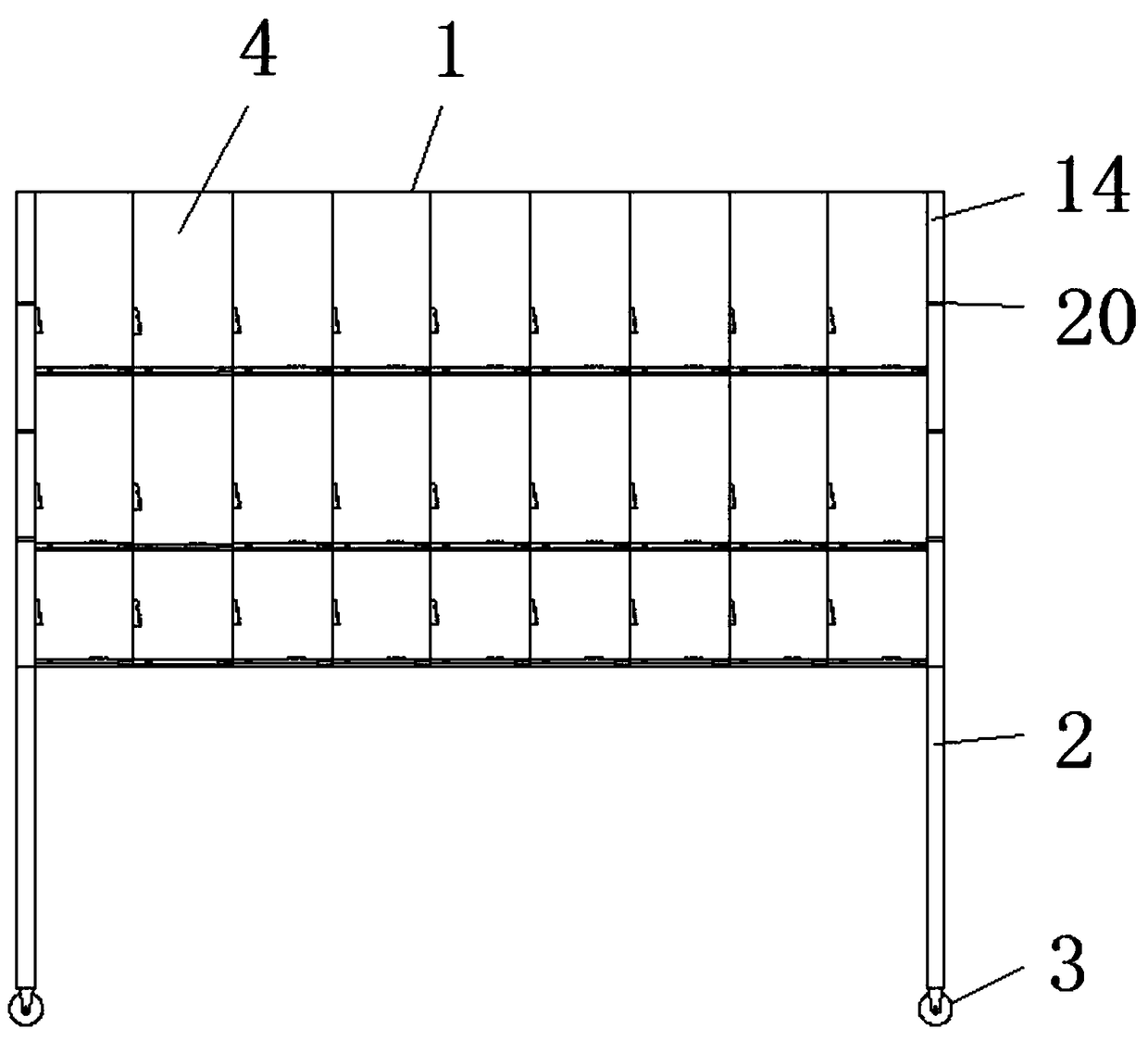

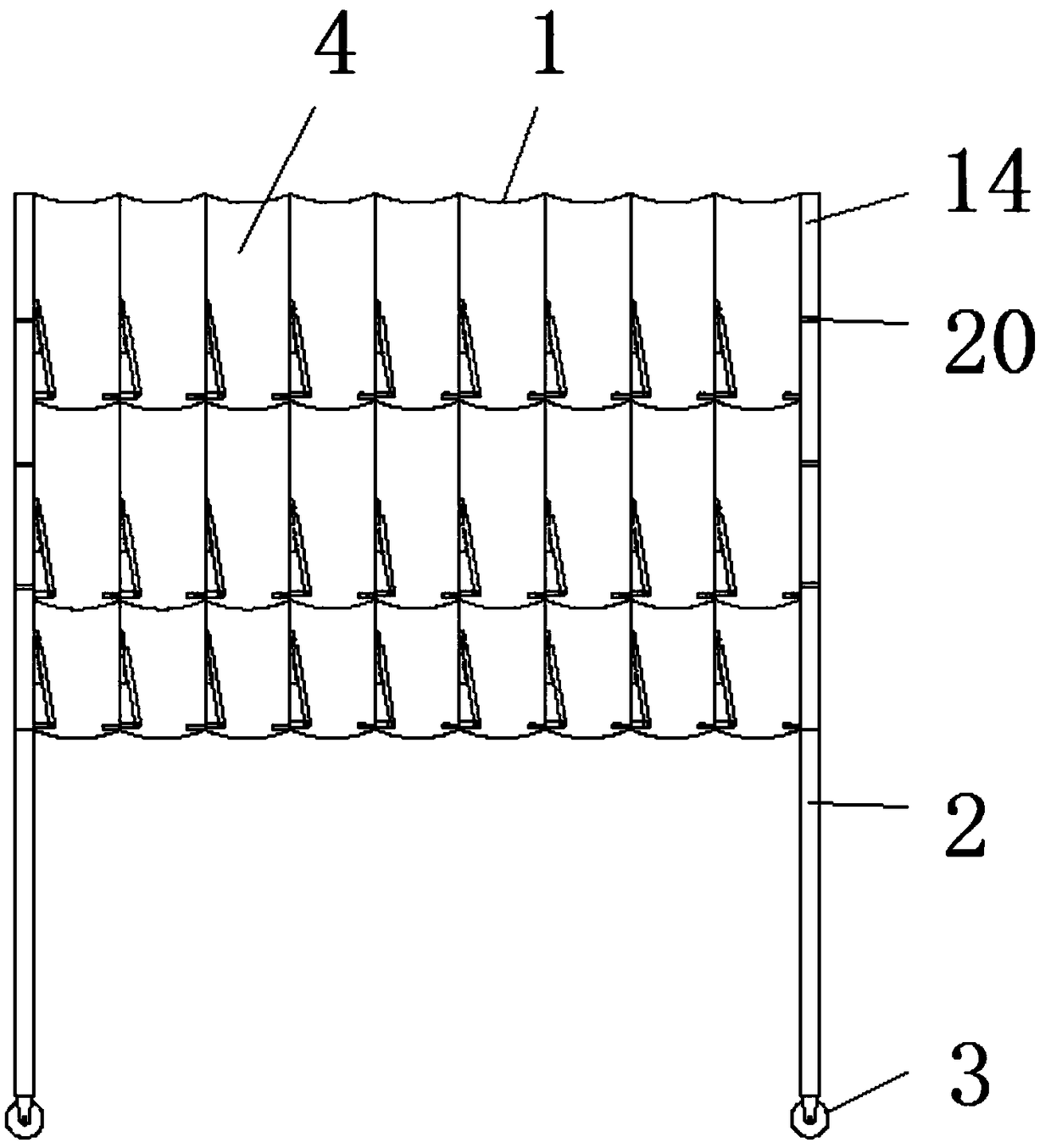

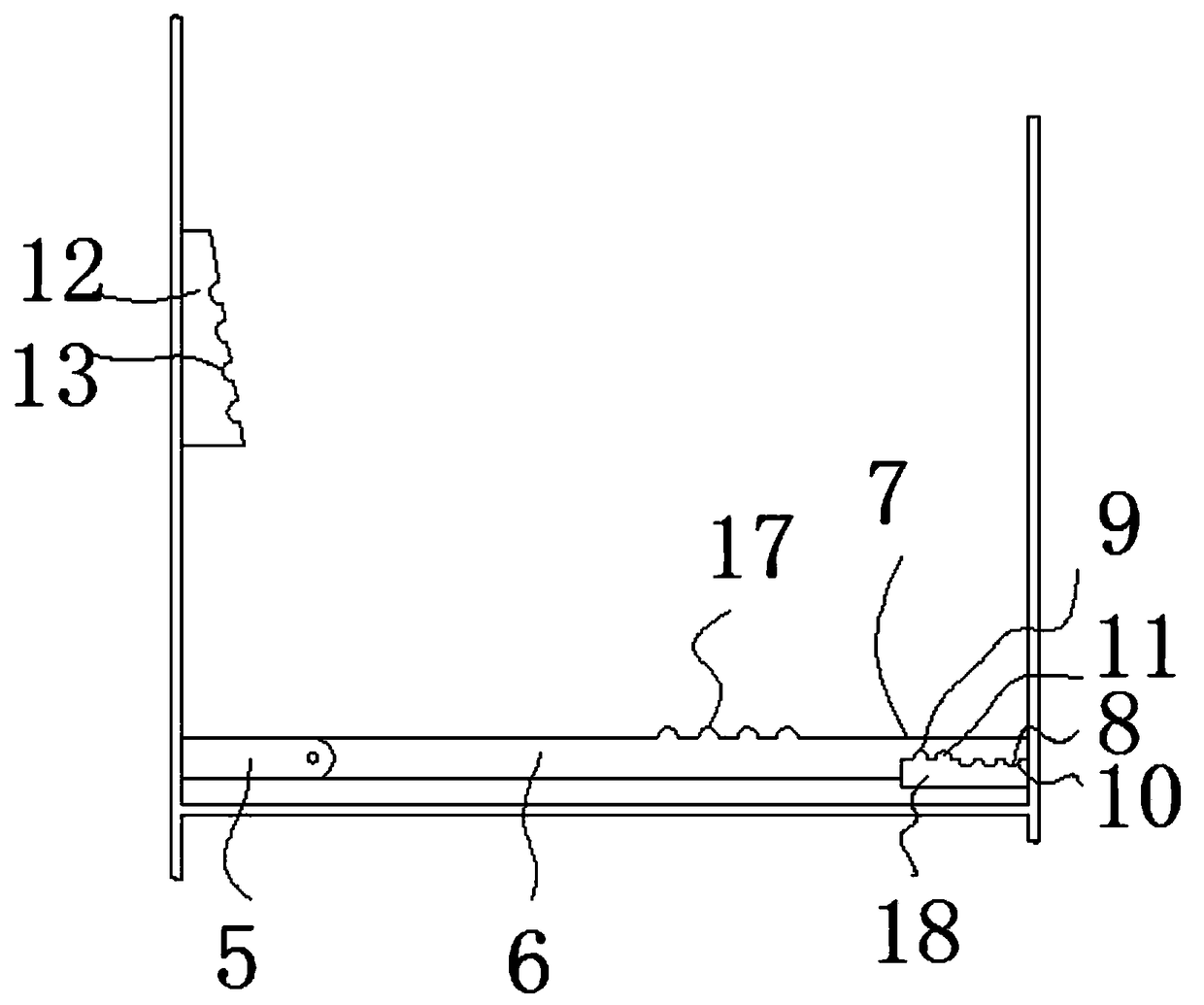

Automobile interior trim part arranging shelf

The invention discloses an automobile interior trim part arranging shelf and relates to the field of automobile interior trim parts. The automobile interior trim part arranging shelf comprises an arranging cabinet and a support rack, wherein the corners of the arranging cabinet are provided with the support rack, and the lower end of the support rack is provided with walking wheels; the arrangingcabinet is provided with a plurality of cabinet units; one side wall of the opening of every cabinet unit is provided with a fixed rod to which a moving rod is hinged, the front end of the moving rodis provided with a lapping plate, the lower end of the lapping plate is provided with a lower protrusion and a lower hemispherical groove, the upper end surface of the moving rod is provided with an upper protrusion, the side wall of the cabinet unit which is opposite to the fixed rod is fixedly provided with a lower positioning plate, the upper end surface of the lower positioning plate is provided with a positioning hemispherical groove and a positioning protrusion, the side wall of the cabinet unit where the fixed rod is arranged is fixedly provided with a side positioning plate, the edge of the side positioning plate is provided with a side hemispherical groove, the upper protrusion and the lower hemispherical groove are matched with the positioning hemispherical groove and the positioning protrusion respectively, and the upper protrusion is matched with the side hemispherical groove. The automobile interior trim part arranging shelf is simple in structure, integrally light, easy to mount, flexible in movement and capable of being applied to placing various automobile interior trim parts and related accessories.

Owner:芜湖鑫沃汽车零部件有限公司

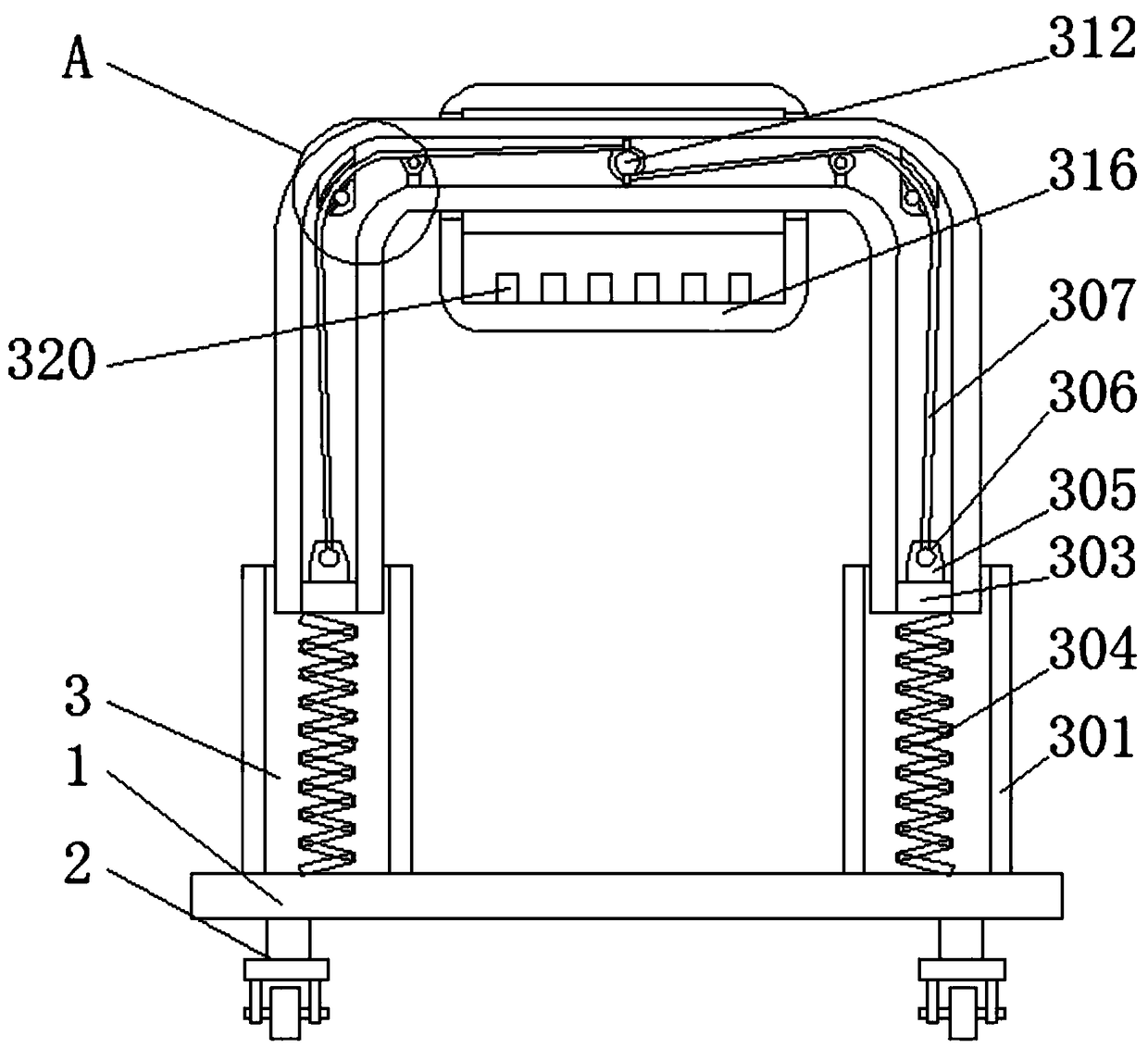

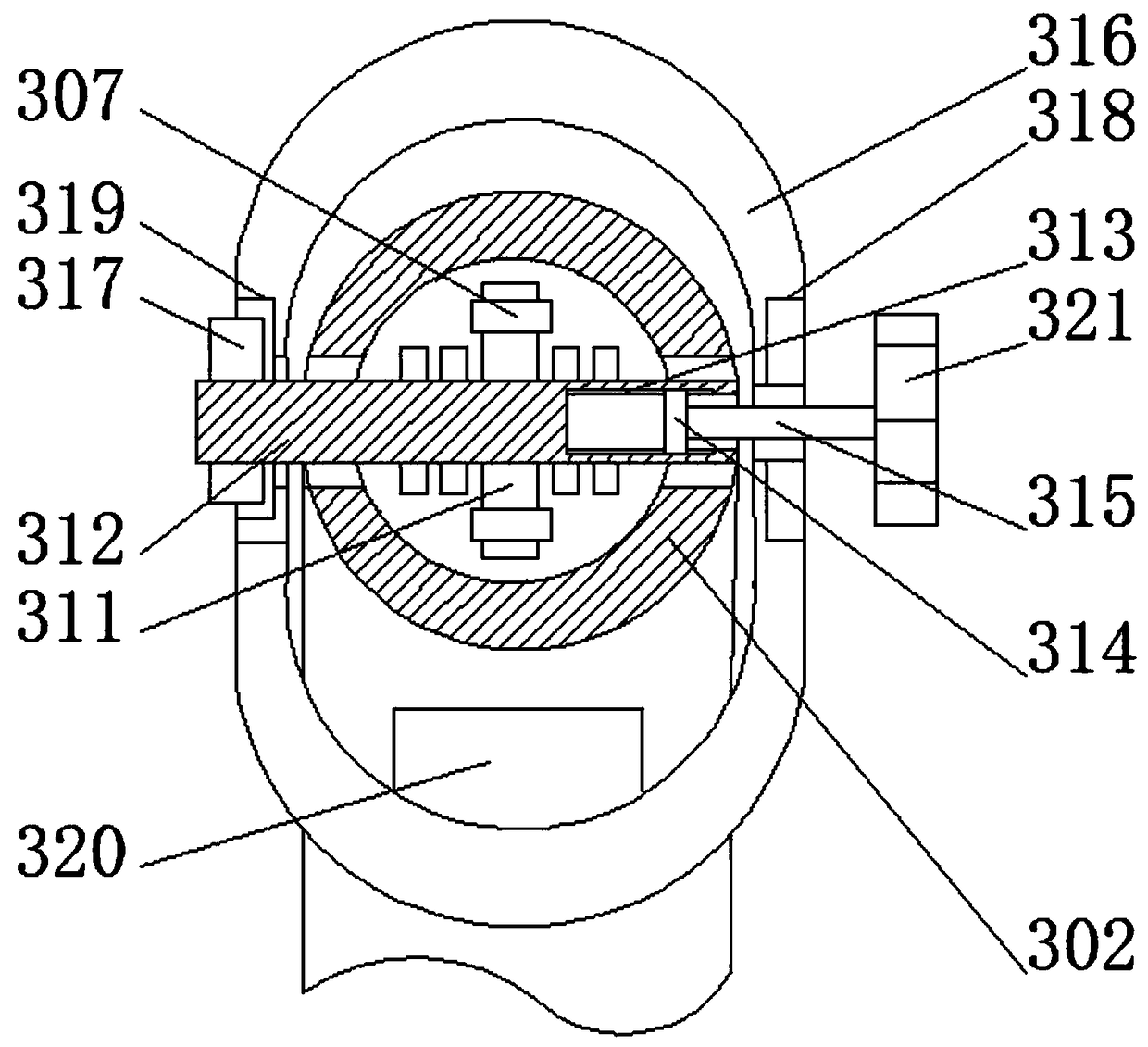

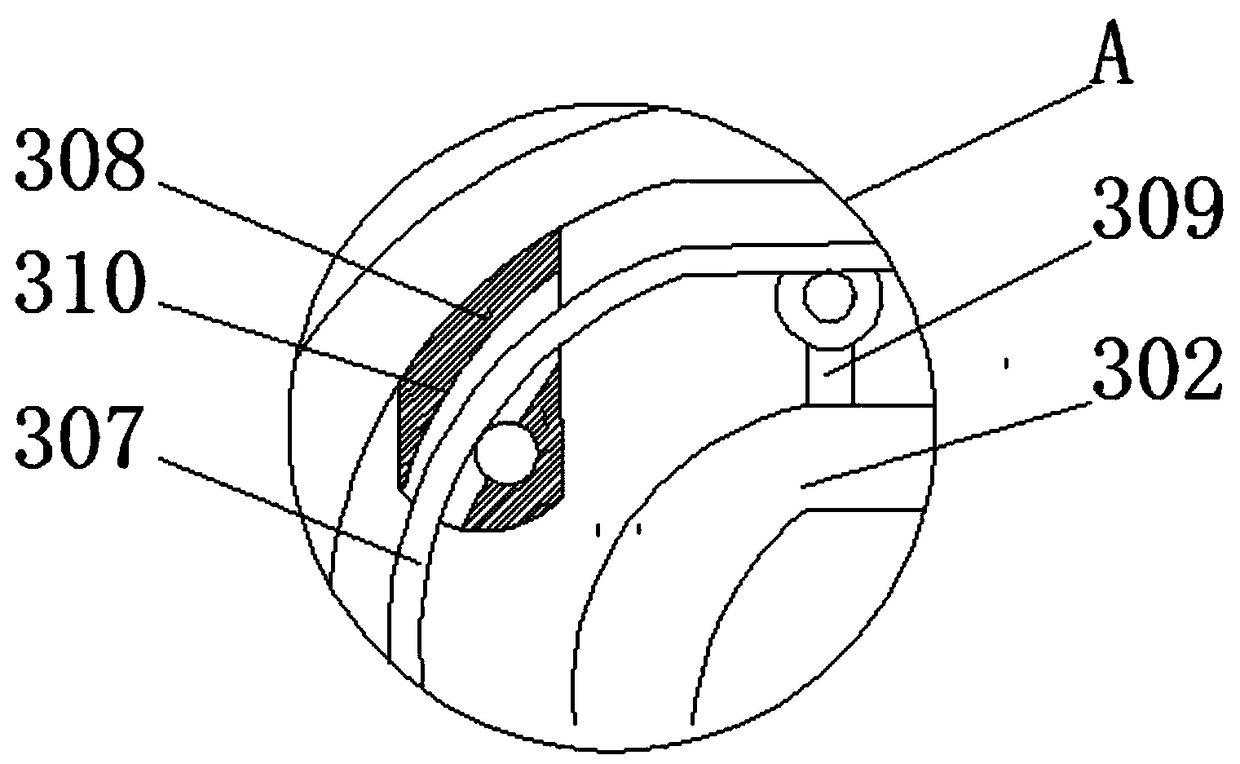

Adjustable mobile clothes hanger for household

InactiveCN109259558AHeight adjustableEasy to adjustApparel holdersClothes hangerComputer engineering

The invention discloses an adjustable mobile clothes hanger for household, Including a clothes hanger base, the bottom surface of the clothes hanger base is fixedly connected with a moving universal wheel, the top surface of the clothes hanger base is fixedly connected with an adjustable clothes hanger, the adjustable hanger includes a hanger telescopic sleeve, the inner wall of the clothes hangertelescopic sleeve is movably connected with a clothes hanger U-shaped pipe, the inner wall of the clothes hanger U-shaped pipe is movably connected with a spring expansion and contraction block, thebottom surface of the spring expansion block is fixedly connected with an expansion spring, the bottom end of the expansion spring is fixedly connected with the top surface of the coat hanger base, the top surface of the spring expansion block is fixedly connected with an adjustment rope fixing block, and the surface of the adjustment rope fixing block is provided with an adjustment rope fixing hole. The adjustable mobile clothes hanger for household use achieves the effect of conveniently adjusting the height of the mobile clothes hanger by means of the adjusting rod, the adjusting rope, theadjusting rope fixing rod, the n adjusting rope fixing block, the expansion spring and the clothes hanger telescopic sleeve.

Owner:王鸳

A kind of formaldehyde eliminating agent and preparation method thereof, adhesive, wood product and wood-based panel

ActiveCN105131862BNo reverse reactionWon't spring backNon-macromolecular adhesive additivesWood treatment detailsAdhesiveHydrazide

The invention relates to a formaldehyde elimination agent and a preparation method thereof as well as an adhesive, a wooden product and an artificial board. The formaldehyde elimination agent comprises the following ingredients in parts by weight: 64-92.9 parts of pure water, 5-20 parts of urea, 2-15 parts of hydrazide compound and 0.1-1 part of an anionic surfactant. The formaldehyde elimination agent can be added into the adhesive and can be also sprayed on the wooden product and the artificial board. The formaldehyde elimination agent has the benefits as follows: on the basis of reaction between urea and formaldehyde, the hydrazide compound is added, so that the technical effect of no reverse reaction after reaction is realized; since the anionic surfactant is added, the reaction between effective ingredients in the product and formaldehyde in the artificial board is reinforced; the pH of the formaldehyde elimination agent is 7-9, the color of the wood material is not changed after the formaldehyde elimination agent is sprayed on the wood material with a light color, and the contents of formaldehyde in the adhesive, the artificial board and the wooden product reach the national compulsorily-executed health standard level.

Owner:潘春尧

A production process of fake double-faced wool

Owner:杭州汇丰呢绒有限公司

A safety protection device for sliding doors based on the principle of centrifugal rotation

The invention relates to the technical field of buffer devices, and discloses a sliding door safety protection device based on the principle of centrifugal rotation, which includes a door body, a door frame is cut above the door body, and a pull rope is fixedly connected to the bottom of the slider. The bottom of the tension rope is fixedly connected with a handle, the corner of the door frame is provided with a buffer box, the interior of the buffer box is provided with a rotating shaft, the outer side of the rotating shaft is fixedly connected with a gear, and the teeth of the gear A fixed card is rotatably connected to the buffer box, a fixed block is arranged on the inner wall of the buffer box, and an elastic band surrounds the outer side of the rotating shaft. This kind of sliding door safety protection device based on the principle of centrifugal rotation, by setting a fixed card, a fixed block and an elastic belt in the buffer box, using the action of centrifugal force, the buffer device is stopped when the door is slowly pushed and pulled, reducing the slow push and pull. When pushing and pulling the door body quickly, open the buffer device to prevent accidental pinching.

Owner:绍兴市华获智能装备有限公司

A kind of pcb board soldering method

The invention provides a PCB welding method. The PCB welding method comprises the steps of a, completely stripping a sheath on an electric wire; and b, welding the stripped copper wire of the electricwire on a PCB. According to the invention, the sheath on the electric wire is completely stripped without damaging an internal copper wire, and meanwhile, the stripped electric wire sheath is not adhered to the copper wire and does not rebound, so that the welding of the electric wire is not influenced. Parallel connection of the electric wire and a PCB can realize only by designing the conventional bonding pad according to the conventional specification. In this way, the production efficiency can be greatly improved, the product tension is increased, and the attractiveness is improved.

Owner:TIANTAI TIANYU OPTOELECTRONIC CO LTD

Clamp

The invention provides a clamp, and relates to the technical field of electronic device testing. The clamp comprises a rack, a pressing part and a driving assembly. The pressing part is in sliding connection with the rack; and the driving assembly comprises a first connecting piece and a second connecting piece, the first connecting piece and the second connecting piece are hinged to form a first hinge point, and meanwhile the two ends of the first connecting piece and the two ends of the second connecting piece are hinged to the rack and the pressing part to form a second hinge point and a third hinge point respectively. The first hinge point, the second hinge point and the third hinge point have a collinear state and a non-collinear state under the action of external force, and the three points can drive the pressing part to do linear motion so as to press or loosen a piece to be clamped in the switching process of the two states. Through the clamp, the technical problem that the accuracy of the electrical performance index of an isolator cannot be ensured by manually pressing the isolator and a test frame in the prior art is solved, and the effect of improving the debugging efficiency and the accuracy of the electrical performance index is achieved.

Owner:无锡市高宇晟新材料科技有限公司

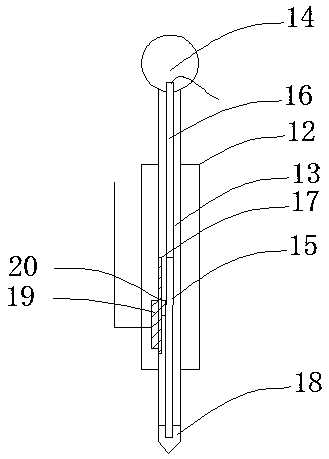

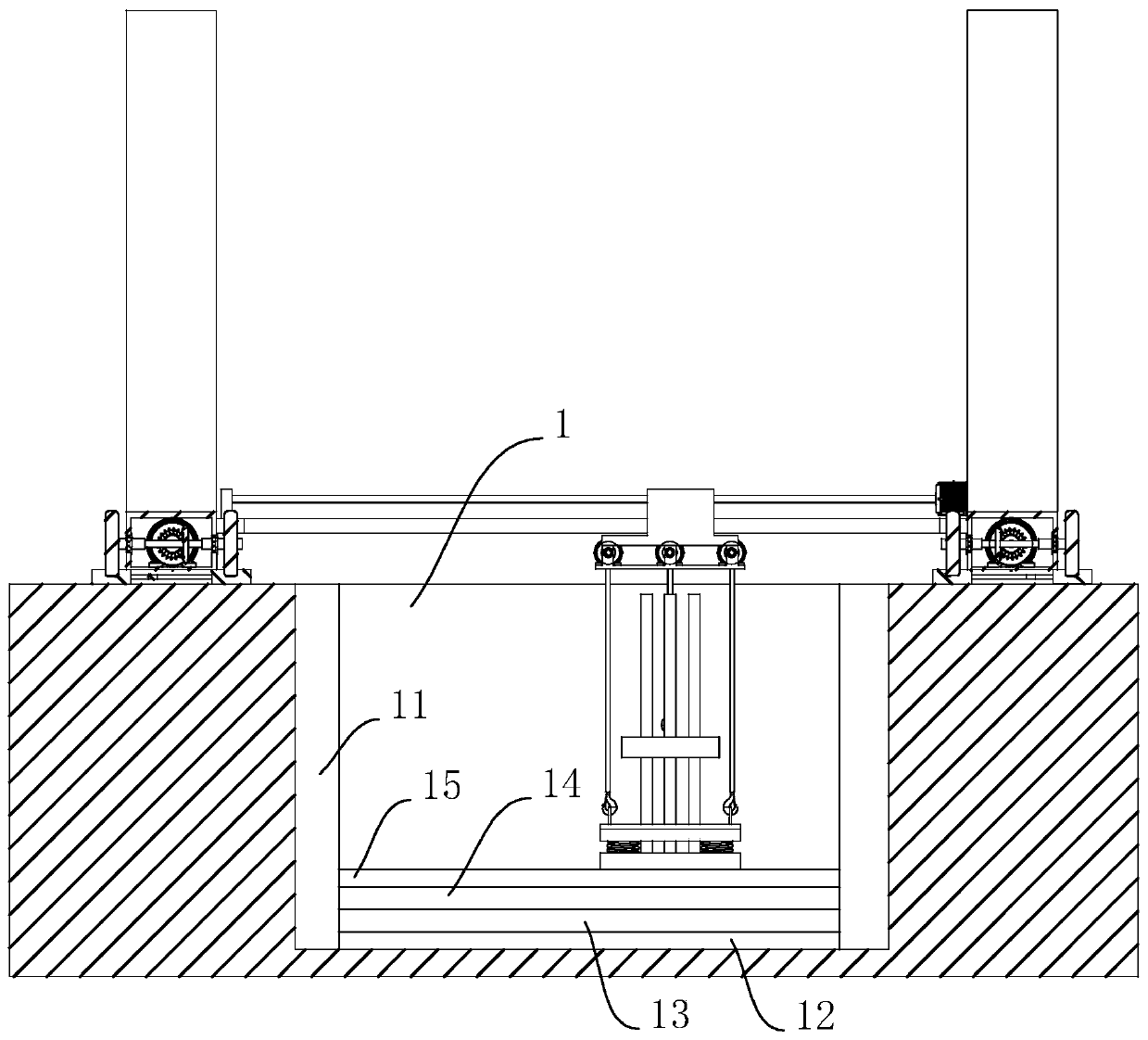

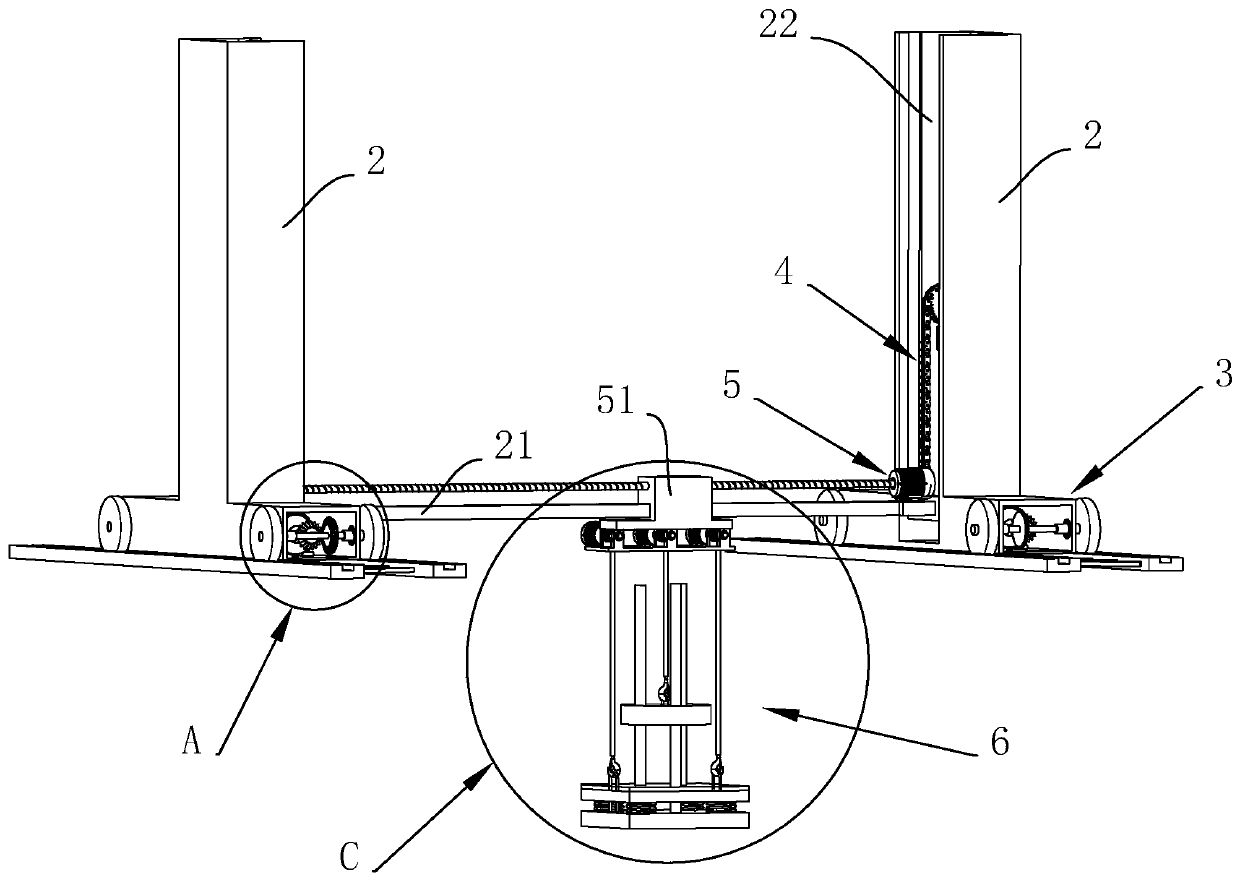

Ground reinforcement equipment and deep ground treatment methods

ActiveCN108193663BGuaranteed firmnessImprove work efficiencyProtective foundationExcavationsStructural engineeringGap filling

The invention discloses a deep layer foundation treatment method and foundation strengthening equipment formed through the method, and belongs to the field of foundation treatment. The problem that according to an existing dynamic consolidation method, a deep layer foundation is not pounded conveniently is solved. According to the technical scheme, the deep layer foundation treatment method and the foundation strengthening equipment formed through the method are characterized in that a drying agent, a gap filling agent, a water passing expansion rubber layer and a rubble layer are sequentiallyadded in the deep layer foundation, and finally the foundation strengthening equipment is used for conducting strengthening treatment on the deep layer foundation. The deep layer foundation treatmentmethod and the foundation strengthening equipment formed through the method have the beneficial effects that the firmness and the cost performance of the deep layer foundation are high.

Owner:浙江立鹏建设有限公司

Bicycle elbow device

The invention discloses a bicycle elbow device comprising a bottom plate, an elbow mold, a pneumatic cylinder, a first hydraulic cylinder, a second hydraulic cylinder and a bicycle head fixed seat, wherein the elbow mold is fixed on the bottom plate, the first hydraulic cylinder and the bicycle head fixed seat are fixed on the bottom plate at the right side of the elbow mold, the pneumatic cylinder and the hydraulic cylinder are fixed on the bottom plate at the left side of the elbow mold, a positioning block adaptive to the head of the elbow is arranged on the pneumatic cylinder, a compression block adaptive to the surface of the elbow is arranged on the first hydraulic cylinder, and a buckling device is arranged on the second hydraulic cylinder. The bicycle elbow device has the advantages of being capable of setting holding-up time according to performances of a straight pipe, and further keeping no bouncing of the bent elbow, and ensuring the product quality.

Owner:ZHEJIANG NORMAL UNIVERSITY

Paste tube with yak felts

InactiveCN105346822AWon't spring backFlexible containersPliable tubular containersToothpasteEngineering

The invention discloses a paste tube with yak felts. The paste tube with the yak felts structurally comprises a tube body, a tube body cover and the yak felts, wherein the tube body adopts a paste tube structure, the tube body cover is arranged at the front end of the tube body, one yak felt is arranged on a front side surface of the tube body, the other yak felt is also arranged on the rear side surface of the tube body, and the yak felt on the front side surface meshes with the yak felt in the rear side surface. The paste tube with the yak felts has the beneficial effects as follows: when toothpaste in the rear end in the tube body is used up, the tube body in the rear end of the paste can be crimped due to the mutual meshing of the yak felts on the two sides of the paste body, therefore, resilience can be avoided, and the toothpaste which is positioned at the front end of the tube body and not used can flow back.

Owner:CHONGQING WUSHAN YUANXIAO MACHINERY CO LTD

Novel constructional engineering construction reinforcing steel bar cutting device

The invention discloses a novel constructional engineering construction reinforcing steel bar cutting device which comprises a bottom plate, a cutting device protection sleeve is fixedly connected to the upper end of the left side of the bottom plate, a supporting column is fixedly connected to the middle of the upper end of the bottom plate, a fixing frame is rotatably connected to the top end of the supporting column, and a motor is arranged on the left side of the fixing frame. The fixing frame is connected with a blade through a second rotating shaft, the right end of the fixing frame is fixedly connected with an operating rod, the front side of the bottom end of the cutting device protection sleeve is rotationally connected with a buckle, the right end of the buckle is fixedly connected with a first clamping rod, and the inner wall of the right end of the first clamping rod is fixedly connected with a spring. The top end of the spring is fixedly connected to the bottom end of the second clamping rod. According to the steel bar cutting device, the second clamping rod is clamped at the lower end of the limiting rod while the clamping buckle is rotated to buckle the steel bar, so that the clamping buckle cannot rebound, the cutting action is carried out in the protective sleeve, noise and light pollution are effectively isolated, and the steel bar cutting device is worthy of being vigorously popularized.

Owner:北京城建轨道交通建设工程有限公司

Light anti-seismic floor slab connecting joint and using method thereof

InactiveCN113235793APop up normallyEasy to useFloorsProtective buildings/sheltersFloor slabClassical mechanics

The invention relates to a light anti-seismic floor slab connecting joint and a using method thereof. The light anti-seismic floor slab connecting joint comprises floor slab bodies and a concrete pre-embedded block, wherein connecting boxes are fixedly connected to the two sides of each floor slab body correspondingly, second mounting grooves are formed in the sides, away from each other, of every two connecting boxes correspondingly, a connecting assembly used for connecting the two floor slab bodies is arranged in each second mounting groove, connecting holes and first mounting grooves are formed in the concrete pre-embedded block, the connecting holes communicate with the first mounting grooves, fixing assemblies used for fixing the connecting assemblies are arranged in the first mounting grooves, and Z-shaped grooves are formed in the two sides of the concrete pre-embedded block correspondingly; limiting assemblies used for limiting the fixing assemblies are arranged in Z-shaped grooves, fixing blocks are fixedly connected to the two sides of the concrete pre-embedded block correspondingly, and the problems that the mounting process of the floor slab connecting joint is too tedious, the mounting stability is poor, the workload of workers is increased, and the working efficiency is further reduced in the prior art are solved.

Owner:温州富贾科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com