Ground reinforcement equipment and deep ground treatment methods

A foundation reinforcement and equipment technology, applied in excavation, soil protection, infrastructure engineering, etc., can solve the problems of difficult crane position adjustment and low efficiency, and achieve the effect of improving work efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

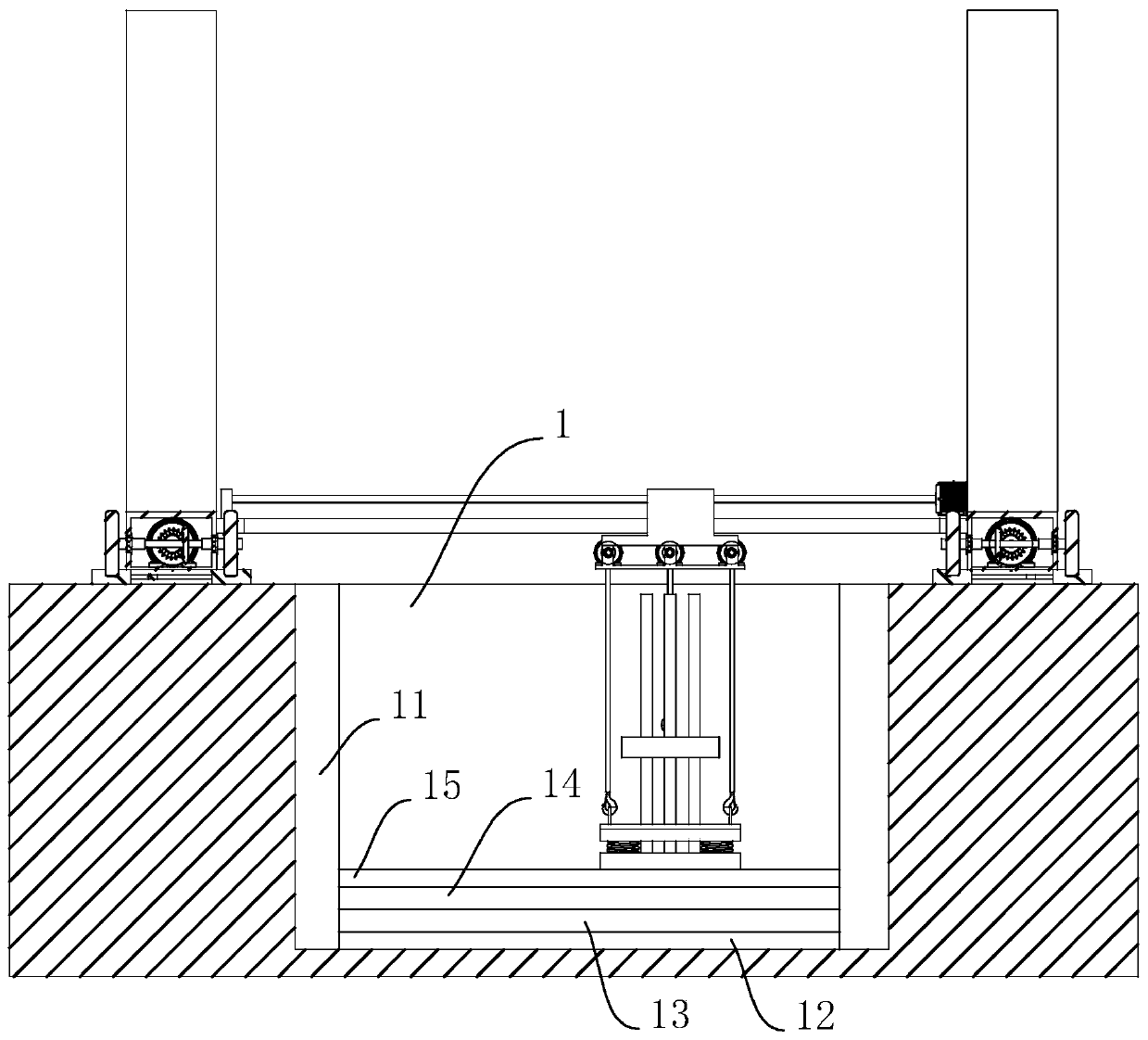

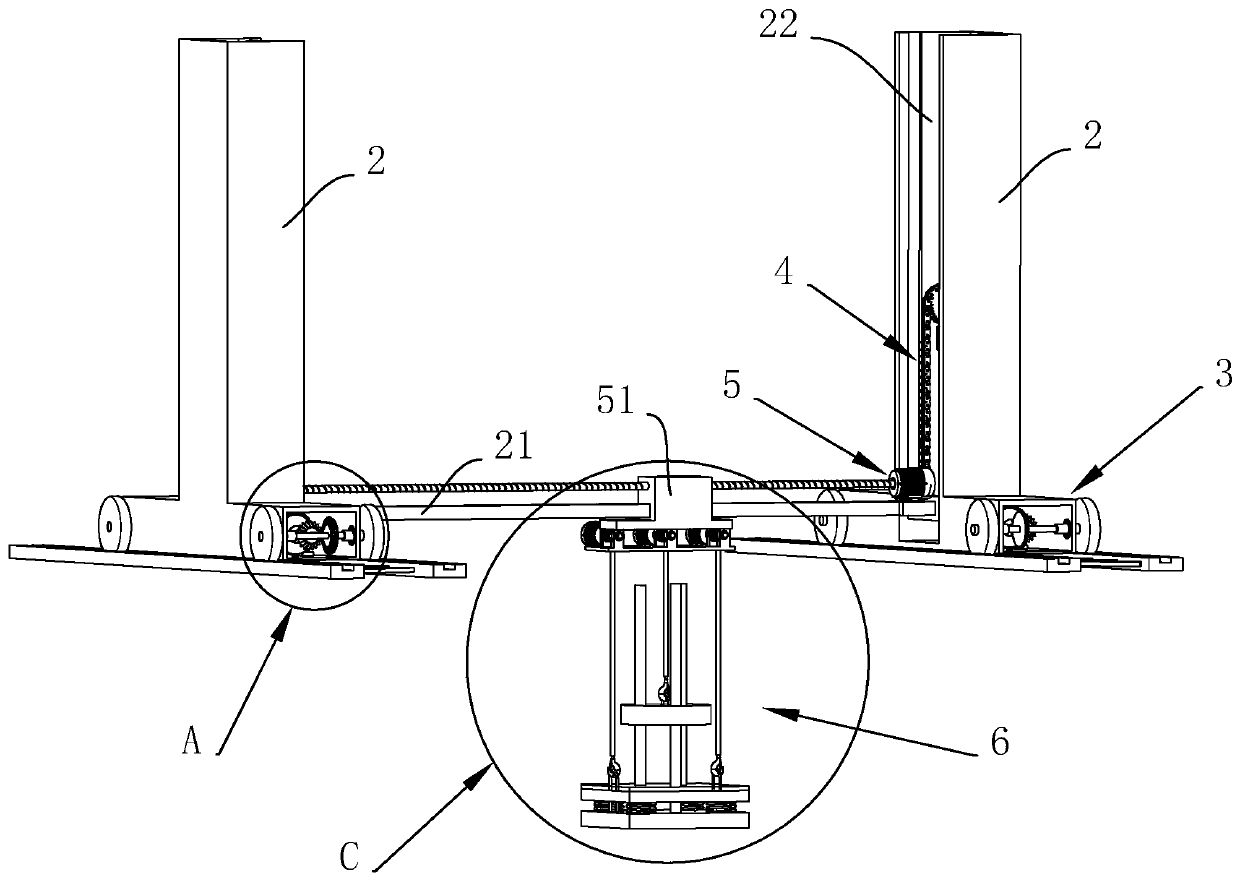

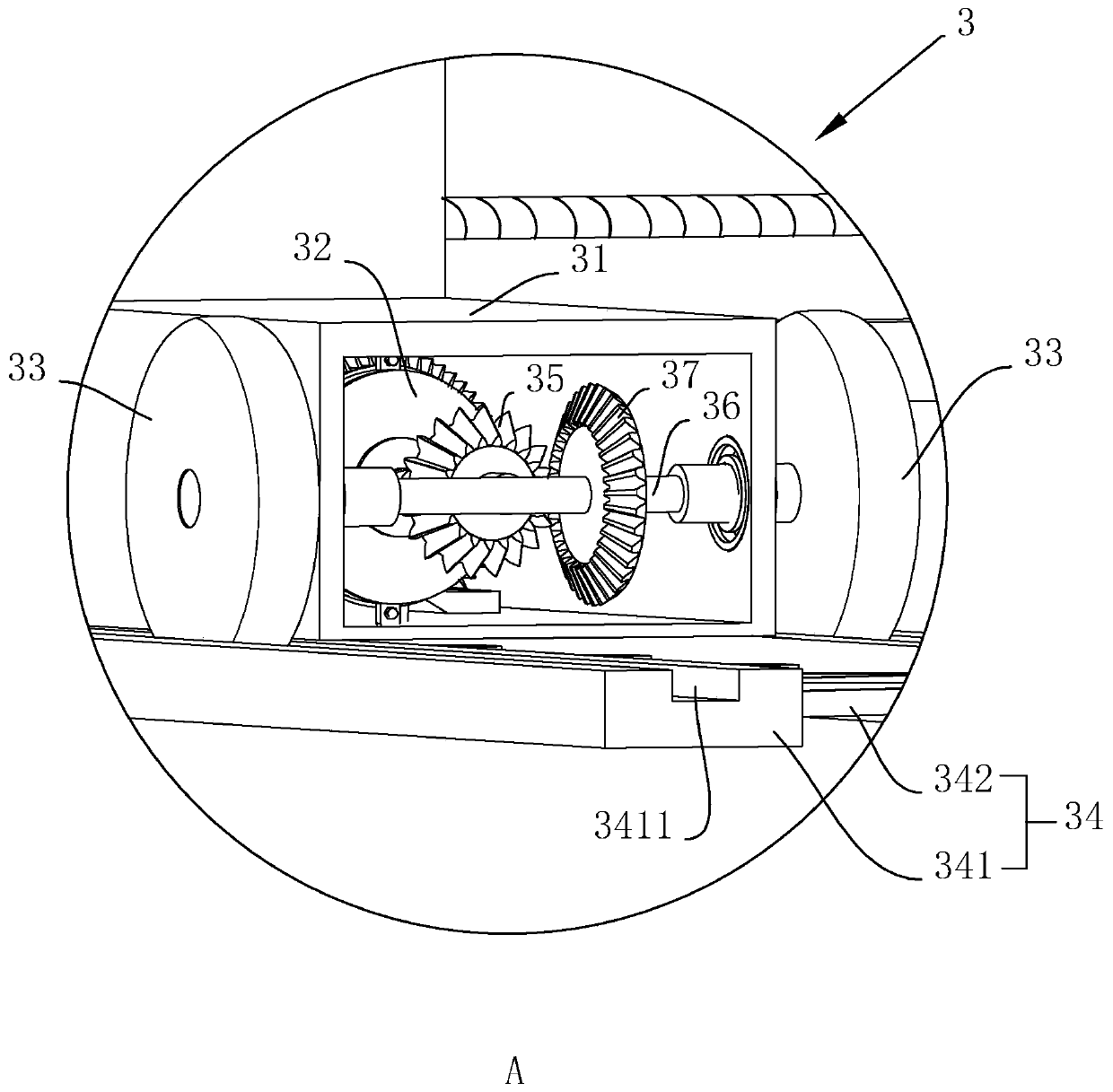

[0055] A kind of ground reinforcement equipment is disclosed, such as figure 1 , 2 As shown, a ground reinforcement equipment formed by a deep foundation treatment method includes two fixed frames 2, a slide rail 21 horizontally installed between the two fixed frames 2, and a sliding block movably sleeved on the slide rails 21 51. The two fixing frames 2 are respectively fixedly installed on the ground surface on both sides of the deep foundation pit 1. There are displacement components 3 for lateral movement on both sides of the bottom of each fixing frame 2. Lifting grooves are provided on the opposite surface of each fixing frame 2. 22 and a lifting mechanism 4 for moving the slide rail 21 up and down in the lifting groove 22; the slide rail 21 is also provided with a drive assembly 5 for controlling the sliding block 51 to move along the length direction of the slide rail 21, and the sliding block 51 A tamping assembly 6 for tamping deep foundations is connected below.

...

Embodiment 2

[0070] Such as figure 1 As shown, a deep foundation processing method includes the following steps:

[0071] S1: Set the excavation sideline on the ground surface and excavate the foundation pit according to the sideline;

[0072] S2: When the foundation pit is excavated to a depth of about 1.5m, arrange reticulated reinforcement on the side wall of the foundation pit and pour cement on the side wall to cover the reticulated rebar to form a cement wall 11, the cement wall 11 can The effect of waterproof and anti-seepage;

[0073] S3: Repeat S1 and S2 to make it a deep foundation pit 1 with a depth greater than 5m;

[0074] S4: Sprinkle a layer of desiccant 12 on the foundation, the desiccant 12 is preferably lime powder, the thickness is preferably 2mm, and is mainly used to absorb moisture in the foundation;

[0075] S5: After the foundation is dry, pour a layer of caulking agent 13 on the foundation. The caulking agent 13 is preferably crack filling glue, which is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com