Method for assembling non-metallic flexible net at sound holes of acoustic device

An assembly method and flexible mesh technology, applied in the direction of sensors, electrical components, etc., can solve the problems of burrs on flexible mesh, low assembly efficiency, poor waterproof and dustproof effect, etc. Simple and easy to achieve, combined with high firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

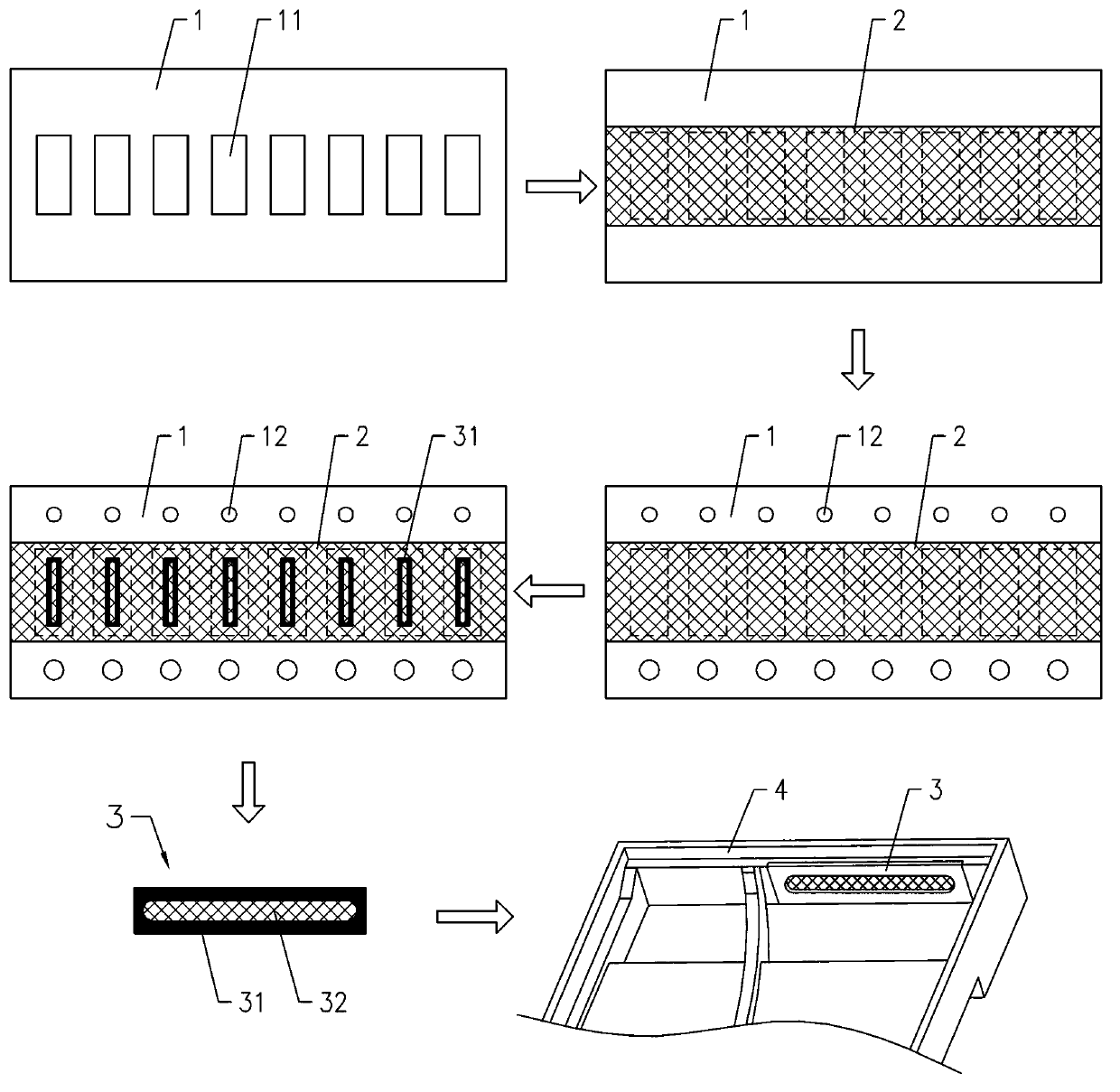

[0028] Such as figure 1 As shown, an assembly method of a non-metallic flexible net at the sound hole of a loudspeaker module, wherein the non-metallic flexible net used in this embodiment is a nylon net, which can save costs. Of course, it can also be other known plastic nets. The thickness The choice is 0.05~0.3mm, the mesh aperture is 0.03~0.1mm, further, in order to achieve better results, the thickness can be controlled at 0.05~0.1mm, the specific thickness can be 0.05mm, and the mesh aperture can be controlled at 0.03~ 0.05mm. Compared with the use of metal mesh, non-metallic flexible mesh can be made thinner, which can reduce the occupied space and will not increase the product volume; and the aperture of its mesh can be made very small, which can improve the waterproof and dustproof performance of acoustic devices , and will not rust, improving the service life and reliability of acoustic devices.

[0029] The assembly method among the present invention specifically ...

Embodiment 2

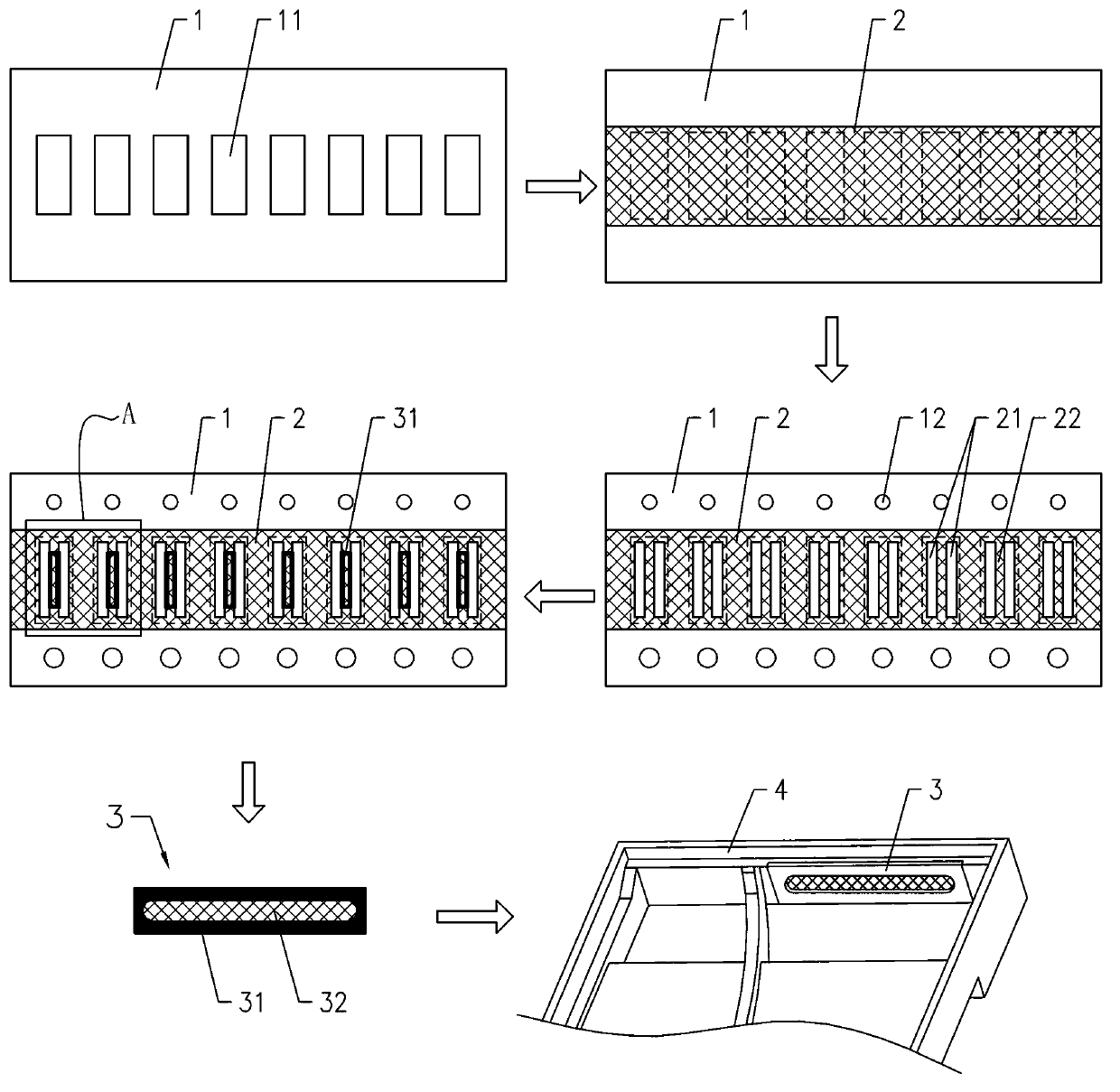

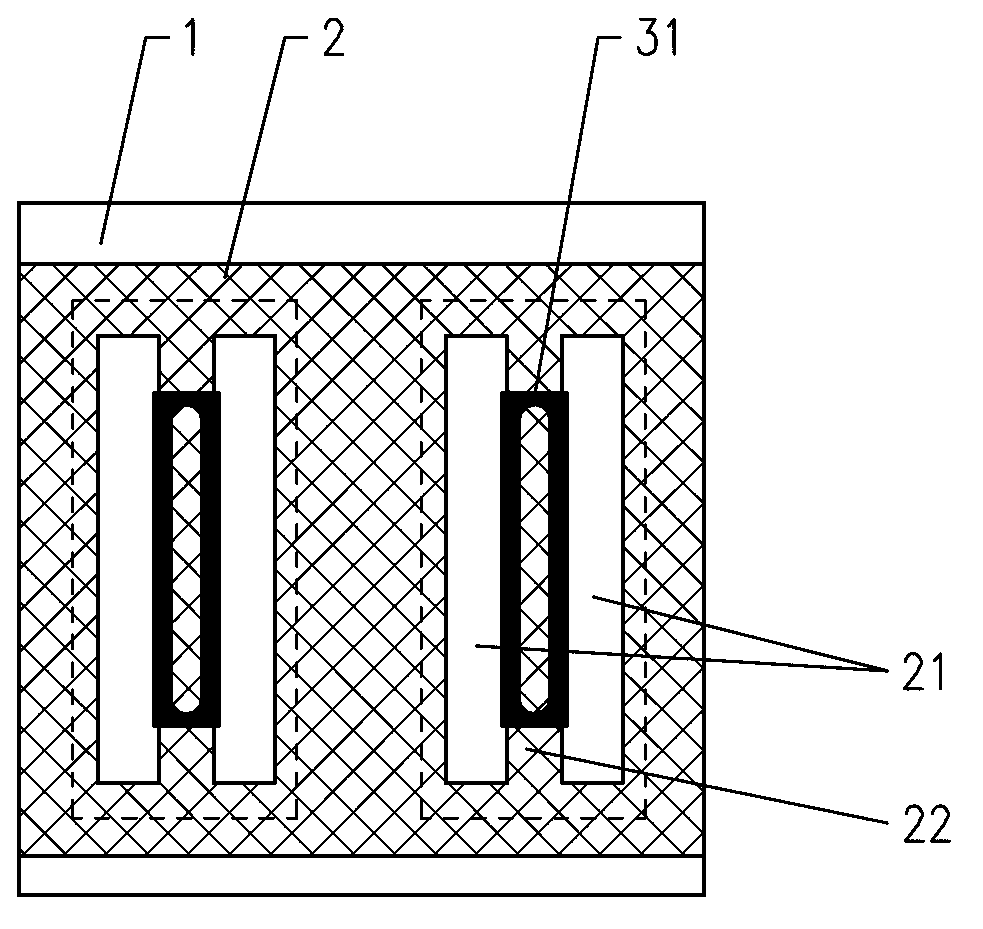

[0037] The difference between this embodiment and the first embodiment is that: between the above-mentioned step (2) and step (3), the material is removed on both sides of the flexible mesh belt 2 corresponding to each hollow hole 11 to form two The material removal holes 21 form a flexible mesh span beam 22 between the two material removal holes 21 . In step (3), the first injection molding body 31 is formed on the flexible mesh span beam 22 , the length of the flexible mesh span beam 22 is greater than the length of the first injection molding body 31 , and it completely covers the first injection molding body 31 in the width direction. Bore. In the above steps, before the first injection molding, first remove the material on both sides of the flexible mesh belt 2 corresponding to each hollow hole 11, so that the simple operation on the flat flexible mesh belt 2, compared with the first injection molding After the body 31 is formed, the two sides are cut, which is easier to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com