Patents

Literature

129results about How to "Reduce the difficulty of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

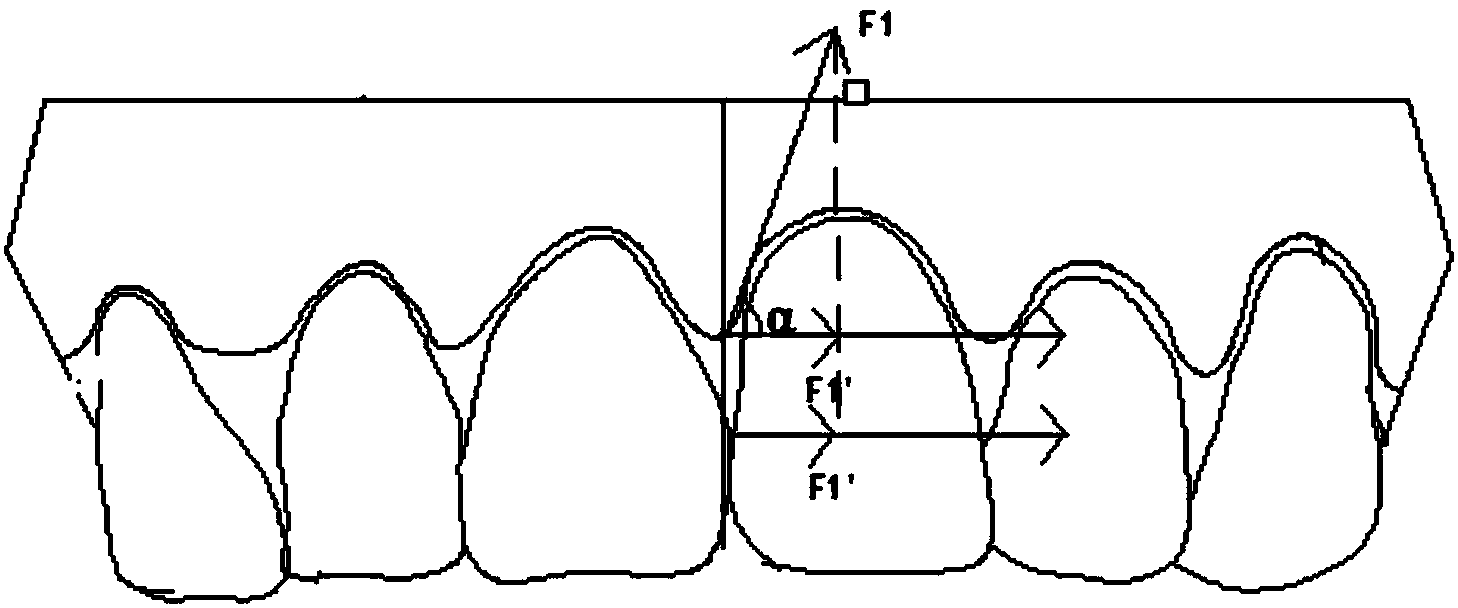

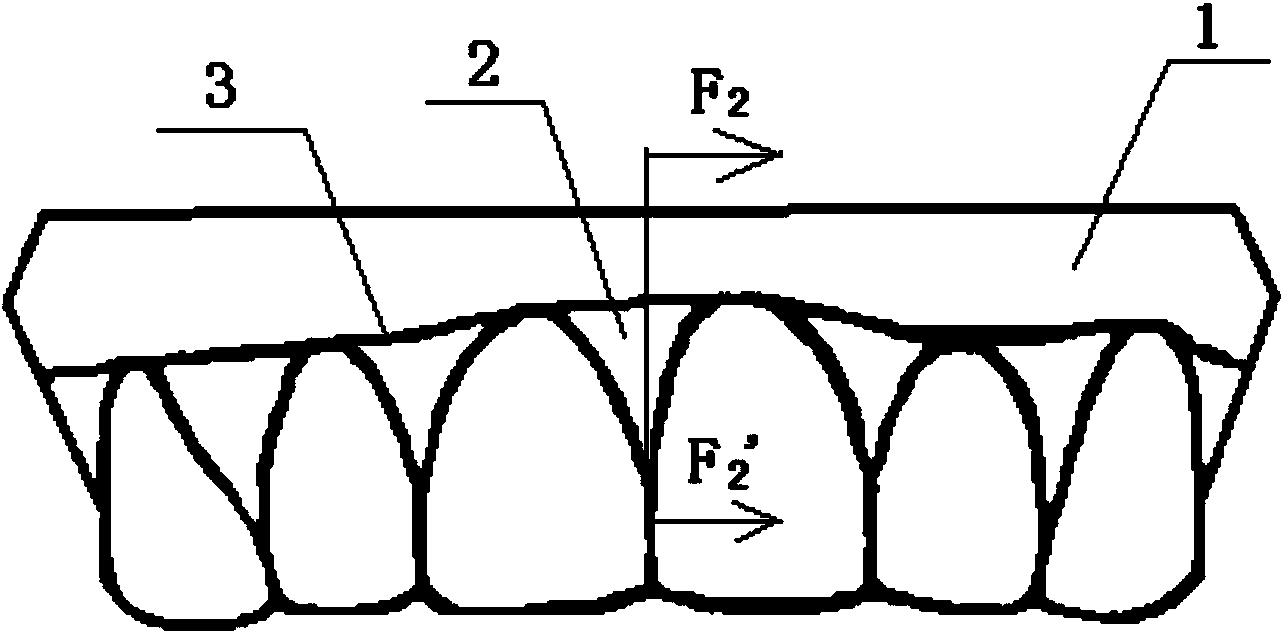

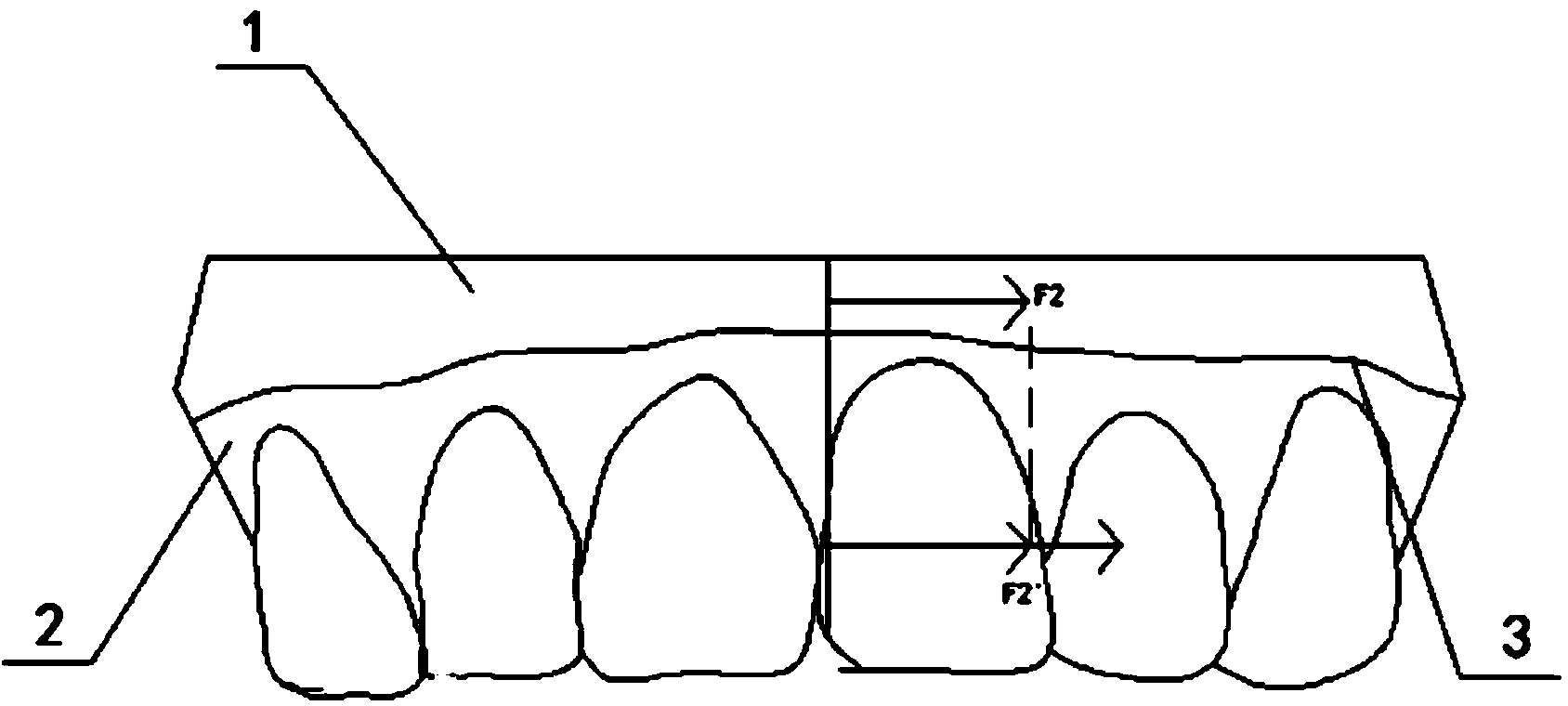

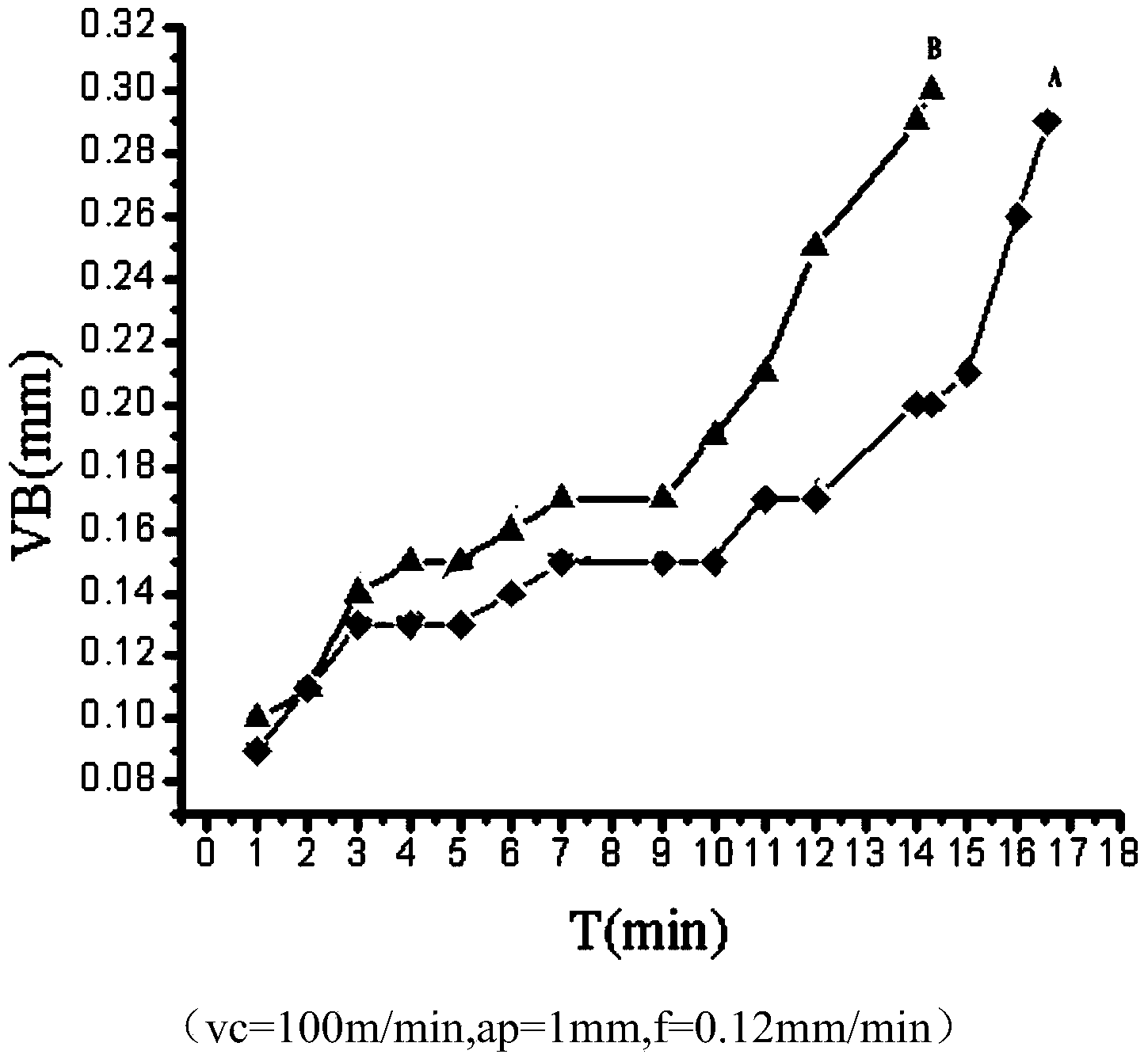

Bracketless invisible appliance and manufacturing method thereof

ActiveCN104224331AImprove protectionReduce the difficulty of cuttingOthrodonticsDimensional modelingRapid prototyping

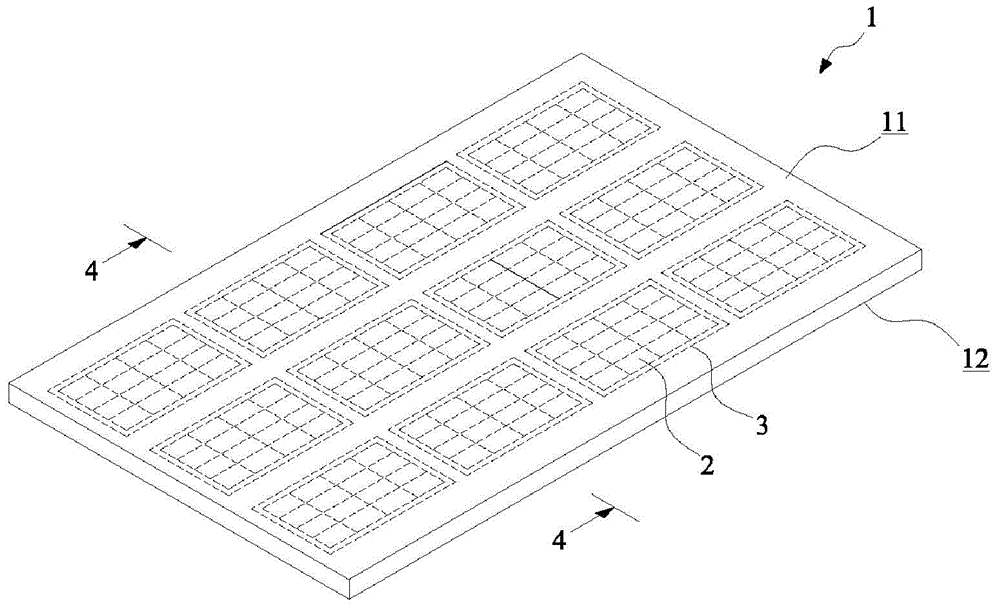

The invention relates to a manufacturing method of a bracketless invisible appliance. The manufacturing method comprises the following steps: obtaining the oral data of a patient and establishing a three-dimensional model for an oral cavity of the patient according to the oral data, wherein the three-dimensional model comprises tooth data and gum data; designing a correction scheme, adjusting the position of a tooth to be corrected to a target correction position and obtaining a dental model; generating a cutting line on the dental model; forming the three-dimensional dental model into an entity dental model in a quick forming mode or a 3D printing mode and covering a diaphragm on the entity dental model in a vacuum diaphragm pressing way; cutting the entity dental model coated with the diaphragm by taking the cutting line of the three-dimensional dental model as a cutting path and demolding the diaphragm after the completion of cutting so as to form the appliance. The bracketless invisible appliance is obtained by the manufacturing method. The bracketless invisible appliance and the manufacturing method thereof have the advantages of high processing efficiency, large bearing capacity and difficulty in breakage.

Owner:杭州一牙数字口腔有限公司

Totally-synthesized water-based stainless steel cutting liquid, and preparation method and using method thereof

ActiveCN103865622AGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

Diamond particle reinforced metal matrix composite material and preparation method and application thereof

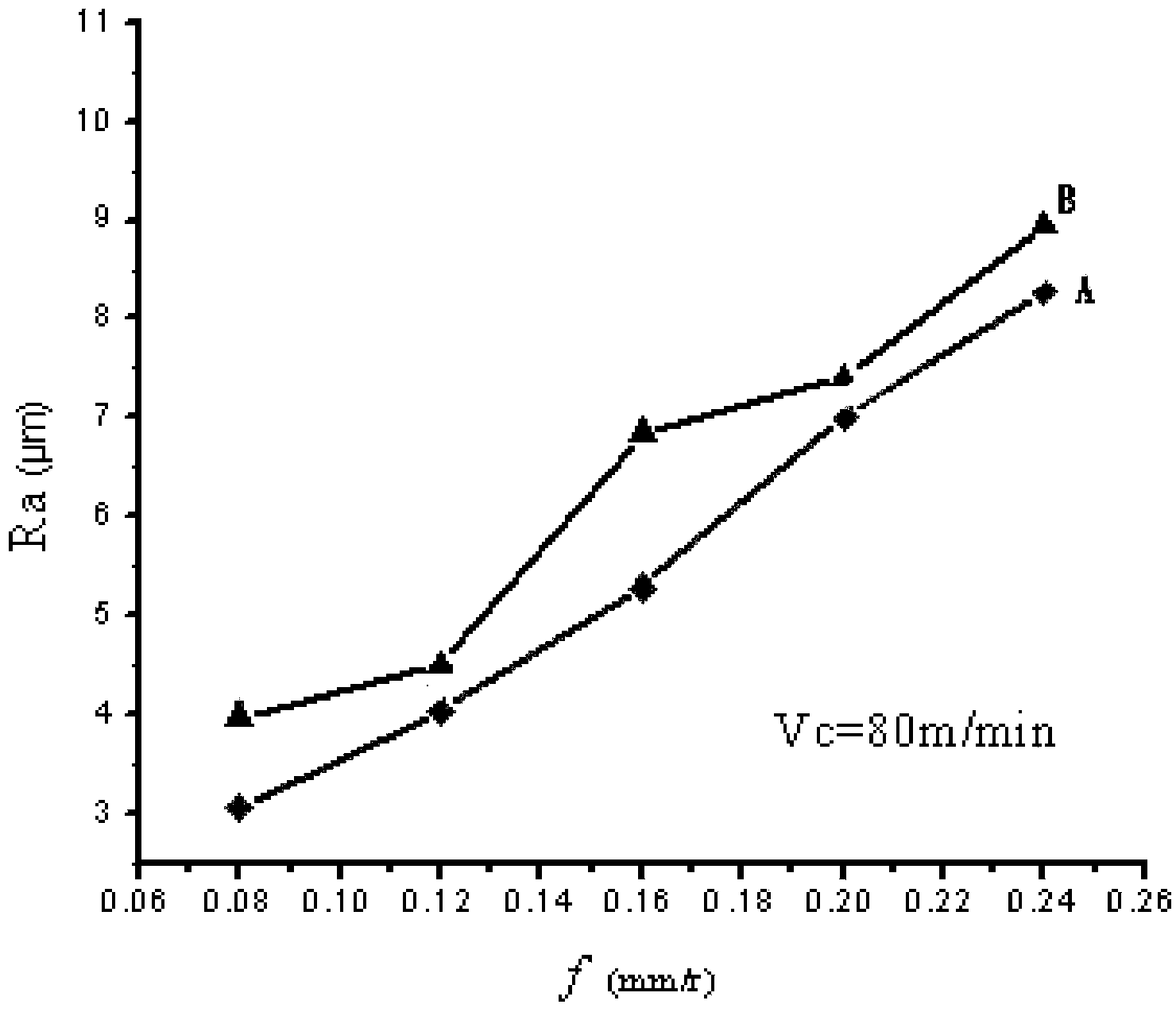

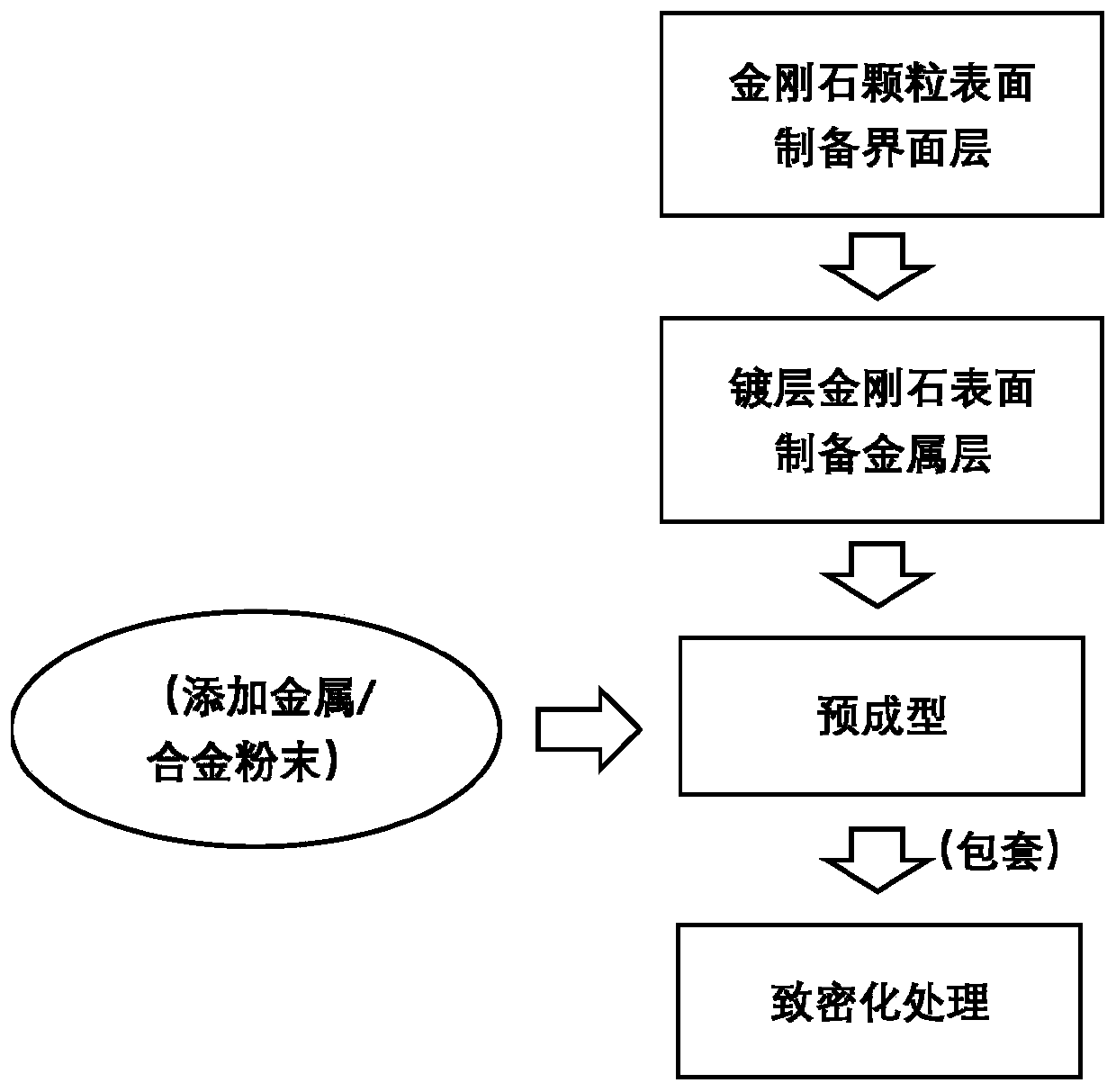

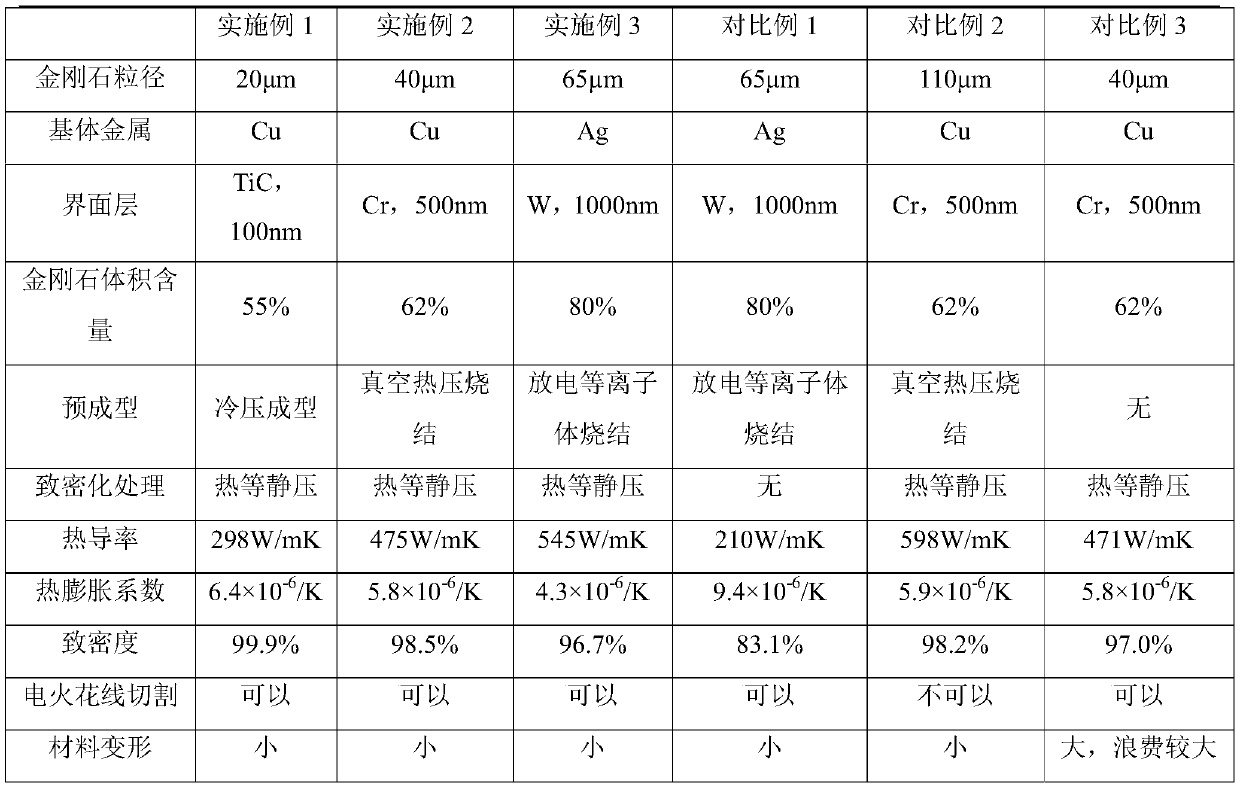

InactiveCN111519076AEliminate uneven powder mixingHigh thermal conductivityTransportation and packagingMetal-working apparatusInterface layerThermal expansion

The invention discloses a diamond particle reinforced metal matrix composite material and a preparation method and application thereof. The preparation method comprises the steps of 1, preparing an interface layer; 2, preparing a metal layer; 3, premolding; and 4, carrying out densification treatment. According to the diamond particle reinforced metal matrix composite material and the preparationmethod and application thereof, the adopted sintering of a two-step solid-phase method combined with the premolding and densification treatment is characterized by complementing for each other, fostering strengths and circumventing weaknesses, so that the the characteristic that the solid-phase sintering method capable of preparing a material with smaller particle size is retained, the size of thematerial prepared in a single batch is larger, the thickness reaches the centimeter level or a higher level, the production efficiency is higher, and the cost is greatly reduced; the prepared material has higher thermal conductivity, adjustable thermal expansion coefficient and better uniformity and reliability, and can be directly cut for processing by an electric spark wire; and meanwhile, thepremolding before the densification treatment can solve the problem that a bag sintered by directly adopting hot isostatic pressing is deformed too much so as to result in too much waste of the material, and the material utilization rate is higher.

Owner:成都本征新材料技术有限公司

High-carbon hot-rolled automobile diaphragm spring steel and production method thereof

The invention discloses high-carbon hot-rolled automobile diaphragm spring steel. The high-carbon hot-rolled automobile diaphragm spring steel is prepared from the following constituents in percentage by weight: 0.70-0.90% of C, Si smaller than or equal to 0.10%, Mn smaller than or equal to 0.80%, P smaller than or equal to 0.008%, S smaller than or equal to 0.003%, 0.010-0.030% of Alt, 1.20-1.80% of Cr, 0.10-0.30% of V, 0.002-0.006% of Ca, and N smaller than or equal to 0.004%, and is prepared by the following production steps: molten iron desulphurization, smelting in a converter, refining in an LF (Ladle Furnace) furnace, processing in an RH vacuum furnace, continuous casting to form blanks, pit type slow cooling after cutting of cast blanks, cast blank heating, segmented hot rolling, reeling, slow cooling, annealing, quenching, tempering, and inspection for standby. The steel disclosed by the invention is quenched and tempered to achieve tensile strength of 1600-2200 MPa, HRC (Rockwell Hardness) of 47-57, high limit of elasticity, high limit of yielding, high fatigue limit resistance and longer service life, and can be used for manufacturing various vehicle clutch assemblies for large engineering machinery.

Owner:武汉钢铁有限公司

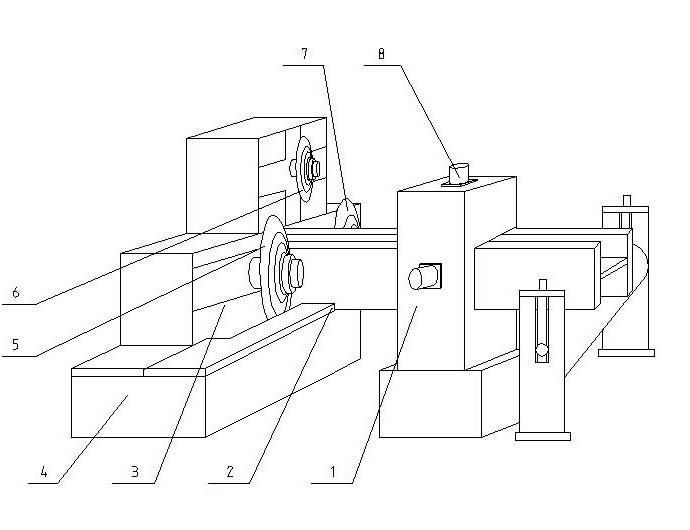

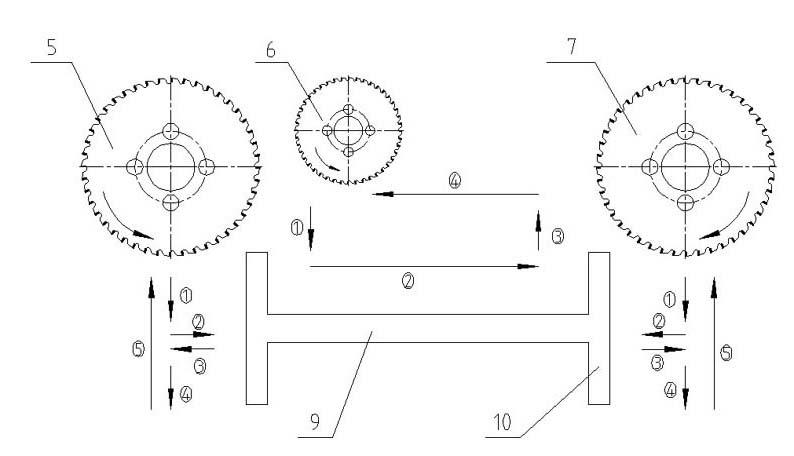

Three-segment profiled H-shaped steel rapid saw cutting device and method

InactiveCN102658397ASimple structureEasy to operateMetal sawing devicesMetal sawing toolsCircular sawEngineering

The invention discloses a three-segment profiled H-shaped steel rapid saw cutting device, which comprises a sawing machine provided with a circular saw web, wherein a loading workbench is arranged at the bottom of the sawing machine; a roller path is formed on the loading workbench; a horizontal saw web for cutting an H-shaped steel web plate and vertical saw webs for cutting an H-shaped steel flange are arranged on the sawing machine; the vertical saw webs are arranged on both sides of H-shaped steel respectively; the horizontal saw web is arranged between the two vertical saw webs and above the H-shaped steel; and the three blades are arranged on the same plane. The saw cutting device provided by the invention has the advantages of simple structure, convenience for operating, low manufacturing cost and high saw cutting precision; and a method for performing rapid saw cutting on the H-shaped steel by using the device is simple, the conventional discontinuous saw cutting is replaced by three-segment continuous cutting, the cutting difficulty is lowered, and the saw cutting stability is improved.

Owner:TANGSHAN METALLURGICAL SAW BLADE

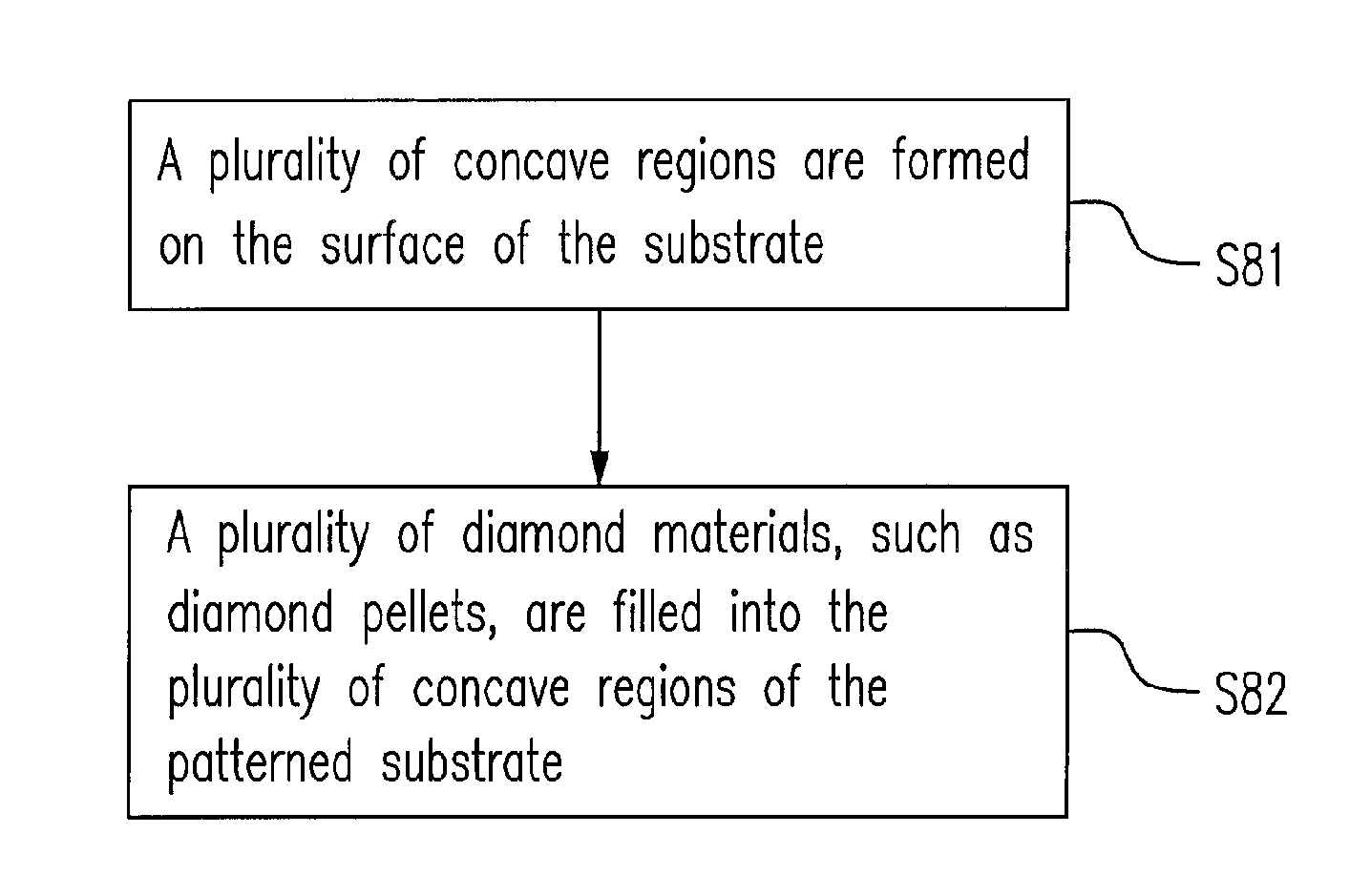

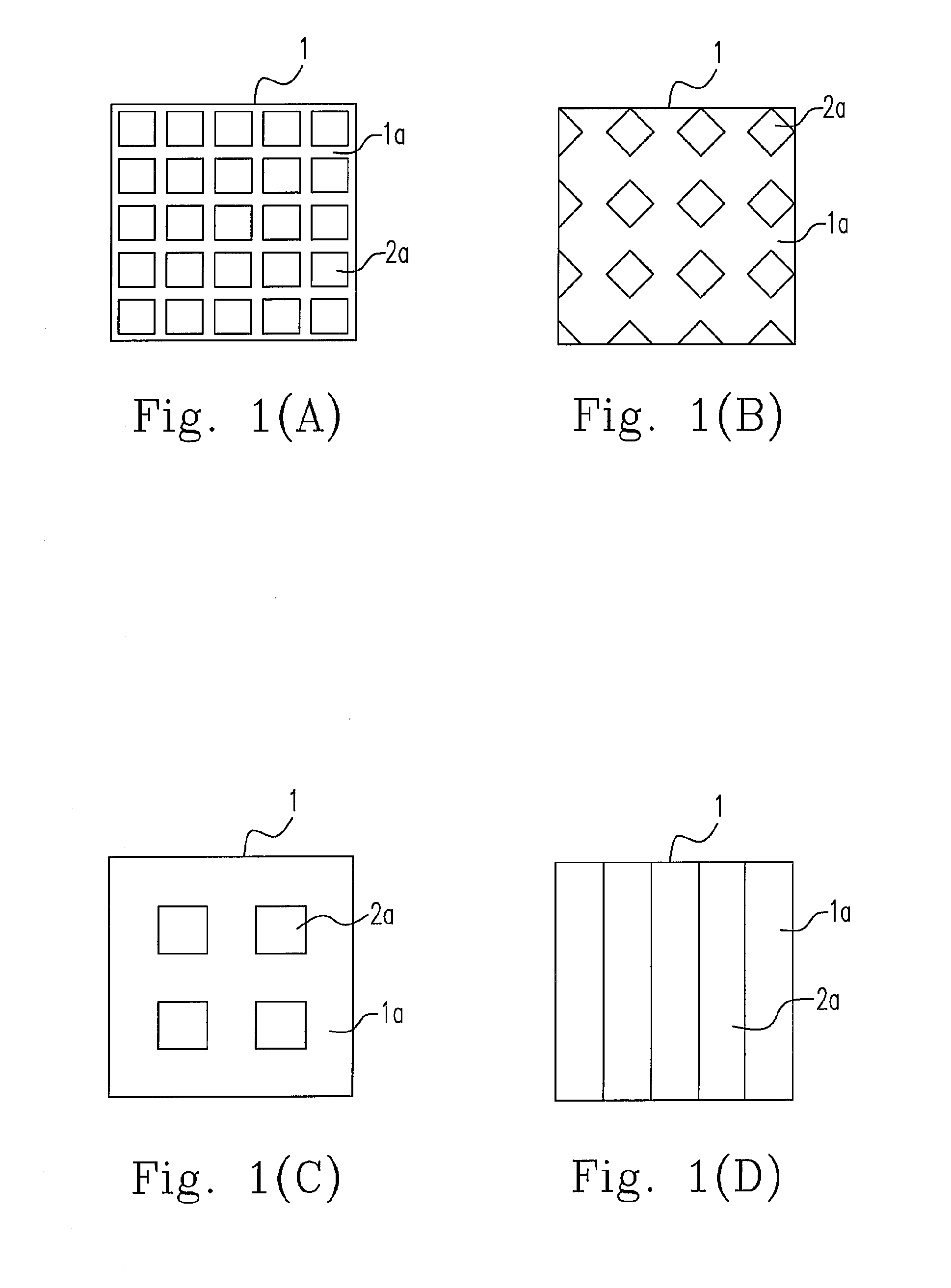

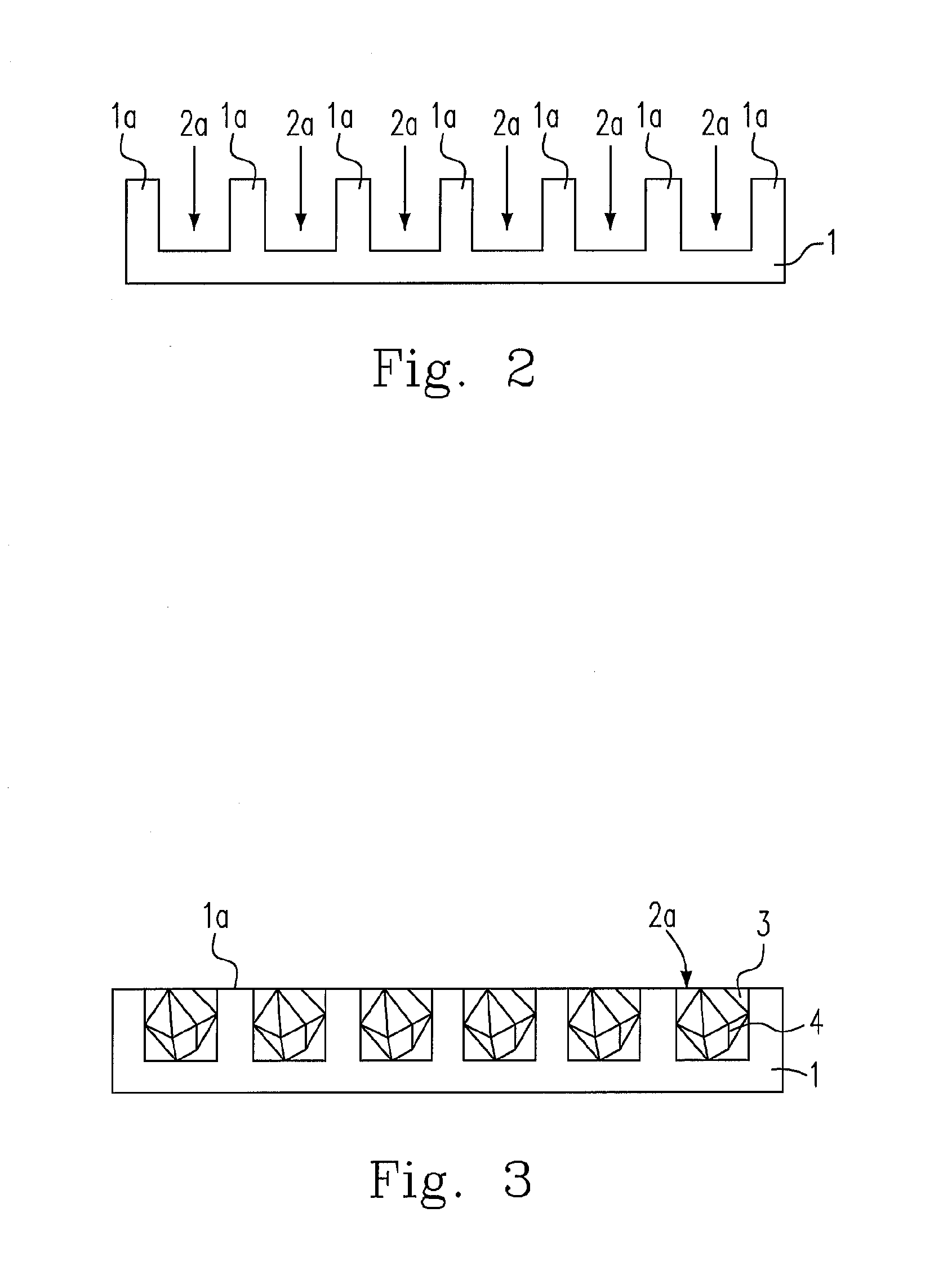

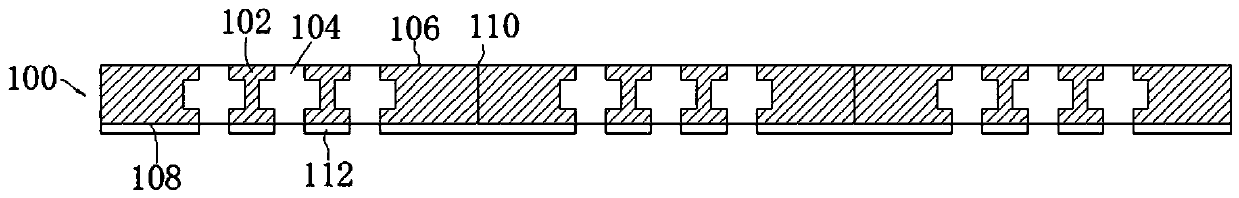

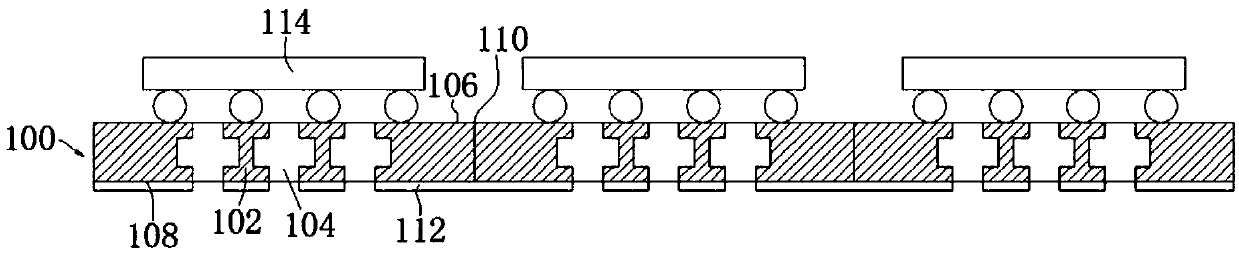

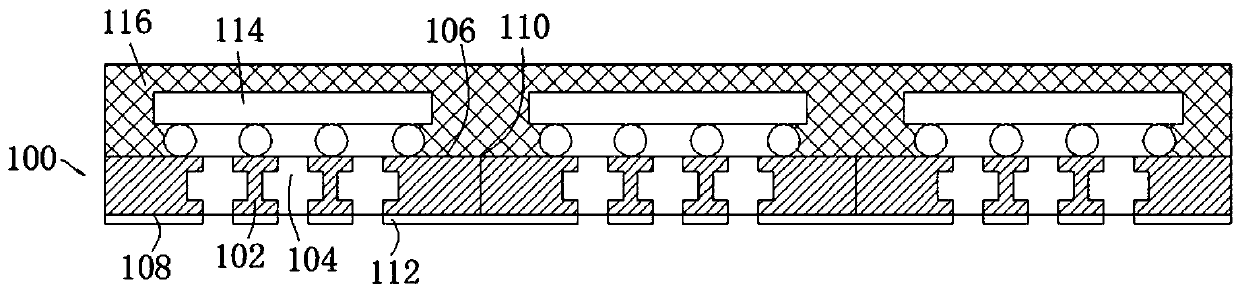

Thermal dissipation substrate

InactiveUS20120273803A1Reduce the difficulty of cuttingSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceThermal coefficient

The present invention related to a method for manufacturing a thermal dissipation substrate and a thermal dissipation substrate. The method includes steps of: (a) providing a substrate body having a surface; (b) forming a plurality of concave regions on the surface; and (c) filling the plurality of concave regions with a plurality of diamond materials. The thermal dissipation substrate includes: a substrate having a surface at a first horizontal; a plurality of regions formed on the surface at a second horizontal; and a plurality of diamond materials having a relatively high thermal coefficient and disposed on the plurality of regions.

Owner:NAT CHIAO TUNG UNIV

Clipping device for pipes

InactiveCN106217467ACause some damagesSo as not to damageMetal working apparatusEngineeringHuman health

The invention discloses a clipping device for pipes. The clipping device comprises a device base, a rotating cylinder and a clamping device; the rotating cylinder is provided with a cutting device used for cutting the pipes and the rotating cylinder is further provided with a heating device for heating and softening cut openings of the pipes; fragments and floating dust do not occur after the pipes are heated and softened, dedusting effects are better, environment and human health are not damaged, no extra dust collection equipment needs to be arranged, working noises are reduced, cost is reduced, and funding is reduced; notches are flatter, and cutting effects are better; the clipping device is particularly suitable for hard large-caliber PVC pipes, the cutting difficulty of the large-caliber PVC pipes can be greatly reduced, the cut end faces are flat, smooth, attractive and free of burrs, the pipes are not damaged, knives are not snapped, and cutting efficiency is improved; and the clipping device is simple in structure and practical.

Owner:司徒文芳

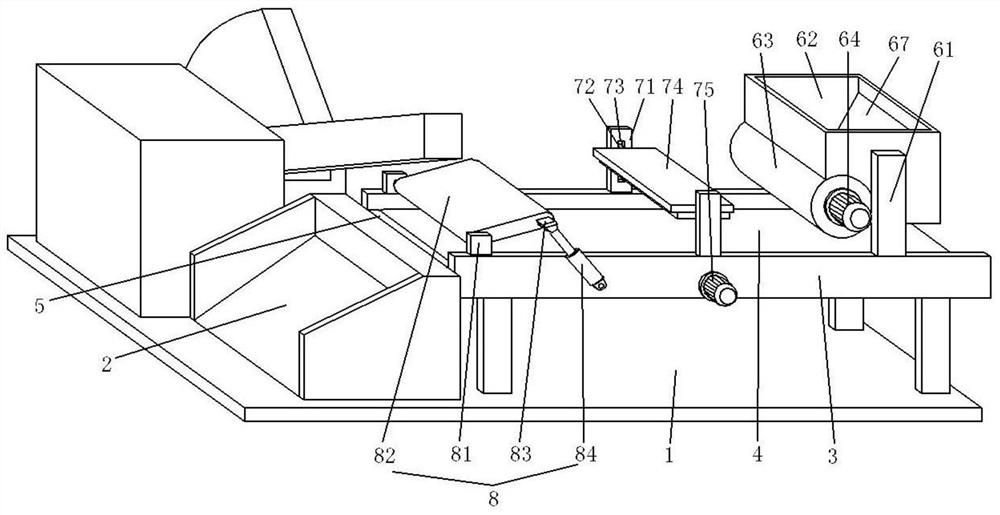

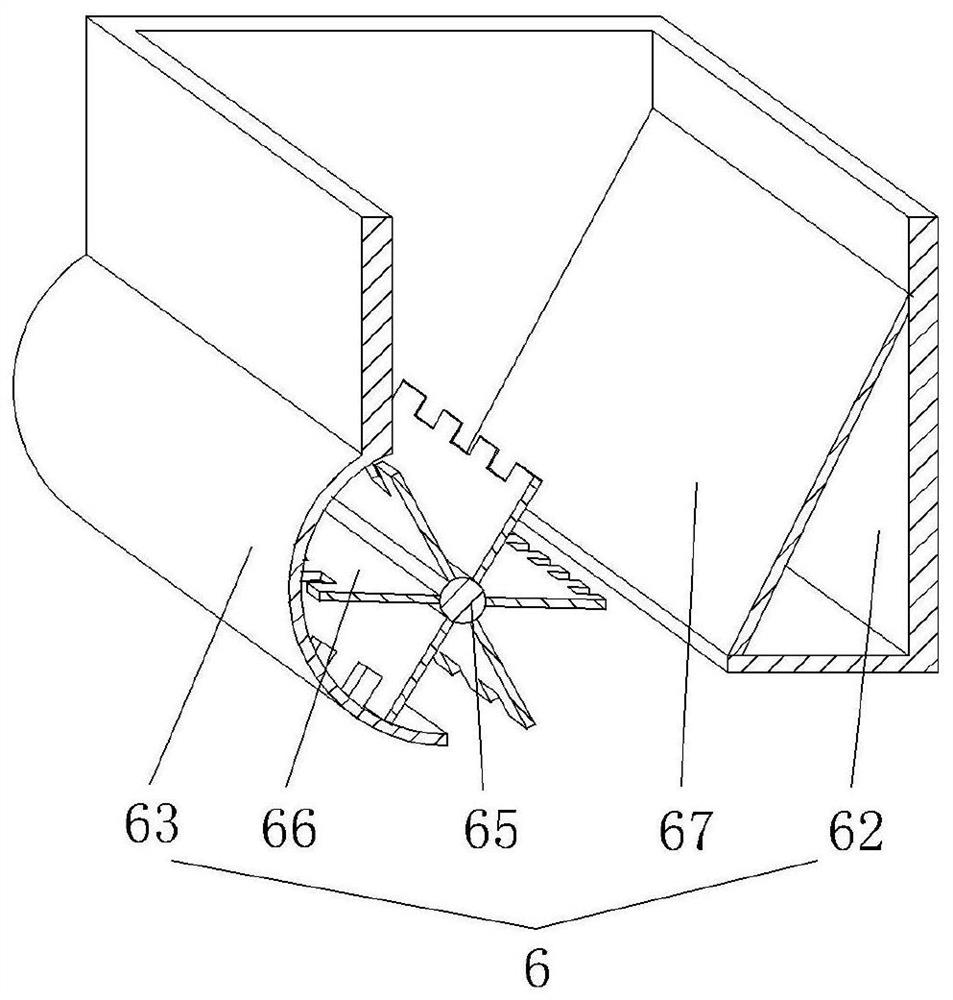

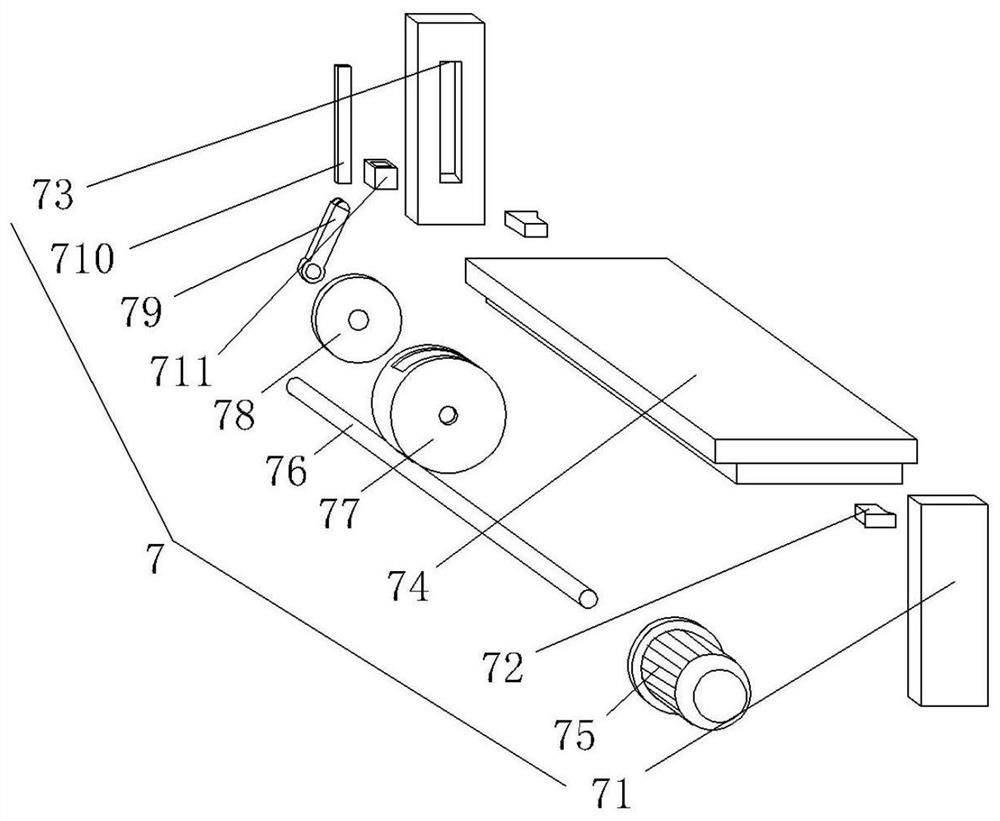

Full-automatic intelligent cutting all-in-one machine

A fully automatic intelligent cutting all-in-one machine, including a strip cutting mechanism, a fixed manipulator and a twisting and cutting mechanism. One end of the cutting wire of the strip cutting mechanism is wound on the wire roller, and the other end first passes through the wire hole on the first guide block. Then pass through the upper line hole of the second guide block, and finally be fixedly connected to the strip cutting frame. The annular track and the chain ring of the twisted block cutting mechanism are fixed on the outer wall of the cylinder, and pulleys are installed on the cube frame around the cylinder. The installation position of the pulley is matched with the ring track, the sprocket is installed on the output shaft of the cylinder drive motor, the sprocket is engaged with the chain ring, one end of the cut twisted rope is fixed on the cylinder, and the other end of the cut twisted rope is fixed on the cube frame superior. Taking hair cake as an example, using the present invention can first cut a large piece of round or square hair cake into strips of a certain specification, so that it can be cut into small pieces later, reducing the difficulty of cutting and improving work efficiency.

Owner:GUANGXI PROVINCE NANNING CITY XUXI TECH CO LTD

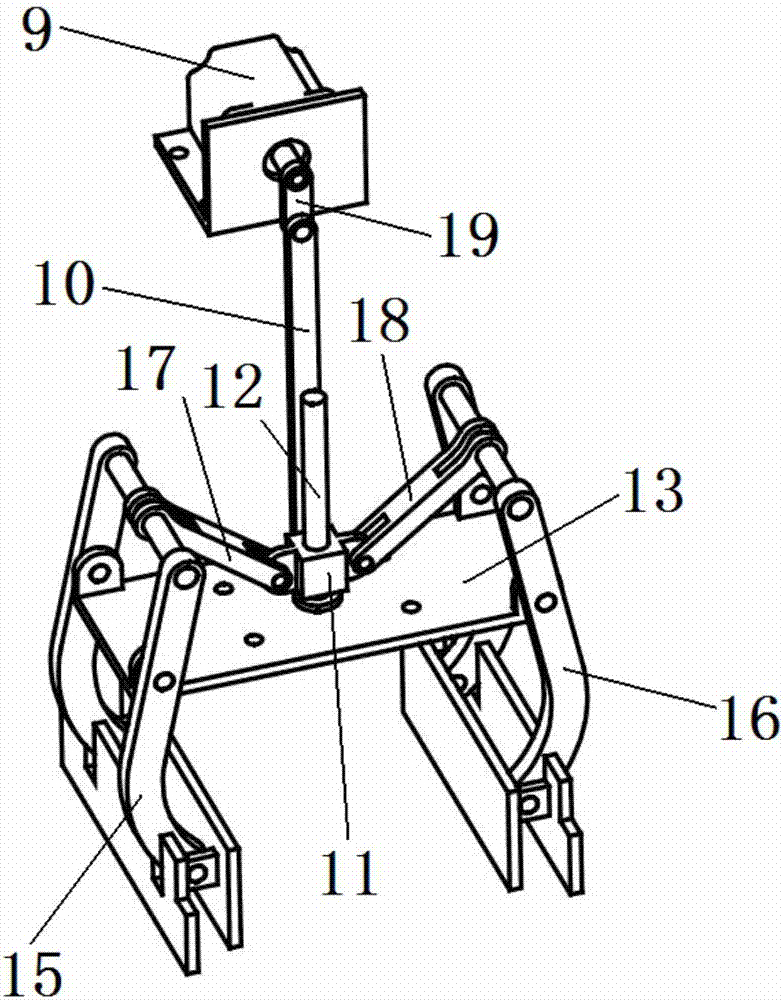

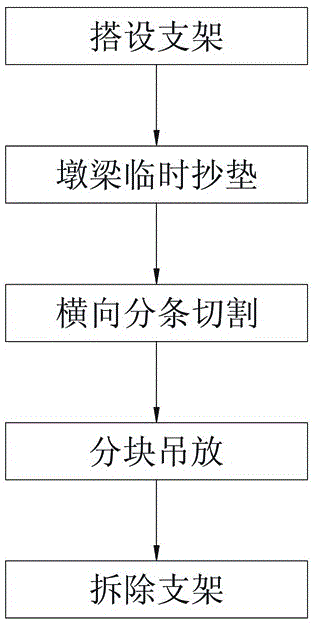

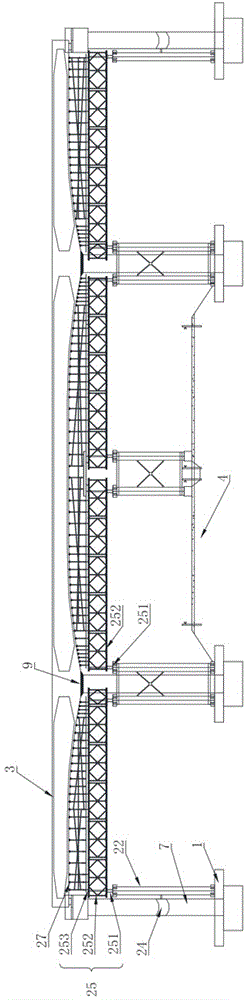

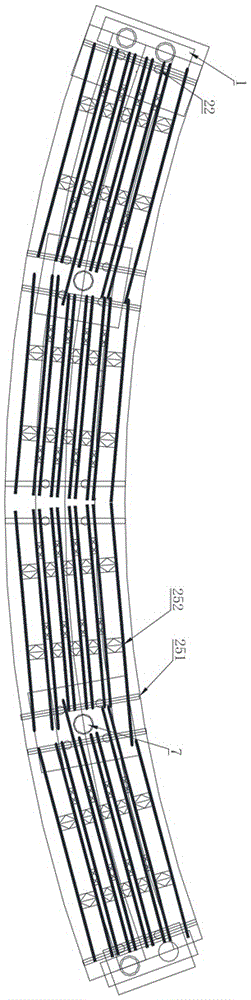

Over-line continuous beam removing method and support for removing

ActiveCN106638336AReduce bearing riskImprove securityBuilding repairsBridge strengtheningContinuous beamEngineering

The invention discloses an over-line continuous beam removing method. The method comprises the following steps of 1 support erecting, 2 temporary pier beam padding, 3 transverse stripping, 4 blocking hanging and 5 support removing. The invention further discloses a support for removing in the method. The support comprises supporting pieces and hoops, the supporting pieces are arranged on bearing platforms on the peripheries of the bottoms of the corresponding piers and are parallel to the piers, the supporting pieces are clamped on the sides of the piers through the hoops, distribution beam groups are installed on the tops of the adjacent two supporting pieces in an overlapping mode, and a bearing support used for bearing the weight of a bridge when the bridge is removed is installed on the tops of the distribution beam groups. The method has the advantages of being safe, stable, environmentally friendly in construction and the like, and the support has the advantages of being convenient to operate, capable of reasonably utilizing the mechanics principle and high in construction efficiency.

Owner:SINOHYDRO BUREAU 8 CO LTD

Numerical control cutting machine tool

InactiveCN107186784AEasy to cleanReduce the difficulty of cuttingMetal working apparatusNumerical controlEngineering

A CNC cutting machine tool, the first pulley is installed on the first rotating shaft, the second pulley and the sixth pulley are installed on the second rotating shaft, the fifth pulley and the wire roller are installed on the fifth rotating shaft, The first belt tension is installed on the first pulley and the second pulley, the third belt tension is installed on the fifth pulley and the sixth pulley, the third pulley is installed on the third shaft, and the fourth belt The pulley is installed on the fourth rotating shaft, the second belt tension is installed on the third pulley and the fourth pulley, the first guide block is fixed on the first belt, the second guide block is fixed on the second belt, the cutting line One end is wound on the wire roller, the other end first passes through the wire hole on the first guide block, then passes through the wire hole on the second guide block, and finally is fixedly connected to the strip cutting frame. Taking hair cake as an example, using the present invention can make large A piece of round or square hair cake is cut into strips of certain specifications for subsequent cutting, reducing cutting difficulty and improving work efficiency.

Owner:GUANGXI PROVINCE NANNING CITY XUXI TECH CO LTD

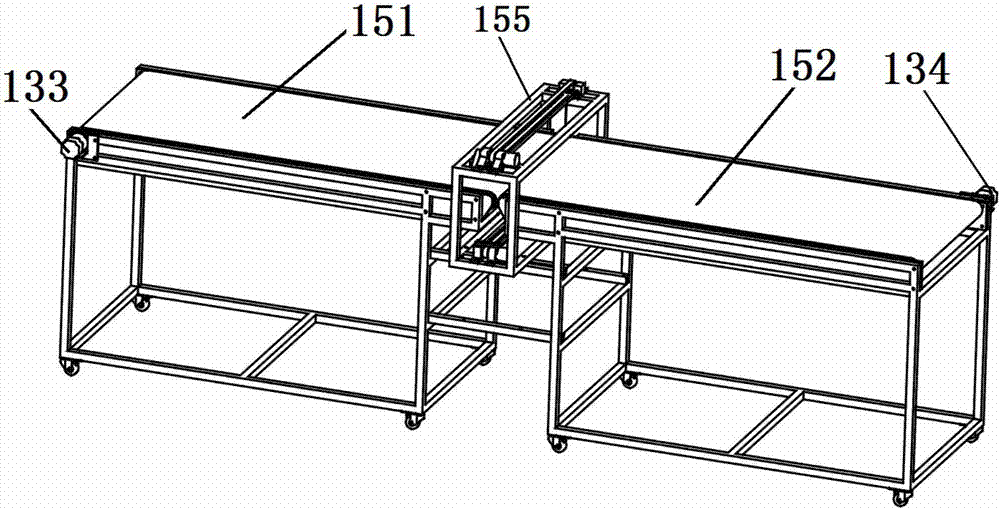

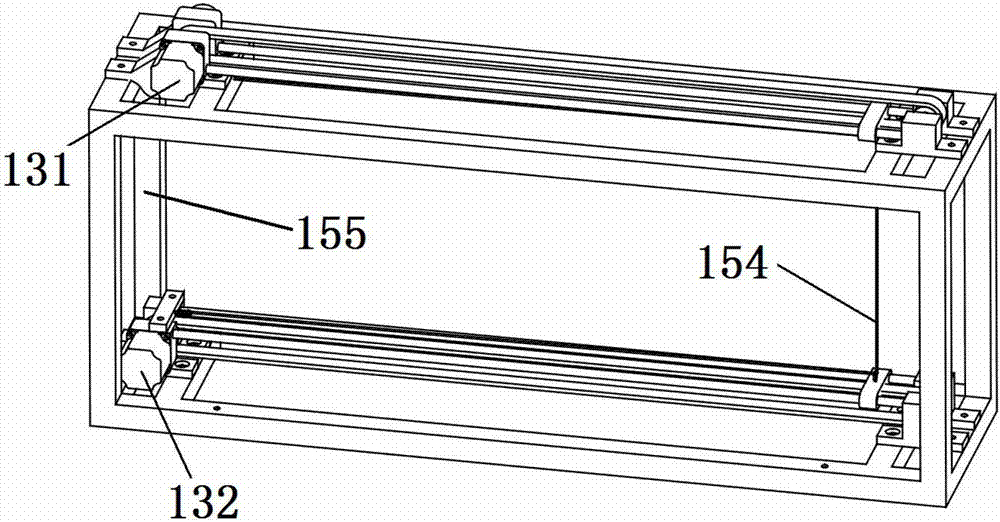

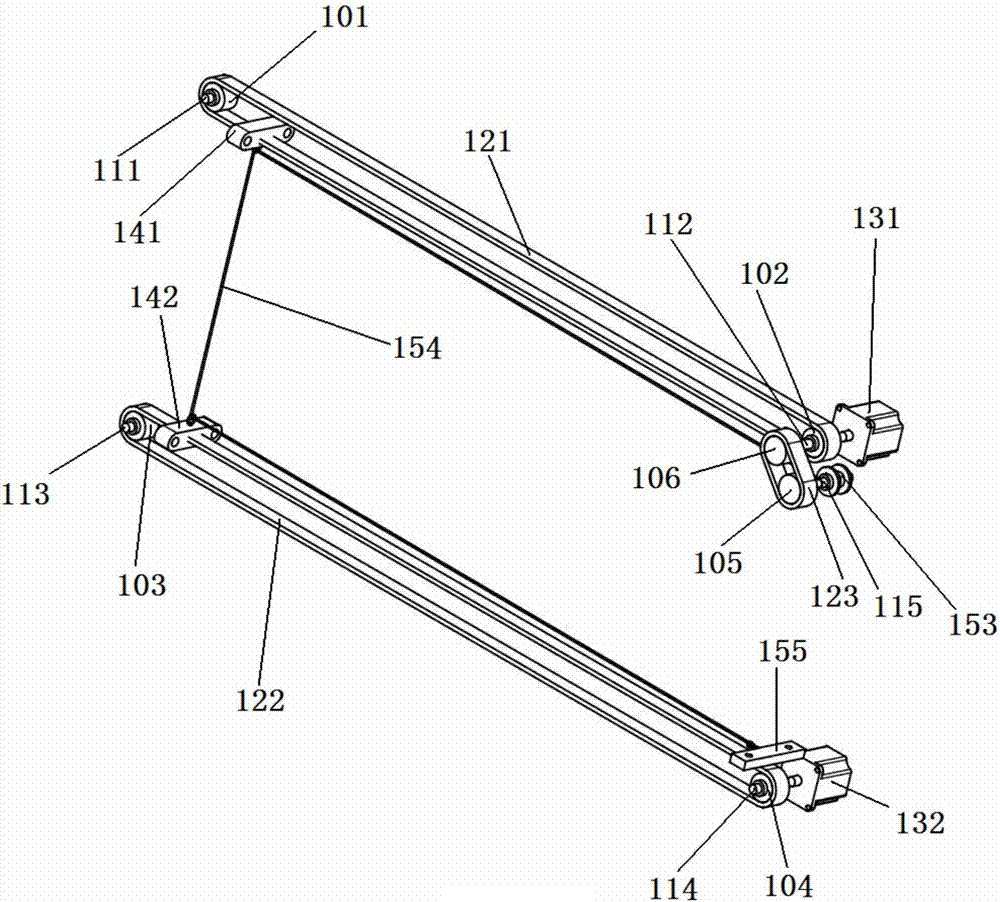

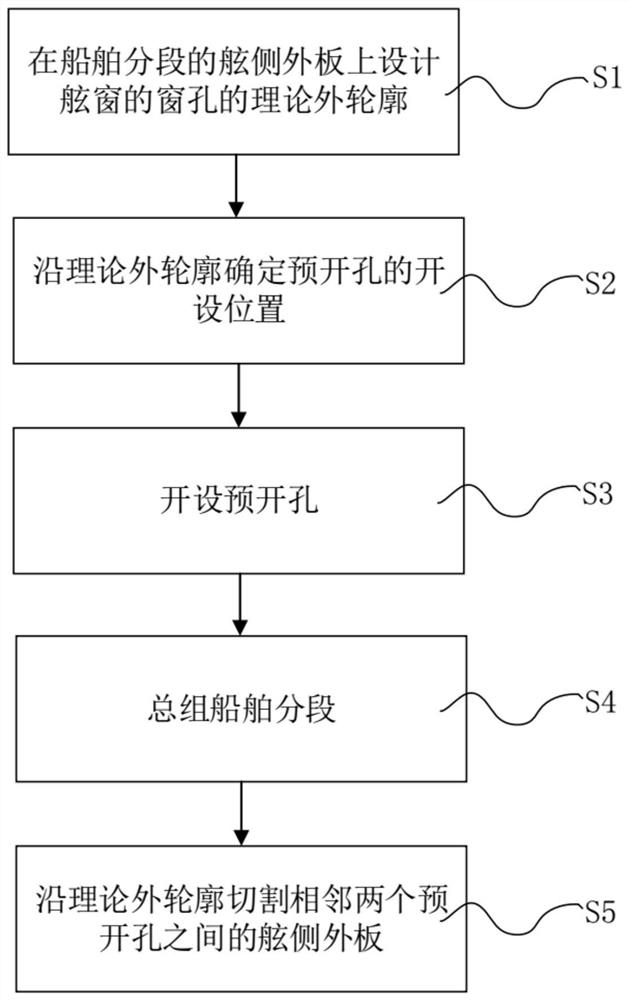

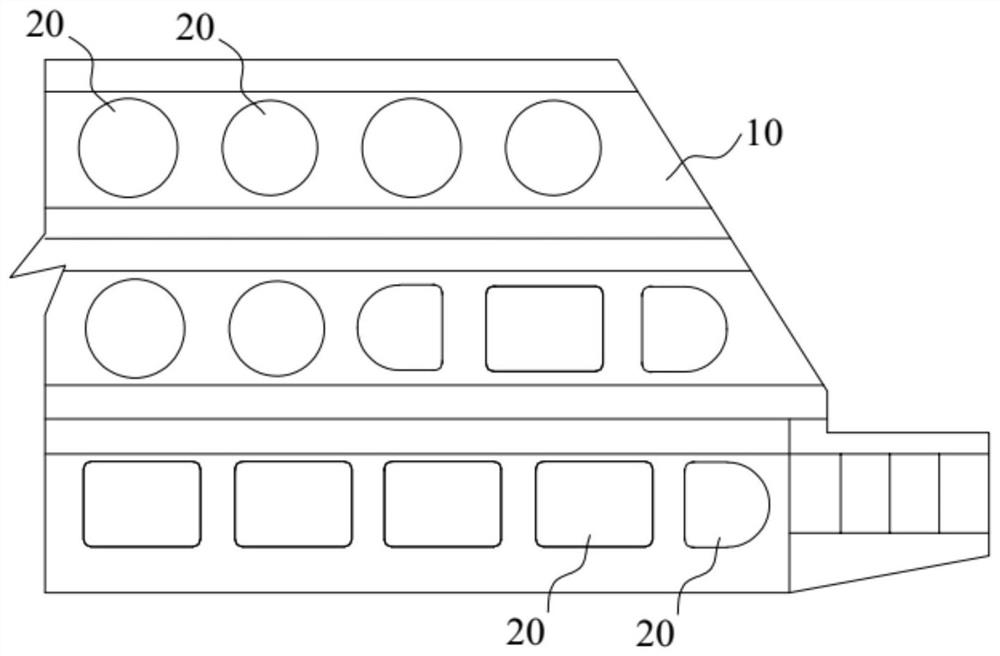

Ship porthole forming method, porthole and ro-ro passenger ship

ActiveCN111776165AShorten the construction periodImprove efficiencyVessel portsClassical mechanicsOpen hole

The invention relates to the technical field of ships, and discloses a ship porthole forming method, a porthole and a ro-ro passenger ship. The ship porthole forming method comprises the following steps: S1, the theoretical outer contour of porthole holes of a porthole is designed on a broadside outer plate of a ship segment; S2, the forming positions of pre-formed holes are determined along the theoretical outer contour; S3, the pre-opened holes are tapped; S4, total ship block segmentation is performed; and S5, a broadside outer plate between every two adjacent pre-formed holes is cut alongthe theoretical outer contour. The tapping efficiency and the tapping quality are improved, the cost is reduced, and the construction period of a ship is shortened.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

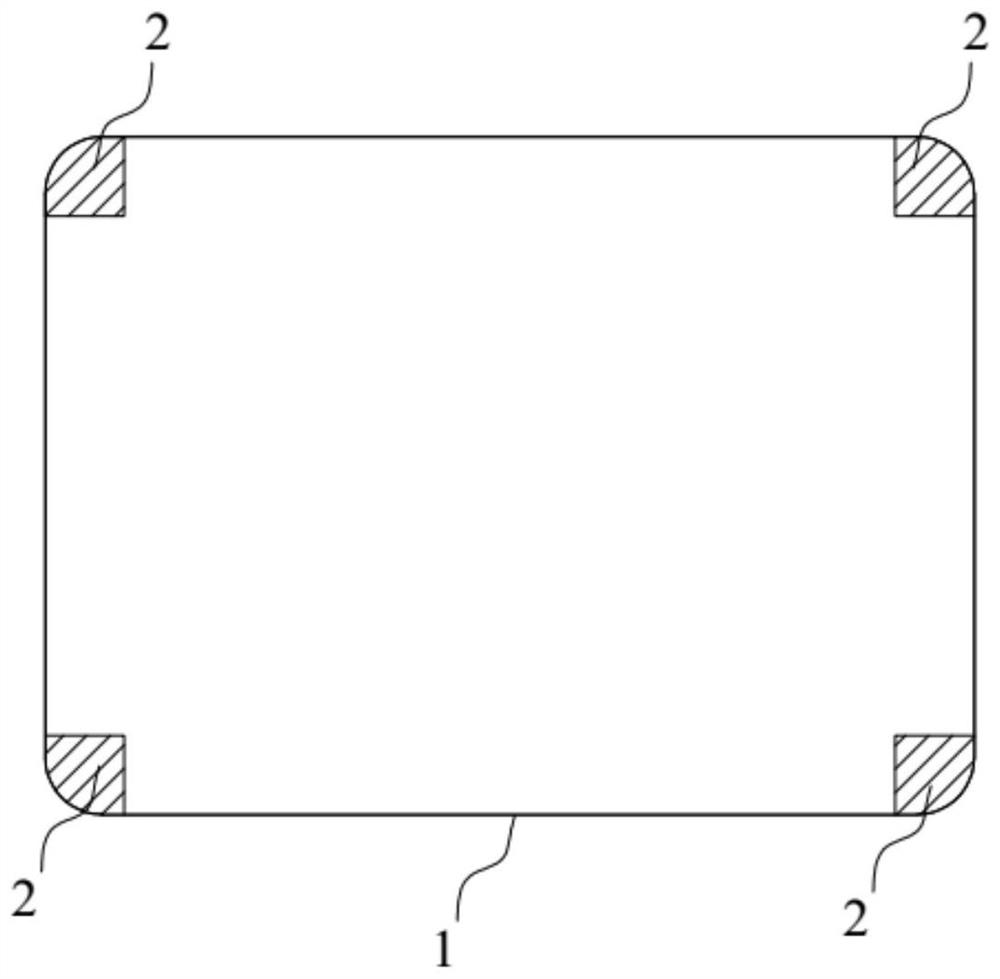

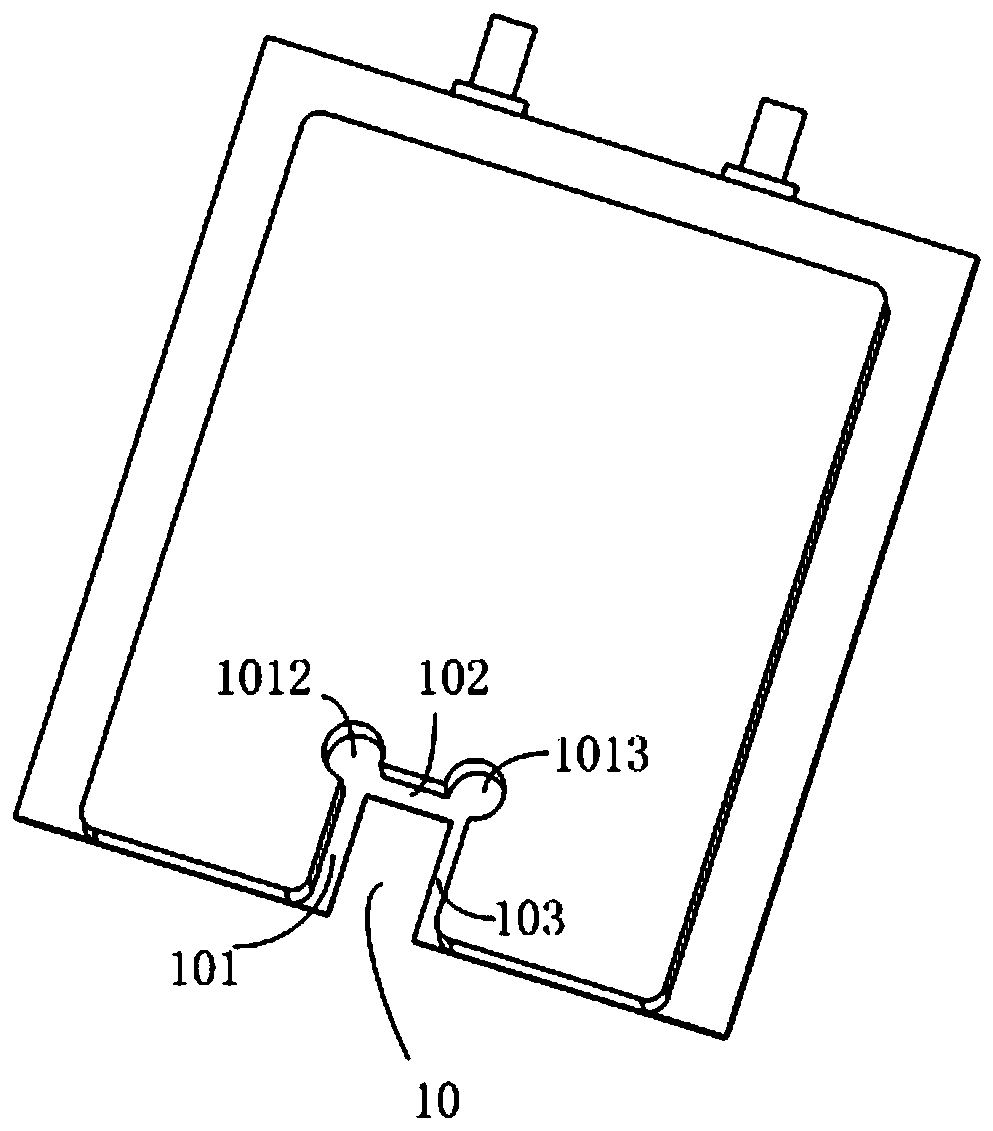

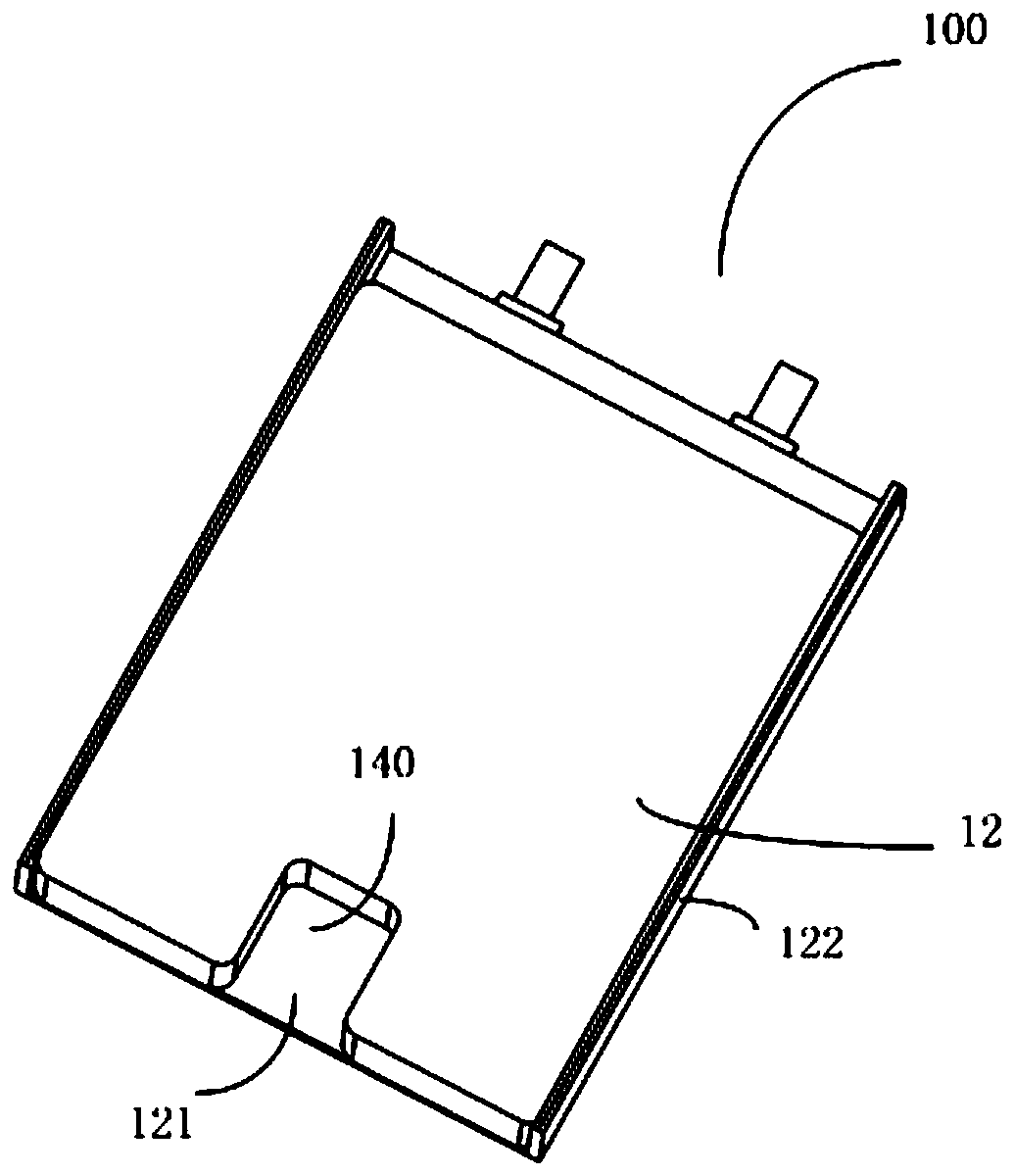

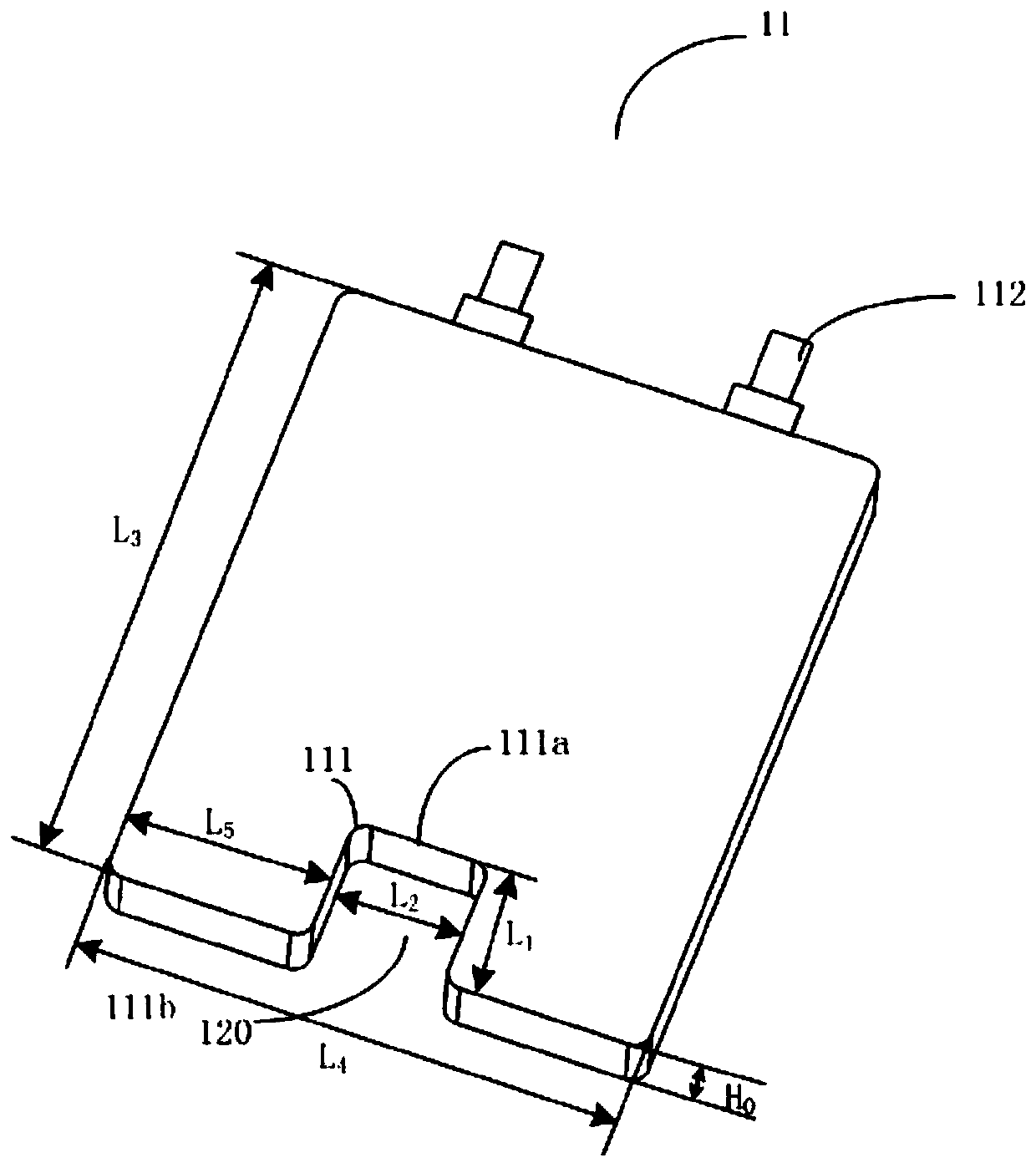

Battery, packaging method thereof and terminal

ActiveCN109786844ASimple processImprove packaging efficiencyFinal product manufactureCells structural combinationEnergy densityElectrical and Electronics engineering

The embodiment of the invention provides a battery packaging method and a battery. The battery comprises a naked battery core and a packaging film, wherein the edge of the naked battery core comprisesat least one first open space; the first open space passes through the thickness direction of the naked battery core; no naked battery core is arranged in the first open space; an enclosed space foraccommodating the naked battery core is enclosed with the packaging film; the packaging film is provided with a first sealing part in the first open space; the first sealing part does not cover the naked battery core; a second open space is enclosed by the first sealing part and the packaging film on a side wall of the first open space; and the first open space and the second open space are coincided partially. Through adoption of the battery packaging method, on the basis of keeping the battery shape flexibility, the cutting and folding times of the packaging film in the packaging process arereduced, and the packaging process is simplified. Moreover, a large-sized chamfer does not need to be formed at the corner of the open space of the naked core edge; energy density loss is avoided; and meanwhile the pole plate cutting difficulty is lowered. The embodiment of the invention also provides a terminal including the battery.

Owner:HUAWEI TECH CO LTD

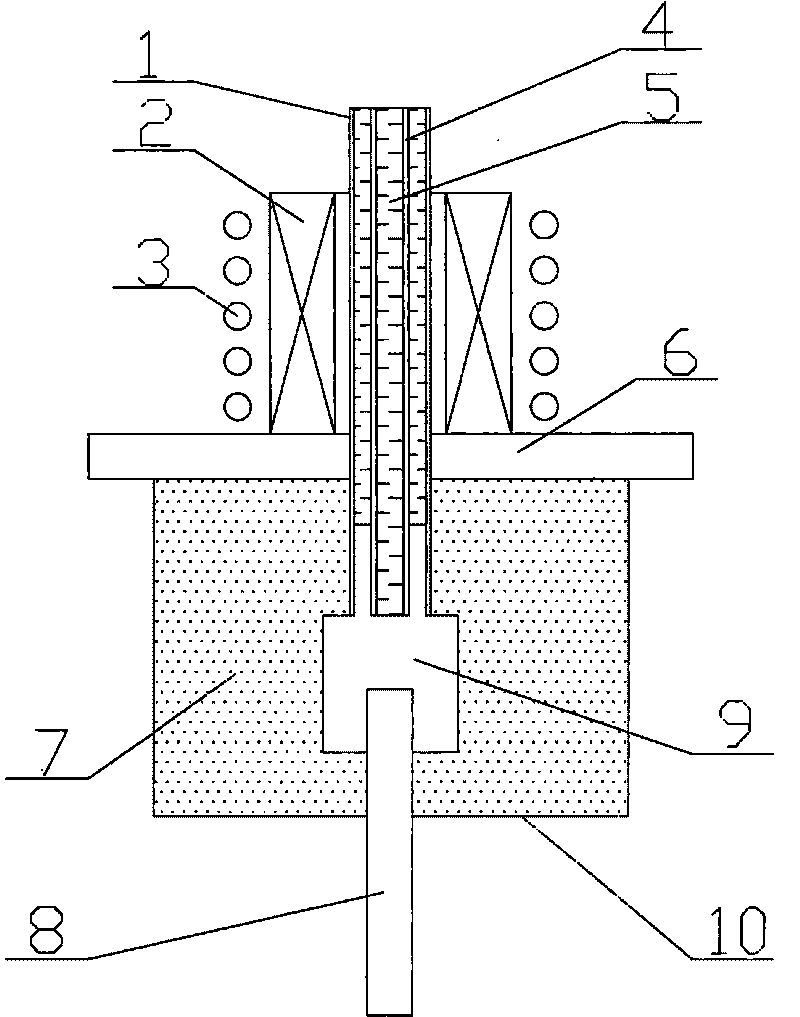

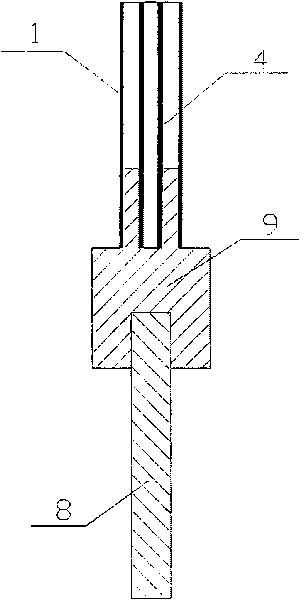

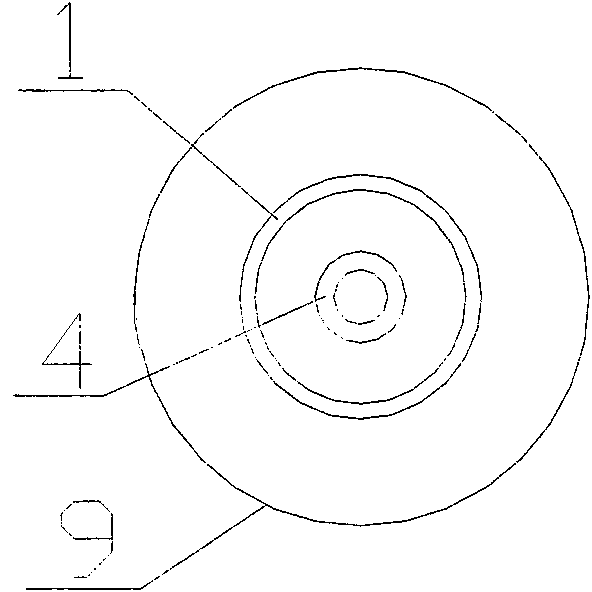

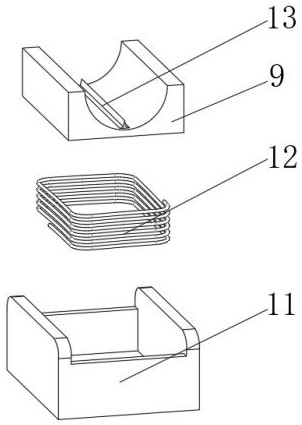

Growing device and growing method of lithium triborate (LBO) crystal

ActiveCN103668455ASimple structureEasy to manufactureAfter-treatment apparatusPolycrystalline material growthCrucibleSingle crystal

The invention relates to a growing device of a lithium triborate (LBO) crystal. The growing device comprises a crucible and a convex part which is arranged on the inner bottom of the crucible. The invention also relates to a growing method of the LBO crystal. Growth of the LBO crystal is carried out by adopting the growing device. The growing device provided by the invention is simple in structure, simple and convenient to manufacture, and low in cost. By adopting the growing device and the growing method provided by the invention, large-caliber flat LBO single crystal can be directly grown, the cutting difficulty of a crystal apparatus is reduced, the utilization rate of the crystal is obviously improved, the processing link is reduced, the growth period of the crystal is shortened, and the manufacturing cost is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

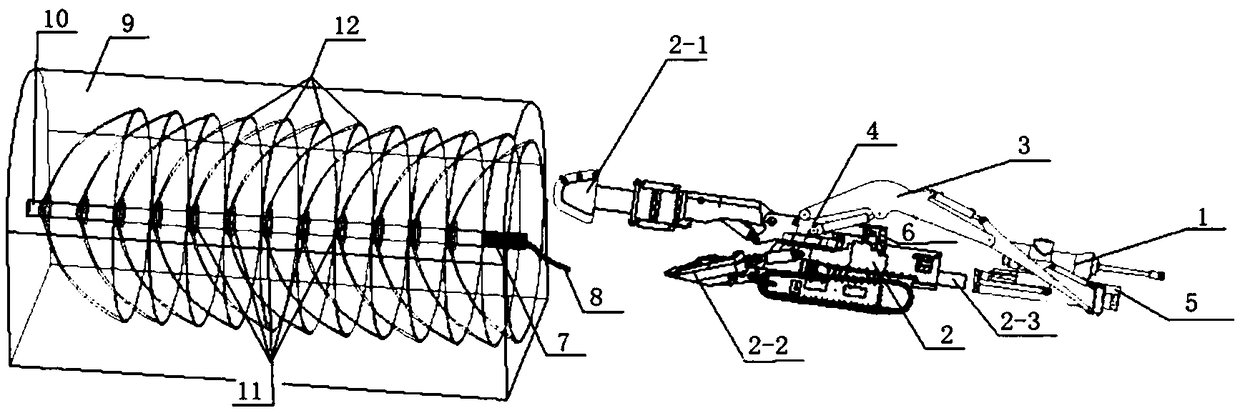

Tunneling method capable of weakening hard rock strength

ActiveCN108691508ADrilling heightImprove efficiencyLiquid/gas jet drillingSlitting machinesEngineeringHigh pressure water

The invention discloses a tunneling method capable of weakening hard rock strength. According to the method, a tunneling machine, an integrated grinding jetting drilling machine with the tunneling machine as a carrier, and a high-pressure water pump are arranged on a tunneling working surface; the integrated grinding jetting drilling machine is adopted to form drilled holes in a rock body, and a series of conical crack clusters are formed through cracking cutting on the basis of hole drilling; a high-pressure hole sealing device is used for sealing the tunneling surface for a distance, the high-pressure hole sealing device is communicated with a high-pressure water pump through a water inlet pipe, the characteristic that the rock body is resistant to pressure but not resistant to drawing is utilized, the conical crack clusters in the rock body are expanded to form a dense conical crack net, and therefore the rock strength is weakened; a tunneling machine cutting head is adopted to cutthe rock which has an internal conical crack net, the tunneling efficiency is greatly improved, the service life of the tunneling machine can be prolonged, and the tunneling cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

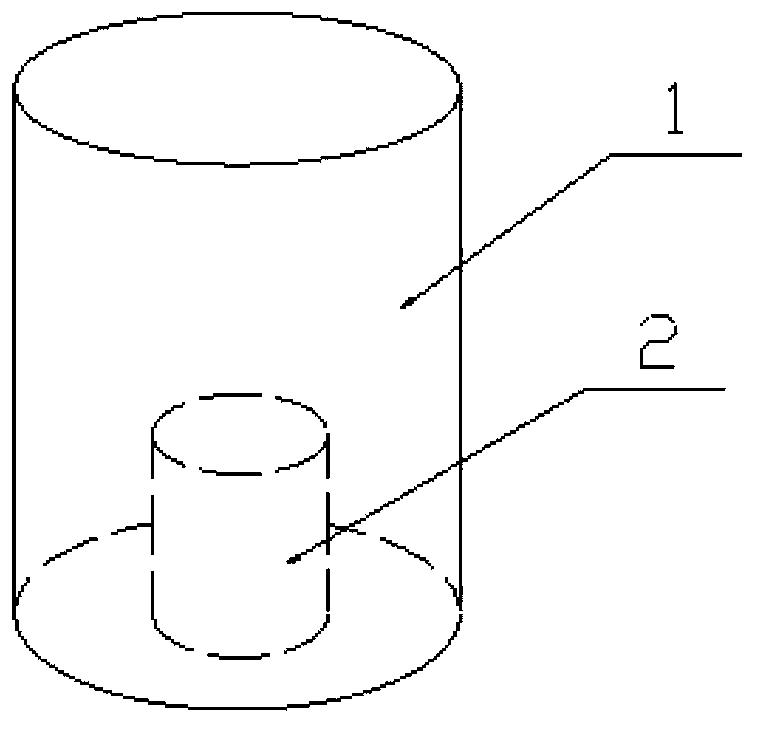

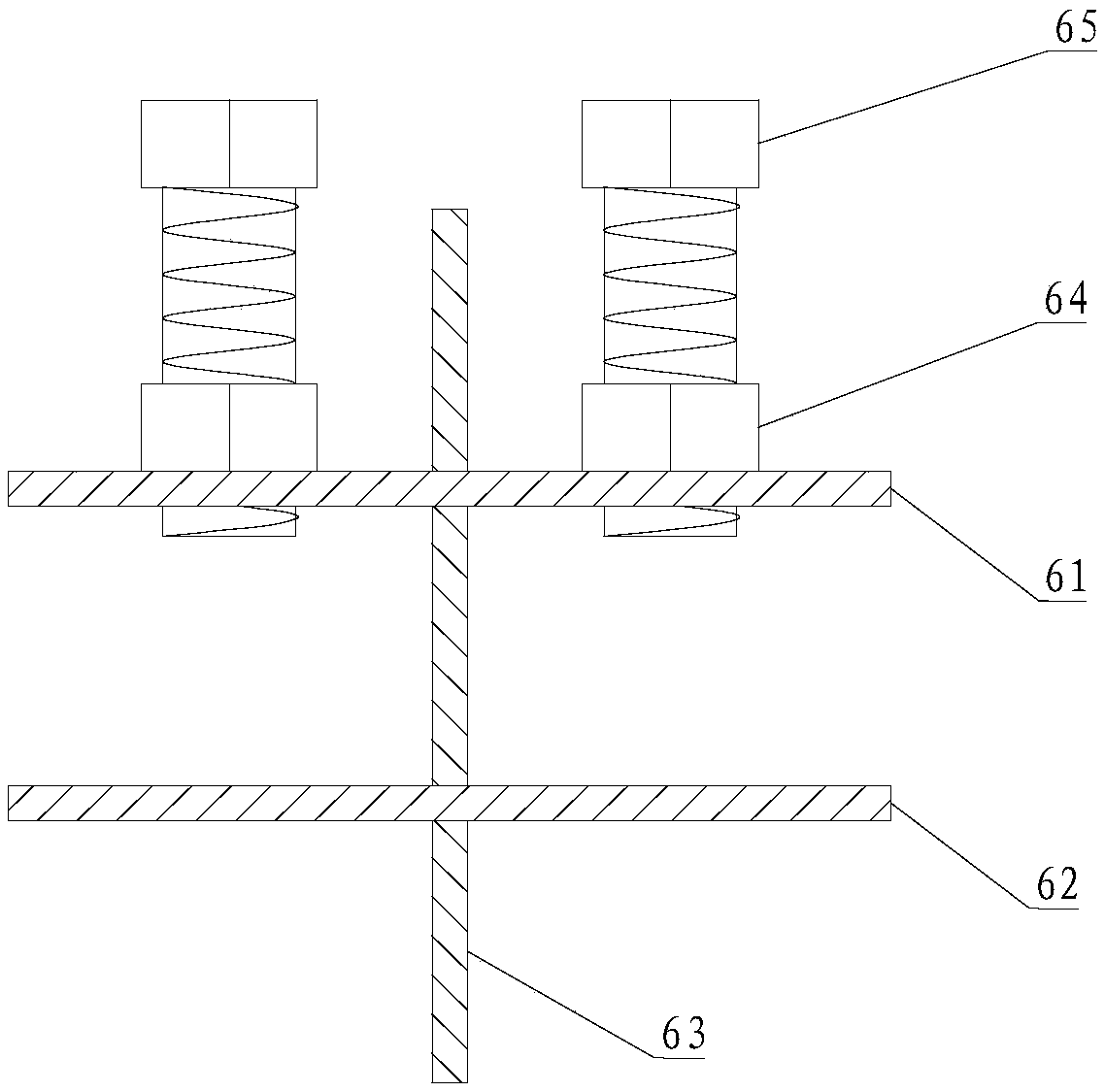

Double-crucible directional solidification device

InactiveCN101718722AReduce the difficulty of cuttingEliminate the effects ofMaterial thermal analysisCrucibleEngineering

The invention relates to a double-crucible directional solidification device. A crucible comprises a big crucible (1) and a small crucible (4), wherein the small crucible (4) is nested in the big crucible (1); the big crucible (1) and the small crucible (4) are coaxial and form a double crucible; one end of the double crucible is positioned in a cooler (10) and is connected with the other end of a joint (9); and the other end of the double crucible penetrates through a through hole in the center of a heat insulation plate (6) and is arranged in an induction coil (3). In the invention, the temperature fields of fusants in the two coaxial crucibles are consistent, and a condition that test bars with different diameters are drawn and pulled simultaneously under the same experimental parameter is provided. Compared with the prior art, the invention eliminates the influence of different temperature fields on the directional solidification microstructures of samples, is more suitable for researching the influence of the convection of the fusants on the microstructures in a directional solidification process and has the characteristics of convenient use and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

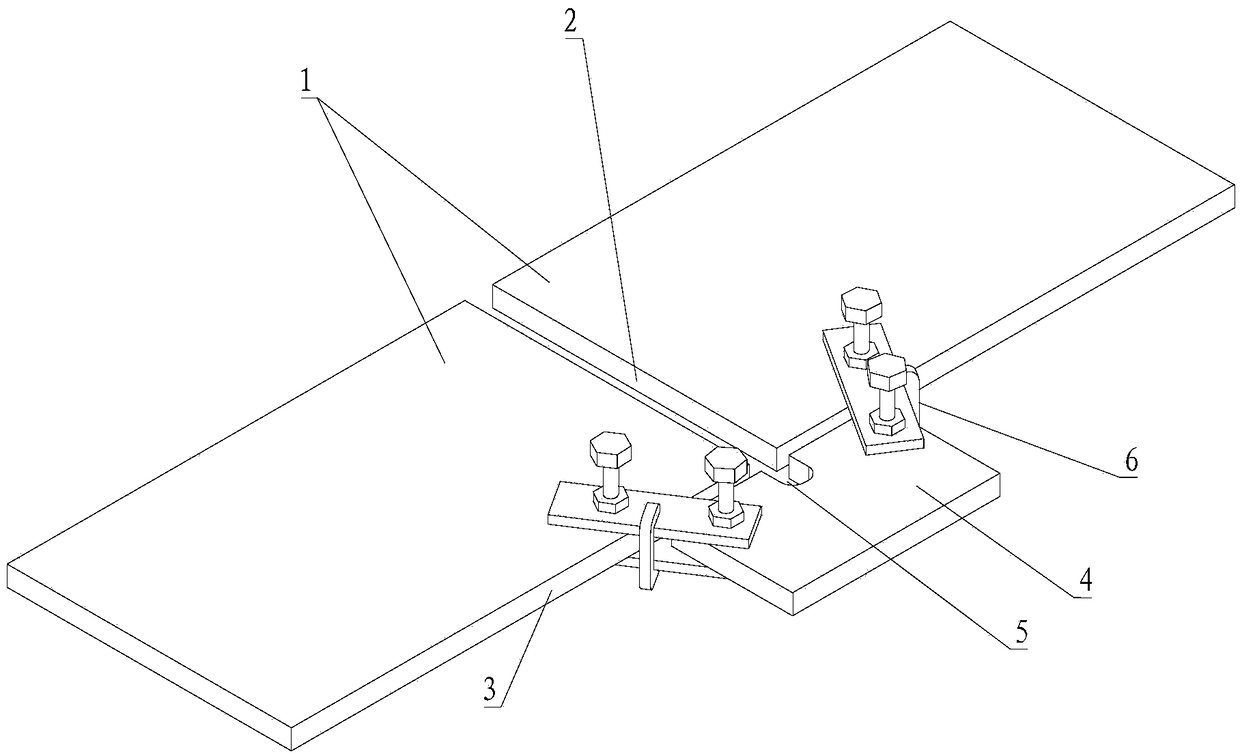

Connection auxiliary structure for metal splicing plate, and connection method for metal splicing plate

PendingCN108857218APrevent falling and hurting peopleAvoid destructionWelding/cutting auxillary devicesArc welding apparatusButt jointMetal

The invention relates to the technical field of metal splicing plates, in particular to a connection auxiliary structure for a metal splicing plate, and a connection method for the metal splicing plate. The surface, facing the connection auxiliary structure, of base metal is a free surface, and a metal plate comprises an alignment surface facing the free surface; the free surface is parallel withthe alignment surface, and the distance between the free surface and the alignment surface is 0.1-5 mm; the metal plate is provided with a guide slot which is parallel with and aligned to a butt joint, and the guide slot extends toward the interior of the metal plate from the alignment surface; and the metal plate is connected the base metal through clippers. According to the connection auxiliarystructure, the metal plate is connected to the base metal through the clippers; through the set distance between the metal plate and the base metal, the allowance can be reserved for cutting a weld joint; when the metal plate is separated from the base metal, only the weld joint needs to be cut, and the reprocessing of a plurality of working procedures including repair and grinding of the free surface is avoided; and only the weld joint in the base metal needs to be ground.

Owner:FUJIAN MAWEI SHIPBUILDING

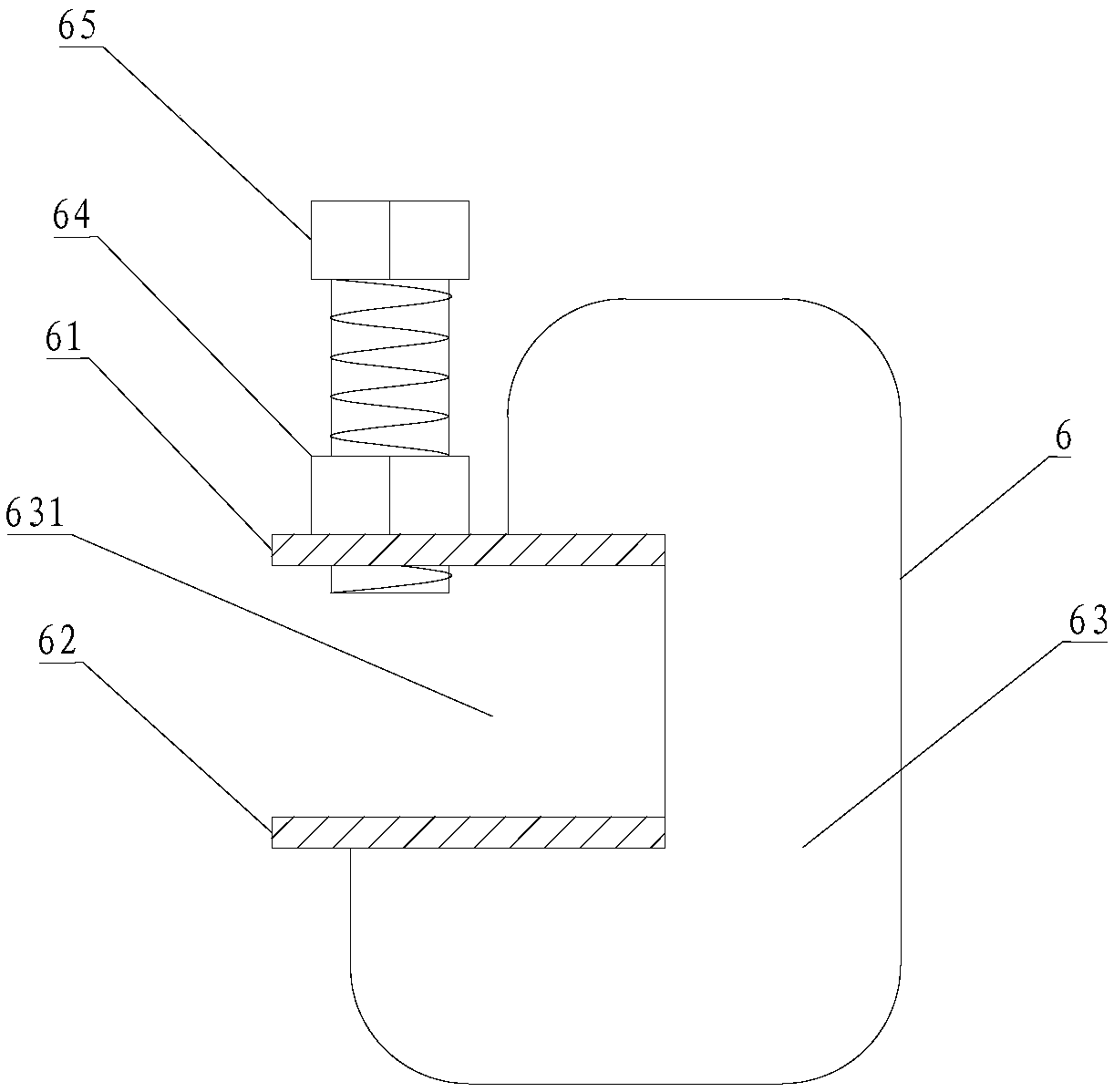

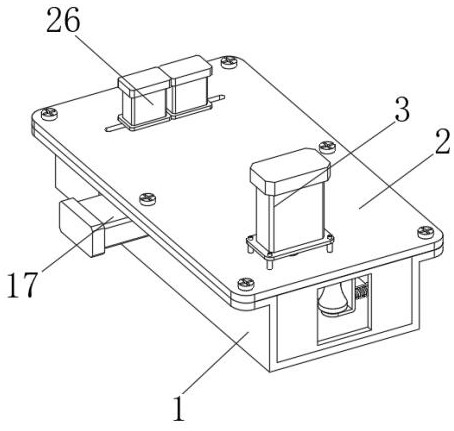

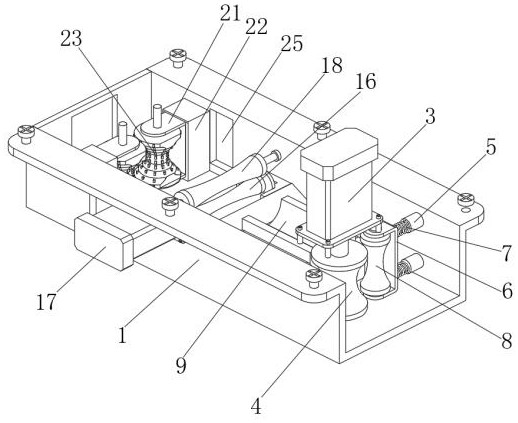

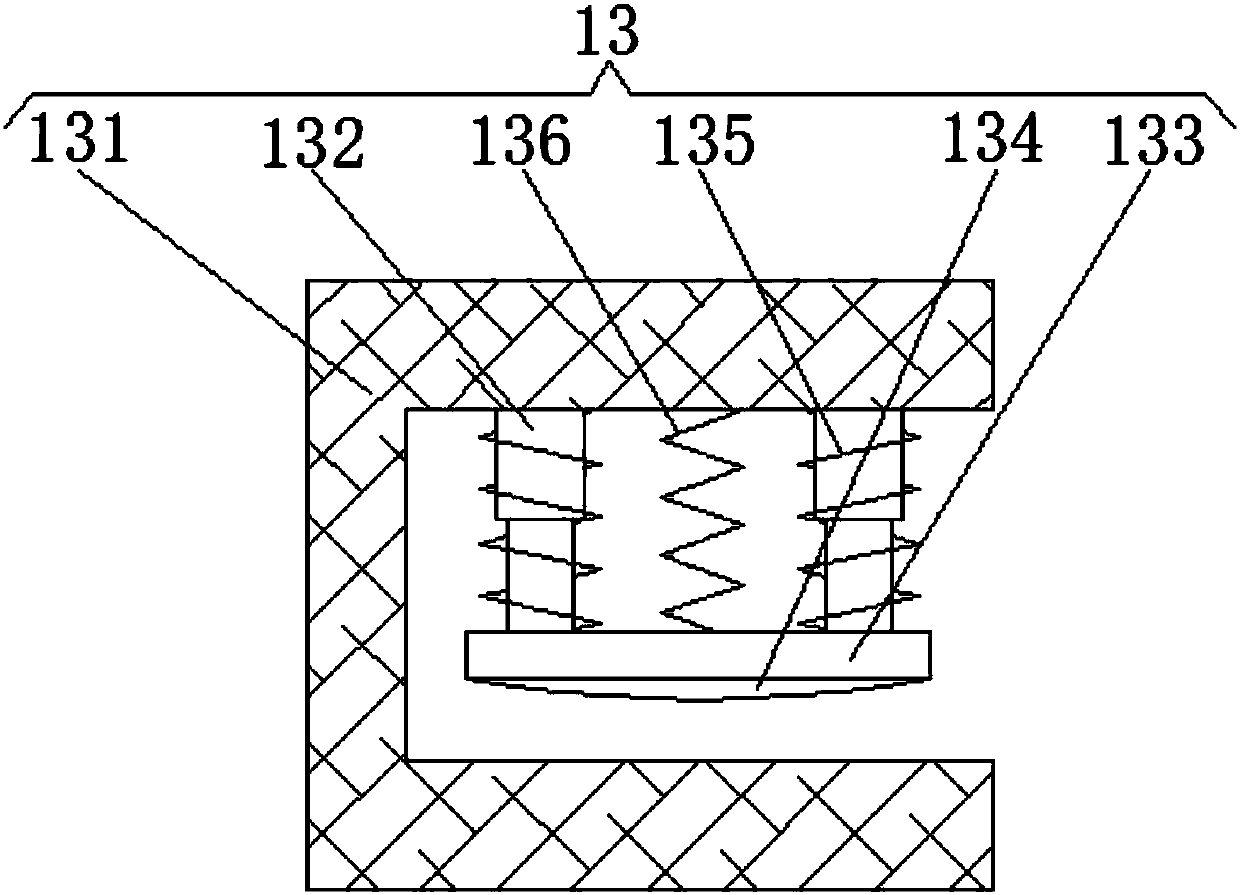

Peeling mechanism matched with cables with different diameters

ActiveCN112928705AAchieve initial choppingImprove universal applicabilityApparatus for removing/armouring cablesElectronic waste recyclingElectric machineryStructural engineering

The invention belongs to the technical field of cable processing, and discloses a peeling mechanism matched with cables with different diameters. The peeling mechanism comprises a device shell, wherein a top cover is fixedly mounted at the top of the device shell, a first motor is fixedly mounted at the top of the top cover, and a rotating shaft of the first motor penetrates through the top cover, extends into the device shell and is fixedly connected with a first driving conveying wheel. According to the invention, spring adjusting mechanisms are arranged on each conveying wheel, each shearing knife and each peeling wheel, so distances among the conveying wheels, the shearing knives and the peeling wheels can be changed along with the diameters of the cables, the conveying wheels can stably convey the cables with different diameters, the shearing knives can be matched with an upper cutter groove and a lower cutter groove to automatically adjust the distance so as to achieve preliminary splitting of the cable, and the peeling wheels can hook the outer skin of a cable and peel off the outer skin; and therefore, the purpose of being matched with the cables of different diameters is achieved, and the universal applicability of the peeling mechanism is improved.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY

Color template-based offline handwritten character extraction method

ActiveCN105654087AImprove integrityQuick fixCharacter and pattern recognitionHandwritingTemplate based

The present invention provides a color template-based offline handwritten character extraction method. The method includes the following steps that: S11, a template image of a writing area is obtained from a preset template containing color squares and auxiliary lines; S12, black channels and color channels are extracted from the template image according to the characteristics of characters and borders, wherein the black channels are used for storing character handwriting features, and the color channels are used for storing the border characteristics of the preset frame; S13, binarization processing is performed on the black channels and the color channels, so that a binarized image is obtained, and stray points are removed from the binarized image, so that a standard image can be obtained; and S14, in the standard image, the image of the black channels is segmented according to the preset grids of the color channels, and black characteristic images can be obtained after segmentation, and the black characteristic images are adopted as extracted handwritten characters.

Owner:李宇

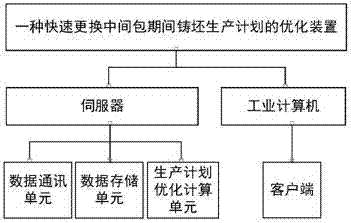

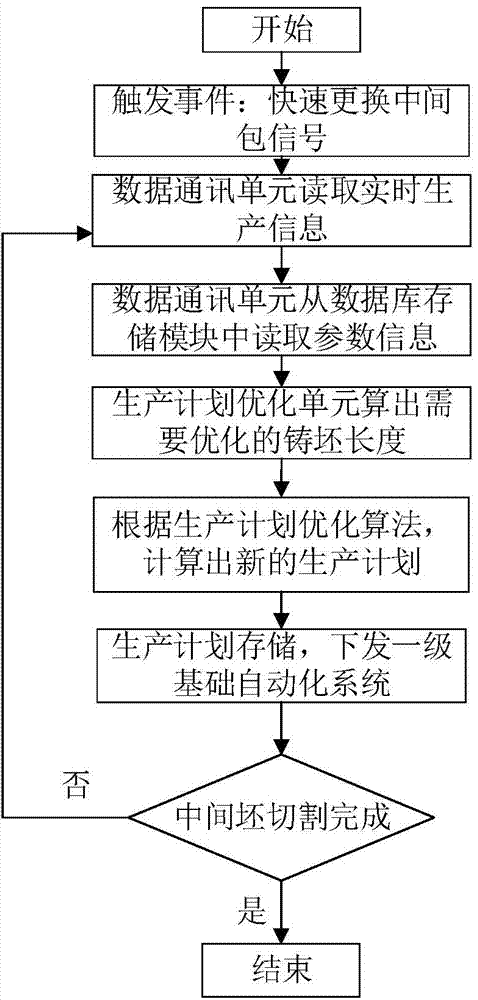

Optimization device and method for casting blank production plan during period of rapidly exchanging tundish

An optimization device and method for a casting blank production plan during a period of rapidly exchanging a tundish belongs to the field of automatic control of continuous casting. The length of an intermediate blank is adjusted into the sum of the length of a fixed size blank length, a blank head setting length and a blank tail setting length through optimizing the casting blank production plan before a joint point is optimized; when the optimization device is used for linearly cutting, only the blank head setting length and the blank tail setting length are cut off, and a residual casting blank is still a casting blank product without quality problems. The device is composed of industrial equipment and a software processing unit; the industrial equipment comprises a server and an industrial computer; the software processing unit comprises a data communication unit, a data storage unit, a production plan optimization calculation unit and a client. The optimization device and method have the advantages that waste blanks are reduced with regard to cutting optimization treatment of the tundish produced during the period of rapidly exchanging the tundish, the yield of liquid steel is improved and the production cost is reduced.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

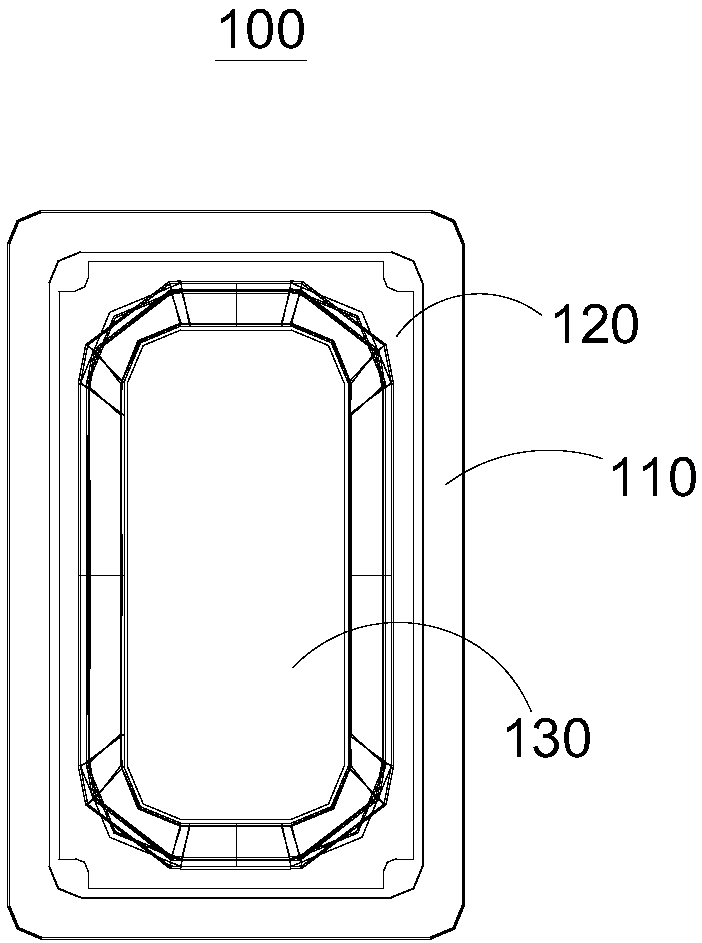

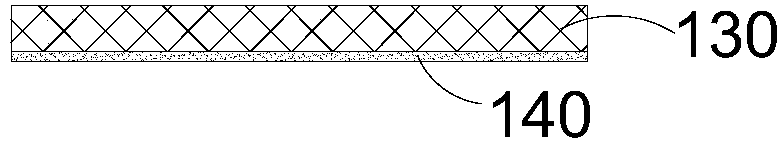

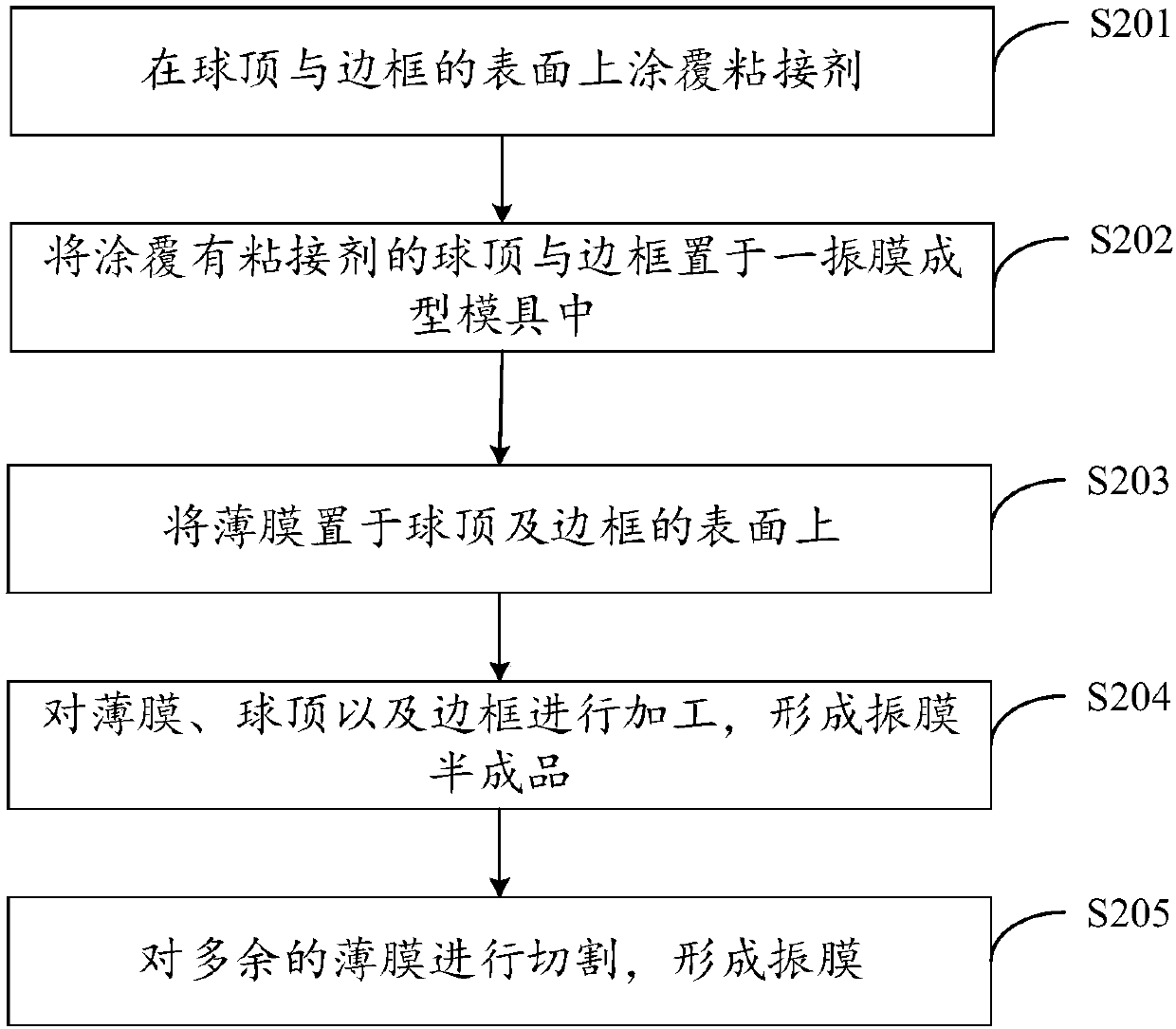

Vibrating diaphragm and vibrating diaphragm manufacturing method

InactiveCN107820193AEasy to assembleEasy to operatePolymeric diaphragmsMetallic diaphragmsProduction lineEngineering

The invention provides a vibrating diaphragm and a vibrating diaphragm manufacturing method, and relates to the technical field of loudspeakers. The vibrating diaphragm comprises a frame, a ball top and a thin film. The area enclosed by the frame is larger than the area of the ball top, and the edges of the thin film are all connected with the frame surface, and the thin film is connected with thesurface of the ball top. The vibrating diaphragm and the vibrating diaphragm manufacturing method provided by the invention have the advantages of high efficiency, low difficulty and low cost duringouter diameter cutting of the vibrating diaphragm and production line assembly.

Owner:JIANGSU YUCHENG ELECTRONICS

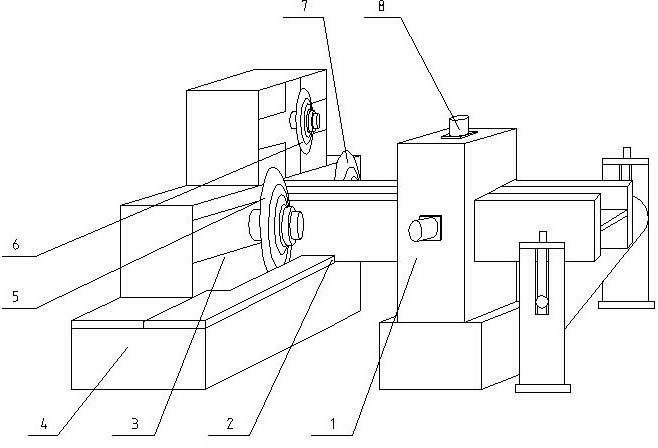

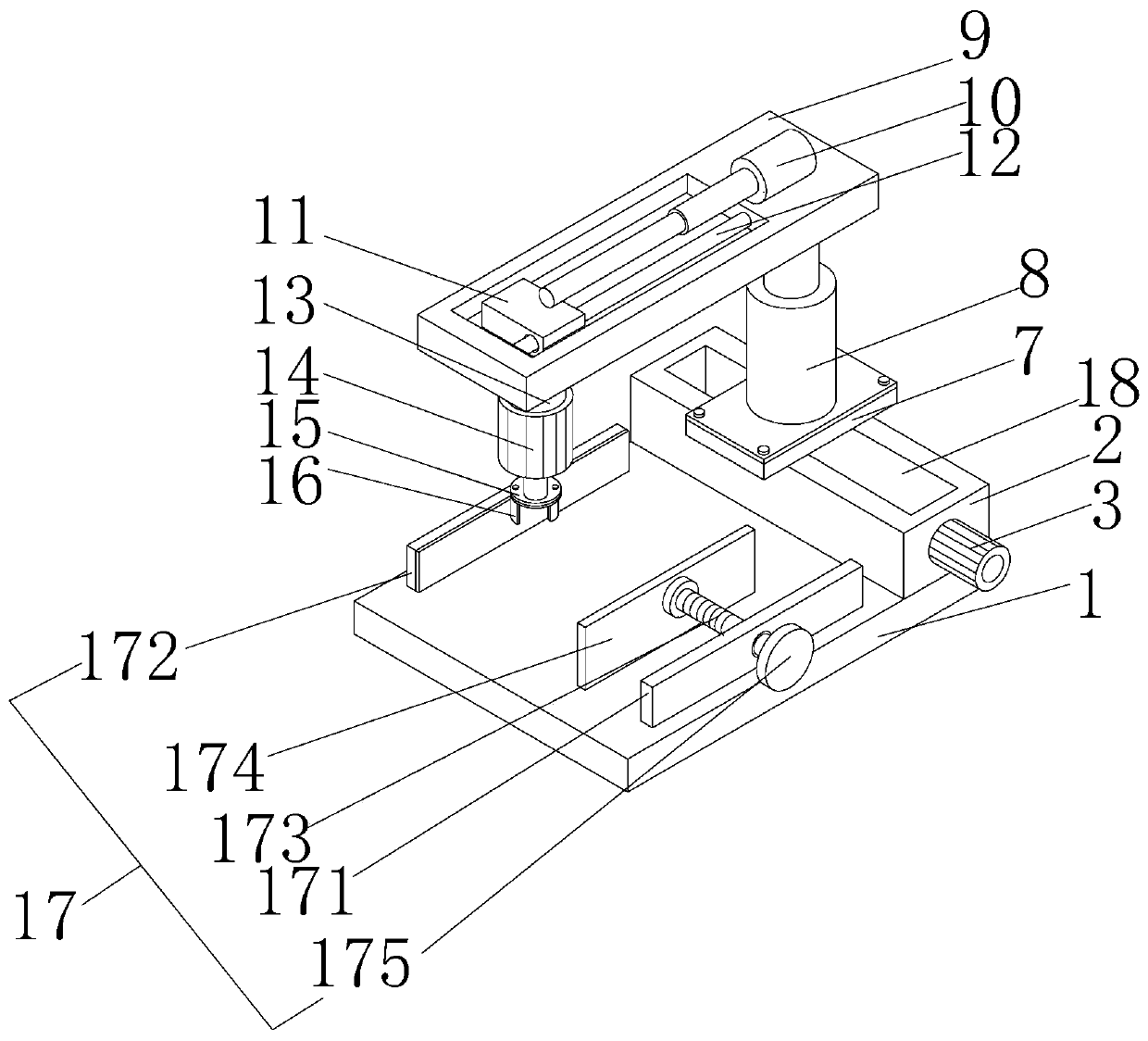

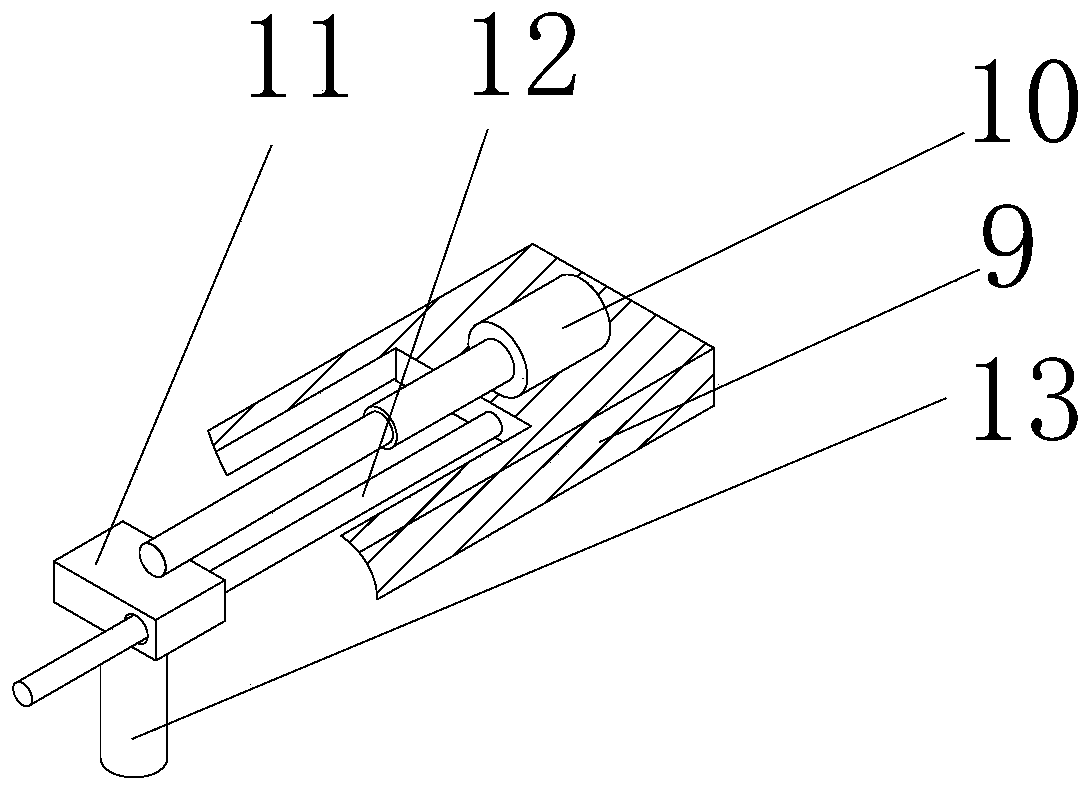

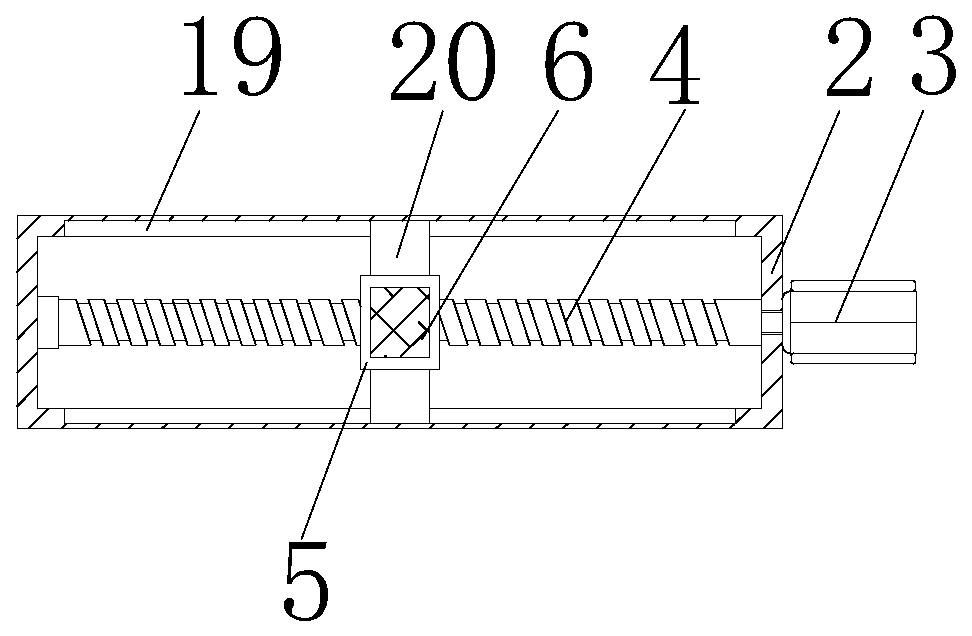

Cutting table used for metal sectional material machining machine

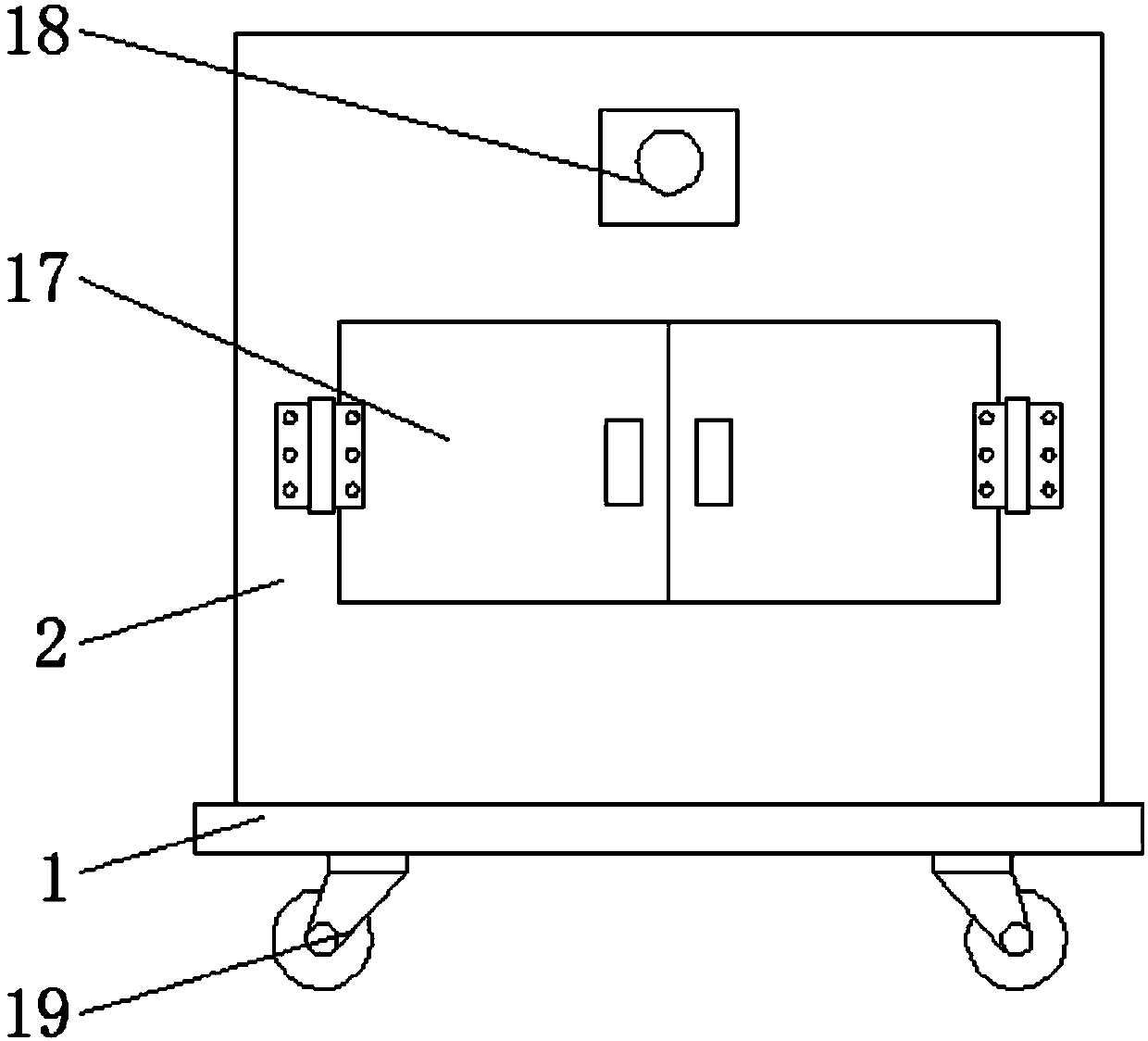

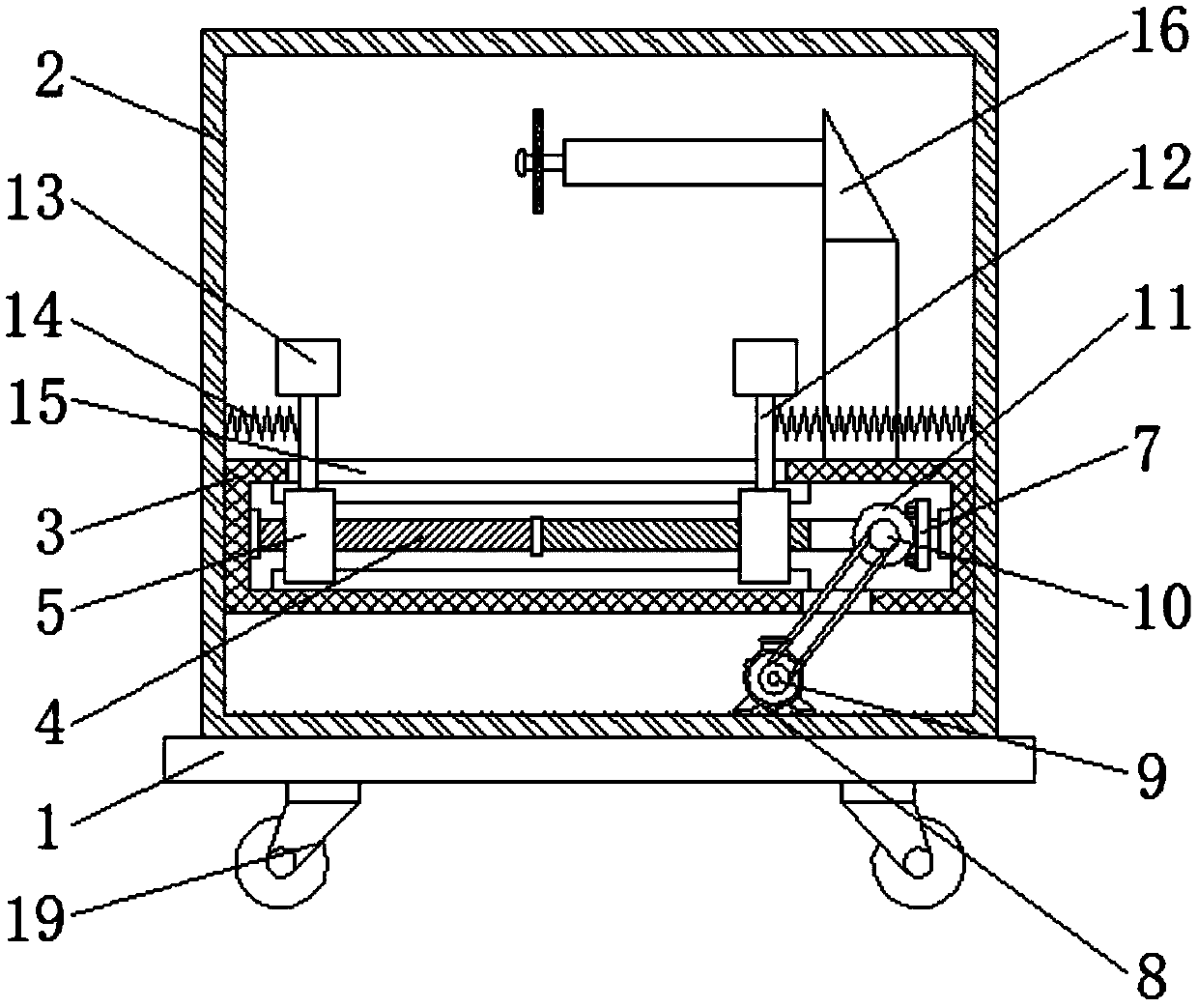

InactiveCN110695464AReduce the difficulty of cuttingEasy to cutFeeding apparatusLarge fixed membersElectric machineEngineering

The invention discloses a cutting table for a metal sectional material machining machine. The cutting table comprises a supporting base. A box body is fixedly connected with the right side of the topof the supporting base. A servo motor is fixedly connected to the front face of the box body. An output shaft of the servo motor penetrates the box body and extends to an inner cavity of the box bodyto be fixedly connected with a threaded rotating rod. The back face of the threaded rotating rod is rotationally connected with the inner wall of the box body through a bearing. By means of the cutting table used for the metal sectional material machining machine, due to the cooperation of the servo motor, the threaded rotating rod, a threaded sleeve, a connecting plate and a moving plate, a firstelectric air cylinder is driven to move front and back, meanwhile, the first electric air cylinder drives the supporting plate to move vertically, a second electric air cylinder slides on a sliding rod through a sliding sleeve to drive a rotating motor to move left and right, meanwhile, the rotating motor drives a cutting tool to cut a metal workpiece, a clamping mechanism is used for clamping the metal workpiece, the cutting fixing performance is also improved while cutting is facilitated, and the cutting difficulty of machining personnel on the workpiece is lowered.

Owner:广东博恒金属制品有限公司

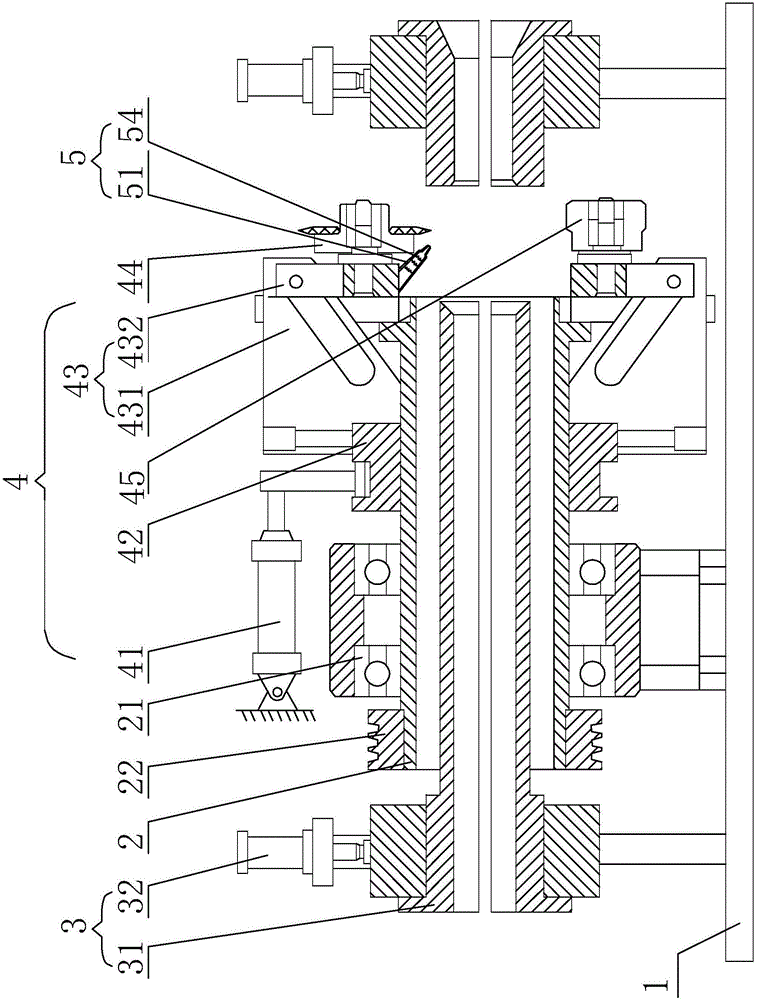

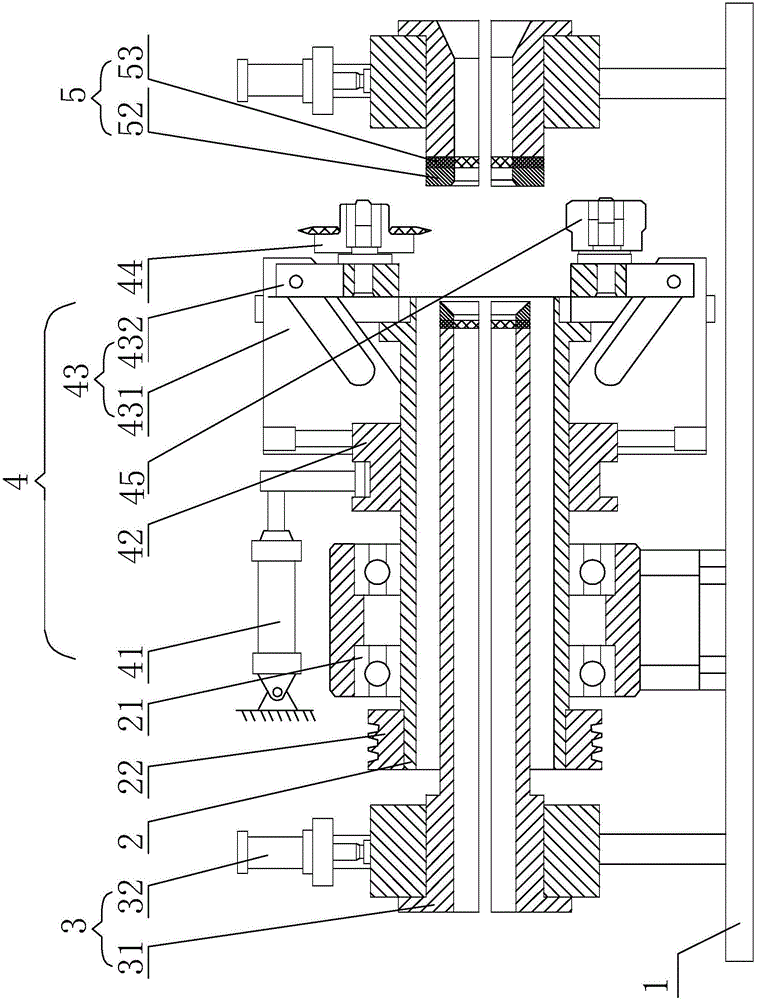

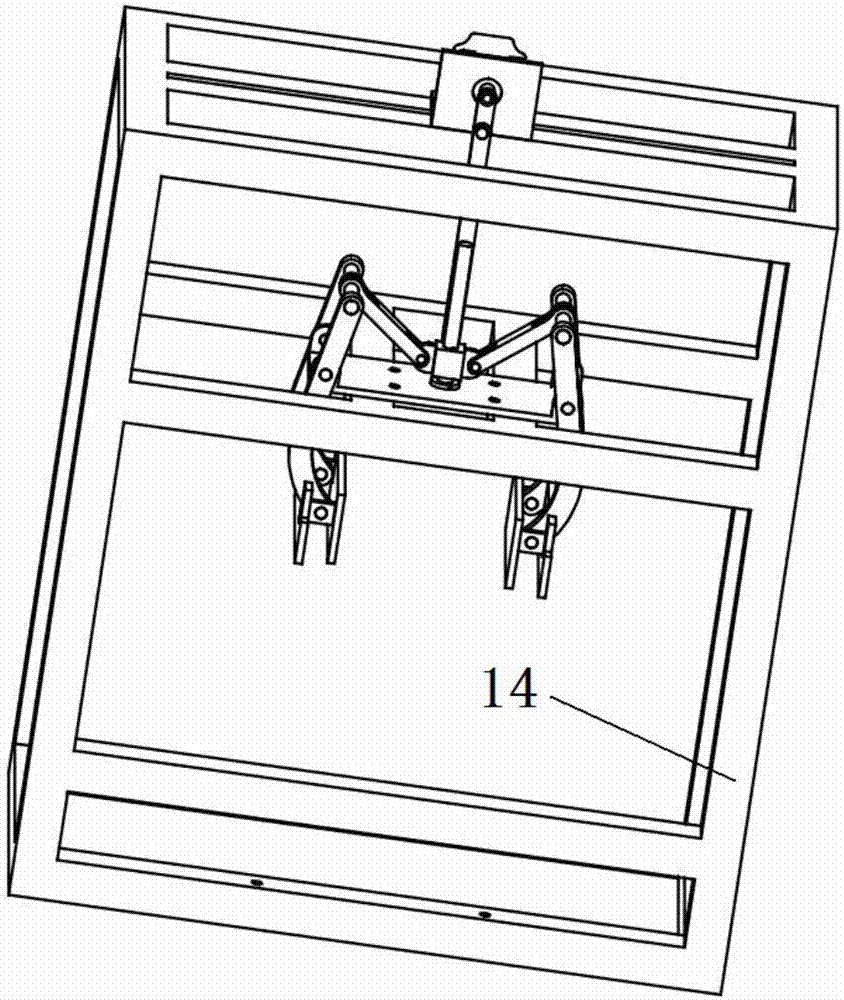

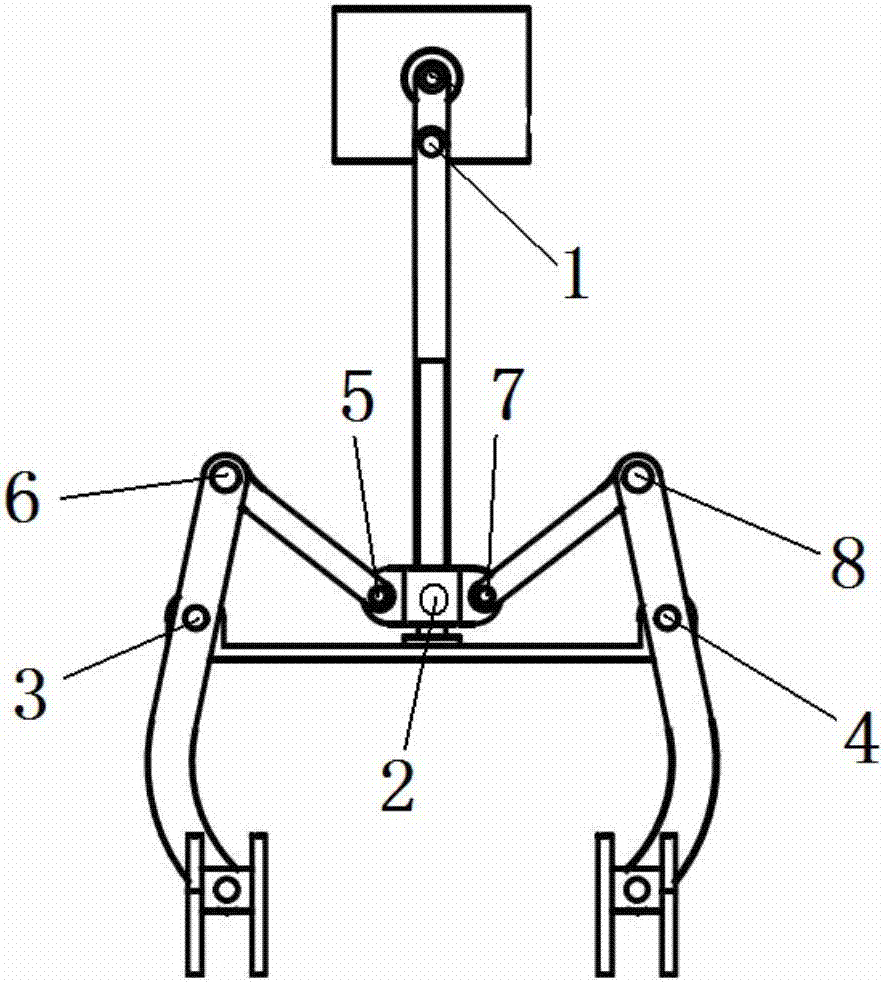

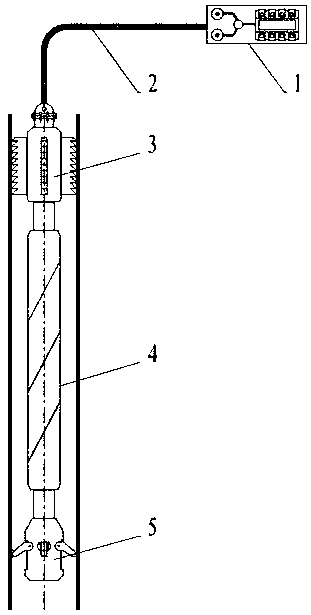

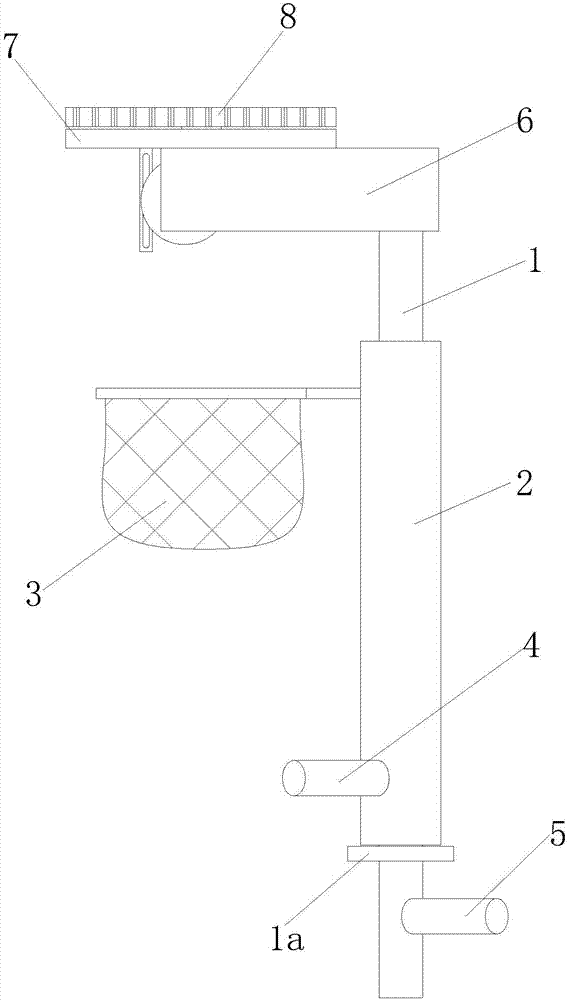

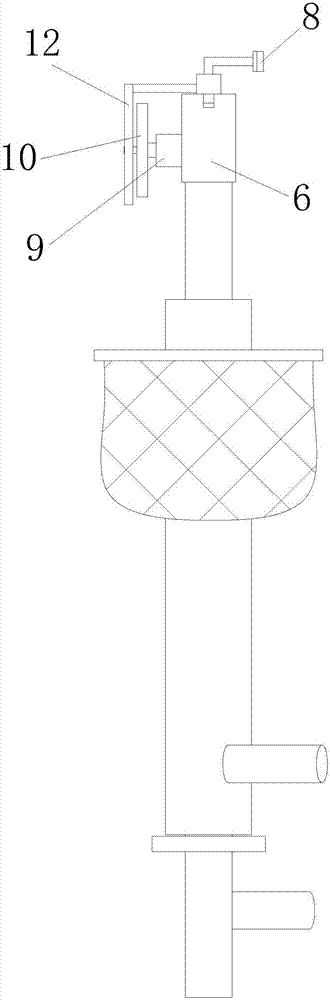

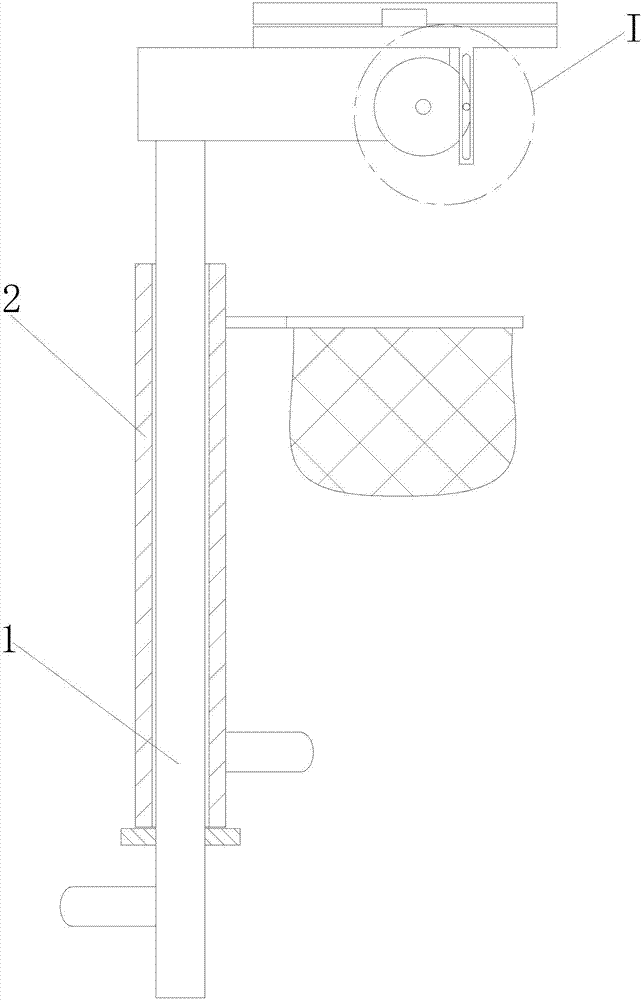

Portable wellbore cutting device

PendingCN109779557ACompact structureStrong independent cutting abilityBorehole/well accessoriesEngineeringHigh pressure water

The invention provides a portable wellbore cutting device. The portable wellbore cutting device comprises a high-pressure water pump 1, a high-pressure hose 2, a clamping fixer 3, a hydraulic rotator4 and a cutting tool bit 5, wherein the high-pressure water pump 1 is connected to the clamping fixer 3 through the high-pressure hose 2, the hydraulic rotator 4 is hung below the clamping fixer 3 andforms axial limiting and circumferential rotating fit with the clamping fixer 3, and the cutting tool bit 5 is installed on an output shaft on the lower portion of the hydraulic rotator 4. Accordingto the device, high-pressure water provided by the high-pressure water pump drives the output shaft of the hydraulic rotator to rotate to drive the cutting tool bit to rotate to realize wellbore cutting. Vertical and axial fixation of the cutting pipe string is realized through the clamping fixer mounted at the top. Through the implementation of the portable wellbore cutting device, wellbore cutting operation can be independently achieved under the condition that drilling / workover equipment is not used for supporting, the offshore wellbore cutting construction cost and difficulty are reduced,and the offshore wellbore cutting feasibility is improved.

Owner:中石化石油工程技术服务有限公司 +2

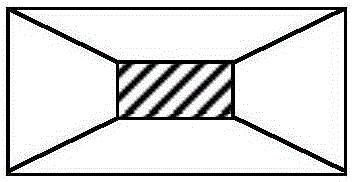

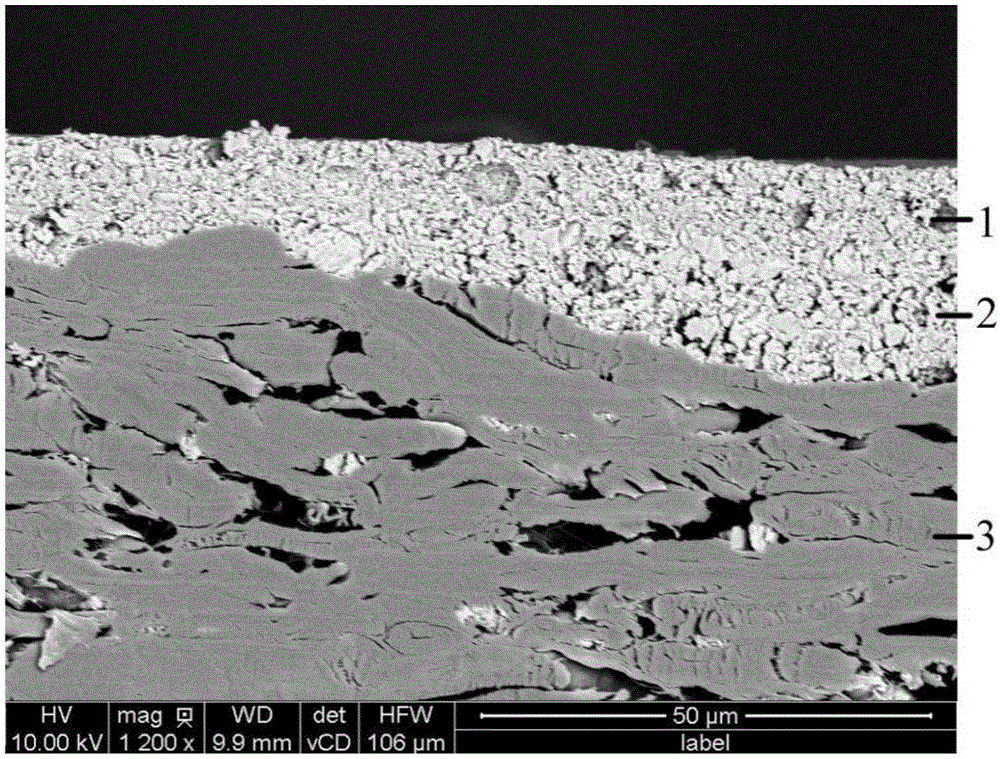

Scanning electron microscopy sample production method of coated white cardboard fracture

InactiveCN106442032AImprove flatnessReduce distortionPreparing sample for investigationCardboardScanning electron microscope

The invention provides a scanning electron microscopy sample production method of a coated white cardboard fracture. The method comprises the following steps: shearing a coated white cardboard to form a long strip, wherein one end of the long strip along the length direction is sharp-pointed, and the width of the tip is less than or equal to 0.5 mm; and slicing the tip of the long strip through adopting a mechanically propelled ultrathin slicing machine by using a diamond cutter at a slicing rate of below 0.5 mm / sec in order to obtain the coated white cardboard fracture. The coated white cardboard fracture produced by using the method is clean and flat without pollutant shielding, so the clear coated white cardboard fracture microscopic picture of the sample fracture is obtained, and analysis test of the thickness of a white cardboard coating and the particle size and the shape of particles is realized by using a scanning electron microscope.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

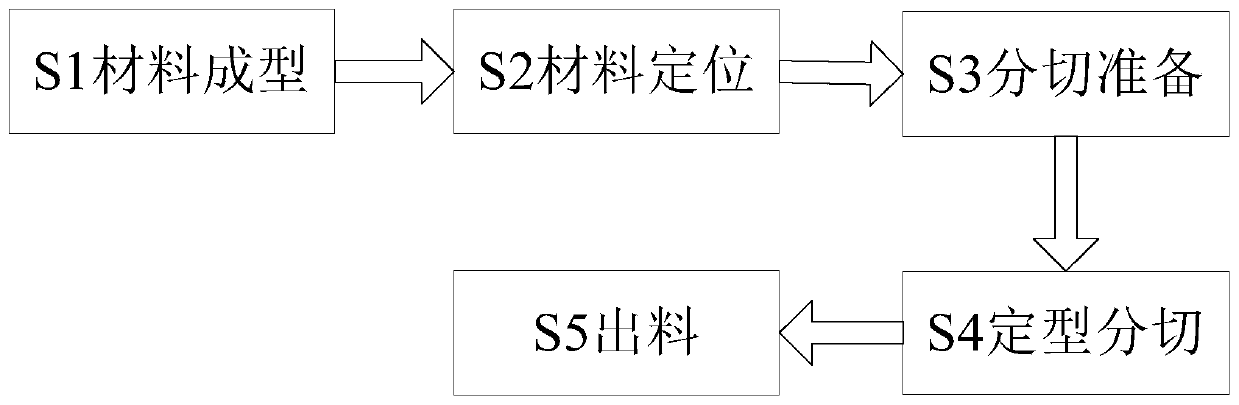

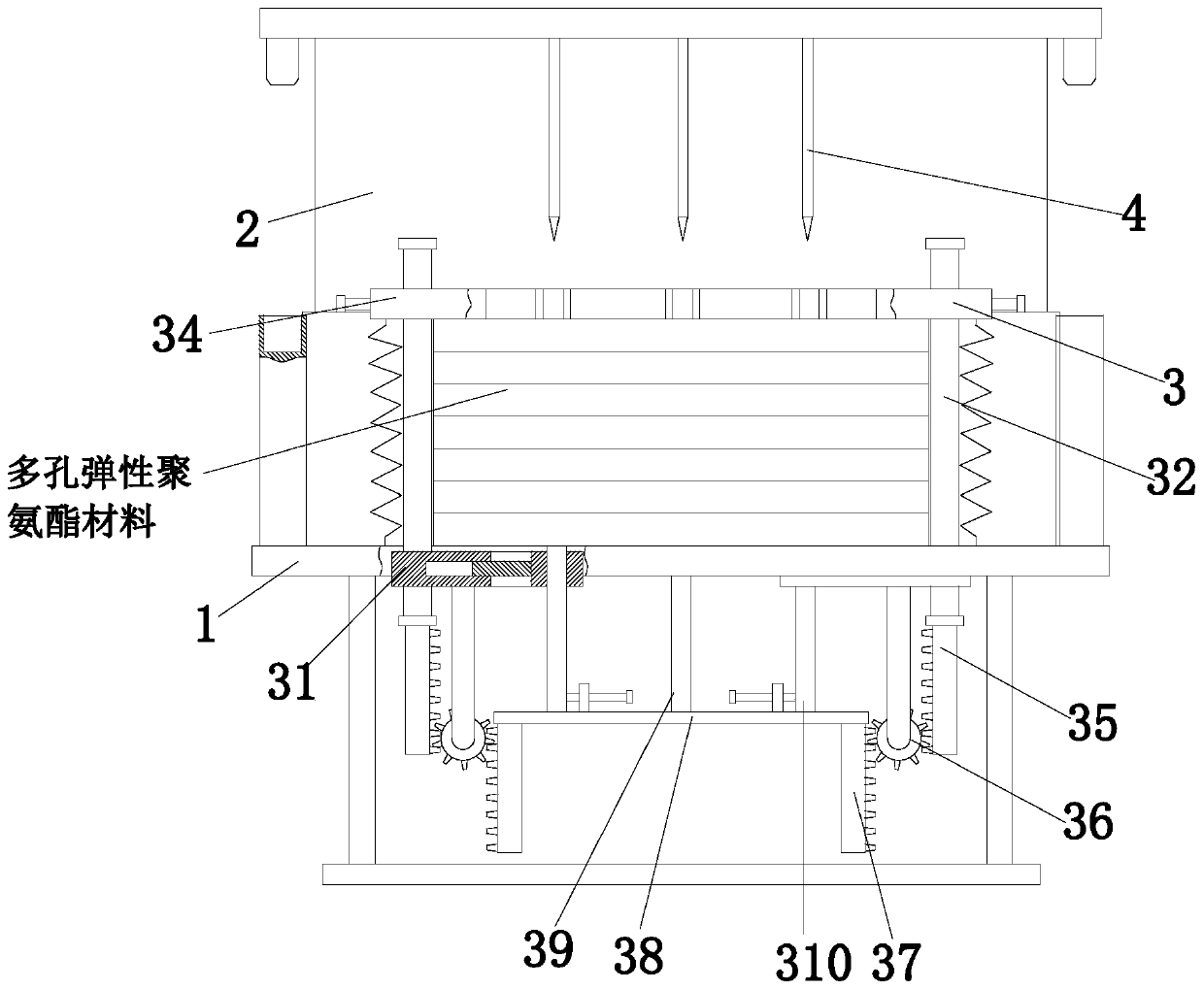

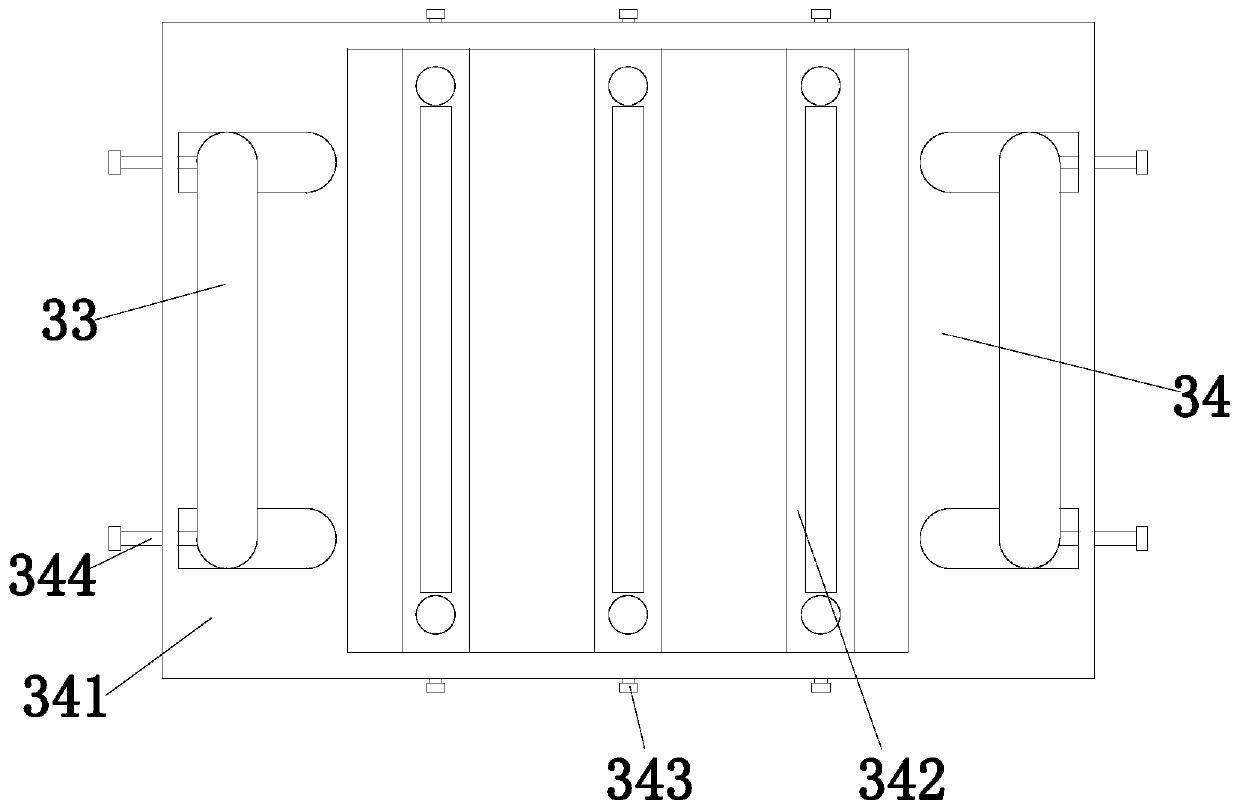

Manufacturing process of porous elastic polyurethane material

The invention relates to a manufacturing process of a porous elastic polyurethane material, which uses special slitting equipment. The slitting equipment comprises a workbench, a mounting frame, a positioning device and a slitting device, the process for manufacturing the porous elastic polyurethane material by using the slitting equipment comprises the following steps of material forming, material positioning, slitting preparation, shaping slitting and discharging, and the positioning device comprises a positioning sliding block, a positioning rod, a linkage plate, a top plate, a driving rack, a transmission gear, a driving rack, a connecting plate, a middle limiting rod and a side limiting rod. According to the manufacturing process, materials are limited in all directions through the positioning device, the position stability of the materials in the cutting process is effectively guaranteed, the slitting device conducts slitting on the materials in the mode that punching is conducted firstly and then cutting is conducted, the slitting difficulty can be obviously reduced, it is guaranteed that a slitting tool bit can rapidly cut the materials into blocks, and the situation that the cutting surface is rough and uneven after repeated cutting is avoided.

Owner:SHANDONG TAIRUIFENG NEW MATERIAL CO LTD

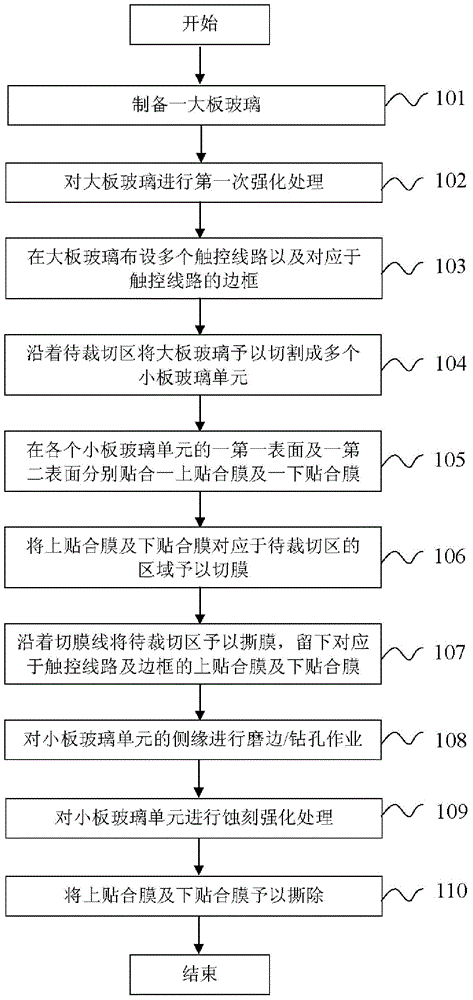

Method for carrying out edge etching and strengthening of cut one-glass-solution touch panel with one-time film lamination

InactiveCN104951119AIncrease production capacitySimple processGlass severing apparatusInput/output processes for data processingEngineeringControl circuit

A method for carrying out edge etching and strengthening of a cut one-glass-solution (OGS) touch panel with one-time film lamination is disclosed. A large-sized glass panel, after subjected to strengthening treatment and forming touch control circuits and edge frames thereon, is cut to form small-sized glass panel units. An upper lamination film and a lower lamination film are respectively laminated on surfaces of each of the small-sized glass panel units and portions of the upper and lower lamination films are out so as to form film cutting lines between the cutting zones and the edge frame. The portions of the upper and lower lamination films of each of the small-sized glass panel units corresponding to the cutting zones are peeled off along the film cutting line so as to leave portions of the upper and lower lamination films corresponding to the touch control circuit and the edge frame. Finally, the small-sized glass panel units are each subjected to etching and strengthening along side edges thereof.

Owner:GHITRON TECH

High-lubrication stable cutting fluid and preparation method thereof

PendingCN111117754AThe shear angle becomes largerReduce cutting difficultyLubricant compositionLubricationOrganosilicon

The invention belongs to the technical field of metal processing, and particularly relates to a high-lubrication stable cutting fluid and a preparation method thereof. The high-lubrication stable cutting fluid is prepared from, by weight, 40 to 46 parts of diethylene glycol, 5 to 8 parts of triethanolamine, 2 to 5 parts of diethanolamine, 5 to 10 parts of an emulsifier, 14 to 18 parts of a corrosion inhibitor, 0.02 to 0.5 part of an organic silicon defoamer and 20 to 25 parts of water. A special emulsifier is adopted to improve the permeability and the lubricating property, and the high-lubrication stable cutting fluid serving as an oil-free cutting fluid product can replace a semi-synthetic cutting fluid with low oil content under the same condition. Besides, compounding of a special antirust agent makes the surface of a lubricating film keep smooth for a long time, so that dry friction caused by direct contact between a cutter surface and a workpiece is avoided, the contact length between a cutter and chips is shortened, the shearing angle is increased, and the cutting difficulty is reduced.

Owner:深圳金泽万长石化有限公司

Cutting device capable of cutting different sizes of ceramic tiles

PendingCN107856209AImprove practicalityEasy to cutWorking accessoriesStone-like material working toolsElectric machineryBevel gear

The invention relates to the technical field of ceramic tile cutting equipment and discloses a cutting device capable of cutting different sizes of ceramic tiles. The cutting device comprises a bottomplate. The top of the bottom plate is fixedly connected with a box. A fixed box is fixedly connected between the inner walls of the two sides of the box. A bi-directional threaded rod is rotatably connected between the two sides of the inner wall of the fixed box through bearings. The outer surface of the bi-directional threaded rod is in threaded connection with a first moving block and a secondmoving block from left to right in sequence. The portion, located on one side of the second moving block, of the outer surface of the bi-directional threaded rod is sleeved with a first bevel gear. One side of the bottom of the inner wall of the box is fixedly connected with a motor. One end of an output shaft of the motor is sleeved with a first belt pulley. The cutting device capable of cuttingdifferent sizes of ceramic tiles can cut different sizes of ceramic tiles so that workers can cut the ceramic tiles more conveniently; the cutting difficulty is reduced, and the practicality of the cutting device is improved.

Owner:WUXI HUIOU CERAMIC CO LTD

Grape collecting device

The invention relates to a grape collecting device. The grape collecting device comprises a main rod, a long shaft sleeve is installed on the main rod, net bags are fixed to the upper end of the long shaft sleeve, a first handle is fixed to the lower end of the long shaft sleeve, and a limiting boss attached to the bottom of the long shaft sleeve is fixed to the lower end of the main rod; a second handle is fixed to the lower end of the main rod, a supporting plate horizontally distributed is fixed to the upper end of the main rod, a long sliding strip is installed on the upper end face of the supporting plate in a sliding mode, a saw strip is fixed to the upper end face of the long sliding strip, a rectangular plate is connected to the back end of the long sliding strip, a strip-type through hole vertically distributed is formed in the rectangular plate, a motor is fixed to the bottom of the supporting plate, a disc is connected on an output shaft of the motor, and a protruding block which is in sliding fit with the strip-type through hole and away from the circle center of the disc is fixed on the disc. According to the grape collecting device, positions of peduncles of grapes are not required to be sought, the peduncles of the grapes can be rapidly separated from fruit trees, the working efficiency is improved, the cutting difficulty is reduced, harm to the human body is avoided during cutting, once collection of the multi-bunch grapes can be achieved, and collection time is greatly saved.

Owner:无为县雲桃家庭农场

Feeding device for scrap steel shearing machine

InactiveCN112589505AReduce labor intensityReduce the difficulty of operationMetal working apparatusConveyor partsEngineeringStructural engineering

The invention discloses a feeding device for a scrap steel shearing machine. The feeding device for the scrap steel shearing machine comprises a base, a shearing machine, a frame body, a scrap steel conveying belt, a bearing plate, a feeding mechanism, a first pressing mechanism and a second pressing mechanism, wherein the shearing machine is fixedly arranged on one side of the top end of the base; the frame body is fixedly arranged on the other side of the top end of the base; the scrap steel conveying belt is arranged on the inner side of the frame body; the bearing plate is fixedly arrangedon one side of the shearing machine; one side of the top end of the bearing plate makes contact with one side of the scrap steel conveying belt; the feeding mechanism is arranged on the right side ofthe top end of the frame body; the first pressing mechanism is arranged in the middle of the top end of the frame body; and the second pressing mechanism is arranged on the left side of the top end of the frame body. According to the feeding device for the scrap steel shearing machine, a grabbing machine does not need to be used for dispersing the scrap steel, so that the operation difficulty isreduced, and the labor intensity of workers is relieved; and a pressing plate can flatten the scrap steel on the scrap steel conveying belt again, so that the scrap steel can be sheared by the shearing machine, and the shearing difficulty is reduced.

Owner:商井芳

Pre-plastic lead frame, semiconductor packaging structure and unit thereof, and packaging method

PendingCN109256367AReduce blade wear and tearReduce cutting difficulty and production costSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingMetal

The invention provides a pre-plastic lead frame, a semiconductor packaging structure and unit thereof, and a packaging method. the pre-plastic lead frame comprises a plurality of lead frame units, thelead frame units at least have a conductive element located on the outermost side, an insulating layer is embedded between the conductive elements of the adjacent lead frame units through a pre-plastic packaging process, and the insulating layer covers at least a part of the outer side walls of the conductive element. As that embodiment of the invention can carry out oxidation protection on the conductive element, the preparation process of the pre-plastic lead frame can be simplified and tightly connected, and the manufacturing cost can be reduced; In addition, the problem of metal residue existing in the prior art cutting is eliminated, and the quality and yield of the packaged product are improved.

Owner:嘉盛半导体(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com