High-lubrication stable cutting fluid and preparation method thereof

A stable cutting fluid technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of high cutting heat, high cutting temperature, lubricity, anti-rust performance and low penetration ability, and achieve a larger shear angle , Reduce the effect of cutting difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

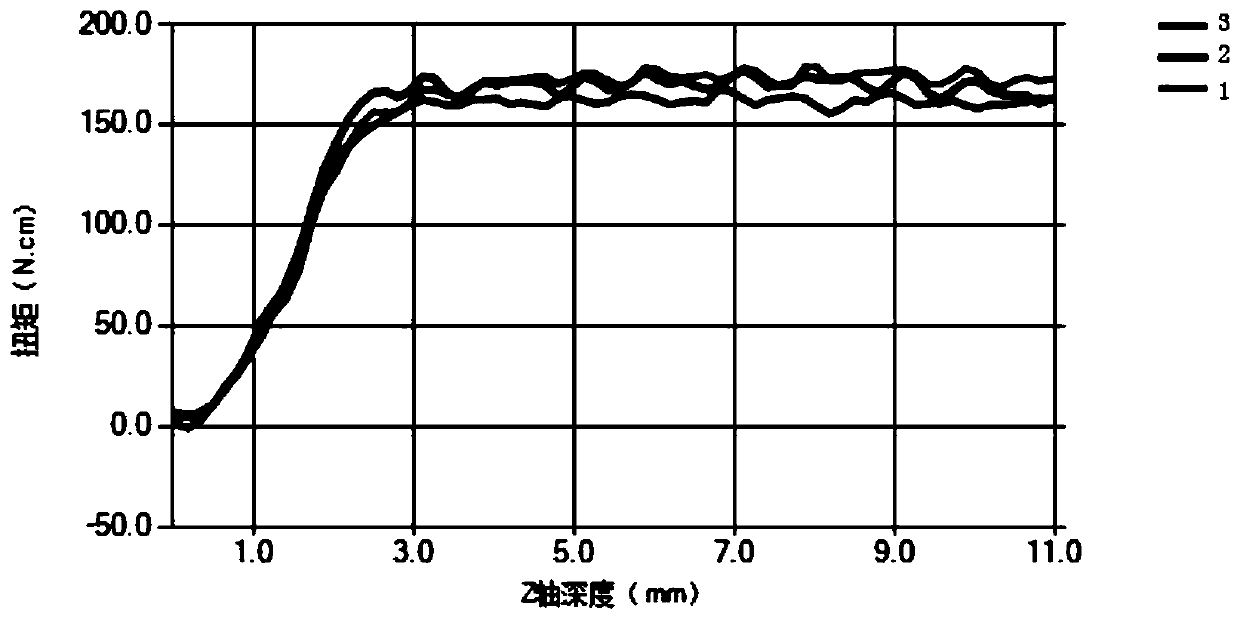

Image

Examples

preparation example Construction

[0041] The second aspect of the present invention provides a method for preparing the above-mentioned high-lubricating and stable cutting fluid, the steps comprising:

[0042] (1) Add the diethylene glycol, triethanolamine, diethanolamine, emulsifier, defoamer, and water into the container, and stir for 0.5-1h at normal temperature and pressure;

[0043] (2) Add the corrosion inhibitor to the previous step, and continue to stir for 0.5-1h under normal temperature and pressure to obtain the product.

Embodiment 1

[0047]Embodiment 1 provides a high-lubricating stable cutting fluid, which includes the following components in parts by weight: 40.5 parts of diethylene glycol, 8 parts of triethanolamine, 2 parts of diethanolamine, 10 parts of emulsifier, 14.2 parts of corrosion inhibitor parts, 0.3 parts of silicone defoamer, and 25 parts of water.

[0048] The emulsifier is fatty alcohol ether phosphate potassium salt MOA-3PK-70;

[0049] The corrosion inhibitor is a mixture of boric acid, triethanolamine borate, and benzotriazole in a weight ratio of 10:4:0.2;

[0050] The organosilicon defoamer is methyl silicone oil;

[0051] The preparation method of described high-lubricating stable cutting fluid, the steps include:

[0052] (1) Add the diethylene glycol, triethanolamine, diethanolamine, emulsifier, defoamer, and water into the container, and stir for 1 hour at normal temperature and pressure;

[0053] (2) Add the corrosion inhibitor to the previous step, and continue to stir for 0...

Embodiment 2

[0055] Embodiment 2 provides a kind of high-lubricating and stable cutting fluid, including the following components in parts by weight: 45.5 parts of diethylene glycol, 5 parts of triethanolamine, 5 parts of diethanolamine, 5 parts of emulsifier, 17.1 parts of corrosion inhibitor parts, 0.4 parts of silicone defoamer, and 22 parts of water.

[0056] The emulsifier is fatty alcohol ether phosphate potassium salt MOA-3PK-40;

[0057] The corrosion inhibitor is a mixture of boric acid, triethanolamine borate, and benzotriazole in a weight ratio of 12:5:0.1;

[0058] The organosilicon defoamer is methyl silicone oil;

[0059] The preparation method of the high-lubricating and stable cutting fluid has the same steps as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com