Double-crucible directional solidification device

A directional solidification, double crucible technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult cutting, different temperature fields of melts, different axes of heating bodies, etc., to reduce the difficulty of cutting and use. Convenience and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment is a double-crucible directional solidification device for lead-bismuth alloy samples.

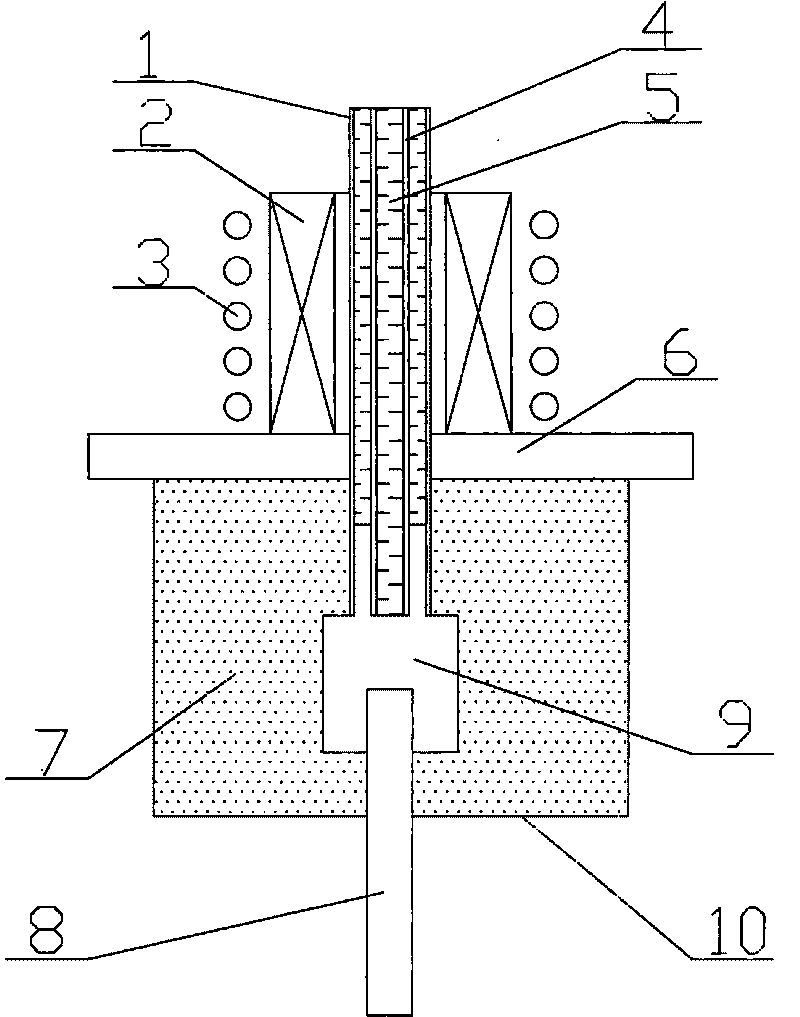

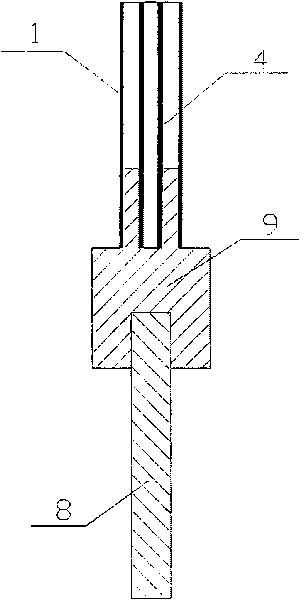

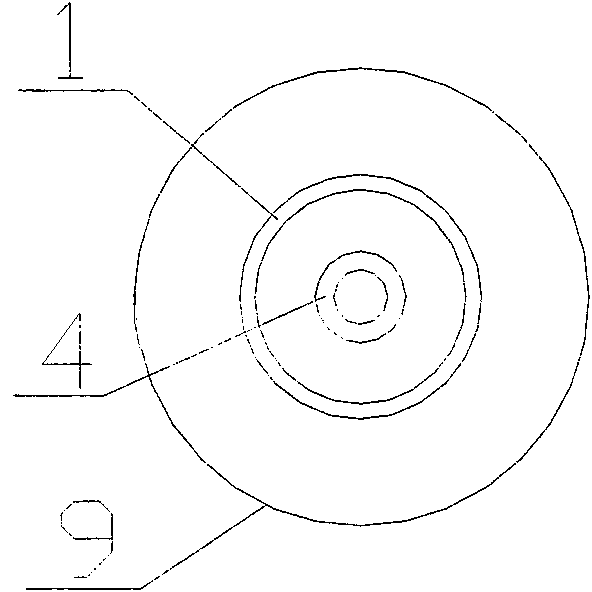

[0021] This embodiment includes a large crucible 1, a graphite heating element 2, an induction coil 3, a small crucible 4, a sample 5, a heat shield 6, a liquid Ga-In-Sn alloy 7, a pull rod 8, a joint 9 and a cooler 10, Wherein, the heat insulation board 6 is located at the upper end of the cooler 10, and the joint 9 is located in the cooler 10; one end of the drawing rod 8 is located in the cooler 10, and is connected with one end of the joint 9, and the other end of the drawing rod 8 passes through the bottom plate of the cooler 10. The drawing hole is located outside the cooler 10. The small crucible 4 is nested in the large crucible 1, and the two crucibles are coaxial to form a double crucible. One end of the double crucible is located in the cooler 10 and connected to the other end of the joint 9 ; the other end of the double crucible passes through the via ho...

Embodiment 2

[0029] This embodiment is a double-crucible directional solidification device for aluminum-copper alloy samples.

[0030] This embodiment includes a large crucible 1, a graphite heating element 2, an induction coil 3, a small crucible 4, a sample 5, a heat shield 6, a liquid Ga-In-Sn alloy 7, a pull rod 8, a solidified sample 9, and a joint 9 And the cooler 10, wherein, the heat shield 6 is located at the upper end of the cooler 10, and the joint 9 is located in the cooler 10; one end of the drawing rod 8 is located in the cooler 10, and is connected with one end of the joint 9, and the other end of the drawing rod 8 passes through the cooling The drawing hole on the base plate of the cooler 10 is located outside the cooler 10. The small crucible 4 is nested in the large crucible 1, and the two crucibles are coaxial to form a double crucible. One end of the double crucible is located in the cooler 10 and connected to the other end of the joint 9 ; the other end of the double ...

Embodiment 3

[0038] This embodiment is a double-crucible directional solidification device for Ni-base superalloy samples.

[0039] This embodiment includes a large crucible 1, a graphite heating element 2, an induction coil 3, a small crucible 4, a sample 5, a heat shield 6, a liquid Ga-In-Sn alloy 7, a pull rod 8, a joint 9, a joint 9 and cooling The heat shield 6 is located at the upper end of the cooler 10, and the joint 9 is located in the cooler 10; one end of the drawing rod 8 is located in the cooler 10 and is connected with one end of the joint 9, and the other end of the drawing rod 8 passes through the cooler 10 The drawing hole on the base plate is located outside the cooler 10 . The small crucible 4 is nested in the large crucible 1, and the two crucibles are coaxial to form a double crucible. One end of the double crucible is located in the cooler 10 and connected to the other end of the joint 9 ; the other end of the double crucible passes through the via hole in the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com