Diamond particle reinforced metal matrix composite material and preparation method and application thereof

A technology of diamond particles and composite materials, which is applied in the field of diamond particle reinforced metal matrix composite materials and its preparation, which can solve the problems of low density, poor material uniformity, and difficulty in wire electric discharge processing, etc., and reduce porosity and thickness. Uniform, eliminate the effect of uneven powder mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

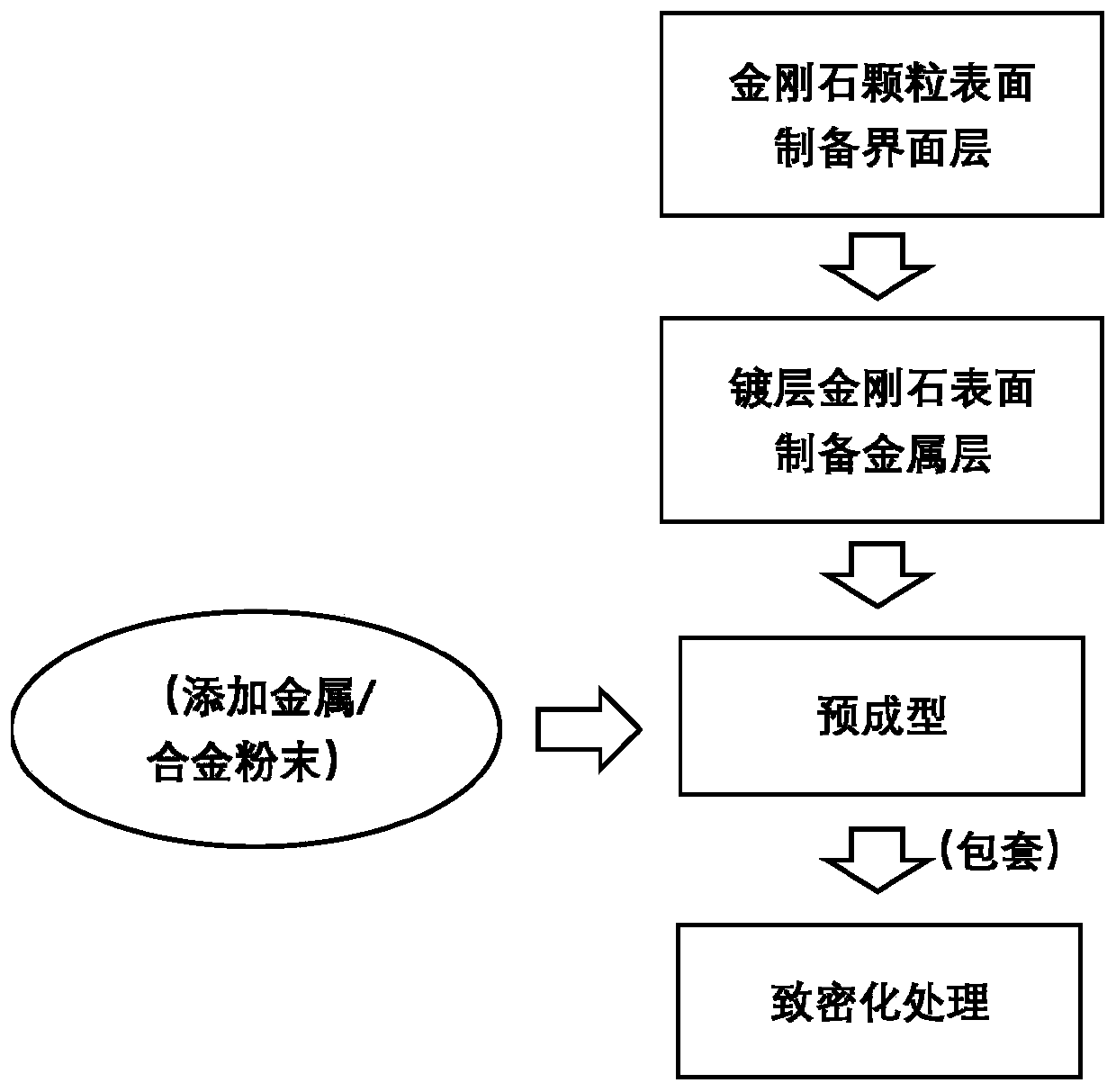

Method used

Image

Examples

Embodiment 1

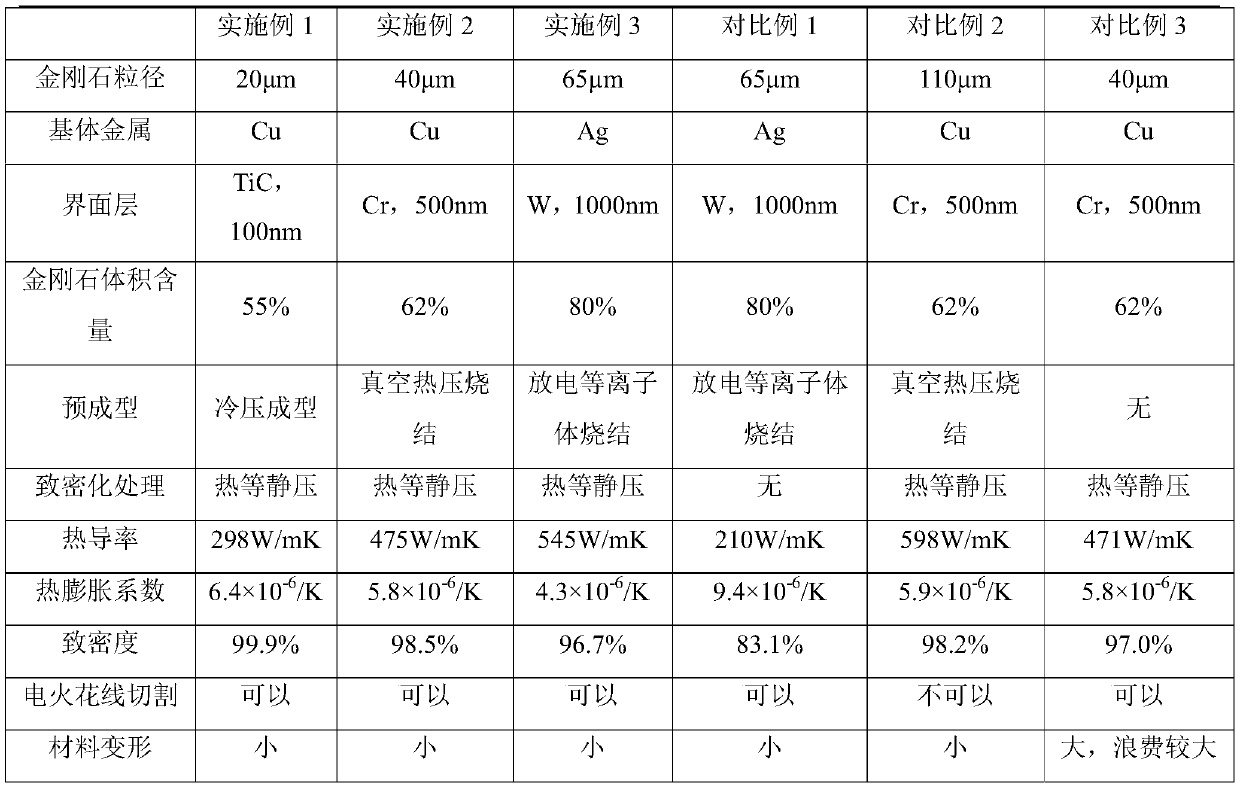

[0038] A method for preparing a diamond particle reinforced metal matrix composite material, comprising the following steps:

[0039] (1) Metallization on the surface of diamond particles: a layer of TiC was first deposited on the surface of diamond particles with a particle size of 20 μm by magnetron sputtering, with a coating thickness of 100 nm.

[0040] (2) Continuously deposit Cu layer on the surface of TiC layer by electroless plating method, so that the volume content of diamond reaches 55%.

[0041] (3) Preforming: put the above-mentioned diamond powder with coating into the mold and make it by cold pressing The billet, pressure 550MPa, holding time 15min.

[0042] (4) Densification treatment: put the billet into a stainless steel sheath, pump air and seal it, then hot isostatic press, the heating rate is 6°C / min, the sintering temperature is 750°C, the pressure is 110MPa, the holding time is 1h, and the bag is removed after cooling in the furnace. Set it up and get...

Embodiment 2

[0045] A method for preparing a diamond particle reinforced metal matrix composite material, comprising the following steps:

[0046] (1) Metallization on the surface of diamond particles: on the surface of diamond particles with a particle size of 40 μm, a layer of Cr is first deposited on the surface of the diamond by vacuum evaporation, and the thickness of the coating is 500 nm.

[0047] (2) Continuously deposit Cu layer on the surface of Cr layer by electroless plating method, so that the volume content of diamond reaches 62%.

[0048] (3) Preforming: put the above-mentioned diamond powder with coating into the mold and make it by vacuum hot pressing and sintering The billet, temperature 820 ℃, pressure 20MPa, time 60min.

[0049] (4) Densification treatment: put the blank into a hot isostatic press for densification treatment, the heating rate is 8°C / min, the sintering temperature is 880°C, the pressure is 120MPa, the holding time is 1h, and it is ready after cooling i...

Embodiment 3

[0052] A method for preparing a diamond particle reinforced metal matrix composite material, comprising the following steps:

[0053] (1) Metallization on the surface of diamond particles: on the surface of diamond particles with a particle size of 65 μm, a layer of W was deposited on the surface of the diamond by salt bath plating, and the thickness of the coating was 1000 nm.

[0054] (2) Continue to deposit Ag layer on the surface of W layer by electroplating method, so that the volume content of diamond reaches 90%.

[0055] (3) Preforming: mixing the above-mentioned diamond powder with coating and Ag powder with a particle size of 10-20 μm, so that the volume content of diamond reaches 80%. The mixed powder is then loaded into a mold and made by spark plasma sintering The billet temperature is 650°C, the pressure is 15MPa, and the time is 10min.

[0056] (4) Densification treatment: put the billet into a stainless steel sheath, pump air and seal it, then hot isostatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com