Battery, packaging method thereof and terminal

A packaging method and battery technology, which are applied to batteries, secondary batteries, battery pack components, etc., can solve the problems of reducing the number of cutting, folding, high difficulty in cutting pole pieces, and cumbersome packaging processes, and reduce cutting The effect of cutting difficulty, optimizing cell structure design, reducing the number of cutting and folding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described below with reference to the accompanying drawings in the embodiments of the present invention.

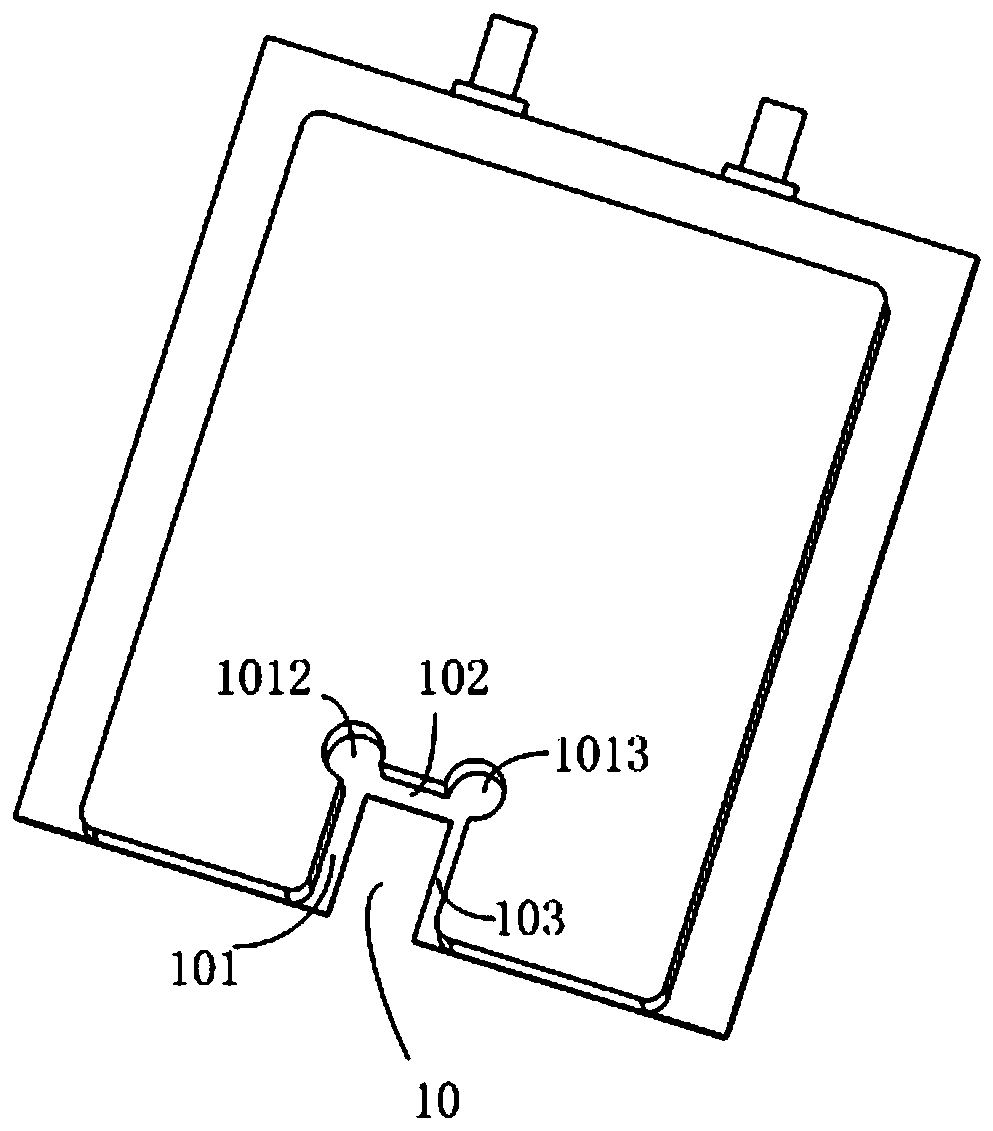

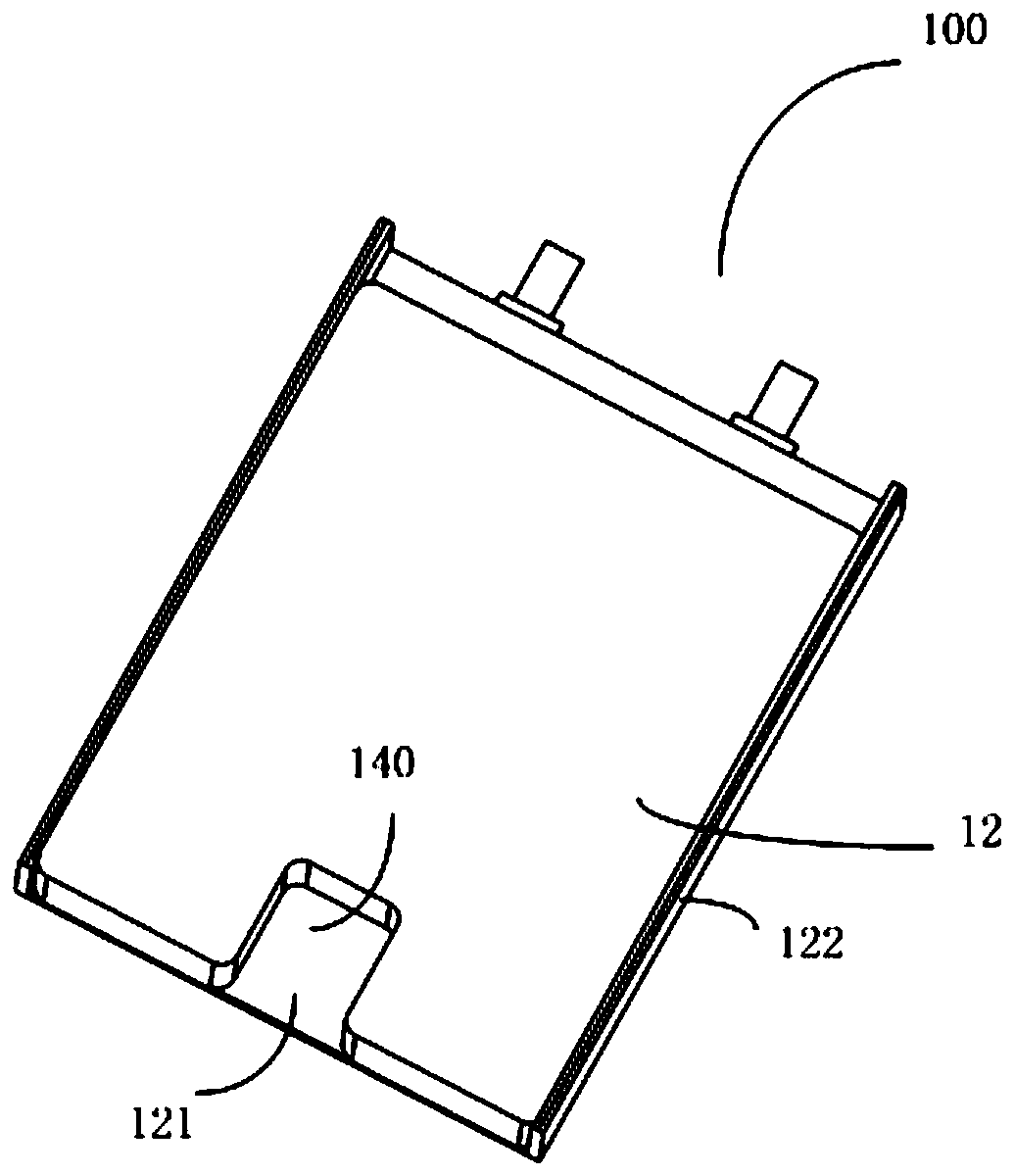

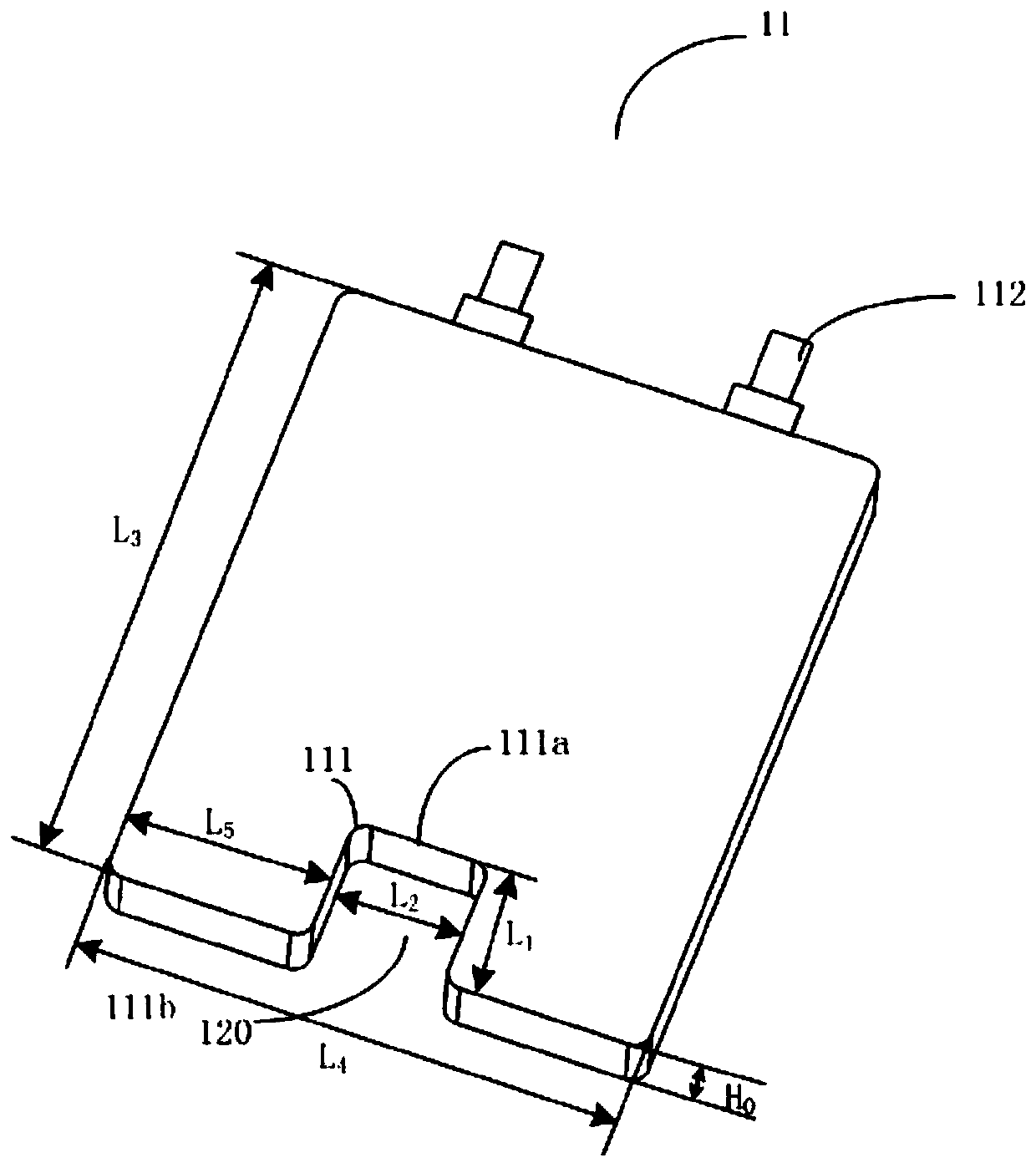

[0048] In the existing special-shaped battery packaging process, it usually involves multiple sealing, cutting and folding operations of the packaging film in the open space on the edge of the special-shaped bare cell, and in order to reserve sufficient space for the corner folding of the open space on the edge, to To improve the maneuverability of folding and reduce safety risks, it is necessary to set large-size chamfers at the corners of the bare chip. However, setting large-size chamfers will cause waste of available space for the bare chip, resulting in a loss of battery energy density. It will increase the difficulty of cutting the pole piece. In order to solve this problem, an embodiment of the present invention provides a battery packaging method and battery, which reduce the number of cutting and folding ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com