Patents

Literature

564results about How to "Simple packaging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

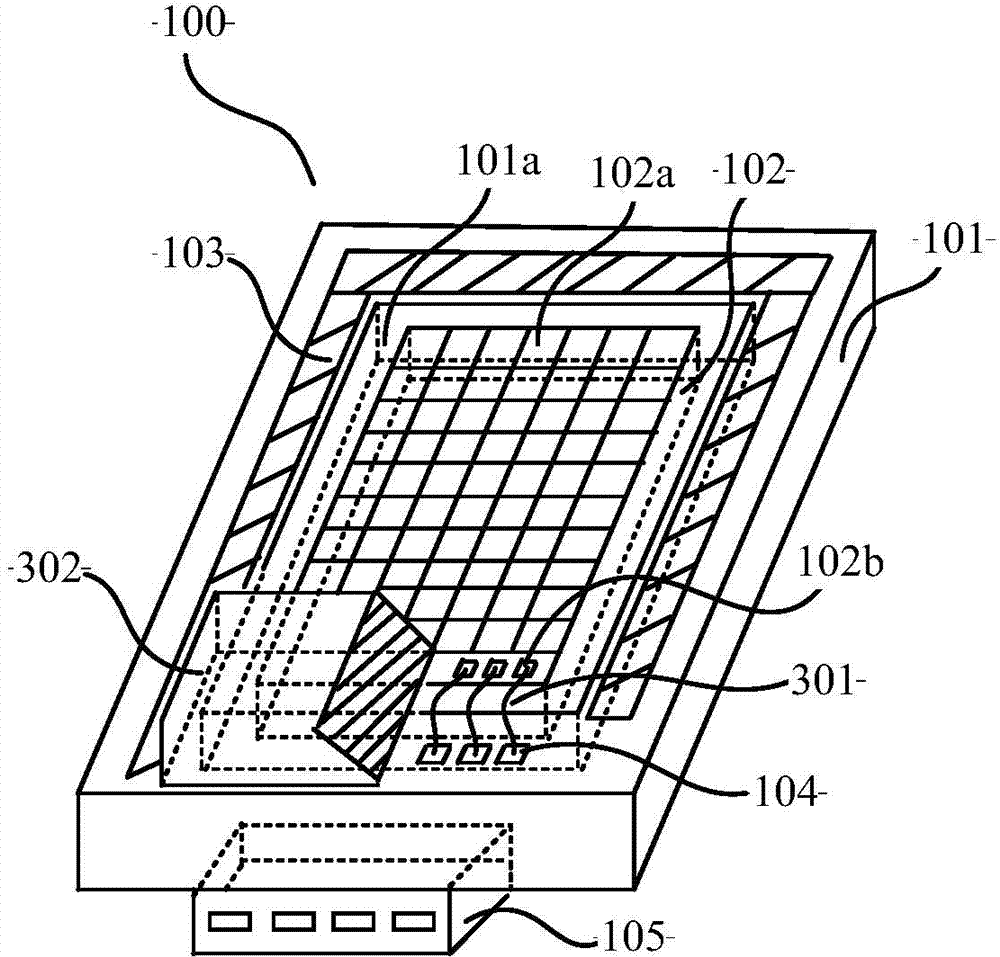

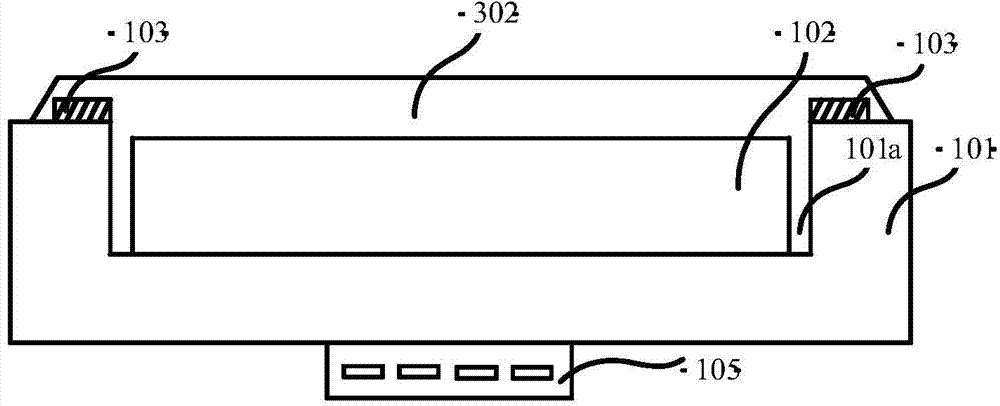

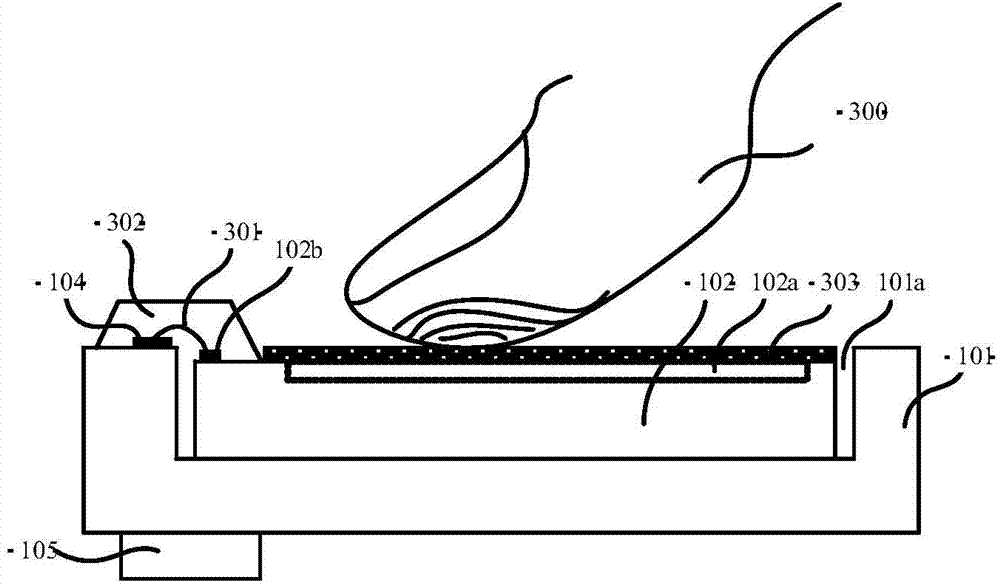

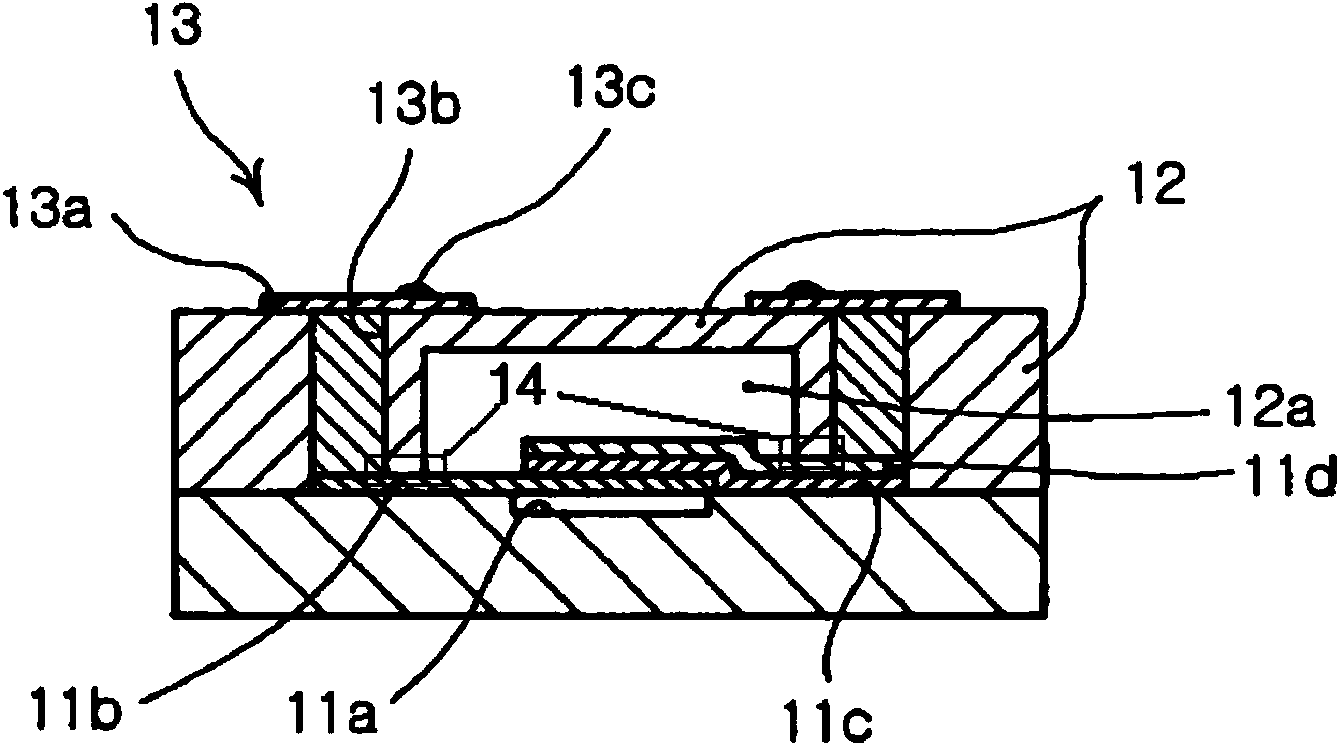

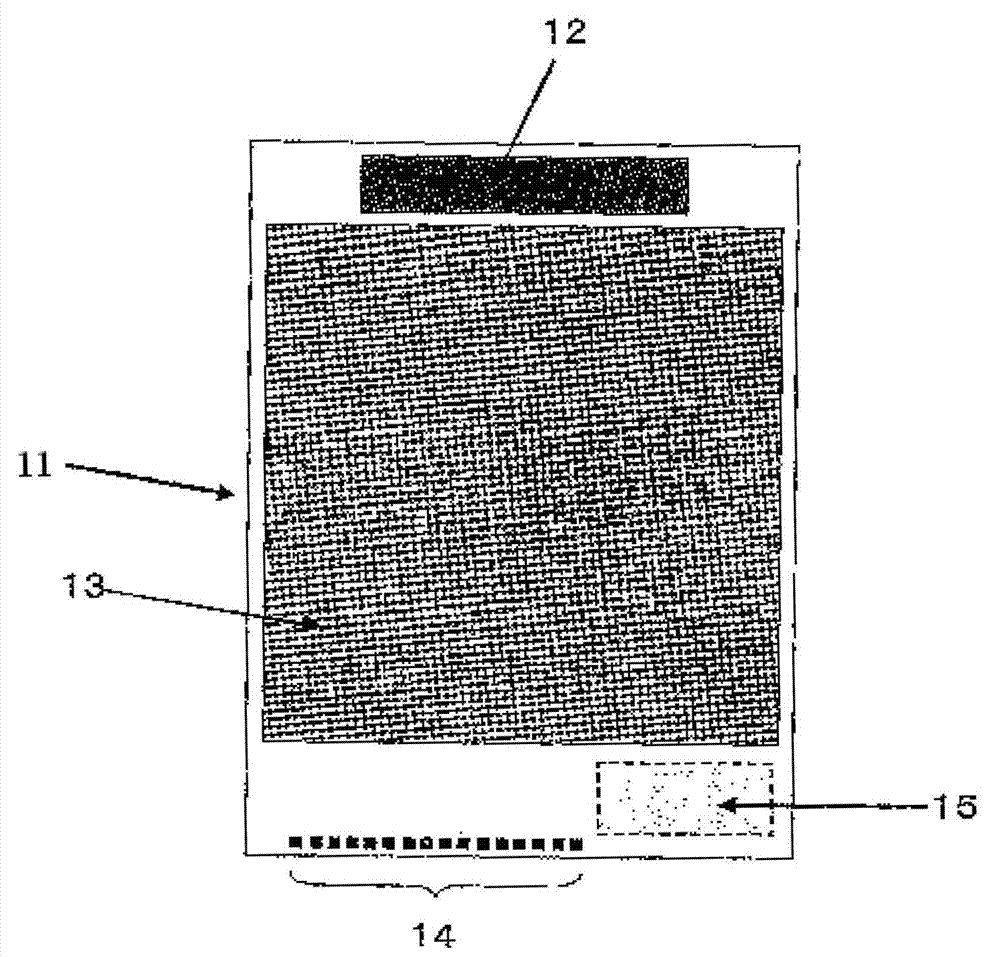

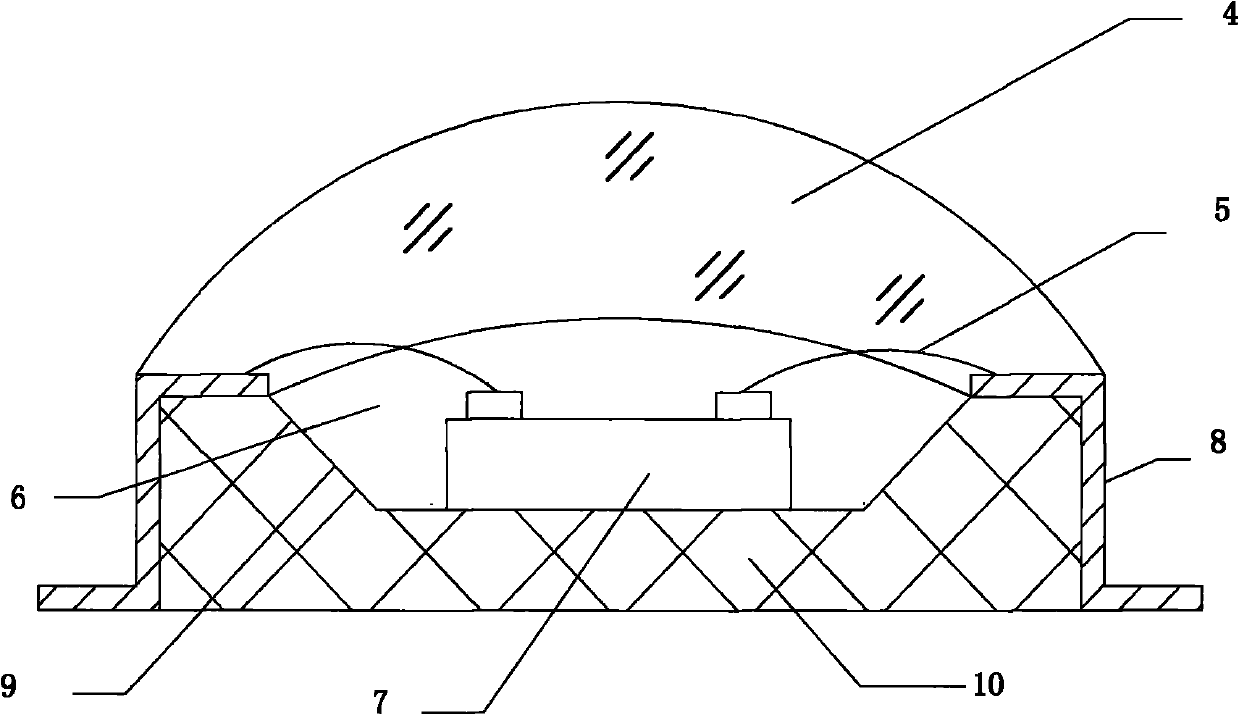

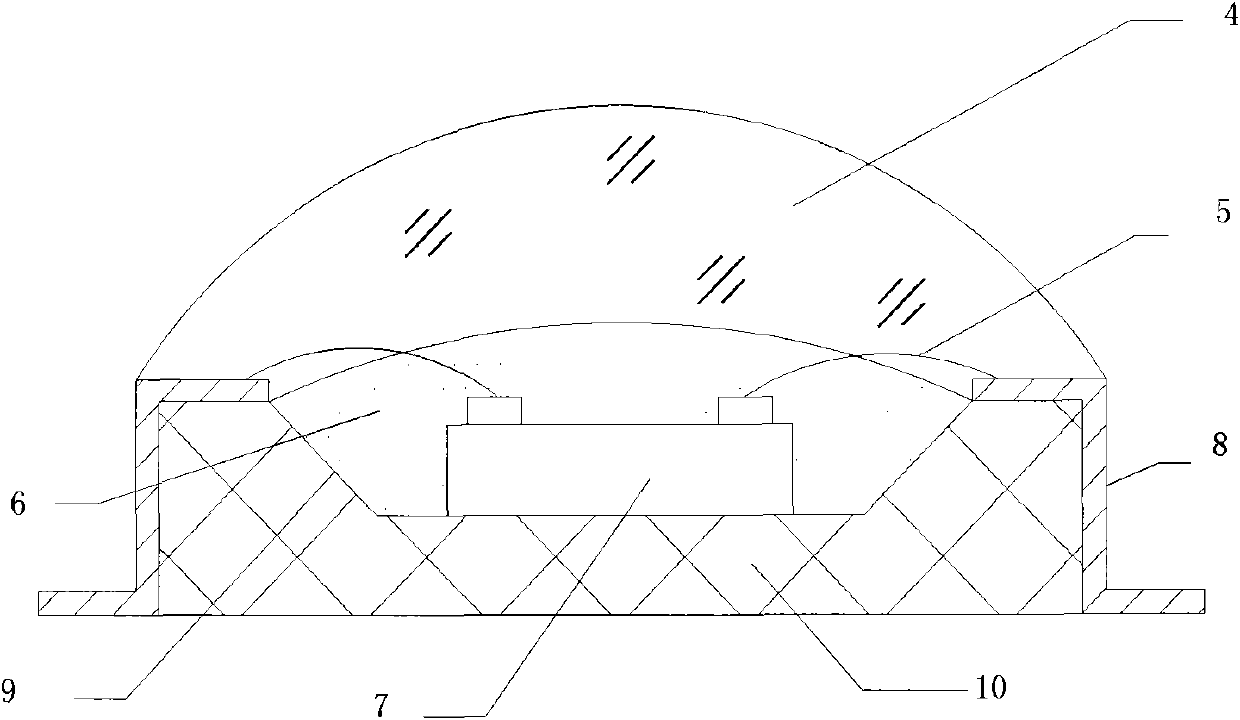

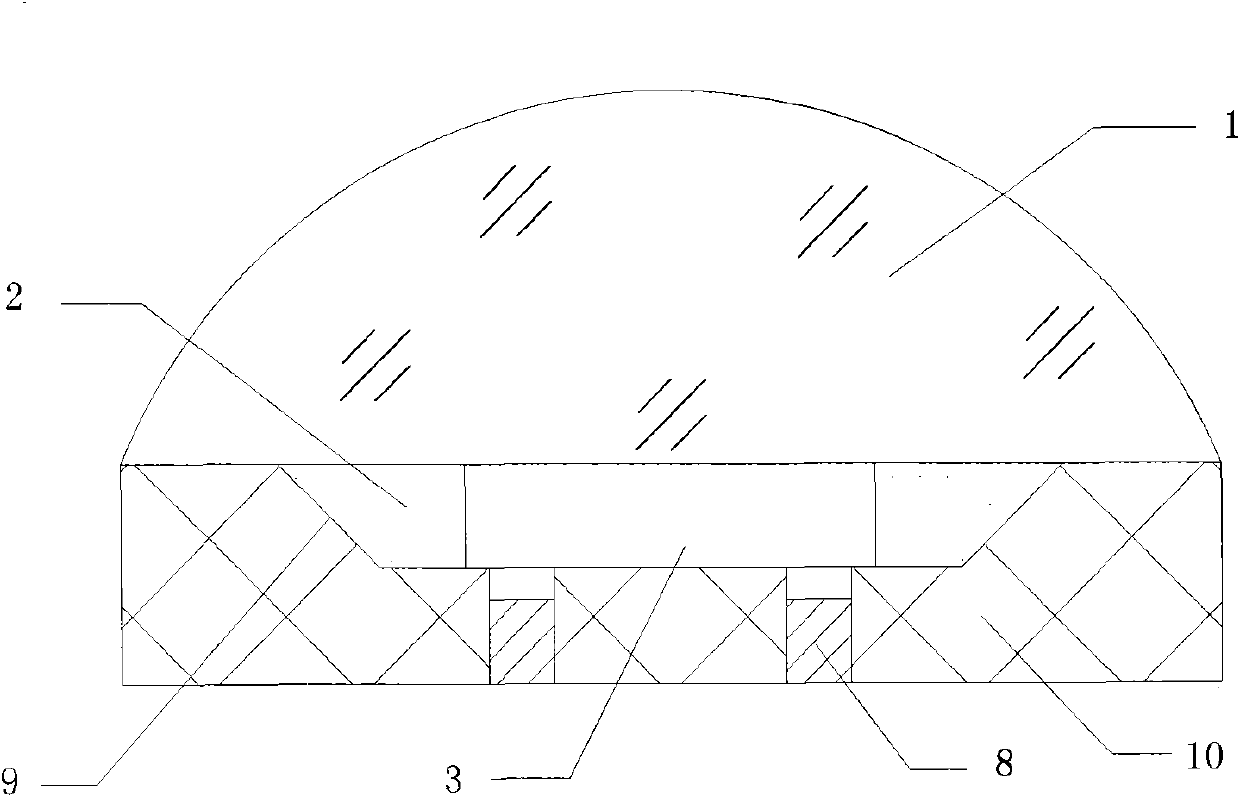

Packaging structure of capacitive fingerprint sensor

ActiveCN103886299ALow costSimple packaging processSolid-state devicesCharacter and pattern recognitionFingerprintGround plane

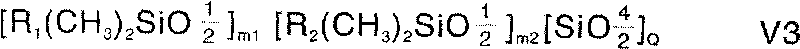

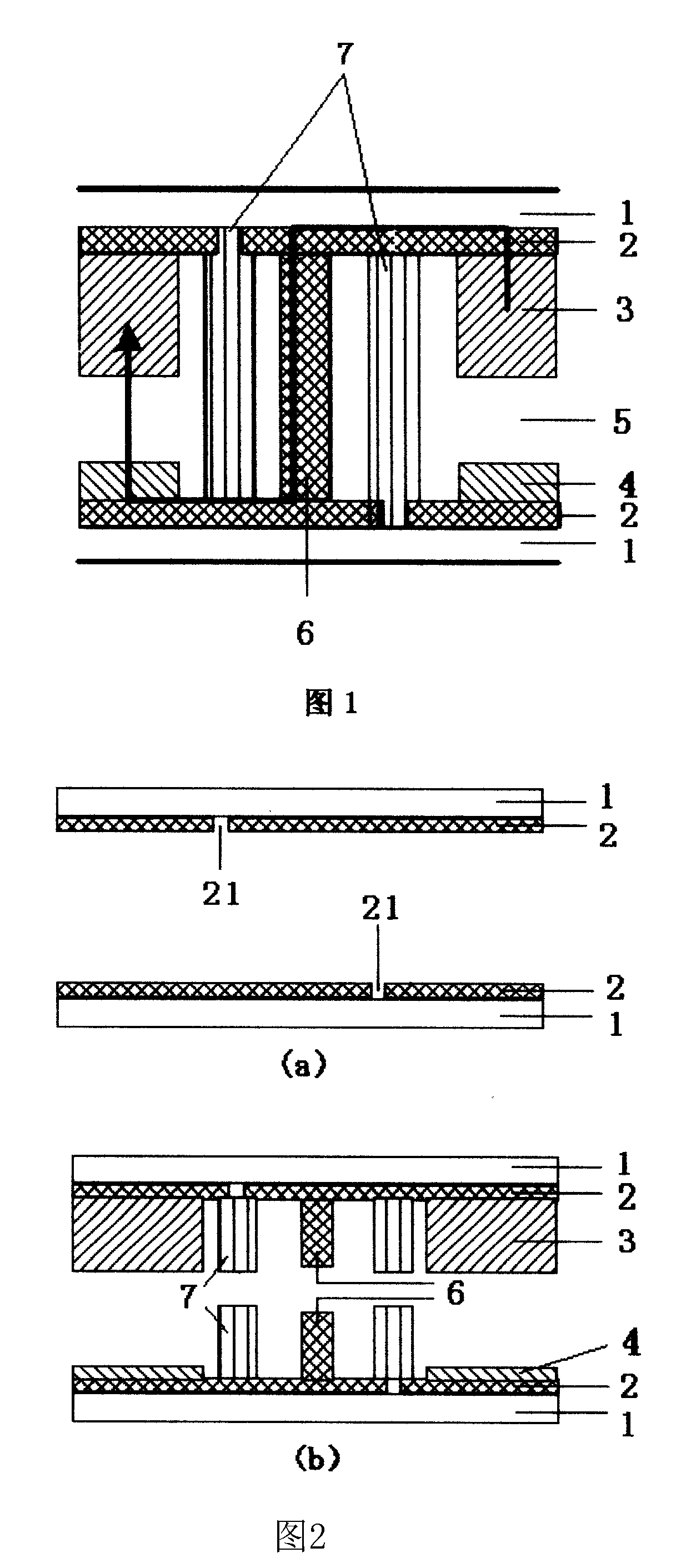

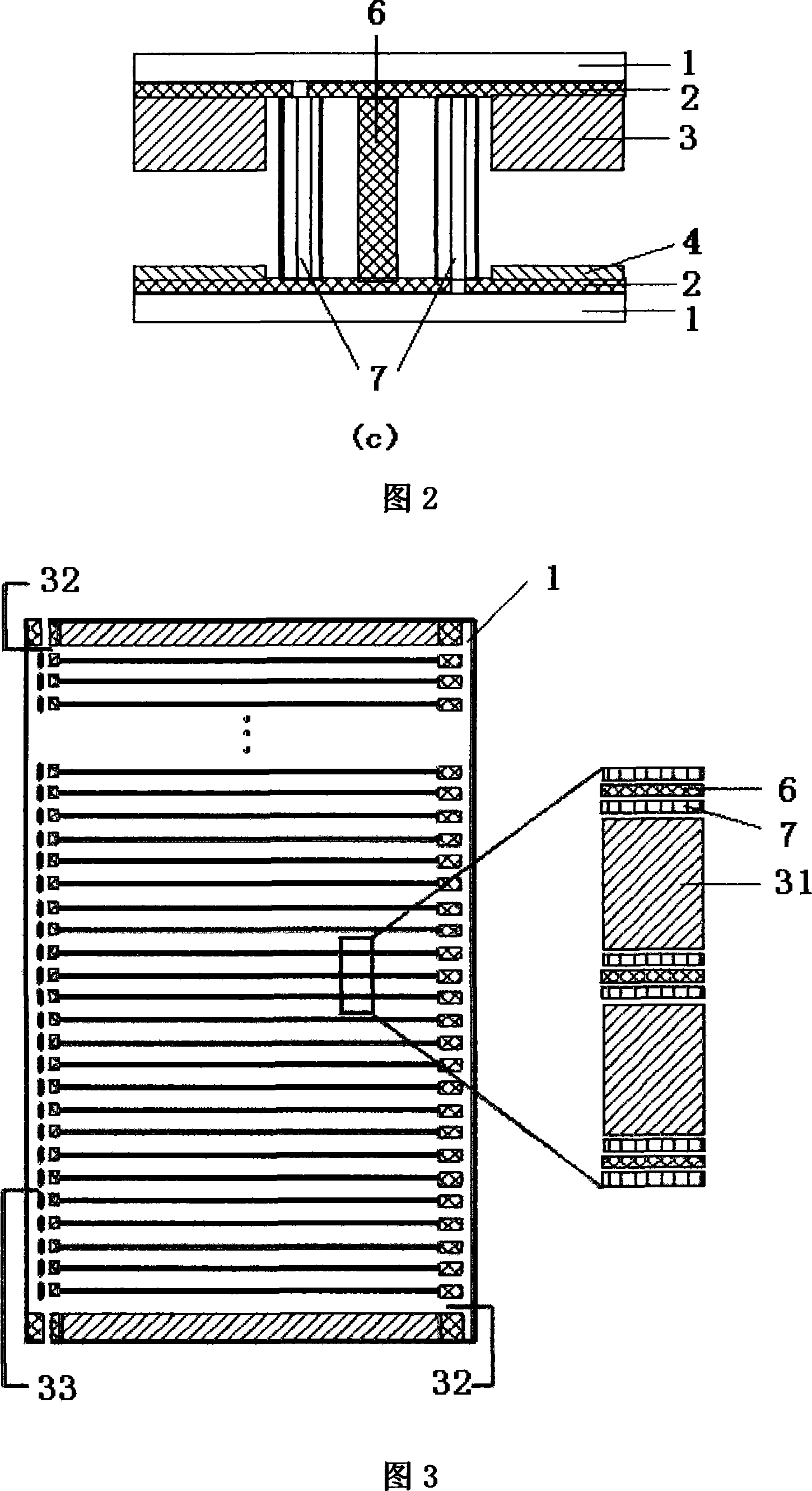

A packaging structure of a semiconductor capacitive fingerprint sensor comprises a semiconductor sensor tube core, a groove type substrate made of insulation materials, a connecting wire, a connector assembly and an injection package structure. The sensor tube core is supported by and fixed at the bottom of a substrate groove through binding agents, the front face or the back face or the side face of the substrate groove is provided with a plurality of multilevel interconnection leads and contact through holes electrically connected between the multilevel interconnection leads, and a connecting welding disc formed by one or more conducting metal edge bars is printed on the grooved face of the substrate. The connecting wire is used for connecting pins of the sensor tube core and the connecting welding disc of the substrate, and the connector assembly is used for enabling the groove type substrate and a printed circuit board to be electrically connected. The connecting welding disc is connected with one or more grounding pins of the connection assembly through the interconnection leads arranged on the front face or the back face of the substrate and located between levels. One or more grounding pins of the connection assembly are electrically connected with the ground plane of the printed circuit board, and the tube core pins, the substrate conducting metal edge bars and the connection wire are packaged through the injection package structure.

Owner:成都费恩格尔微电子技术有限公司 +1

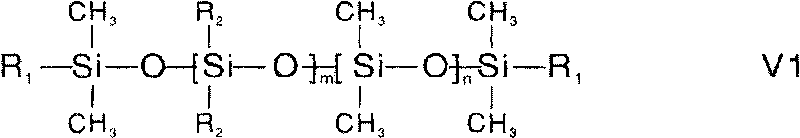

Single component organic silicon packaging glue cured by ultraviolet for high-power LED

InactiveCN101747860ALight attenuation is smallHigh light transmittanceOther chemical processesAdhesivesUV curingPhotosensitizer

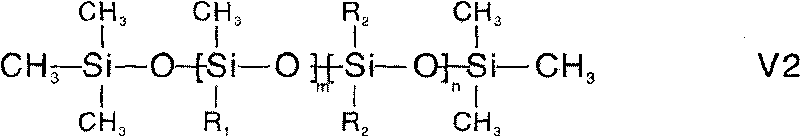

The invention relates to a single component organic silicon packaging glue cured by ultraviolet for high-power LED and a preparation method thereof. The packaging glue is prepared by mixing a prepolymer component A containing acrylate polysiloxanes, a monomer component B containing acrylate polysiloxanes, a photosensitizer component C and a tackifier component D. The packaging glues obtained with different refractive indexes such as level 1.4, level 1.5 and the like are used for packaging multiple types of high-power LEDs or encapsulation of other optical purposes. By adopting ultraviolet curing, the invention enhances the packaging efficiency of the high-power LED product to a great extend without influencing the temperature tolerance, the discoloration and the light transmittance of the product.

Owner:陈俊光

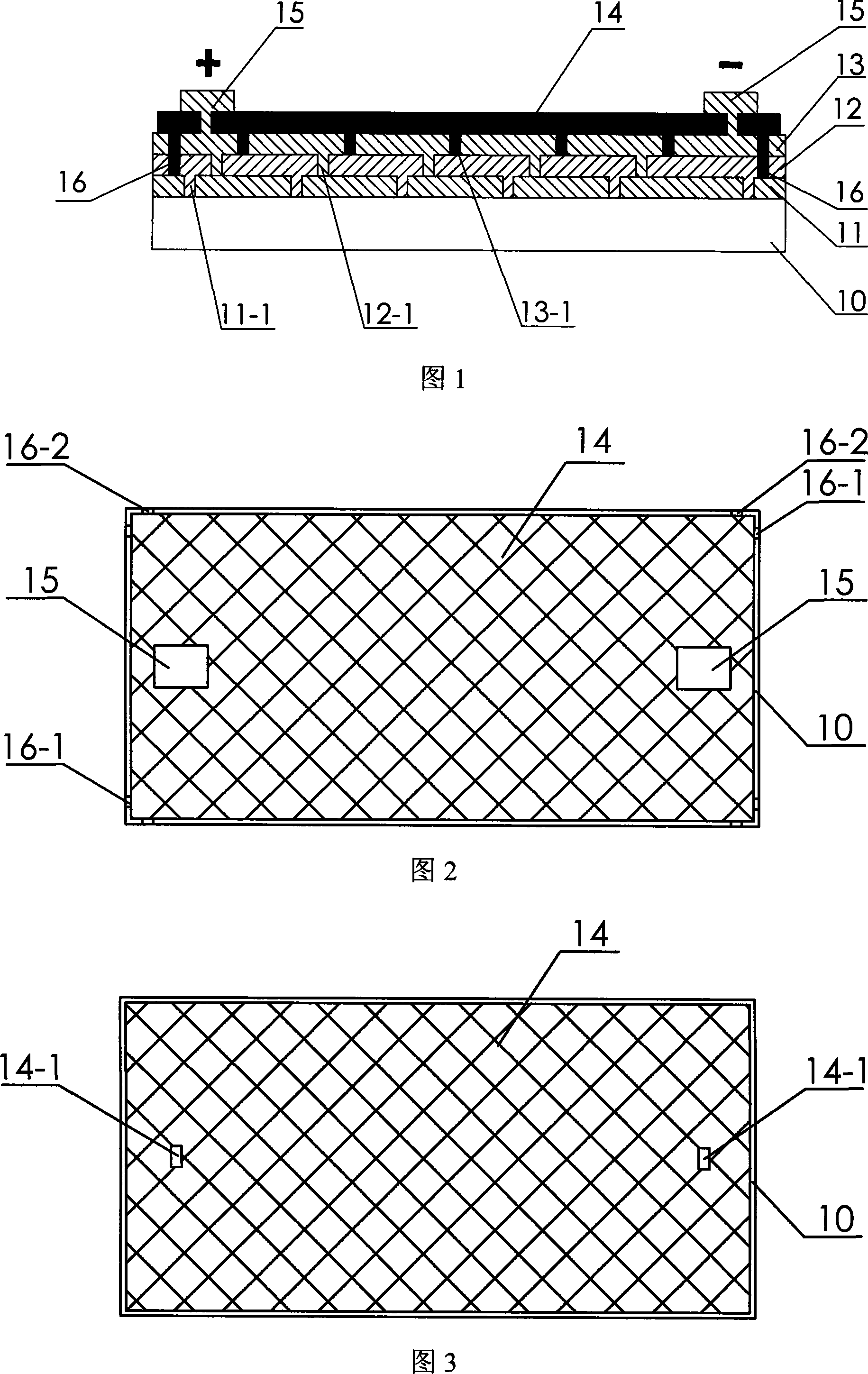

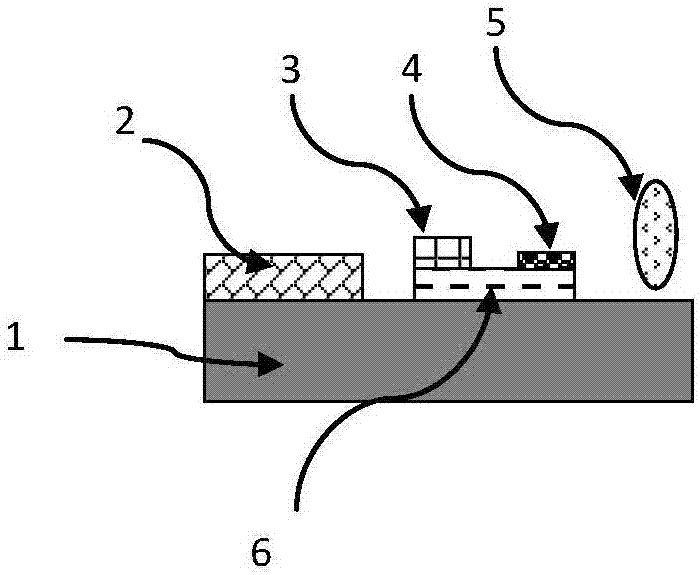

A making method for large-area nano film solar battery

InactiveCN101241956ASimple packaging processLow costLight-sensitive devicesFinal product manufactureTectorial membraneScreen printing

The present invention relates to the technique field of the solar cell, concretely to a method for manufacturing a large-area nano thin-film solar cell, and the method has the following characters: the monomer DSSC is made to strip, the corrosion resistant interlinking strip is used for series-connecting the strip monomer DSSC to a large-area solar cell, the two sides of the corrosion resistant interlinking strip are respectively arranged with a protecting interlayer, or the low resistance grid electrode prepared with the silk screen printing method is adopted, and the surface of the low-resistance grid electrode is covered with a protecting film, afterwards the low resistance grid electrode covered with protecting film is adopted for parallel-connecting a plurality of strip monomers DSSC to a large-area solar cell, the contact surface between on side glass of the large-area solar cell and the TCO is arranged with a bottling groove, when the electrolyte and dye are pumped from the bottling groove which is arranged at one end of the large-area solar cell, the bottling groove is broken off and the sealing is executed. Comparing with the existing technique the invention has the advantages of simplifying the packaging technology, reducing the cost, and guaranteeing the longevity and high stability of the product.

Owner:上海纳晶科技有限公司

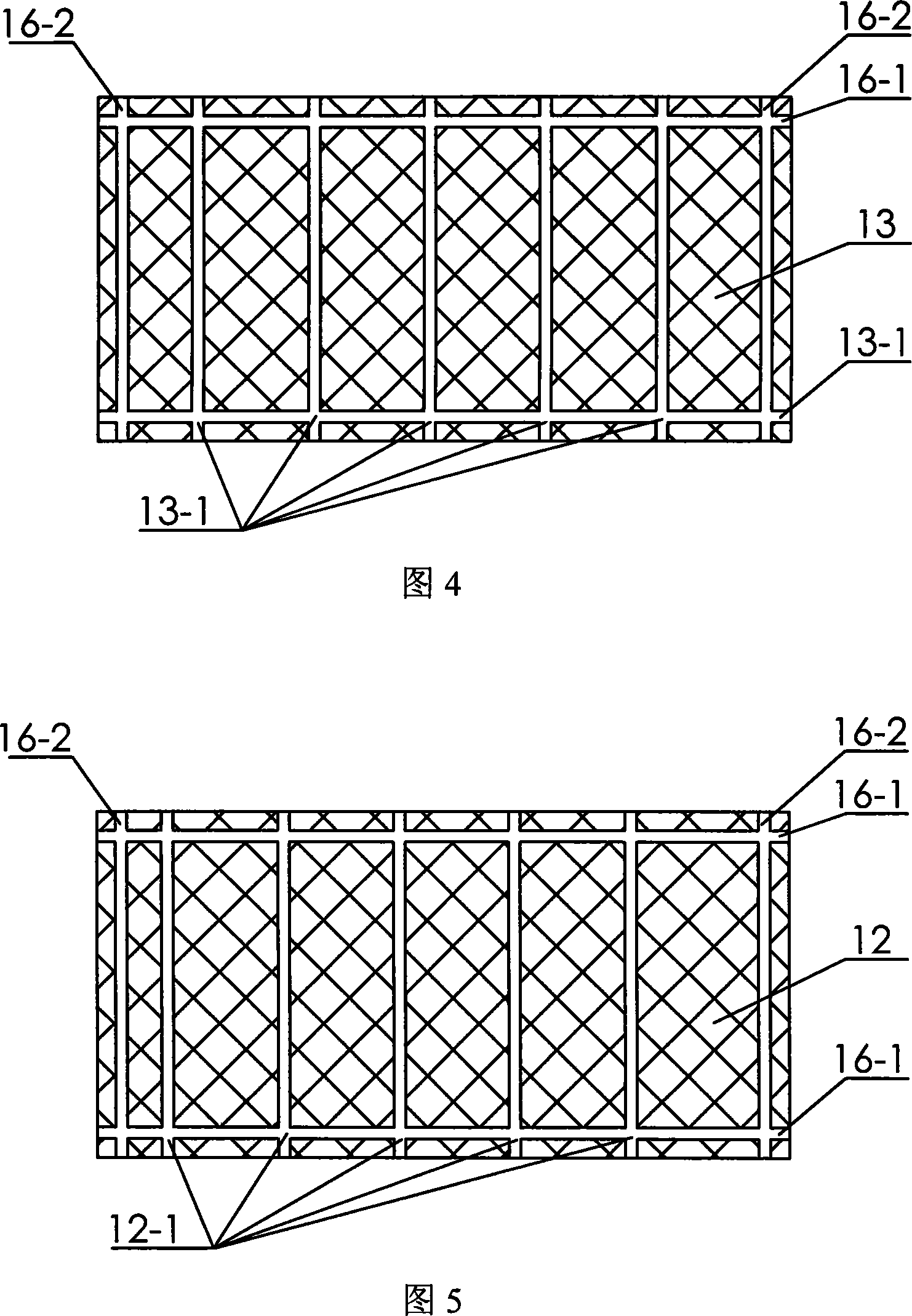

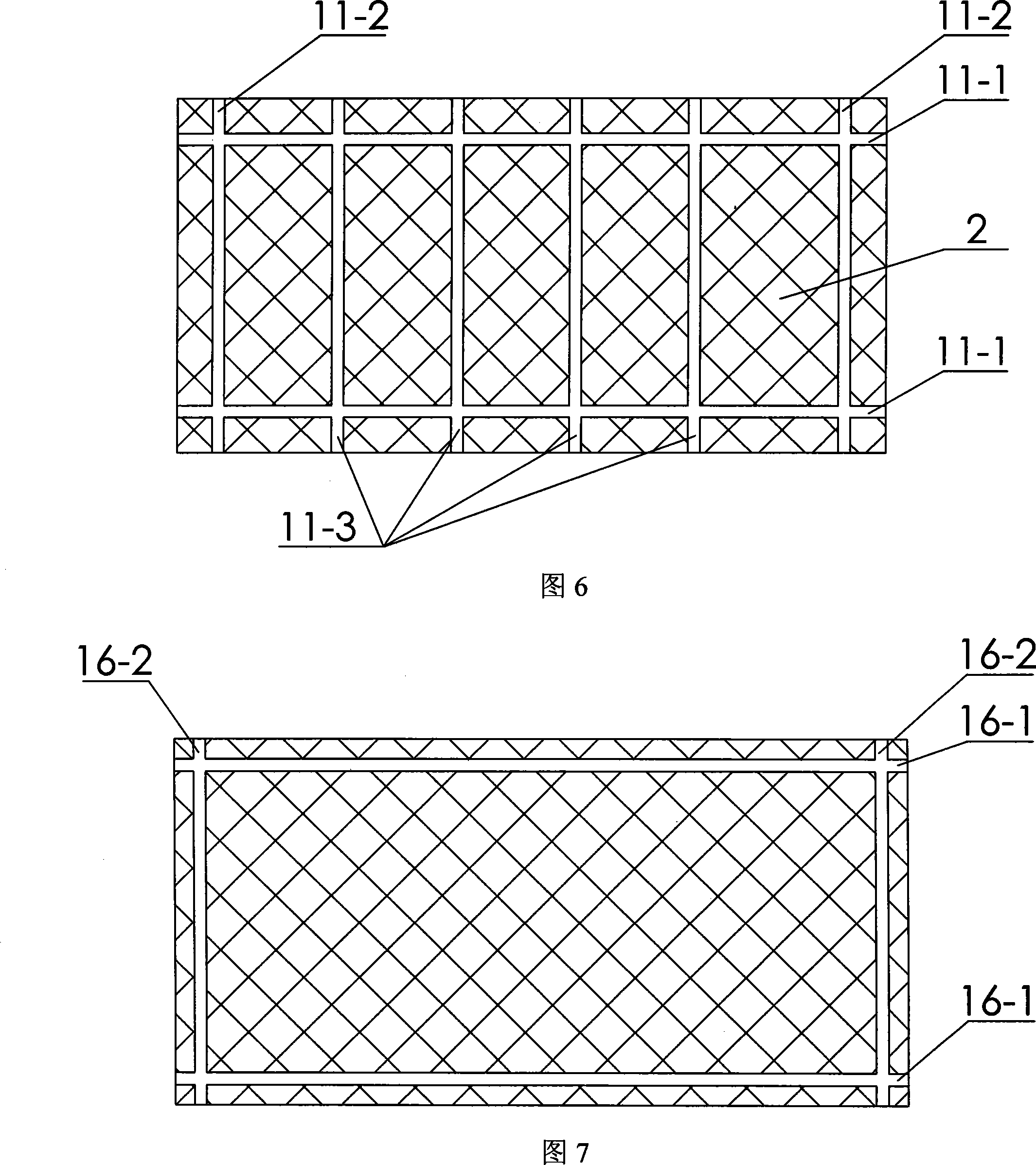

Silicon thin-film solar cell and manufacturing method therefor

ActiveCN101179087APrevent leakageGood weather resistanceSemiconductor/solid-state device manufacturingDiodeCell layerMoisture resistance

The invention relates a thin film silicon solar cell and the manufacturing method thereof; the thin film silicon solar cell is widely applied to the energy-saving electronic products such as the lawn lambs, the yard lambs, etc. The thin film silicon solar cell consists of the large-scale integrated tandem type cell units, uses a transparent conducting basal-plate as the substrate, and comprises a front electrode layer, a thin film cell layer, a back electrode layer and a back layer which are sequentially superposed; the elementary cell consisting of the tandem type cell units is provided with an insulation groove etched by the laser around the cell, and a screen-printed back paint layer within the groove having the performances of insulation, welding resistance, moisture resistance, and acid and alkali resistance. The thin film silicon solar cell provided by the invention can not only prevent the short circuit and the leakage current around the cell, but also prevent the moisture in the air from entering the cell with causing the deliquescence.

Owner:李毅

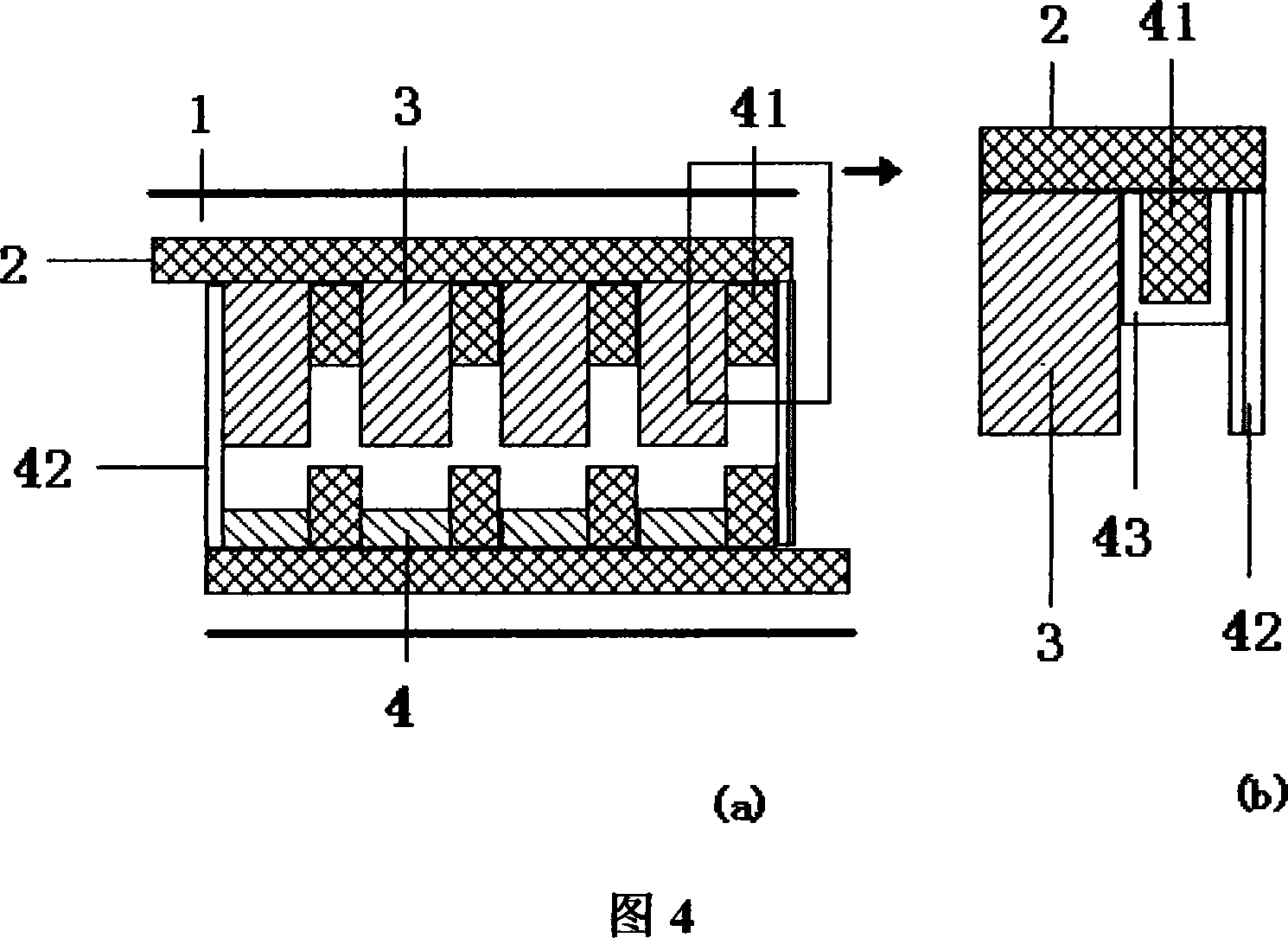

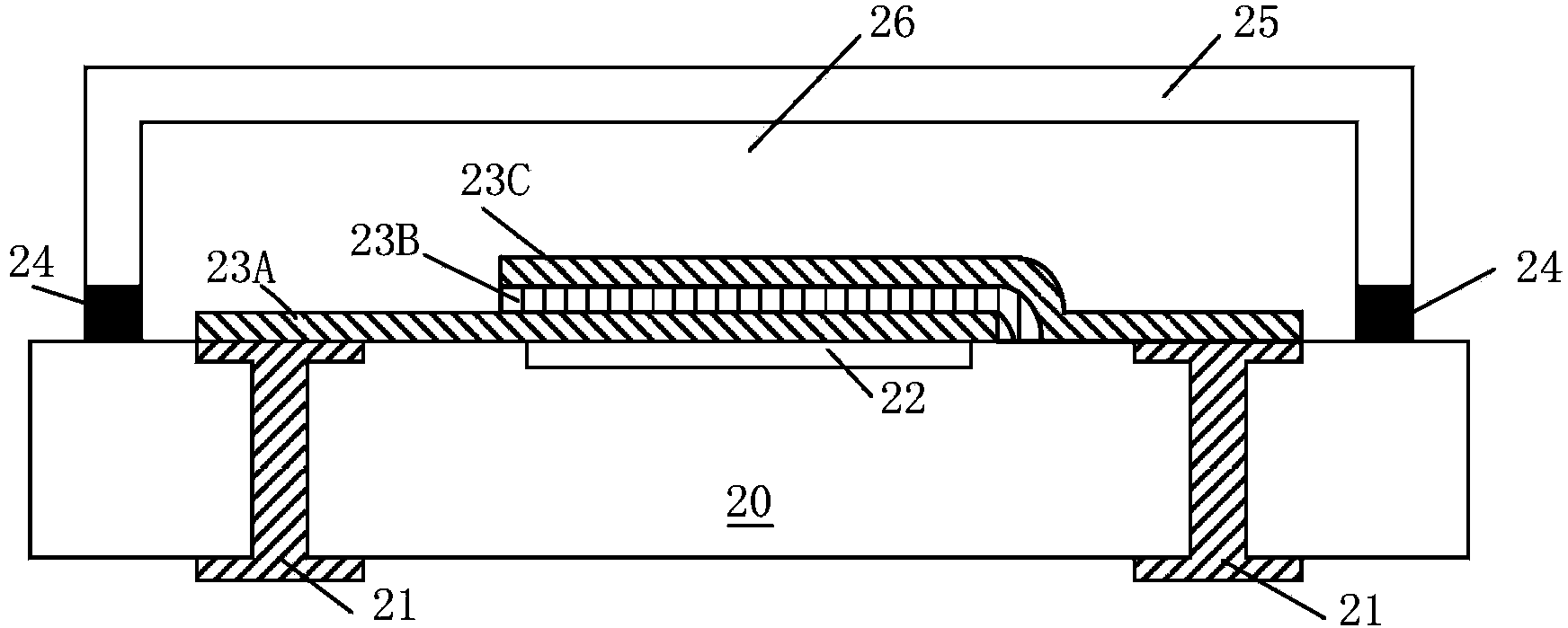

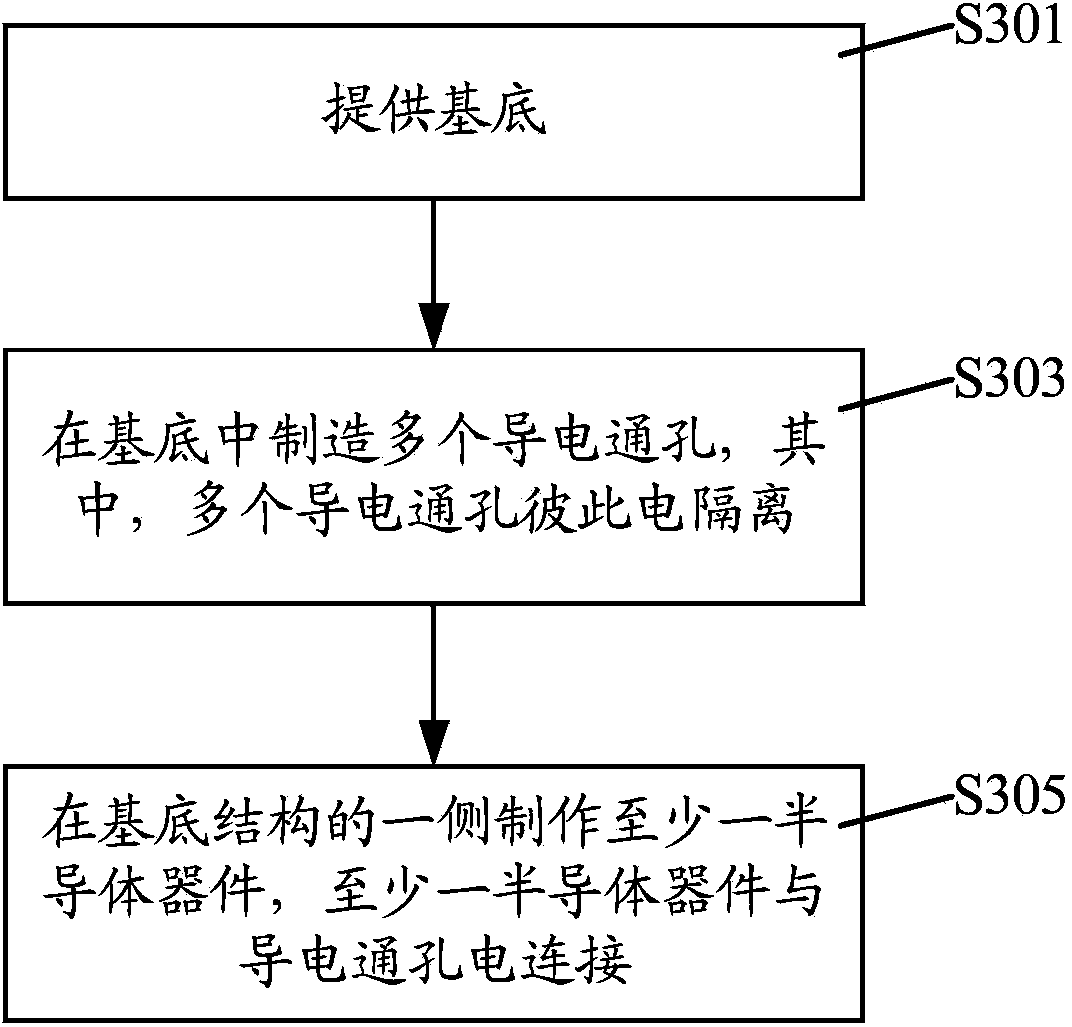

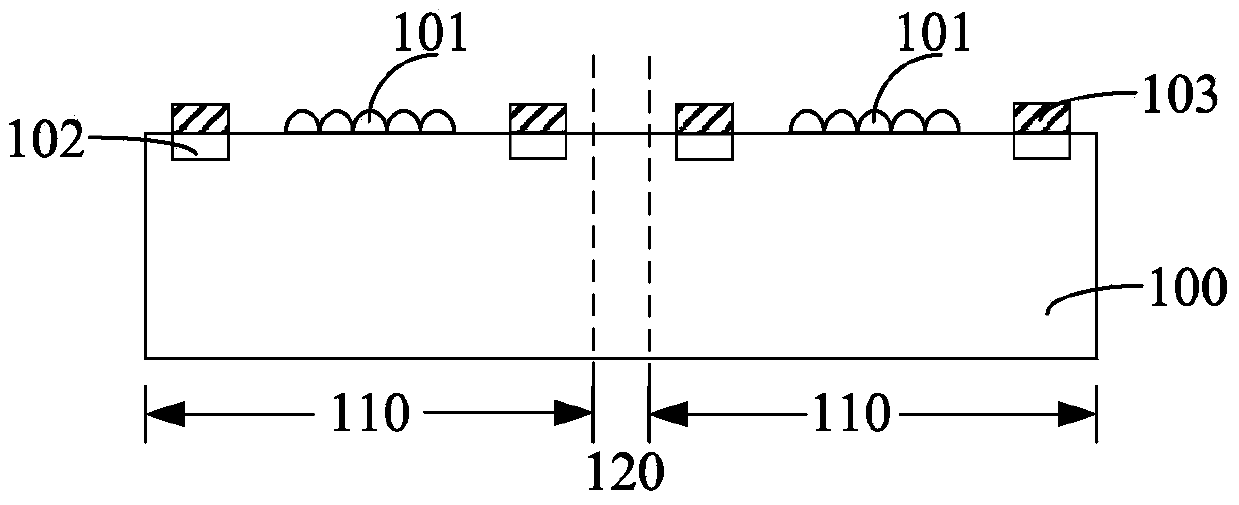

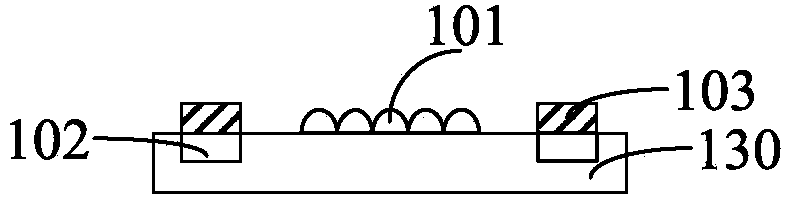

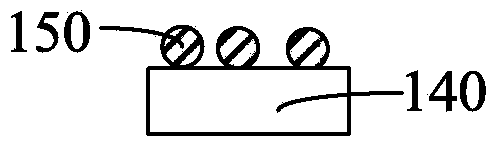

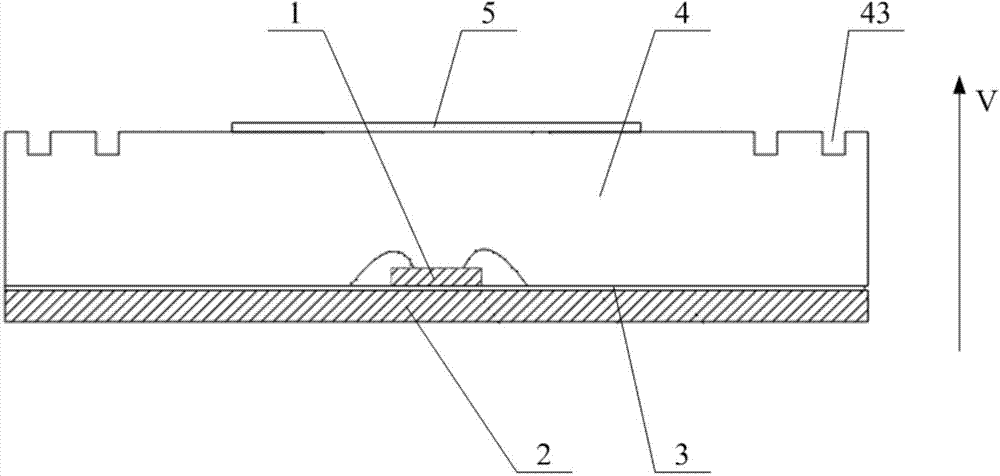

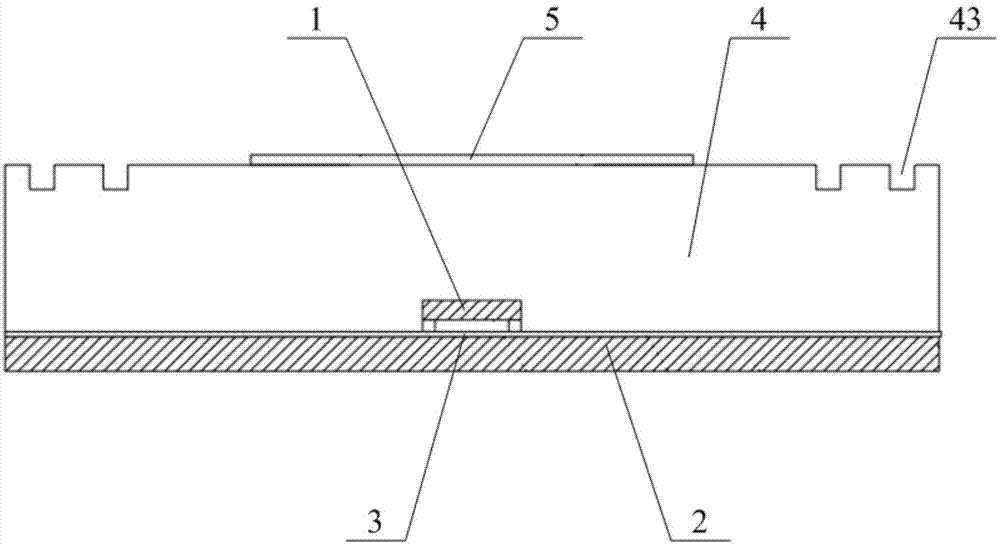

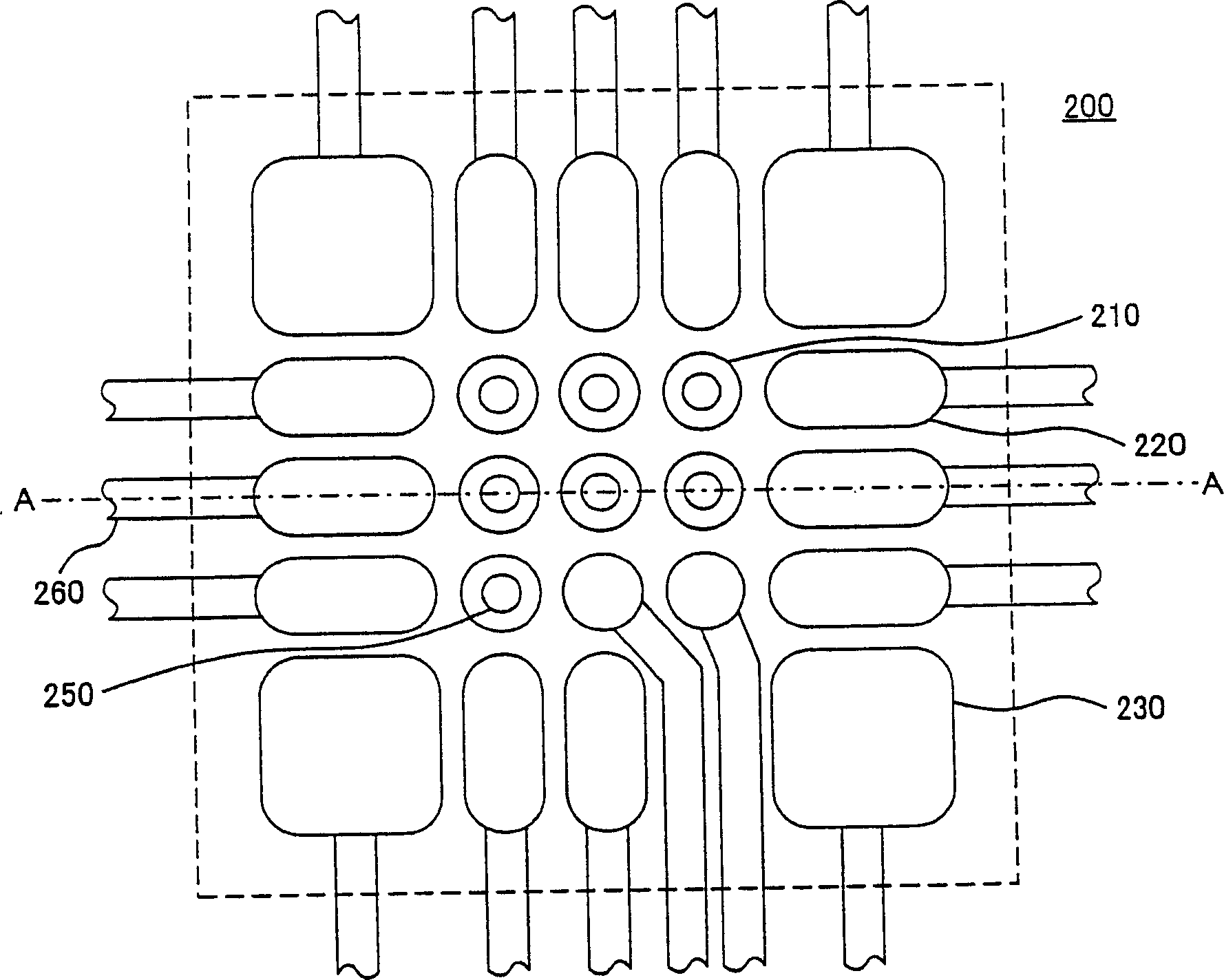

Semiconductor device packing structure and semiconductor device packing technological process

ActiveCN103413795ASimple packaging processReduce areaSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor

The invention discloses a semiconductor device packing structure and semiconductor device packing technological process. The packing structure comprises a substrate and at least one semiconductor device, wherein a plurality of conductive through holes are formed in the substrate and are electrically isolated from one another, and the semiconductor device is arranged on one side of the substrate and electrically connected with the conductive through holes. The conductive through holes in the substrate of the packing structure of the semiconductor device can simplify the packing processes of the semiconductor device, improve the flexibility for choosing the packing processes and reduce the whole size of the packed semiconductor device. In addition, the semiconductor device can be electrically connected with the outside through the conductive through holes.

Owner:TIANJIN UNIV

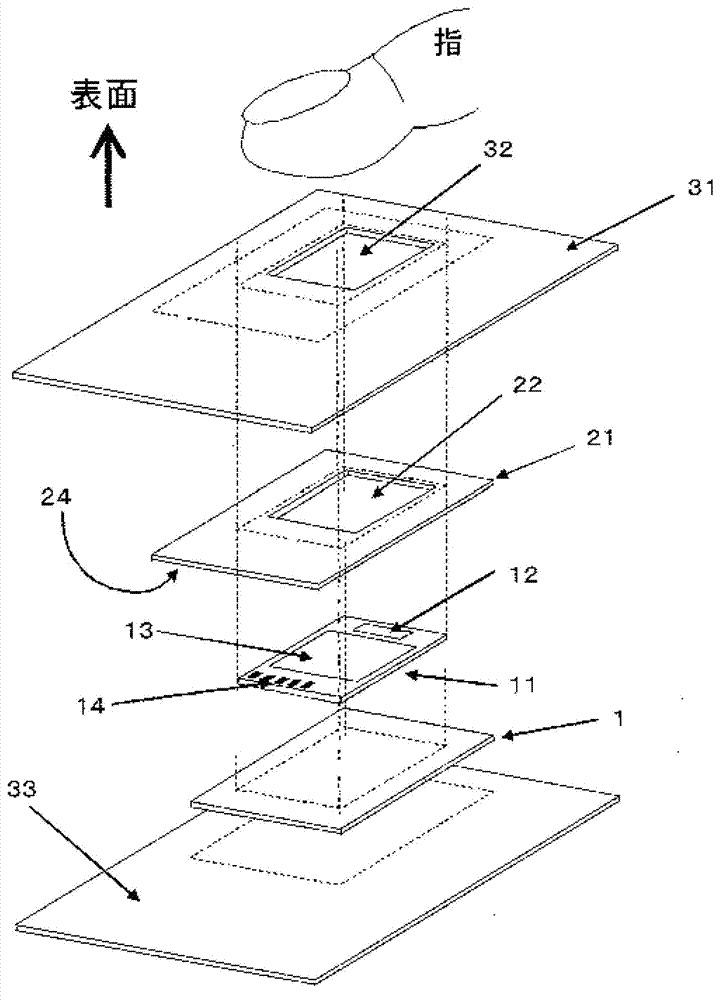

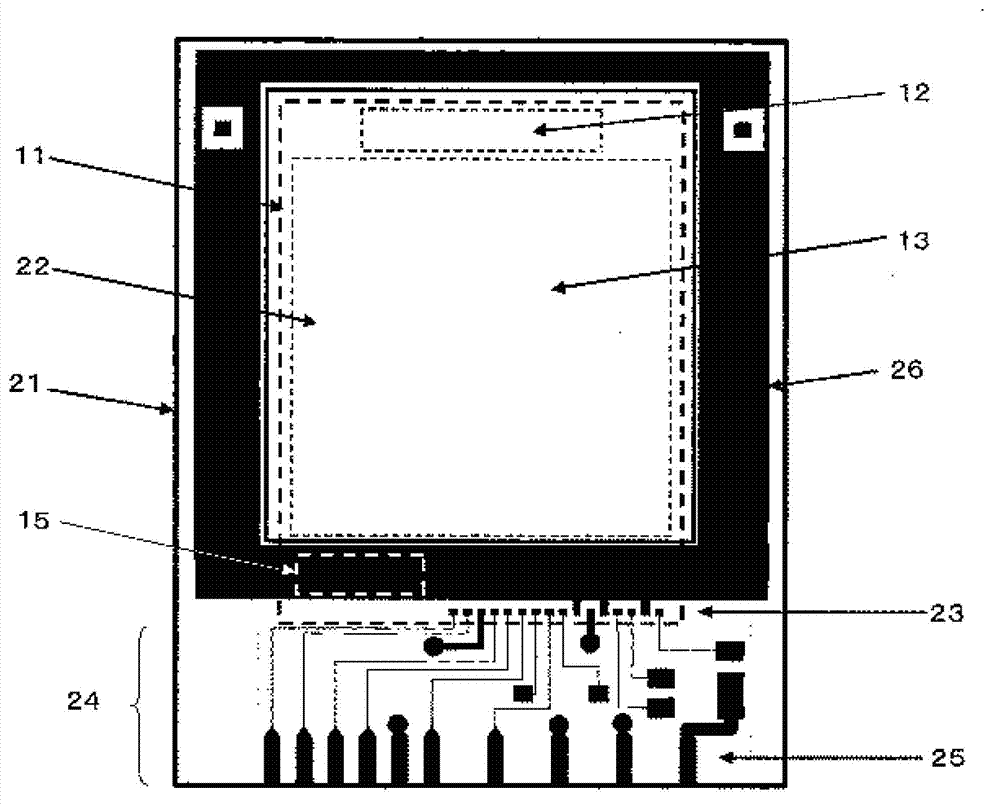

Fingerprint reading sensor IC (Integrated Circuit) card and packaging method thereof

InactiveCN103400181ASimple packaging processCompact structureRecord carriers used with machinesElectricityControl circuit

The invention relates to an IC (Integrated Circuit) card and a packaging method thereof, in particular to a fingerprint reading sensor IC card and a packaging method thereof, and belongs to the technical field of sensor IC cards. According to the technical scheme provided by the invention, the fingerprint reading sensor IC card comprises a fingerprint sensor IC chip, wherein a thin-film substrate is arranged on the front face of the fingerprint sensor IC chip; a reinforcing plate is arranged on the rear face of the fingerprint sensor IC chip; the thin-film substrate is provided with a first window penetrating through the thin-film substrate; the first window of the thin-film substrate corresponds to a fingerprint sensing part on the fingerprint sensor IC chip; the fingerprint sensing part is exposed from the first window ; a sensor control circuit of the fingerprint sensor IC chip is electrically connected with a data processing circuit which is arranged on the rear face region of the thin-film substrate and is used for identifying and processing fingerprint data. The fingerprint reading sensor IC card provided by the invention is simple and compact in structure, simple in packaging process, low in manufacturing and packaging cost, wide in application range, and safe and reliable.

Owner:JIANGSU HENGCHENG HI TECH INFORMATION TECH

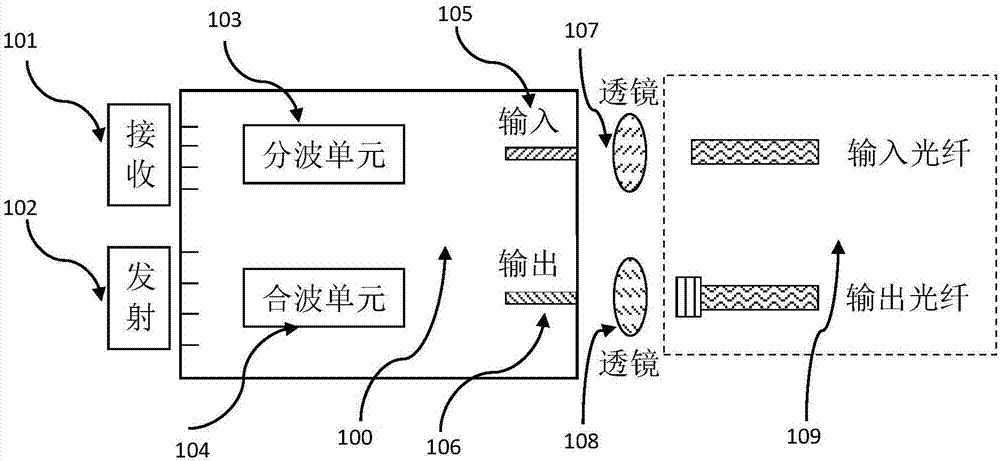

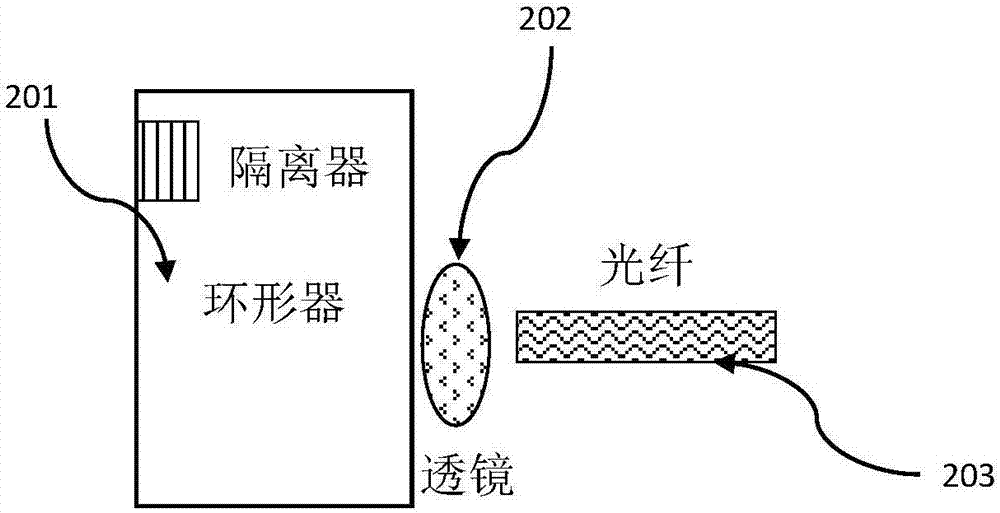

Multichannel silicon substrate wavelength division multiplexing high-speed optical transmitting-receiving integral device

The invention discloses a multichannel silicon substrate wavelength division multiplexing high-speed optical transmitting-receiving integral device which comprises a transmitting unit and a receiving unit, wherein the transmitting unit and the receiving unit are coupled with a planar optical waveguide chip; a wave division unit and a wave combining unit are arranged on the planar optical waveguide chip; the input end and the output end of the planar optical waveguide chip are respectively coupled with an input optical fiber and an output optical fiber correspondingly. On the basis of a silicon photon technique, a multichannel high-speed transmitting unit and a multichannel high-speed receiving unit are integrated, multiple transmission velocities can be compatible, the integration degree is increased, the sealing process is simplified, the cost is effectively lowered, and very high practical values are made.

Owner:HUAZHONG UNIV OF SCI & TECH

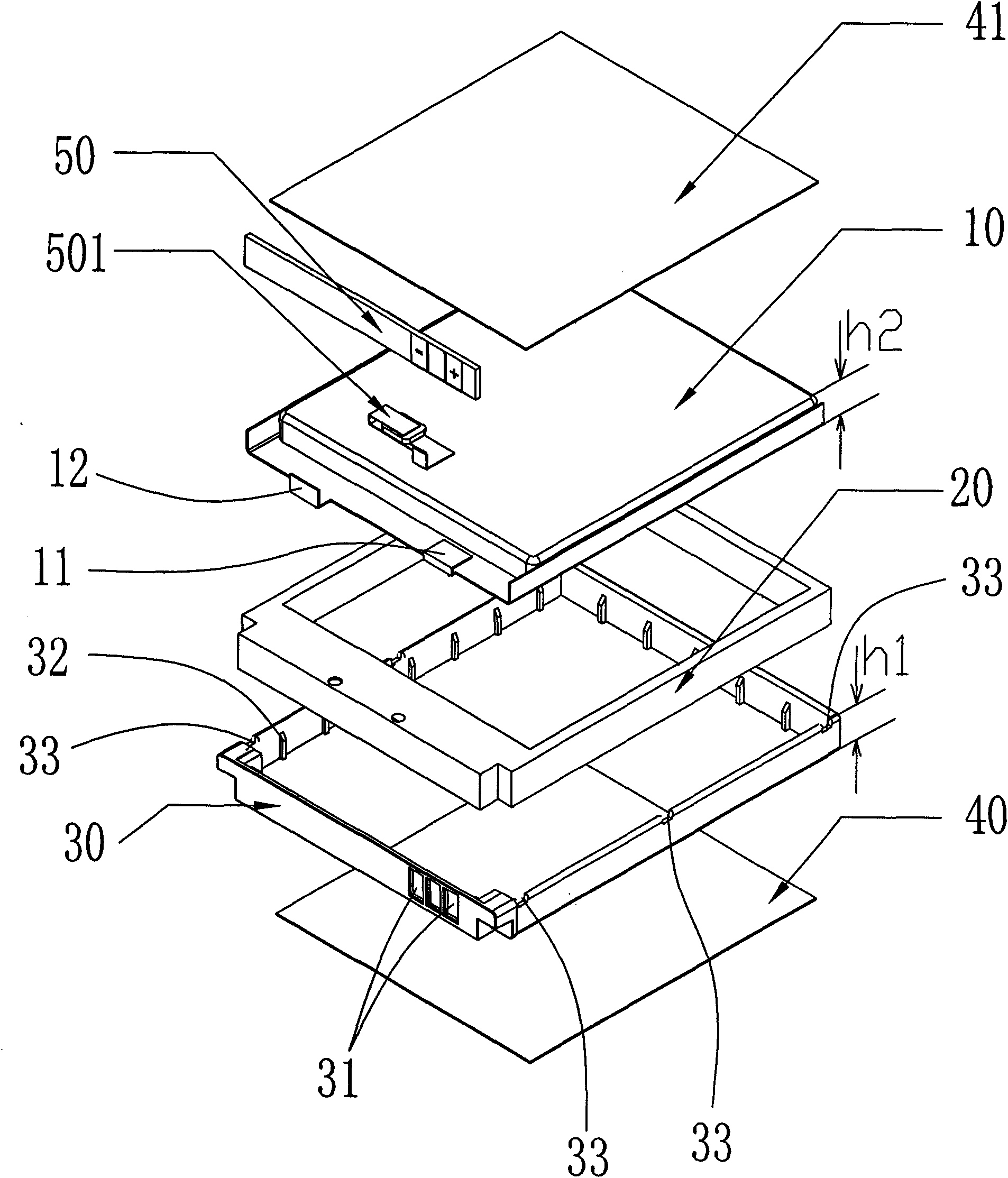

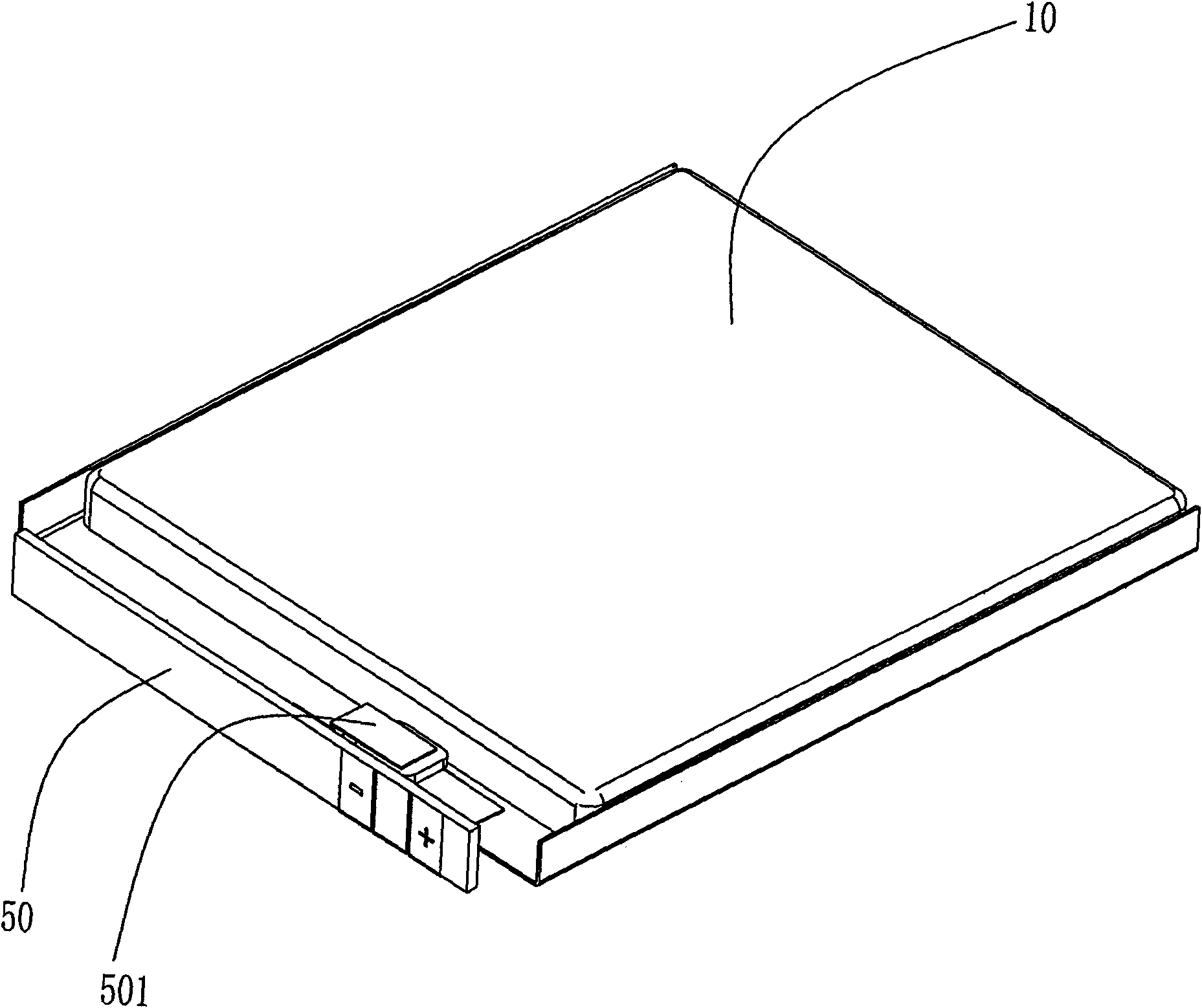

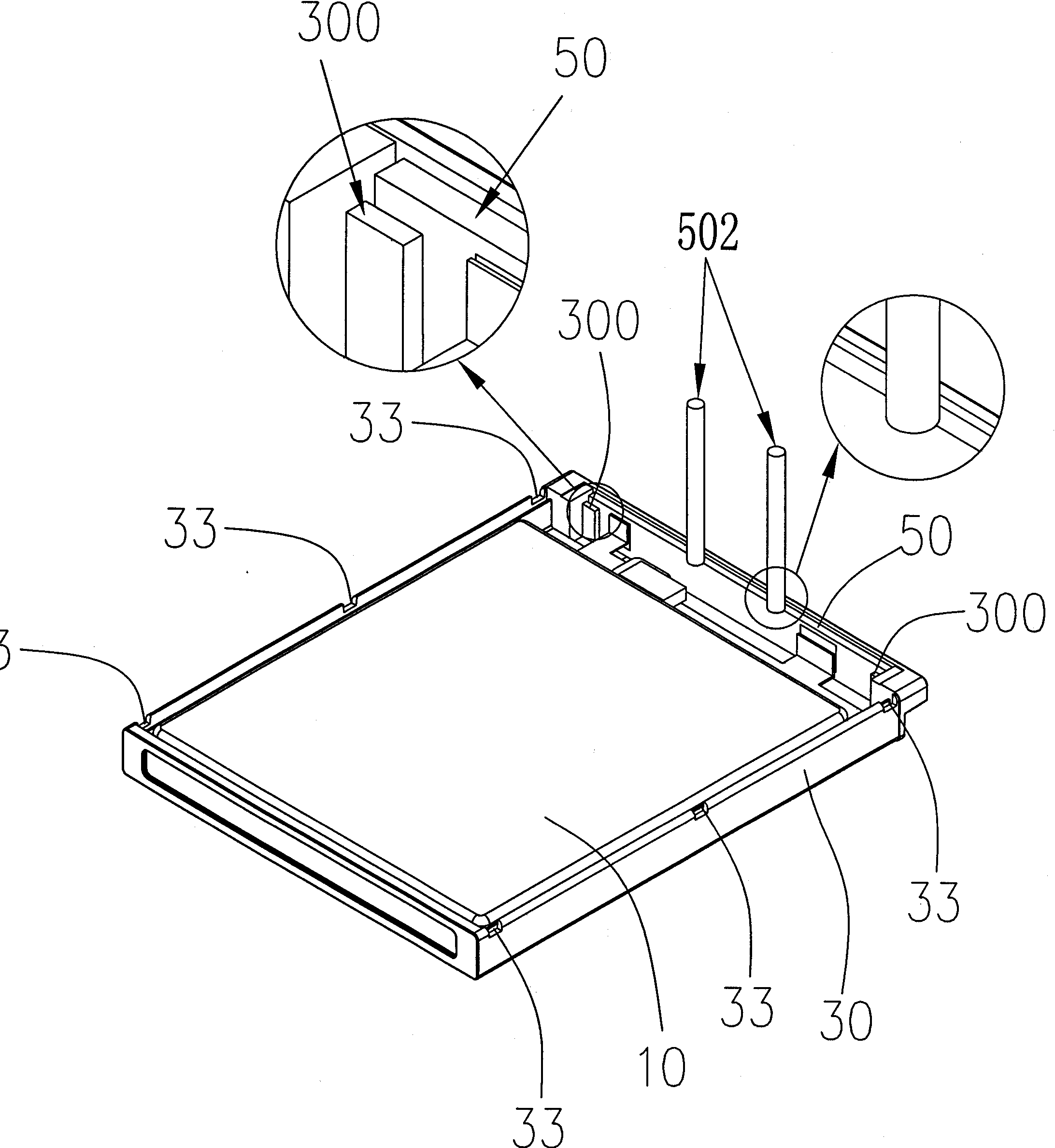

Low-pressure injection molding encapsulation method of polymer battery and low-pressure injection molding polymer battery

InactiveCN101783417AOvercoming Dimensional InstabilityOvercome stabilityFinal product manufactureLi-accumulatorsEngineeringMechanical property

The invention relates to a low-pressure injection molding encapsulation method of a polymer battery and a low-pressure injection molding polymer battery. The battery of the invention comprises a battery protecting board, a battery cell and an adhesive wherein the battery protecting board is welded with the positive pole and the negative pole of the battery cell; the adhesive frame is composed of a front side, a back side, a left side and a right side; the height of the adhesive frame is equivalent to the thickness of the battery cell; the battery protecting board is clamped on one side, which is provided with an electrode hole, of the adhesive frame; a plurality of convex ribs are arranged on the inner sides of the other three sides of the adhesive frame; the convex ribs abut against the corresponding side of the battery cell, so a gap is formed between the battery cell and the adhesive frame; and hot melt adhesive molded by low-pressure injection molding is filled in the residual space in the adhesive frame. The invention has the advantages of simple structure, low manufacturing cost, good mechanical property, low height of the battery, precise dimension and high realizability.

Owner:SHENZHEN RUIDE ELECTRONICS IND

Novel solar cell packaging adhesive film

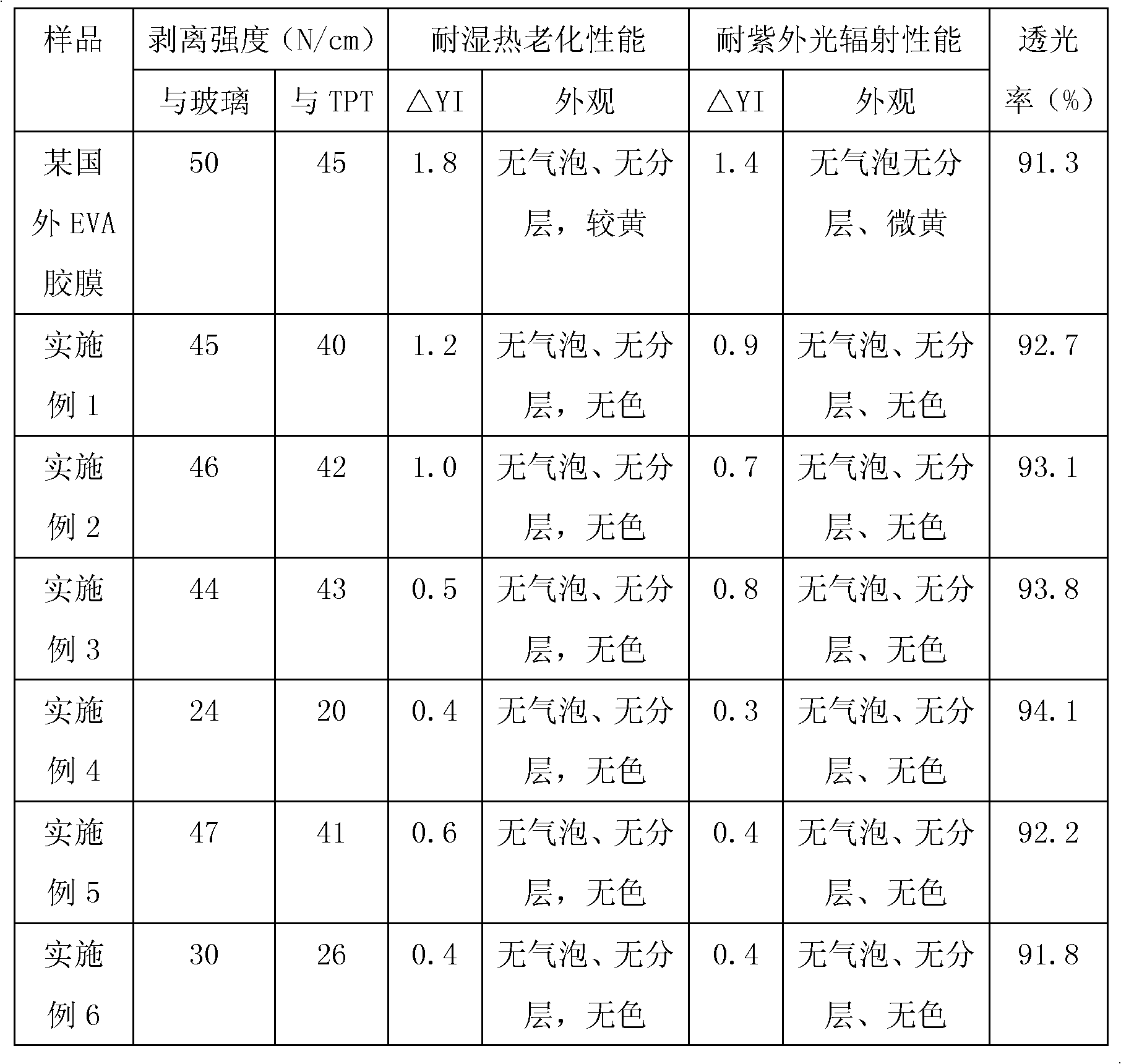

InactiveCN102115643ASimple packaging processGood yellowing resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryAdhesive

The invention relates to a novel solar cell packaging adhesive film. The adhesive film is prepared by the following steps of: adding various functional aids into a matrix material of poly(ethylene-co-methacrylic acid)ionomer, premixing, and casting. The adhesive film comprises the following components: 100 parts of poly(ethylene-co-methacrylic acid)ionomer, 0.1 to 1 part of hindered phenol antioxidant, 0.05 to 0.2 part of subphosphate complemental antioxidant, 0.2 to 1.0 part of ultraviolet absorber, 0.05 to 0.2 part of light stabilizer and 0.5 to 1.5 parts of tackifier. Compared with the traditional solar cell packaging material of ethylene vinyl acetate (EVA), the adhesive film is a thermoplastic material, and simple in packaging process, and facilitates repairing defected solar modules in the packaging process or in the using process to improve the utilization rate of precious cells; moreover, the adhesive film also has the characteristics of high transmittance and excellent yellowing resistance, and can make the service life of the solar modules longer.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

High-voltage flexible solid super capacitor and preparation method thereof

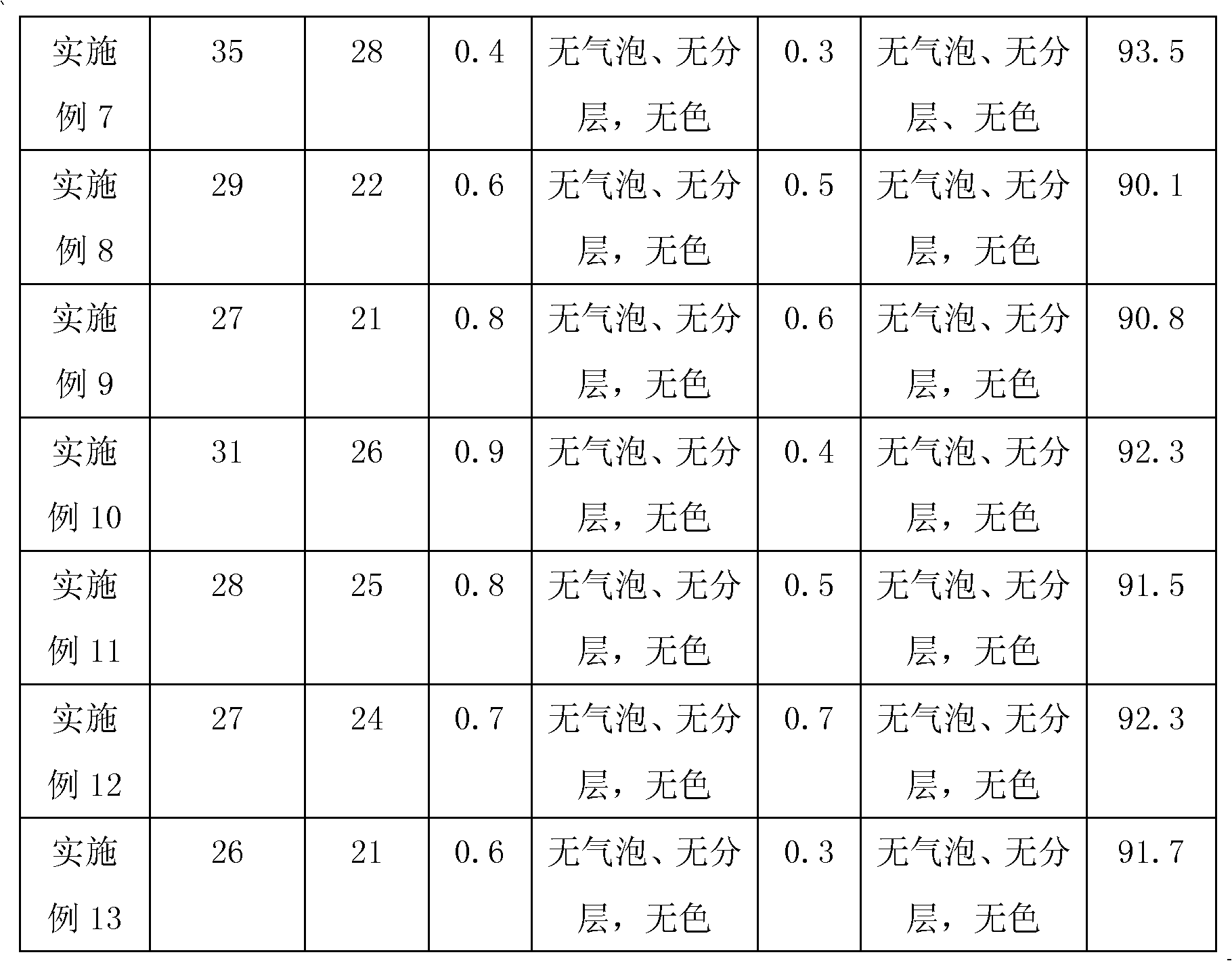

ActiveCN107919233AHigh voltageIncrease energy densityHybrid capacitor electrolytesHybrid capacitor electrodesEngineeringActive electrode

The invention relates to a high-voltage flexible solid super capacitor and a preparation method thereof. The super capacitor comprises a gel electrolyte film, flexible current collectors, electrodes and packaging layers, the surfaces of the flexible current collectors are coated with the electrodes to form flexible electrode slices respectively, one packaging layer, one flexible electrode slice, the gel electrolyte film, the other flexible electrode slice and the other packaging layer are stacked successively, and the packaging layers wrap the flexible electrode slice, the gel electrolyte filmand the other flexible electrode slice. Active electrode materials and the flexible electrode slices are prepared, ion gel is prepared and casted into the film, one flexible electrode slice, the gelfilm and the other electrode slice are stacked sequentially, and the flexible electrode slice, the gel electrolyte film and the other flexible electrode slice are packaged by thermoplastic high-molecular films to form the high-voltage flexible solid super capacitor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Image sensor module and forming method thereof

ActiveCN103956370AImprove structural performanceImprove packaging effectRadiation controlled devicesEngineeringSignal processing

The invention discloses an image sensor module and a forming method of the module. The image sensor module comprises a PCB substrate, a metal layer, an image sensing chip, welding protrusions and a signal processing chip. The PCB substrate is provided with a front face and a back face opposite to the front face, a hole penetrating through the PCB substrate is formed in the PCB substrate, circuit distribution is arranged in the PCB substrate, the metal layer is arranged on the front face of the PCB substrate, the metal layer is electrically connected with the circuit distribution, the image sensing chip is inversely arranged above the front face of the PCB substrate, the image sensing chip is provided with an image induction area and a bonding pad surrounding the image induction area which is arranged above the hole, the bonding pad is electrically connected with the metal layer, the welding protrusions are arranged on the surface of the metal layer, the signal processing chip is arranged on the back face of the PCB substrate, and the signal processing chip is electrically connected with the circuit distribution. The image sensing chip and the signal processing chip are separately arranged, the packaging process difficulty and the packaging cost are reduced, and the packaging performance of the image sensor module is improved.

Owner:CHINA WAFER LEVEL CSP

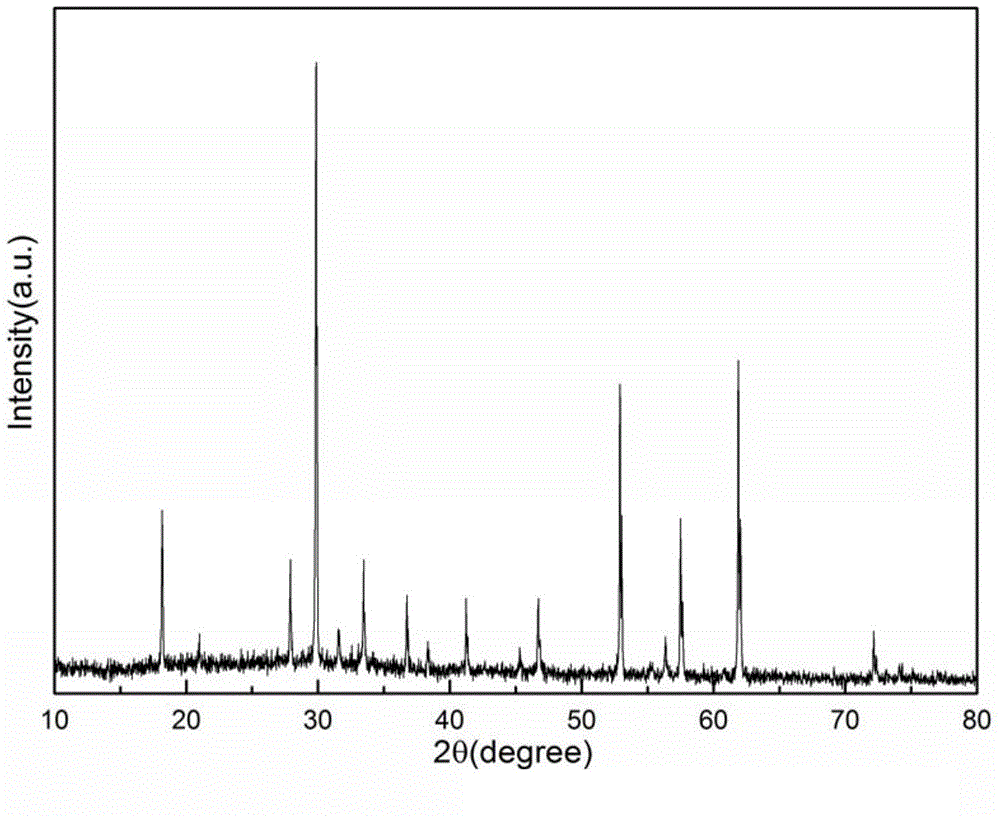

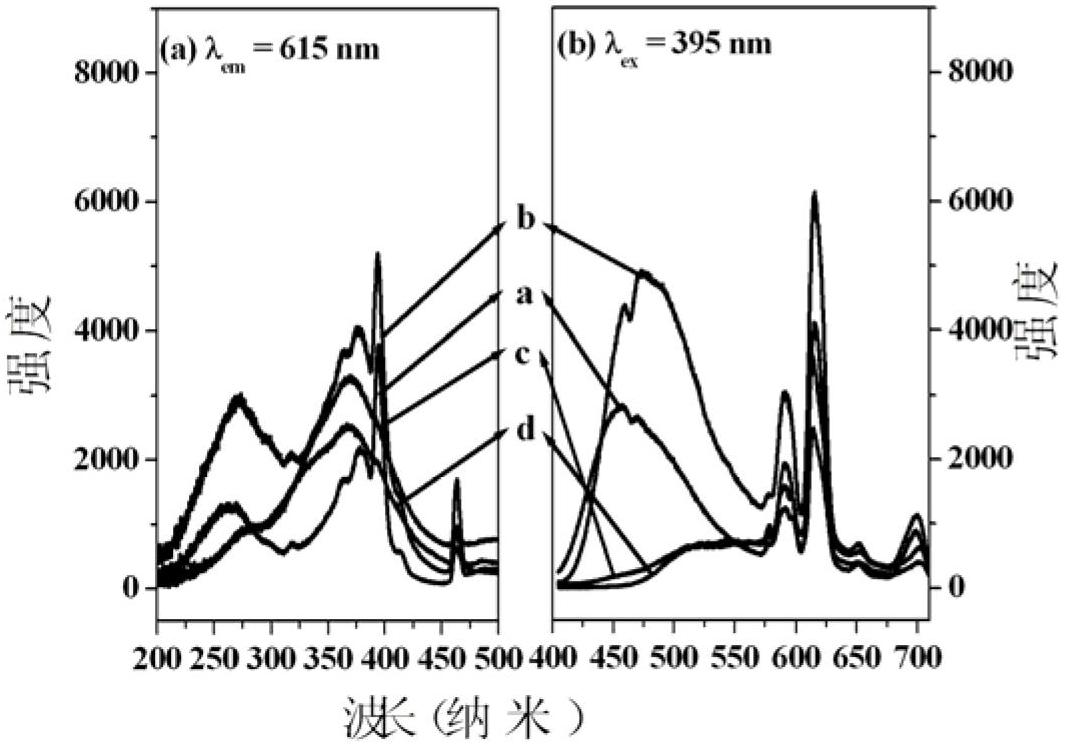

Ce: YAG microcrystalline glass and application thereof in white-light LED

ActiveCN104529166AHigh light efficiencyHigh excitation and emission efficiencyCrucibleRoom temperature

The invention discloses Ce: YAG microcrystalline glass and application thereof in a white-light LED. The microcrystalline glass is prepared from the following raw materials in mole percentage: 19-24% of Y2O3, 33-39% of Al2O3, 28-40% of SiO2, 4-5% of ZrO2 and 3-5% of a fluoride nucleation agent; the preparation method of the microcrystalline glass comprises the following steps: (1) mixing glass materials; (2) melting glass materials, namely heating the glass materials in a crucible by virtue of a high-temperature resistant furnace, melting at a temperature is 1600-1700 DEG C, preserving heat for 2-5hr, pouring a glass melt on a cast iron mould, then annealing the glass melt in a high-temperature furnace, preserving heat at glass transition temperature Tg for 2-5hr and cooling with the furnace to 50 DEG C; turning off the power supply of the high-temperature furnace, automatically cooling to room temperature and taking out glass; and (3) carrying out insulation treatment, namely carrying out heat treatment on the glass in a precision annealing furnace at 1200-1400 DEG C for 1-10hr, cooling with the furnace to 50 DEG C, turning off the power supply of the precision annealing furnace, and automatically cooling to room temperature so as to obtain the semitransparent Ce: YAG microcrystalline glass.

Owner:WENZHOU UNIVERSITY

Process for encapsulating square flat outer-pin-free encapsulating structure

InactiveCN101740407AAchieve natural separationFlexible arrangementSolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingEngineering

The invention relates to a process for encapsulating a square flat outer-pin-free encapsulating structure. The encapsulating structure comprises a chip, a metal structure, a metal wire and a plastic encapsulating material; the encapsulating process comprises the following steps: manufacturing grooves with preset depth between adjacent inner pins and in connecting parts between the inner pins and other parts of the metal structure; adhering the chip to a preset position of the upper surface of the metal structure; connecting an input / output port of the chip with the inner pin which is positioned on the metal structure and corresponds to the input / output port through the metal wire; performing plastic encapsulation on the upper surface of the metal structure by the plastic packaging material so as to protect the chip, the metal wire and the upper surface of the metal structure; and thinning the metal structure upwards from the bottom plane of an encapsulating body with exposed metal after the plastic encapsulation so as to separate the adjacent inner pins and separate the inner pins from the other parts of the metal structure.

Owner:SAMSUNG ELECTRONICS CO LTD +1

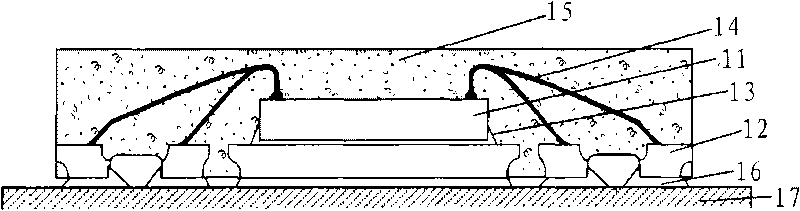

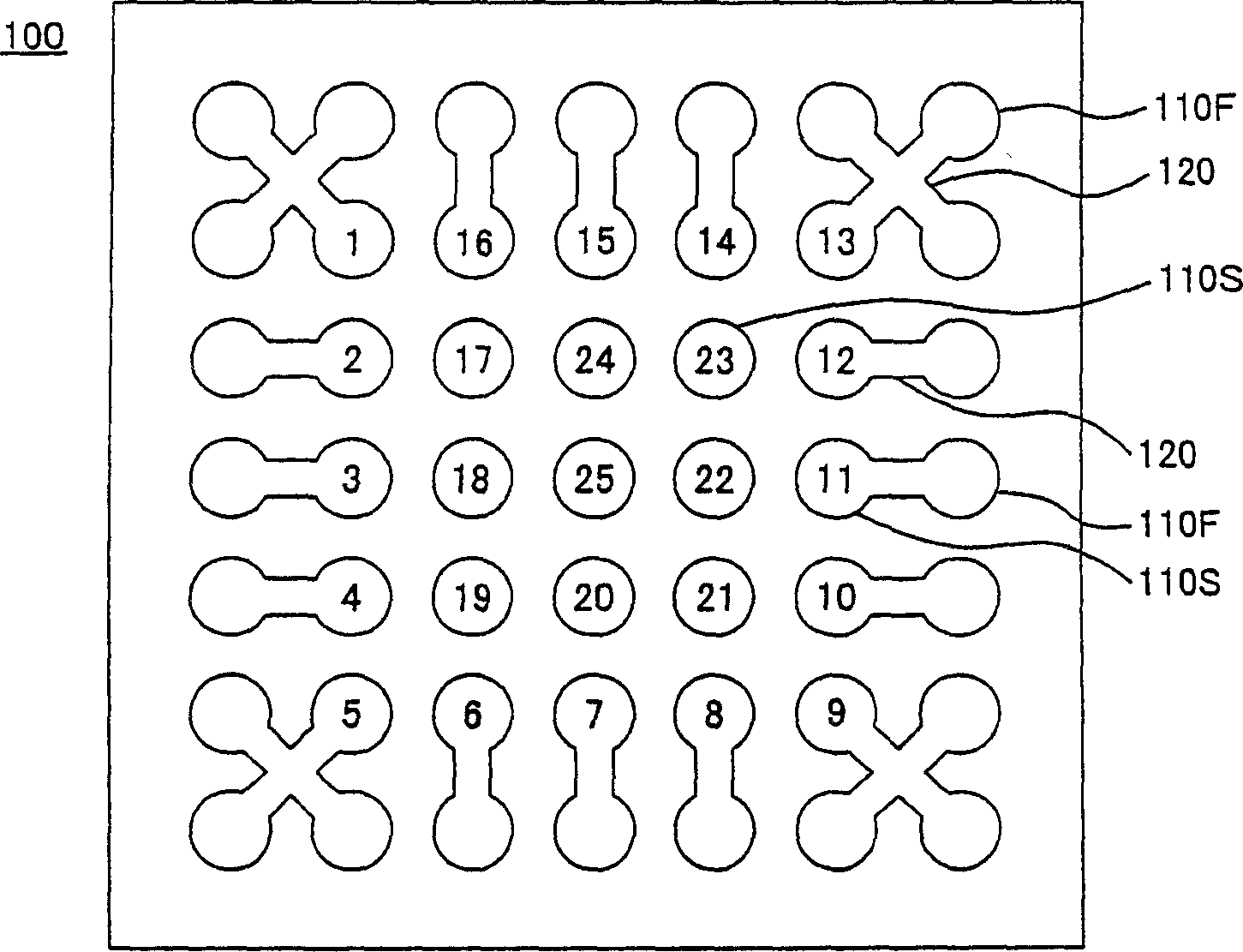

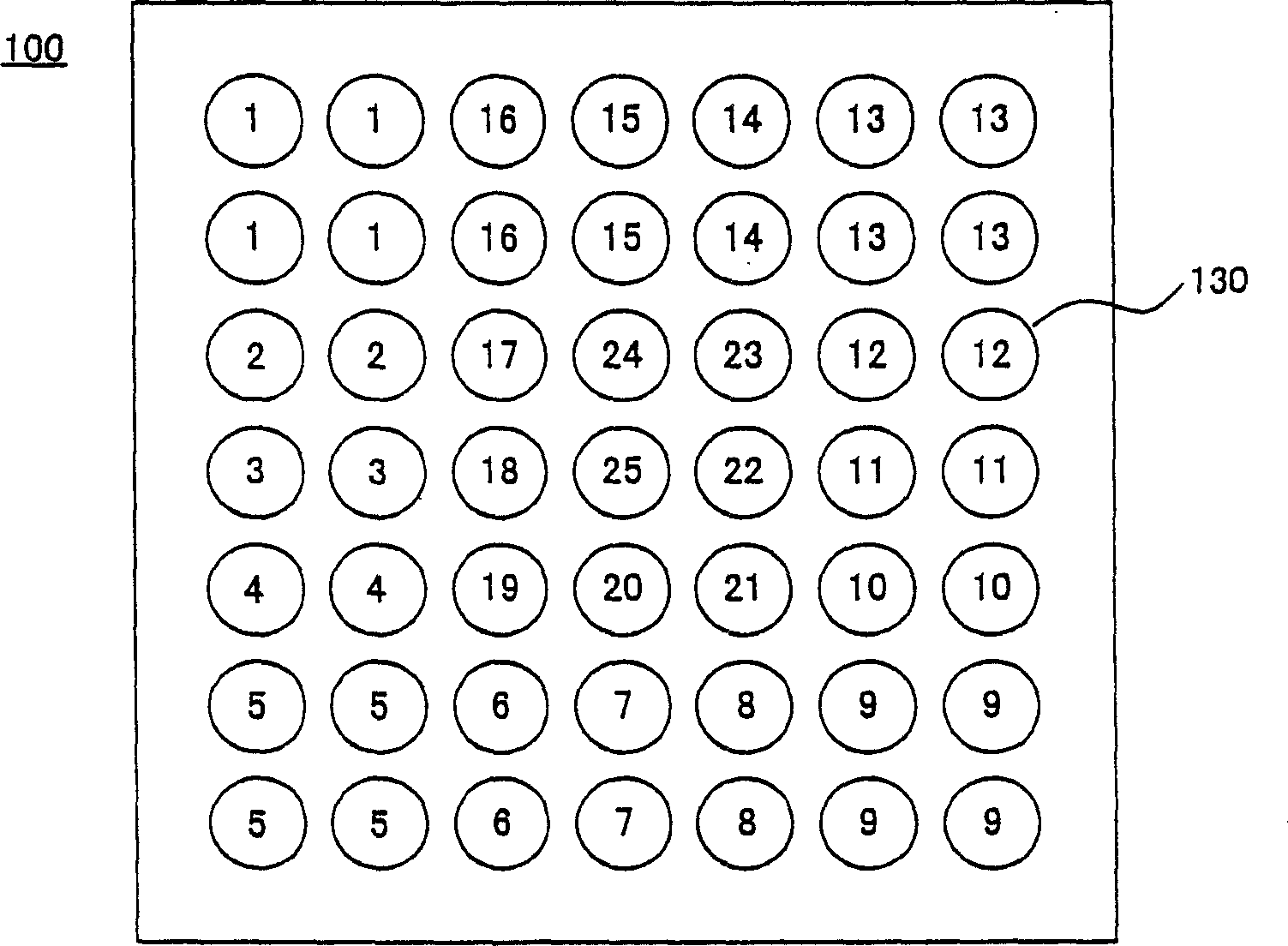

LED (Light-emitting Diode) package unit, package methods thereof, and array area light source

ActiveCN103700758ALow costSimple packaging processSemiconductor devicesBatch productionScattered light

The invention relates to an LED (Light-emitting Diode) package unit, package methods thereof, and an array area light source. The LED package unit comprises an LED chip, a base plate for installing the LED chip, an optical thin film covering on the LED chip and a reflective layer, and a scattering component for uniformly scattering light emitted by the LED chip, wherein the base plate is covered with the reflective layer on an end face for installing the LED chip; a reflective piece is arranged at a position of the optical thin film along a vertical upper surface, corresponding to the LED chip; compared with an edge LED light guiding module, components such as a light guiding plate and a diffusion plate are omitted, so that the cost for manufacturing an area light source by utilizing the LED chip is effectively reduced. The invention also provides the array area light source, batch production is convenient, and the cost is reduced. The invention also provides two LED package methods, and through utilization of the LED package unit manufactured by the two methods, the cost for manufacturing the area light source by utilizing the LED light source can be effectively reduced.

Owner:贵州中晟泰科智能技术有限公司

Epoxy resin base damping packaging material

InactiveCN101186803AImprove liquidityCuring reaction is gentleOther chemical processesWorking temperaturePolyamide

The invention relates to a damping package material of epoxy resin group, which consists of component A and component B, wherein the component A is composed of 0-90 parts of bisphenol A epoxy resin, 0-60 parts of polyurethane epoxy resin, 20-90 parts of flexible epoxy resin according to part by weight, the component B is composed of 25-55 parts of aliphatic amine, 10-45 parts of aliphatic cyclic amine, 0-80 parts of versamid and 0-8 parts of silane coupling agent according to part by weight, the parts are mixed uniformly according to part by weight of A:B=100:15-100. The invention has the advantages that the mixture has good mobility, the solidification reaction is mild, the condensate has good mechanical property and good tensile shear strength with metals, the invention can resist high and low temperature impact, thermal aging and humidity heat aging, the condensate does not erode rigid aluminium alloy, steel, aldary and PVC plastics in sealed humidity heat condition, the solidification shrinkage ratio is low, with the damping coefficient (tan delta max>=0.5). Particularly, the invention has instantaneous high impact property and the operational temperature is from -54 DEG C to 70 DEG C.

Owner:张向宇

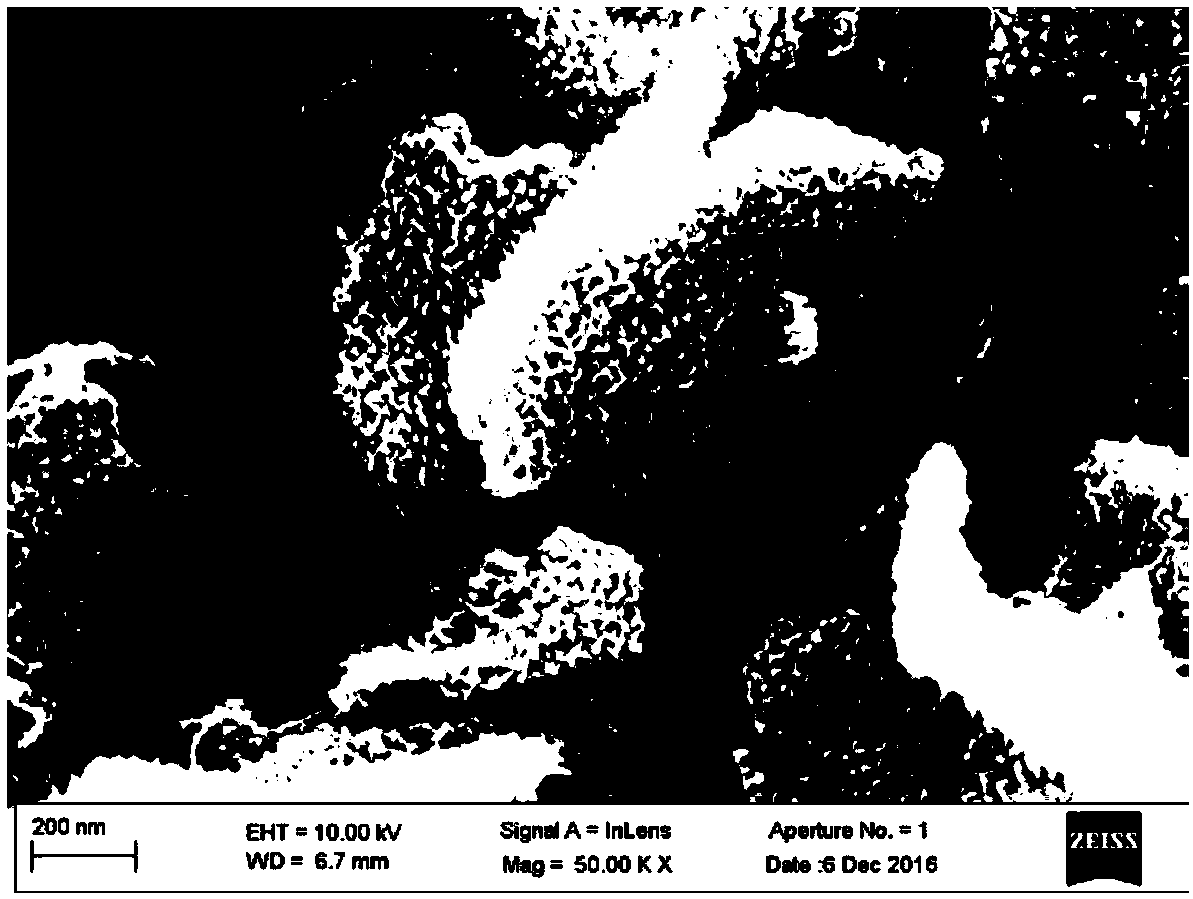

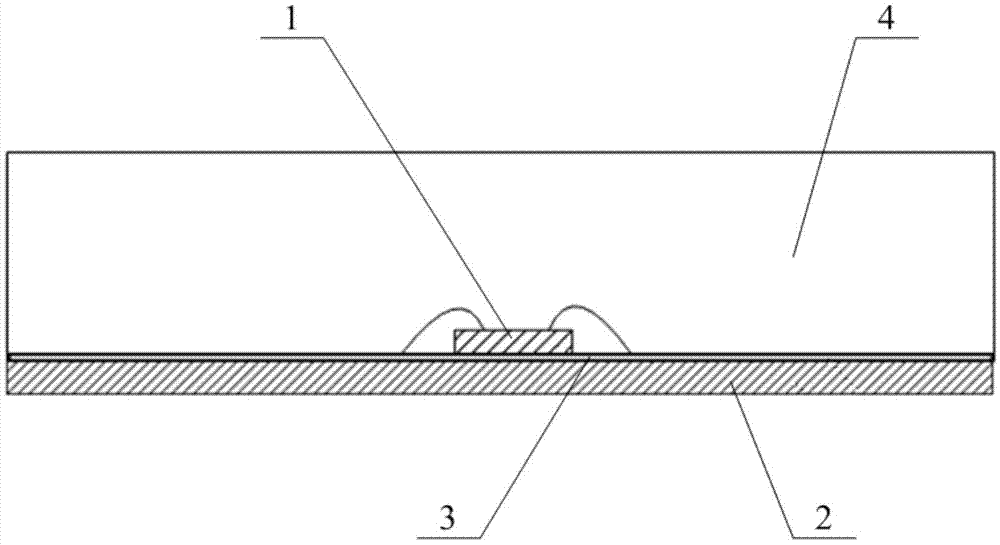

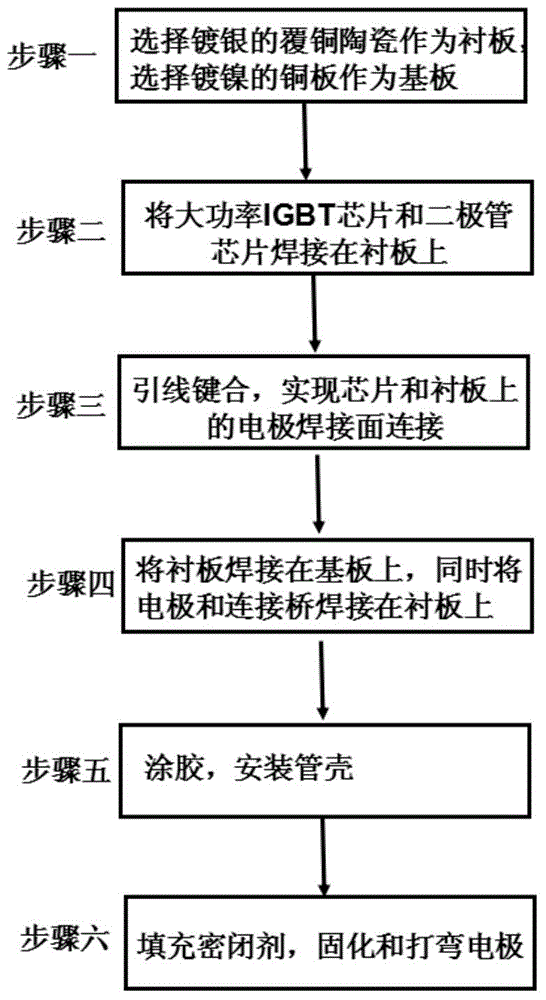

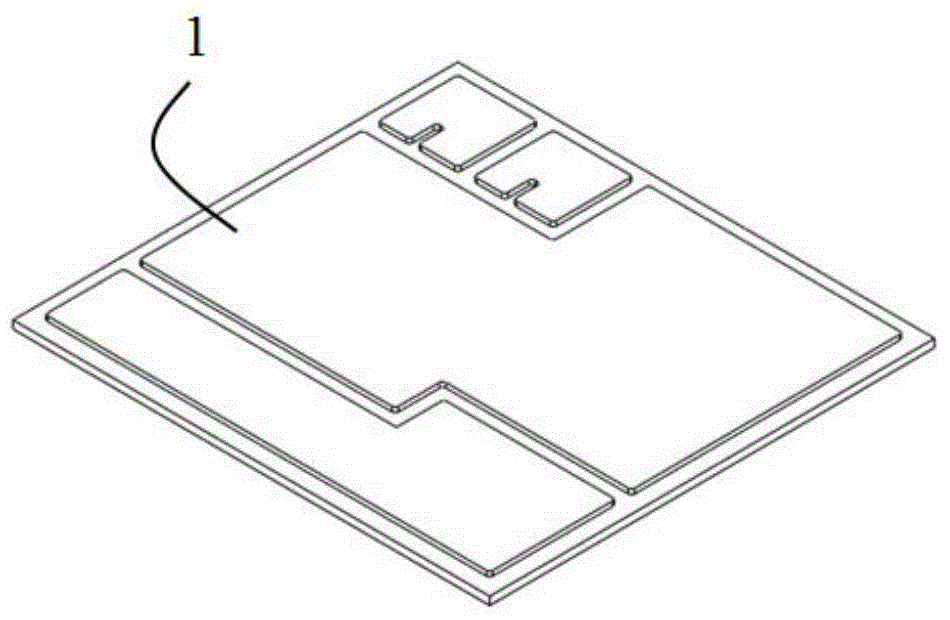

Method for encapsulating high-power IGBT device through performing non-pressure low-temperature sintering on nano silver soldering paste

InactiveCN104392942AImprove work efficiencyExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingVoid ratio

The invention relates to a method for encapsulating a high-power IGBT device through performing non-pressure low-temperature sintering on nano silver soldering paste. The method includes the following steps that: the nano silver soldering paste is printed on a welding surface of a lining plate, the shape of the printed nano silver soldering paste is cross-shaped; a chip is arranged on the nano silver soldering paste which has been subjected to steel screen printing molding; and a heating stage is set to temperature from 250 DEG C to 270 DEG C, and sintering molding is performed. With the method adopted, void ratio can be lower than 2%. The use performance of the high-power IGBT module encapsulated through adopting the method can be improved, and encapsulation process can be simplified, and at the same time, it can be ensured that the adhesion strength of the chip which is higher than 30MP can satisfy use requirements in working, and it can be also ensured that a soldering paste layer has lower void ratio; and the work efficiency of the high-power IGBT module encapsulated through adopting the method can be improved, and the service life of the high-power IGBT module can be prolonged.

Owner:TIANJIN UNIV

Power type white LED based on fluorescence lens

InactiveCN101950788AImprove thermal stabilityImprove light extraction efficiencySolid-state devicesSemiconductor devicesEpoxyFluorescence

The invention discloses a power type white LED based on a fluorescence lens, comprising an LED chip packaged by flip-chip bonding, an electrode, a reflective cup and a heat sink, wherein the fluorescence lens doped with light-emitting ions serves as a functional device with three functions of fluorescence conversion, optical light distribution and package protection. The invention has the technical effects that a glass-based fluorescence lens with high heat stability is adopted to realize more superior overall heat stability of the power type white LED; the heat dissipation efficiency and the light emitting efficiency of the LED chip are improved, thereby improving the overall light-emitting efficiency and the thermal stability of the power type white LED and overcoming the defect of coordinate drifting of illuminant colors brought by the fact that optical epoxy resin is easy to age and turn to yellow; and the package process has clear steps and is simple, therefore the overall package process of the power type white LED is simple and is easy to operate and realize.

Owner:CHONGQING UNIV

Low-reflectivity 3D polarized light film, low-reflectivity polarized light LED and preparation method

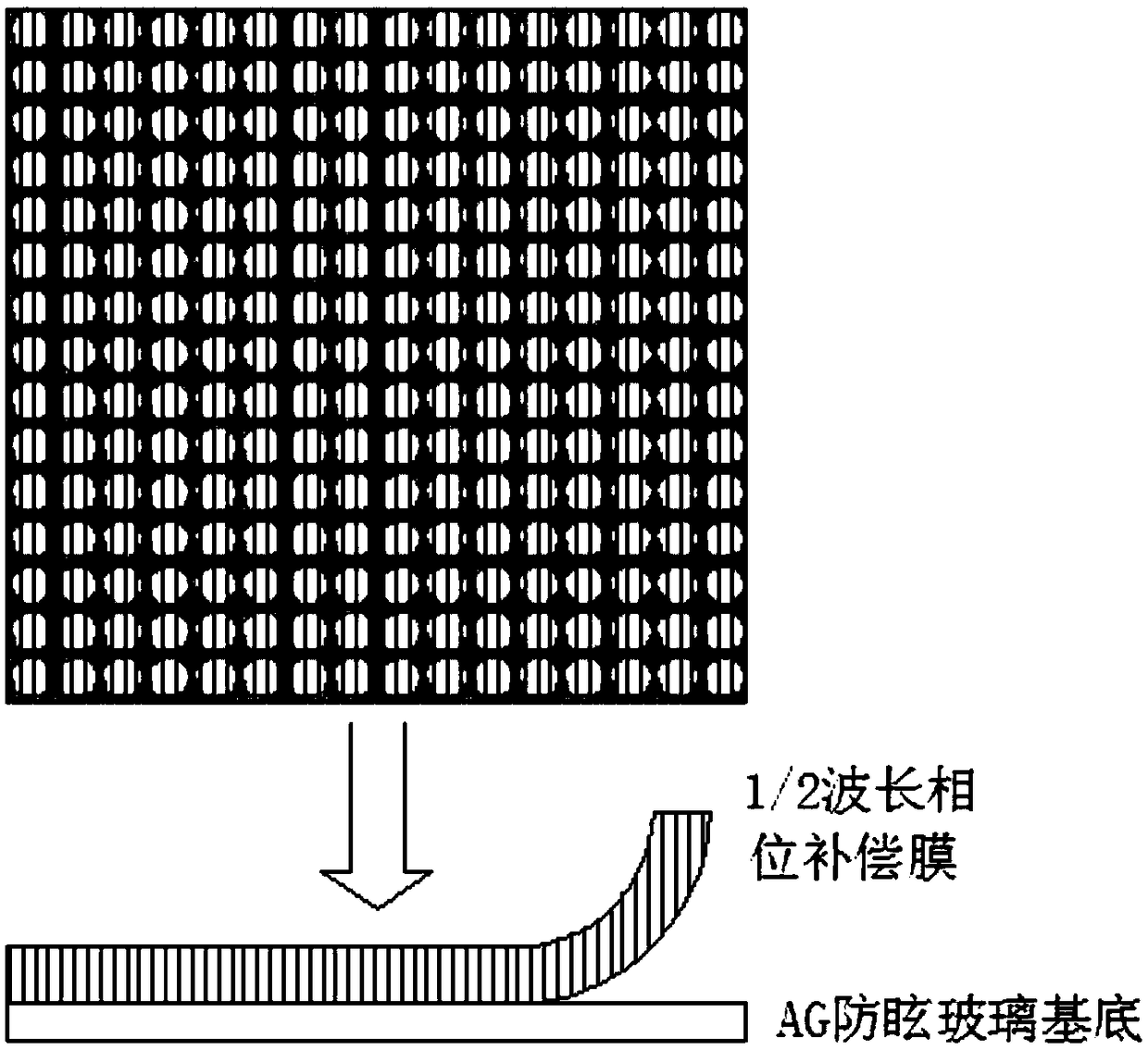

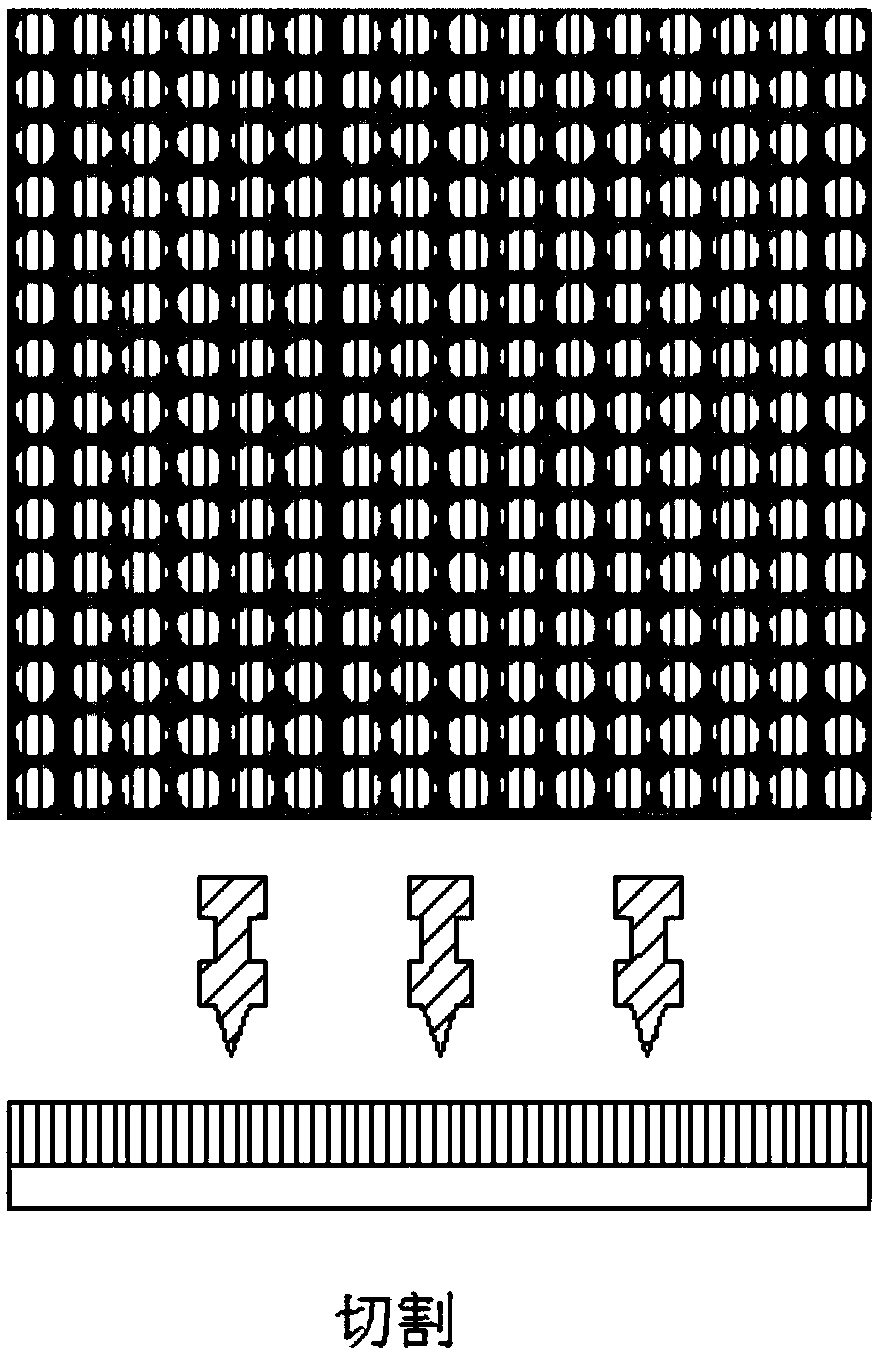

ActiveCN108919406AAchieve precise preparationSolve the difficulties that splicing is difficult to achievePolarising elementsPhase differenceOptoelectronics

The invention relates to a low-reflectivity 3D polarized light film, a low-reflectivity polarized light LED and a preparation method. The low-reflectivity 3D polarized light film, the low-reflectivitypolarized light LED and the preparation method aim to solve the problems that a traditional polarized light film preparation method has large accumulative seam splicing error, large crosstalk interval and poor flatness and high reflectivity of a manufactured product. The preparation method of the low-reflectivity 3D polarizing film comprises the following steps that patterned AG anti-glare glassis manufactured; 1 / 2 wavelength phase difference compensation film is attached to the non-AG surface of an AG anti-glare glass layer; cutting is carried out to form a patterned structure; invalid areastripping is carried out; filling is carried out to form a planarization layer; a polarizer is aligned and attached to the planarization layer or a black shading layer of AG anti-glare glass to prepare the low-reflectivity 3D polarized light film; and furthermore, glue is applied to the patterned AG anti-glare glass, polarizer or an LED module of the 3D polarized light film, and the 3D polarizedlight film and the LED module are aligned and attached to prepare the low-reflectivity polarized light LED.

Owner:NINGBO VISION DISPLAY TECH

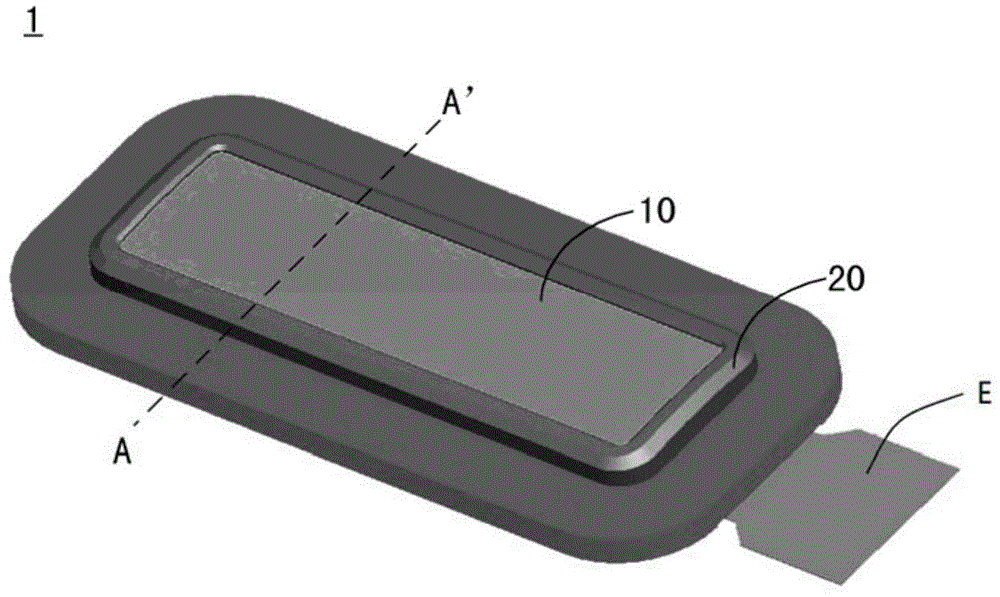

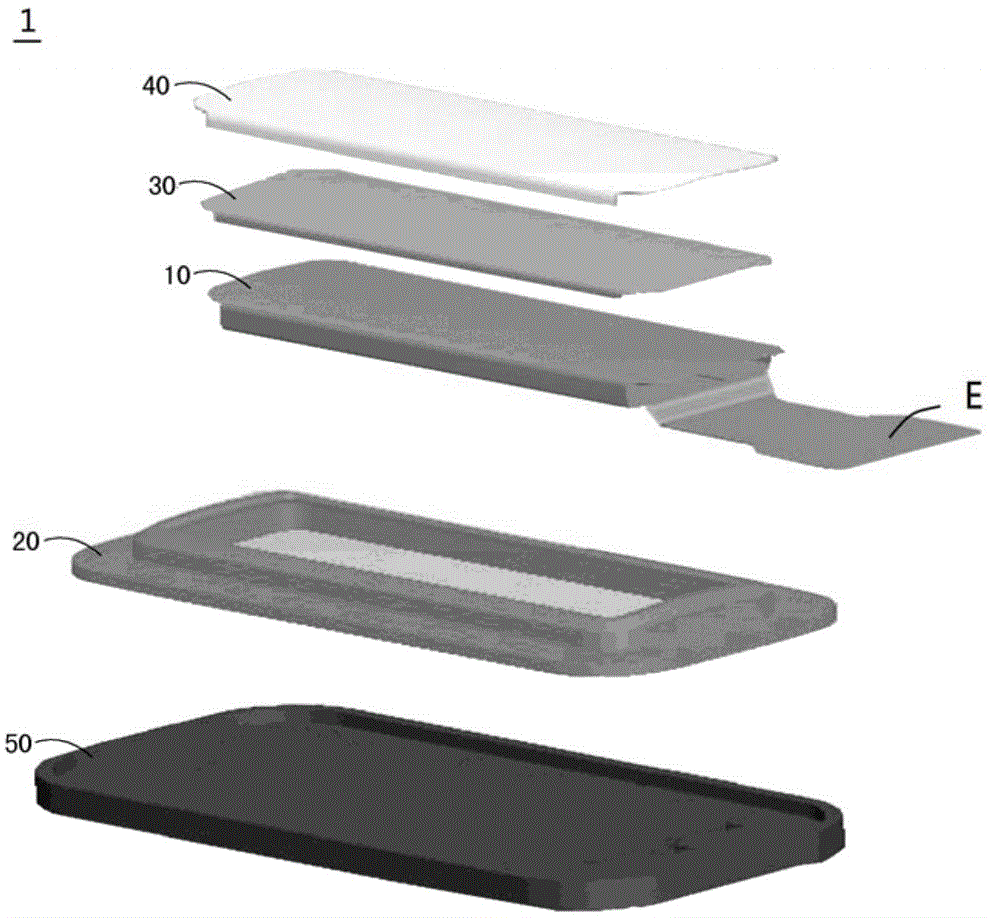

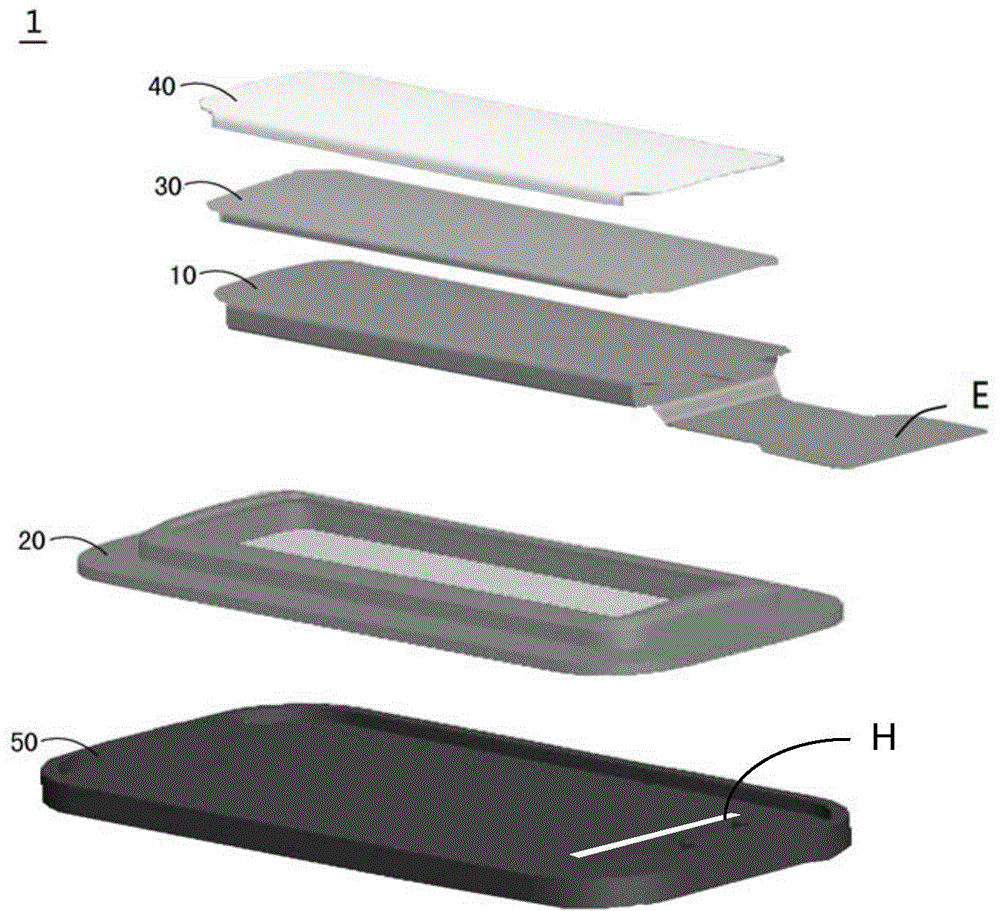

Fingerprint recognition device and terminal device

InactiveCN104156713AMeet the needs of light and thinSimple packaging processCharacter and pattern recognitionFlexible circuitsTerminal equipment

The invention discloses a fingerprint recognition device and a terminal device. The fingerprint recognition device comprises a fingerprint recognition assembly, a supporting piece, a protection layer and a base ring, wherein the fingerprint recognition assembly comprises a flexible circuit film, sensors and a control chip, the sensors and the control chip are formed on the flexible circuit film, and the sensors are electrically connected with the control chip; the supporting piece comprises an upper part and a lower part, the upper part protrudes relative to the lower part, the supporting piece is shaped like inverted T and partially wrapped in the fingerprint recognition assembly, and the sensors are located on the top surface of the upper part; the protection layer is formed above at least part of the fingerprint recognition assembly and located above the sensors; the base ring is provided with a top opening and placed on part of the supporting piece, and at least part of the fingerprint recognition assembly is contained in the base ring; the upper part of the protection layer is exposed through the top opening of the base ring.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH +3

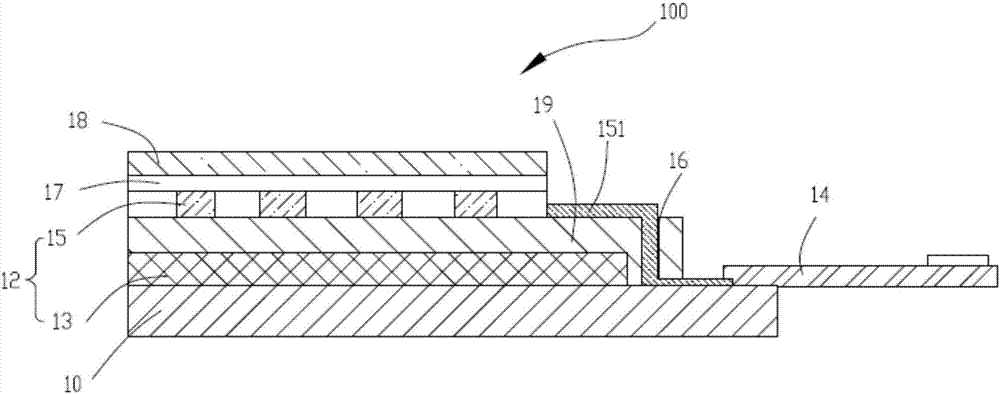

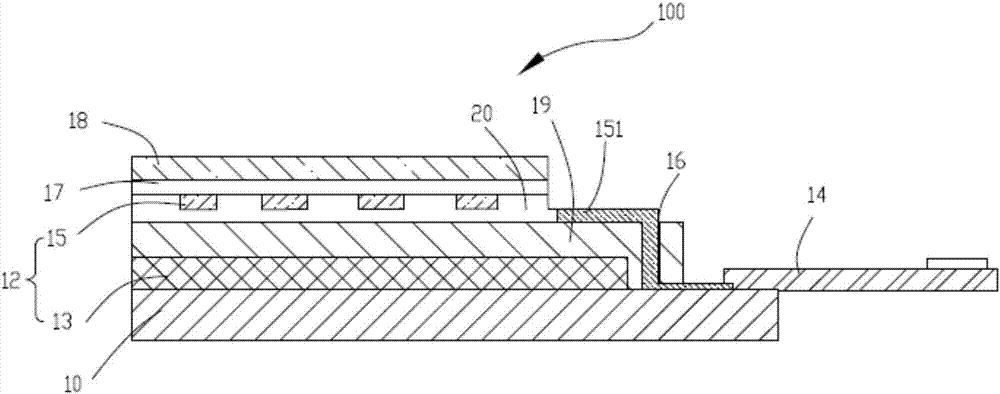

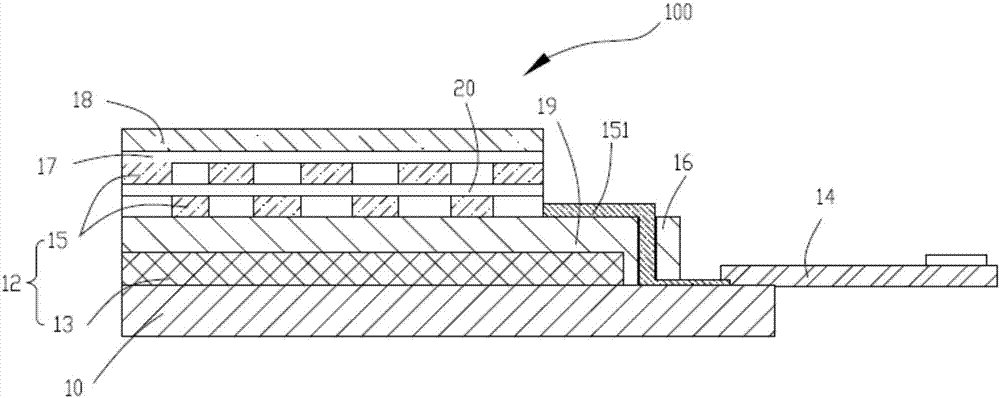

Organic light emitting touch display screen

InactiveCN106876431ASimple packaging processSolid-state devicesInput/output processes for data processingFlexible circuitsPhysics

The invention provides an organic light emitting touch display screen. The organic light emitting touch display screen comprises an array substrate, an OLED display panel which is stacked on the array substrate, and a flexible circuit board which is positioned on one side of the array substrate, wherein a display electrode route of the array substrate is connected to the flexible circuit board; the OLED display panel comprises an OLED layer and a touch electrode layer, wherein the touch electrode layer and the OLED layer are arranged in a stacked manner; a via hole corresponding to a touch electrode route of the touch electrode layer is formed in the peripheral region of the OLED layer; the touch electrode route extends to the array substrate through the via hole to be in the same layer with the display electrode route and to be connected with the flexible circuit board.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

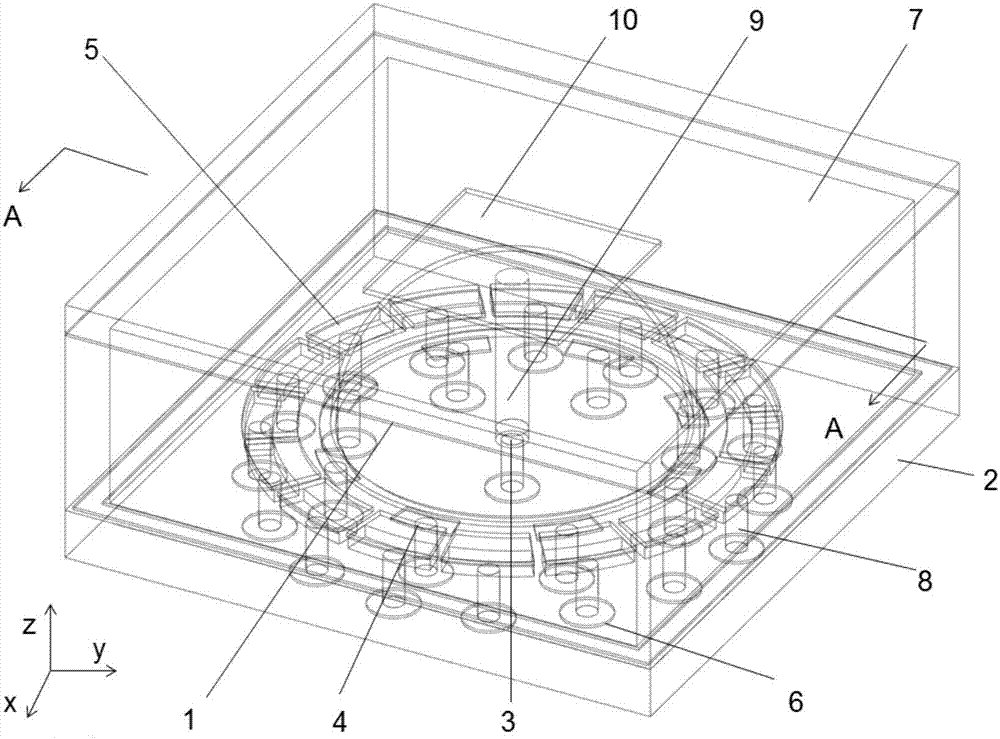

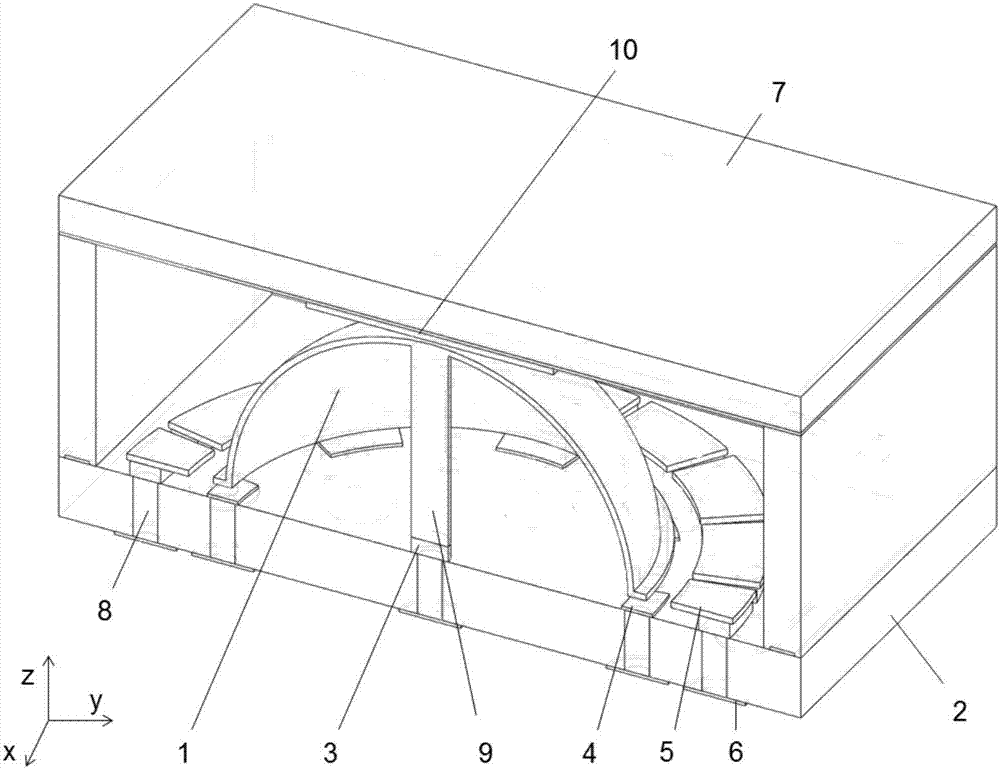

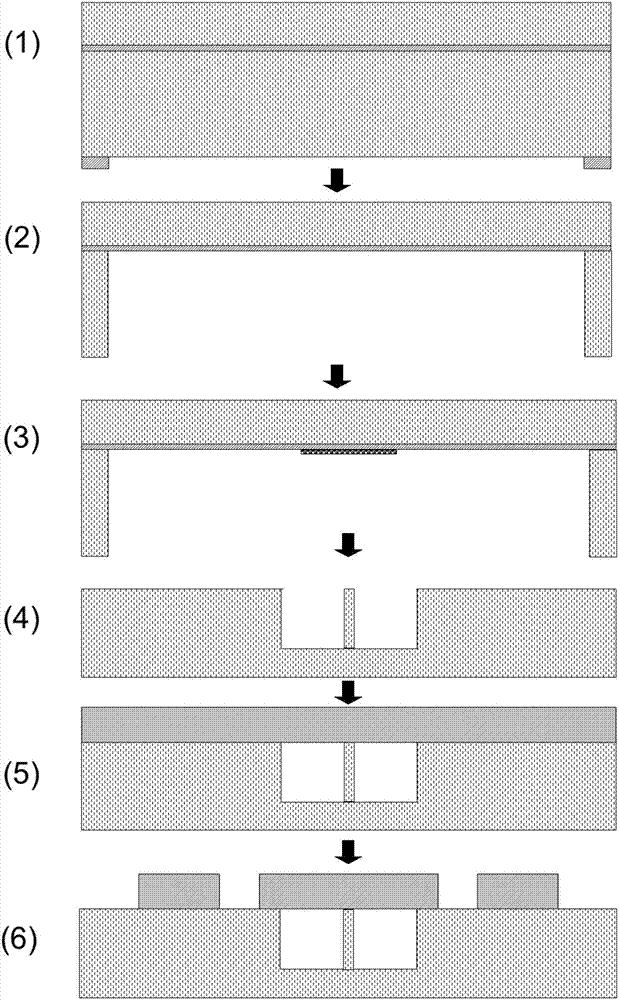

Fused quartz micro-hemispheric resonance gyroscope packaged based on SOI and processing method of fused quartz micro-hemispheric resonance gyroscope

ActiveCN106959106AImprove dynamic performanceEasy to applyTurn-sensitive devicesResonanceHemispherical resonator gyroscope

The invention discloses a fused quartz micro-hemispheric resonance gyroscope packaged based on an SOI and a processing method of the fused quartz micro-hemispheric resonance gyroscope. The fused quartz micro-hemispheric resonance gyroscope packaged based on the SOI comprises a glass substrate, an SOI sealing shell, a fused quartz micro-hemispheric shell resonator, a micro-hemispheric shell support post, a reference electrode, 8 sensitive electrodes, 16 exciting electrodes, a round metal bonding pad and a cylindrical electrode through hole. The electrodes are located below a spherical shell lip, so that an eccentric error caused by a problem of bonding alignment accuracy when the micro-hemispheric shell resonator and the electrode are assembled can be avoided; and an outer lip edge is added to the spherical shell lip, so that the opposite area of the electrode and the spherical shell lip is increased and the detection accuracy can be improved. The advantages of an SOI wafer are fully utilized and the micro-hemispheric resonance gyroscope is packaged, so that the packaging technology of the whole gyroscope is greatly simplified; and the micro-hemispheric resonance gyroscope is provided with 8 sensitive electrodes and 16 exciting electrodes, so that an all-angle working mode can be adopted and the dynamic property of the micro-hemispheric resonance gyroscope is strengthened.

Owner:SOUTHEAST UNIV

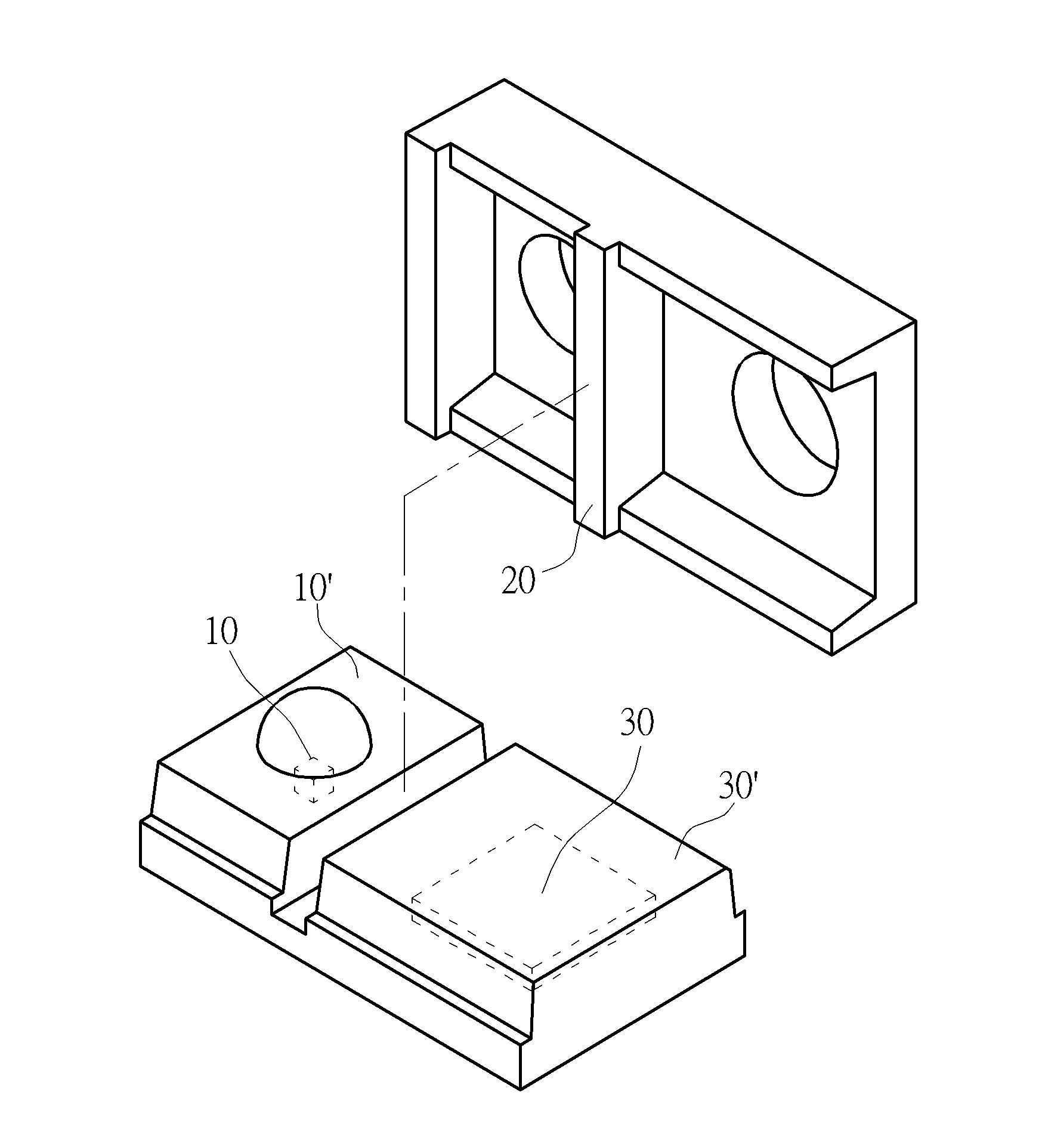

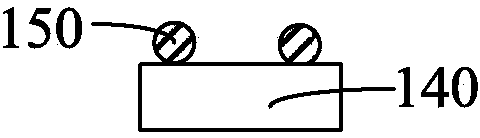

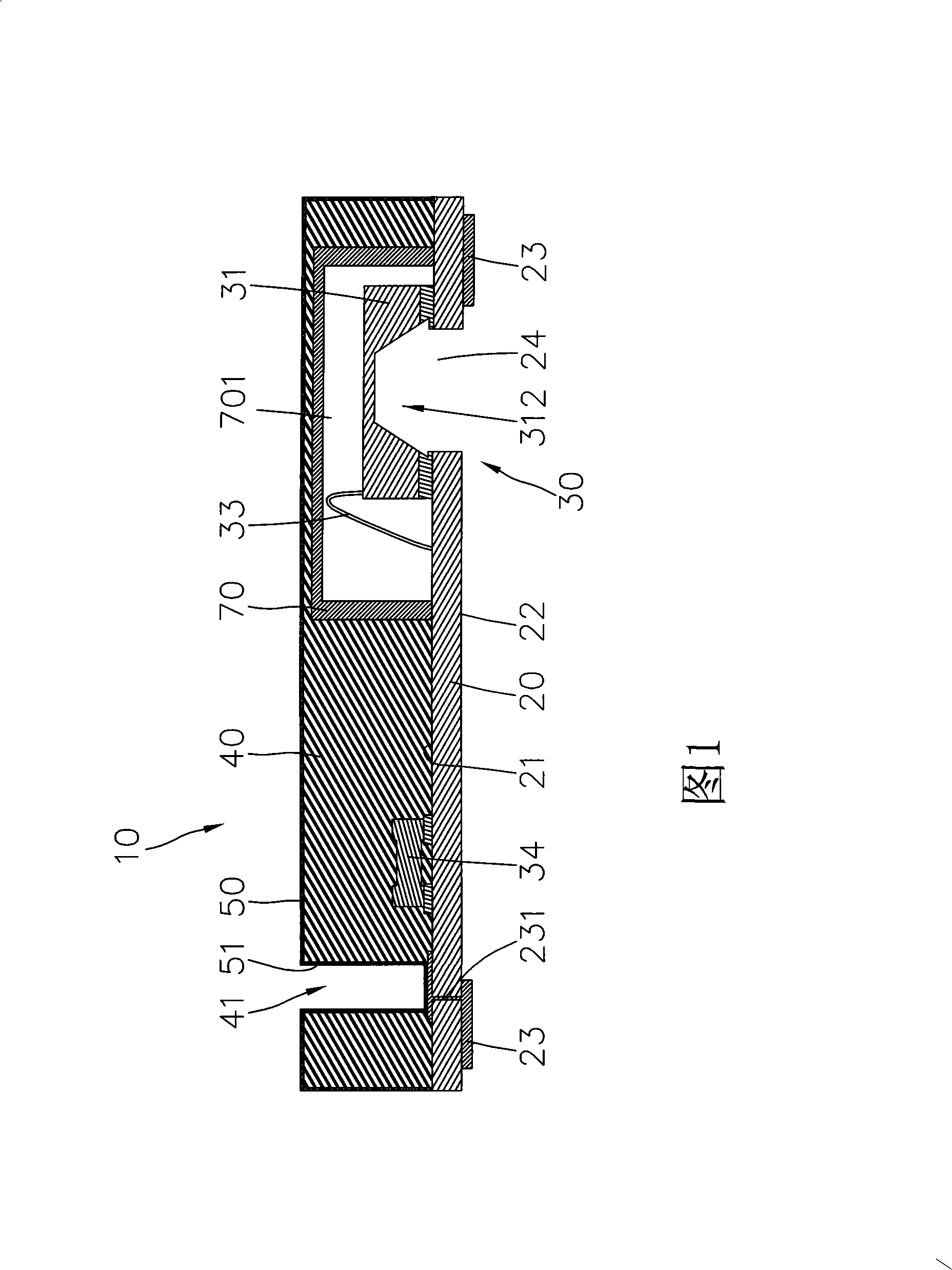

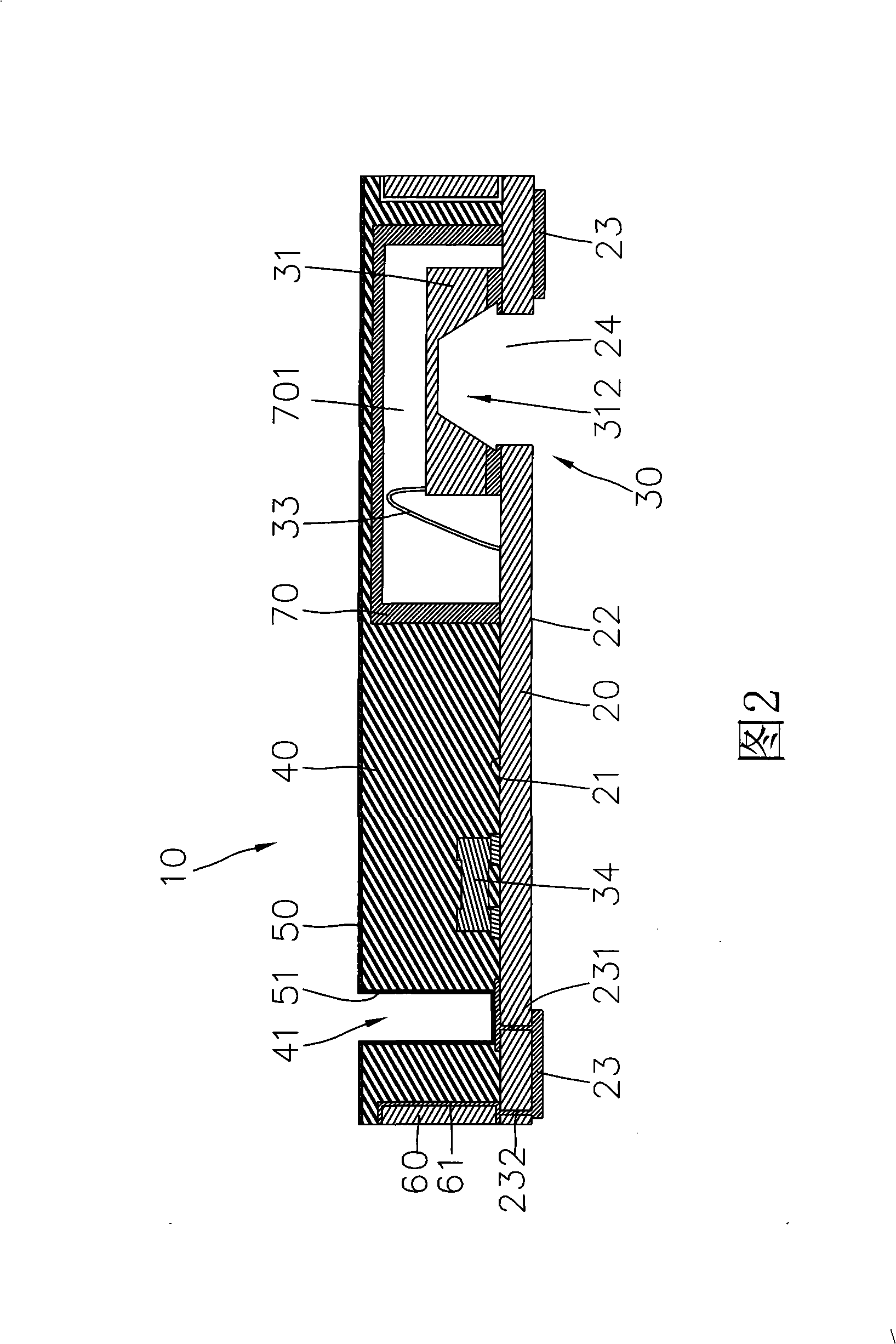

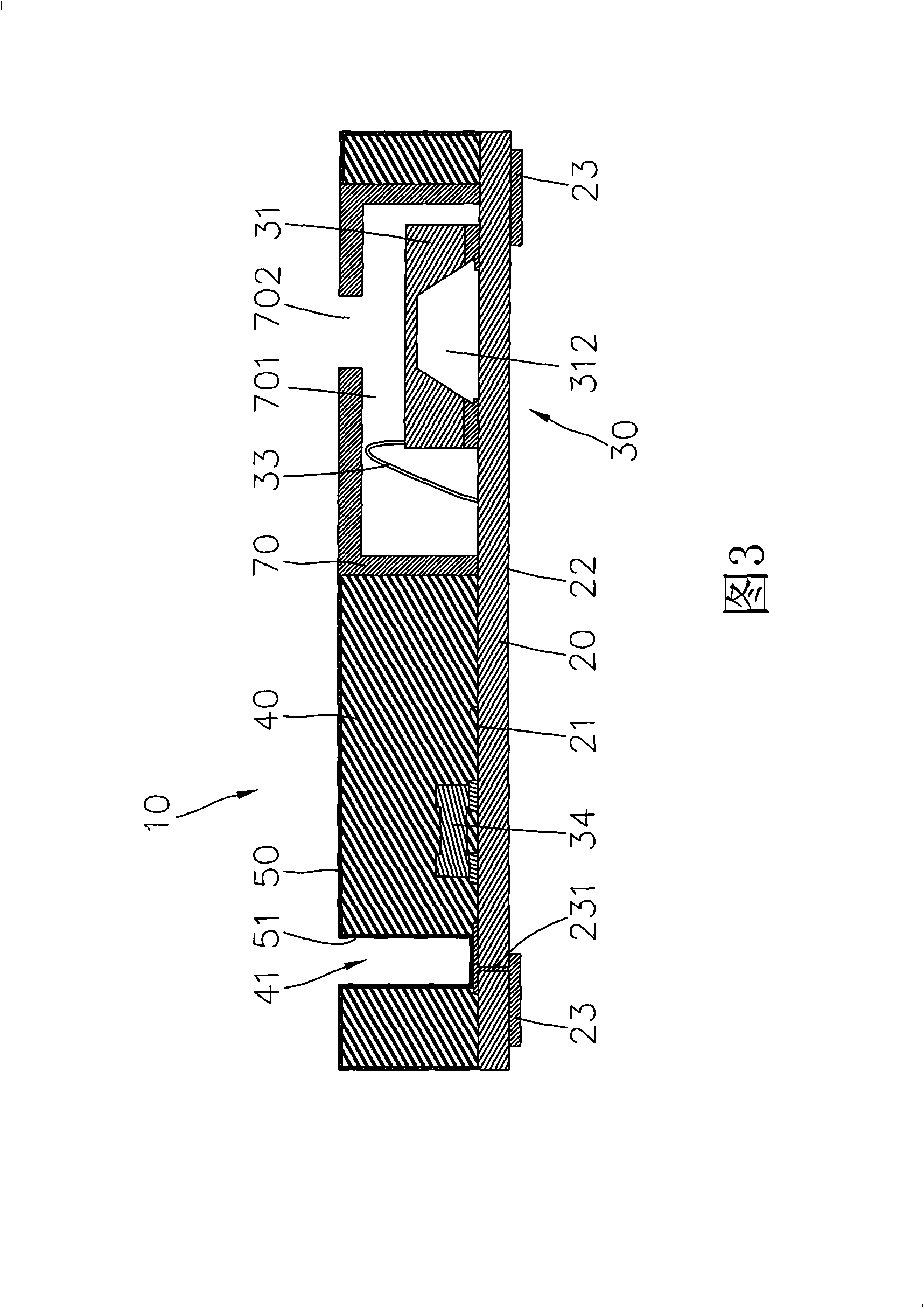

Package structure with optical barrier, optical package structure and manufacturing methods thereof

ActiveUS20160111561A1Simple packaging processSolid-state devicesSemiconductor/solid-state device manufacturingOptical barrierPhysics

A package structure with an optical barrier is provided. An emitter for emitting an optical signal and a detector for receiving the optical signal are disposed on a substrate. The optical barrier is disposed between the emitter and the detector for shielding the excess optical signal. A package material is used to completely cover the optical barrier, the emitter and the detector so that the optical barrier is completely disposed within the package material.

Owner:SENSORTEK TECH

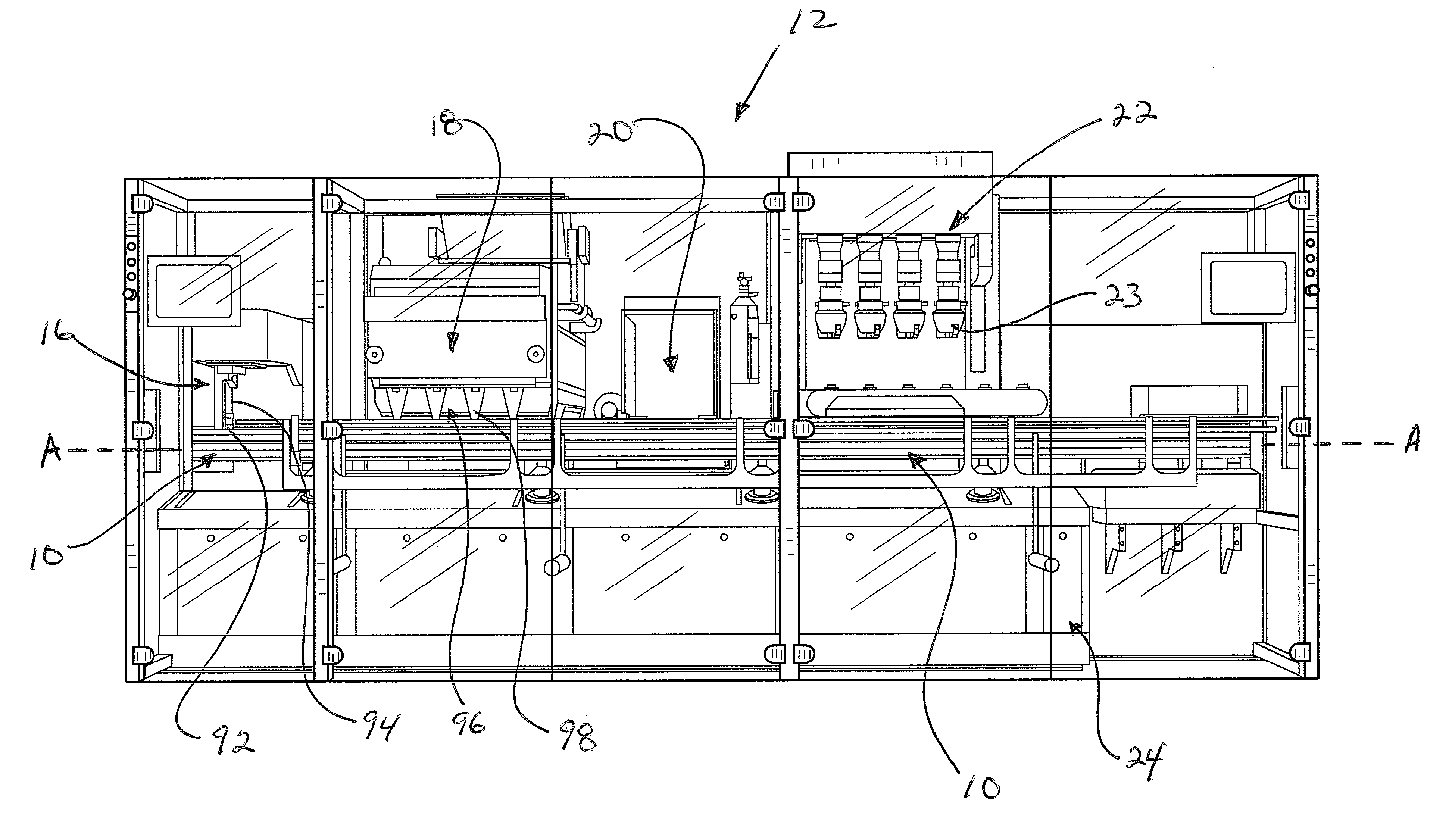

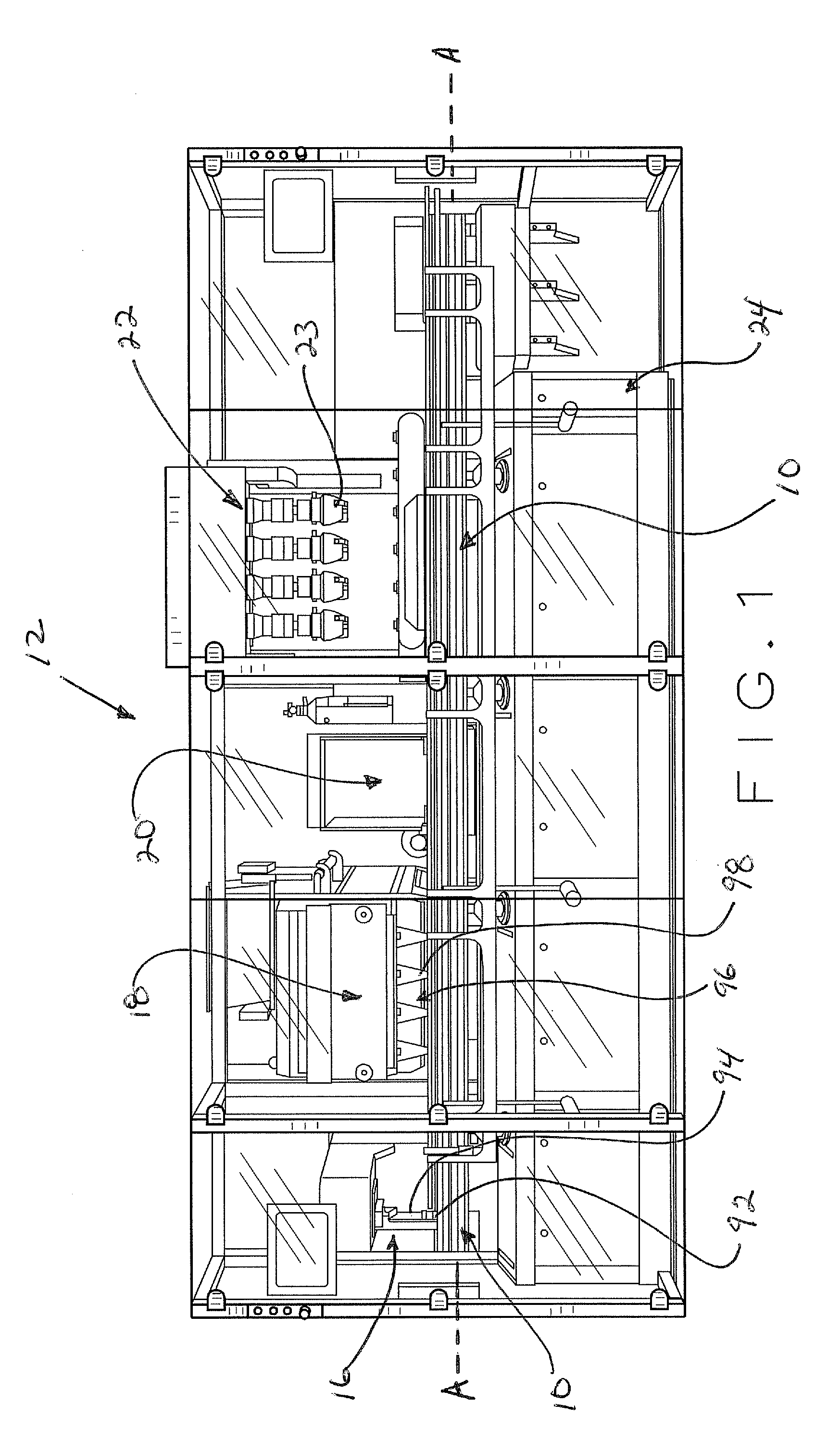

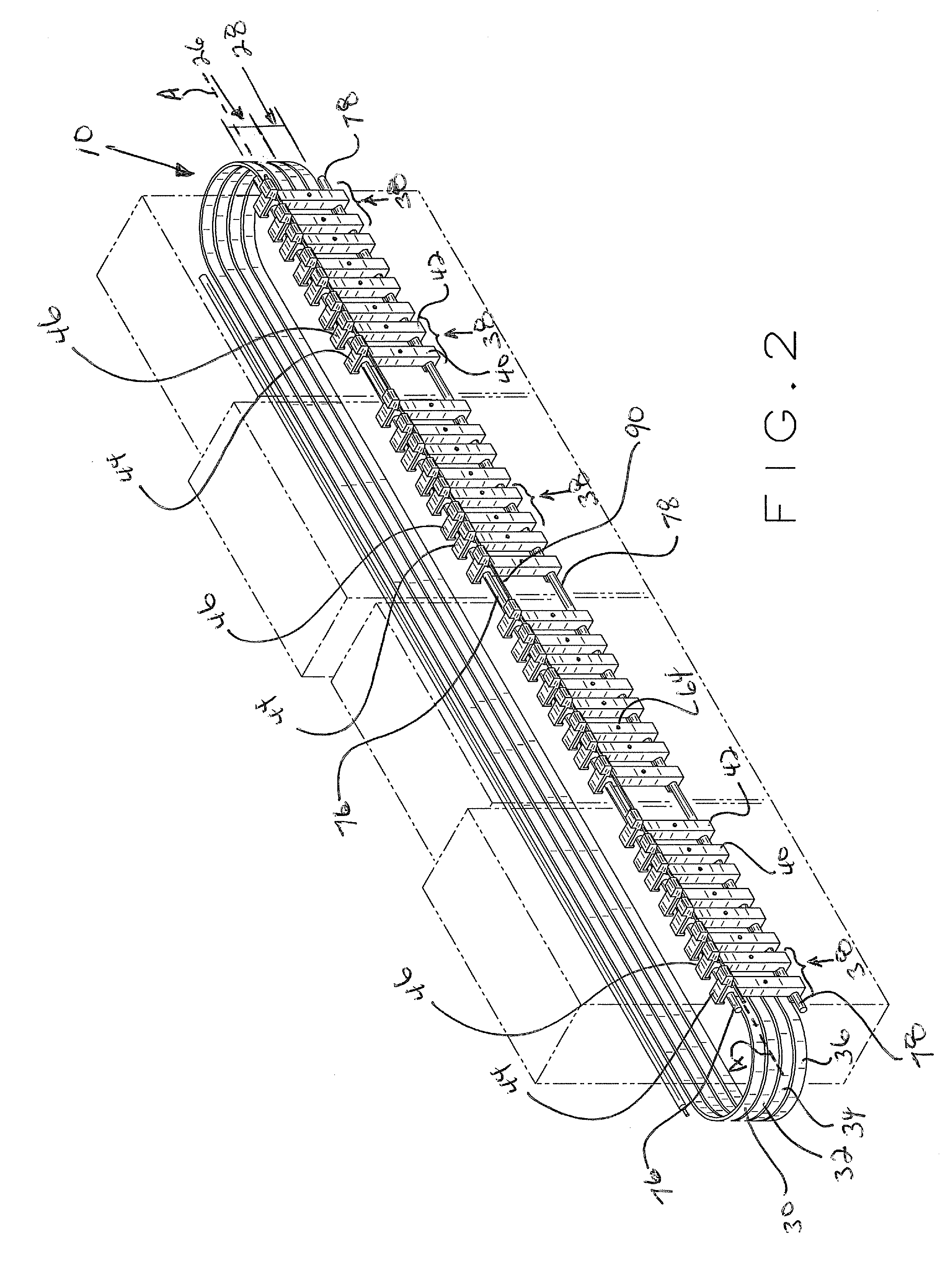

Transport system for moving a plurality of containers through a plurality of work stations

ActiveUS20100258404A1Simple packaging processSimple processMetal sawing devicesFeeding devicesComputer control systemTransport system

An apparatus for transporting a plurality of containers through a plurality of work stations including at least two conveyor assemblies, each conveyor assembly being adapted to sequentially convey at least one group of containers therealong in a row from one work station to another. The apparatus further includes a plurality of holder assemblies for holding the containers, some of the holder assemblies being associated with one of the conveyor assemblies and some of the holder assemblies being associated with the other conveyor assembly. The holder assemblies are located on the respective conveyor assemblies such that the plurality of containers are positioned adjacent to each other as they move through the plurality of work stations. A computer control system is programmable to control the coordinated operation of the conveyor assemblies so as to move such conveyor assemblies at different cycles of movement as the containers move through the work stations.

Owner:FUSO PHARMA INDS

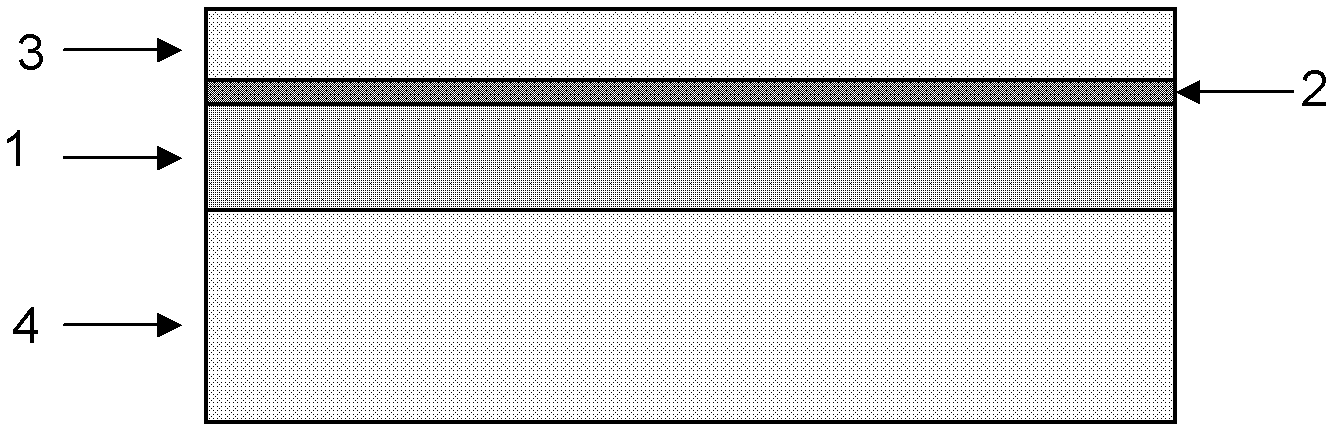

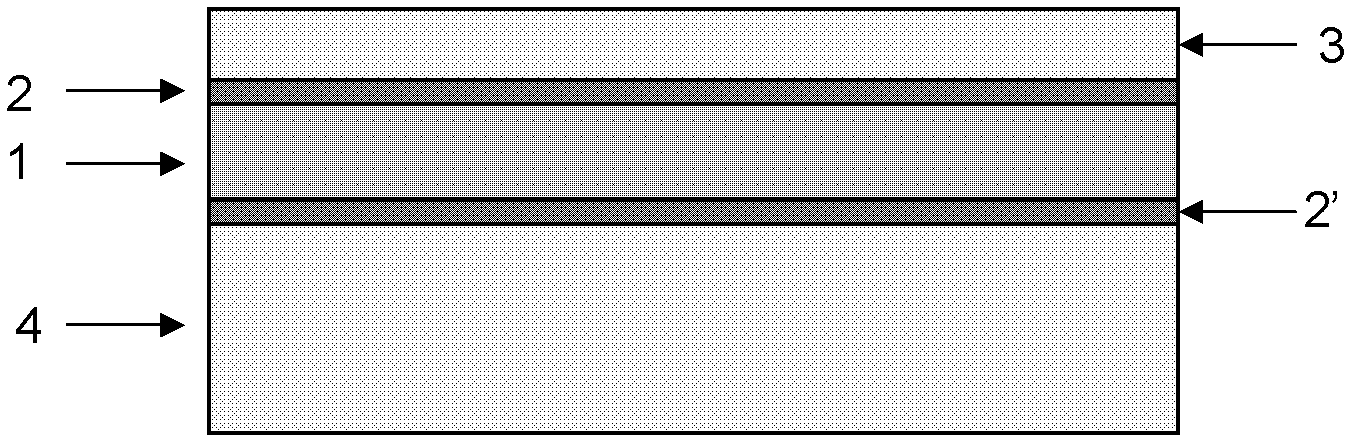

Functional solar cell module backboard and manufacture method thereof

InactiveCN102623531AWith encapsulation functionImprove performanceSynthetic resin layered productsPhotovoltaic energy generationElectrical batteryEngineering

The present invention provides a functional solar cell module backboard which includes a backboard functional layer. The inner side of the backboard functional layer is provided with a packaging functional layer. The backboard functional layer comprises a base film layer whose one side is connected with the packaging functional layer, an adhesive layer on the other side of the base film layer, and a third layer at the outboard of the adhesive layer. The functional backboard has a packaging function, and packaging process and flow of solar cell are simplified. The invention also provides a manufacturing method of the backboard, melt extrusion process can be used, the backboard functional layer and packaging layer are directly combined, and production cost is reduced.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

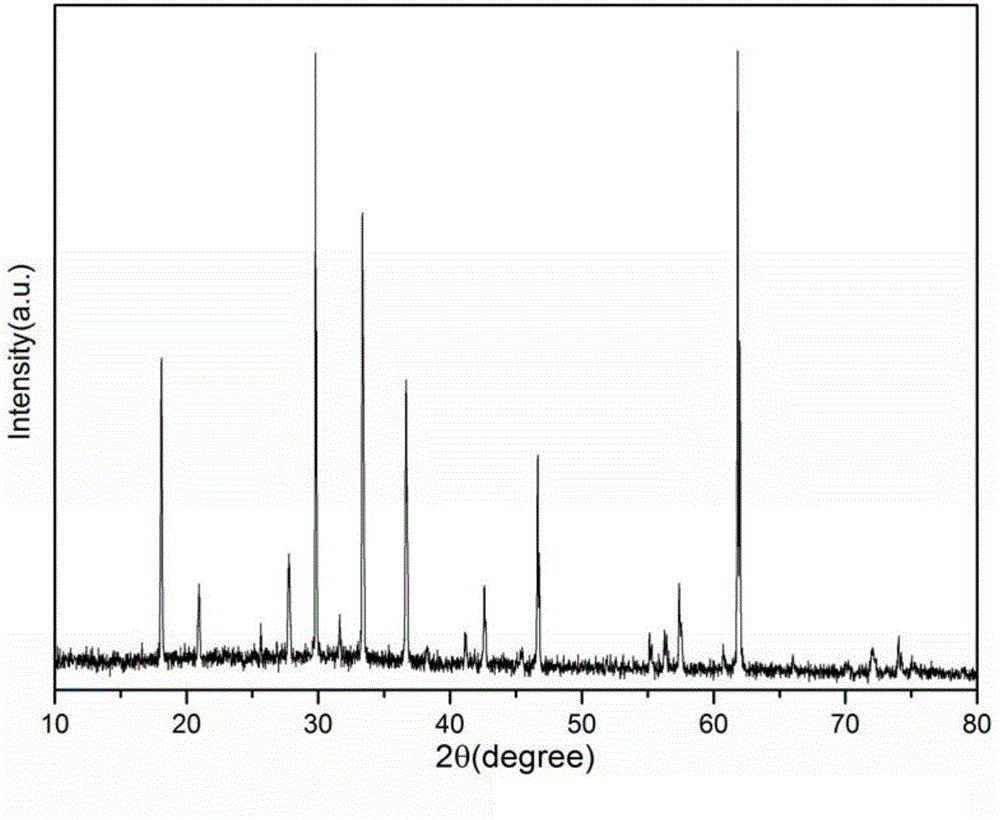

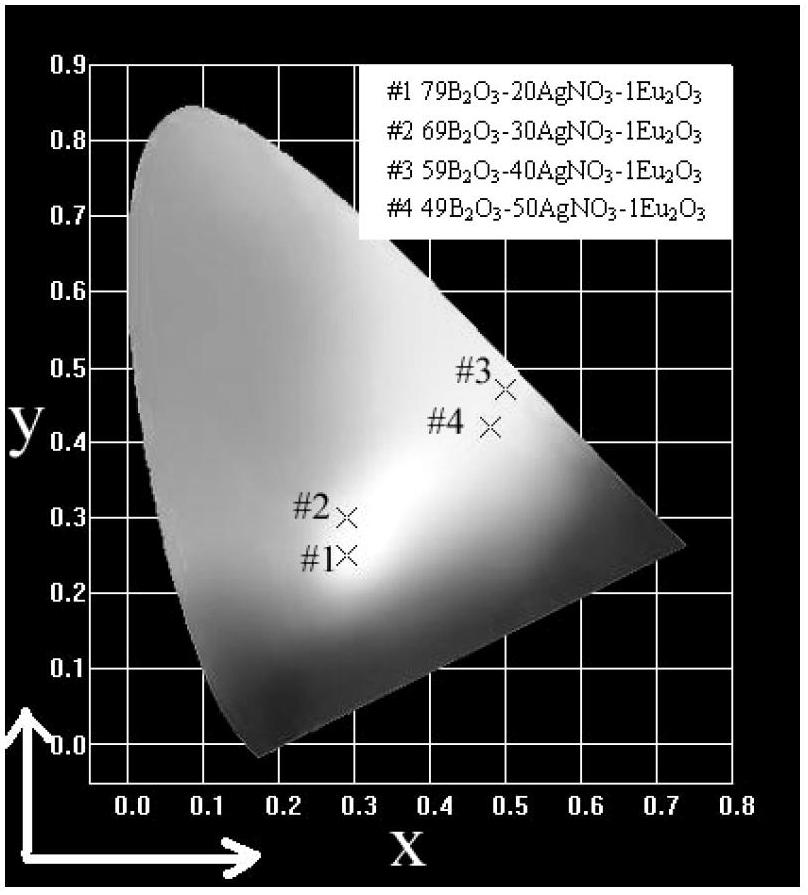

Full-color emission glass phosphor and preparation method thereof

InactiveCN102674693AFluorescence enhancementAchieve full color emissionFluorescenceLight-emitting diode

The invention discloses a full-color emission glass phosphor for near ultraviolet or blue light stimulating white light LEDs (Light Emitting Diodes) and a preparation method thereof. The glass phosphor is a rare earth ion doped glass phosphor containing silver ion polymers. The preparation method comprises the following steps of: by using a glass system as a substrate and AgNO3 as a raw material, introducing silver ion polymers into the glass material; and by using rare earth ions such as Eu3+, Sm3+, Pr3+, Tb3+, Dy3+, Er3+ or Ho3+ as a luminescence center, singly or jointly doping the rear earth ions in the glass substrate to be matched with the silver ion polymers for giving out white lights. The single glass phosphor is used for replacing fluorescent powder for the traditional white light LED and encapsulating materials, thereby simplifying the packaging technology; and the full-color emission glass phosphor has the advantages of being capable of solving the aging problem of the while light LED devices, increasing the stability of the devices, increasing the stimulation efficiency on the rare earth ions and realizing the high brightness fluorescence-emission.

Owner:DALIAN MARITIME UNIVERSITY

Semiconductor integrated circuit and electronic apparatus having the same

InactiveCN1601736AReduce problems such as peelingSimple packaging processPrinted circuit assemblingFinal product manufactureEngineeringSemiconductor

An IC has a multiplicity of electrodes or terminals arranged in a grid array configuration. The IC is provided with a multiplicity of pads in a similar grid array configuration. The pads other than the outermost pads of the array are used as signal pads. The outermost pads are used as reinforcing pads, which are connected to the signal pads adjacent the reinforcing pads. Bumps provided on the reinforcing pads and on the signal pads connected to the reinforcing pads are connected to associated bumps en bloc on an assembly board, thereby allowing the IC to be bonded to the assembly board with sufficient mechanical strength.

Owner:ROHM CO LTD

Image sensor module and forming method thereof

InactiveCN103956371AExcellent structural performanceReduce design difficultyRadiation controlled devicesImage sensorEngineering

The invention discloses an image sensor module and a forming method of the image sensor module. The image sensor module comprises a PCB substrate, a metal layer, an image sensing chip, a signal processing chip and welding protrusions. The PCB substrate is provided with a hole penetrating through the PCB substrate, the metal layer is arranged on the surface of the PCB substrate, the image sensing chip is inversely arranged above the PCB substrate, the image sensing chip is provided with an image induction area and a bonding pad surrounding the image induction area which is arranged above the hole, the bonding pad is electrically connected with the metal layer, the signal processing chip is inversely arranged above the PCB substrate, the signal processing chip is electrically connected with the metal layer, and the welding protrusions are arranged on the surface of the metal layer. The packaging performance of the image sensor module is improved, and the production cost of the image sensor module is reduced.

Owner:CHINA WAFER LEVEL CSP

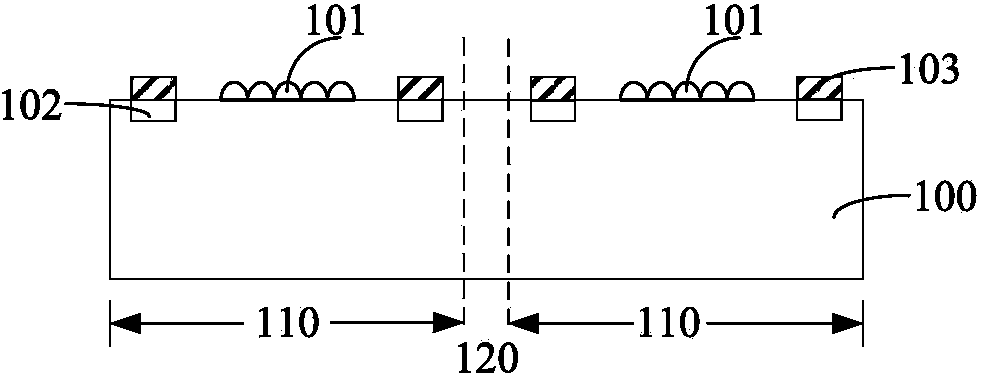

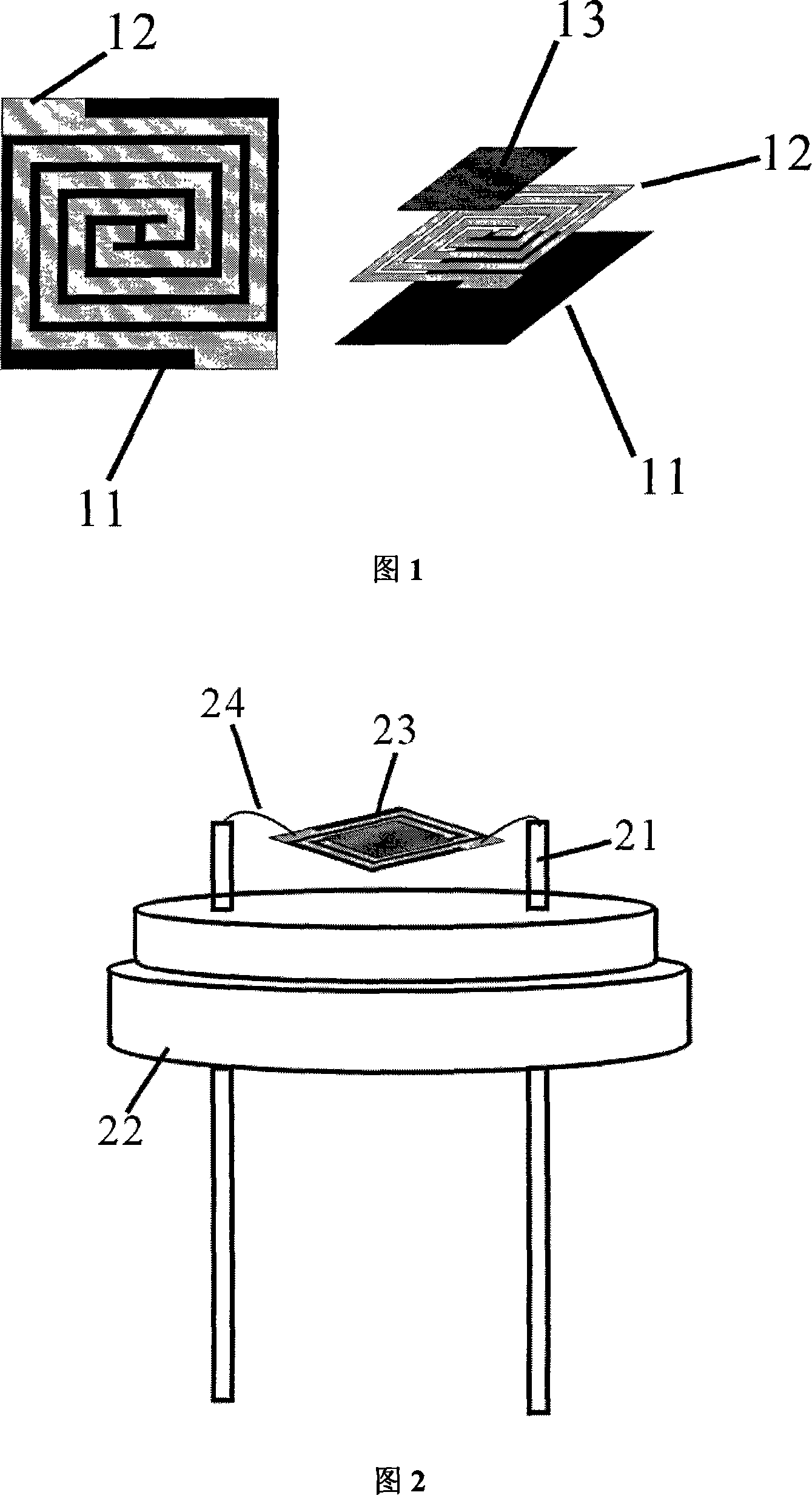

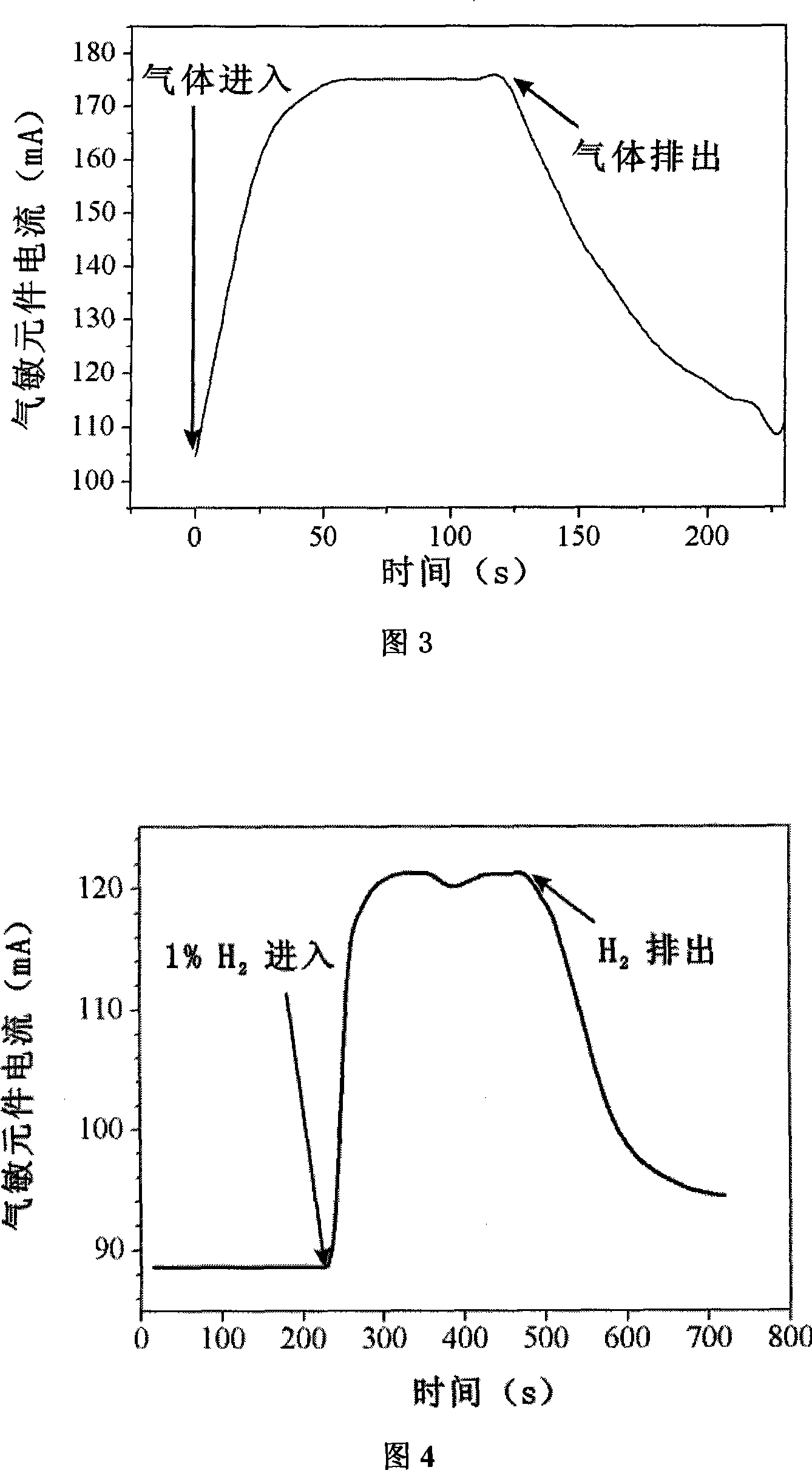

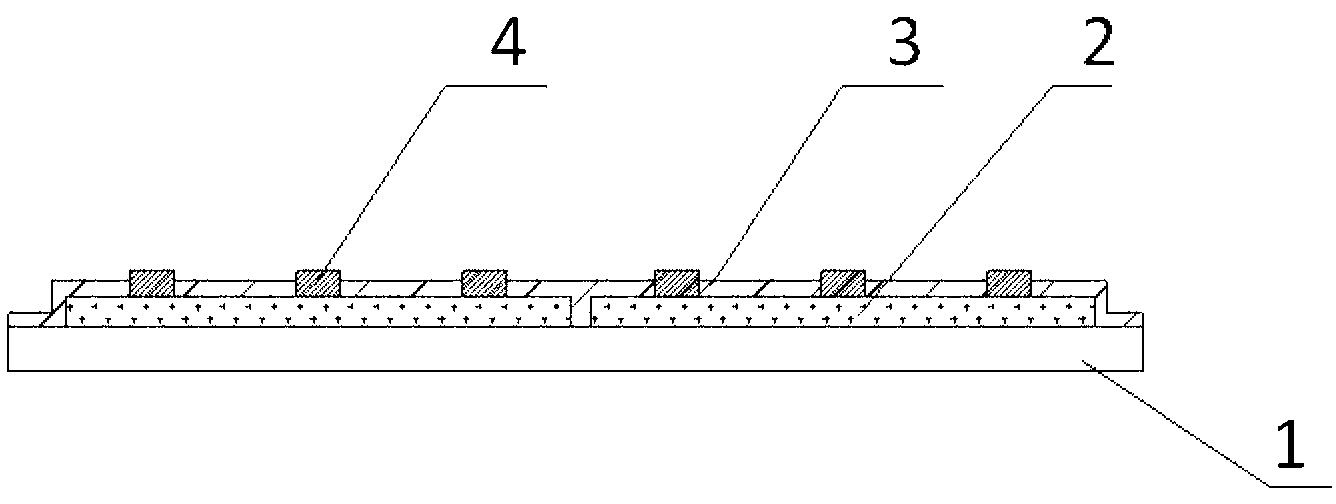

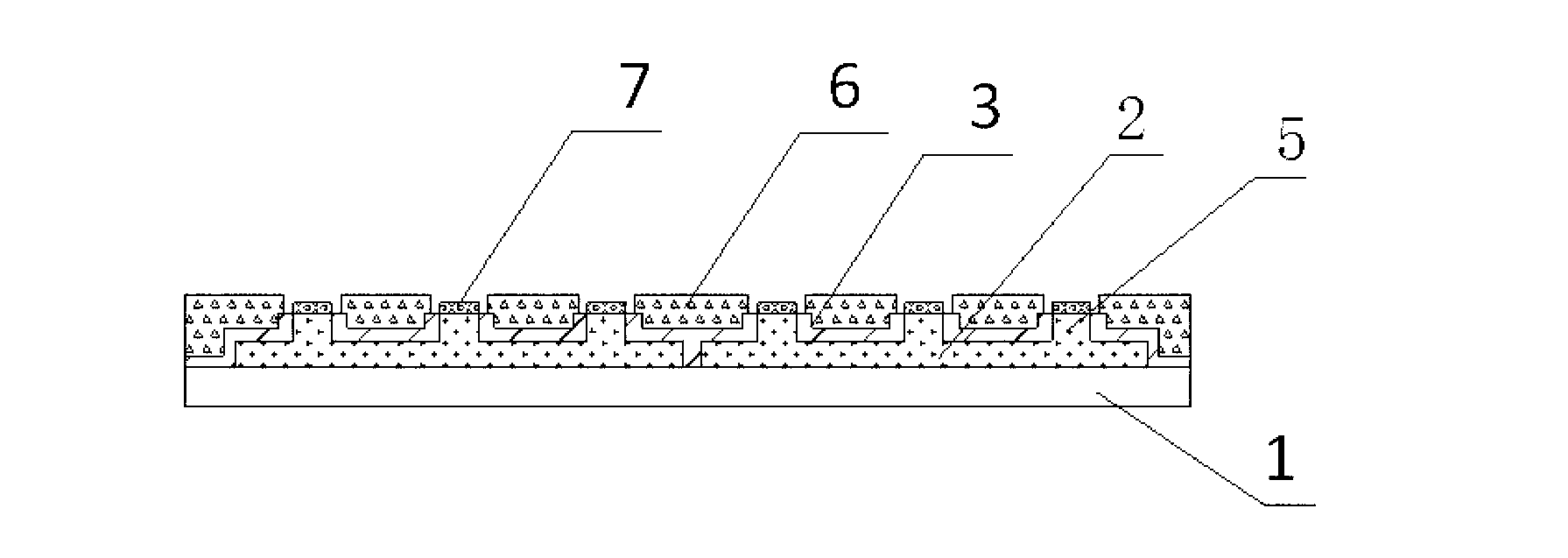

Micro- machining gas sensor and method for making same

InactiveCN101241101ASimple packaging processLow production costMaterial analysis by electric/magnetic meansProcess engineeringMicroelectrode

The present invention relates to a micro-machining gas sensor and preparation method thereof, which includes tube base, substrates parts and connected parts to connect the tube base and substrates parts. Wherein, the substrates parts comprises of substrates, microelectrode on the substrates, low resistant gas-sensing material layer coated on substrates and microelectrode from bottom to top. Interval microelectrode bar is made on substrates by micro-machining technics, and low resistant gas-sensing material layer is coated on the substrates and microelectrode to form substrates parts which is electrified to work in heat insulation state. Required working temperature obtained by joule heat produced by resistance in series and electrified microelectrode of gas sensor of present invention without adding heating electrode or heating device, the encapsulation techics of device and complexity of subsequent conditioning circuit are predigested, preparation cost is reduced and produce efficient is improved. The present invention is suit for batch produce, and shortened elements area of the present invention realizes gas sensor miniaturization and element power consumption reduced.

Owner:SUN YAT SEN UNIV

Composite conductive rear panel of solar cell assembly and preparation and usage methods thereof

ActiveCN102709359AGuaranteed contactSimple packaging processLaminationLamination apparatusPunchingAdhesive

The invention relates to a composite conductive rear panel of a solar cell assembly and preparation and usage methods thereof. The composite conductive rear panel comprises an outer polymer layer, a conductive metal foil, a dielectric layer and an adhesive-sandwiched film which are sequentially compounded, a corresponding protruded structure is arranged on the conductive metal foil, a composite conductive resin layer is printed on the protruded structure of the conductive metal foil by using a laminating transfer print method, the dielectric layer and the adhesive-sandwiched film are compounded and formed at one time by using a heated offset roller before being compounded with the conductive metal foil, the electrode of the battery is placed on the composite conductive rear panel of the solar cell assembly and aligned to the composite conductive resin layer, then the adhesive-sandwiched film and the panel are laminated on the battery to form a laminating part, and lamination is performed to obtain an assembly. According to the invention, the punching and alignment procedures and alignment and dispensing steps of the single adhesive-sandwiched film structure can be reduced, the encapsulation technique of a back contact type battery can be greatly simplified, and the productivity of the back contact type battery assembly can be improved.

Owner:TRINA SOLAR CO LTD

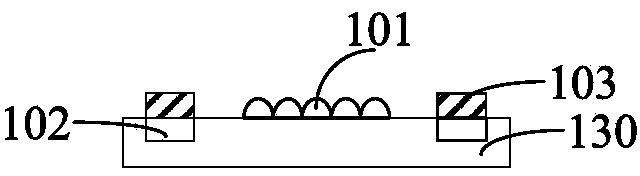

Encapsulation construction for silicon crystal microphone

InactiveCN101325823ASimple packaging processGood signal to noise ratioElectrical transducersSolid-state devicesElectronic componentSilicon

The invention discloses an encapsulation structure of a silicon crystal microphone, which comprises a substrate, an electronic component set, a cover body, an insulated filling body and a conducting layer. The substrate has an upper surface and a lower surface. The electronic component set comprises a silicon crystal microphone arranged on the upper surface of the substrate. The cover is arranged on the upper surface of the substrate and covers the silicon crystal microphone. The insulated filling body is combined on the upper surface of the substrate and the circumference side of the cover body, and provided with a hole communicating with the upper surface of the substrate. In addition, the conducting layer is formed out of the insulated filling body, and the hole of the insulated filling body is provided with a conducting part so as to electrically connect with the substrate.

Owner:MERRY ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com