Ce: YAG microcrystalline glass and application thereof in white-light LED

A glass-ceramic and glass technology, applied in the field of LED fluorescent materials, can solve the problems of inability to use commercial blue light chips, poor optical performance of glass-ceramic, poor uniformity of rare earth ions, etc., and achieves low cost, stable physical and chemical properties, and excitation and emission efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 22.26 parts by mole Y 2 o 3 , 37.22 Al 2 o 3 , 31.30 parts of SiO 2 , 2.72 parts AlF 3 , 4.63 parts of ZrO 2 and additionally doped with 1.91 parts of CeF 3Accurately weigh and analyze pure raw materials, then put them into an agate mortar, mix and grind evenly, and then melt them in a crucible at a temperature of 1600°C. After 2 hours of heat preservation, pour the glass melt into a cast iron mold, and then place it at high temperature Annealing in the furnace, after holding for 2 hours at the glass transition temperature Tg, then cooling down to 50°C with the furnace, turning off the power supply of the high temperature furnace to automatically cool down to room temperature, taking out the glass, and then placing the prepared glass in a precision annealing furnace at 1250 ℃ for 2 hours, then cooled to 50 ℃ with the furnace, turned off the power of the precision annealing furnace, and automatically cooled to room temperature to obtain a translucent yttrium alumin...

Embodiment 2

[0034] 21.66 parts by mole Y 2 o 3 , 36.21 Al 2 o 3 , 34.99 parts of SiO 2 , 2.65 parts AlF 3 , 4.50 parts of ZrO 2 and additionally doped with 1.82 parts of CeF 3 Accurately weigh and analyze pure raw materials, then put them into an agate mortar, mix and grind evenly, and then melt them in a crucible at a temperature of 1600°C. After 2 hours of heat preservation, pour the glass melt into a cast iron mold, and then place it at high temperature Carry out annealing in the furnace, keep warm at the glass transition temperature Tg for 2 hours, then cool down to 50°C with the furnace, turn off the power supply of the high temperature furnace and automatically cool down to room temperature, take out the glass, and then place the prepared glass in a precision annealing furnace at 1300 ℃ for 2 hours, then cooled to 50 ℃ with the furnace, turned off the power of the precision annealing furnace, and automatically cooled to room temperature to obtain a translucent yttrium aluminum...

Embodiment 5

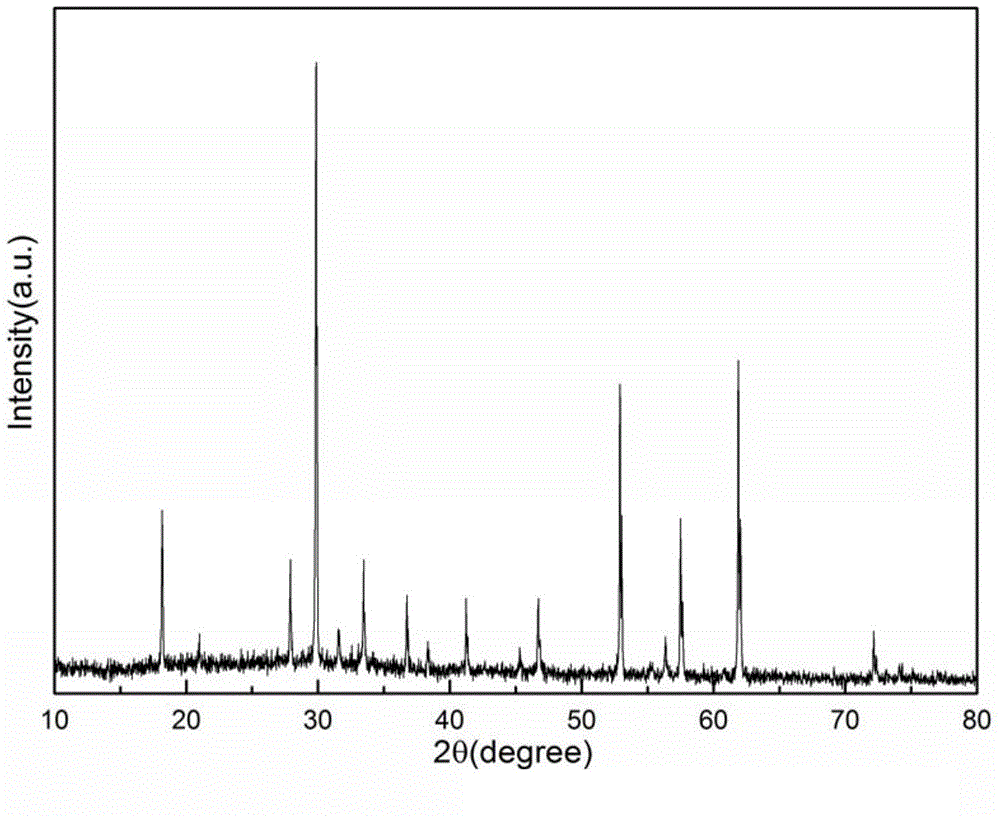

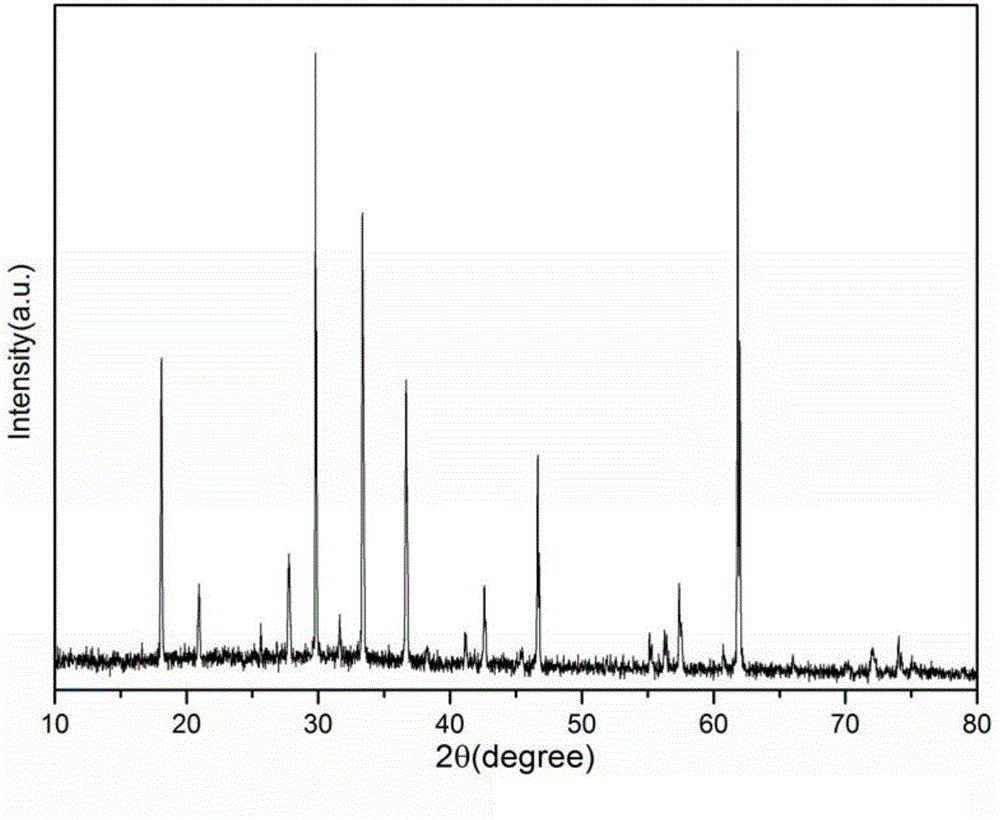

[0039] Embodiment 5: Test the spectral properties of the prepared YAG glass-ceramics

[0040] The XRD pattern of the glass obtained in embodiment 1, 2 and comparative example 3 after microcrystallization treatment is as follows respectively figure 1 , figure 2 and image 3 As shown, the result is as follows: the main diffraction peaks of the sample XRD diffraction peaks obtained through heat treatment are consistent with the standard diagram of the YAG crystal phase, and the obtained material crystal phase is a glass-ceramic of the YAG phase, without other impurity phases; Example 1 The emission wavelength of the sample is 538nm ( Figure 5 ) and the emission wavelength of the sample of Example 2 is 534nm ( Figure 7 ) and the emission wavelength of the comparative example 3 sample is 533nm ( Figure 9 ), their respective excitation spectra such as Figure 4 , Figure 6 and Figure 8 As shown, it is similar to the fluorescence spectrum of Ce:YAG crystal, and the fluore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com