A making method for large-area nano film solar battery

A technology of solar cells and nano-thin films, applied in the field of solar cells, can solve problems such as complicated processes, shortened service life, and decreased battery performance, and achieve the effects of simplifying the packaging process, ensuring long life, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

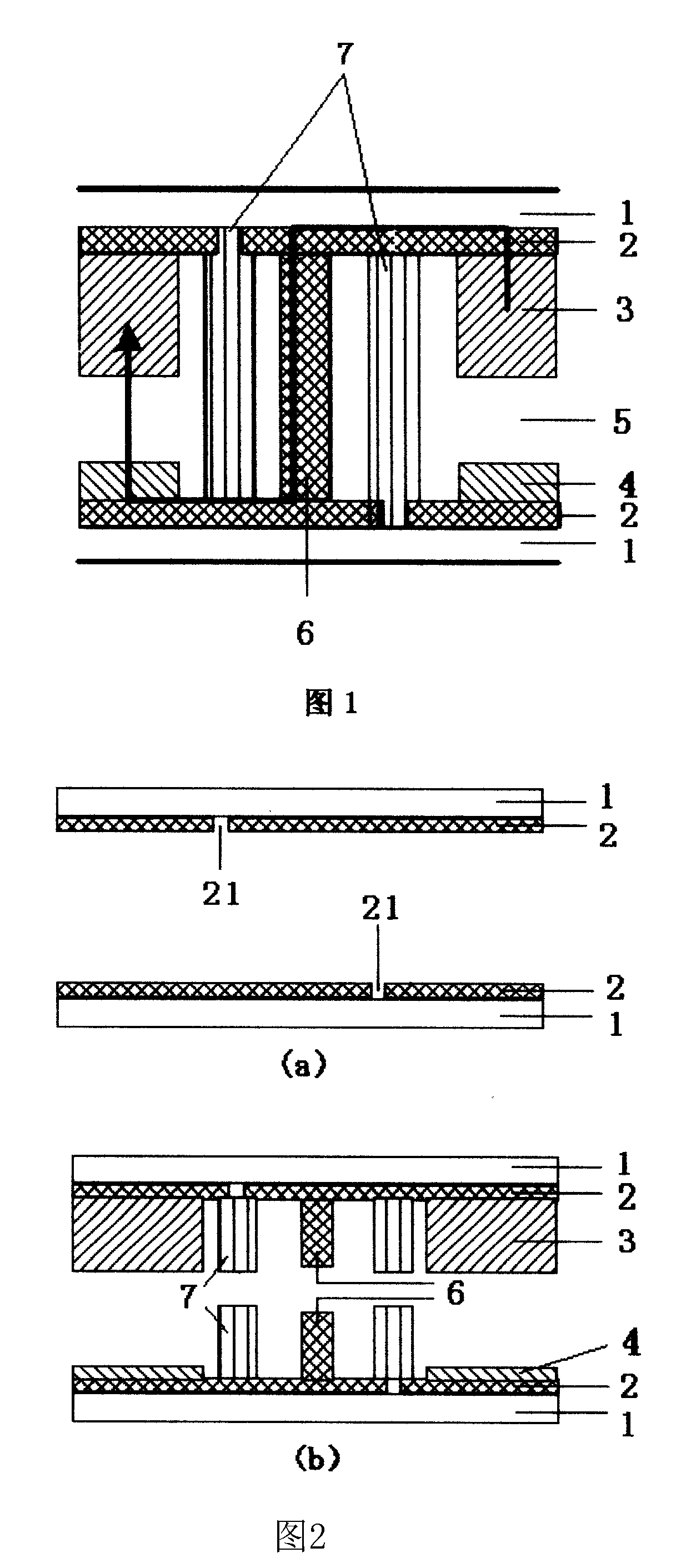

[0020] Referring to Fig. 1, it is a schematic diagram of the basic structure of the tandem structure solar cell module of the present invention, a large-area DSSC battery is connected in series by a plurality of strip-shaped single DSSC batteries, and the large-area DSSC battery of the tandem structure is increased by adding internal corrosion-resistant interconnecting strips Connection, corrosion-resistant interconnection bar is composed of electrode protective film and low-resistance electrode terminal formed by covering the electrode surface with polymer material or glass or ceramics as a protective film; corrosion-resistant interconnection of adjacent strip-shaped single DSSC cells Strips, i.e. low resistance wires protected by a protective spacer such as glass frit, are deposited by screen printing.

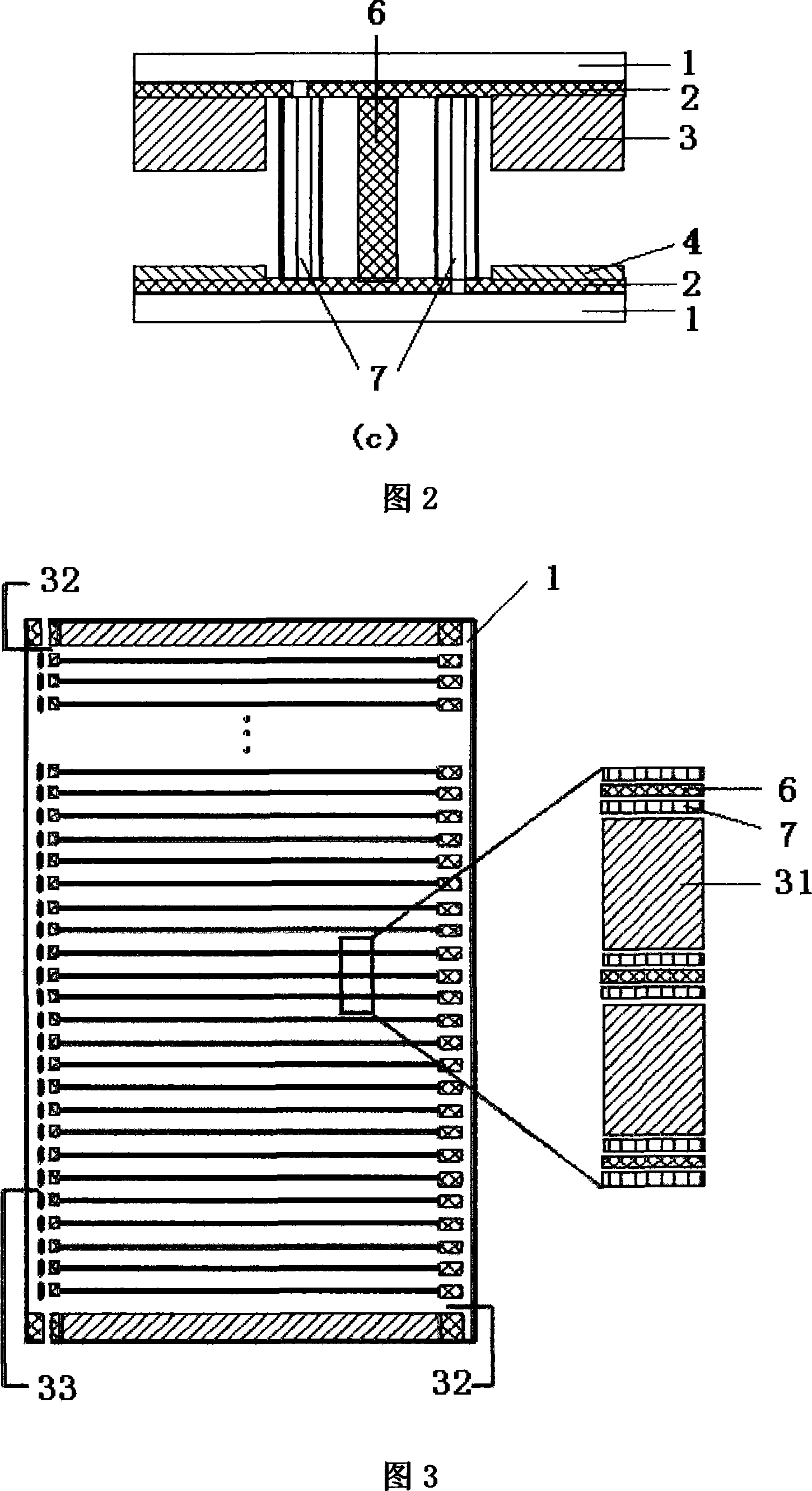

[0021]Referring to Figure 2 and Figure 3, TiO is prepared according to the process for making dye-sensitized single solar cells 2 Colloidal solution and made into slurry, an...

Embodiment 2

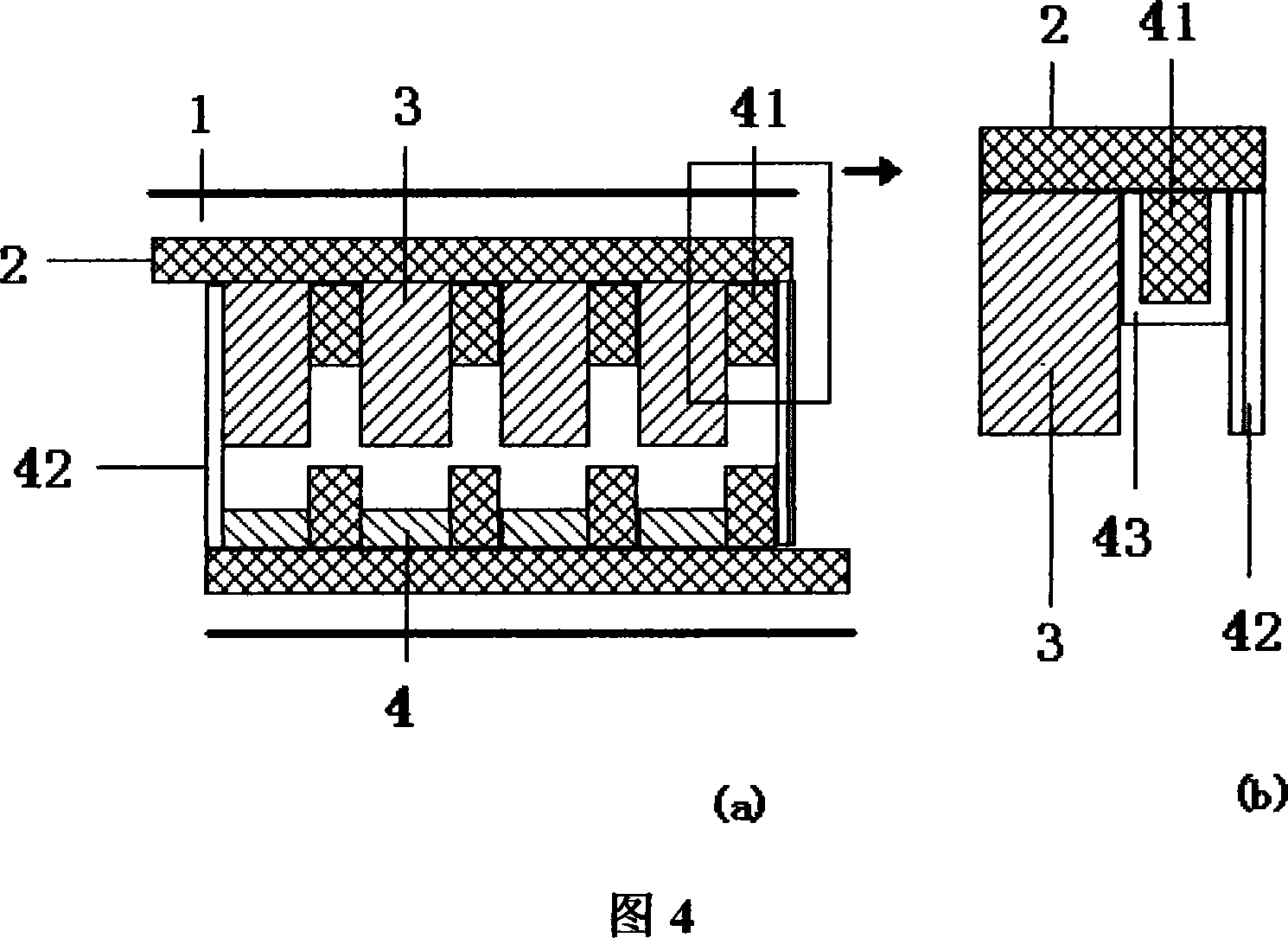

[0024] Referring to Figures 4a and 4b, it is a schematic diagram of the basic structure of the tandem structure solar cell assembly of the present invention. A plurality of strip-shaped single DSSC cells are connected in parallel through low-resistance grid electrodes to form a large-area battery, and the low-resistance grid electrodes pass through the wire mesh. Printing preparation, while using polymer materials or glass or ceramics to cover the electrode surface to protect the electrode, and prepare a large-area DSSC connected in parallel.

[0025] Preparation of TiO according to the process method for making dye-sensitized monolithic solar cells 2 The colloidal solution is made into a slurry, and the screen printing slurry such as platinum counter electrode, silver glue, glass powder, etc. is prepared, and prepared at the corresponding position of the glass substrate, including TiO 2 Functional layers of nanoporous film, platinum counter electrode, and silver glue line.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com